Resin base composite material parts quick forming method

A composite material and molding method technology, which is applied in the field of ultraviolet curing rapid prototyping, can solve the problems of insufficient strength, slow curing speed, poor internal organization and compactness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0105] The present invention will be further described below in conjunction with accompanying drawing:

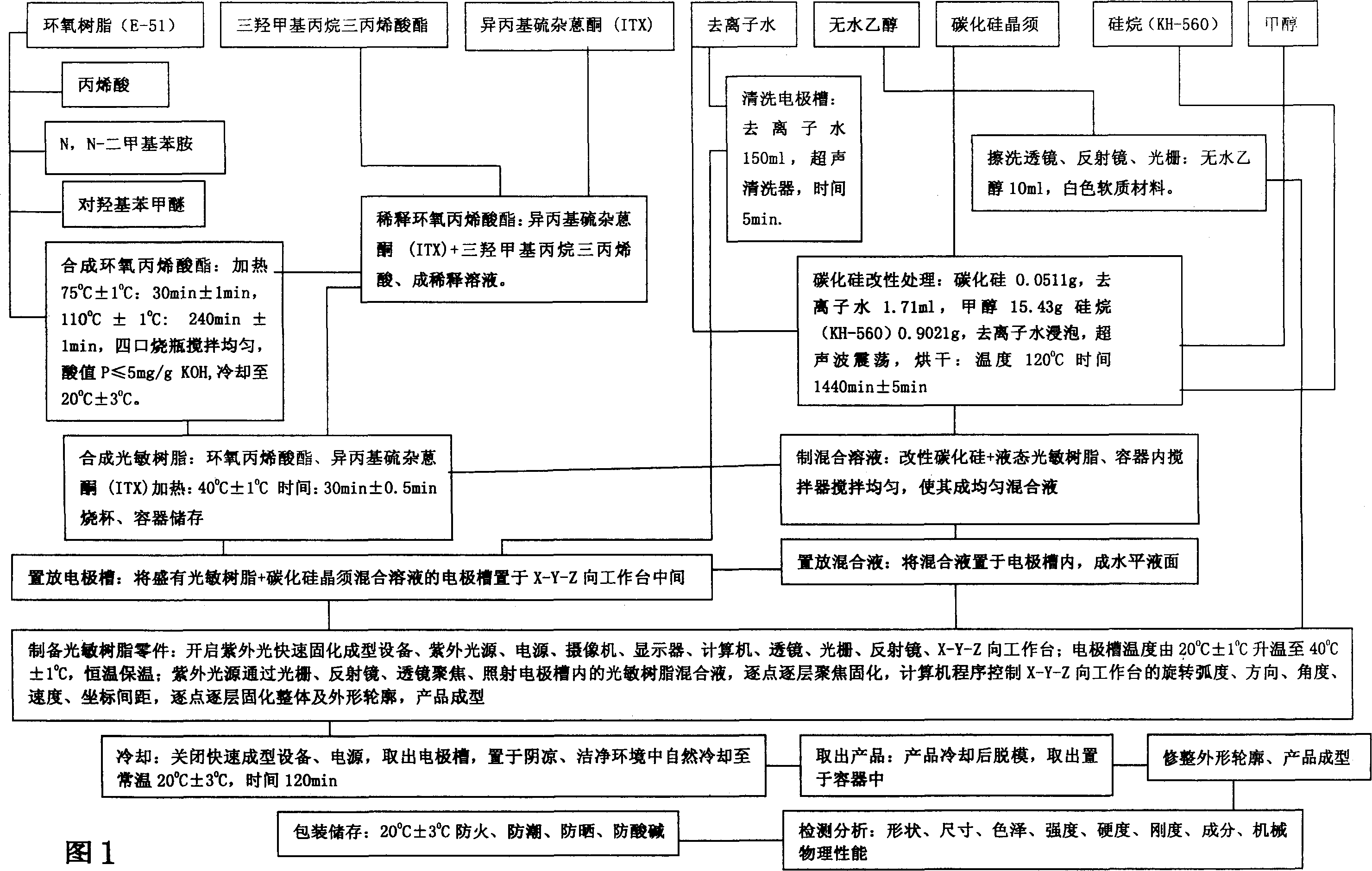

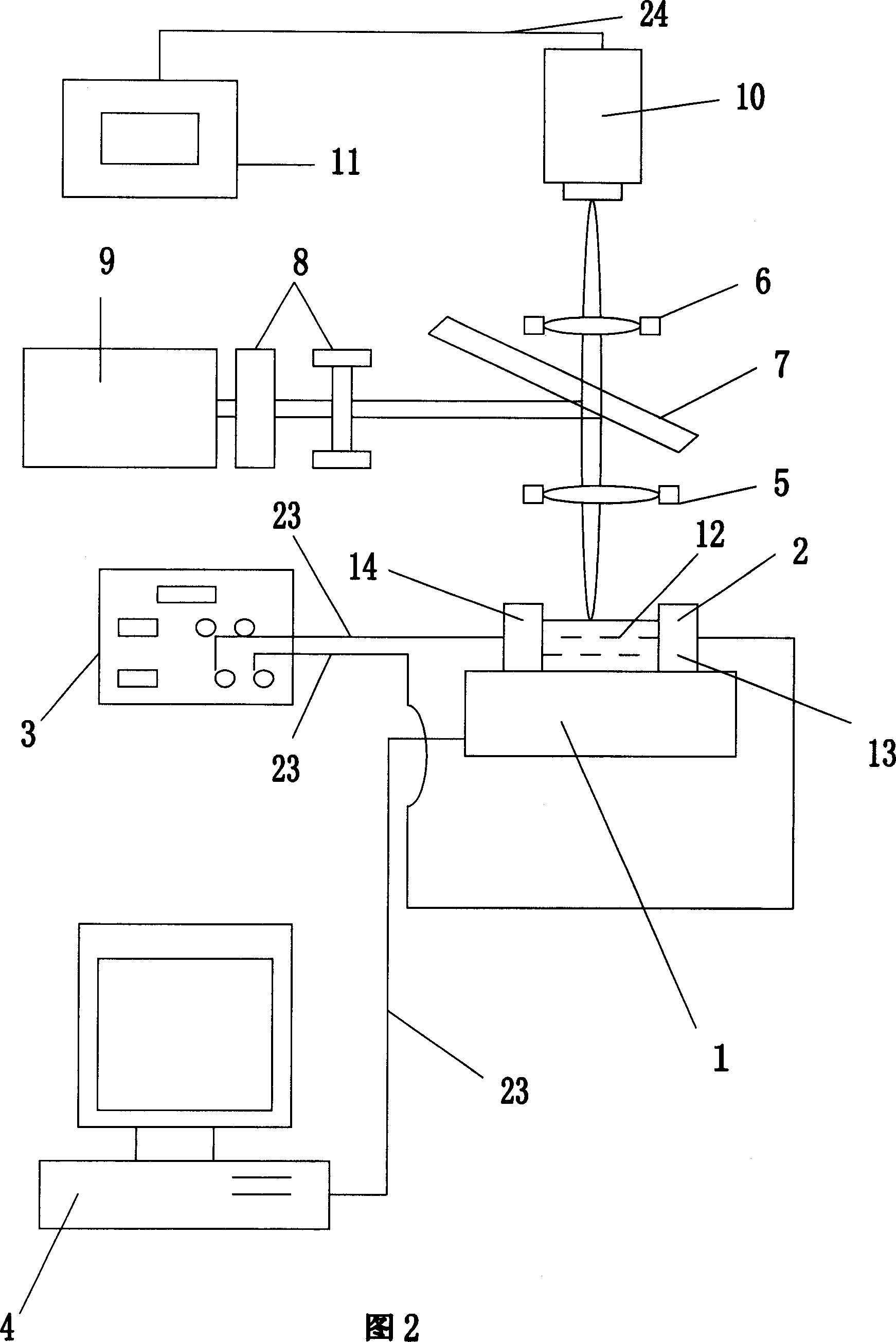

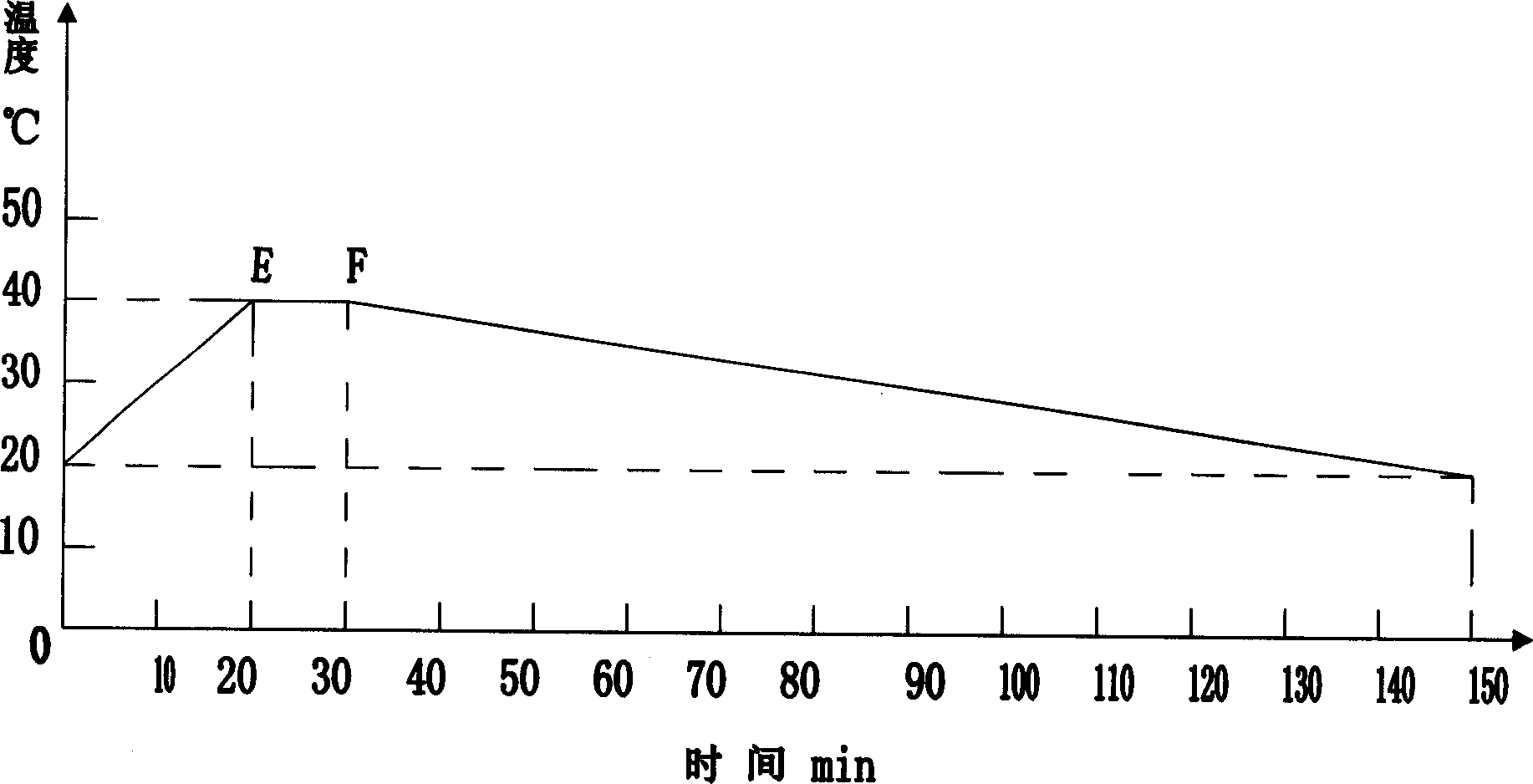

[0106] As shown in Figures 1 and 2, it is a flow chart of the rapid preparation and molding process of photosensitive resin. The preparation parameters must be strictly controlled and operated in sequence.

[0107] For the preparation of the chemical materials required for molding, epoxy resin (E-51), acrylic acid, N,N-dimethylaniline, p-hydroxyanisole, isopropylthioxanthone (ITX), trimethylol Propane triacrylate (TMPTA), silicon carbide whiskers, silane coupling agent (KH-560), anhydrous ethanol, methanol, and deionized water must be strictly selected and controlled for purity, and no impurities are allowed to intervene. Prevent by-products from forming and affecting the mechanical physical properties of product parts.

[0108] The required chemical substances must be weighed strictly according to the ratio, and the values must not exceed the maximum and minimum ranges,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com