Fair-faced concrete and preparation method thereof

A technology of fair-faced concrete and water-reducing agent, which is applied in the field of building materials and can solve problems such as pockmarks and honeycombs, veneer cracks, cold joints, etc., achieve less cement content, improve bonding strength, increase tensile strength and tensile strength The effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

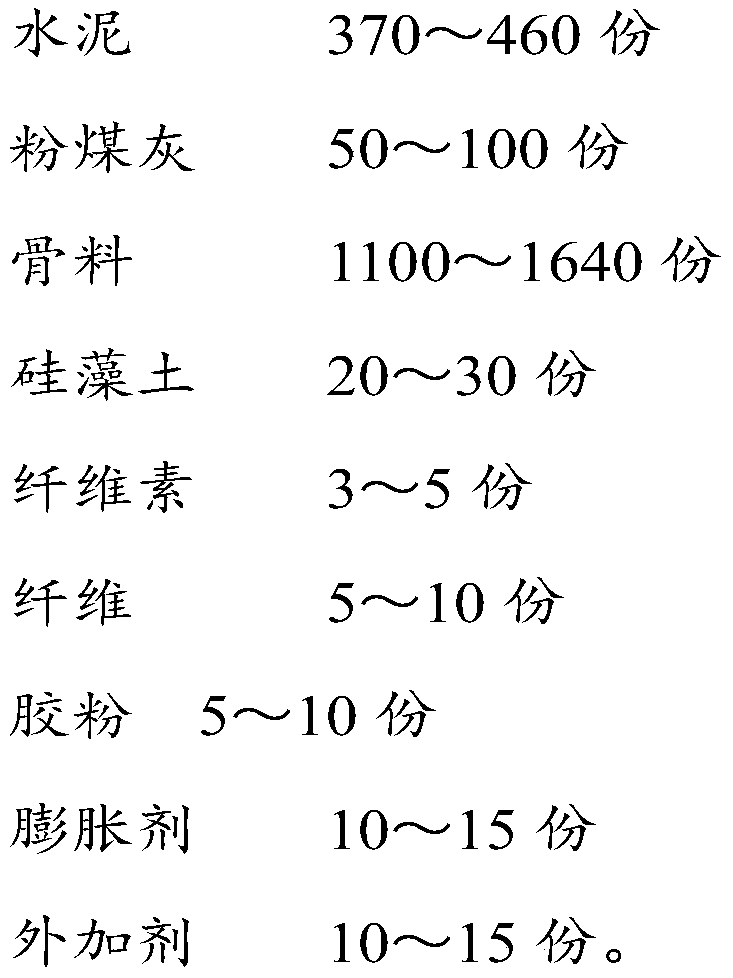

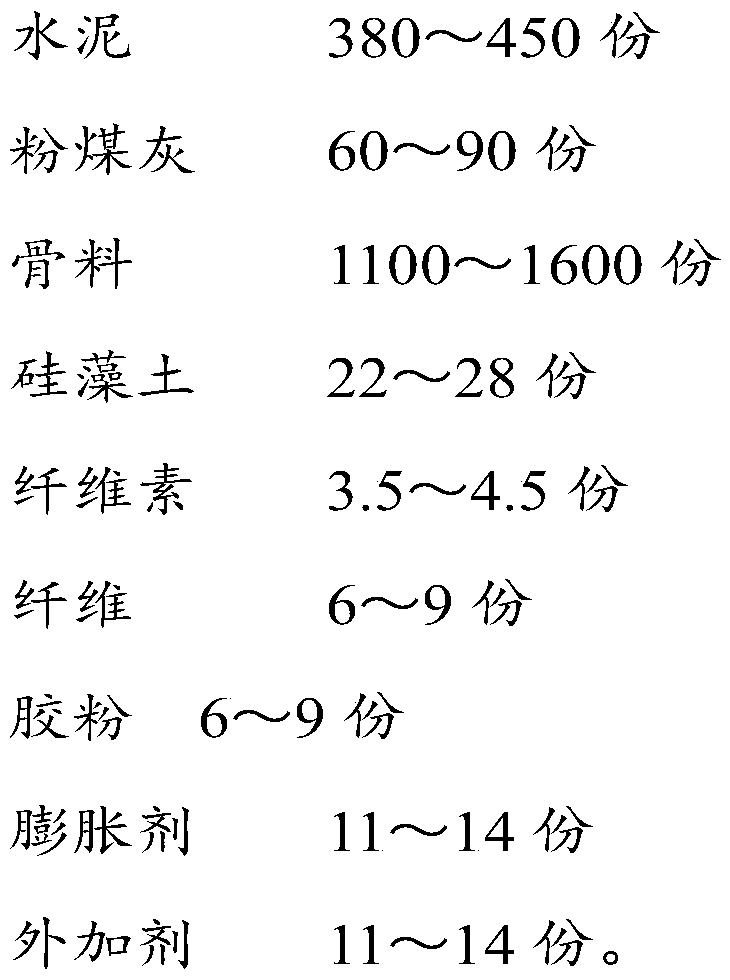

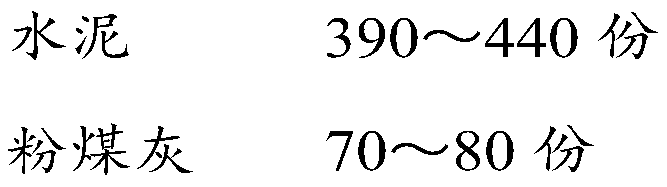

[0057] Examples 1 to 4 are fair-faced concrete, and their specific components are shown in Table 1, wherein the unit of each component is g.

[0058] Table 1

[0059]

[0060]

[0061] Wherein, the admixture used in embodiment 1~4 is identical, and admixture comprises by weight percentage: polycarboxylate superplasticizer 88%, defoamer 2.5%, retarder 8%, silane-based water repellent 1% , Cellulase water retention agent 0.5%.

Embodiment 5

[0063] This embodiment is a kind of fair-faced concrete. Compared with Embodiment 2, the difference is that the admixtures used are different, wherein, in this embodiment, the admixtures include: 90% polycarboxylate water reducer, dispersant Foam agent 1.4%, retarder 8%, silane-based water-repellent agent 0.5%, cellulase water-retaining agent 0.1%.

Embodiment 6

[0065] This embodiment is a kind of fair-faced concrete. Compared with Embodiment 2, the difference is that the admixtures used are different, wherein, in this embodiment, the admixtures include: polycarboxylate water reducer 70%, dispersant Foam agent 5%, retarder 15%, silane-based water-repellent agent 5%, cellulase water retention agent 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com