Nano modified aqueous epoxy rust-resisting paint and production method thereof

A technology of water-based epoxy and anti-rust paint, which is applied in the direction of epoxy resin coating, anti-corrosion coating, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

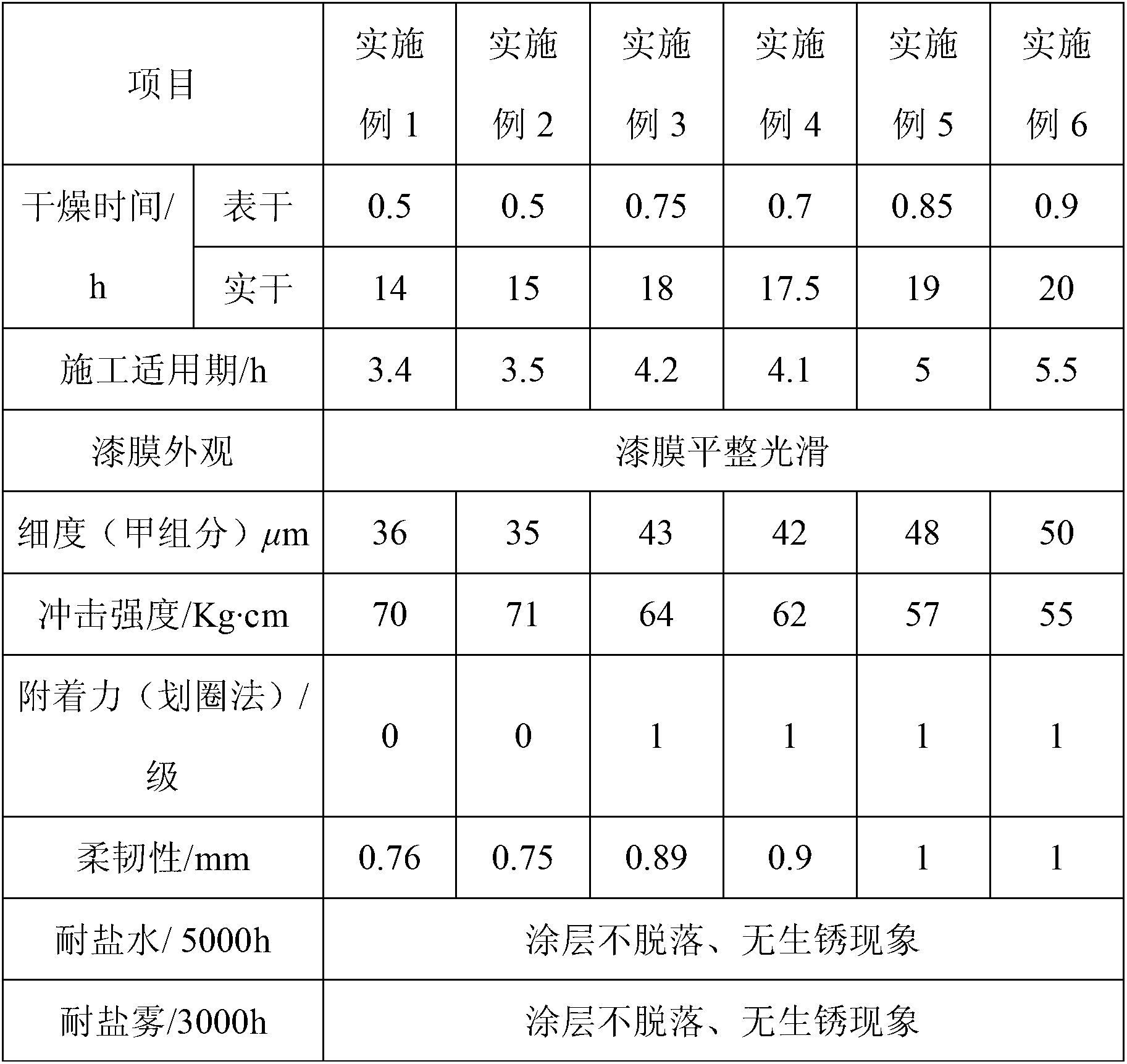

Embodiment 1

[0109] (1) Preparation of component A:

[0110] ① Prepare materials according to the following formula: 20wt% water-based epoxy emulsion, 4wt% nano-inorganic silicon solution, 0.8wt% wetting and dispersing agent, 1.2wt% leveling agent, 2.5wt% film-forming aid, 0.7wt% defoamer, Talc powder 5wt%, heavy calcium carbonate 5wt%, wet sericite powder 5wt%, anti-flash rust agent 0.6wt%, wet iron oxide red 16wt%, zinc phosphate 6wt%, aluminum tripolyphosphate 6wt%, deionized Water 27.2wt%;

[0111] The water-based epoxy emulsion is a product of Shanghai Lujia Water-based Paint Co., Ltd., and the model is GEM02.

[0112] The nano-inorganic silicon solution is a KN series nano-inorganic silicon solution produced by Anyang Hongyang Silicon Industry Technology Co., Ltd.

[0113] The wetting and dispersing agent is a product of San Nopco Auxiliaries Co., Ltd., Japan, and the model is SN-5040.

[0114] The leveling agent is Rohm and Haas leveling agent RM2020.

[0115] The film-forming a...

Embodiment 2

[0134] (1) Preparation of component A:

[0135] ① Prepare materials according to the following formula: water-based epoxy emulsion 22wt%, nano-inorganic silicon solution 5.5wt%, wetting and dispersing agent 0.6wt%, leveling agent 1.8wt%, film-forming aid 3.5wt%, defoamer 1wt%, Talc powder 4wt%, heavy calcium carbonate 4wt%, wet sericite powder 4wt%, anti-flash rust agent 0.5wt%, wet iron oxide red 12wt%, zinc phosphate 5wt%, aluminum tripolyphosphate 5wt%, deionized Water 31.1wt%;

[0136] ② Weigh the water-based epoxy emulsion, wetting and dispersing agent, defoamer and deionized water in the formula, add them to the dispersion tank in turn at a rate of 800rpm for 10 minutes, and use them as base materials for later use;

[0137] 3. Weigh the filler and the anti-rust pigment of the formula, and add them to the base material of step 1 while stirring, and the stirring is carried out at a slow speed of 80rpm;

[0138] ④Add glass beads and grind for 60min at a rate of 3200rpm t...

Embodiment 3

[0146] (1) Preparation of component A:

[0147] ① Prepare materials according to the following formula: water-based epoxy emulsion 25wt%, nano-inorganic silicon solution 4.5wt%, wetting and dispersing agent 1wt%, leveling agent 1wt%, film-forming aid 4wt%, defoamer 0.6wt%, talc powder 5wt%, heavy calcium carbonate 5wt%, wet sericite powder 5wt%, anti-flash rust agent 0.4wt%, wet iron oxide red 15wt%, zinc phosphate 6wt%, aluminum tripolyphosphate 7wt%, deionized water 20.5 wt%;

[0148] ② Weigh the water-based epoxy emulsion, wetting and dispersing agent, defoamer and water in the formula amount, and add them into the dispersion tank in sequence at a rate of 900rpm for 8 minutes, and use them as the base material for later use;

[0149] ③ Weigh the filler and anti-rust pigment of the formula, and add them to the base material of step ① while stirring, and the stirring is carried out at a slow speed of 100rpm;

[0150] ④Add glass beads and grind for 50min at a rate of 3300rpm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com