Exhaust steam pressure control system and method for direct air cooling unit

An air-cooled unit and exhaust pressure technology, which is applied to steam/steam condensers, lighting and heating equipment, etc., can solve the problems of steam turbine exhaust pressure fluctuations and long stabilization times, and achieve increased follow-up speed, elimination of thermal inertia, and improved Effects of Controlling Stability and Rapidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

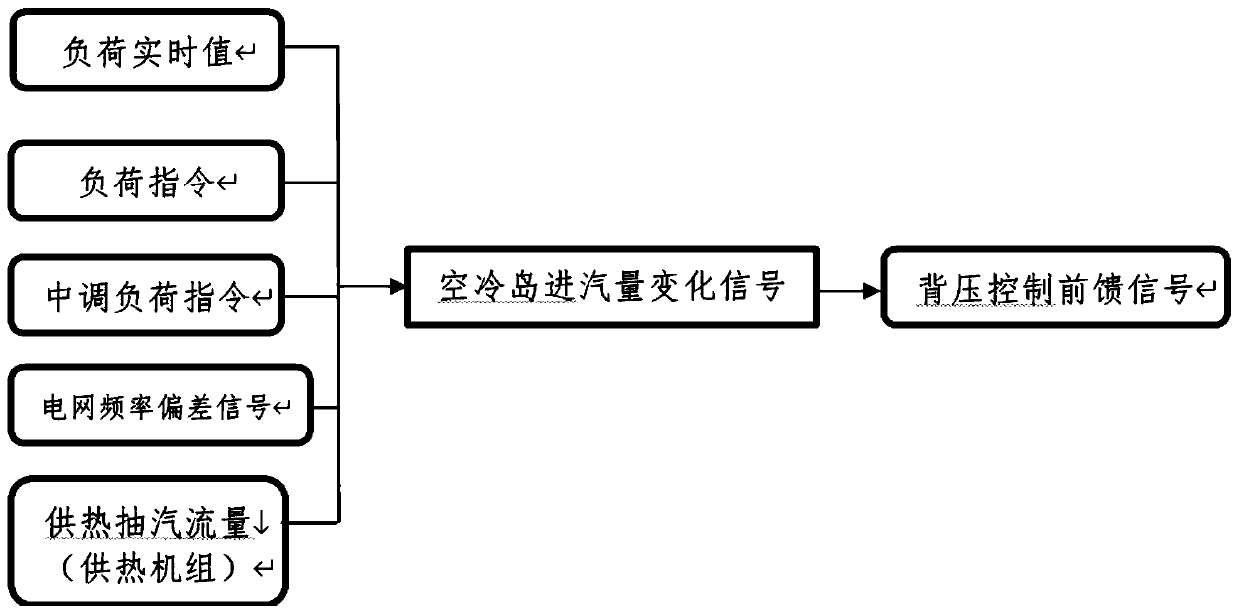

[0035] In a typical implementation of the present application, such as image 3 , Figure 4 As shown, the control method proposed by the present invention selects the load real-time value Pw and the load command Pw in the unit DCS system ins , Medium load command Pw dis-ins , grid frequency deviation signal ⊿f and heating extraction steam flow (heating unit) G heat ; Then after calculation, the air-cooled island steam intake change signal ⊿G is obtained ac , ⊿G ac = α 1 (Pw ins -Pw)+α 2 (Pw dis-ins -Pw)+α 3 ⊿f-β 1 G heat , where α 1 , α 2 , α 3 and beta 1 is the fitting coefficient. The air-cooled island steam intake change signal ⊿Gac is used as a feed-forward signal for back pressure control. The PID control system predicts the change trend of the air-cooled island steam intake in advance, and adjusts the fan control command according to this change trend. By changing the speed of the fan in advance, the change of the speed of the fan is synchronized with the...

Embodiment 2

[0039] This embodiment also proposes a direct air-cooling unit exhaust pressure control system based on unit load variation trend, as follows:

[0040] An acquisition module, the signal acquisition device acquires the real-time value of the load in the DCS system of the unit, the load command, the mid-load load command, the grid frequency deviation signal and the heating and extraction flow;

[0041] The data processing device performs arithmetic processing on the received signal to obtain the change signal of the air-cooled island steam intake, and sends the air-cooled island steam intake change signal as the feed-forward signal of the air-cooled fan back pressure control to the air-cooled fan back pressure controller ;

[0042] The air-cooling fan back pressure controller predicts the change trend of the air-cooling island's steam intake in advance, and adjusts the air-cooling fan control command according to this change trend.

[0043] The signal acquisition device in this...

Embodiment 3

[0046] This embodiment discloses a controller, which includes a memory, a processor, and a control program that is stored on the processor and can run on the processor, and the control program is configured to implement the control program in Embodiment 1. The steps of the control method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com