Front-face electrode slurry with low silver content for silica-based solar cell main grid and preparation method of front-face electrode slurry

A technology of solar cells and front electrodes, applied in conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve the problems of no busbar and fine grid, distinction, etc., to reduce the cost of paste , The effect of strong film density and good weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

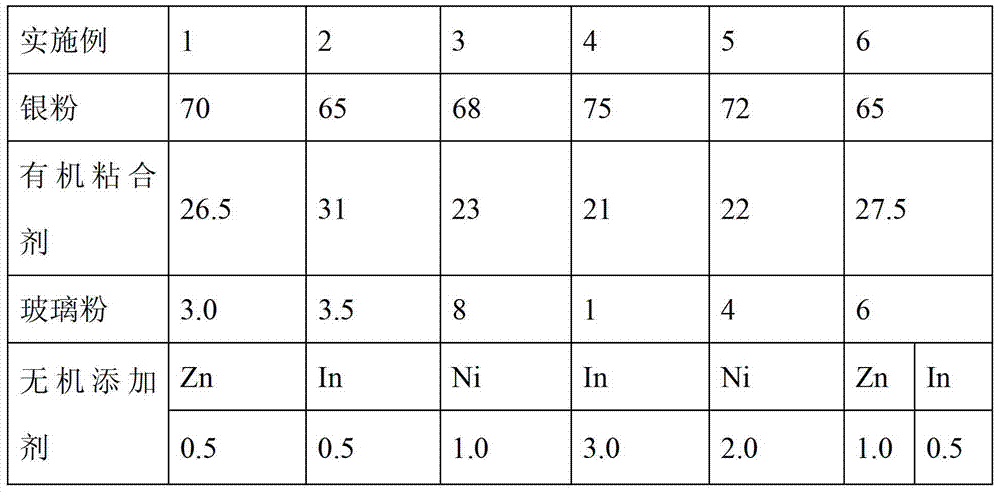

[0036] A front electrode paste with low silver content for the main grid of silicon-based solar cells is prepared by mixing the raw materials shown in Table 1 in terms of mass percentage. Put the silver powder, glass powder, organic binder and inorganic additives into the vacuum mixer according to the ratio in Table 1, and keep stirring for about 2 hours to form a uniform mixture, and then grind and disperse through a three-roll mill to form a homogeneous slurry. Control the fineness of the scraper to ≤10 μm, and then filter through a 500-mesh screen to obtain a front electrode slurry with a viscosity of 50-70 Pa·s.

[0037] Table 1 (weight: g)

[0038]

[0039] ①Silver powder

[0040]The silver powder that each embodiment adopts: the spherical silver powder prepared by selective liquid phase reduction method, its purity >=99.95% of silver powder, average particle diameter 1.54 μ m, specific surface area 1.25 m 2 / g, tap density 5.60g / ml. The above-mentioned silver powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com