A kind of soft, light and warm knitted fleece fabric and preparation method thereof

A fabric and light technology, applied in knitting, weft knitting, fabric surface trimming, etc., can solve the problems of hard hand feeling, poor comfort, heavy fabric, etc., achieve full suede, low cost, and solve the effect of hard hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Material selection

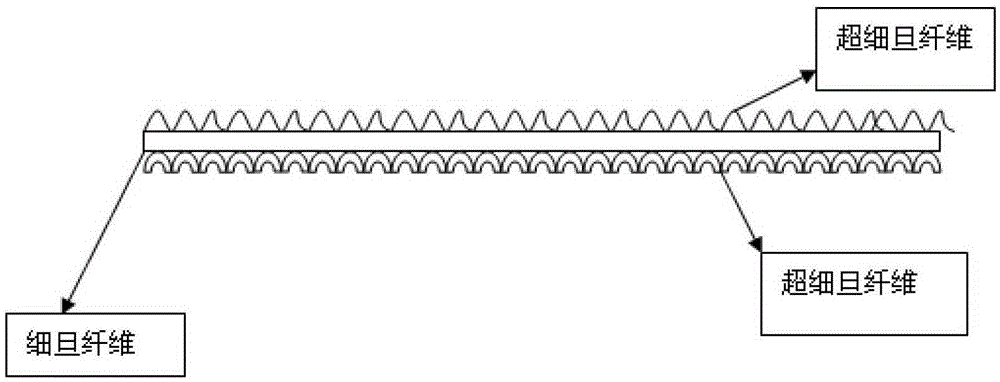

[0028] Fabric of the present invention is made of terry yarn and ground yarn, and wherein terry yarn selects 65D / 144F for use, superfine denier polyester hollow network filament, the network point of network silk is 130 / m, and its twist direction is Z twist; The bottom yarn described is selected from 65D / 72F fine denier polyester hollow filaments, and its twist direction is Z.

[0029] 2. weaving method

[0030] The weaving method provided by the present invention is as follows: first, the workshop temperature is set to 25° C., and the humidity is 75%. Use 65D / 144F ultra-fine denier hollow fiber filaments as the loop yarn, 65D / 72F fine denier hollow fiber filaments as the ground yarn layer, and weave the positive covered terry weave on the 24G gauge.

[0031] The loop height of the above-mentioned structure is selected as 2.2 mm.

[0032] In the terry structure, the ground yarn and the terry yarn are fed through the same path in the loom. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com