Patents

Literature

34results about How to "Increased humidity sensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

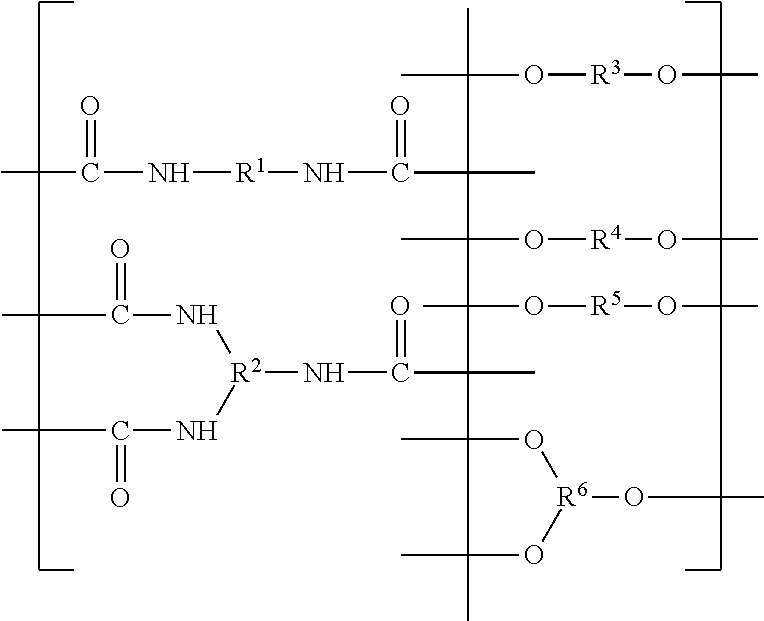

Image receiver elements

ActiveUS20110117299A1High dye transfer efficiencyMore saturated color densityAblative recordingDyeing processWater dispersibleSide chain

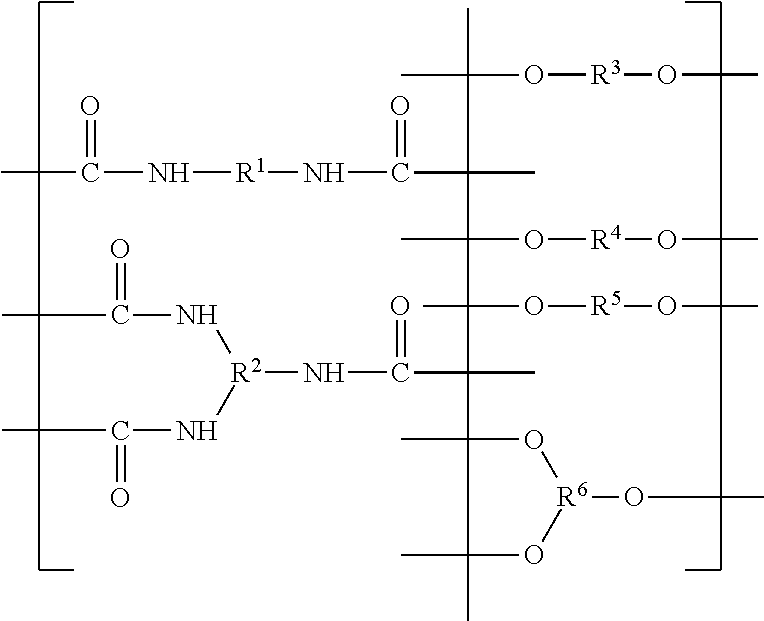

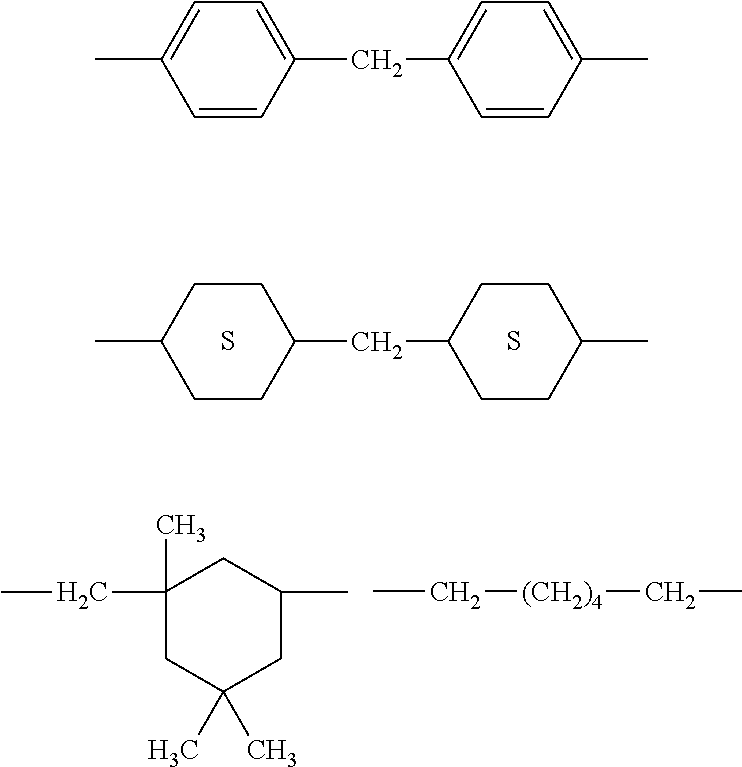

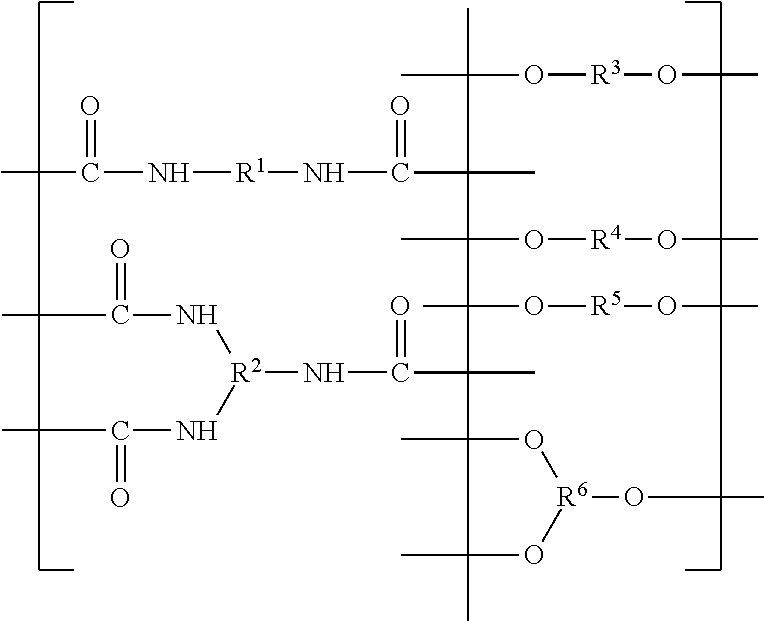

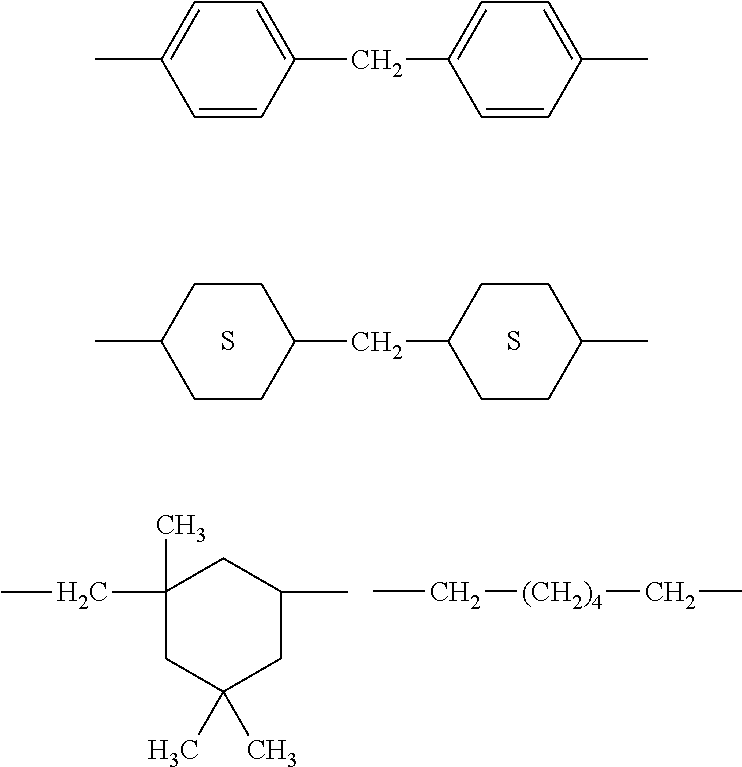

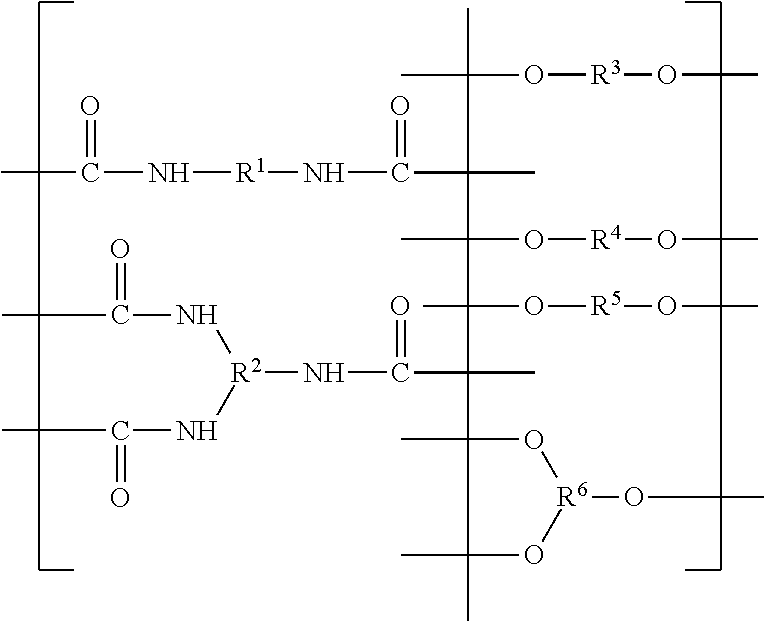

An image receiver element includes a water-soluble or water-dispersible polyurethane binder in the image receiving layer. This polyurethane has a Tg of from about 60 to about 80° C., a molecular weight of at least 25,000, and an acid number of from about 16 to about 35 mg KOH / g. Moreover, the polyurethane comprises from about 42 to about 60 weight % of recurring urethane units, from about 8 to about 20 weight % of alkylene glycol recurring units, from about 18 to about 40 weight % of carbonate recurring units having aliphatic side chains, and from about 3 to about 15 weight % of recurring units having a water-soluble or water-dispersible acid group, based on total binder weight.

Owner:KODAK ALARIS INC

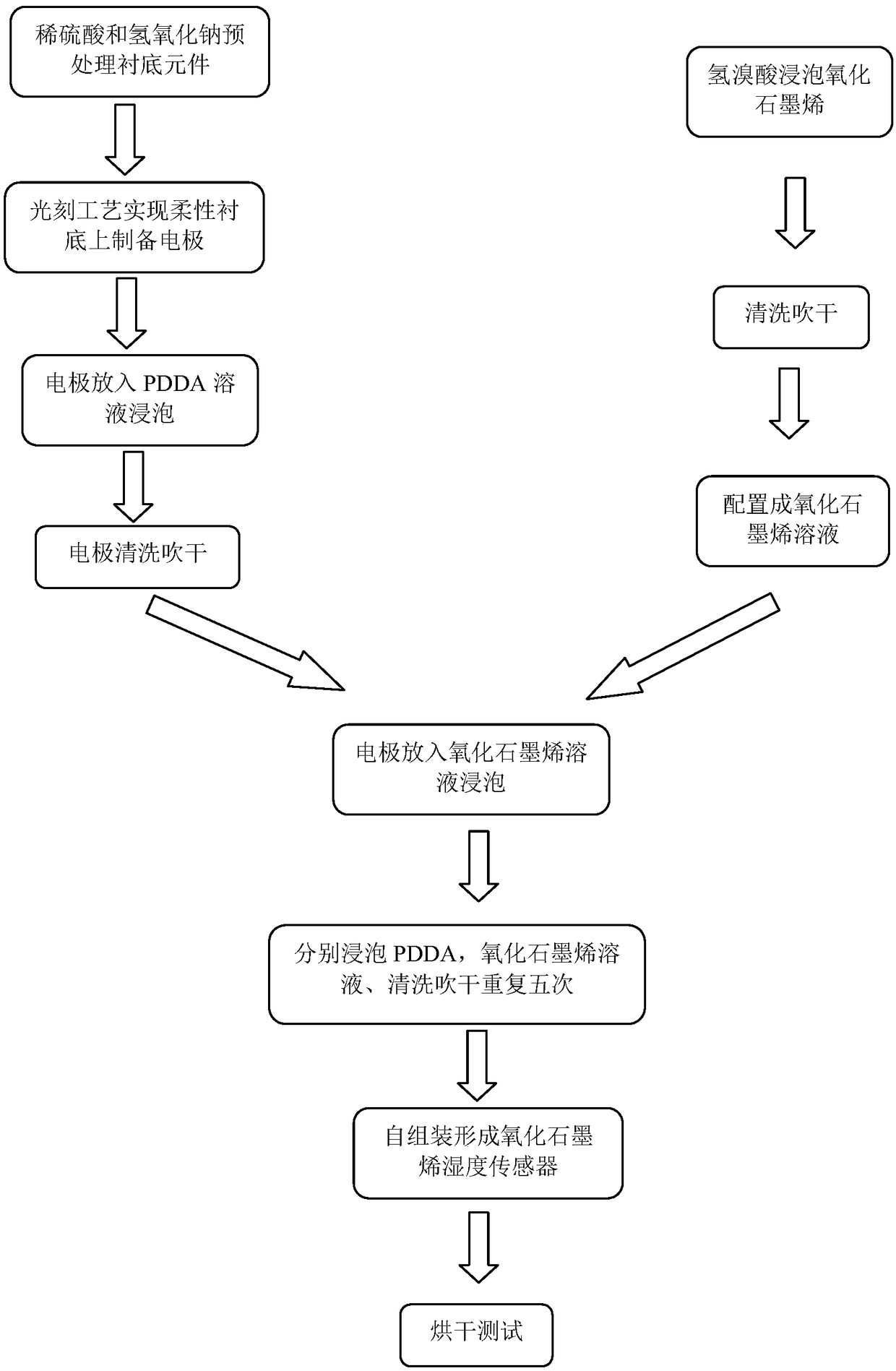

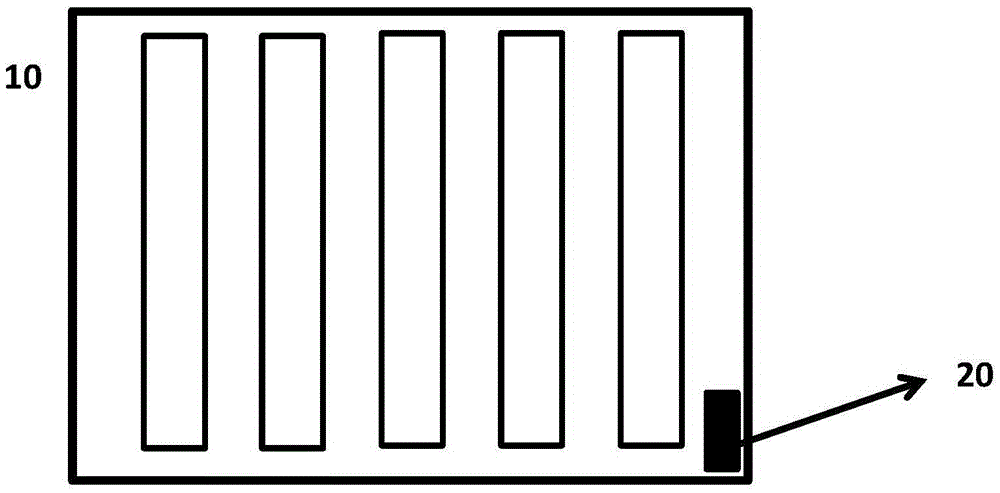

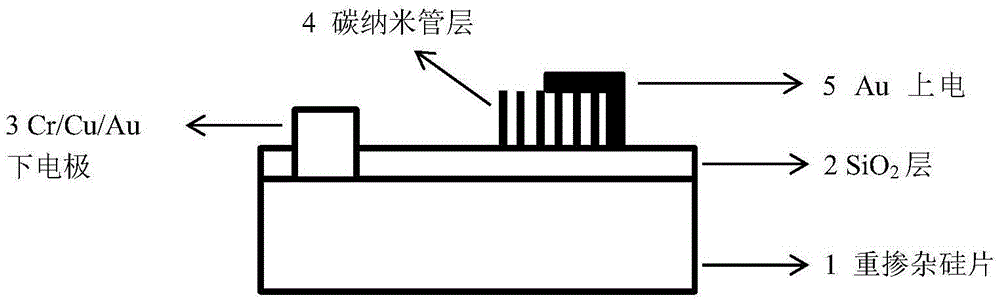

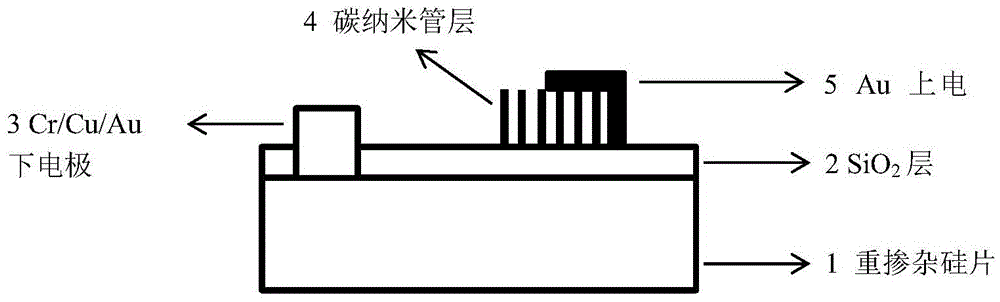

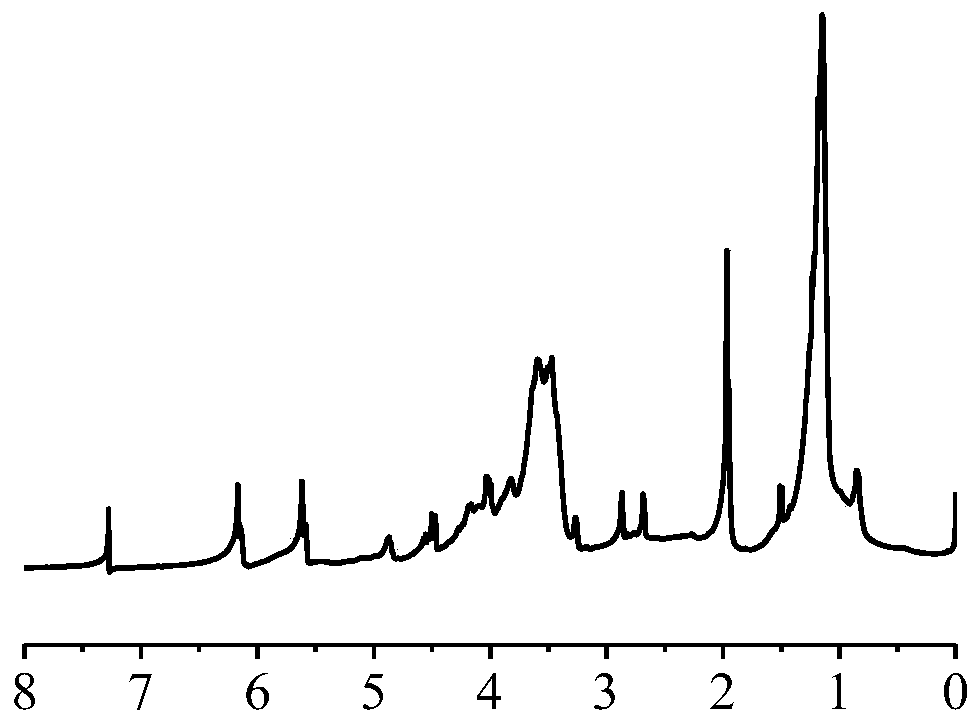

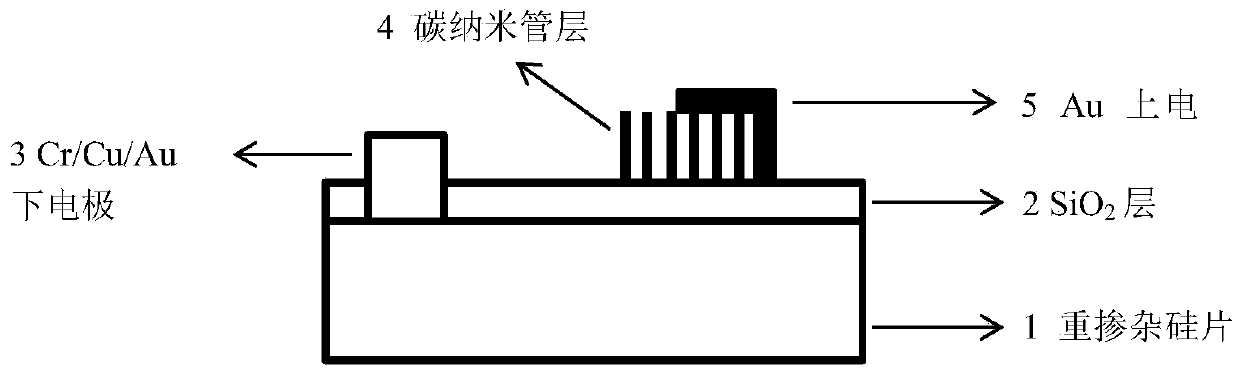

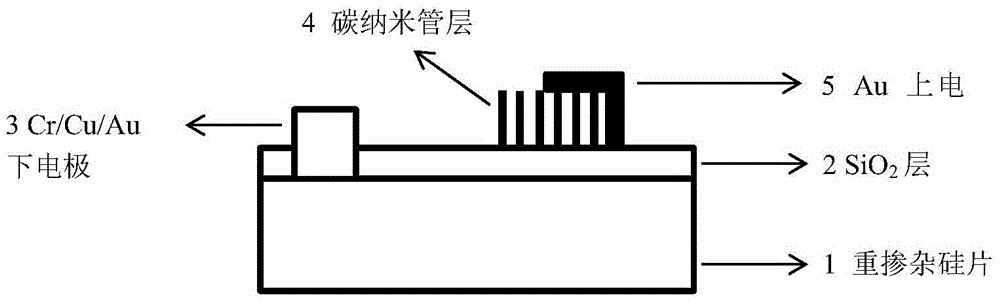

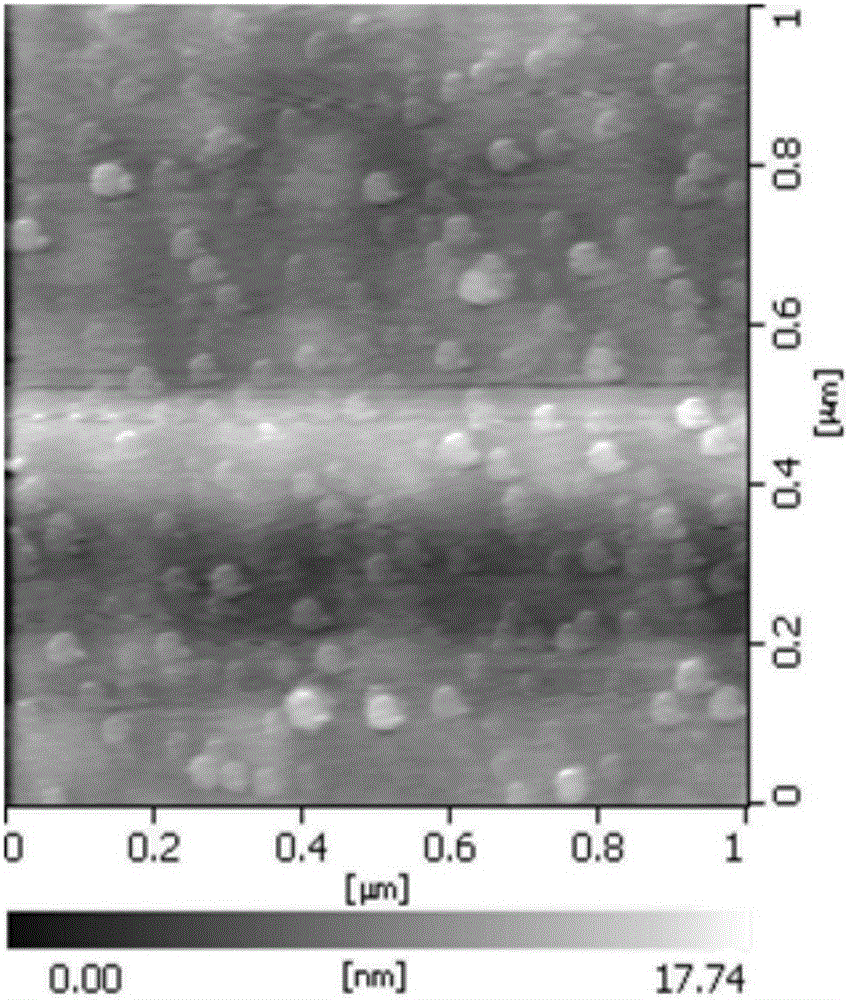

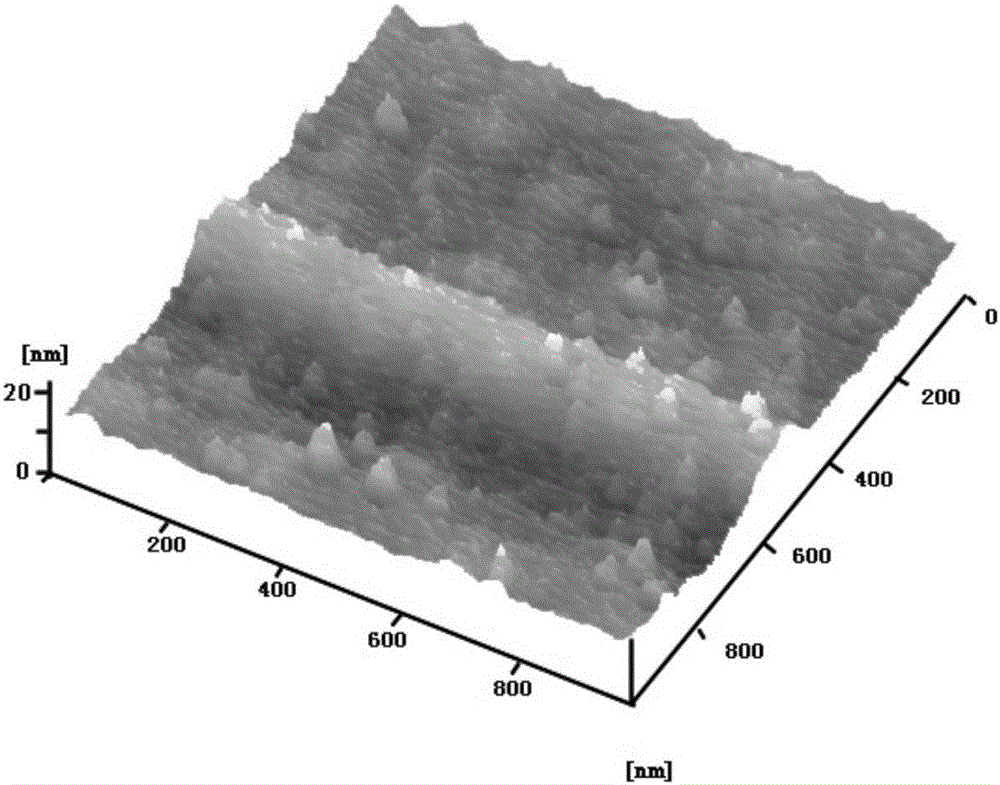

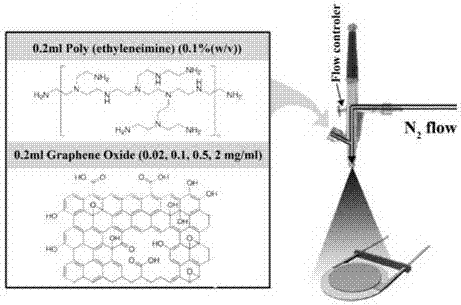

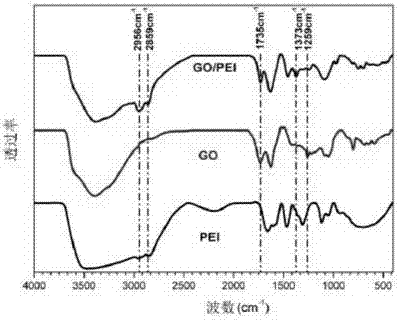

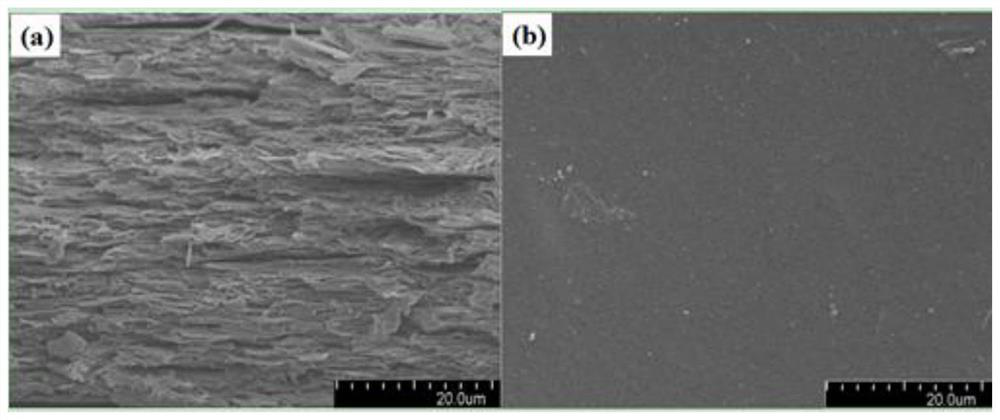

Humidity sensor and improvement and preparation of humidity sensor based on graphene oxide

InactiveCN108414583AImprove conductivityIncreased sensitivityMaterial resistanceCvd grapheneHydrobromic acid

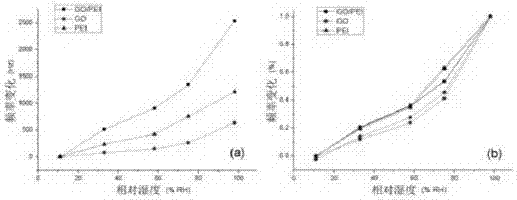

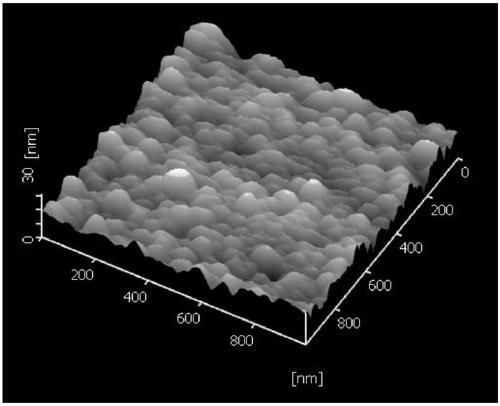

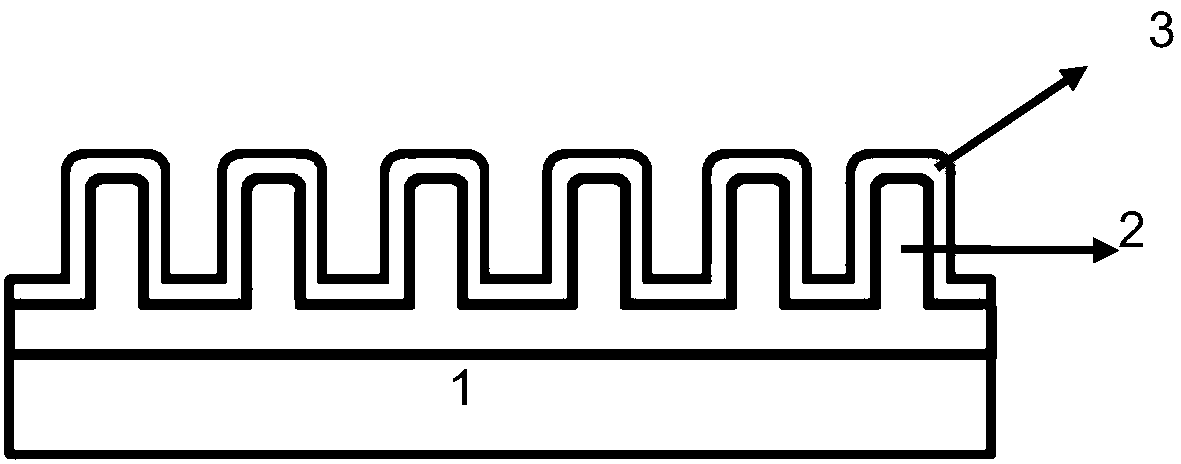

The invention discloses a humidity sensor and improvement and preparation of the humidity sensor based on graphene oxide. The humidity sensor is provided with a humidity sensitivity component based ona reduced graphene oxide material, a graphene oxide material is treated by hydrobromic acid solution to obtain the reduced graphene oxide material in the humidity sensitivity component, the humiditysensitivity component can respond to environment humidity, and the environment humidity is sensed. According to the humidity sensor, a treatment process of the key graphene material humidity sensitivity component in the humidity sensor and a micro-composition, a structure and the like of the correspondingly acquired reduced graphene oxide material are improved, the graphene oxide material is treated by the hydrobromic acid solution to obtain the reduced graphene oxide material or the graphene oxide material and a polycationic polymer alternately deposit to form a graphene oxide composite filmby an electrostatic inducement layer by layer self-assembly method, and the acquired humidity sensor can keep good stability, humidity sensitivity and humidity stickiness in high-humidity environments.

Owner:HUAZHONG UNIV OF SCI & TECH +1

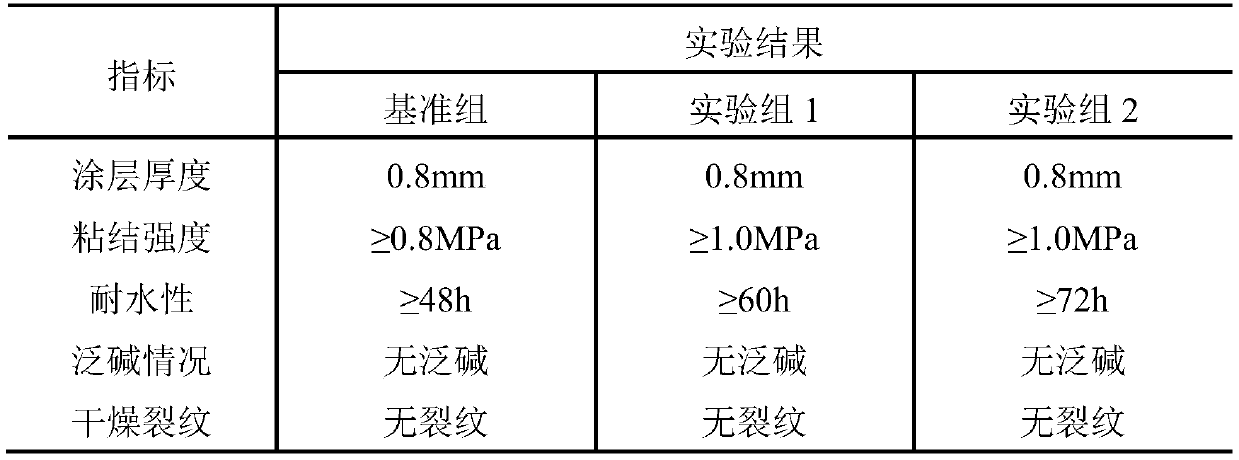

Pulverized-fuel-ash-based geopolymer steel structure non-shrinking anti-corrosive coating

InactiveCN110117424AImprove performanceIncreased humidity sensitivityAlkali metal silicate coatingsAnti-corrosive paintsCrack resistanceCarbonization

The invention provides a non-shrinking pulverized-fuel-ash-based geopolymer steel structure anti-corrosive coating. Surface coatings of steel structures can obstruct direct contact of corrosive mediums such as chloride ions with reinforcing steel bars, and the anti-corrosive performance of the reinforcing steel bars is effectively improved; however, currently, surface coatings of the reinforcing steel bars have shortcomings that the interface bonding performance of the reinforcing steel bars and the concrete is lowered, pitting corrosion is triggered due to the defects of the coatings, and application of the coatings in practical engineering is seriously restricted accordingly. According to the non-shrinking pulverized-fuel-ash-based geopolymer steel structure anti-corrosive coating, by conducting blending to obtain a proper alkali excitation matching proportion, the cracking resistance and saltpetering resistance of the pulverized-fuel-ash-based geopolymer inorganic anti-corrosive coating are improved; meanwhile, the compactness, carbonization resistance and ion infiltration resistance of the coating are improved, the bonding strength between the coating and the reinforcing steelbars is improved, and the cost is reduced.

Owner:CHONGQING UNIV

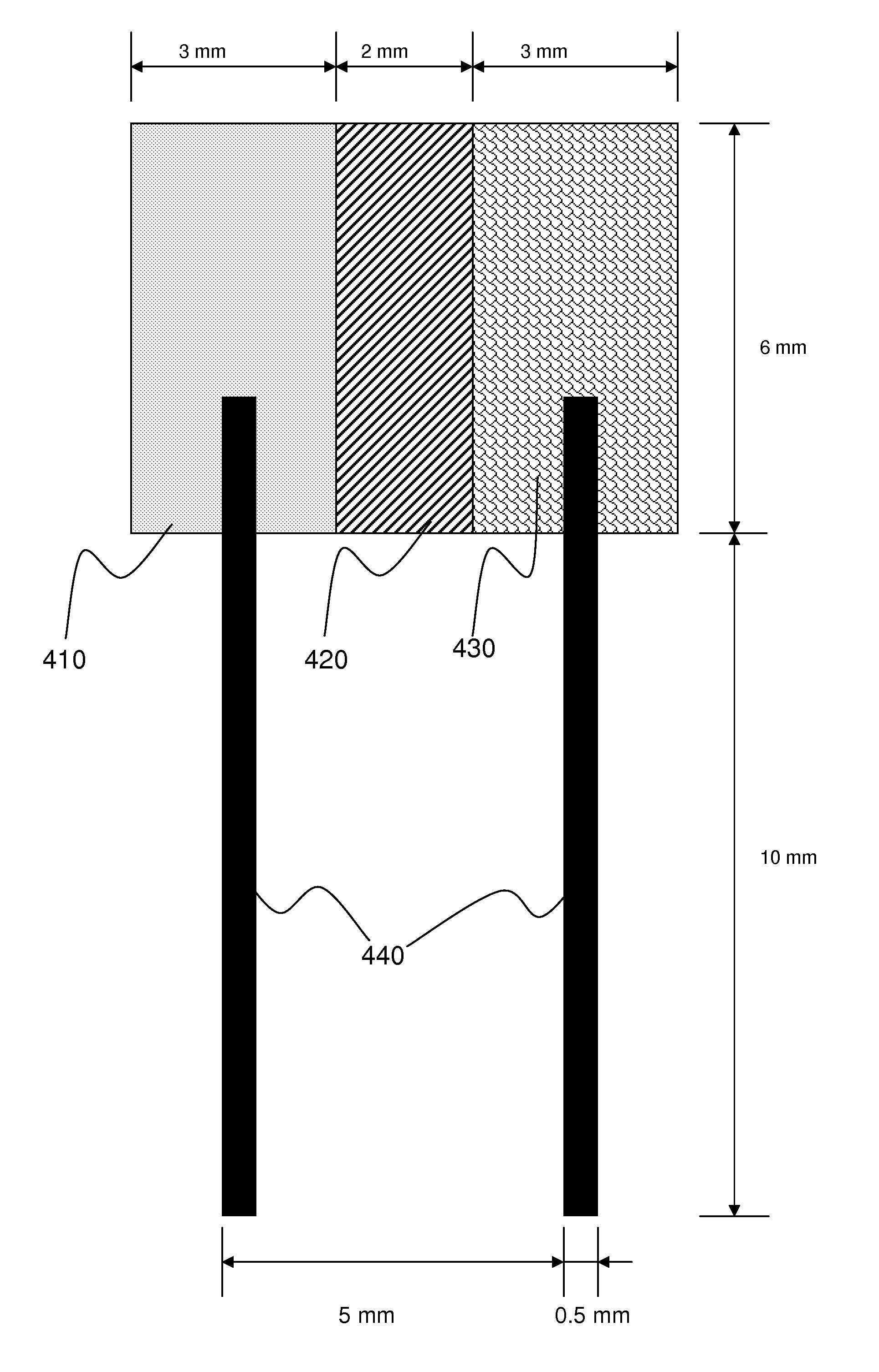

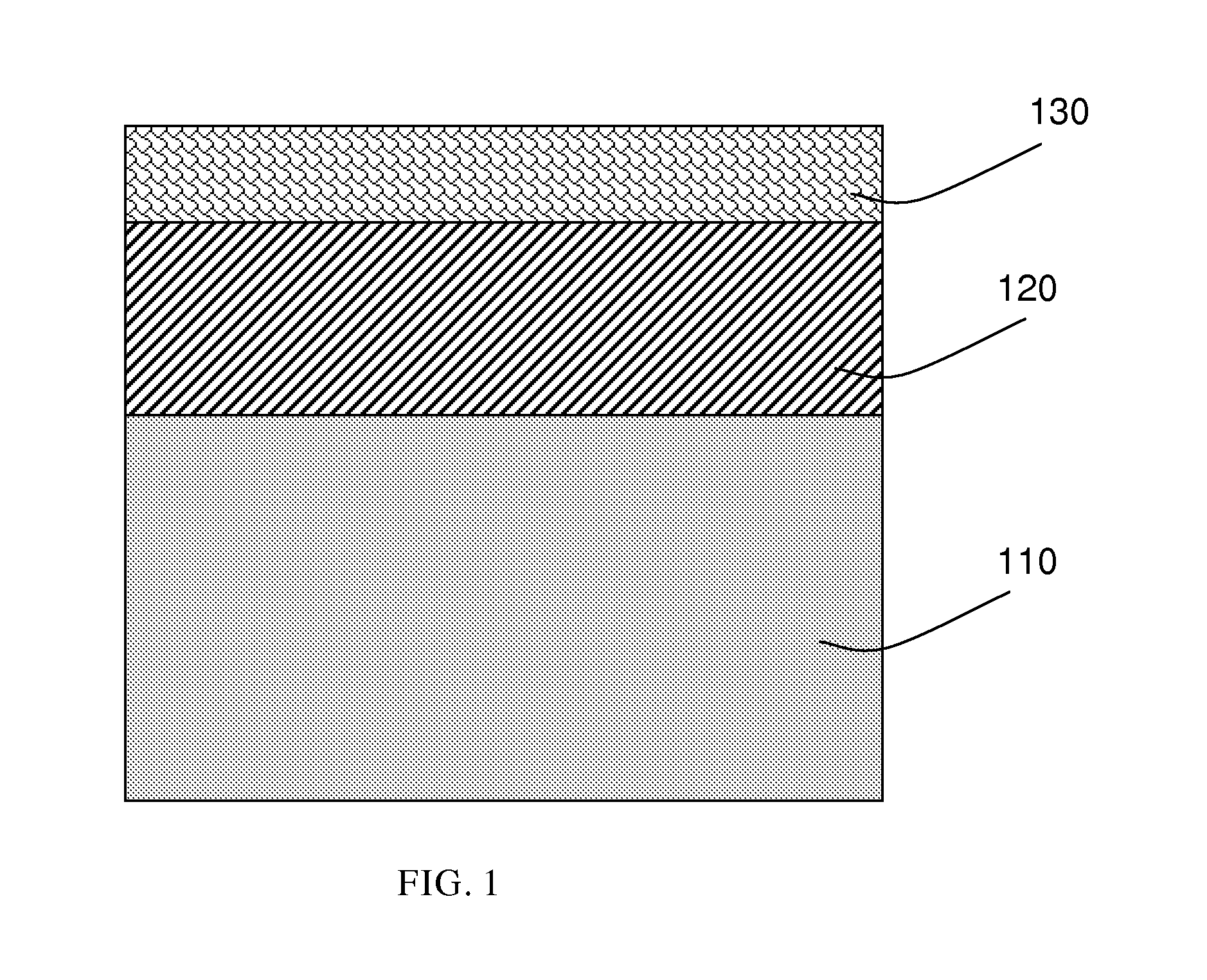

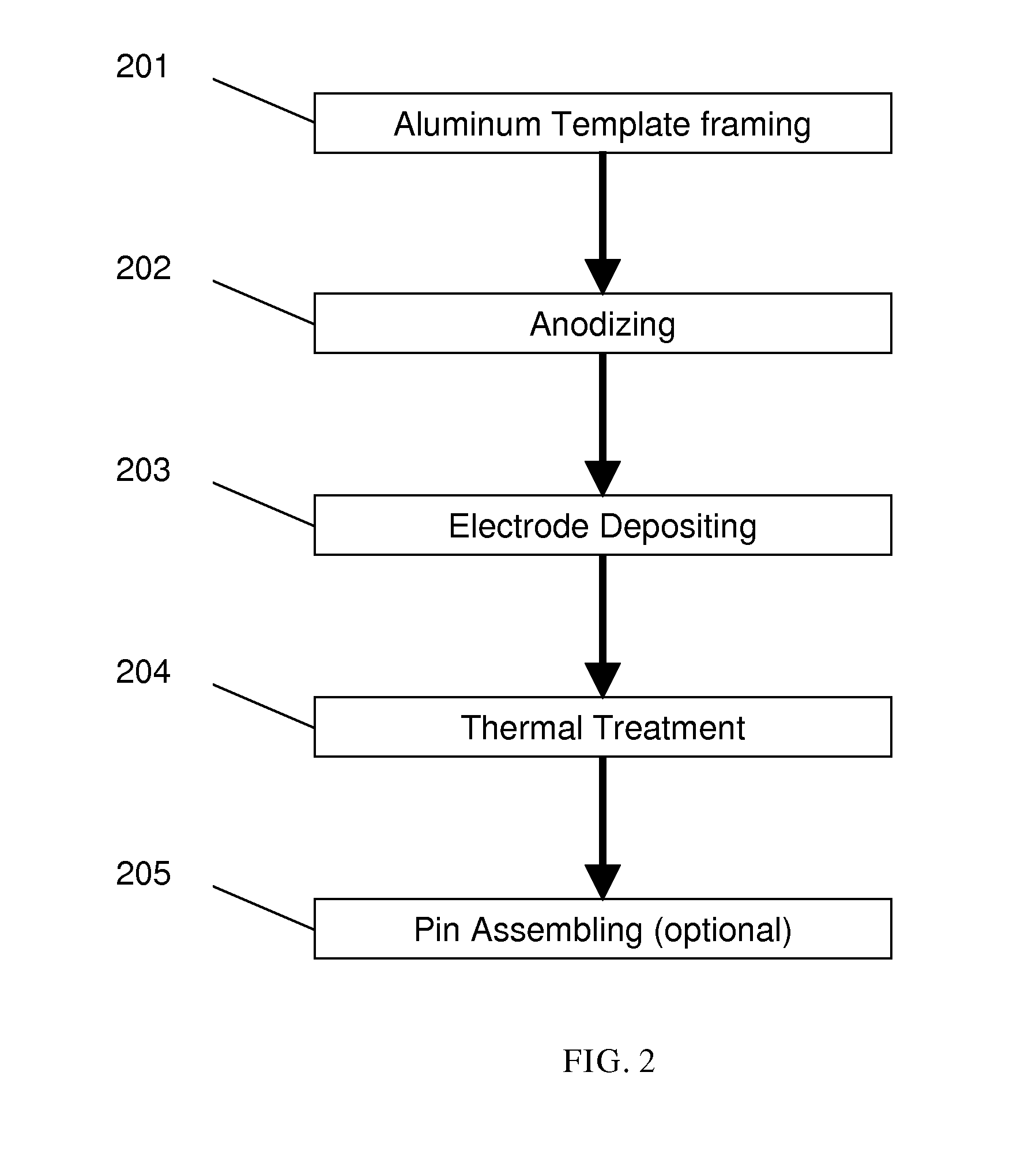

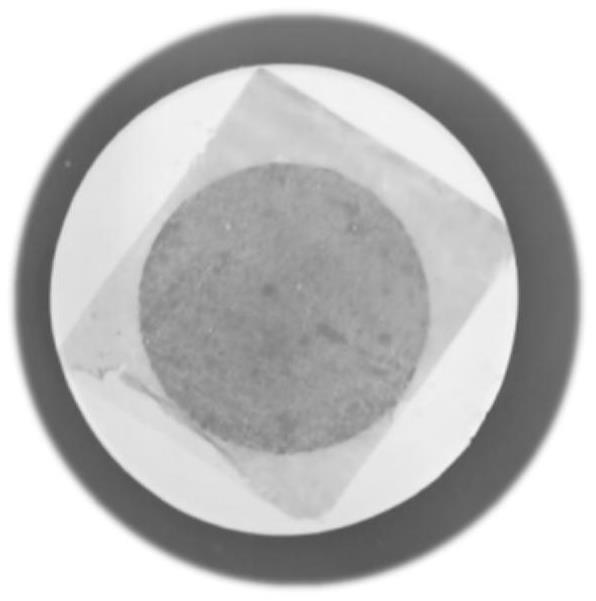

Rapid response relative humidity sensor using anodic aluminum oxide film

InactiveUS8783101B2Simple and cost-effectiveStable responseSurface reaction electrolytic coatingUsing mechanical meansCapacitanceHysteresis

Owner:NANO & ADVANCED MATERIALS INST

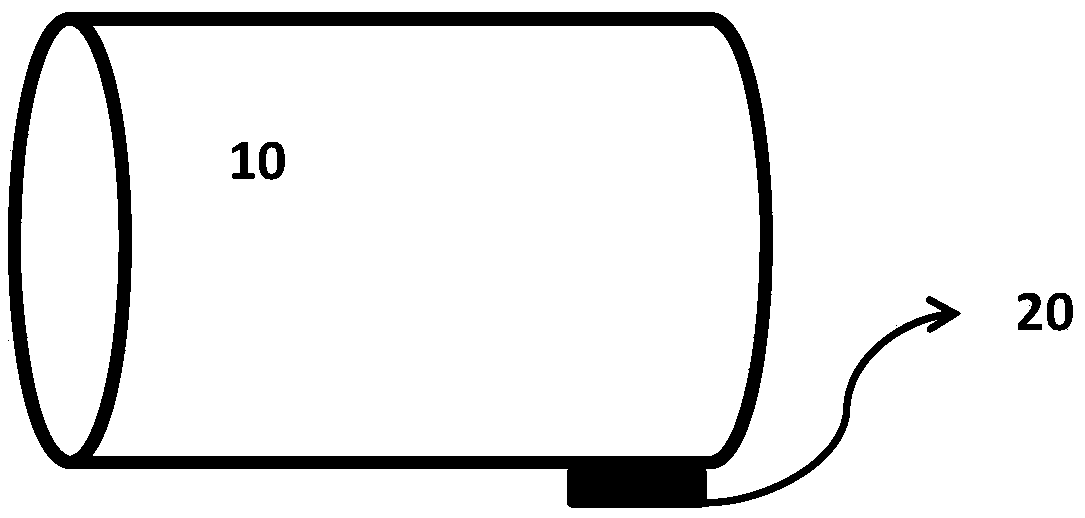

Gas water heater for preventing moisture corrosion

InactiveCN105651834AHigh sensitivityShort response timeFluid heatersMaterial capacitanceComputer moduleEngineering

The invention discloses a gas water heater for preventing moisture corrosion. A moisture-sensitive sensor module is mounted on the external part of the gas water heater, so that the change in humidity in the ambient environment can be detected in the use process of the gas water heater and the gas water heater can be effectively protected. The moisture-sensitive sensor module is creatively designed at the aspects of sensitive material, making condition, structure and the like of sensors; the sensitivity can be greatly increased; the testing repeatability is excellent; an unexpected technical effect is achieved; and the market application prospect is wide.

Owner:董超超

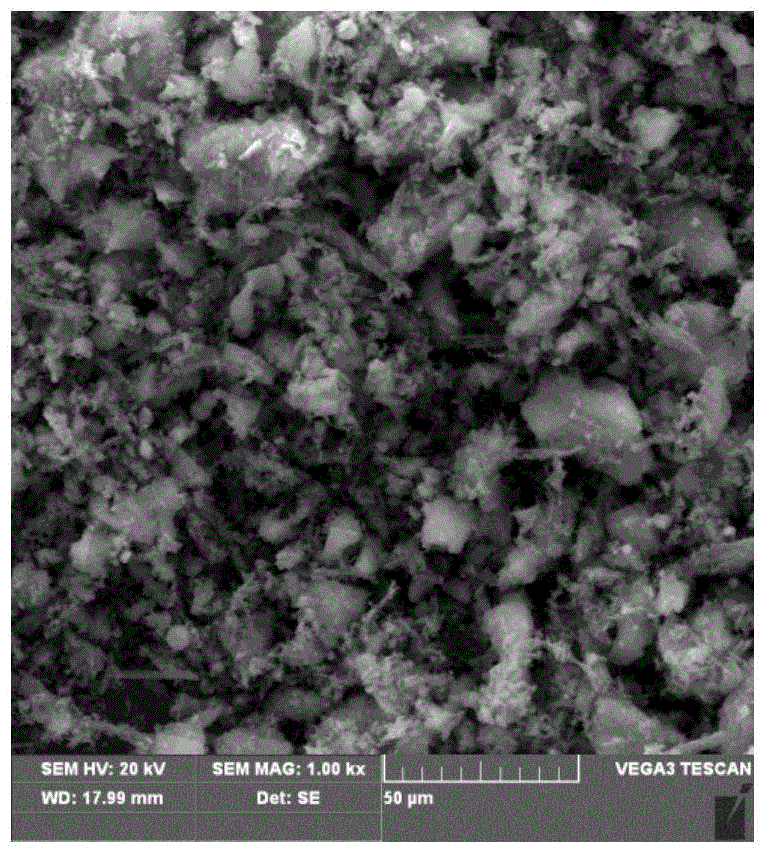

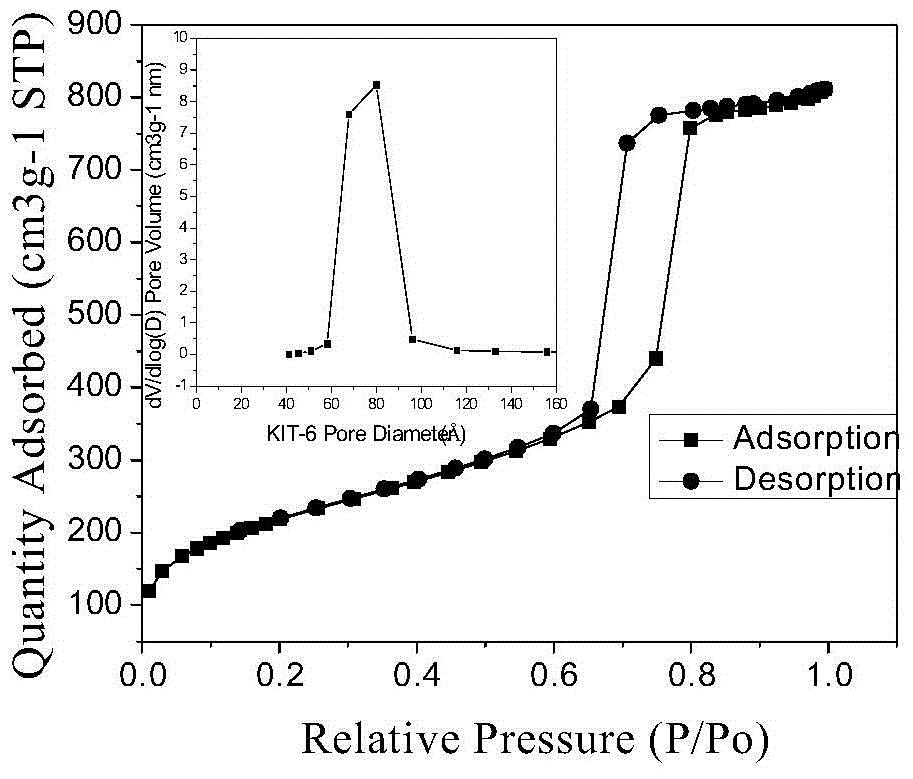

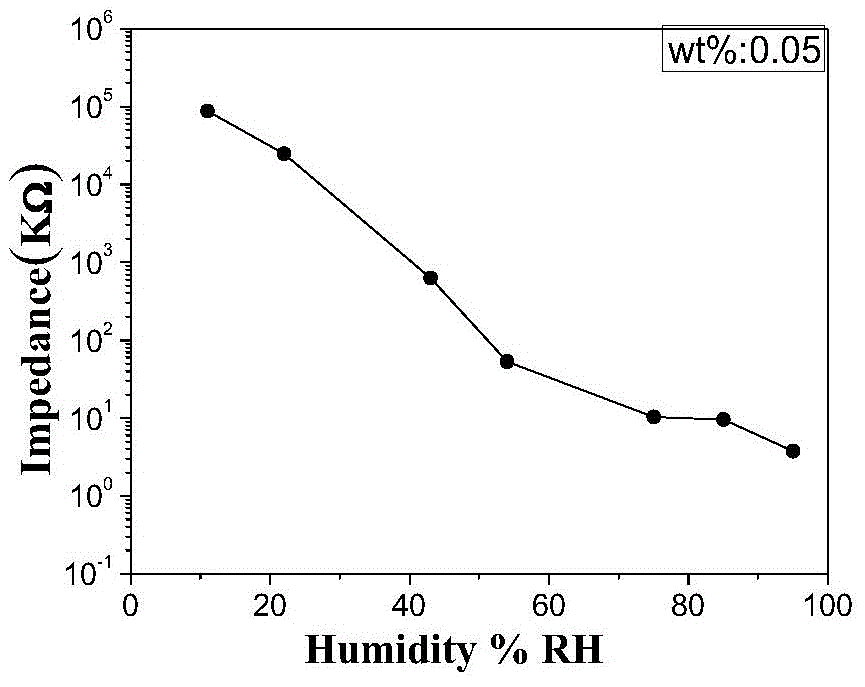

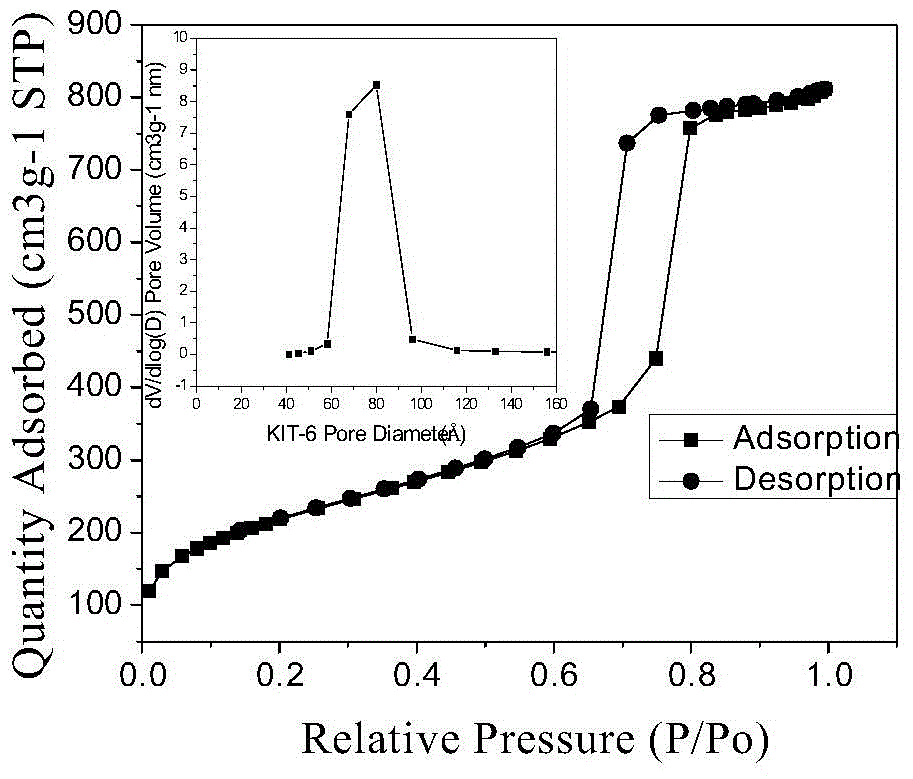

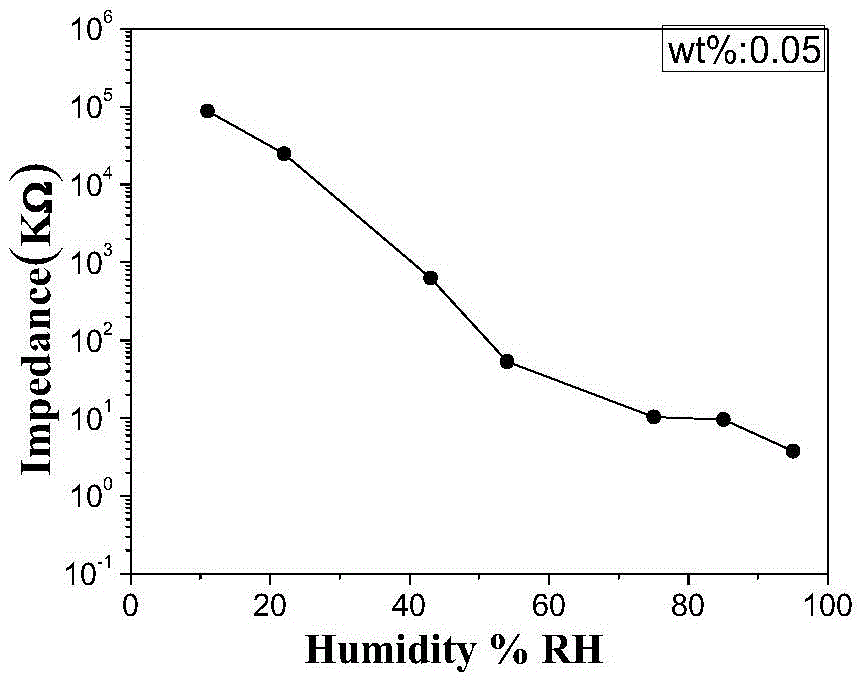

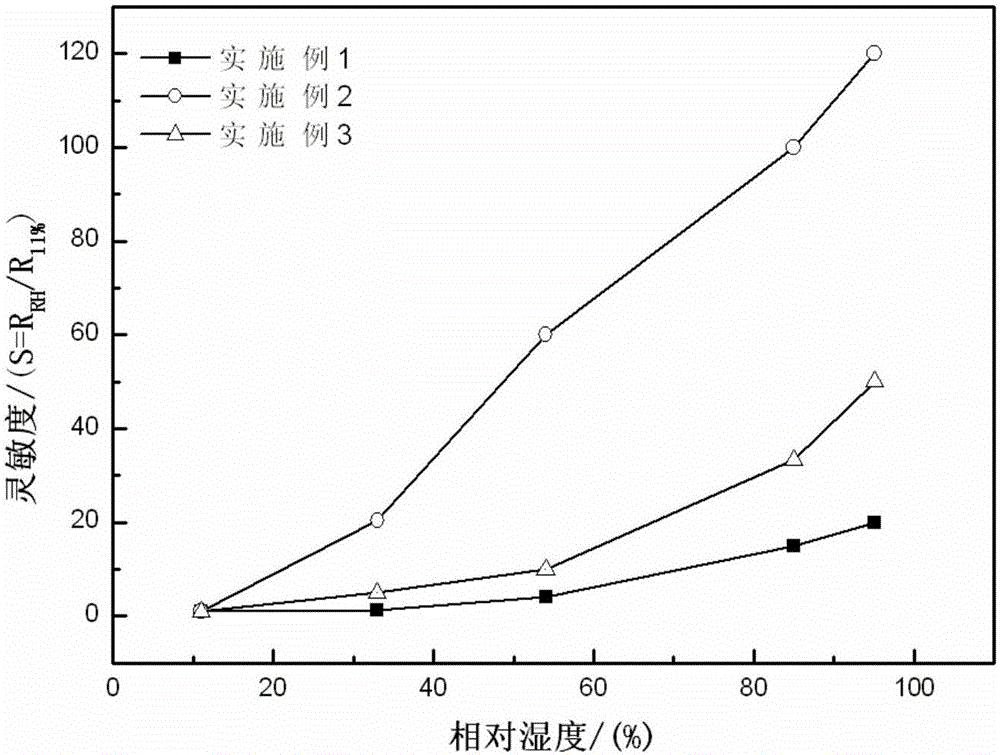

Preparation method of low-cost high-sensitivity NaCl doped mesoporous silica resistor type humidity-sensitive material

ActiveCN104458819AHigh humidity sensitive sensitivityDoping process is simpleSilicaMaterial resistanceMesoporous silicaSolvent

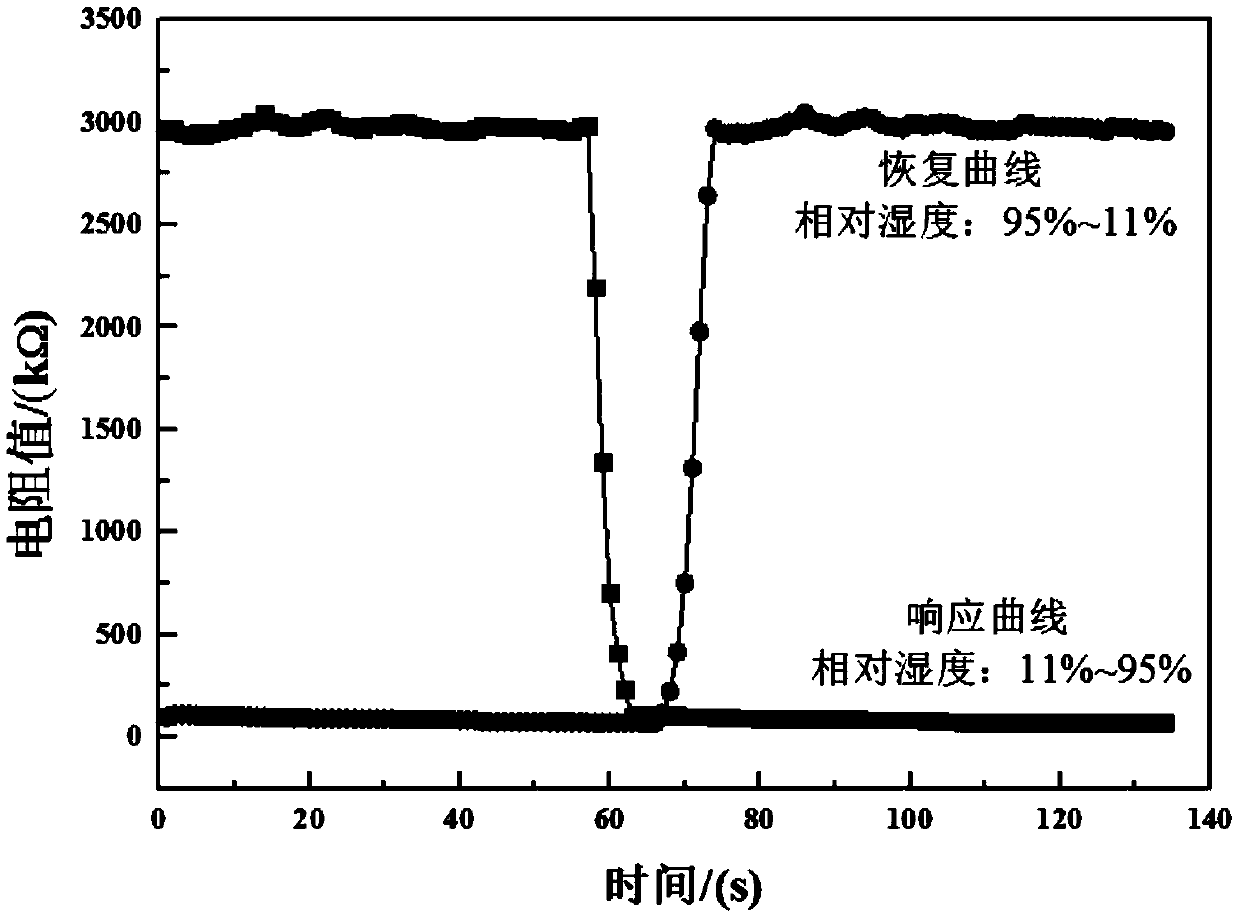

The invention relates to a preparation method of a low-cost high-sensitivity NaCl doped mesoporous silica resistor type humidity-sensitive material. The preparation method comprises the following steps of synthesizing a mesoporous silicon dioxide molecular sieve by adopting a hydrothermal method, forging the obtained mesoporous material at 550 DEG C so as to remove a surfactant, mixing the forged mesoporous material with a proper amount of sodium chloride, grinding again by taking absolute ethyl alcohol as a solvent, and doping. The preparation method has the characteristics of simple doping process, no need of thermal treatment and simplified preparation technology. According to the low-cost high-sensitivity NaCl doped mesoporous silica resistor type humidity-sensitive material, the humidity-sensitive sensitivity is high; within the full-humidity range ability of 11%RH-95%RH, the impedance change order of magnitude is greater than four orders of magnitude and approaches five orders of magnitude, and the ideal doping proportion is obtained by testing for multiple times; the humidity-sensitive performance of the material is improved effectively; within the full-humidity range ability of 11%RH-95%RH, the impedance change order of magnitude is greater than four orders of magnitude and approaches five orders of magnitude, and meanwhile, the preparation technology of the type of materials is simplified.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

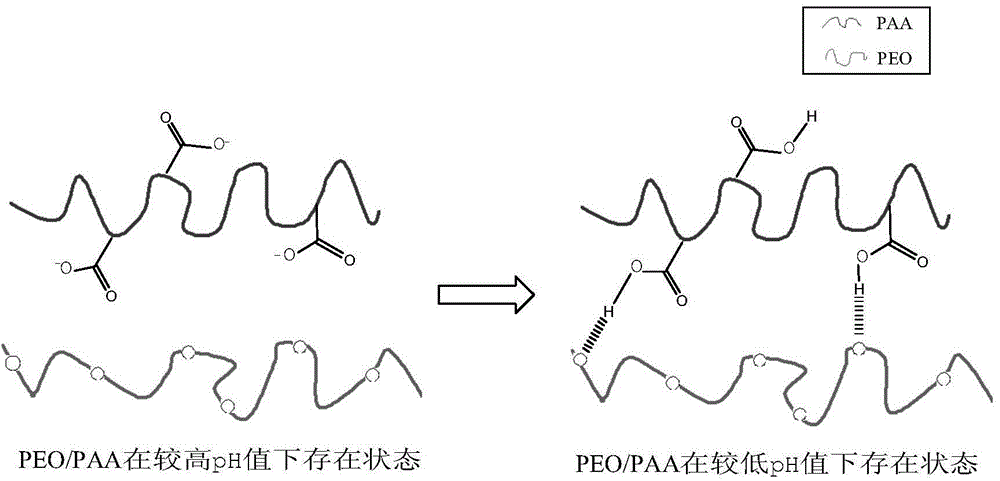

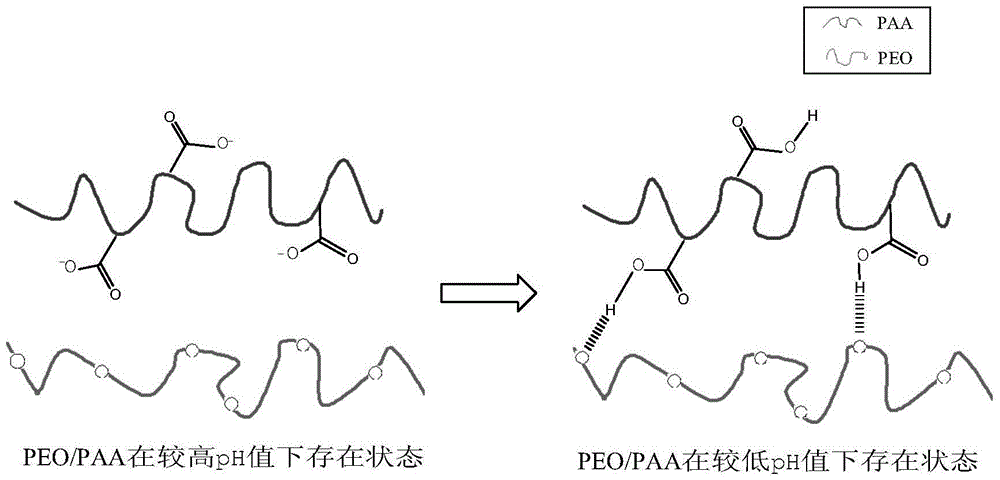

Preparation method of macromolecular hydrogen bond compound fiber

ActiveCN104532395AIncrease elasticityIncreased humidity sensitivityWet spinning methodsConjugated synthetic polymer artificial filamentsFiberHydrogen

The invention relates to a preparation method of a macromolecular hydrogen bond compound fiber. The method comprises the following steps: respectively dissolving and mixing a macromolecular hydrogen bond donor and a macromolecular hydrogen bond acceptor, so as to obtain a uniform spinning solution; defoaming, filtering, standing and deforming the spinning solution, metering, entering a coagulating bath to coagulate and mold through a spinneret plate, so as to obtain a nascent fiber; and drying the nascent fiber, so as to obtain the macromolecular hydrogen bond compound fiber. Two high polymers which are difficult in fiber forming are successfully spun into a compound fiber on the basis of mutual action of hydrogen bonds, so that the spinning field and the application space of the high polymers are expanded; the high polymers also have novel properties, such as high elasticity and humidity sensitivity.

Owner:DONGHUA UNIV

Vacuum pump for preventing water vapor corrosion

The invention discloses a vacuum pump for preventing water vapor corrosion. According to the vacuum pump disclosed by the invention, by installing a humidity-sensitive sensor module at the outer part of a pump body of the vacuum pump, the variation of humidity in a surrounding environment of the vacuum pump can be detected during a using process of the vacuum pump, and the vacuum pump can be well protected; the humidity-sensitive sensor module is creatively designed in many aspects of sensitive materials, manufacturing conditions, structures and the like of sensors, so that the sensitivity of the humidity-sensitive sensor module is greatly increased, the testing repeatability is good, an unexpected technical effect is generated, and a very large market application prospect is obtained.

Owner:韦醒妃

Switch voltage stabilizer based on calibration environment humidity changes

The invention discloses a switch voltage stabilizer based on calibration environment humidity changes. A humidity-sensitive sensor module is mounted outside a cabinet of the switch voltage stabilizer, so that when in use, the switch voltage stabilizer can detect changes of humidity in surrounding environment and is well protected. Sensitive material, manufacturing condition and structure of a sensor of the humidity-sensitive sensor module are designed creatively, so that sensitivity of the switch voltage stabilizer is improved greatly, testing repeatability is high, unexpected technological effect is generated, and the switch voltage stabilizer has huge market application prospect.

Owner:肖锐

Electric vehicle charging station for resistance to water vapor corrosion

The invention discloses an electric vehicle charging station for resistance to water vapor corrosion. A humidity-dependent sensor module is installed on the outside of each charging pile. Thus, during the application process of the electric vehicle charging station, changes of humidity in the ambient environment can be detected, and the electric vehicle charging station is greatly protected. Sensitivity of the humidity-dependent sensor module is high, test repeatability is good, and an unexpected technical effect is generated. The electric vehicle charging station has a great market application prospect.

Owner:杨炳

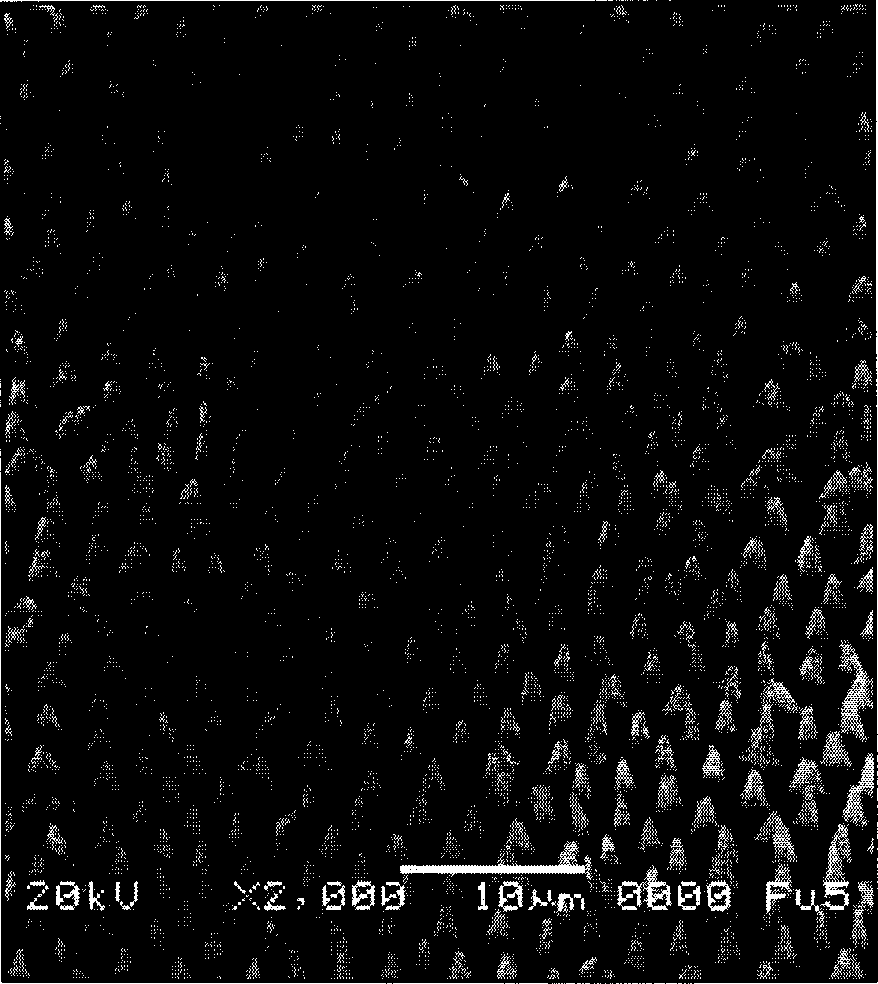

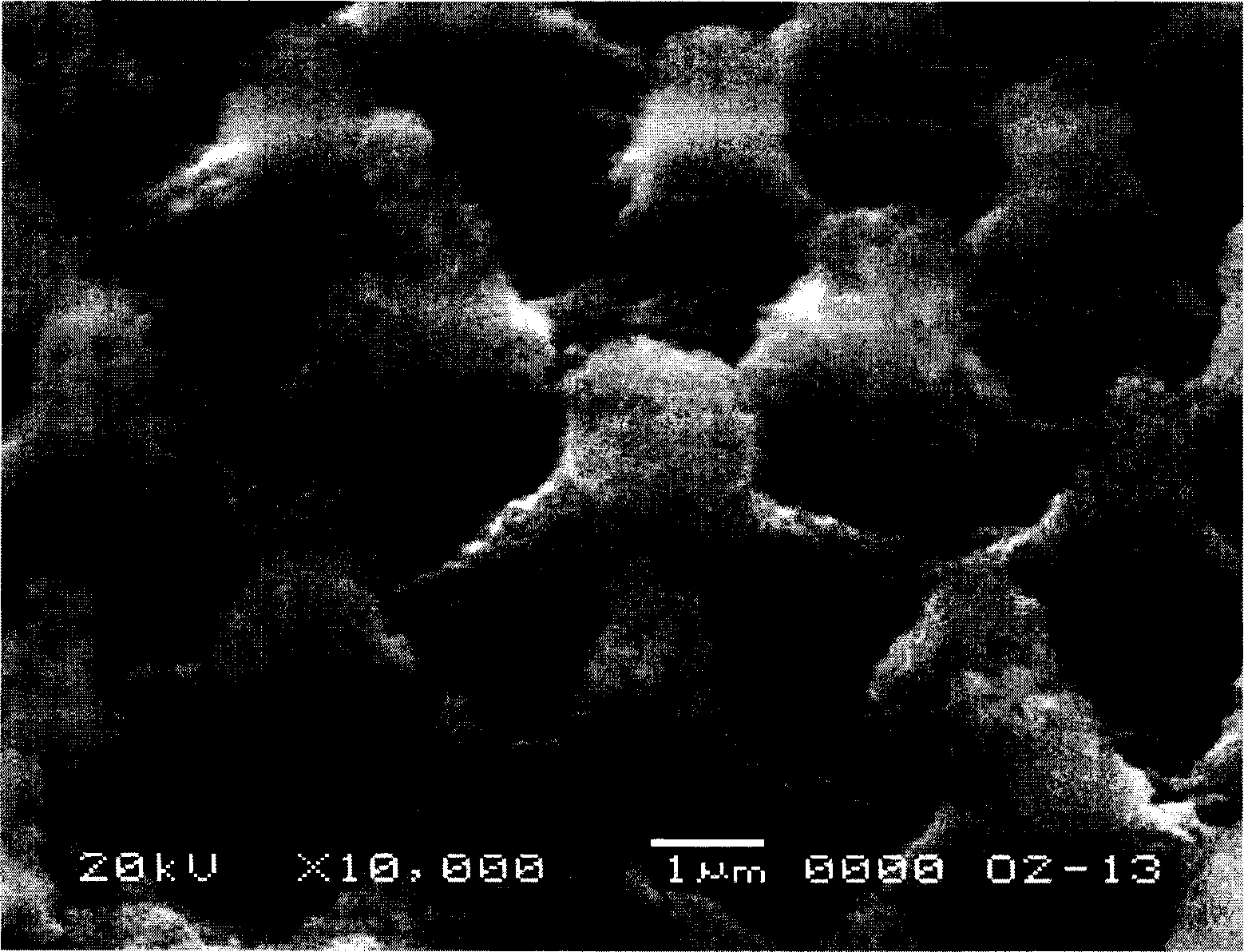

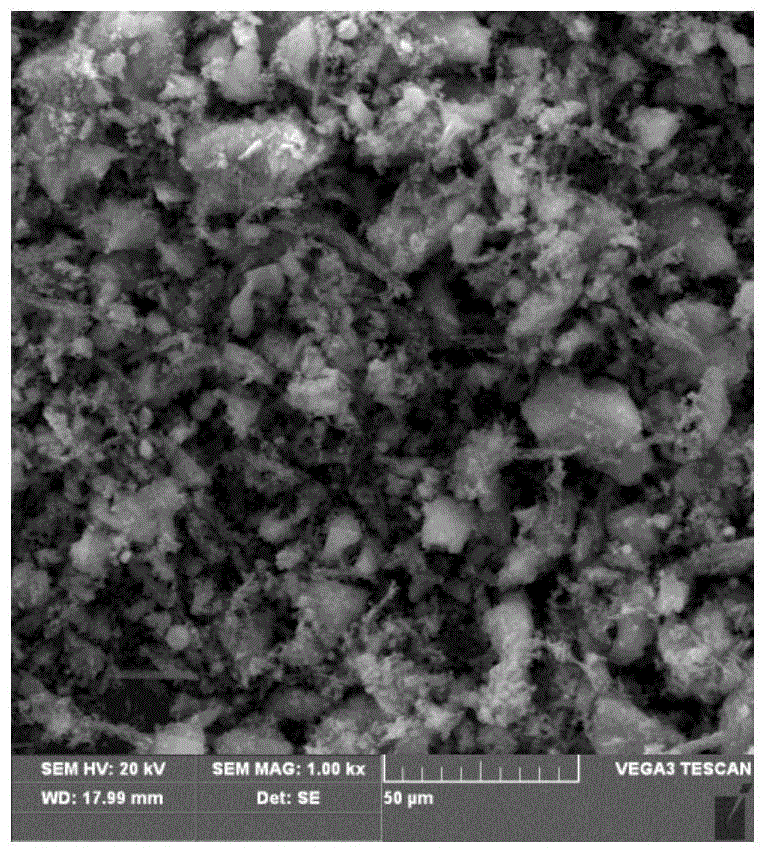

Fe3O4/Si nanometer porous array composite material preparation method

InactiveCN1766164AImprove magnetismIncreased humidity sensitivityNanostructure applicationLiquid/solution decomposition chemical coatingMaterials preparationHigh density

The invention discloses a preparation method for Fe3O4 / Si nano porous array composite material, which comprises: forming a silicon-metal bond passivation layer of even, high-density, well thermal stability on single-crystal silicon by hydrothermal method; preparing nano Fe3O4 particle with un-agglomerated even particle size by microporous-hydrothermal method, then preparing the product by rotation spraying method. This invention improves magnetism and wet sensitive of Fe3O4, and heeds simple devices and low cost.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Image receiver elements

ActiveUS8304370B2High transfer efficiencyMore color densityAblative recordingDyeing processWater dispersibleSide chain

An image receiver element includes a water-soluble or water-dispersible polyurethane binder in the image receiving layer. This polyurethane has a Tg of from about 60 to about 80° C., a molecular weight of at least 25,000, and an acid number of from about 16 to about 35 mg KOH / g. Moreover, the polyurethane comprises from about 42 to about 60 weight % of recurring urethane units, from about 8 to about 20 weight % of alkylene glycol recurring units, from about 18 to about 40 weight % of carbonate recurring units having aliphatic side chains, and from about 3 to about 15 weight % of recurring units having a water-soluble or water-dispersible acid group, based on total binder weight.

Owner:KODAK ALARIS INC

A polyimide film for high-altitude humidity detection and its preparation method

The invention discloses a polyimide film used for high-altitude humidity detection and a preparation method thereof. The polyimide film is obtained by high-temperature imidization of polyamic acid, and the polyamic acid is composed of 5%-20% It is composed of a mixture of diamine and dianhydride and 80%-95% of non-protonated solvent, wherein the molar mass ratio of diamine and dianhydride in the mixture of diamine and dianhydride is 1:0.8-1.2. The specific steps of the preparation method are: synthesizing polyamic acid, diluting polyamic acid, preparing polyamic acid film, imidizing the polyamic acid film together with the substrate material; polyimide film. The polyimide film of the present invention has good moisture absorption and dehumidification characteristics, fast adsorption and desorption of water molecules, and high humidity sensitivity; the implementation process of the preparation method is simple and easy to process, and it is suitable for use in the field of humidity detection, especially high-altitude humidity The application prospect in the field of detection is good.

Owner:北京航天微电科技有限公司 +1

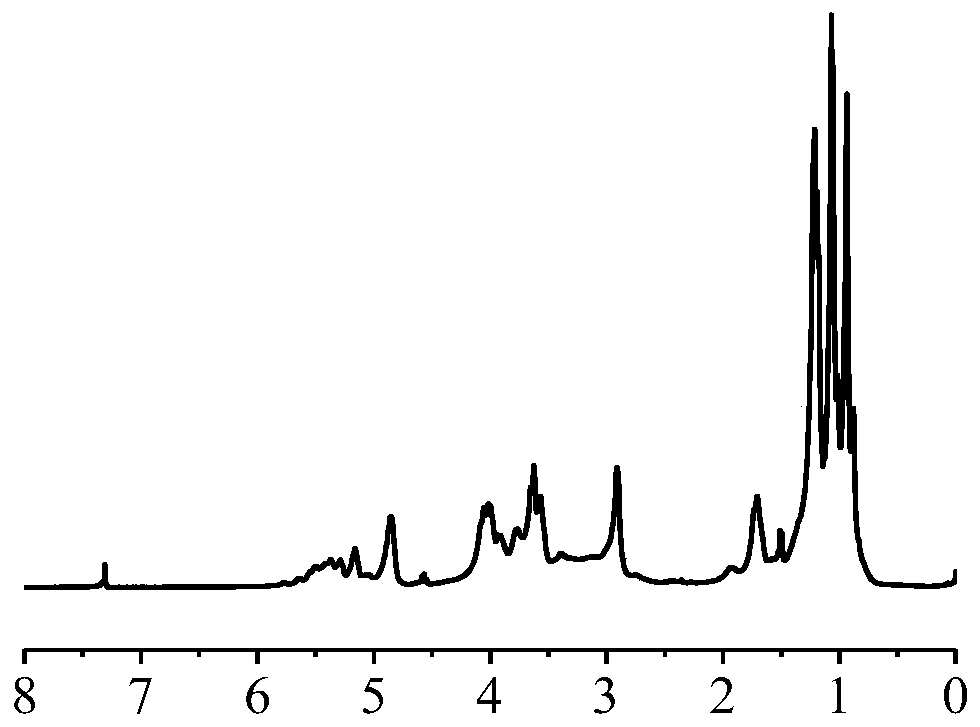

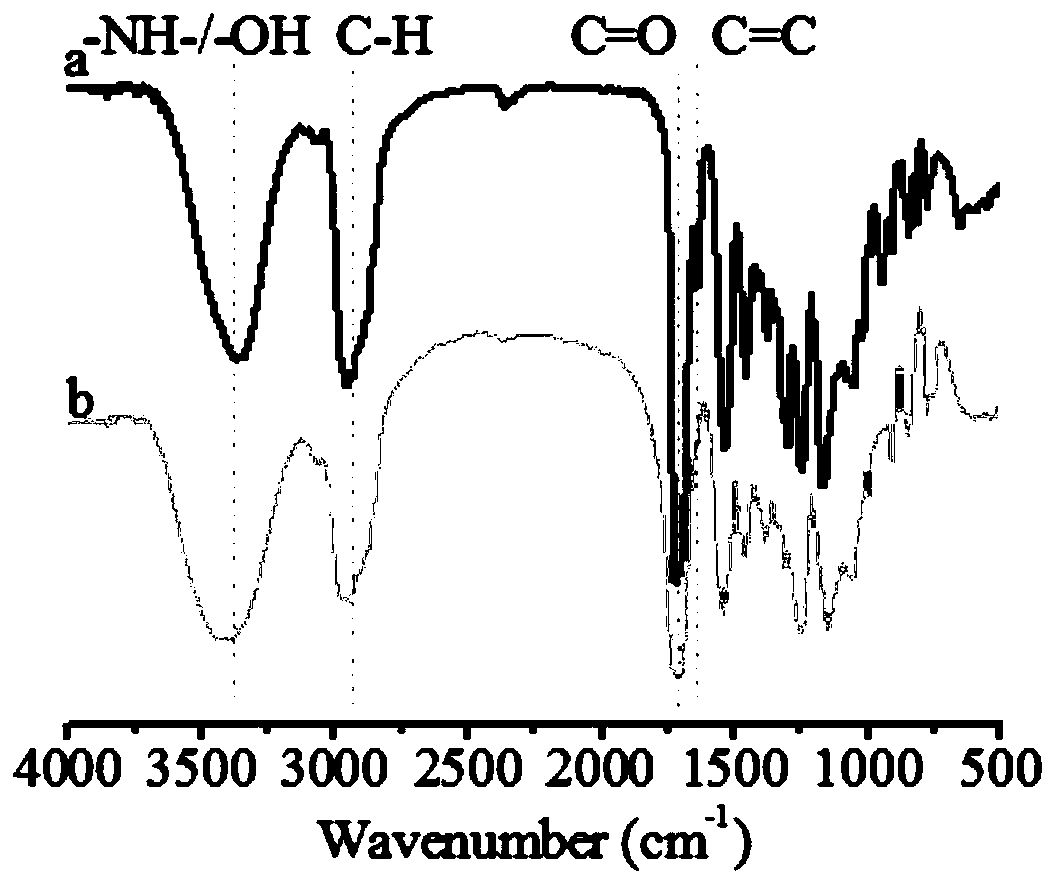

A kind of polyurethane prepolymer and its preparation method and ultraviolet light curing polyurethane prepolymer composition

ActiveCN107177035BIncreased toxicityIncreased humidity sensitivityPolyurea/polyurethane coatingsPolyurethane adhesiveIrritation

The invention provides a polyurethane prepolymer which is novel environment-friendly non-isocyanate polyurethane, does not contain an isocyanate group with high toxicity and high moisture sensitivity, has no pollution to the environment and has no damages to human health. A preparation method provided by the invention has a simple operation process; a technology is optimized and raw materials are readily available; and the reaction selectivity is high and a preparation process is safe and clean. A low-viscosity ultraviolet-cured composition can be obtained through mixing the polyurethane prepolymer provided by the invention with a photoinitiator; a system does not contain any active diluting agent and is not retracted and deformed in a curing process; the low-viscosity ultraviolet-cured composition can be widely used for preparing ultraviolet-cured polyurethane coating, 3D (Three Dimensional) printing photosensitive resin, ultraviolet-cured polyurethane ink or an ultraviolet-cured polyurethane adhesive which has low viscosity, does not contain the active diluting agent, has small irritation to human bodies and is green and environmentally friendly.

Owner:GUANGDONG UNIV OF TECH

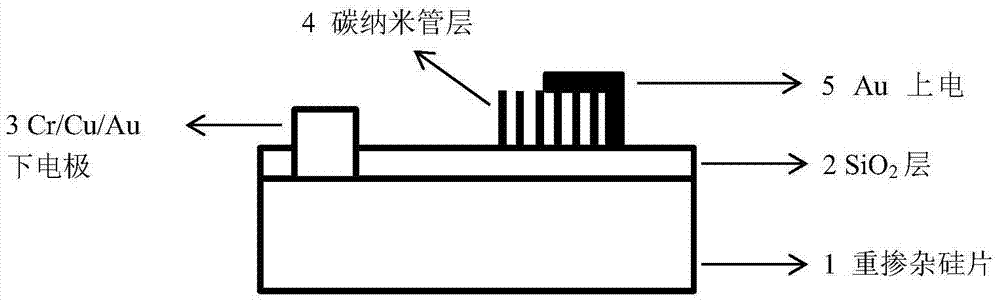

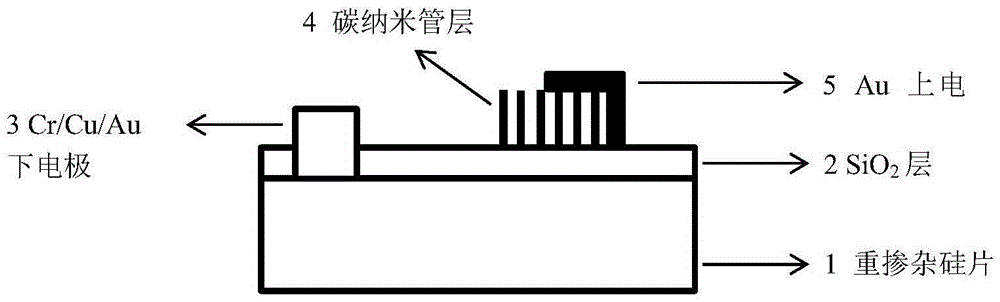

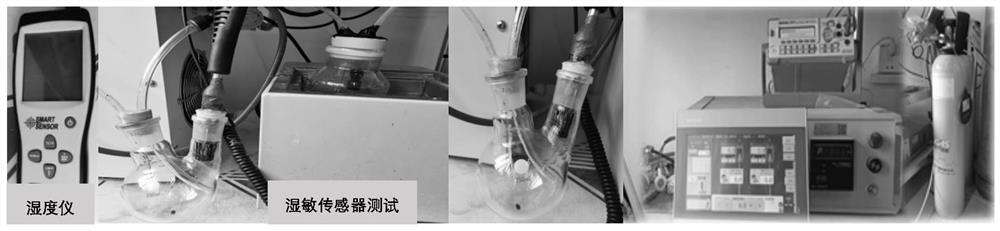

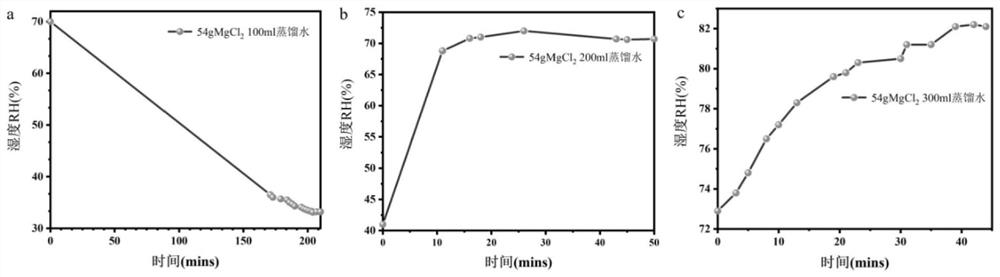

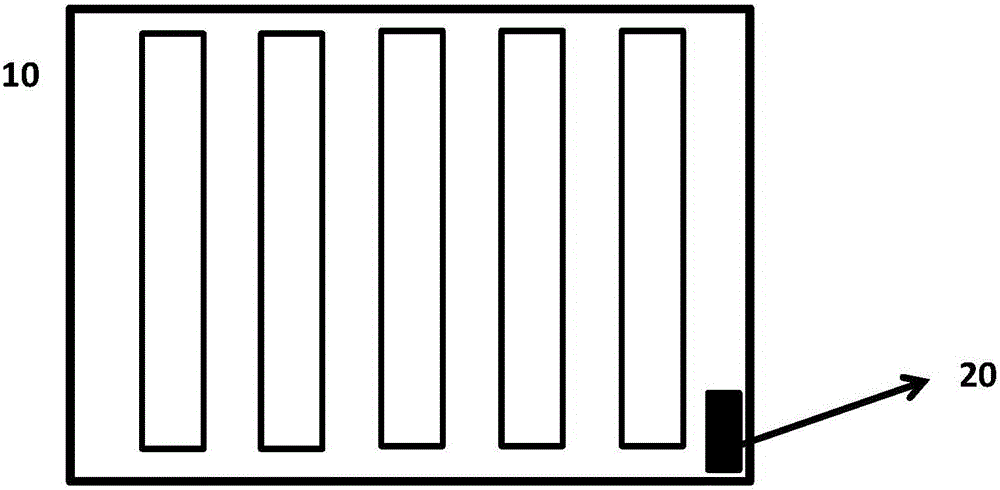

Purple phosphorus alkenyl humidity-sensitive sensor as well as preparation method and application thereof

PendingCN114487038AShort response timeIncreased humidity sensitivityMaterial resistanceHeterojunctionGraphite

The invention discloses a purple phosphorus alkenyl humidity-sensitive sensor as well as a preparation method and application thereof, and belongs to the technical field of humidity-sensitive sensors. The humidity-sensitive sensor is composed of a purple phosphorus alkene / graphene heterojunction and an electrode located on the surface of the purple phosphorus alkene / graphene heterojunction. Different amounts of purple phosphorene and graphene films are prepared into heterojunctions by adopting a vacuum filtration method, conductive silver adhesives are coated on the purple phosphorene / graphene heterojunctions, silver wires are connected, the purple phosphorene-based humidity-sensitive sensor is prepared, a humidity-sensitive test platform is assembled, different humidity is prepared by adopting a saturated salt solution, and the humidity-sensitive test result is obtained. A sensitivity detection experiment is carried out under the condition that the humidity is relatively stable. The prepared purple phosphorus-based humidity-sensitive sensor is short in response time, high in humidity sensitivity and obvious in humidity induction.

Owner:SHAANXI UNIV OF SCI & TECH

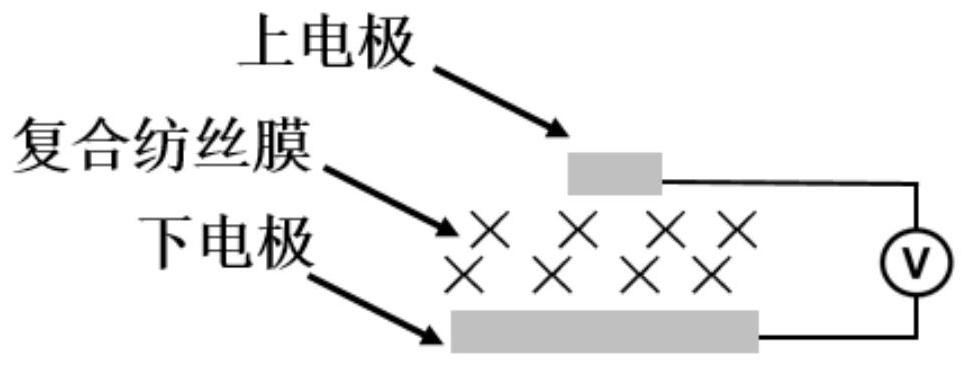

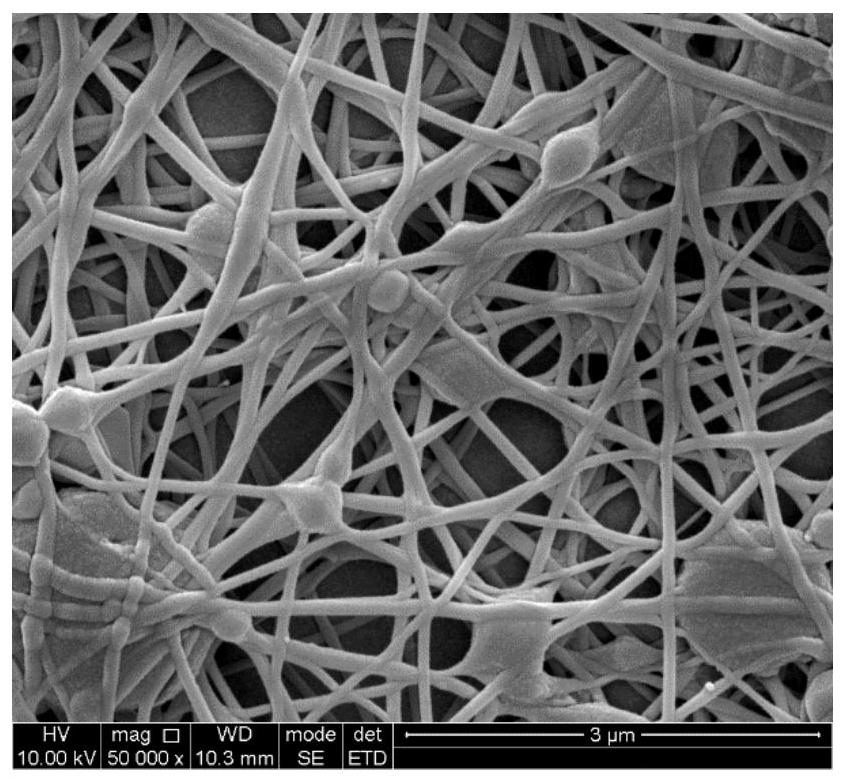

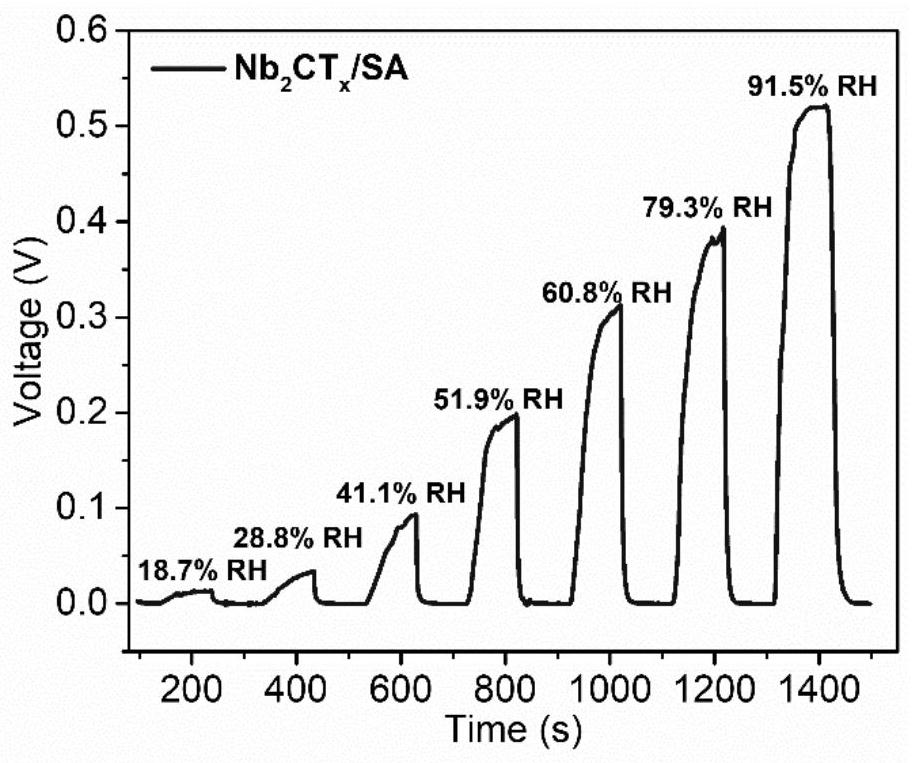

A self-powered humidity sensor based on composite spinning film and its preparation method

ActiveCN112924492BGreenSave energyMaterial analysis by electric/magnetic meansFilament/thread formingSpinningElectrospinning

The invention discloses a self-powered humidity sensor based on a composite spinning film and a preparation method thereof, and relates to energy collection technology and sensitive electronics technology. Based on Nb 2 CT x The self-powered humidity sensor of the sodium alginate composite spinning film comprises a sensitive device and a spinning sensitive film arranged on the sensitive device, the sensitive device is an upper and lower electrode structure, and the sensitive film is made of Nb 2 CT x / Sodium alginate composites were prepared by electrospinning process. Utilize Nb 2 CT x The nanosheet and the nanocomposite fiber structure obtained by spinning provide a three-dimensional network space for the diffusion of water molecules; after the water molecules are adsorbed from top to bottom, the ion gradient diffuses to form a potential difference between the upper and lower electrodes and output a voltage signal. Compared with the traditional humidity sensor, the self-powered humidity sensor of the present invention does not require an external power supply system, and has the advantages of low power consumption, environmental protection, convenient portability, flexibility and lamination.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Preparation method of low-cost and high-sensitivity nacl-doped mesoporous silicon oxide resistive humidity-sensitive material

ActiveCN104458819BHigh humidity sensitive sensitivityDoping process is simpleSilicaMaterial resistanceMesoporous silicaSolvent

The invention relates to a preparation method of a low-cost high-sensitivity NaCl doped mesoporous silica resistor type humidity-sensitive material. The preparation method comprises the following steps of synthesizing a mesoporous silicon dioxide molecular sieve by adopting a hydrothermal method, forging the obtained mesoporous material at 550 DEG C so as to remove a surfactant, mixing the forged mesoporous material with a proper amount of sodium chloride, grinding again by taking absolute ethyl alcohol as a solvent, and doping. The preparation method has the characteristics of simple doping process, no need of thermal treatment and simplified preparation technology. According to the low-cost high-sensitivity NaCl doped mesoporous silica resistor type humidity-sensitive material, the humidity-sensitive sensitivity is high; within the full-humidity range ability of 11%RH-95%RH, the impedance change order of magnitude is greater than four orders of magnitude and approaches five orders of magnitude, and the ideal doping proportion is obtained by testing for multiple times; the humidity-sensitive performance of the material is improved effectively; within the full-humidity range ability of 11%RH-95%RH, the impedance change order of magnitude is greater than four orders of magnitude and approaches five orders of magnitude, and meanwhile, the preparation technology of the type of materials is simplified.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Gas pipeline with high-sensitivity humidity detection device

InactiveCN105510407AHigh sensitivityGood repeatabilityMaterial nanotechnologyMaterial capacitanceEngineeringRepeatability

The invention discloses a gas pipeline with a high-sensitivity humidity detection device. Due to the fact that a humidity sensitive sensor module is installed on the exterior of the gas pipeline, the content of water steam in the environment can be detected by the gas pipeline in the using process, and therefore safe working of the gas pipeline is guaranteed; creative design is conducted on the humidity sensitive sensor module in multiple aspects of sensitive materials, making conditions, structures and the like of a sensor, the response speed is high, the sensitivity is greatly improved, the test repeatability is good, unexpected technical effects are achieved, and the great market application prospect is achieved.

Owner:肖小渝

Numerically controlled lathe for preventing water vapor corrosion

InactiveCN105548276AQuick responseHigh sensitivityMeasurement/indication equipmentsMaterial resistanceWater vaporComputer module

The invention discloses a numerically controlled lathe for preventing water vapor corrosion. A humidity-dependent sensor module is installed outside the numerically controlled lathe, so that in the using process of the numerically controlled lathe, the humidity-dependent sensor module can detect changes of humidity in the surroundings and produces humidity early warning, and the numerically controlled lathe is well protected. The humidity-dependent sensor module is creatively designed from the aspects of sensitive materials, manufacturing conditions, the structure and the like of the sensor, is high in response speed, high in sensitivity and good in test repeatability, produces wonderful technical effects and has the wide market application prospect.

Owner:林燕萍

A kind of preparation method of macromolecular hydrogen bond composite fiber

ActiveCN104532395BIncrease elasticityIncreased humidity sensitivityWet spinning methodsConjugated synthetic polymer artificial filamentsFiberPolymer science

Owner:DONGHUA UNIV

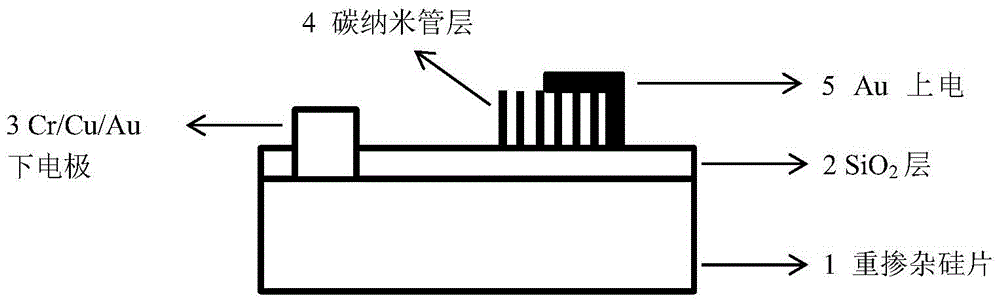

a cotio 3 Preparation method of nano-array humidity-sensitive film

ActiveCN104561919BIncreased humidity sensitivityHigh sensitivityVacuum evaporation coatingSputtering coatingSputteringRoom temperature

The invention discloses a preparation method for a CoTiO3 nanoarray humidity-sensitive film. The preparation method comprises the following steps: adding a hydrochloric solution of TiCl3 into a cobalt chloride aqueous solution to obtain a mixed solution A; regulating the pH value of the mixed solution to be 6-10, and obtaining a precursor solution B; transferring the precursor solution B into a hydrothermal reaction kettle, soaking a cleaned silicon substrate in the precursor solution B for reaction, and washing the silicon substrate to obtain a film C on the silicon substrate; putting the silicon substrate provided with the film C onto a sample stage of a magnetron sputtering apparatus, performing magnetron sputtering by adopting a Co2O3 radio-frequency target and a TiO2 radio-frequency target, and forming a film D on the silicon substrate; keeping the silicon substrate provided with the film D at a temperature ranging from 600 DEG C to 750 DEG C, and obtaining the CoTiO3 nanoarray humidity-sensitive film. The preparation method can effectively regulate and control the morphology of the film, is good in film-forming property, convenient to carry out, short in production period, high in efficiency and suitable for industrial production. The prepared CoTiO3 film has excellent moisture sensitivity at the room temperature and is short in response-recovery time.

Owner:SHAANXI UNIV OF SCI & TECH

Vacuum packaging equipment based on quick response to humidity changes

InactiveCN105675668AHigh sensitivityShort response timeAnalysing gaseous mixturesMaterial capacitanceEngineeringRepeatability

The invention discloses a vacuum packaging device based on rapid response to humidity changes. By installing a humidity sensor module at the bottom of the cabinet of the vacuum packaging device, the vacuum packaging device can detect the humidity of the gas environment during the working process. Changes, which play a very good role in protecting the normal operation of the vacuum packaging equipment; the humidity sensor module is creatively designed from the sensor's sensitive materials, manufacturing conditions, structure, etc., so that the response speed is fast and the sensitivity is greatly improved. The test has good repeatability, has produced unexpected technical effects, and has great market application prospects.

Owner:肖白玉

Storage battery module for quickly responding humidity change

InactiveCN105576311AQuick responseHigh sensitivitySecondary cellsMaterial capacitanceEngineeringRepeatability

The invention discloses a storage battery module for quickly responding humidity change. A humidity-sensitive sensor module is mounted outside the storage battery module, so that the humidity-sensitive sensor module can detect the change of humidity in the ambient environment of the humidity-sensitive sensor module in the using process of a storage battery, and the storage battery can be well protected; the humidity-sensitive sensor module is creatively designed in the aspects such as the sensitive material, manufacturing condition and structure of the sensor, so that the storage battery module is high in response speed, high in sensitivity and good in test repeatability, an unexpected technical effect is generated, and the storage battery module has great market application prospects.

Owner:孟玲

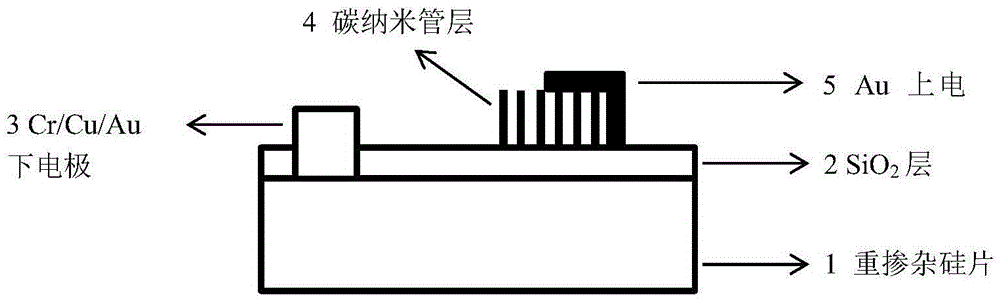

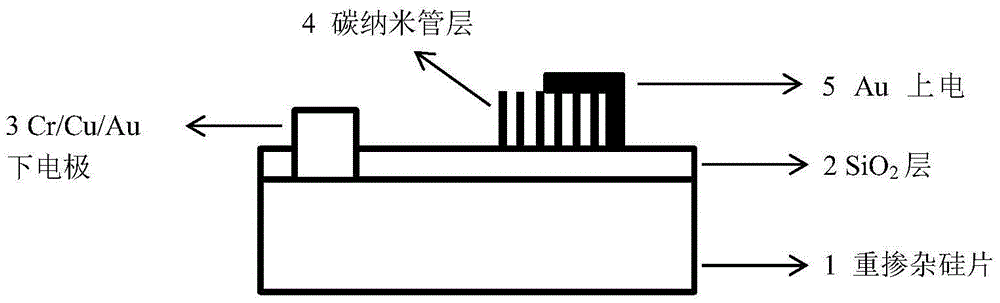

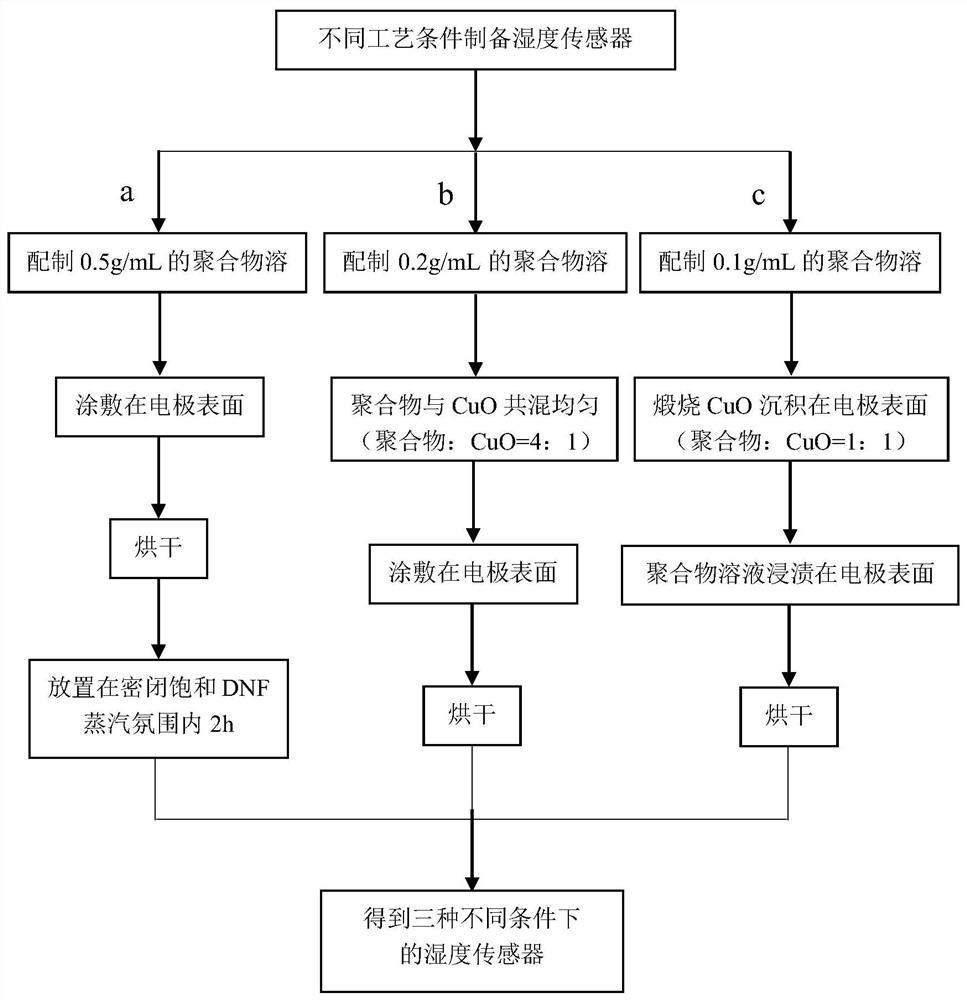

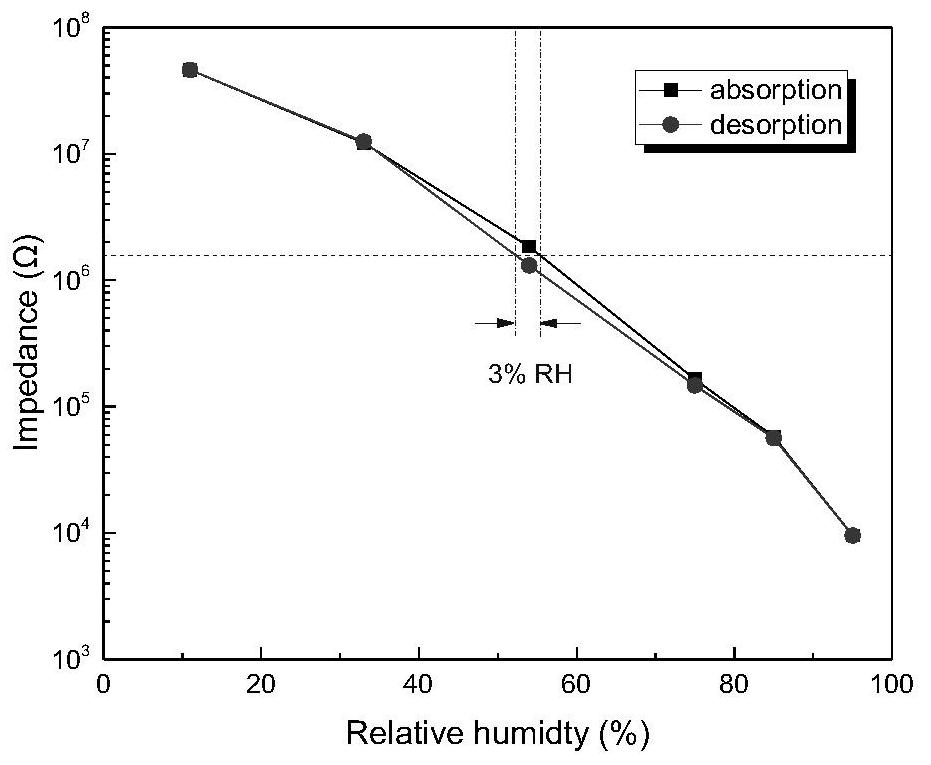

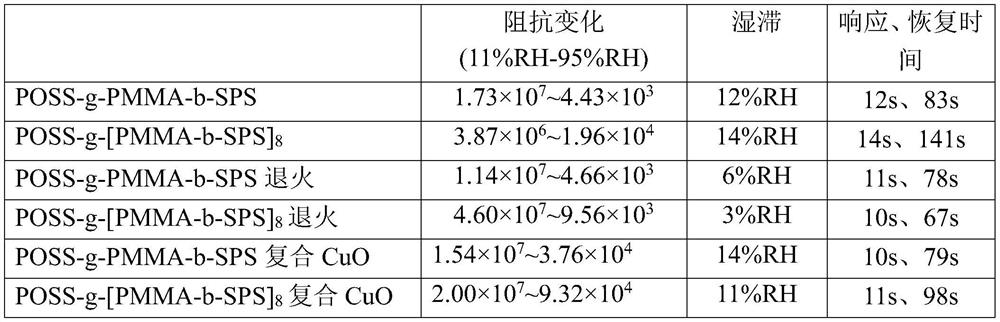

A kind of ionic poss block copolymer base humidity sensor and preparation method

ActiveCN109085207BHigh sensitivityIncreased durabilityMaterial resistanceHigh humiditySilsesquioxane

The invention relates to an ionic-type polyhedral oligomeric silsesquioxane (POSS) block copolymer based humidity sensor and a preparation method thereof. The humidity sensitivity performance of the ionic-type POSS block copolymer based humidity sensor is improved through solvent annealing and porous CuO doping methods. An ionic-type POSS block copolymer selects a POSS grafted methyl methacrylatetype-sulfonated styrene block copolymer prepared by the research group, two types of topological structures, namely the star type and the tadpole type, of the polymer and the different block ratios (1:1)-(1:3) are researched, the humidity sensor with the excellent humidity sensitivity performance is prepared, through solvent annealing, hydrophilic and hydrophobic phases of the humidity sensor arepromoted to be separated, the durability and mechanical properties of a humidity sensitive material can be improved significantly, and the sensitivity of the ionic-type POSS block copolymer based humidity sensor is advantageously improved through doping of porous CuO.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Humidity sensor film based on microregion redissolution reaction and preparation method thereof

InactiveCN106908514ASimple preparation processPerformance Tuning and ImprovementAnalysing fluids using sonic/ultrasonic/infrasonic wavesChemical reactionDissolution reaction

The invention discloses a humidity sensor film based on a microregion redissolution reaction and a preparation method thereof, and belongs to the technical field of the composite material and humidity sensor. The preparation method comprises the following steps: based on the technology and feature of an atomization process, such as the gas release, dissociating uniform solution to micron-type microdrops, conveying the microdrops to a film formation substrate by the gas, forming the micron-type redissolution reaction microregion in the guide layer film, and reacting by two or more materials in the microregion and finishing the film deposition process. The preparation method is capable of overcoming the problem in the traditional film preparation process that two or more materials cannot form the film because of the reaction deposition between the materials or the bad effect of the solution dispersion state caused by the generation. The humidity-sensitivity film prepared by the preparation method is capable of obviously improving the sensor feature characters, such as wet hysteretic property, because of the physical and chemical reactions, such as the bonding between the materials, and the electrostatic adsorption.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

A core-shell structure n-titanium dioxide@p-cobalt titanate nanocrystalline film and its preparation method

ActiveCN107313017BIncreased humidity sensitivityAdjust shapeVacuum evaporation coatingSputtering coatingOptoelectronicsCobalt

The invention relates to a core shell structure n - titanium dioxide @ p - cobalt titanate nanocrystalline thin film and a preparing method thereof. A clean substrate is installed on a sample stage of a magnetron sputtering device firstly, and a CoTiO3 target and a TiO2 target are installed at two radio frequency target positions of the magnetron sputtering device correspondingly; a sputtering film coating chamber of the magnet control sputtering device is vacuumized and injected with inactive gas, and gas pressure of the sputtering film coating chamber is kept at 0.1Pa - 2Pa; the CoTiO3 target is pre-sputtered for 5min - 15min; the substrate is heated up to 300 DEG C - 600 DEG C and is subjected to heat preservation, sputtering of the CoTiO3 target is started for 30min - 90min, and a CoTiO3 orderly nanocrystalline thin film is obtained; and the CoTiO3 orderly nanocrystalline thin film is adjusted to be parallel with the TiO2 target, the TiO2 target is sputtered for 10s - 120s, and the core shell structure n - titanium dioxide @ p - cobalt titanate nanocrystalline thin film is obtained. According to the core shell structure n - titanium dioxide @ p - cobalt titanate nanocrystalline thin film and the preparing method thereof, appearance of the thin film can be adjusted effectively, the film-forming property is good, operation is convenient, the producing period is short, efficiency is high, and the core shell structure n - titanium dioxide @ p - cobalt titanate nanocrystalline thin film and the preparing method thereof are suitable for industrial production.

Owner:SHAANXI UNIV OF SCI & TECH

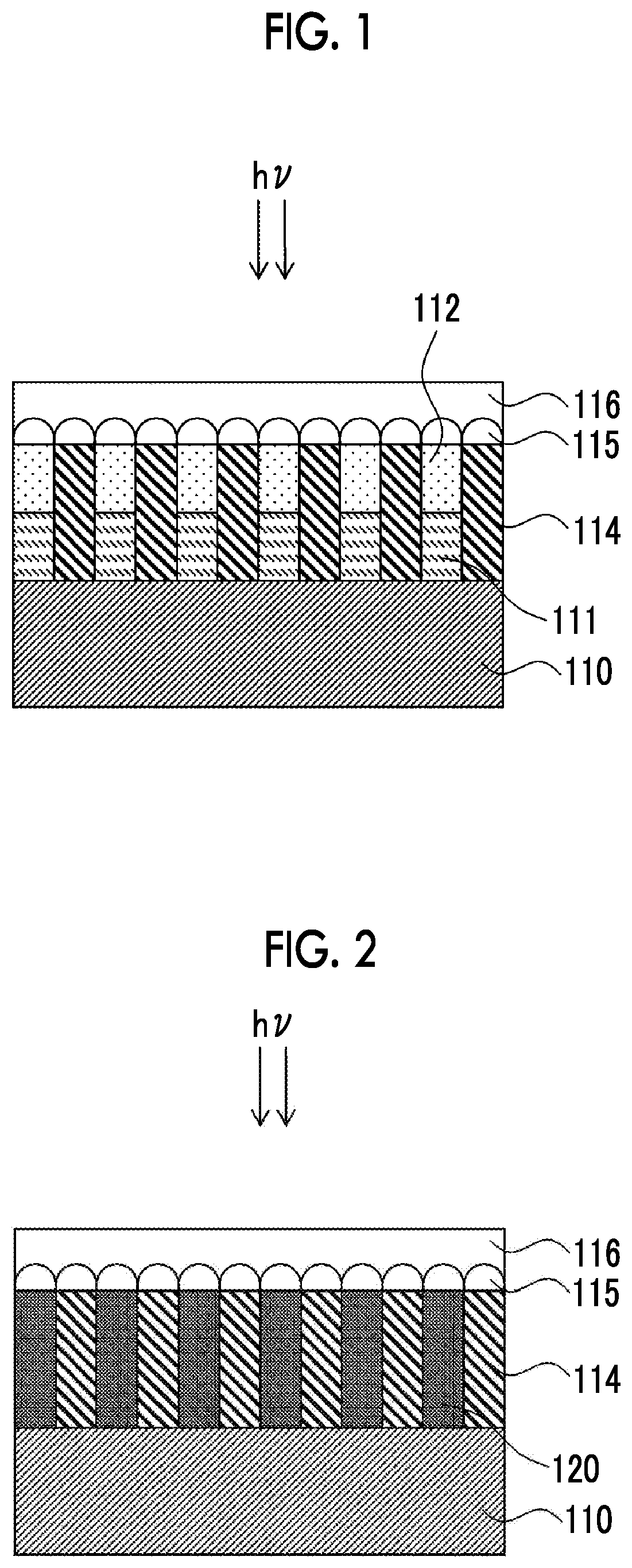

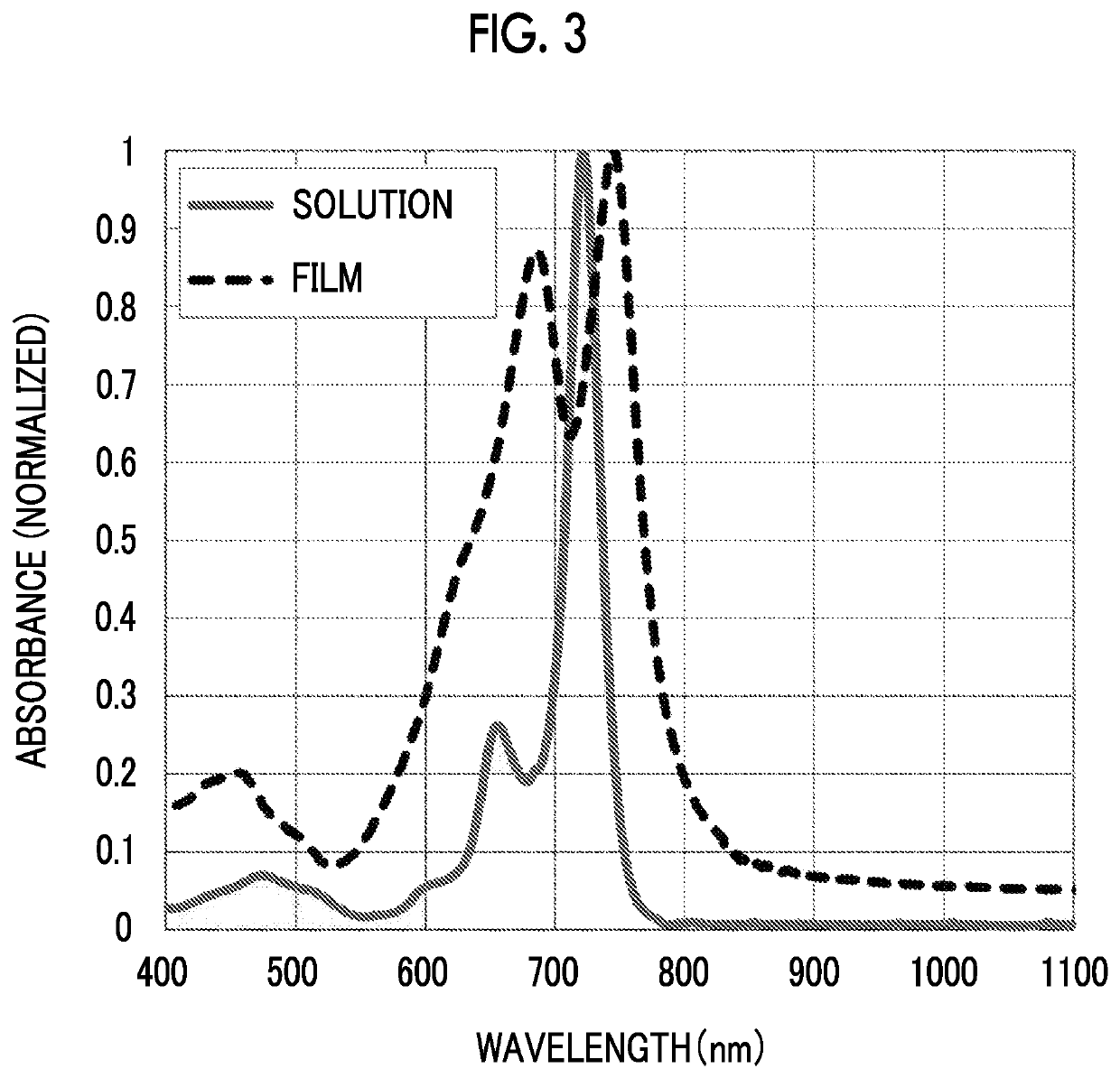

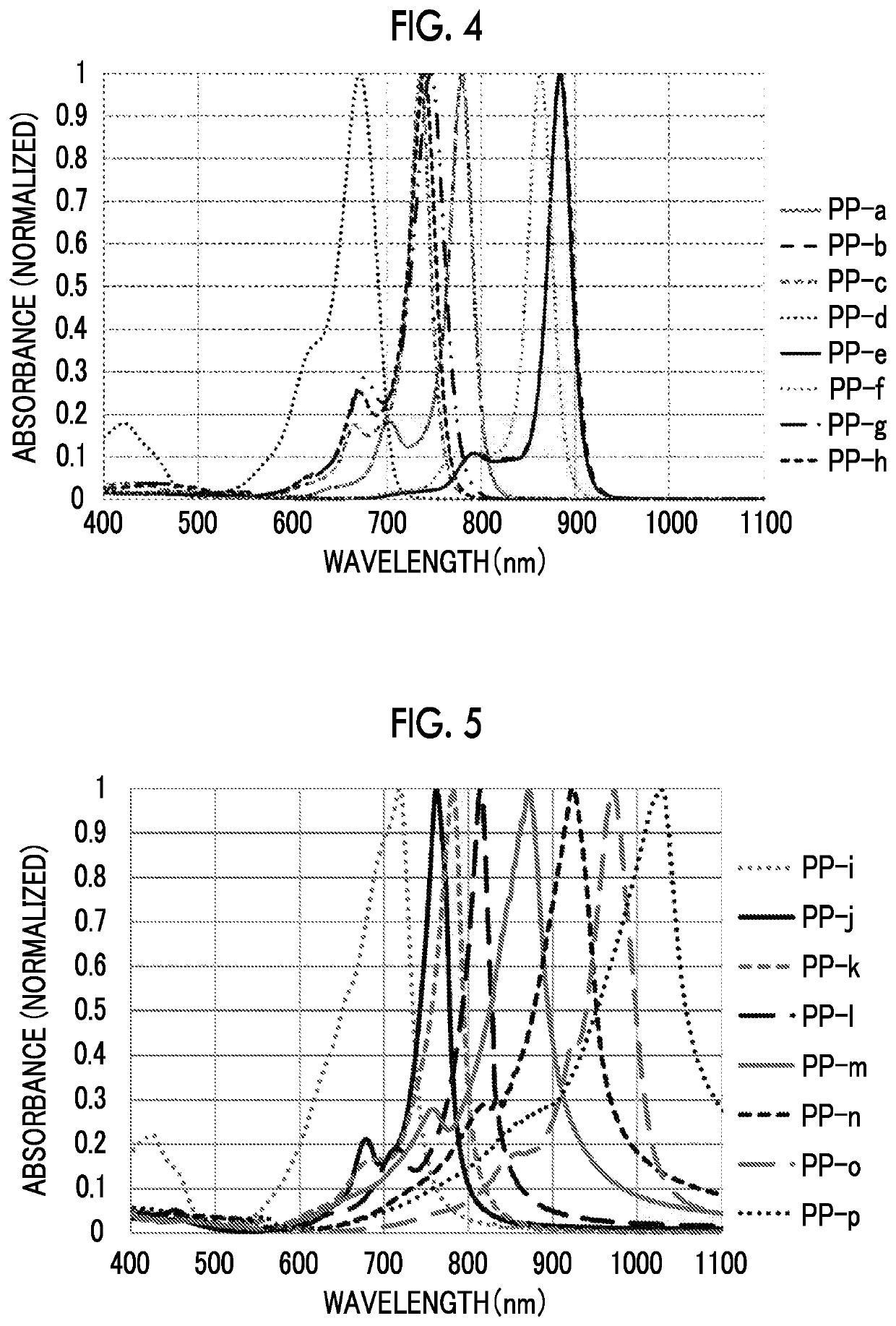

Curable composition, cured film, infrared transmitting filter, laminate, solid-state imaging element, sensor, and pattern forming method

PendingUS20210163634A1Suppresses noise generationReduce humidityOptical filtersSynthetic resin layered productsLight filterInfrared transmission

A curable composition includes a specific infrared absorber and a curable compound and has specific wavelength characteristics.

Owner:FUJIFILM CORP

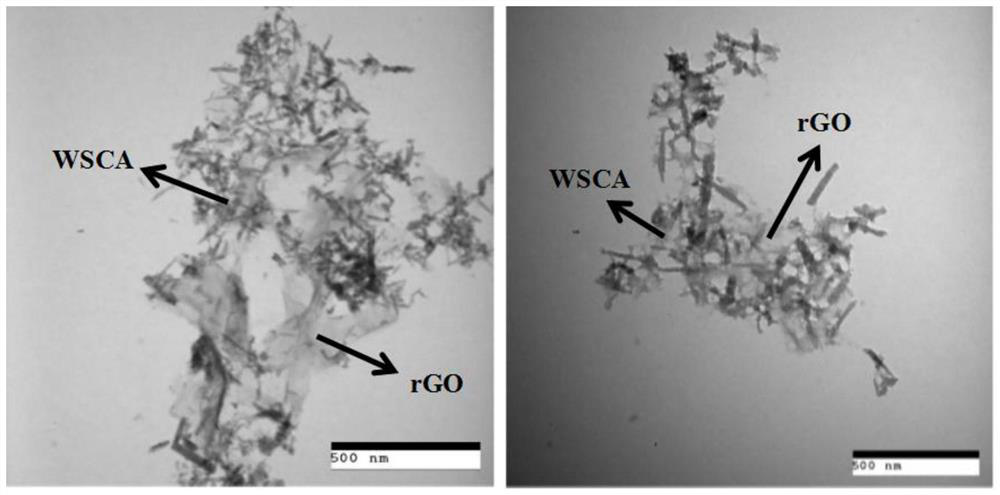

A kind of preparation method of moisture sensitive sensing film

ActiveCN109810295BIncreased humidity sensitivityRapid expansionMaterial electrochemical variablesCellulose acetateIonic liquid

The invention relates to a moisture sensitive sensing film and discloses a preparation method of the moisture sensitive sensing film. The preparation method comprises using valeryl chloride as a modifying agent in an ionic liquid solution of 1-ethyl-3-methylimidazole acetate to modify the cellulose to prepare water-soluble cellulose acetate WSCA; The water-soluble cellulose acetate is configured into a cellulose aqueous solution, and the graphene oxide is configured into a solution and added to the configured cellulose solution to obtain a cellulose / graphene oxide uniform mixed solution; to the above-mentioned cellulose / graphene oxide mixed A reducing agent was added to the solution, and the obtained reduced graphene oxide / cellulose aqueous solution was treated to obtain a flexible rGO / WSCA moisture-sensitive sensing film. The moisture-sensitive film has the advantages of not easy to fall off, no hysteresis phenomenon, good humidity sensitivity, and environmentally friendly materials.

Owner:QINGDAO UNIV OF SCI & TECH

Solar cell with high-sensitivity humidity detector

The invention discloses a solar battery with a highly sensitive humidity detection device. By installing a humidity sensor module on the outside of the solar battery, the solar battery can detect the change of the humidity in the surrounding environment during use, and has an effect on it. It has a good protective effect; the humidity sensor module is creatively designed from the aspects of sensor sensitive material, manufacturing conditions, structure, etc., so that its sensitivity is greatly improved, the test repeatability is good, and unexpected technical effects are produced. Great market application prospects.

Owner:黎海纤

Fe3O4/Si nanometer porous array composite material preparation method

InactiveCN100368594CImprove magnetismIncreased humidity sensitivityNanostructure applicationLiquid/solution decomposition chemical coatingMaterials preparationHigh density

The invention discloses a preparation method for Fe3O4 / Si nano porous array composite material, which comprises: forming a silicon-metal bond passivation layer of even, high-density, well thermal stability on single-crystal silicon by hydrothermal method; preparing nano Fe3O4 particle with un-agglomerated even particle size by microporous-hydrothermal method, then preparing the product by rotation spraying method. This invention improves magnetism and wet sensitive of Fe3O4, and heeds simple devices and low cost.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com