Patents

Literature

121results about How to "Crystal clear appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Camellia oil preparation method for cosmetics

ActiveCN101305974AImprove quality requirementsCrystal clear appearanceCosmetic preparationsToilet preparationsCamellia oleiferaFiltration

The invention relates to a preparation method of cosmetics camellia oil. High-quality camellia seeds are selected to be used as the raw material; the camellia seeds are roasted under the negative pressure and at the lower temperature, and are husked after natural cooling and are squeezed at the room temperature to obtain high-quality crude oil with low acid value and pale yellow color; impurities are removed through filtration under the heating condition, alkali refining and ethanolic extracting two-stage process is utilized for acid stripping and de-coating; then the mixture composed of active carbon and floridin is used as de-coloring agent for de-pigmentation; peroxide and unclean flavor are removed through deodorization; then the drying winterization is acted; finally, the cosmetics camellia oil is obtained, wherein, the acid value is less than 0.1 mgKOH / g, the peroxide value is less than 0.5 mmol / kg, the appearance is colourless approximately as well as clear and translucent, and no unclean flavor exists. The cosmetics camellia oil reaches or exceeds the requirement of the national standard GB11765-2003 on first level expressed tea-seed oil, and can be directly used for manufacturing the cosmetic such as skin care oil for babies; in addition, an edible camellia oil fabrication plant can be improved for production, thereby lowering the investment cost greatly.

Owner:广东新大地生物科技股份有限公司

Method for making bitter melon preserves

The invention discloses a method for making bitter melon preserves, and belongs to the technical field of food processing. The method for making bitter melon preserves is characterized by mainly comprising the steps of material selection, raw material pre-processing, slicing, hardening, rinsing, hot ironing, cooling, sugar curing, sugar stewing, drying, packaging and the like. The method for making bitter melon preserves is simple, the cost of the raw materials and processing equipment is low, implementation is convenient, and products are rich in nutrient, crisp and tasty in taste, both sweet and bitter, bright glittering and translucent in appearance, and have the fresh scent of bitter melons. The method provides technical support for deep processing bitter melons, further improves the commercial value of deep-processed products of bitter melons, and achieves good economical benefits.

Owner:陶峰

Green plum fruit jelly and preparation method thereof

The invention relates to a green plum fruit jelly and a preparation method thereof, wherein the green plum fruit jelly is characterized in that the green plum fruit jelly is prepared from fresh green plum fruit, green plum juice, compound gelatinizing agent, sugar, acid, and water; the green plum fruit jelly comprises the following raw materials according to mass percent: 1-5 wt% of green plum juice, 5-7 wt% of green plum fruit, 25-30 wt% of white sugar, 0.1-0.4 wt% of citric acid, 6-8 wt% of compound gelatinizing agent, and rest of water; the jelly has the characteristics of suitable sour and sweet, smooth mouthfeel, good elasticity and rich nourishment; therefore, the green plum fruit jelly is popular with consumers.

Owner:LABIXIAOXIN (FUJIAN) FOOD INDUSTRY CO LTD

Quick-frozen coarse grain dumplings and preparation method thereof

The invention discloses quick-frozen coarse grain dumplings and a preparation method thereof. Each quick-frozen coarse grain dumpling comprises a dumpling wrapper and stuffing, wherein the dumpling wrapper is mainly prepared from coarse grain and hot water; and the coarse grain comprises the following components in part by weight: 10 to 50 parts of taro and 20 to 90 parts of tapioca. The quick-frozen coarse grain dumplings have excellent mouthfeel and crystal clear appearance, are rich in dietary fibers, and can basically maintain the moisture contained in dumpling wrappers under freezing conditions so as to avoid the cracking of the dumpling wrappers caused by the loss of the moisture.

Owner:罗晖

Liquid capsule and production method thereof

InactiveCN1568942AImprove bioavailabilityImprove sealingCapsule deliverySemi solidBiomedical engineering

Owner:HAINAN PULIN PHARMA +2

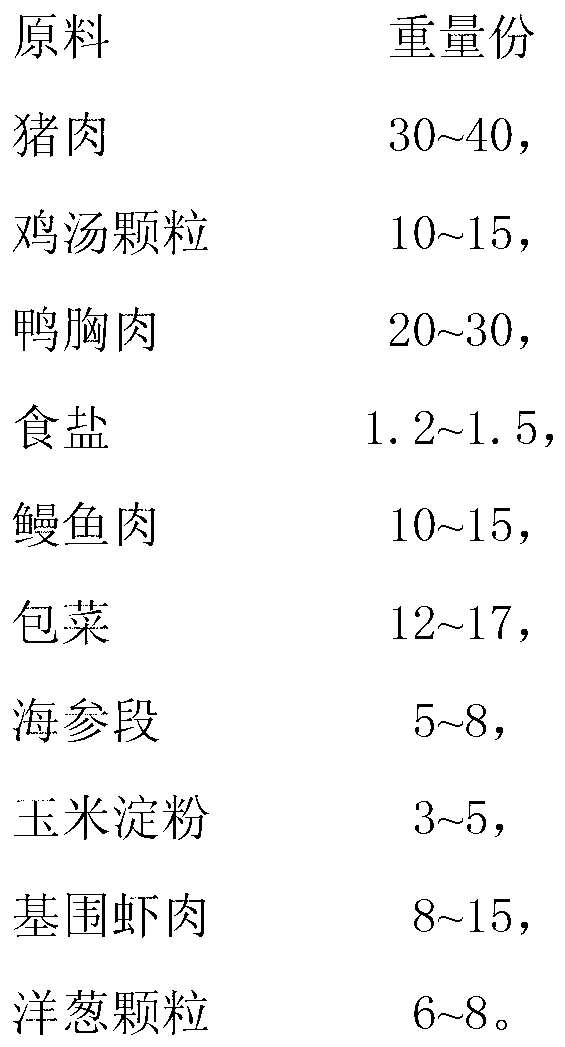

Quick-frozen dumplings and making method thereof

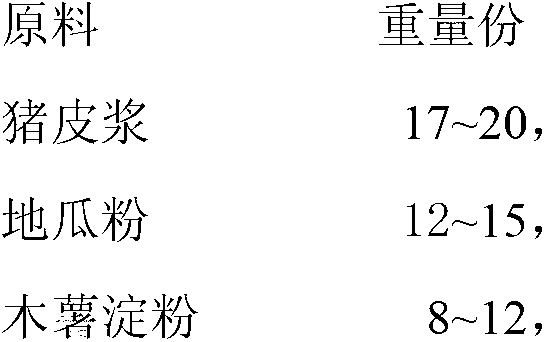

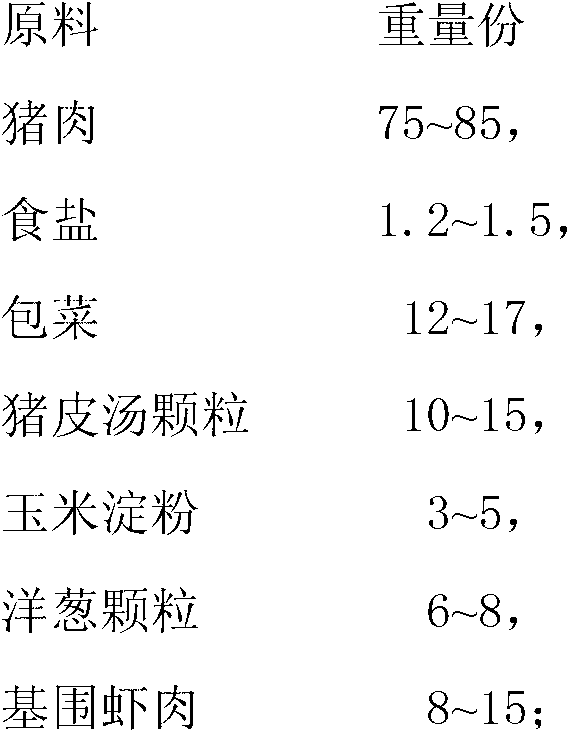

The invention belongs to the technical field of quick-frozen foods and specifically discloses quick-frozen dumplings and a making method thereof. The quick-frozen dumplings disclosed by the invention are made by wrappers and stuffing according to the weight ratio of 1:(2-3), wherein the wrappers take pig skin slurry, sweet potato flour, cassava starch and gluten flour as raw materials; and stuffing takes pork shoulder, common salt, cabbage, pig skin soup particles, corn starch, onion particles and shrimp meat as raw materials, wherein the pig skin soup particles in the stuffing are formed by slow cooking of fresh pig skin, pony roll bones and assistant spices, and the remaining pig skin is further used for making the pig skin slurry. According to the quick-frozen dumplings disclosed by the invention, the quality of the dumplings is improved, and the production cost is simultaneously greatly saved; and in addition, the pig skin soup used in the quick-frozen dumplings disclosed by the invention is added into the meat stuffing in the form of frozen small particles and slowly fused with the meat stuffing during the stewing process of the dumplings, thus the taste is more delicious. The products are directly placed into boiling water for boiling continuously for 6 minutes and then taken out, thus the appearance is glittering and translucent, the taste of the wrappers is elastic and smooth, the stuffing is delicious and unchanged in original taste, and the soup of the dumplings is clear.

Owner:WUHAN MINYI FOOD

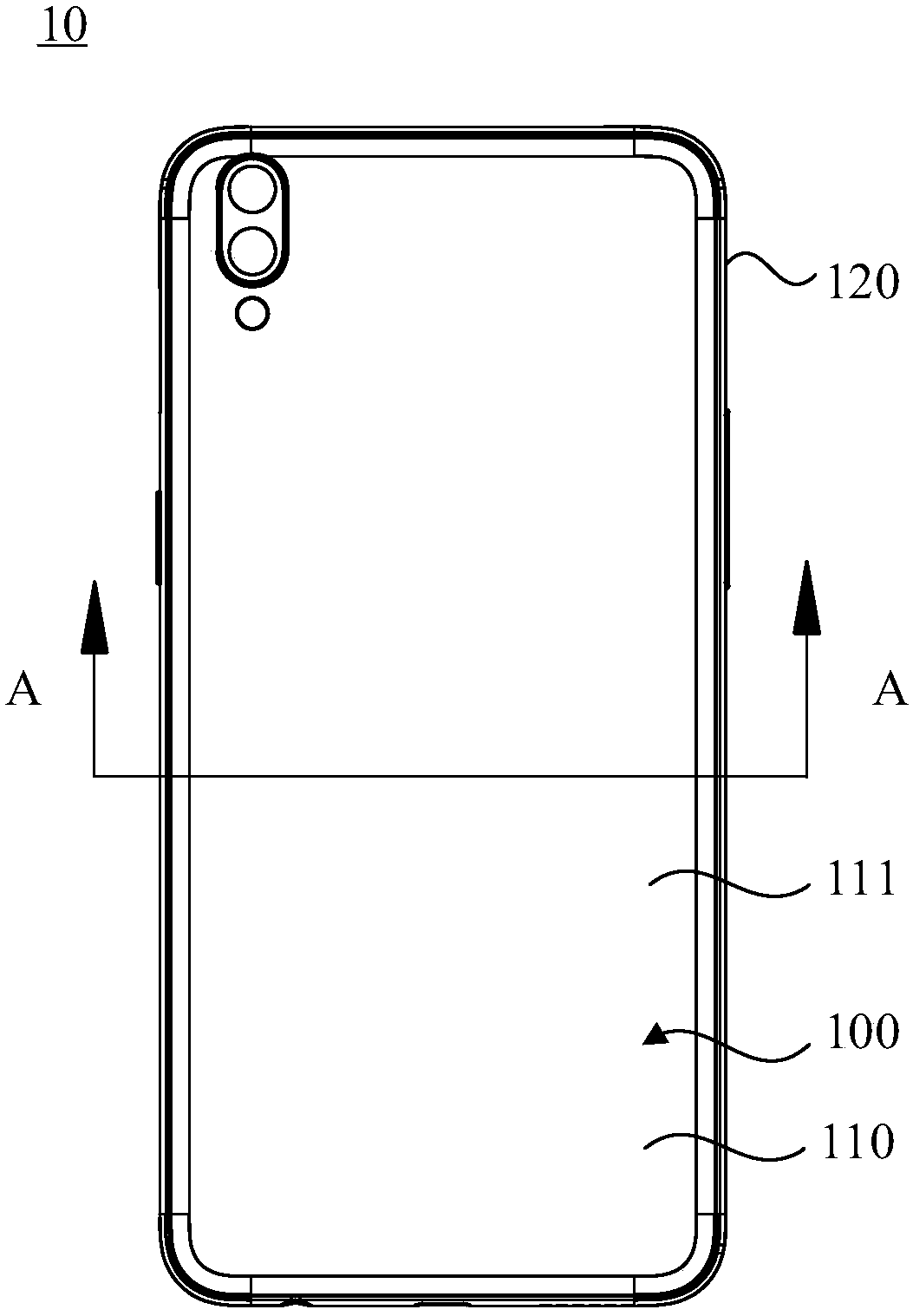

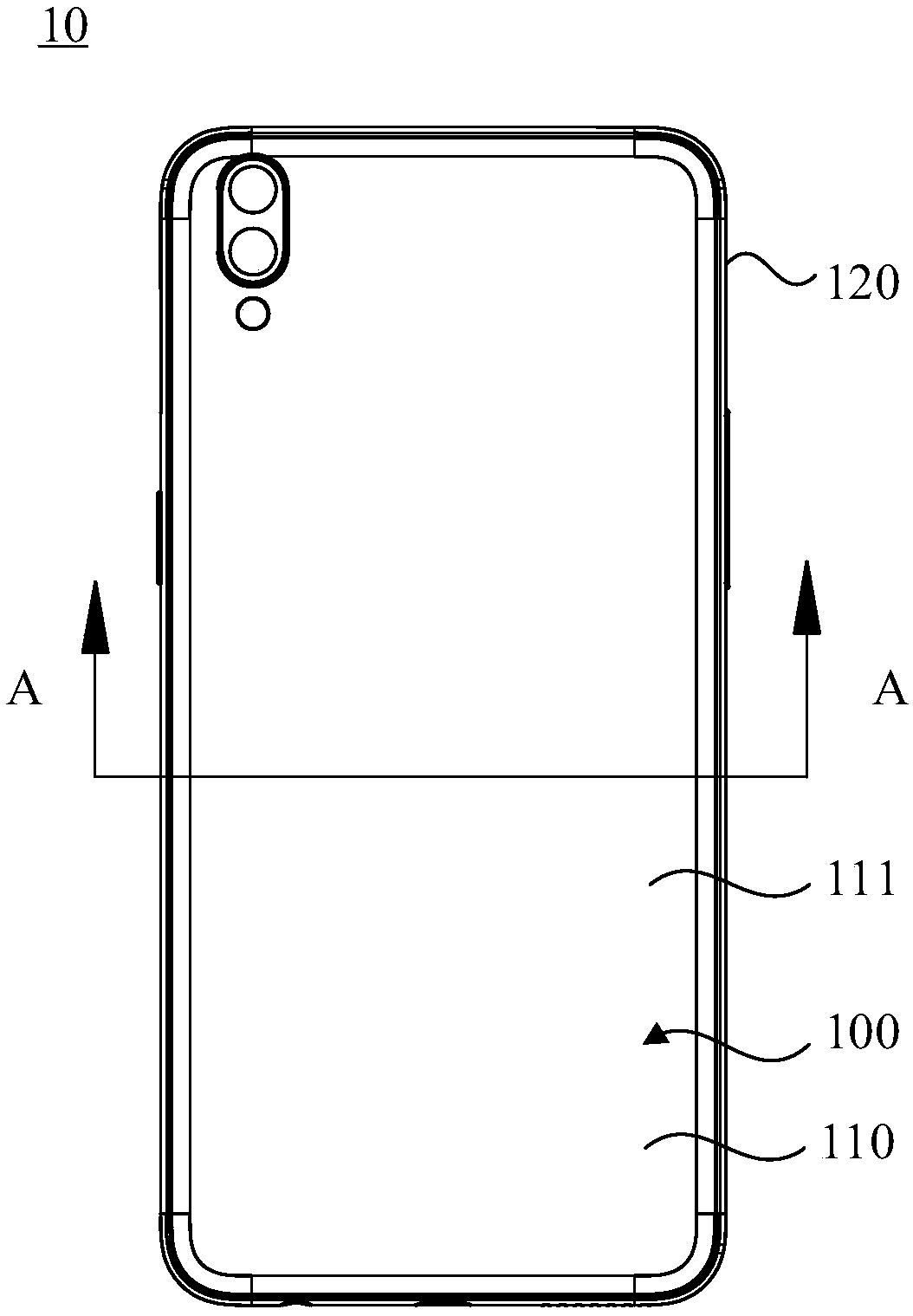

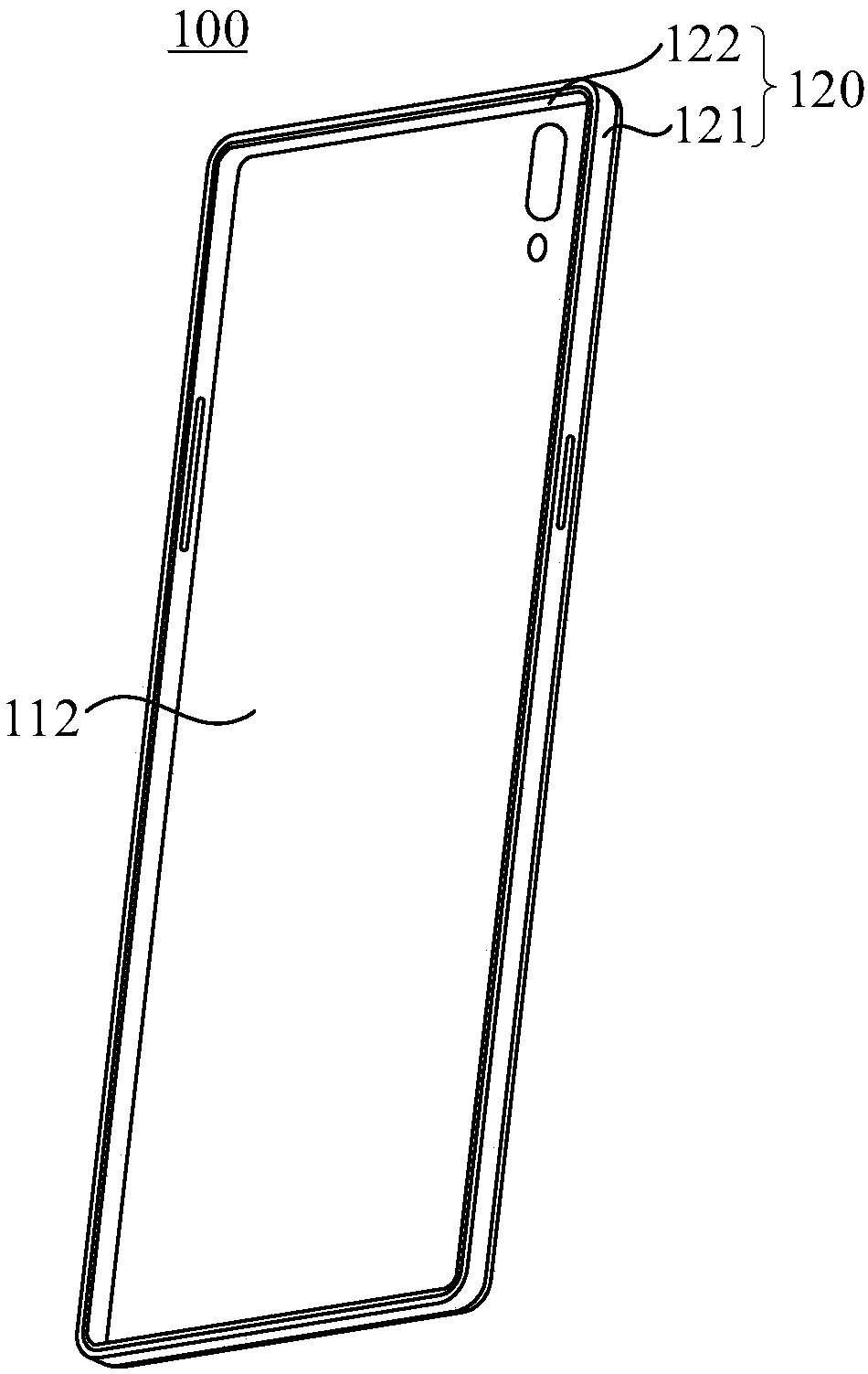

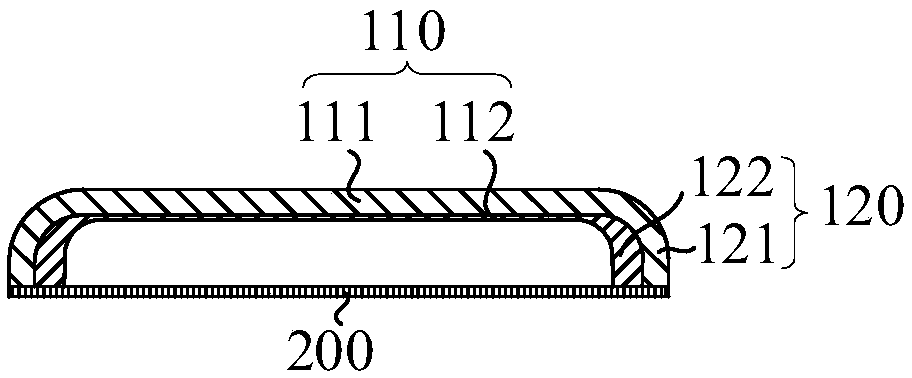

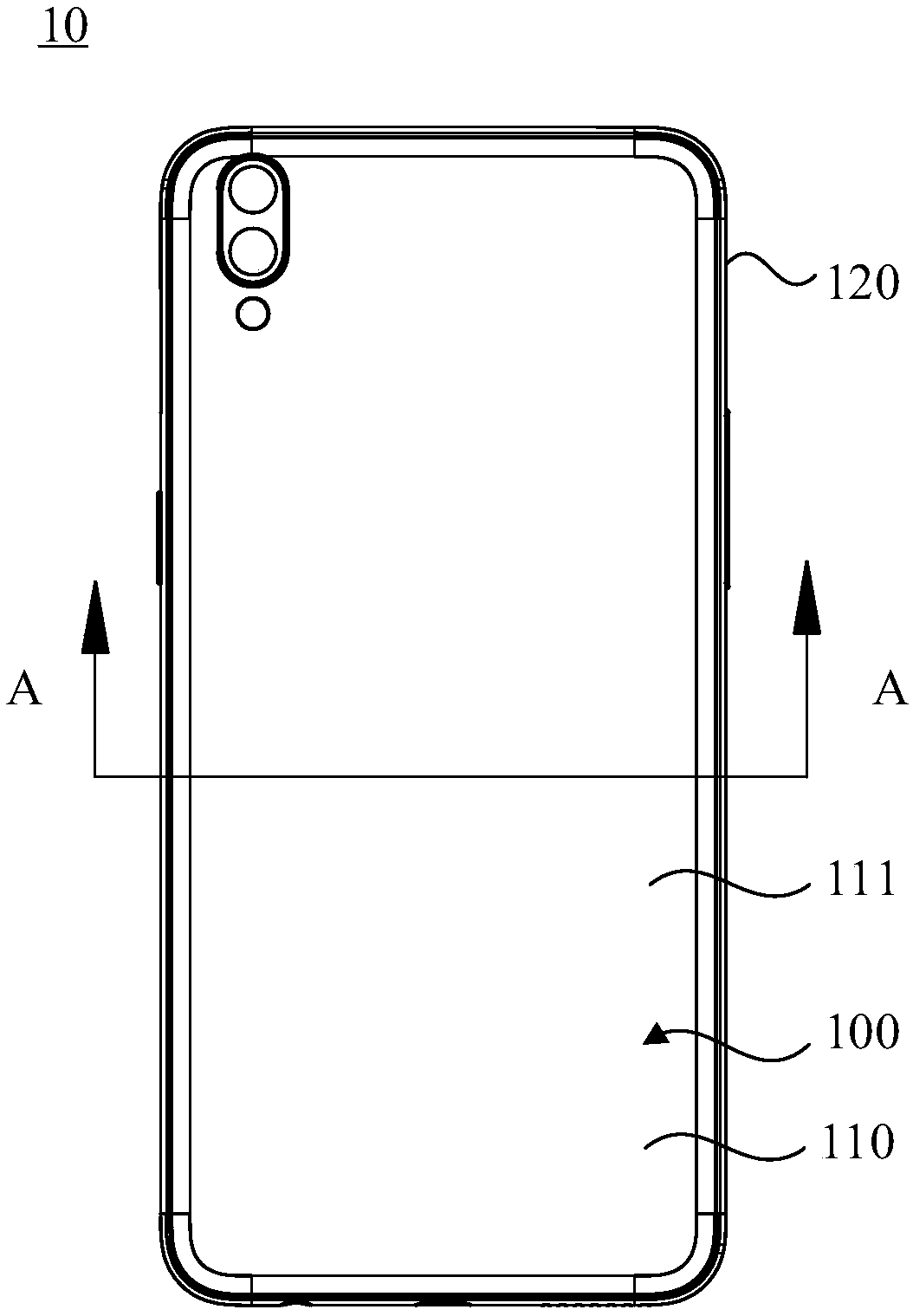

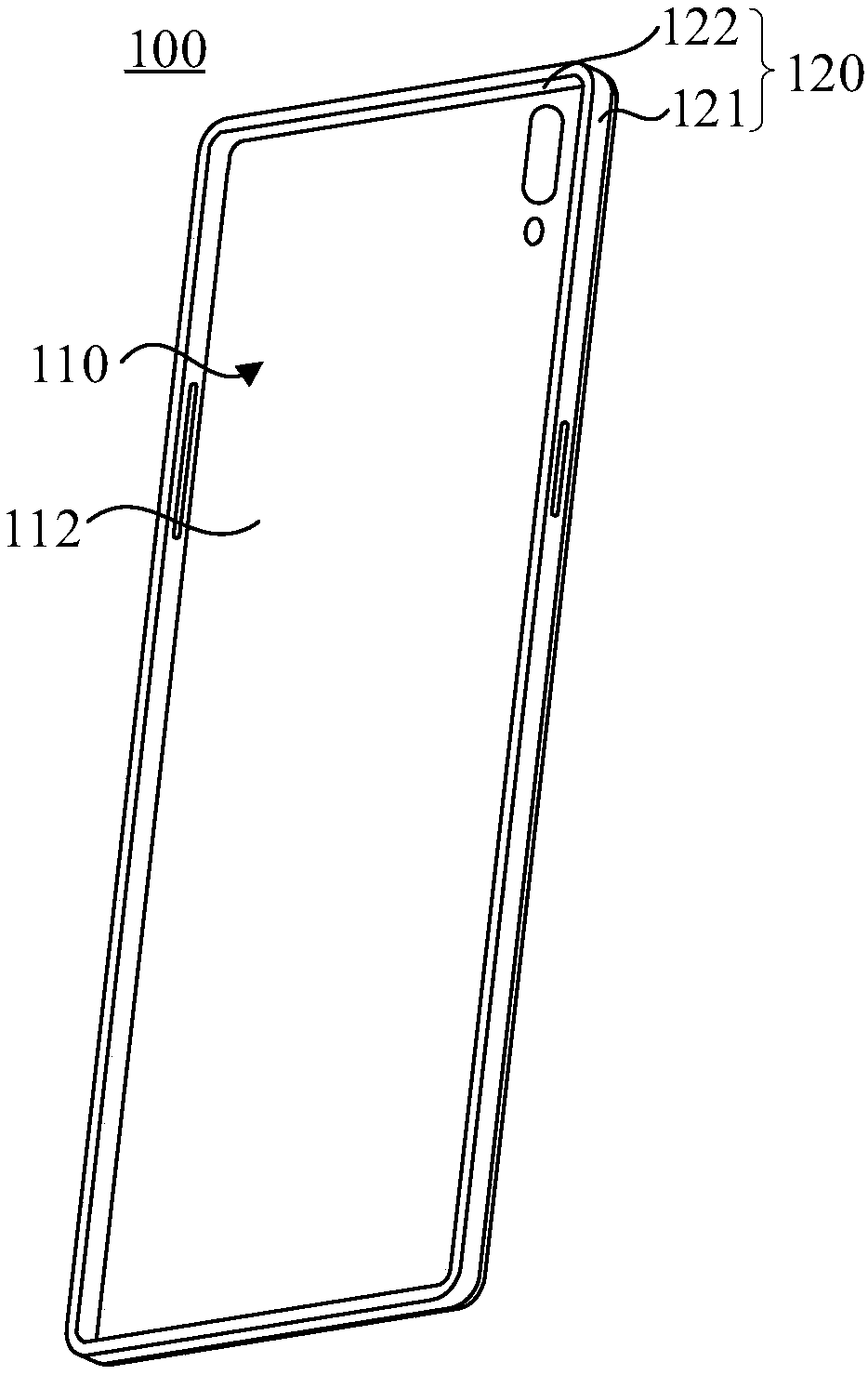

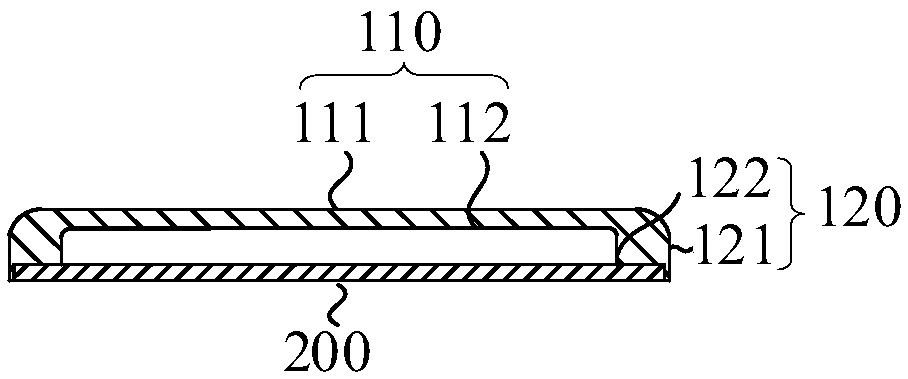

Shell, electronic device and production method for shell

InactiveCN108401049AImprove the three-dimensional effectCrystal clear appearanceGlass reforming apparatusTelephone set constructionsFlat glassSurface processing

The invention relates to a shell, an electronic device and a production method for the shell. The production method for the shell comprises the following steps of a, providing plate glass and carryingout hot bending on each edge of the plate glass, thereby obtaining a glass body comprising a plate part and bended edges; b, carrying out thinning processing on the plate part at the side wherein anouter surface of the plate part of the glass body is; and c, carrying out surface processing on the outer surface of the glass body, thereby obtaining the shell comprising a main body and a side wallpart, wherein the side wall part is thicker than the main body. According to the production method for the shell, the hot bending is carried out to obtain the glass body and the thinning processing iscarried out on the plate part of the glass body to obtain the shell of which side wall part is thicker than the main body, so the operation is simple, and the production cost is reduced. The shell isan integrated structure and is seamless. The appearance of the shell is glittering and translucent, and a visual effect is good. The side wall part is thicker than the main body, namely, the thickness difference exists between the side wall part and the main body, so the stereoscopic impression of the shell is high, and the aesthetic feeling and hand feeling of the shell are improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

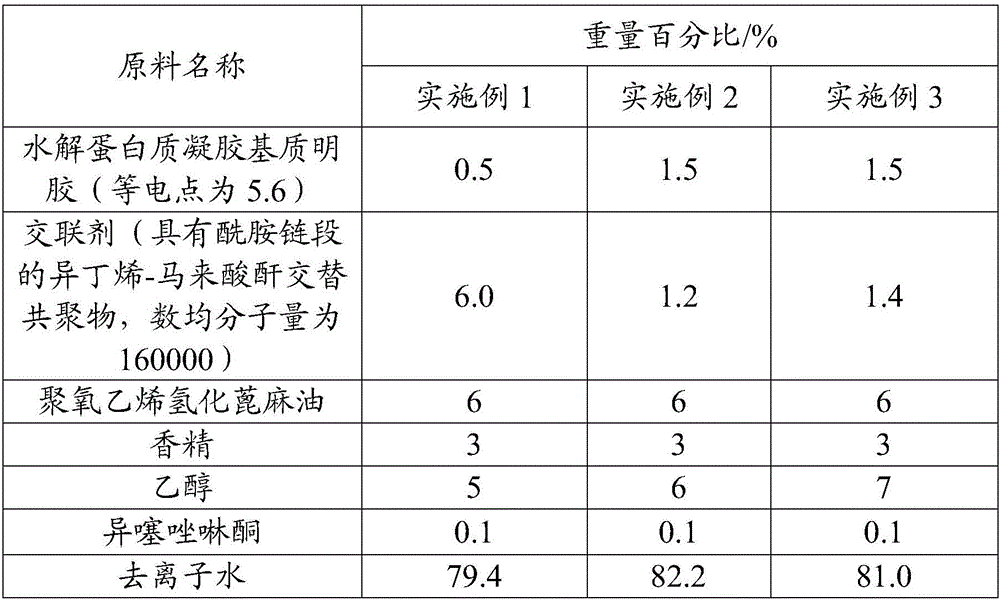

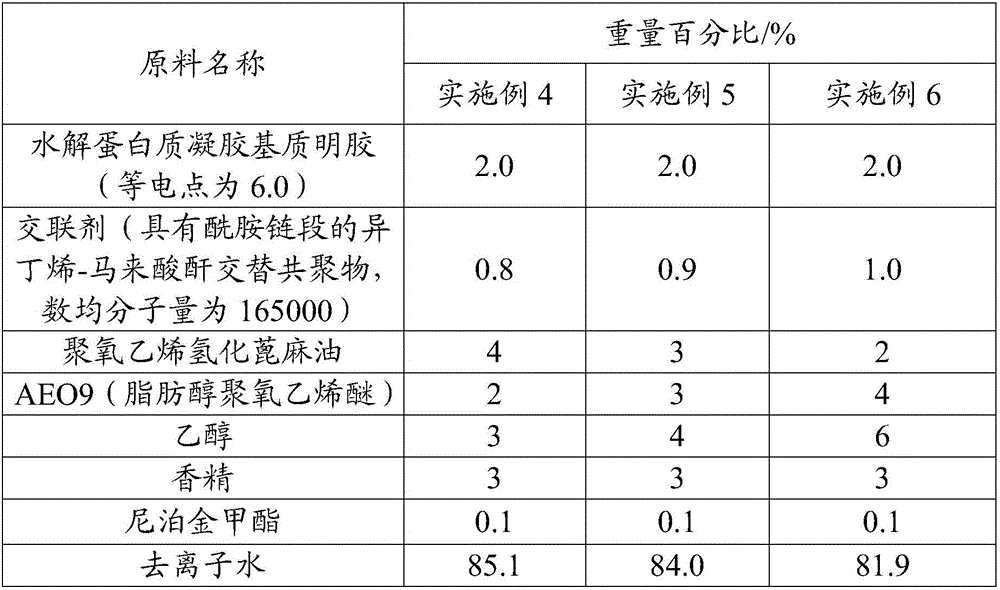

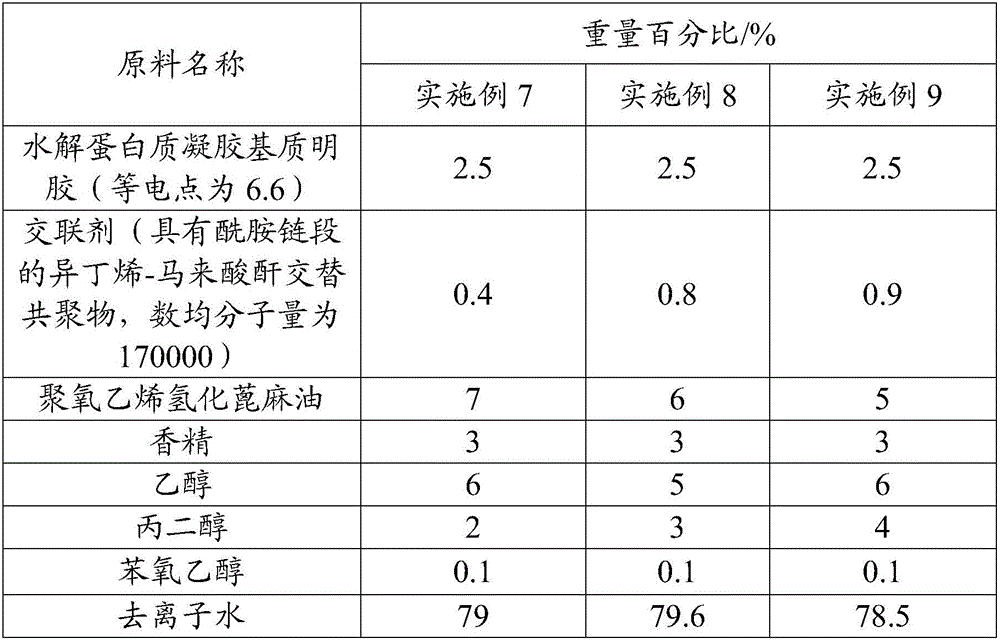

Air freshener and preparation method thereof

The invention relates to an air freshener and a preparation method thereof. The air freshener is prepared from the following components as raw materials by weight percent: 0.4%-6% of cross-linking agents, 0.5%-10% of gel, 1%-15% of solubilizers, 0.1%-15% of cosolvents, 0.05%-0.5% of preservatives, 0.5%-6% of flavor and fragrance and the balance of water. The air freshener provided by the invention is a gel solid with penetrating appearance, has good high temperature stability and excellent colloid elasticity, can slowly release, can have long-lasting fragrance and can please mind and body.

Owner:广州超威生物科技有限公司

Healthcare water-chestnut cake and preparing method thereof

InactiveCN104026514ASignificant progressHeat-clearing and detoxifyingNatural extract food ingredientsFood ingredient functionsFlavorWater Chestnuts

The invention belongs to the technical field of food preparation, and in particular relates to healthcare water-chestnut cake and a preparing method thereof. According to the preparing method, wheat starch, mulberry, rose apple, mint, chrysanthemum, rock candy and honey are added into the water-chestnut cake, so that the prepared water-chestnut cake has various healthcare functions of clearing away heat and toxic materials, protecting the skin and beautifying, clearing liver and improving vision, cooling blood and promoting secretion, smoothening urea, relaxing the bowel, resolving dampness and eliminating phlegm, helping digestion to relieve swelling, reducing the weight and fat, tonifying spleen and appetizing, and the like; the water-chestnut cake is glittering and translucent in appearance, contains fruit grains inside, is fresh and cool and elastic in taste, further has the characteristics of natural fragrance of flowers and fruits, rich taste, no sweet greasiness, unique flavor and the like, moreover the raw materials are easily available, the preparation is simple, and requirements of different markets and people can be met.

Owner:陈国勇

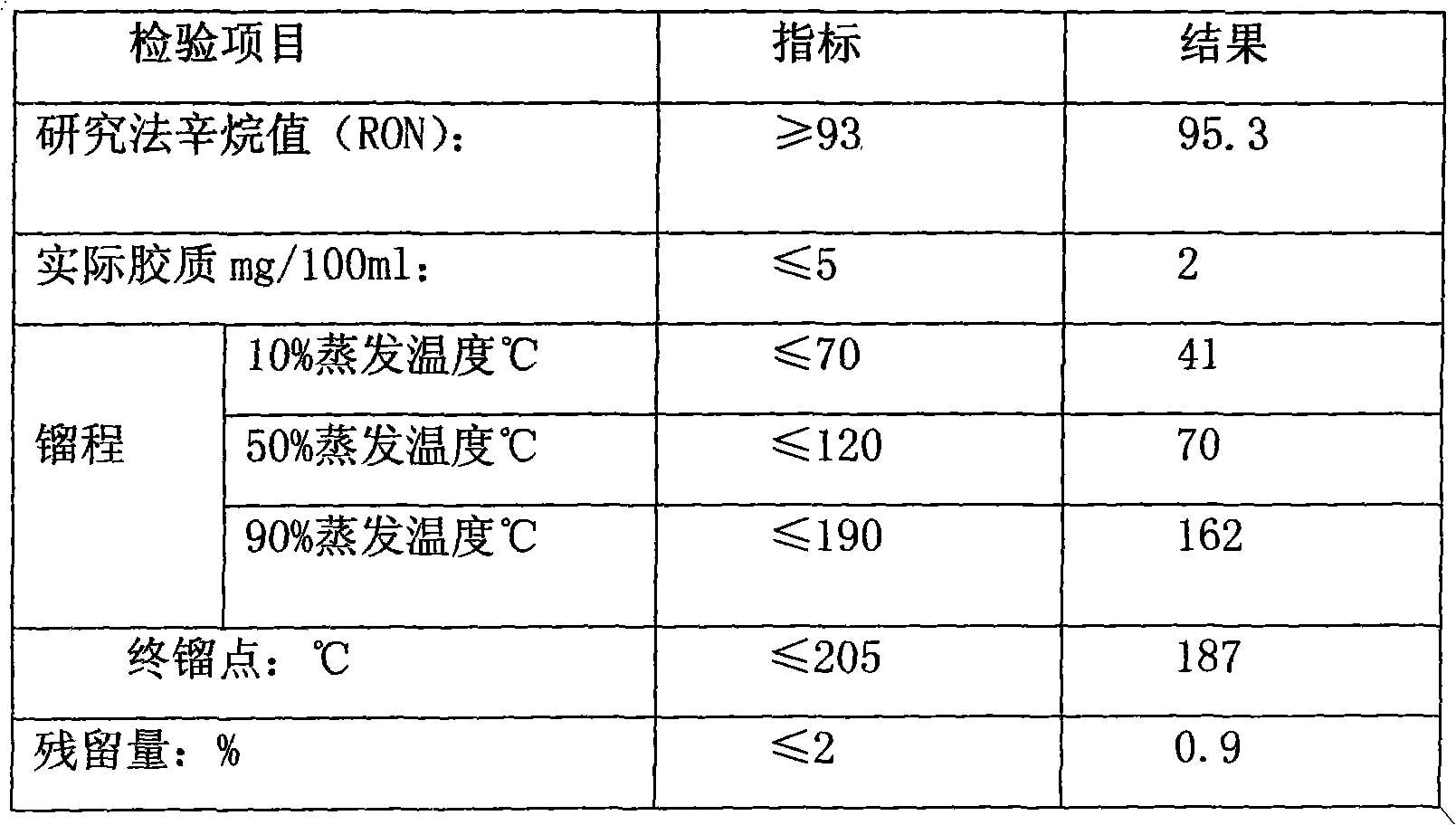

Environment-friendly fuel for novel automobile and preparation method of the environment-friendly fuel

The invention discloses an environment-friendly fuel for novel automobiles and a preparation method of the environment-friendly fuel. The environment-friendly fuel for novel automobiles comprises the following raw materials by weight: 35-85% of methanol and less than 60% of dimethyl ether as main combustible ingredients, 1-7% of isobutanol as a combustion improver, 1.5-5% of diethyl ether as an igniting agent, 0.2-1% of dodecanol as a cosolvent, 0.05-0.1% of hexamethylenetetramine as a preservative, 0.05-0.1% of T501 as an antioxidant, 0.2-1% of N,N'-disalicyl-1,2-propane diamine as an anticorrosive agent, and 0.1-1% of dimethyl carbonate as a dispersant. The preparation method of the environment-friendly fuel for novel automobiles comprises adding the materials in step 1, circulating in step 2, standing in step 3, and checking in step 4. The environment-friendly fuel for novel automobiles described by the invention has the characteristics of being stable in property, good in shock resistance, strong in dynamic property, sufficient in combustion, low in oil consumption, clean and friendly to the environment, easy starting, no air lock, and no delamination.

Owner:张长生

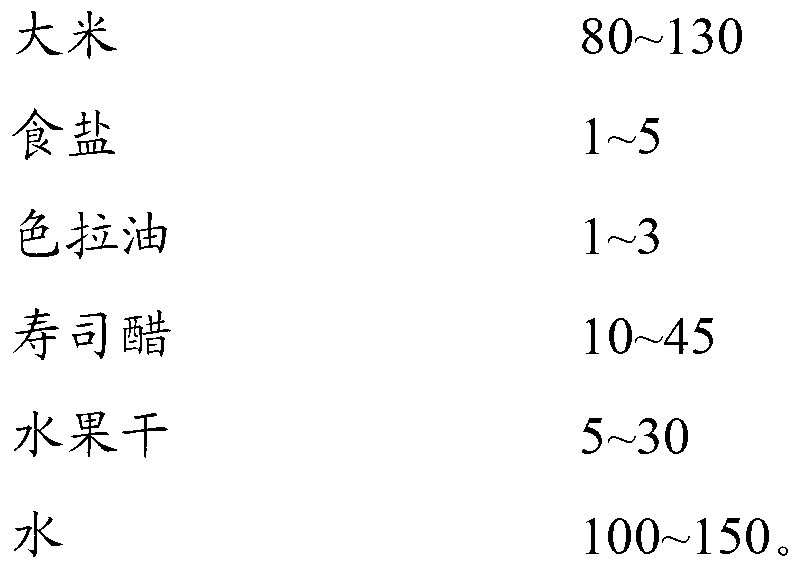

Sushi rice for nutritive fruit sushi and preparation method of sushi rice

The invention relates to sushi rice for nutritive fruit sushi as well as a preparation method and an application of the sushi rice, belonging to the technical field of food processing. The fruit sushi rice consists of 80-130 parts of rice, 1-5 parts of common salt, 1-3 parts of salad oil, 10-45 parts of sushi vinegar, 5-30 parts of dried fruits and 100-150 parts of water, and the sushi rice is prepared by stewing the rice soaked by the sushi vinegar, adding the dried fruits and uniformly mixing. The sushi rice is simple in preparation method, glittering and translucent in appearance, and good in water-retaining property, and due to the addition of various dried fruits, the sushi rice is intense in flavor, good in mouthfeel, and suitable for people of all ages; the sushi rice, when being matched with fresh fruits or canned fruits to prepare the fruit sushi, is colorful and attractive in appearance dolor, refined and aesthetic in shape, and better in both mouthfeel and taste of product, thus achieving a sensory effect which is unreachable for normal fruit sushi.

Owner:亚洲渔港股份有限公司

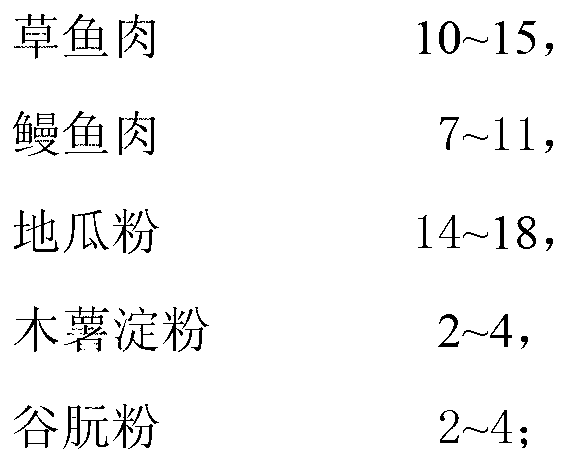

Quick-frozen dumplings and making method thereof

The invention relates to the technical field of quick-frozen foods and specifically discloses quick-frozen dumplings and a making method thereof. The dumplings disclosed by the invention adopt grass carp meat, eel meat, sweet potato flour, cassava starch and gluten flour as raw materials for making wrappers, and are rich in nutrition and less prone to producing paste soup or cracking; and stuffing of the dumplings disclosed by the invention adopts pork shoulder, chicken soup particles which are finely cooked, duck breast meat, eel meat, Stichopus japonicus, shrimps and other precious food materials as raw materials, thus the dumplings are rich in nutrition and excellent in taste.

Owner:WUHAN MINYI FOOD

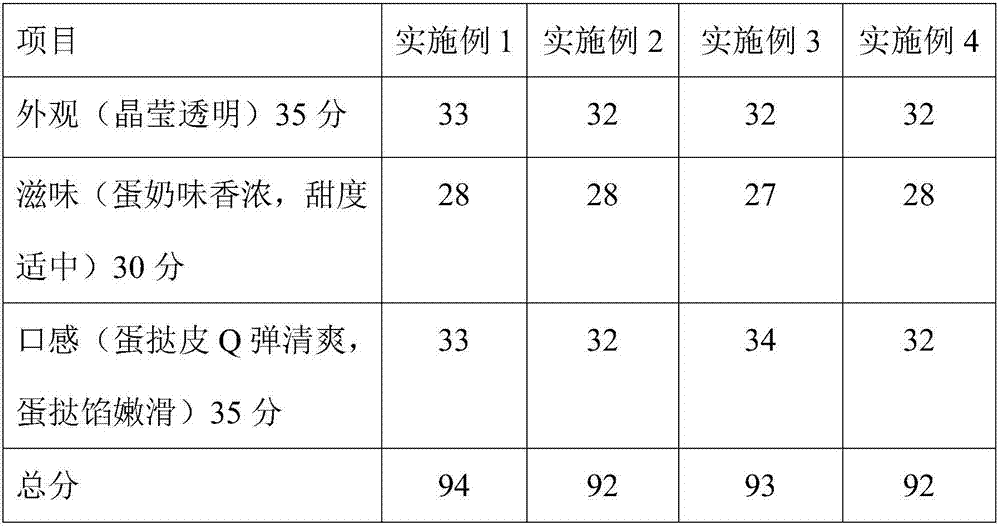

Crystal egg tart and preparation method thereof

The invention discloses a crystal egg tart which comprises an egg tart peel and an egg tart liquor. The egg tart peel comprises the following components in parts by weight: 140-180 parts of etherified starch, 40-80 parts of oxidized starch, 380-450 parts of clean water and 550-700 parts of syrup; the egg tart liquor comprises the following components in parts by weight: 450-550 parts of milk, 350-460 parts of white sugar, 200-260 parts of egg yolk liquor, 550-650 parts of egg cream and 950-1200 parts of light cream. The invention also provides a preparation method for the crystal egg tart. The crystal egg tart provided by the invention has transparent appearance, tastes elastic and cool, can reduce calories, has the egg fragrance of egg tart once entering into the mouth, is low in calories, will not increase internal heat, is especially suitable for people in summer, can meet the requirement of a consumer for health and nice taste, is simple in preparation, is prepared only in the manner of cooking without an oven, and can greatly increase the market value of egg tarts in summer.

Owner:广东奇乐趣食品科技有限公司

Weakly-acidic high transparent soap and preparation method thereof

InactiveCN104531371AModerate degreasing powerReduce stimulationAnionic surface-active compoundsShaping soapActive agentSarcosine

The invention discloses a weakly-acidic high transparent soap which is mainly prepared from amino acid surfactant, humectant, neutralizer and deionized water, wherein the amino acid surfactant comprises glutamic acid surfactant, glycine surfactant and sarcosine surfactant; and based on the total mass of the weakly-acidic high transparent soap, the mass percent of the glutamic acid surfactant is 25-30%, the mass percent of the glycine surfactant is 8-10%, and the mass percent of the sarcosine surfactant is 5-8%. The invention also discloses a preparation method of the transparent soap. The pH value of the weakly-acidic high transparent soap is close to that of the skin; and the weakly-acidic high transparent soap has moderate degreasing power, does not hurt the skin, is easy to foam and can produce abundant foam.

Owner:INFINITUS (CHINA) CO LTD

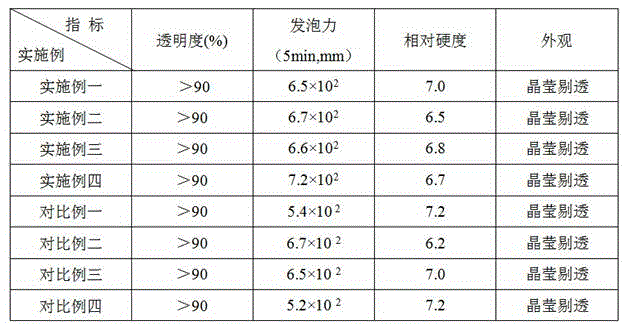

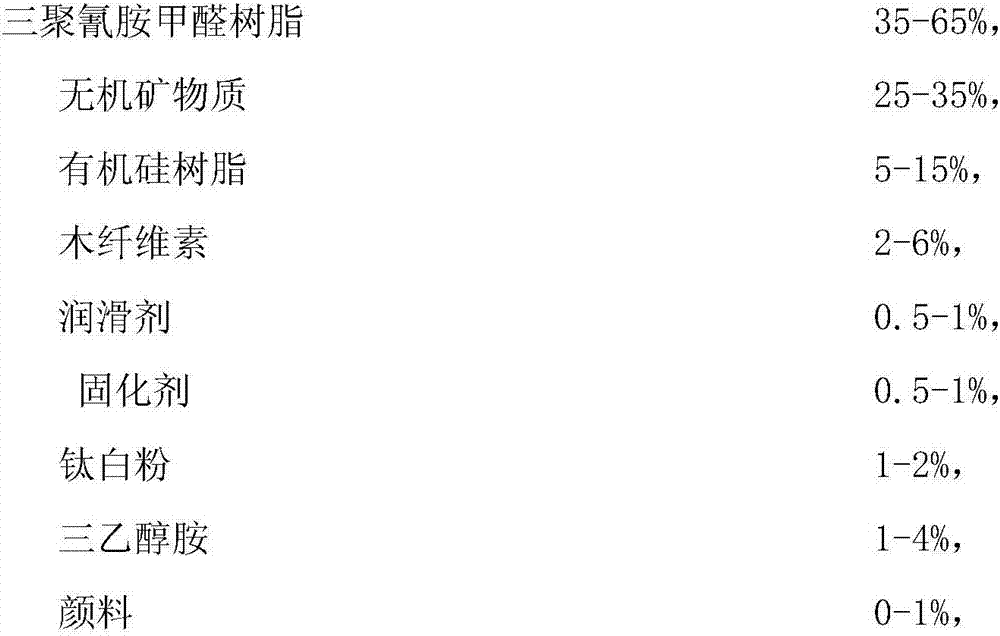

Moulding material used for high-grade melamine tableware and preparation method thereof

The invention relates to a moulding material used for high-grade melamine tableware and a preparation method thereof. The moulding material is prepared from the following raw materials in percentage by mass: 35-65% of melamino-formaldehyde resin, 25-35% of inorganic minerals, 5-15% of organic silicon resin, 2-6% of wood cellulose, 0.5-1% of a lubricating agent, 0.5-1% of a curing agent, 1-2% of titanium white, 1-4% of triethanolamine and 0-1% of pigment, wherein the sum of the weight percents of all the raw materials is 100%; and the inorganic minerals are formed by mixing silica powder, jade porcelain and calcium carbonate in a ratio of 3:(0.5-1.5):(0.5-1.5). The preparation method comprises the following steps: preparing the melamino-formaldehyde resin, kneading, drying, crushing and carrying out ball milling, and packaging. According to the invention, the inorganic mineral and organic silicon resin are added into melamine resin, and compression moulding is carried out, so that the tableware has the characteristics of higher density, strong compactness, higher break resistance, light transmission, glittering and translucent carving appearance and better quality compared with ceramic tableware.

Owner:DEQING LIANCHENG AMINO PLASTIC PROD CO LTD

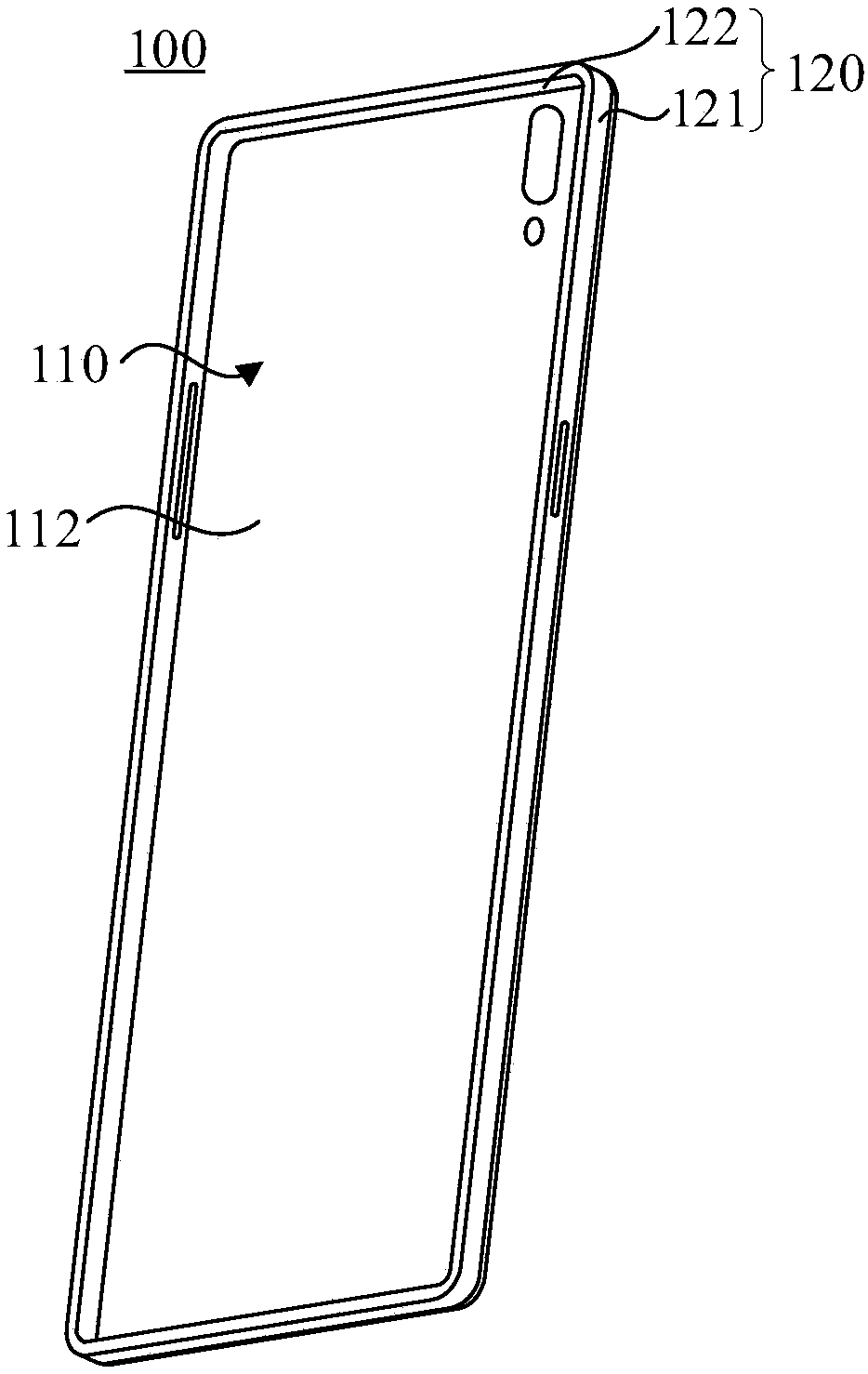

Shell, electronic device and shell manufacturing method

PendingCN108705786AImprove the three-dimensional effectCrystal clear appearanceTelephone set constructionsEpoxyCrystal Clear

The invention relates to a shell, an electronic device and a shell manufacturing method. The shell manufacturing method comprises the following steps: step a, providing a mold which comprises a convexmold and a concave mold, wherein a cavity exists between the convex mold and the concave mold; step b, laying prepreg on the convex mold, and manufacturing a composite laminated board; and step c, combining the convex mold with the composite laminated board to the concave mold, and injecting epoxy resin to obtain the shell which comprises a main body portion and a side wall portion, wherein the thickness of the side wall portion is greater than that of the main body portion. According to the shell manufacturing method, after the prepreg is manufactured into the composite laminated board, thecomposite laminated board and the transparent epoxy resin are used for manufacturing the shell together, and the thickness of the side wall portion of the shell is greater than that of the main body portion of the shell; and the shell manufacturing method is simple to operate, and the cost is reduced. The shell has an integrated structure, is seamless, and is crystal clear in appearance and good in visual effect. The thickness of the side wall portion is greater than that of the main body portion, thickness difference exists between the side wall portion and the main body portion, thus, the stereoscopic effect of the shell is high, and the aesthetic feeling and the hand feeling of the shell are improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Shell, electronic device, and manufacturing method of shell

InactiveCN108748848AImprove the three-dimensional effectCrystal clear appearanceTelephone set constructionsGlass fiberEpoxy

The invention relates to a shell, an electronic device, and a manufacturing method of the shell. The manufacturing method of the shell comprises the following steps that a, fiberglass is put into liquid epoxy resin and stirred evenly; b, a mold is provided and comprises a male mold and a female mold, and a cavity exists between the male mold and the female mole after mold closing; and c, the epoxyresin containing the fiberglass is injected into the cavity of the mold to be formed, and thus the shell comprising a main body part and a side wall part is obtained, wherein the thickness of the side wall part is greater than the thickness of the main body part. The manufacturing method of the shell is easy to operate, and the production cost is reduced. The shell is of an integrated structure and has no seam, the appearance is crystal clear, and the visual effect is good. The thickness of the side wall part is greater than the thickness of the main body part, namely the thickness differenceexists between the side wall part and the main body part, thus the stereoscopic sensation of the shell is high, and the attractiveness and hand feel of the shell are improved; and the shell internally contains the fiberglass, and thus the intensity of the shell can be enhanced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Green tea health-care crystal sugar

InactiveCN101371702ABright colorColor light greenPre-extraction tea treatmentFood preparationAdditive ingredientColloid

The invention relates to a green tea health rock sugar which is prepared by aqueous solution crystallization which takes green tea-colored crystal and white granulated sugar as main components; each component has the following parts by weight: 1-2 parts of the green tea-colored crystal and 800-1200 parts of white granulated sugar. The tea-colored crystal is prepared by soaking and extracting commercial tea with water or extracting the commercial tea with colloid grinding pulp; The green tea health rock sugar is prepared after green tea, white granulated sugar and water are mixed and crystallized under certain conditions, has simple raw materials and low cost and is suitable for large-scale industrial production; the prepared finished products have glittering and translucent appearance and vivid and beautiful color, besides, the finished products not only have pleasurable feeling but also have good taste and high nutritional value.

Owner:TIANJIN HONGLU FOODS

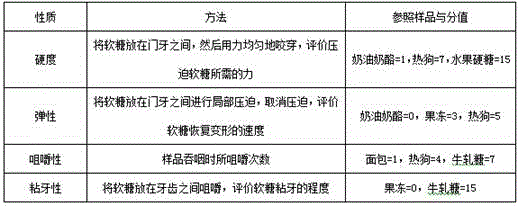

Sugar-free fudge composition containing probiotics and preparation method of sugar-free fudge composition

The invention relates to sugar-free fudge composition containing probiotics and a preparation method of the sugar-free fudge composition. The sugar-free fudge composition containing probiotics is prepared from the following raw materials in parts by mass: 2-20 parts of probiotics, 10-90 parts of prebiotics pulp, 1-20 parts of colloid, 1-15 parts of gloss oil and 10-30 parts of water. The sugar-free fudge composition containing probiotics can supplement the prebiotics while supplementing the probiotics, and is of great help to maintain intestinal health, reduce constipation and promote absorption of vitamins and minerals; the sugar-free fudge composition containing probiotics contains higher content of living probiotics and can meet demand for the probiotics supplement of people; the probiotics in the composition have better stability, and therefore, the composition is suitable for long-term shelf storage.

Owner:GUANGZHOU XINTIANRAN MEDICAL TECH

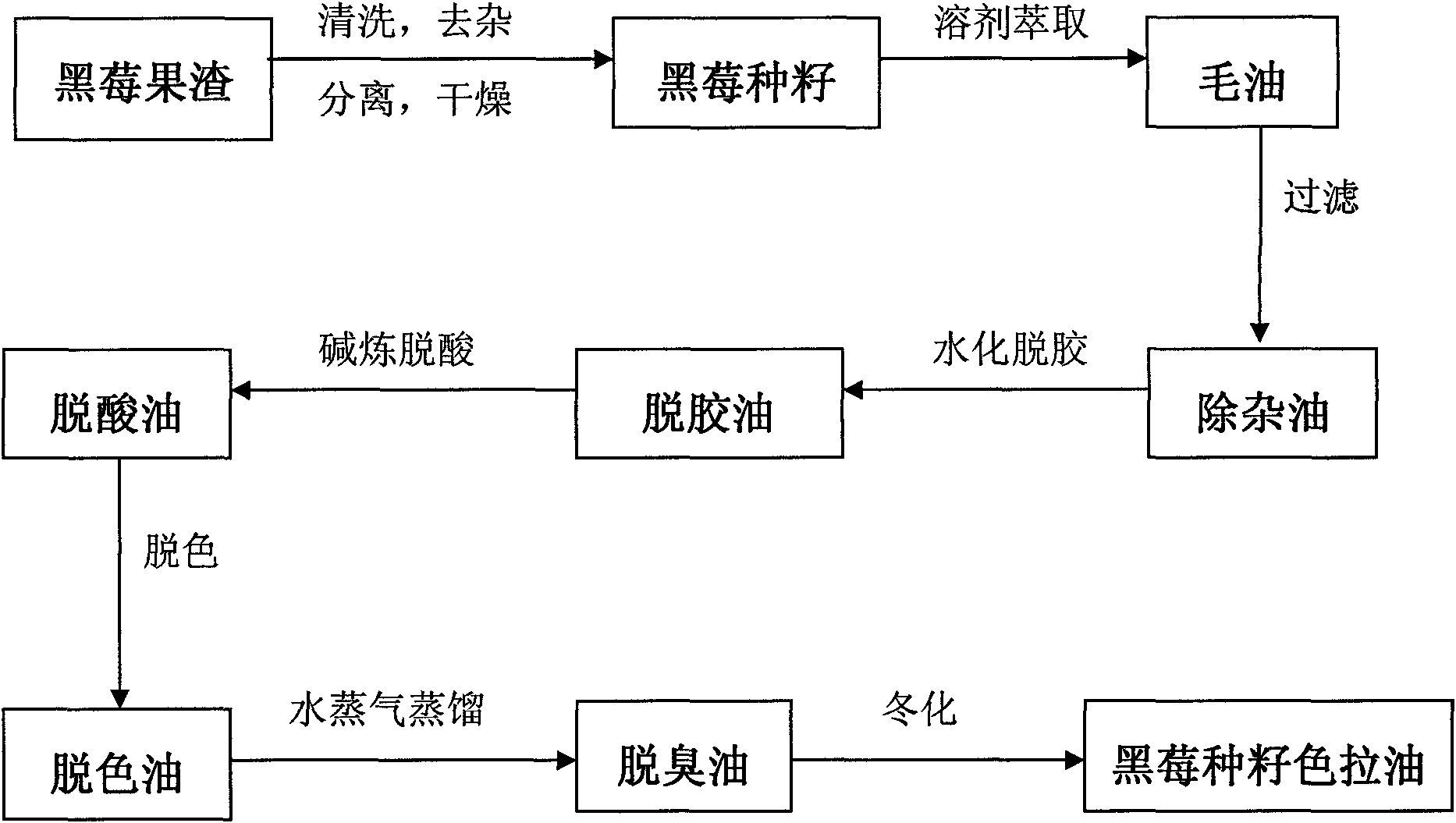

Preparation method of plant oil from blackberry seeds

InactiveCN101617720ACrystal clear appearanceNo smellEdible oils/fatsFood preparationBiotechnologyOil processing

The invention relates to an effective and economic preparation method of plant oil from blackberry seeds. Residues of processed blackberries are used as materials, and seeds are separated from the residues and then broken after drying, and finally, the seeds are processed into plant oil with the functions of nutrition and health care from blackberry seeds through the processes of low-temperature extraction based on solvents, filtering for residue removal, degumming by hydration, alkali refining and deacidification, decolorization, deodorization and winterization in turn. The invention can adopt common oil processing equipment for producing the oil, and has the advantages of low cost, simple process, high extraction and high efficiency, and obtained products have clear color and stable quality, conform to national standards on edible oil, and simultaneously maintain bioactive substances with special functions.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

Polyphenol compound coating liquid for refrigeration and preservation of abalones, preparation method thereof and use method thereof

InactiveCN106387015AGuarantee the inherent shapeKeep the flavorMeat/fish preservation by coatingMeat/fish preservation by freezing/coolingGlycerolChloride

The present invention discloses a polyphenol compound coating liquid for refrigeration and preservation of abalones. The compound coating liquid comprises: sodium alginate, glycerol, tea polyphenols, a rosemary extract, a bamboo leaf antioxidant and water. The present invention also provides a preparation method of the polyphenol compound coating liquid. The preparation method comprises sodium alginate solution preparing, polyphenol solution preparing and polyphenol compound coating liquid preparing. The present invention also provides a use method of the polyphenol compound coating liquid. The method comprises the following steps: abalone pleopod is taken, the taken abalone pleopod is placed into the polyphenol compound coating liquid to be soaked; the soaked abalone pleopod is taken out to be drained, and the drained abalone pleopod is placed into a pre-cooled calcium chloride solution to be soaked; the soaked abalone pleopod is leached with cold water and the leached abalone pleopod is drained; and the drained abalone pleopod is put into a sterile preservation bag to be sealed and refrigerated. The method combines the coating technology, compound preservation agent and low-temperature storage together, which play a synergistic effect. The used method is simple in operation technology, less in device investment, small in operation space, low in cost consumption, low in energy consumption, and suitable for industrialized mass production.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Highly-transparent hand-made essential oil soap and preparation method thereof

InactiveCN108004064ACrystal clear appearanceGentle and moisturizingSurface-active detergent compositionsSurface-active non-soap compounds and soap mixture detergentsSucroseSOAP

The invention discloses a highly-transparent hand-made essential oil soap and a preparation method thereof, wherein the highly-transparent hand-made essential oil soap comprises, by weight, 25-30 parts of sodium aliphatate, 8-12 parts of propylene glycol, 7-11 parts of glycerin, 2-4 parts of alkyl glycoside, 1-3 parts of shea butter, 1-2 parts of vitamin E, 15-18 parts of sucrose, 10-14 parts of sorbitol, 4-7 parts of essential oil, 9-13 parts of deionized water, and 1-3 parts of tartaric acid. The preparation method comprises: taking propylene glycol, glycerin, sorbitol and deionized water, mixing, heating to a temperature of 70-80 DEG C, sequentially adding sodium aliphatate, alkyl glycoside, shea butter, sucrose and tartaric acid, uniformly stirring, finally adding essential oil, carrying out standing defoaming, pouring into a mold, cooling, demolding, and carrying out stamping molding. According to the present invention, the highly-transparent hand-made essential oil soap has advantages of clear and transparent appearance, mild and moist performance, weak alkalinity, rich and delicate foam, refreshing and no damage on skin, and is suitable for sensitive skin and infants.

Owner:深圳市科迪生物科技有限公司

Production method of coarse grain tea pellet

A production method of a coarse grain tea pellet comprises the following steps: fully stirring and mixing leachates of coarse grain pure powder, cassava-kind starch, white sugar, tea powder or tea to prepare wet powder, steaming the powder to be cooked by steam; performing strip rolling by a strip rolling machine, performing dicing by a dicing cutter, cooking by microwave, and keeping in reserve;performing rounding in a rounding machine to obtain a coarse grain tea pellet with a diameter of 0.8-0.9 cm, drying the coarse grain tea pellet to obtain a water weight percentage of 10-12%, and packaging to obtain a finished product. The invention changes the original habitual production process which simply adopts cassava starch as a main raw material, adopts coarse grain powder as a a main rawmaterial, uses cassava starch as a coating, not only maintains the mouthfeel of products in the prior art, but also greatly increases the nutritive value of the tea pellet; the coarse grain tea pellet processed by microwave technology has good formation, and high yield, is not fragile, has transportation tolerance, long shelf life, significantly better mouthfeel during chewing than cassava-kind starch pellets, and good color and mouthfeel, is smooth and elastic, has boiling tolerance, is not turbid, has glistening appearance after rehydration, and has better marketability.

Owner:SHANGQIUYINZHIJIANFOODCO LTD

Preparation method of complex nutritional fruit jam

The present invention discloses a preparation method of a complex nutritional fruit jam. The preparation method is characterized in comprising the following steps: (1) preparing jujube pulp; (2) preparing potato pulp; (3) preparing strawberry pulp; (4) adding milk; (5) preparing a batching liquid; (6) mixing the pulps; (7) preparing product. According to the present invention, jujube, strawberry, sweet potato, honey and other raw materials with rich nutritional value are adopted as raw materials, and the prepared complex nutritional fruit jam has advantages of rich nutrition, low cost and the like. The complex nutritional fruit jam contains phospholipid which has an affinity for fat and can lower serum cholesterol, prevent cirrhosis of the liver and help restore liver function. The prepared complex nutritional fruit jam has characteristics of crystal clear appearance, smooth taste, rich flavor, green and safe and health care. And the production process is simple, is easy to operate, and needs no complex equipment. The complex nutritional fruit jam can be produced by slightly adjusting on manufacturer original production line of juice drinks and condiments.

Owner:QINGDAO BOYANDA IND TECH RES INST GENERAL PARTNERSHIP

Method for making candied muskmelon

InactiveCN104206632ALow costSimple preparation processConfectionerySweetmeatsPre treatmentMusk melon

The invention discloses a method for making candied muskmelon, and belongs to the technical field of food processing. The method is characterized by mainly comprising the steps of sorting, treatment of raw materials, stripping and slicing, hardening, bleaching, blanching, cooling, sugaring, candying, drying and packing. The method has the beneficial effects that a making process is simple; the costs of raw materials and processing equipment are low; the method is convenient to implement; the product is rich in nutrition, tastes crispy, fresh and sweet, is bright in appearance, and has the fresh scent of the muskmelon; and technical support is provided for deep processing of the muskmelon, and the commodity value of a highly-processed muskmelon product is increased.

Owner:谈茁

Transparent amino acid crystal soap and method for preparing same

InactiveCN108587802AHigh hardnessCrystal clear appearanceCationic surface-active compoundsOrganic detergent compounding agentsBathingSOAP

The invention relates to transparent amino acid crystal soap and a method for preparing the same. The transparent amino acid crystal soap comprises, by weight, 5-12 parts of water, 0.5-2 parts of urea, 5-15 parts of glycerin, 5-10 parts of propylene glycol, 0-5 parts of polyquaternium-7, 20-45 parts of lauroyl glutamic acid, 5-20 parts of lauroyl sodium glutamate, 1-2 parts of ethyl alcohol, 10-30parts of triethanolamine, 2-10 parts of lactose (crystal sugar), 1-10 parts of lactitol (erythritol) and 0-2 parts of essence. The transparent amino acid crystal soap and the method have the advantages that the transparent amino acid crystal soap which is a product is in crystal clear appearance, is made of pure amino acid foaming agents, is similar to skin of human bodies, is safe and mild and is applicable to pregnant women and infants; fine, smooth and abundant bubble can be generated, accordingly, the skin can be mildly cleaned, and the transparent amino acid crystal soap can be used as face washing soap, bathing soap, shampoo soap, baby bathing soap and the like, is high in hardness, is durable and can be in modeled to be in diversified special shapes.

Owner:SHANDONG ZHUSHI PHARMA GRP CO LTD

Preparation process for sugar-coated haw

InactiveCN102422964ACrystal clear appearanceNice appearanceConfectionerySweetmeatsSatiationsCitric acid

Owner:周桂英

Method for processing rice flour dumplings

The invention discloses a method for processing rice flour dumplings. Based on the traditional rice flour processing technology and the conventional rice flour dumpling processing technology, different kinds of rice are matched to form a wrapper main material, a proper amount of starch can be added into the main material, the main material is heated and gelatinized, and the gelatinized main material is injected into a dumpling machine and added with stuffing to form the rice flour dumplings. The processed rice flour dumplings can be eaten by heating for short time; various meats, vegetables, coarse cereals, nutrients and seasonings are prepared into the stuffing, and the stuffing is filled into the rice flour dumplings, so that the rice flour dumplings are quick and convenient to eat, are safe and sanitary and have balanced nutrition. The processing technology is reasonable, the manufacture is simpler and more convenient, and the method is easy for large-scale industrialized automatic production. The produced rice flour dumplings have extremely good mouthfeel, crystal clear appearance and attractive fragrance and color, are not broken after being boiled for long time, can be eaten by heating for about 5 minutes, and are instant and convenient; and the rice flour dumplings are not polluted due to sterilization treatment and achieve long shelf life without adding any preservation under refrigeration conditions, and the commercial quality guarantee period of the rice flour dumplings can reach 6 to 12 months.

Owner:沈哲明

Preparation method of exocarpium antioxidant gel mask

InactiveCN108721157AImprove antioxidant capacityEfficient use ofCosmetic preparationsToilet preparationsChemistryAntioxidant

The invention discloses a preparation method of an exocarpium antioxidant gel mask and the preparation method comprises the steps: A, exocarpium preparation: picking 70% mature fresh citrus grandis tomentosa, cleaning and drying, drying moisture under the temperature of 90 DEG C and pretreating to obtain exocarpium; B, flavone extraction: softening the exocarpium, cutting into slices, smashing andextracting flavone through ethyl alcohol under microwave assistance to obtain flavone extracting solution; C, gel mask preparation: taking acrylamide dimethyl taurine ammonium / VP copolymer (an ice crystal forming agent AVC), glycerinum, carboxymethyl chitosan, hyaluronic acid, the flavone extracting solution, grapefruit essential oil and phenoxyethanol and micro heating and stirring to evenly mixthe material to obtain the mask. The mask has the advantages of amber crystal clear appearance, grapefruit fragrance, low cost, simpleness in preparation, convenience in painting and good moisturizing, antibacterial and antioxidant effects; meanwhile, a requirement of exocarpium product diversity is met, and the mask can meet related stipulations related to the gel mask in QB / T2872-2007; thus, the gel mask has a stronger development and utilization prospect.

Owner:彭颖

A super-flat glaze frit and a method of manufacturing super spar from the same

The invention discloses a super-flat glaze frit and a method of manufacturing super spar from the same. The super-flat glaze frit can allow glazes to have good viscosity and fluidity at high temperature. The frit and a raw material are used in match according to a mass ratio of (50-100):100. The super-flat glaze frit plays a large role in glazes to allow flatter glaze surfaces with high hardness and good transparency after firing. The frit has a high beginning melting point so as to avoid generation of gas bubbles. The cost of the super-flat glaze frit is 25% of the cost of one-firing minicrystal frit dry particles, thus greatly saving the cost.

Owner:江西宏瑞新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com