Patents

Literature

33results about How to "Extended crushing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

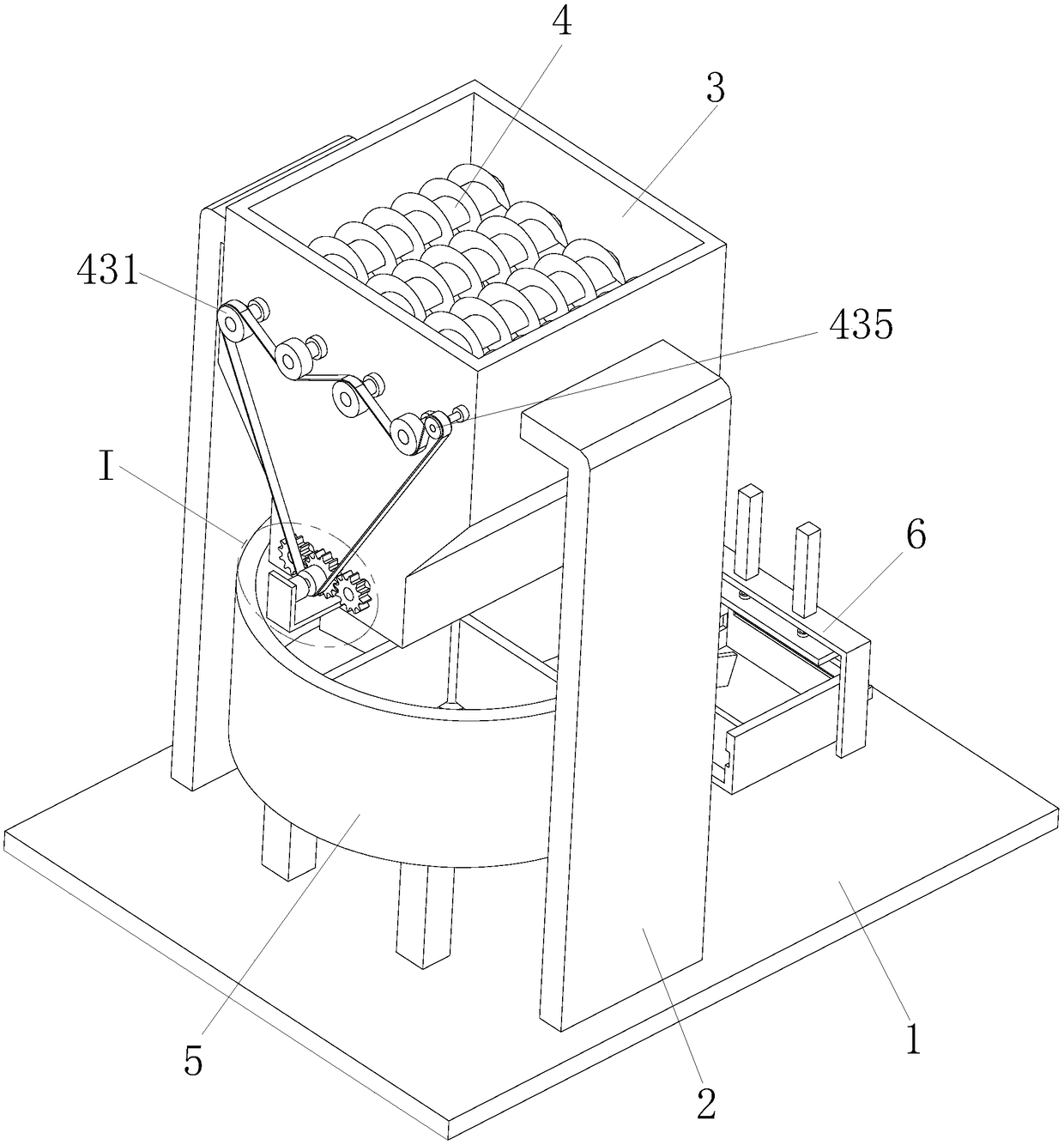

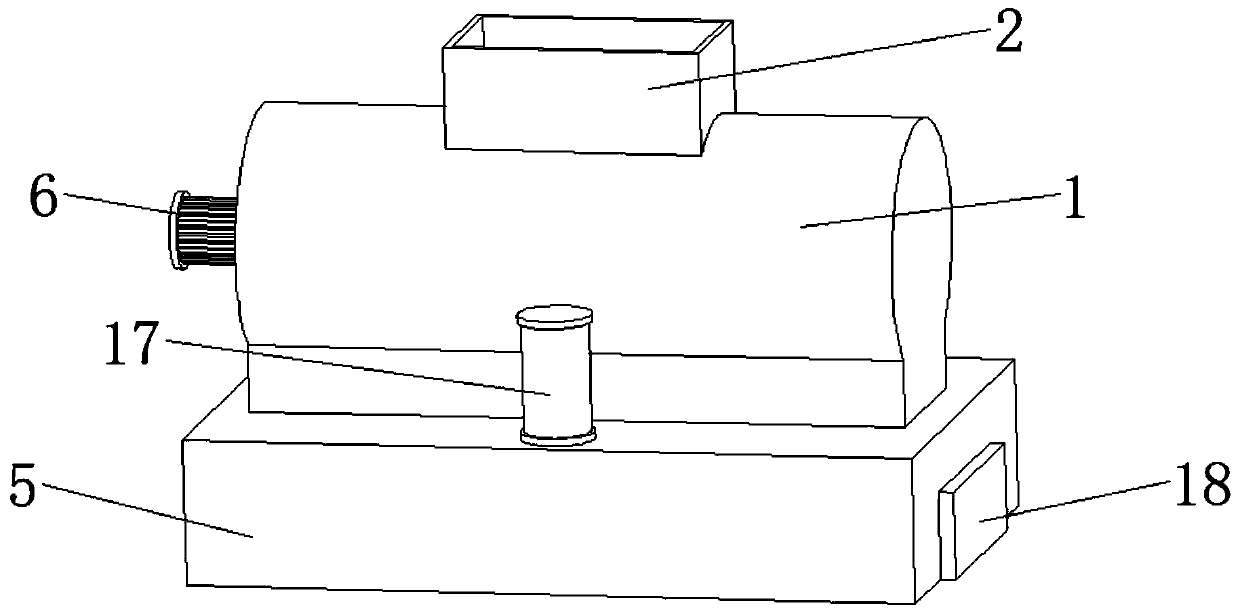

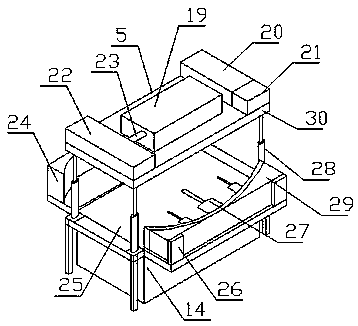

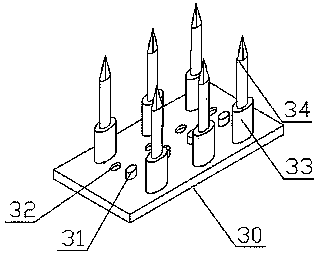

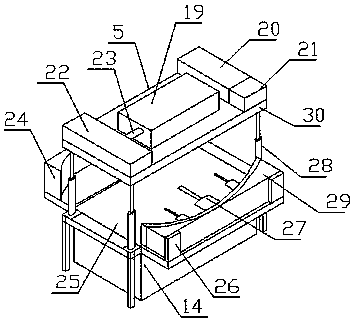

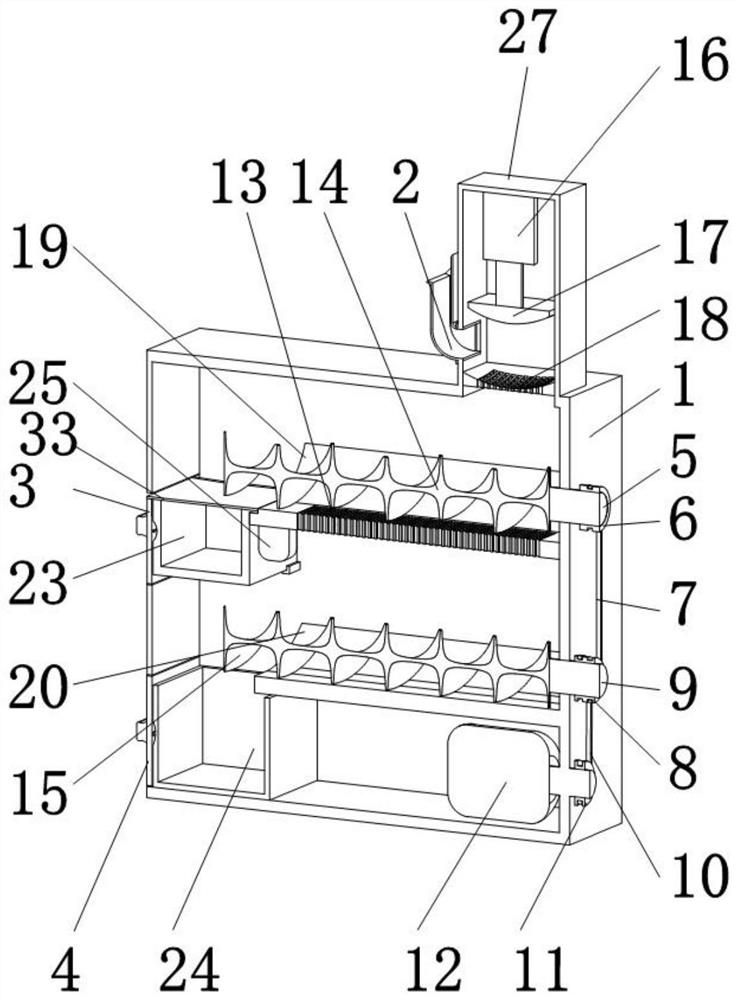

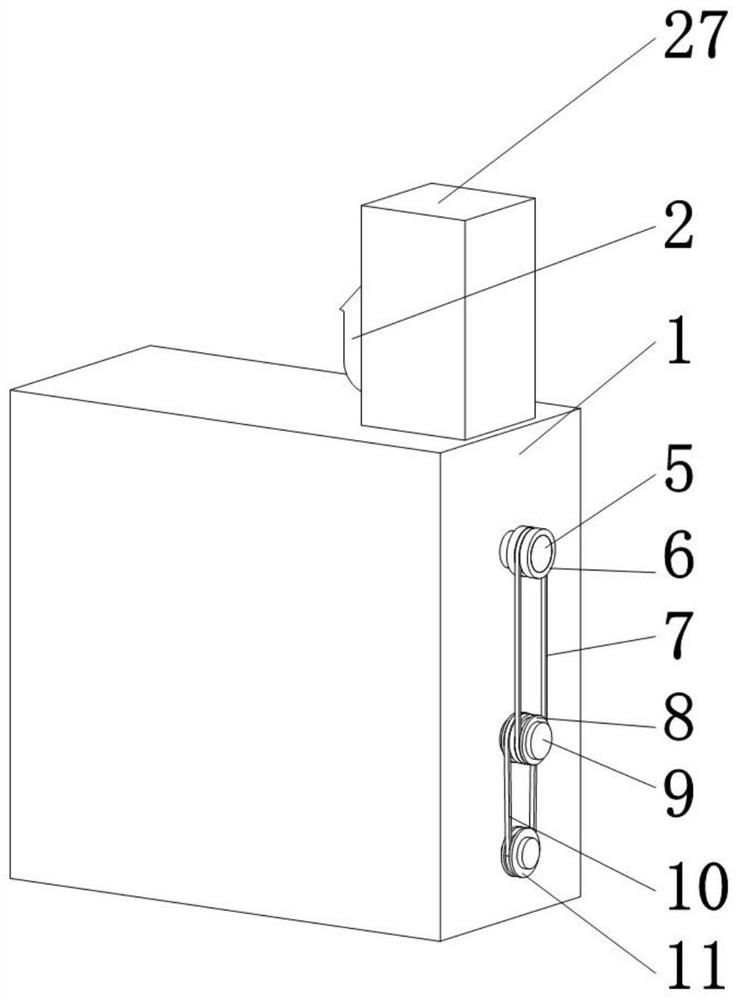

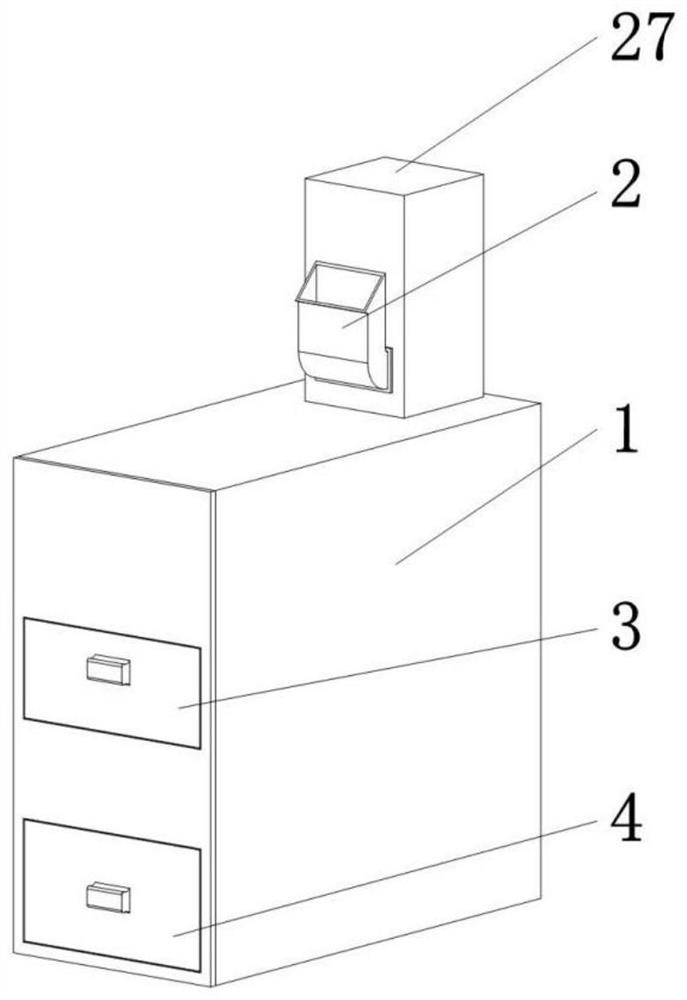

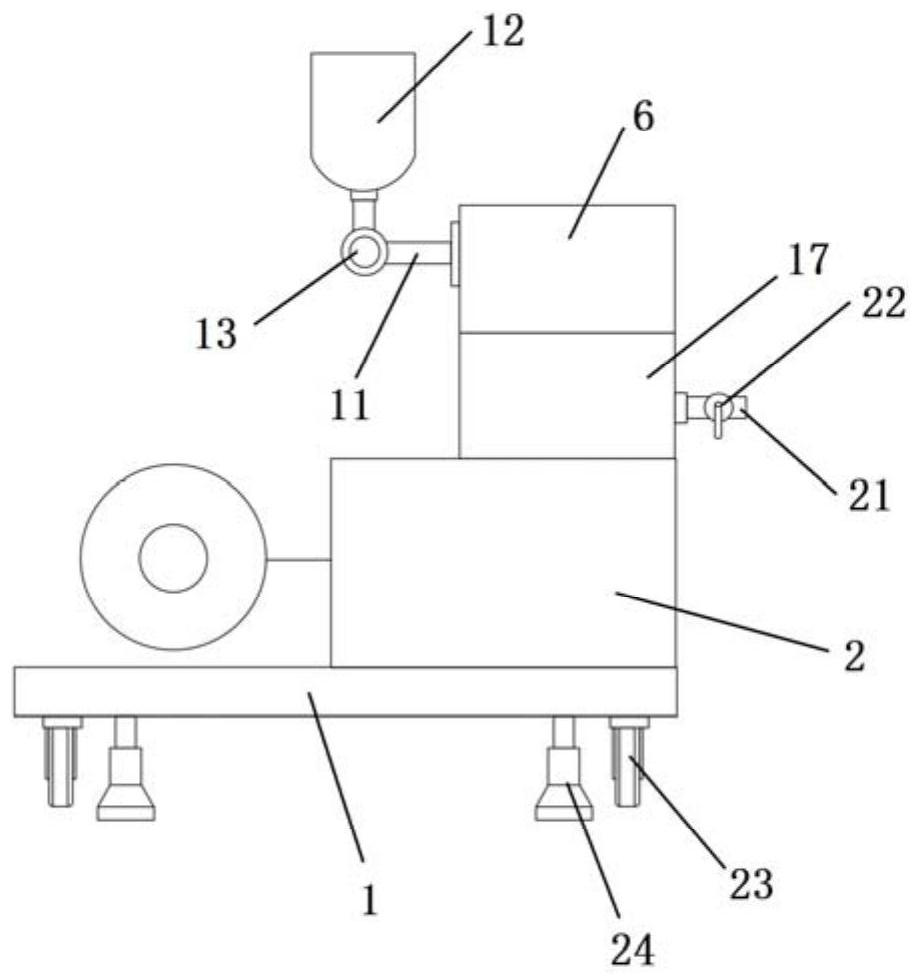

Straw pulverizing compressor

InactiveCN109076799AGuaranteed forming rateWon't scatterCuttersBundling machine detailsHydraulic cylinderEngineering

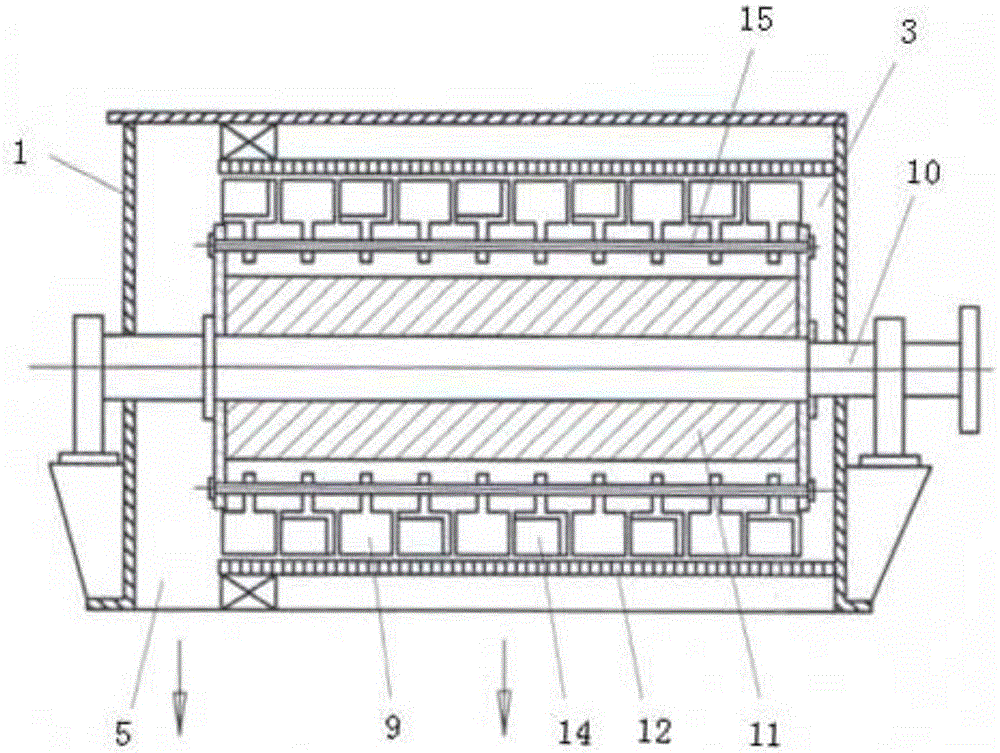

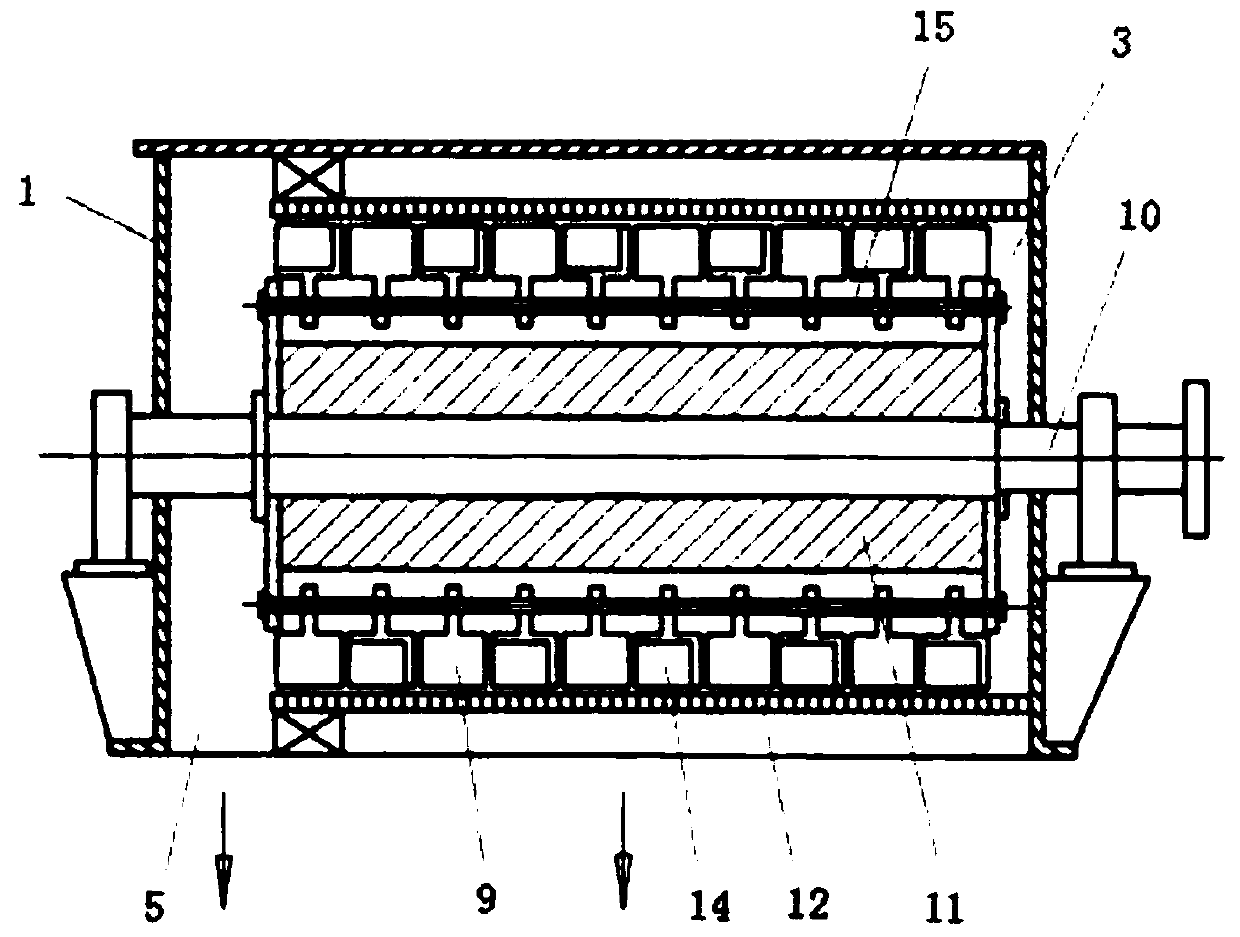

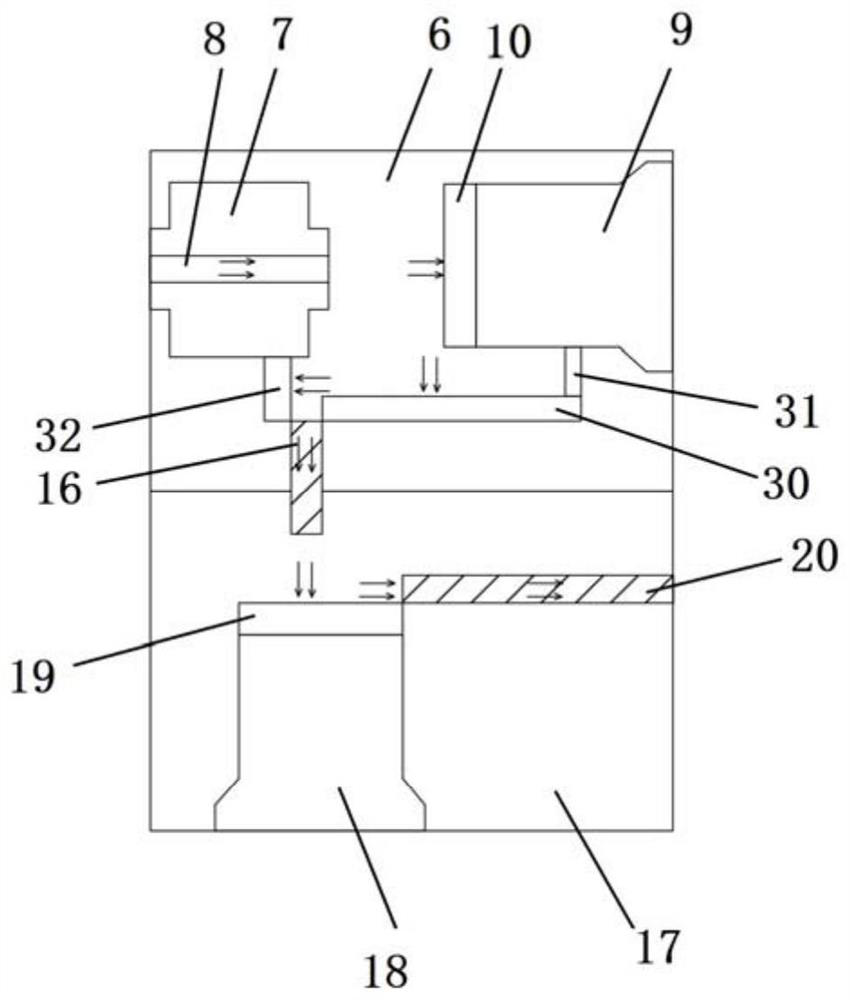

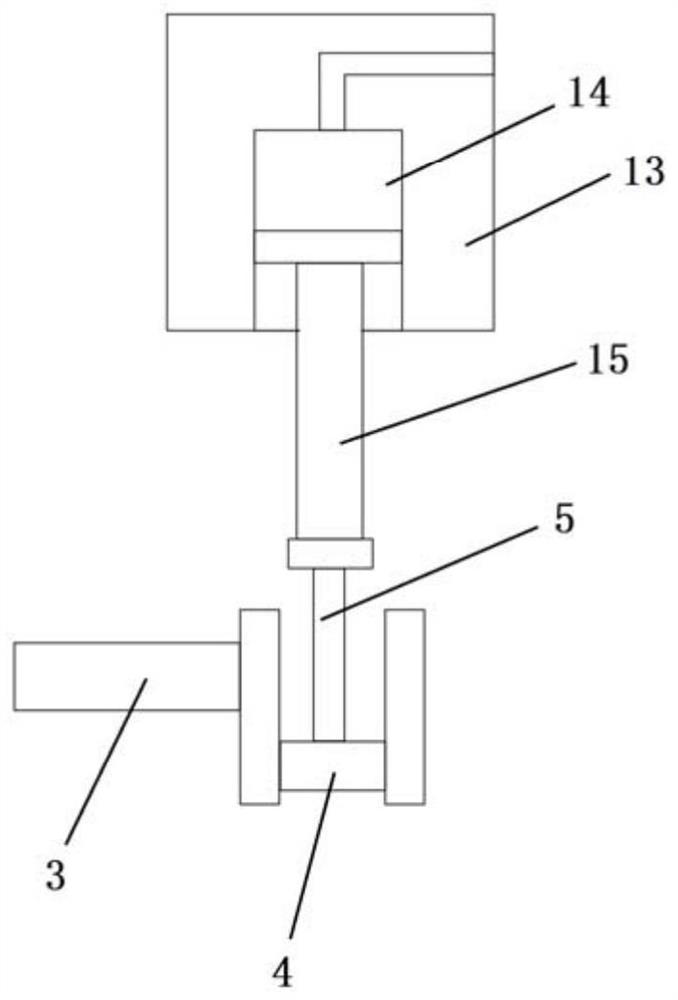

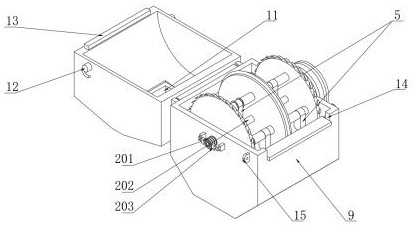

The invention relates to a straw pulverizing compressor. The compressor comprises a bottom plate and an installing frame installed on the bottom plate, a pulverizing box is fixed to the installing frame, a pulverizing mechanism which can perform multi-layer pulverizing is installed in the pulverizing box, collecting mechanisms used for collecting straw powder are distributed between the bottom plate and the pulverizing box, and a bundling mechanism which is used for bundling the straw powder is installed on the bottom plate. According to the straw pulverizing compressor, multi-layer pulverizing is conducted by the cooperation of first and second pulverizing knives to improve pulverizing efficiency, the first and second pulverizing knives are cooperatively driven to rotate synchronously through a chain wheel transmission mechanism and gear transmission, energy is saved, the working efficiency is improved, pulverizing time is saved, bundling is cooperatively conducted through multiple groups of shaping plates and hydraulic cylinders to ensure the shaping rate of straw powder, and it is ensured that the straw powder does not scatter after being shaped to make packaging and stacking convenient..

Owner:无为县黄姑农机专业合作社

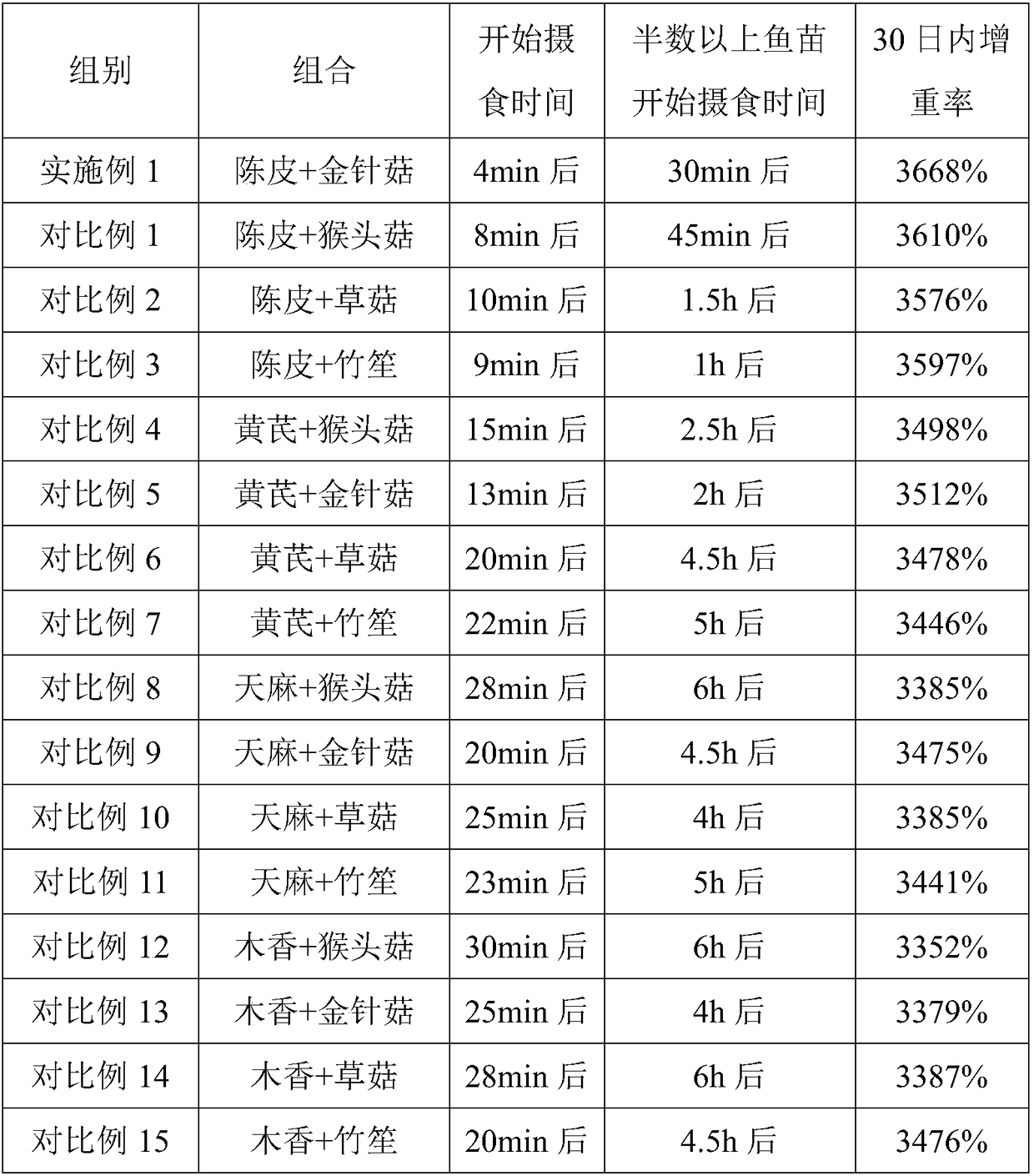

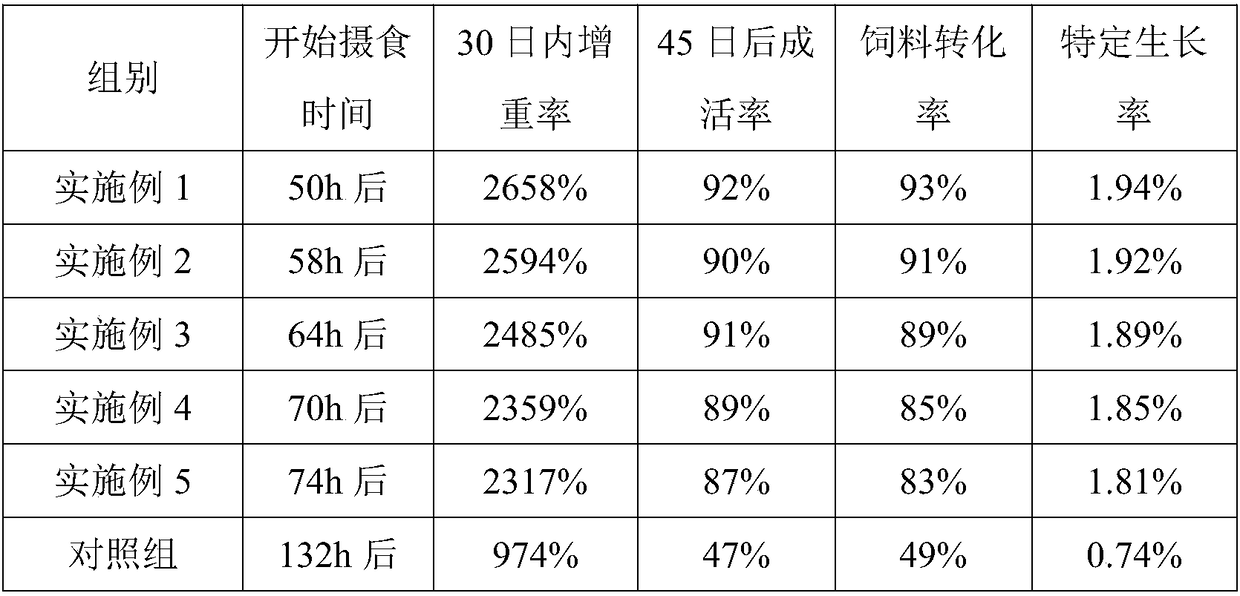

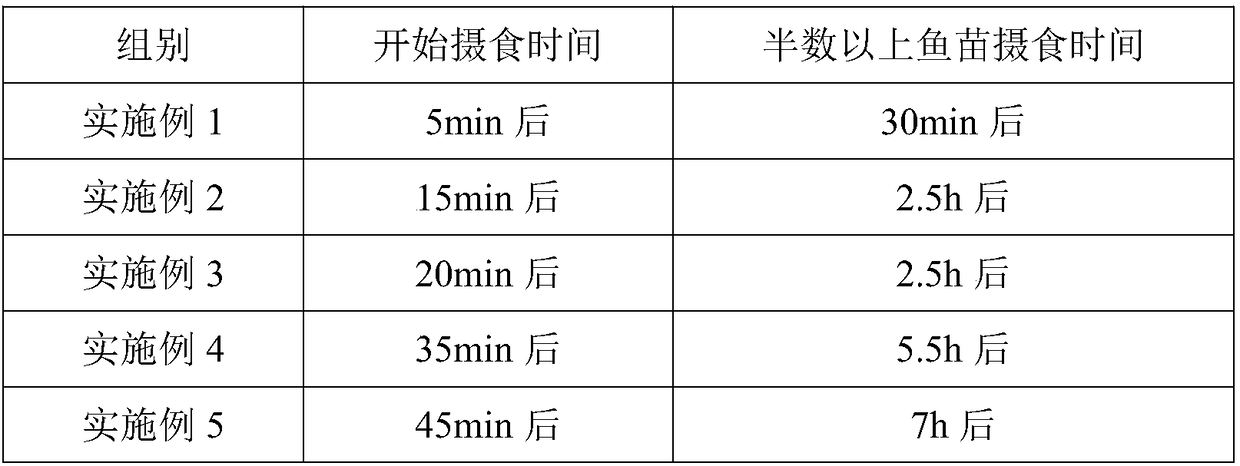

Starter feed for mandarin fish and preparation method thereof

InactiveCN108065132AIncrease digestibility and absorptionIncrease contentFood processingClimate change adaptationBetaineAnimal science

The invention discloses starter feed for mandarin fish and a preparation method thereof. The starter feed is made from, by weight, 20-60% of white fish meal, 10-30% of chicken meal, 3-10% of egg meal,3-10% of beer yeast, 10-30% of wet brine shrimp, 10-30% of fresh shrimp, 15-30% of flour, 1-5% of fish oil, 1-3% of phospholipids, 1-3% of betaine, 1-2% of vitamin mixture, 2-4% of mineral mixture, 2-6% of EPA (eicosapentaenoic acid), 1-5% of DHA (docosahexaenoic acid), 1-5% of a microbial preparation, and 1-2% of a food attractant. The starter feed herein is developed and researched according tonutrient needs and feeding characteristics of the mandarin fish, and the content of animal proteins is increased; the whole formulation is optimized, the particle size of the starter feed may reach dozens and even hundreds of micrometers, the requirements of different specifications of young fishes for particle size palatability can be met, digestibility, absorbability and attractiveness of the starter feed are effectively improved, starting rate is significantly increased, and fry survival rate is effectively increased.

Owner:GUANGDONG YUEQUN BIOTECHNOLOGY CO LTD

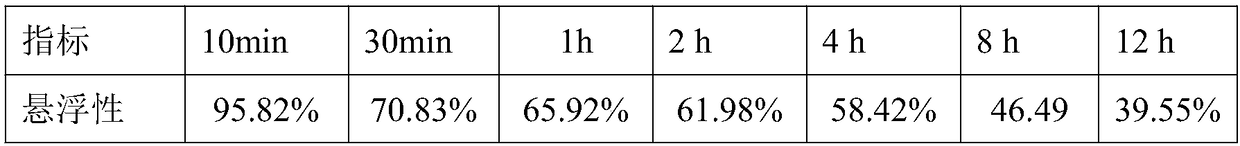

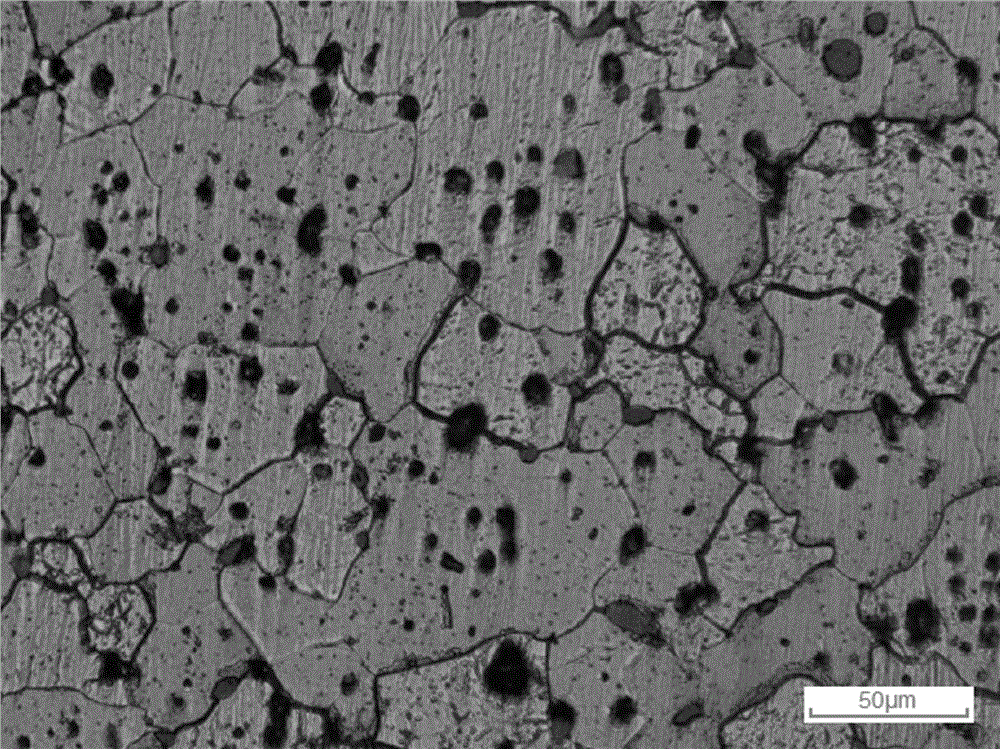

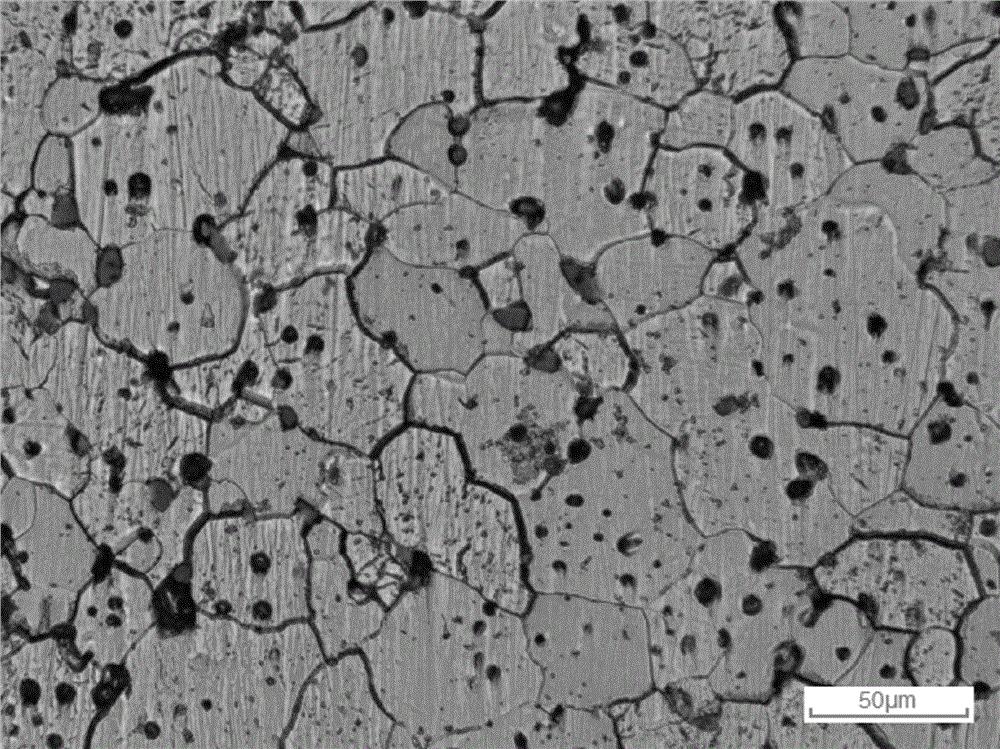

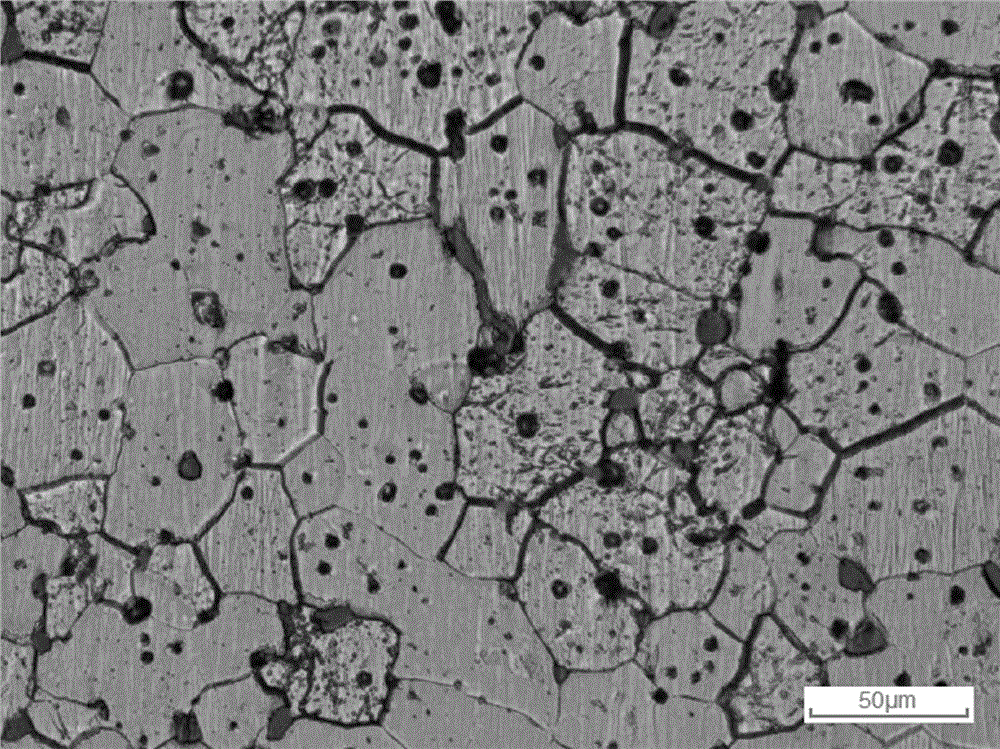

Preparation technology of molybdenum-niobium alloy sputtering target material

ActiveCN105887027ALower surface energyAvoid sticky ballsTransportation and packagingMetal-working apparatusEthyl stearatePolyvinyl alcohol

The invention belongs to the technical field of metallurgy materials, and particularly relates to a preparation technology of a molybdenum-niobium alloy sputtering target material. The preparation technology comprises the steps of milling, molding, vacuum sintering, machining, and the like, wherein the milling process comprises the steps of putting molybdenum powder and columbium powder into a ball mill according to the principle that the ratio of molybdenum powder to columbium powder is (6 to 10) to 1; then, adding a process control agent and zirconia grinding balls; carrying out ball milling under argon protection; sieving; and separating to obtain molybdenum-niobium alloy composite powder; weights of the process control agent and the zirconia grinding balls are respectively (0.01 to 0.05) times and (5 to 20) times the total weight of molybdenum powder and columbium powder; and the process control agent is one or more of zinc stearate, palmitic acid, ethyl stearate, polyvinyl alcohol and stearic acid. According to the preparation technology, the obtained molybdenum-niobium alloy sputtering target material is a single phase structure, the structure is uniform and free of holes, the average grain size is 40 to 65 [mu]m, the density is 9.85 g / cm<3> or above, the performance is excellent, and the molybdenum-niobium alloy sputtering target material can be widely applied to the fields such as flat displays.

Owner:洛阳丰联科绑定技术有限公司

Dicentrarchus labrax starter feed and preparation method thereof

InactiveCN108157681APromote healthy growthPromote growthClimate change adaptationAnimal feeding stuffYeastShrimp

The invention discloses dicentrarchus labrax starter feed and a preparation method thereof. The starter feed is prepared from the following components in percentage by mass: 20-40 percent of fish meal, 10-30 percent of chicken meal, 3-10 percent of shrimp shell meal, 3-10 percent of yeast, 10-30 percent of blood worms, 5-15 percent of squid meal, 5-15 percent of copepods, 15-30 percent of flour, 1-5 percent of soybean oil, 1-3 percent of phospholipids, 1-3 percent of glycine betaine, 1-2 percent of vitamin mixture, 2-4 percent of mineral mixture, 1-5 percent of EPA, 1-5 percent of a compound exogenous enzyme preparation, 1-5 percent of a microbial preparation and 1-2 percent of attractant. The feed is designed, researched and developed according to the rule of nutritional requirements of dicentrarchus labrax fries, has a grain size meeting the high requirement of dicentrarchus labrax grow seedlings, has strong attraction performance and strong digestability and absorbability, and can be used for remarkably reinforcing the starting rate and immune level, effectively promoting healthy growth of fries and remarkably increasing the survival rate of larvae.

Owner:GUANGDONG YUEQUN BIOTECHNOLOGY CO LTD

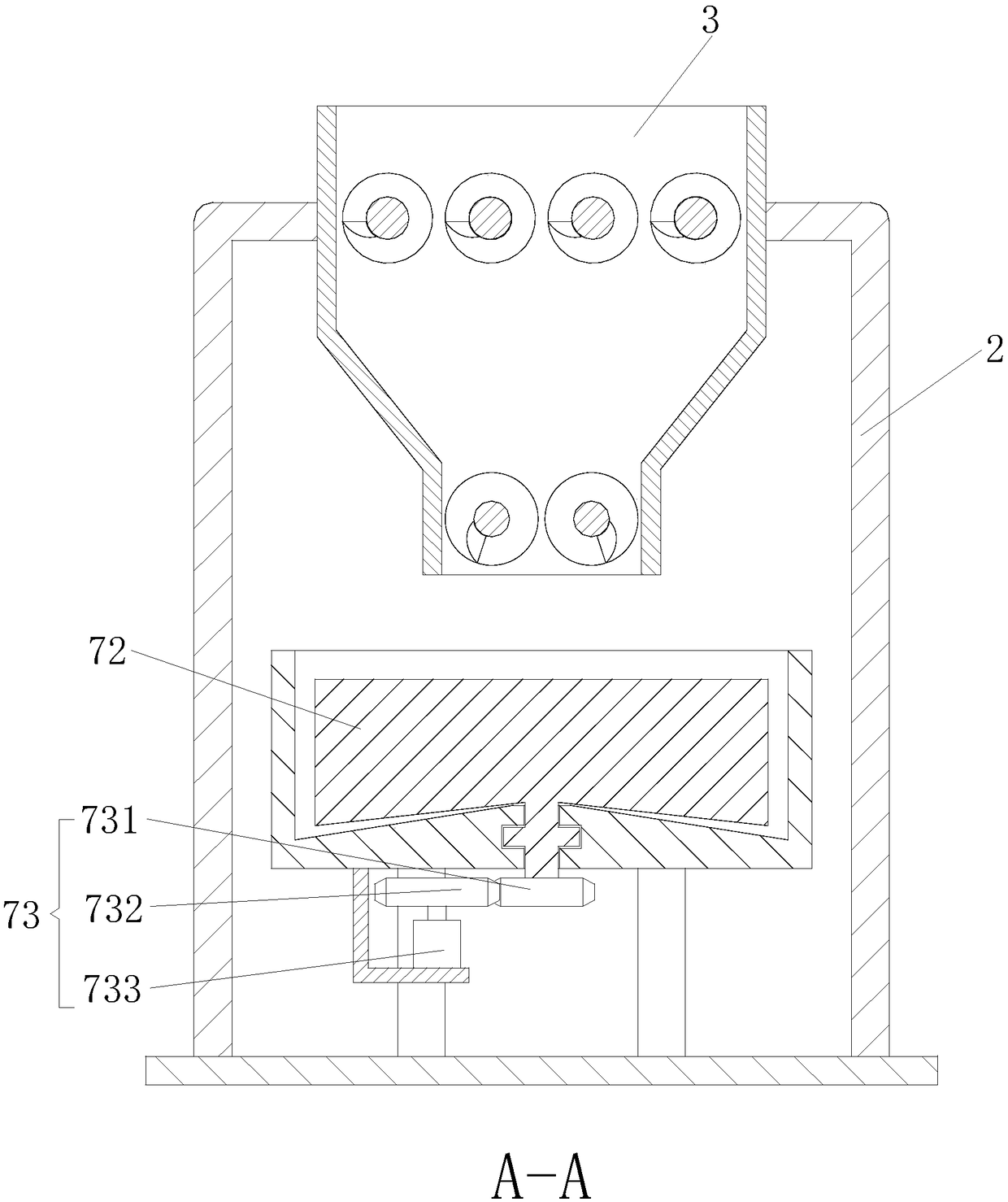

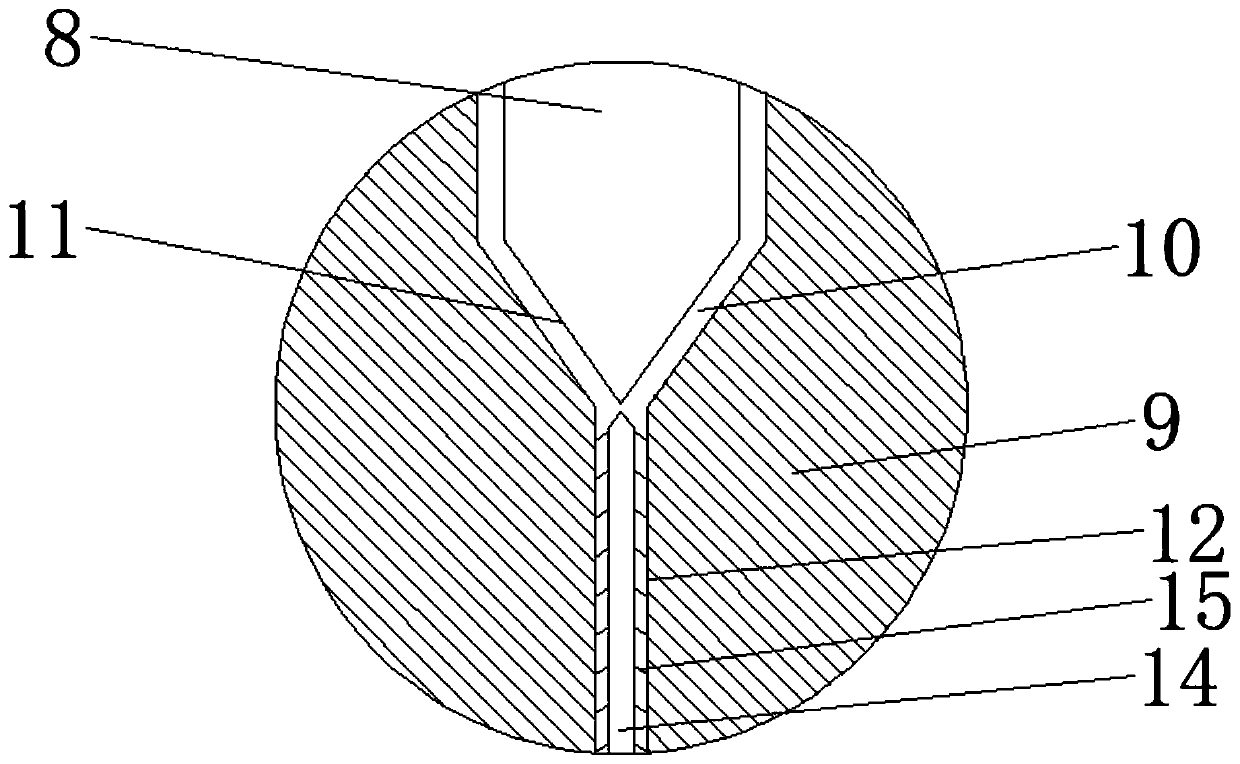

Extrusion type soil crushing equipment for agriculture

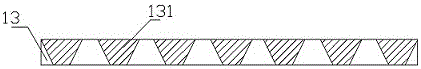

InactiveCN110976019AExtended crushing timeConvenient whereaboutsDrying gas arrangementsGrain treatmentsAgricultural engineeringStructural engineering

The invention relates to the field of agriculture, and particularly discloses extrusion type soil crushing equipment for agriculture. The equipment comprises a cylinder, a base, a feeding port, a screen and a collecting box, wherein an extrusion plate with the same length as the inside of the barrel is fixedly mounted on the bottom of the barrel; a plurality of extrusion grooves with upward openings are uniformly formed in the extrusion plate, extrusion blades which are in one-to-one correspondence with the extrusion grooves are coaxially and fixedly mounted on a transmission shaft, the extrusion blades extend into the extrusion grooves, discharging gaps in the radial direction are formed in the two side walls of the extrusion blades; the bottoms of the extrusion grooves communicate with adischarging groove penetrating through the bottom of the extrusion plate, and the lower end of the discharging groove communicates with the collecting box. According to the extrusion type soil crushing equipment, by arranging the extrusion blades rotating in the extrusion grooves, the soil is subjected to extrusion friction in the extrusion grooves, the soil is refined, the refined soil falls into the collecting box, the soil is crushed continuously, manual crushing of the soil does not need to be performed manually, and the labor intensity of workers is reduced.

Owner:赵国宝

Two-stage crusher

The invention discloses a two-stage crusher. The two-stage crusher comprises a machine shell. A first crushing cavity and a second crushing cavity are formed in the machine shell. The first crushing cavity and the second crushing cavity are communicated and distributed in the two sides of the machine shell. The first crushing cavity is shorter than the second crushing cavity. A feeding inlet is formed in the first crushing cavity. A discharging outlet is formed in the second crushing cavity. A first main shaft is arranged in the first crushing cavity. A first rotor is arranged on the first main shaft. The first rotor is provided with a plate hammer or / and a hammerhead. A second main shaft is arranged in the second crushing cavity. A second rotor is arranged on the second main shaft. A sieve plate is arranged below the second rotor. The second rotor is provided with a plate hammer or / and a hammerhead. At least one of the plate hammer or / and the hammerhead arranged on the second rotor is a material moving plate hammer or / and a material moving hammerhead having an axial material moving function. The two-stage crusher can be used for crushing materials with large granularities and is high in crushing ratio, not prone to blockage and even in product granularity, and products which are high in yield and small in granularity can also be obtained.

Owner:CHANGSHA SHENXIANG UNIVERSAL MACHINE

Differential three-roller roller press

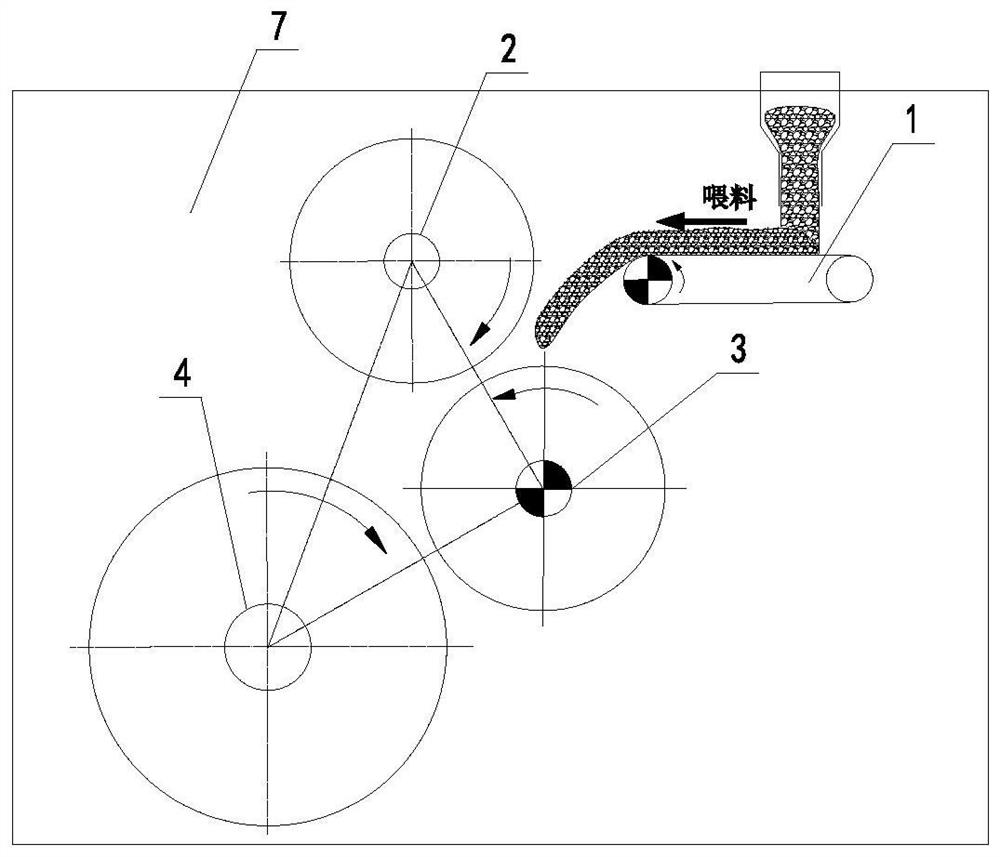

PendingCN112958201AImprove grinding effectExtended crushing timeGrain treatmentsHydraulic cylinderStructural engineering

The invention discloses a differential three-roller roller press. The differential three-roller roller press comprises a rack, a driving device, a movable roller and a feeding device, and is characterized in that an upper pressing roller and a lower pressing roller are installed at the upper position and the lower position of the movable roller respectively, the movable roller is a driving roller, the driving device drives the movable roller to rotate, the upper pressing roller and the lower pressing roller are driven rollers, and the upper pressing roller and the lower pressing roller are driven by the movable roller and materials to extrude and grind powder. According to the differential three-roller roller press, the driving device drives the movable roller to realize single transmission, so that the power consumption is reduced; differential rolling grinding is adopted, and through the extrusion of the extrusion rollers on the materials and the shearing action among the materials, the one-time yield of grinding can be improved, and the rollers can be controlled not to be excessively abraded; the materials are extruded and sheared through the differential speed between the two rollers, and are rolled twice, so that the one-time yield is improved; and a hydraulic device and the movable roller are further arranged in a position-adjustable mounting mode, and a hydraulic cylinder is controlled to advance and retreat when necessary so as to impact and extrude materials by the movable roller.

Owner:山东博研粉体技术装备有限公司

Tear substitutes

InactiveCN103501804ARelieves symptoms of eye irritationReduce sensitivitySenses disorderPeptide/protein ingredientsTear substituteTears

Owner:RECOPHARMA AB

Special micro-expansion corundum wear-resistant coating for waste heat air pipe

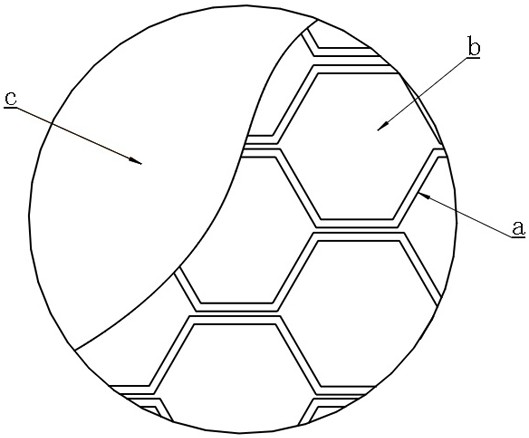

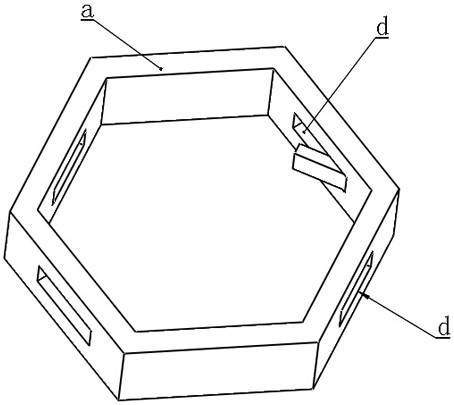

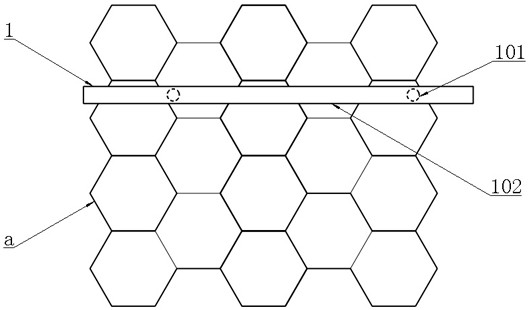

PendingCN113651622AEnough integrityExtended crushing timeThermal insulationPipe protection by thermal insulationCarbide siliconAggregate (composite)

The invention belongs to the technical field of wear-resistant coatings, and particularly relates to a special micro-expansion corundum wear-resistant coating for a waste heat air pipe. A wear-resistant aggregate is used, a composite expanding agent and a plastic sintering aid are newly added, and an arc-shaped scraping frame is used for compacting the wear-resistant coating, so that the effect that the wear-resistant coating can be stably attached to the hexsteel for a long time is achieved. Compared with the prior art, the invention has the following advantages that firstly, the wear-resistant aggregate containing corundum and silicon carbide provides enough wear resistance for the final lining layer, and the plastic sintering aid containing clay and boron gangue provides enough integrity for the final lining layer, so that the self-crushing time of the lining layer is prolonged; and secondly, kyanite and silica have the heated micro-expansion performance, actively expand and are clamped in the hexsteel, and the whole block is not prone to falling off.

Owner:长兴兴鹰新型耐火建材有限公司

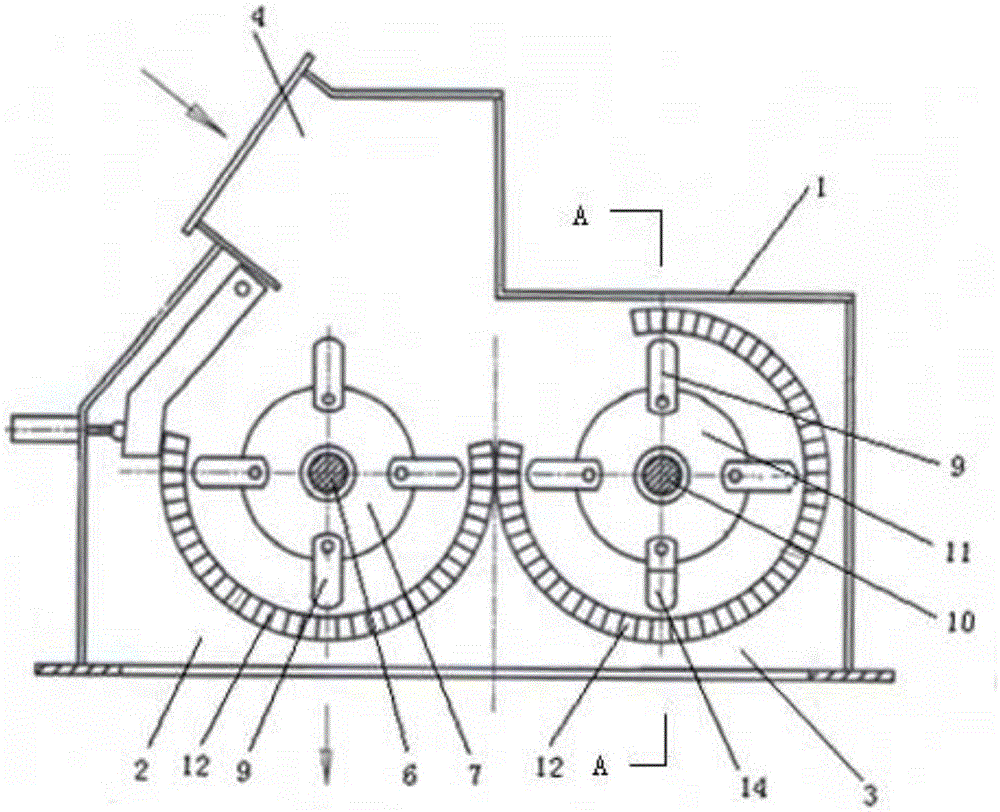

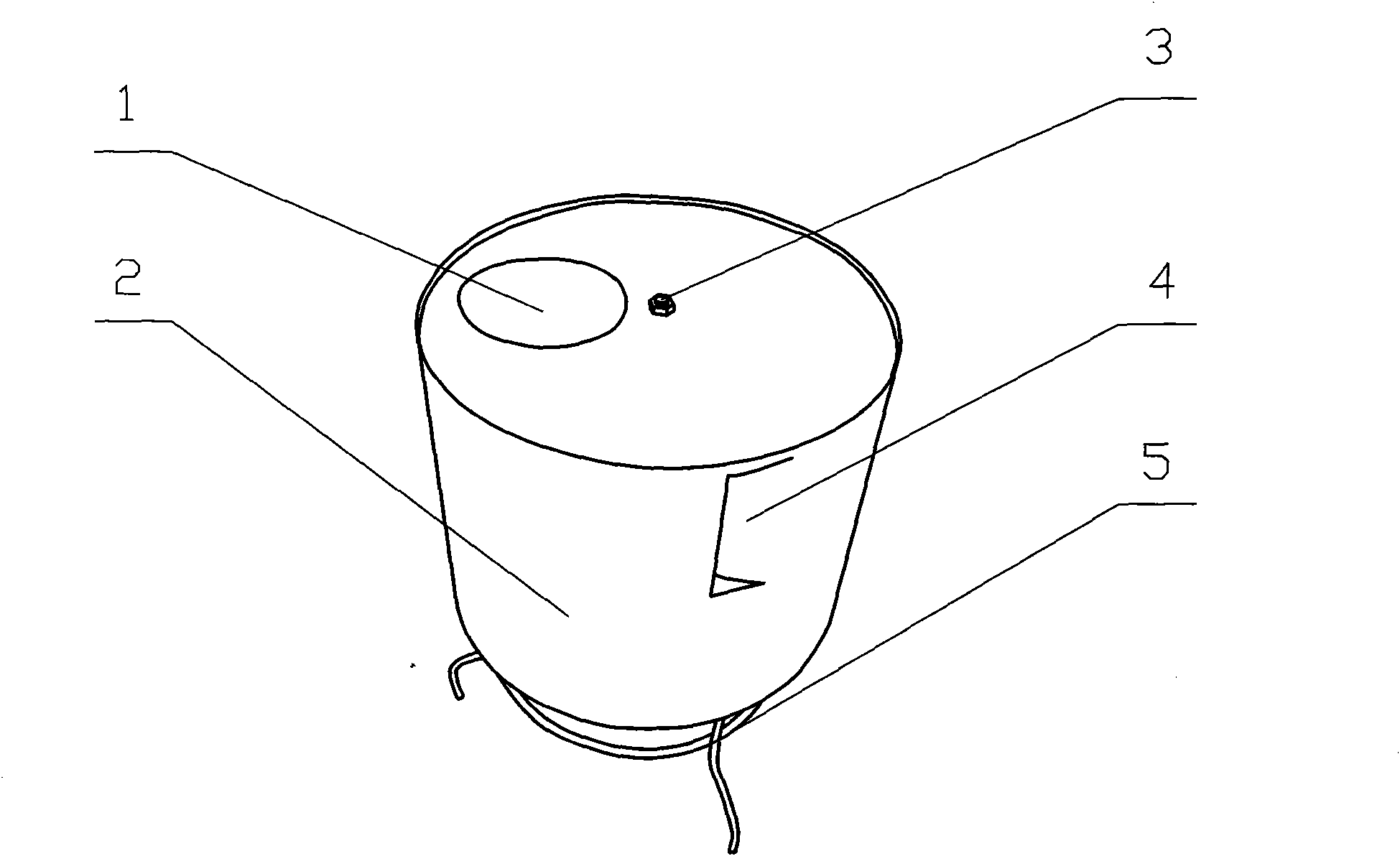

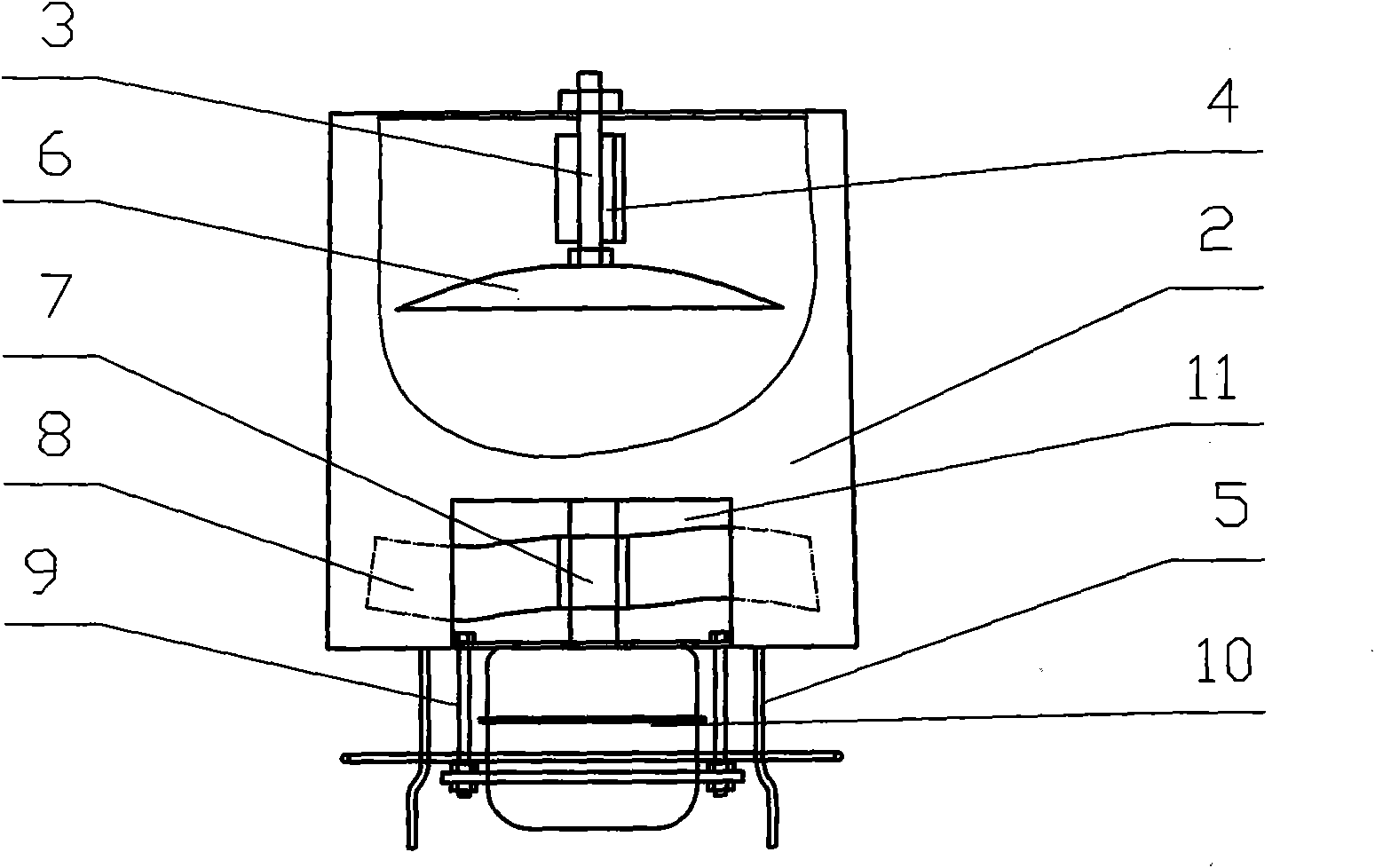

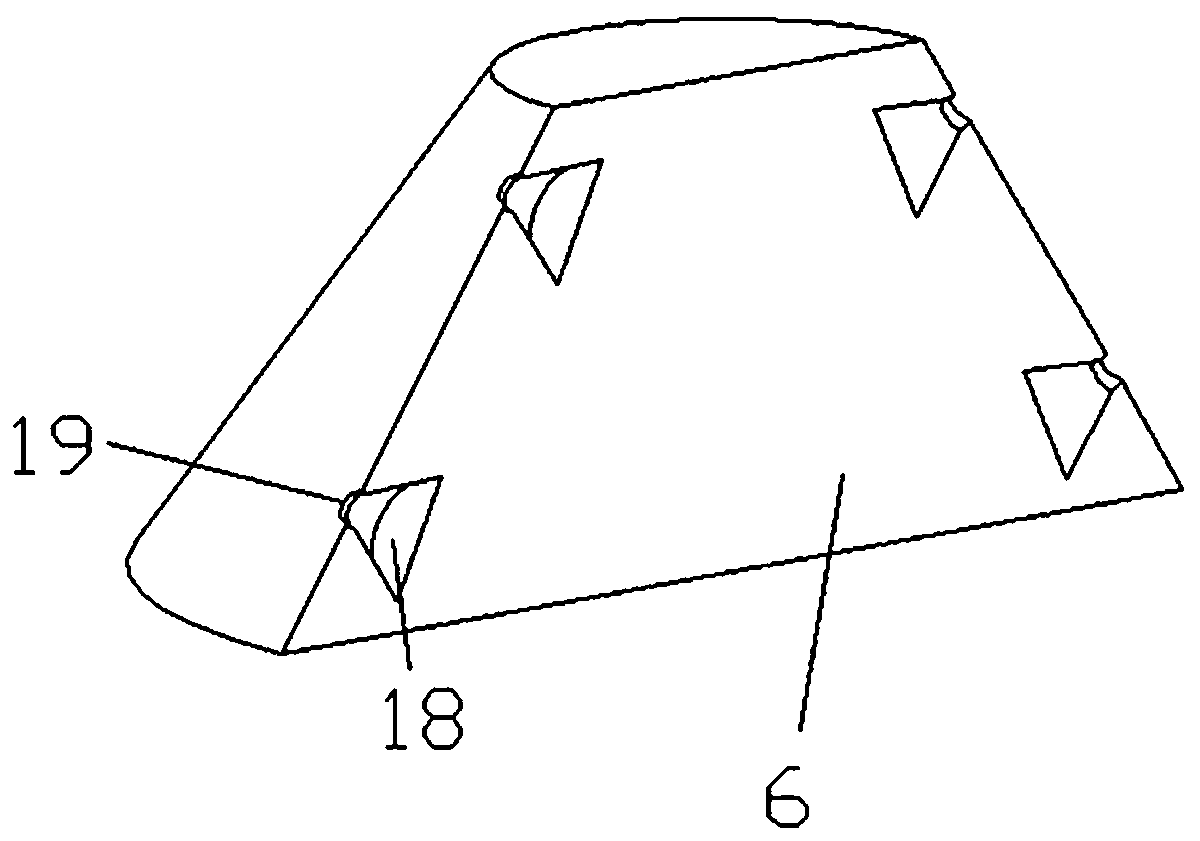

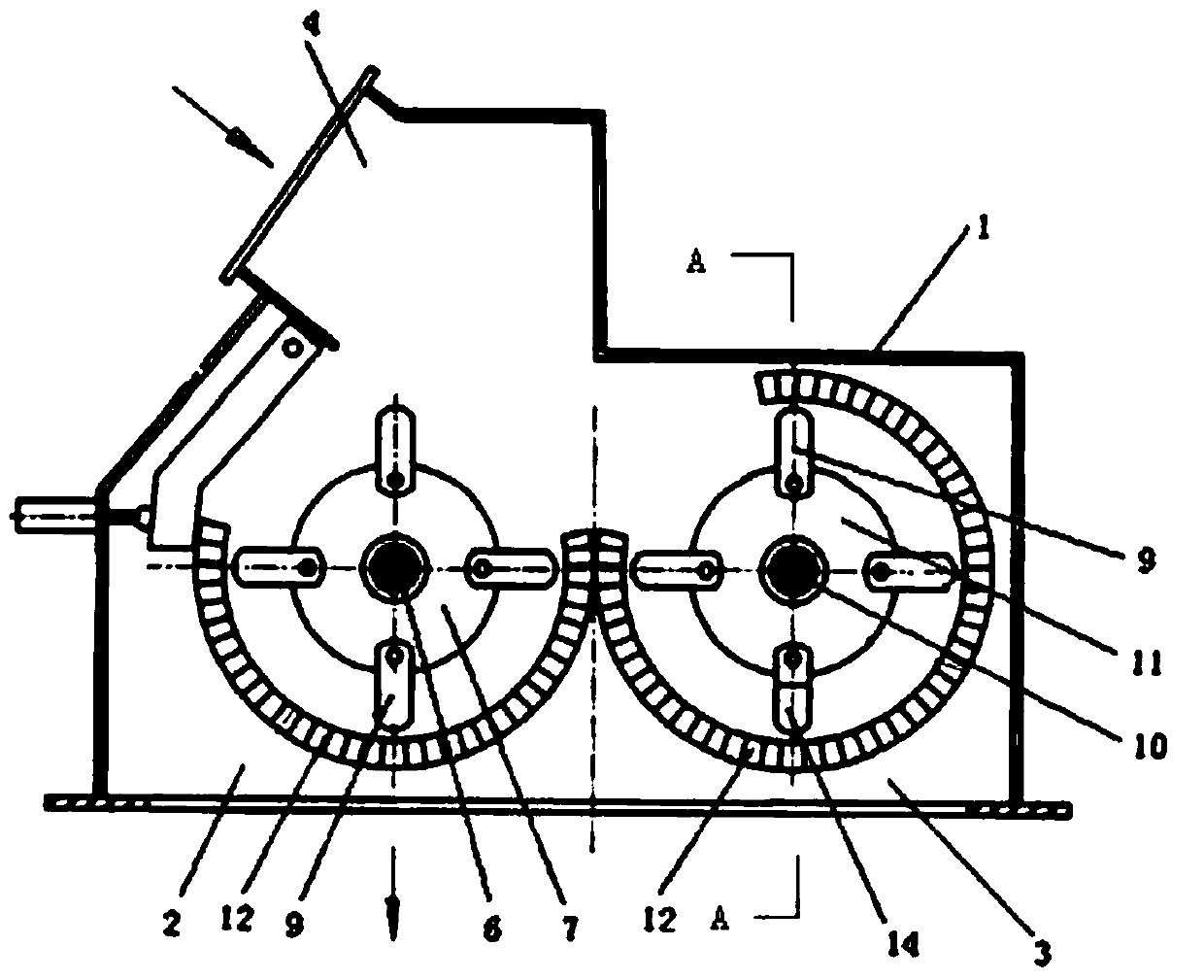

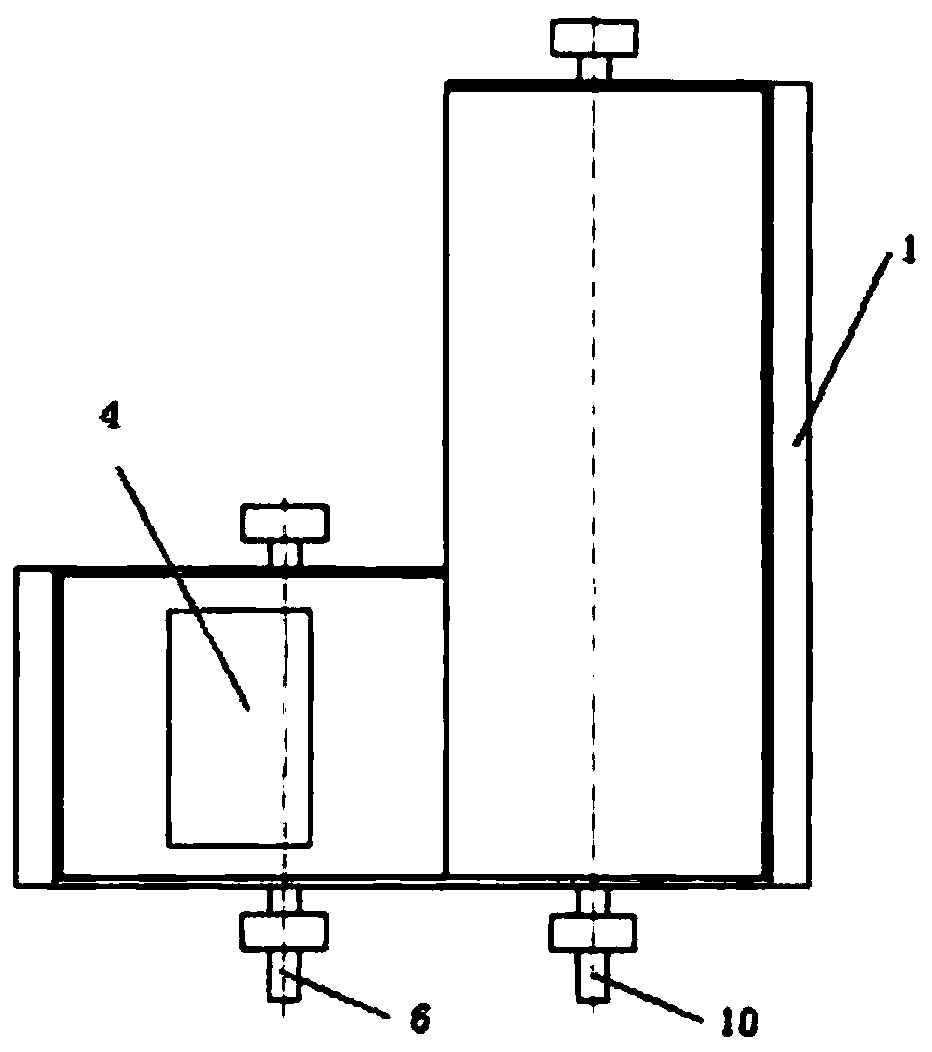

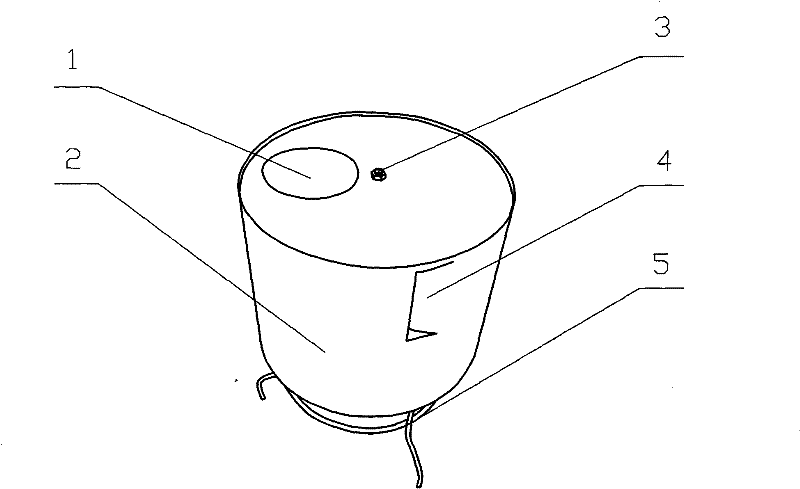

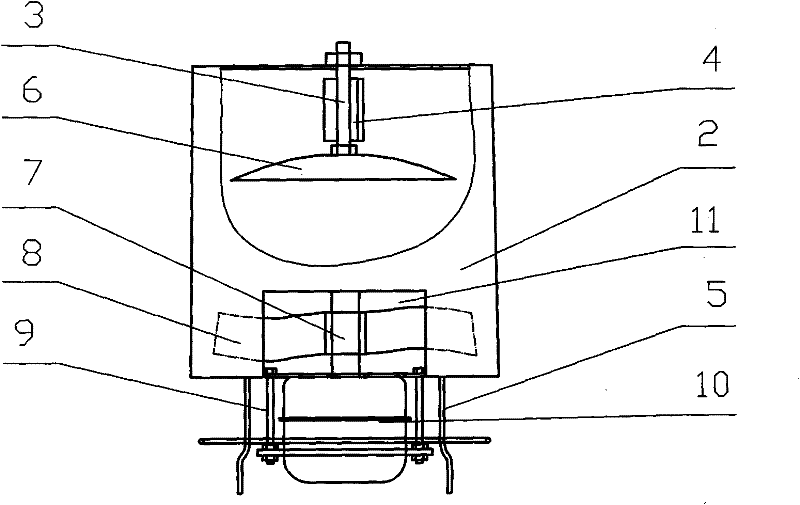

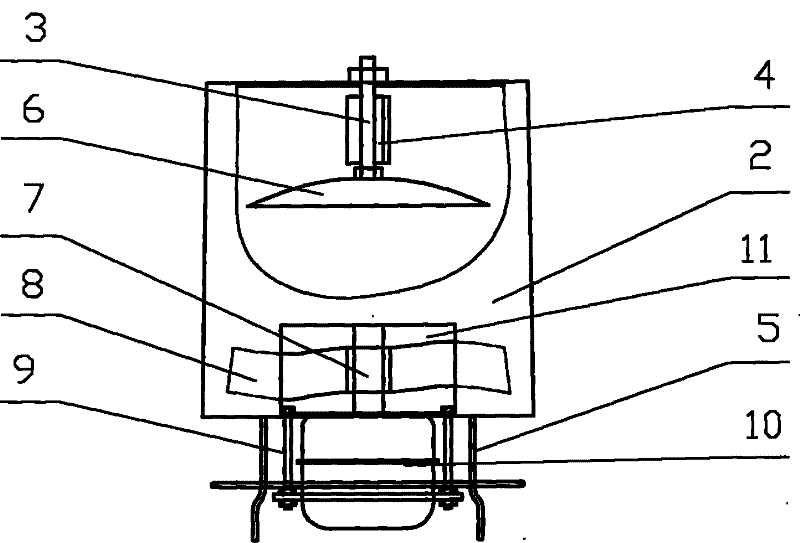

Cotton separating device

InactiveCN101857973ARealize automatic separationReduce volumeVegetable fibre separation from seedsElectric machineryEngineering

The invention relates to a cotton separating device, which comprises a shell and a bracket, wherein the bracket is provided with a motor used for driving a working mechanism in the shell; the shell is provided with a feed inlet and a cotton outlet and is a cylindrical barrel; the bracket is arranged below the shell and supports the barrel; the upper surface of the shell is provided with a circular charging opening, the upper part of the side wall of the shell is provided with a fragment outlet, and the lower part of the upper side wall of the shell is provided with the cotton outlet at a position corresponding to the fragment outlet; and the bracket is fixedly provided with the motor which is connected with the lower surface of the shell via a flange and a fixed lead screw, the output shaft of the motor penetrates through the central part of the lower surface of the shell upwards to be fixedly connected with the center shaft of vanes, and the multiple vanes are arranged in an axisymmetric manner. The cotton separating machine in the invention has small volume and convenient use, and is quite suitable for small-scaled cotton growers to use.

Owner:张务谨

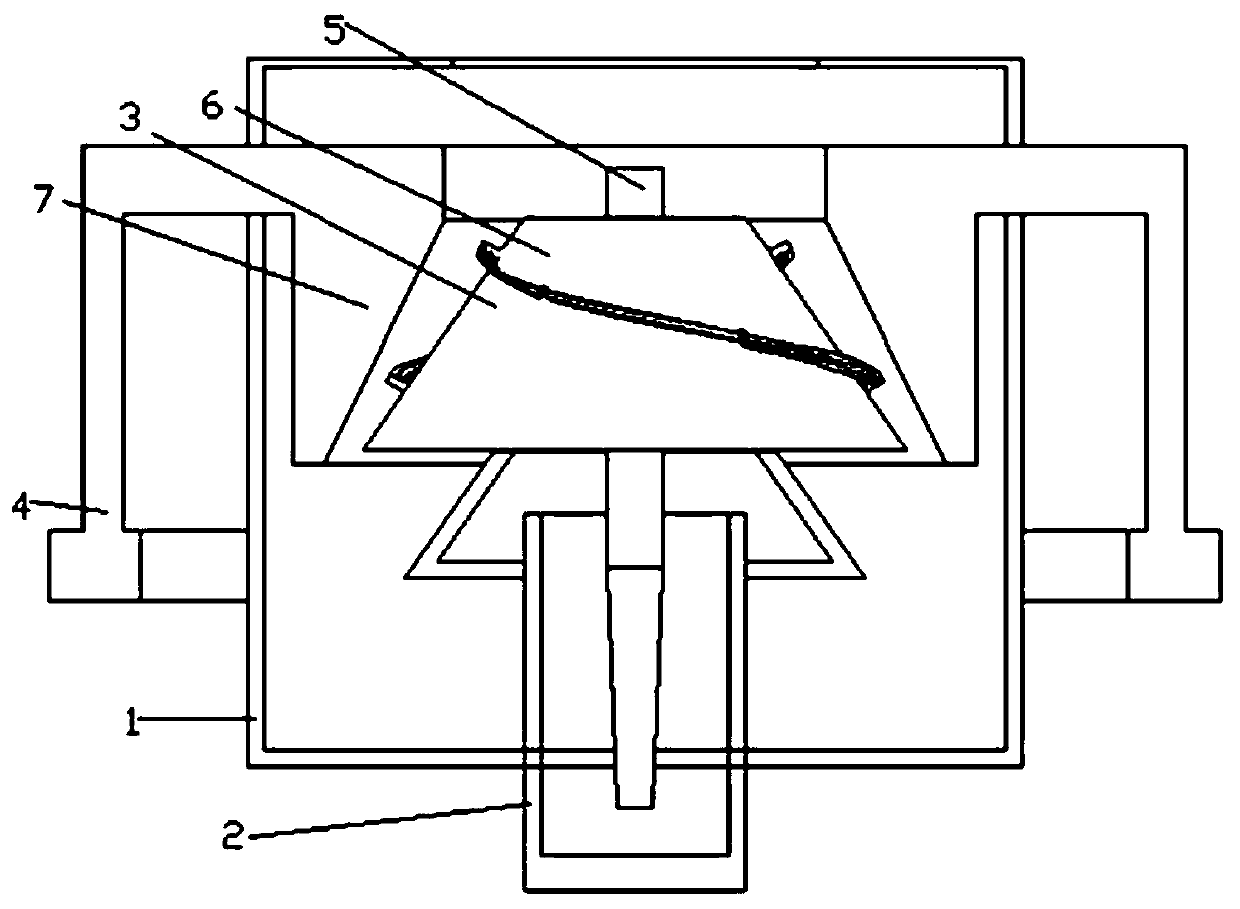

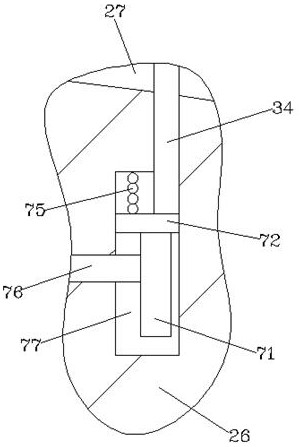

Novel rock cone crusher movable cone and using method thereof

The invention discloses a novel rock cone crusher movable cone and a using method thereof. The novel rock cone crusher movable cone comprises a rack, a movable cone assembly comprises a movable cone,and a front side blocking module and a rear side blocking module are arranged at the opposite positions of the front side and the rear side of the movable cone respectively; the front side blocking module is taken as an example, the front side blocking module comprises a first buffering module, a second buffering module, a third buffering module and a fourth buffering module, and the first buffering module, the second buffering module, the third buffering module and the fourth buffering module are the same in structure; and first blocking cloth is arranged between the first buffering module and the second buffering module, second blocking cloth is arranged between the second buffering module and the third buffering module, and third blocking cloth is arranged between the third buffering module and the fourth buffering module. The novel rock cone crusher movable cone has the beneficial effects that the front side blocking module and the rear side blocking module are arranged on the movable cone, so that the rock crushing quality is improved, and the working efficiency is improved.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

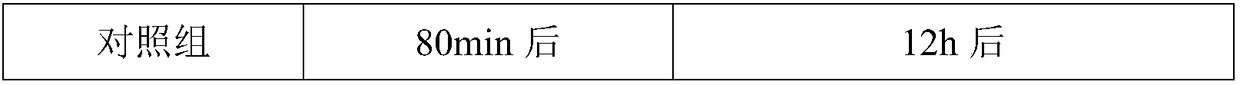

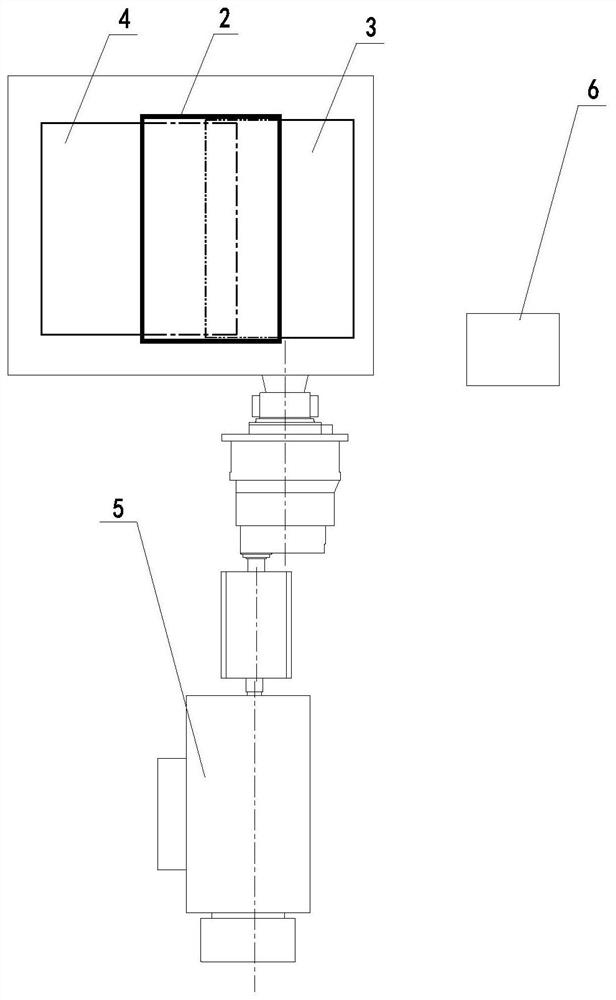

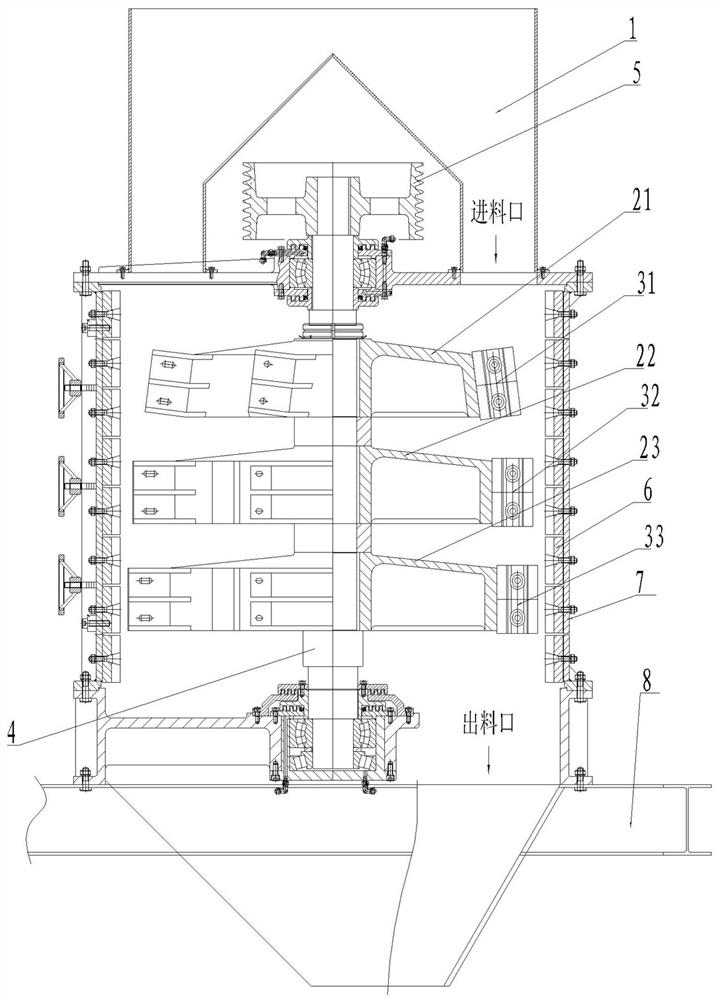

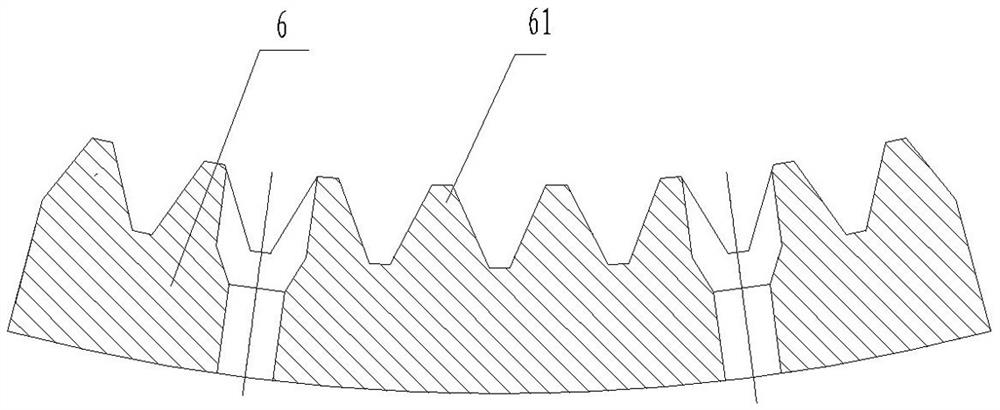

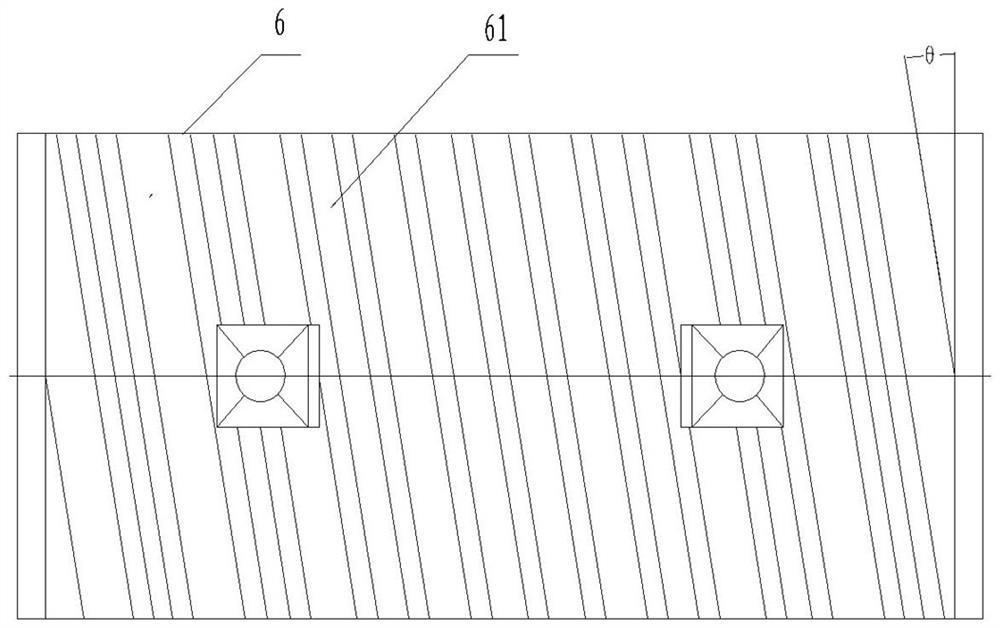

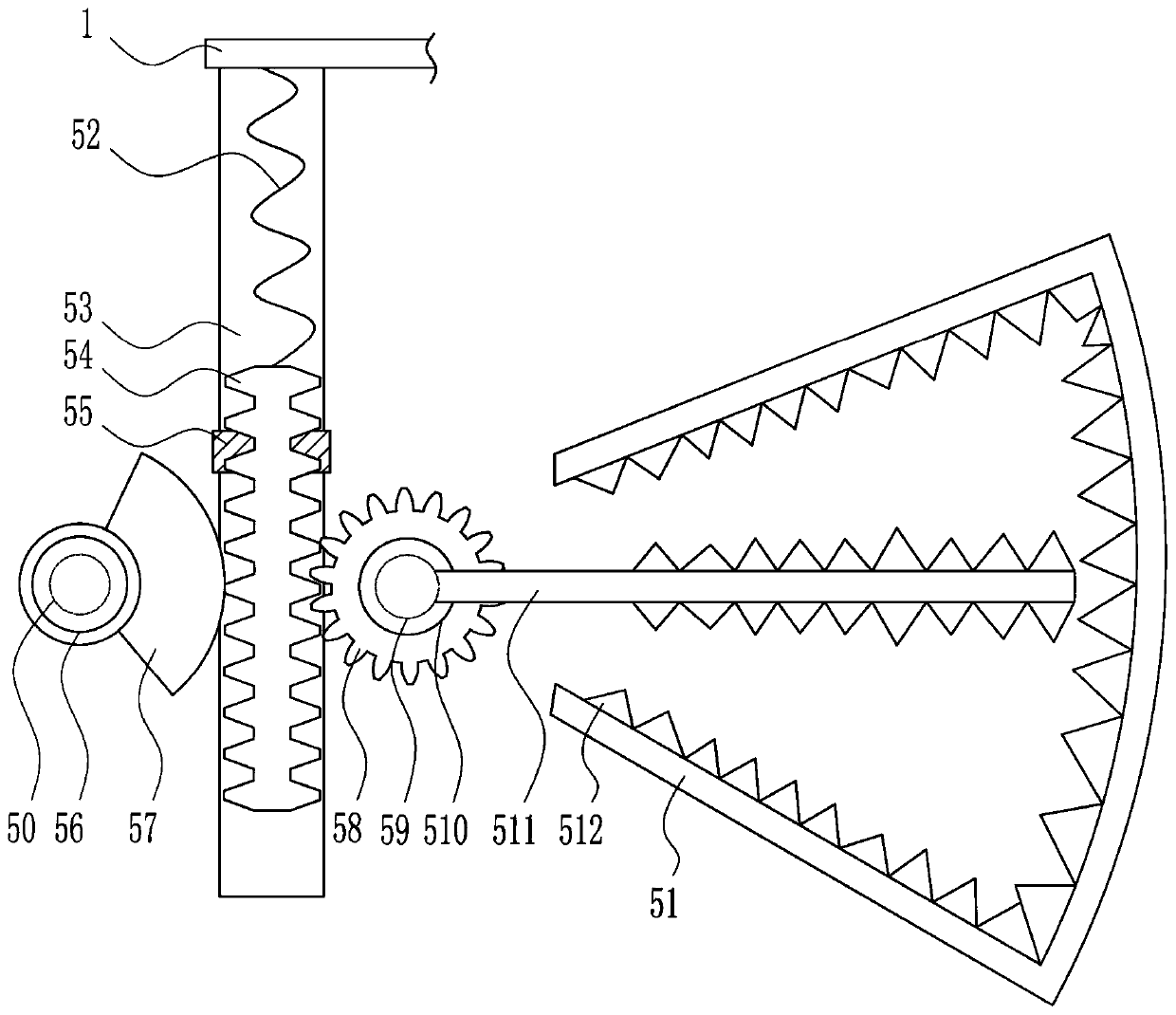

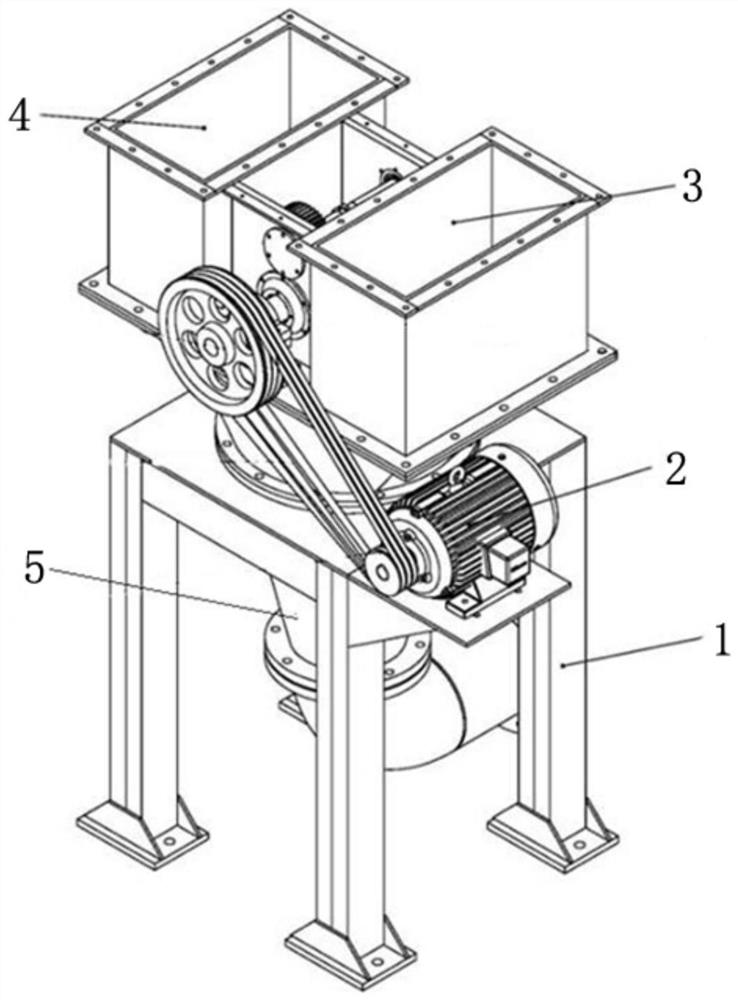

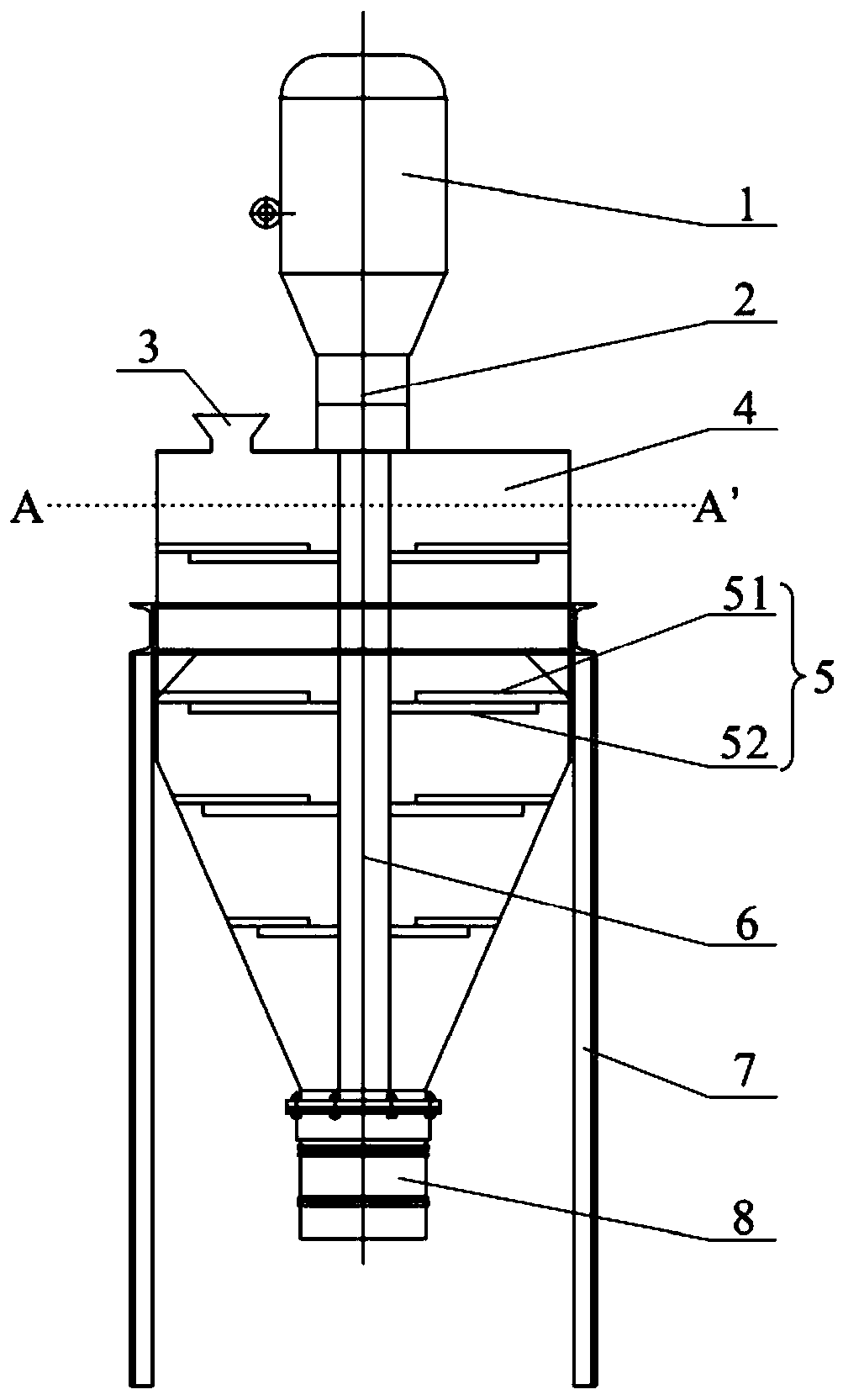

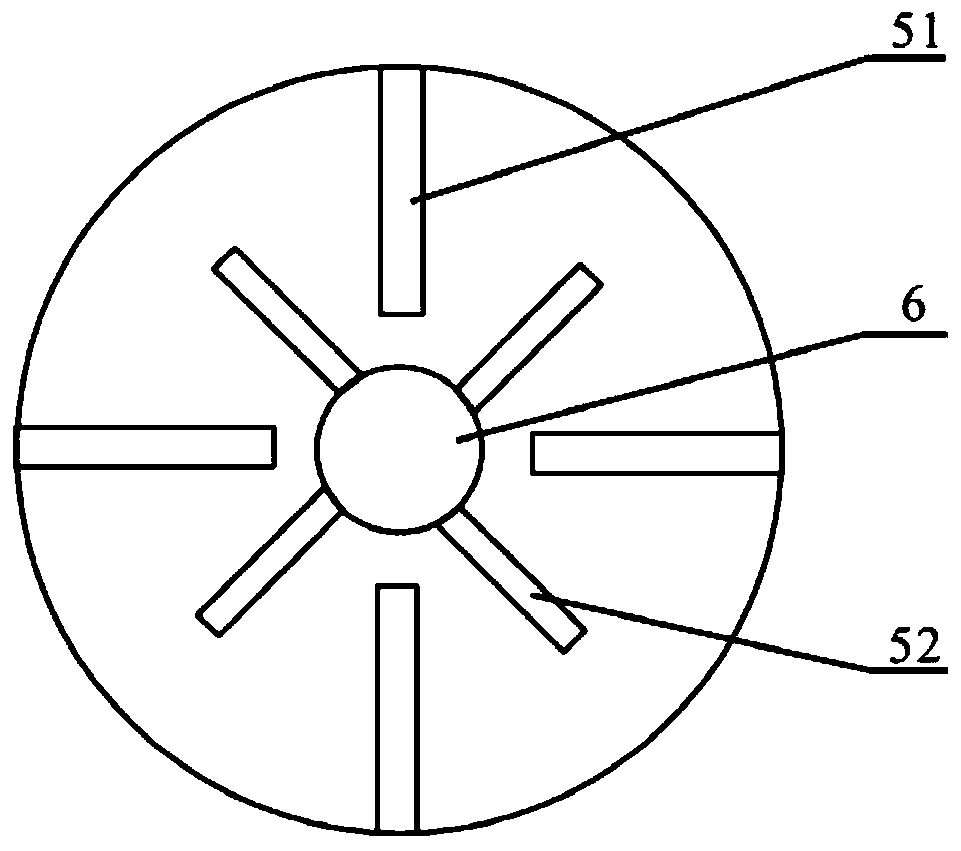

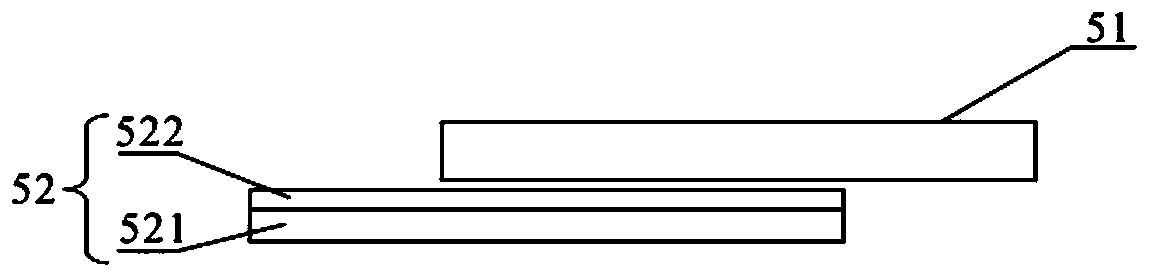

Efficient crushing sand making machine with novel lining plate

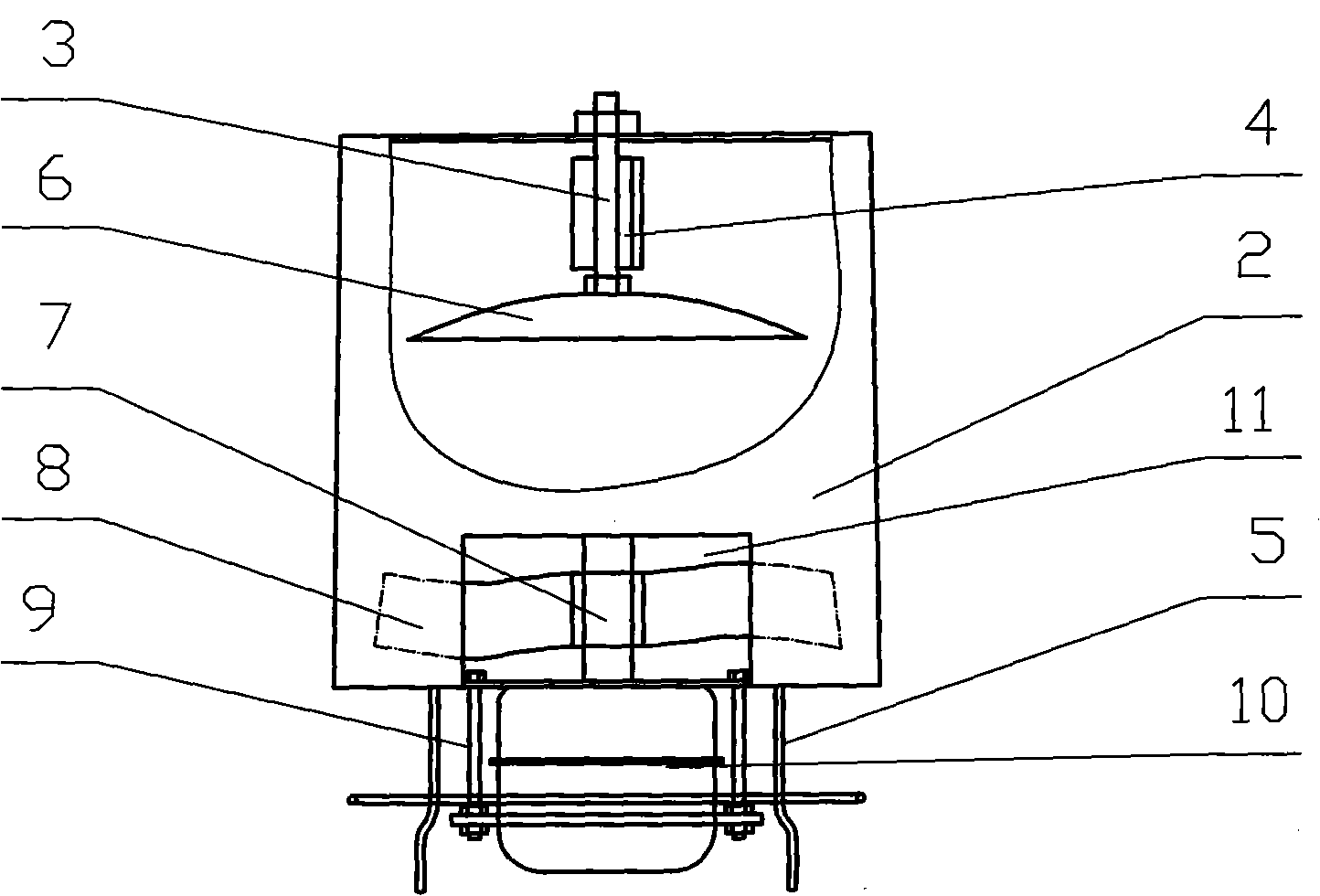

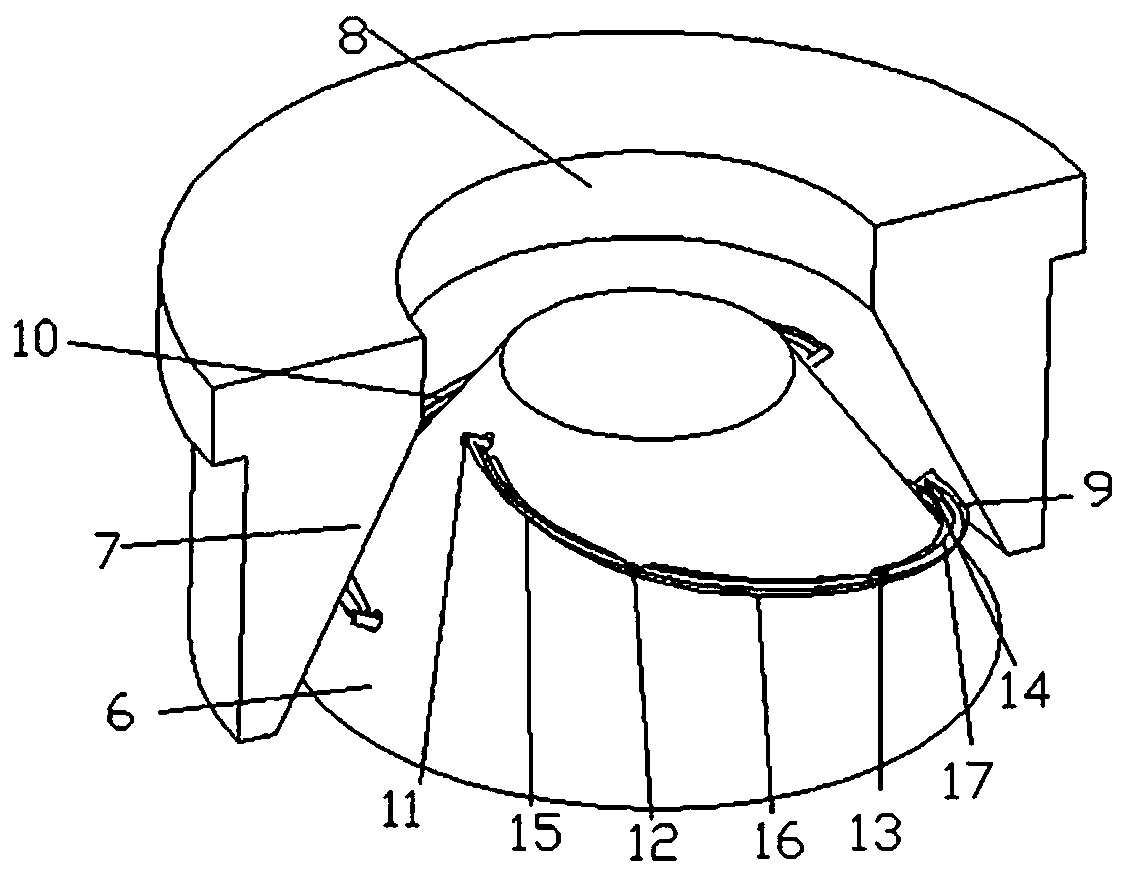

PendingCN112892735AExtended crushing timeImprove crushing efficiencyGrain treatmentsGeotechnical engineeringStructural engineering

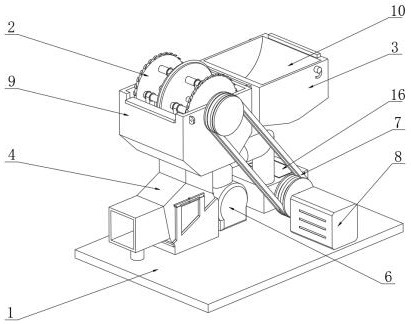

The invention provides an efficient crushing sand making machine with a novel lining plate. The efficient crushing sand making machine comprises a discharging hopper 1, a hammer body, a hammer head, a rotating shaft 4, a belt wheel 5, the lining plate 6, an outer cylinder 7 and a base 8. The discharging hopper 1 is installed on the base 8 through the outer cylinder 7; the rotating shaft 4 is installed in the outer cylinder 7 through a rotating shaft base; the belt wheel 5 is located on the discharging hopper 1 and installed at the upper end of the rotating shaft 4; the hammer body is installed on the rotating shaft 4 and the hammer head; and the lining plate 6 is installed on the inner wall of the outer cylinder 7; and the tooth-shaped rotating direction of the lining plate is left-handed rotation, and the tooth-shaped rotating angle theta of the lining plate is larger than 6 degrees and smaller than or equal to 12 degrees. According to the efficient crushing sand making machine, due to the fact that the tooth-shaped rotating direction of the lining plate of the crushing sand making machine is left-handed rotation and is opposite to the rotating direction of a rotating body of the crushing sand making machine, an effective shearing effect is formed on blocky stone, meanwhile, the effective crushing time is prolonged, and compared with an existing crushing sand making machine, the efficient crushing sand making machine has the beneficial effect of being high in crushing efficiency.

Owner:衡阳市朝阳重机有限公司

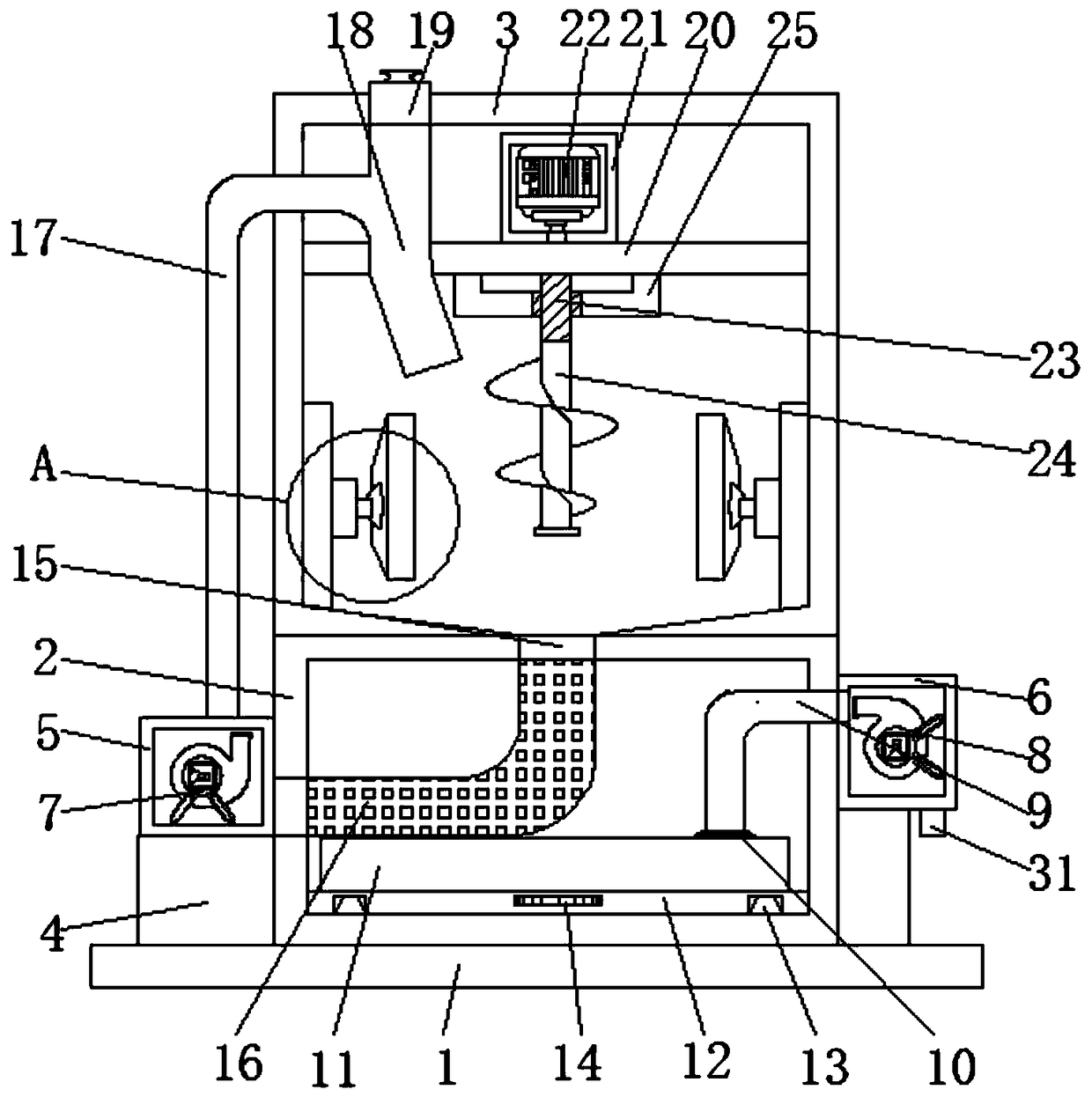

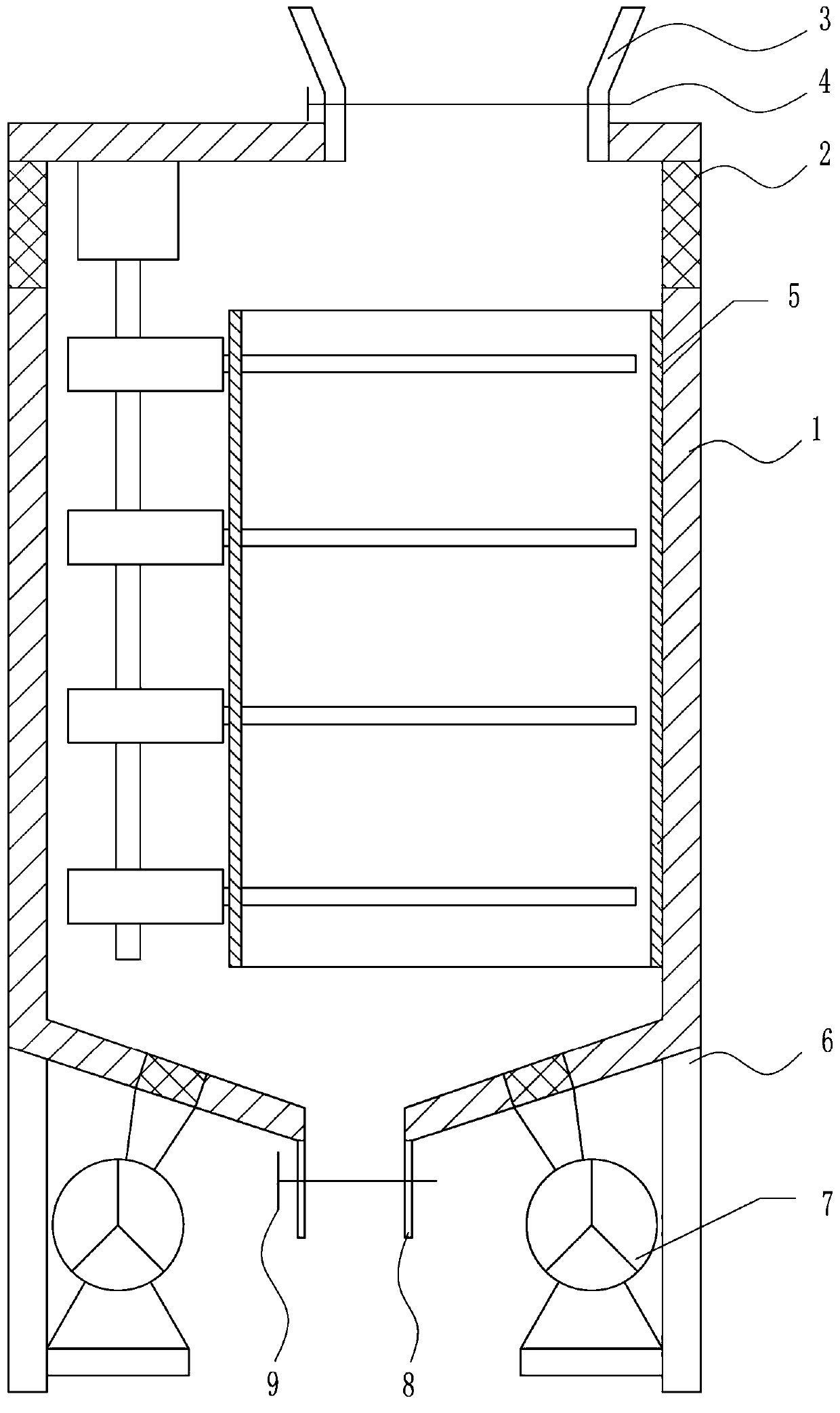

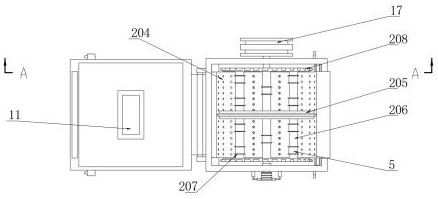

Agricultural straw pulverizing equipment

The invention discloses agricultural straw pulverizing equipment. The equipment comprises a bottom plate, a collecting box and a pulverizing box, the top of the bottom plate is fixedly connected withthe bottom of the collecting box, the top of the collecting box is fixedly connected with the bottom of the pulverizing box, fixing blocks are fixedly connected with the parts, located on both left and right sides of the top of the bottom plate, of both left and right sides of the collecting box, the tops of the two fixing blocks are fixedly connected with a first air pump box and a second air pump box respectively, the interiors of the first and a second air pump boxes are fixedly connected with a first air pump and a second air pump respectively, and the bottoms of the air pumps are communicated with vacuum boxes through connecting nets. The invention relates to the technical field of pulverizing. The equipment has the advantages that by the cooperatively use of the first air pump, the second air pump, a filtering pipe and the vacuum boxes, materials with proper sizes are screened out, vacuum treatment is conducted under the action of the second air pump, fuel is directly produced, the fuel production cost is reduced, and the working efficiency is improved.

Owner:肥西县堰丰农业农民专业合作社

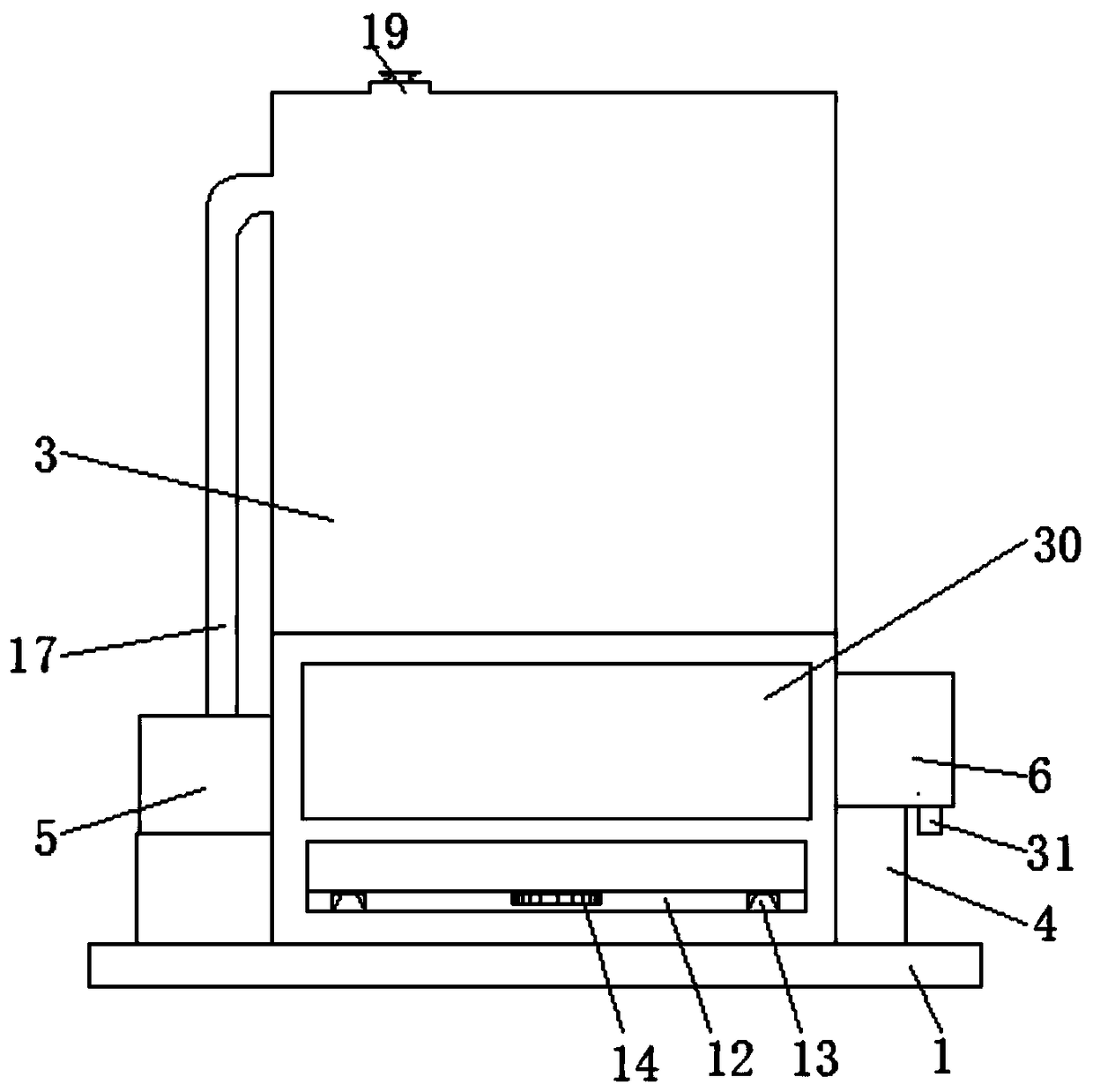

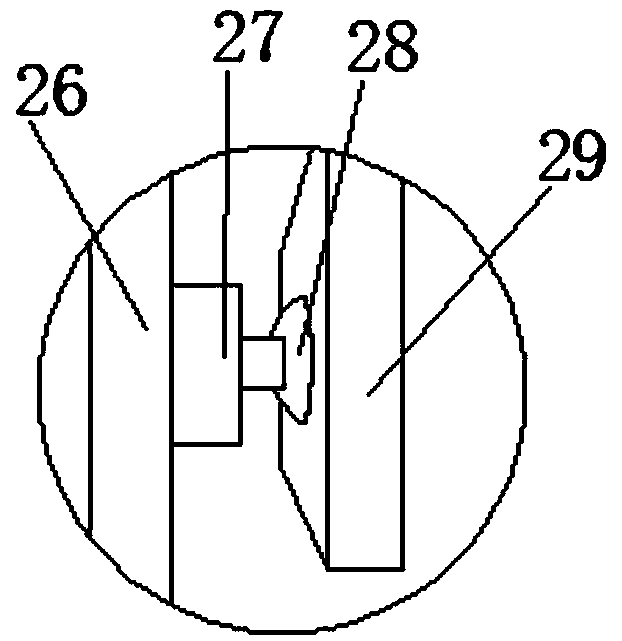

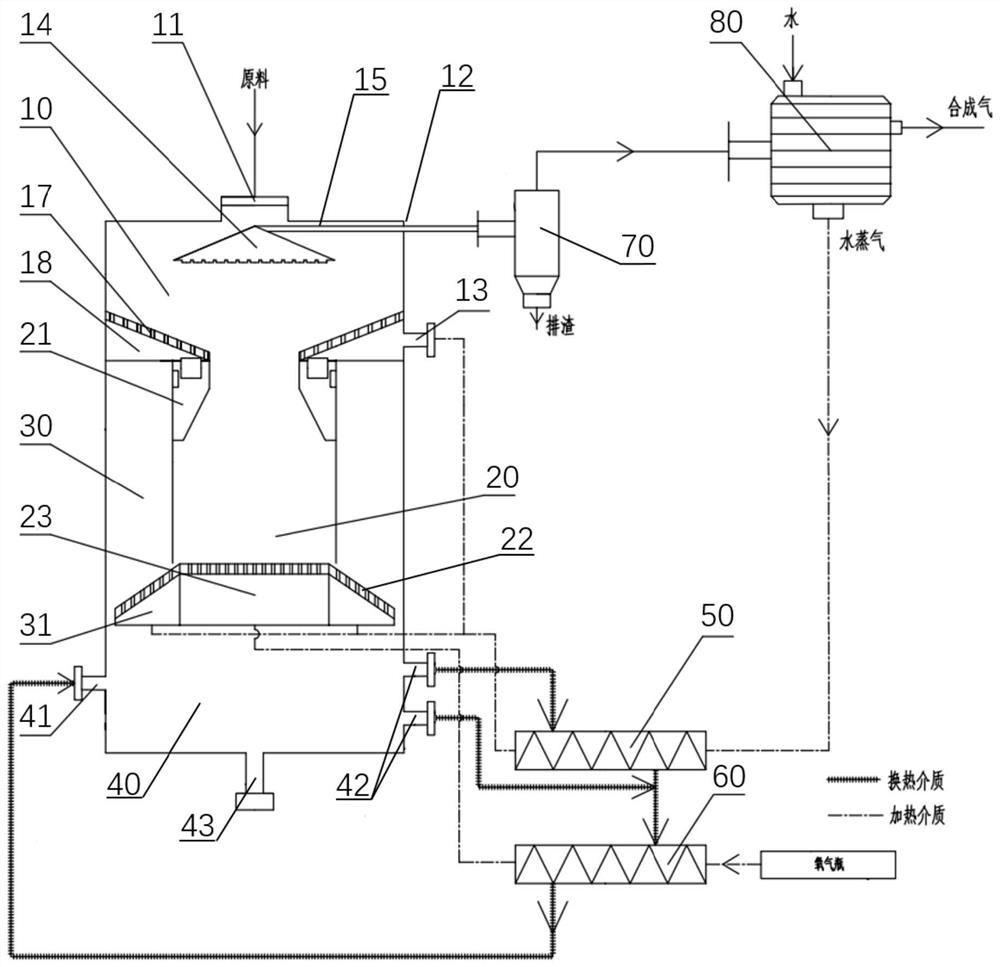

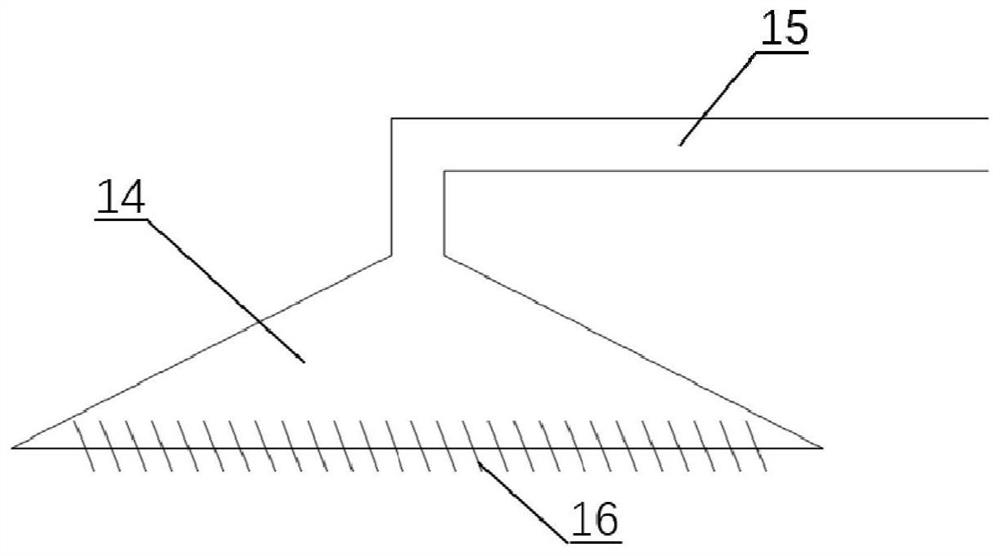

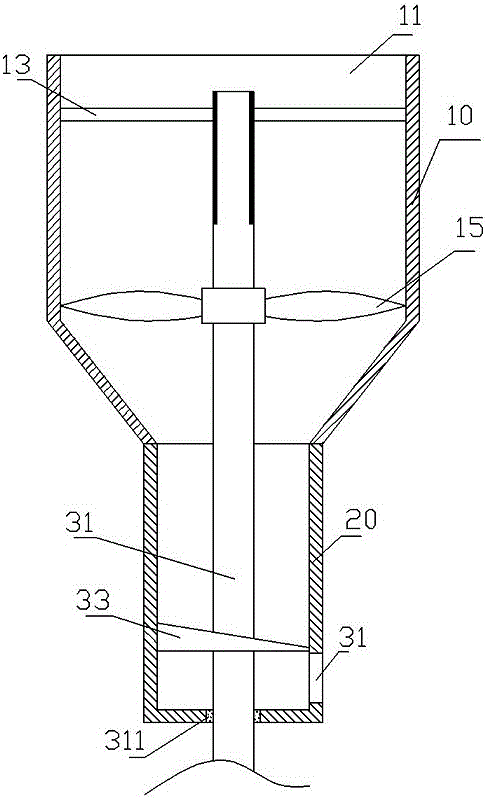

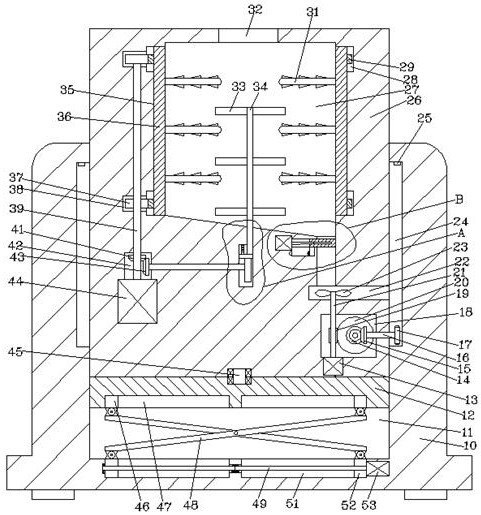

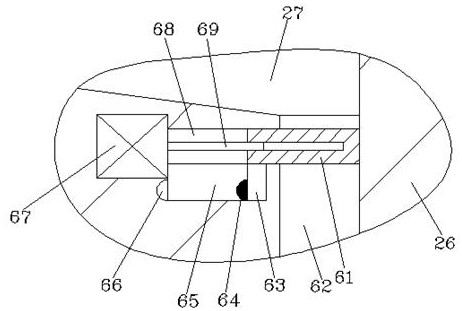

A gasification reactor suitable for wide screening of raw materials

ActiveCN113801701BCompact structureSmall footprintEnergy inputGasification processes detailsFixed bedSolid fuel

The invention belongs to the technical field of solid fuel utilization, and discloses a gasification reactor suitable for wide screening raw materials, which includes a reactor body, and the reactor body includes a first reaction chamber, a second reaction chamber and a third reaction chamber communicated with each other. Reaction chamber; the second reaction chamber and the third reaction chamber are located below the first reaction chamber, and the third reaction chamber is sheathed on the periphery of the second reaction chamber; the side wall of the first reaction chamber is provided with a first air vent for introducing gas The oxidizing agent makes the small particle raw materials in the first reaction chamber fluidized and undergoes gasification reaction; the second vent is provided at the bottom of the second reaction chamber, which is used to pass in the oxidant to make the particle bed accumulated in the second reaction chamber undergo oxidation reaction ; The bottom of the third reaction chamber is provided with a third vent, which is used to feed gasification agent so that the particles in the third reaction chamber are fluidized and gasification reaction occurs. The reactor of the invention combines the characteristics of the fixed bed and the fluidized bed to realize high-efficiency gasification of wide-screened solid fuels, which is helpful for the popularization and application of gasification technology.

Owner:HUAZHONG UNIV OF SCI & TECH

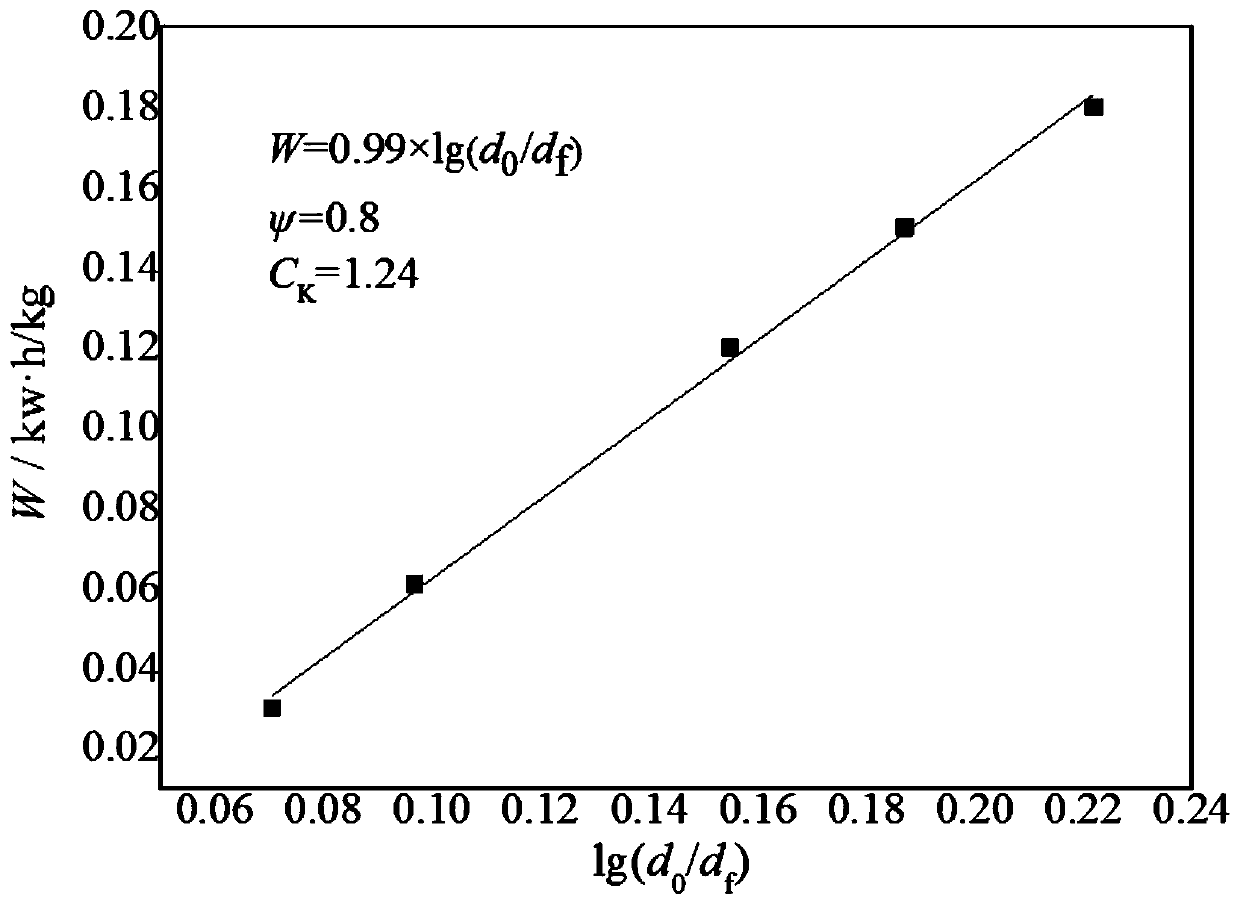

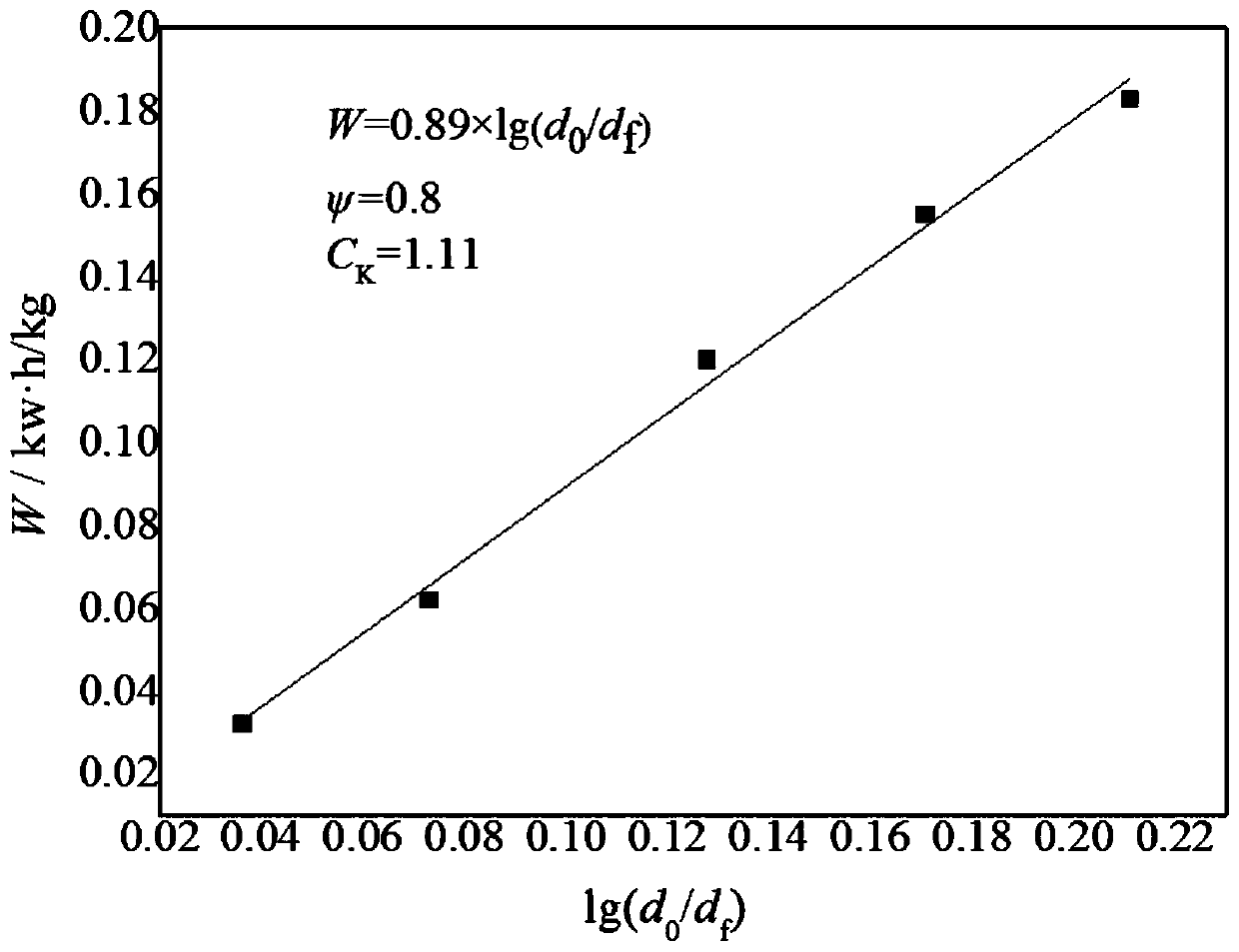

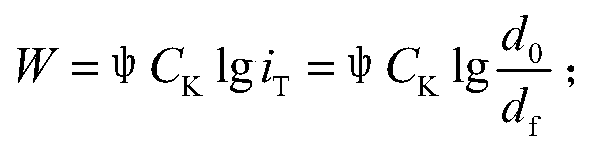

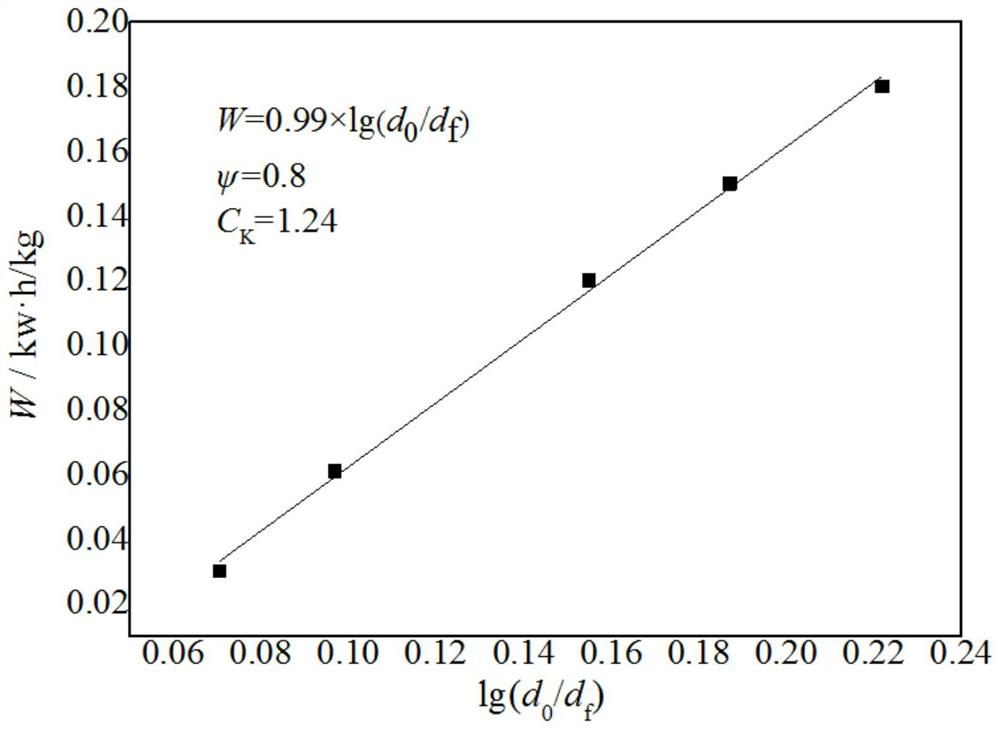

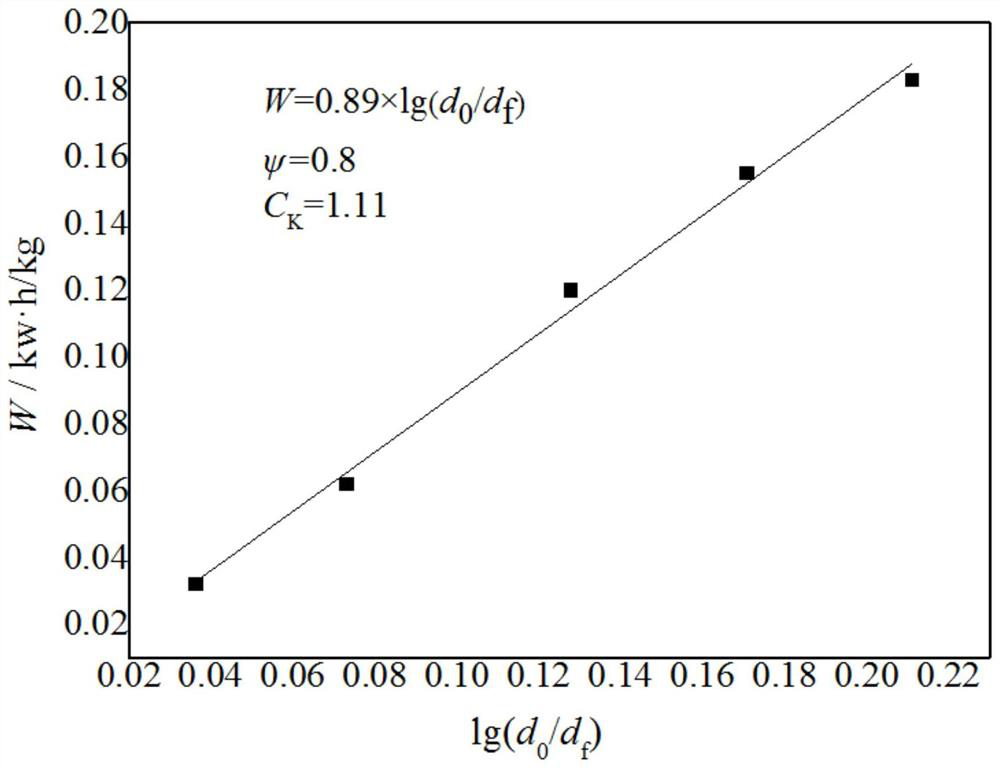

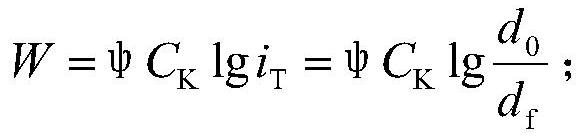

Method for measuring and evaluating high temperature performance of lump coal in smelting reduction ironmaking

ActiveCN110045082ASimple processStable process parametersFuel testingParticle size analysisCoalParticle-size distribution

The invention discloses a method for measuring and evaluating the high temperature performance of lump coal in smelting reduction ironmaking. The method comprises the steps of: weighing a lump coal sample having the pre-set mass m<1>, wherein the average particle size of the lump coal sample is d<0>; increasing the temperature of the weighed lump coal sample in 100% N<2> atmosphere, and keeping the temperature; increasing the temperature of the lump coal sample to 700-850 DEG C in 20% CO<2> and 80% N<2> atmosphere, and keeping the temperature; increasing the temperature of the lump coal sampleto 1100 DEG C in 20% CO<2> and 80% N<2> atmosphere, then, switching the atmosphere into 100% CO<2>, and completely reacting; obtaining the reactivity C of the lump coal by calculation; measuring particle size distribution of the reacted lump coal sample in different input power W, and obtaining the average particle size d<f> after reaction by calculation; and, performing linear fitting and mapping by taking a formula as shown in the specification as the horizontal coordinate and the input power W as the vertical coordinate, and obtaining the fracture coefficient of the lump coal sample bycalculation according to the fit straight slope k. The method in the invention considers influence of the smelting intensity, the atmosphere and the actual temperature schedule of a melting gasification furnace; and an evaluation result is relatively objective and true.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

Preparation process of a molybdenum-niobium alloy sputtering target

ActiveCN105887027BLower surface energyAvoid stickingTransportation and packagingVacuum evaporation coatingPolyvinyl alcoholAlloy composite

The invention belongs to the technical field of metallurgical materials, and specifically relates to a preparation process of a molybdenum-niobium alloy sputtering target, which includes the steps of powder making, molding, vacuum sintering and mechanical processing. The powder making includes the following steps: molybdenum powder and niobium powder Load it into a ball mill according to a weight ratio of 6-10:1, then add a process control agent and zirconia grinding balls, perform ball milling under argon protection, sieve, and separate to obtain a molybdenum-niobium alloy composite powder; the process control The weight of agent and zirconia grinding ball is respectively 0.01-0.05 times and 5-20 times of the total weight of molybdenum powder and niobium powder; described process control agent is zinc stearate, palmitic acid, ethyl stearate, polyester One or more of vinyl alcohol and stearic acid. The molybdenum-niobium alloy sputtering target obtained in the present invention has a single phase structure, uniform structure without holes, average grain size of 40-65 μm, density ≥ 9.85g / cm3, excellent performance, and can be widely used in fields such as flat-panel displays .

Owner:洛阳丰联科绑定技术有限公司

Ore crushing machine suitable for different sizes

InactiveCN108525812AWon't breakExtended service lifeGrain treatmentsInitial treatmentHydraulic cylinder

The invention provides an ore crushing machine suitable for different sizes. The machine comprises an ore crushing machine body, a material conveying conveyor belt, a feeding conveyor belt, a baffle plate, an initial treatment device, a feeding hopper, a crushing box, a material discharging opening, a gearbox, a motor box, a control box, a power control panel, a second motor, a rubber base, a belt, a third motor, supporting legs, conveyor belt rolling roller, a combustion box, a water tank, a water pump, a gas tank, a gas delivery pipe, a first pressing plate, a crushing table, a first hydraulic cylinder, an electric drill, a second hydraulic cylinder, a second pressing plate, a top plate, a fire spraying head, a water spraying head, a connecting rod and a drill bit. According to the ore crushing machine, large ores can be rapidly crushed into small ores by an fire-burning water-cooled electric drill, and then the small ores are conveyed to a crusher through a conveying belt for crushing, so that blockage is prevented, the crushing efficiency is improved, the crusher is protected and prevented from being damaged by the large ores, the service life of the crusher is prolonged, the crushing time is rapid, the quality is good, convenience is brought to people, the structure is simple, and the popularization is convenient.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

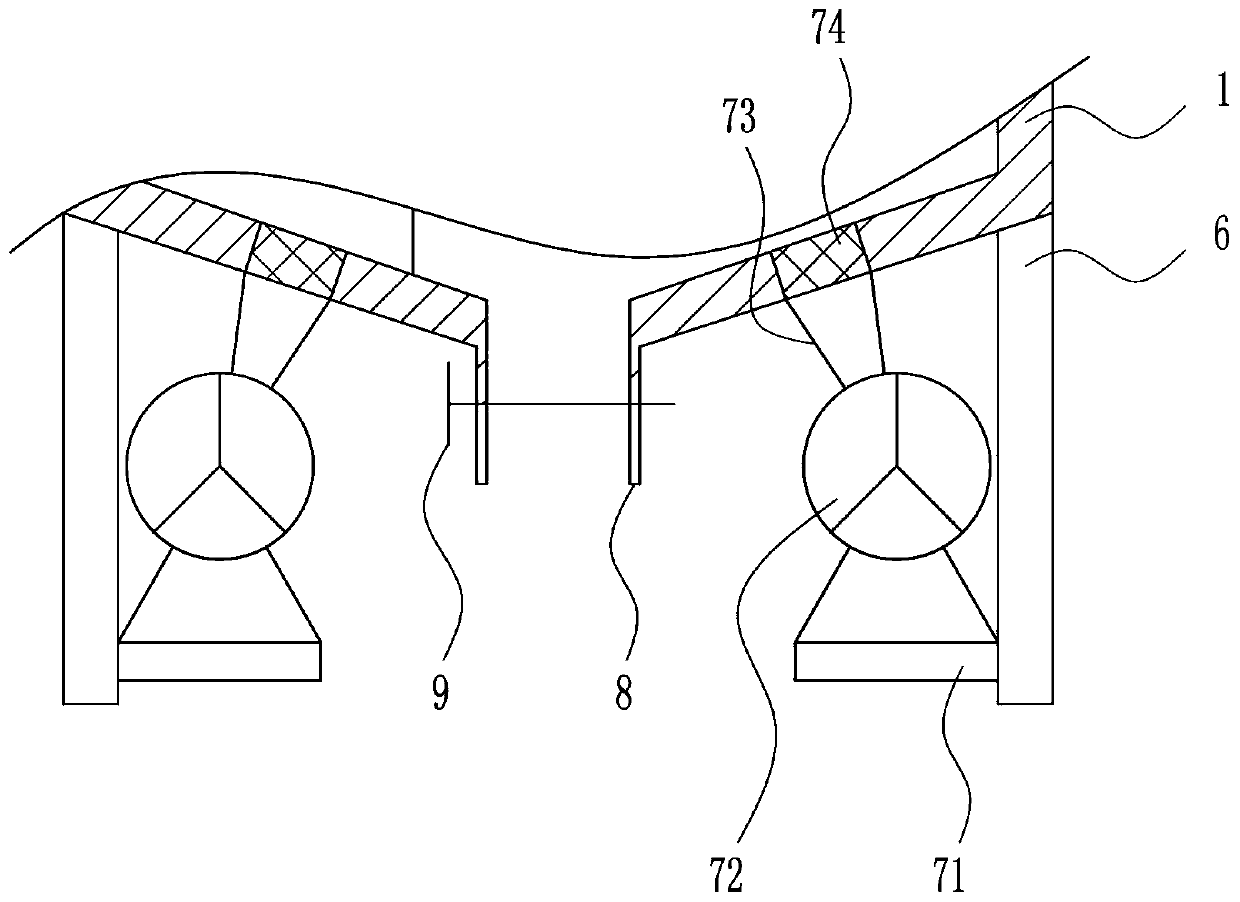

A tea uniform crushing device

The invention relates to a crushing device, in particular to the uniform crushing device for tea leaves. The technical problem to be solved is to provide a uniform crushing device for the tea leaves.The uniform crushing device comprises a crusher body, first mesh plates, a feed hopper, a first valve, a crushing mechanism and racks; air blowing devices are arranged on the racks on the left side and the right side, and the air blowing device is connected with the bottom of the crusher body; the crusher body is arranged on the tops of the racks on the left side and the right side, and the feed hopper is arranged on the right side of the top of the crusher body; the first valve is arranged on the feed hopper, and the crushing mechanism is arranged inside the crusher body; a discharging pipe is arranged in the middle of the bottom of the crusher body, and a second valve is arranged on the discharging pipe. According to the uniform crushing device for the tea leaves, the effects of being small in crushing degree difference and high in uniformity are achieved.

Owner:安徽青春塘健康产业有限公司

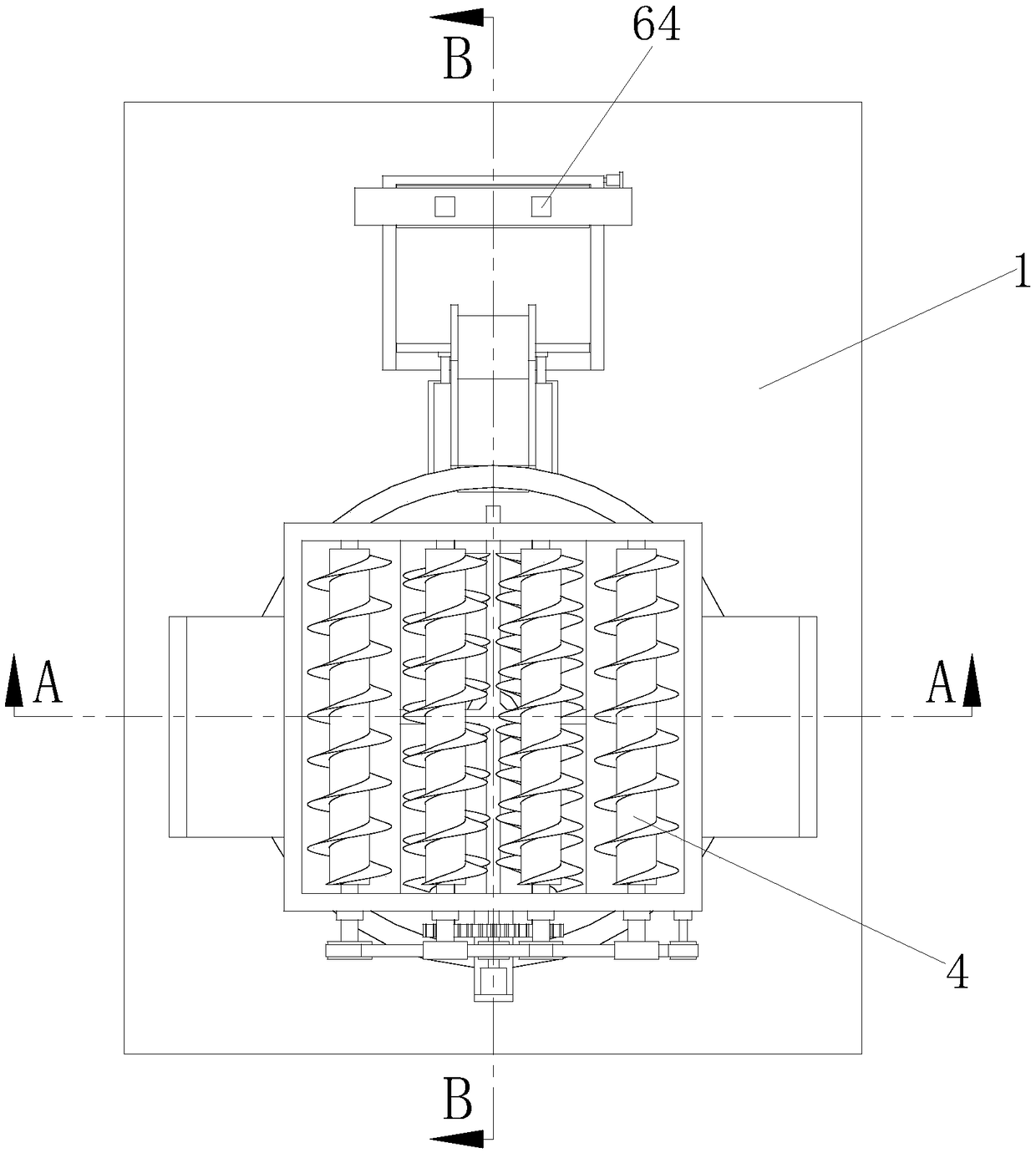

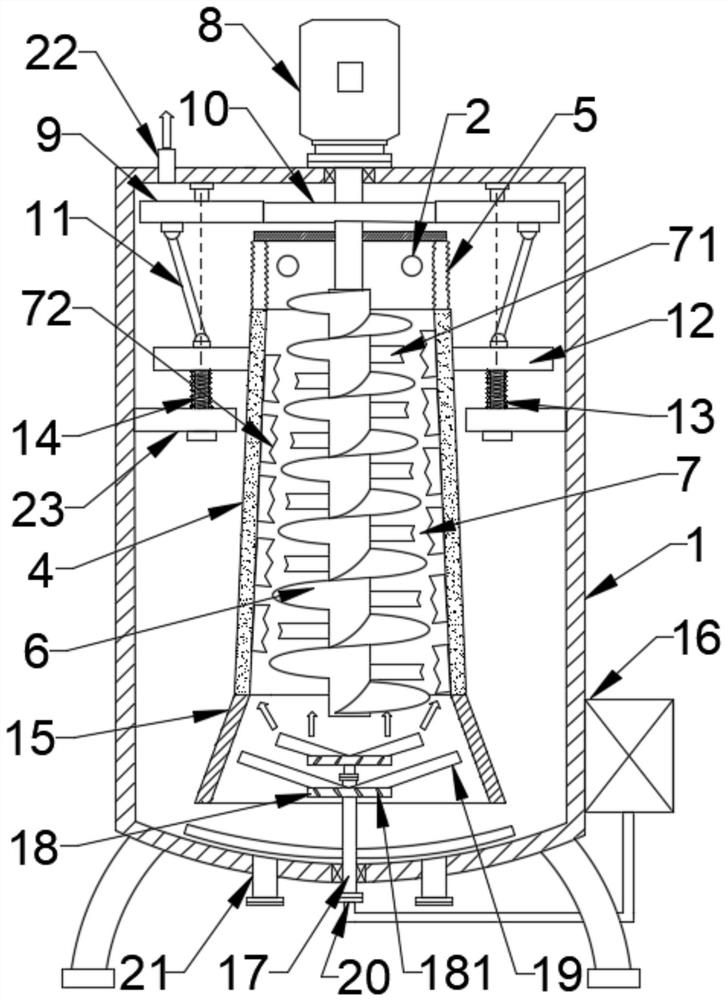

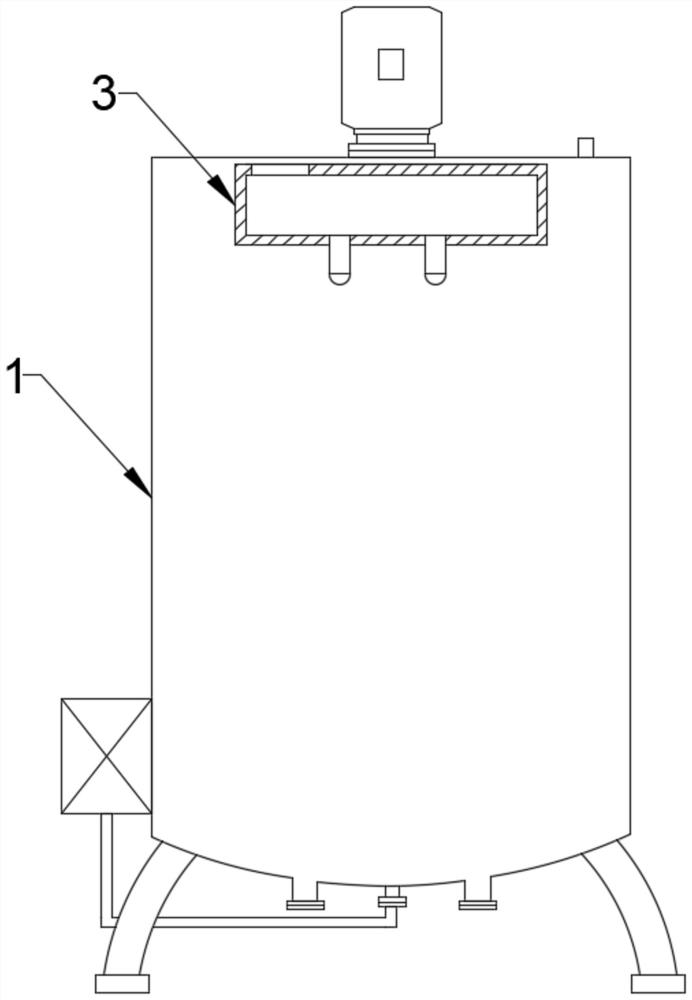

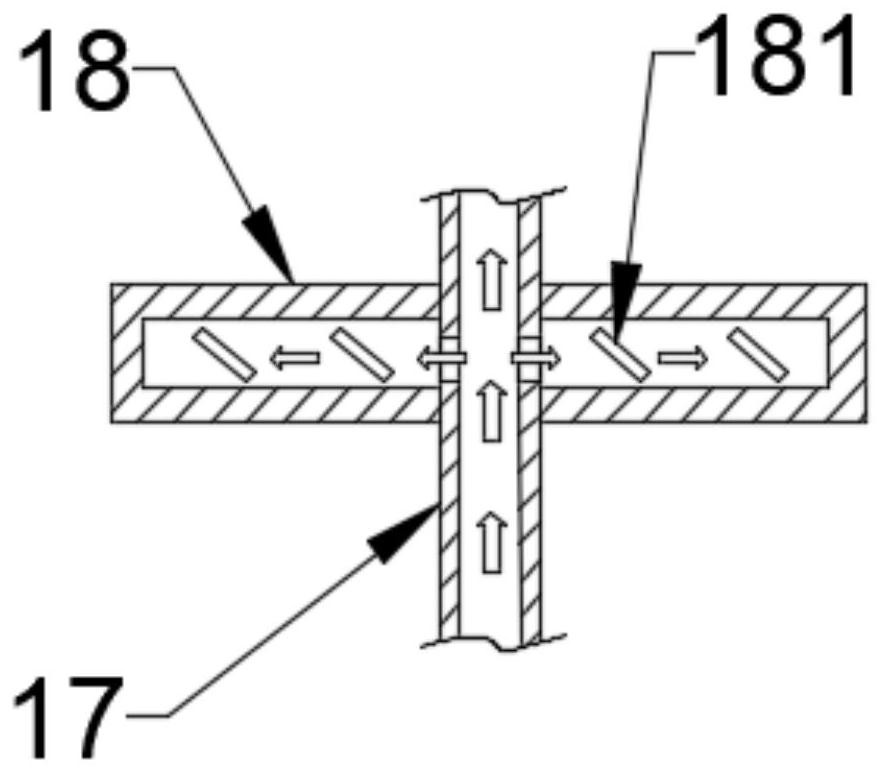

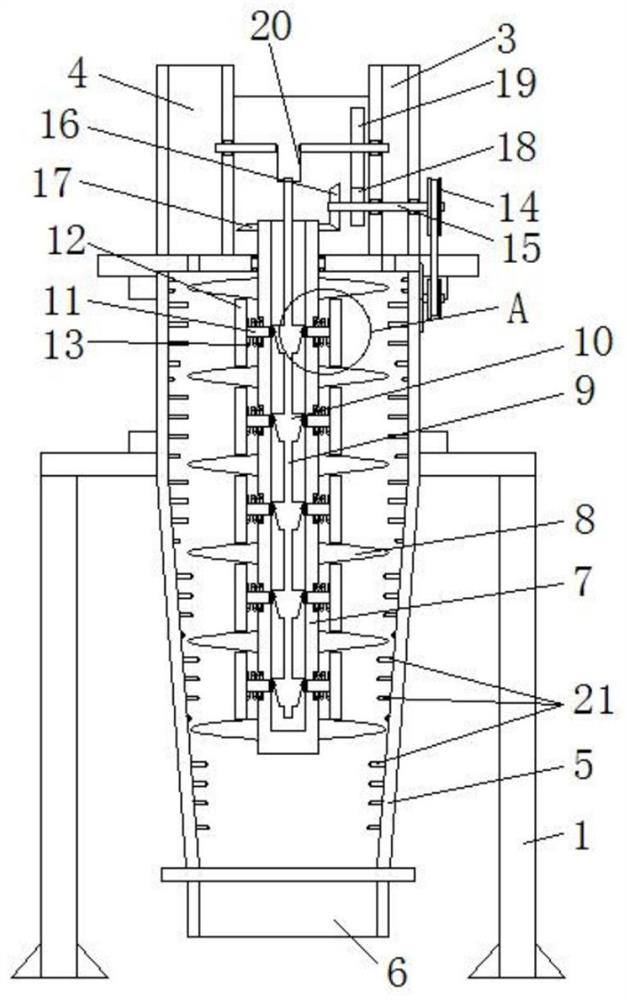

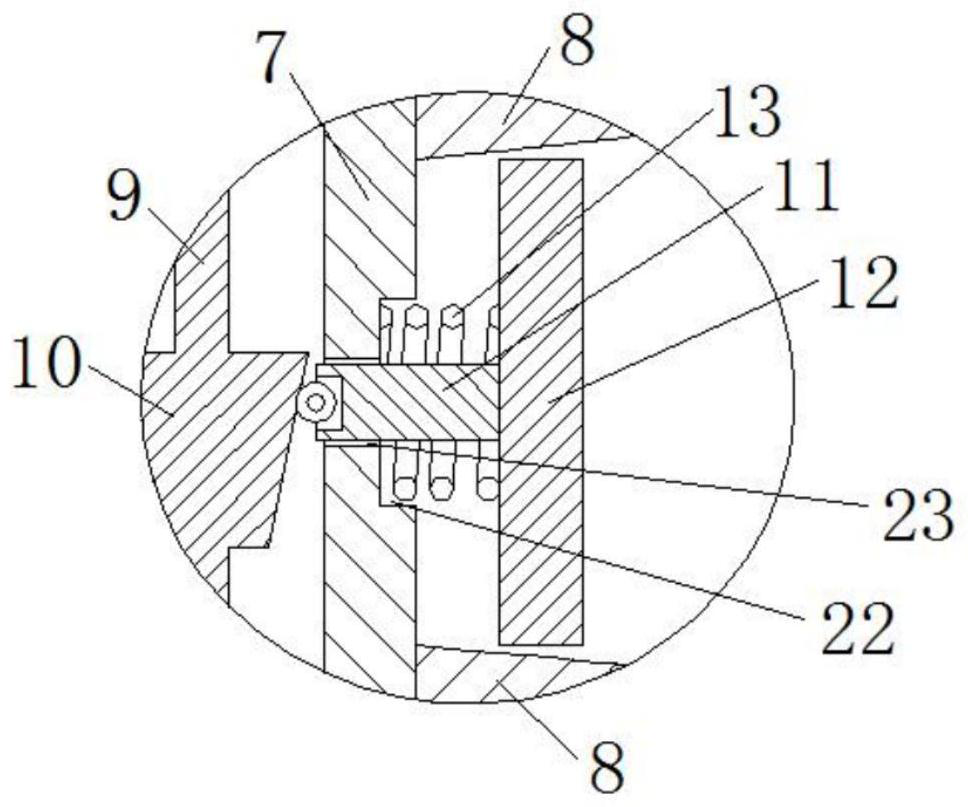

A kind of powdery seasoning crushing preparation device

ActiveCN113333115BImprove dredging effectRealize the phenomenon of jammingDrying gas arrangementsGrain treatmentsHelical bladeProcess engineering

The present invention is applicable to the technical field of seasoning processing, and provides a powdered seasoning pulverization and preparation device and a casing. The device further comprises: a rounded table bucket, which is movably arranged in the casing; a pulverizing component is installed in the rounded table bucket , the pulverizing assembly includes: a helical blade fixed on the periphery of the central shaft, the central shaft is driven to rotate by a power member installed on the casing, the central shaft and the rounding table bucket are concentrically arranged, and the helical radius of the helical blade is The radius of the rounded table bucket increases in sequence, and a crushing channel is formed between the inner wall of the rounded table bucket and the central axis. The powdery seasoning preparation device provided by the embodiment of the present invention has good crushing and The drying effect simplifies the production process, and can effectively prevent the jamming phenomenon in the process of crushing and preparing crushing. The design is novel and worthy of promotion.

Owner:青岛花帝食品配料有限公司

A two-stage crusher

Owner:CHANGSHA SHENXIANG UNIVERSAL MACHINE

Beancurd jelly discharging device for bean products

InactiveCN106578124AFully brokenCompletely brokenCheese manufactureFood scienceSpiral bladeHysteresis phenomenon

The invention relates to the bean product production field, and in particular, relates to a beancurd jelly discharging device for bean products. The device comprises a material containing barrel, a material dropping channel and a driving mechanism; the upper part of the material containing barrel is provided with a feed inlet; the driving mechanism comprises a movable rod; the lower part of the movable rod is connected with a driving element, and the movable rod passes through the material dropping channel and extends into the material containing barrel; the interior of the material containing barrel is connected with a grid plate, and the center of the grid plate is provided with a threaded hole; the movable rod is in thread fitting with the grid plate; the movable rod is connected with a spiral blade, and the spiral blade is located below the grid plate; the material dropping channel is connected at the lower end of the material containing barrel; the material dropping channel is internally connected with a material dropping plate in a sliding manner, and the material dropping plate is supported at the bottom surface of the material dropping channel through a press spring; the side wall of the material dropping channel is provided with a discharge port. The invention aims at providing the beancurd jelly discharging device for the bean products, and the problems that in a conventional device, the problem that bean milk and water are insufficient in mixing because incomplete cutting and hysteresis phenomena appear when beancurd jelly is cut by a screen is solved.

Owner:CHONGQING CHUANRUI YUCHU FOOD

Waste treatment device for rubber processing

ActiveCN113183364AAvoid lossReduce lossPlastic recyclingMechanical material recoveryElectric machineryProcess engineering

The invention belongs to the technical field of rubber processing, and discloses a waste treatment device for rubber processing. The waste treatment device for rubber processing comprises a first shell, wherein a tension sensor is fixed at the top of the first shell; a sieve plate is fixedly mounted on the front and rear inner walls of the first shell; a motor is fixedly mounted on the right side of the bottom surface of an inner cavity of the first shell; the tension sensor is connected with a crushing plate through a spring; the crushing plate is slidably connected with the first shell through a sliding groove; the right end of the crushing plate is connected with a first throttling valve; the first throttling valve is communicated with a cooling system; the left end of the crushing plate is communicated with the cooling system; a first spiral material rolling shaft is arranged at the top of the sieve plate; a second spiral material rolling shaft is arranged below the sieve plate; and the right end of the first spiral material rolling shaft is fixedly connected with one end of a first transmission rod. According to the waste treatment device for rubber processing provided by the invention, through mutual cooperation of the crushing plate, the first spiral material rolling shaft and the like, the energy loss is reduced, the crushing efficiency is improved, and the energy utilization rate is increased.

Owner:广东智环研生态科技发展有限公司

Cotton separating device

InactiveCN101857973BRealize automatic separationReduce volumeVegetable fibre separation from seedsEngineeringFlange

Owner:张务谨

A screw conveying crushing device for garbage disposal

ActiveCN111760650BNot easy to damageAvoid entanglementGrain treatmentsHelical bladeStructural engineering

The invention belongs to the technical field of garbage crushing, and discloses a screw conveying crushing device for garbage treatment, in order to solve the problem in the prior art that the blades used for cutting flexible garbage wound on a rotating shaft are easily damaged. The present invention includes a machine body, a feeding bin is installed on the top of the body, a crushing cylinder communicated with the feeding bin is installed under the feeding bin, a rotating shaft is installed in the crushing drum, and a rotating shaft is installed on the rotating shaft. The screw blade, the body is equipped with a driving device for driving the rotating shaft to rotate, the screw blade includes at least two groups of screw blade units, and the at least two groups of screw blade units are installed on the rotating shaft in the crushing cylinder at equal intervals Peripherally, each group of helical blade units includes at least two cutting blades, and a cutting device for cutting flexible materials wound on the rotating shaft is installed on the rotating shaft between adjacent helical blade units.

Owner:CHONGQING THREE GORGES UNIV

A modern fish feed crushing and throwing equipment for aquaculture

ActiveCN110250071BImprove crushing efficiencyReduce crushing timeClimate change adaptationPisciculture and aquariaEngineeringZoology

The invention discloses a modern aquaculture fish feed crushing and throwing equipment, which includes a frame, the top end surface of the frame is provided with a lifting cavity, and a sliding device is installed in the lifting cavity to control the up and down movement through a lifting drive device. The top of the lifting plate is rotated by a rotating shaft to install a crushing body. The invention has a simple structure and is easy to operate. The fish feed is crushed by the rotation of the crushing arm and the shaking of the shaking plate up and down, thereby effectively increasing the crushing efficiency of the fish feed , to save time for crushing fish feed, by starting the lifting motor, the crushing machine body rises until the throwing hole extends out of the lifting cavity, at this time, the height of the throwing hole is increased, and the throwing range is further improved, and the crushing body can rotate 360°, which can be used in a wide range For throwing fish feed, this equipment solves the cumbersome problem of manual throwing and throwing of feed in the traditional technology, and speeds up the crushing time of fish feed.

Owner:余娅君

A cement cracking device and concrete production system

InactiveCN108687952BIncrease profitExtended crushing timeClay processing apparatusMaterials scienceBuilding construction

Owner:CHINA UNIV OF MINING & TECH

A method for measuring and evaluating the high temperature performance of lump coal in smelting reduction ironmaking

ActiveCN110045082BExtended crushing timeImprove reliabilityFuel testingParticle size analysisThermodynamicsPhysical chemistry

The invention discloses a method for measuring and evaluating the high-temperature performance of lump coal in smelting reduction ironmaking, comprising: weighing a preset mass m 1 The lump coal sample, the average particle size of the lump coal sample is d 0 ; Take the lump coal sample at 100%N 2 Heat up and keep warm under the atmosphere; put the lump coal sample in 20% CO 2 +80%N 2 Under the atmosphere, heat up to 700 ℃ ~ 850 ℃ and keep it warm; put the lump coal sample in 20% CO 2 +80%N 2 The temperature was raised to 1100°C under the atmosphere, and then the atmosphere was switched to 100% CO 2 ;Calculated to obtain lump coal reactivity C I ; Measure the particle size distribution of the lump coal sample after the reaction under different input power W, and calculate the average particle size d after the reaction f ; Take the abscissa as the abscissa and the input power W as the ordinate to perform linear fitting and plot, and calculate the fracture coefficient of the lump coal sample according to the slope k of the fitted line. The evaluation result of the method of the present invention is more objective and true.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

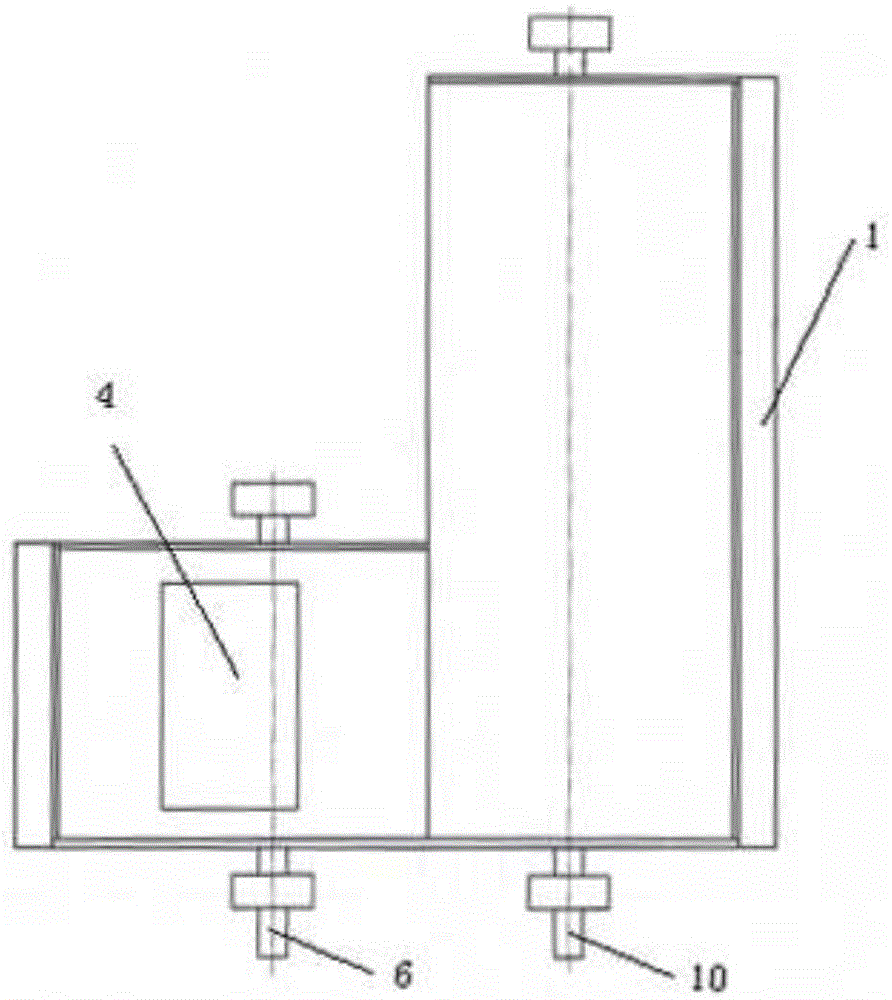

Ultrahigh-pressure nano homogenizer

PendingCN113058452AAvoid wear and tearGuaranteed crushing effectFlow mixersTransportation and packagingEngineeringCrankcase

The invention discloses an ultrahigh-pressure nano homogenizer which comprises a base, a crankcase is fixedly arranged at the top of the base, a first-stage homogenizing mechanism and a second-stage homogenizing mechanism are fixedly arranged at the top of the crankcase, the first-stage homogenizing mechanism is located over the second-stage homogenizing mechanism, the first-stage homogenizing mechanism communicates with the second-stage homogenizing mechanism through a first material channel; a valve base and a first valve element are oppositely arranged in the first-stage homogenizing mechanism in the horizontal direction, a second material channel is formed in the valve base in the horizontal direction, a first homogenizing head is fixedly arranged at the end, facing the valve base, of the first valve element, and a second valve element, a second homogenizing head and a discharging channel are arranged in the second-stage homogenizing mechanism; the second valve element and the first material channel are oppositely arranged, a second homogenizing head is fixedly arranged at the position, facing the first material channel, of the second valve element, and a second material homogenizing area is formed between the first material channel and the second homogenizing head. The homogenizing effect is effectively improved, the refining time is shortened, and the service life of equipment is prolonged.

Owner:上海睿迈机械科技有限公司

A crushing device for animal husbandry feed production

ActiveCN114074008BAvoid cakingRealize transmissionFeeding-stuffGrain treatmentsAnimal scienceAgricultural science

The present invention relates to the technical field of animal husbandry breeding, in particular to a crushing device for producing feed for animal husbandry breeding, which includes a base, and one side of the upper surface of the base is fixedly installed with a discharge assembly, and the discharge assembly includes a second A discharge box, a first discharge box is installed on the upper end of the second discharge box, a storage tank is fixedly installed on the upper end of the first discharge box, and a processing component is installed inside the storage tank. The present invention uses the processing component to thereby The power required for crushing can be transmitted, and the material can be cut in advance to prevent the prolongation of the crushing time caused by the one-time entry of large materials, and the power transmission to multiple crushing head components can be realized through this component. The heating operation is realized, thereby effectively avoiding the problem of agglomeration when wet materials are crushed compared with the prior art, and it is realized that there is no need for post-drying operation, and the process of feed processing is effectively shortened.

Owner:江苏碧云天高新技术有限公司

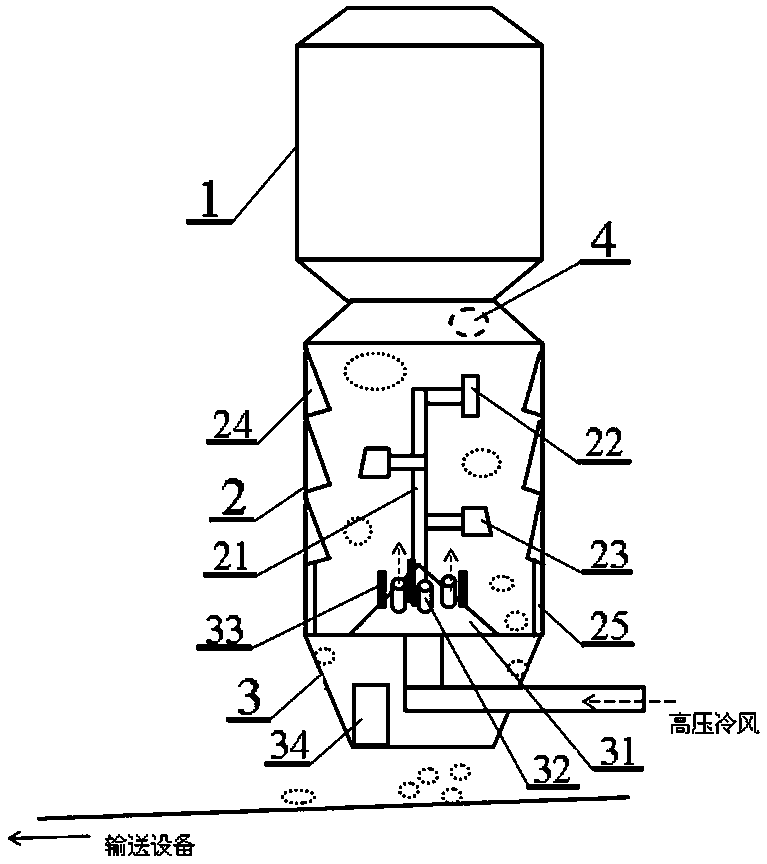

Method and system for crushing and cooling high-temperature solid waste residue blocks

PendingCN109780550AExtended crushing timeExtended cooldownIncinerator apparatusAcute angleEngineering

The invention provides a method and system for crushing and cooling high-temperature solid waste residue blocks. The system comprises a garbage incinerator, a crushing chamber and a collecting bin; avertical shaft is arranged at the bottom of the crushing chamber; a hammer shaft is arranged on the vertical shaft; a hammer head is arranged on the hammer shaft; the rotation radius of the hammer head is gradually reduced from top to bottom; the hammer head at the uppermost layer is a rectangular hammer head; the hammer head at the lower layer is a right-angle trapezoid hammer head; the acute angle of each right-angle trapezoid hammer head is gradually reduced from top to bottom; a counterattack plate is arranged on the inner wall of the crushing chamber; a high-pressure cooling air chamber is arranged at the lower part of the crushing chamber; a smooth umbrella plate is arranged at the top of the high-pressure cooling air chamber; a high-pressure cooling air pipe is arranged on the smooth umbrella plate; and the lower part of the smooth umbrella plate is connected with the collecting bin. The residue blocks are crushed in a graded manner, the temperatures of the residue blocks are rapidly reduced, and the energy consumption caused by high linear velocity of a multi-layer hammer head and the weight of the hammer head in existing equipment is reduced; and the diameters of the crushed residue blocks are 5-30 mm, so that the problem that large pieces of residue blocks fall and squash conveying equipment is avoided.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com