Method and device for eliminating thermal inertia of hot air drier

A technology of hot air dryer and thermal inertia, applied in the directions of drying gas arrangement, dryer, drying, etc., can solve problems such as poor effect, improve the utilization rate of thermal energy, improve sensitivity and reliability, and eliminate thermal inertia. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific examples.

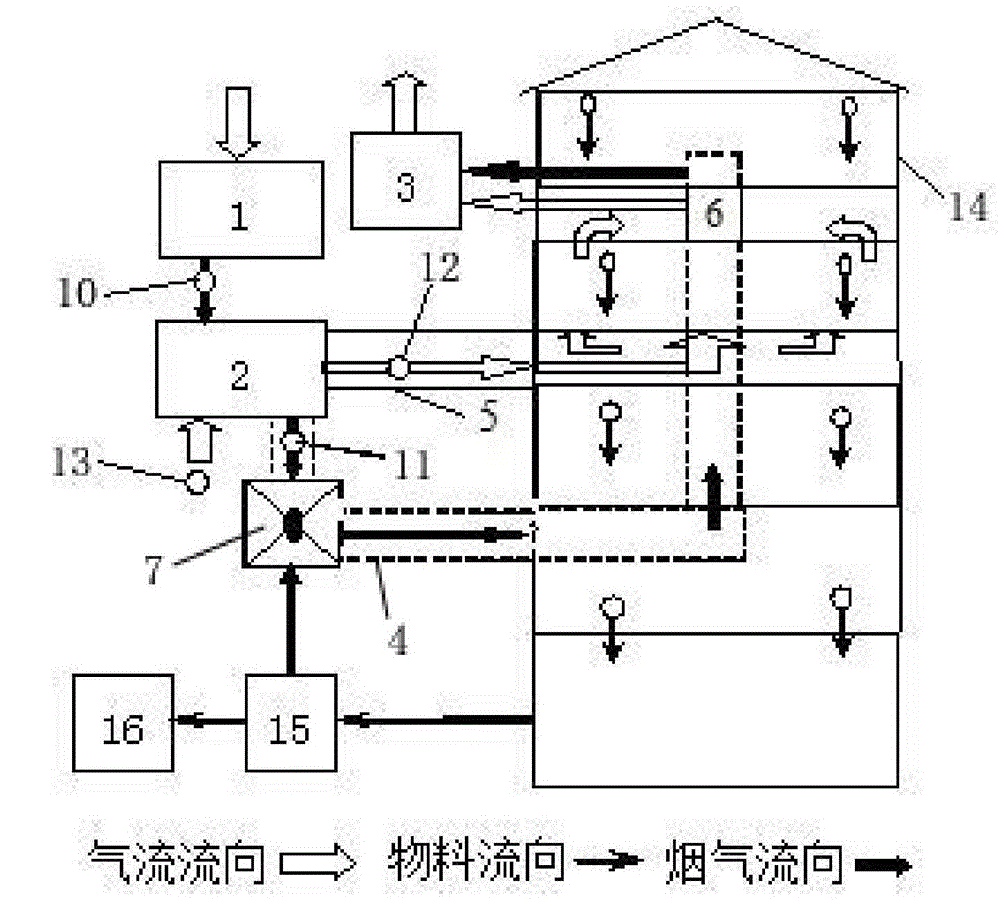

[0023] The method for eliminating the thermal inertia of the hot air dryer described in this embodiment adopts the principle that the main means of heating the dryer (the material and the hot air spontaneously carry out moisture exchange to realize the main equipment for drying the material) is to burn fuel through the hot blast stove The flue gas is generated, and then the heat is exchanged to the air by the heat exchanger to form hot air, and the hot air is introduced into the dryer under the action of the fan. There is a definite correspondence between the ratio of air flow to dry air flow). Based on this principle, this method uses the same fan to achieve smoke induction and air drying, and adjusts the ratio of flue gas to hot air in real time by designing a proportional valve in the air duct. The details are as follows:

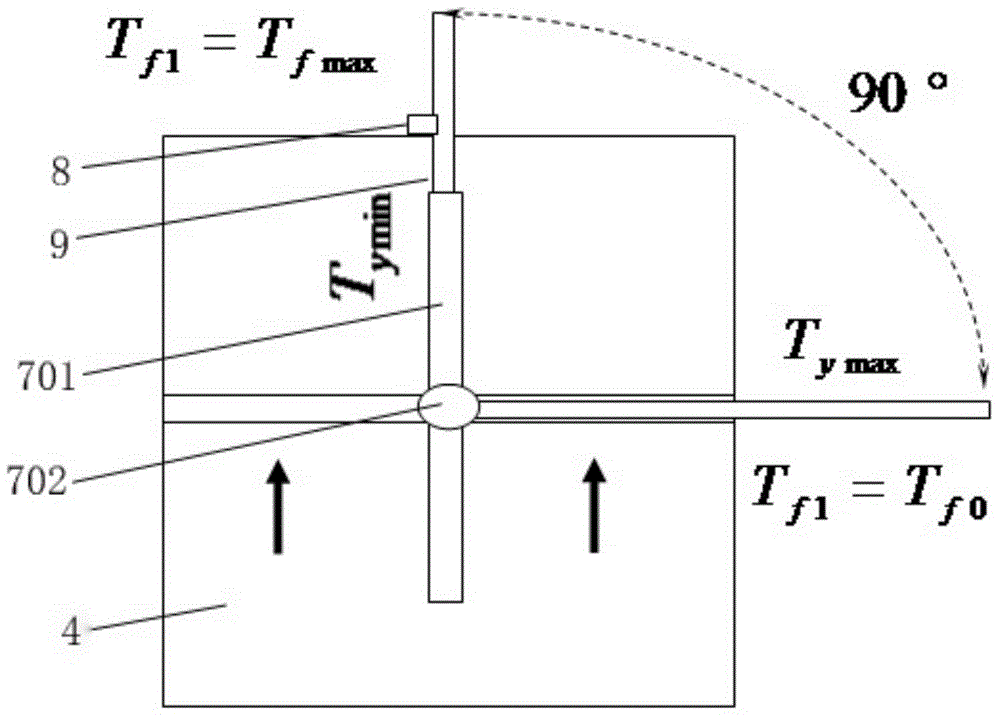

[0024] First of all, a proportional valve is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com