Film coiling system of heat transfer machine

A thermal transfer machine and transfer film technology, applied in rotary printing machines, printing machines, transfer printing, etc., can solve the problems of limited life, high maintenance costs, inaccurate positioning, etc., and achieve high reliability and accurate positioning. , the effect of stable speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

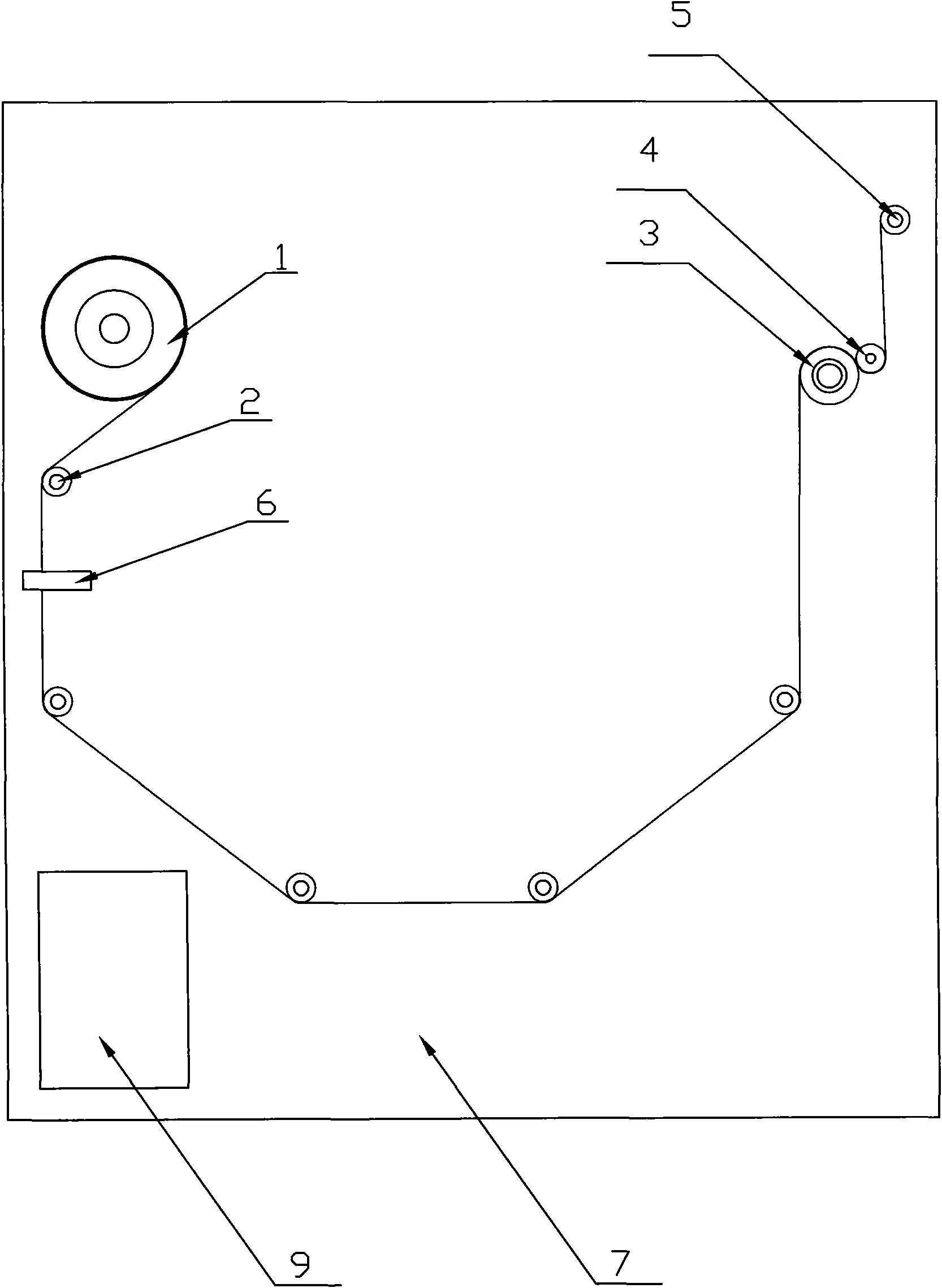

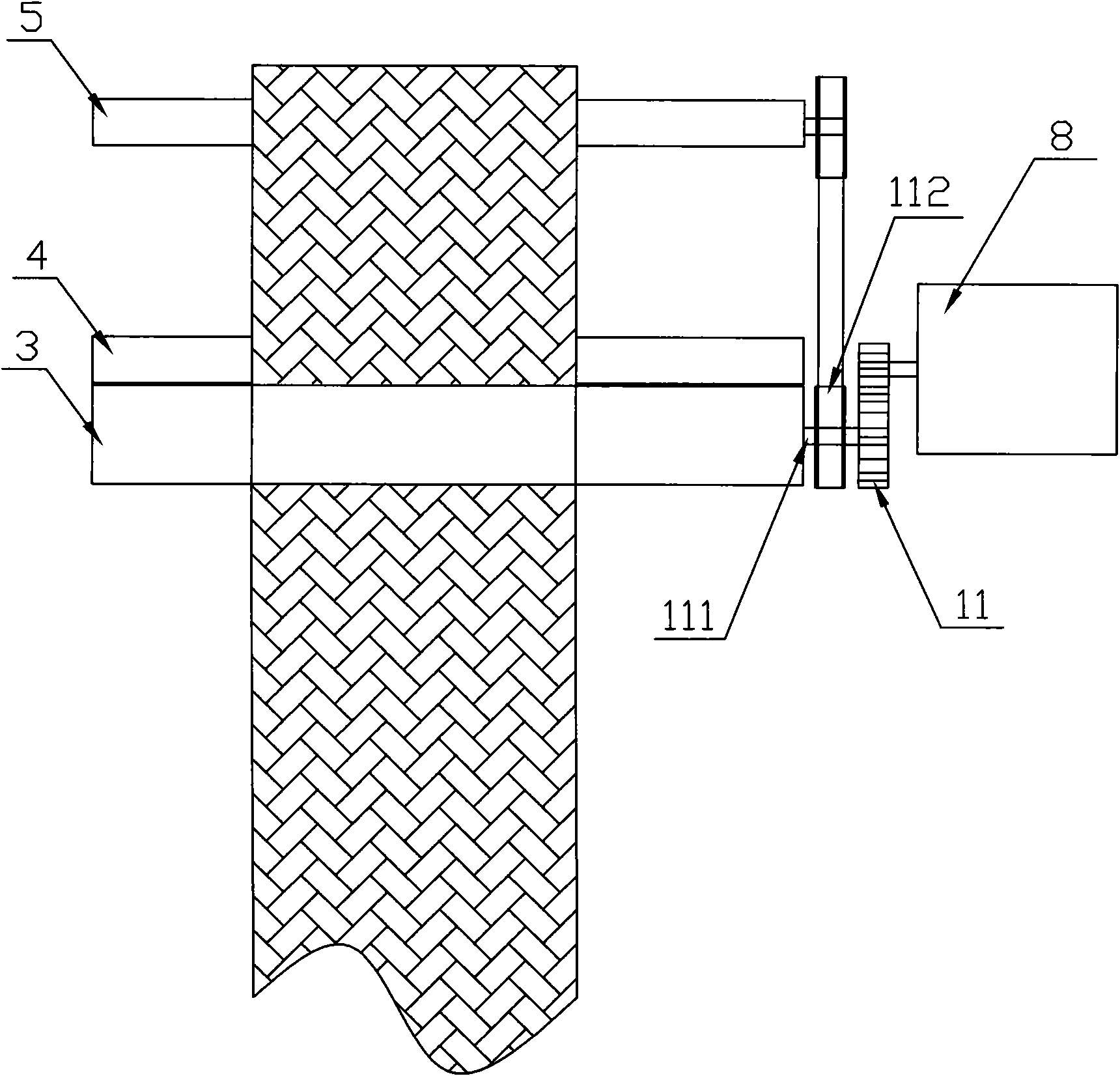

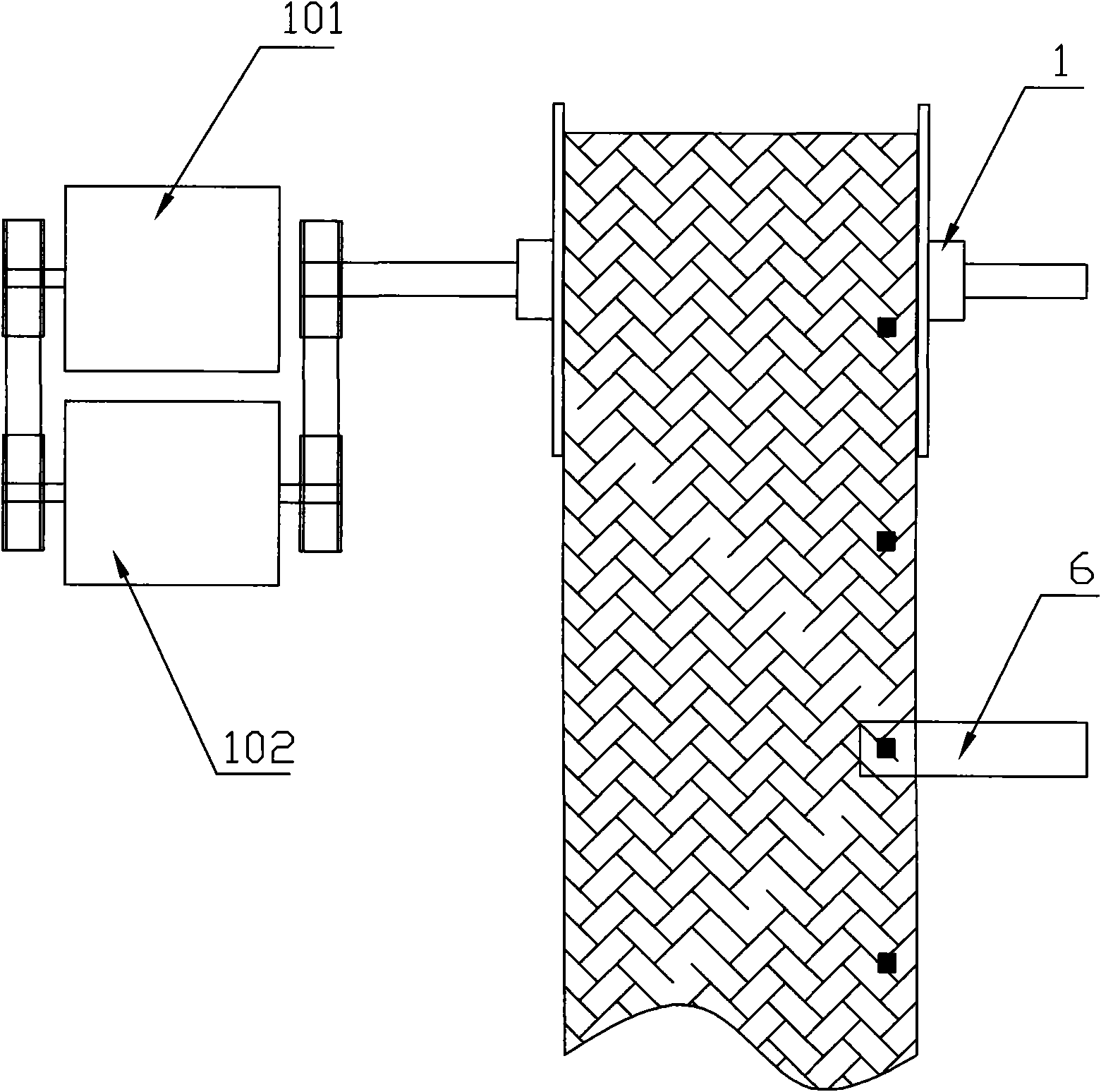

[0013] Embodiment: A film rolling system of a thermal transfer machine, including a film roll bearing shaft 1, a steering shaft group 2, a film rolling cylinder 3, a film pressing wheel 4, a film winding wheel shaft 5, a photoelectric switch 6 and a frame 7, for use The direction is the reference, the film roll bearing shaft 1 can be rotated and axially stopped and positioned on the frame 7, the photoelectric switch 6 and the steering shaft group 2 are fixed on the frame 7, the photoelectric switch 6 can sense the cursor on the transfer film, Film rolling cylinder 3, film pressing wheel 4 and film collecting wheel shaft 5 are rotatable and axially stopped and positioned on the frame 7, and the radially outer side wall of pressing film wheel 4 is tightly against the radially outer side wall of film rolling roll 3, and also includes stepping Motor (including stepper motor driver) 8, programmable logic controller 9 and transfer film tensioning device 10, the stepper motor is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com