Preparation method of humidity-sensitive sensing film

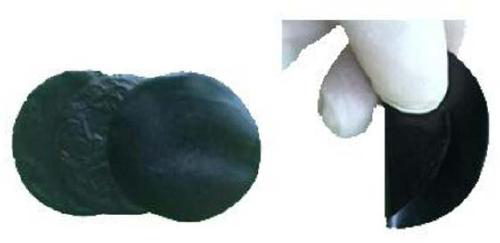

A technology of sensing film and moisture sensitivity, which is applied in the field of preparation of moisture sensitive sensing film, can solve problems such as poor humidity sensitivity, insufficient environmental protection of materials, and easy peeling off of moisture sensitive film, so as to improve humidity sensitivity, Easy film formation and low substitution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of embodiment 1 water-soluble cellulose acetate

[0026] Take 1.8mL of valeryl chloride and slowly add it dropwise to 30g of ionic liquid 1-ethyl-3-methylimidazolium acetate, take 1.00g of cotton linter cellulose and infiltrate it into the above solvent system. Magnetic stirring was carried out to obtain a transparent, viscous and completely dissolved cellulose solution, and under the condition of continuous magnetic stirring, the reaction was kept at 70°C for 12 hours. After the reaction, the system was poured into 200ml of ethanol to terminate the reaction, and then repeatedly washed with a large amount of ethanol and filtered until the ionic liquid and unreacted reagents were cleaned to obtain a pure cellulose product, which was verified to be soluble in water.

Embodiment 2

[0037] The preparation method of embodiment 2 moisture-sensitive sensing film

[0038] S 1 1. Take 1.8mL of valeryl chloride and slowly add it dropwise to 30g of ionic liquid 1-ethyl-3-methylimidazole acetate, take 1.00g of linter cellulose and infiltrate it into the above solvent system. Under magnetic stirring, a transparent, viscous, and completely dissolved cellulose solution was obtained. Under the condition of continuous magnetic stirring, the reaction was maintained at 70° C. for 12 hours. After the reaction, pour the system into 200ml of ethanol to terminate the reaction, then repeatedly wash and filter with a large amount of ethanol until the ionic liquid and unreacted reagents are cleaned to obtain a pure cellulose acetate product;

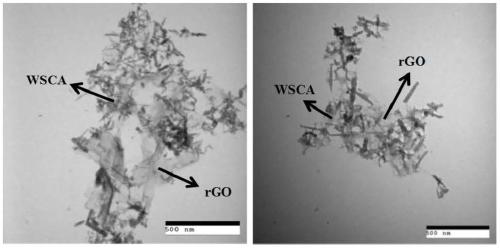

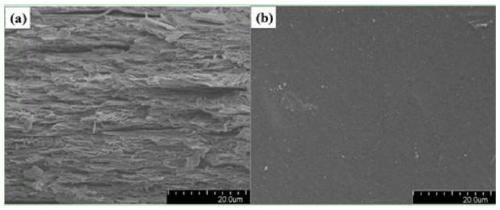

[0039] S 2 1. Take a certain mass of WSCA to prepare 10mL of a 1% aqueous solution, weigh 0.0025g of rGO to prepare a 0.25mg / mL aqueous solution, add the graphene aqueous solution to the prepared WSCA solution, and perform ultrasonic t...

Embodiment 3

[0047] The preparation method of embodiment 3 moisture-sensitive sensing film

[0048] S 1 1. Take 1.5mL of valeryl chloride and slowly add it dropwise to 30g of ionic liquid 1-ethyl-3-methylimidazolium acetate, take 0.6g of woody cellulose and intrude into the above solvent system, under the condition of 63℃ oil bath Magnetic stirring was carried out to obtain a transparent, viscous, and completely dissolved cellulose solution. Under the condition of continuous magnetic stirring, the reaction temperature was maintained for 9 hours. After the reaction, pour the system into 200ml of ethanol to terminate the reaction, then repeatedly wash and filter with a large amount of ethanol until the ionic liquid and unreacted reagents are cleaned to obtain a pure cellulose acetate product;

[0049] S 2 1. Take a certain mass of WSCA to prepare 20mL of a 0.5% aqueous solution, weigh 0.0005g of rGO to prepare a 0.25mg / mL aqueous solution, add the graphene aqueous solution to the prepared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com