Vibration auxiliary control method and control system of vibratory roller and vibratory roller

A vibratory roller, auxiliary control technology, applied in the direction of general control system, control/regulation system, computer control, etc., can solve the problems of soil material fragmentation, unstable compaction process, etc., and achieve the effect of simplifying structure and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

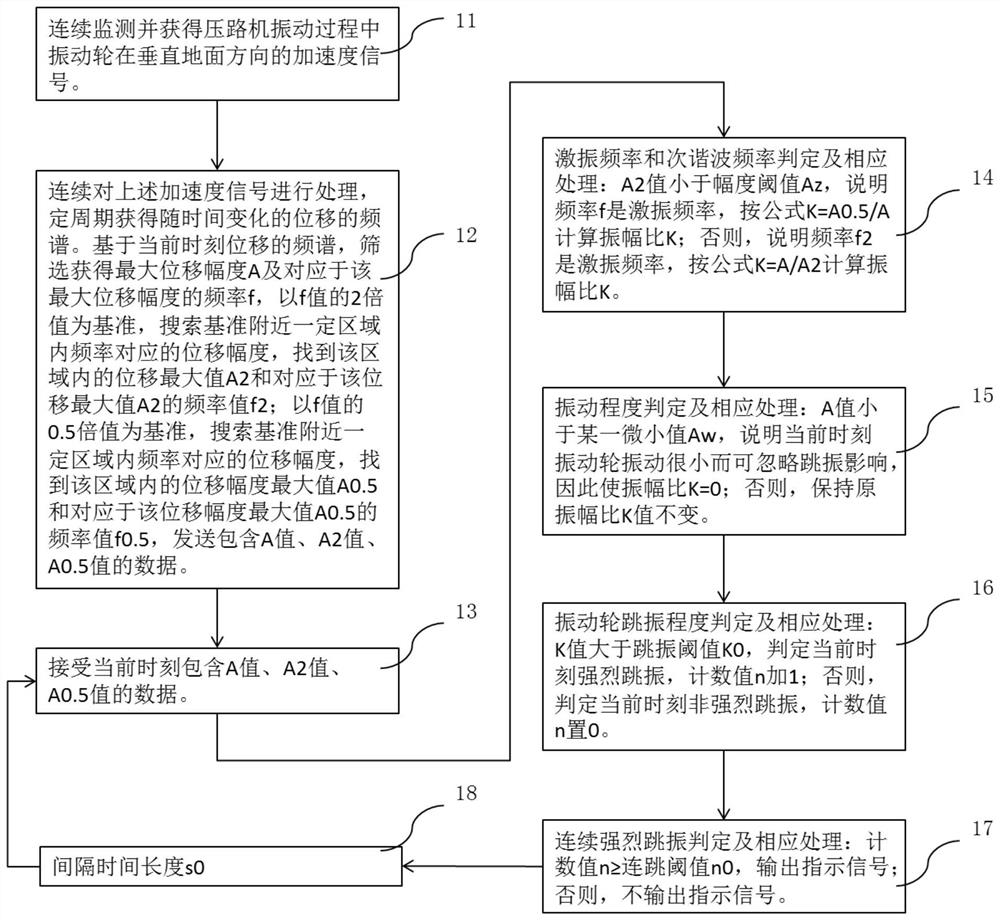

[0100] For the vibration auxiliary control method of a vibratory roller provided in this embodiment, see figure 1 , including the following steps:

[0101] Step 11, continuously monitor and obtain the acceleration signal of the vibration wheel in the direction vertical to the ground during the vibration process of the road roller.

[0102] In some implementations of this embodiment, the vibration process can be selected in the following manner:

[0103] The vibration process includes the whole process from vibration start to complete vibration stop.

[0104] The vibration process includes a certain period from the start of the vibration to the complete stop of the vibration.

[0105] Step 12, continuously process the above acceleration signal, and obtain the frequency spectrum of the displacement with time at regular intervals. Based on the frequency spectrum of the displacement at the current moment, the maximum displacement amplitude A and the frequency f corresponding to t...

Embodiment 2

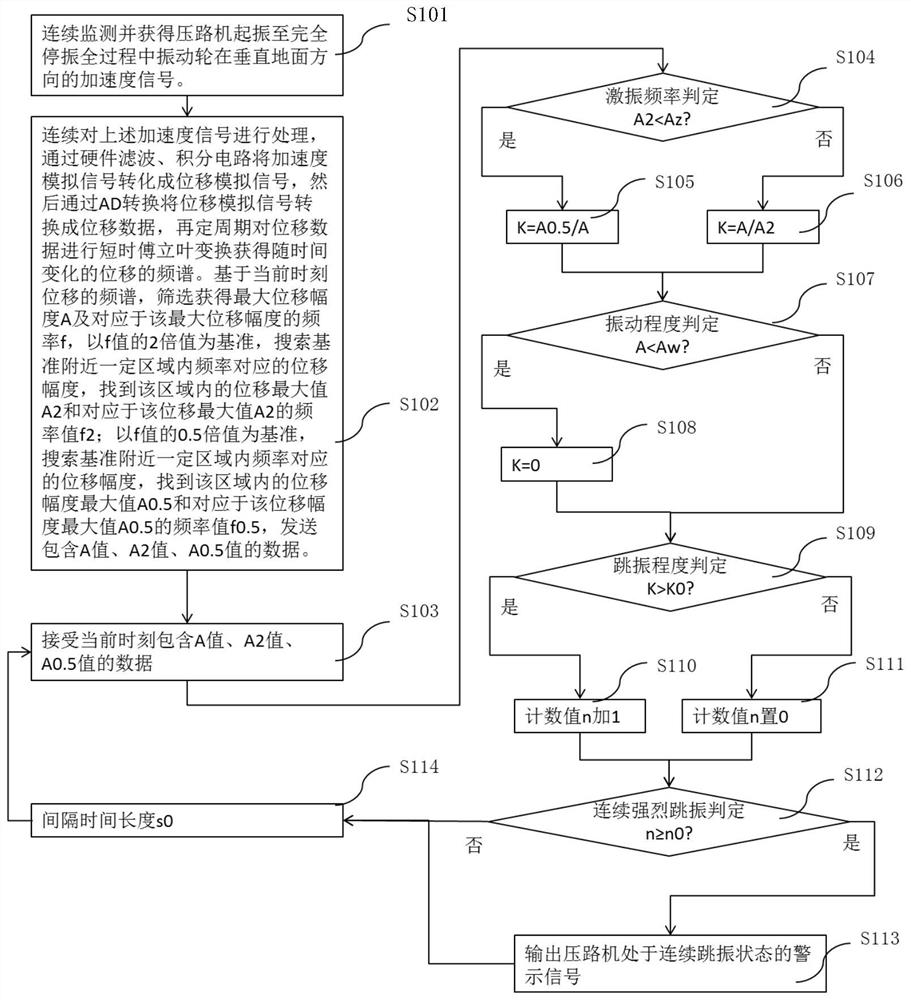

[0126] For the vibration auxiliary control method of a vibratory roller provided in this embodiment, see figure 2 ,include:

[0127] Step S101: Continuously monitor and obtain the acceleration signal of the vibrating wheel in the direction vertical to the ground during the whole process from the start of vibration of the road roller to the complete stop of vibration.

[0128] For example, when the complete road roller is powered on, the acceleration sensor arranged on the vibrating wheel starts to continuously monitor and obtain the acceleration signal of the vibrating wheel of the road roller in the direction vertical to the ground, and continues until the complete machine is powered off.

[0129] For example, when the engine of the road roller is started, the acceleration sensor arranged on the vibration wheel starts to continuously monitor and obtain the acceleration signal of the vibration wheel of the road roller in the direction vertical to the ground, and continues unt...

Embodiment 3

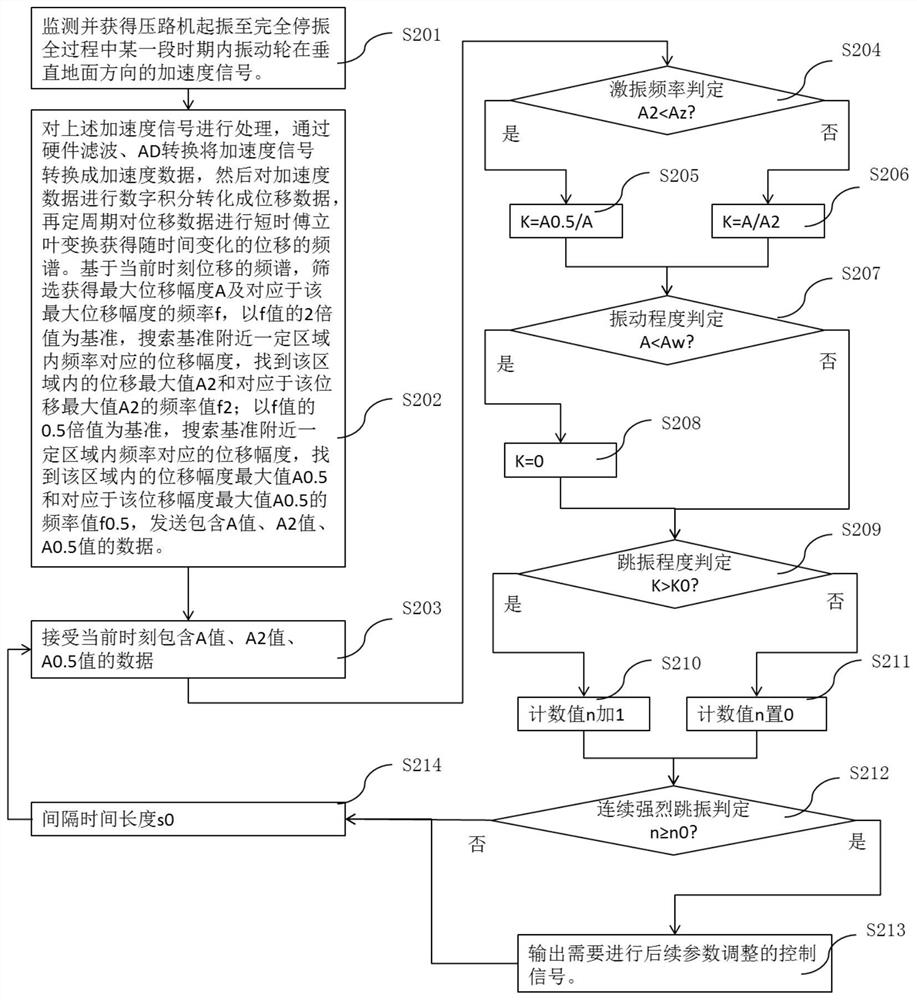

[0159] For the vibration auxiliary control method of a vibratory roller provided in this embodiment, see image 3 ,include:

[0160] Step S201: Monitor and obtain the acceleration signal of the vibrating wheel in the direction vertical to the ground during a certain period of time during the whole process from the start of vibration of the road roller to the complete stop of vibration.

[0161] Segmentation helps to combine other information to count the vibration results in a certain area.

[0162] For example: monitor the vibration process of the vibrating wheel from the moment the roller starts pressing the vibrating button to when the vibrating button is disconnected, and obtain the acceleration signal of the vibrating wheel in the direction vertical to the ground for a period of time. This period does not include the acceleration signal from when the vibration button is disconnected to when the vibration wheel completely stops vibrating, but it can be obtained simply by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com