Design method for particle size distribution of fractured leakage bridging leaking stoppage particle material

A technology of plugging material and particle size distribution, applied in the field of petroleum engineering drilling, can solve the problems of poor adaptability of fracture leakage, unsatisfactory effect of bridging and plugging, and huge differences in the connotation of design methods. The effect of easy engineering operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

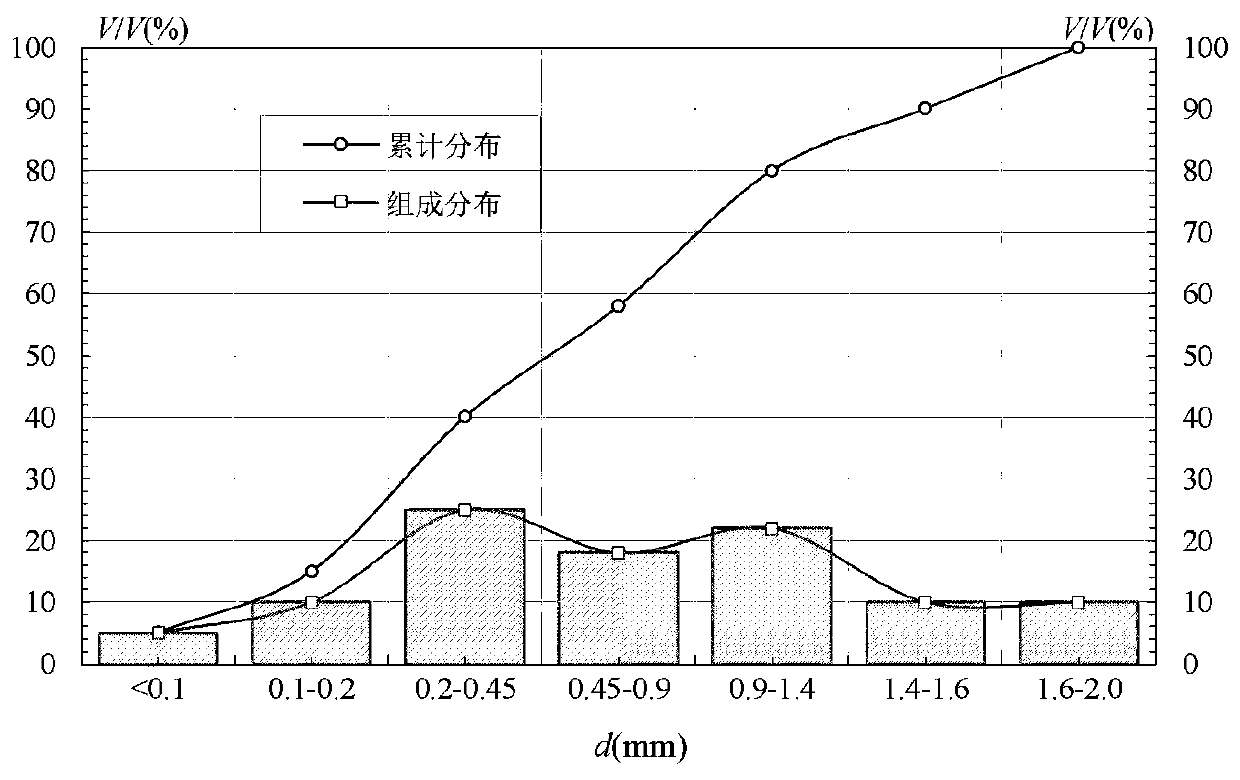

[0069] Get the crack width W i =3, W o =2; Calculate the expected range of D10, D50, and D90 according to the crack width and the above-mentioned particle size selection criteria; then set the weight ratio relationship A of A~G grade granular materials based on 100 parts by weight of the plugging material: B:C:D:E:F:G=5:10:25:18:22:10:10, take particles of different sizes and mix to form bridge plugging material S1, particle size composition distribution and cumulative distribution of plugging material S1 Figure such as figure 1 shown. According to the cumulative distribution curve of the plugging material and using the particle size distribution function, the characteristic particle size values D10, D50, and D90 of the plugging material are 0.15, 0.69, and 1.59, respectively, and these three values are all within the expected range.

[0070] Based on 100 parts by weight of plugging base slurry, 200 parts by weight of bridging plugging material was taken, and its pluggi...

Embodiment 2

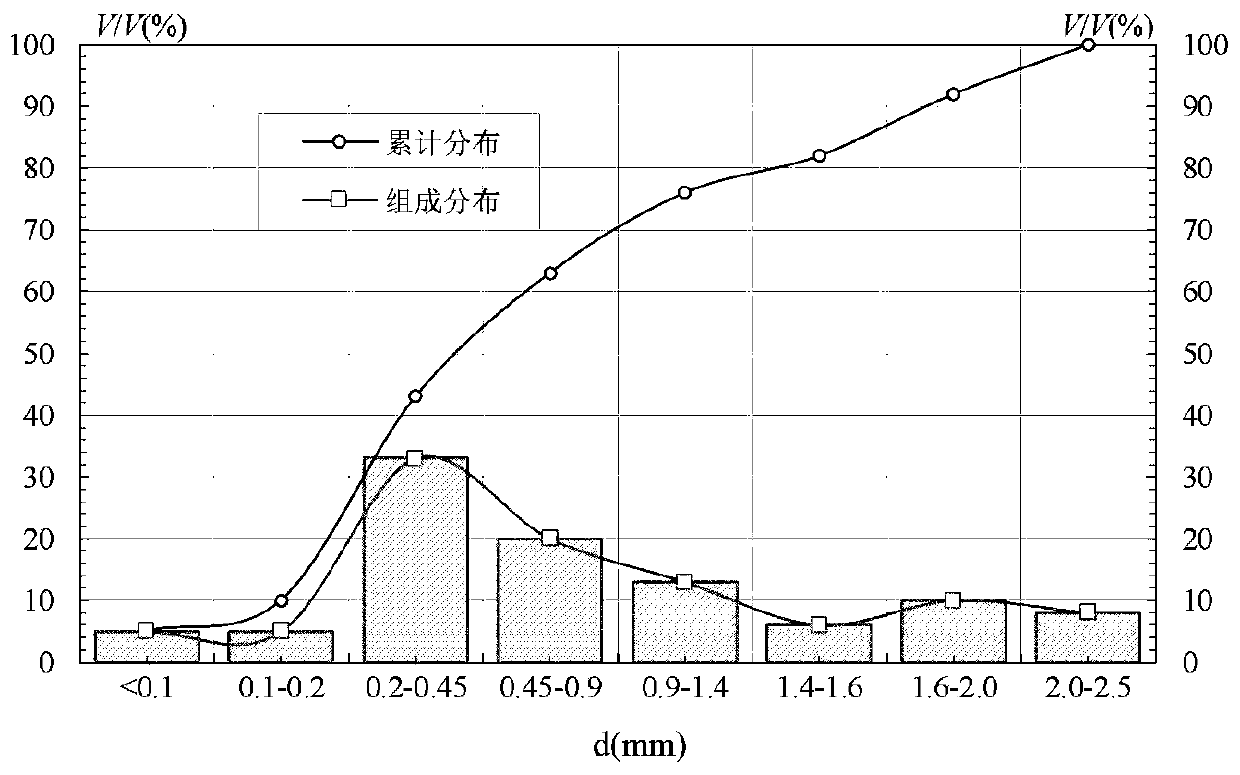

[0072] According to the crack width and test method described in Example 1, the difference is that the proportioning relationship A:B:C:D:E:F:G:H=5:5 by weight of A~H grade granular materials :33:20:13:6:10:8, the bridging plugging material S2 is formed by mixing particles of different particle sizes, and its particle size distribution and cumulative distribution are shown in figure 2 shown. According to the cumulative distribution curve of the plugging material and using the particle size distribution function, the characteristic particle size values D10, D50, and D90 of the plugging material are 0.2, 0.53, and 1.89, respectively, and these three values are all within the expected range.

Embodiment 3

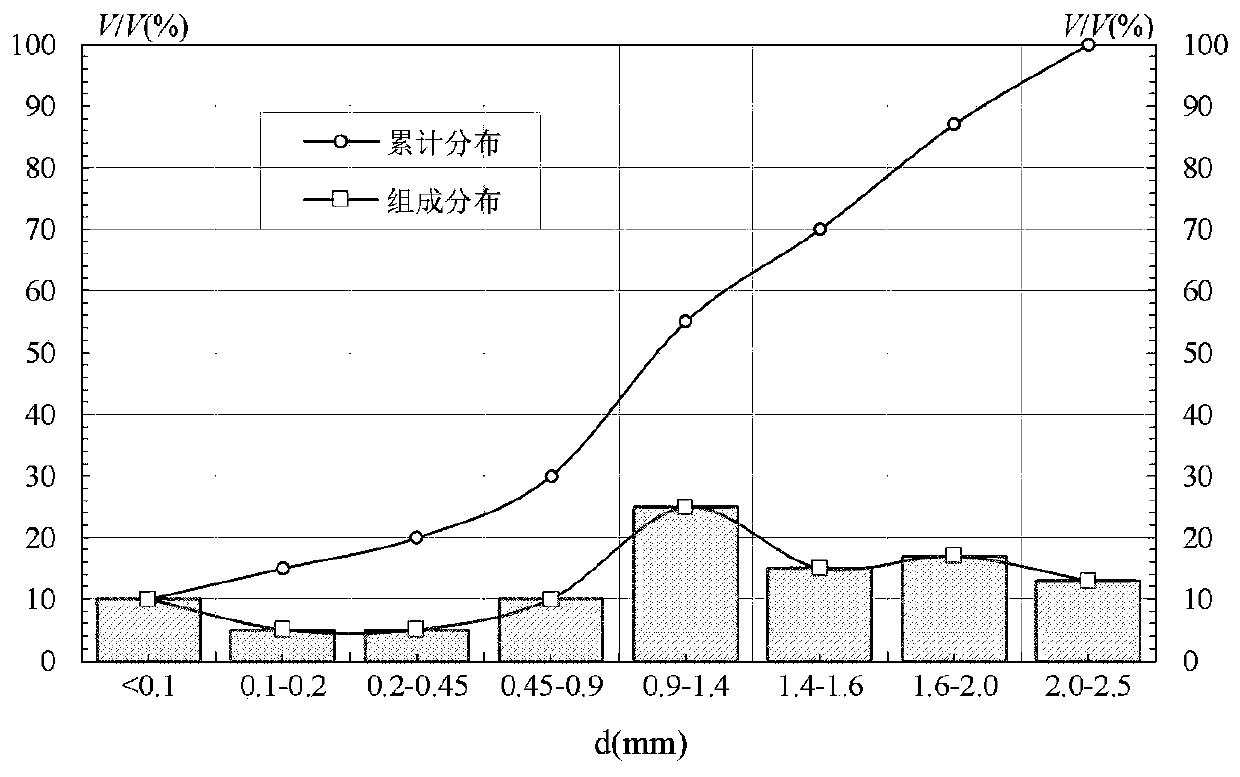

[0074] According to the crack width and test method described in Example 1, the difference is that the proportioning relationship A:B:C:D:E:F:G:H=10:5 by weight of A~H grade granular materials :5:10:25:15:17:13, the bridging plugging material S3 is formed by mixing particles of different particle sizes, and its particle size distribution and cumulative distribution are shown in image 3 shown. According to the cumulative distribution curve of the plugging material and using the particle size distribution function, the characteristic particle size values D10, D50, and D90 of the plugging material are 0.1, 1.33, and 2.1, respectively, and these three values are all within the expected range.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com