Patents

Literature

195results about How to "Strong compactness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method for environment-friendly type insulator shell

InactiveCN101840757AImprove mechanical propertiesImprove insulation performanceInsulatorsEpoxyDark color

The invention relates to a manufacturing method for an environment-friendly type insulator shell, comprising the following steps: firstly mixing the following components uniformly in parts by weight: 100 parts of modified BPA epoxy resin, 280-310 parts of silica powder, 100 parts of curing agent, 40-45 parts of dark color paste and 40-60 parts of fire retardant, and degassing for 1.5-2 hours under the vacuum degree of 0-minus1 MPa; then injecting the degassed mixture into a mold to conduct the primary curing, and curing for 30-40 minutes under the condition of 140 plus or minus 5 DEG C; demolding, conducting the secondary curing, and curing for 8 hours plus or minus 10 minutes under the condition of 128-135 DEG C; and finally, conducting finish machining on the blank after being cured secondarily. The Epoxy resin insulating component manufactured by the method has the advantages of high mechanical strength, strong arc resistance, high compactness, bright and clean surface, better cold-resistant and heat-resistant properties, good electrical insulating property and the like, is widely applied in the power sector, and mainly plays a role in supporting and insulating.

Owner:YANGZHOU DONGYU ELECTRIC

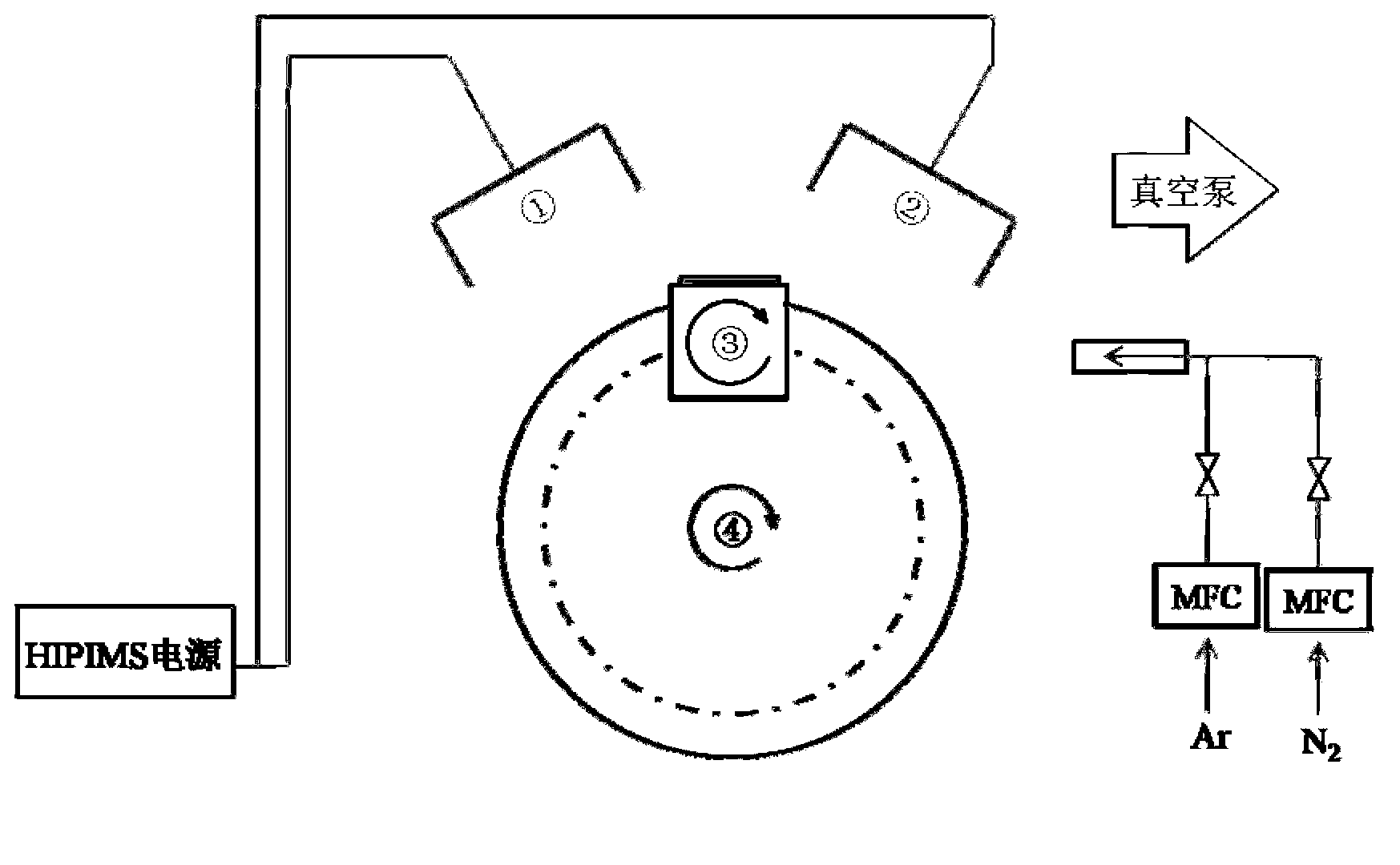

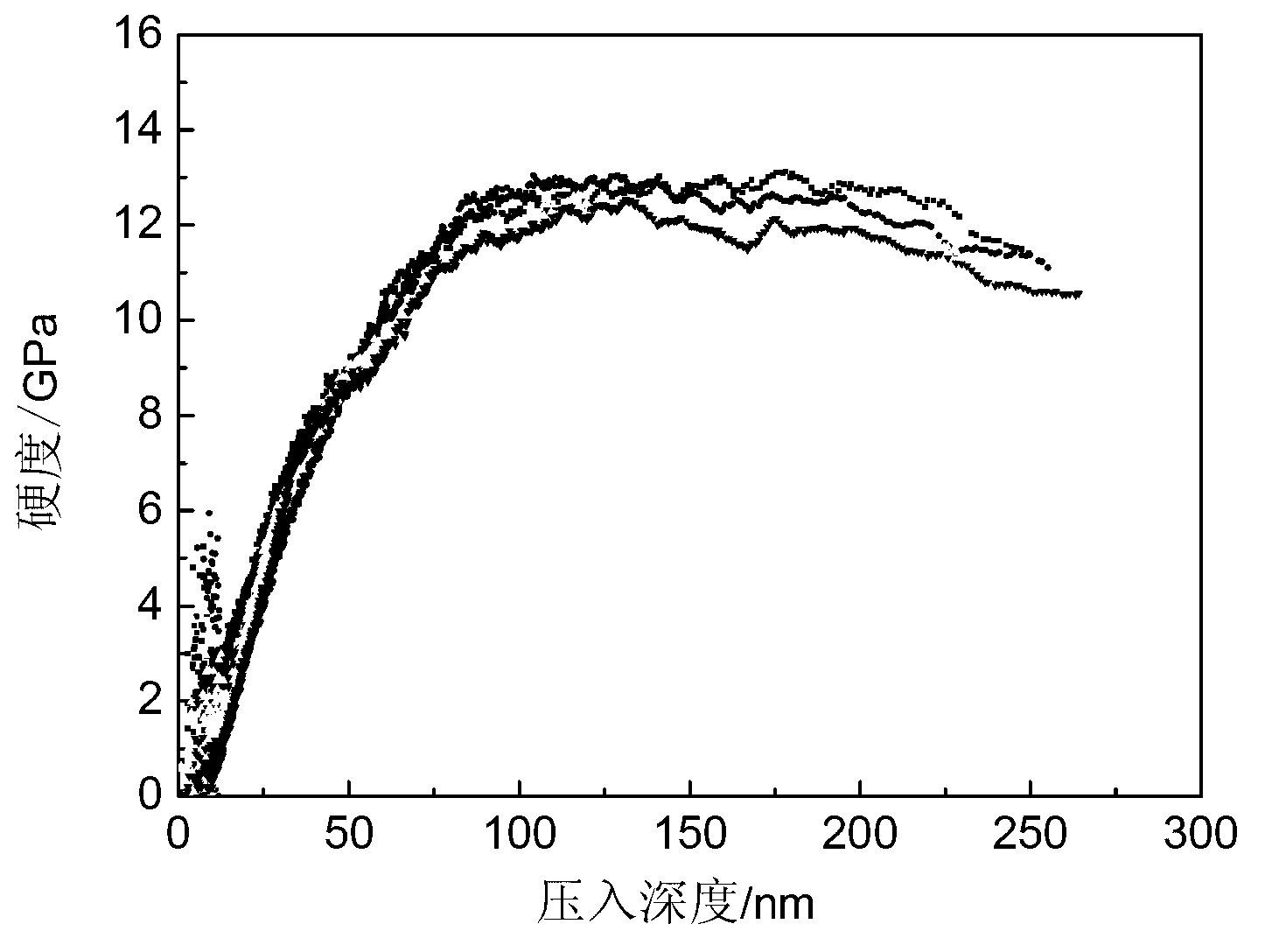

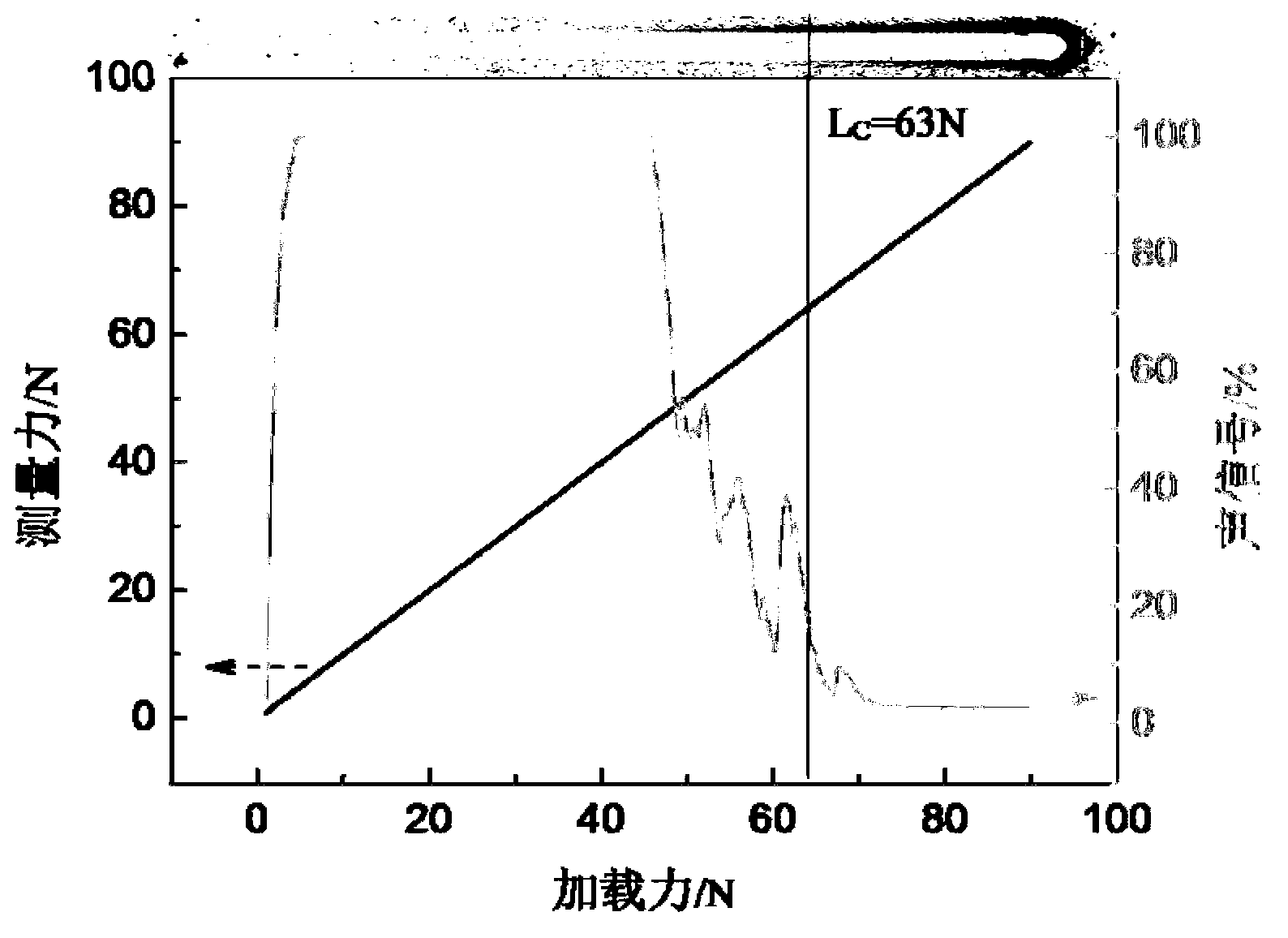

Preparation method of MoS2 composite thin film with high hardness and loss abrasion on surface of substrate

ActiveCN103060765AFast sputtering rateIncrease ionization rateVacuum evaporation coatingSputtering coatingComposite filmCritical load

The invention discloses a preparation method of a MoS2 composite thin film with high hardness and loss abrasion on a surface of a substrate. The method comprises the following step: sequentially depositing a metal Ti priming coat, a TiN transitional layer and a Ti / MoS2 composite thin film on the surface of the substrate by using a high power pulse magnetron sputtering technology combined with optimized process conditions to obtain the MoS2 composite thin film which is strong in film binding force and high hardness and has low frictional coefficient and wear rate in various frictional environments. The nano hardness of the composite thin film is over 11GPa, the critical load value is over 60N, and the frictional coefficients in room-temperature air with relative humidity of 30%, 50% and 70%, an N2 atmosphere and a hydraulic oil environment are below 0.055. Therefore, the substrate is effectively protected in frictional reduction, and the composite thin film has a good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

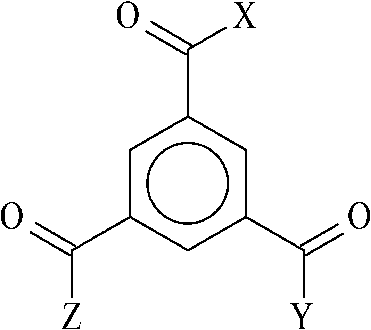

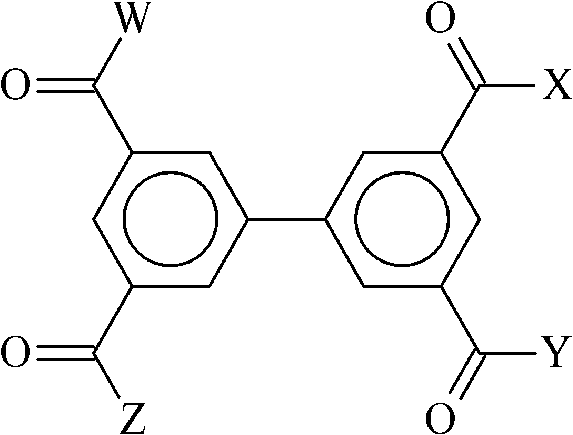

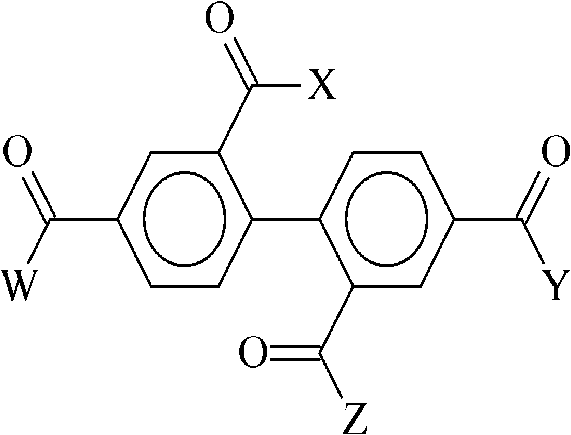

Complex reverse osmosis membrane

InactiveCN101601975AHigh desalination rateExcellent anti-compression densification performanceSemi-permeable membranesPolyamidePetrochemical

The invention discloses a complex reverse osmosis membrane which comprises a non-woven fabric layer and a polysulfone supporting layer, wherein a crosslinked polyamide layer which uses polyamine and an organic solution containing an acyl halide compound for interfacial synthesis is arranged on the polysulfone supporting layer. In the invention, the polyamine and the organic solution containing the acyl halide are adopted on the polysulfone supporting layer of the prior reverse osmosis membrane to obtain the polyamide layer with a three-dimensional crosslinked structure through interfacial condensation, thus the performance of the complex reverse osmosis membrane is further improved, and the membrane molecules have better compactness and stronger rigidness, wherein the improved compactness can improve the salt rejection rate of the membrane, and the improved rigidness can enable the membrane to have excellent anti-densification performance, thus the rate of decay of the performance of the membrane can be reduced, and the service life of the membrane can be prolonged. Therefore, the complex reverse osmosis membrane has the advantages of high salt rejection rate, large water flux, long service life and obvious reduction of engineering investment and production cost, and can be widely applied to the fields of electricity, metallurgy, petroleum and petrochemical industry, medicine, food, municipal engineering, seawater desalination, and the like.

Owner:VONTRON MEMBRANE TECH CO LTD

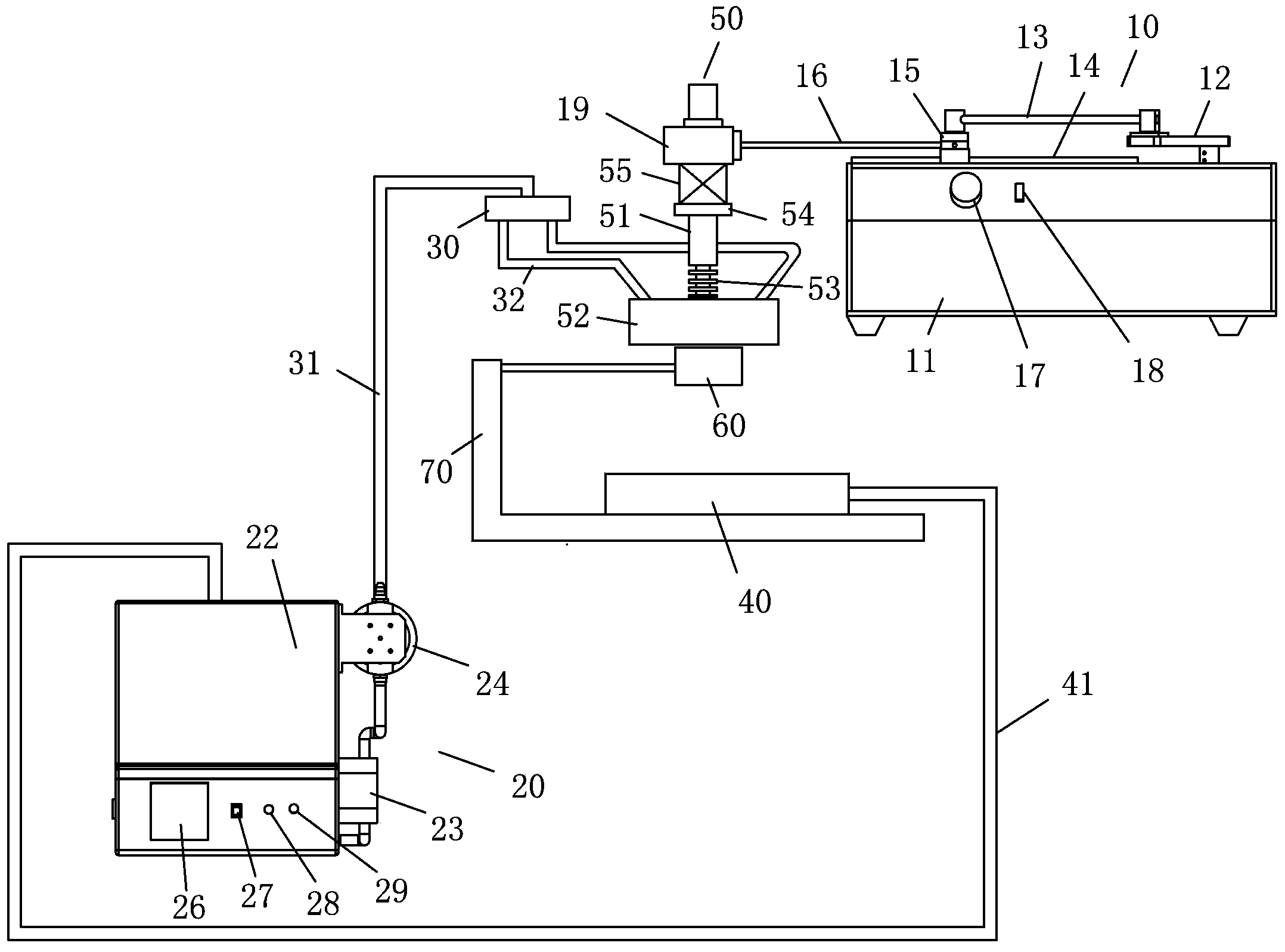

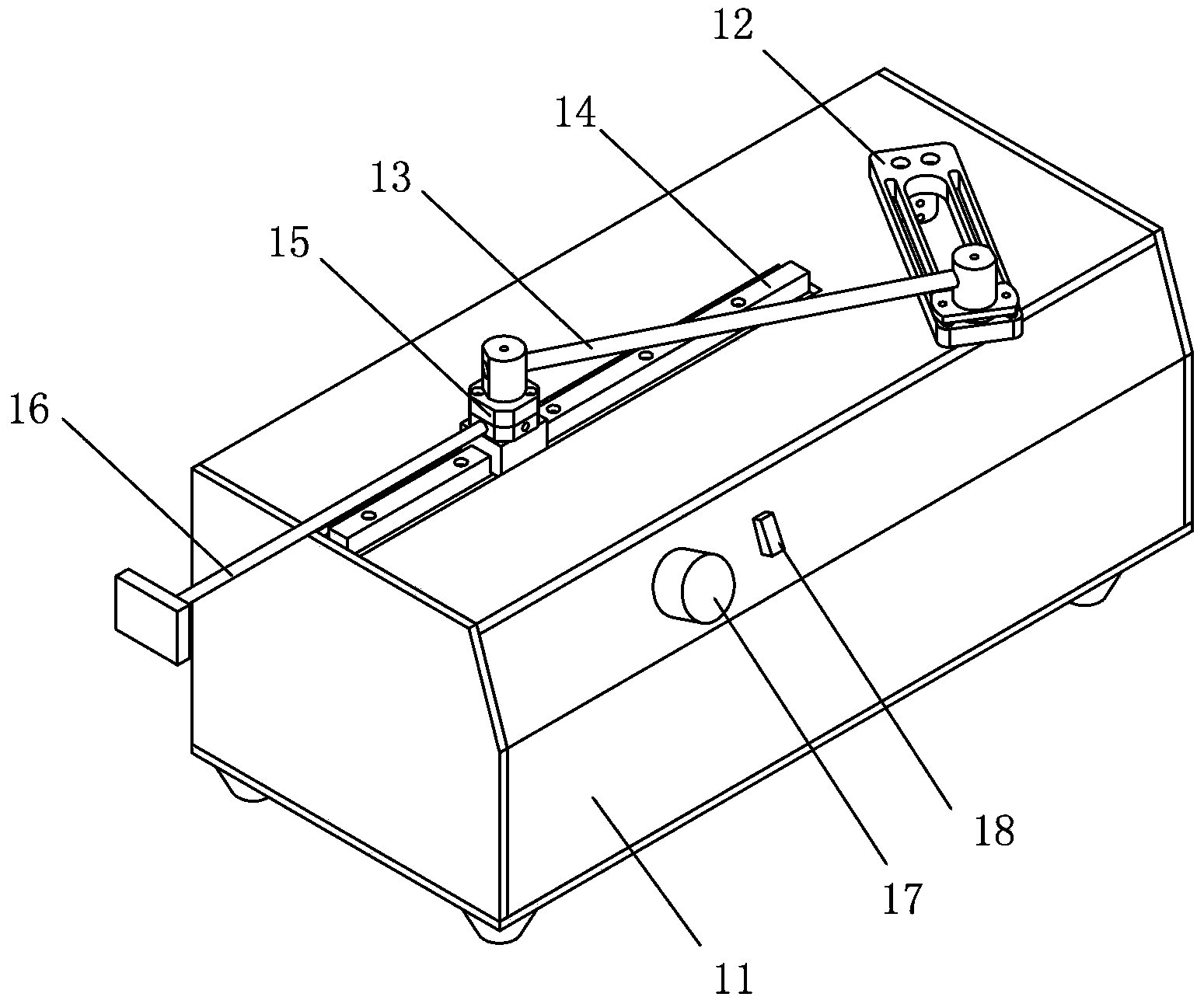

Brush plating device and method for repairing scratches of mechanical parts

The invention discloses a brush plating device and method for repairing scratches of mechanical parts. The device comprises a plating pen drive device, a bracket and a plating solution circulating feeding device, wherein the plating pen drive device clamps a plating pen and drives the plating pen to move in a straight line in a reciprocating manner; the bracket is used for fixing a plating part; the plating pen comprises a conductive pen handle; a graphite nib with a hollow cavity is arranged at one end part of the conductive pen handle; a plating solution lead-in hole and a plating solution seepage hole, which are communicated with the inner cavity, are formed on the nib; the plating solution circulating feeding device comprises a liquid storage tank; the liquid inlet of the liquid storage tank is connected with the liquid outlet of a liquid collecting box; the liquid outlet of the liquid storage tank is connected with the plating solution lead-in hole of the nib; the conductive pen handle and the plating part are connected with a positive electrode and a negative electrode of a direct current power supply. The method comprises the following steps: circularly feeding liquid; carrying out linear friction motion by the nib by tightly attaching to the scratched part of the plating part after stabilization; electrifying the conductive pen handle and the plating part, and beginning the brush plating operation. A coating is prepared by adopting the modes of liquid feeding inside the graphite plating pen and linear friction on the scratched parts of the mechanical parts in the reciprocating manner; repair on the scratched parts is achieved; the repair effect is good.

Owner:ACADEMY OF ARMORED FORCES ENG PLA +1

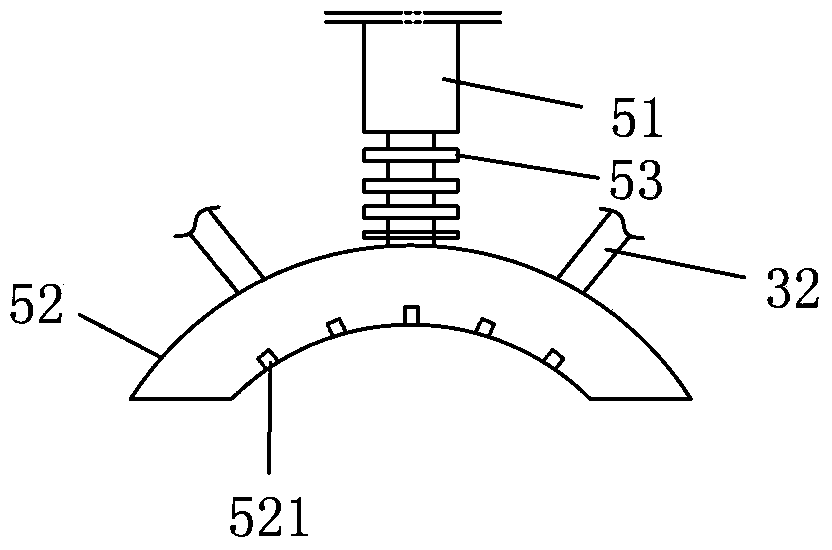

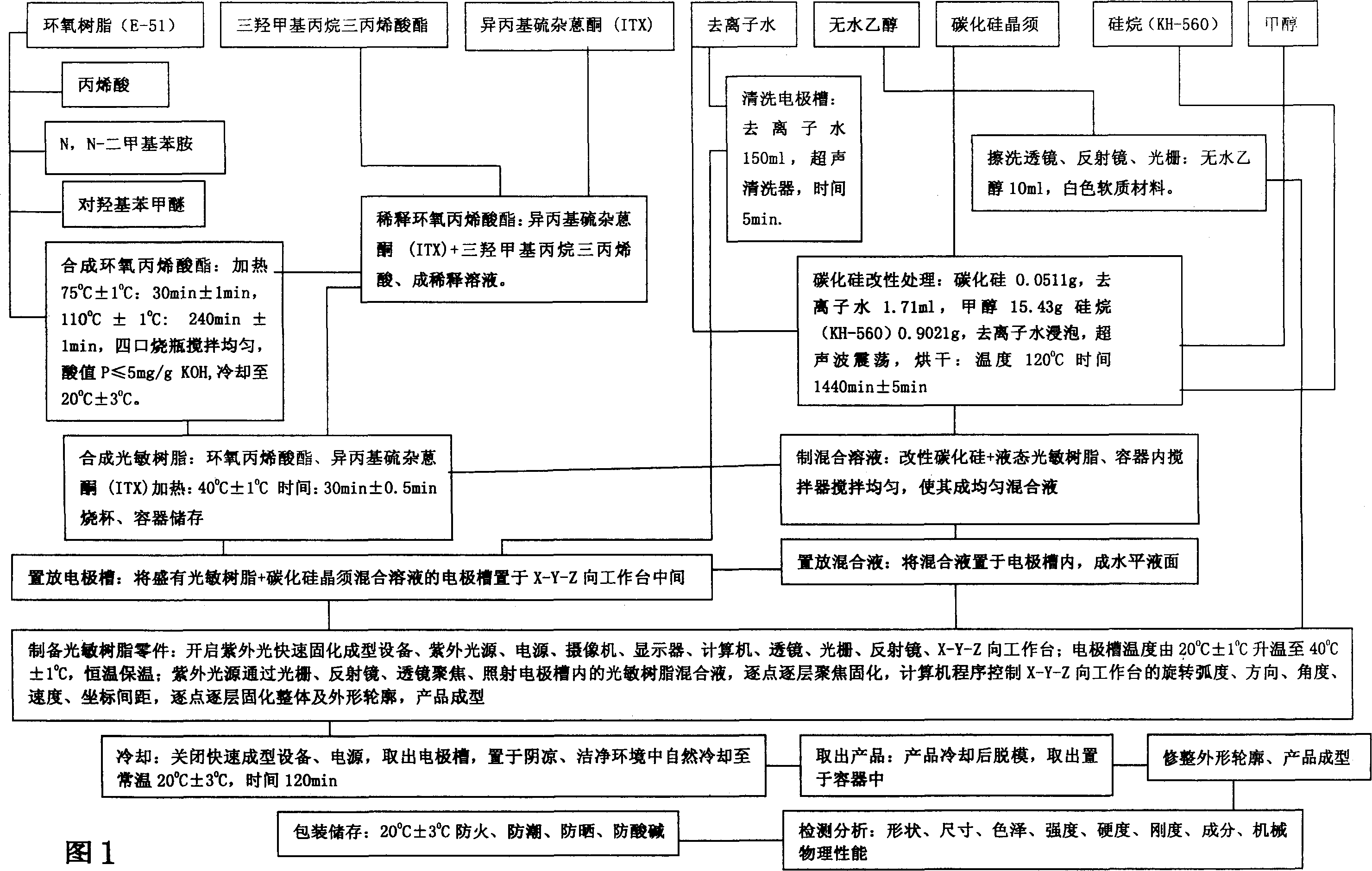

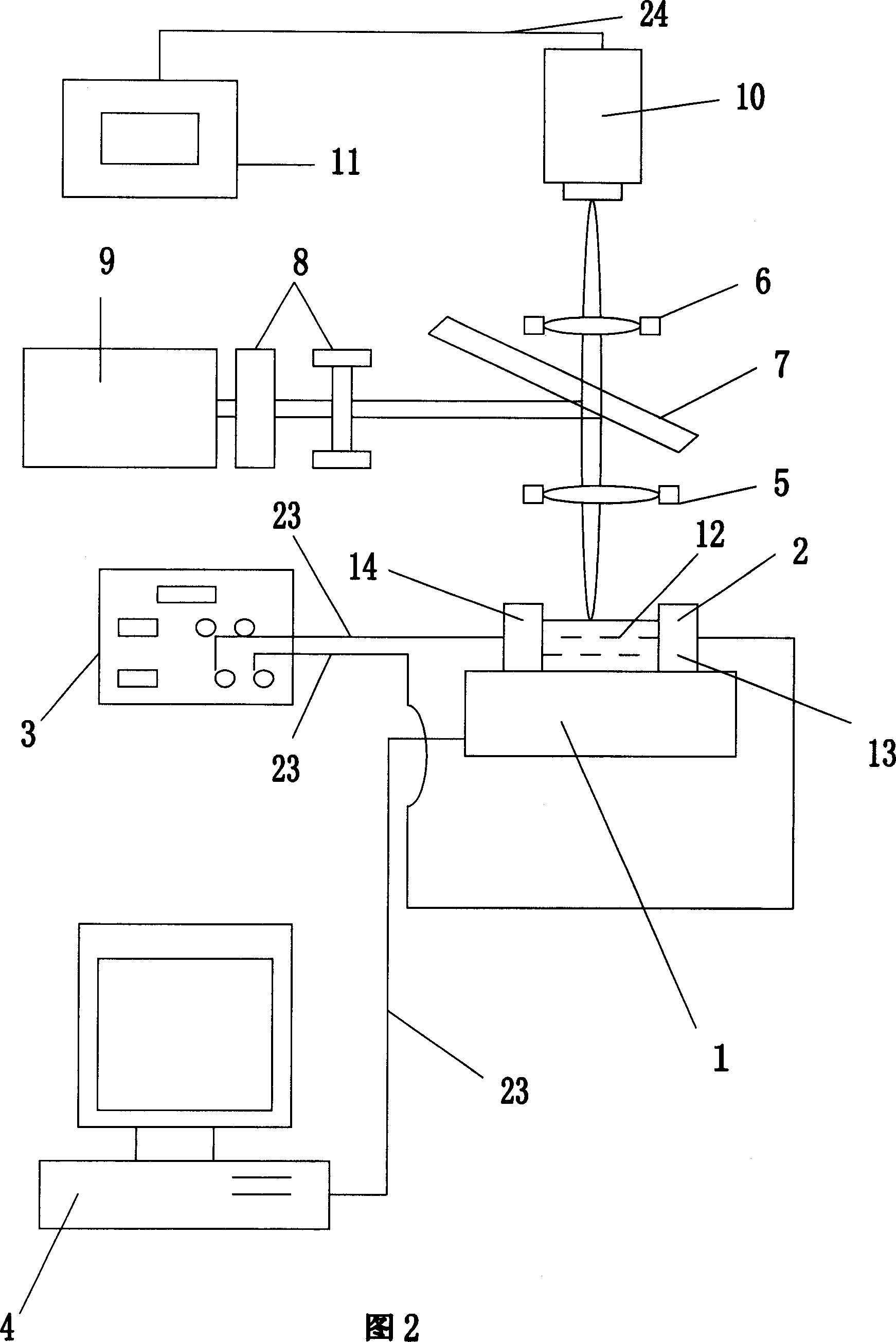

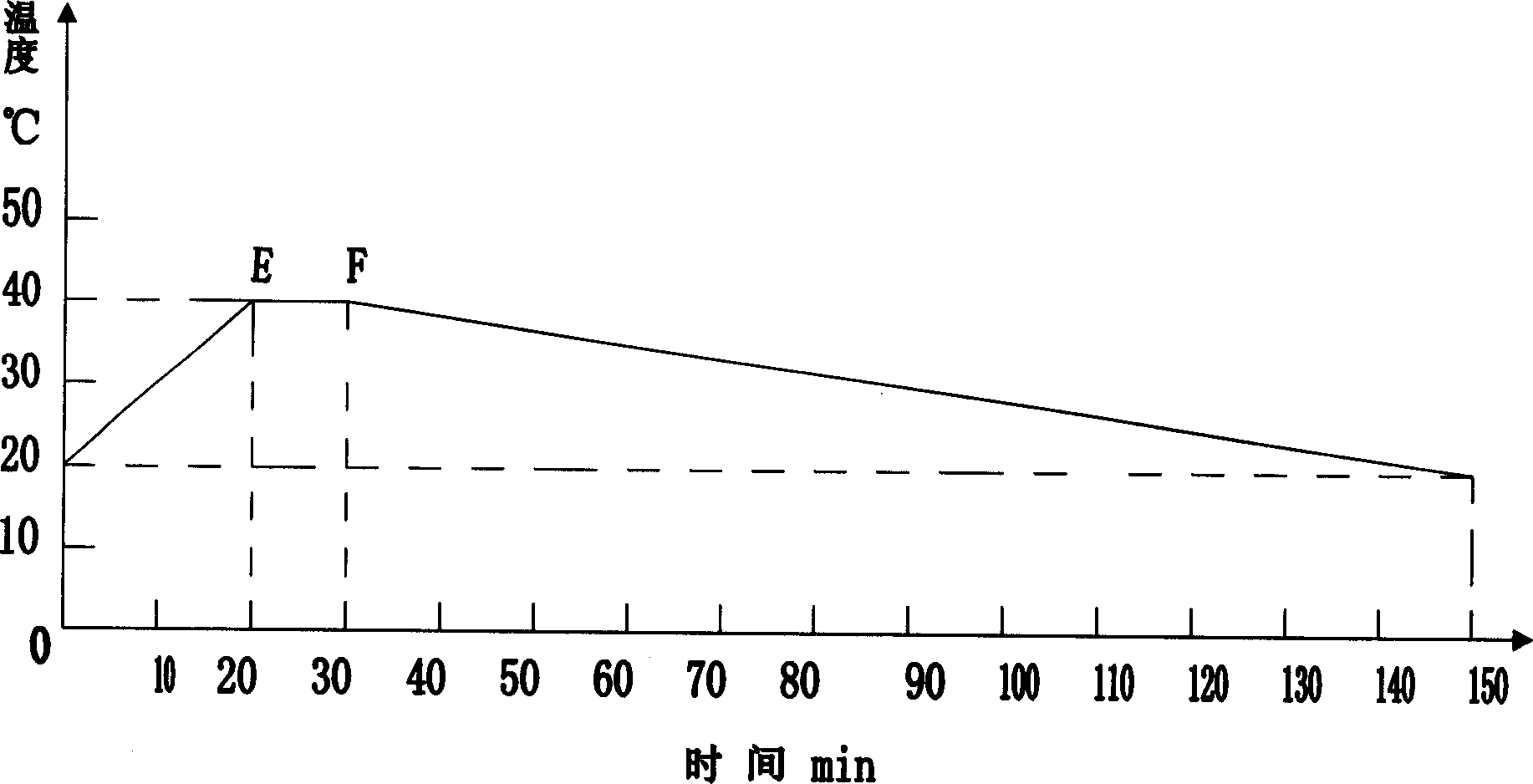

Resin base composite material parts quick forming method

The invention relates to a fast method for shaping resin composite material element, employing epoxy resin (E-51) and acrylic acid, carbonized silicon crystal whisker as intensifier, N,N-dimethylaniline as accelerant, p-methyl phenoxide as inhibitor, trimethylolpropane acrylate as diluting monomer, isopropyl thioxanthones as photo-initiation agent, silane coupling agent (KH-560) as modifier, and methanol as dissolvent. The method comprises following steps: synthesizing epoxy acrylate, diluting with trimethylolpropane acrylate, synthesizing photosensitive resin, synthesizing resin composite material miscible liquids with photosensitive resin and carbonized silicon crystal whisker, fast shaping element on photo-hardening shaping device, the composite material miscible liquid is controlled by ultraviolet light source, focusing lens focusing lens and computer program in electrode tank of X-Y-Z working bench. The invention provides a fast method for preparing injecting mold, flake grinder, ultra-thin element and accessory in special shape.

Owner:TAIYUAN UNIV OF TECH

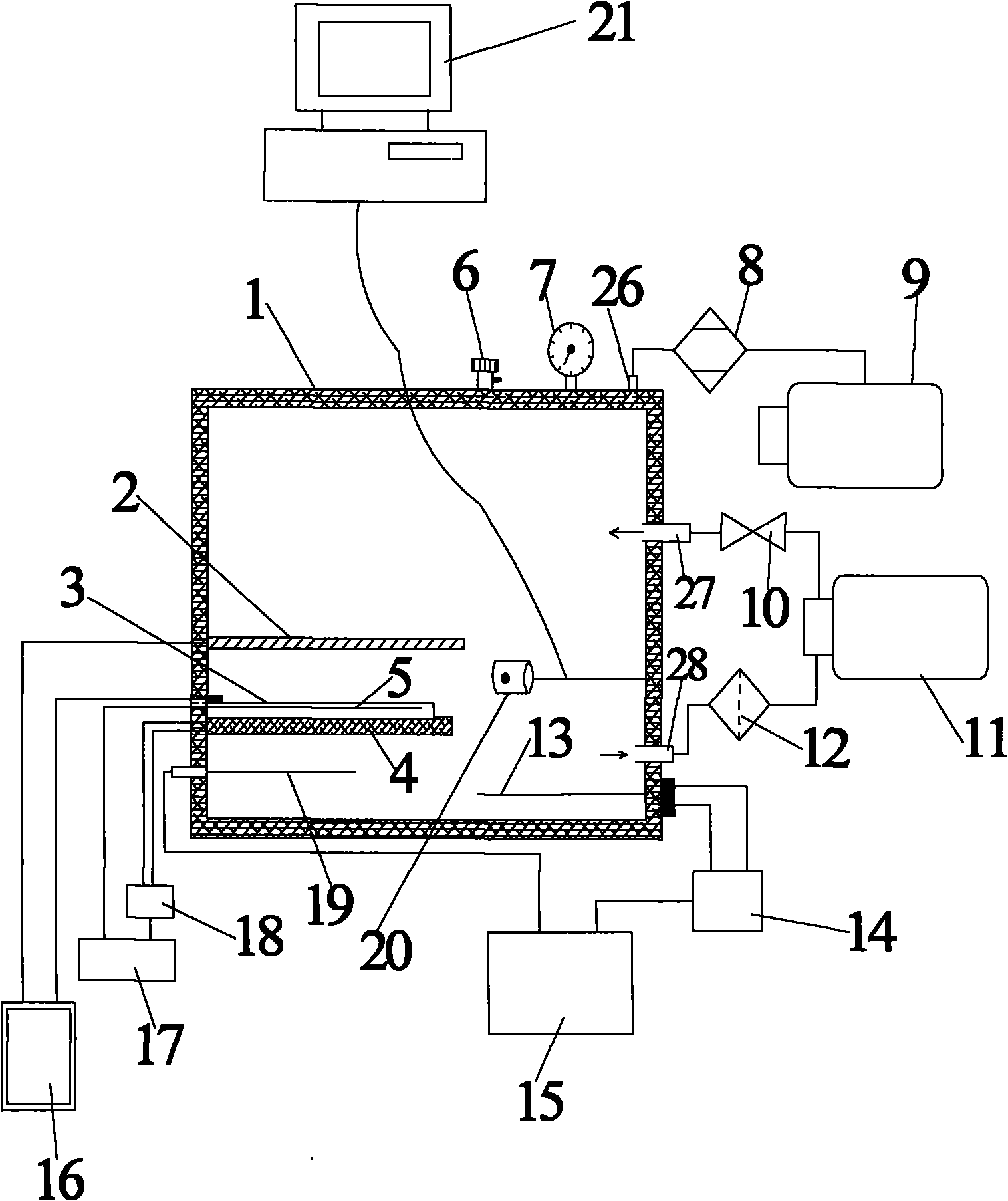

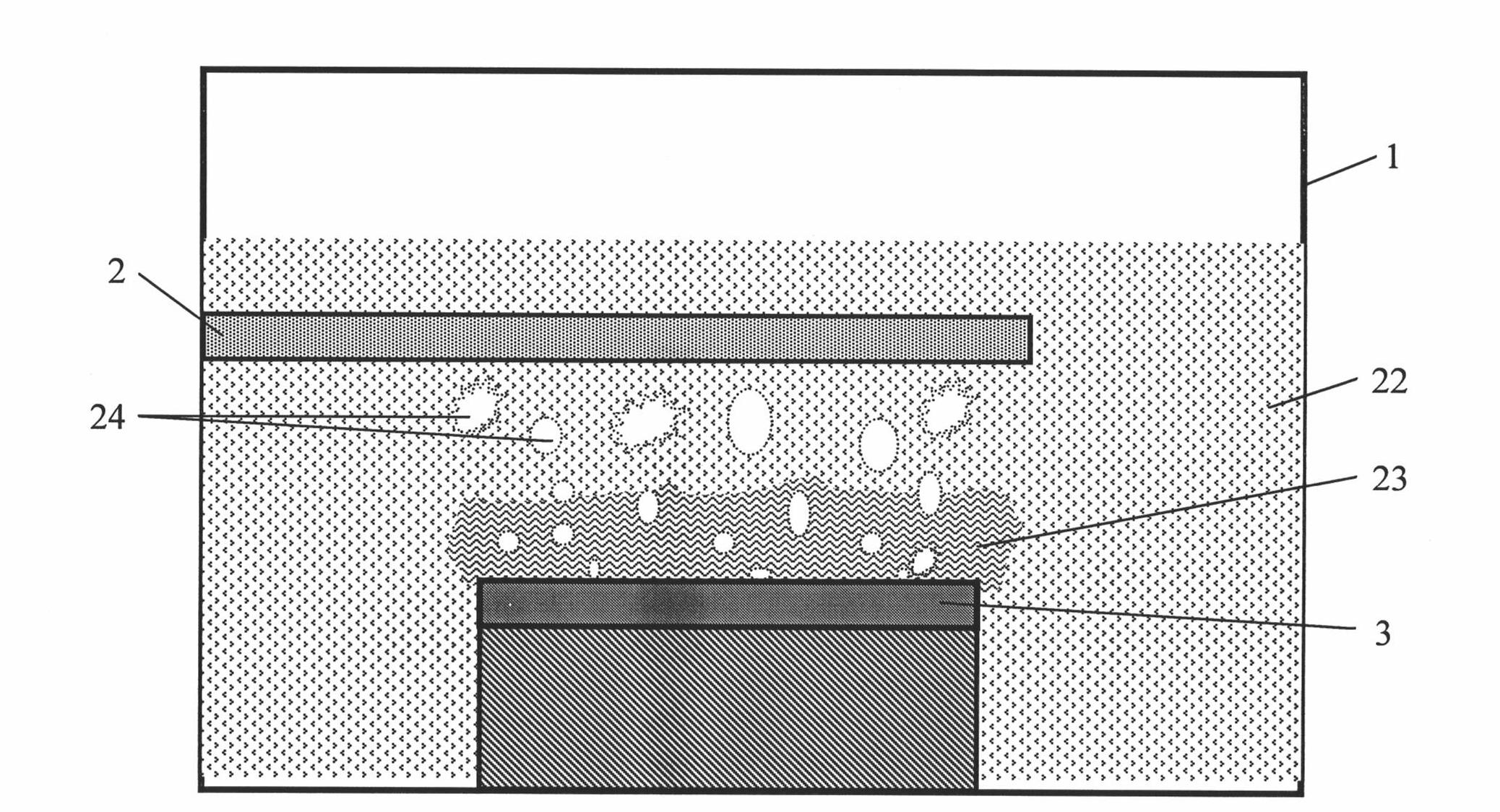

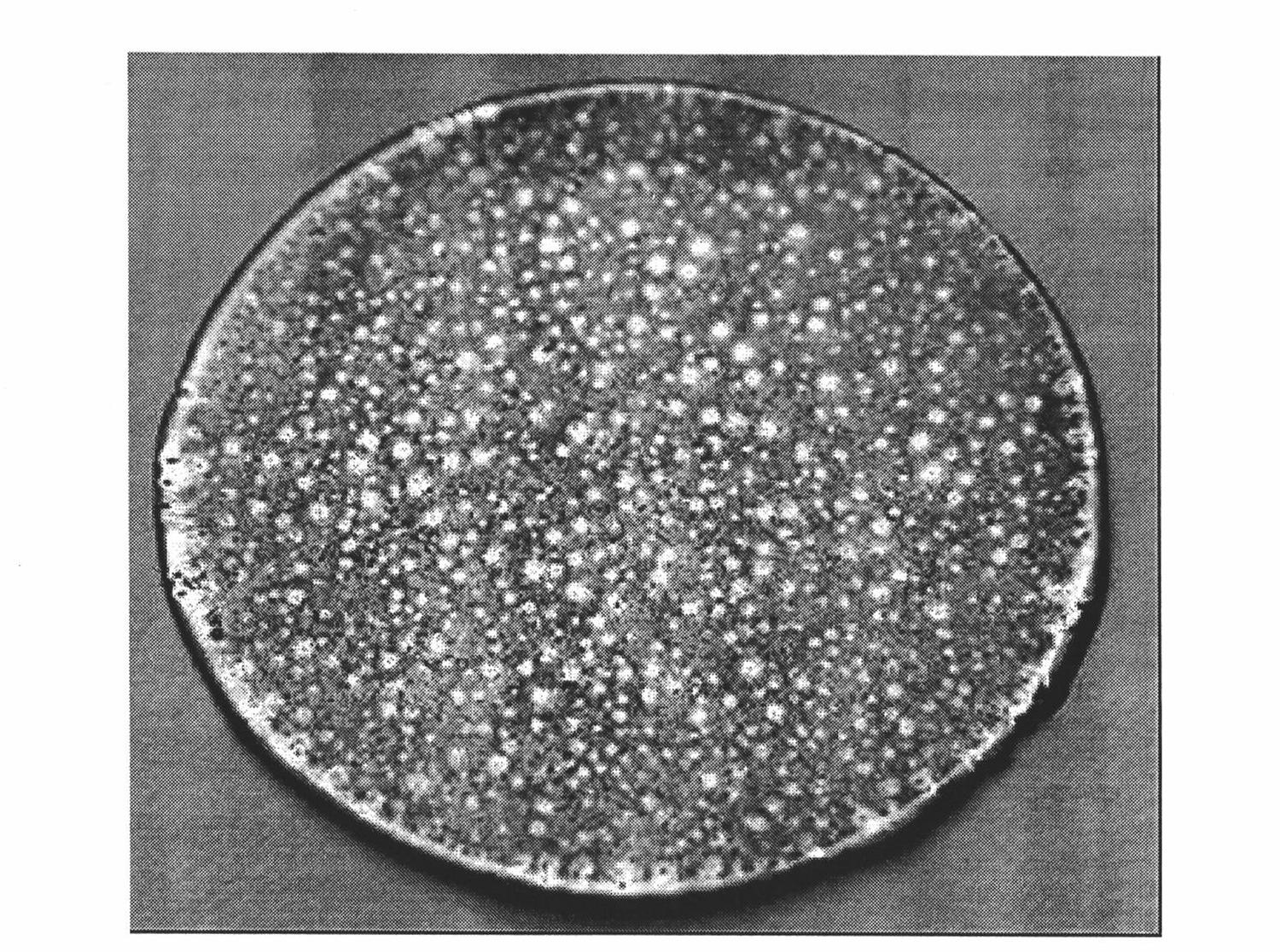

Electrolyte vacuum boiling type high speed electro-deposition method and device thereof

The invention relates to an electrolyte vacuum boiling type high speed electro-deposition method. The method comprises the following steps of: a, fixing an anode and a cathode in an electro-deposition tank, adding a suitable amount of additive-free electrolyte to the electro-deposition tank, and sealing the electro-deposition tank, starting an electrolyte recycle filter system and an electrolyte state observing system, starting an electrolyte temperature control system and a cathode face temperature control system, and respectively controlling the temperature of the electrolyte in the tank to be 25-40 DEG C and the temperature of the cathode face at 55-70 DEG C; b, starting an electro-deposition tank vacuum degree control system, vacuumizing the electro-deposition tank and adjusting the vacuum degree in the tank to enable the electrolyte close to the surface of the cathode face to boil; and c, starting the power supply to carry out the electro-deposition, till the coating reaches the demanded thickness. The invention also discloses a device for carrying out the above electro-deposition method. A coating or a component with fewer defect, fine crystal particle, good compactness, and polished surface can be rapidly produced by electro-depositing under the condition without additive by the method of the invention. The invention is adapted to common machining situations, such as the electroplating, electroforming, electro-brush plating and the like, as well as the micro machining situation.

Owner:HENAN POLYTECHNIC UNIV

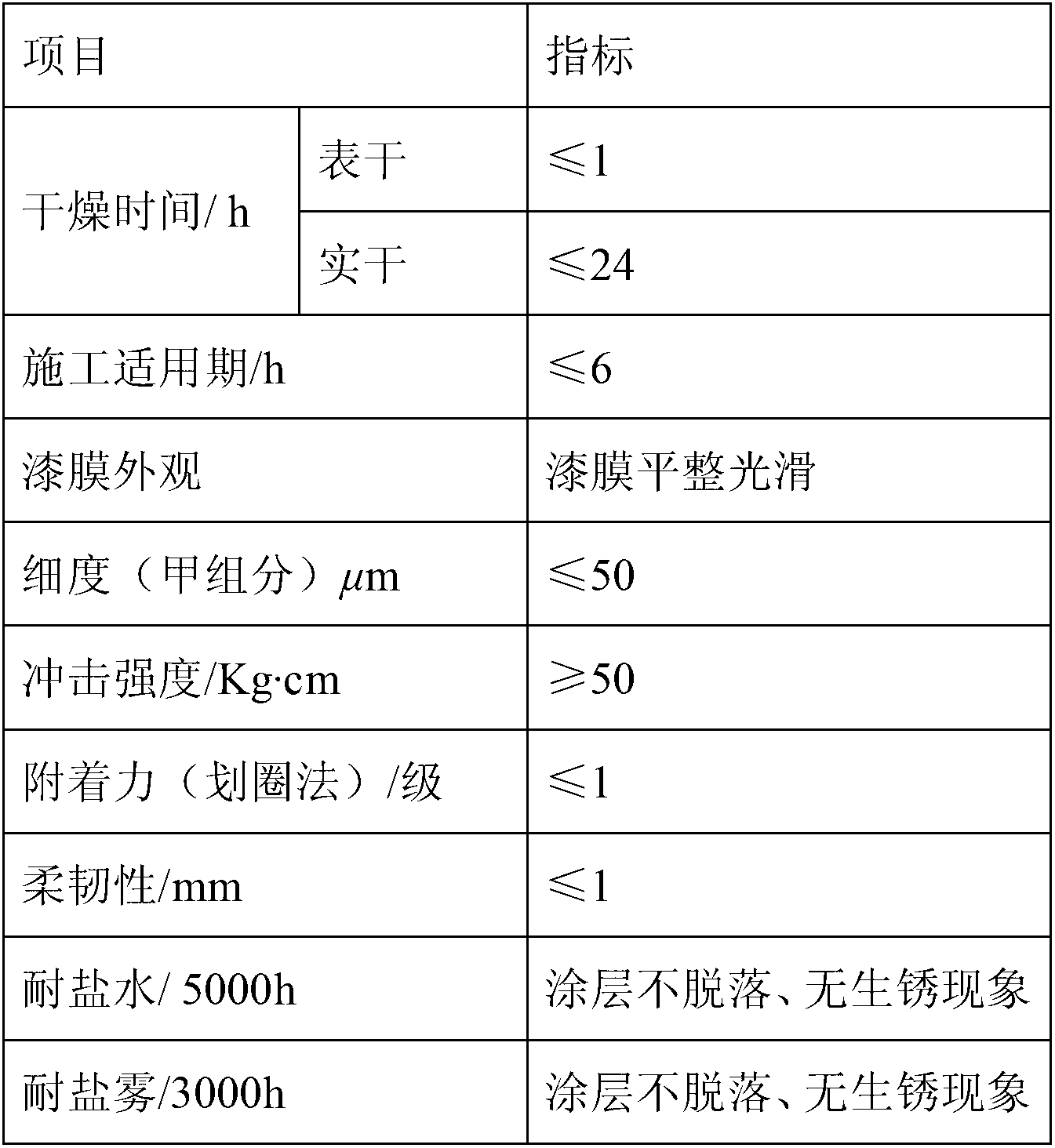

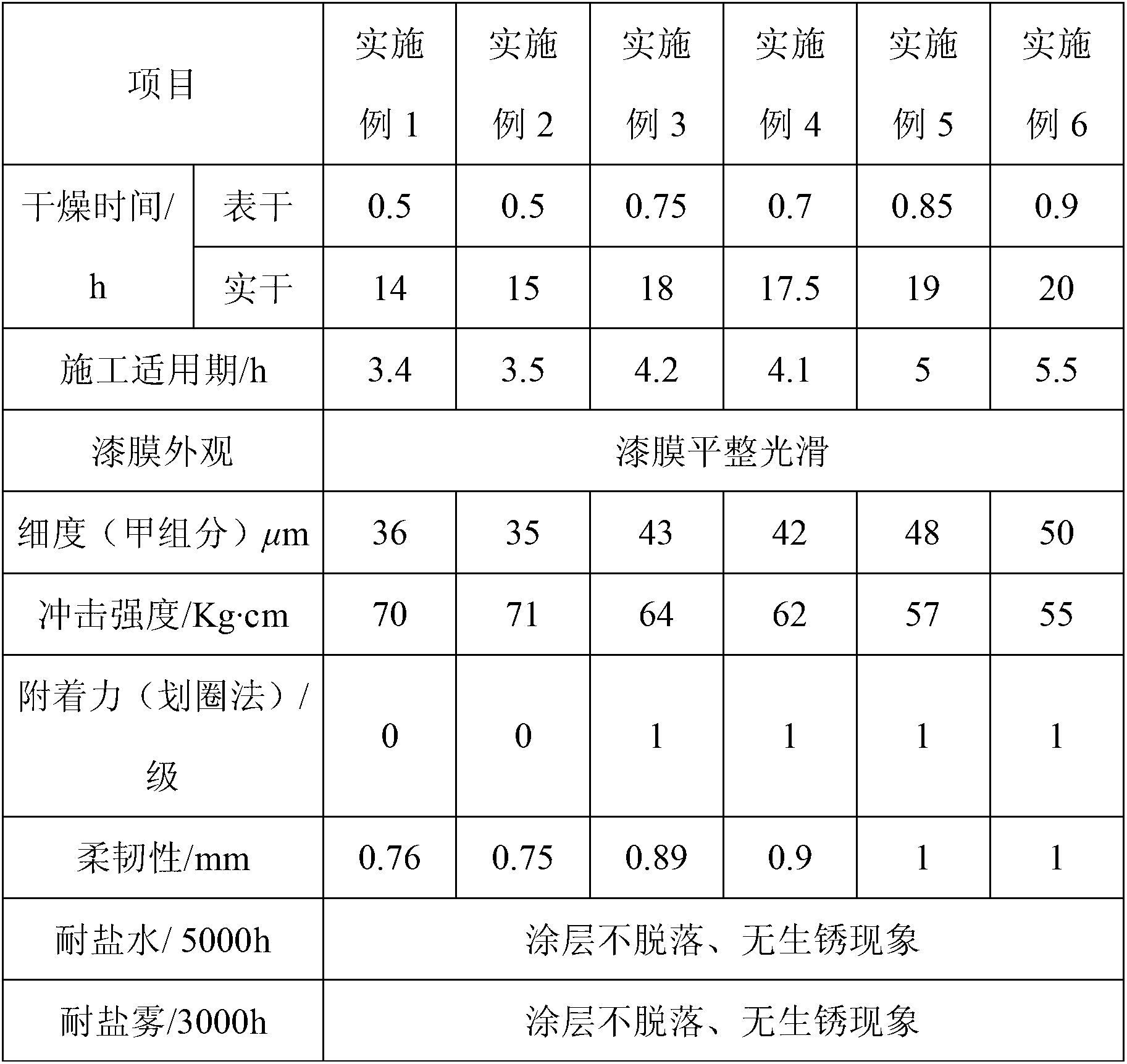

Nano modified aqueous epoxy rust-resisting paint and production method thereof

InactiveCN102796436AImprove rust resistanceStrong compactnessAnti-corrosive paintsEpoxy resin coatingsEmulsionHardness

The invention relates to the field of metal anticorrosive paints, particularly relates to a nano modified aqueous epoxy rust-resisting paint and a production method thereof. The nano modified aqueous epoxy rust-resisting paint comprises a component A and a component B, wherein the component A comprises aqueous epoxy emulsion, wetting dispersant, levelling agent, film forming auxiliary agent, antifoaming agent, filling material, anti-flash rust agent, antirust pigment and water and especially nano organic silicon solution, and the component B comprises aqueous cashew nut shell oil modified amine hardener and water. According to the invention, by using the nano inorganic silicon solution to modify the aqueous epoxy rust-resisting paint, compared with unmodified aqueous epoxy rust-resisting paint, the paint film is denser after solidification, and the anlirust property is better; the hardness of the paint film is strengthened, the thixotropy is good, and there is no sagging during facade construction; and compared with the usage of modified polyurethane, alkali swelling and other thickening rheological auxiliary agents, the cost is greatly reduced.

Owner:ANHUI JINDUN PAINT

Glazing method for enhancing ceramic durability

The invention mainly relates to the technical field of ceramic glaze processing, and discloses a glazing method for enhancing ceramic durability. The glazing method includes the steps: wet glaze preparation; primary glazing; dry glaze preparation; secondary glazing; firing and drying. The method is simple and convenient to operate, glaze and a green body are closely combined, expansion coefficients are matched, surfaces are smooth and uniform, colors are bright, corrosion resistance is high, the service life is prolonged by 12.4%, and economic income is improved by 26.7%. The glaze is frozen by adding water, grinding is facilitated, anhydrous alcohol is added, the glaze is grinded in a high-temperature dry environment, unfreezing of the glaze is accelerated, and the bright colors are kept. The green body is placed in a high-temperature and high-humidity environment after primary glazing, adsorption of the green body for the glaze is promoted, needle holes and bubbles are decreased, and the service life is prolonged. The sprayed glaze is freeze-dried, the colors of the glaze are kept bright, adsorptivity of the glaze is enhanced, the glaze is applied by dry pressing, so that a glaze layer is smooth and uniform, and durability is improved. The green body is fired at low temperature after the glaze is applied, durability of the green body is improved, environments are protected, and energy is saved by 9.6%.

Owner:福建省德化佳旺达陶瓷有限公司

Polymer repairing mortar and preparation method thereof

The invention discloses a polymer repairing mortar. The polymer repairing mortar comprises 400-500 parts of cement, 500-600 parts of quartz sand, 1-5 parts of a high-molecular polymer, 5-15 parts of a polymer, 1-5 parts of silicon micropowder and 0.1-0.3 parts of wood fiber, wherein the high-molecular polymer is cellulose ether, and the polymer is re-dispersible latex powder. The purpose of the invention is to provide the polymer repairing mortar with the characteristic of long service life and no cracking, and a preparation method thereof.

Owner:浙江泰正建材有限公司

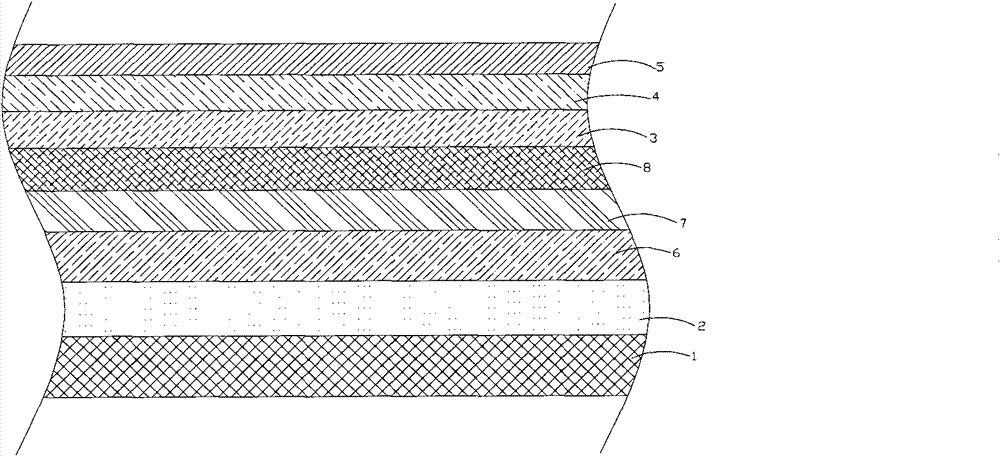

Composite barrier structure having self-restoration capability

ActiveCN105280837APlay a water and oxygen barrier effectGood water and oxygen barrierSolid-state devicesSemiconductor/solid-state device manufacturingStructural engineeringOxygen barrier

The invention discloses a composite barrier structure having the self-restoration capability. The composite obstruction structure has a plurality of functional structure layers, and includes a basic Al2O3 layer, a middle aluminium layer, a middle Al2O3 layer, and an external compact structure layer that are successively superposed on a substrate, the basic Al2O3 layer forms a first barrier layer, the external compact structure layer can obstruct water and oxygen molecules to pass through, the middle Al2O3 layer and the external compact structure layer form a second barrier layer together, a pure aluminium layer is a repairing agent layer which supplies Al atoms when the superposed basic Al2O3 layer and middle Al2O3 layer have slit defects, and the Al atoms spontaneously oxidate at the defect parts to form Al2O3 to fill the corresponding defects. The composite barrier structure having the self-restoration capability has an excellent water and oxygen barrier property, an excellent repeated bending property, and the self-restoration capability after the defects are formed, and has wide application prospects on the improvement of the water and oxygen barrier property and the bending property of a flexible substrate.

Owner:SHANGHAI UNIV

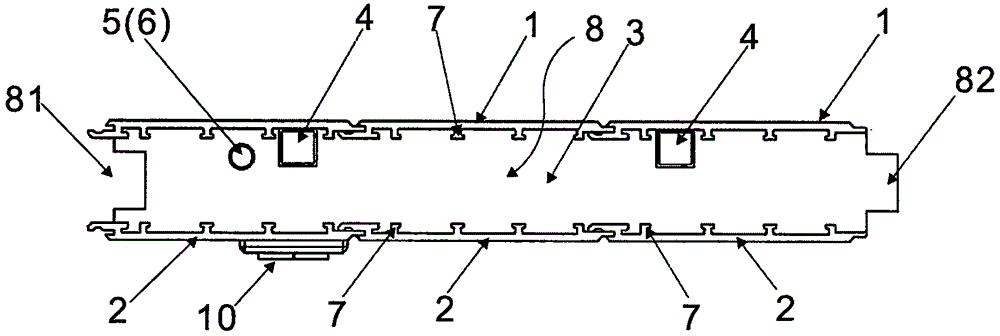

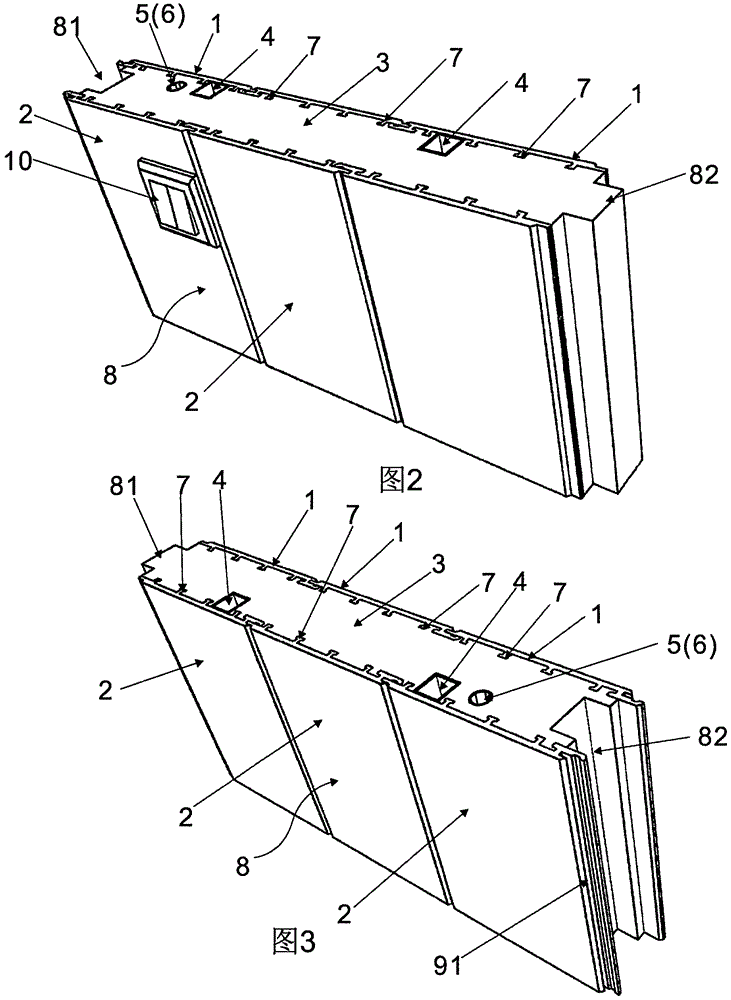

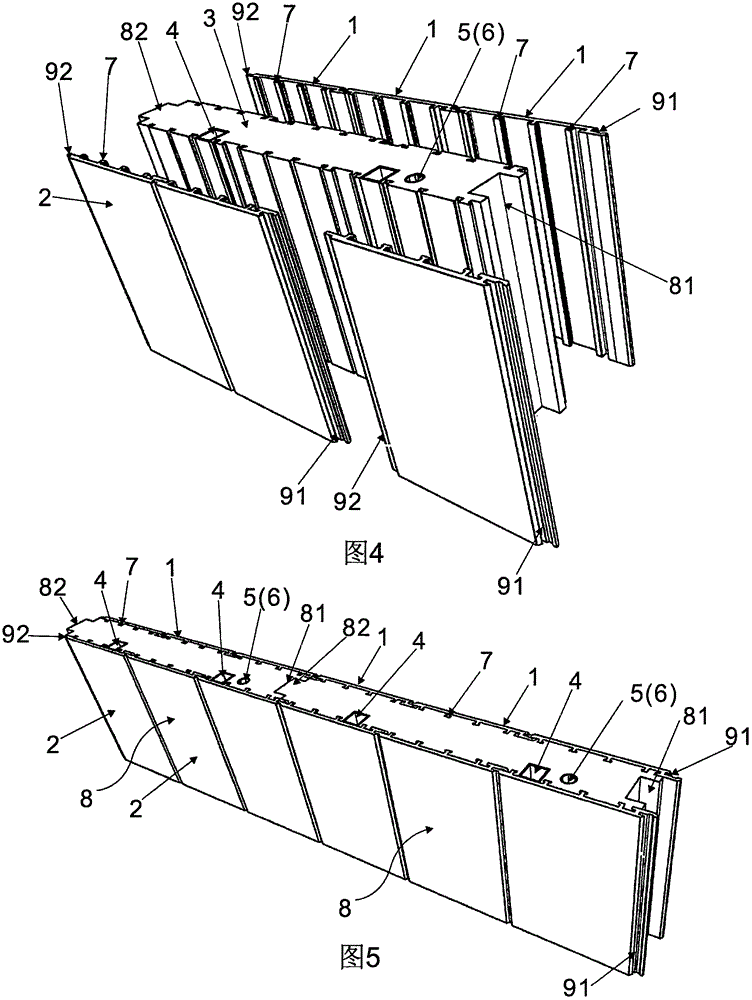

Making method of integrated multifunctional wall module and multifunctional wall module

The invention relates to a making method of an integrated multifunctional wall module and a multifunctional wall module. The method comprises the following steps: 1, fixing an inner wall board and an outer wall board at preset wall thickness, and reserving a certain distance between the inner wall board and the outer wall board; and 2, filling a slurry thermal insulation material between the inner wall board and the outer wall board, wherein the inner wall board and the outer wall board are mutually adhered by the thermal insulation material to form a whole body. The multifunctional wall module comprises the inner wall board and the outer wall board, and the fluid thermal insulation material is filled between the inner wall board and the outer wall board, so that the inner wall board and the outer wall board are mutually adhered and fixed to form an integrated wall module. The multifunctional wall board not only has the advantages of being simple in production process, simple and convenient in installation and operation, strong in stability and easy for mastering, but also has the prominent performances of good thermal insulation and sound insulation; and the multifunctional wall module also has the benefits of being low in making cost, long in service life, strong in strength, small in size and light in weight.

Owner:GUANGDONG MULIFANG WOODEN HOUSE CO LTD

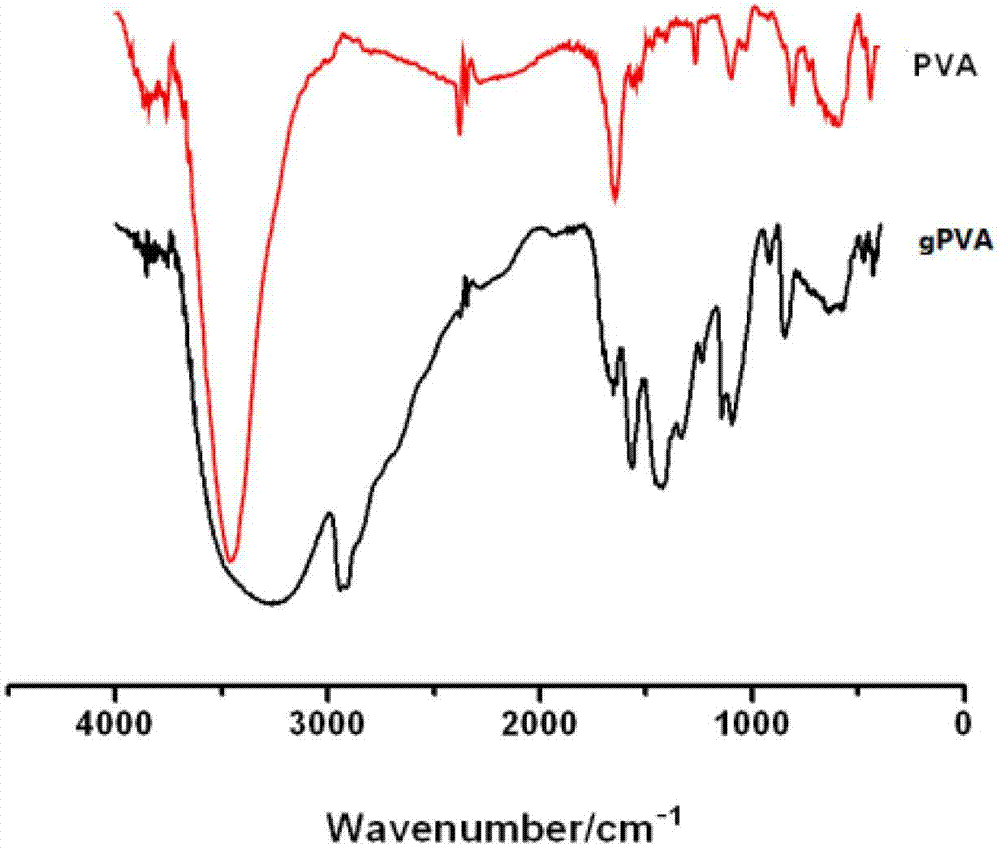

Waterproof cement additive and cement containing same

InactiveCN102757196AImprove hydrophilicityExcellent continuous film-forming performancePolymer scienceCrazing

The invention relates to a waterproof cement additive and cement containing the same. The waterproof cement additive is prepared through the following steps: dissolving polyvinyl alcohol in water, adding methyl acrylate in the solution, then adding an initiator, carrying out water bath at 60 to 90 DEG C, introducing nitrogen, and reacting for 2 to 10 hours, wherein the ratio of polyvinyl alcohol to methyl acrylate is 2g:(1 to 2) ml, and the weight ratio of polyvinyl alcohol to the initiator is (15 to 30):1. After the waterproof cement additive is blended with emulsion formed after cement is dissolved, cement has excellent continuous film forming performance, so that active groups in polymer molecules are possibly in the cross-linking reaction with Ca and Al in hydration products of cementto form a special bridge bonding effect, the physical organizational structure of hard cement mortar is improved, the internal stress is relieved, the generation of the microcracks is reduced, the compactness of waterproof polymer paint is enhanced, and the compactness is stronger.

Owner:天津市南开区房地产管理局

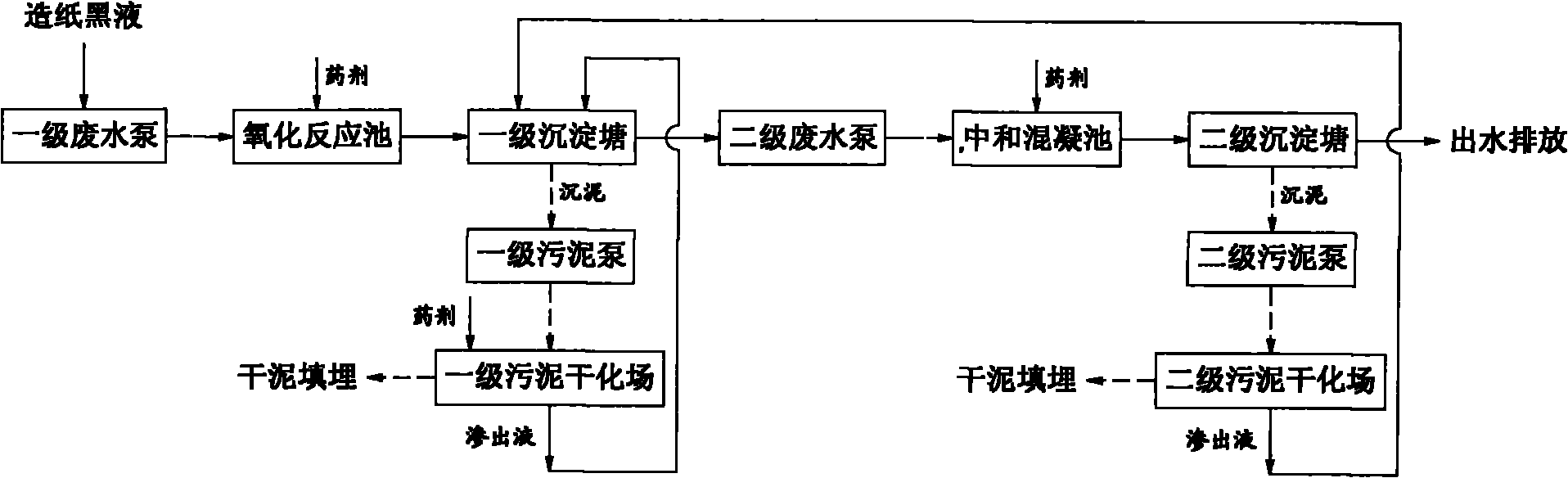

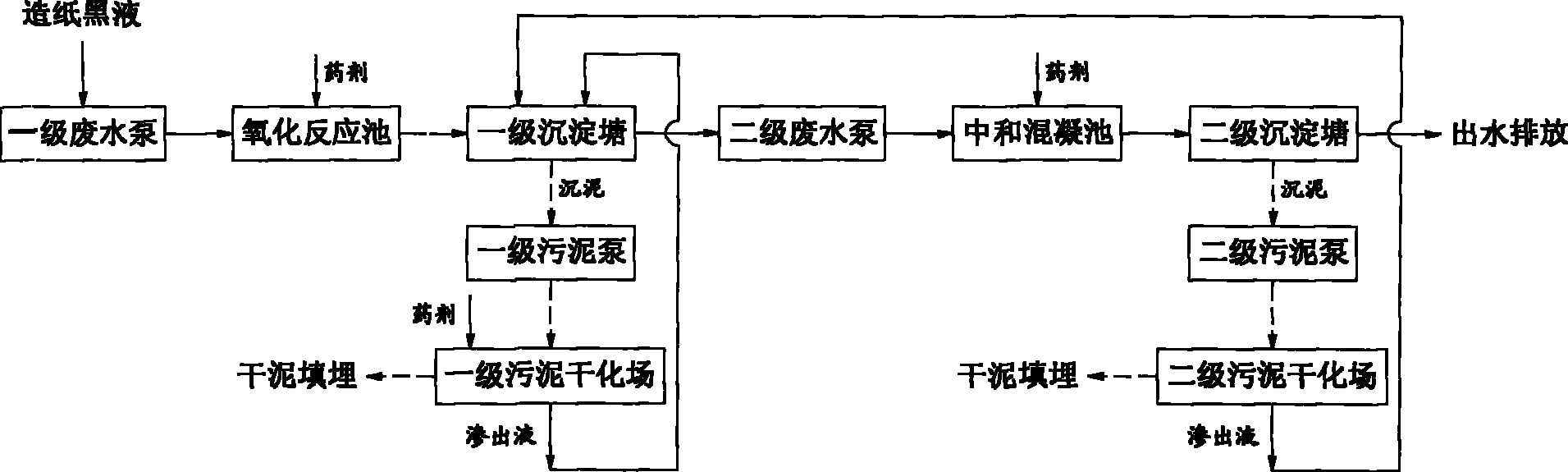

Processing technique for residual papermaking black liquor

InactiveCN101767892AStrong sludge compactnessReduce viscosityPulp liquor regenerationMultistage water/sewage treatmentChemistryAluminium salts

The invention provides a processing technique for residual papermaking black liquor, relating to the processing technique for industrial sewage. The provided processing technique clears the black liquor by leading lignin and glycan in the papermaking black liquor to become inorganic so as to solidify and discharge harmful substances in the black liquor. As to the papermaking black liquor containing the lignin and the glycan, the processing technique in the invention includes the following steps: 1) oxidizing reaction; 2) neutralization and coagulation. Certain quantity of sulfuric acid, ferrous sulfate and hydrogen peroxide is added to the black liquor, and the pH value is adjusted, so as to carry out the oxidizing reaction; then, most of the lignin and the glycan become inorganic, the COD of supernate which is precipitated for 12 to 16 hours is reduced to about 600mg / L, the color of waste water becomes light yellow from dark black, and the chroma is about 80 times. Certain quantity of sodium hydroxide and aluminum sulfate is added to the light yellow supernate so as to carry out the reaction of neutralization and coagulation, the COD of the precipitated water is reduced to lower than 350mg / L, the chroma is lowered to about 16 times, and the water quality is stable and reaches the standard.

Owner:王永广

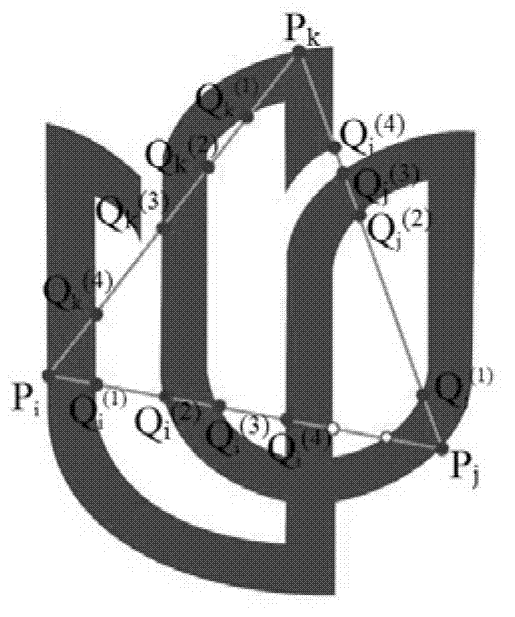

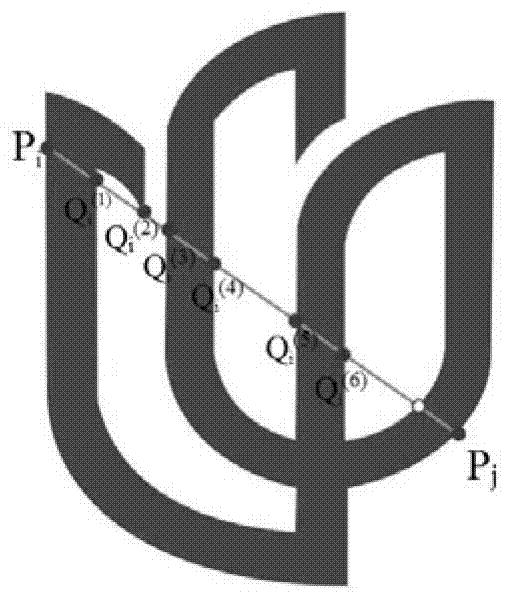

Geometric graphic feature point-based method for establishing shape descriptor

ActiveCN103208003AImprove stabilityStrong compactnessCharacter and pattern recognitionFeature vectorGraphics

The invention relates to a new geometric invariant (namely feature number)-based shape descriptor, and belongs to the field of computer vision. The shape descriptor is an outline-based shape descriptor which combines a global feature and a local feature. A geometric graphic feature point-based method for establishing the shape descriptor comprises the following steps of: sampling convex hulls of an image uniformly to obtain a series of sample points; and selecting three points sequentially among the sample points according to the definition of feature numbers to obtain a series of feather numerical values, so that a feature vector, namely the shape descriptor of the image is formed. According to the shape descriptor, the information of an internal outline of a shape is utilized fully; the content which is described by each component of the descriptor can cover a certain area of the shape, so that the capacity and accuracy degree of describing the shape are improved; the descriptor is used as a projection invariant, so that the shape descriptor can be suitable for various geometric transformations; and for the interference of noise of different degrees, the shape descriptor is high in stability. In the matching stage, a point-to-point dynamic matching mode is replaced by a first-point matching mode, so that recognition time is prolonged greatly. The feature number-based shape descriptor has high compactness and stability and high practical value.

Owner:DALIAN UNIV OF TECH

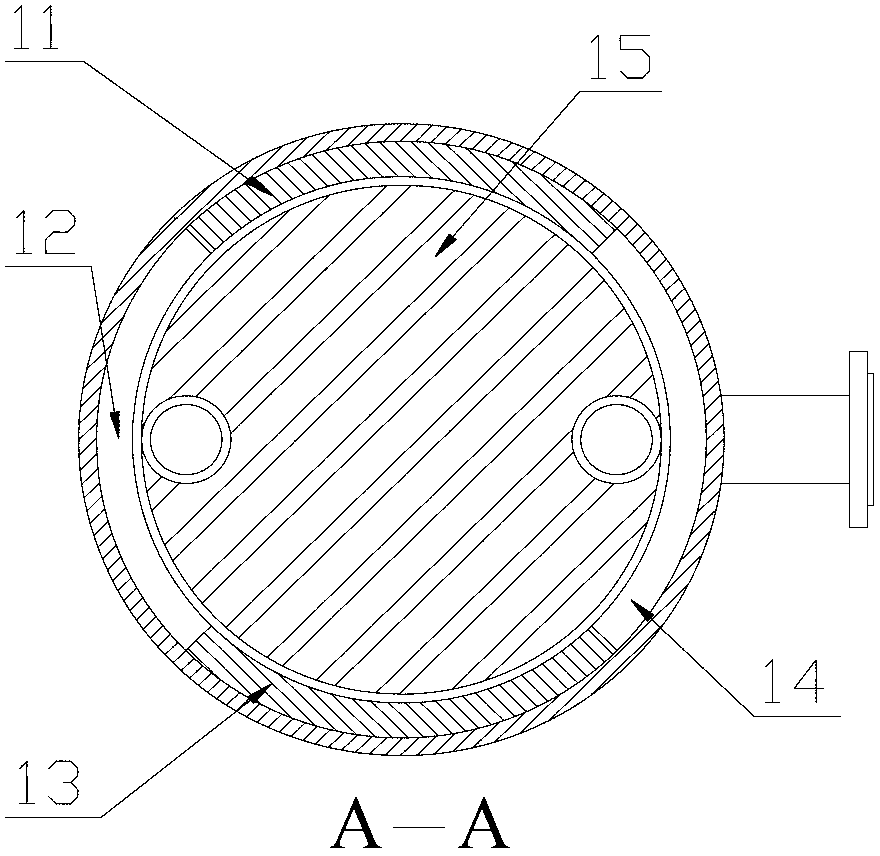

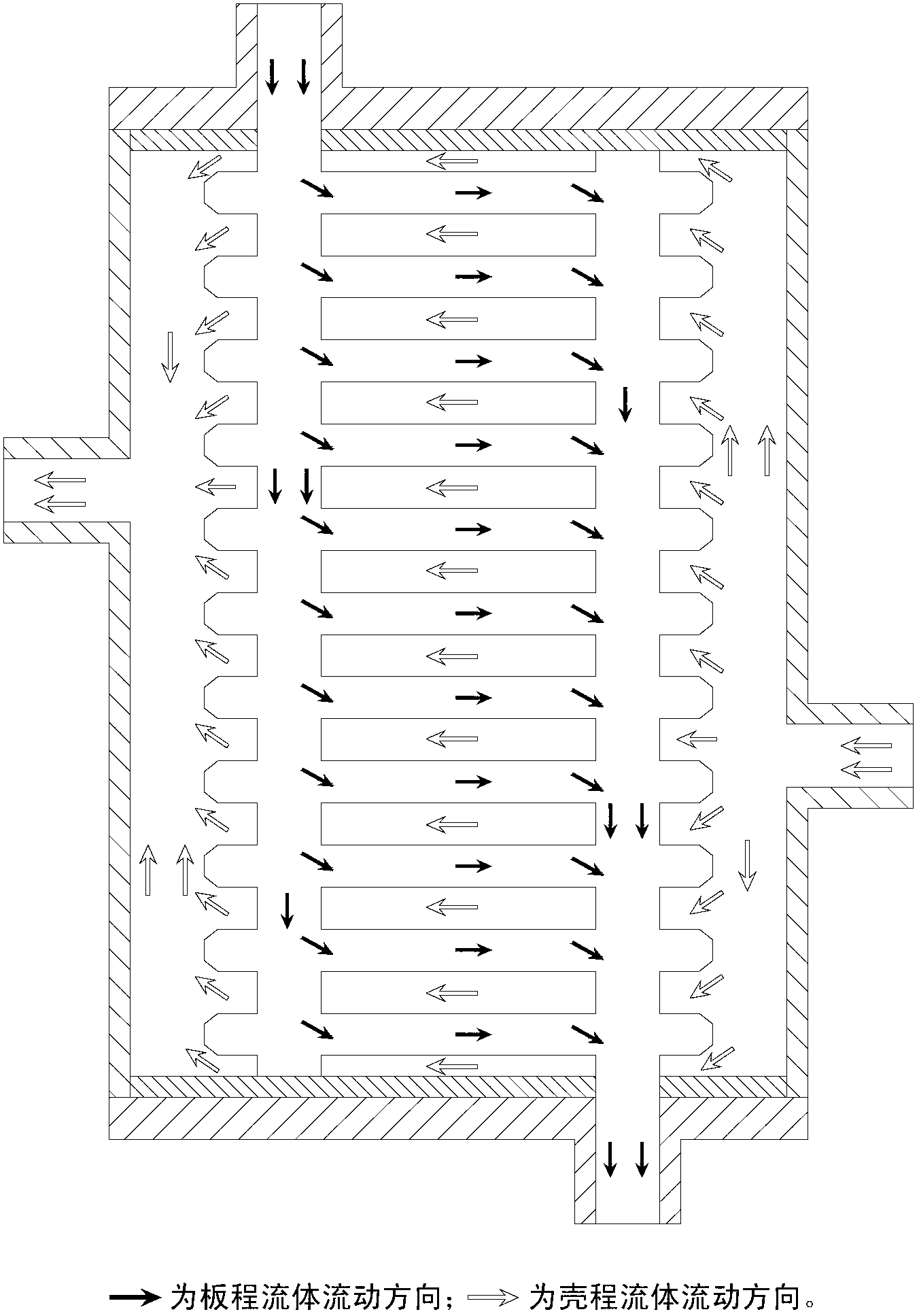

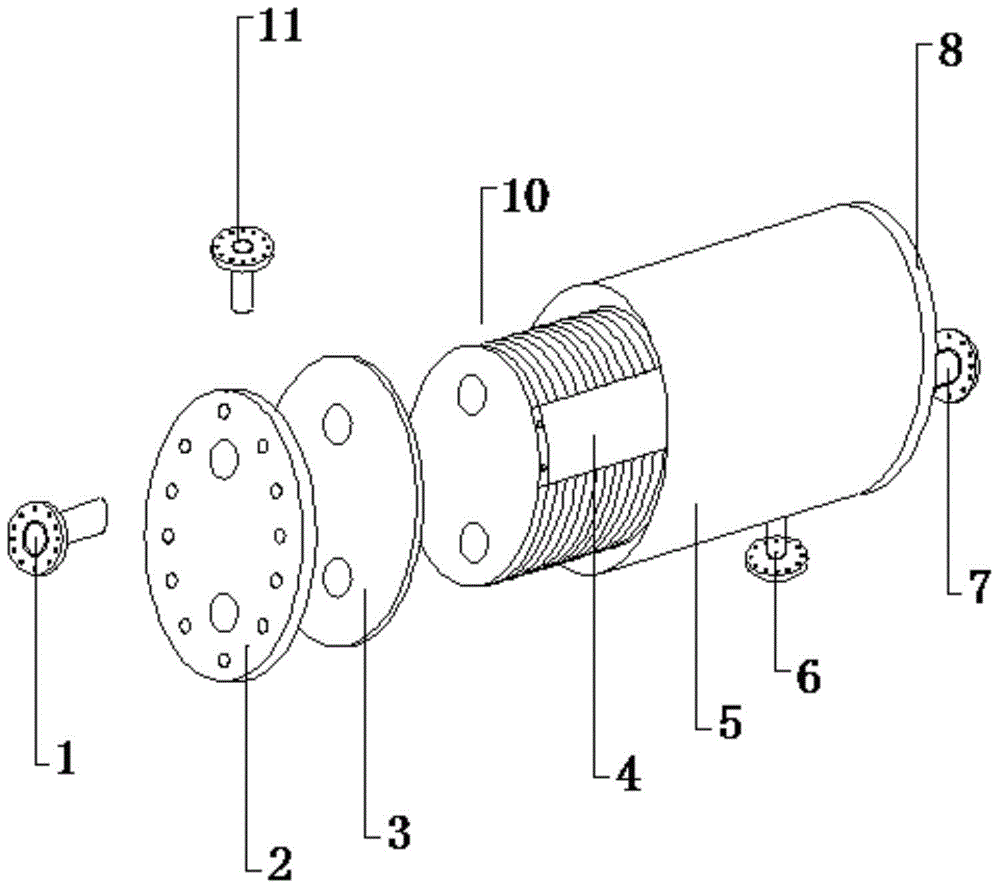

High-pressure resistant lamella heat exchanger adopting round corrugated plates

InactiveCN102706188AUniform stress distributionStrong pressure capacityLaminated elementsStationary plate conduit assembliesEngineeringHigh pressure

The invention aims to provide a high-pressure resistant lamella heat exchanger adopting round corrugated plates, which includes a shell, cover plates, a corrugated plate lathed bundle, flow guiding blocks and support plates, wherein the corrugated plate lathed bundle includes corrugated plates and is fixed in the shell through the support plates; the two ends of the shell are sealed by the cover plates; a shell side outlet and a shell side inlet are arranged in the shell; a plate side inlet and a plate side outlet are arranged in the cover plates; an annular zone between the shell and the corrugated plate lathed bundle is divided into a shell side inlet chamber and a shell side outlet chamber through the flow guiding blocks; the shell side inlet is communicated with the shell side inlet chamber; the shell side outlet is communicated with the shell side outlet chamber; angular holes are formed in the corrugated plate lathed bundle; and the plate side inlet is communicated with the plate side outlet through the angular holes in the corrugated plate lathed bundle. The high-pressure resistant lamella heat exchanger provided by the invention has the advantages of high pressure bearing capability, high heat exchange efficiency, compact structure, big heat transfer area in a unit volume, wide material selection range, wide application range, as well as simplicity in processing and installation.

Owner:HARBIN ENG UNIV

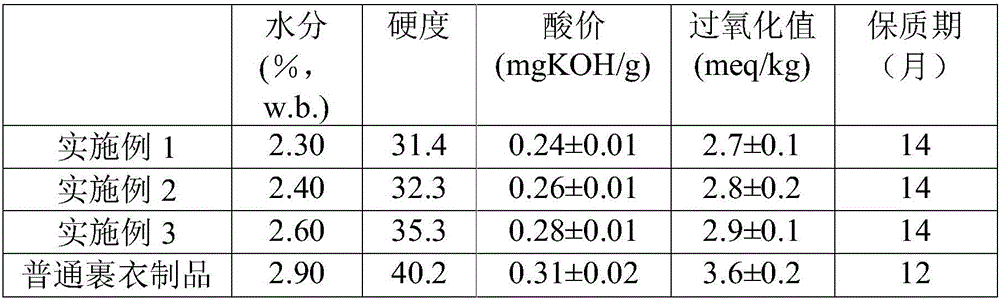

Processing technology of butter honey nuts

InactiveCN106174328AImprove uniformityImprove texture firmnessSugar food ingredientsFood coatingAdhesive materialsNutrient

The present invention discloses a processing technology of butter honey nuts. The processing technology specifically consists of the following steps: (1) wrapping liquid preparing; (2) pre-powder and post-powder preparing; (3) spraying and coating; (4) oil-frying and residue removing; (5) oil blowing; (6) cooling and beating; (7) butter spraying; and (8) nut finished product wrapping. The processing technology enriches the fragrant and sweet mouthfeel of the coated butter honey, effectively improves the uniformity of the powder wrapping, improves the texture tightness of the coating, and effectively prevents the falling of the coating, so that the product appearances, physicochemical indicators and other various performance indicators of the butter honey nuts are more stable. The processing technology effectively prevents the losses of the nuts, honey, butter and other nutrients, the low-temperature oil-frying reduces the destruction of the product nutrients, and the processing technology improves the nutritional values of the products, enables the coating to be translucent in appearances and uniform in color and luster, reduces the defective percentage to be 20-30%, improves the yields, and can well separate the adhesive materials. The oil blowing technology is conducive to the rapid drying of the surfaces of the butter honey nuts and prolongs the shelf life of the products.

Owner:青岛果果爸爸食品有限公司

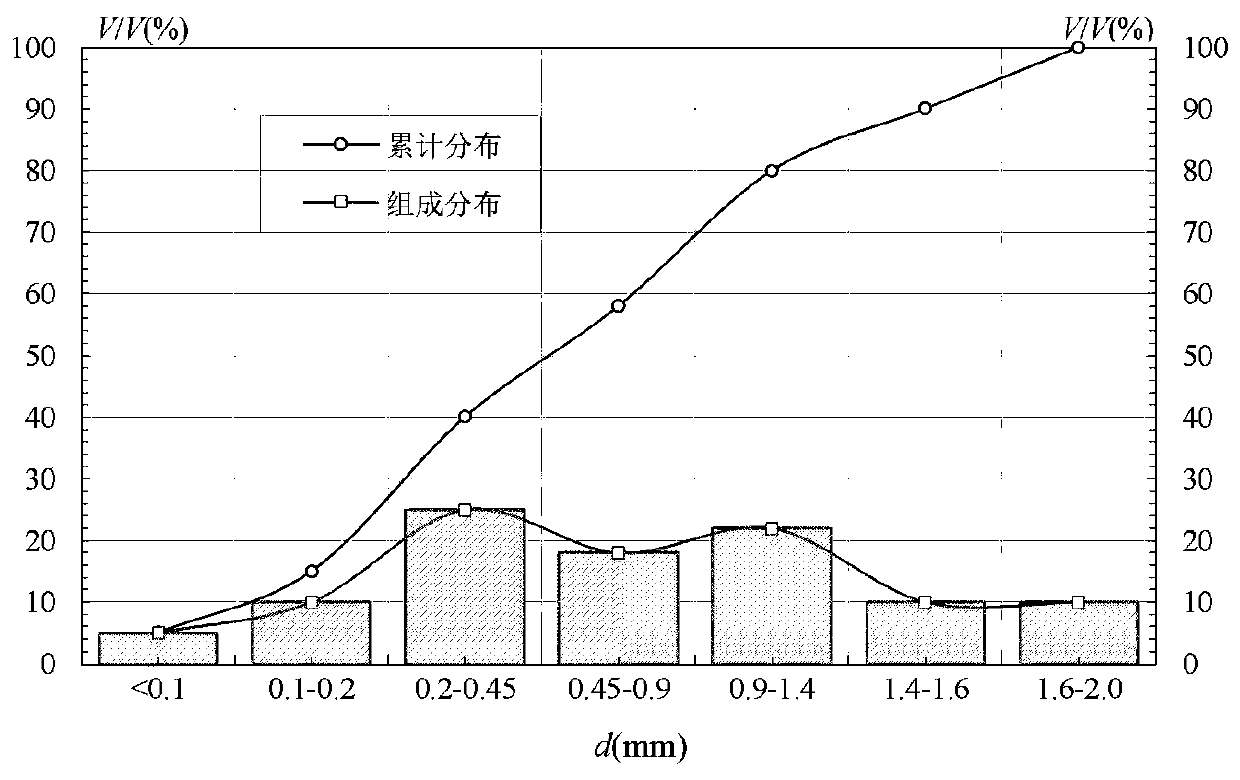

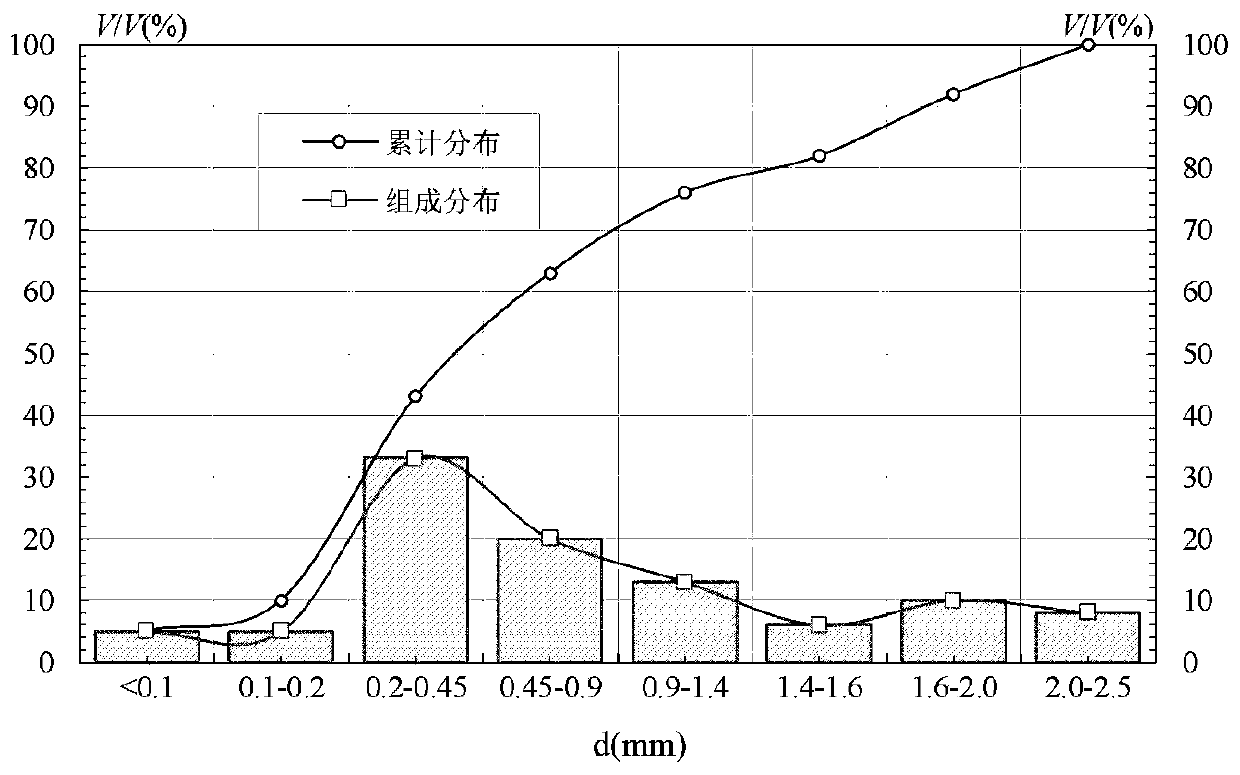

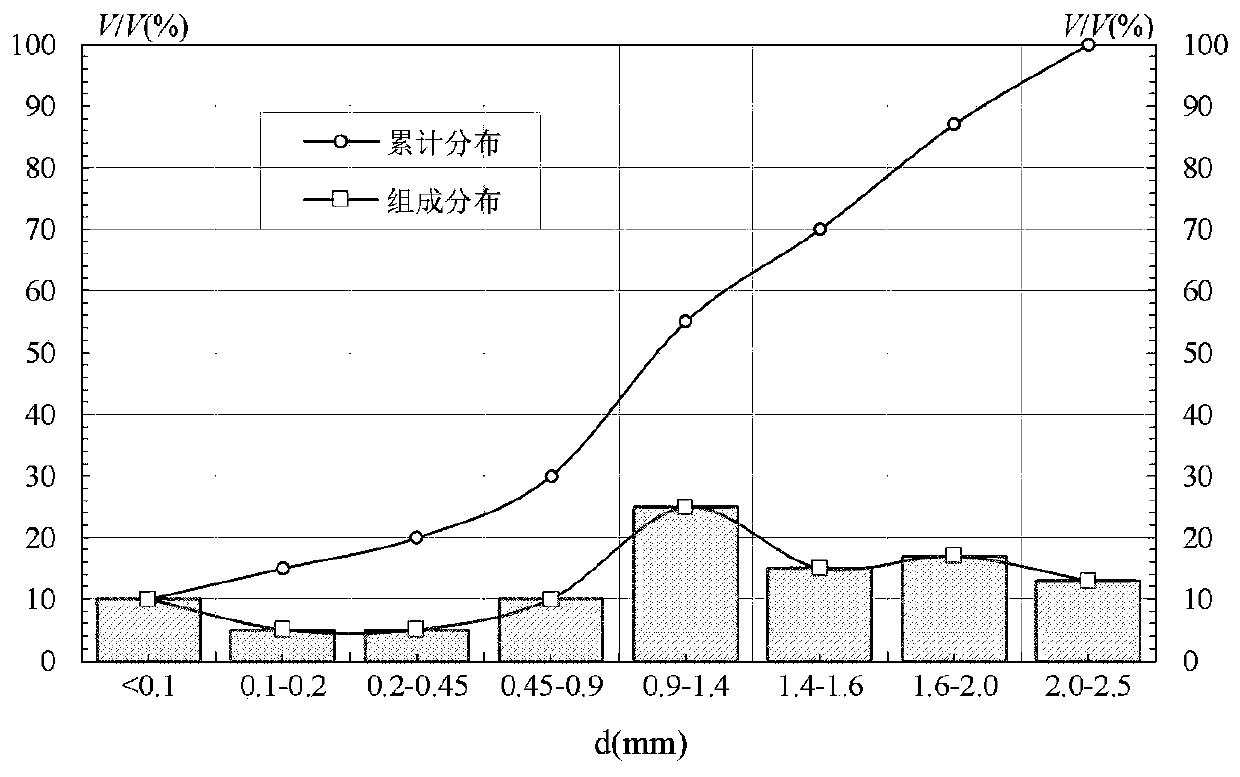

Design method for particle size distribution of fractured leakage bridging leaking stoppage particle material

ActiveCN110147644AStrong compactnessEase of engineering operationGeometric CADParticle size analysisSelection criterionParticle composition

The invention discloses a design method of particle size distribution of a fractured leakage bridging leaking stoppage particle material. The design method comprises the following steps of grading theleaking stoppage material according to the particle size; calculating the expected range of the characteristic particle size value of the leaking stoppage material according to the crack width and particle size selection criterion; setting the relative percentage content of each stage of leaking stoppage material; fitting a particle size distribution curve by using a particle size distribution function; calculating a characteristic particle size value of the plugging material according to the particle size distribution curve; judging whether the calculated characteristic particle size value conforms to the expected range of the characteristic particle size value calculated in the step S20 or not; and finally generating the particle composition of the plugging material according with the particle selection criterion. According to the method, it can be guaranteed that the leaking stoppage granular materials enter the cracks to form the stable blocking interlayer, the blocking interlayeris high in compactness and suitable for the bridging leaking stoppage technology of fractured formation leakage, and the method has the beneficial effects of being clear in physical significance, facilitating engineering operation and the like.

Owner:SOUTHWEST PETROLEUM UNIV

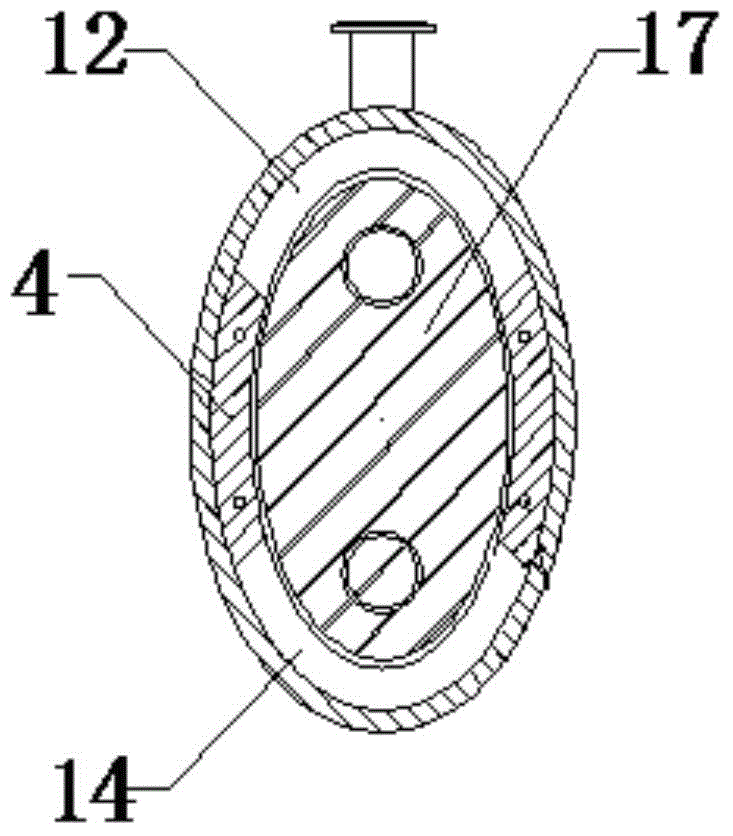

Plate-shell heat exchanger with oval corrugated plates

InactiveCN104089503AImprove heat transfer efficiencyReduce leakageLaminated elementsStationary plate conduit assembliesPlate heat exchangerEngineering

The invention relates to a plate-shell heat exchanger with oval corrugated plates. The multiple oval corrugated plates form a corrugated plate bundle, each corrugated plate is provided with two corner holes correspondingly, the corrugated plate bundle is arranged in a shell, the shell is provided with a plate pass inlet and a plate pass outlet, and the plate pass inlet and the plate pass outlet are communicated through the corner holes in the corrugated plates; a guide block is formed between the corrugated plate bundle and the shell and divides the annular area between the corrugated plate bundle and the shell into a shell pass inlet cavity and a shell pass outlet cavity; the shell is provided with a shell pass inlet and a shell pass outlet correspondingly. The plate-shell heat exchanger is characterized in that the corrugated plates are oval, and the two corner holes of each corrugated plate are formed in the upper portion and the lower portion of the corrugated plate respectively.

Owner:HARBIN ENG UNIV

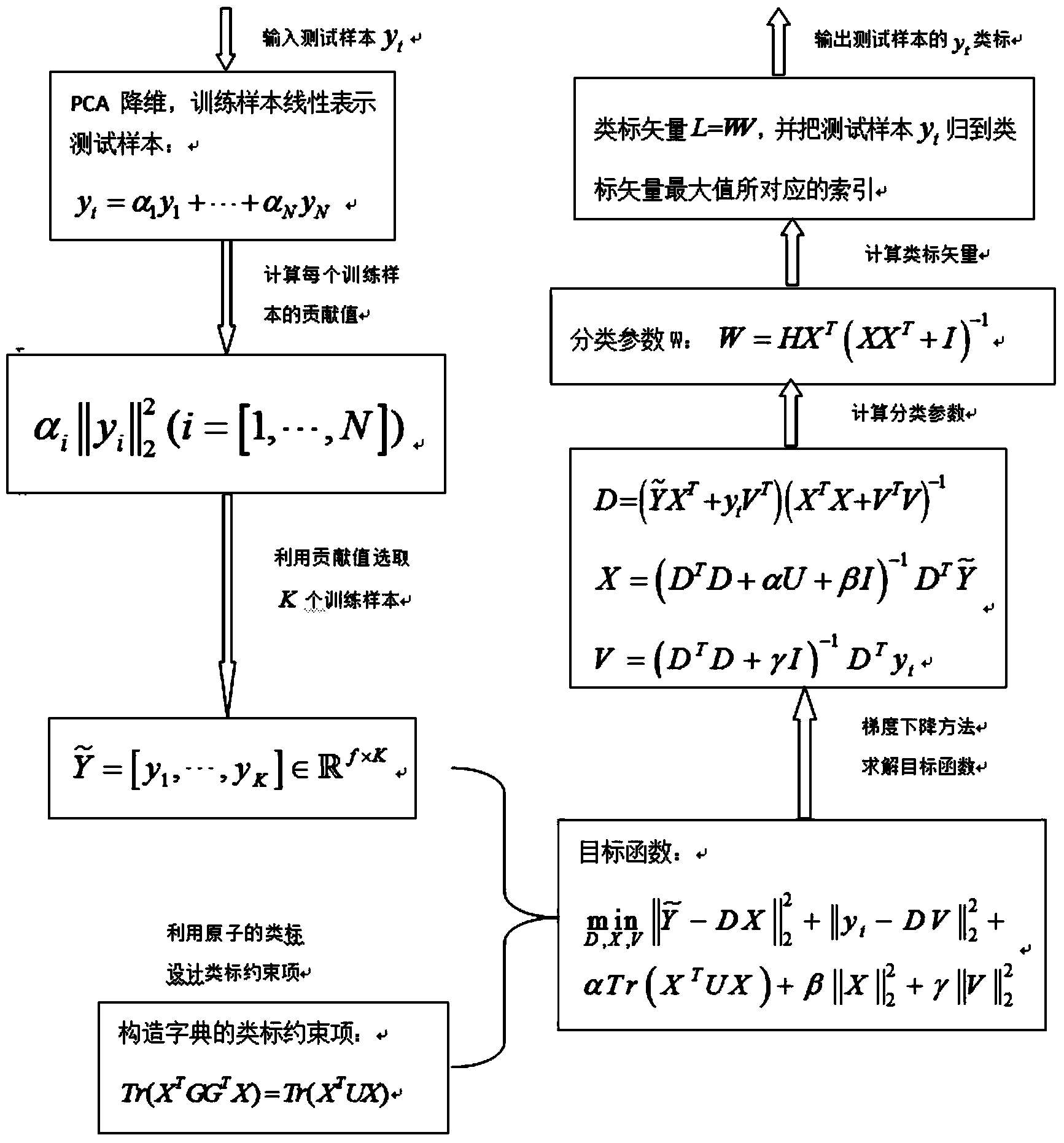

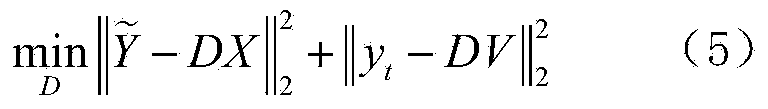

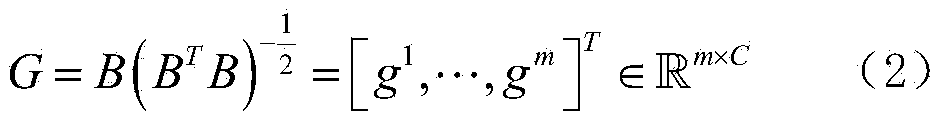

Constraint-based face identification method for single test sample

ActiveCN104166860AReduced classification performanceEasy to identifyCharacter and pattern recognitionComputation complexityDesign testing

The invention provides a constraint-based face identification method for a single test sample. The method comprises the following steps: step 1, performing preprocessing on a training sample set and a test sample; step 2, in a first phase of an algorithm, designing a function relation between the test sample and a training sample, and establishing the function relation between the test sample and the training sample through a method of representing the test sample by use of the training sample in a linearity mode; step 3, designing a class embedded item of a dictionary; step 4, in a second phase of the algorithm, learning the dictionary which is also optimal expression of the test sample by use of the training sample set; and step 5, a classification method, i.e., classifying the test sample by use of a linearity classification method. A test result indicates that the algorithm which is brought forward has the advantages of low calculation complexity, high reconstruction performance, high identification performance and high compactness and the like, and can further improve the face identification rate.

Owner:HANGZHOU YIYOU INFORMATION TECH CO LTD

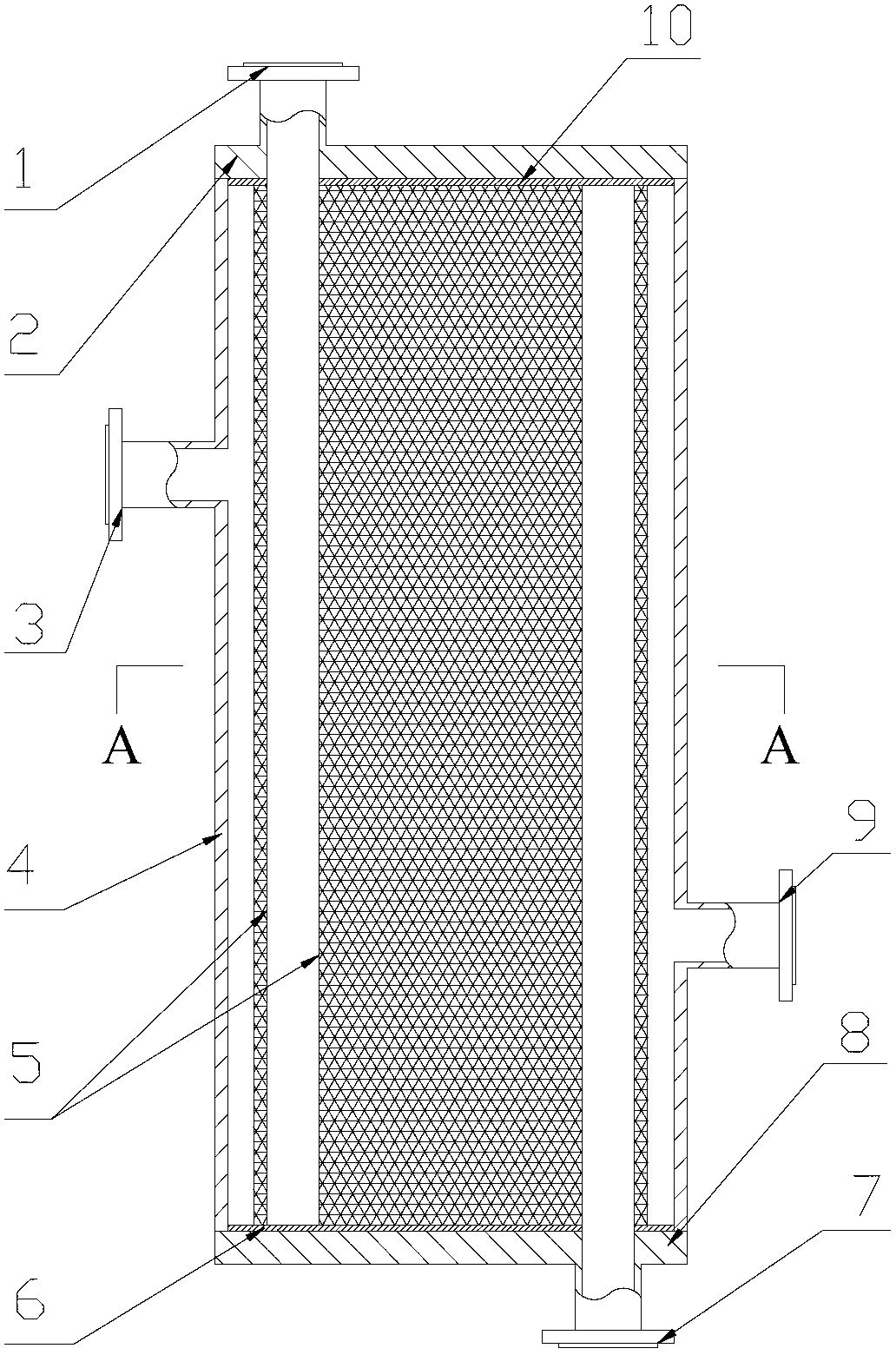

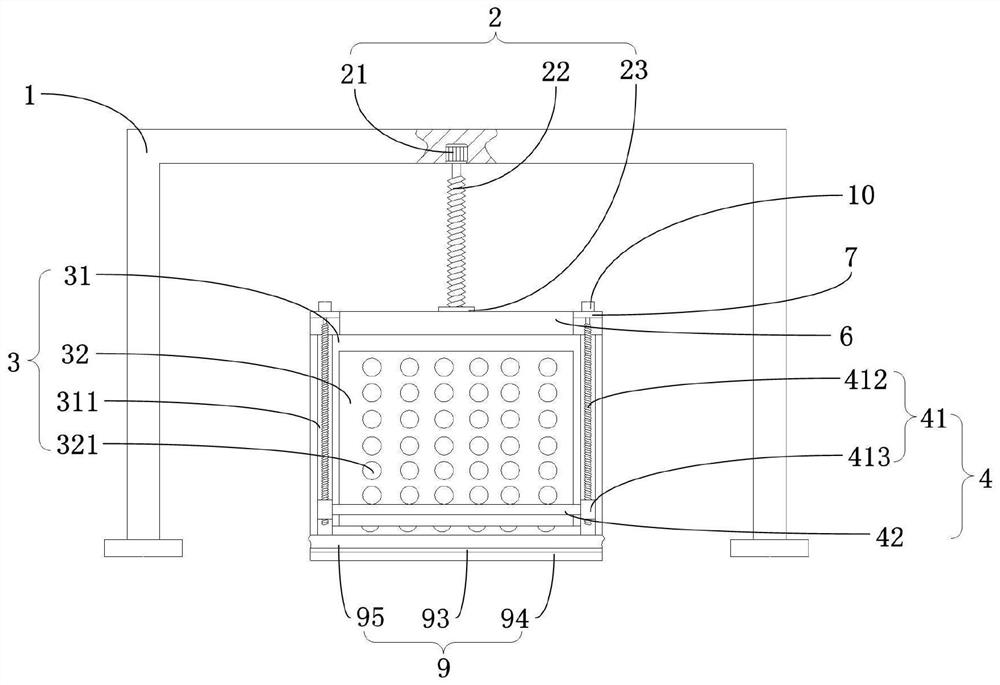

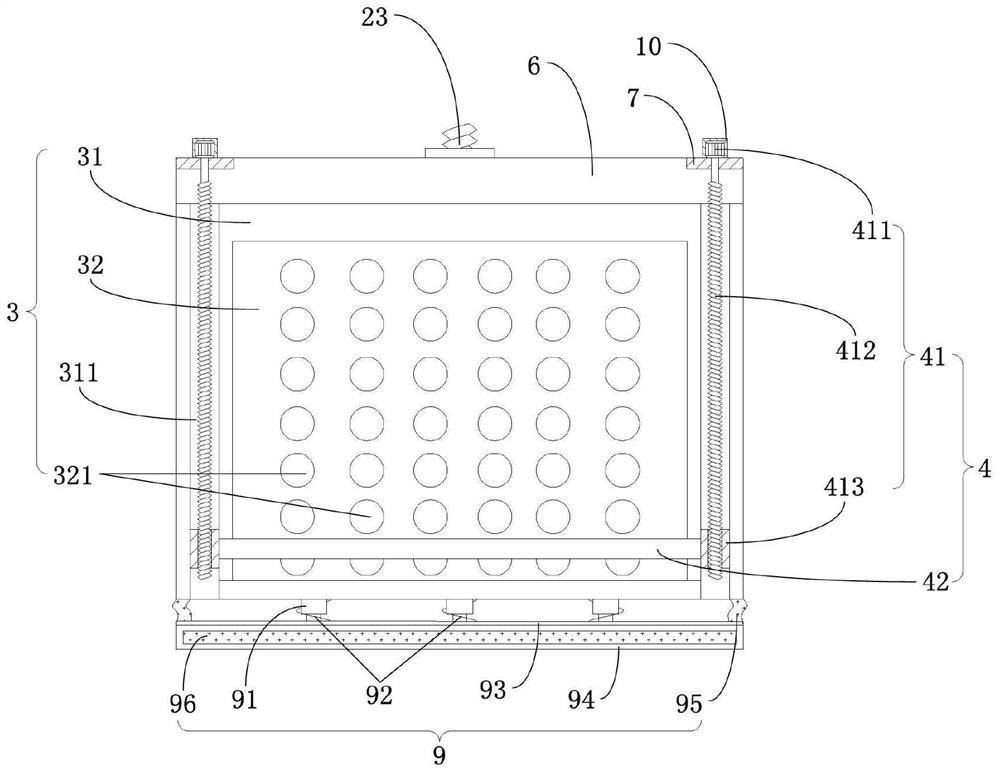

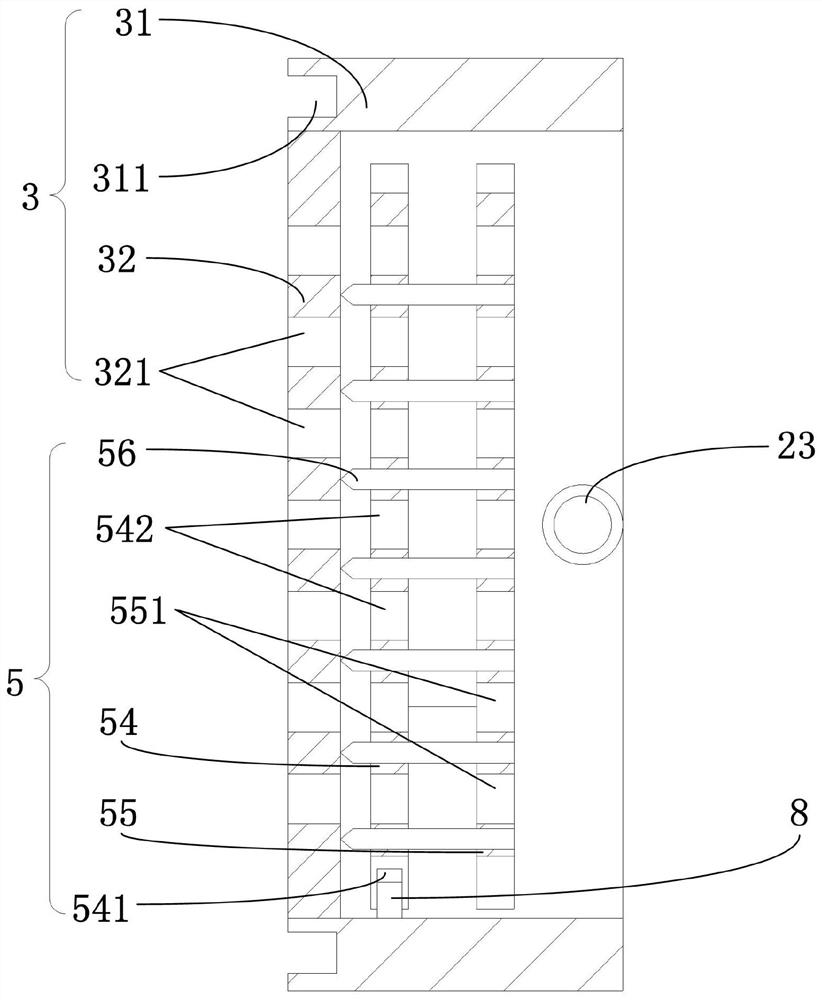

Lifting type intercepting device based on wastewater treatment and using method thereof

PendingCN111632421AEasy to placeImprove cleaning efficiencyStationary filtering element filtersWastewaterStructural engineering

The invention discloses a lifting type intercepting device based on wastewater treatment and a using method of the lifting type intercepting device. The device comprises a base, a lifting assembly, wherein one end of the lifting assembly is fixed in the middle of the base, an intercepting assembly which comprises an intercepting frame and a filter screen, wherein the filter screen is fixed to oneside wall of the intercepting frame, the other end of the lifting assembly penetrates through the top wall of the intercepting frame to extend into the intercepting frame and is rotationally connectedwith the intercepting frame and a buffer attaching assembly is arranged at the bottom of the intercepting frame, a collecting assembly which is arranged on the side wall of the intercepting frame andis in sliding connection with the intercepting frame, an anti-blocking cleaning assembly which is arranged in the intercepting frame and is in sliding connection with the intercepting frame, whereinthe anti-blocking cleaning assembly and the filter screen are oppositely arranged, and a controller which is electrically connected with the lifting assembly, the collecting assembly and the anti-blocking cleaning assembly. The intercepting device is reasonable in design, rich in function, easy to operate, good in anti-blocking cleaning effect, high in working efficiency and capable of effectivelyachieving centralized collection and treatment on large-size garbage.

Owner:河北宏龙环保科技有限公司

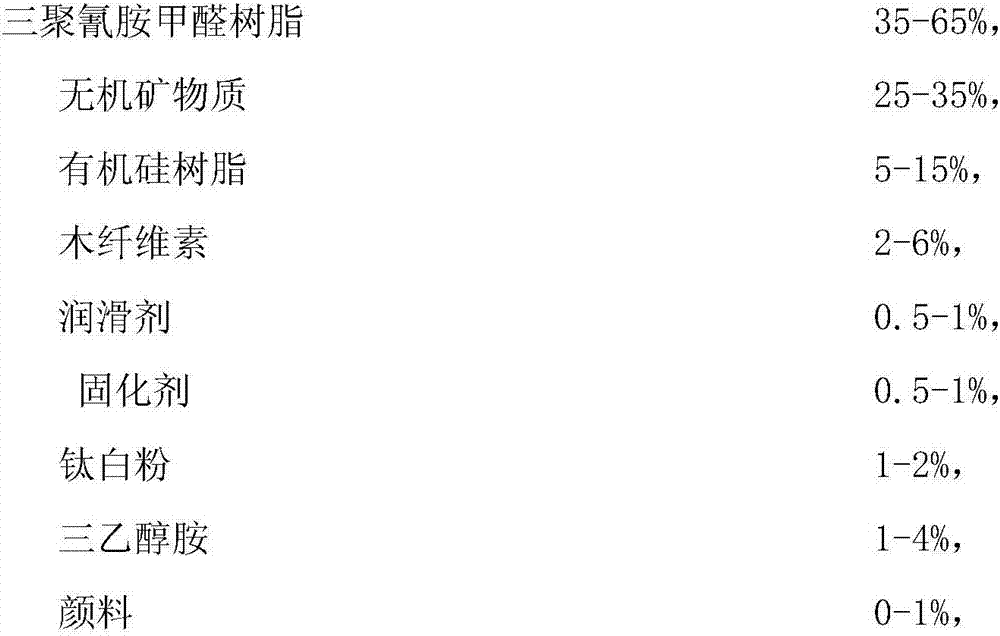

Moulding material used for high-grade melamine tableware and preparation method thereof

The invention relates to a moulding material used for high-grade melamine tableware and a preparation method thereof. The moulding material is prepared from the following raw materials in percentage by mass: 35-65% of melamino-formaldehyde resin, 25-35% of inorganic minerals, 5-15% of organic silicon resin, 2-6% of wood cellulose, 0.5-1% of a lubricating agent, 0.5-1% of a curing agent, 1-2% of titanium white, 1-4% of triethanolamine and 0-1% of pigment, wherein the sum of the weight percents of all the raw materials is 100%; and the inorganic minerals are formed by mixing silica powder, jade porcelain and calcium carbonate in a ratio of 3:(0.5-1.5):(0.5-1.5). The preparation method comprises the following steps: preparing the melamino-formaldehyde resin, kneading, drying, crushing and carrying out ball milling, and packaging. According to the invention, the inorganic mineral and organic silicon resin are added into melamine resin, and compression moulding is carried out, so that the tableware has the characteristics of higher density, strong compactness, higher break resistance, light transmission, glittering and translucent carving appearance and better quality compared with ceramic tableware.

Owner:DEQING LIANCHENG AMINO PLASTIC PROD CO LTD

Precision vacuum-casting method for foaming-mould aluminum casting

InactiveCN102527935ASpeed up the flowSolve the "packing" problemFoundry mouldsFoundry coresDesign standardAluminum can

The invention discloses a precision vacuum-casting method for foaming-mould aluminum castings, which comprises the following steps of: placing models, covering a film, arranging a casting-head rod and a steam-discharging pipe, molding an upper box, demoulding, repairing, molding a bottom box, closing the boxes and matching the models, casting and the like. Multiple defects in the aspects of foaming-mould aluminum casting are radically solved according to the invention, so that the increasingly-perfect process effect of a casting product is achieved, and design standards can be reached without accurately machining the castings. The precision vacuum-casting method has the advantages of simple process, easiness in operation and strong applicability; and compared with the traditional vacuum-casting method, more than 20 percent of molten aluminum can also be saved, and the precision vacuum-casting method is economical and practical.

Owner:NANTONG CHAODA EQUIP CO LTD

Nano environmental protection liquid aluminium foil and its preparation method and use method

InactiveCN1429871ACorrosion resistance exceedsSufficient sourceLiquid surface applicatorsCoatingsSolventNanometre

An environmental-protection type nano-class liquid aluminium foil as a chemicoplating material on the surface of metal is prepared from pure coster oil, TDI, epoxy resin, aluminium powder and nano-class filler through a special process. It has solvent type and water type. Its advantages are low cost, excellent anticorrosion performance, and no environmental pollution.

Owner:程新华

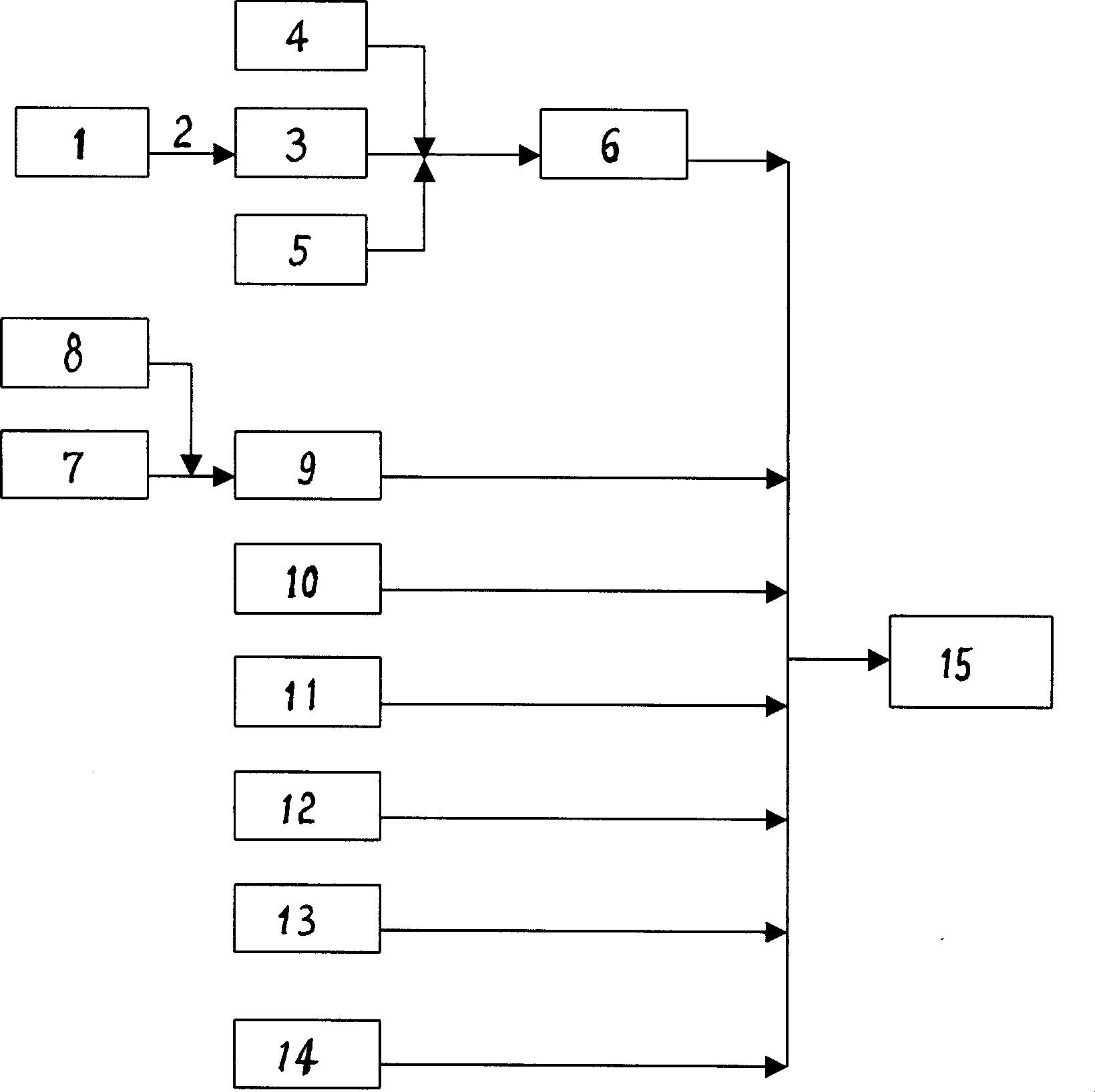

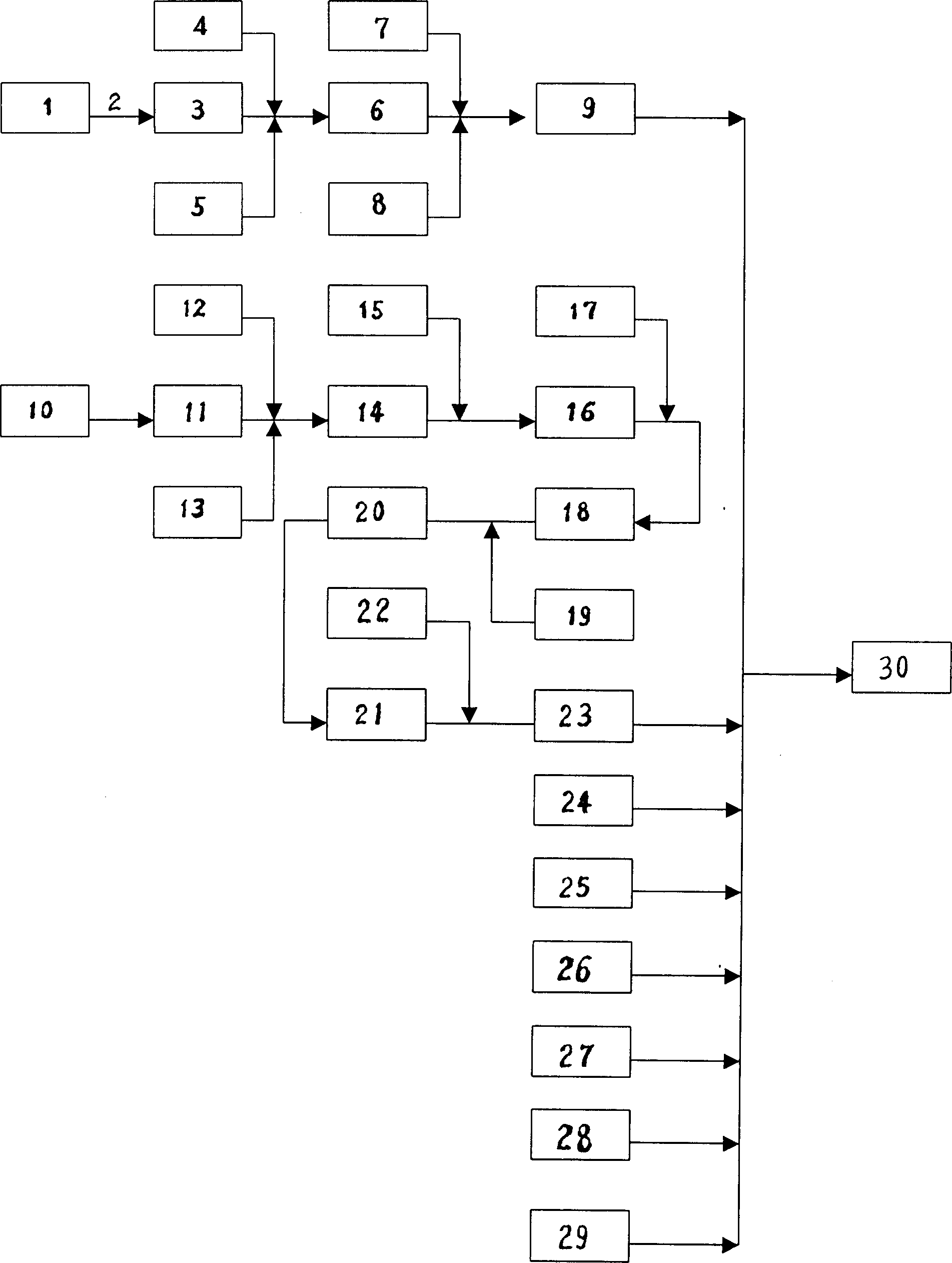

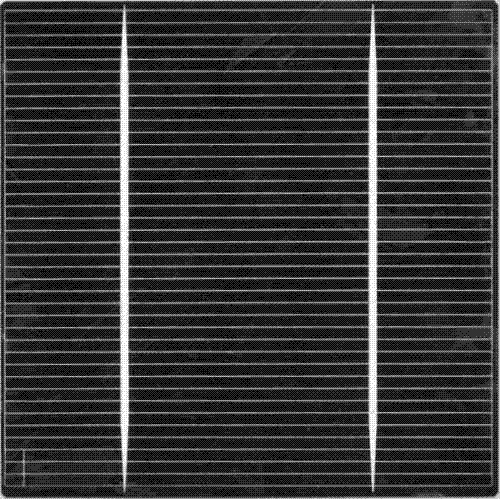

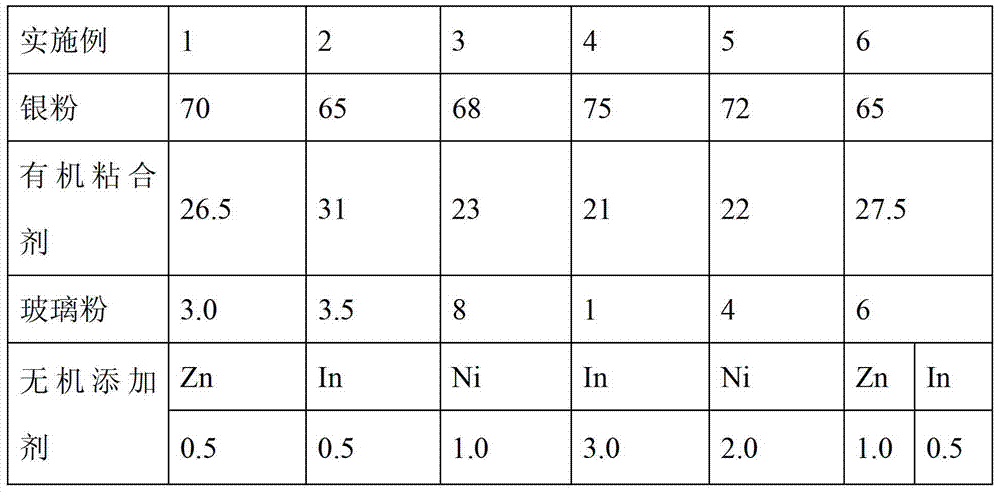

Front-face electrode slurry with low silver content for silica-based solar cell main grid and preparation method of front-face electrode slurry

ActiveCN103578604AStrong compactnessEasy to fillNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver electrodeSilicon solar cell

The invention relates to an electrode material of a crystalline silicon solar cell, in particular to front-face electrode slurry with the low silver content for a silica-based solar cell main grid and a preparation method of the front-face electrode slurry. The front-face electrode slurry with the low silver content for the silica-based solar cell main grid is mainly formed by mixing, by weight, 65-75% of silver powder, 21-31% of organic bond, 1-8% of glass powder and 0.5-3% of inorganic additives. The front-face electrode slurry is used for crystalline silicon solar cell main grid lines, and developed for reducing the production cost and the manufacturing cost of the silica-based solar cell. The front-face electrode slurry is printed on the back face of the crystalline silicon solar cell, and forms a silver electrode with the high adhesive force and the high reliability on the main grid on the front face of the crystalline silicon solar cell through the infrared fast-burning process, wherein the actual peak temperature of the surface of a silicon wafer is 780-810 DEG C, and the peak time is 1-2s.

Owner:HANGZHOU RIGHTSILVER ELECTRONICS MATERIAL

Landscape tree cultivation method applicable to saline-alkali soil

The invention discloses a landscape tree cultivation method applicable to saline-alkali soil. The landscape tree cultivation method applicable to the saline-alkali soil comprises step1, soil improvement, wherein a soil conditioner is sprayed on the saline-alkali soil with 0.3 to 0.4 % salt content before the rain and nutrient soil and saline-alkali sandy soil are uniformly mixed according to the ratio of 1:3 to 4 for standby application; step 2, ditch excavation, wherein a 1 m width and 1 m depth of ditch is excavated out of the soil after the soil improvement in the step 1; step 3, ditch finishing, wherein 20 cm thickness of carpolite is embedded into the bottom of the ditch in the step 2 and a plastic film with holes covers the carpolite; step 4, landscape tree buried cultivation, wherein a landscape tree with the root with a soil ball is planted into the ditch, the soil ball is located below the horizontal position of the ditch, the soil ball is 5 to 6 times of the tree diameter of the landscape tree, and a plurality of pores penetrate the soil ball; step 5, landscape tree filling, wherein gaps around the landscape tree are filled with a mixture of the nutrient soil and the saline-alkali sandy soil which are prepared well in the step 1 to enable the landscape tree to be tight until the soil ball is covered; step 6, management and protection and step 7 forming.

Owner:FLOWER KING ECO ENG CO LTD

Waterproof paint for building material and preparation method thereof

InactiveCN107011772AStrong corrosion resistanceIncreased durabilityAntifouling/underwater paintsPaints with biocidesEpoxyEmulsion

The invention discloses a waterproof paint for a building material, belonging to the technical field of building materials. The waterproof paint comprises the following raw materials by weight: 50 to 60 parts of epoxy resin emulsion, 3 to 10 parts of polyacrylate, 1 to 5 parts of a dispersing agent, 40 to 45 parts of cement, 8 to 12 parts of talcum powder, 0.2 to 5 parts of a dehydrating agent, 0.5 to 2 parts of a silane coupling agent, 0.2 to 0.4 part of an antiseptic, 1 to 3 parts of a polycarboxylate water reducer, 5 to 10 parts of pigment, 0 to 2 parts of a pH value regulating agent, 3 to 6 parts of a plasticizer, 0 to 2 parts of an antifoaming agent and 0.8 to 1 part of a liquid aromatic. The invention also discloses a preparation method for the waterproof paint for the building material. The waterproof paint provided by the invention has good corrosion resistance, durability, impermeability, compactness and high adhesion stress; and the preparation method is simple and reliable.

Owner:合肥慧林建材有限公司

Coating glaze and use method thereof

ActiveCN107601883AImprove performanceImprove heating efficiencyMelt-holding vesselsBall millSpray coating

The invention discloses a coating glaze, which comprises main materials and auxiliary materials, wherein the main materials comprise, by weight, 15-25% of quartz, 3-10% of boron carbide, 40-60% of boron glass, 3-10% of toner, 5-15% of glaze dissolving powder, and 5-15% of white corundum, and the auxiliary materials comprise a binder accounting for 20-35% of the total weight of the main materials,water glass accounting for 30-50% of the total weight of the main materials, a dispersant accounting for 0.5-1% of the total weight of the main materials, and a suspending agent accounting for 0.2-0.5% of the total weight of the main materials. The invention further discloses a use method of the coating glaze, wherein the use method comprises: 1, mixing the main materials and the auxiliary materials, and carrying out ball milling for 2-3 h to prepare a uniformly-mixed coating glaze composition; and 2, carrying out spray coating at a working area, and carrying out high temperature heating. According to the present invention, quartz, boron carbide, boron glass and white corundum are used as the main materials, have different melting temperatures, and can well react with each other during thehigh temperature firing to generate the dissolving phase, wherein the continuous casting member and the coating glaze can be closely combined through the dissolving phase so as to solve the technicalproblem of the unstable use performance of the physical coating.

Owner:ZHEJIANG IRON LION HIGH TEMPERATURE MATERIALS CO LTD

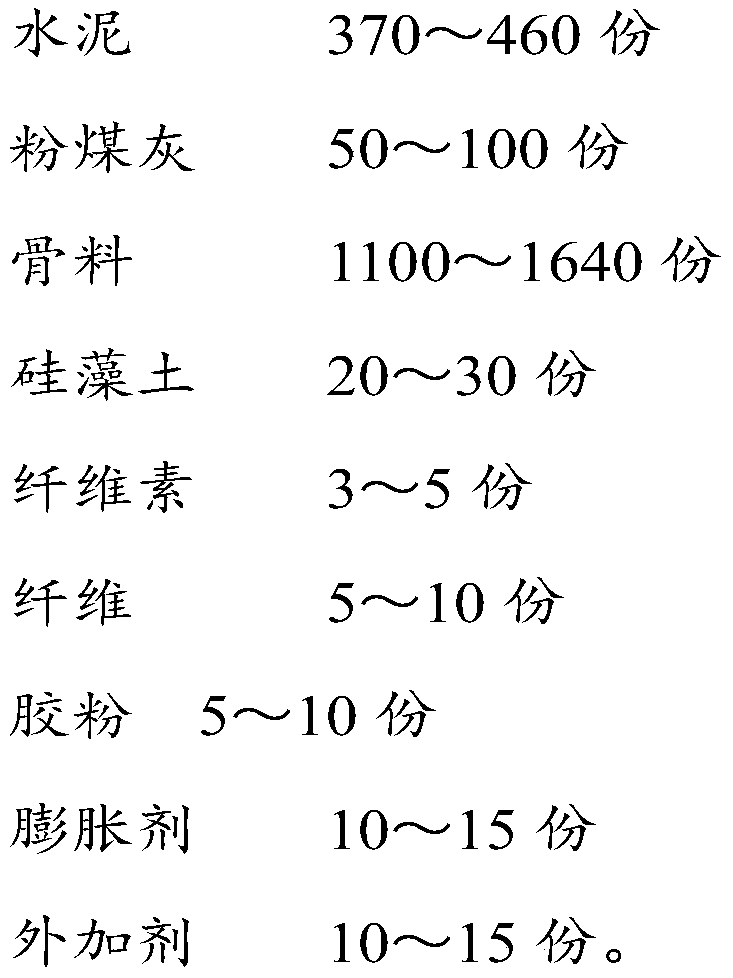

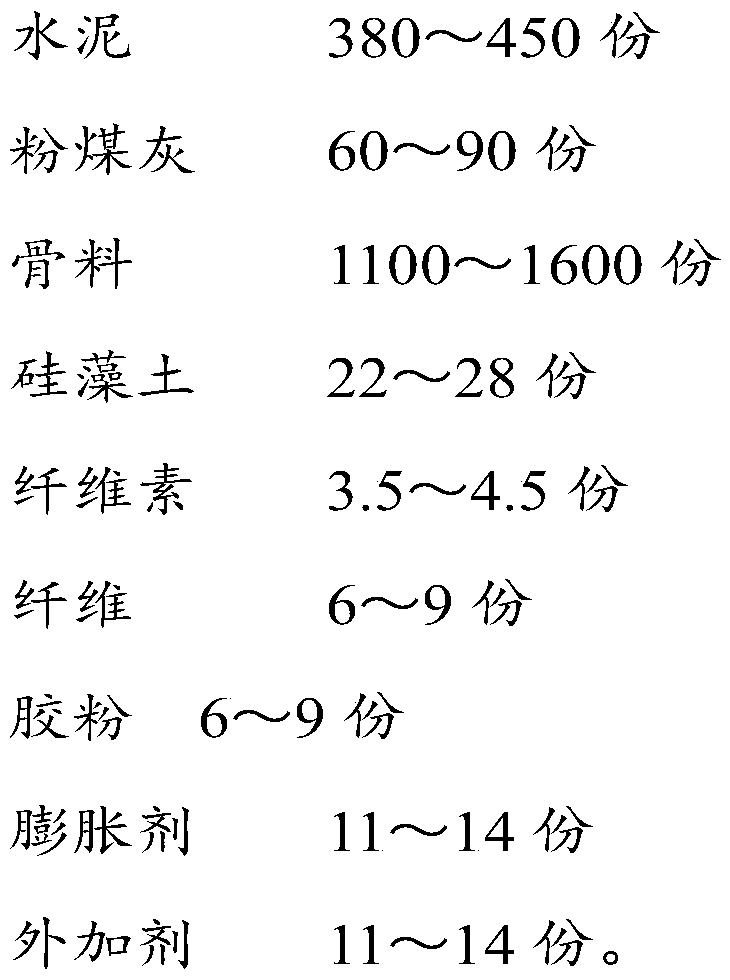

Fair-faced concrete and preparation method thereof

The invention provides fair-faced concrete and a preparation method thereof and relates to the field of building materials. The fair-faced concrete comprises the following raw materials in parts by weight: 370-460 parts of cement, 50-100 parts of fly ash, 1250-1640 parts of aggregate, 20-30 parts of diatomite, 3-5 parts of cellulose, 5-10 parts of fiber, 5-10 parts of rubber powder, 10-15 parts ofan expanding agent and 10-15 parts of an additive. According to the invention, the technical problem of lack of fair-faced concrete with good fluidity and high appearance quality after pouring in thedomestic market can be solved, and the purpose of improving the effect of the fair-faced concrete after pouring is achieved.

Owner:江西蓝宝新材料有限公司

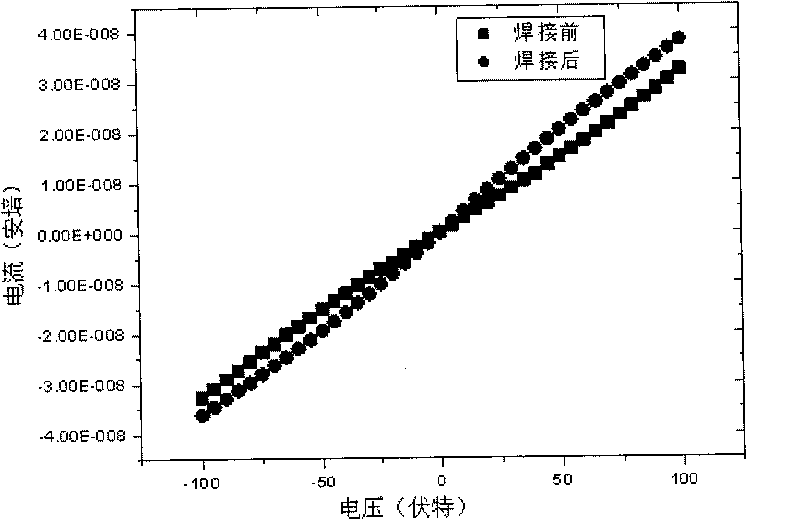

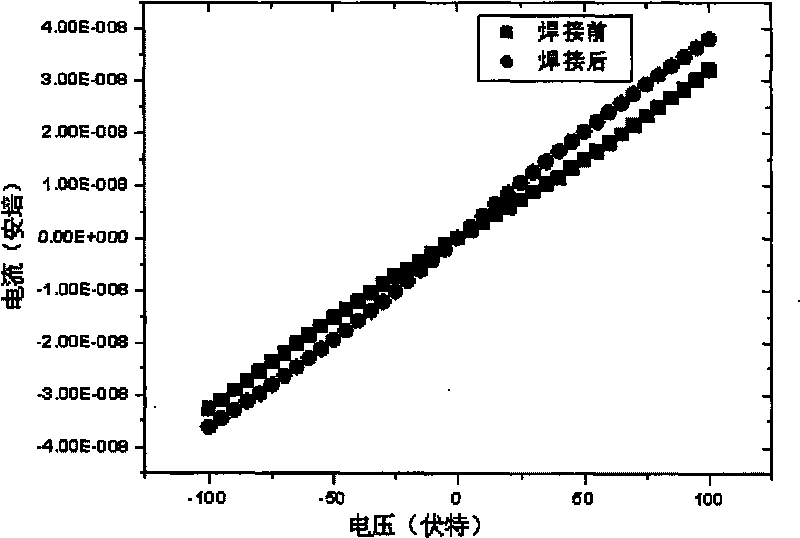

Method for preparing gold electrode on CdZnTe crystal

InactiveCN101740666AInhibit sheddingAvoid instabilityFinal product manufactureRadiation intensity measurementHigh resistanceNitrogen atmosphere

The invention discloses a method for preparing a gold electrode on a CdZnTe crystal, which is used for preparing the gold electrode and a lead-out wire on the CdZnTe crystal. The method comprises the following steps: firstly, selecting a high resistance CZT with the resistance greater than 109 ohms as a CZT substrate of the electrode; sputtering a layer of Au film; depositing a layer of Au film; and immediately putting the substrate into a quick atmosphere annealing furnace, and performing quick annealing in the nitrogen atmosphere to complete the preparation of the Au electrode, wherein the annealing parameters are that: the temperature is between 150 and 250 DEG C and the time is 5 to 10 minutes. Because a method of performing ion sputtering first, then gold depositing and final annealing is adopted to prepare the gold electrode, the method has the advantage of large bonding force between Au and the CZT substrate in the sputtering plating and the advantages of good compactness and evenness of the Au film and strong bonding force between the Au film and the lead-out wire in the gold depositing, and effectively prevents the electrode from falling off and being unstable. The electrode with good bonding force and good ohm property is prepared and the effective connection of the electrode and the lead-out wire is realized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

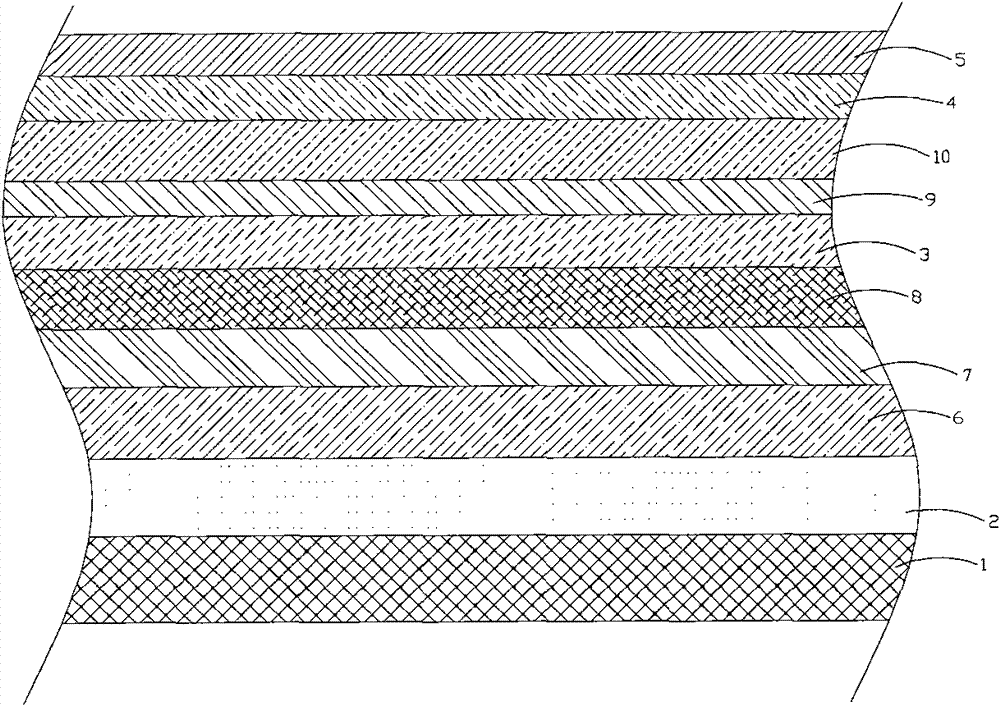

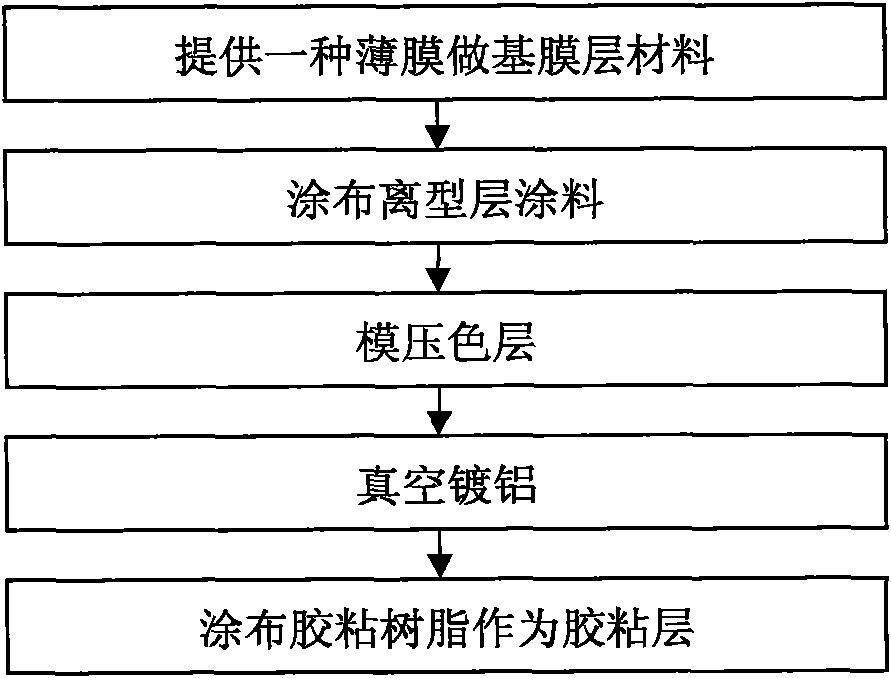

Two-dimension code electrochemical aluminum and method for making same

ActiveCN103198756AEffective coverageStrong compactnessStampsSynthetic resin layered productsWater basedPolyester

The invention provides two-dimension code electrochemical aluminum which comprises a base film layer made of a PET (polyester) film or a BOPP (biaxially-oriented polypropylene) film, a release layer positioned on the base film layer and made from organic silicon resin, a coloring layer positioned on the release layer, an aluminum-coated layer positioned on the coloring layer and formed by coating of gaseous aluminum under vacuum condition, an adhesive layer positioned on the aluminum-coated layer and made from thermoplastic resin, a coverage layer arranged between the release layer and the coloring layer, positioned on the release layer and made of scratch card ink, an isolation layer positioned on the coverage layer and formed by a water-based polishing oil coating, and a code spraying layer positioned on the isolation layer and used for printing two-dimension code in a computer code-spraying way. According to the two-dimension code electrochemical aluminum, a digital layer can be effectively covered by configuring the coverage layer, so that people cannot see the information content of the digital layer from the surface; and the two-dimension code electrochemical aluminum is strong in compactness and high in copy protection performance.

Owner:SHENZHEN JINJIA GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com