Patents

Literature

138 results about "Hysteresis phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for automatically clearing background application programs

InactiveCN104866069ARun fastSave powerPower supply for data processingElectricityHysteresis phenomenon

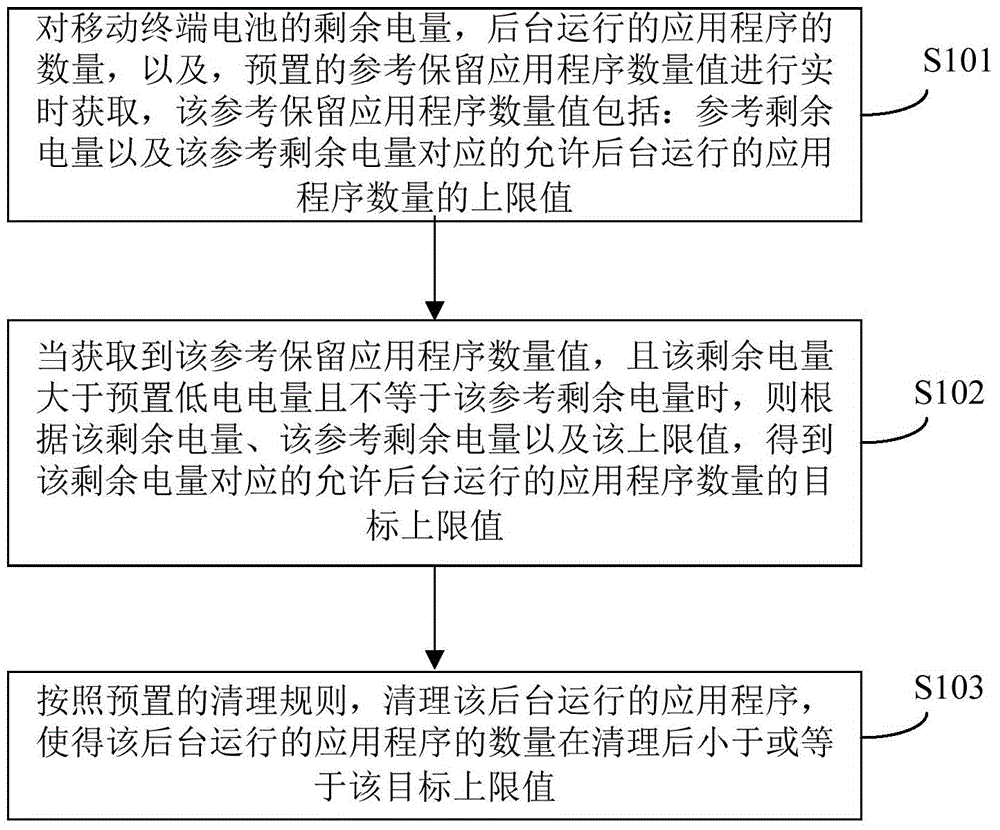

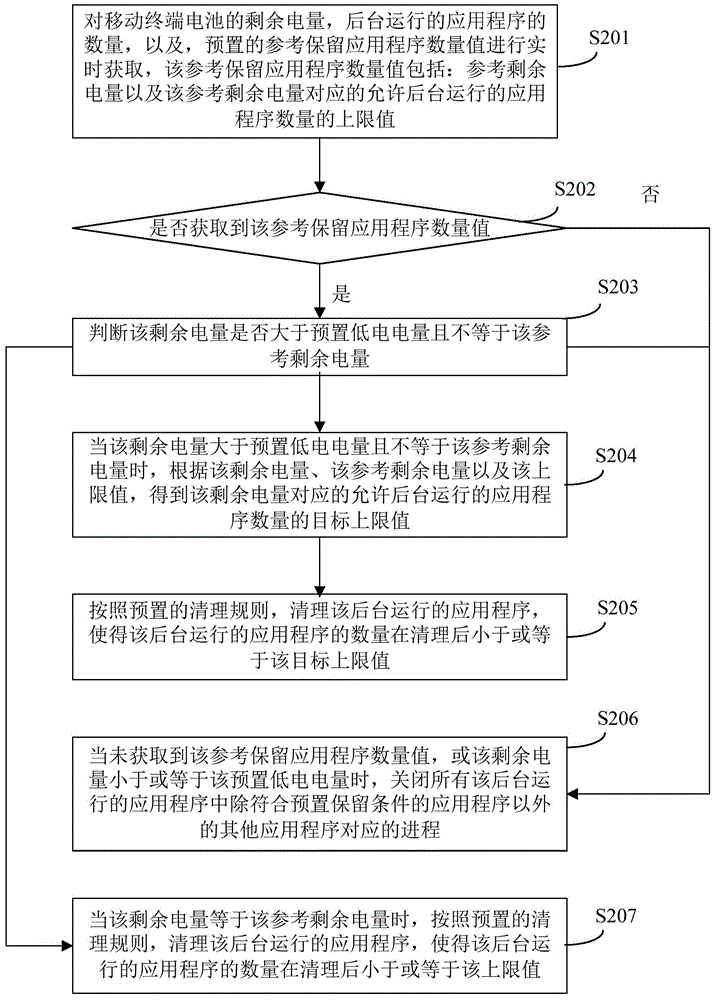

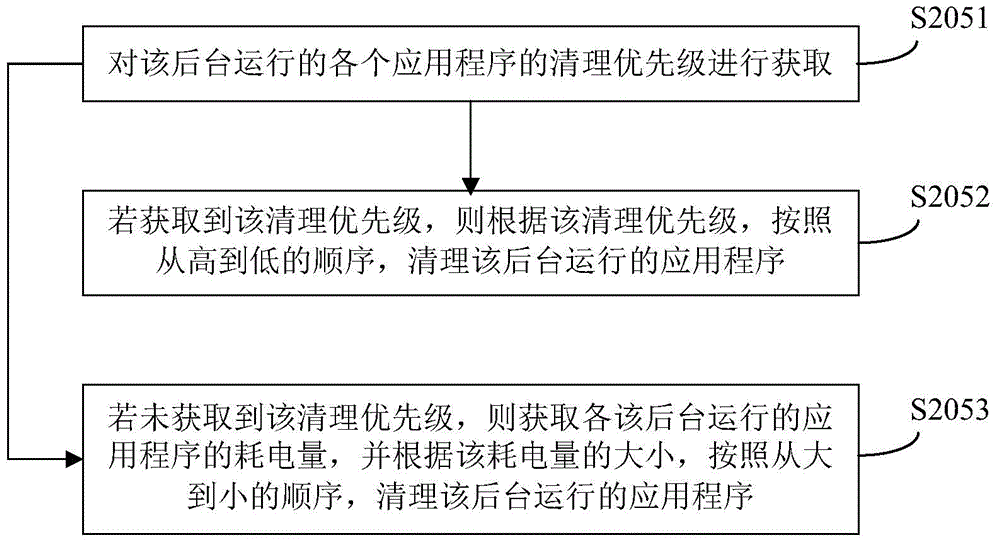

The invention discloses a method and a device for automatically clearing background application programs. The method comprises the following steps that: the residual electricity quantity of a mobile terminal battery, the number of background running application programs and the preset reference retention application program number value are obtained in real time; when the reference retention application program number value is obtained, and the residual electricity quantity is greater than the preset low-electricity electricity quantity but not equal to the reference residual electricity quantity, the target upper limit value of the allowed background running application program number corresponding to the residual electricity quantity is obtained according to the residual electricity quantity and the reference retention application program number value; and the background running application programs are cleared according to preset clearing rules, so that the background running application program number is smaller than or equal to the target upper limit value. The background running application programs can be cleared in real time according to the residual electricity quantity of the mobile terminal battery, so that compared with the prior art, the method and the device have the advantages that the occurrence of clamping and hysteresis phenomena can be prevented, and the problem of great battery electricity consumption is effectively solved.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

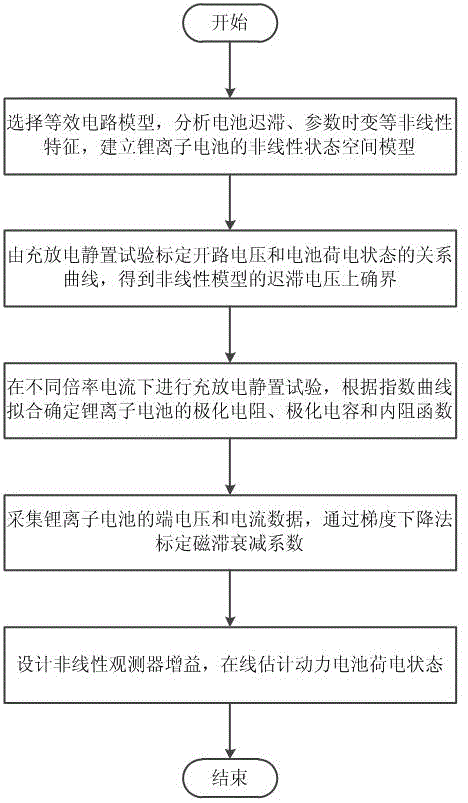

Lithium ion battery charge state estimating method

ActiveCN104535932AIn line with the actual useReduce estimation errorElectrical testingInternal resistanceAutomotive battery

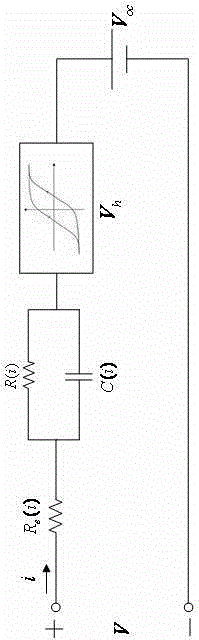

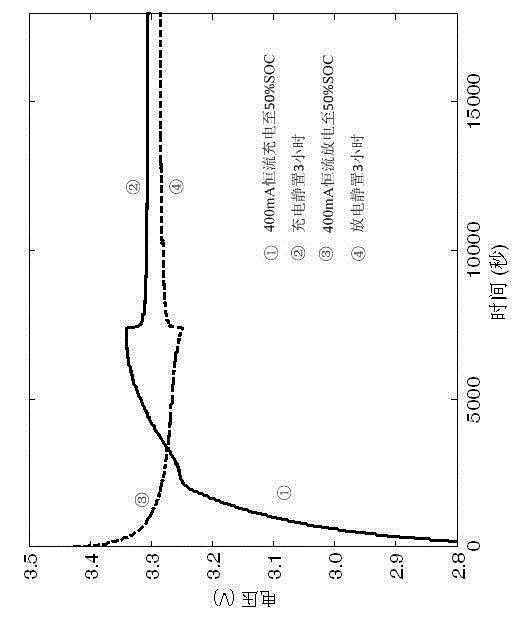

The invention relates to a lithium battery charge state estimating method and belongs to the technical field of batteries of electric vehicles. The lithium battery charge state estimating method aims at estimating the charge state of a lithium battery under the complex working conditions of charging and discharging at different multiplying power levels through an estimation method based on a parameter time varying observer. The lithium battery charge state estimating method specifically comprises the step that a battery charge state is regarded as a state variable to be introduced into a lithium ion battery continuous model, the upper limit of hysteresis voltages is determined according to the charging and discharging open-circuit voltage, the battery hysteresis phenomenon is considered to be a first order dynamic process related to the current absolute value, a battery polarization voltage model with parameters changing along with currents and an internal resistance model with parameters changing along with currents are structured through RC rings, battery model end voltages are structured, and a nonlinear parameter time-varying battery model is obtained. The lithium battery charge state estimating method is based on a parameter time-varying lithium ion battery equivalent circuit model, the model parameters are calibrated to be a function of current multiplying power, the characteristics of the battery can be accurately expressed, and meanwhile an existing estimation method can be easily used.

Owner:JILIN UNIV

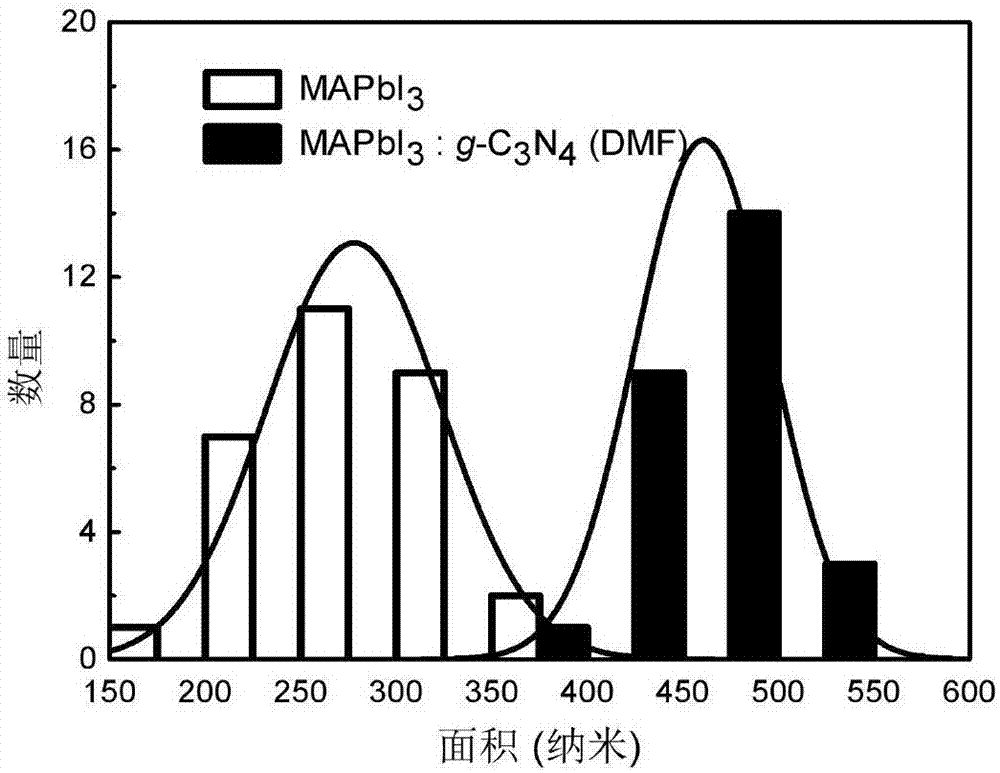

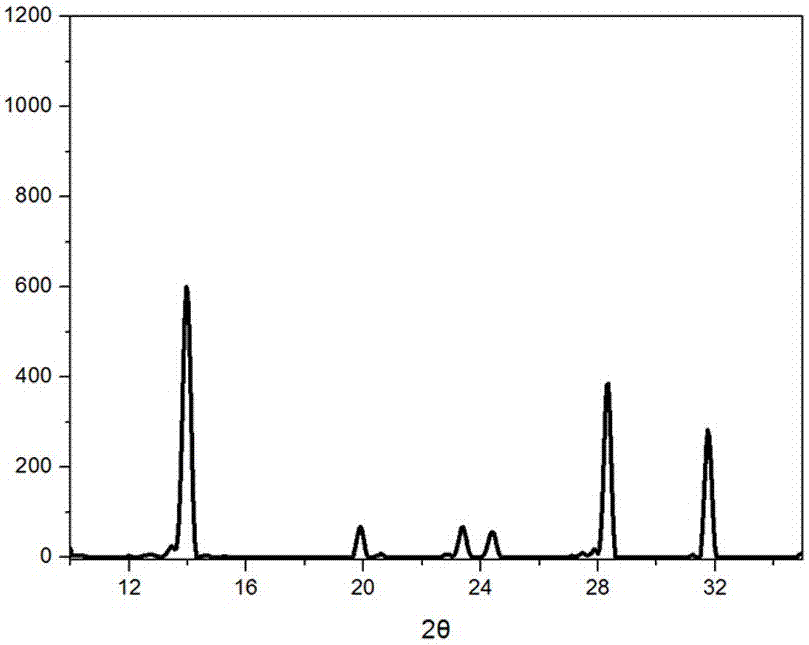

Method for preparing perovskite solar cell on basis of two-dimensional material graphene-phase carbon nitride

ActiveCN107887511AImprove crystallizationStable manufacturingSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsSolvent

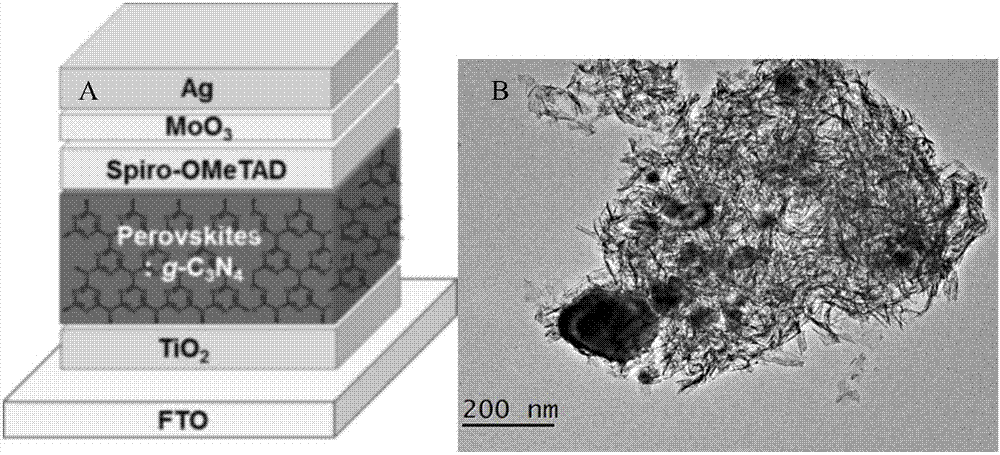

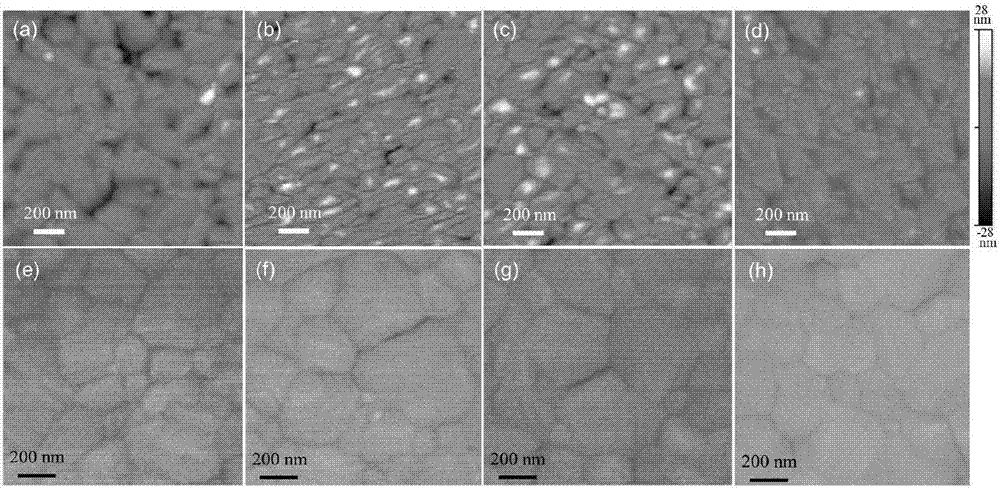

The invention provides a method for preparing a perovskite solar cell on the basis of a two-dimensional material graphene-phase carbon nitride. The graphene-phase carbon nitride is doped into a perovskite precursor solution to prepare the perovskite solar cell. The method has the following advantages that (1) the raw material required for synthesis of the material is low in cost, and the product is small in toxicity; (2) solvent volatilization during the annealing process is effectively slowed down, so that a perovskite thin film crystal is more uniform and compact; (3) the grain crystal sizeof a perovskite layer is increased, a crystal boundary easy to combine with charge is effectively reduced, and the filling factor of a device is improved; (4) a surface of the perovskite thin film ispassivated, and the hysteresis phenomenon of the device is effectively improved; and (5) the conductivity of the surface of the perovskite thin film is improved, the contact resistance of the interface is reduced, and the short-circuit current of the device is increased. The preparation process is simple and convenient and is low in preparation difficulty; by doping of the graphene-phase carbon nitride, the smoothness and the uniformity of the perovskite thin film can be effectively improved; and by a series of gradient doping, the device performance is remarkably changed.

Owner:SUZHOU UNIV

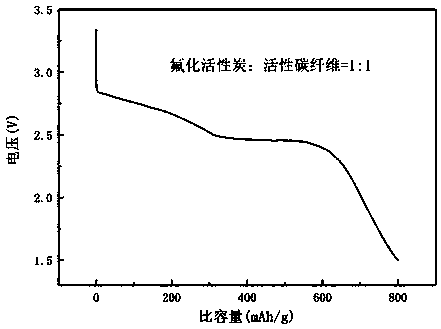

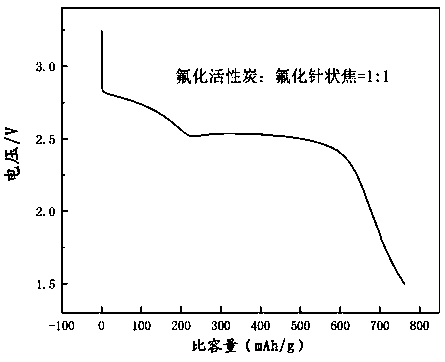

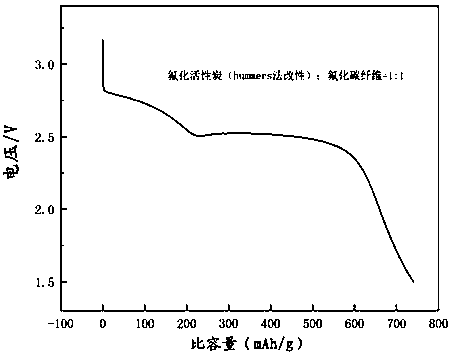

Composite carbon fluoride cathode material for lithium primary battery, preparation method and application thereof

ActiveCN109461923AHigh specific capacityHigh capacity densityCell electrodesNon-aqueous electrolyte cellsMass ratioPorous carbon

The invention belongs to the technical field of a cathode material for a lithium primary battery, particularly relates to the field of preparation of the cathode material for a fluorocarbon battery, and in particular to a composite carbon fluoride cathode material for the lithium primary battery, a preparation method and an application thereof. The material is a composite material prepared by ballmilling and mixing a porous carbon fluoride material having a high tap density and a carbon fluoride material having a high graphitization degree and then fluorinating the mixture. The composite material has a carbon content of 38-60%, a fluorine content of 40-62% and a tap density of greater than 0.8g / ml; the mixing mass ratio is in the range of 1:0.1-1:10; and the composite material has high specific surface area, high tap density and high graphitization degree. Due to the high tap density of the material, the overall high volumetric specific energy of the material is guaranteed; through anion diffusion channel composed of porous carbon fluorides, the voltage hysteresis phenomenon at the initial stage of the battery discharge is effectively improved and the overall discharge performance of the material is improved.

Owner:SHANDONG ZHONGSHAN PHOTOELECTRIC MATERIAL CO LTD

Multi-target tracking method for PHD smoother adaptive to target nascent strength

ActiveCN105182291AIncrease the number ofHigh precisionWave based measurement systemsMulti target trackingHysteresis phenomenon

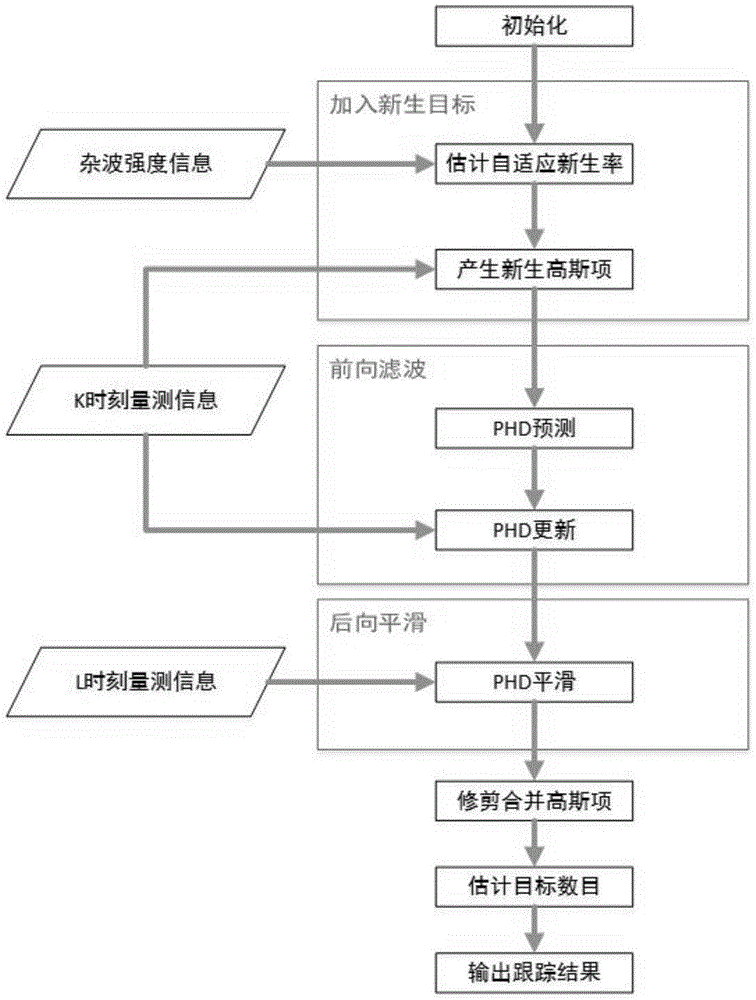

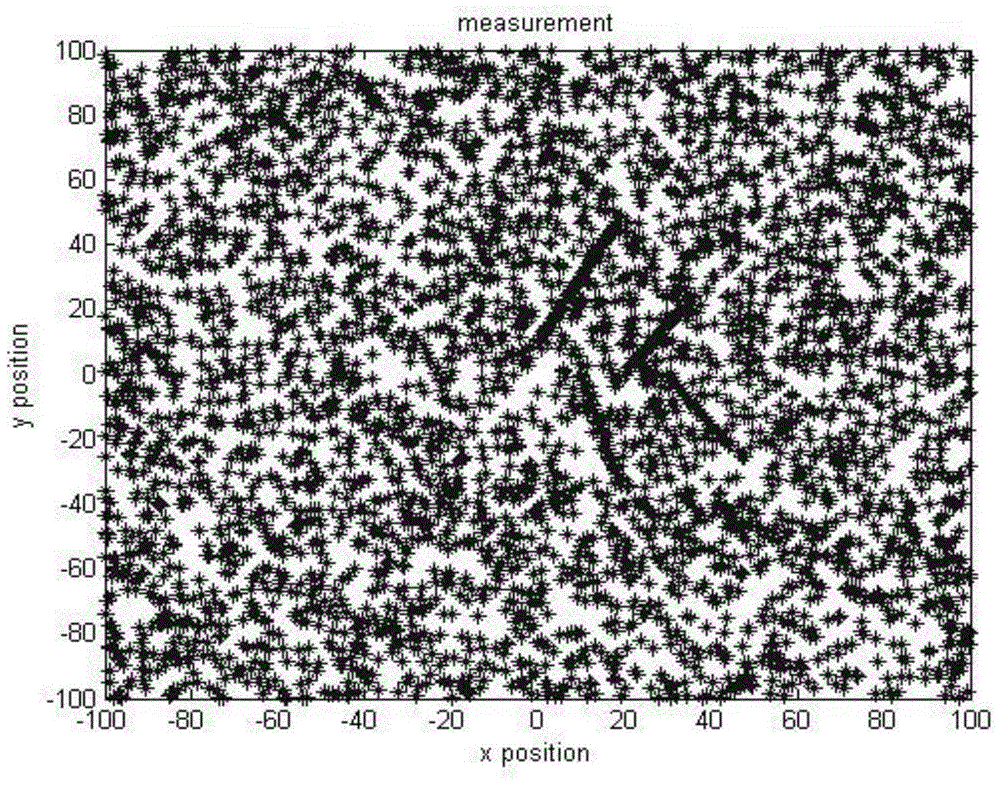

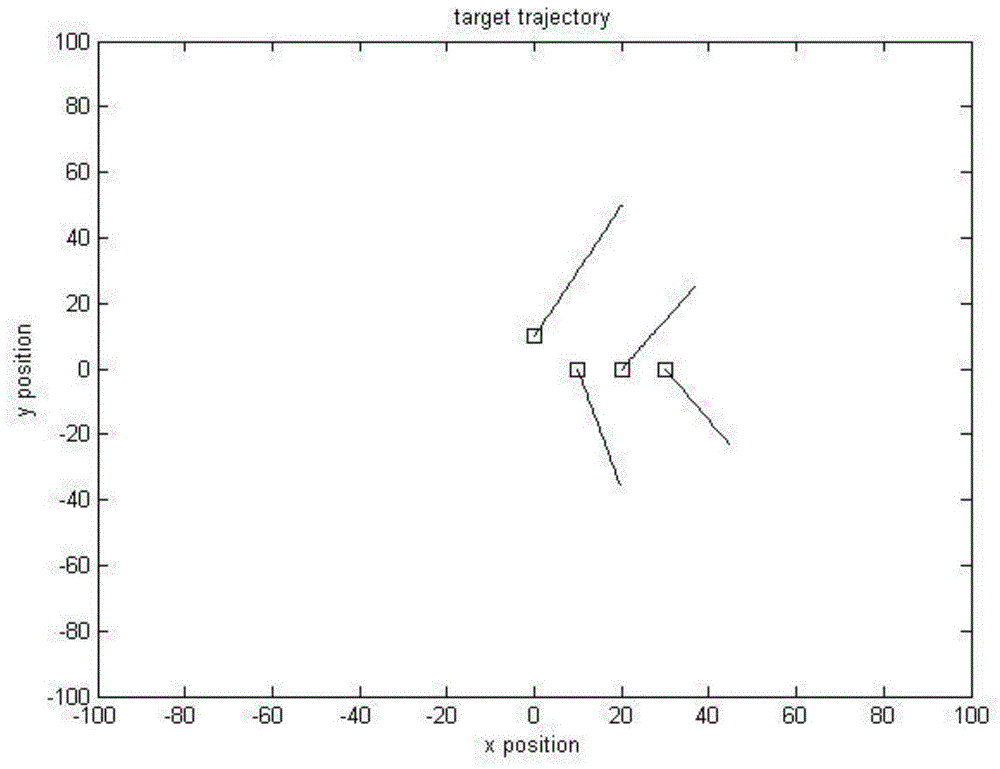

The invention discloses a multi-target tracking method for a PHD smoother adaptive to the target nascent strength. According to the invention, the target confirmation hysteresis phenomenon of the PHD smoother adaptive to the target nascent strength at the target nascent time in the clutter environment is mainly solved. Meanwhile, the implementation form of the PHD smoother in the Linear gaussian condition is provided. Through the forward filtering process and the backward smoothing process, the number of targets and the states of the targets are accurately estimated. The influence of the target confirmation hysteresis phenomenon on the track formation at the target nascent time is relieved. The method comprises the steps of target nascent rate estimation, forward filtering and backward smoothing. That means, firstly, the nascent rate of targets at the moment k is estimated according to the mean value of the number of transcendental clutters. Secondly, the targets are predicted and updated to realize the forward filtering based on the measurement value at the moment k. Thirdly, the backward smoothing is conducted on the filtering result based on the time hysteresis L. Finally, a tracking result is outputted through the clipping, combining and state extracting process.

Owner:XIDIAN UNIV

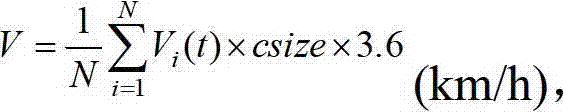

Traffic flow microscopic simulation method based on car following behavior

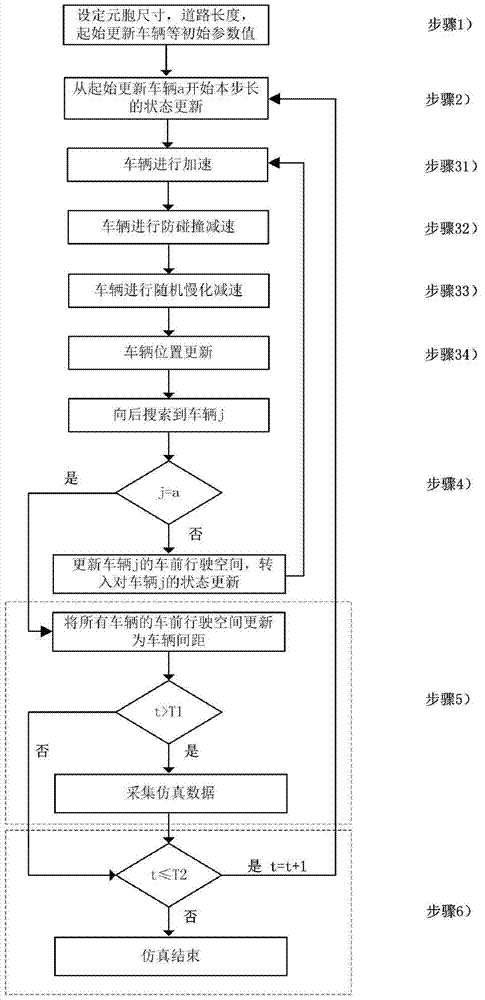

InactiveCN102968541AFit closelyGood auxiliary effectSpecial data processing applicationsStable stateCellular automation

Owner:SOUTHEAST UNIV

Manufacturing method of methylamine lead iodine perovskite solar cell

ActiveCN107359246AImprove securityWon't breakSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellAnti solvent

The invention relates to the field of solar cells, and provides a manufacturing method of a methylamine lead iodine perovskite solar cell. A photosensitive layer is a methylamine lead iodine perovskite film. The methylamine lead iodine perovskite film is manufactured by the spin coating technology and the anti-solvent dropping and cleaning technology with combination of the solvent annealing technology. The spin coating technology refers to the process that a methylamine lead iodine perovskite CH3NH3PbI3 precursor solution is spin-coated on a PEDOT:PSS film. The anti-solvent cleaning technology refers to the process that the anti-solvent amyl alcohol is dropped in the process of spin-coating the CH3NH3PbI3 methylamine lead iodine perovskite precursor solution so that the perovskite is enabled to be quickly crystalized and precipitated, wherein the anti-solvent amyl alcohol is sec-amyl alcohol or tertiary amyl alcohol. The adopted preparation technology is simple so that the methylamine lead iodine perovskite solar cell of high efficiency and great repeatability without the hysteresis phenomenon can be prepared.

Owner:TAIYUAN UNIV OF TECH

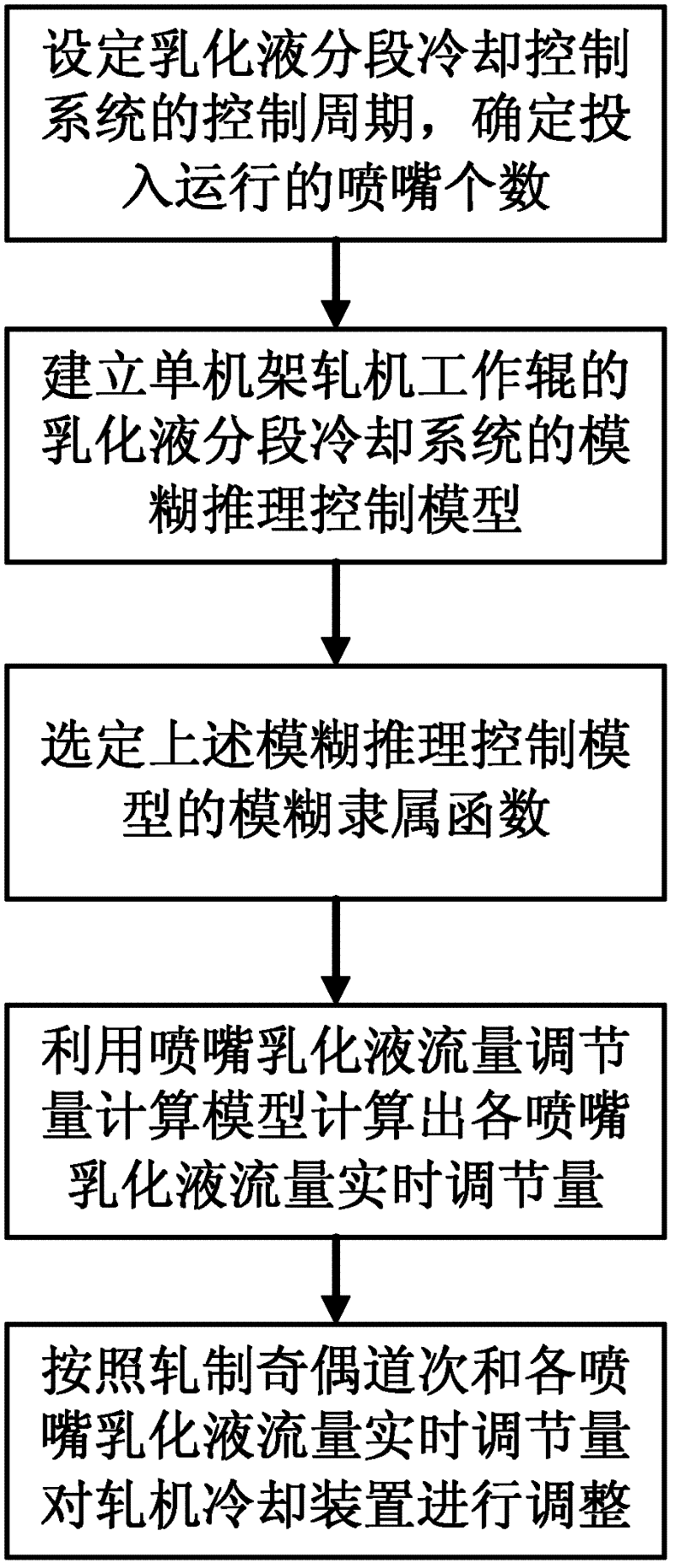

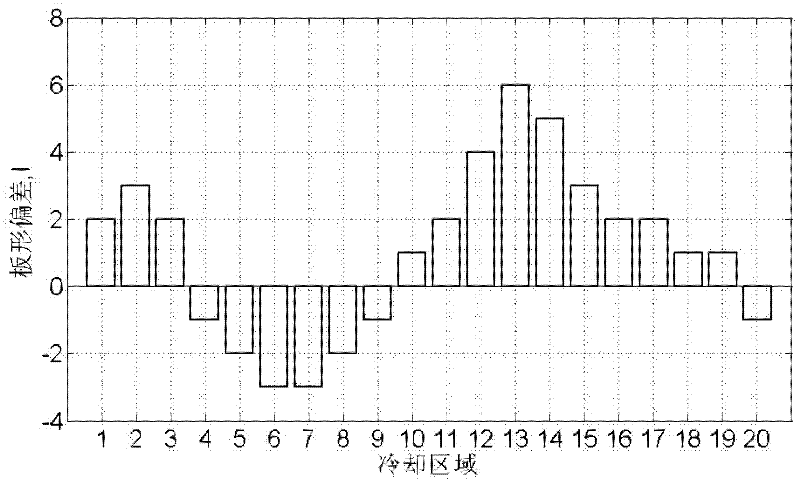

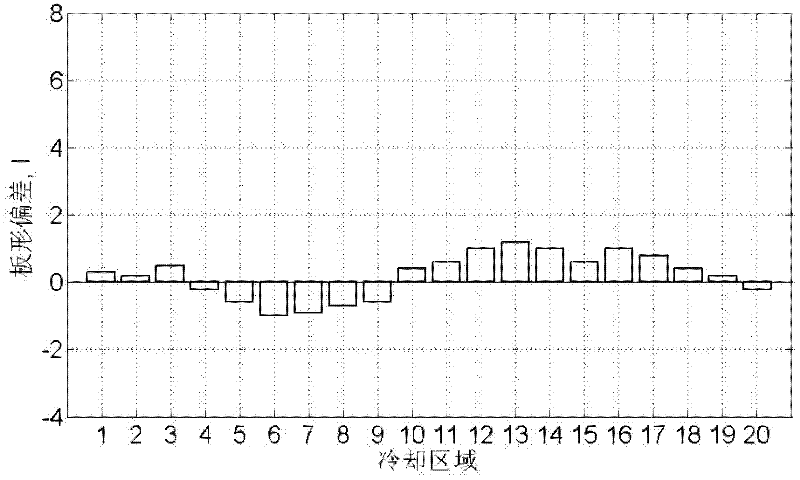

Sectional cooling control method for emulsion of working roller of single-frame rolling mill

InactiveCN102389902AOvercome technical problems that cannot be precisely controlledEliminate high order shape deviationRollsProfile control deviceTerra firmaEmulsion

The invention relates to a sectional cooling control method for an emulsion of a working roller of a single-frame rolling mill. Particularly, a fuzzy modeling method is used for establishing a quantitative relation among a plate-shape deviation, a previous regulating quantity of injected flow of the emulsion and a present regulating quantity of the injected flow of the emulsion, thereby realizinghigh-precision sectional cooling control of the emulsion of the working roller of the single-frame rolling mill. The method provided by the invention overcomes the technical problem that precise control cannot be realized because a long-time hysteresis phenomenon exists in an emulsion injecting cooling action mechanism; high-precision sectional cooling control of the emulsion of the working roller of the single-frame rolling mill is realized, thereby efficiently eliminating high plate-shape deviation of cold-rolling strip steel and promoting the quality of the plate shape of a cold-rolling strip steel product; the method is simple and practicable, fully meets a real-time demand of a sectional cooling control system and is characterized by effectiveness and practicability; and a firm foundation is established for high-precision plate-shape control of the cold-rolling strip steel.

Owner:WISDRI ENG & RES INC LTD

Nonaqueous electrolyte and lithium-ion battery

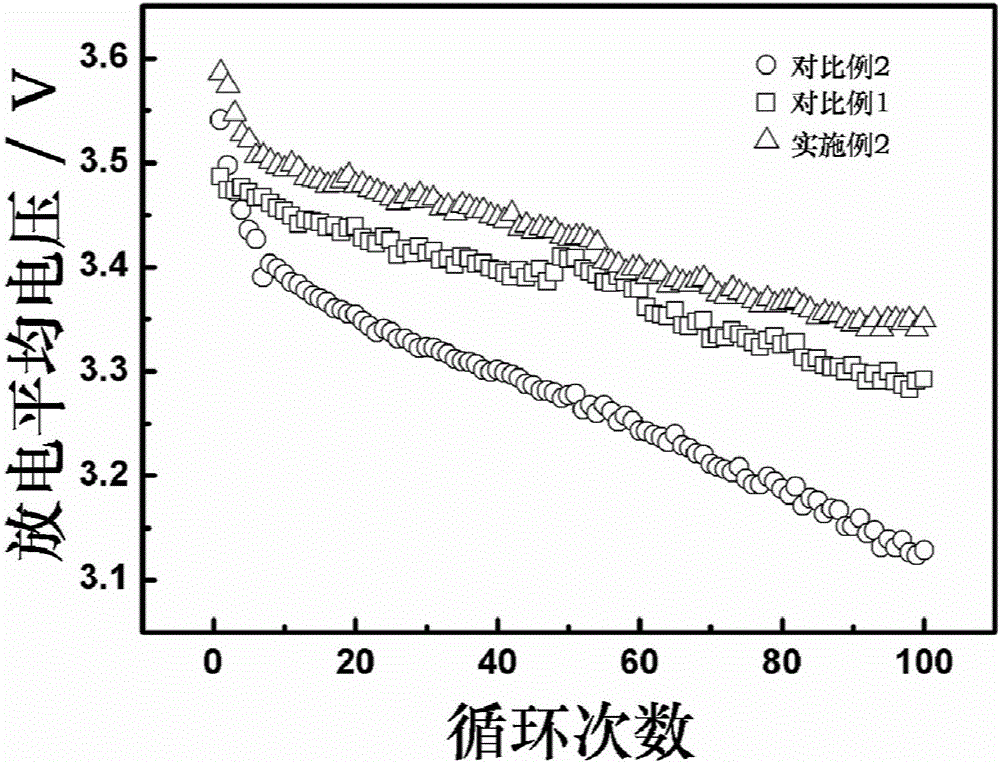

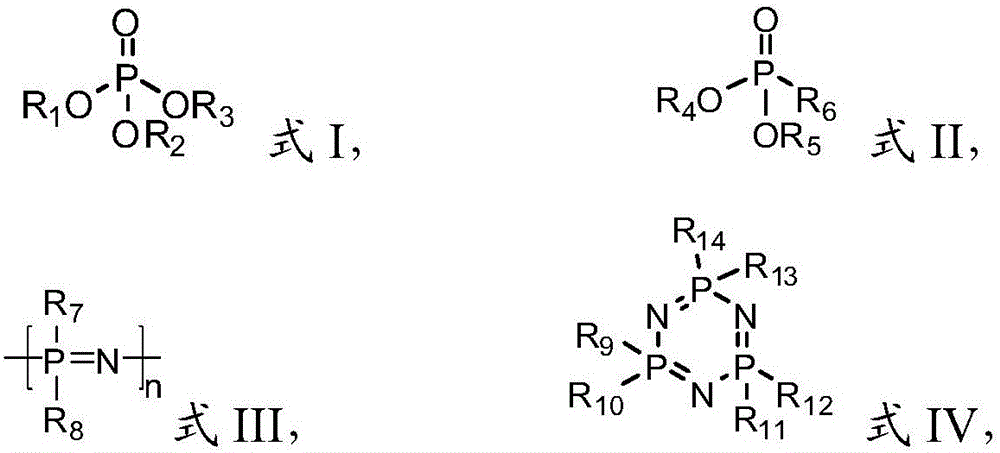

ActiveCN105720304AGood resistance to nucleophilic attackImprove antioxidant capacitySecondary cellsOrganic electrolytesSolventLithium-ion battery

The invention provides a nonaqueous electrolyte, which comprises an organic solvent and a lithium salt, wherein the organic solvent is selected from a non-carbonate solvent. The provided nonaqueous electrolyte has relatively good nucleophilic attack resistance; high-activity radical ions O2.<-> and these solvents are not easily subjected to nucleophilic reaction, so that Li2O loss in the material is effectively inhibited; the structure of a lithium-rich cathode material is stabilized; and the voltage hysteresis phenomenon of the material is effectively relieved. Meanwhile, the provided nonaqueous electrolyte has good oxidation resistance and non-combustible characteristics, so that a lithium-rich battery prepared from the nonaqueous electrolyte has relatively good cycle performance and relatively high safety.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

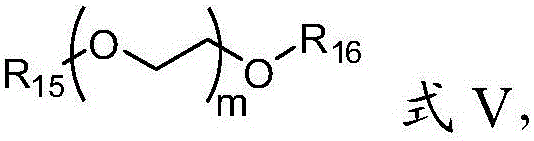

Hand shaking correction device

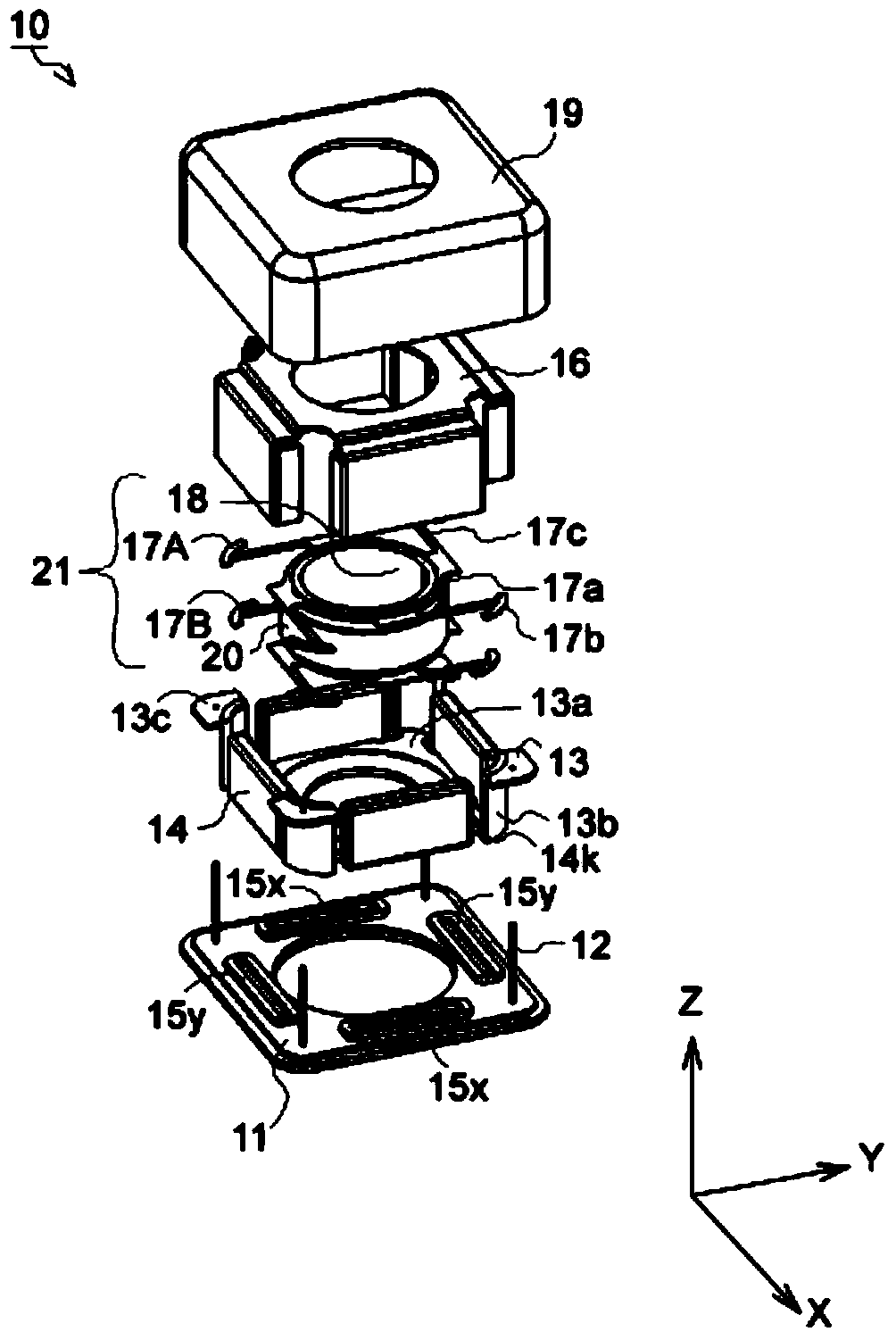

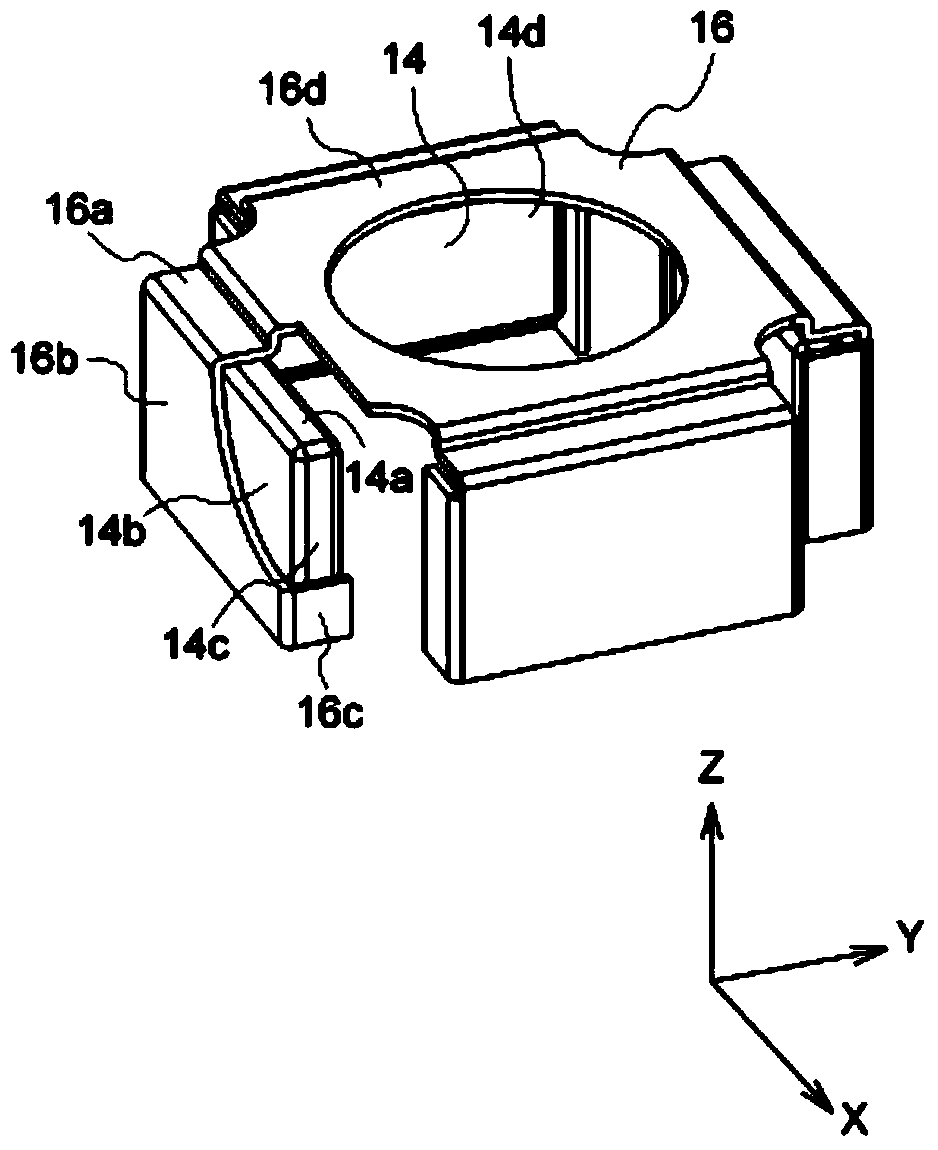

ActiveCN103901702ANo hysteresisSuppress resonanceTelevision system detailsPrintersHand shakesDrop impact

The present invention provides a shake correction device which can not generate the hysteresis phenomenon and can suppress unnecessary resonance and improve endurance with respect to drop impact. In this shake correction device, the eddy current induction plate 16a of +Z side is opposite to and has a gap with the surface (14a) of the +Z side of the permanent magnet (14) which is arranged to wind around the optical axis at an interval of 90 degree in the Z direction, the eddy current induction plate 16b of radial direction is opposite to and has a space with the surface (14b) of the outside in the radial direction, and the eddy current induction plate 16c of the periphery direction is opposite to and has a gap with the surface (14c) in the periphery direction.

Owner:JIANGXI SENYANG TECH

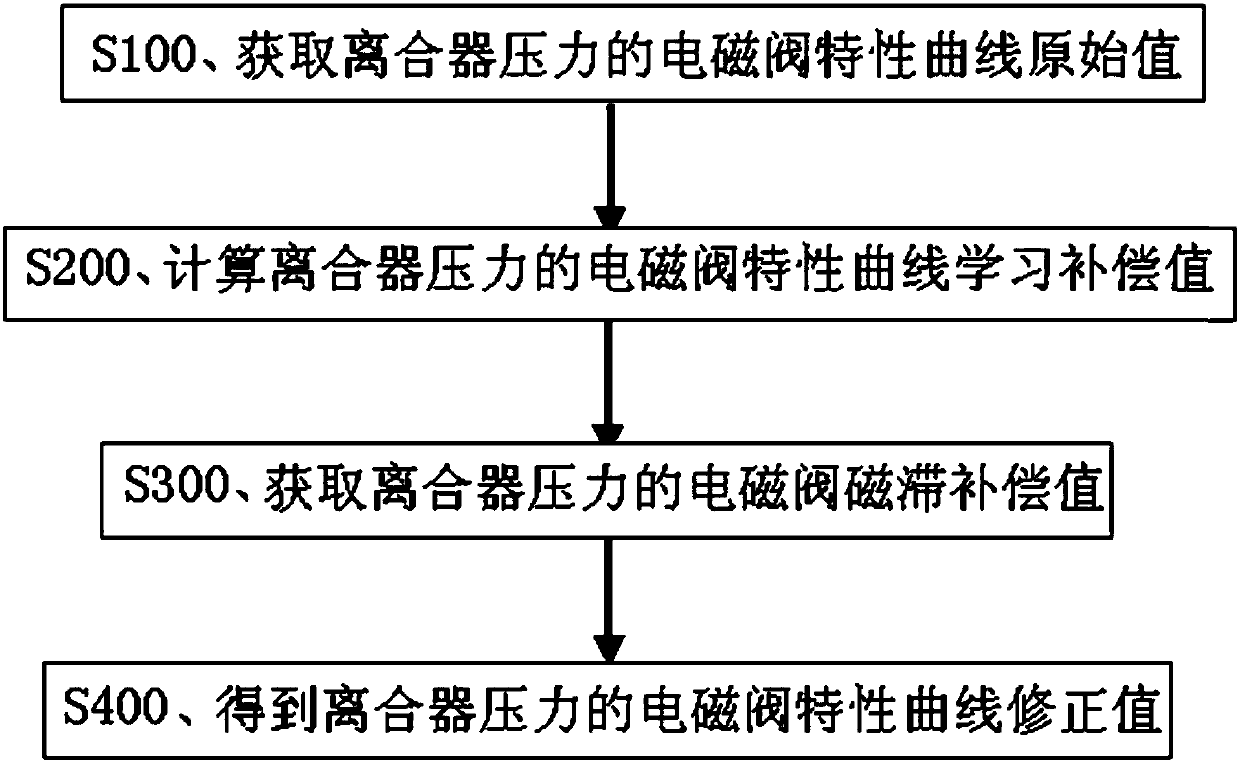

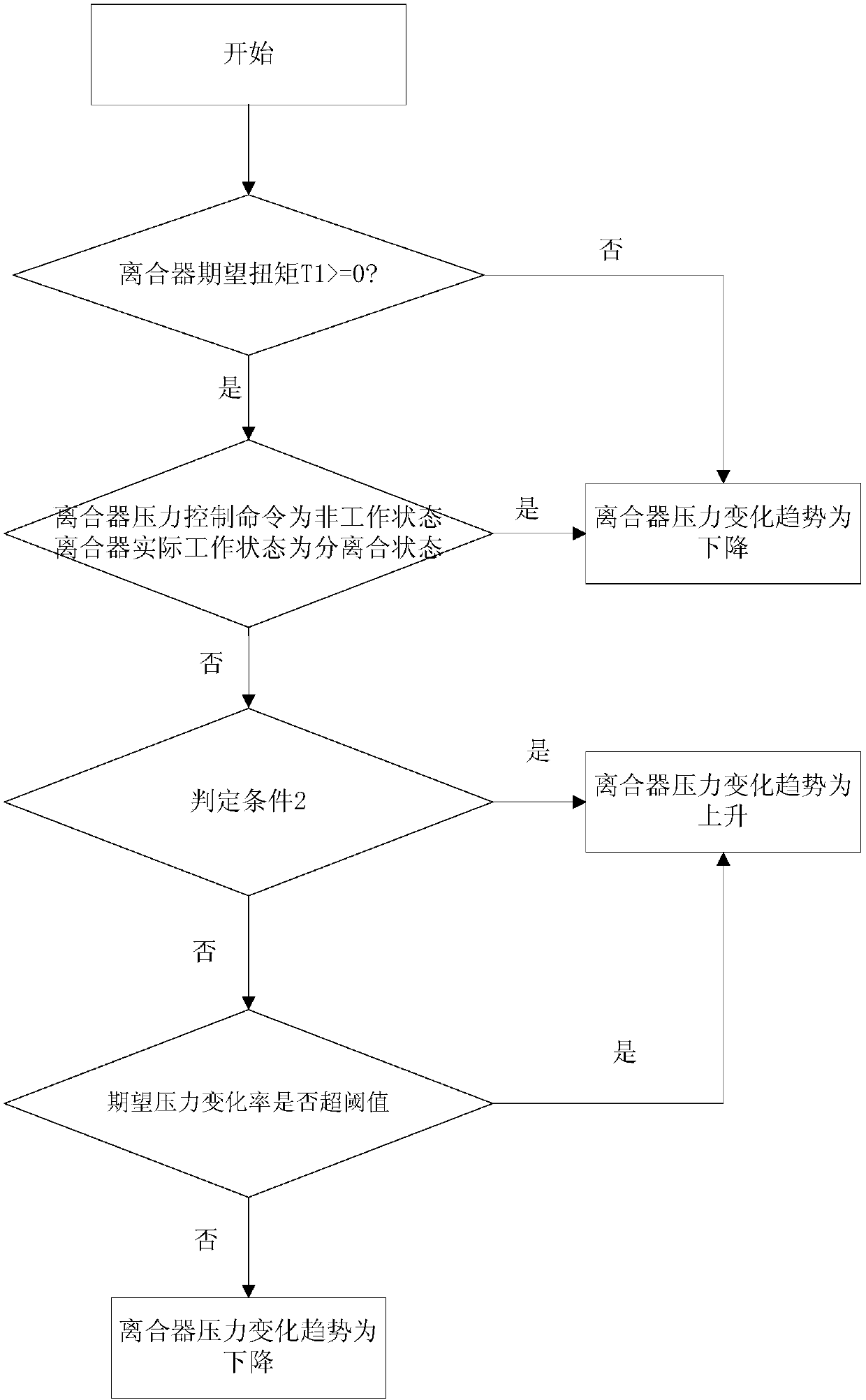

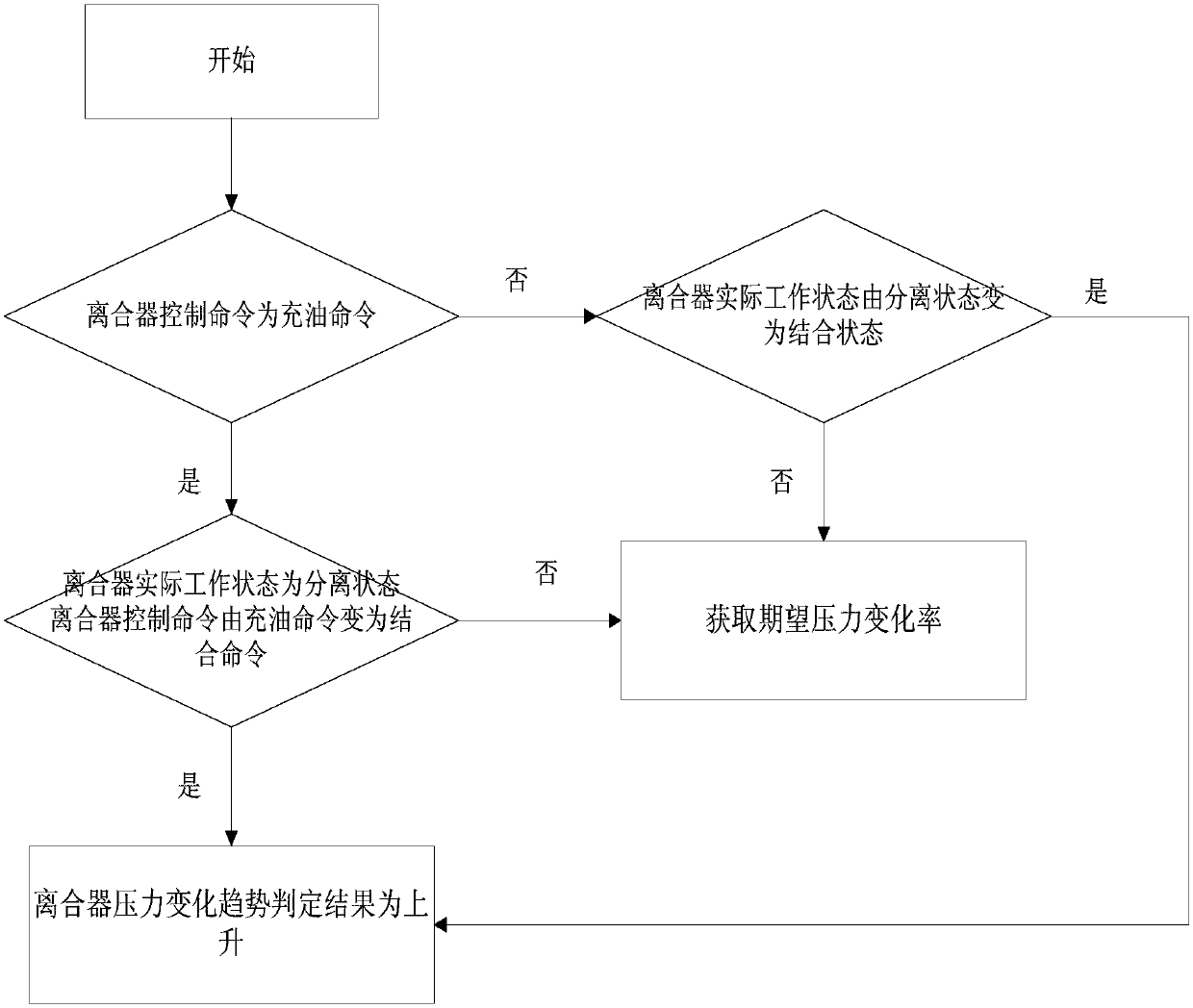

Clutch gearbox solenoid valve characteristic curve correction method and system

ActiveCN107605989AHigh precision of pressure controlHigh control precisionClutchesSolenoid valveEngineering

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

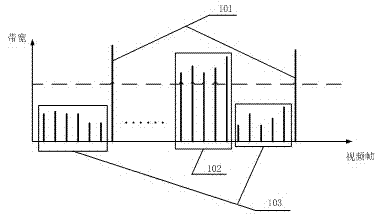

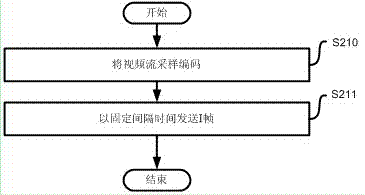

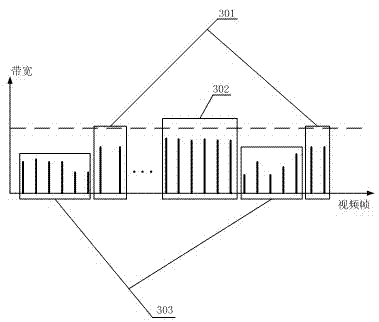

Transmission method for quickly previewing H.264 coded picture

InactiveCN102547375AReduce packet lossImprove stabilitySelective content distributionNetwork packetHysteresis phenomenon

The invention discloses a transmission method for quickly previewing an H.264 coded picture. A video stream is sampled and coded to generate the coded picture. The coded picture comprises a plurality of I pictures and a plurality of P pictures corresponding to the I pictures, wherein the I pictures are preferably generated and transmitted, and the data of each I picture is transmitted at a fixed time interval T until the data of all the I pictures of the video stream is transmitted; the P pictures are transmitted in a time bucket with an idle network bandwidth between the transmission of every two I pictures; and a large coded picture is divided into a plurality of data packets for transmission. The hysteresis phenomenon of the transmission of the I pictures is avoided, the real-time performance of the transmission of the I pictures is ensured, and a client can most quickly generate a preview picture.

Owner:上海讯垒网络科技有限公司

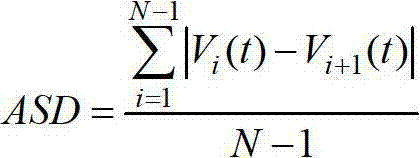

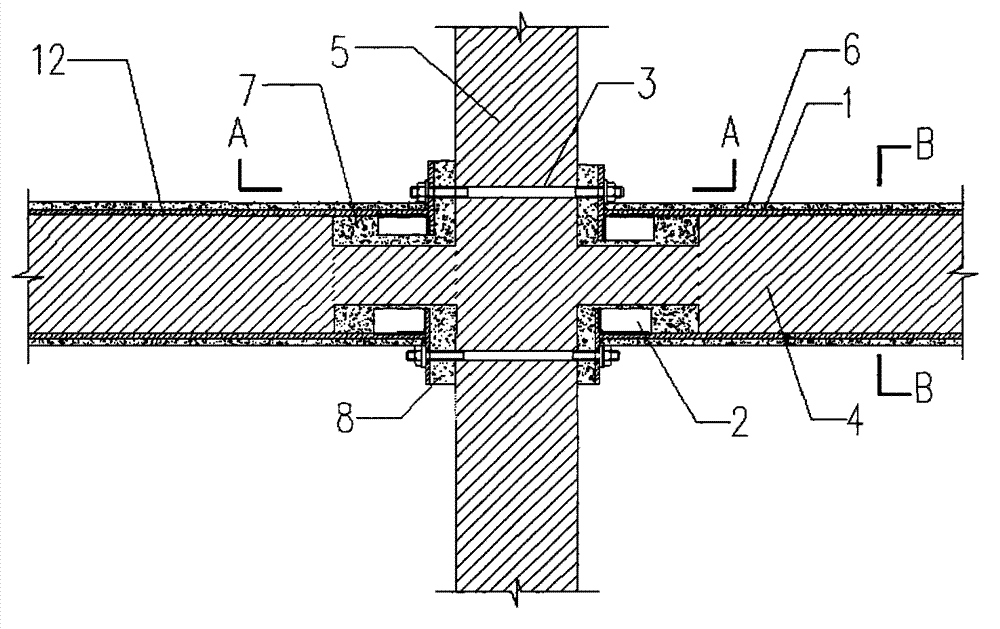

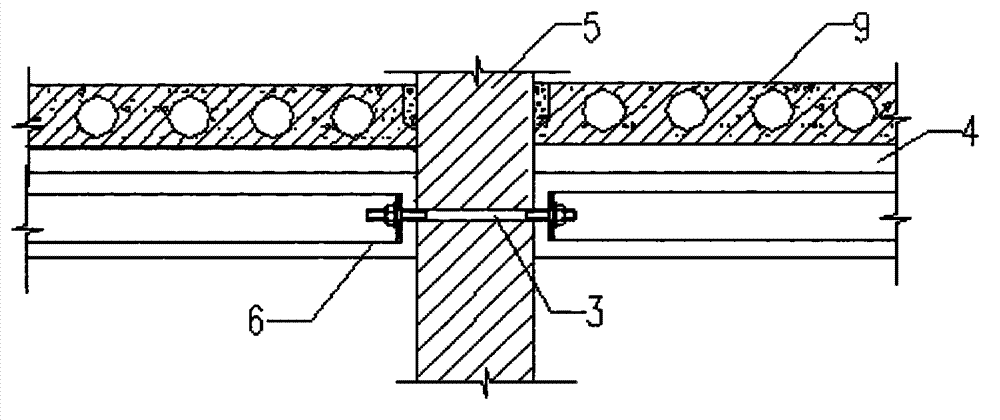

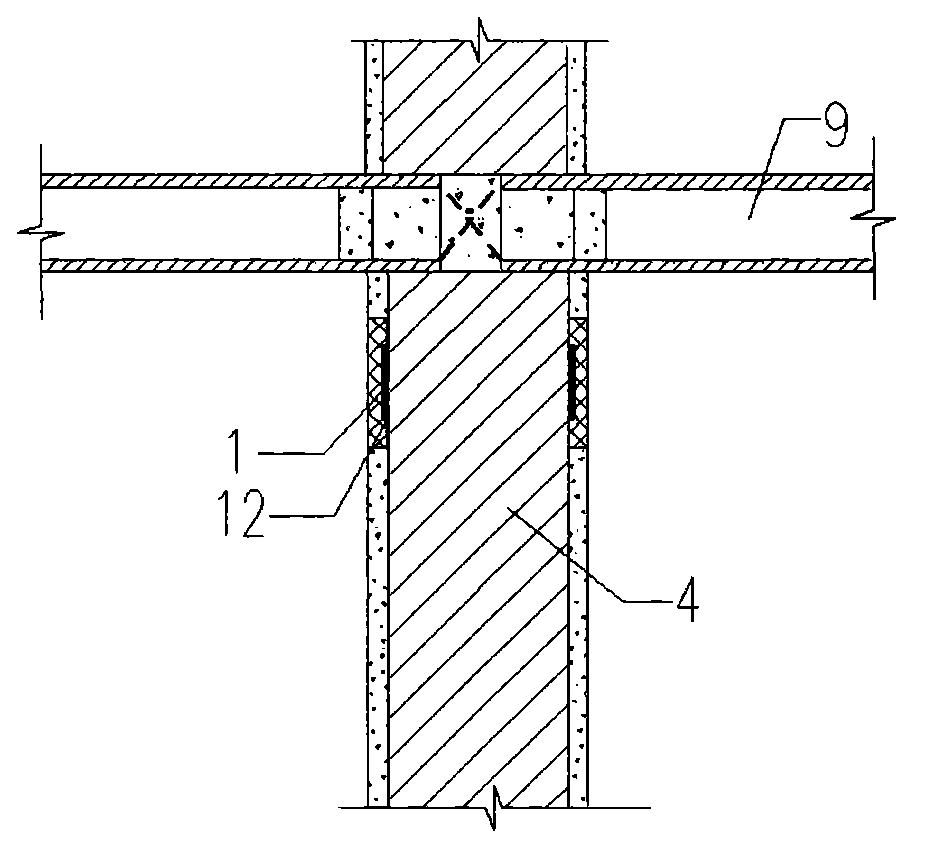

System and method for reinforcing masonry structure by using cross wall and flat steel draw bar

InactiveCN102926550AGuarantee collaborative workReduce stress hysteresisBuilding repairsShock proofingFloor slabPre stress

The invention relates to a system and a method for reinforcing a masonry structure by using a cross wall and flat steel draw bars, and belongs to the field of seismic resistant reinforcement. An upper floor plate of the cross wall or the lower side of a roof board (close to the wall surface) is horizontally provided with the flat steel draw bars; two ends of the flat steel draw bars are respectively provided with flat steel supports; and the flat steel supports at two ends are respectively arranged in open slots at two ends of the cross wall, and are symmetrically pulled and combined through tension bolts. According to the structure system and the method thereof provided by the invention, the flat steel draw bars are utilized for replacing the steel draw bars in the conventional binding-type reinforcing method, flat steel is laid close to the walls and are protected by stainless mortar, and the defect that the steel draw bars are easy to rust is overcome; especially prestress tension is applied to the flat steel, so that the cooperative operation of the flat steel draw bars and a wall body is ensured, and the stress hysteresis phenomenon is reduced; and the flat steel draw bars have greater tension force than that of steel draw bars, so that the seismic resistant reinforcement effect is played relatively effectively.

Owner:江西省坤泽建筑工程有限公司

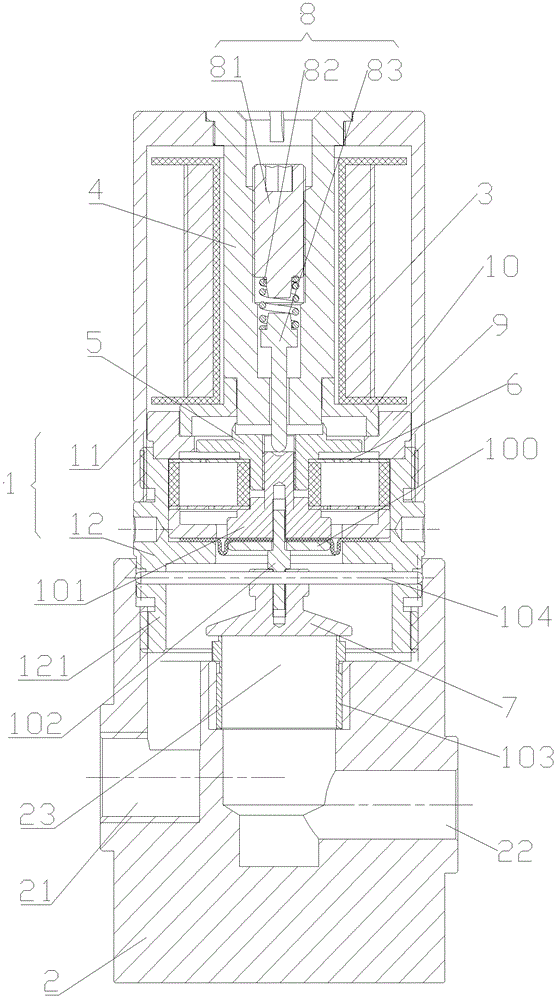

Breathing machine and proportional valve

The invention provides a breathing machine and a proportional valve. The proportional valve comprises a shell body and a valve seat. The shell body comprises a cavity body, an inlet, an outlet and a valve port are formed in the valve seat, the shell body is connected with the valve seat in a sealing mode, and the inlet is communicated with the valve port. A coil, a first soft magnet, an armature, a first elastic element and a seal cover plate are arranged inside the shell body. The coil is wound on the outer periphery of the first soft magnet, the first magnet is arranged on an axial first side of the armature, the seal cover plate is connected with an axial second side of the armature, the first elastic element is arranged on the second side of the armature, and the first soft magnet drives the armature to enable the surface of the seal cover plate to contact with or separate from the end face of the valve port. Flow control of the proportional valve is realized through the opening and the closing between the seal cover plate and the end face of the valve port, wherein the opening and the closing are controlled in an electromagnetic mode. Therefore, the aging problem of a seal ring when the seal ring is used for sealing does not exist, and the proportional valve has the advantages of being good in sealing effect, high in response speed, low in cost, convenient to repair, and capable of reducing hysteresis phenomenon.

Owner:BEIJING AEONMED

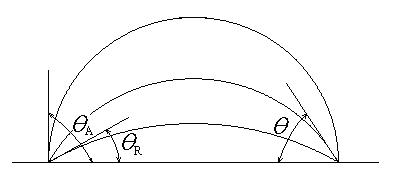

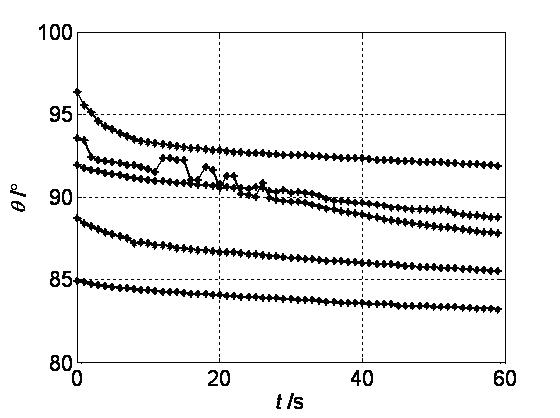

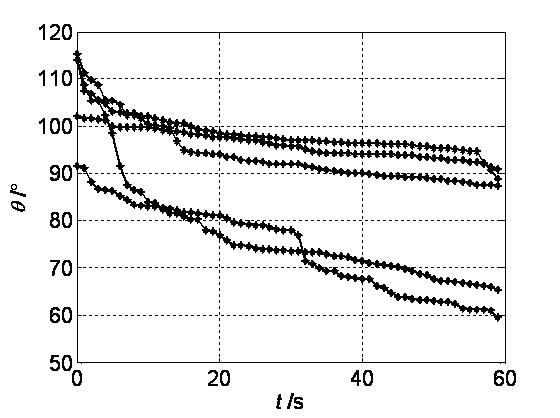

Method for detecting hydrophobic nature of composite insulator based on dynamic contact angles

InactiveCN102494971ASmall fluctuationImprove calculation stabilitySurface/boundary effectCamera lensComposite insulators

The invention relates to a method for detecting hydrophobic nature of a composite insulator based on dynamic contact angles. The method is characterized by comprising steps of photographing a contact angle meter at the position perpendicular to a plane where an umbrella skirt or a protecting bush is located through a digital camera or a camera lens, an industrial camera and an image acquisition card to obtain a water drop image, continuously shooting through injection of deionized water to obtain a series of water drop images, calculating out an advance angle theta A through a survey meter, then continuously shooting through extraction of water drops to obtain a series of water drop images, and calculating out an advance angle theta R through the survey meter. The method for detecting the hydrophobic nature of the composite insulator based on the dynamic contact angles has the advantages of (1) high calculating accuracy which represents that influences of roughness of the surface of a material and solute settling on the surface can be restrained to some extent, and an receding angle can better reflect the hydrophobic nature of the surface of the material particularly; and (2) high calculating stability which represents that fluctuations among a plurality of measurement results are small, and calculating stability is high due to the fact that the influence of hysteresis phenomena on measurement of the contact angles are restrained.

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD +1

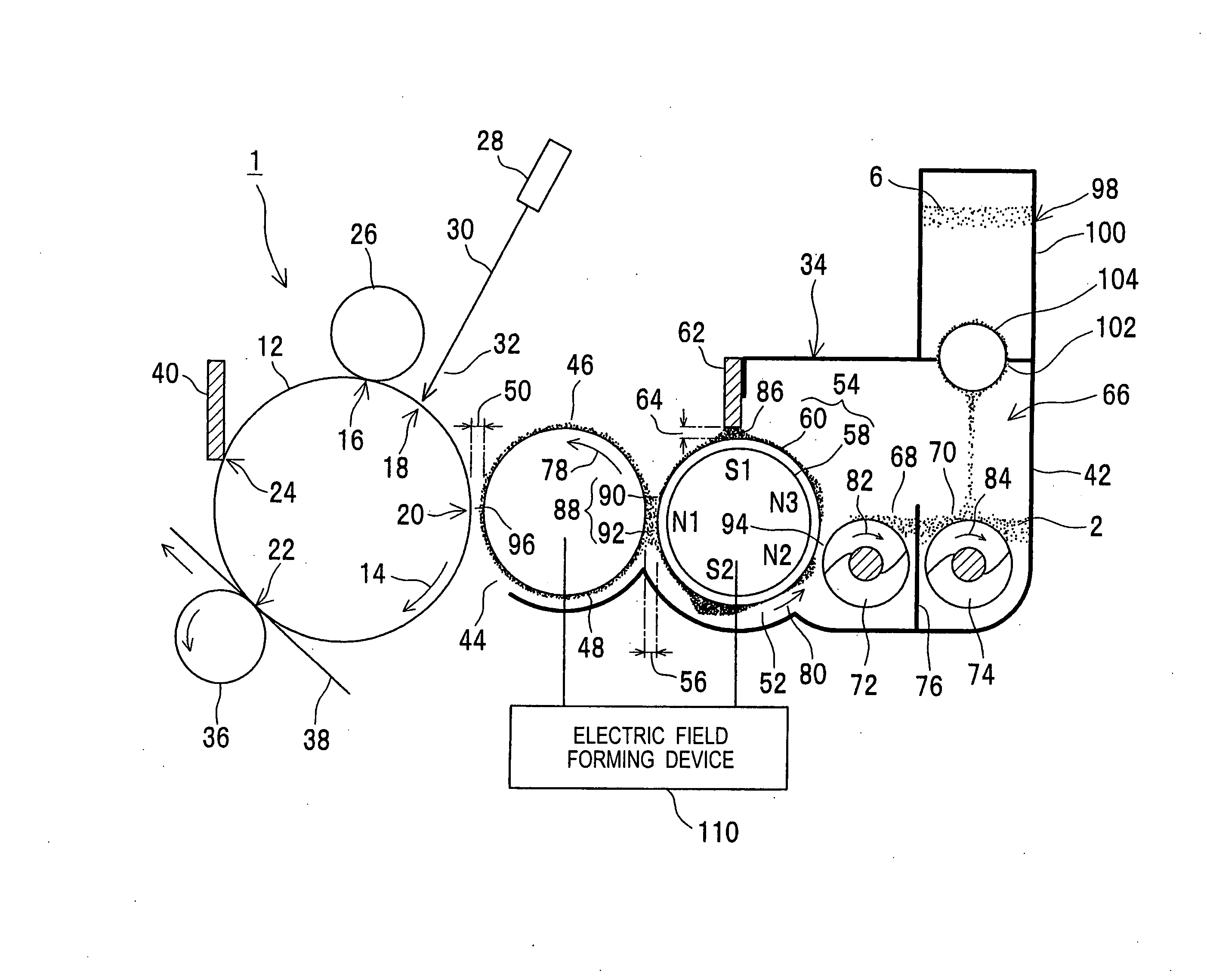

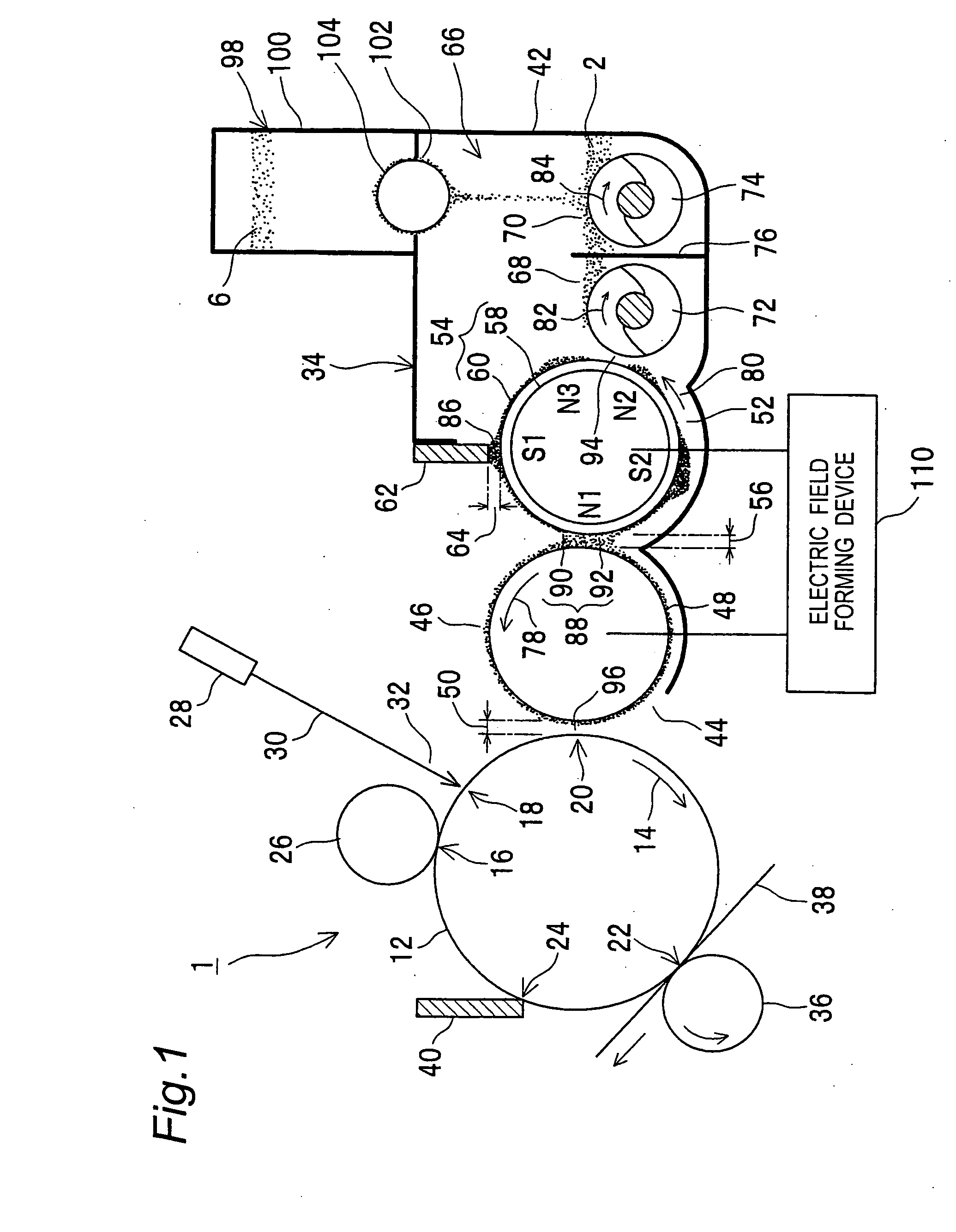

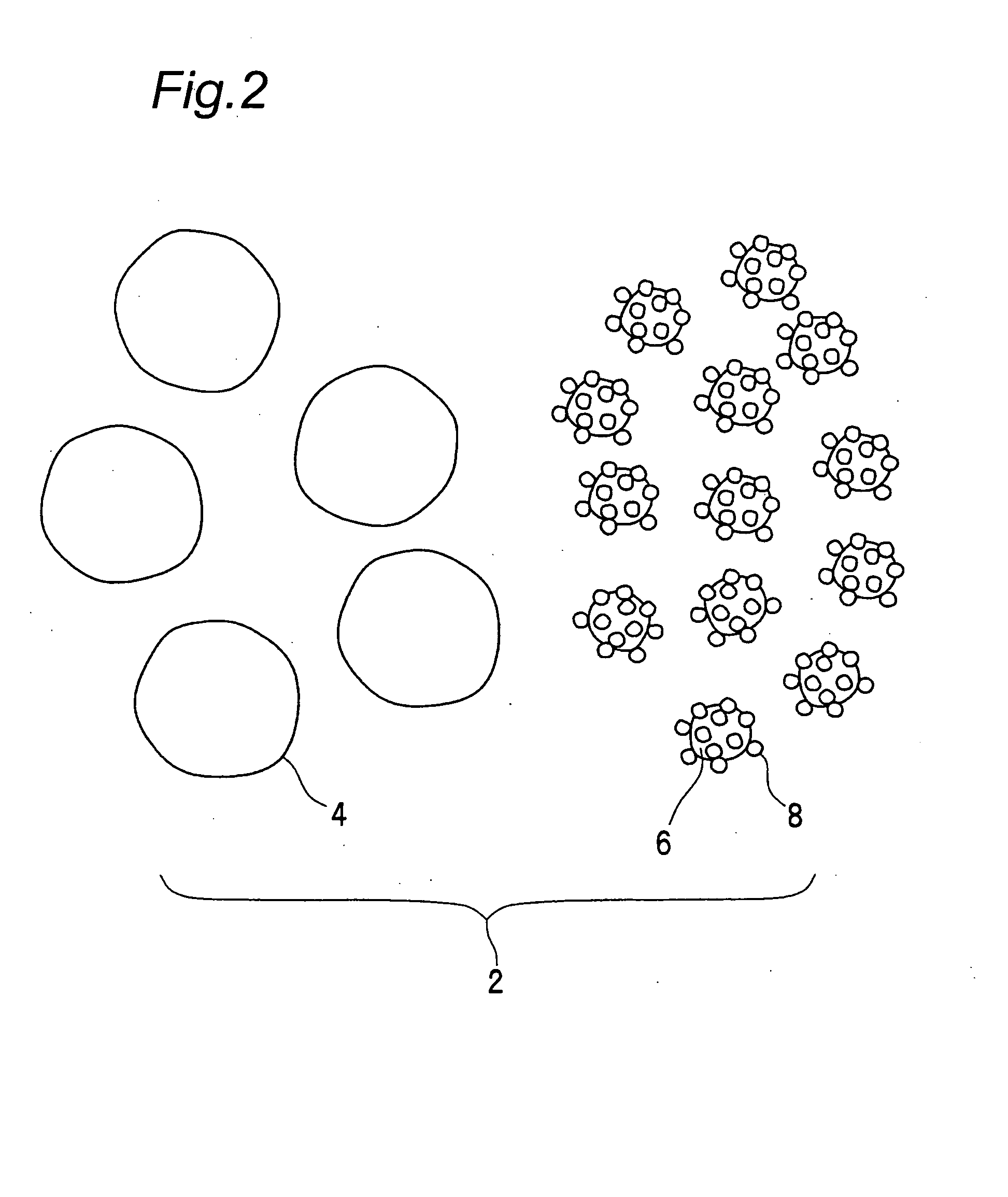

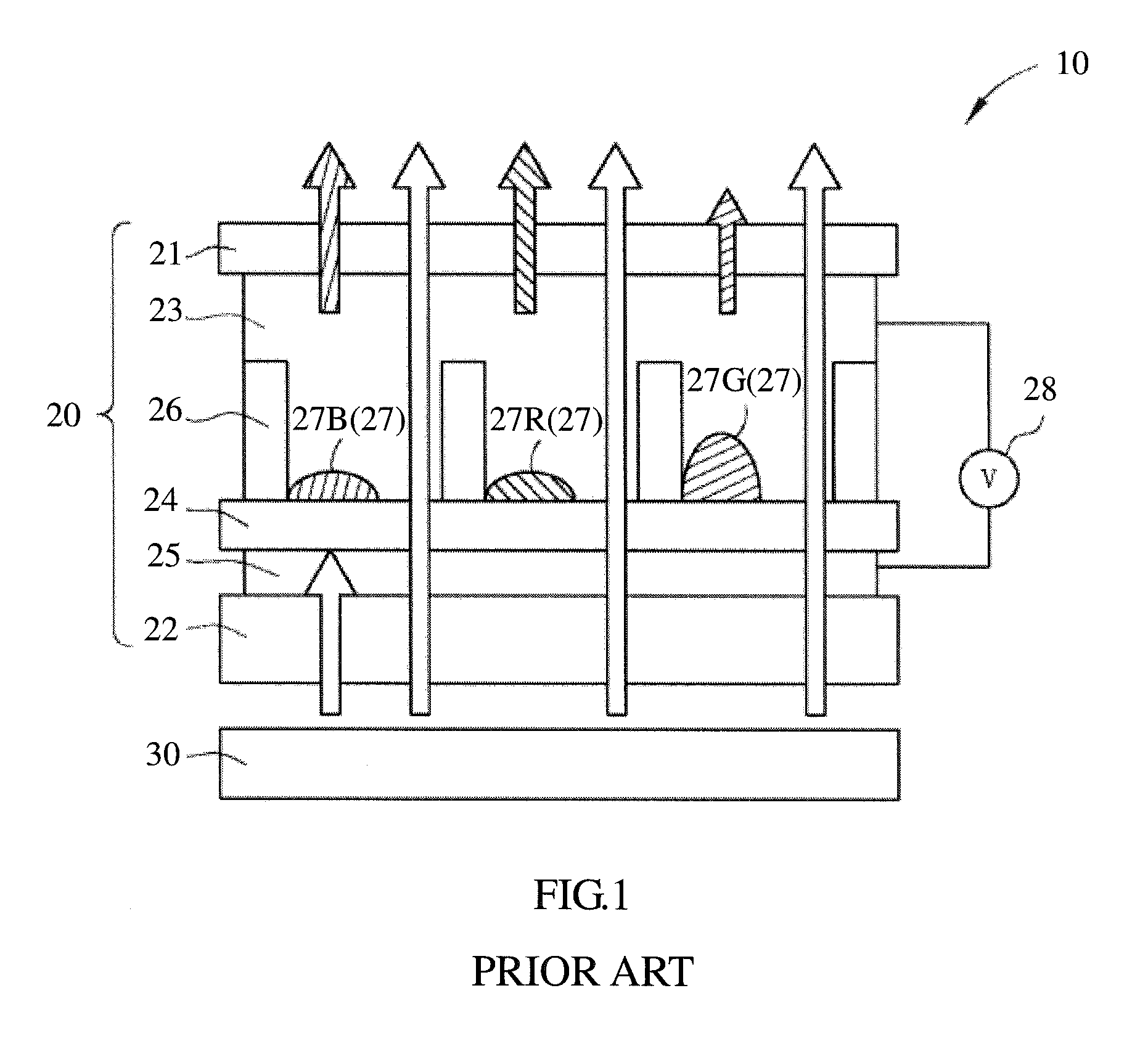

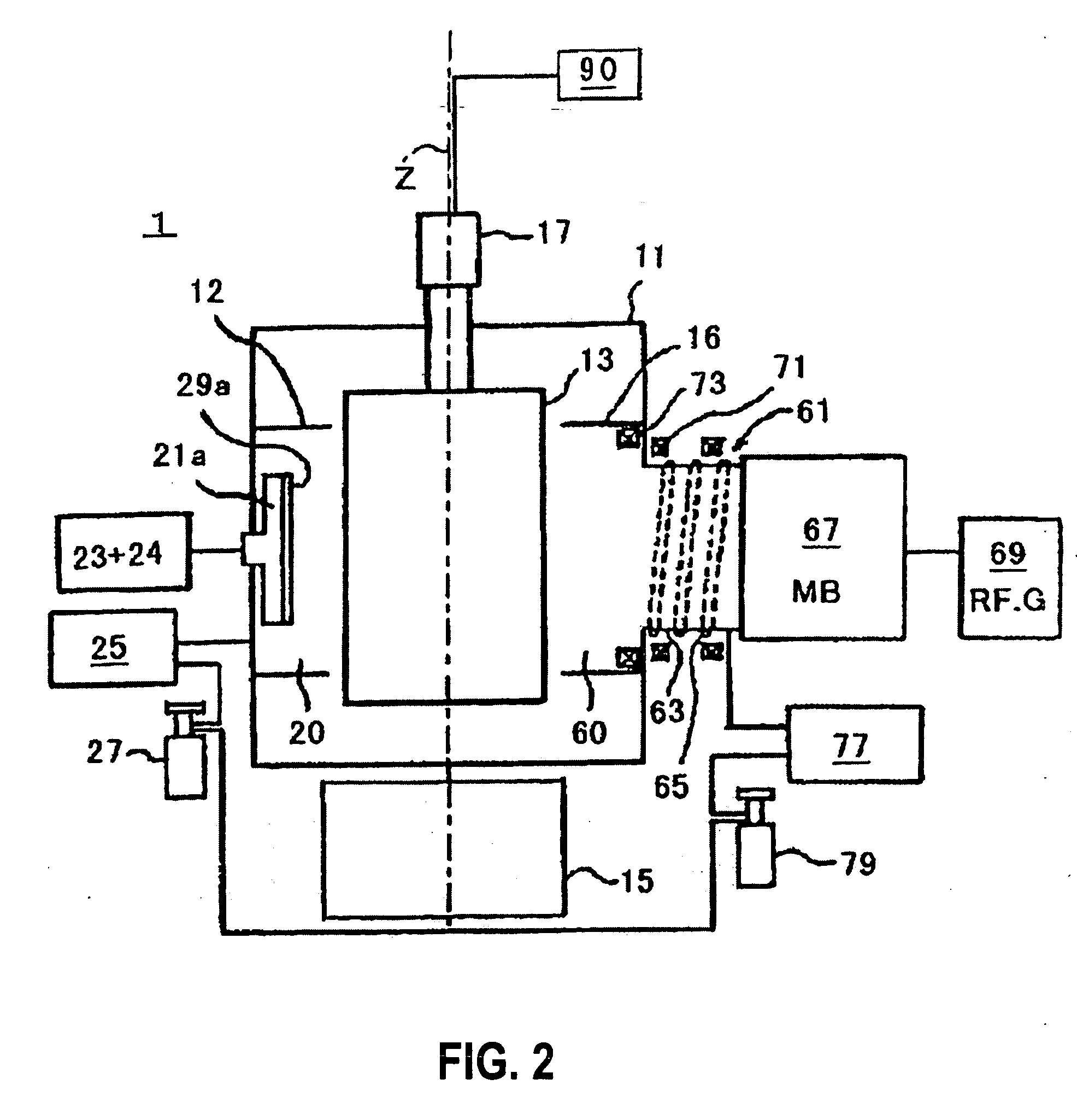

Developing device and image forming apparatus

ActiveUS20080226350A1Efficient collectionImprove chargeabilityElectrographic process apparatusLatent imageDevice form

To provide a developing device capable of preventing the hysteresis phenomenon. The developer of the developing device contains a toner and a carrier. The toner and the carrier are charged to a polarity different from each other by frictional contact thereof. The developing device has a first conveyance member and a second conveyance member which faces an electrostatic latent image bearing body via the second region. An electric field forming device forms a first electric field between the first conveyance member and the second conveyance member to move the toner in the developer retained by the first conveyance member to the second conveyance member, and forms a second electric field between the second conveyance member and the electrostatic latent image bearing body to move the toner retained by the second conveyance member to an electrostatic latent image of the electrostatic latent image bearing body. The first electric field is an oscillating electric field having both a function to supply the toner to the second conveyance member and a function to collect the toner from the second conveyance member while a time average field strength is biased to a side where the toner is supplied from the first conveyance member to the second conveyance member, and a time ratio for carrying out the function to collect the toner from the second conveyance member to the first conveyance member is 60 to 80%.

Owner:KONICA MINOLTA BUSINESS TECH INC

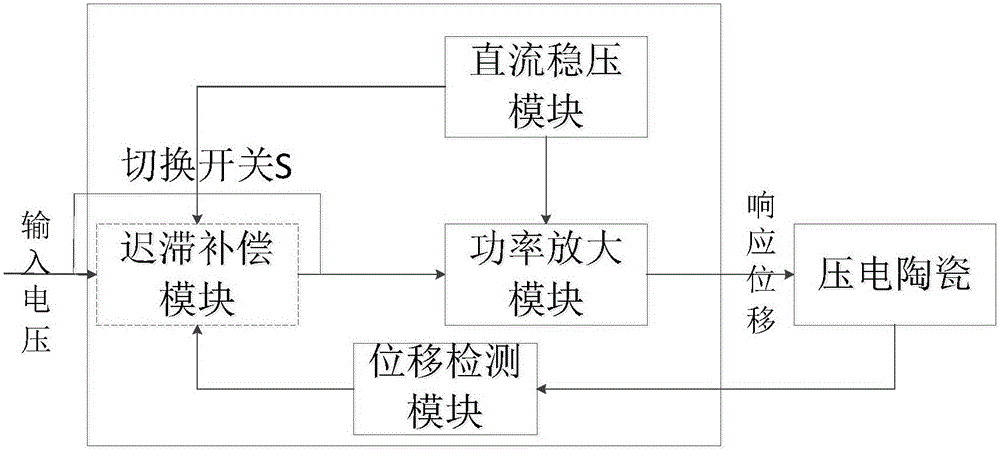

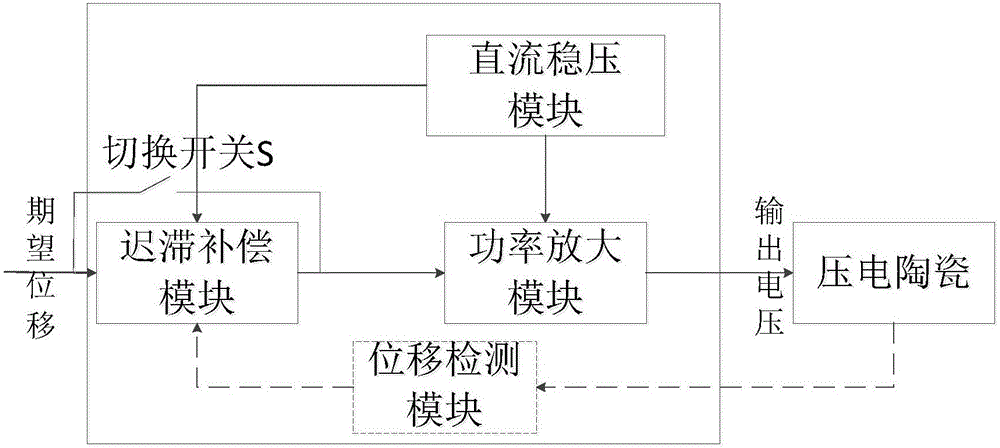

Piezoelectric ceramic driving power supply with hysteresis compensation function

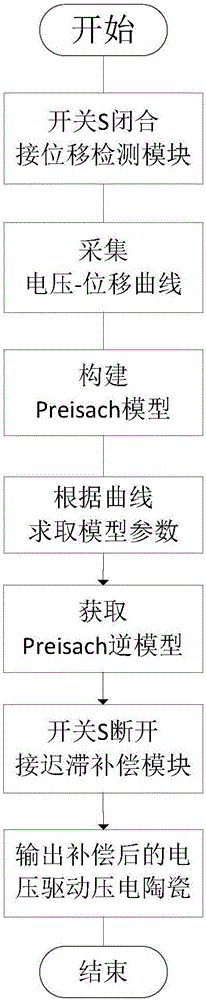

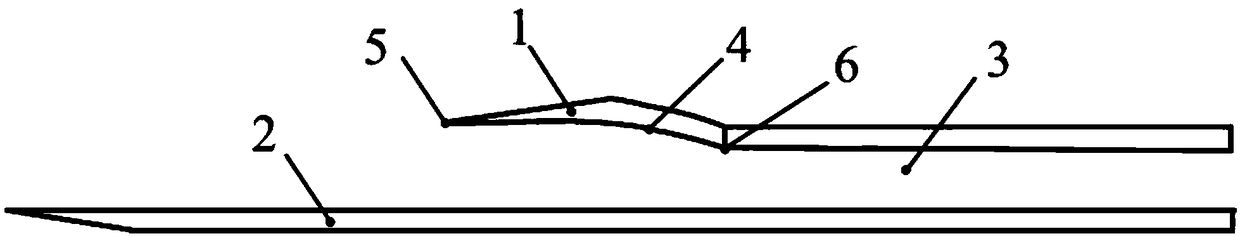

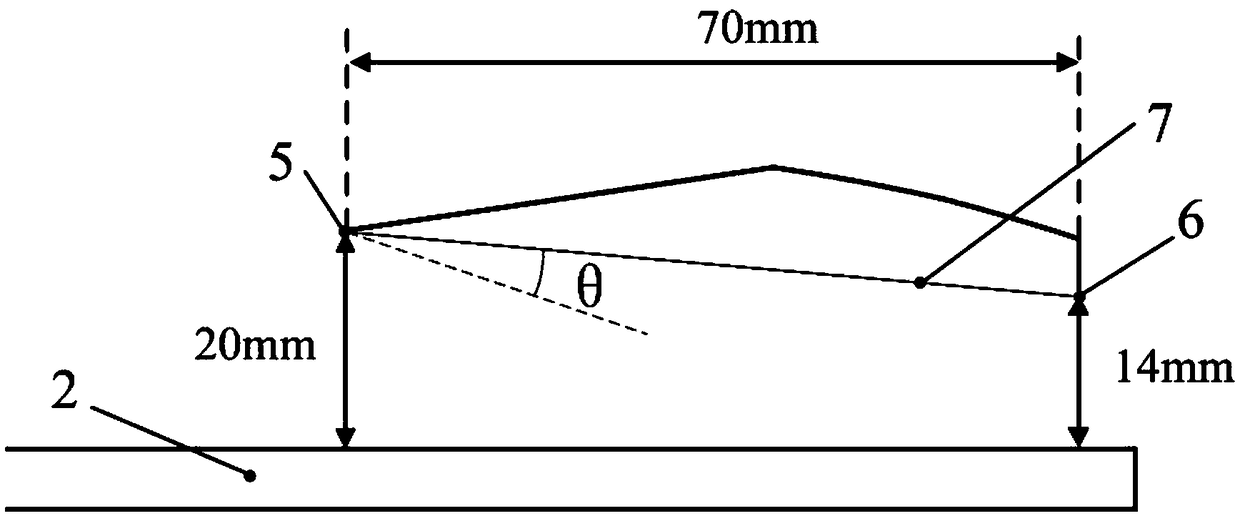

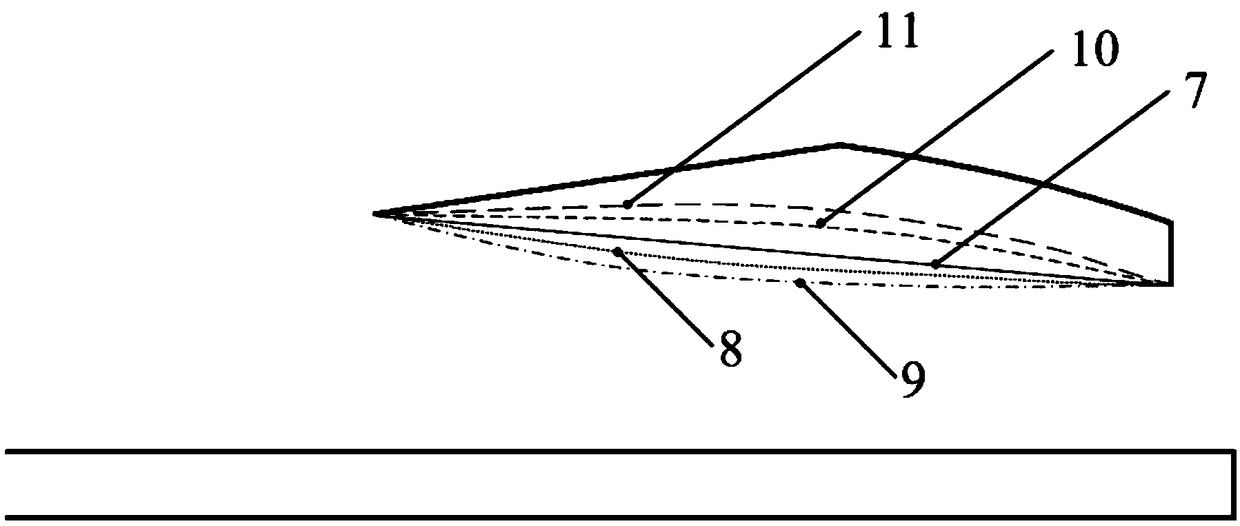

ActiveCN106059385AReduce the impactPiezoelectric/electrostriction/magnetostriction machinesElectricityHysteresis phenomenon

The invention relates to a piezoelectric ceramic driving power supply with a hysteresis compensation function, which comprises a DC voltage stabilization module, a hysteresis compensation module, a power amplification module and a displacement detection module, wherein the DC voltage stabilization module provides DC voltage for the power amplification module and the hysteresis compensation module; the hysteresis compensation module is used for compensating hysteresis nonlinearity of the piezoelectric ceramic, a switch is arranged between the input end and the output end of the hysteresis compensation module, the switch is closed in the case of first-time use or when a piezoelectric ceramic chip of a different type is replaced, and the hysteresis compensation module is short-circuited; the power amplification module carries out voltage and power amplification on output signals of the hysteresis compensation module; and the displacement detection module is started only in the case of first-time measurement or a piezoelectric ceramic chip of a different type is replaced and is used for measuring response displacement and storing the response displacement to the hysteresis compensation module. The hysteresis compensation module is introduced, the influence on the control precision by a hysteresis phenomenon can be greatly reduced, and the structure is simple, and the stability is high.

Owner:NANJING UNIV OF SCI & TECH

Hypersonic-speed gas inlet channel starting method and starting device

ActiveCN108999704AConsider startingControl deformationTurbine/propulsion engine ignitionTurbine/propulsion engine startersInlet channelHysteresis phenomenon

The invention discloses a hypersonic-speed gas inlet channel starting control method and control device. The method comprises the following steps that according to known gas inlet channel performanceparameters, a lip cover inner side design type line and a starting controlling mach number, the lip cover inner side optimum starting type line is acquired; when the flight state of an aircraft reaches the controlling mach number, the lip cover inner side type line is controlled to deform and tend to be the lip cover inner side optimal starting type line; after the gas inlet channel is started andflowing is stable, the lip cover inner side type line is controlled to deform and tend to be the lip cover inner side design type line. According to the scheme, the hysteresis phenomenon in the gas inlet channel starting process is utilized, the gas inlet channel starting performance can be greatly improved only by changing the lip opening type line, and meanwhile, the anti-backpressure performance of a gas inlet channel and the overall performance of an engine are ensured.

Owner:NAT UNIV OF DEFENSE TECH

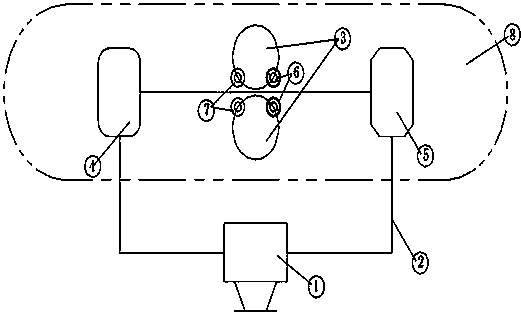

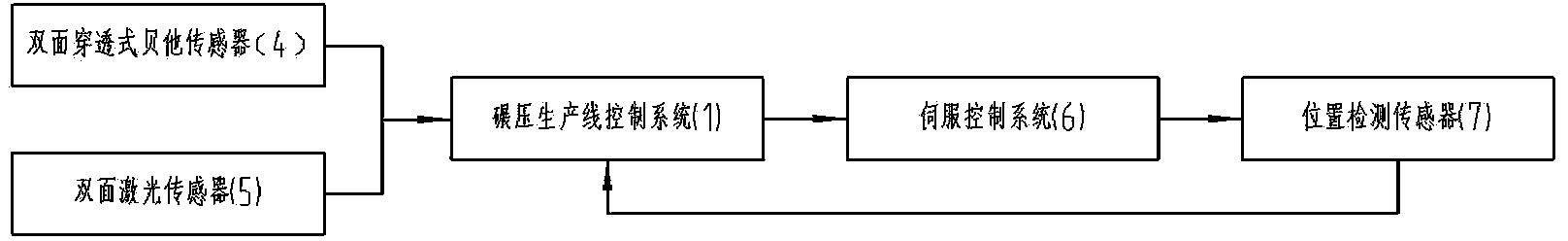

Automatic control system and control method for compaction density of pole piece

ActiveCN104393229ASimple structureReasonable designElectrode manufacturing processesSecondary cellsProduction lineLocation detection

The invention discloses an automatic control system for compaction density of a pole piece. According to the system, the coated pole piece passes through a rolling production line, production is controlled by a rolling production line control system, the surface density of the pole piece is detected by a double-face penetration type beta sensor, the thickness is detected by a double-face laser sensor, detection data is transmitted to the rolling production line control system via a data transmission network, the pole pipe is rolled through rolling rollers, a servo control system is installed on the rolling rollers for controlling the roller gaps, and a position detection sensor is installed on the rolling rollers for detecting the actual roller gap. The automatic control system for compaction density of the pole piece is simple in structure and reasonable in design, reduces artificial intervention on regulating of pole-piece rolling degree, and realizes automatic regulation, reduces the regulation hysteresis phenomena on pole-piece thickness and compaction density during production, realizes automatic stable controlling on compaction density during rolling of the pole piece, and is relatively intelligent. A novel rolling method for the pole piece is provided, and the control manner on pole-piece rolling production is expanded.

Owner:ZHONGTIAN ENERGY STORAGE TECH +1

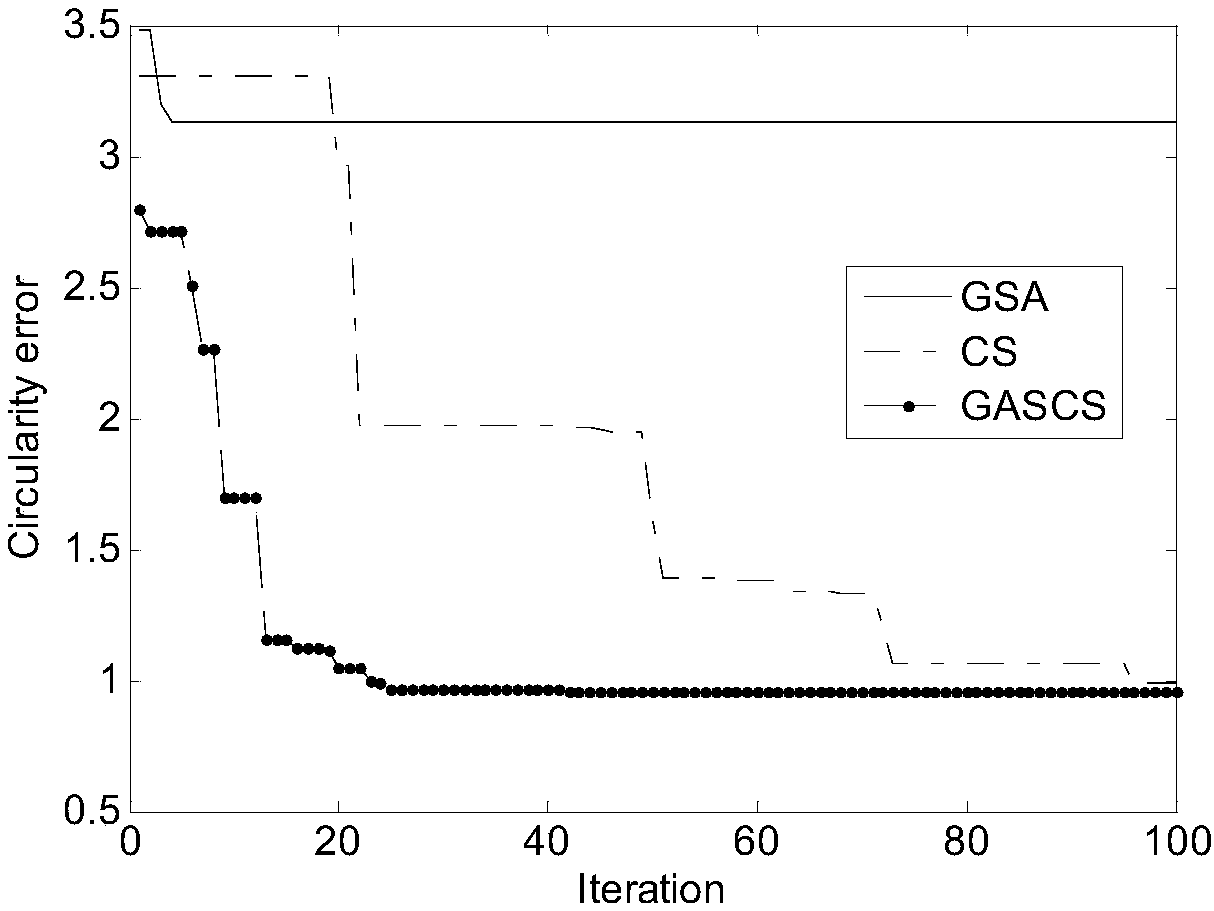

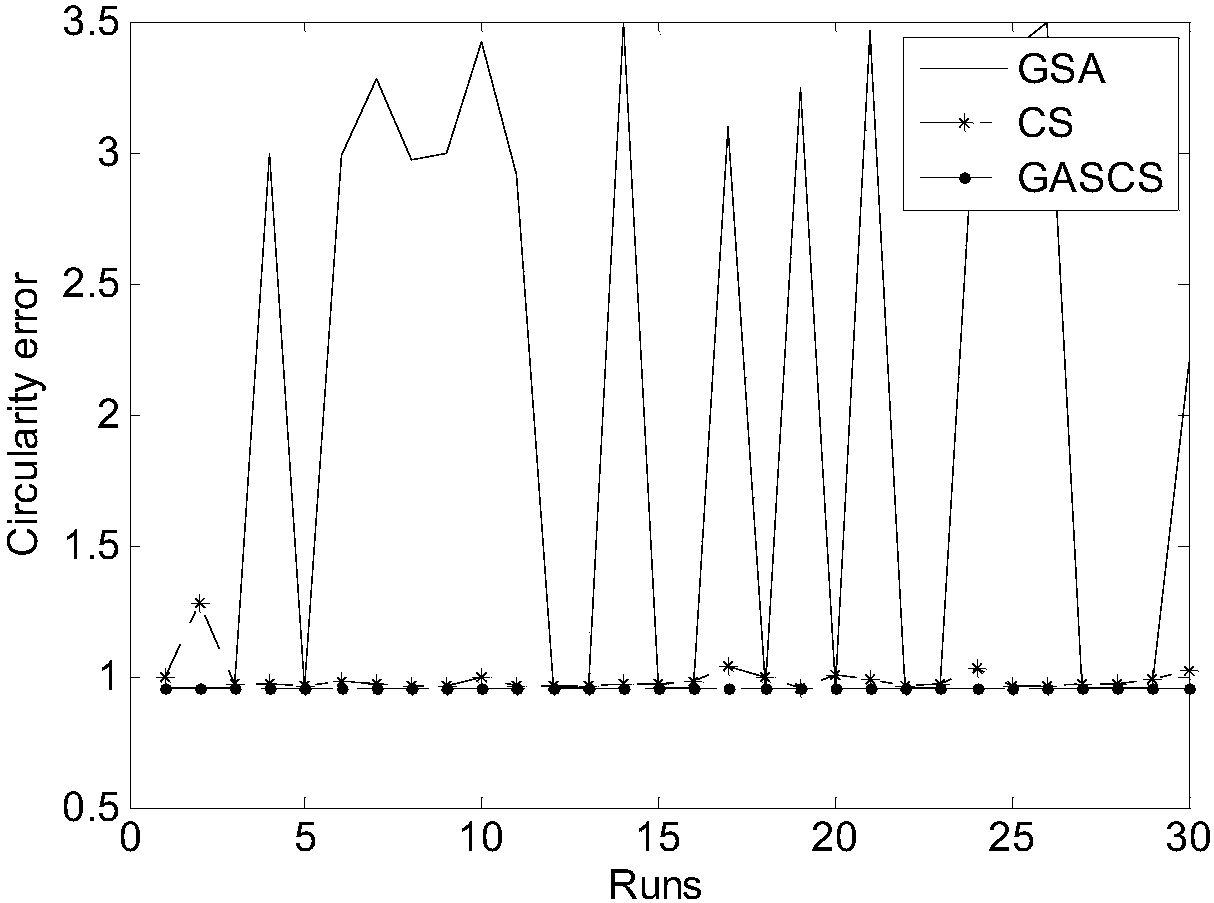

Roundness error evaluating method based on gravitational acceleration cuckoo algorithm

ActiveCN107747930AAvoid hysteresisImprove efficiencyMeasurement devicesArtificial lifeCuckooHysteresis phenomenon

Disclosed is a roundness error evaluating method based on a gravitational acceleration cuckoo algorithm. Based on gravitational search, the characteristics of global optimal information can still be perceived without learning the change of external environmental factors. Cuckoo nests are endowed with different individual masses, and the cuckoo nests obey the law of gravitation in the optimizationprocess. Acceleration search is carried out on Levy flight random walk and preferential random walk in the cuckoo algorithm based on the gravity among optimization individuals to get the update locations of corresponding cuckoo parasitic nest individuals. Under the action of gravity, the global search ability and the local search ability of the cuckoo algorithm are balanced, the hysteresis phenomenon due to the fact that the algorithm gets into a local extreme point at the end of execution is avoided, and the global search efficiency and convergence precision of the algorithm are improved. Theroundness error E to be optimized can quickly tend to be a stable optimal value. The ideal centers Xmin(1) and Xmin(2) of two concentric circles are calculated, and thus, the area between the two concentric circles is the minimum.

Owner:HUAQIAO UNIVERSITY

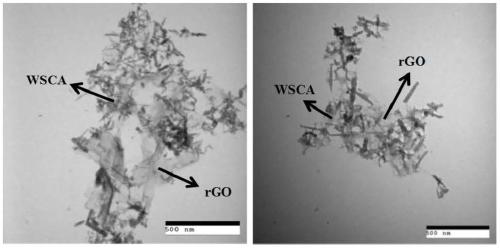

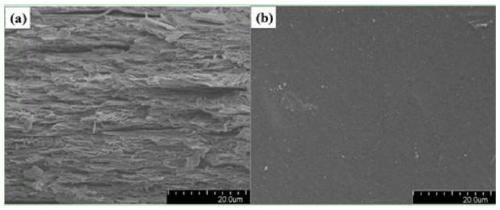

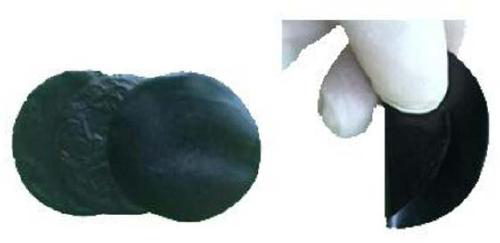

Preparation method of humidity-sensitive sensing film

ActiveCN109810295AIncreased humidity sensitivityRapid expansionMaterial electrochemical variablesCellulose acetateHysteresis phenomenon

The invention relates to humidity-sensitive sensing films and discloses a preparation method of the humidity-sensitive sensing film. The preparation method comprises the following steps: taking valeryl chloride as a modifier; carrying out modification treatment on cellulose in an ionic liquid solution, i.e., 1-ethyl-3-methyl-methylimidazole acetate, so as to prepare water-soluble cellulose acetateWSCA; preparing the water-soluble cellulose acetate to a cellulose water solution; preparing graphene oxide into a solution and adding the solution into the cellulose water solution, so as to obtaina cellulose / graphene oxide uniform mixed solution; adding a reduction reagent into the cellulose / graphene oxide mixed solution and treating an obtained reduced graphene oxide / cellulose water solutionto obtain a flexible rGO / WSCA humidity-sensitive sensing film. The humidity-sensitive film provided by the invention has the advantages of uneasiness of falling off, no hysteresis phenomenon, relatively good humidity sensitivity, environment-friendly material and the like.

Owner:QINGDAO UNIV OF SCI & TECH

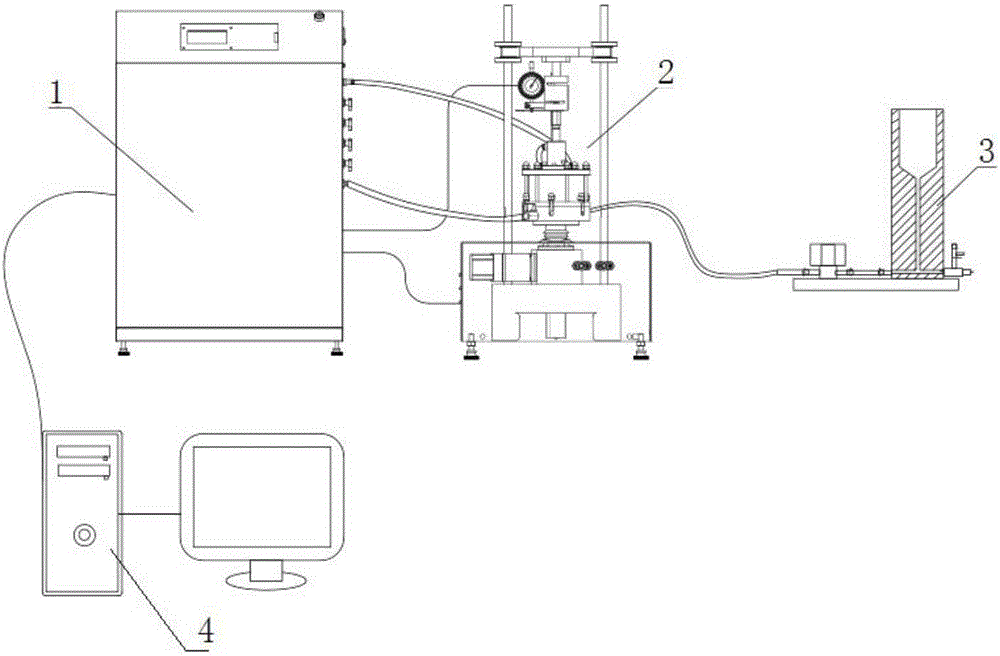

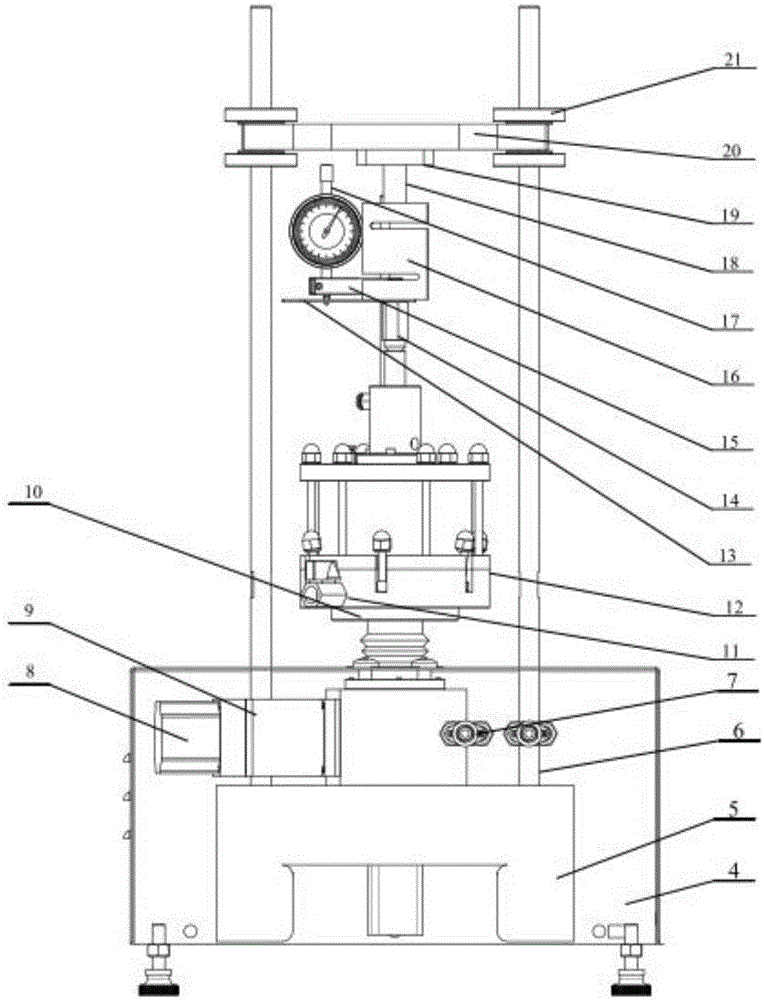

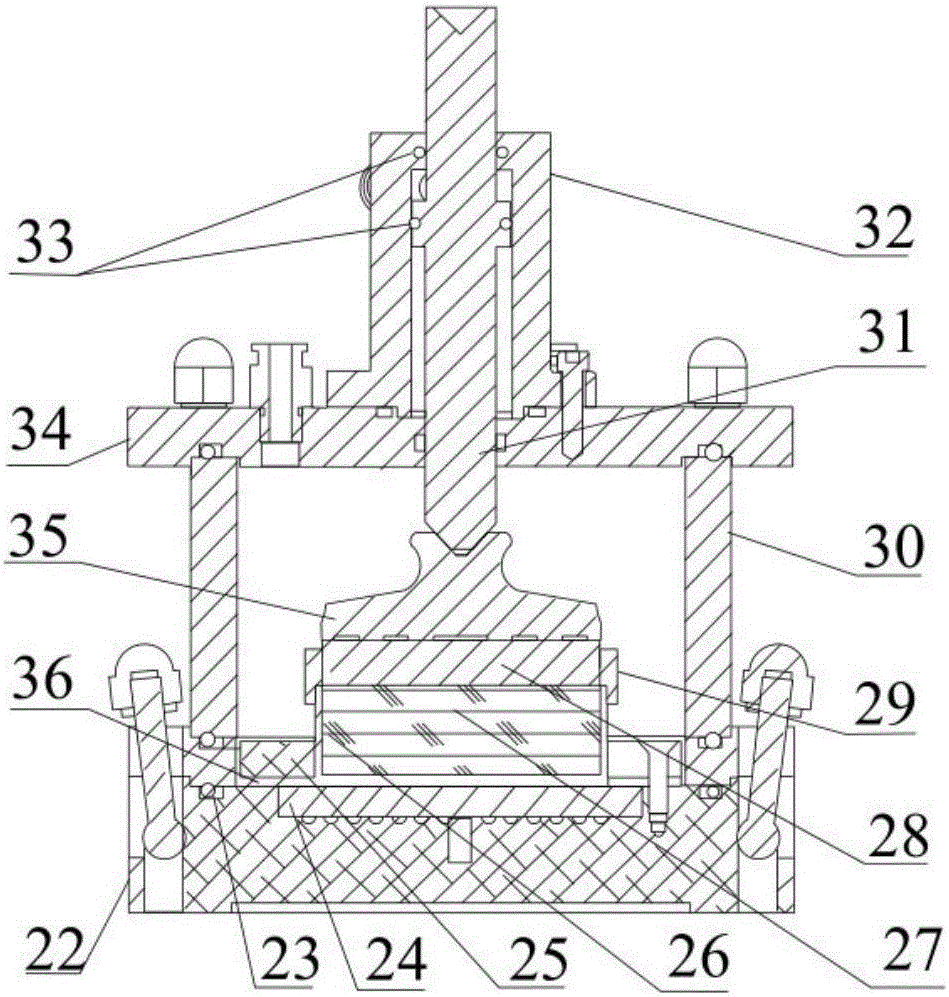

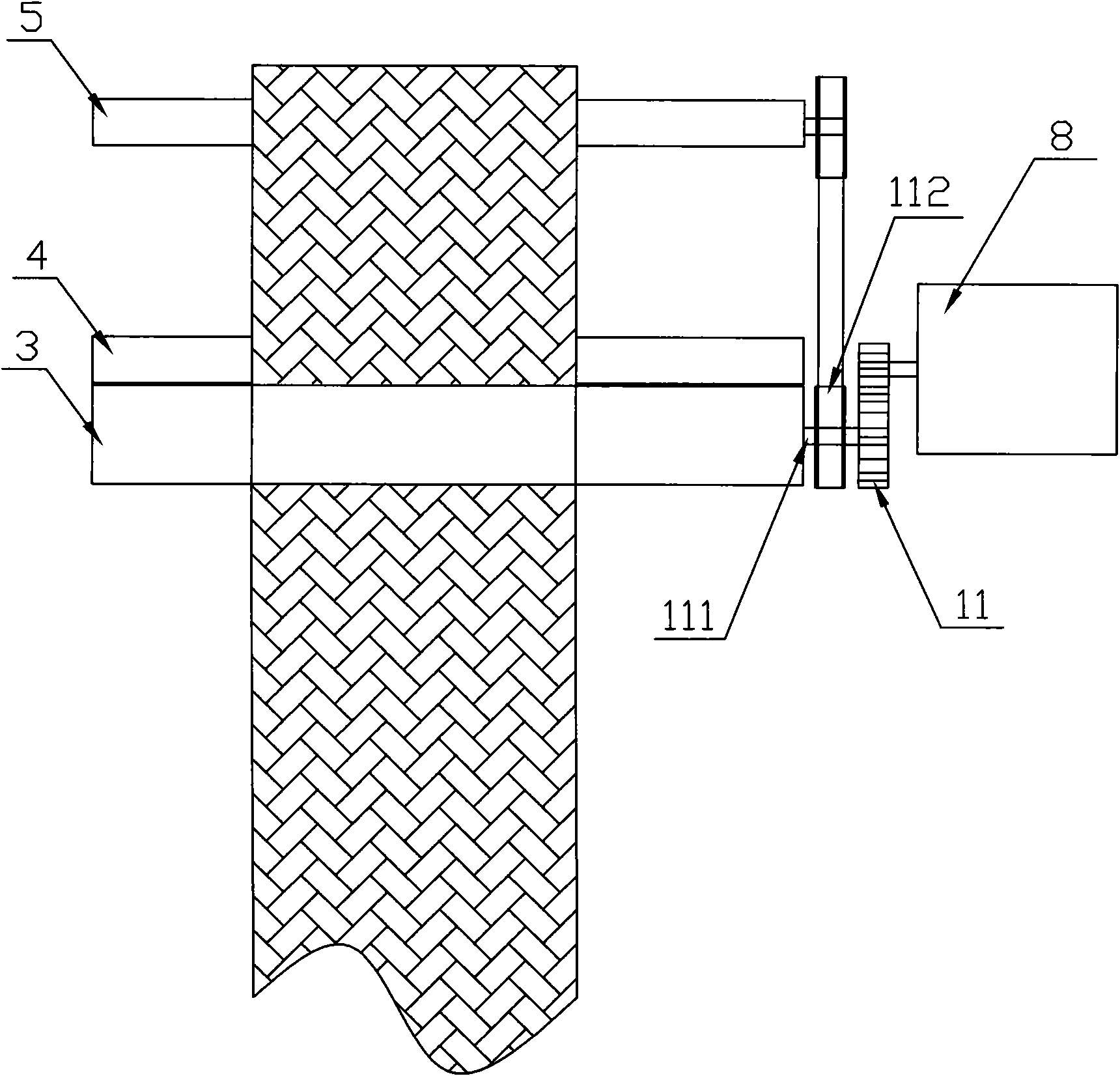

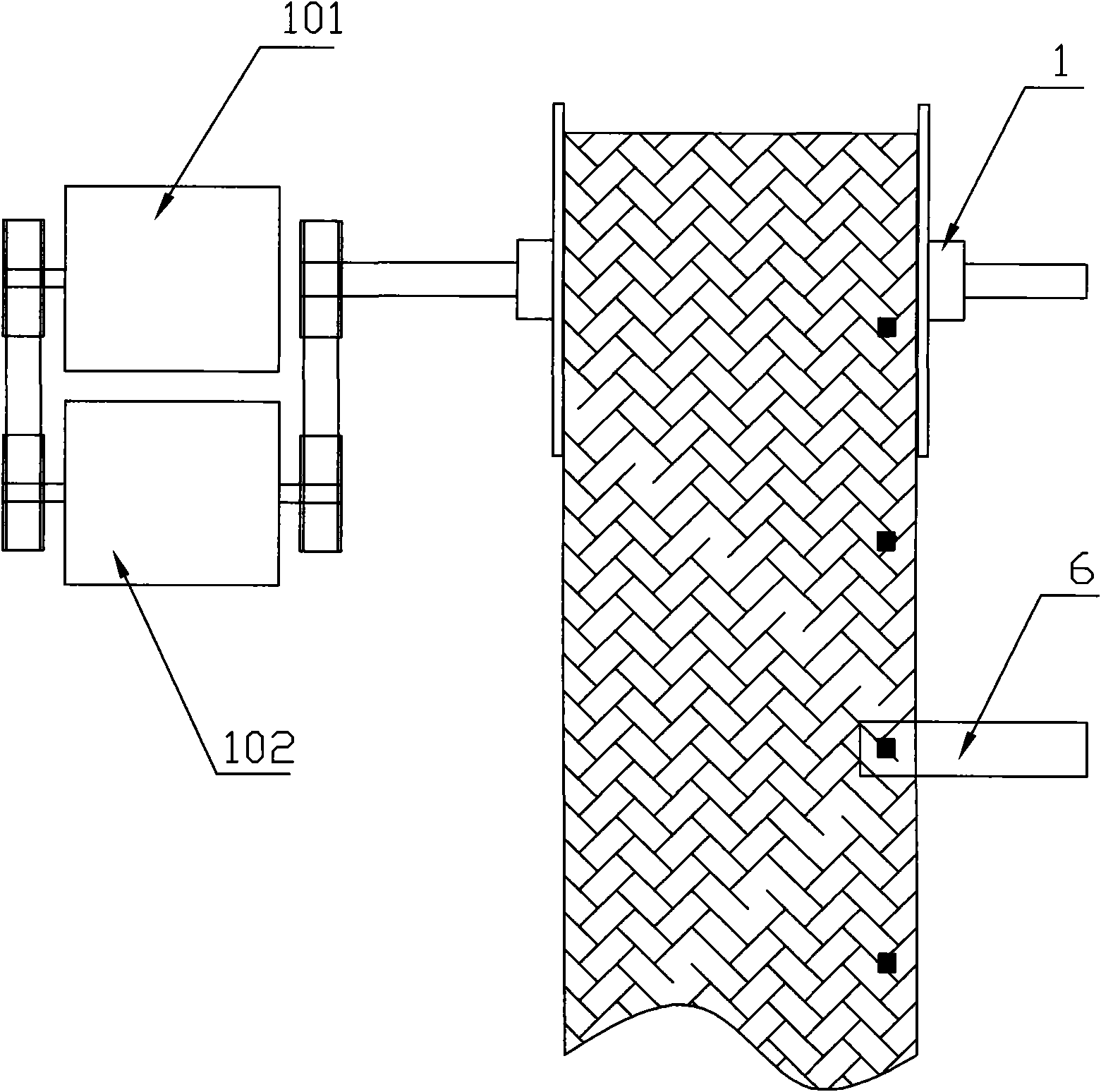

Full-automatic unsaturated soil consolidometer

PendingCN106483993ARealize servo/stepper controlEasy to controlMaterial strength using tensile/compressive forcesFluid pressure control using electric meansSuction stressData acquisition

The invention discloses a full-automatic unsaturated soil consolidometer, which comprises a control cabinet (1), a consolidometer body (2) connected with the control cabinet (1), and a diffused bubble scouring device (3) connected with the consolidometer body (2), wherein the consolidometer body (2) comprises a pressure chamber (12), a pressure loading device, a suction control device, an information detection device and a data acquisition device. The full-automatic unsaturated soil consolidometer has the advantages of reasonable structural design, simple operation and high degree of automation, can be applied to the study of unsaturated soil consolidation tests for controlling matric suction or vertical net stress, can be used for studying soil-water characteristic curves and hysteresis phenomena thereof during the unsaturated soil moisture absorption and dehumidification processes in different stress states, can replace the traditional soil-water characteristic curve pressure plate extractor, can realize precise, permanent and efficient control over matric suction, can greatly improve the precision of unsaturated soil experiments, and has wide application range.

Owner:南京泰克奥科技有限公司

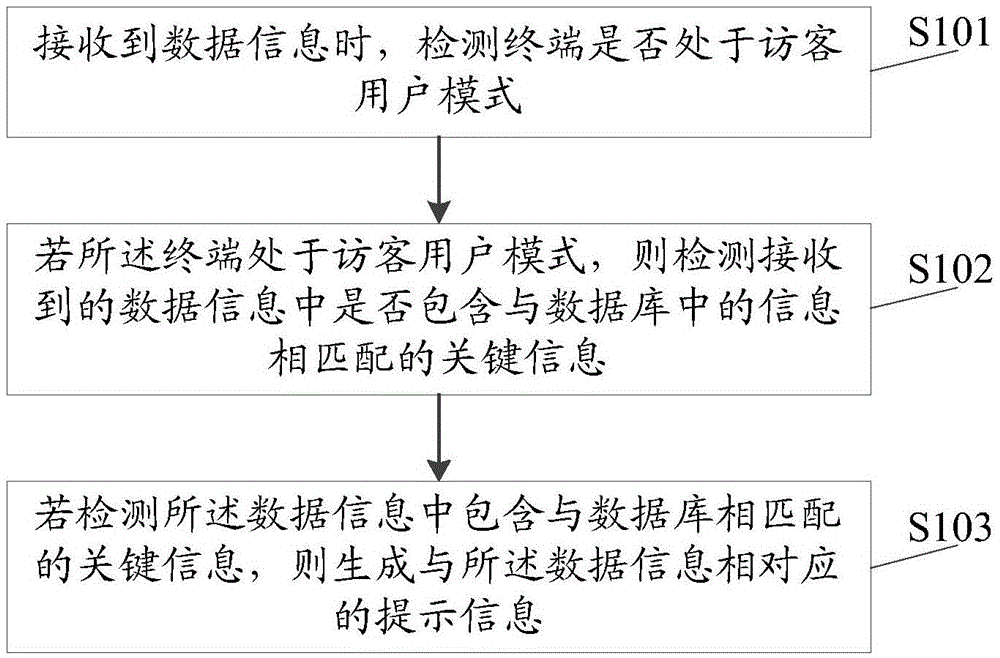

Message reminding method and device

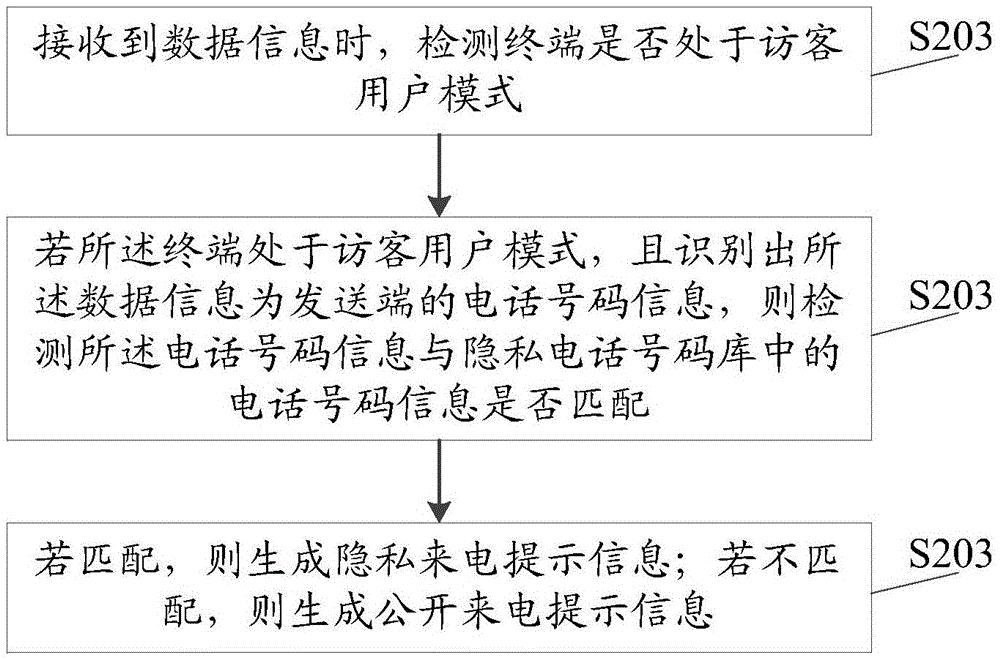

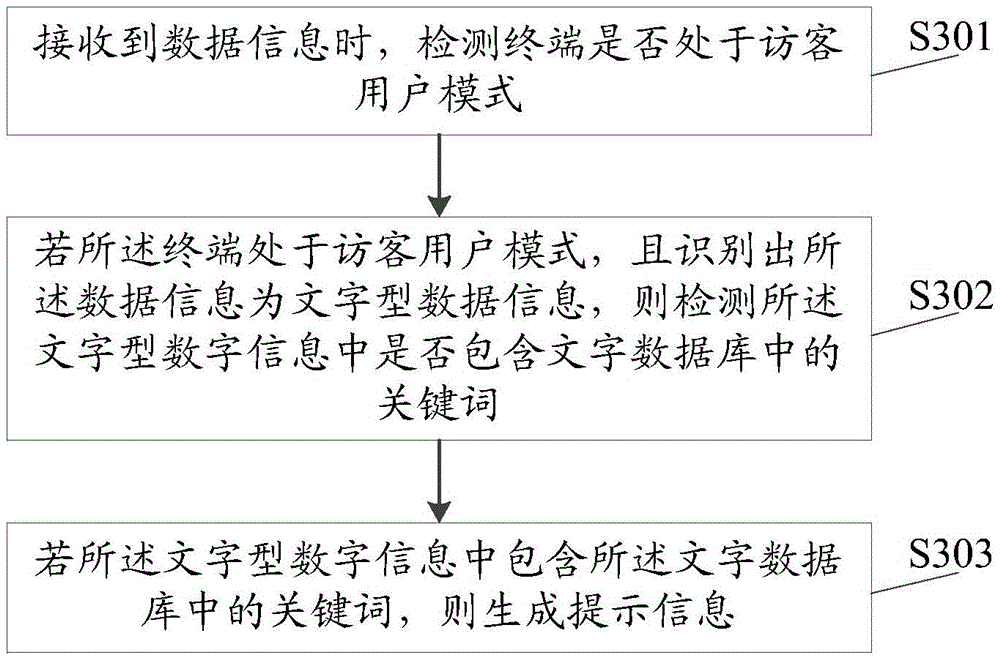

InactiveCN105681564AAvoid lostReduce hysteresisCurrent supply arrangementsSubstation equipmentData informationHysteresis phenomenon

The invention discloses a message reminding method and device. The method comprises the following steps: detecting whether a terminal is in a visitor user mode while receiving data information; if the terminal is in the visitor user mode, detecting whether the received data information contains key information matched with the information in a database; if detecting that the data information contains the key information matched with database, generating prompt information corresponding to the data information. In the embodiment of the invention, when the terminal is in the visitor user mode, the device can automatically detect whether the received data information contains the key information, and sends the corresponding prompt information if the received data information contains the key information, thereby reducing the hysteresis phenomenon of important information and avoiding unnecessary loss for the user.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

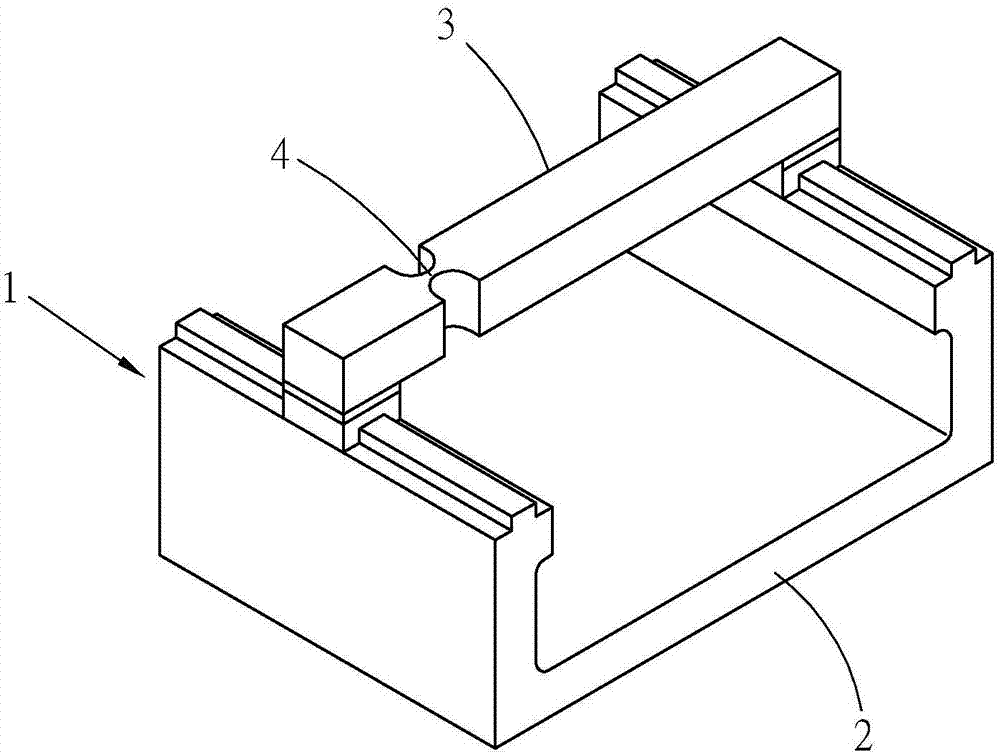

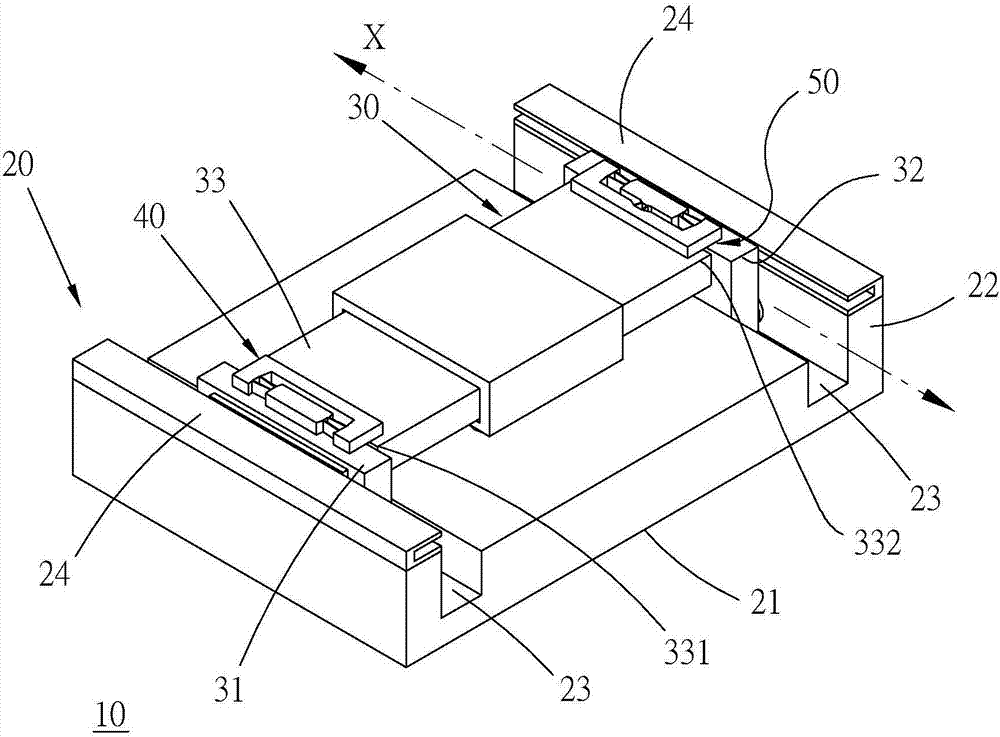

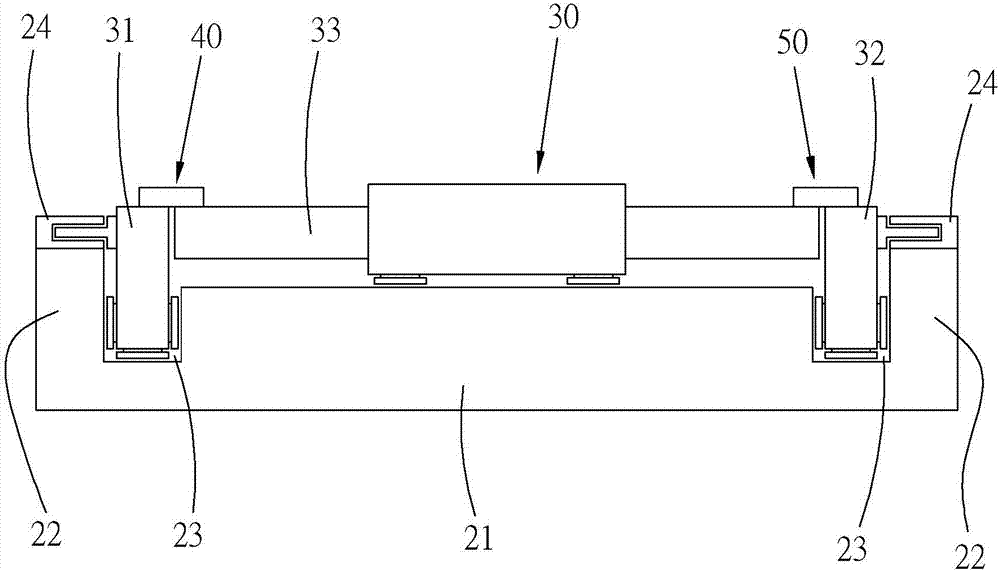

Flexible mechanism and gantry device containing flexible mechanism

ActiveCN107378514AImprove rigidityAvoid errorsLarge fixed membersMaintainance and safety accessoriesFlexible MechanismsCoupling

The invention provides a flexible mechanism and a gantry device comprising the flexible mechanism. The flexible mechanism comprises a first coupling piece, a second coupling piece, a first flexible part and a second flexible part, wherein the rigidity of the first flexible part is larger than that of the second flexible part, so that the deformation resistance of the first flexible part in the first axial direction is improved; and the gantry device comprises a base, a beam and a first flexible mechanism, the rigidity of the first flexible part of the first flexible mechanism is larger than that of the second flexible part, so that the deformation resistance of the first flexible part in the first axial direction is improved. The flexible mechanism is used for providing compensation for the position space errors caused by the factors such as motion errors and deformation of a gantry cross beam, and the flexible parts can improve the rigidity relative to the moving axial direction where external force is exerted on the cross beam, so that the cross beam is protected against the hysteresis phenomenon in motion.

Owner:HIWIN MIKROSYST

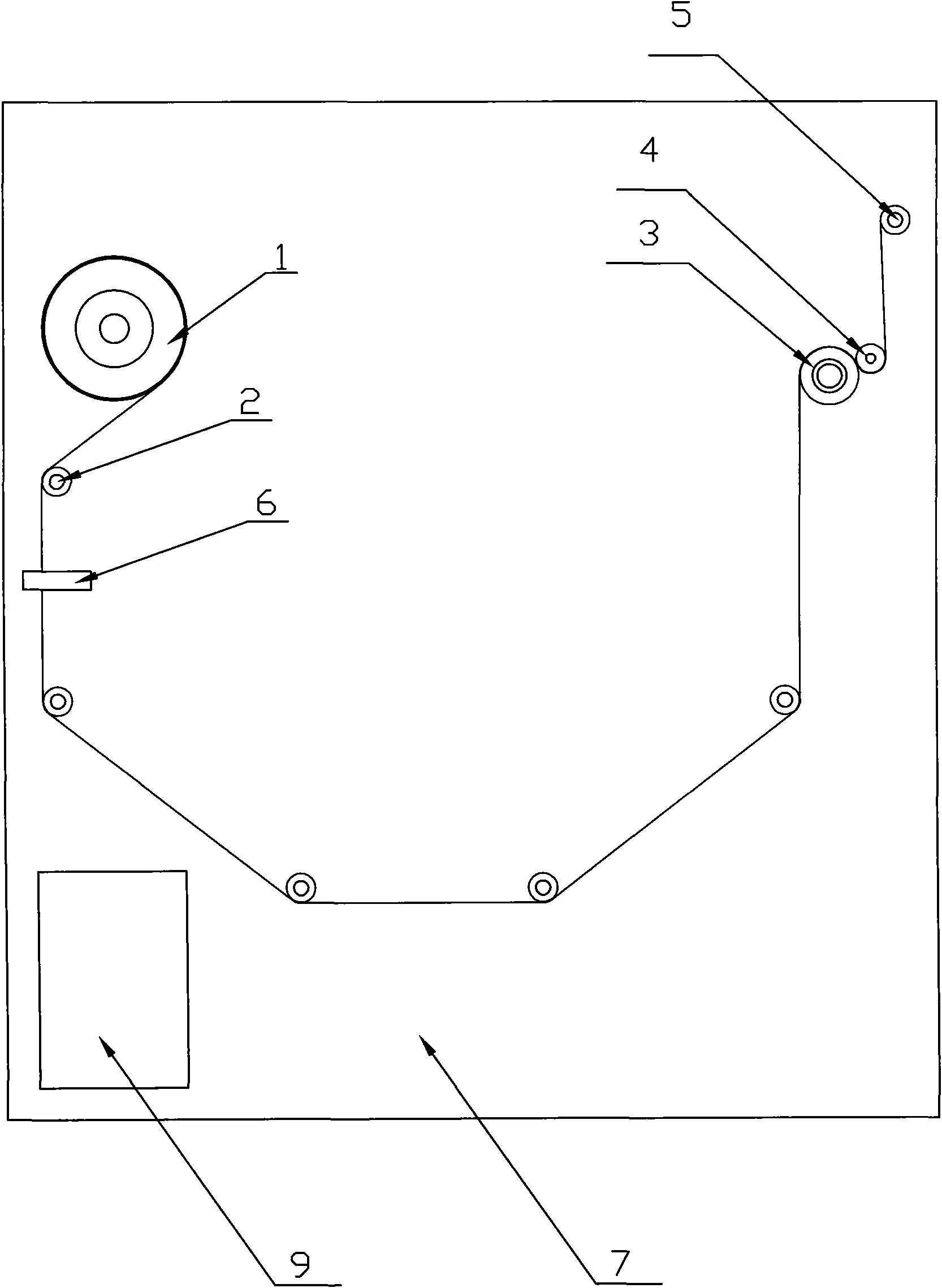

Film coiling system of heat transfer machine

InactiveCN101863159APrecise positioningNo frictionTransfer printingPrinting press partsMotor driveProgrammable logic controller

The invention discloses a film coiling system of a heat transfer machine. A film coiling carrying shaft, a film coiling roller, a film pressing wheel and a film reeling wheel shaft are stopped and positioned on a machine frame in the axial direction in a rotatable way, a photoelectric switch, a steering shaft group and a step motor are fixedly arranged on the machine frame, the photoelectric switch can sense optical markers on a transfer printing film, the outer wall of the film pressing wheel in the radial direction is tightly butted against the outer side wall of the film coiling roller in the radial direction, the motive power output end of the step motor drives the film coiling roller and the film reeling wheel shaft to rotate in the same direction at the same speed, the photoelectricswitch transfers sensing signals to a programmable logic controller, the programmable logic controller controls the starting and the stopping of the step motor, and a transfer printing film tensioning device makes the transfer printing film maintain the tensioning state. The invention uses the programmable logic controller for controlling the step motor to drive the film coiling roller, the starting and the stopping of the step motor are in pure electric control without mechanical friction and hysteresis phenomena, so the operation speed is stable, the reliability is high, the service life islong, the maintenance is not needed, the transfer printing film always maintains the tensioning state, and the positioning of the photoelectric switch is precise.

Owner:LOTUS STATIONERY

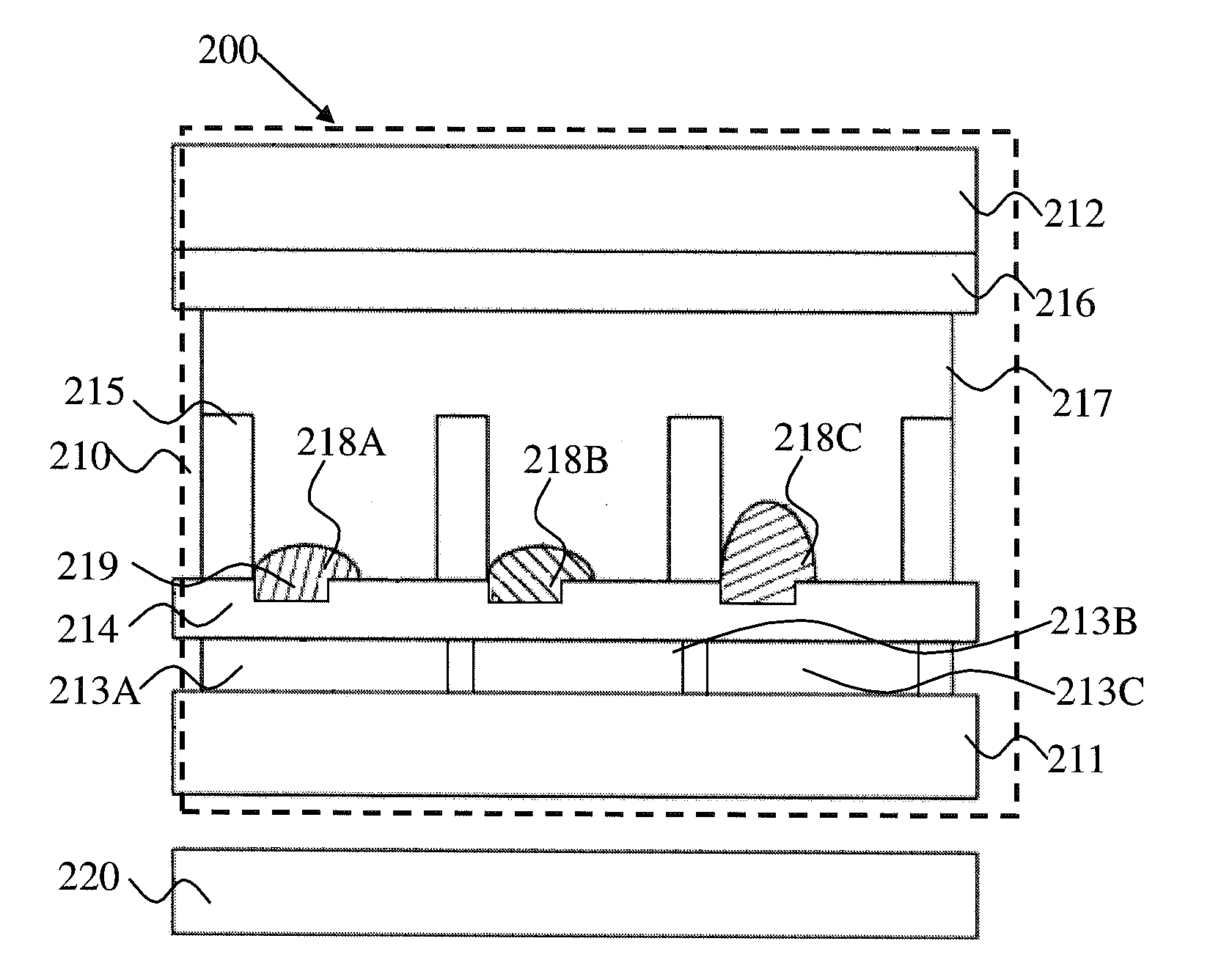

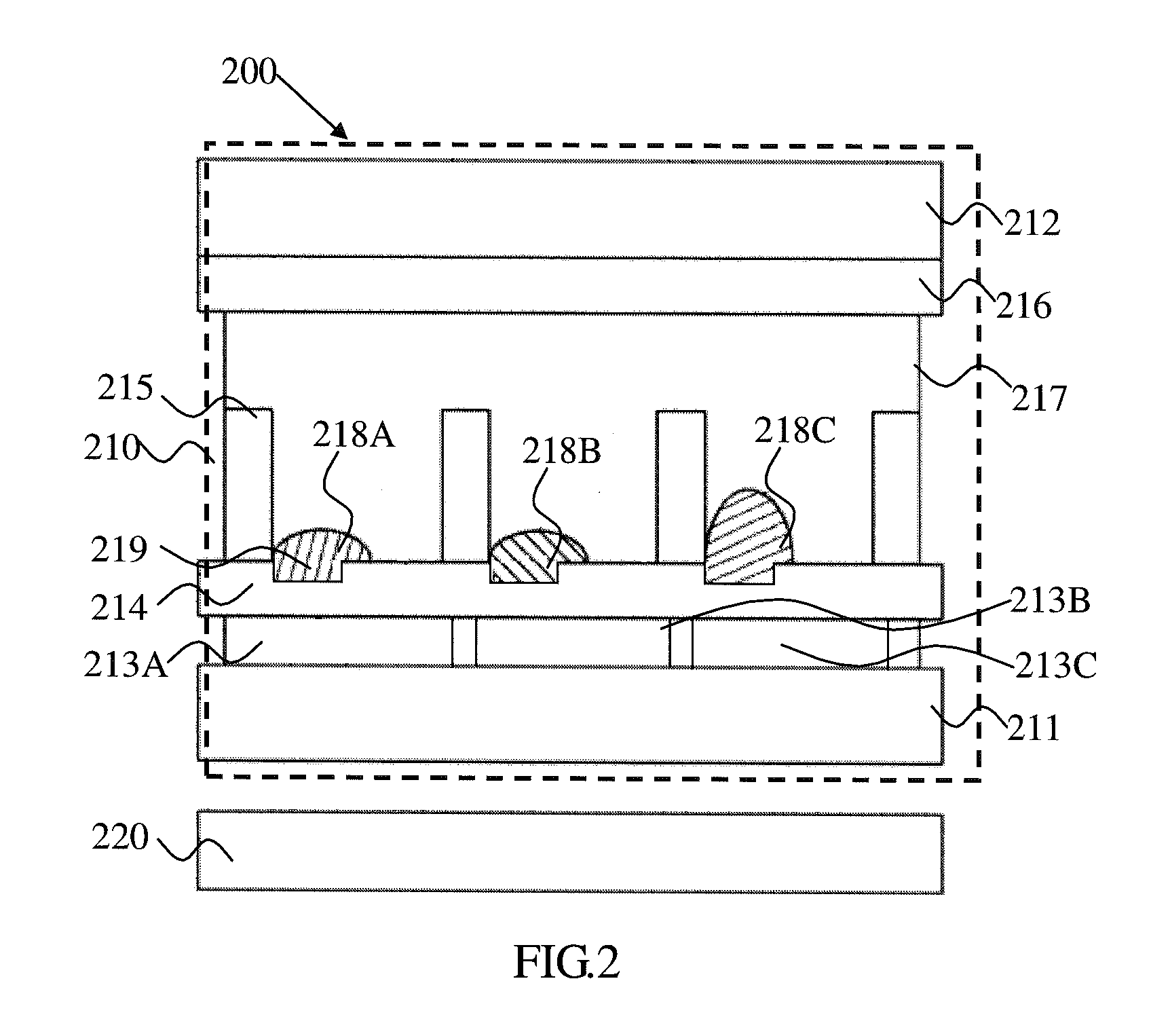

Electro-wetting display panel and electro-wetting display apparatus

ActiveUS20160259160A1Avoid layeringQuality improvementOptical elementsHysteresis phenomenonComputer science

An electro-wetting display panel is provided. The electro-wetting display panel comprises a first transparent substrate, a second transparent substrate, and pixel units. The pixel units comprise first electrodes, a first hydrophobic layer, a plurality of first barriers, a second electrode, a polarized liquid and a plurality of first non-polarized liquids. The hysteresis phenomenon of the non-polarized liquids can be prevented by using the recess areas on the hydrophobic layer.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Automatic coating control method and system

ActiveCN104209246ASimple structureReasonable designElectrode manufacturing processesPretreated surfacesProduction lineAutomatic control

The invention discloses an automatic coating control method and an automatic coating control system. The automatic coating control system comprises a coating production line control system, a data transmission network, a coating steel roller, a double-faced penetration-type beta sensor, a coating cavity, a pressure detection sensor, a feeding tank, a feeding pump, a feeding pipeline, a coating production line and a drying box, wherein a battery pole piece is allowed to pass through a coating production line; the coating production line control system is used for controlling production; the battery pole piece is produced through the coating cavity, the coating steel roller and the drying box; the pressure detection sensor is mounted on the coating cavity; after the double-faced penetration-type beta sensor is mounted on the drying box, detected data are transmitted to the coating production line control system through the data transmission network; the feeding tank is used for feeding slurry to the coating cavity through the feeding pump and the feeding pipeline. The automatic coating control system is simple in structure and reasonable in design, manual intervention to adjustment of the slurry feeding amount in the coating process is reduced, automatic regulation is achieved, and the hysteresis phenomenon of surface density adjustment in the coating process is reduced.

Owner:ZHONGTIAN ENERGY STORAGE TECH +1

Method and device for eliminating thermal inertia of hot air drier

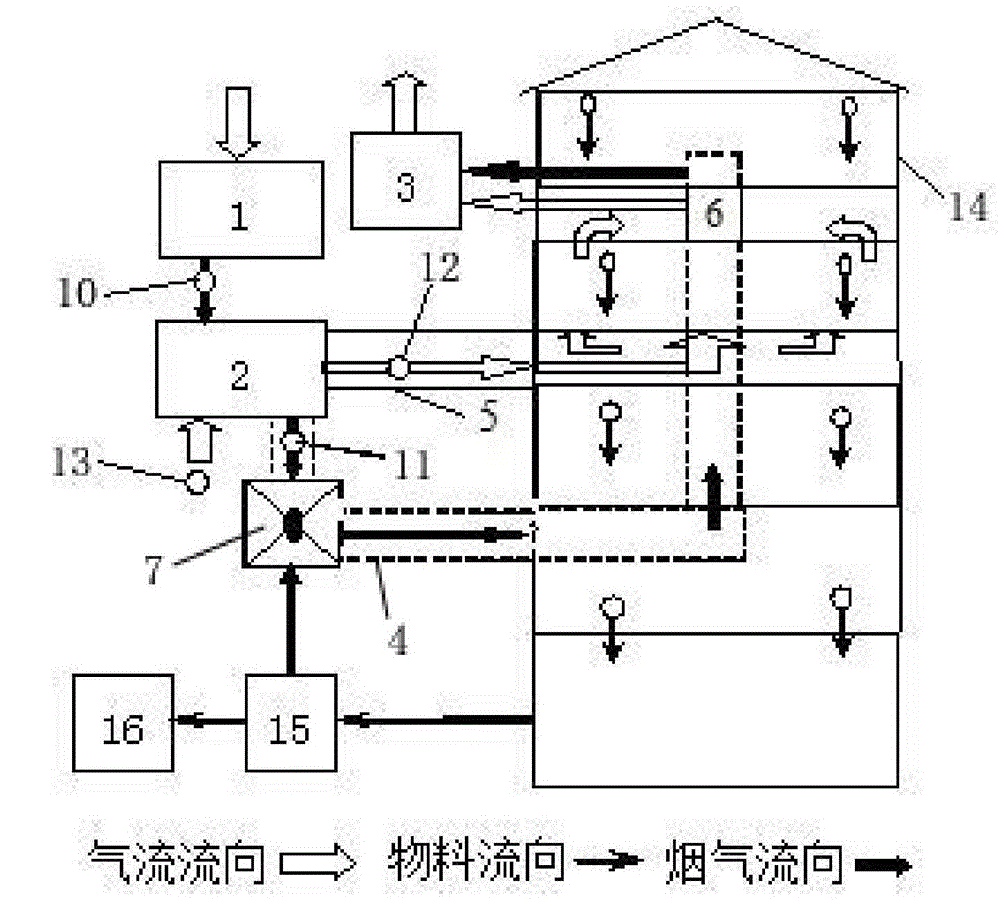

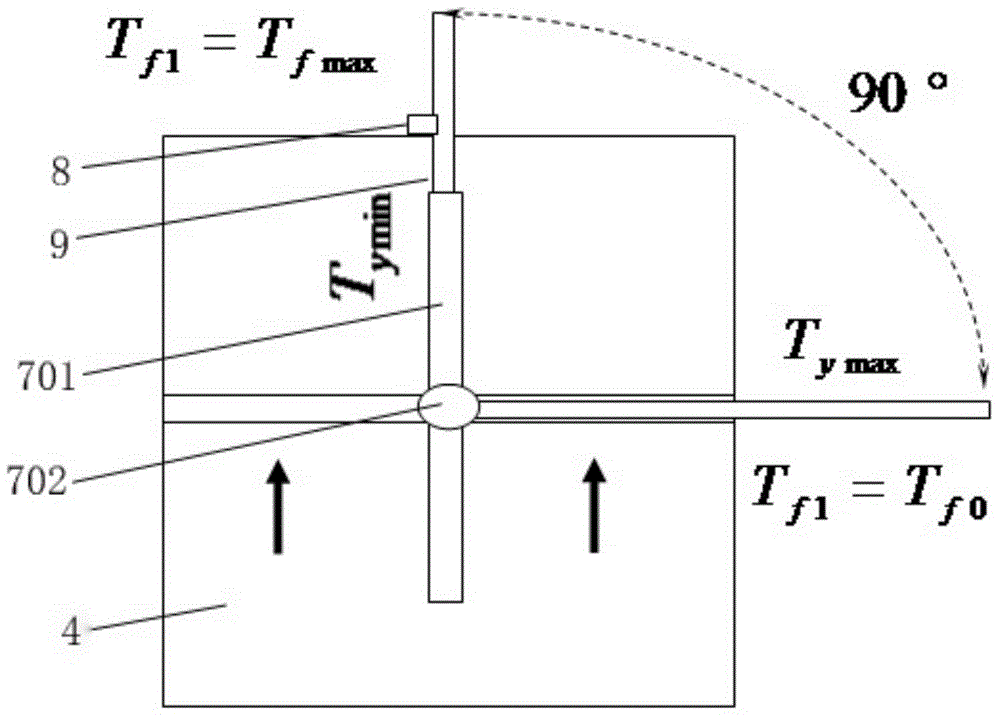

ActiveCN104482751AReal-time safe drying conditionsEliminate thermal inertiaDrying gas arrangementsDry heatMulti variable

The invention discloses a method and a device for eliminating thermal inertia of a hot air drier. The method comprises the steps of arranging a proportional valve for adjusting smoke amount and hot air amount in a smoke channel connected with a heat exchanger, respectively measuring an inlet smoke temperature Ty1 and an outlet smoke temperature Ty2 of the heat exchanger, a hot air inlet temperature Tf1 of the drier and an external environment temperature Tf0 respectively by a temperature sensor, taking a smoke and hot air ratio as the matching principle of drying heat energy, and realizing the principle by controlling the opening degree of the proportional valve, so the temperature of the drying hot air is automatically matched and the thermal inertia of the hot air drier is eliminated. The device and method can be used in real time under complex ambient environment of drying equipment, the serious large hysteresis phenomenon in high inertia, multi-variable and nonlinear process operation in a hot air drying process is solved, the seed quality is guaranteed, the drying temperature is controlled, the thermal inertia in drying process is eliminated, and meanwhile, the method and device are beneficial for an efficient and energy-saving drying process.

Owner:SOUTH CHINA AGRI UNIV

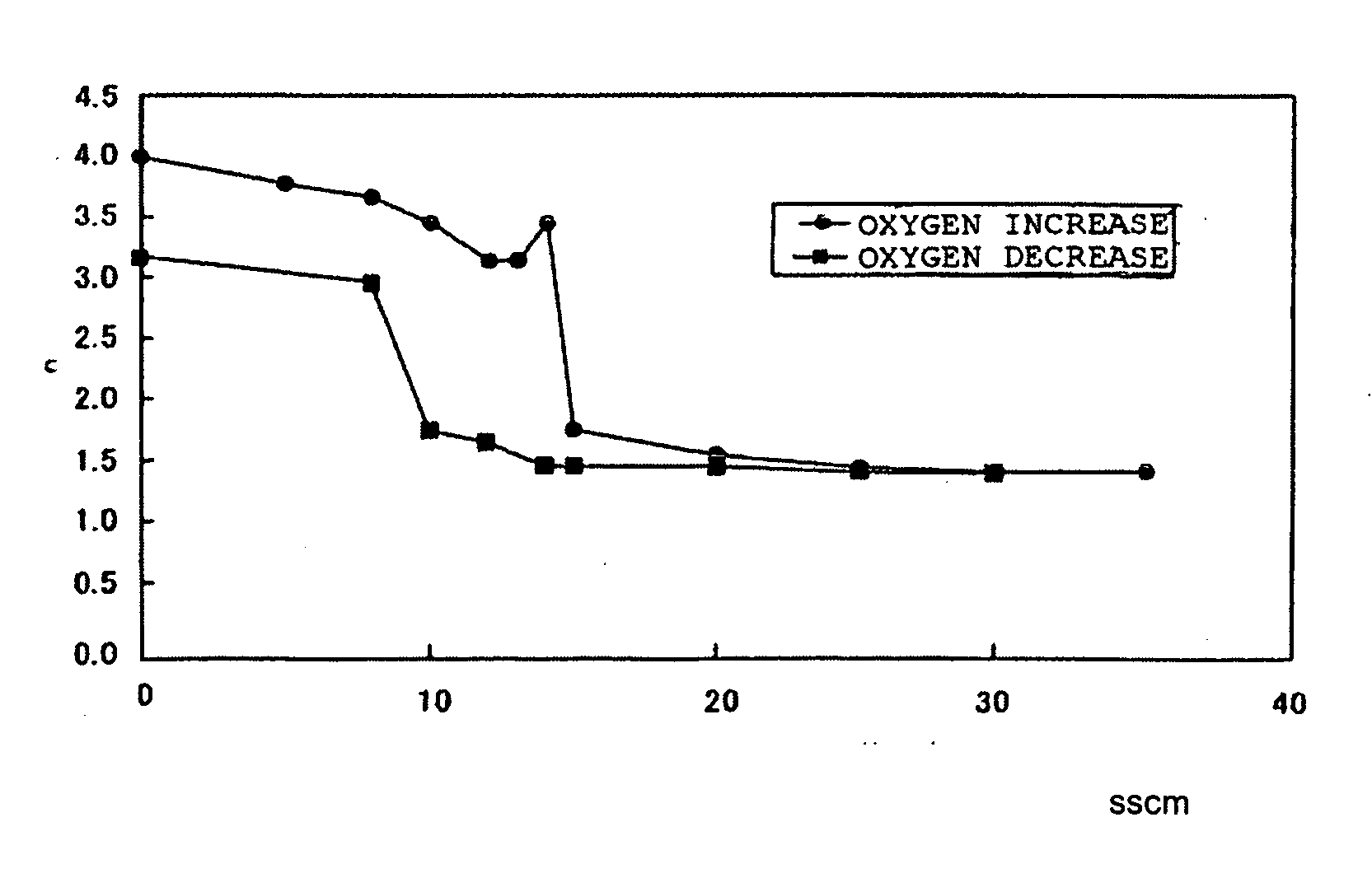

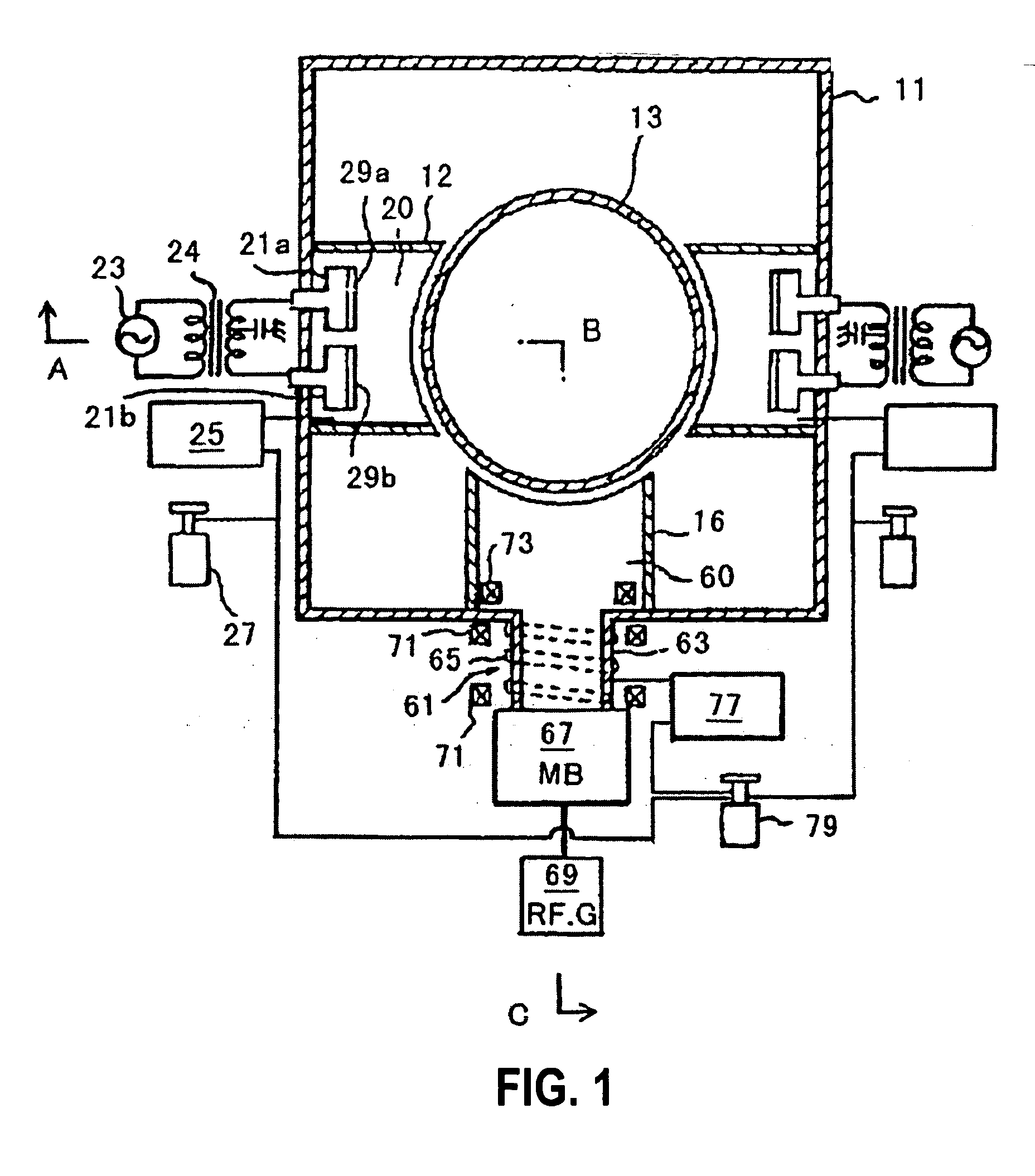

Thin film forming method and forming device therefor

InactiveUS20060189046A1Good reproducibilityLimit on characteristicSolid-state devicesVacuum evaporation coatingOptoelectronicsHysteresis phenomenon

A method of forming a thin film of the present invention comprises: an optical characteristic adjusting step of repeatedly conveying a substrate holder between a zone to perform an intermediate thin film forming step and a zone to perform a film composition converting step while controlling a conveying speed of the substrate holder for holding a substrate, and adjusting a film composition of a finally formed thin film to form the thin film having an optical characteristic value of a region where a hysteresis phenomenon occurs.

Owner:SHINCRON KK

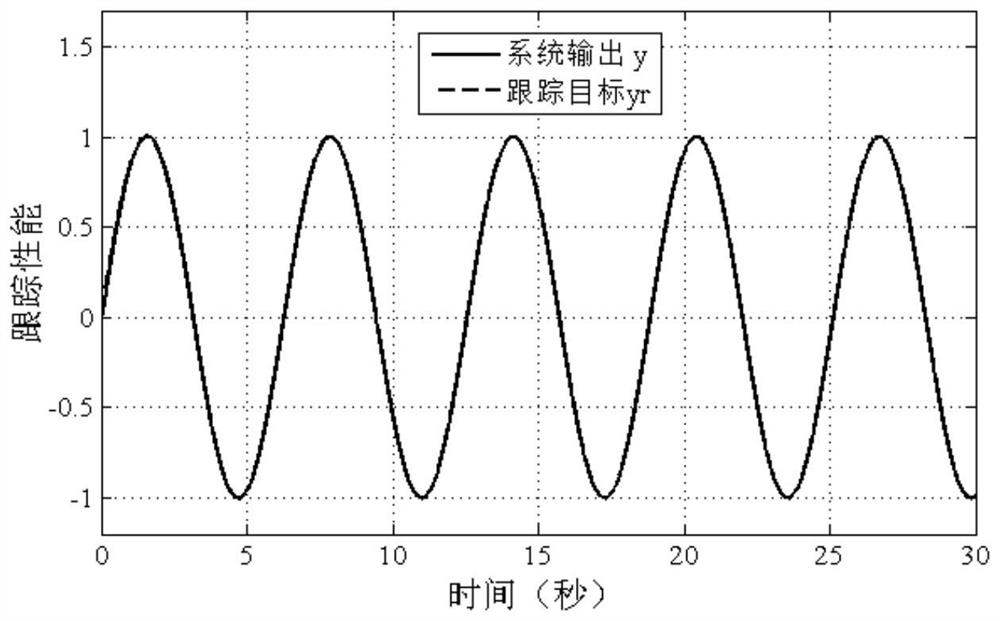

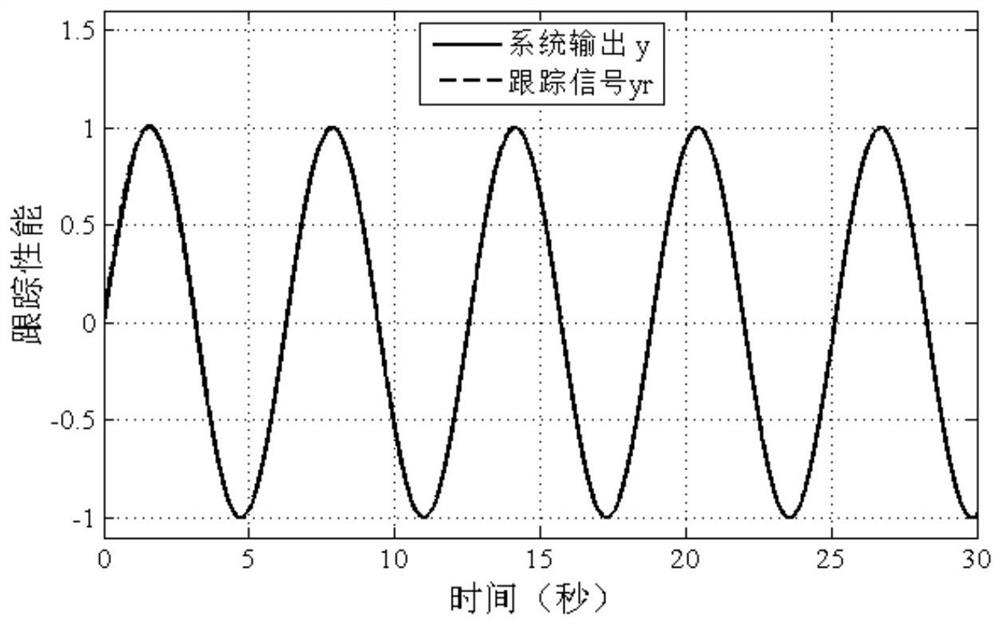

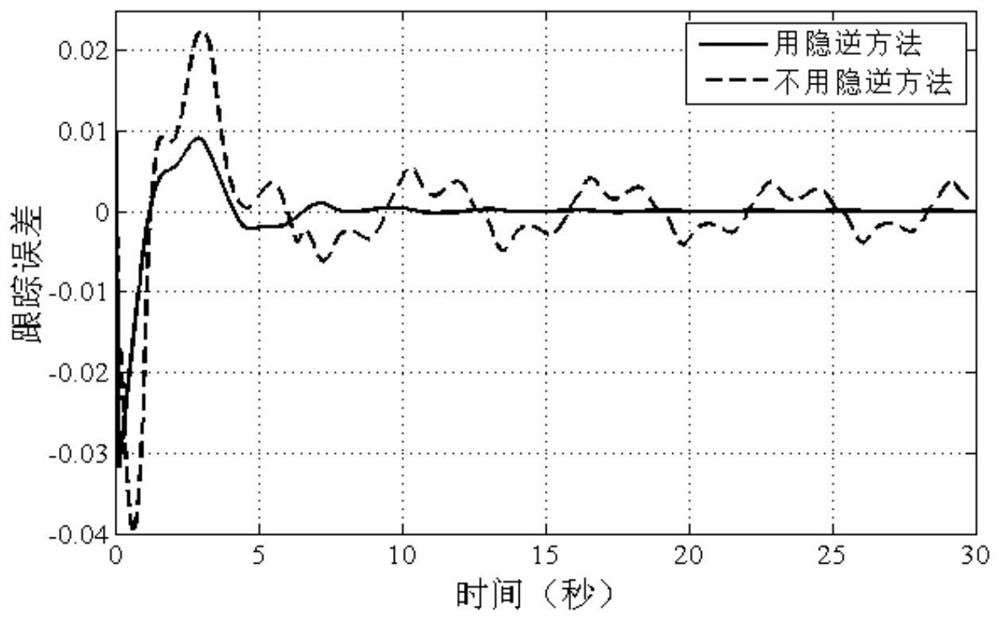

Nonlinear system dynamic surface implicit inverse controller with unknown saturated PI hysteresis

ActiveCN111766775AAvoid difficultiesAchieve traceabilityControllers with particular characteristicsAdaptive controlClassical mechanicsPerformance index

The invention discloses a nonlinear system dynamic surface implicit inverse controller with unknown saturated PI hysteresis. The nonlinear system dynamic surface implicit inverse controller comprisesthe following steps: 1) constructing a nonlinear system model with saturated PI hysteresis; 2) modeling a saturated PI model in the system; 3) defining an error performance conversion function with asaturated PI hysteresis nonlinear system to ensure that the tracking error of the system meets a predetermined performance index; and 4) combining an adaptive dynamic surface algorithm with an implicit inverse method to design a controller with a saturated hysteresis strict feedback nonlinear system. According to the controller, it can be ensured that the system tracking error meets the preset performance index, the problem that a hysteresis inverse model is difficult to construct is solved, the influence of the hysteresis phenomenon in the system is effectively solved, the system tracking error meets the L-infinity performance index, and stable operation of the system is achieved.

Owner:NORTHEAST DIANLI UNIVERSITY +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com