Method for detecting hydrophobic nature of composite insulator based on dynamic contact angles

A composite insulator and dynamic contact angle technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of pollution flashover voltage reduction, low surface resistance, and further research, and achieve small fluctuations and high calculation stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] According to the operation of the technical solution in the summary of the invention above.

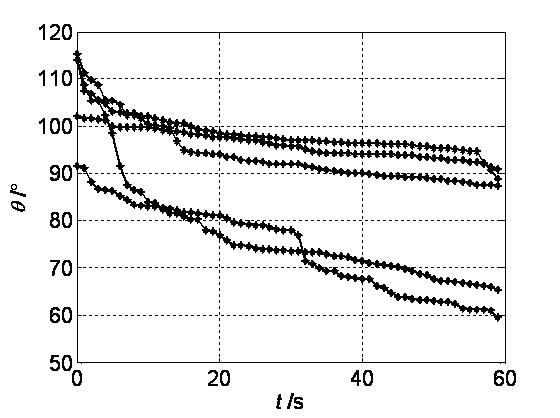

[0033] The following is an analysis of the measurement results for the two test objects:

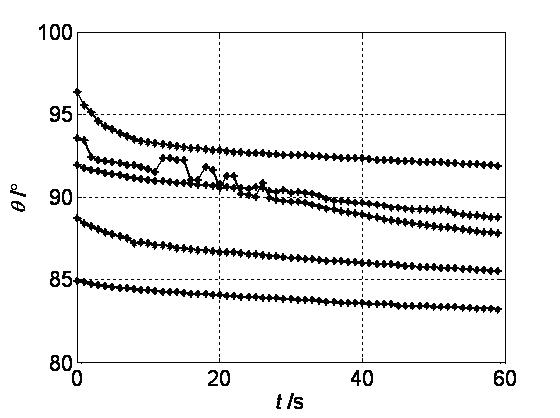

[0034] 1. The test object is the analysis of the measurement results of the hydrophobicity of the soaked silicone rubber sample:

[0035] The sample has a mass fraction of 0.05% CaSO 4 Soak in the solution for several days, take out the sample and put it into deionized water to clean the residual liquid on the surface, then shake off the liquid on the surface and leave it for about 10 minutes until the surface is dry.

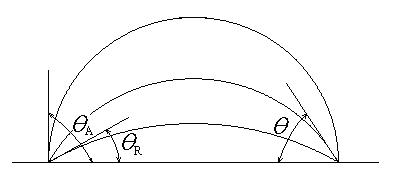

[0036] The static contact angles of the 5 measuring points of the soaked samples and their changes over time are shown in the attached Figure 2a shown. The static contact angle varies greatly with different measurement results. When 0 s is selected as the comparison time, the static contact angle difference of the five different points of the sample reaches a maximum o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com