Preparation method of low-cost high-sensitivity NaCl doped mesoporous silica resistor type humidity-sensitive material

A mesoporous silicon oxide, high-sensitivity technology, applied in the directions of silicon oxide, silicon dioxide, material resistance, etc., can solve the problems of narrow measurement range, short service life, complex process, etc., and achieve high humidity sensitivity and response recovery time. Fast, simple doping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

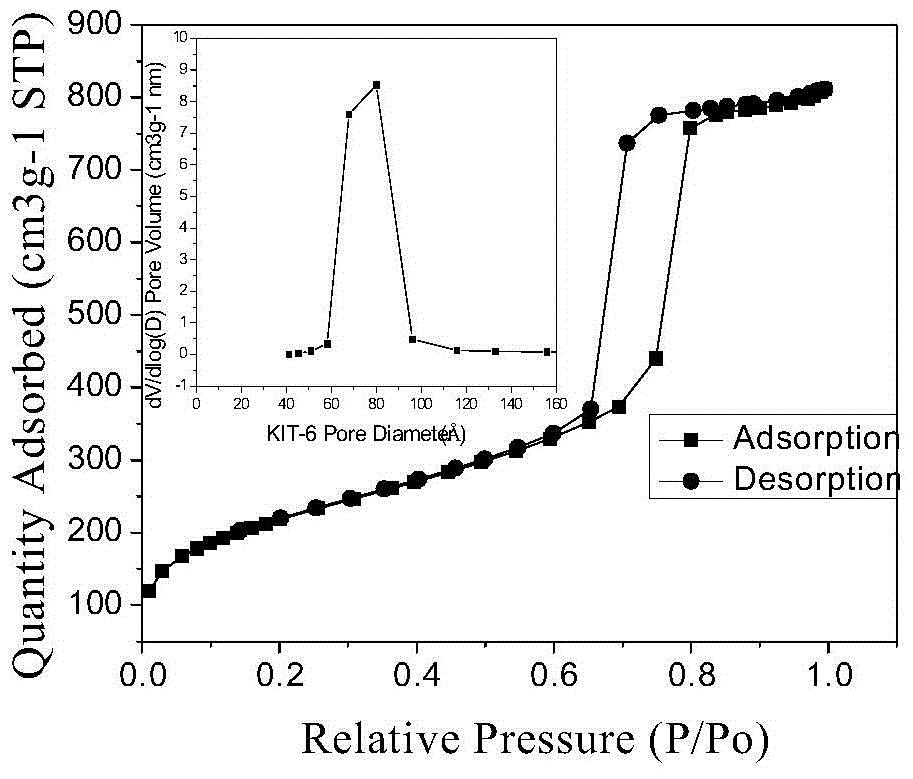

[0027] Dissolve 1 g of surfactant P123 in proportion to 34.1 g of distilled water, add 1.9 g of 36% concentrated hydrochloric acid and stir to form a uniform solution. Add 1 g of n-butanol and stir at 35 °C for 1 h. Then add 2.15g tetraethyl orthosilicate (TEOS) solution and stir for 24h. The mixed solution was transferred to a reaction kettle and subjected to hydrothermal treatment at 100° C. for 24 hours. The resulting product was suction filtered, washed with distilled water and absolute ethanol, and dried in an oven at 100°C for 12 hours. Then the product was calcined at 550° C. in air for 6 hours to obtain the three-dimensional cubic mesoporous silica material KIT-6. Take 0.1024g KIT-6 in a mortar, add 1ml of absolute ethanol dropwise to completely soak it, then add 0.0051g NaCl, grind for 0.5h, and dry at 100°C for 0.5h to obtain a mesoporous silicon oxide resistance type wet sensitive material.

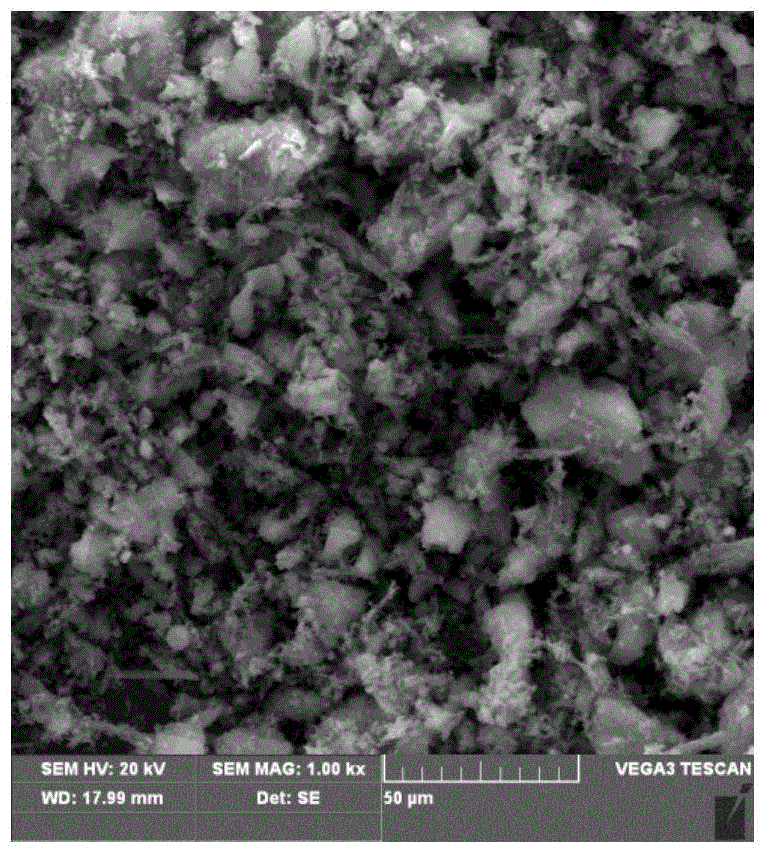

[0028] The microscopic morphology of KIT-6 was prepared as figure 1 s...

Embodiment 2

[0030] At 45° C., 0.067 g of CTAB was dissolved in 32 ml of ammonia solution (2% by mass, pH 11.35), and then 0.9 ml of n-butanol was added. 0.312g TEOS was added dropwise under static conditions. The mixture was placed in a water bath at 45°C for 24h, and then the mixture was transferred into a reaction kettle and reacted at 100°C for 24h. The resulting product was suction filtered, washed with distilled water, and dried in an oven at 100°C for 12 hours. The product was calcined at 550° C. for 6 h in air to remove the template, and a two-dimensional hexagonal mesoporous silica material SBA-15 was obtained. Take 0.1344g of SBA-15 in a mortar, add 1ml of absolute ethanol dropwise to completely soak it, then add 0.0134g of NaCl, grind for 0.5h, and dry at 100°C for 0.5h to obtain a mesoporous silicon oxide resistance type wet sensitive material.

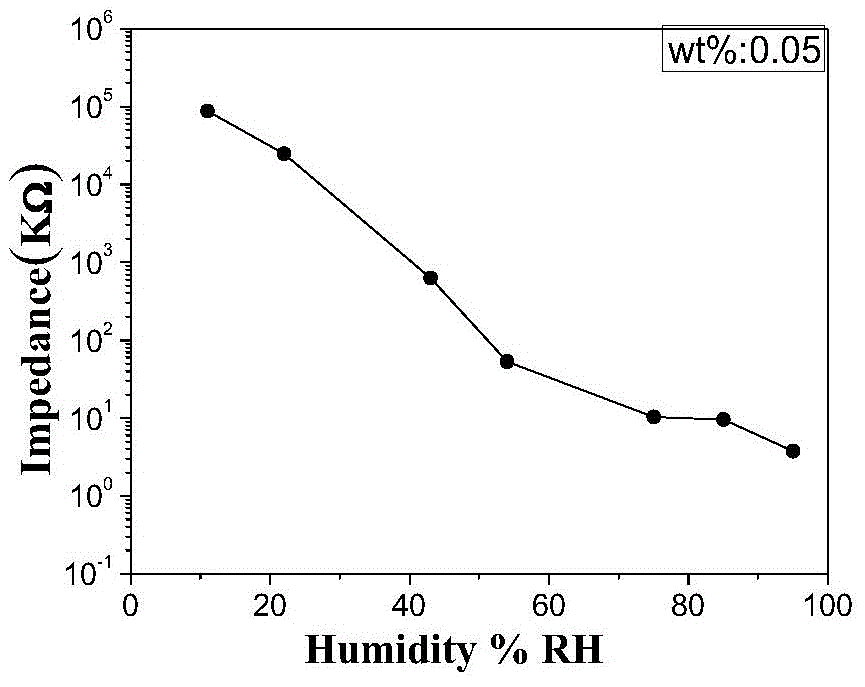

[0031] From Figure 4 It can be concluded that the impedance of the doped humidity-sensitive material varies by nearly five order...

Embodiment 3

[0033] Dissolve 1 g of surfactant P123 in proportion to 34.1 g of distilled water, add 1.9 g of 36% concentrated hydrochloric acid and stir to form a uniform solution. Add 1 g of n-butanol and stir at 35 °C for 1 h. Then add 2.15g TEOS solution and stir for 24h. The mixed solution was transferred to a reaction kettle and subjected to hydrothermal treatment at 100° C. for 24 hours. The resulting product was suction filtered, washed with distilled water and absolute ethanol, and dried in an oven at 100°C for 12 hours. Then the product was calcined at 550° C. in air for 6 hours to obtain the three-dimensional cubic mesoporous silica material KIT-6. Take 0.1276g KIT-6 in a mortar, drop an appropriate amount of ethanol to completely soak it, then add 0.0176g NaCl, grind for 0.5h, and dry at 100°C for 0.5h to obtain a mesoporous silicon oxide resistance type wet sensitive material.

[0034] From Figure 5 It can be concluded that the doped moisture-sensitive material has an imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com