Method for preparing gold electrode on CdZnTe crystal

A technology for preparing gold and crystals, which is applied in circuits, electrical components, semiconductor devices, etc. It can solve the problems of difficult control of film thickness, difficulty in connecting external leads, and falling off, so as to prevent electrode instability, good ohmic characteristics, and prevent electrode Shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: select component to be Cd 0.8 Zn 0.2 Te wafers were used to prepare Au electrodes.

[0017] First, select Cd 0.8 Zn 0.2 The Te single crystal was wire-cut, mechanically polished, and cleaned by an ultrasonic cleaner for 15 minutes. After taking it out, it was observed under a microscope to confirm that the surface was clean and pollution-free, and then dried with nitrogen.

[0018] In the second step, put the processed CZT wafer into a KYKYSBC-12 ion sputtering apparatus, and sputter a 30nm-thick Au film on the CZT substrate in an environment with a vacuum degree of 6Pa and a current of 10A.

[0019] The third step is to quickly take the CZT wafer out of the sputtering apparatus and put it into the ZHD-300 resistance evaporation coating machine. The vacuum degree is 2×10 -4 Under the Pa environment, a 60 nm Au film was deposited on the sputtered Au film.

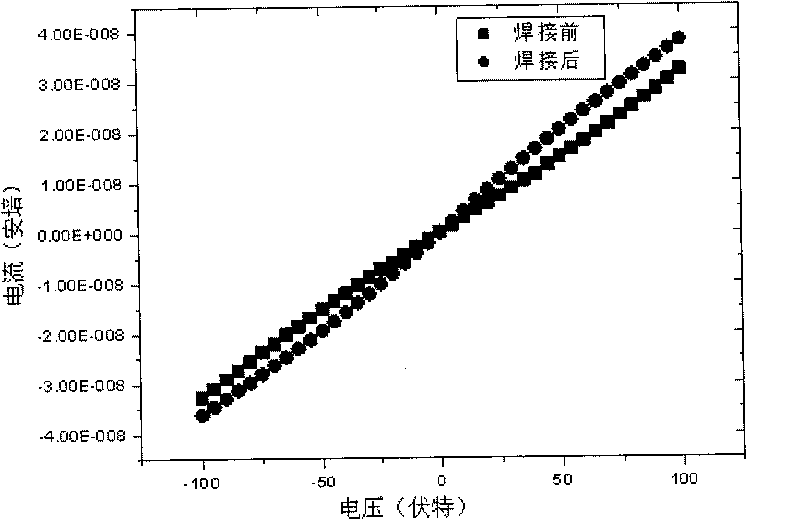

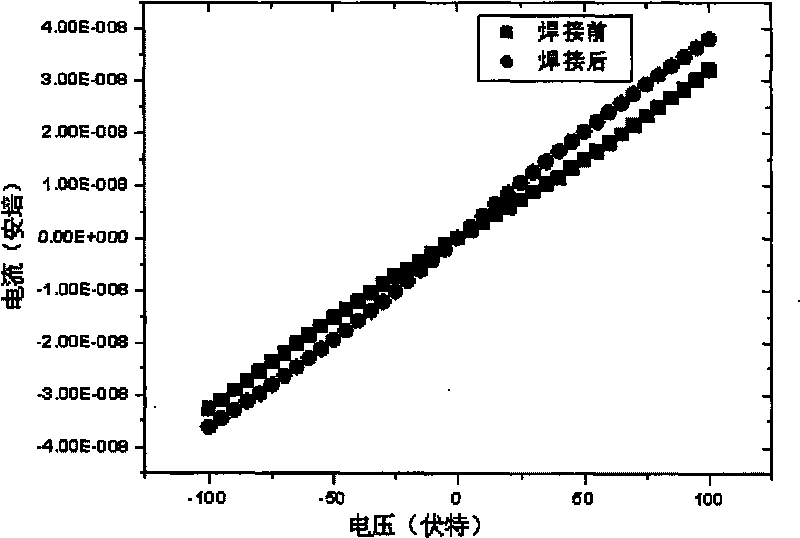

[0020] The fourth step is rapid atmosphere annealing. Quickly take the CZT wafer out of the eva...

Embodiment 2

[0025] Example 2: Au electrodes were prepared by selecting a wafer whose composition was Cd0.8Zn0.2Te.

[0026] First, select a Cd0.8Zn0.2Te single crystal by wire cutting, mechanical polishing, and use an ultrasonic cleaner to clean it for 20 minutes. After taking it out, observe it under a microscope to confirm that the surface is clean and pollution-free, and then dry it with nitrogen.

[0027] In the second step, put the processed CZT wafer into a KYKYSBC-12 ion sputtering apparatus, and sputter a 60nm-thick Au film on the CZT substrate in an environment with a vacuum degree of 4Pa and a current of 11A.

[0028] The third step is to quickly take the CZT wafer out of the sputtering apparatus and put it into the ZHD-300 resistance evaporation coating machine. The vacuum degree is 2×10 -4 A 40nm Au film was vapor-deposited on the sputtered Au film under Pa environment.

[0029] The fourth step is rapid atmosphere annealing. Quickly take the CZT wafer out of the evaporation ...

Embodiment 3

[0031] Example 3: Au electrodes were prepared by selecting a wafer whose composition was Cd0.8Zn0.2Te.

[0032] First, select a Cd0.8Zn0.2Te single crystal by wire cutting, mechanical polishing, and use an ultrasonic cleaner to clean it for 19 minutes. After taking it out, observe it under a microscope to confirm that the surface is clean and pollution-free, and then dry it with nitrogen.

[0033] In the second step, put the processed CZT wafer into a KYKYSBC-12 ion sputtering apparatus, and sputter a 60nm-thick Au film on the CZT substrate in an environment with a vacuum degree of 5Pa and a current of 8A.

[0034] The third step is to quickly take the CZT wafer out of the sputtering apparatus and put it into the ZHD-300 resistance evaporation coating machine. The vacuum degree is 2×10 -4 A 40nm Au film was vapor-deposited on the sputtered Au film under Pa environment.

[0035] The fourth step is rapid atmosphere annealing. Quickly take the CZT wafer out of the evaporation c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com