Patents

Literature

66results about How to "Gorgeous appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based cold-pigment multifunctional heat-insulating true stone paint for exterior wall and preparation method thereof

The invention discloses a water-based cold-pigment multifunctional heat-insulating true stone paint for an exterior wall and a preparation method thereof. The water-based cold-pigment multifunctional heat-insulating true stone paint is prepared by mixing water, auxiliary agents, a synthetic resin emulsion, pigments and fillers and natural colorized sand. The preparation method comprises the following steps: firstly, adding water, fiber, a defoaming agent, glycol, a film-forming auxiliary agent and an multifunctional auxiliary agent into a dispersing tank; secondly, adding a styrene-acrylic emulsion; thirdly, sequentially adding a cold pigment, hollow glass microspheres, hollow ceramic microspheres, rutile titanium dioxide, ultrafine talcum powder and infrared ceramic powder; fourthly, slowly adding quartz sand; and finally, adding a sterilizing agent, the defoaming agent and a thickening agent and stirring uniformly. By adding the cold pigment, the hollow glass microspheres and other pigments and fillers, the water-based true stone paint for the exterior wall is endowed with three heat-insulating effects, namely blocking heat insulation, reflective heat insulation and radiative heat insulation; by selecting the water-based synthetic resin emulsion and the water-based paint auxiliary agents, the true stone paint is water-based and environment-friendly; natural quartz sand with different fineness and different colors is used as aggregate, so that the true stone paint has a vivid effect for imitating natural stone, marble and granite, and is rich in paint film color and gorgeous in appearance.

Owner:HUNAN JINHAI SCI & TECH

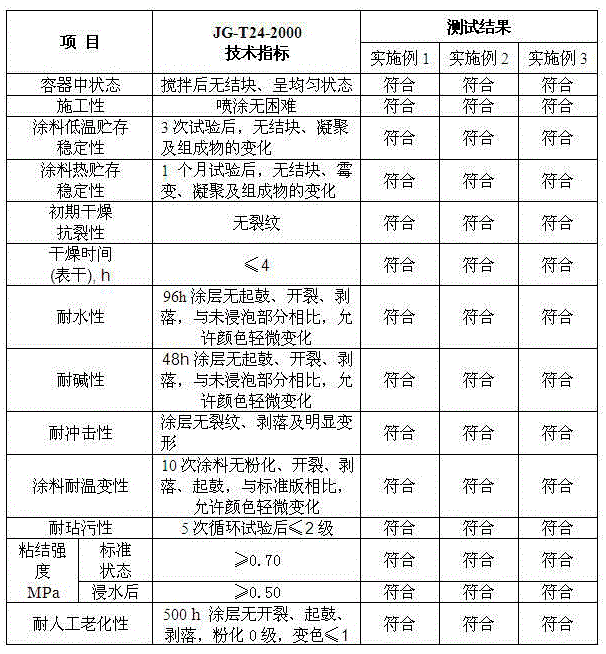

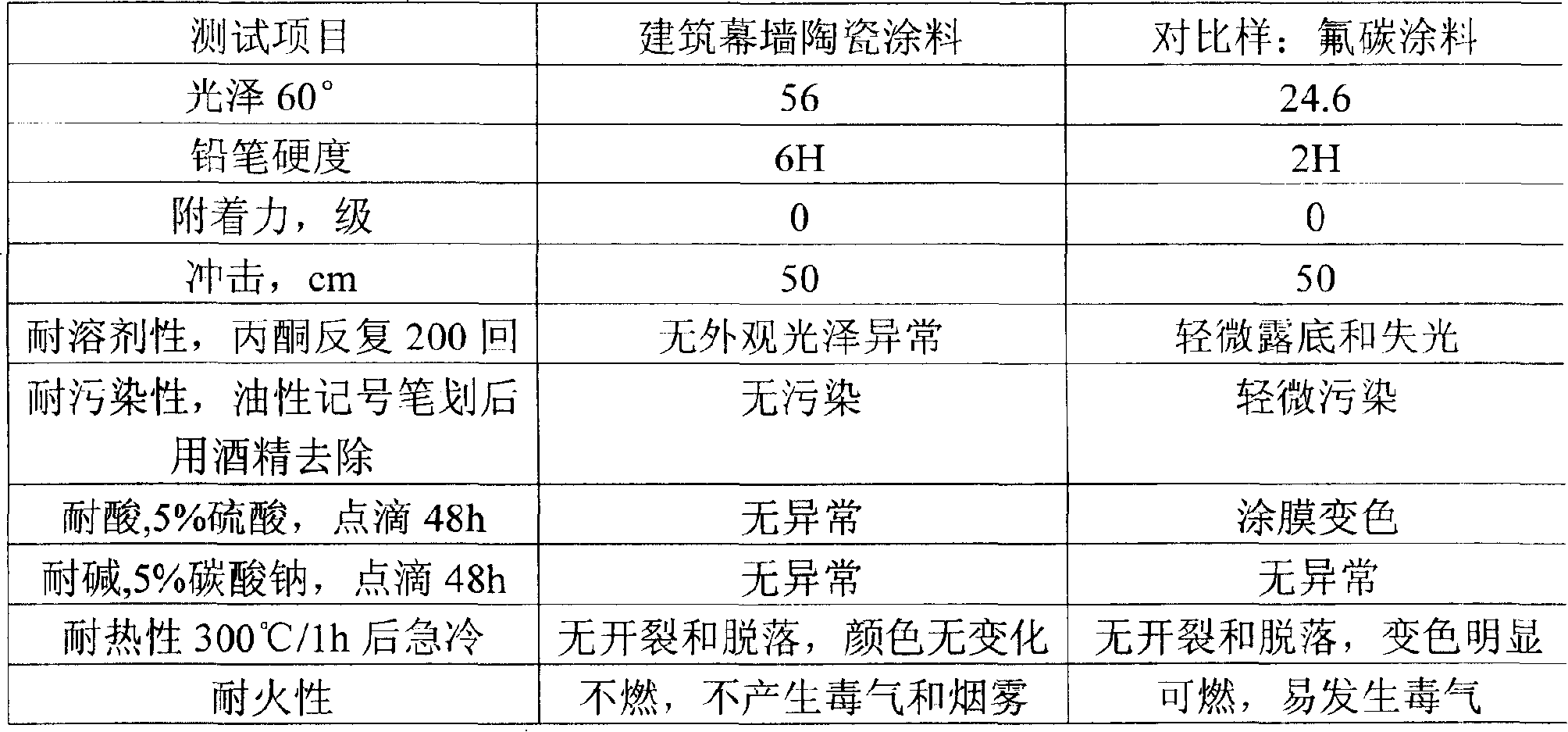

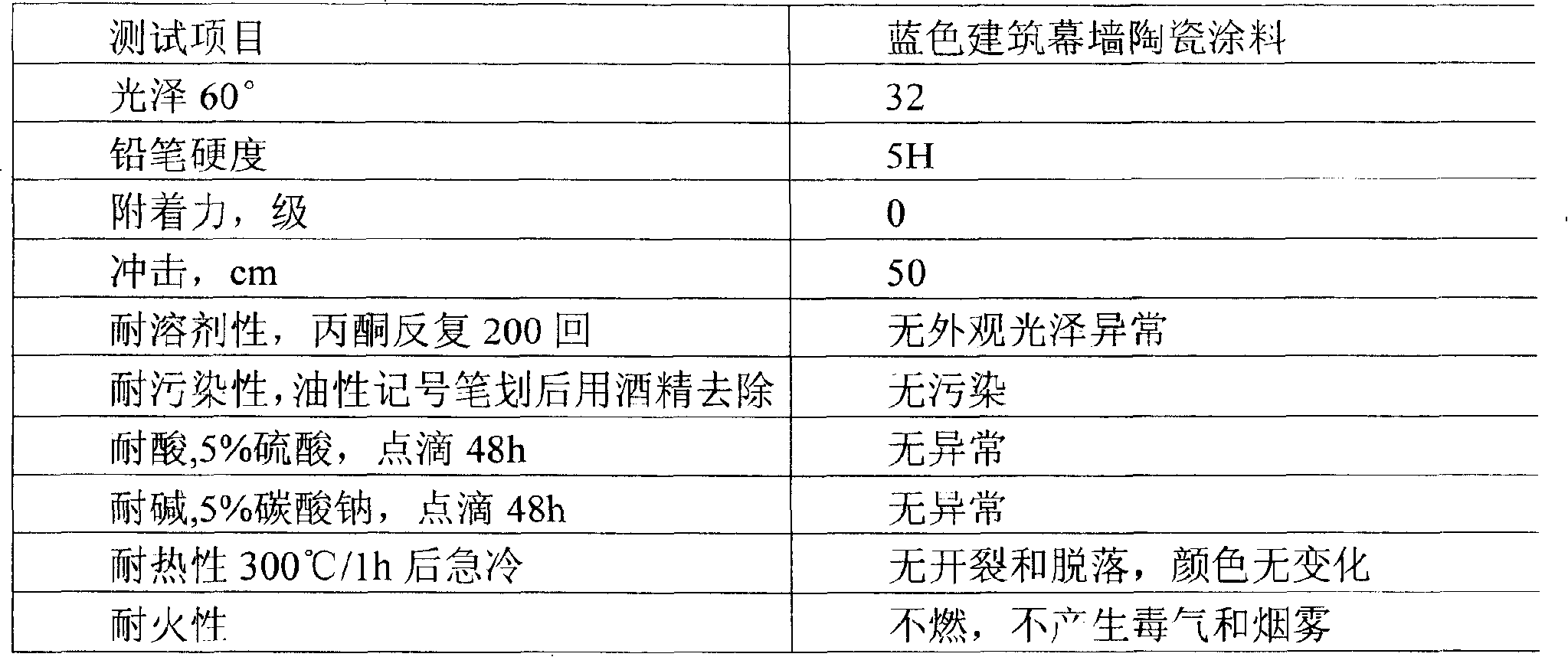

Paint for building curtain wall

The invention discloses a nanometer ceramics building curtain wall coating which consists of nanometer metallic oxide, tinting pigment, organic silicon curing agent and accessory ingredient, etc. The coating has the advantages of super weather resistance, anti-scratch property, fireproof and self-cleaning property, etc. The coating can be used for the coating of aluminum curtain walls, aluminum plates of subway engineering and aluminum honeycomb panels.

Owner:上海金力泰化工股份有限公司

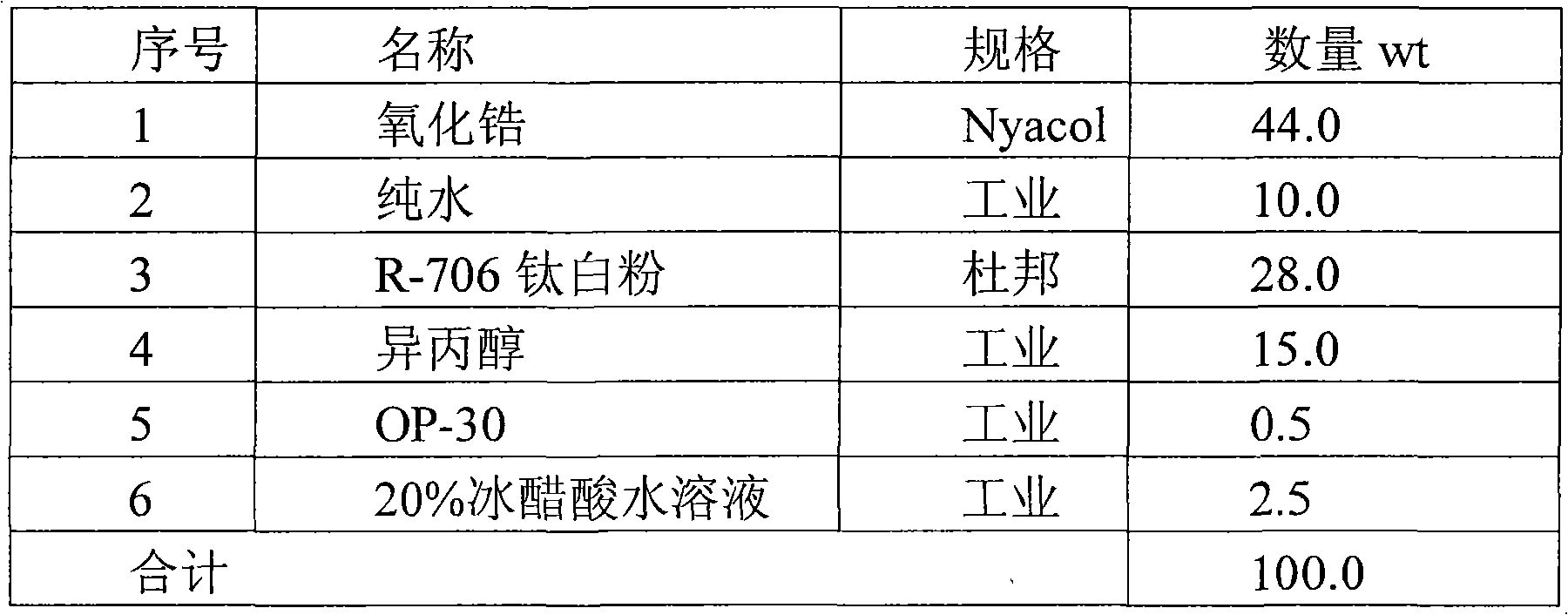

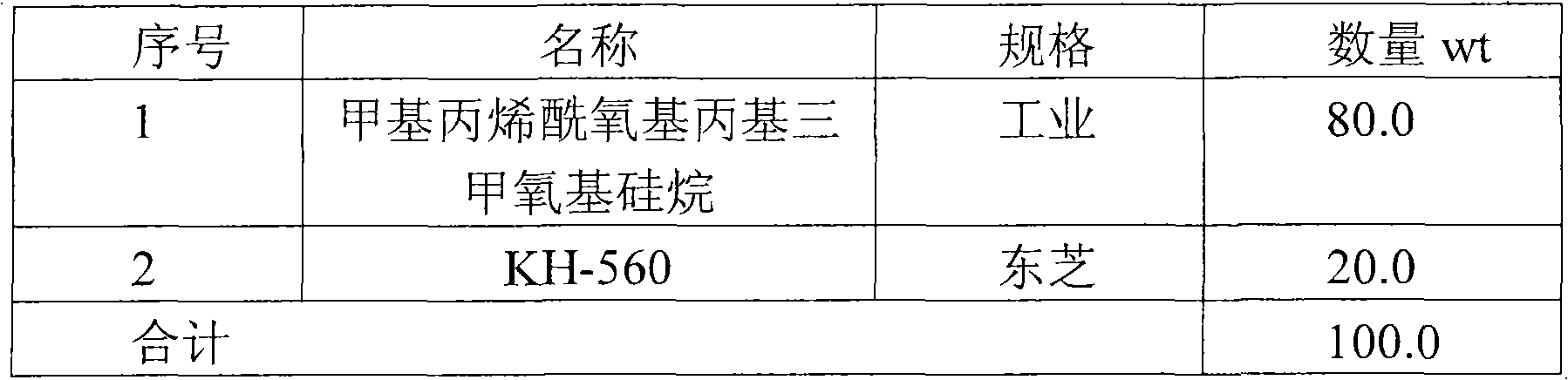

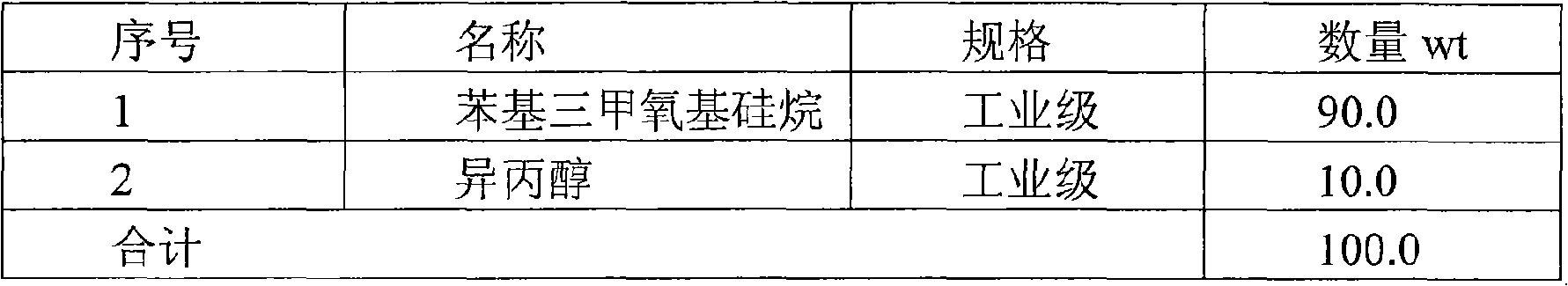

Construction curtain wall ceramic

The invention discloses a nanometer ceramic building curtain wall paint which comprises a nanometer oxide, a coloring pigment, an organosilicon curing agent and an auxiliary agent. The paint is characterized by super weathering resistance, scratch resistance, fireproofness, non-inflammability and self-cleaning, etc. The products of the invention are applicable to the hull painting of an outdoor aluminum curtain wall, and an aluminum veneer and an aluminum honeycomb panel which are used for indoor decoration.

Owner:上海金力泰化工股份有限公司

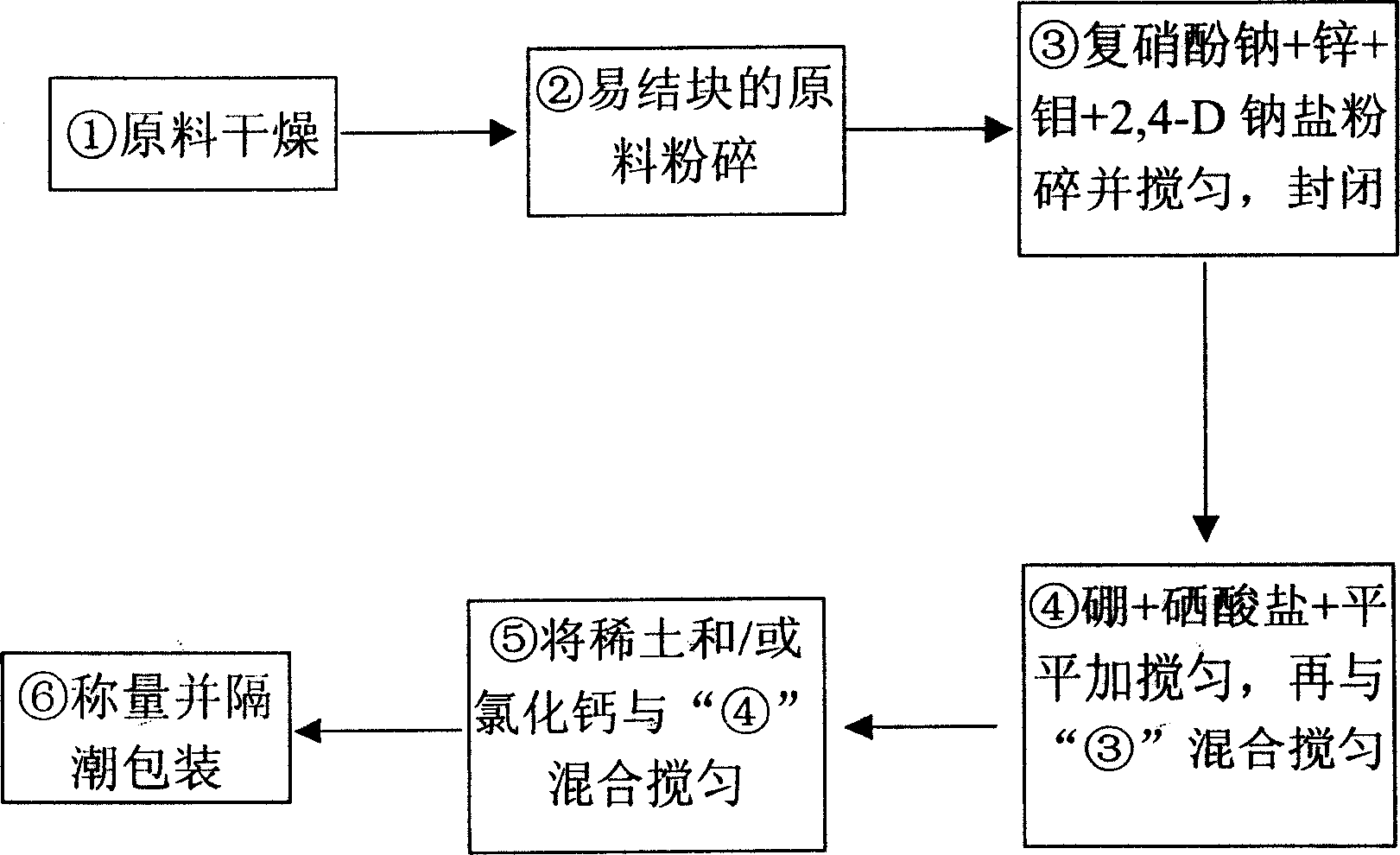

Selenium-rich sweetener and its preparing method

The selenium-rich sweetener consists of selenate 10-20 wt%, sodium nitropeolate compound 5-10 wt%, RE and / or calcium chloride 20-40 wt%, 2, 4-D sodium 0.1-0.6 wt%, peregal 0.1-0.6 wt%, Mo 7.5-12.5 wt%, Zn 12.5- 25 wt%, and B 12.5-25 wt%. It is prepared through drying material, crushing, mixing and packing. The selenium-rich sweetener is applied to melon and fruit to increase selenium content, sweeten, raise quality and raise yield.

Owner:喻米玲

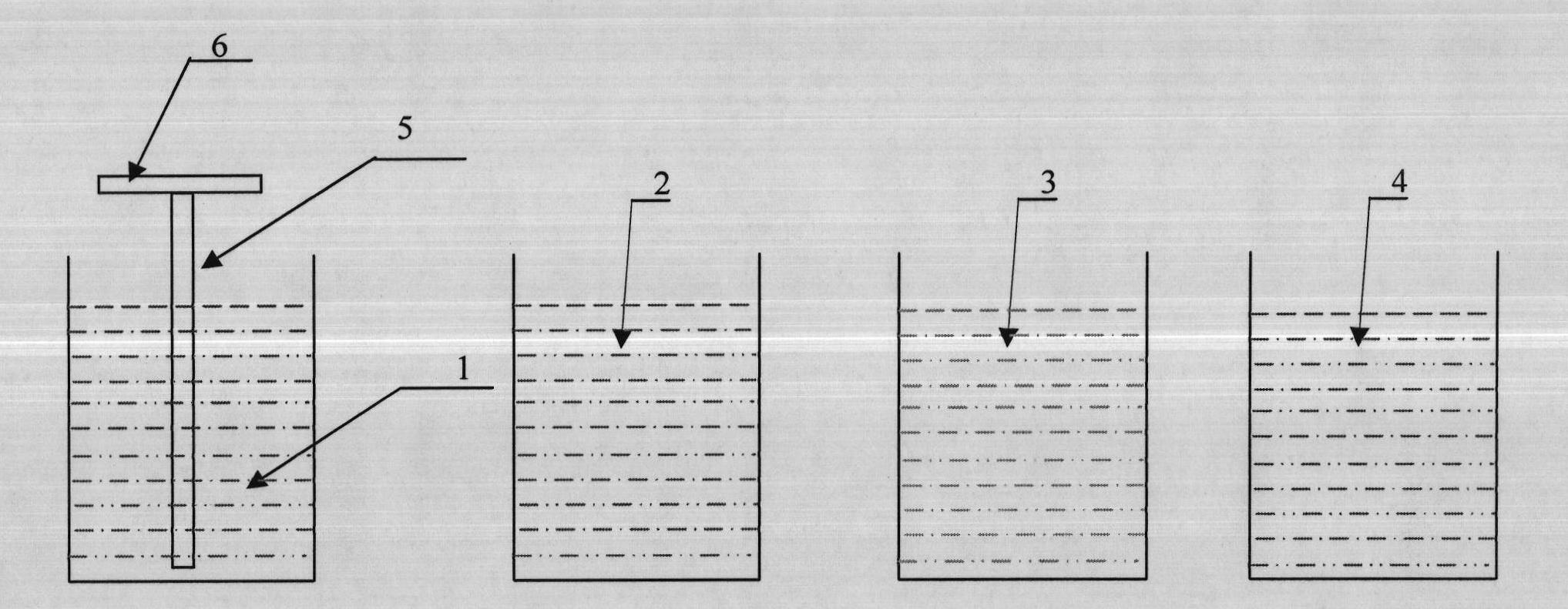

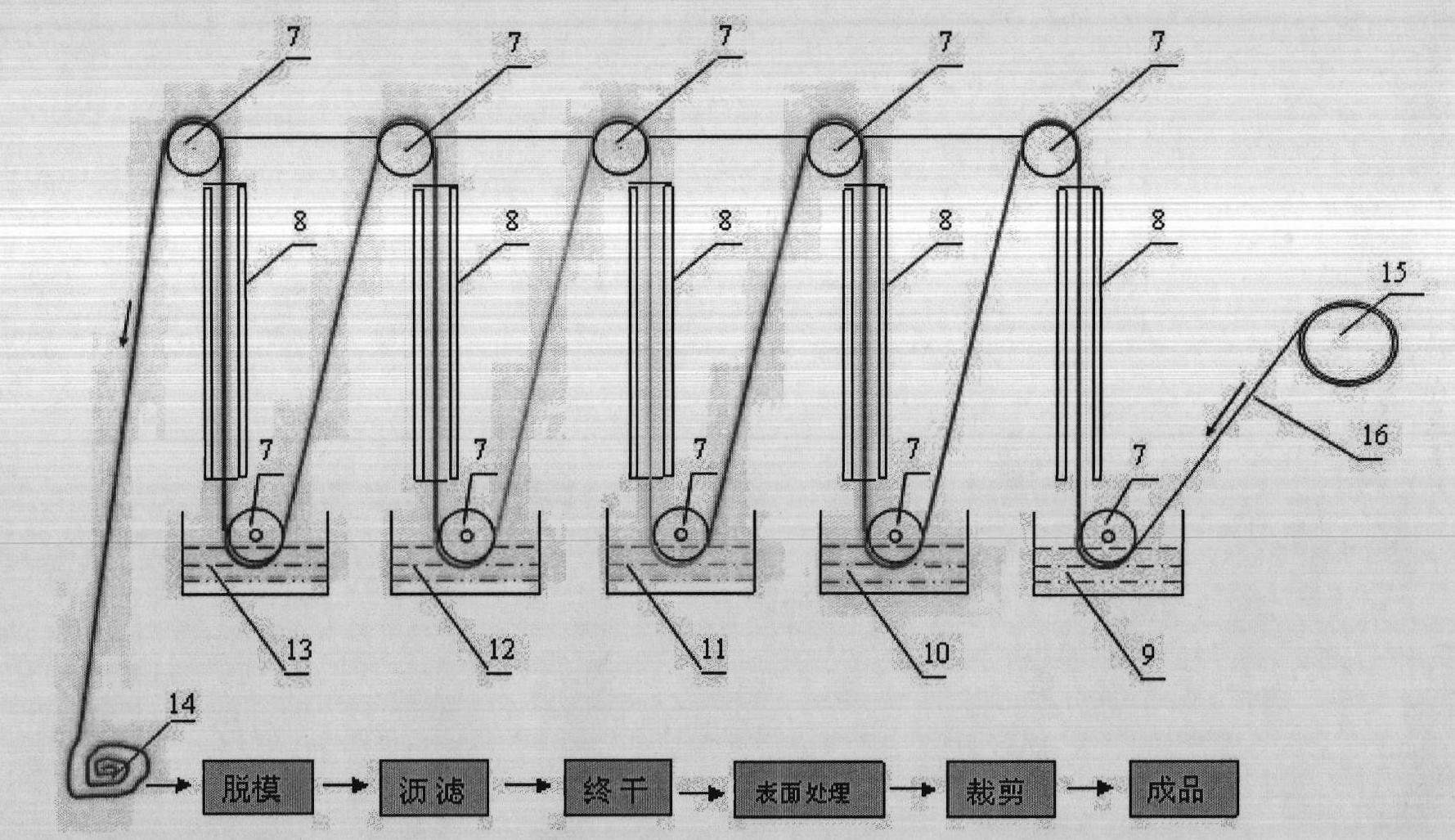

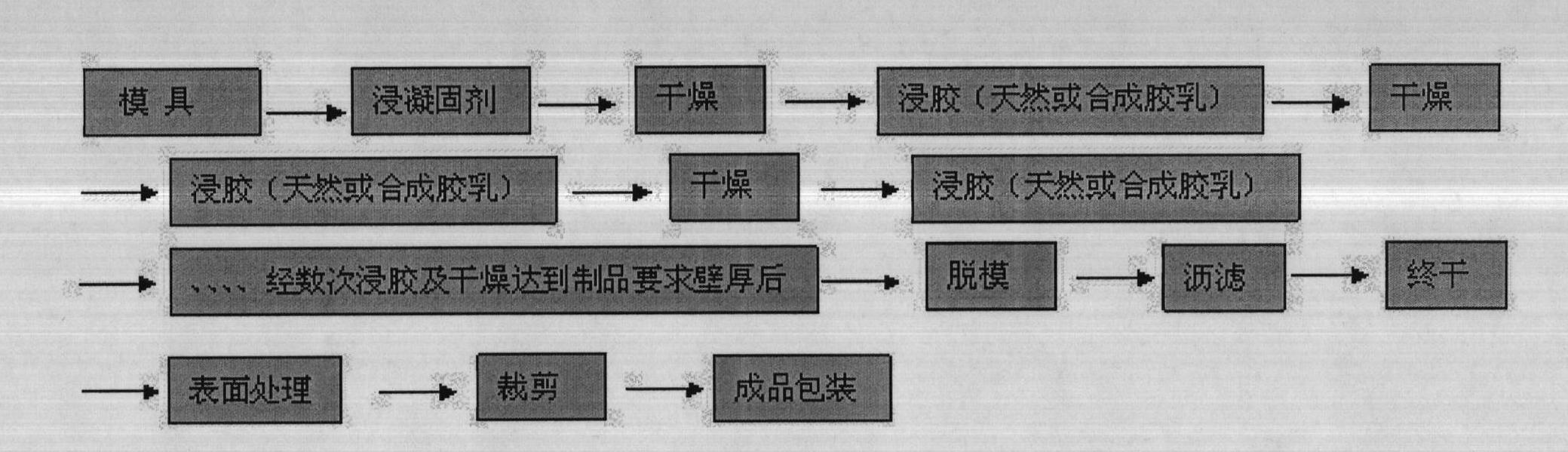

New process for producing multi-layer composite high-elasticity rubber hoses

The invention discloses a new process for forming and producing multi-layer composite high-elasticity rubber hoses by carrying out emulsion impregnating multiple times. The new process comprises a simple type production process and a continuous production process. According to the new process, manual or continuous mechanical mode is adopted, a mould is impregnated in a coagulator, then dried and cooled to room temperature, and then the mould is impregnated in emulsion and dried so that a layer of emulsion film is formed on the surface of the mould; every time the above operations are repeated, a layer of emulsion film is added on the surface of the dried emulsion film, wherein the coagulator impregnating step can be omitted; multi-layer composite rubber hoses with random thickness can be produced by implementing the combined process of emulsion impregnating and drying repeatedly; multiple layers are composited by heating and vulcanizing by virtue of a vulcanizer mixed in the emulsion; and then demoulding, leaching, final drying, surface treatment and cutting auxiliary process steps are carried out to finally obtain the finished product. Multi-layer composite high-performance rubber hoses with specific length, thickness, property and color can be produced by using the simple type production process and multi-layer composite high-performance rubber hoses with random length, thickness, property and color can be produced by using the continuous production process. Rubber hoses produced by using the new process have high quality and can meet special requirements of physical training.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI +1

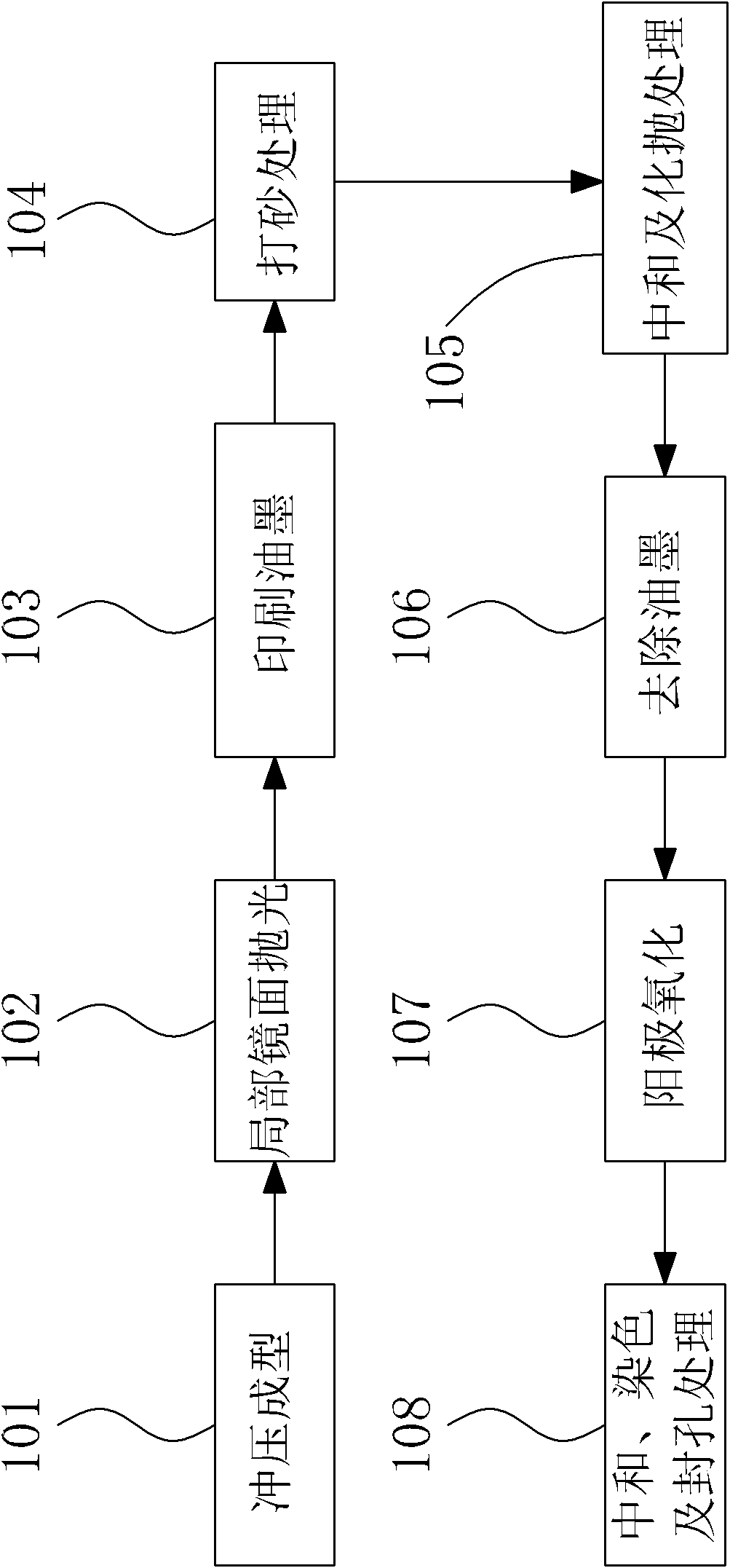

Aluminum alloy surface treatment method and aluminum alloy surface treatment product

The invention discloses an aluminum alloy surface treatment method and an aluminum alloy surface treatment product. The method comprises the following steps of: stamping an aluminum alloy piece to be in a required shape; performing partial mirror polishing on the stamped aluminum alloy piece to achieve a mirror effect; printing ink in a mirror region, and baking; sanding the treated aluminum alloy piece to enable an ink-unprinted region to be sandy; neutralizing and chemically polishing the sanded aluminum alloy piece; removing the ink from the treated aluminum alloy piece; placing the treated aluminum alloy piece into an acid liquor groove for anodizing; neutralizing the anodized aluminum alloy piece, and performing dyeing and hole-sealing treatment to obtain a required product. The product is an aluminum alloy product which is generated through the aluminum alloy surface treatment method. The surface of the product has the mirror effect and a sandy effect through one-time anodizing, the method is short in manufacturing process and high in efficiency, and the production cost can be saved.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Simulated marble slab and production method thereof

InactiveCN102700205AHard textureImprove wear resistanceNatural patternsSynthetic resin layered productsBuilding materialSubstrate surface

The invention relates to a marble slab, in particular to an artificial simulated marble slab and a production method of the artificial simulated marble slab. The invention aims to overcome defects of natural marble and provide the simulated marble slab which has low price, is light, is easy to pave, has no harm and pollution and can replace the natural marble. The simulated marble slab comprises a substrate layer. A priming paint layer, a marble pattern layer and a finish layer are sequentially arranged on the positive face of the substrate layer from bottom to top. The invention also aims to provide a production method of the simulated marble slab, which comprises the following steps of: selecting a substrate; tailoring the selected substrate to a required size; tenoning on tailored substrate; coating priming paint on the positive surface of the substrate; spraying natural marble patterns on the surface coated with the priming paint of the substrate; and coating finish on the surface sprayed with the natural marble patterns of the substrate. The simulated marble slab provided by the invention can be widely applied in multiple industries such as building material, advertisement, furniture, decoration and the like.

Owner:GUANGZHOU GUANGYANG FU BULGARI HOME MATERIAL

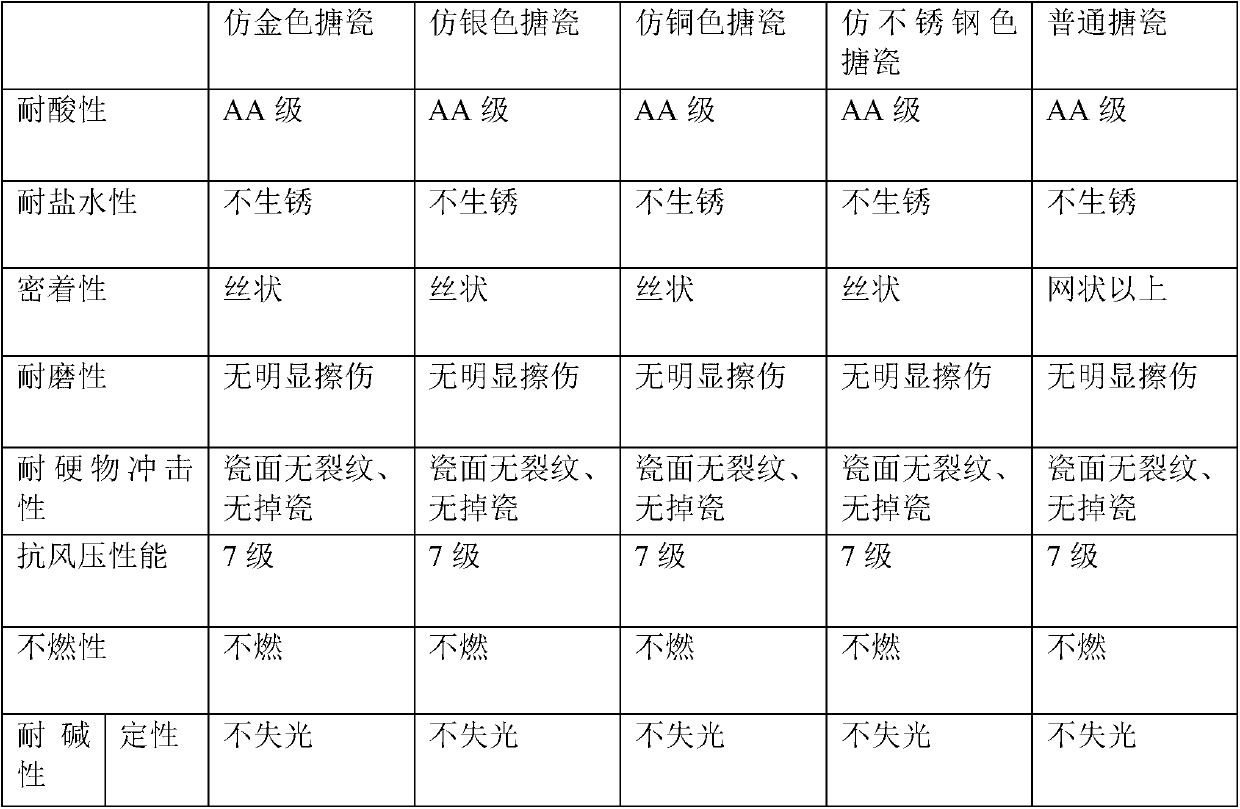

Preparation method of imitated-metal enameled steel sheet

The invention relates to a preparation method of an imitated-metal enameled steel sheet. The prepared enameled steel sheet has the advantages of good mechanical properties, good heat resistance, excellent chemical stability, clean and gorgeous appearance, and easy cleaning and decontamination. The enameled steel sheet is suitable to be used in decorative enamel of building interior and exterior wall decorations and decorative enamel of public places such as tunnels and subways. The enameled steel sheet has good imitated metal effect. A production process of the enameled steel sheet comprises the steps that: a suspending agent, water, sodium fluoroborate, urea, and potassium fluorosilicate are added into a transparent base glaze; ball milling is carried out, such that a glaze slurry is obtained; imitated-metal powder is added into the glaze slurry, and the mixture is well mixed, such that an imitated-metal enamel glaze is obtained; the imitated-metal enamel glaze is sprayed on a biscuit by using a spray gun; and the material is fired under a temperature of 800-860 DEG C, such that the imitated-metal enameled steel sheet is obtained.

Owner:ZHEJIANG KAIER NEW MATERIALS

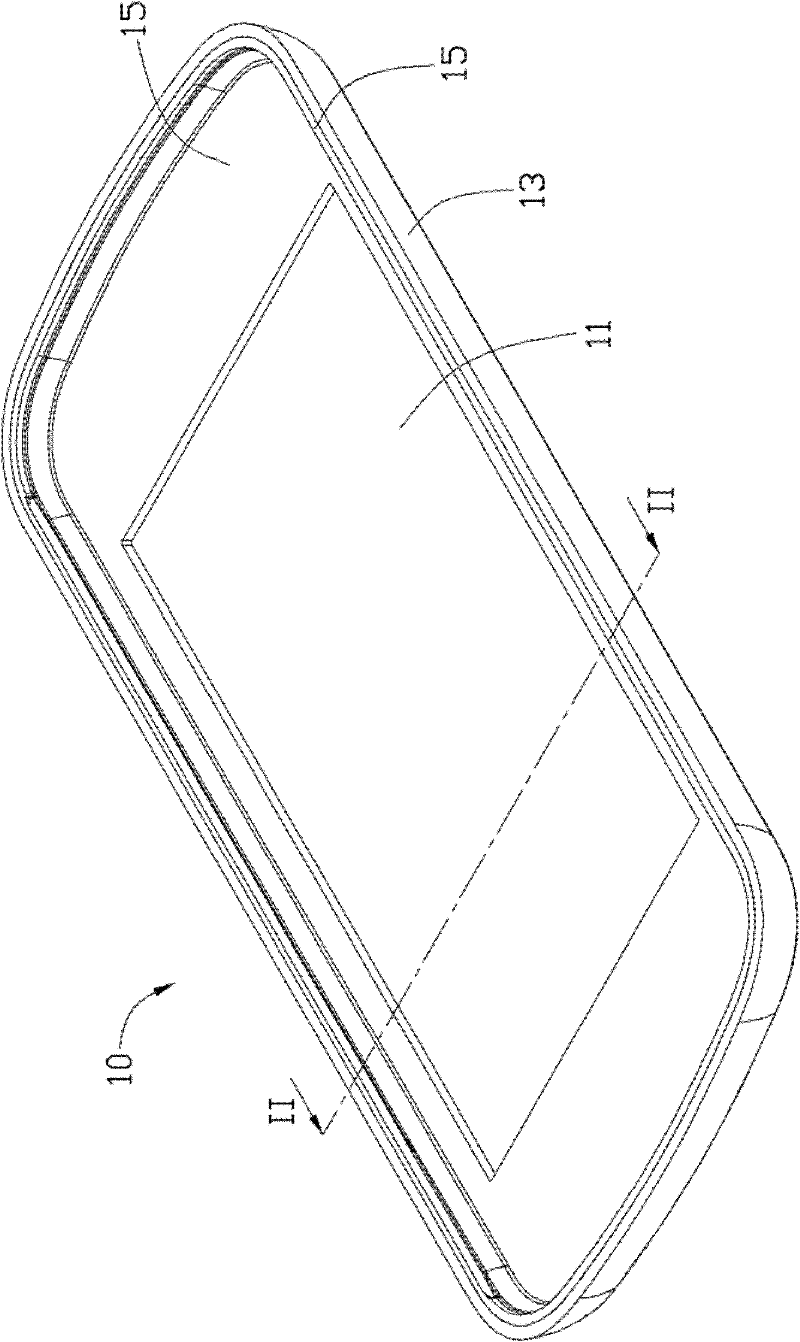

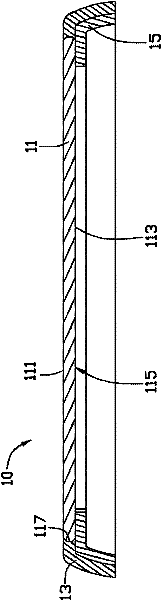

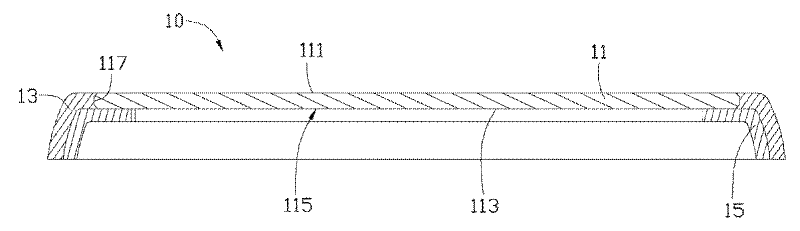

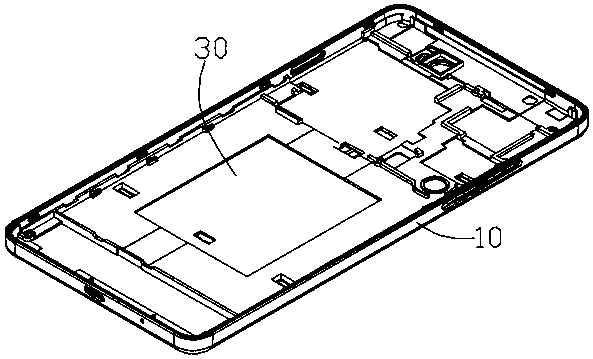

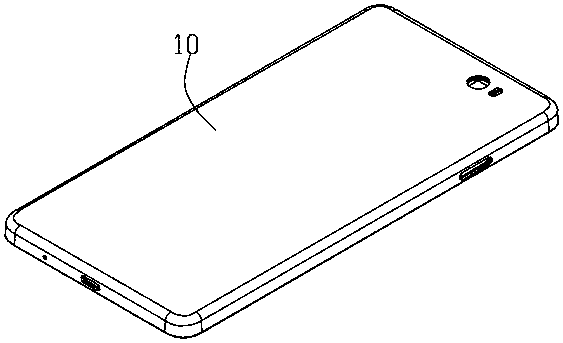

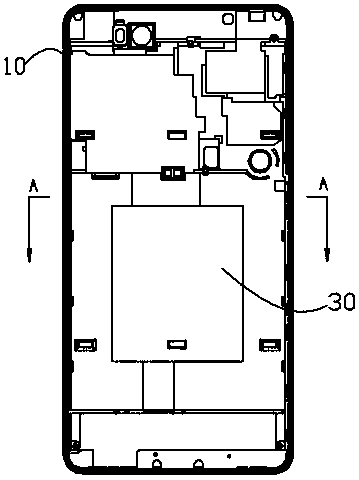

Shell of electronic device and manufacturing method thereof

InactiveCN102196686AGorgeous appearanceHigh hardnessCasings with display/control unitsDomestic articlesEngineeringInjection moulding

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Flash paint and its manufacturing method

A flash paint including oil and water ones is prepared from acrylic acid series, nacreous powder, golden powder and solvent through proportional mixing and stirring. Its advantages are high ultraviolet and ageing resistance and weatherability, high adhesion, not decolouring and low cost.

Owner:广州市黄埔区宏泰建筑材料厂

Plastic shell structure and preparation method thereof

InactiveCN109659667ARealize waterproof, dustproof and dropproofStable and durableAntenna supports/mountingsRadiating elements structural formsOptical coatingEngineering

The invention discloses a plastic shell structure. The plastic shell structure comprises a plastic shell and a PET composite decorative film attached to the inner side surface of the plastic shell. The PET composite decorative film comprises a PET substrate, and the PET substrate comprises a fitting surface and a decoration surface. The decoration surface of the PET substrate is provided with an ink printing layer, a UV grain layer and an optical coating layer in sequence; the optical coating layer of the PET composite decorative film is provided with an LDS antenna. The invention also discloses a manufacturing method of a plastic shell structure. The large-area waterproof and dustproof antenna manufactured in the plastic shell solves the industrial problems that the surface of the fragmented and dispersive electronic component assembly structures in a traditional 3C electronic product plastic shell has no enough space to design a 5G signal antenna, and when the antenna is made at thesurface of the plastic shell, the product appearance decoration effect is influenced, the antenna is easy to be damaged to cause whole damaging of the product and difficult to maintain. The plastic shell structure has glass or ceramic appearance effects, is light and fashion and novel in appearance, and is anti-fall and waterproof.

Owner:GUANGZHOU HUAXIA VOCATIONAL COLLEGE

Rain-shielding greenhouse fence frame type planting method for minicure finger

InactiveCN103444486AGorgeous appearanceImprove yield per muCultivating equipmentsHorticulture methodsVitis viniferaFruit set

The invention discloses a rain-shielding greenhouse fence frame type planting method for minicure finger, comprising the following steps: (1) after grapes sprout and 12 leaves are grown on a young shoot, first pinching is carried out; deputy shoots on the top end continue growing, and pinching is carried out after 5 leaves are grown; the deputy shoots on the top end continue growing, pinching is carried out after 5 leaves are grown, pinching is carried out on a spica growing section and a previous section of deputy shoots when 4 leaves remain, pinching is carried out on other deputy shoots when 2 leaves remain, and the young shoots of the grapes are uniformly bound on a frame surface; (2) the distance between the young shoots on the frame surface of the fence frame is 20cm, and after fruits are set, an ear with a better ear type is reserved on each young shoot; (3) the grapes begin coloring, sun-burn grapes are cut off, and special bags for grapes are sleeved on the ears; (4) after the grapes are harvested, the young shoots are uniformly sheared to 1-1.5m. By using the planting method for the minicure finger, the sun-burning of the grapes is greatly reduced, and the proportion of grapes suffering from the sun-burning is controlled within 5%, the grapes are grown uniformly, the appearance of the ears is bright, and the acre yield of the grapes is improved.

Owner:ZHENJIANG WANSHAN HONGBIAN AGRI PARK

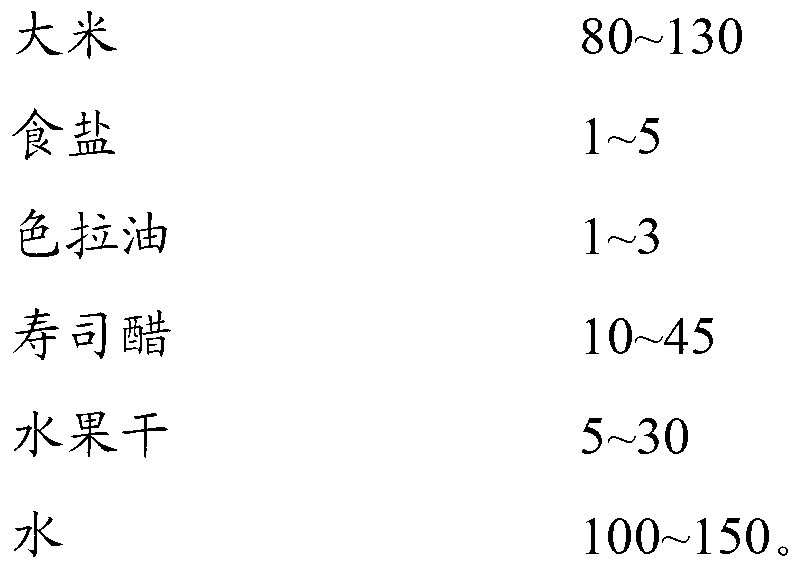

Sushi rice for nutritive fruit sushi and preparation method of sushi rice

The invention relates to sushi rice for nutritive fruit sushi as well as a preparation method and an application of the sushi rice, belonging to the technical field of food processing. The fruit sushi rice consists of 80-130 parts of rice, 1-5 parts of common salt, 1-3 parts of salad oil, 10-45 parts of sushi vinegar, 5-30 parts of dried fruits and 100-150 parts of water, and the sushi rice is prepared by stewing the rice soaked by the sushi vinegar, adding the dried fruits and uniformly mixing. The sushi rice is simple in preparation method, glittering and translucent in appearance, and good in water-retaining property, and due to the addition of various dried fruits, the sushi rice is intense in flavor, good in mouthfeel, and suitable for people of all ages; the sushi rice, when being matched with fresh fruits or canned fruits to prepare the fruit sushi, is colorful and attractive in appearance dolor, refined and aesthetic in shape, and better in both mouthfeel and taste of product, thus achieving a sensory effect which is unreachable for normal fruit sushi.

Owner:亚洲渔港股份有限公司

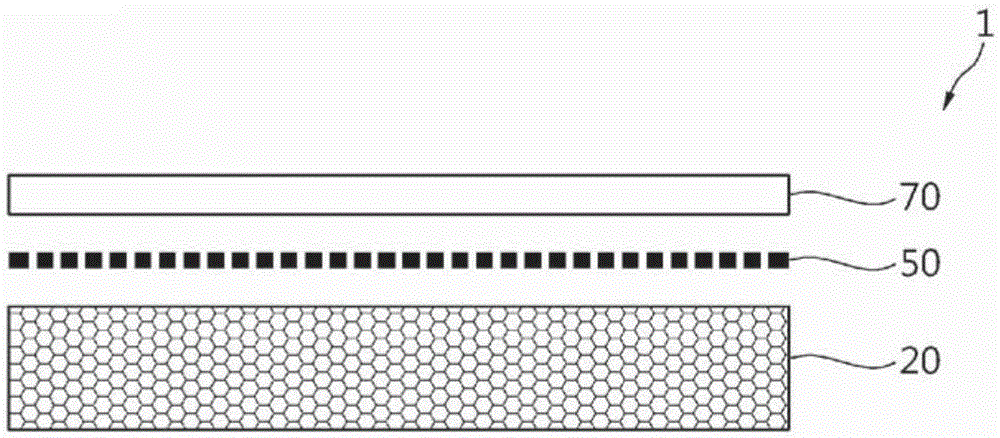

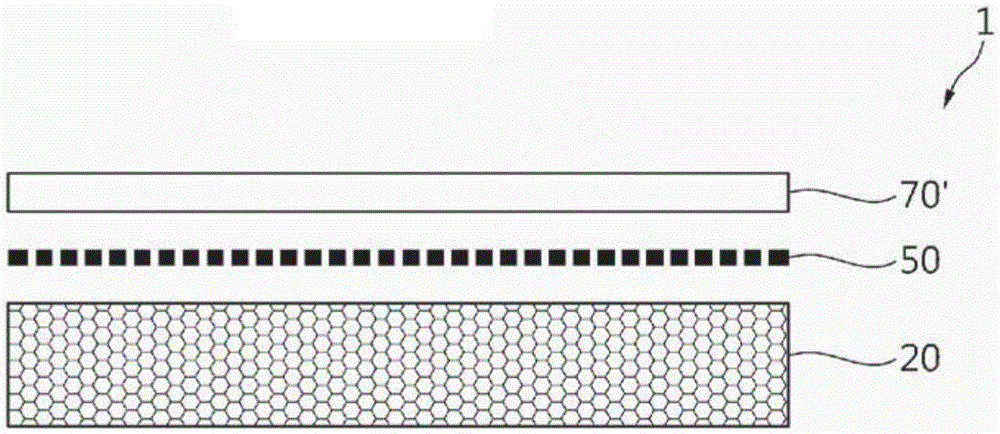

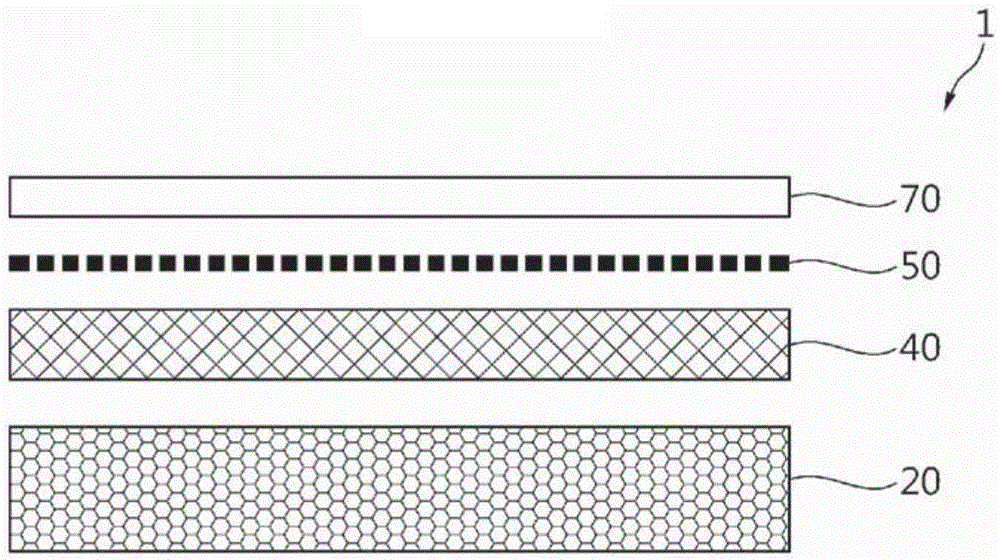

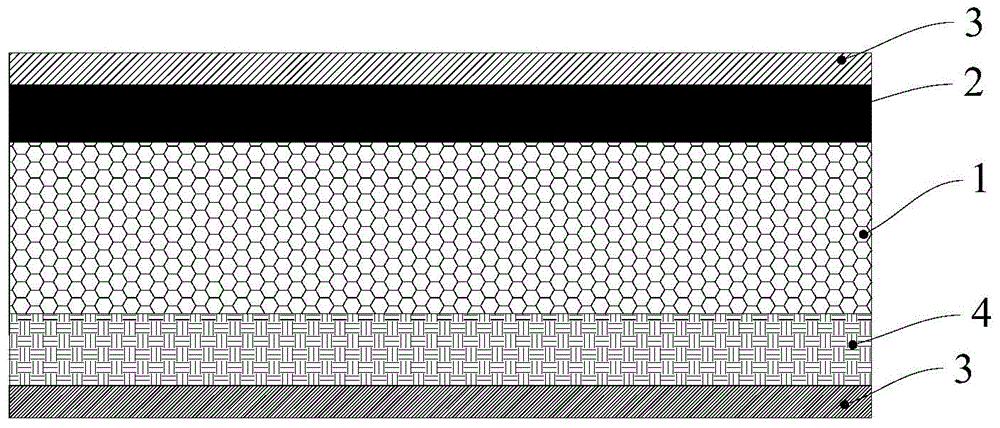

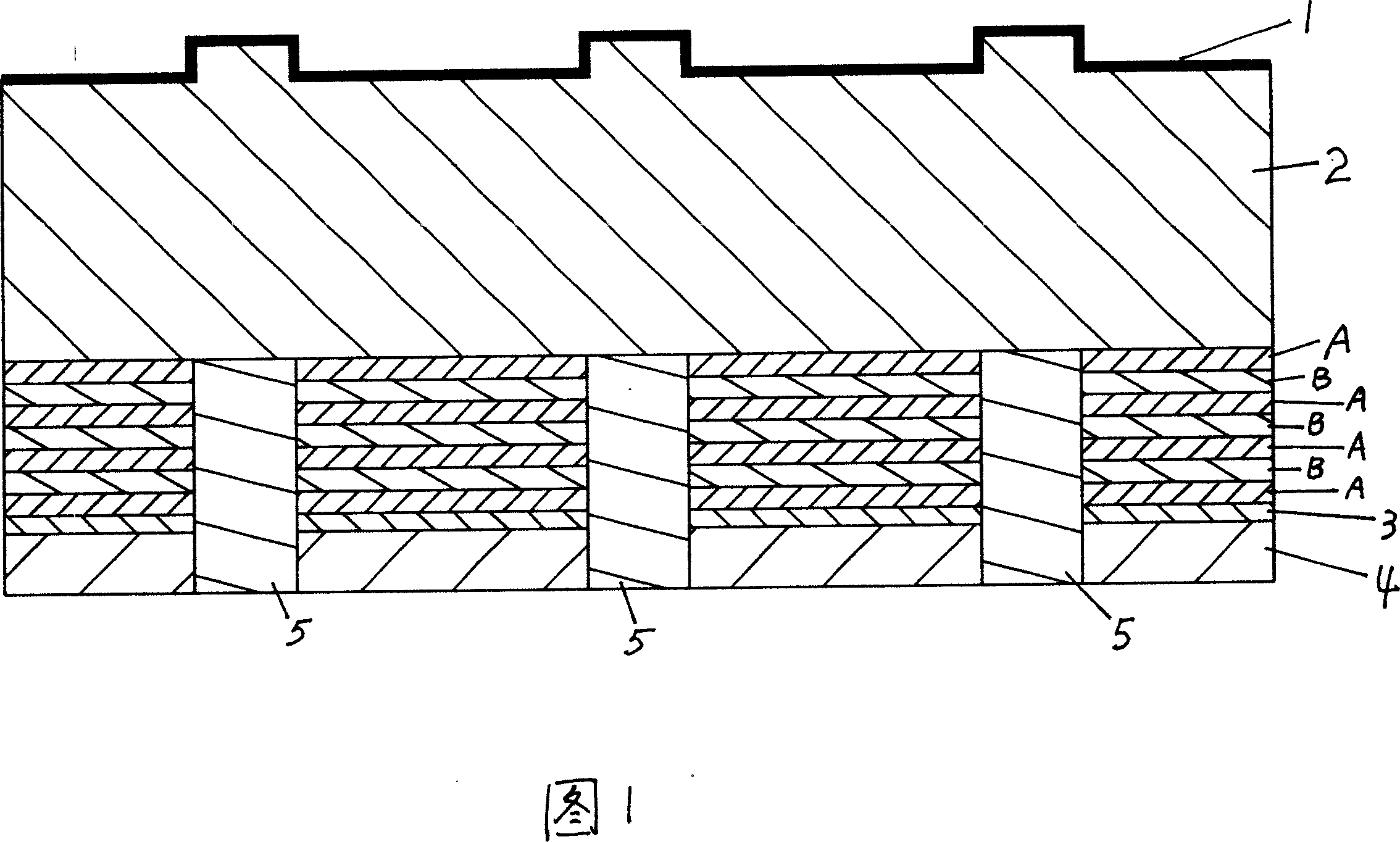

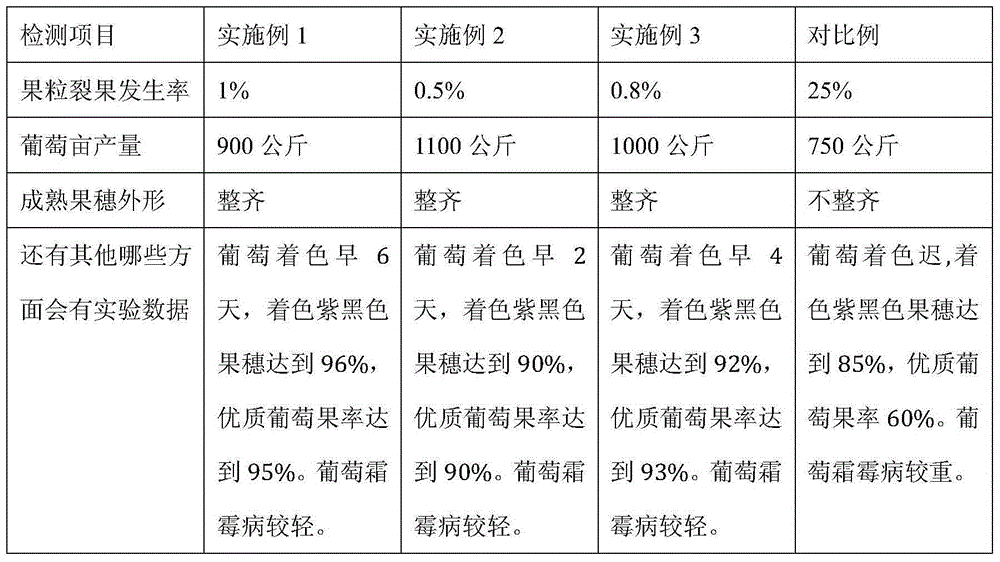

Cushioning flooring material and manufacturing method therefor

InactiveCN105324545AGorgeous appearancePrevent interlayer noiseCovering/liningsFlooring insulationsSurface layerHazardous substance

The present invention relates to a cushioning flooring material and a manufacturing method therefor, and more particularly, to a cushioning flooring material which is non-toxic, eco-friendly, and excellent in sound insulation performance by applying an elastic layer including an acryl-based elastic resin or a composite resin comprising an acryl-based elastic resin and polylactic acid as a surface layer forming the cushioning flooring material, so that a user is not exposed to harmful substances even when a surface treatment layer, disposed on the upper portion of the surface layer, is worn out and the surface layer is exposed, and a manufacturing method therefor.

Owner:LG HAUSYS LTD

LDPE(Low-Density Polyethylene) high-foaming sheet and packing material

InactiveCN104403171AHigh strengthImprove moisture resistanceFlexible coversWrappersLow-density polyethyleneFoaming agent

The invention discloses an LDPE(Low-Density Polyethylene) high-foaming sheet and a packing material. The LDPE high foaming sheet comprises the following components in parts by mass: 90-100 parts of LDPE colloidal particles, 2-5 parts of a nucleating agent, 0.5-2 parts of a foaming agent, and 0.05-0.15 part of an antisbrinking agent and an auxiliary addition agent, so that the sheet has the advantages that the rebound elasticity is good and the strength is high. An aluminum plated membrane of which the texture is PET(polyethylene terephthalate) is arranged on the surface of the LDPE high-foaming sheet of the packing material, weaved cloth of which the texture is PP(propene polymer) is arranged on the other surface of the LDPE high foaming sheet, and cast membranes of which the texture is PE(Poly Ethylene) are respectively arranged on the surfaces of the aluminum plated membrane and the weaved cloth, so that the packing material has the advantages that the rebound elasticity is good, the strength is high, and the humidity resistant property, air resistant property and the light resistant property are higher.

Owner:SUZHOU JIUDING

Aqueous anti-counterfeiting stamp ink

The invention discloses an aqueous anti-counterfeiting stamp ink with stronger anti-counterfeiting performance. The aqueous anti-counterfeiting stamp ink comprises the following components in percentage by weight: 60%-70% of aqueous polyurethane, 15%-25% of infrared transformed fluorescent powder, 1%-2% of super-concentrated slurry, 6%-8% of light calcium carbonate, 6%-8% of polyethylene wax and 2%-4% of mineral oil. The aqueous anti-counterfeiting stamp ink has the advantages of stable stamping performance, good detection on information provided by anti-counterfeiting feature substances, long-term preservation and rapid and accurate true and false discrimination by adopting a discriminating system for collecting stamp features.

Owner:MILITARY TRANSPORTATION UNIV PLA

A manufacturing method for multi-color plastic mobile phone key

ActiveCN101123633AWith appearance textureHigh surface hardnessTelephone set constructionsWear resistantColor film

The present invention proposes a kind of manufacturing method of colorful plastic mobile phone button, comprises following process step: (1) the blank front of plastic mobile phone button is coated with wear-resistant layer: TiO2 or SiO2 or ZrO2 or Al2O3 or diamond film; (2) blank The back is coated with alternately superimposed color films of Ti3O5 and SiO2 or alternately superimposed color films of SiO2 and TiO2 or alternately superimposed color films of Ti3O5 and MgF2 or alternately superimposed color films of ZrO2 and SiO2 or alternately superimposed color films of ZrO2 and MgF2 (3) Print the required color ink on the back of the blank; (4) Process characters on the back of the blank. The back side of the blank is firstly plated with the alternately stacked color film layers, and then plated with Cr or Al or Sn single metal film layers. The invention proposes a method for manufacturing plastic mobile phone keys with a wear-resistant surface and magical colors. The color is produced by refracting or reflecting light of different wavelengths through the film layer through optical principles.

Owner:SINYU TECH FUJIAN

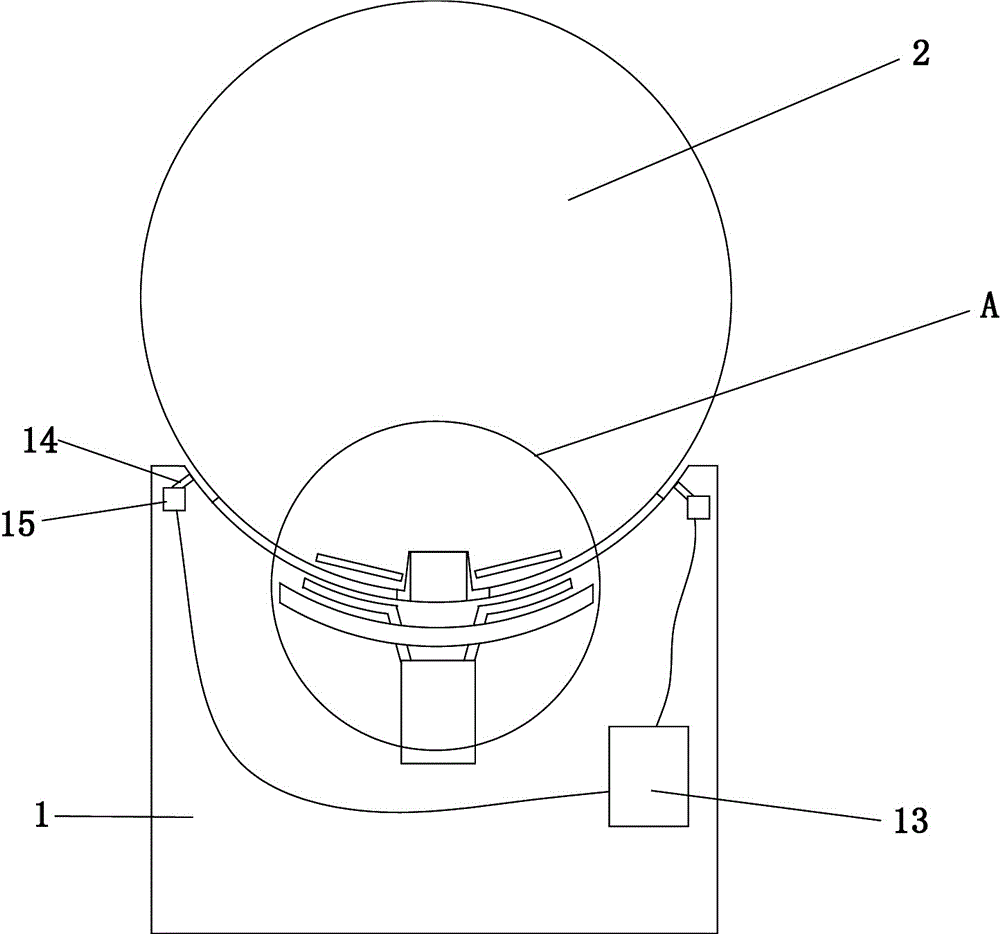

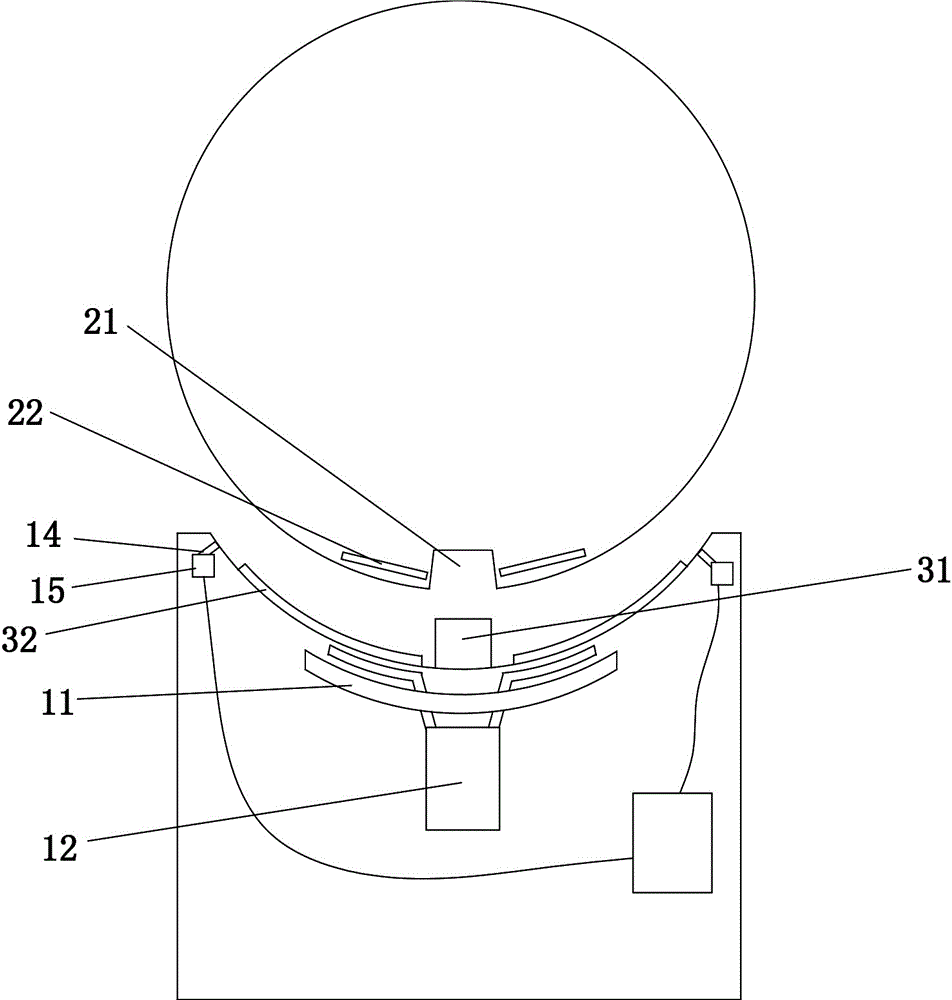

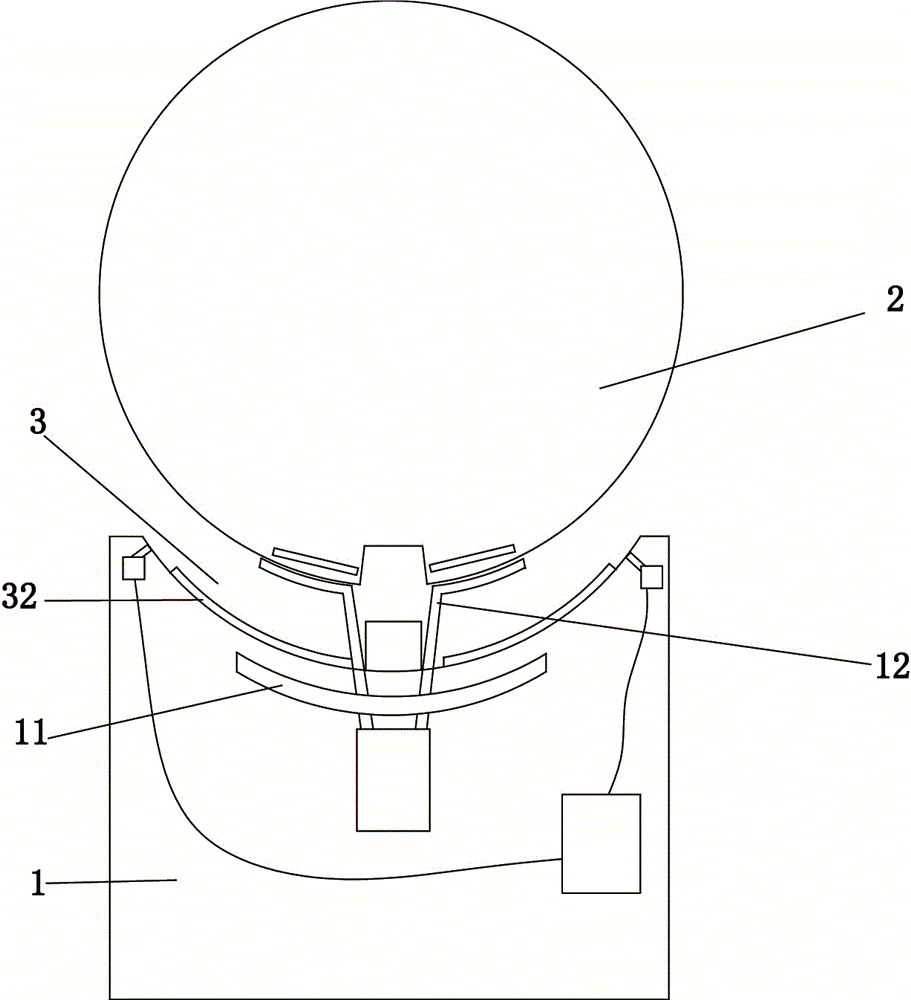

Display cabinet with magnetic suspension device

InactiveCN106175281ASolve the problem that the public needs to walk and watchEye-catchingShow cabinetsGas compressorSpray nozzle

The invention provides a display cabinet with a magnetic suspension device and relates to a display cabinet. The display cabinet comprises a base and further comprises a display ball. An arc-shaped groove is formed in the base, the display ball is placed in the arc-shaped groove, a fixing table is arranged on the arc-shaped groove, the display ball is provided with a fixing groove matched with the fixing table, an adjustable electromagnet is arranged in the base, a magnet matched with the adjustable electromagnet is arranged at the bottom of the display ball, a gas compressor is further disposed in the base, a plurality of sprayers are evenly arranged in the arc-shaped groove circumferentially, the nozzles are connected with the gas compressor, and the nozzles are aligned to the display ball. Compared with the prior art, the display cabinet is provided with the display ball suspending under the action of the magnetic suspension device, and the display ball can be horizontally rotated freely. Compared with an existing display cabinet, masses only need to stop in one place to browse all exhibits, and the problem that the masses need to walk and watch a long-bar-shaped display cabinet in the prior art is solved.

Owner:宁波八瓦供应链管理有限公司

Dyeing process for ramie and tencel woven fabric

The invention relates to the field of dyeing process of fabrics, in particular to a dyeing process for ramie and tencel woven fabric. The dyeing process comprises the following steps: a, selecting plain weave fabric of ramie and tencel; b, seam inversion; c, singeing; d, desizing, boiling, and bleaching; e, dying by a two-bath dyeing method; and f, a post-integration process. The dyeing process improves the dyeing effect, and ensures gorgeous appearance and good comfort. Moreover, the prepared product meets the standard of GB18401-2003 national general safety technical code for textile products, and achieves the purely-natural environmental protection.

Owner:常州吉源棉麻印染有限公司

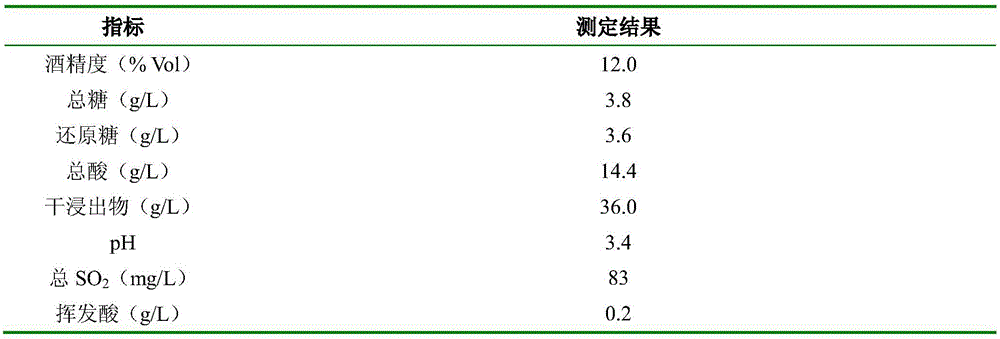

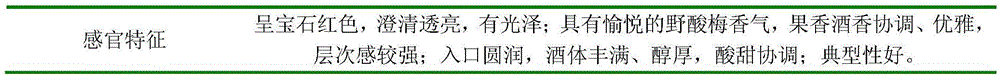

Prunus divaricata sparkling wine

ActiveCN106635651AGuaranteed juice yieldPrevent rotAlcoholic beverage preparationMicroorganism based processesSucroseSaccharum

The invention relates to prunus divaricata sparkling wine. Fresh prunus divaricata, sugar and excellent low-temperature-resistant acid-resistant saccharomyces cerevisiae are used as raw materials; xylitol is used as a flavor regulator; the prunus divaricata is subjected to the steps of freezing, unfreezing, extrusion peel breaking, enzymolysis, regulation, inoculation, fermentation, wine pouring, clarification and the like to obtain the stable-quality dry type prunus divaricata fermented wine base wine; then, sucrose and xylitol are added into the prunus divaricata fermented wine; stirring is performed until the materials are completely dissolved; yeast is inoculated into a fermentation tank; sealed fermentation is performed to obtain a prunus divaricata sparkling wine product. The special fruit of prunus divaricata in Xinjiang area is used as the raw materials for the first time for preparing the prunus divaricata sparkling wine; in addition, the special fruit wine yeast suitable for the low-temperature high-acid fermentation environment of the prunus divaricata is bred and selected; the normal fermentation process can be ensured; the problems of slow fermentation starting, slow progress, incomplete fermentation and the like caused by strong resistance environment can be avoided.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Inkstone and preparation method thereof

The invention provides an inkstone and a preparation method thereof. The inkstone includes a raw lacquer matrix base and an inkstone core embedded inside the base. The preparation method of the inkstone includes the steps that A, according to the shape of the base, an original matrix is manufactured; B, the outer surface of the original matrix is wrapped by cloth, and the surface of the cloth is coated with slurry containing raw lacquer and then dried in the shade; C, the step B is repeated one or more times until the thickness can meet the demand; D, the original matrix is detached and processed by ash coating and polishing to obtain the base; E, raw lacquer is used for embedding the inkstone core into the base, and then the inkstone core is dried in the shade. The inkstone is low in weight, stable and uneasy to deform and can be reinforced for shaping, the preparation method is simple in procedure, the operation conditions are mild, and high-temperature sintering conditions are not required.

Owner:王耀

Technology for processing rainbow multi-color film sheet

InactiveCN107933055AEmission reductionGorgeous appearanceSynthetic resin layered productsLaminationRainbowAging resistance

The invention relates to the field of chemical engineering, in particular to a technology for processing a rainbow multi-color film sheet. The process comprises the following steps: 1, mixing and drying TPU (thermoplastic polyurethane) raw materials; 2, adding the TPU raw materials in the step 1 into casting equipment to make a cast film, wherein screw extrusion temperatures in the casting equipment are as follows: the temperature of a first feeding section is set as 170-185 DEG C; the temperature of a second compression section is set as 180-205 DEG C; the temperature of a third discharging section is set as 185-200 DEG C; the temperature of a die head is set as 180-195 DEG C; 3, bonding the cast film in the step 2 and the upper and lower surfaces of a rainbow film; 4, cooling and rolling. The invention aims to provide a processing technology for processing the rainbow multi-color film sheet capable of realizing direct online lamination and improving the production efficiency. The rainbow multi-color film sheet prepared by the technology has excellent wear resistance, scratch resistance, low-temperature resistance and aging resistance, the experience effect of a user is increased,and economic benefits are increased.

Owner:GUANGDONG JUHANG INST FOR ADVANCED MATERIALS CO LTD +1

Millet compound health care coarse grain and preparation method thereof

The invention discloses a millet compound health care coarse grain and a preparation method thereof. The millet compound health care coarse grain comprises millet, black rice, Gorgon fruit, common yam rhizome, black soya beans, mung beans, peas, grape seed powder, sweet potato, wheat bran, pomegranate seeds, blueberry wine and the like. The millet compound health care coarse grain and the preparation method have the beneficial effects that the artificial compound health care coarse grain prepared by the method is prepared from natural food materials and contains multiple nutrient elements and trace elements, and the finished product is bright-colored and beautiful in appearance and soft in mouthfeel, and can be used for cooking congee or can be mixed with rice for cooling rice.

Owner:ANHUI HUACHUANG MODERN AGRI TECH

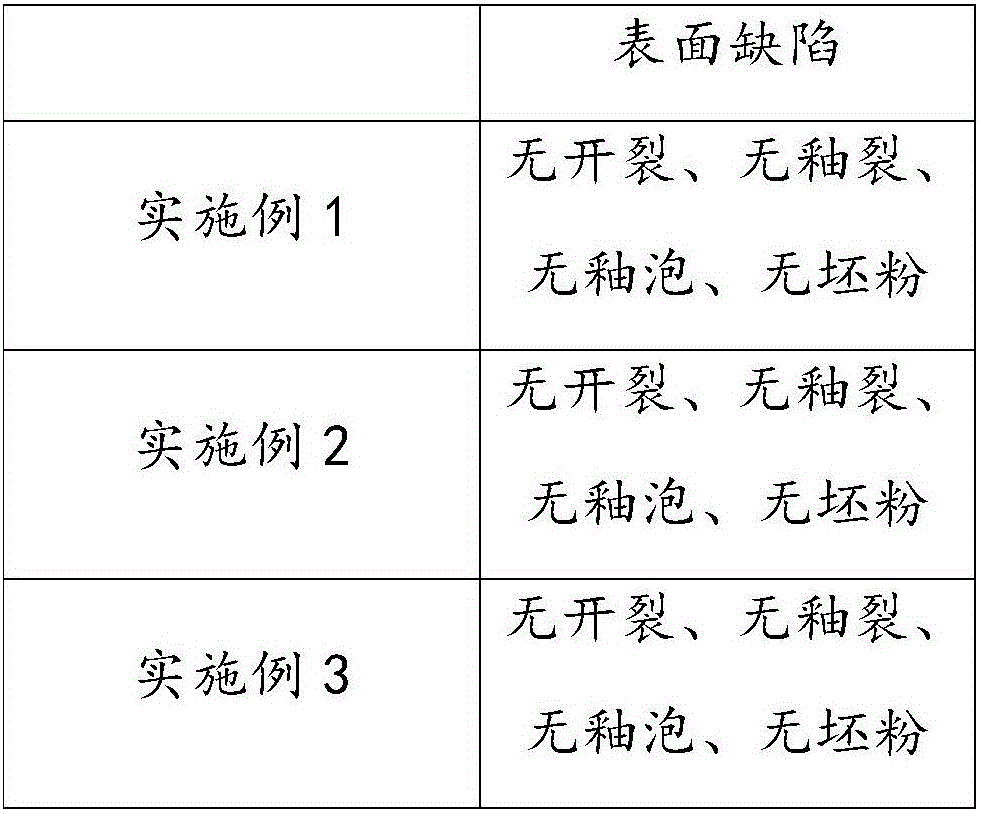

Method for preventing outdoor seedless cultivated Kyoho grapes from cracking

InactiveCN105052670AUniform growthGorgeous appearanceCultivating equipmentsPlant protectionGibberic acidThinning

The invention discloses a method for preventing outdoor seedless cultivated Kyoho grapes from cracking. The method comprises the steps of carrying out spike shaping during an initial flowering stage; carrying out seedless treatment during a full-bloom stage; immersing fruit clusters in gibberellic acid in 10-15 days after the full-bloom stage and carrying out expansion treatment on the fruit clusters by adding forchlorfenuron in the gibberellic acid; then fixing the fruit clusters and timely carrying out fruit thinning; covering a white mulching film on the ground after grapes are bagged, wherein relatively stable water in a grapery is ensured, fruits can gradually grow bigger and bigger, and grape fruits can be prevented from cracking. According to the method disclosed by the invention, through standard management such as spike shaping, fruit cluster fixing, fruit thinning, bagging by dedicated grape bags and shoot pinching, the adnation of fruits is uniform, the fruit clusters are gorgeous in appearance, the grape yield is stabilized, and the grape quality is increased.

Owner:ZHENJIANG AGRI SCI INST JIANGSU HILLY AREAS

UV printing process for color packaging box

InactiveCN111231533AImprove the three-dimensional effectGorgeous appearancePattern printingOther printing apparatusColored microspheresChemistry

The invention discloses a UV printing process for a color packaging box. The process comprises the following steps: (1) taking a box blank, printing color ink on the whole surface area of the box blank by using a first screen plate, and curing the printed color ink by using a UV lamp set to form a background pattern layer; (2) performing UV transparent gloss oil printing on the surface local areaof the background pattern layer by using a second screen plate to form a UV gloss oil bottom layer, wherein the thickness of the UV gloss oil bottom layer is not less than that of the background pattern layer; and (3) spraying colored microspheres on the surface of the UV gloss oil bottom layer before the UV gloss oil bottom layer is not cured. The UV gloss oil bottom layer is printed on the background pattern layer, and the colored microspheres are sprayed on the surface of the UV gloss oil bottom layer, so that a surface pattern layer is formed, the surface pattern layer is made to float onthe background pattern layer, a better three-dimensional effect is achieved, and the product is more beautiful and elegant in appearance.

Owner:深圳市星坤包装制品有限公司

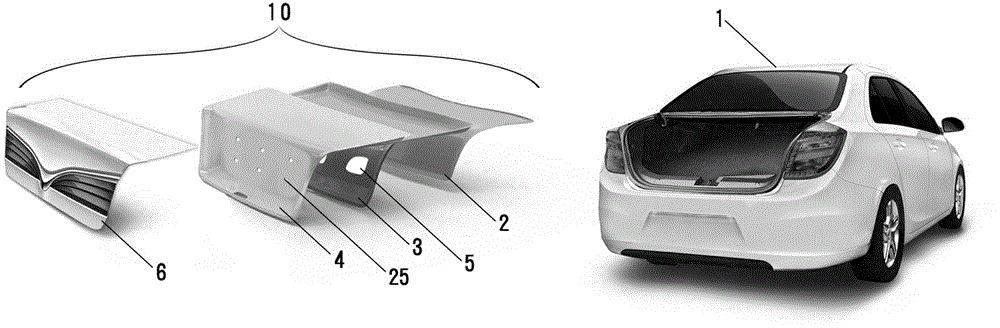

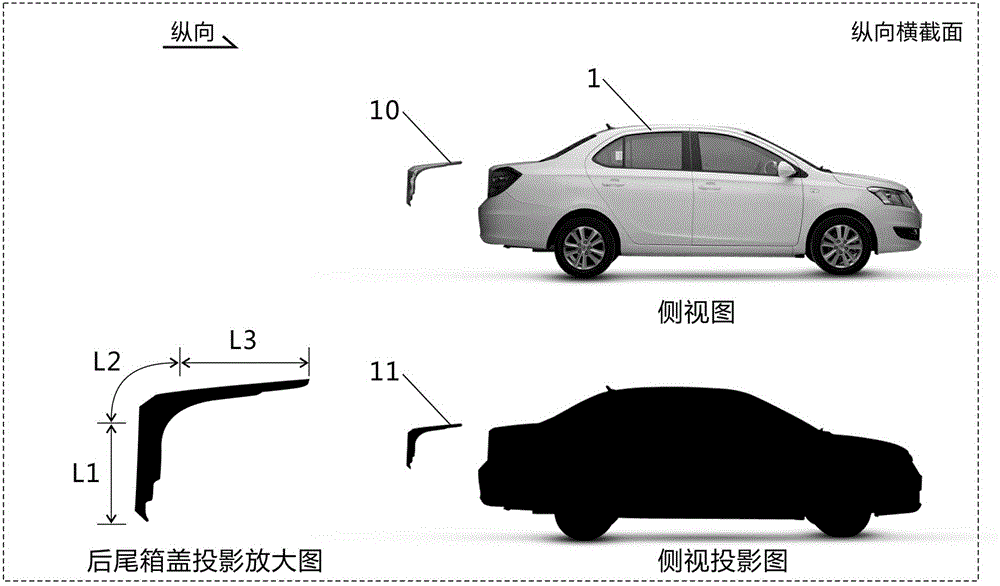

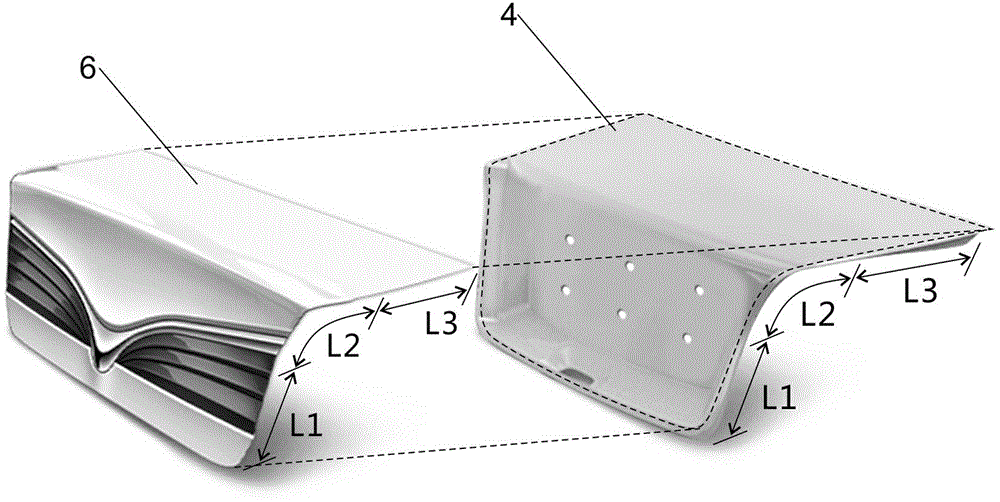

Rear box cover of sedan car

InactiveCN105083390AComplex shapeIngenious shapeSuperstructure subunitsEngineeringStructural engineering

The invention aims to solve the technical problems to ensure that a shell of a rear box cover of a sedan car can be manufactured at a lower cost and replaced in a convenient way, the structure of the shape of the tail part of the sedan car can be more ingenious, the appearance can be more attractive, and warning and decorating actions of local parts can be achieved through light. The rear box cover has a technical scheme that outer side surfaces of a vertical part, a bending part and a horizontal part of an outer shell are offset inwards, an outer decorating body is additionally arranged, and the outer decorating body is formed by decorating parts, of which the types are more than two and the number is more than four, such as transparent decorating bodies, decorating lamps, non-transparent decorating pieces, bright reflection decorating pieces and the like.

Owner:张清华

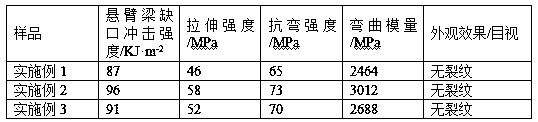

Cloud rhyolitic plastic product processing method taking ABS as base material

The invention discloses a cloud rhyolitic plastic product processing method taking ABS as a base material. Plastic compositions comprises 56-71% ABS plastic grains, 10-15% of cloud color masterbatch,10-20% of modified glass fiber, 5-9% of compatilizer, 1-2% of flexibilizer, 0.5-1.5% of lubricant and 0.2-0.5% of antioxidant. Accordingly, a composite material with rhyolitic color is prepared through melting coextrusion, rhyolitic plastic product processing is achieved by means of an injection molding process, and the plastic product has the gorgeous appearance. By adding the modified glass fiber and ABS-g-MAH in the composite material, interface adhesion between two phases of ABS and cloud color masterbatch and mechanical property of the composite material are improved, and the prepared plastic product has cloud rhyolitic and keeps high mechanical strength.

Owner:广东品凡派塑胶实业有限公司

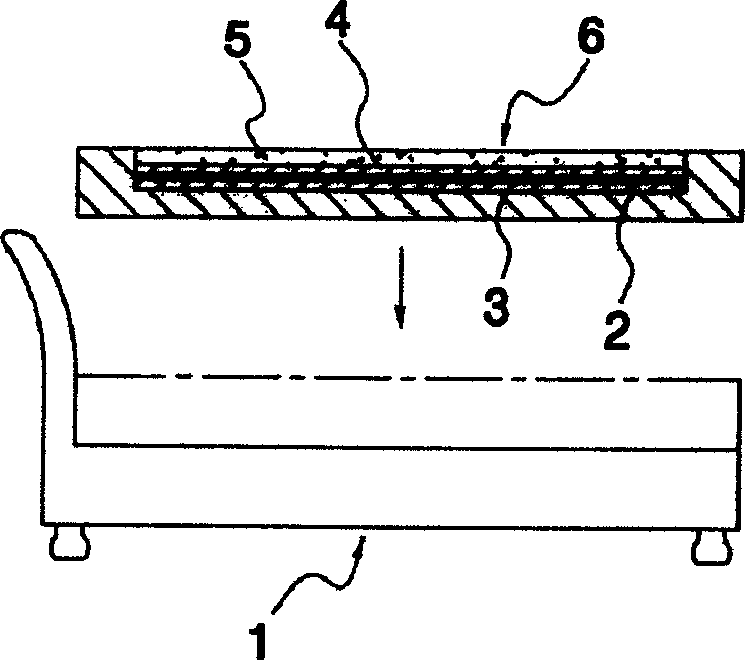

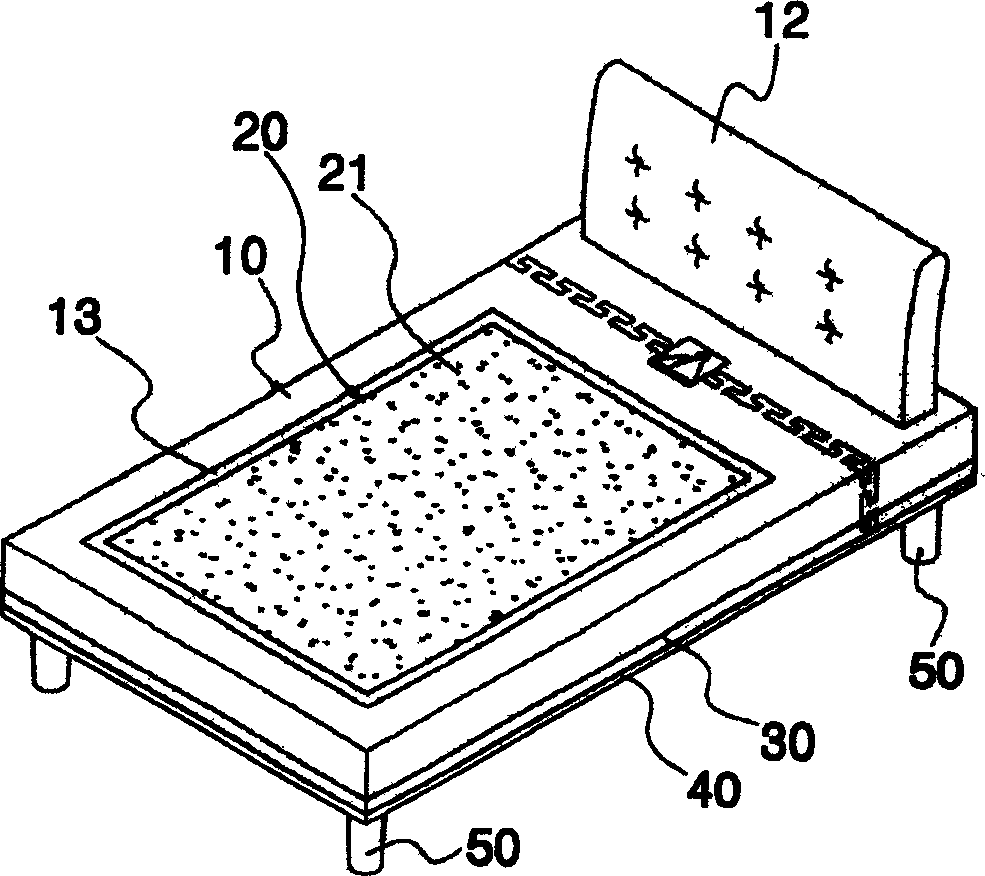

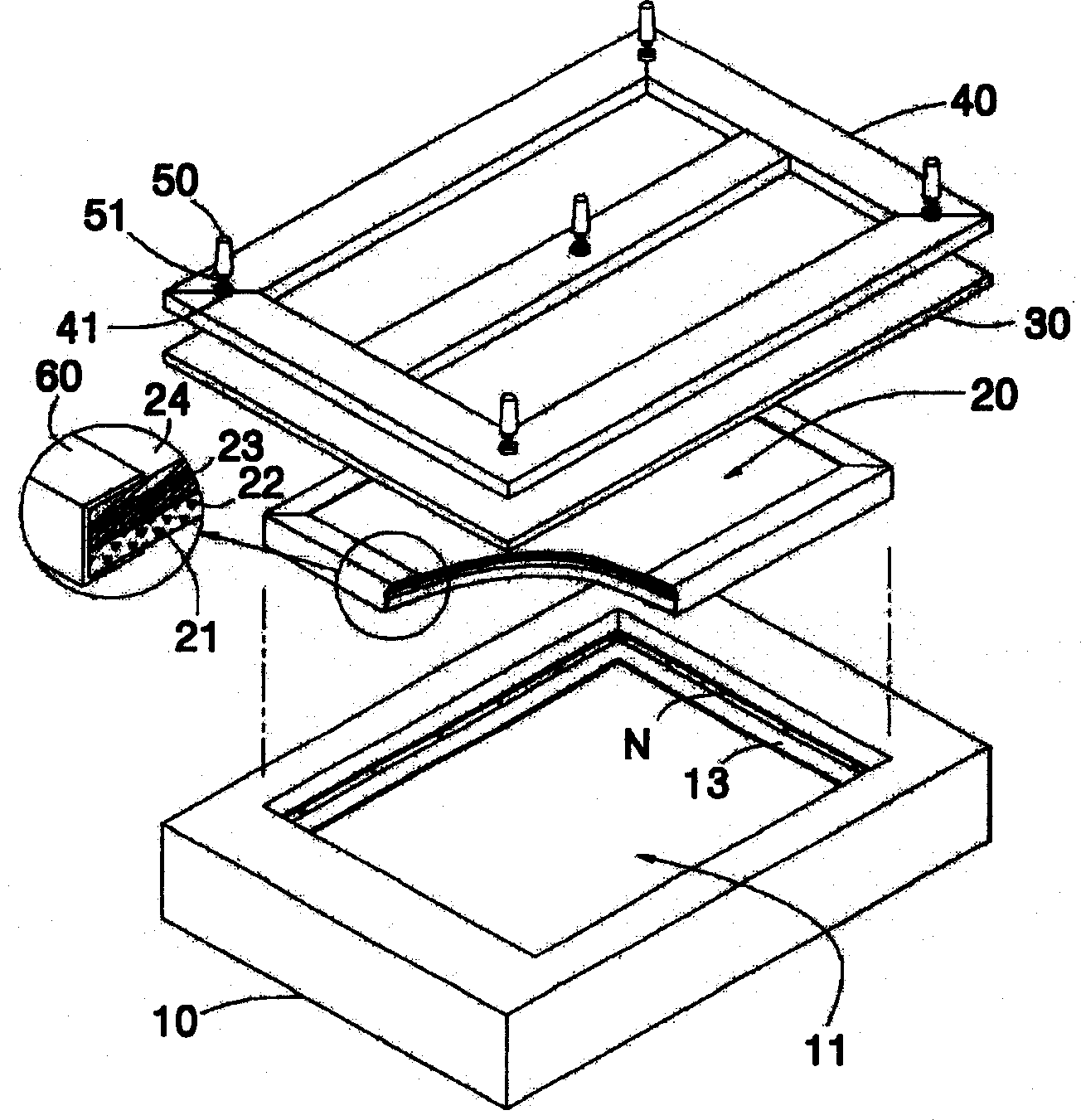

Mattress integrated stone bed

A connector for a synthetic resin pipe is provided to easily and stably connect the synthetic resin pipes by heating fused members with a high-frequency molding machine. Grooves(3,3') and protrusions(4,4') are formed at the outside of connecting bodies(2,2'). Coupling holes(6,6') are formed at both sides of the connecting bodies. Fused members(9,9') are disposed at the inner faces of the connecting bodies. A high-frequency molding machine is connected to a connecting ring(21) and a press plate(22) enclosing the connecting bodies, and heats the fused members.

Owner:曹茂铉

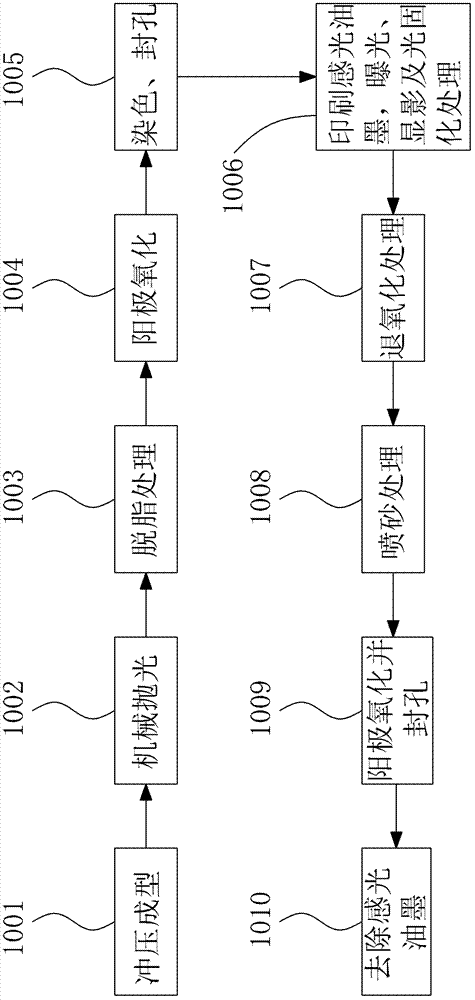

Aluminum alloy surface treatment method and its products

ActiveCN103253072BImprove reflectivityImprove sandblasting resistanceAnodisationDuplicating/marking methodsScreen printingMetallurgy

The invention discloses a method for surface treatment of an aluminium alloy and a product of the aluminium alloy. The method comprises the steps of punching the aluminium alloy into a required shape; conducting mechanical polishing on the aluminium alloy which is subjected to punch forming; conducting degreasing treatment on the aluminium alloy which is subjected to mechanical polishing in a degreasing agent; placing the aluminium alloy which is subjected to degreasing treatment into an acid liquor tank for first-time anodic oxidation; placing the aluminium alloy which is subjected to first-time anodic oxidation into dye for dying, and conducting hole sealing treatment after dying; conducting screen printing on the surface of the aluminium alloy which is subjected to dying and hole sealing treatment with photosensitive ink, and conducting exposure, developing and photocuring treatment; conducting oxidation film removing treatment on the printed aluminium alloy in an alkaline solution; conducting sand blasting treatment on the treated product of the aluminium alloy; conducting second-time anodic oxidation on the product of the aluminium alloy, which is subjected to sand blasting treatment, and conducting hole sealing treatment on the product which is subjected to second-time anodic oxidation; and removing the photosensitive ink from the surface of the product of the aluminium alloy. The product of the aluminium alloy is processed by the method.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Technology for dyeing silk fabric by using indigo pigment

InactiveCN106811995AUniform dyeing effectImprove working environmentDyeing processWorking environmentHue

The invention relates to a dyeing process of indigo dyed silk fabrics, which comprises the following steps: (1) placing the silk fabrics in an aqueous solution in which an alkali agent is dissolved for pretreatment. (2) placing the pretreated silk fabric in a protease solution for enzyme treatment. (3) Soak the silk fabric after the enzyme treatment in the dye material liquid that is configured with dispersant, dye cosolvent, alkali agent, reducing agent, acid agent, antioxidant, anti-over-reducing agent, leveling agent and dye it. The dyed silk fabric is washed and dried to obtain the dyed silk fabric. The invention adopts pretreatment and enzyme treatment for dyeing, which can make the dyeing effect uniform, and endow the fabric with better dyeing rate, abrasion fastness and washing fastness. The indigo dyeing method of the invention is convenient for automatic operation, has a good working environment and stable hue, and improves the competitiveness of products in the market.

Owner:苑少纯

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com