Moulding material used for high-grade melamine tableware and preparation method thereof

A molding compound and melamine technology, which is applied in the field of melamine tableware materials and preparation, can solve the problems of low density, poor temperature resistance, and poor surface density of melamine tableware

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

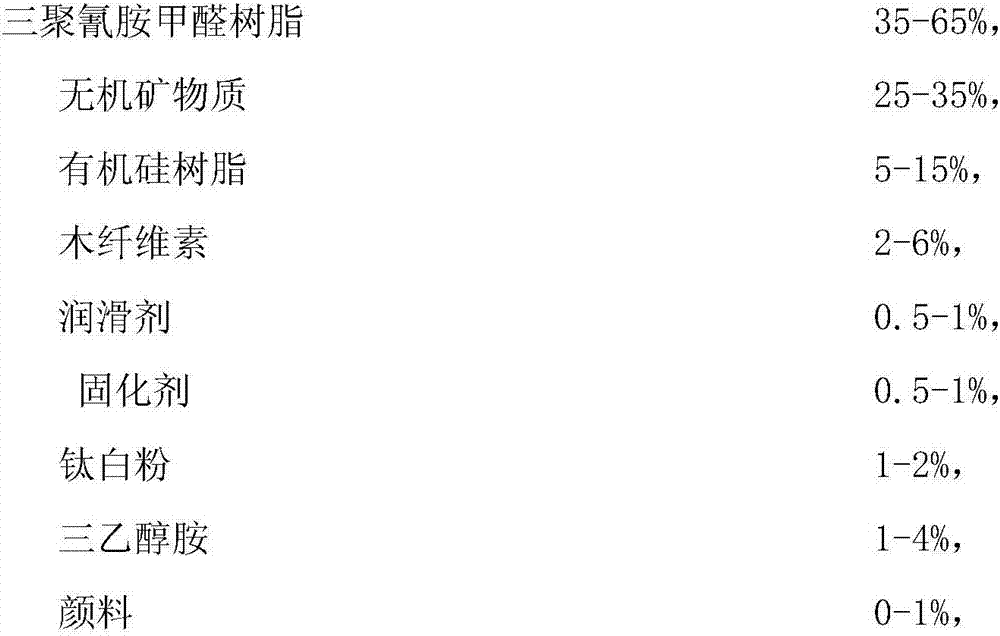

Image

Examples

preparation example Construction

[0033] A kind of preparation method of above-mentioned high-grade melamine tableware molding compound, described preparation method comprises the following steps:

[0034] (1) The formaldehyde solution of 100 parts by weight is added in the reactor, and the pH value is adjusted to 8-9 by adding sodium hydroxide;

[0035] (2) Addition reaction: start to heat up, and add 40-60 parts by weight of melamine to heat up to 80-90°C for reaction;

[0036] (3) Polycondensation reaction: when the resin has white precipitation with 4°C water test, lower the temperature to 70-80°C, adjust the pH value to 8-8.5, and react to the end;

[0037] (4) Add triethanolamine in proportion, adjust the pH value, terminate the reaction, and cool to 70° C. to make melamine formaldehyde resin;

[0038] (5) Kneading: add wood cellulose, lubricant, curing agent and the above-mentioned prepared resin kneading with a Z-type low-speed kneader, change the stirring direction regularly, and stir until uniform; ...

Embodiment 1

[0042] Embodiment 1: The molding compound for high-grade melamine tableware according to the present invention, the molding compound adopts the following raw materials and is composed according to the following mass percentages:

[0043]

[0044]

[0045] The inorganic minerals mentioned therein are prepared from silicon micropowder, jade porcelain powder and calcium carbonate at a ratio of 3:1:1.

[0046] A kind of preparation method of above-mentioned high-grade melamine tableware molding compound, described preparation method comprises the following steps:

[0047] (1) The formaldehyde solution of 100 parts by weight is added in the reactor, and the pH value is adjusted to 8.5 by adding sodium hydroxide;

[0048] (2) Addition reaction: start to heat up, and add 50 parts by weight of melamine and heat up to 85°C for reaction;

[0049] (3) Polycondensation reaction: when the resin has white precipitation with 4°C water test, lower the temperature to 75°C, adjust the pH...

Embodiment 2

[0055] Embodiment 2: A high-grade melamine tableware molding compound according to the present invention, the molding compound is composed of the following raw materials according to the following mass percentages:

[0056]

[0057]

[0058] The above ingredients are based on 100% by weight;

[0059] The inorganic minerals are composed of silicon micropowder, jade porcelain powder and calcium carbonate, wherein the silicon micropowder, jade porcelain powder and calcium carbonate are respectively composed in a ratio of 3:0.5:1.5.

[0060] A kind of preparation method of above-mentioned high-grade melamine tableware molding compound, described preparation method comprises the following steps:

[0061] (1) The formaldehyde solution of 100 parts by weight is added in the reactor, and the pH value is adjusted to 8 by adding sodium hydroxide;

[0062] (2) Addition reaction: start to heat up, and add 40 parts by weight of melamine and heat up to 80°C for reaction;

[0063] (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com