Patents

Literature

39results about How to "Fast compaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

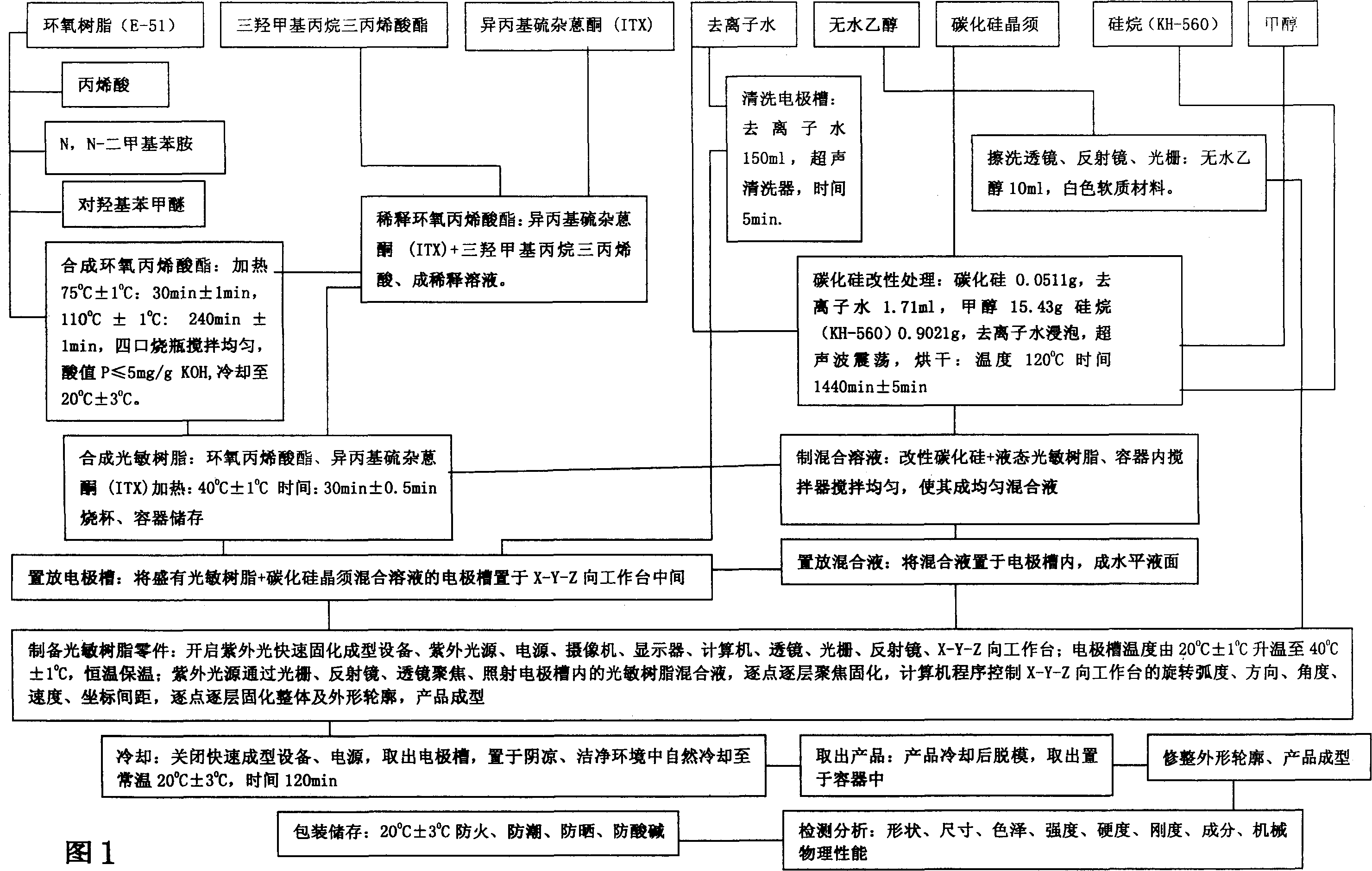

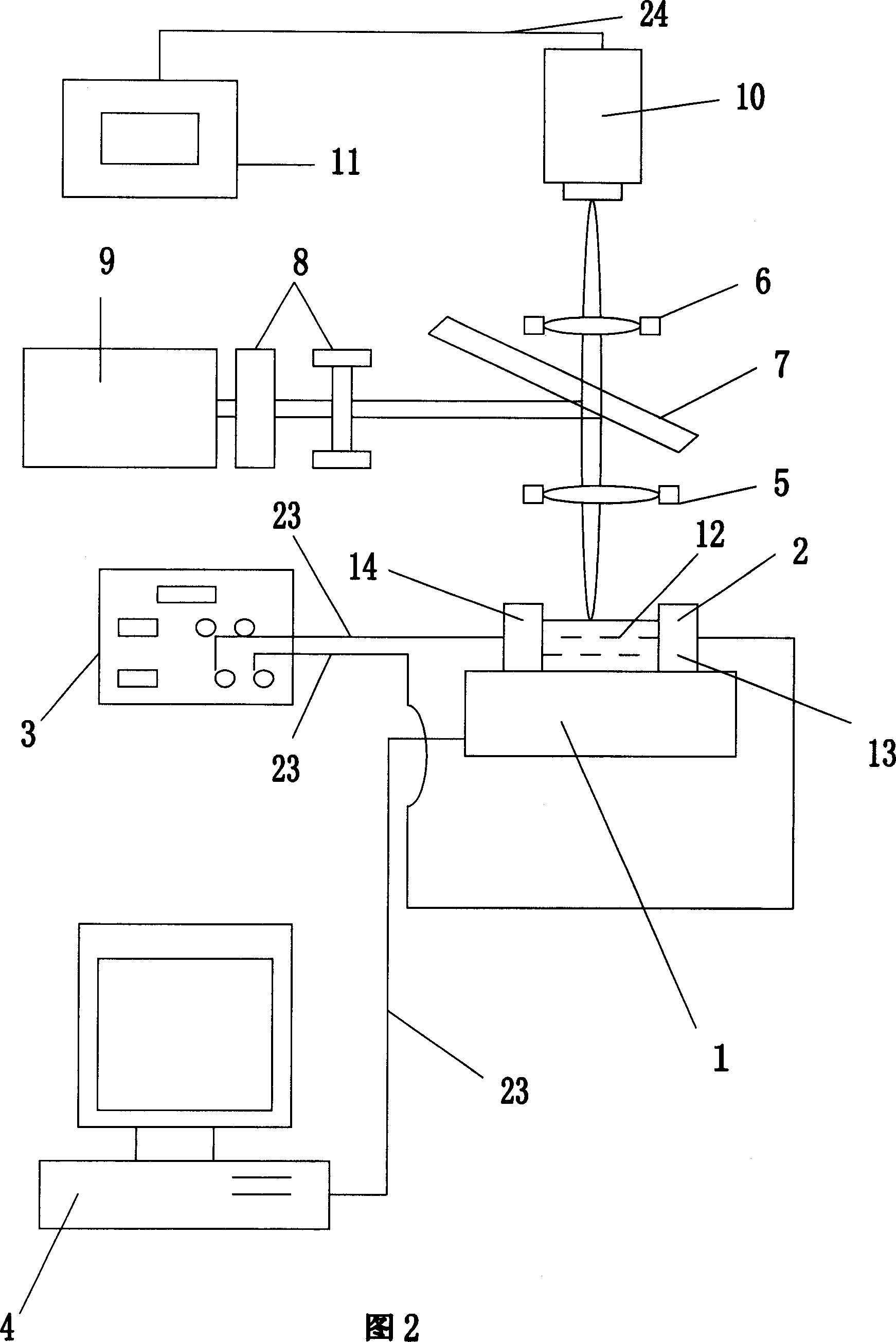

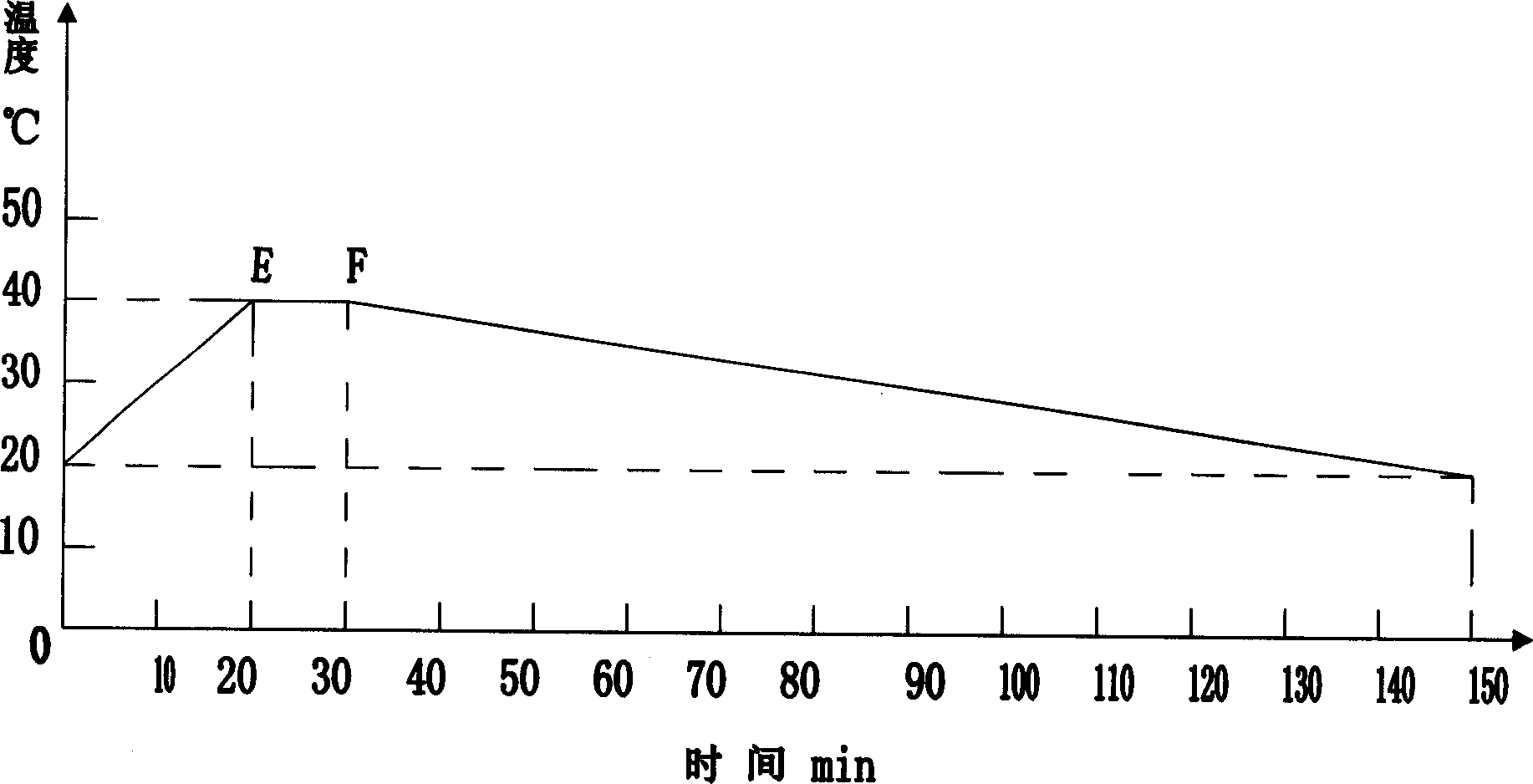

Resin base composite material parts quick forming method

The invention relates to a fast method for shaping resin composite material element, employing epoxy resin (E-51) and acrylic acid, carbonized silicon crystal whisker as intensifier, N,N-dimethylaniline as accelerant, p-methyl phenoxide as inhibitor, trimethylolpropane acrylate as diluting monomer, isopropyl thioxanthones as photo-initiation agent, silane coupling agent (KH-560) as modifier, and methanol as dissolvent. The method comprises following steps: synthesizing epoxy acrylate, diluting with trimethylolpropane acrylate, synthesizing photosensitive resin, synthesizing resin composite material miscible liquids with photosensitive resin and carbonized silicon crystal whisker, fast shaping element on photo-hardening shaping device, the composite material miscible liquid is controlled by ultraviolet light source, focusing lens focusing lens and computer program in electrode tank of X-Y-Z working bench. The invention provides a fast method for preparing injecting mold, flake grinder, ultra-thin element and accessory in special shape.

Owner:TAIYUAN UNIV OF TECH

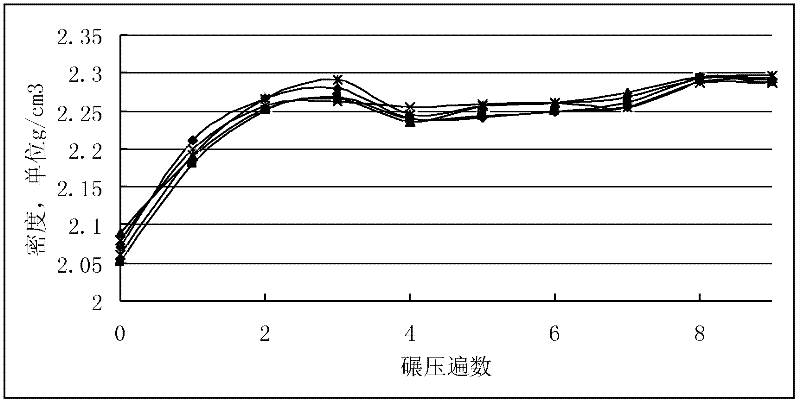

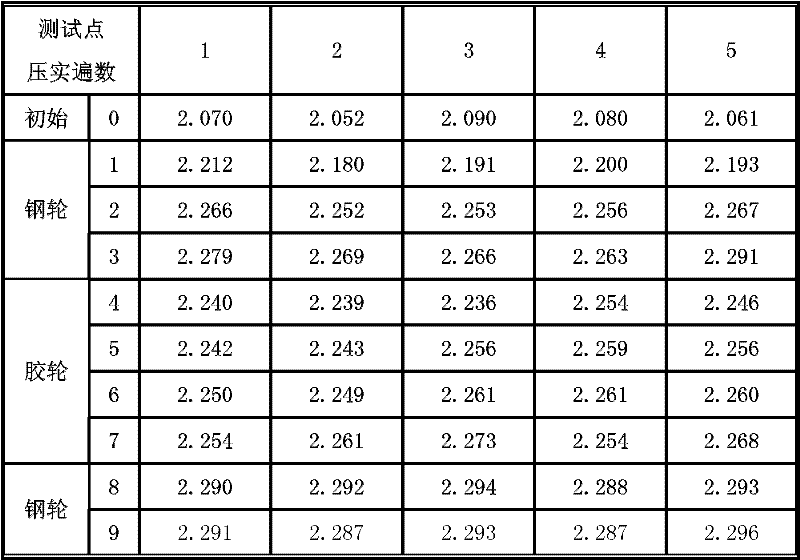

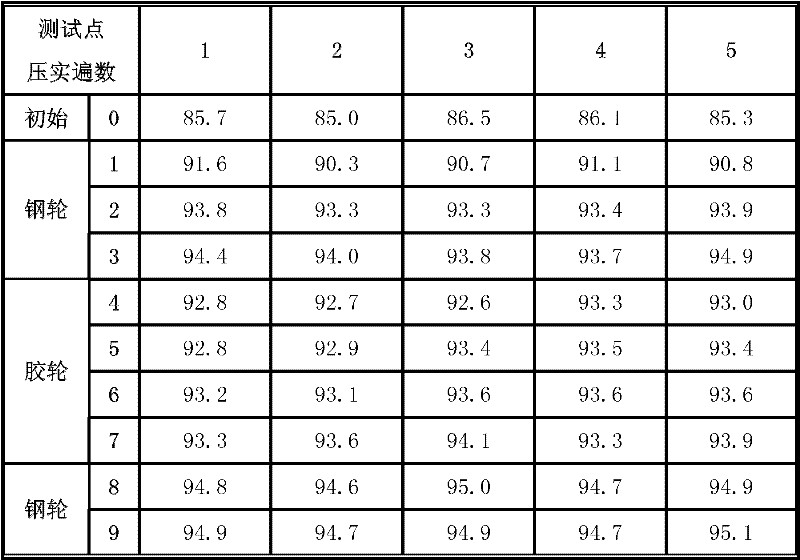

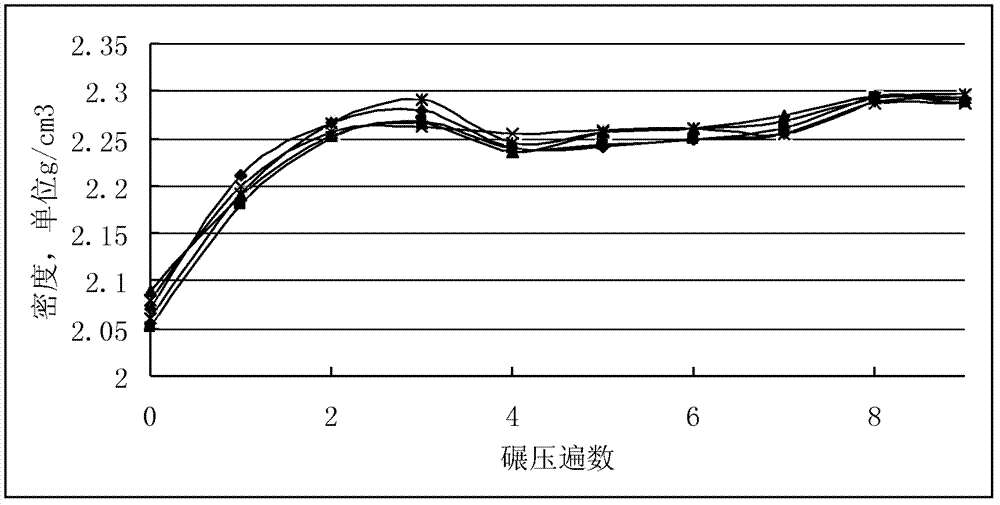

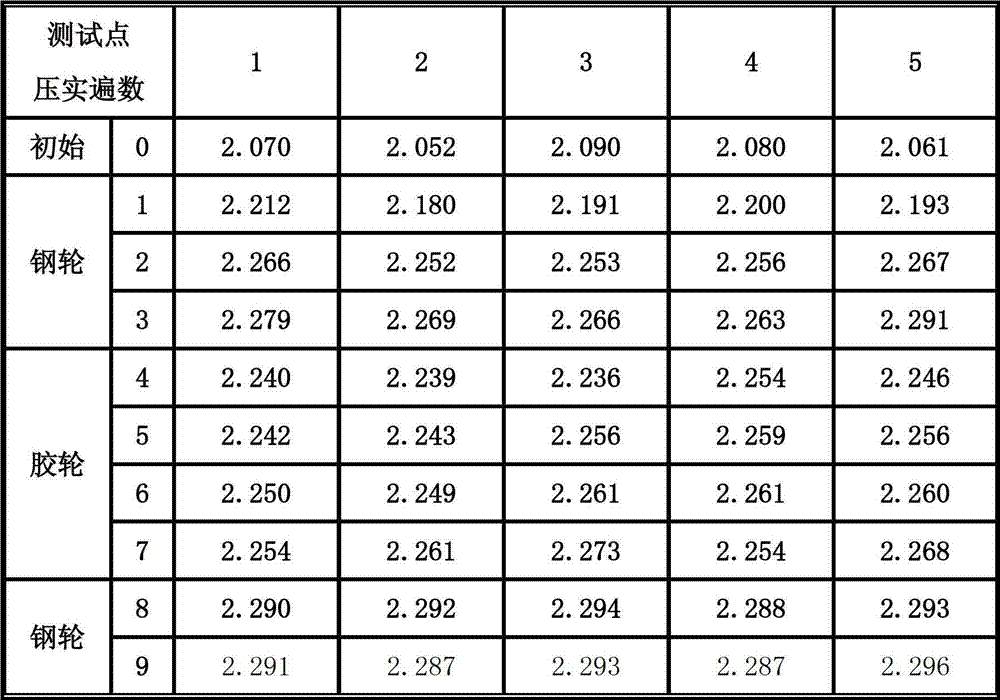

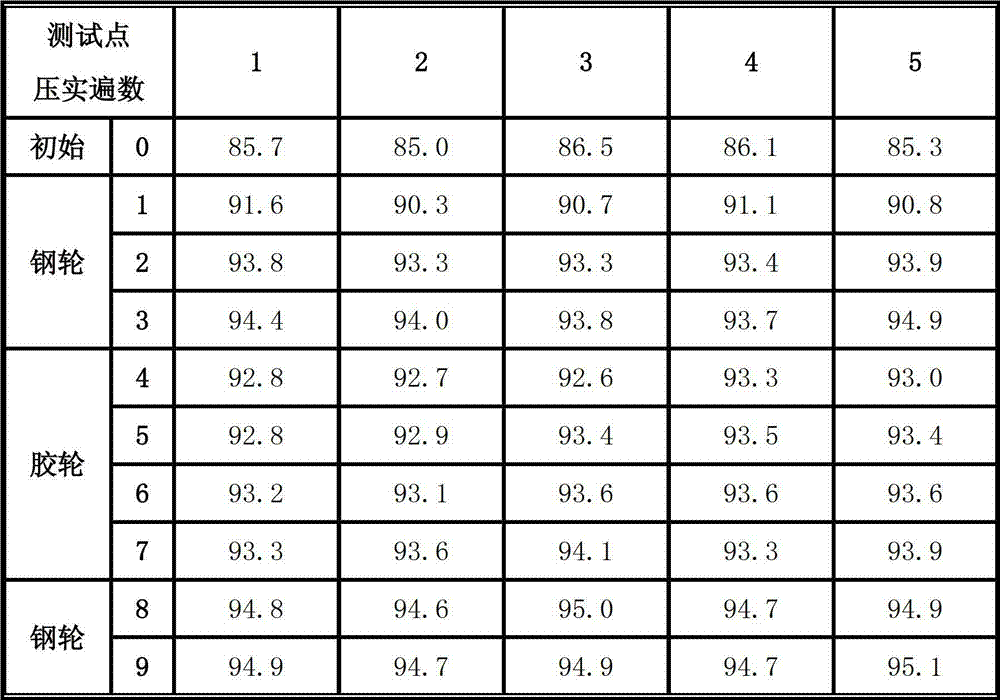

Rubber asphalt compacting technology based on pavement quality indicator

InactiveCN102345269AShort test timeOptimizing the compaction processRoads maintainenceSpecific gravity measurementRubberized asphaltNondestructive testing

The invention belongs to the field of non-destructive testing, and discloses a rubber asphalt compacting technology based on a pavement quality indicator. According to the invention, density data is collected from a rubber asphalt pavement testing path; a relationship figure of the two is drawn; read numbers on the pavement quality indicator are scaled; and real-time monitoring and compaction optimization are carried out upon the compaction degree of the asphalt layer of the rubber asphalt pavement by using the pavement quality indicator. With the technology provided by the invention, the asphalt structural layer of the rubber asphalt pavement is not damaged, the compaction degree of a rubber asphalt surface layer can be simply, rapidly and accurately controlled, and the rolling process of a roller can be optimized. The technology can be simply applied in on-site operations, and provides advantages of no radiation, no damage, and low testing cost.

Owner:GUANGZHOU UNIVERSITY

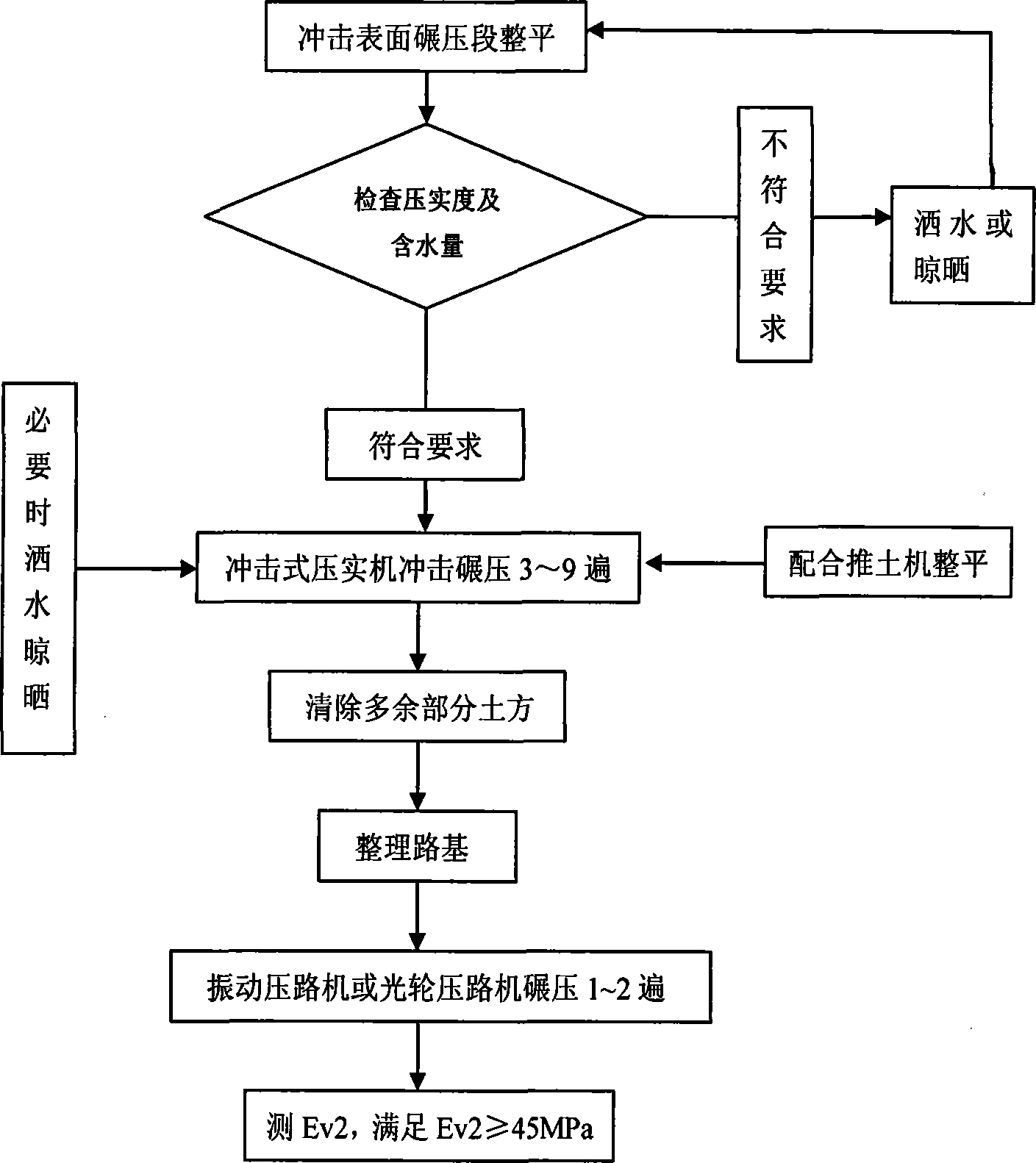

Construction method of impacting and rolling

The invention discloses an impact rolling construction method, belonging to the technical field of roadbed reinforcement construction, comprising the steps of leveling the surface of the impact rolling section, detecting the degree of compaction and water content, and when the degree of compaction and the water content of the surface of the impact rolling section are After the water content meets the design requirements, use an impact compactor to impact and roll 3 to 9 times, and at the same time use a bulldozer to level it, remove excess earthwork, arrange the roadbed, and use a vibratory roller or smooth wheel roller to roll 1 to 2 times. The secondary deformation modulus Ev2 value of the foundation soil after impact rolling; the present invention accurately limits which geological conditions are suitable for the impact rolling reinforcement construction method, more fully exerts the effect of impact rolling, and greatly reduces the impact of rolling. The number of times of rolling is generally 3 to 9 times. The detection index after rolling reaches the German high-speed railway foundation standard, which reduces the project cost and speeds up the project progress. The present invention is especially suitable for the foundation reinforcement construction of high-speed railways and highways.

Owner:CHINA RAILWAY NO 8 ENG GRP CO LTD

Fast-curing waterstop plugging material as well as preparation method and application method thereof

The invention discloses a fast-curing waterstop plugging material as well as a preparation method and an application method thereof, belonging to the field of waterproof plugging projects. The fast-curing waterstop plugging material disclosed by the invention comprises the following components in parts by mass: 4-6 parts of water swelling aggregate, 3-5 parts of fast-hardening cementing material, 0.1-0.9 part of a coagulation accelerator and 0.1-0.9 part of a hardening accelerator, wherein the coarse aggregate in the water swelling aggregate is expanded perlite, and the fine aggregate is bentonite; the particle size of the expanded perlite is 1-5mm, and the particle size of the bentonite is less than 1mm; and the mass ratio of the expanded perlite to bentonite is 1-2. According to the invention, through the water swelling property of the plugging material aggregate, a fast water plugging effect is realized; in the water plugging process, since the concretion body is dense accumulation of the coarse and fine aggregates, the components of the fast-hardening cementing material, the coagulation accelerator and the hardening accelerator do not change in situ, and the concretion body has the effects of waterstop, plugging and stable strength of concretion structure for sure.

Owner:罗强

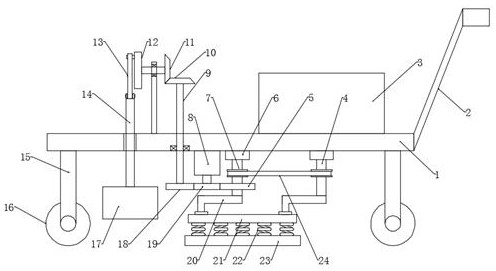

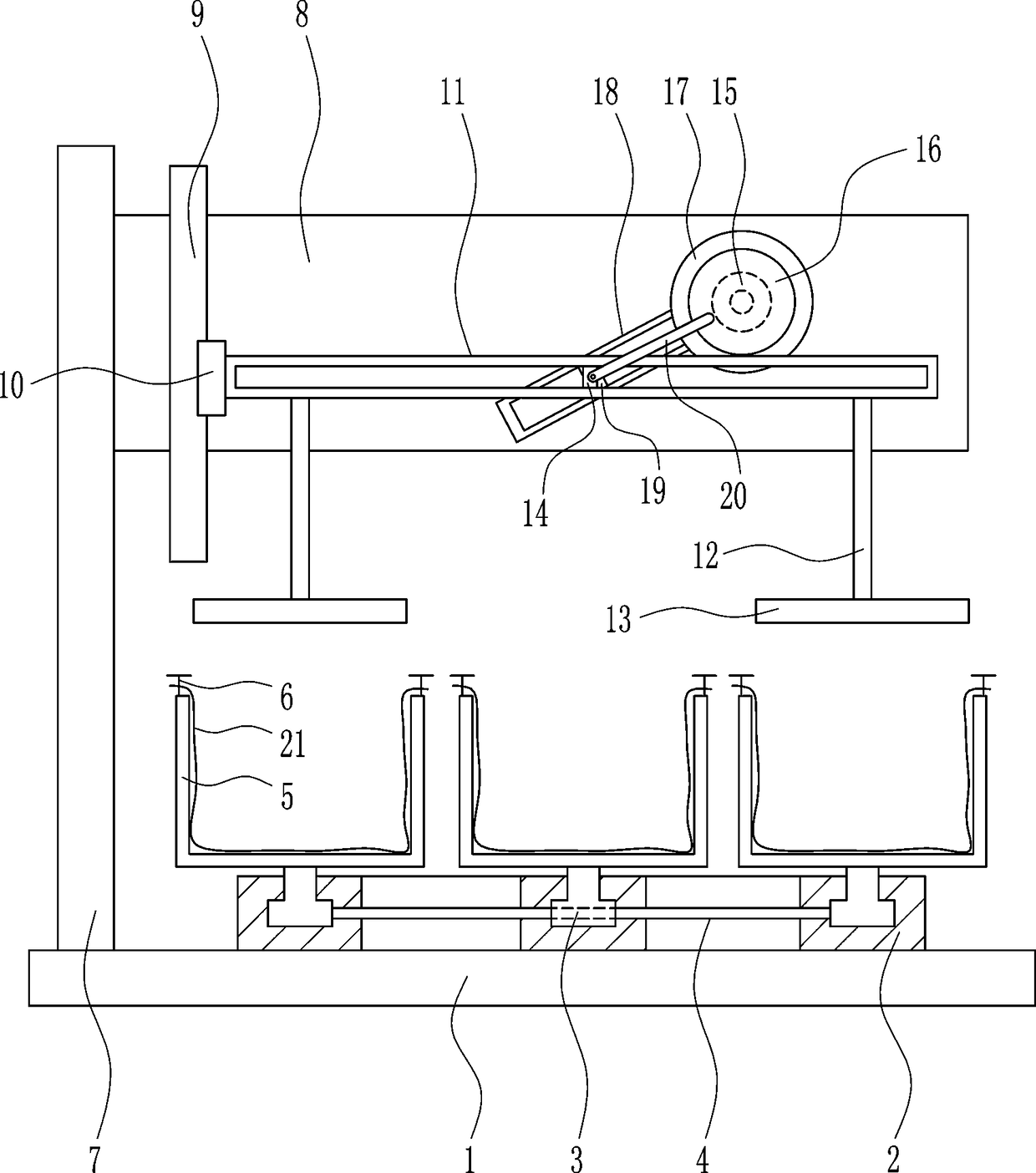

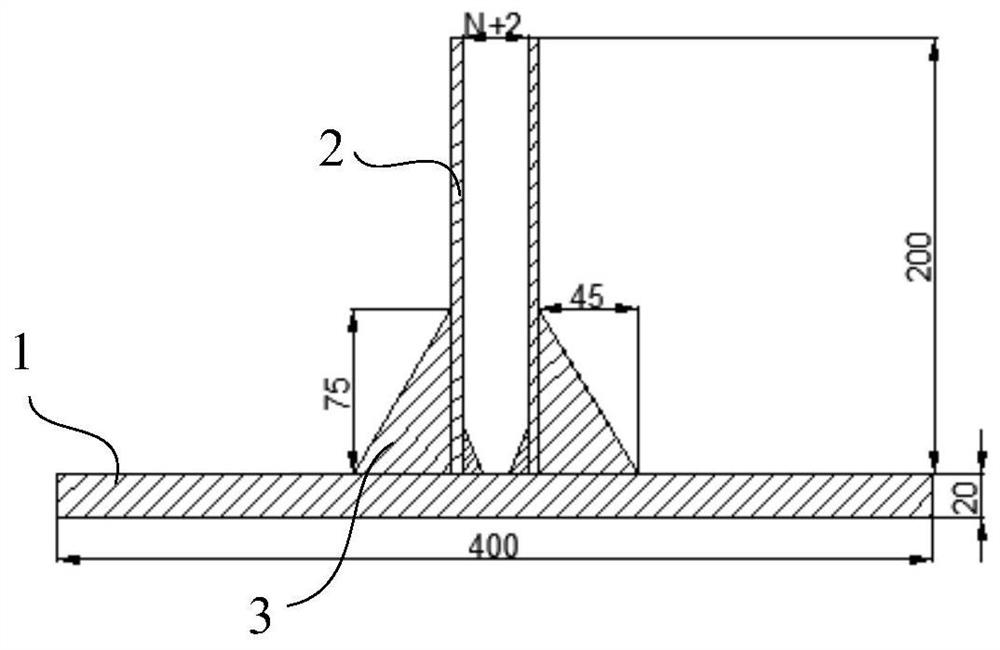

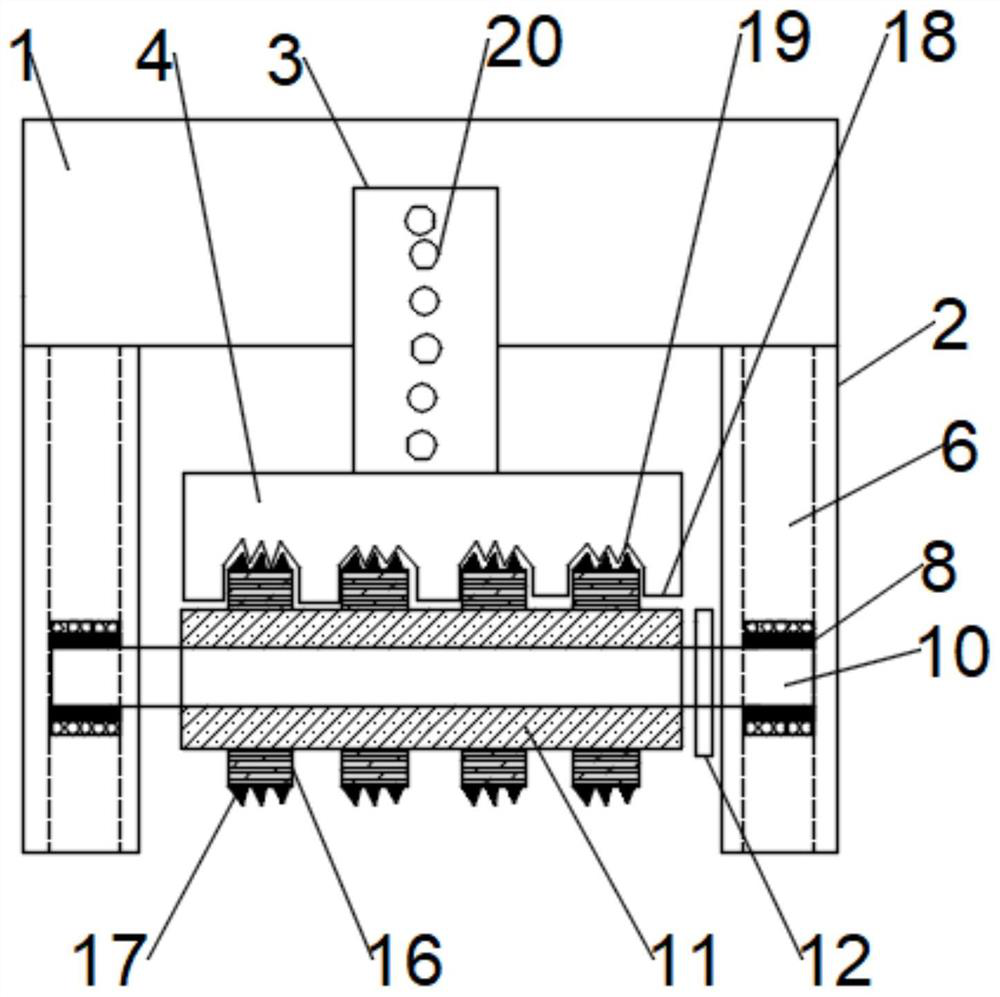

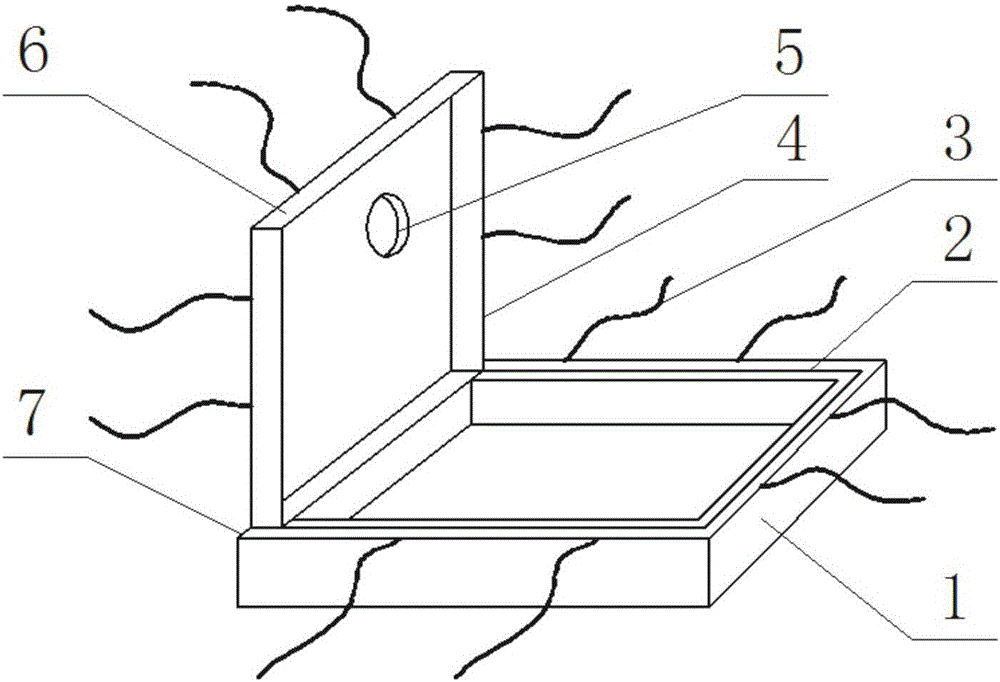

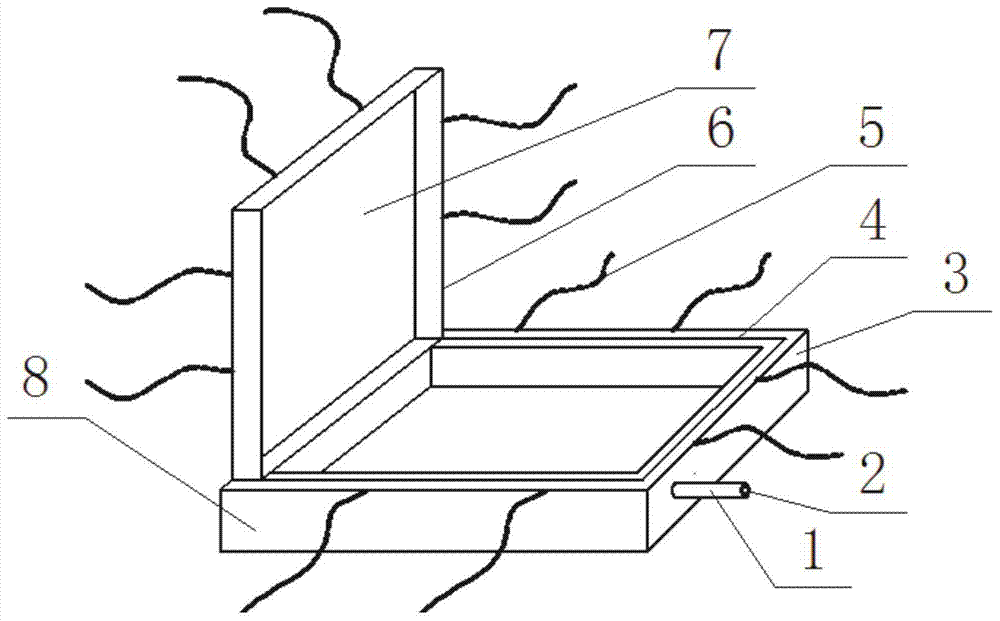

Tamping and trowelling device for building concrete laying

InactiveCN111636277AFast compactionImprove efficiencyRoads maintainenceBuilding material handlingElectric machineryMaterial resources

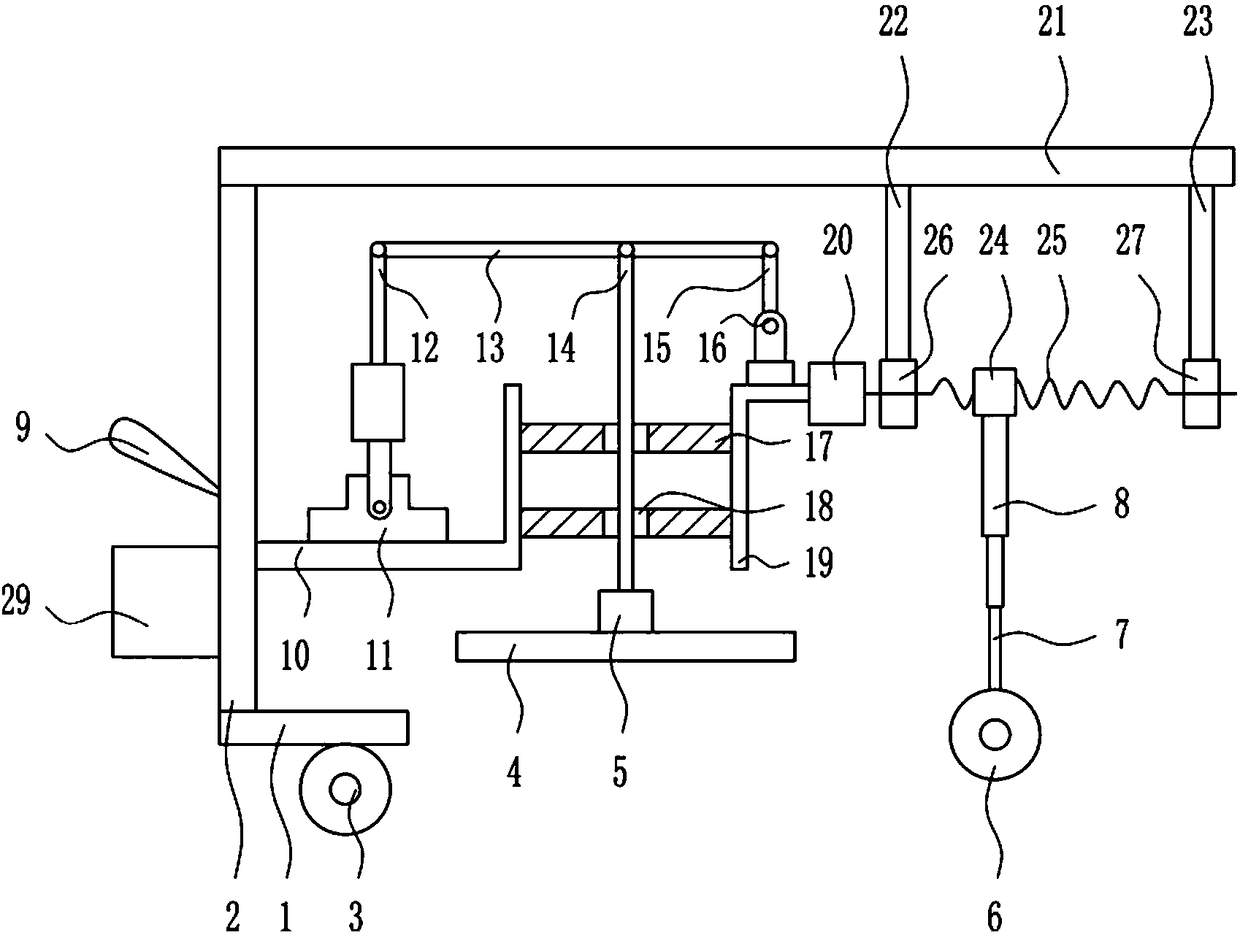

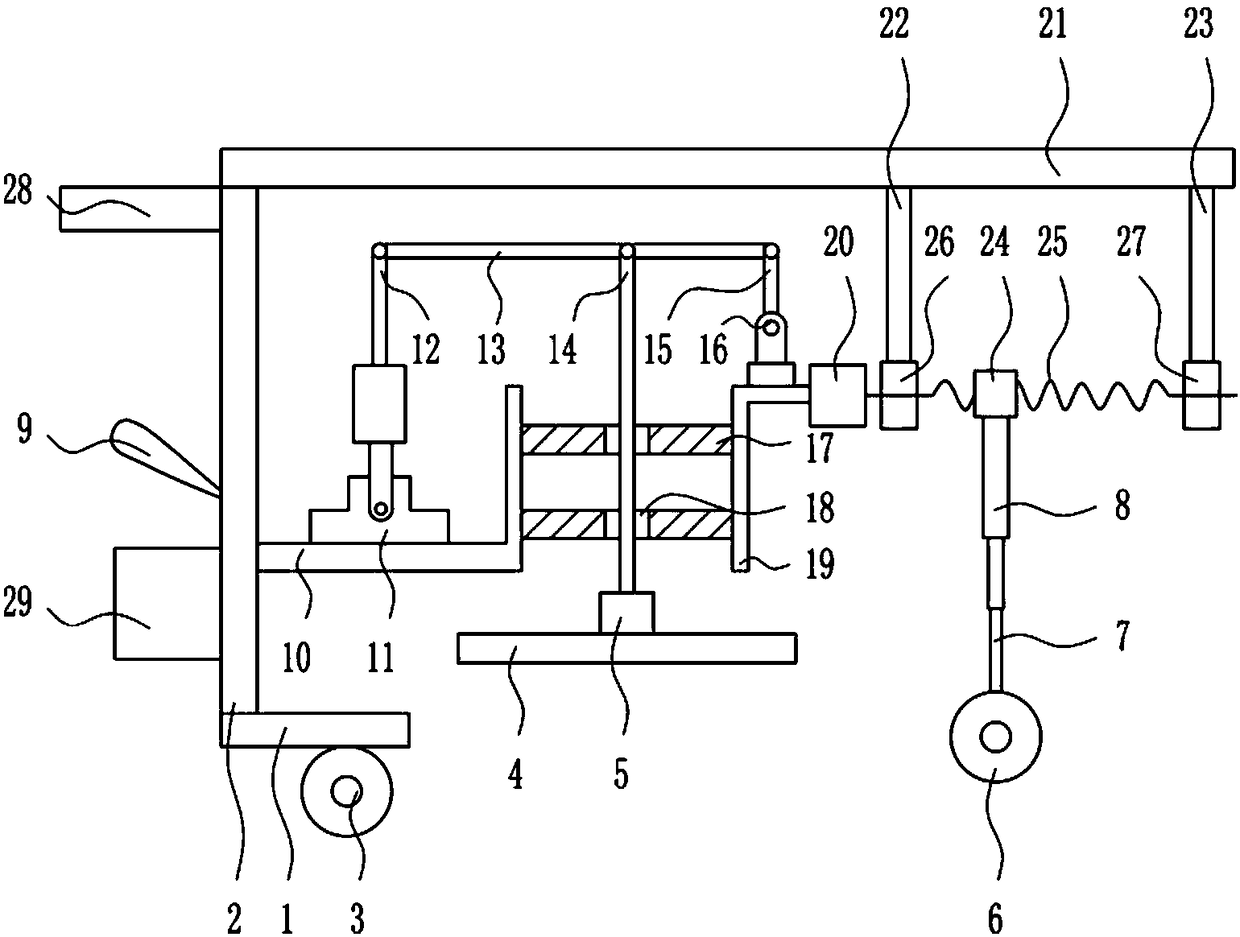

The invention discloses a tamping and trowelling device for building concrete laying. The tamping and trowelling device comprises a bottom plate, a tamping block, a motor, a first gear, a second gear,a first rotating shaft, a first bevel gear, a second bevel gear, a disc, a connecting rod, a movable rod, a tamping block, a third gear, a second rotating shaft, a third rotating shaft, an L-shaped rod and a pressing plate. The tamping and trowelling device is provided with a motor, a first gear, a second gear, a first rotating shaft, a first bevel gear, a second bevel gear, a disc, a movable rodand a tamping block. The tamping block is driven to move up and down, continuous tamping on the road surface is realized, tamping speed is fast, efficiency is high; the third gear, the second rotating shaft, the third rotating shaft, the L-shaped rod, a mounting plate and a pressing plate are adopted for extruding and trowelling of the ground, the working range is large, the efficiency is high, tamping and trowelling functions are achieved at the same time through a motor, the road surface is processed to be smooth, working efficiency is high, and both manpower and material resources are saved.

Owner:栾勇

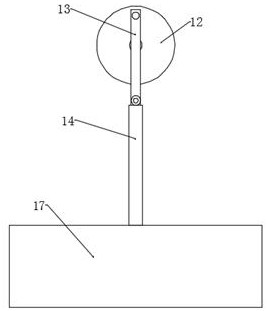

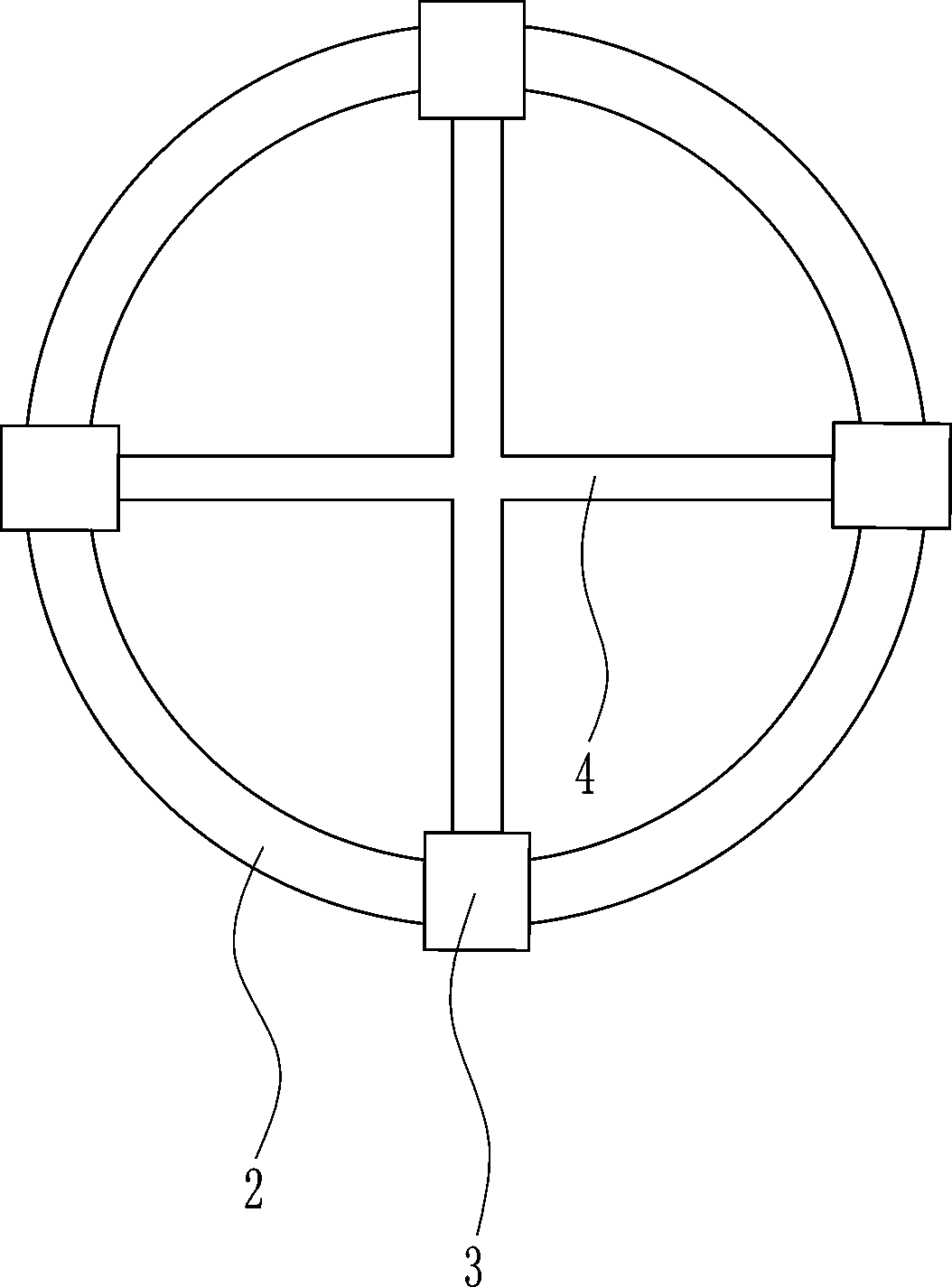

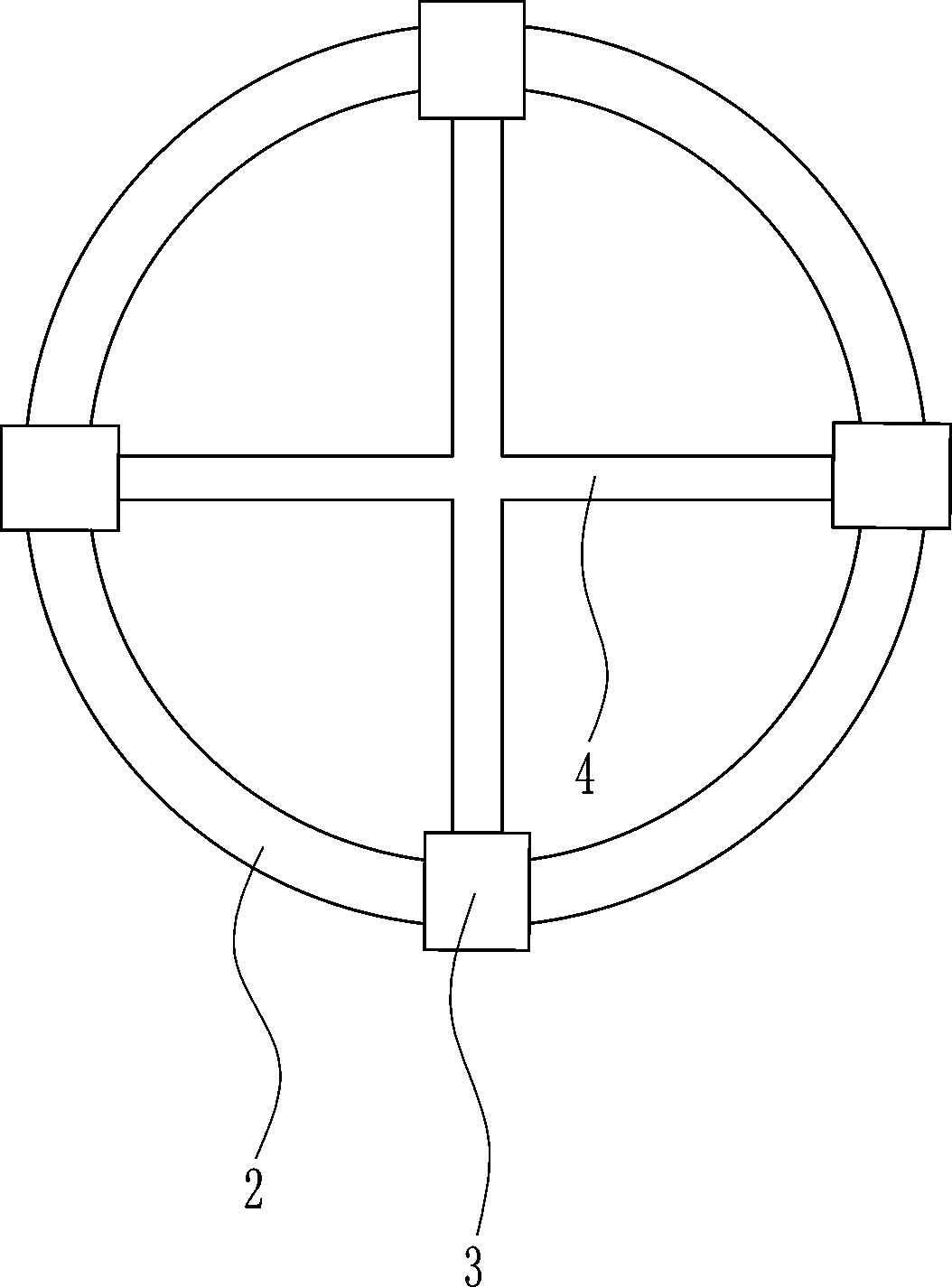

Compacting equipment for medical waste recycling

The invention relates to compacting equipment, in particular to compacting equipment for medical waste recycling. The invention aims to solve the technical problem so as to provide the compacting equipment for medical waste recycling, which is convenient to treat medical wastes and less in occupied space. The invention provides the compacting equipment for medical waste recycling, which comprisesa bottom plate, an annular slide rail, first sliding blocks, a cross-shaped connecting rod, frame bodies, nails, a support, an installation plate, a first slide rail, a second sliding block, a first guide rail, first connecting rods and the like. The annular slide rail is arranged in the middle of the top part of the bottom plate; the four first sliding blocks are slidably connected into the annular slide rail; the cross-shaped connecting rod is connected among the four first sliding blocks; and the frame bodies are arranged on the top parts of the first sliding blocks. The compacting equipment for medical waste recycling provided by the invention achieves the effects of convenience in medical waste treatment and less occupied space; the medical wastes are compacted and re-treated, so thatthe space occupied by the medical wastes is small, and the medical wastes are conveniently treated; and the four frame bodies alternately compact the medical wastes, so that the medical waste compacting speed is faster.

Owner:陈丽 +1

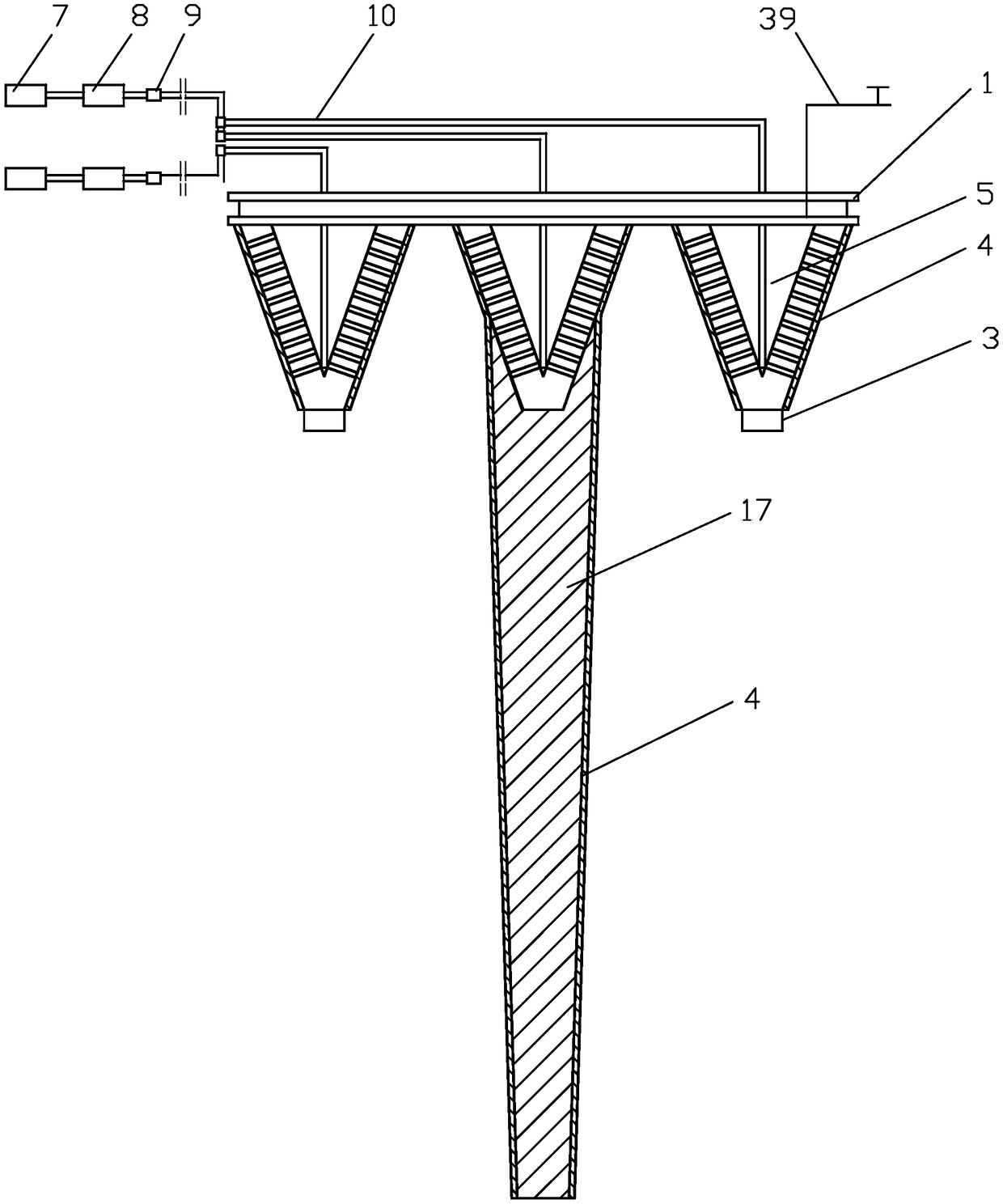

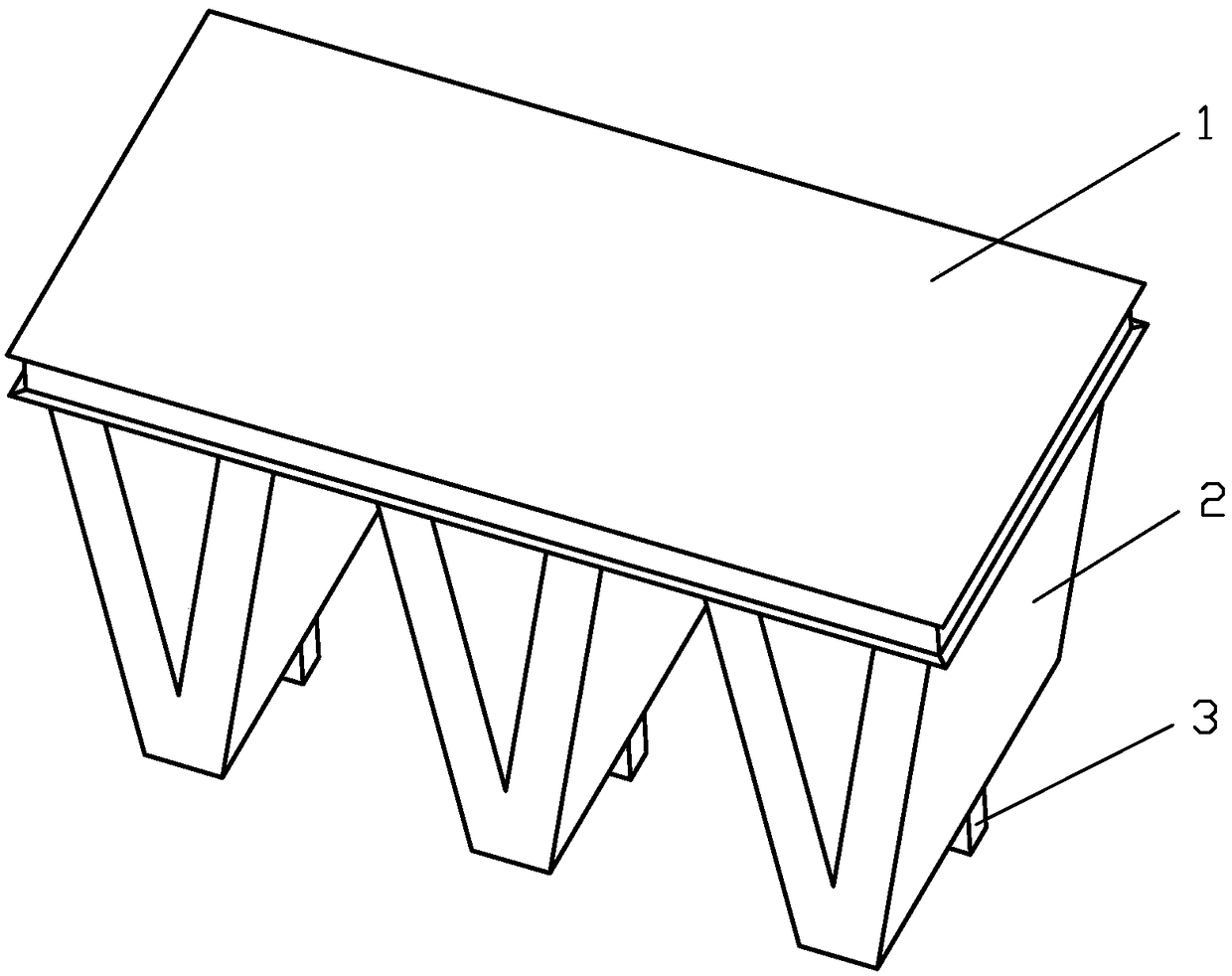

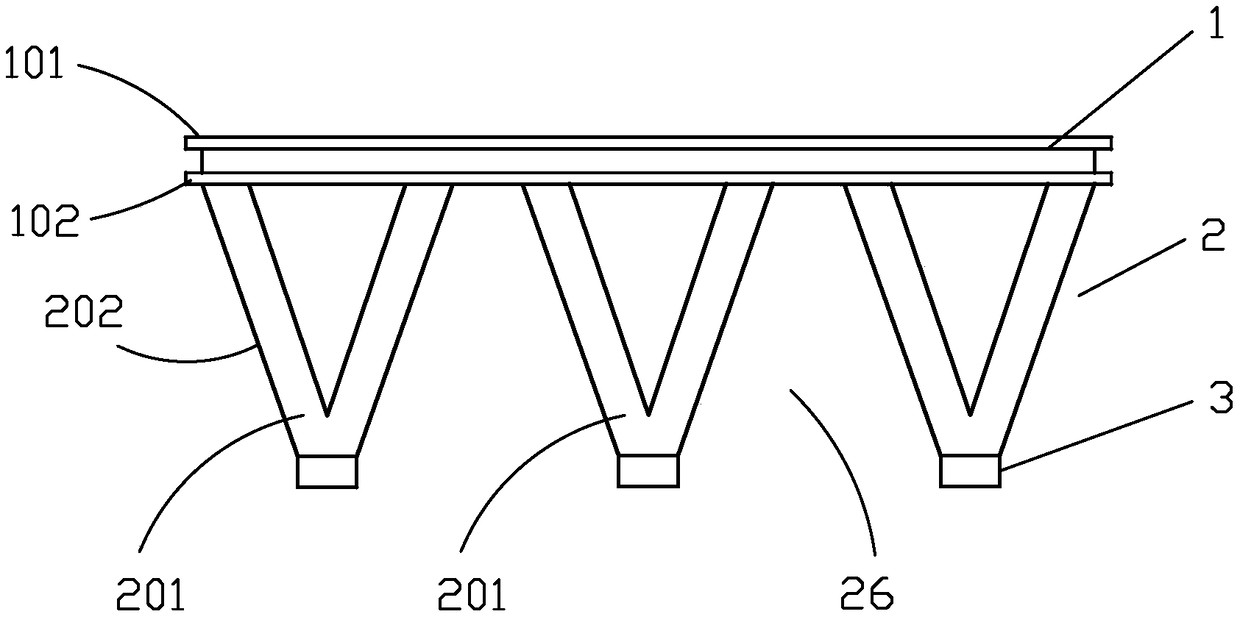

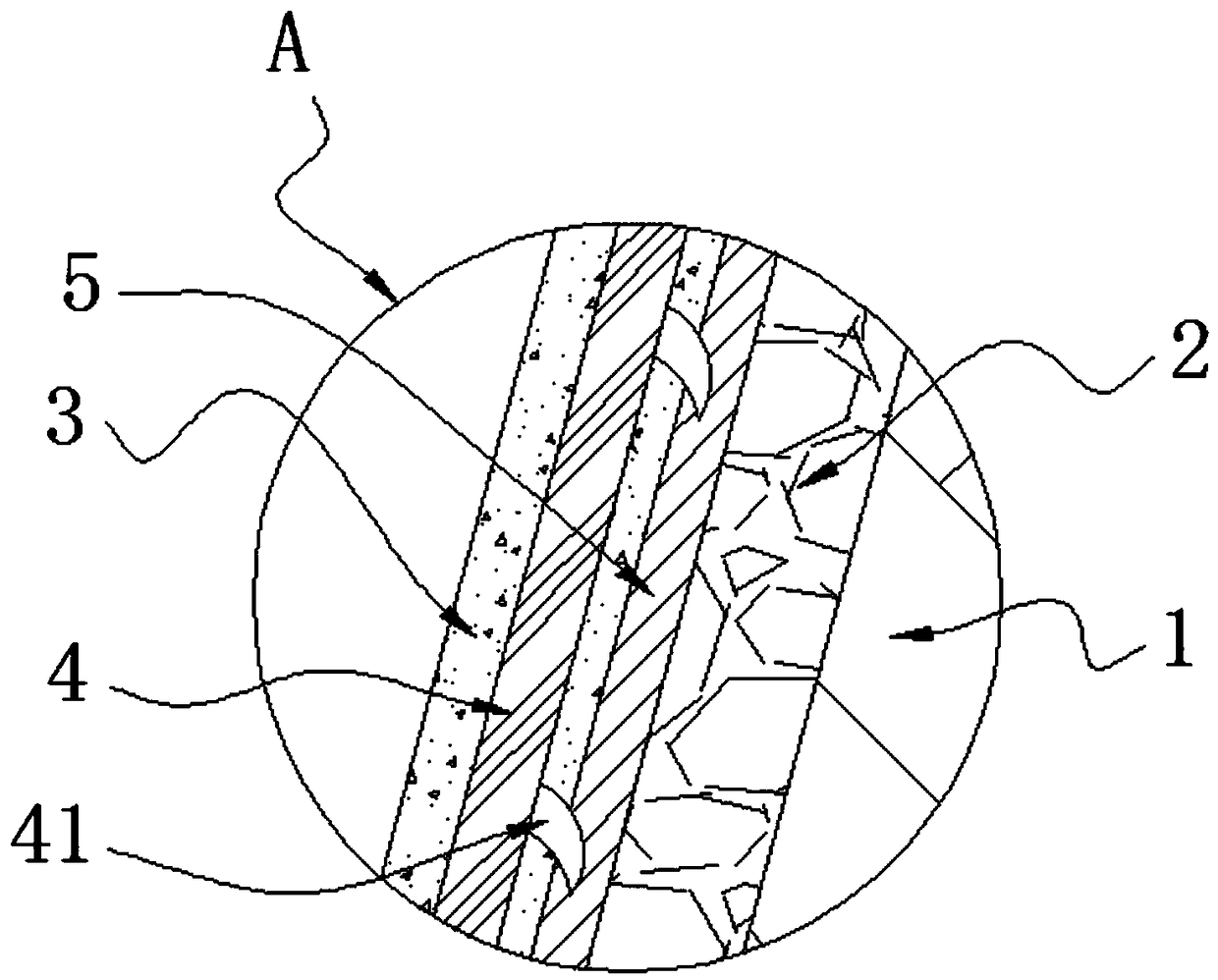

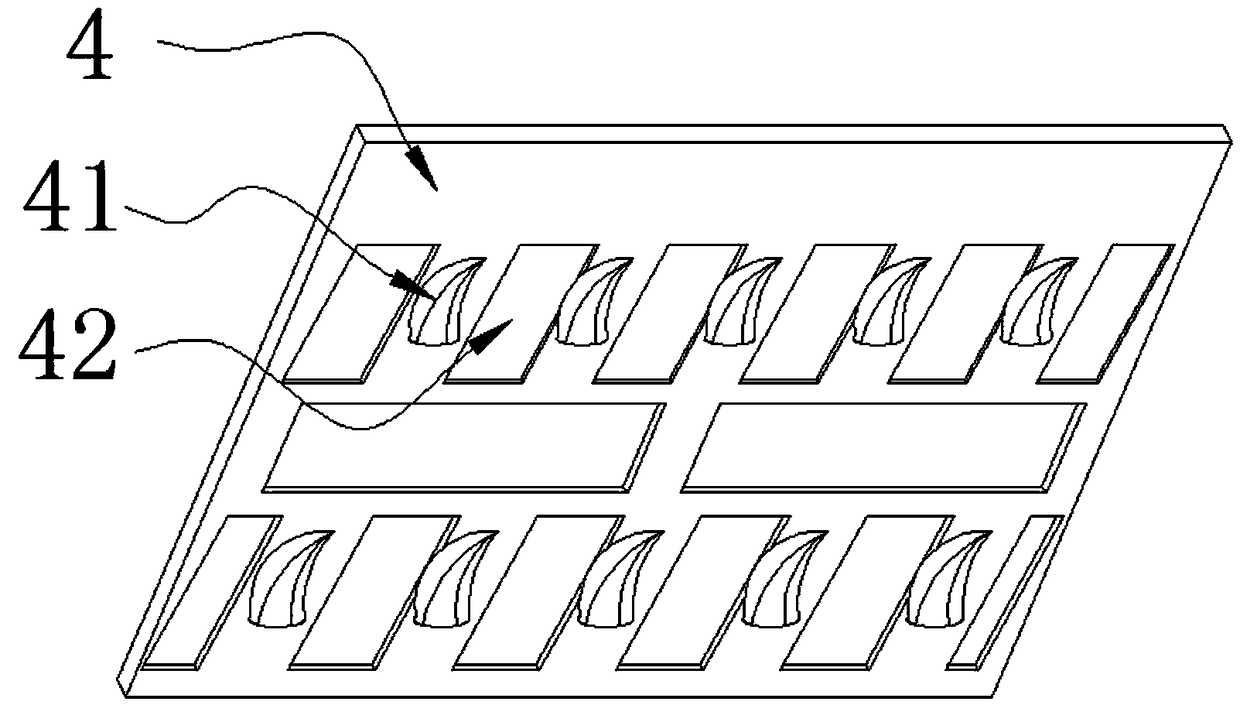

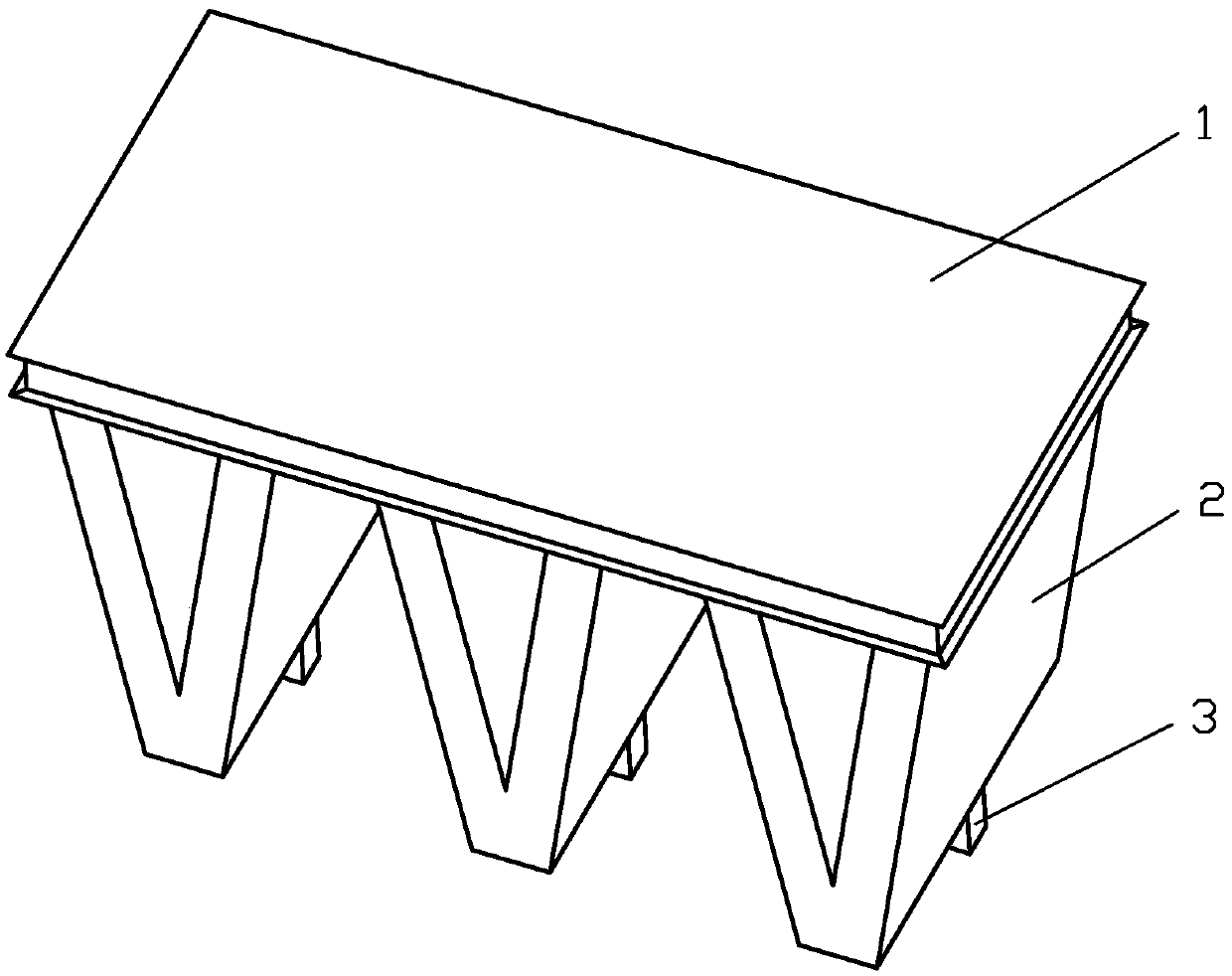

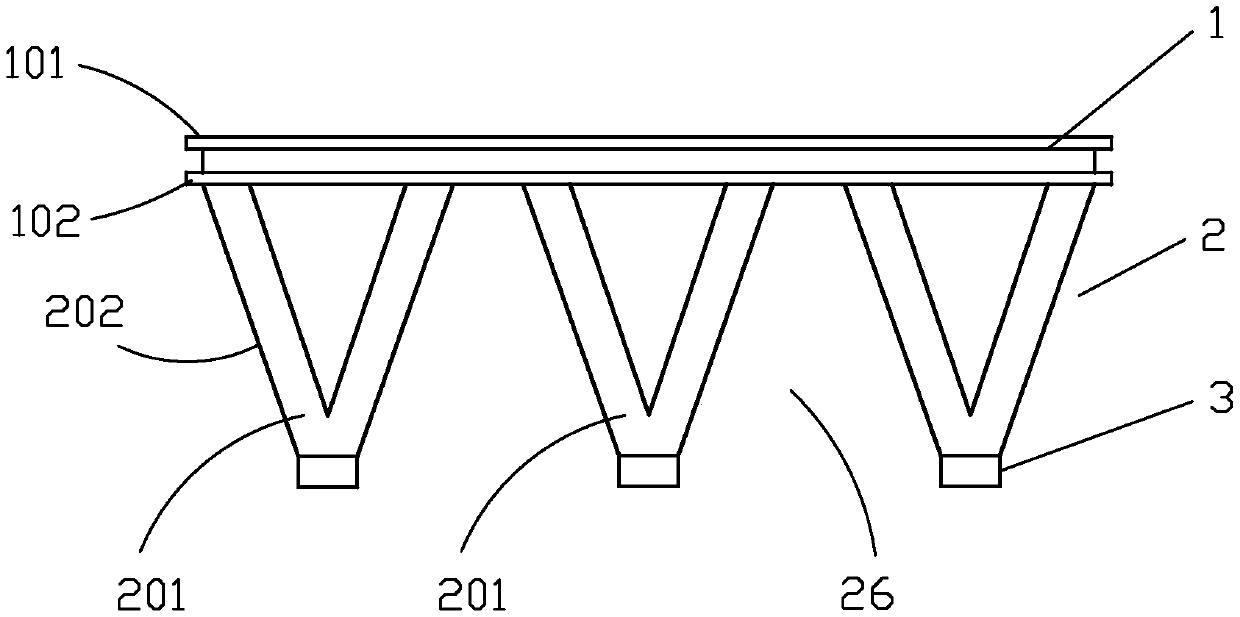

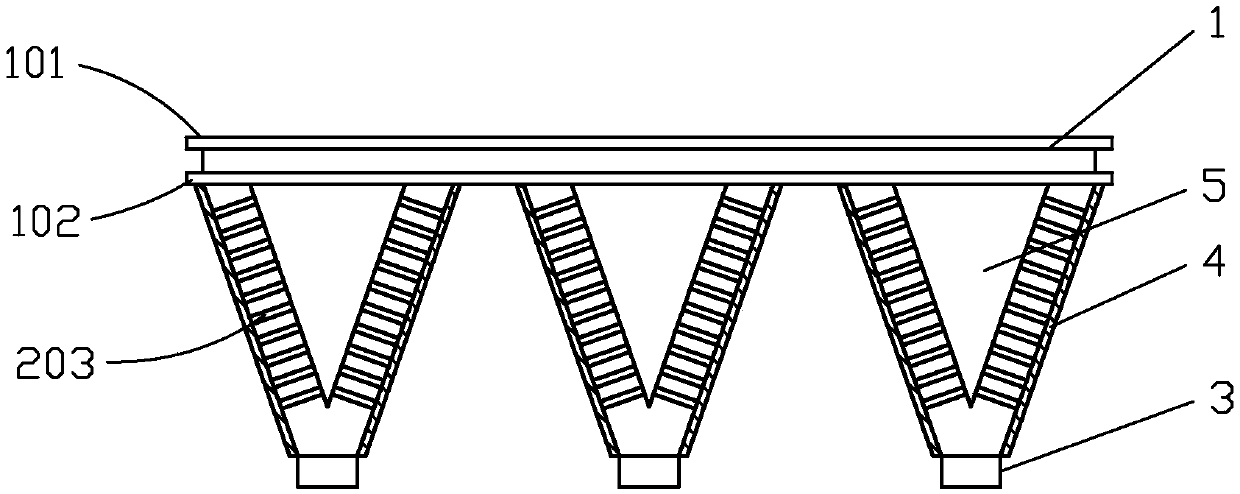

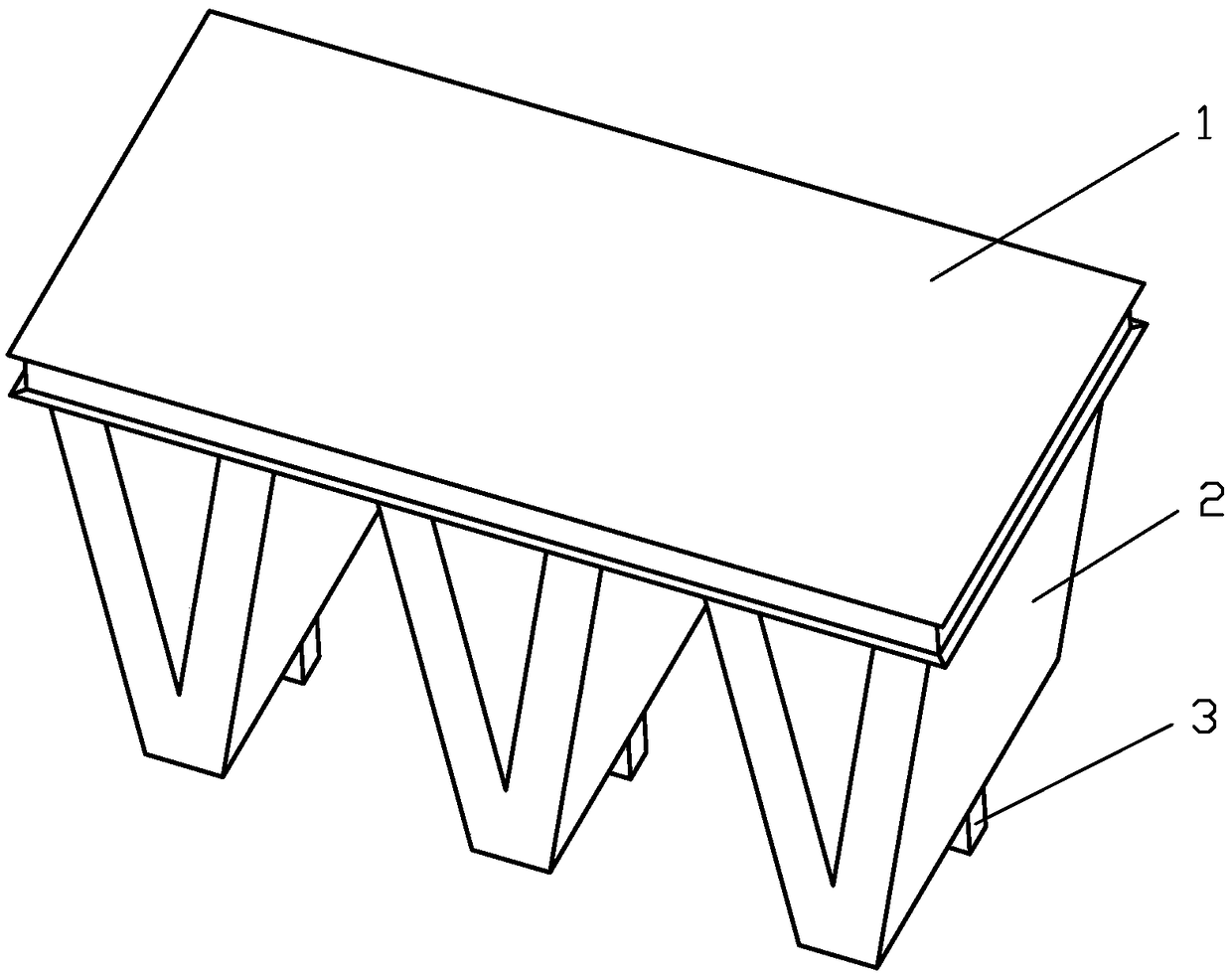

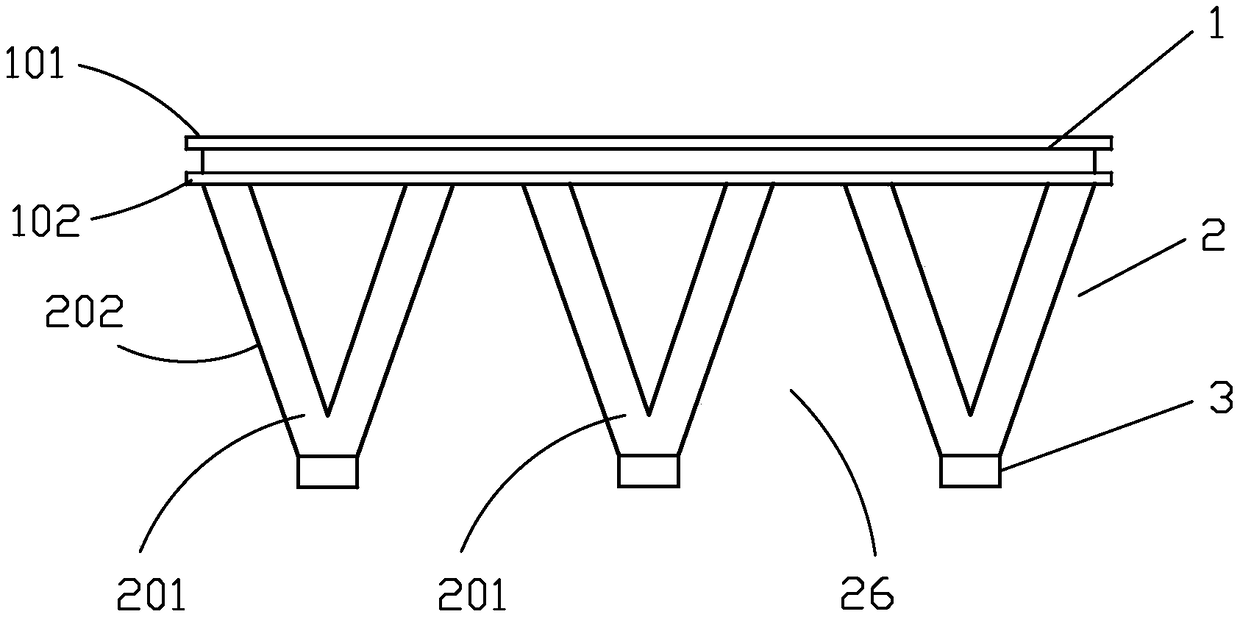

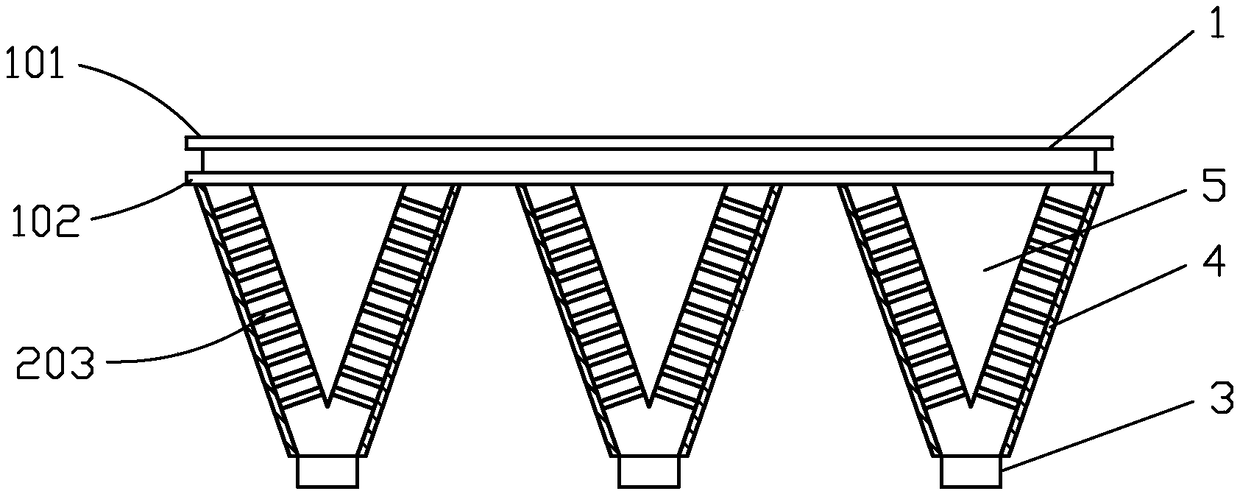

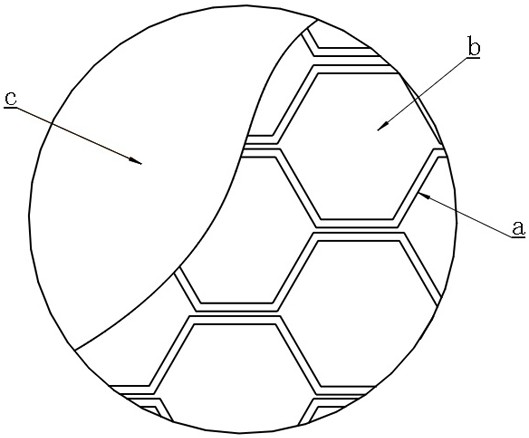

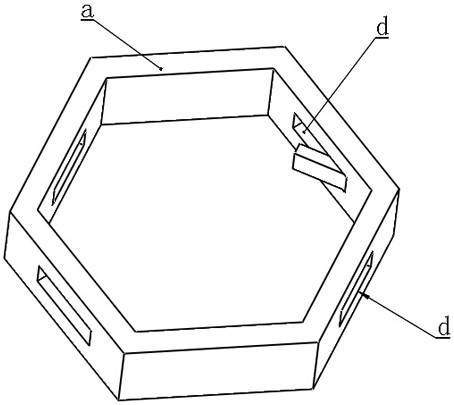

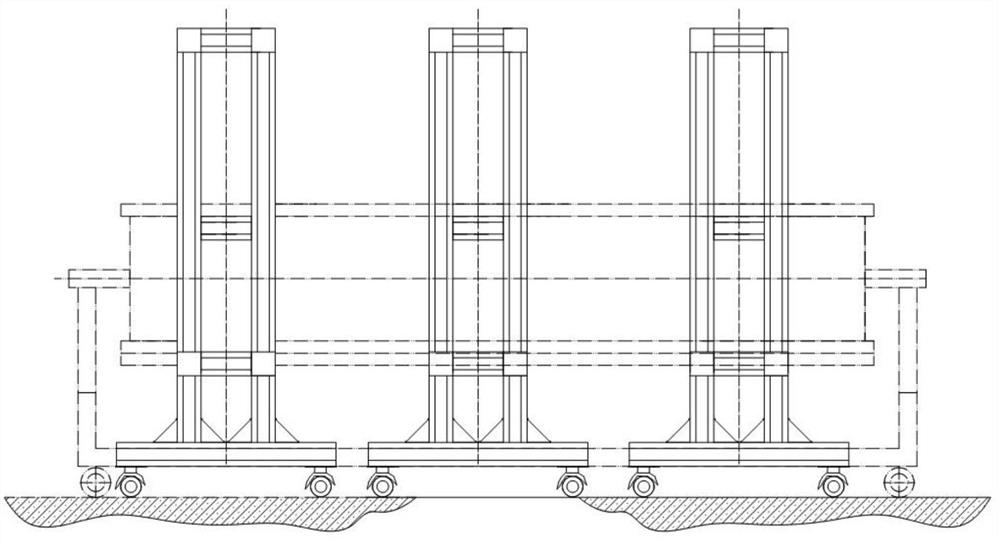

Modular soil compaction molding device applicable for treatment of deep and shallow soft soil foundations

InactiveCN108330948APlay a blocking rolePrevent sideways movementSoil preservationEngineeringUltimate tensile strength

The invention discloses a modular soil compaction molding device applicable for treatment of deep and shallow soft soil foundations. The modular soil compaction molding device comprise an upper frame,a compaction molding module and a soil strength detection device, and is characterized in that the compaction molding module comprises a plurality of convex bodies; the top of the module is connectedto the upper frame, and the part, coming into contact with soil, of the compaction molding module is further provided with a filter device; and the bottom of the compaction molding module is furtherprovided with a vertical pile body. The soil is blocked by the convex bodies at the bottom of the compaction molding module, and prevented from offsetting so that the soil is centralized in spaces among the convex bodies and extruded fully, and the effects of quick drainage and compaction are achieved. Moisture extruded from the soil is discharged through the filter device, and the construction efficiency is improved greatly; and the construction period is shortened, and the construction cost is reduced.

Owner:ZHEJIANG JIA YUAN CIVIL ENG CO LTD

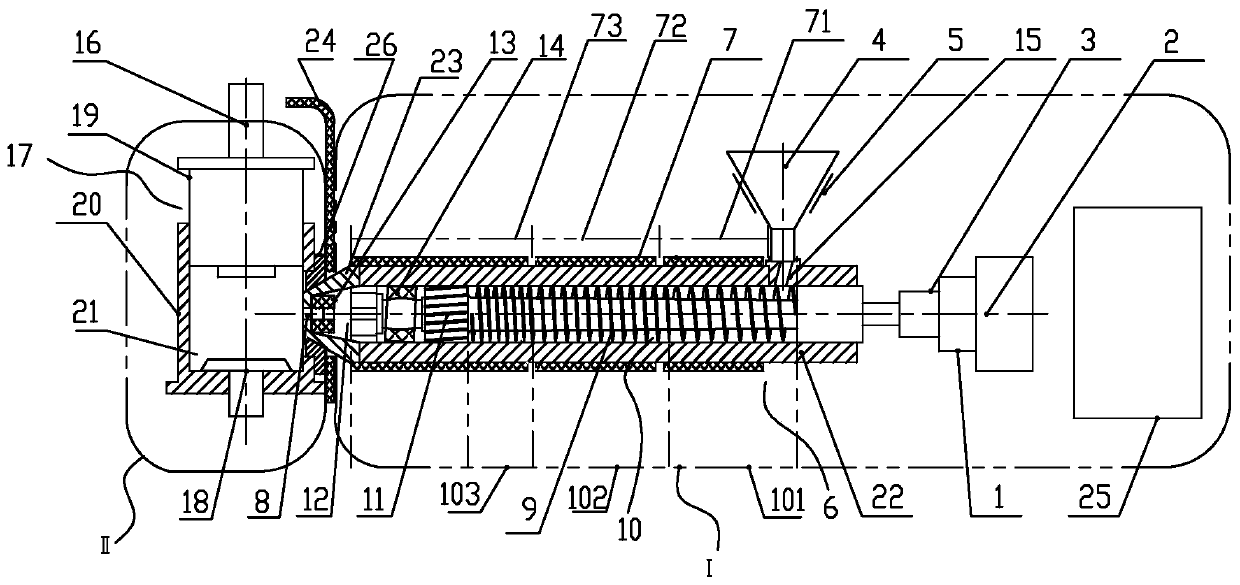

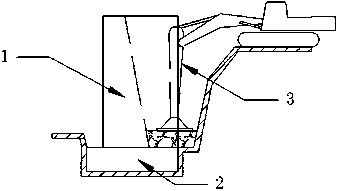

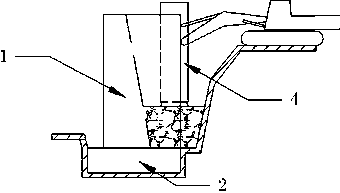

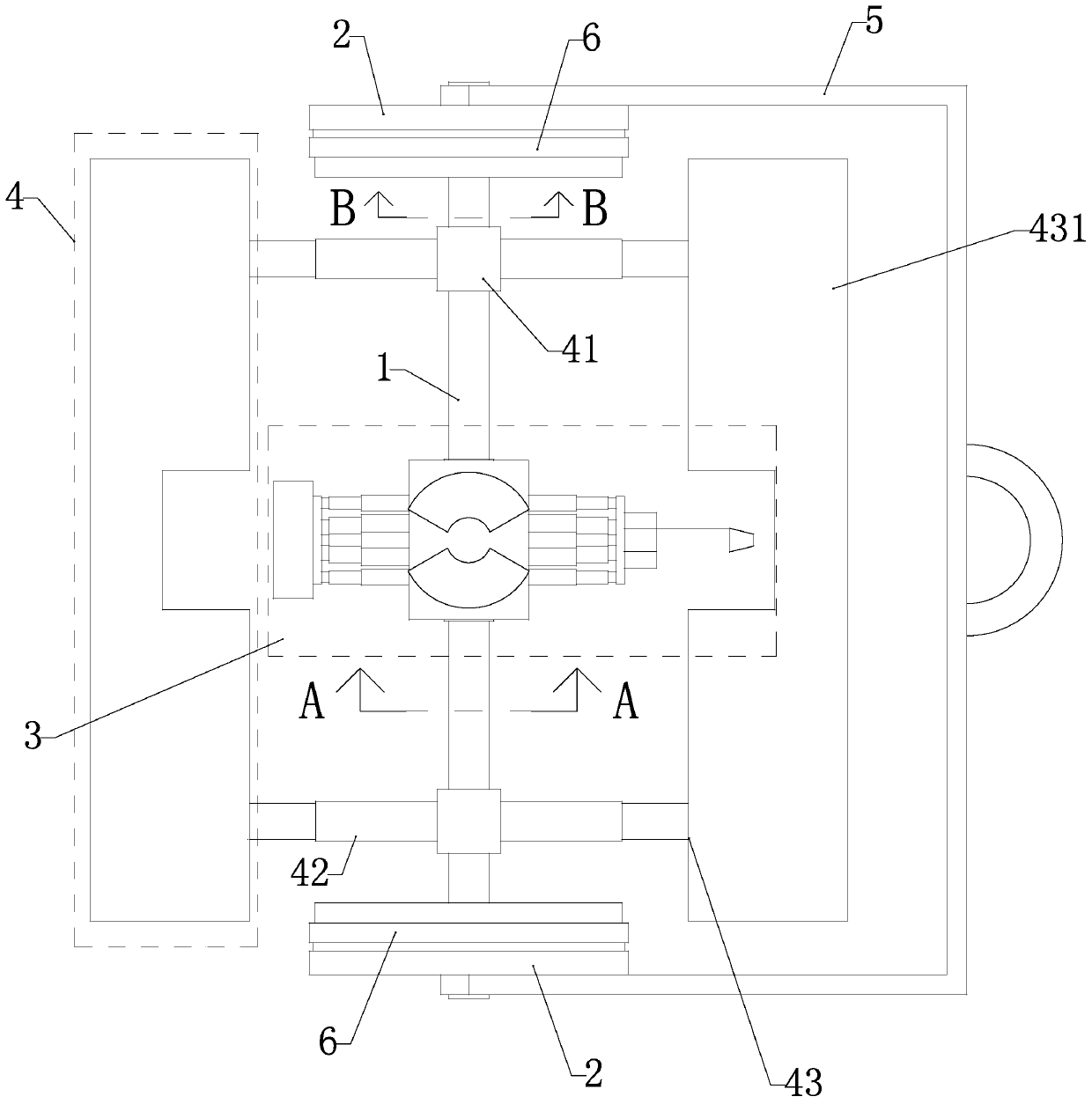

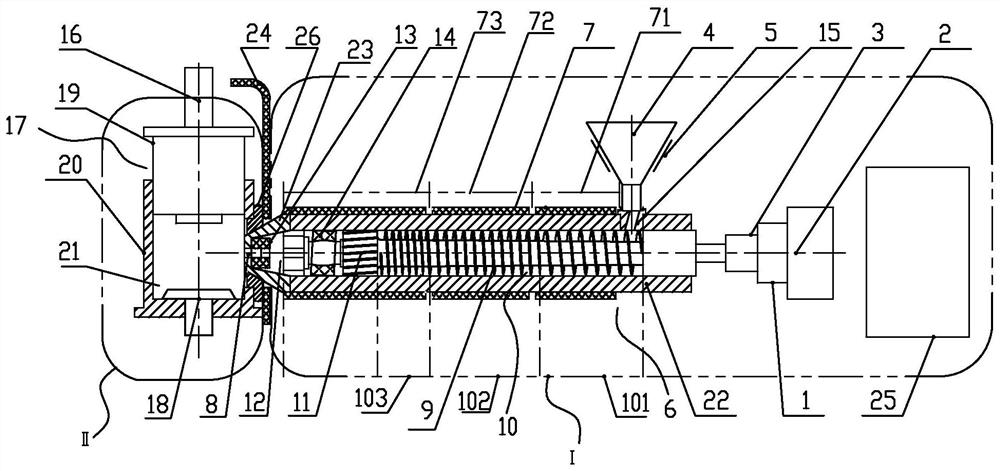

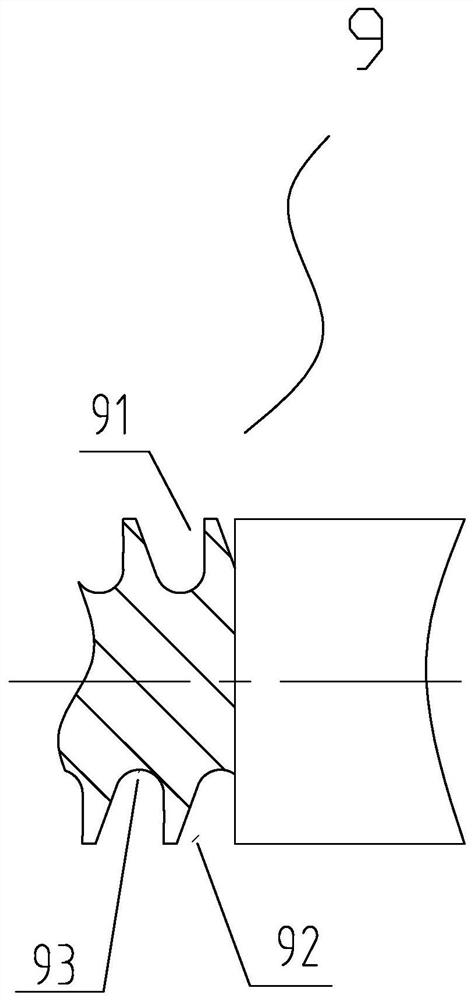

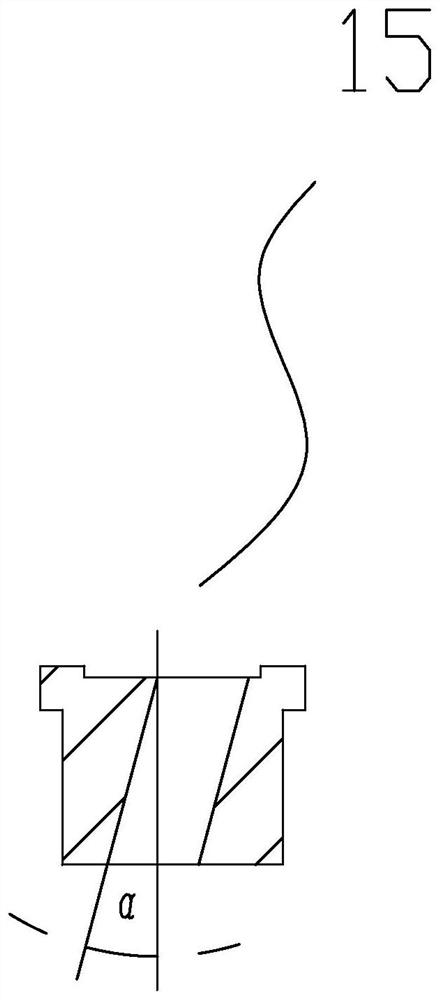

Non-ferrous metal particle semi-solid forming equipment and process

ActiveCN111390139AHigh surface finishGood compactnessMolten metal supplying equipmentsMaterial storageNonferrous metal

The invention discloses non-ferrous metal particle semi-solid forming equipment. The non-ferrous metal particle semi-solid forming equipment comprises a first-section horizontal feeding mechanism anda second-section vertical forming mechanism, wherein the first-section horizontal feeding mechanism is used for conveying, melting, mixing and storing metal particles and feeding the metal particles into a forming die cavity; the first-section horizontal feeding mechanism is provided with a horizontal feeding tube device, a segmented gradient heating system sleeving the feeding tube device, a material storage device in butt joint with the feeding tube device in a shear opening structure and a drying system arranged outside the material storage device; the second-section vertical forming mechanism is used for realizing die forging casting forming; and the working direction of the first-section horizontal feeding mechanism is arranged perpendicular to the working direction of the second-section vertical forming mechanism, the first-section horizontal feeding mechanism communicates with the interior of the second-section vertical forming mechanism, and the first-section horizontal feedingmechanism and the second-section vertical forming mechanism are in butt joint in a sealed mode through a smooth type material outlet to realize the horizontal feeding and vertical forming. The invention further discloses a non-ferrous metal particle semi-solid forming process.

Owner:刘兴军

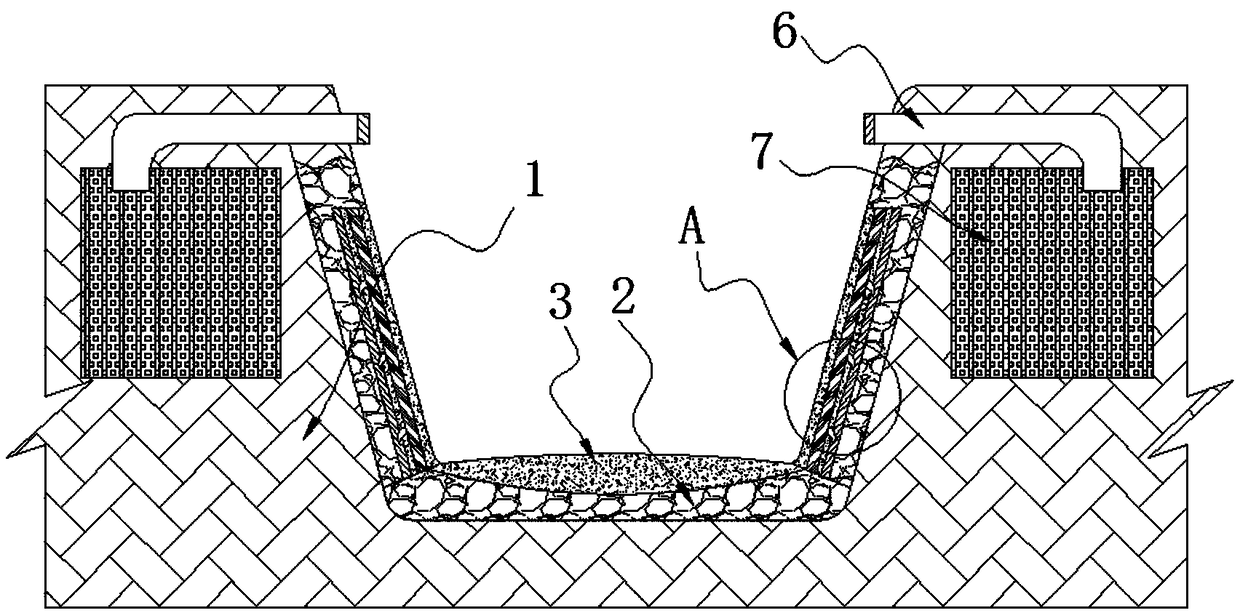

Ecological drainage ditch system of sponge city and construction method

InactiveCN109487901AAchieve water absorptionRealize water storageFatty/oily/floating substances removal devicesSewerage structuresWater storageSoil horizon

The invention discloses an ecological drainage ditch system of a sponge city and a construction method. The system comprises a base soil layer, a gravel layer, a planting soil layer, a fixed plate, abarb, a rectangular through hole, a water seepage layer, a water pipe, a water seepage box body a water permeable hole and permeable geotextile. The municipal ecological drainage ditch system can effectively alleviate the impact of heavy rain on the ecological drainage ditch system, and the high permeability of the ecological drainage ditch system can meet the permeation demand of high precipitation. Not only the greening rate is high, but also certain functions of water purification, water storage, water seepage and water drainage can be achieved. An ecological drainage ditch meets the demandfor building ecological civilization, improves the urban environment, and better maintains the ecological balance. Further, due to the fact that the structure contains organic soil, the microbial community can be formed quickly. The soil is not hardened, the ecological system can be sustained to meet the demand of the sponge city, and the heat island effect of the city can be eliminated and relieved to some extent.

Owner:杞梓林生态建设有限公司

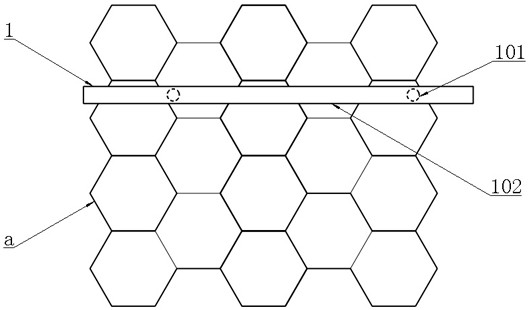

Module type soil pressure applying and forming device and processing method of soft soil foundation

InactiveCN108677911APlay a blocking rolePrevent sideways movementSoil preservationEngineeringUnit structure

The invention discloses a module type soil pressure applying and forming device. The module type soil pressure applying and forming device comprises a top frame, a pressure applying forming module anda soil body strength detecting device, wherein the pressure applying forming module comprises a plurality of convex bodies, and the top of the pressure applying forming module is connected with the top frame. The invention further discloses a processing method of a soft soil foundation, and is used for extruding, draining and forming a soil body by adopting the module type soil pressure applyingand forming device. The device can be integrally manufactured and can also be manufactured in a unit splicing mode. Different functional components can be added on each unit according to needs. The manufacturing mode of unit splicing is adopted, and the size of each unit is small, so that the manufacturing is simpler, and the manufacturing difficulty and the manufacturing cost can be reduced. Moreover, the units can be used as standard sizes or as a series of products, and each series of unit structures are the same in size, so that splicing is carried out according to design or construction requirements, and the design and the use are more flexible.

Owner:HANGZHOU YONGCHUANG INFRASTRUCTURAL ENG SCI & TECHCAL CO LTD

Construction method of collaborative backfill of hydraulic dynamic compaction machine and flat plate roadpacker

InactiveCN108867615AFlexible moving processRealize mechanized workSoil preservationDynamic compactionAbutment

The invention relates to the field of roadbed construction, in particular to a construction method of collaborative backfill of a hydraulic dynamic compaction machine and a flat plate roadpacker. Theprocess of collaborative backfill includes the following steps of check before backfill; backfill in layers and preliminary compaction; high-speed hydraulic dynamic compaction; detection, wherein in the step of high-speed hydraulic dynamic compaction, a bridge abutment back, a culvert table back, a retaining wall back and a pipe network groove are compacted in sequence. Compared with a traditionalmethod, the advantages that part movement is more flexible, the efficiency is higher, the consistency of the backfill compaction degree is further guaranteed while the backfill compaction construction quality is guaranteed, the safety performance is higher, and construction is more convenient and reliable are achieved. The flexibility advantage of the construction method is more obvious especially for some regions which are narrow and irregular and have certain depth.

Owner:CHONGQING CONSTR ENG MUNICIPAL TRAFFIC ENG +1

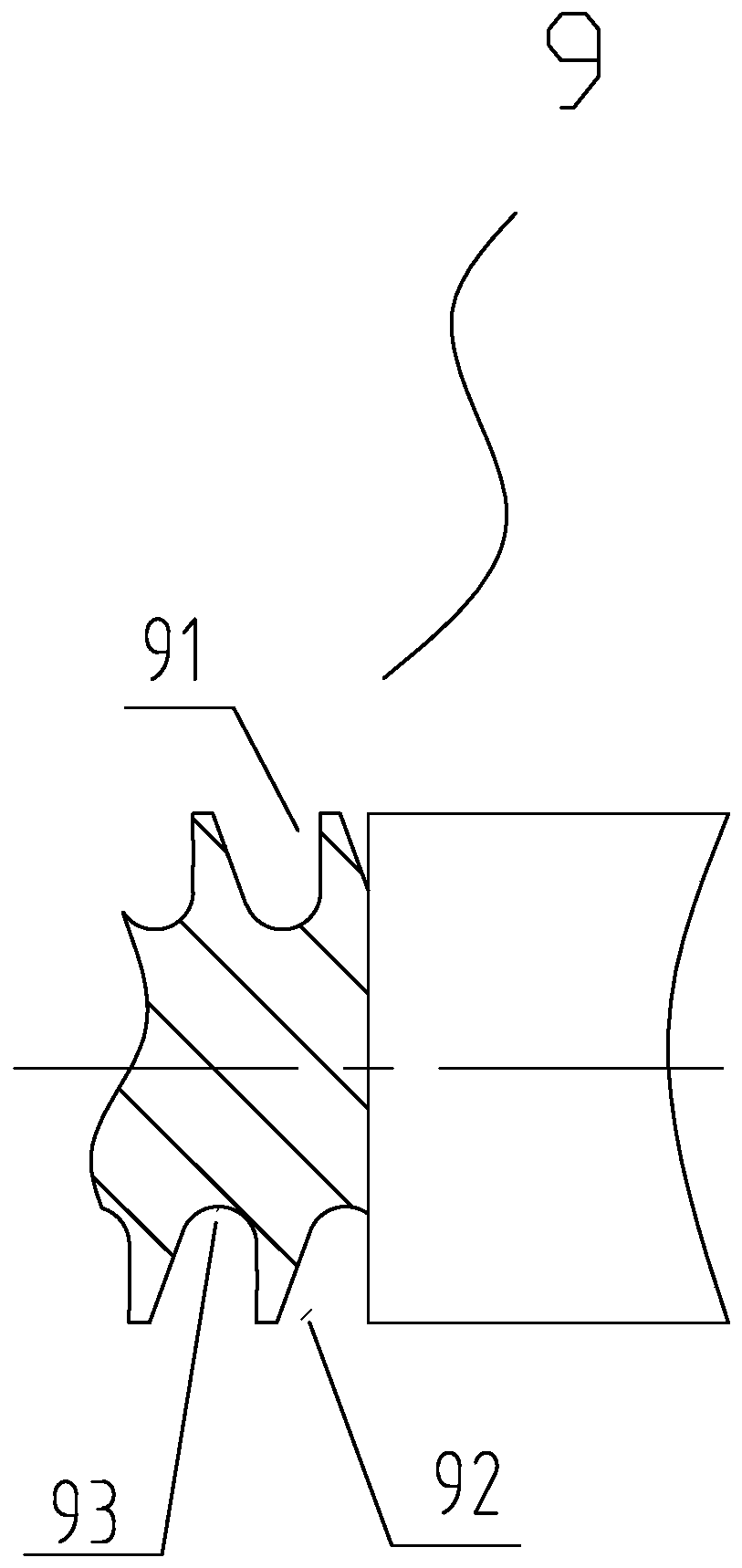

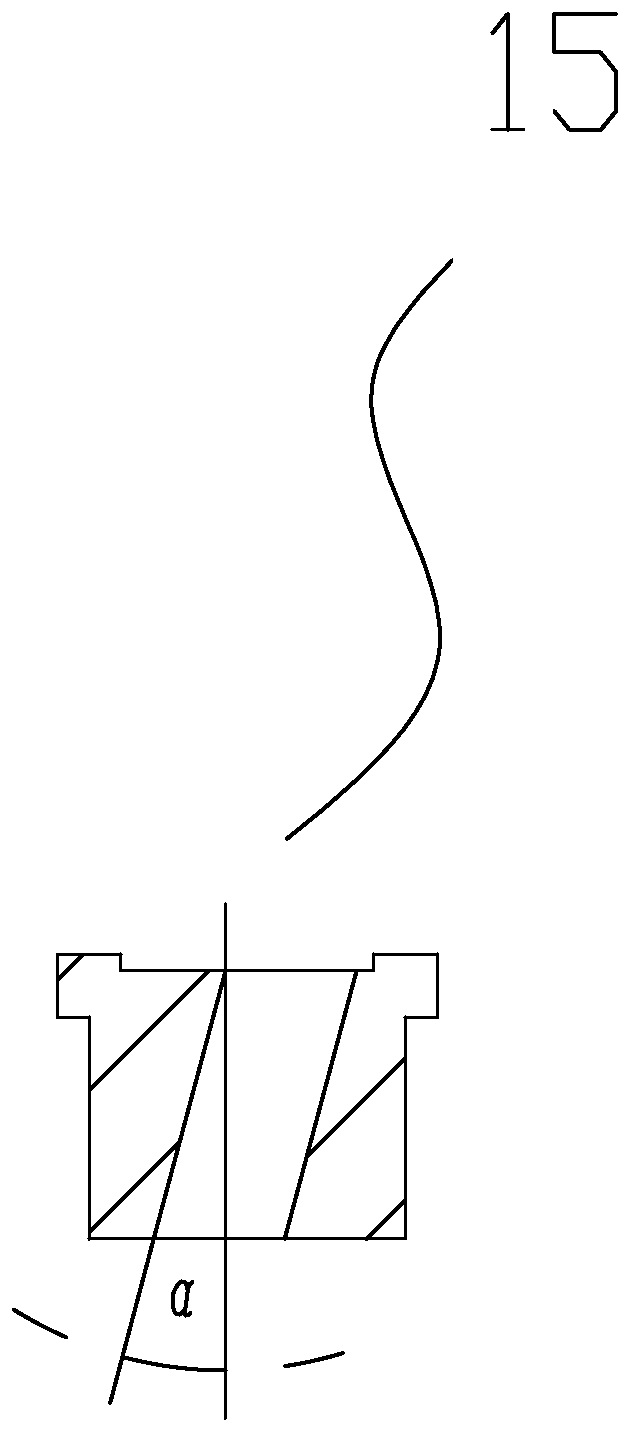

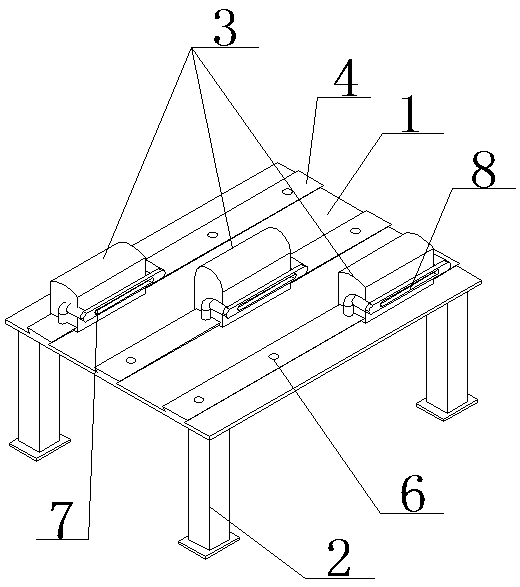

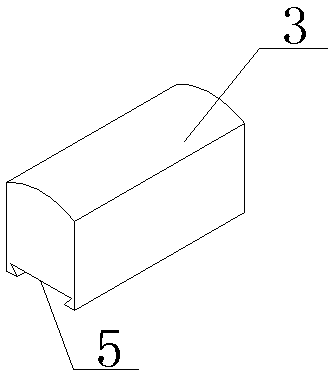

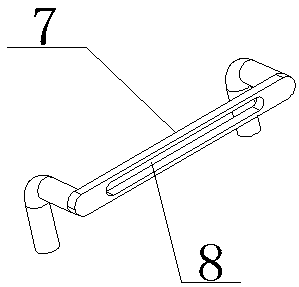

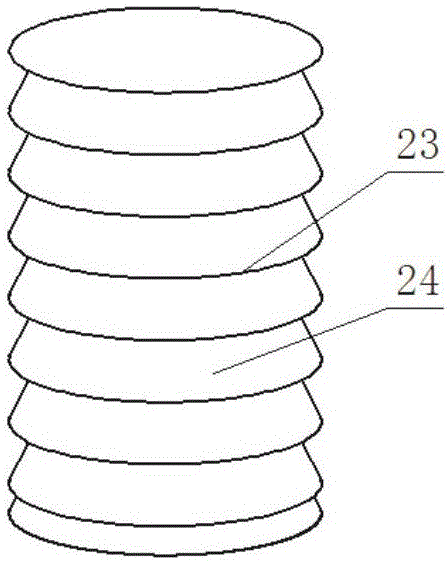

Simple tire semi-finished product joint pressing machine

The invention discloses a simple tire semi-finished product joint pressing machine, and belongs to the technical field of processing devices for tire production. The simple tire semi-finished productjoint pressing machine overcomes the defect of the prior art that the pressing of the joints of the tires of different models by workers or plane pressing machines is not firm, the defective rate is increased, the production and manufacturing cost of the tires is increased, and the quality and production efficiency of the tire are degraded. The simple tire semi-finished product joint pressing machine adopts the technical scheme that the simple tire semi-finished product joint pressing machine comprises a support plate, wherein an even number of support legs is symmetrically arranged at the bottom part of the support plate; a plurality of pressing plates are movably arranged at the top part of the support plate; a plurality of bulges are arranged on the support plate; the bottom part of each pressing plate is provided with a groove which is matched with the corresponding bulge; each pressing plate and the support plate are connected in a slide fit way via the fit connection of the bulges and the grooves; each pressing plate is a pressing plate which is of a rectangular block structure, and is provided with an arc-shaped top part.

Owner:山东汉正橡胶工业有限公司

Vibrating repair compaction device for highway

InactiveCN108360353ASimple structureFast compactionRoads maintainenceVibration exciterIndustrial engineering

Owner:CENXI DONGZHENG POWER TECH DEV

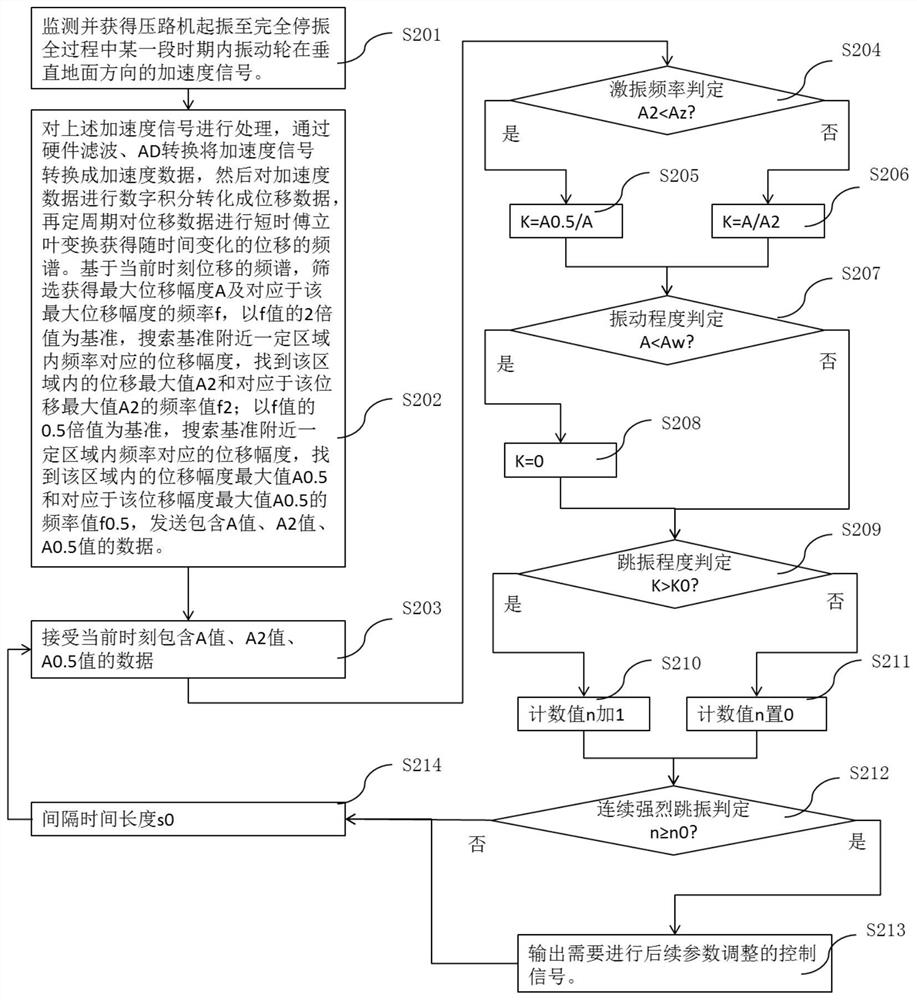

Vibration auxiliary control method and control system of vibratory roller and vibratory roller

PendingCN113867205ASimple structure and operationSimple structureProgramme controlComputer controlStructural engineeringControl system

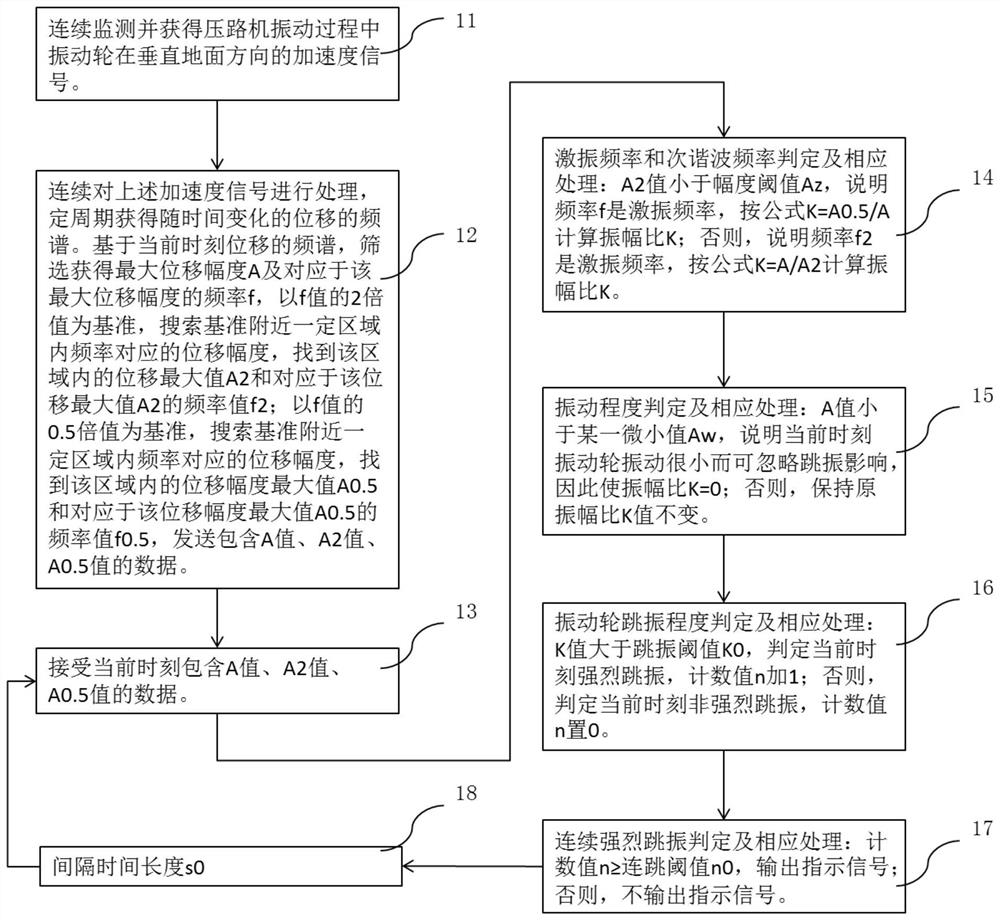

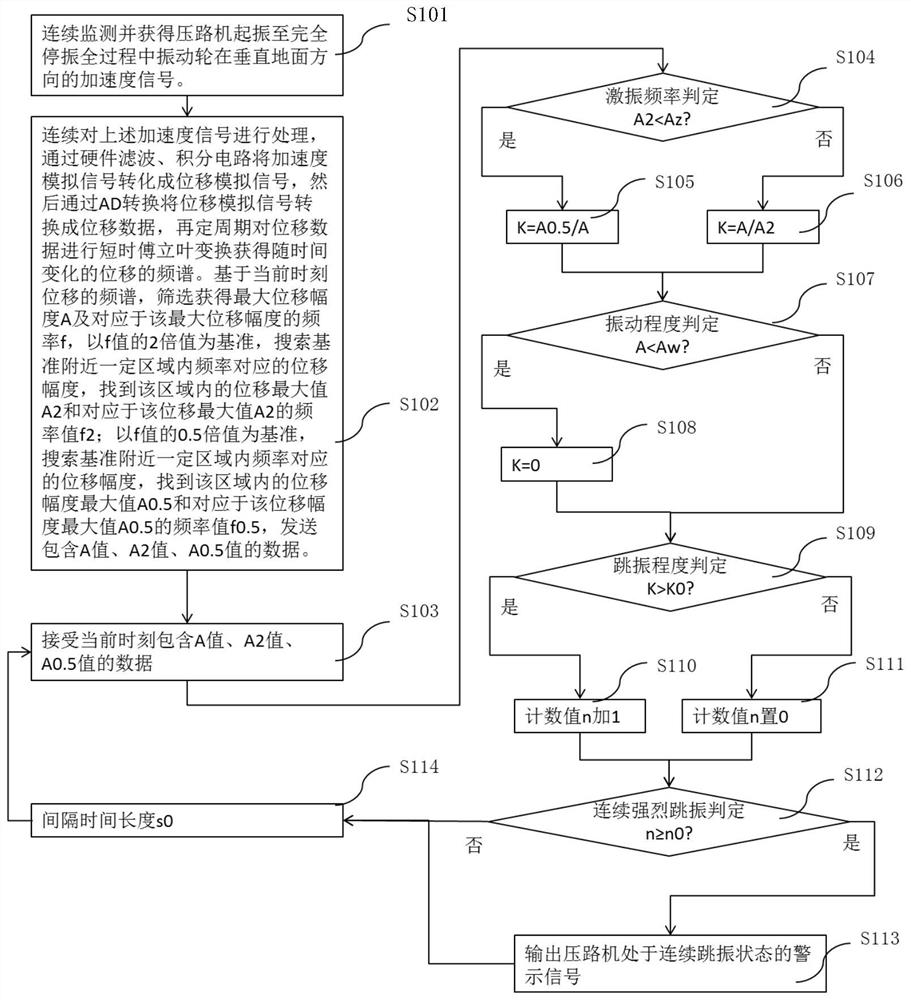

The invention discloses a vibration auxiliary control method and system for a vibratory roller and the vibratory roller. The auxiliary control method comprises the following steps: acquiring excitation frequency, subharmonic frequency and corresponding amplitude through area search; judging the vibration degree, so that misjudgment caused by errors of a measurement system when the road roller is in a vibration-free or weak-vibration state is reduced; intelligently determining the jump vibration degree of the vibration wheel of the road roller by setting an amplitude threshold value, grading the jump vibration degree, and taking corresponding measures. According to the invention, the compaction capability can be enhanced by utilizing jump vibration, so that the soil can be rapidly compacted, and the auxiliary control of the road roller is realized.

Owner:XCMG CONSTR MACHINERY

Combined reinforcing method for soil by drainage consolidation via mechanical pressurizing and compaction

InactiveCN109208569APlay a blocking rolePrevent sideways movementSoil preservationEngineeringHigh water content

The invention discloses a combined reinforcing method for soil by drainage consolidation via mechanical pressurizing and compaction. The method is characterized by comprising the following steps that1) engineering undisturbed soil is laid with at least one layer of geotechnical reinforcement material; and 2) a modularized soil pressurizing and forming device carries out pressurizing compaction drainage and consolidation on the soil, so that the laid geotechnical reinforcement material and the soil are extruded and mixed mutually, composite reinforcement is realized between the soil and the geotechnical reinforcement material, and the constructional weak soil is reinforced. The modularized soil pressurizing and forming device comprises a top rack, a pressurizing and molding module and a soil intensity detector, and the pressurizing and molding module comprises protruded bodies. The soil is extruded for drainage and molded rapidly, and the method is suitable for reinforcing soft soil foundations in a shallow or intermediate shallow layer, and especially for drainage and consolidation on weak soil with high water content as mud, fluid mud, sandy soil, mud and sand blown back fillingsoil, a pond, a lake, a dam, a deposition pond and mining mixed soil and the like.

Owner:HANGZHOU YONGCHUANG INFRASTRUCTURAL ENG SCI & TECHCAL CO LTD

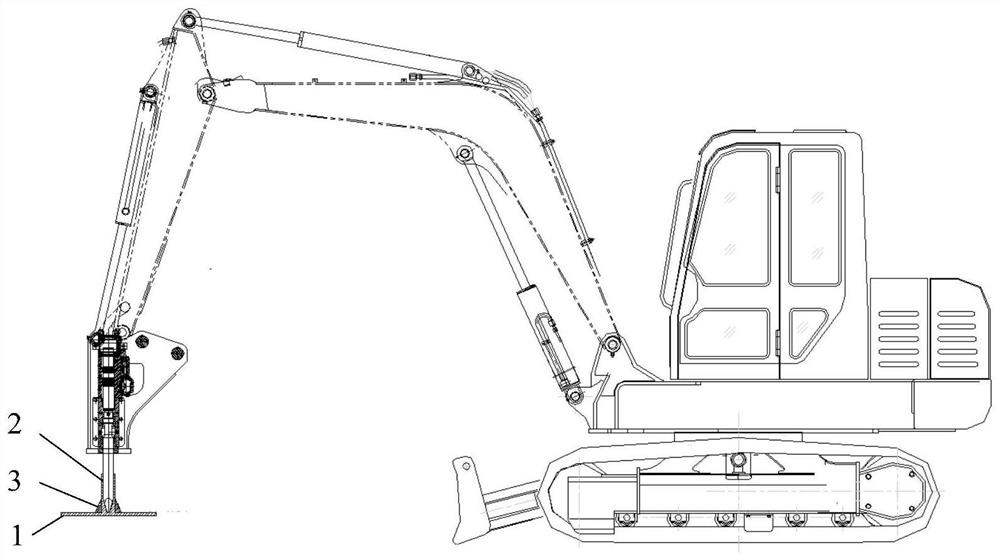

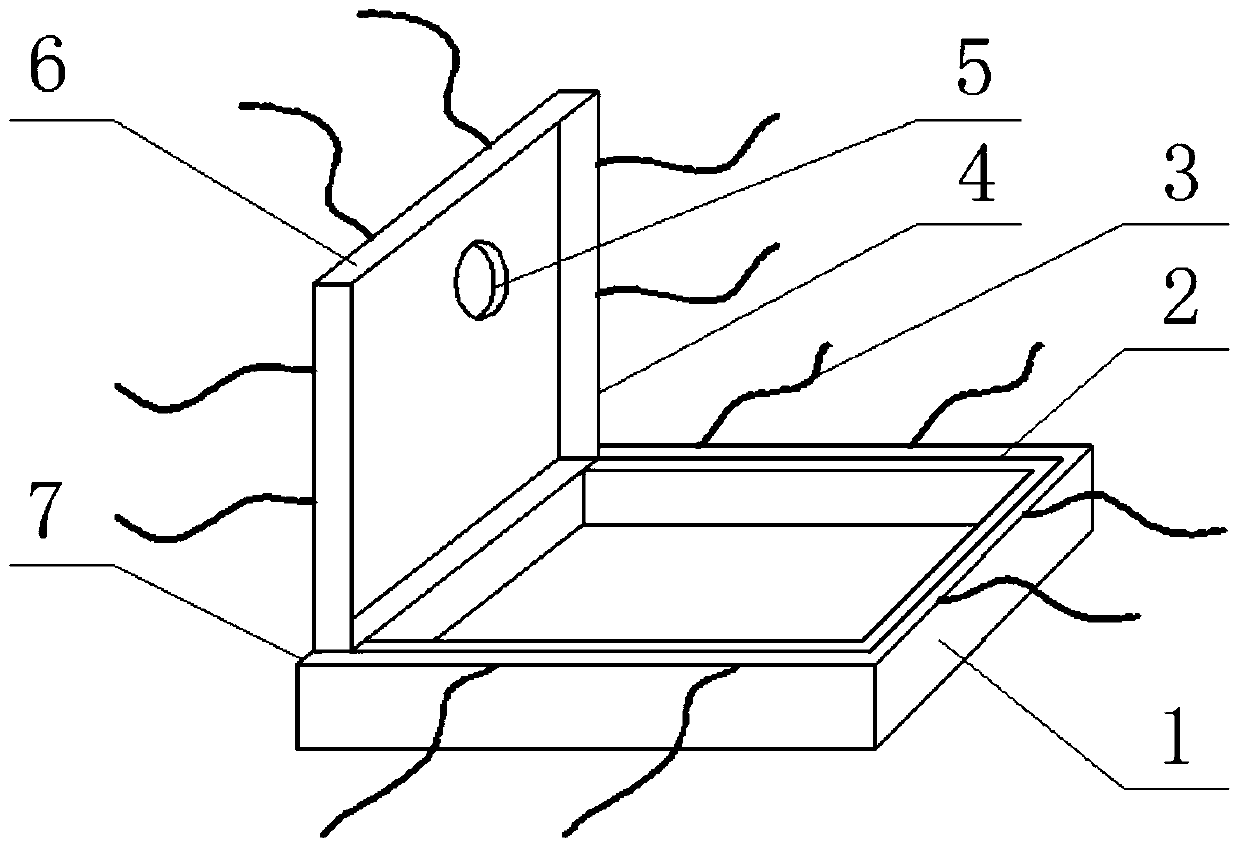

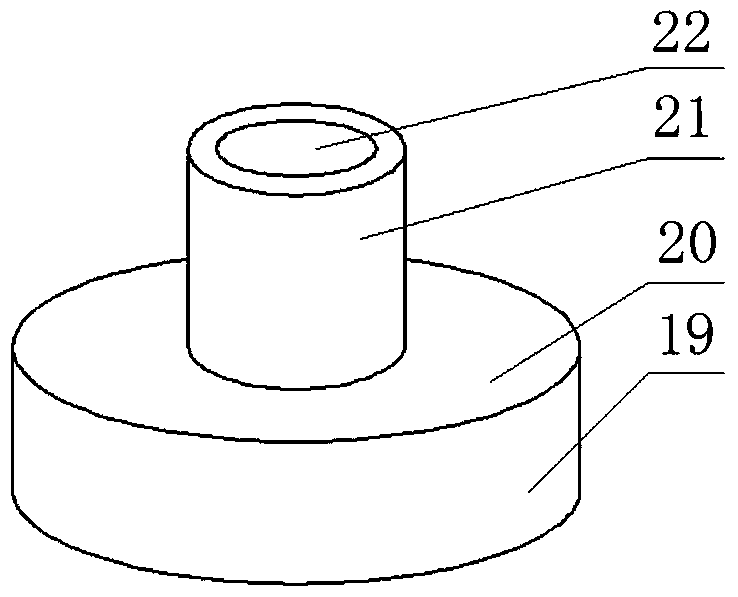

Tamping tool and tamping equipment

PendingCN113417277AFast compactionImprove compaction qualityMechanical machines/dredgersRoads maintainenceArchitectural engineeringExcavator

The invention relates to the technical field of building construction, and discloses a tamping tool and tamping equipment. The tamping tool comprises a pressing plate and a sleeve, wherein the bottom surface of the pressing plate is of a plane structure for compaction; and the central axis of the sleeve is perpendicular to the bottom surface of the pressing plate, the bottom end of the sleeve is fixedly connected with the upper surface of the pressing plate, and an inner hole in the top end of the sleeve is matched with the bottom end of a pickaxe of a breaking hammer. The tamping equipment comprises an excavator cab, the excavator breaking hammer and the tamping tool, wherein the excavator breaking hammer is detachably connected with the sleeve of the tamping tool. According to the tamping tool and the tamping equipment, a small-area can be compacted, and the compaction strength is guaranteed to reach the standard.

Owner:THE FOURTH OF CHINA EIGHTH ENG BUREAU

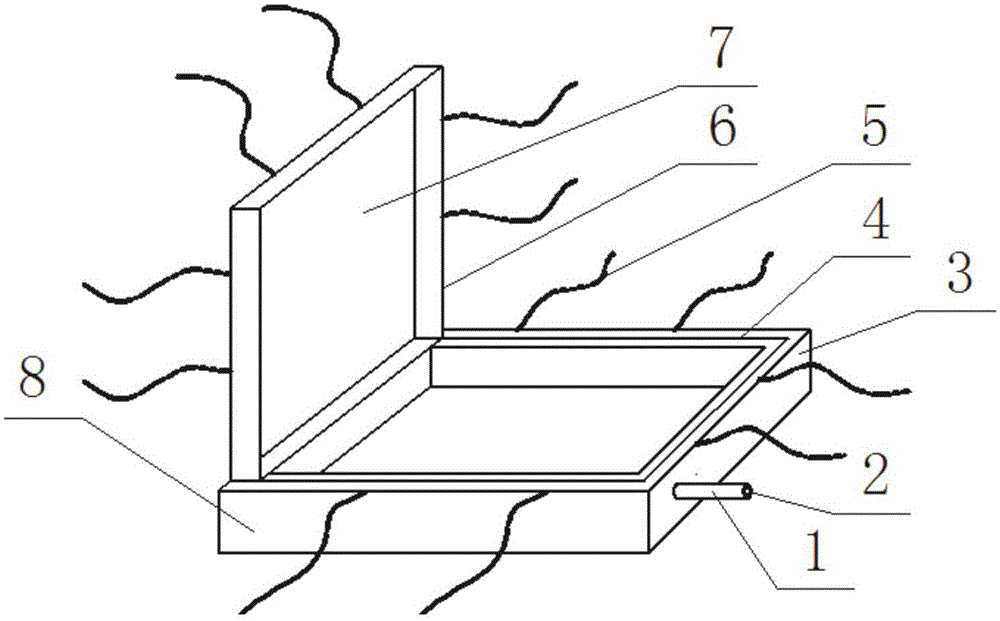

Negative pressure compactor for quilt netting twine

ActiveCN105011649ATightly boundFast compactionNon-woven fabricsBed-coversEngineeringAtmospheric pressure

The invention discloses a negative pressure compactor for quilt netting twine. The compactor mainly comprises a quilt bag and an engine base, wherein the quilt bag is connected to an air pump installed on the engine base by a connecting pipe. Trough the compactor, air is pumped out of the quilt bag so that inner space of the quilt bag is under negative pressure, and the quilt in the bag is compacted by atmospheric pressure. Thus, the netting twine and cotton are closely combined. The compactor proposed by this invention is time-saving and labour-saving and increases compacting speed. Meanwhile, the compactor is low-cost and easy to operate with simple structure.

Owner:GUANGXI UNIV

Rubber asphalt compacting technology based on pavement quality indicator

InactiveCN102345269BNo safety hazardNo damageRoads maintainenceSpecific gravity measurementNon destructiveSurface layer

The invention belongs to the field of non-destructive testing, and discloses a rubber asphalt compacting technology based on a pavement quality indicator. According to the invention, density data is collected from a rubber asphalt pavement testing path; a relationship figure of the two is drawn; read numbers on the pavement quality indicator are scaled; and real-time monitoring and compaction optimization are carried out upon the compaction degree of the asphalt layer of the rubber asphalt pavement by using the pavement quality indicator. With the technology provided by the invention, the asphalt structural layer of the rubber asphalt pavement is not damaged, the compaction degree of a rubber asphalt surface layer can be simply, rapidly and accurately controlled, and the rolling process of a roller can be optimized. The technology can be simply applied in on-site operations, and provides advantages of no radiation, no damage, and low testing cost.

Owner:GUANGZHOU UNIVERSITY

Special micro-expansion corundum wear-resistant coating for waste heat air pipe

PendingCN113651622AEnough integrityExtended crushing timeThermal insulationPipe protection by thermal insulationCarbide siliconAggregate (composite)

The invention belongs to the technical field of wear-resistant coatings, and particularly relates to a special micro-expansion corundum wear-resistant coating for a waste heat air pipe. A wear-resistant aggregate is used, a composite expanding agent and a plastic sintering aid are newly added, and an arc-shaped scraping frame is used for compacting the wear-resistant coating, so that the effect that the wear-resistant coating can be stably attached to the hexsteel for a long time is achieved. Compared with the prior art, the invention has the following advantages that firstly, the wear-resistant aggregate containing corundum and silicon carbide provides enough wear resistance for the final lining layer, and the plastic sintering aid containing clay and boron gangue provides enough integrity for the final lining layer, so that the self-crushing time of the lining layer is prolonged; and secondly, kyanite and silica have the heated micro-expansion performance, actively expand and are clamped in the hexsteel, and the whole block is not prone to falling off.

Owner:长兴兴鹰新型耐火建材有限公司

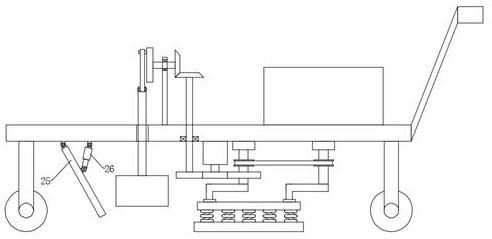

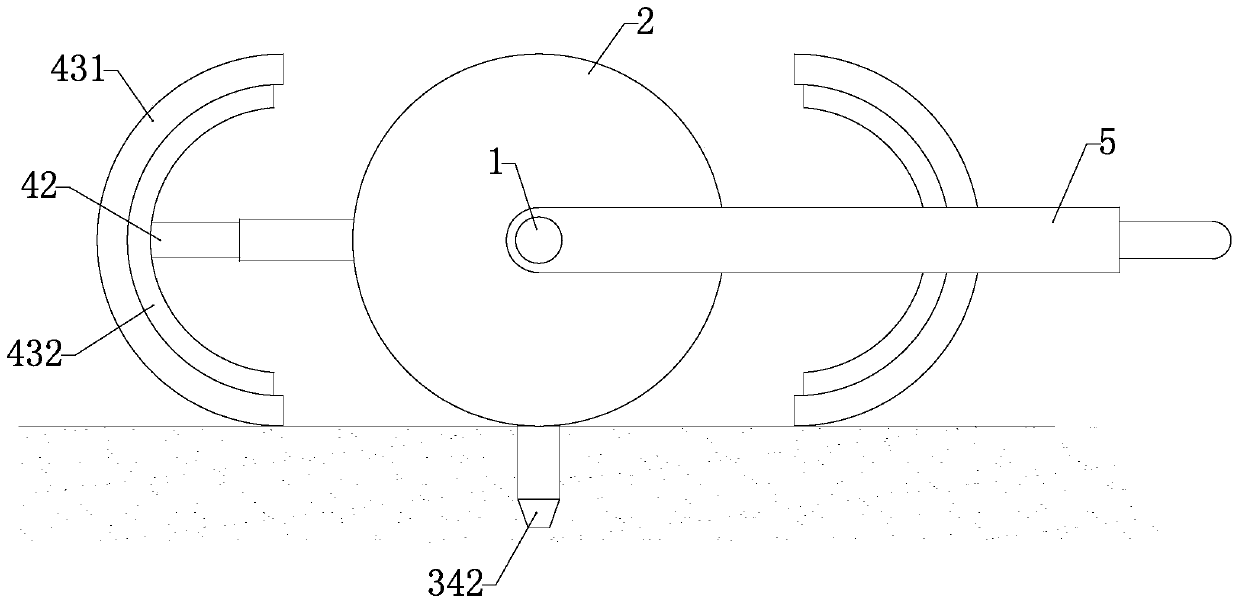

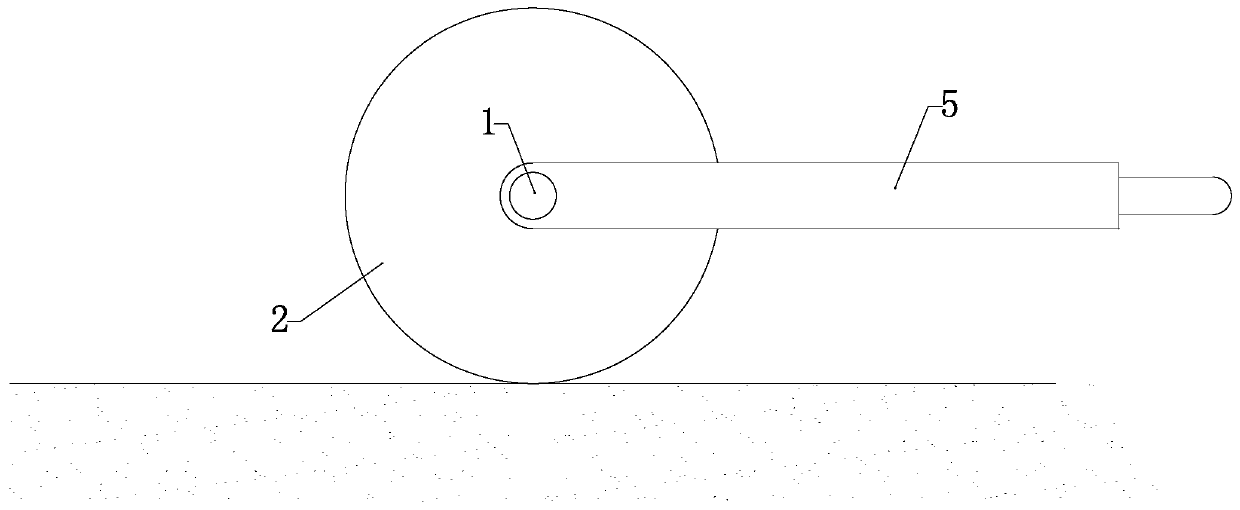

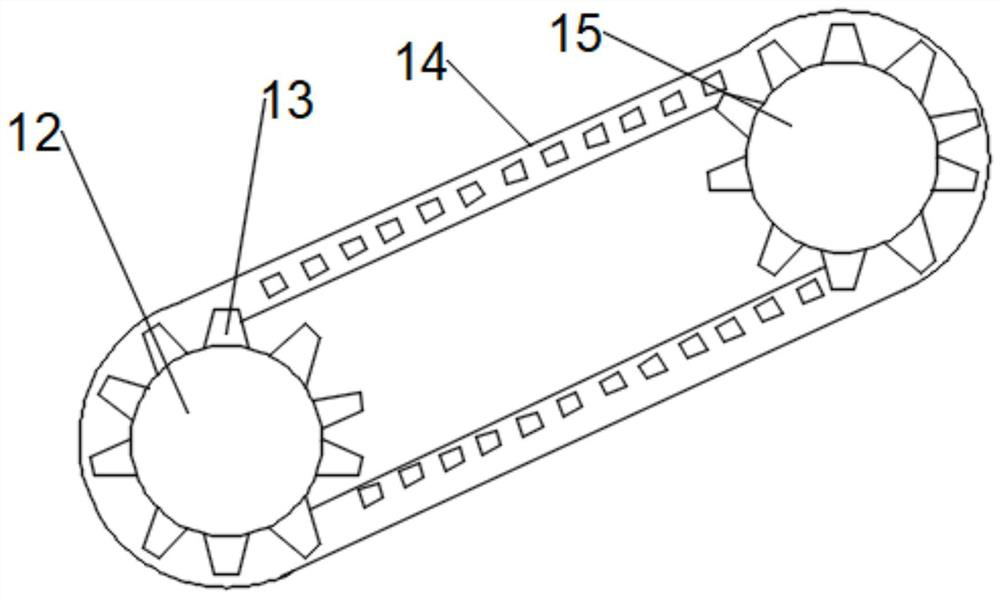

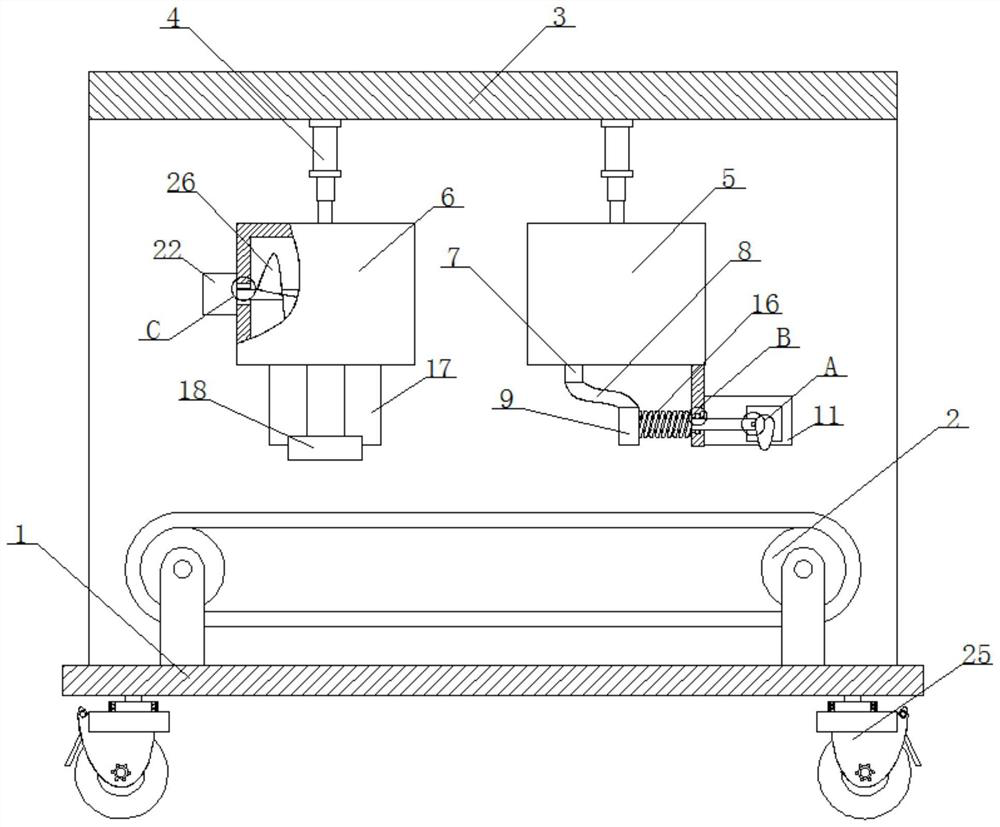

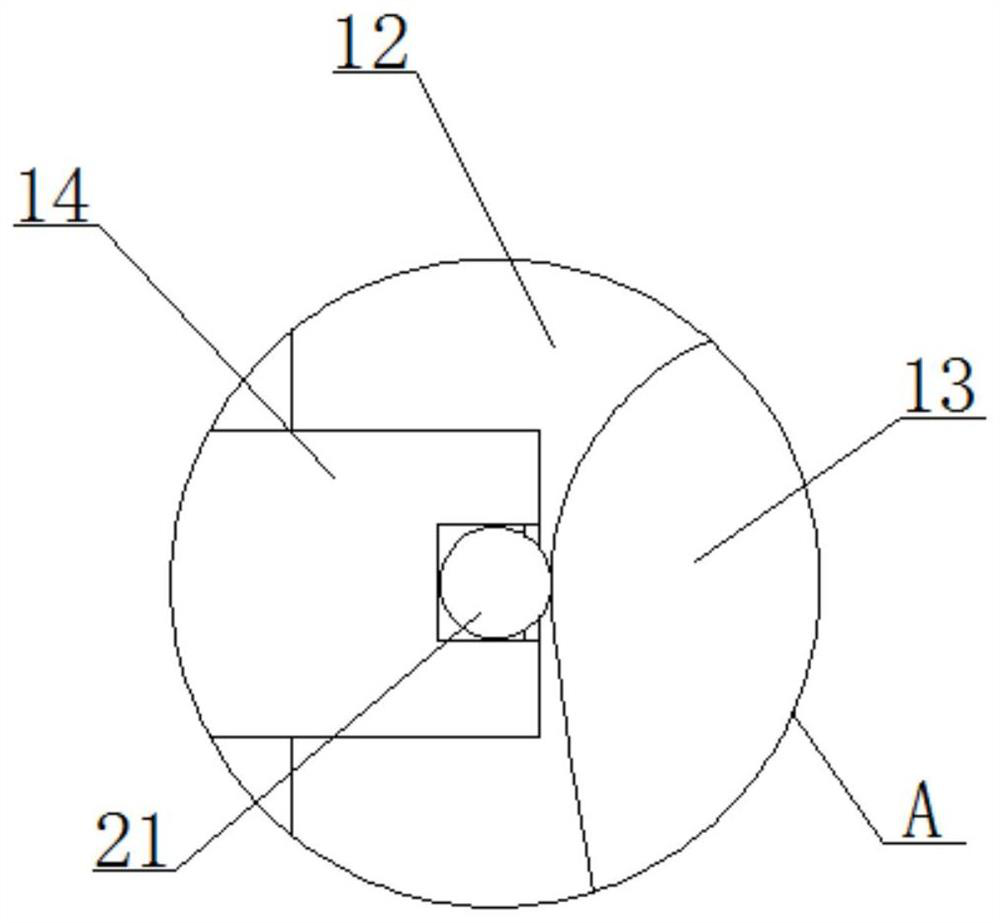

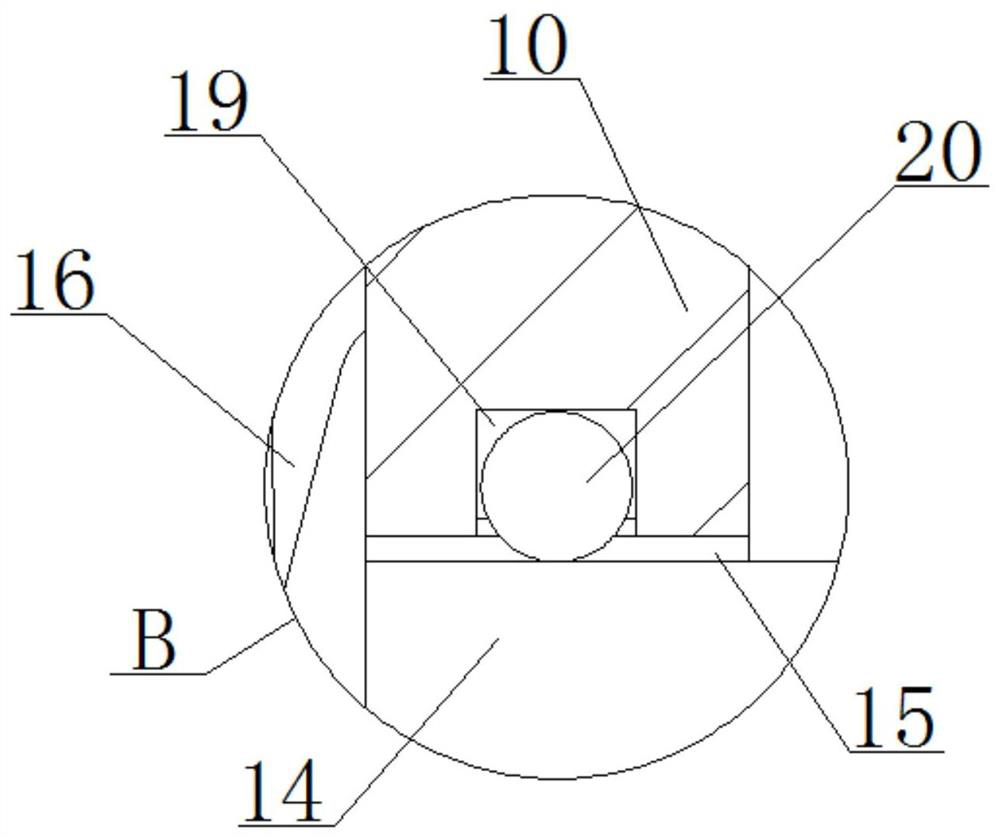

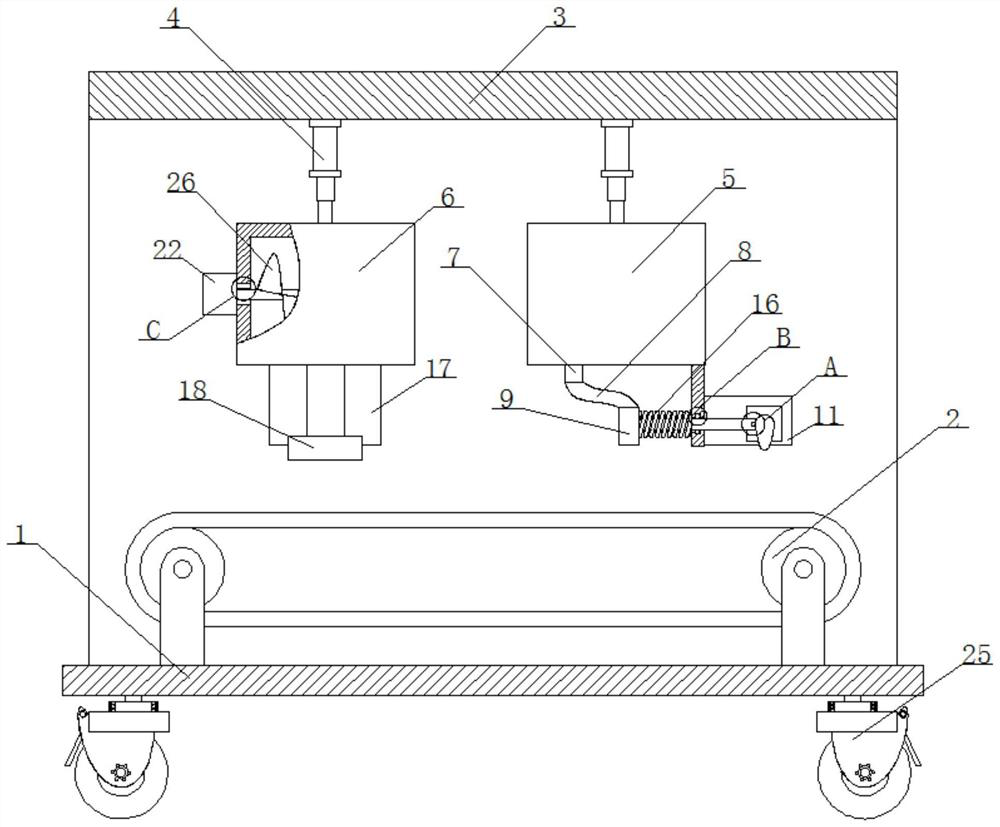

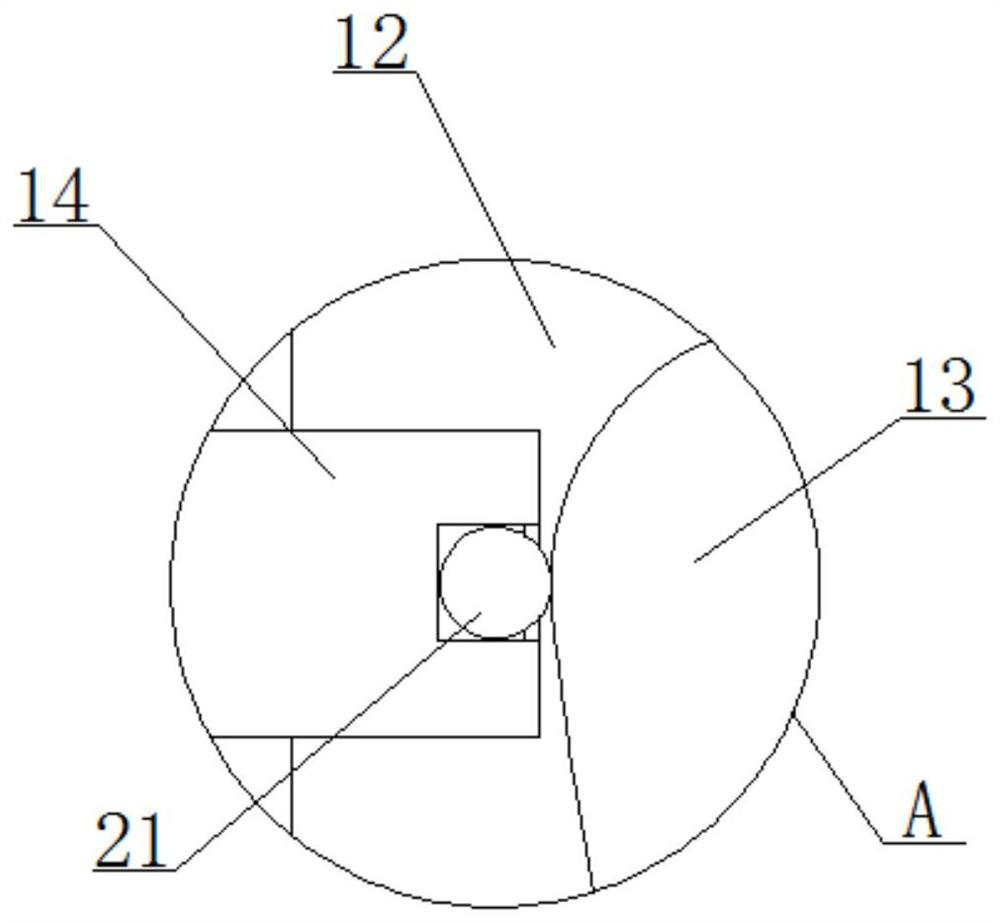

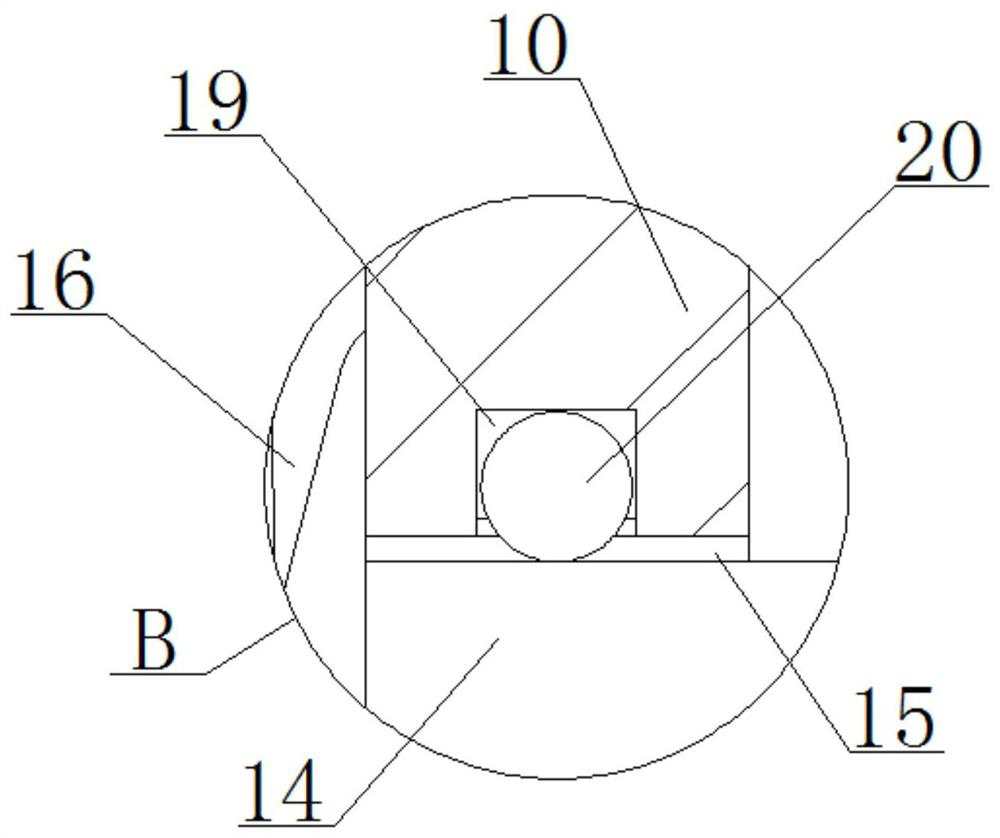

Expansive soil section highway protective construction quick drilling and pile driving equipment

ActiveCN110644922ARealize separation deformationFast compactionDerricks/mastsRoads maintainenceDrill holeGeotechnical engineering

The invention relates to the field of highway protective construction, in particular to expansive soil section highway protective construction quick drilling and pile driving equipment. The equipmentcomprises a main shaft horizontally shaft; the two ends of the main shaft are movably inserted in bearing holes of the middle parts of support wheel bodies at the two ends; a drilling and pile drivingmechanism capable of being quickly converted is arranged at the middle part of the main shaft; the drilling and pile driving mechanism is used for realizing drilling and pile driving of pavements; separate pavement compaction mechanisms are symmetrically arranged on the inner and outer sides of the main shaft between the two support wheel bodies; and the pavement compaction mechanisms are used for compaction of pavements and protective supporting of the drilling and pile driving mechanisms. The equipment can quickly realize the separation deformation of the pavement compaction mechanisms in the procedures of drilling, pile driving and compaction, and realizes stable supporting of the whole equipment; and the pavement compaction mechanisms can serve as road rollers during storage of the equipment, and meanwhile, achieve supporting and protecting effects on internal structures.

Owner:驻马店市华中公路设计有限公司

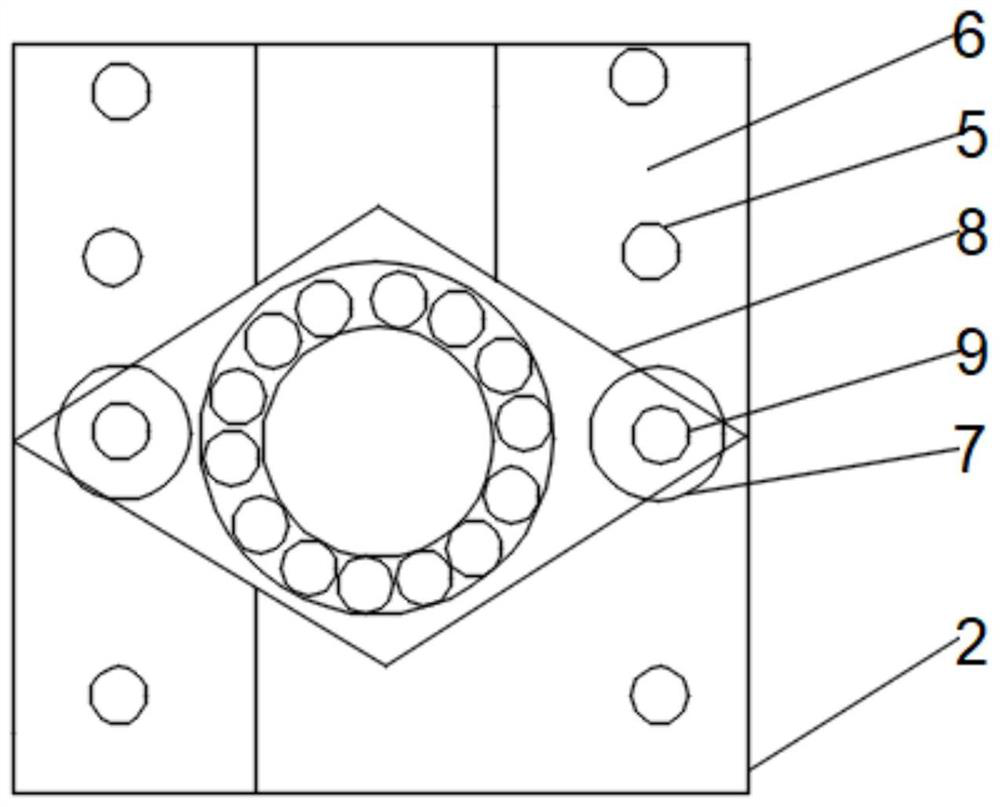

Compacting device for a seeder

ActiveCN107535125BHeight adjustableEasy to compressPlantingFurrow making/coveringSeederAgricultural engineering

Owner:阜阳扬宇充电设备有限公司

Semi-solid molding equipment and process for non-ferrous metal particles

ActiveCN111390139BHigh speedReduce manufacturing costMolten metal supplying equipmentsMolding machineEngineering

The invention discloses a non-ferrous metal granule semi-solid forming equipment, comprising: a section horizontal feeding mechanism, the said one section horizontal feeding mechanism is used to realize metal particle transportation, melting, mixing, storage, into the molding cavity; the one-section horizontal feeding mechanism is equipped with: a barrel device arranged horizontally, a segmental gradient heating system set outside the barrel device, and a shear opening structure with the barrel device The docked material storage device and the drying system arranged outside the material storage device; the two-section vertical forming mechanism, the two-section vertical forming mechanism is used to realize die forging and die-casting; the one-section horizontal feeding mechanism The working direction of the two-section vertical forming mechanism is perpendicular to that of the two-section vertical forming mechanism, and the first-section horizontal feeding mechanism is internally connected with the second-section vertical forming mechanism, and the horizontal feeding is realized through a smooth-type discharge port. , vertically shaped. Also disclosed is a non-ferrous metal particle semi-solid molding process.

Owner:刘兴军

A kind of ceramic tile production molding equipment

Owner:ANHUI PROVINCIAL HANSHAN MINSHENG PORCELAIN

Wool compacting device for spinning

InactiveCN108527908AEasy to fix the limitPrevent deviationDirt cleaningPress ramPulp and paper industryEngineering

The invention discloses a wool compacting device for spinning. The wool compacting device comprises a base, a pressing plate, an operating table and sliding rails, damping gaskets are arranged at fourcorners of the bottom end of the base, a door body is hinged to one side of the base, a control panel is installed on the door body, supporting columns are installed at the two ends of the top of thebase, a dust collector is installed on the supporting column at one end of the top of the base, sliding blocks cooperating with sliding grooves are arranged at the two ends of the bottom of the operating table, the sliding rails are arranged at the two ends of the top of the operating table, clamping plates are fixed on the sliding rails through the sliding blocks, the output end of a temperaturesensor is electrically connected with the input end of the control panel, and the output end of the control panel is electrically connected with the input end of a heating wire. According to the device, the pressing plate and a hydraulic telescopic rod are installed, and the heating wire are arranged at the bottom end inside the pressing plate, so that the wool can be conveniently compacted afterthe pressing plate is heated, the compaction speed is higher, and the effect is better.

Owner:YANCHENG JUNLONG YARN CO LTD

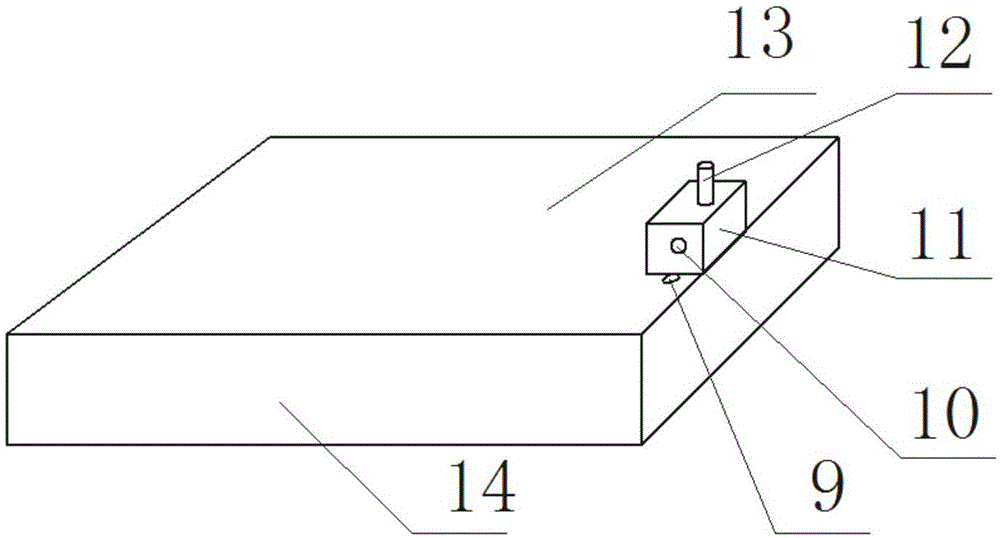

Negative-pressure quilt net wire compaction bag

ActiveCN105029971ATightly boundFast compactionNon-woven fabricsBed-coversEngineeringAtmospheric pressure

The invention discloses a negative-pressure quilt net wire compaction bag. The negative-pressure quilt net wire compaction bag mainly comprises a quilt bag body and an extraction valve. Due to the fact that the quilt bag body can be connected with an external extraction pump through the extraction valve, the negative-pressure quilt net wire compaction bag can extract air in the quilt bag body, and an air hole is sealed to enable the internal space of the quilt bag body to be in a negative-pressure state, so that a quilt in the quilt bag body is compacted by utilizing atmospheric pressure, and net wires are tightly combined with cotton. The negative-pressure quilt net wire compaction bag is time-saving, labor-saving, simple in structure, easy to operate and low in cost, and the compaction speed is increased.

Owner:GUANGXI UNIV

Negative pressure quilt network cable compactor

Owner:GUANGXI UNIV

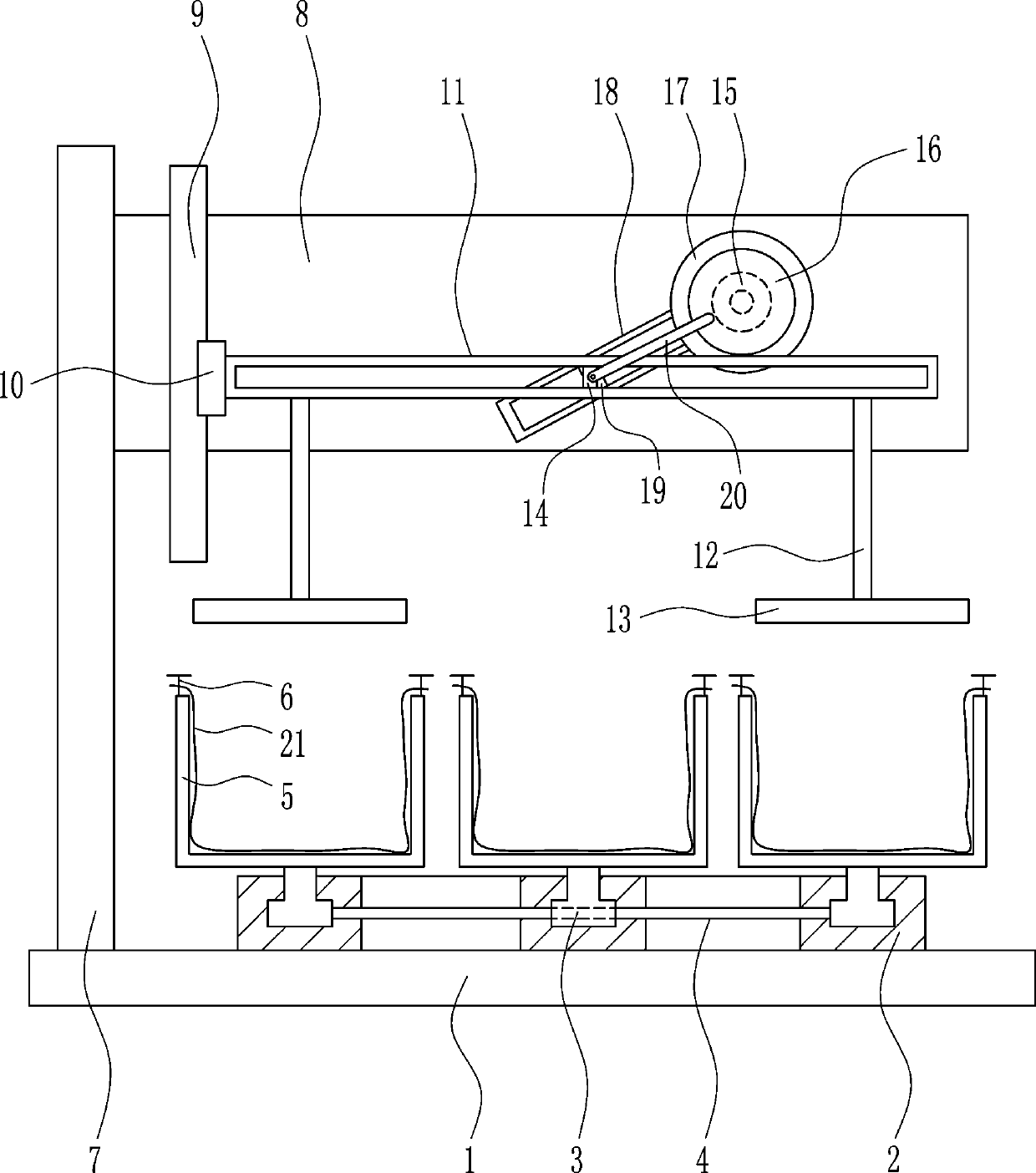

Ceramic tile production forming device

The invention relates to the technical field of ceramic tile manufacturing, and discloses a ceramic tile production forming device. The ceramic tile production forming device comprises a base, a conveying belt and an L-shaped supporting frame are fixedly connected to the upper end of the base, air cylinders are symmetrically and fixedly connected to the lower end of the horizontal end of the supporting frame, a ceramic tile clay storage bin and a body glaze storage bin are connected to the piston ends of the two air cylinders respectively, a clay extrusion head is connected to the lower end ofthe ceramic tile clay storage bin, and a uniform distribution mechanism is connected to the other end of the clay extrusion head. The uniform distribution mechanism comprises a hose, one end of the hose is connected with the end, away from the ceramic tile clay storage bin, of the clay extrusion head, and the other end of the hose is connected with a discharging pipe. The ceramic tile productionforming device can solve the problems that at present, as ceramic tile clay extruded by an extrusion head accumulates in a ceramic tile mold in a pile shape, a stamping head cannot rapidly flatten theceramic tile clay, and the ceramic tile clay in the ceramic tile mold cannot be compacted.

Owner:ANHUI PROVINCIAL HANSHAN MINSHENG PORCELAIN

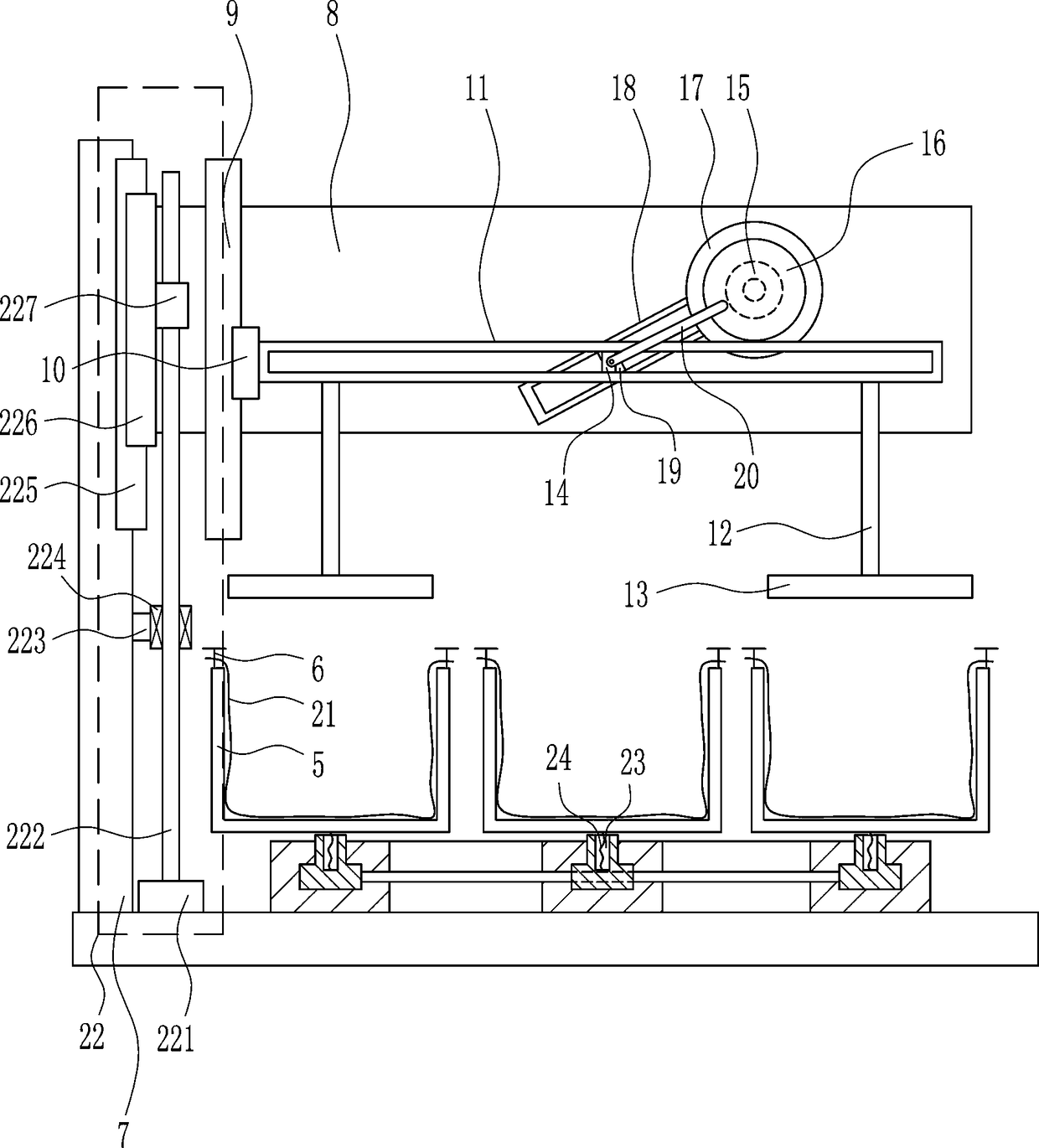

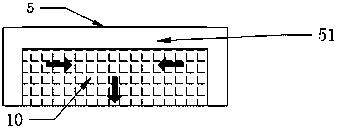

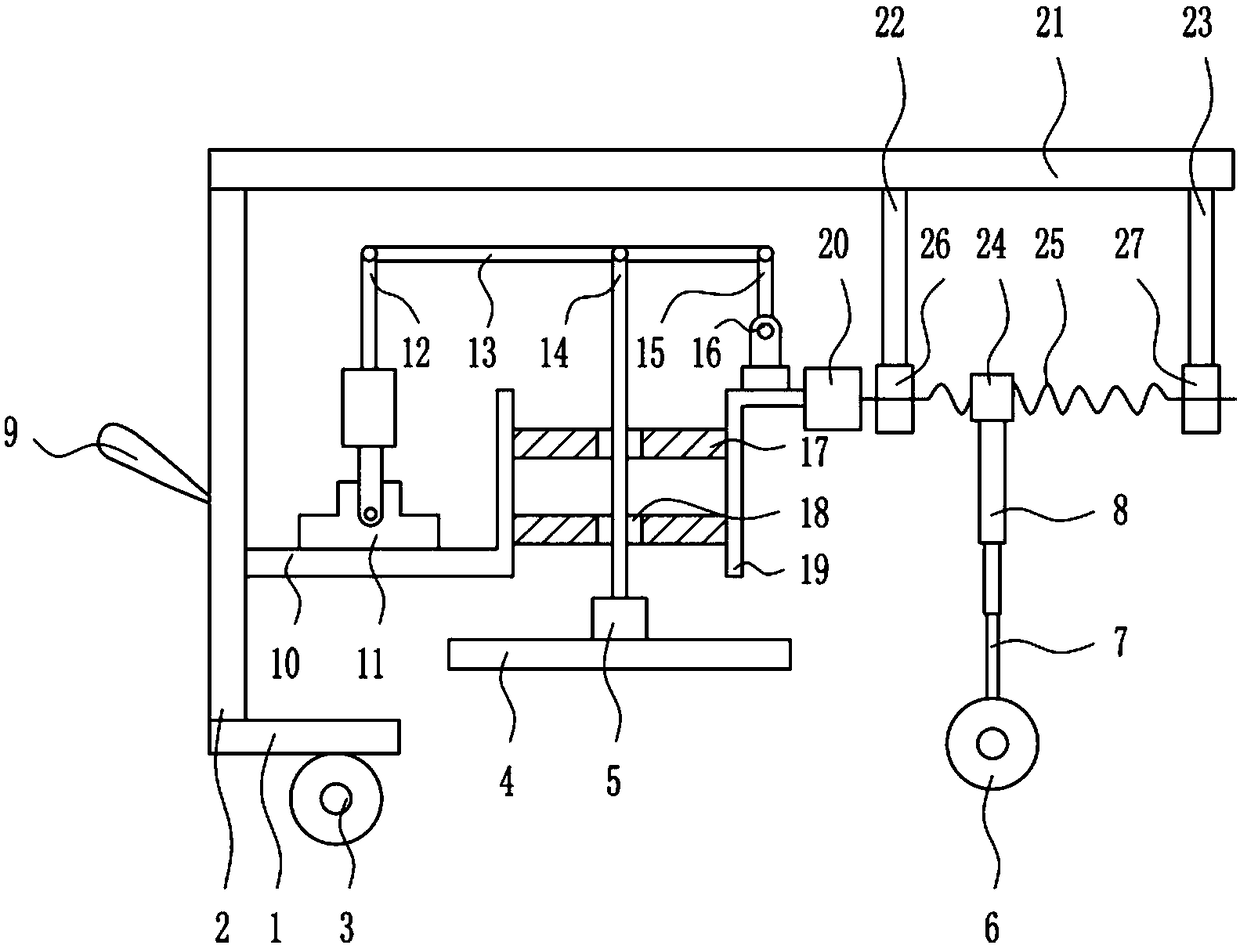

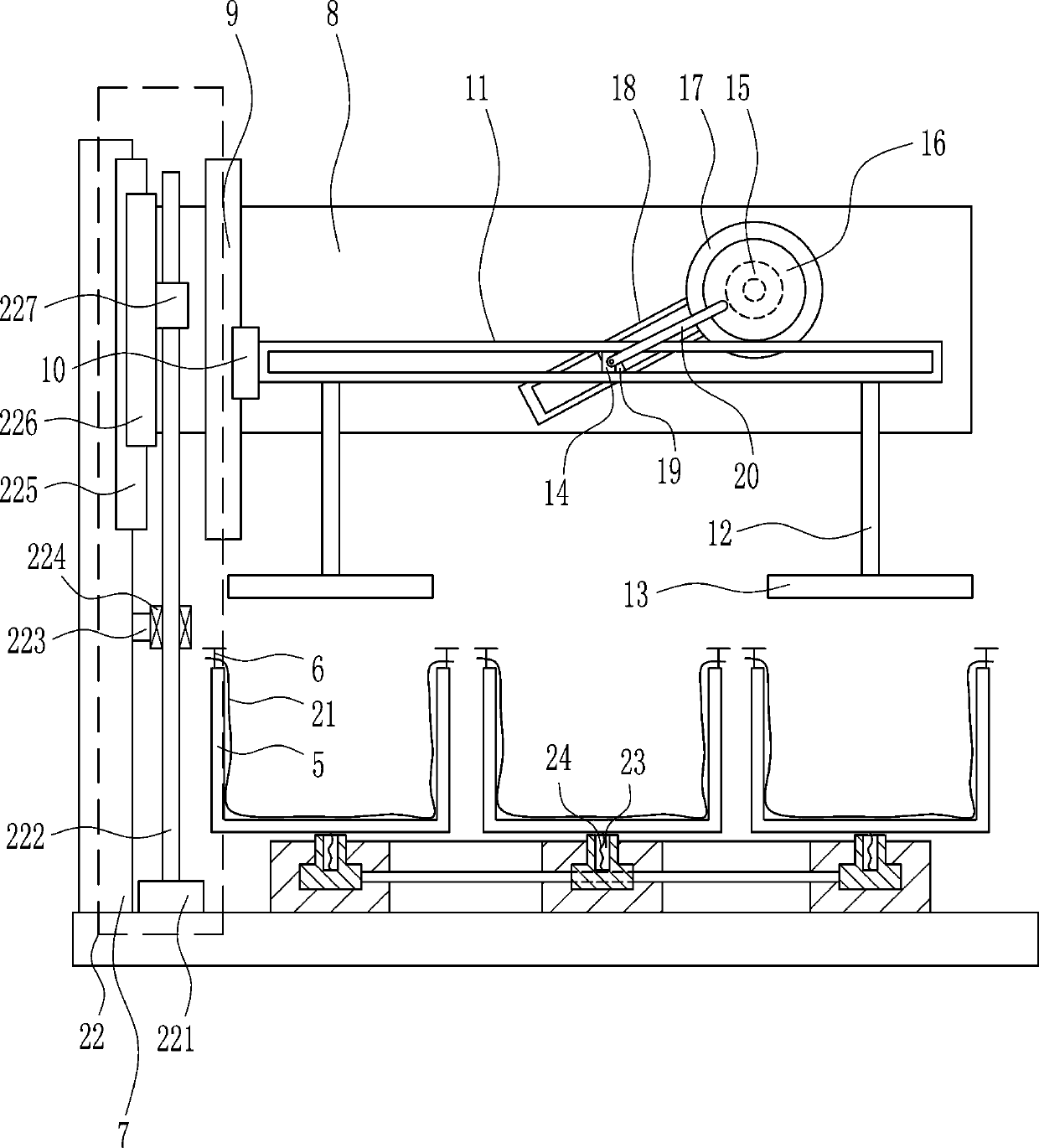

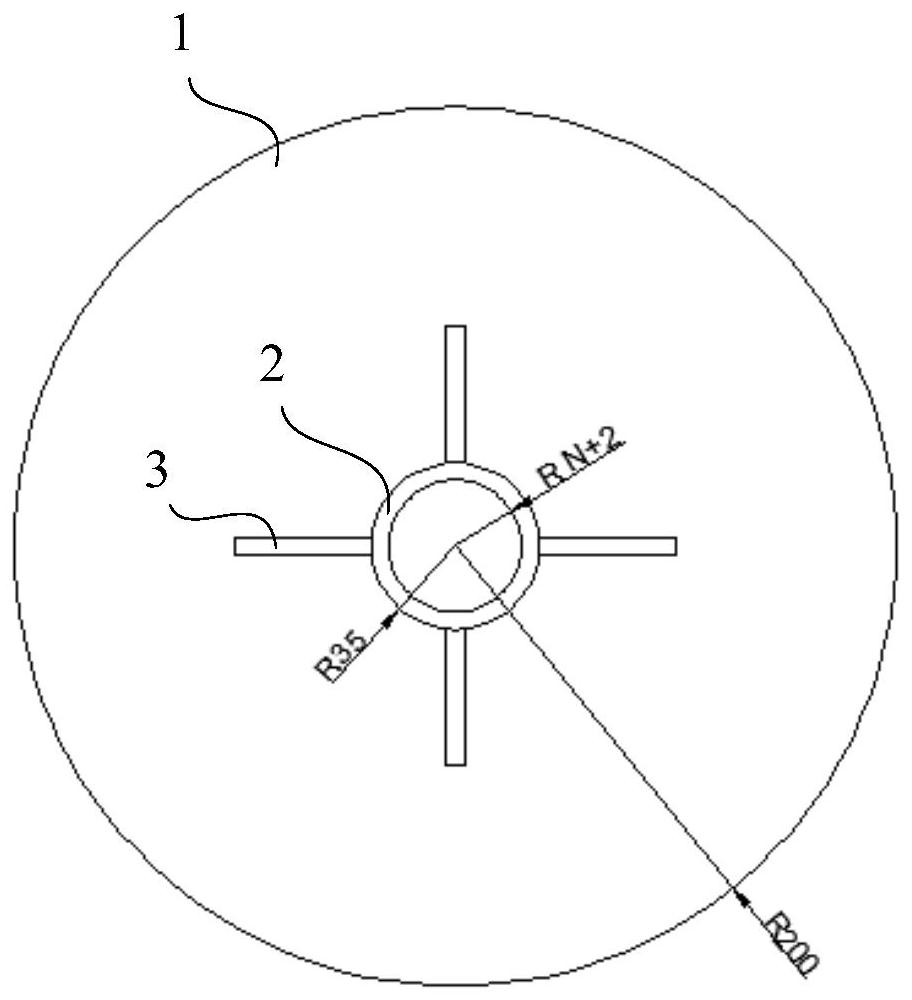

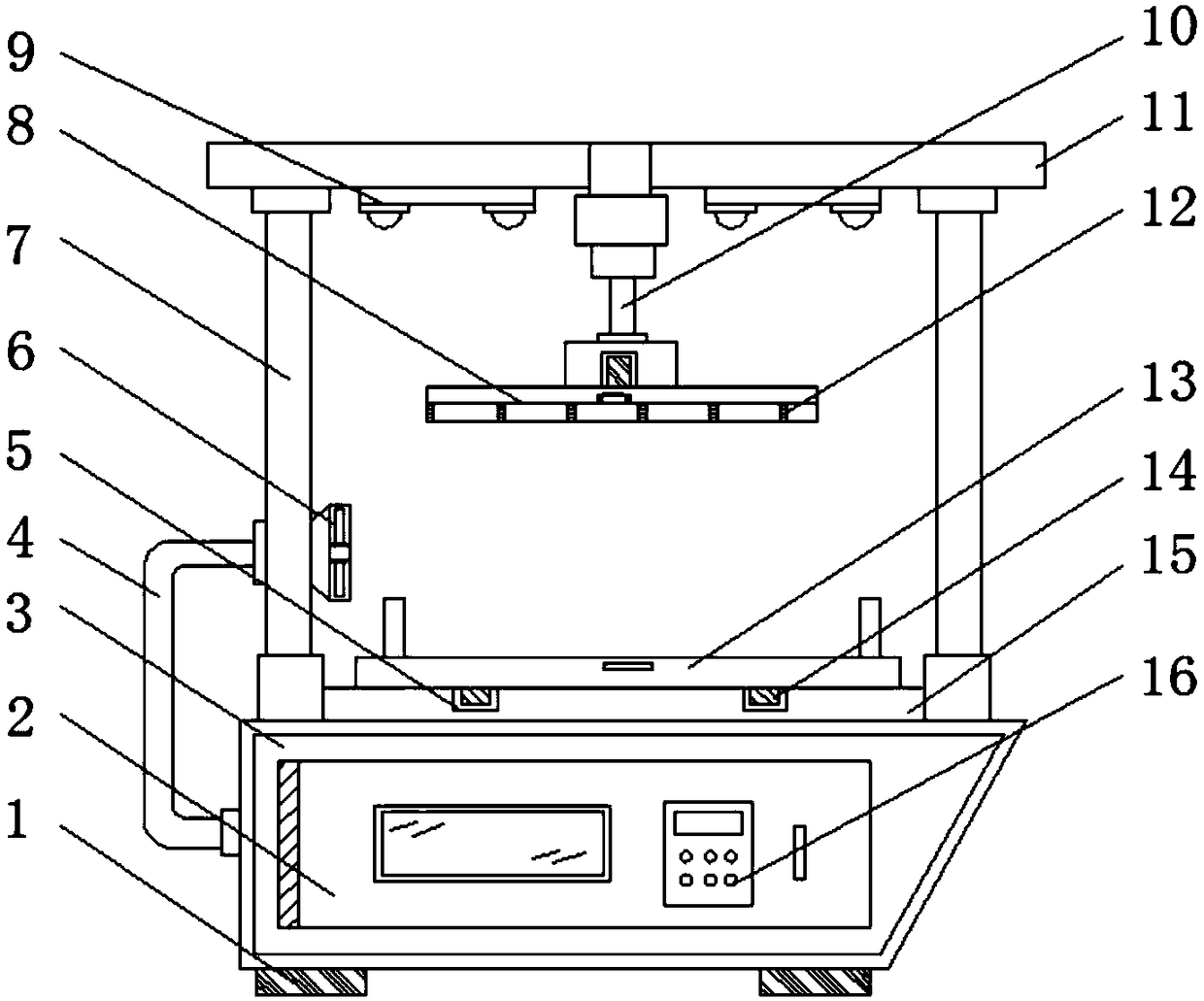

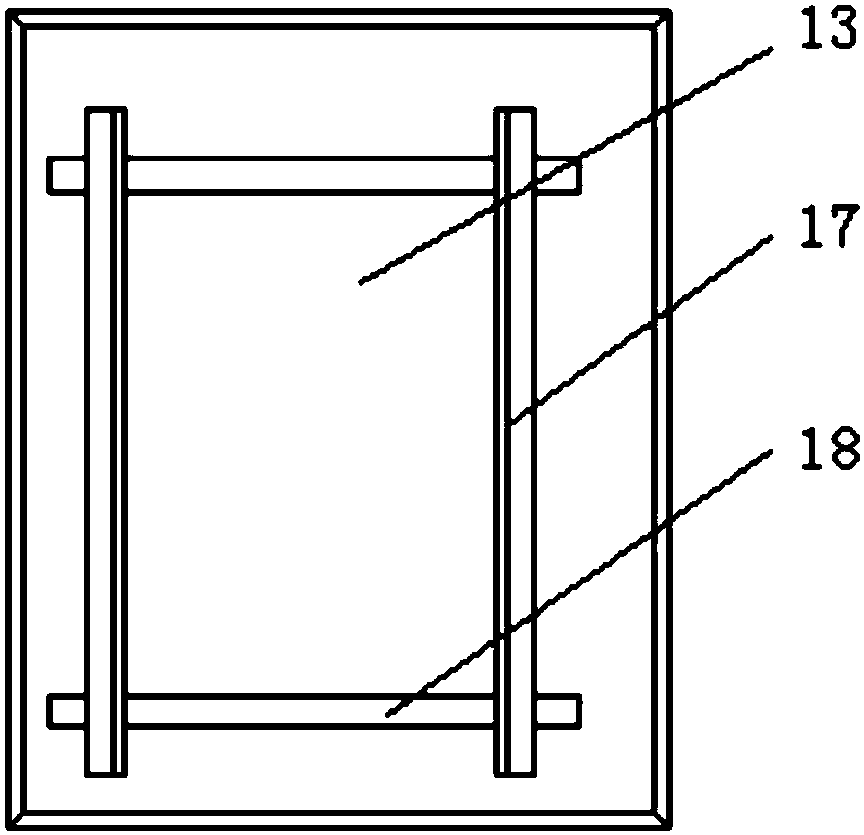

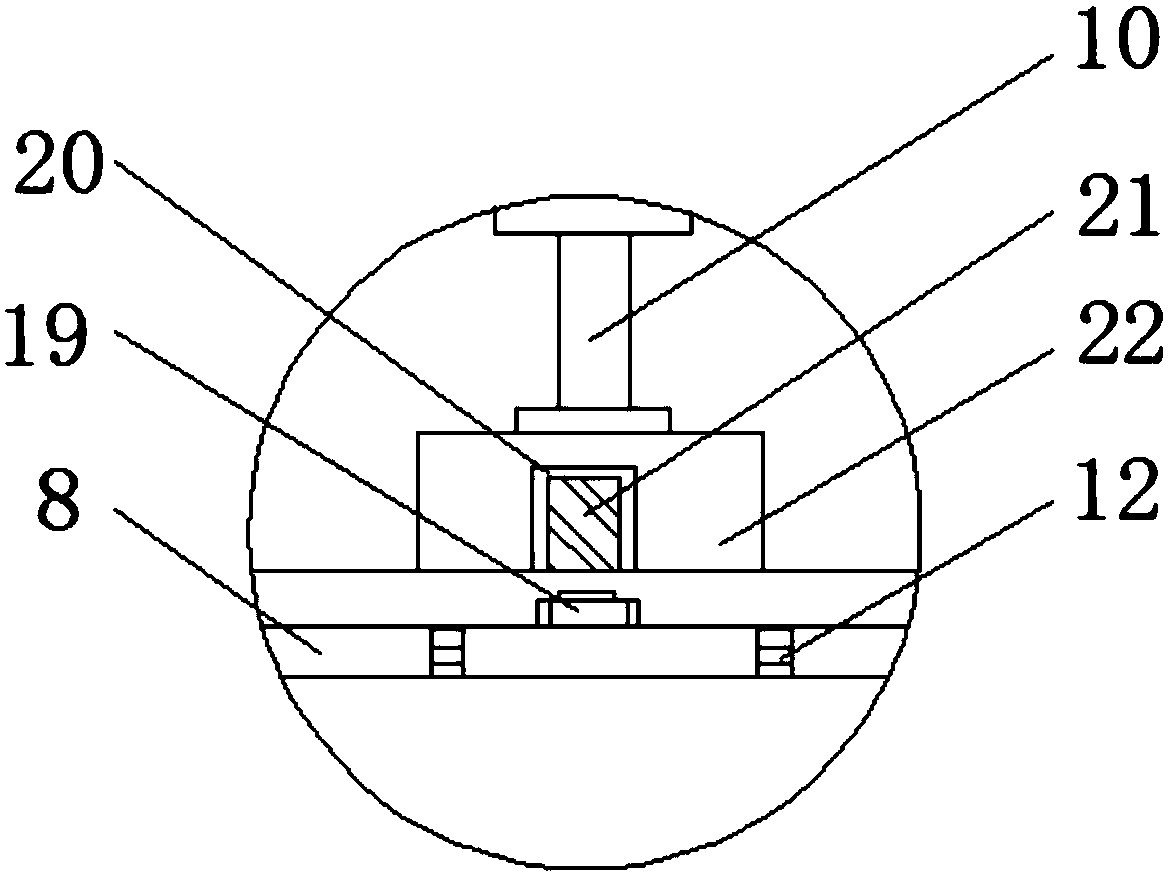

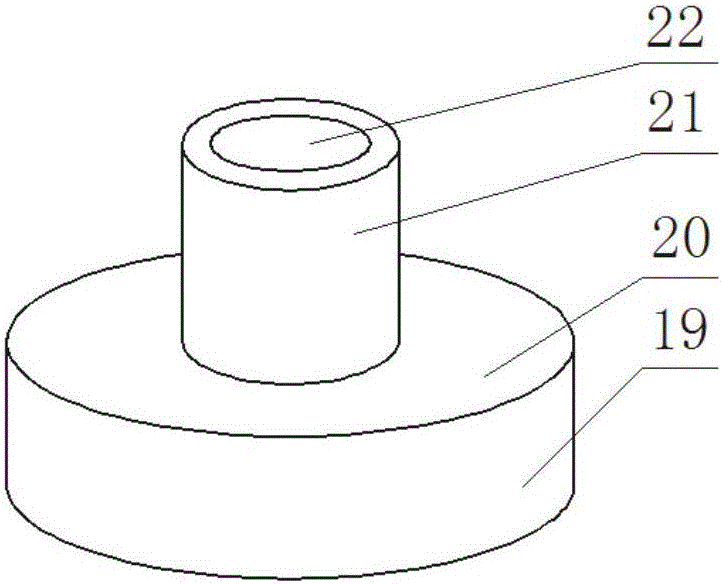

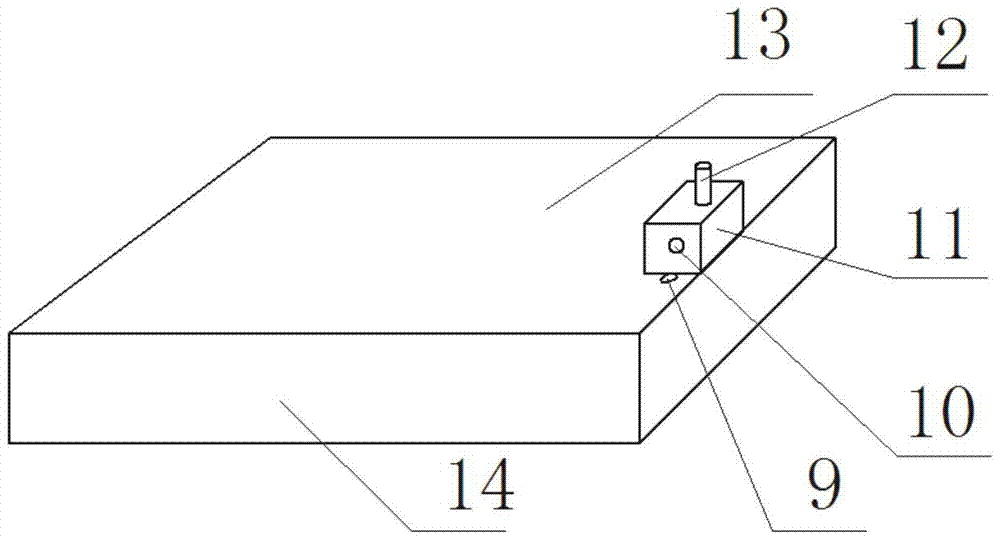

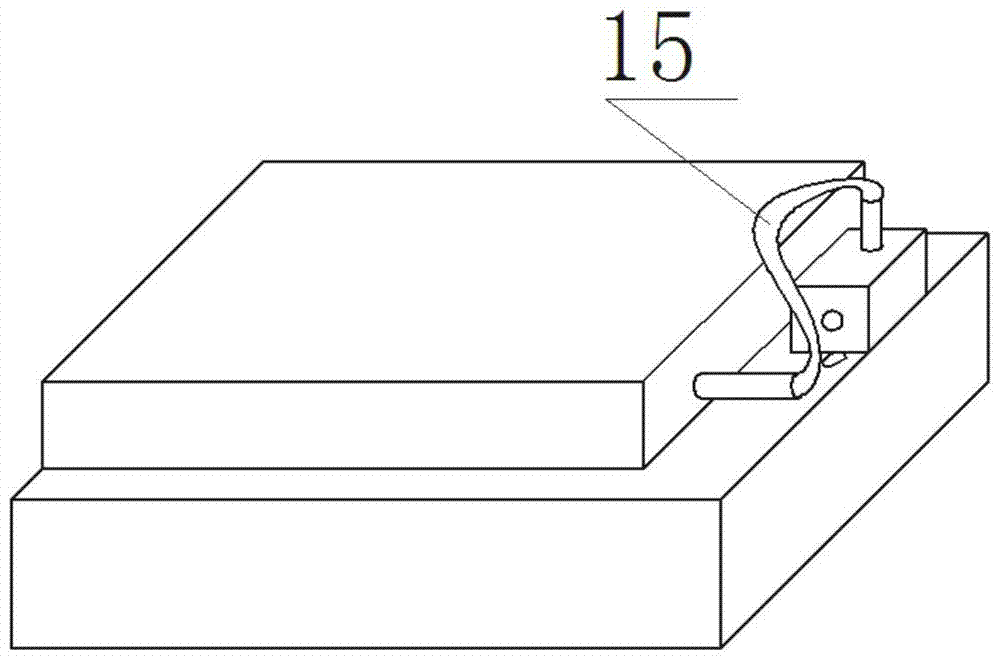

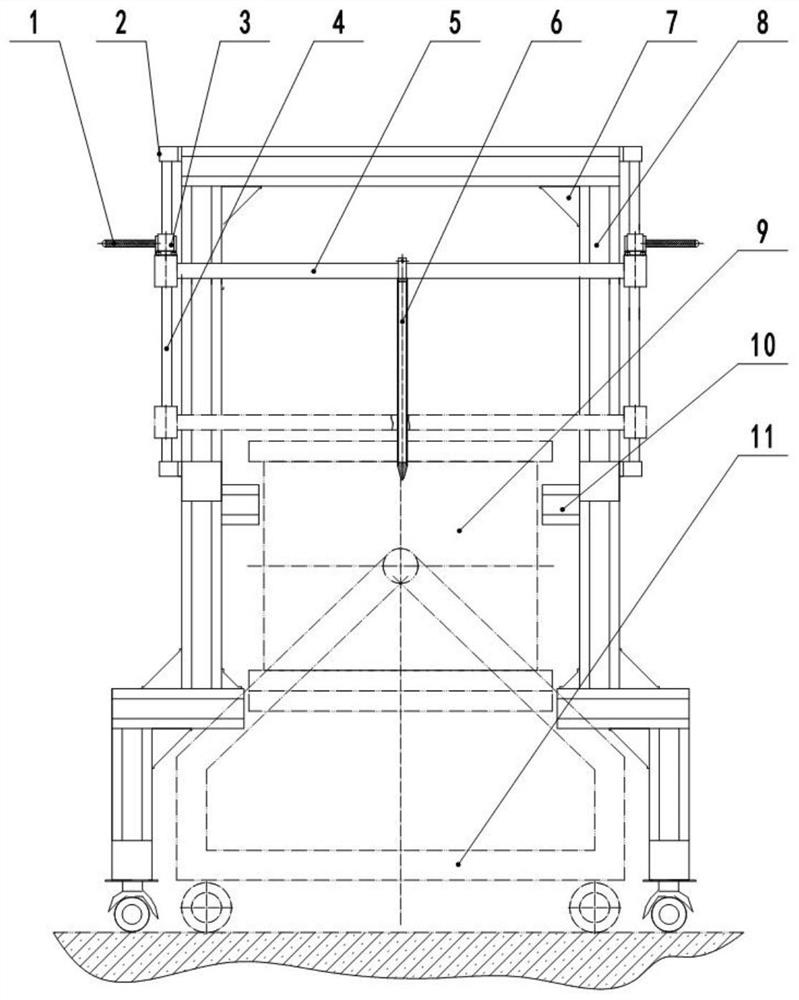

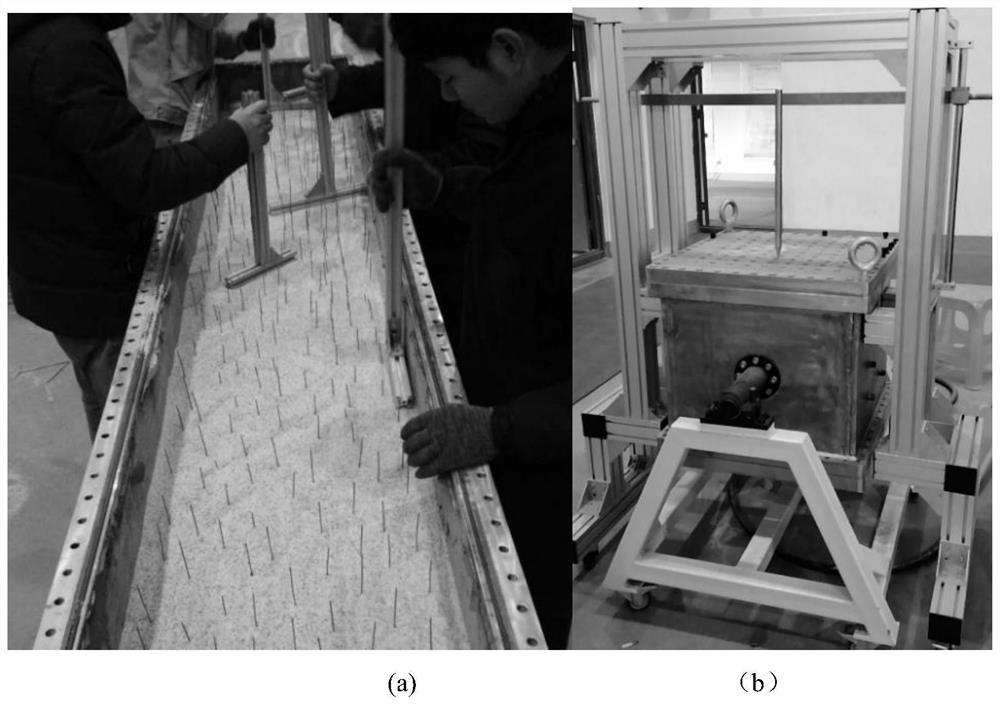

Multi-point compaction device used in model sand filling process in heavy oil thermal recovery experiment

ActiveCN110005408BGuaranteed success rateGuaranteed not to streamFluid removalThermodynamicsEngineering

The invention belongs to the technical field of petroleum and natural gas exploitation simulation, and discloses a multi-point compaction device for the sand filling process of a model in a thickenedoil thermal recovery experiment. A sand filling model is installed on a model bracket, and the sand filling model is supported and positioned through the model bracket; positioning sliding blocks arearranged on the two sides of the sand filling model, and the positioning sliding blocks are connected with supporting frames through positioning bolts to fix and position the sand filling model; the upper ends of the supporting frames are connected with fixed blocks through screws; all the corner ends of the supporting frames are connected through right-angle corner parts; the fixed blocks are located on the upper parts of guiding rods, and the guiding rods successively penetrate through the fixed blocks, sliding blocks and a moving cross beam from top to bottom; the sliding blocks and pneumatic handles with the adjustable pressure are connected and fixed through screws; and the moving cross beam penetrates through a driving hammer, and the driving hammer is located above the sand fillingmodel. According to the multi-point compaction device for the sand filling process of the model in the thickened oil thermal recovery experiment, various defects of existing manual compaction operation are overcome, it can be ensured that the compaction force is the same each time, the safety of a line can also be ensured, and fast, stable and safe compaction operation is realized.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Negative pressure quilt mesh cable compaction bag

ActiveCN105029971BTightly boundFast compactionNon-woven fabricsBed-coversEngineeringAtmospheric pressure

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com