Aluminum alloy surface treatment method and aluminum alloy surface treatment product

A technology of aluminum alloy surface and treatment method, applied in the direction of surface reaction electrolytic coating, anodic oxidation, electrolytic coating, etc., can solve the problems of mirror surface and sandblasting effect, product surface sandblasting marks, long process, etc., to achieve a beautiful appearance Variety, short process, saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

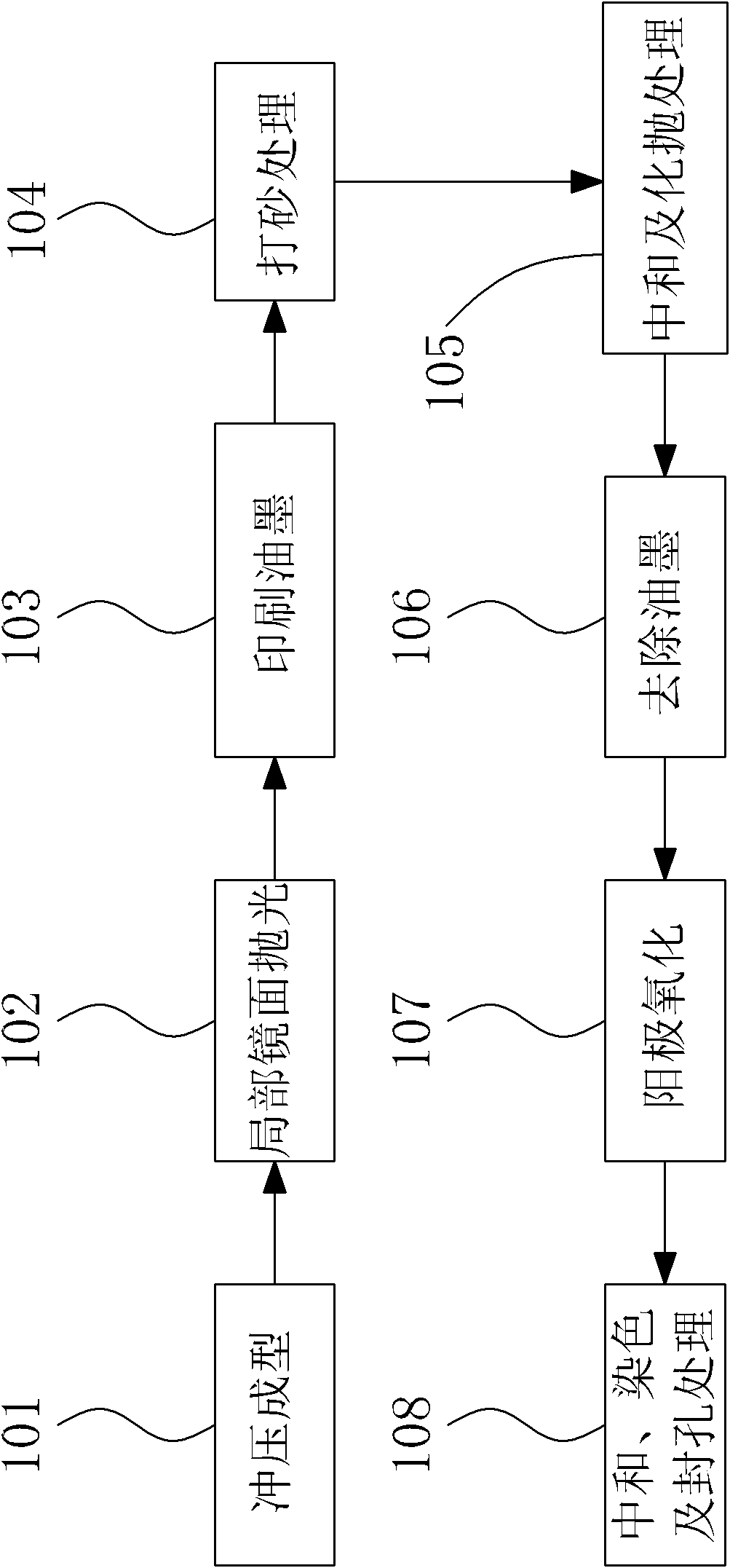

[0024] For having further understanding to the object of the present invention, method step and function, now in conjunction with figure 1 The details are as follows:

[0025] An aluminum alloy surface treatment method of the present invention, in this embodiment, comprises the following steps:

[0026] Step 101: Stamping the aluminum alloy part to a desired shape;

[0027] Step 102: Mirror-polishing part of the stamped aluminum alloy part to achieve a mirror effect;

[0028] Step 103: screen-print acid and alkali-resistant ink on the above-mentioned mirror area, and bake the aluminum alloy part; then place the printed aluminum alloy part in a degreasing agent for degreasing treatment, so as to remove surface grease;

[0029] Step 104: sanding the aluminum alloy parts after the above degreasing treatment. During the sanding treatment, an acidic or alkaline solution is used to corrode the surface of the aluminum alloy parts. The unprinted ink area reacts with corrosion to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com