Fe3O4/Si nanometer porous array composite material preparation method

A composite material and nanoporous technology, which is applied in the field of preparation of nanocomposite materials, can solve problems such as low porosity, uneven particle size distribution, and low density of silicon nanocrystals, and achieve improved magnetic properties and moisture sensitivity, and process instruments Simple, high crystallite density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

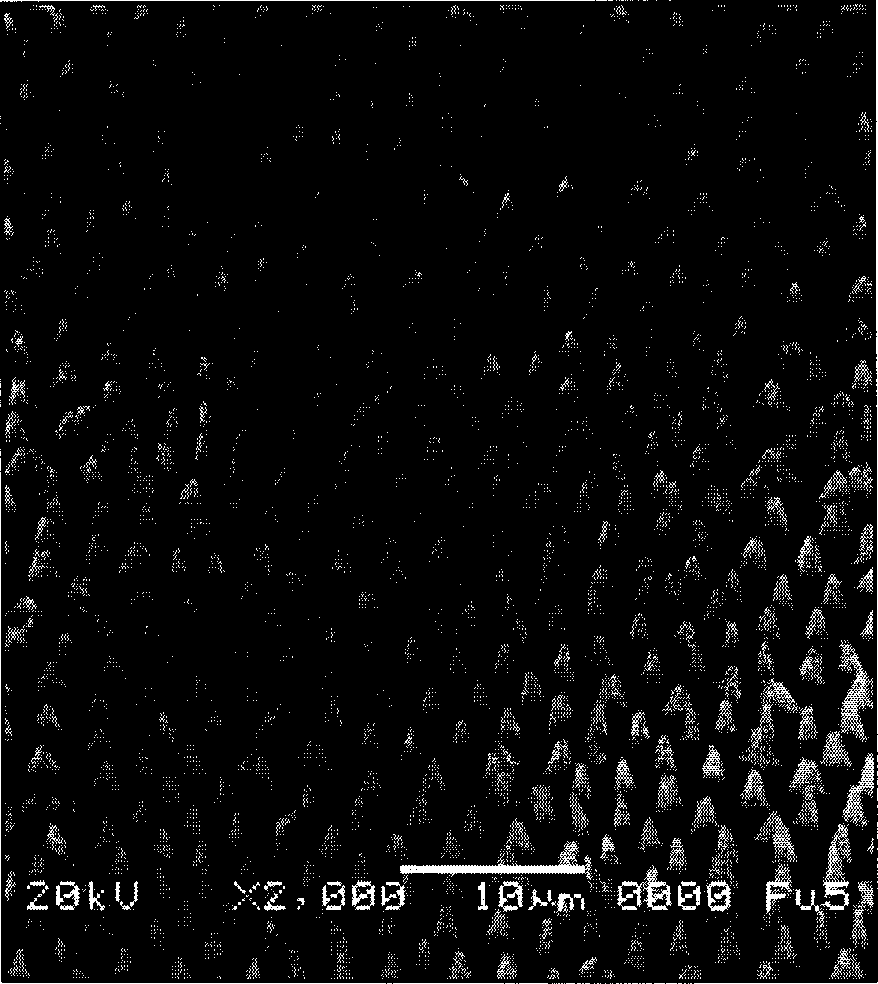

[0013] (1) Preparation of HF / Fe(NO 3 ) 3 Corrosive solution, HF concentration 7mol / L, Fe(NO 3 ) 3 The concentration is 0.08mol / L, the filling degree of the hydrothermal kettle is 85%, the reaction temperature is 170°C, and the reaction time is 1 hour, the Si nanoporous array is prepared, and its scanning electron microscope picture is as follows figure 1 .

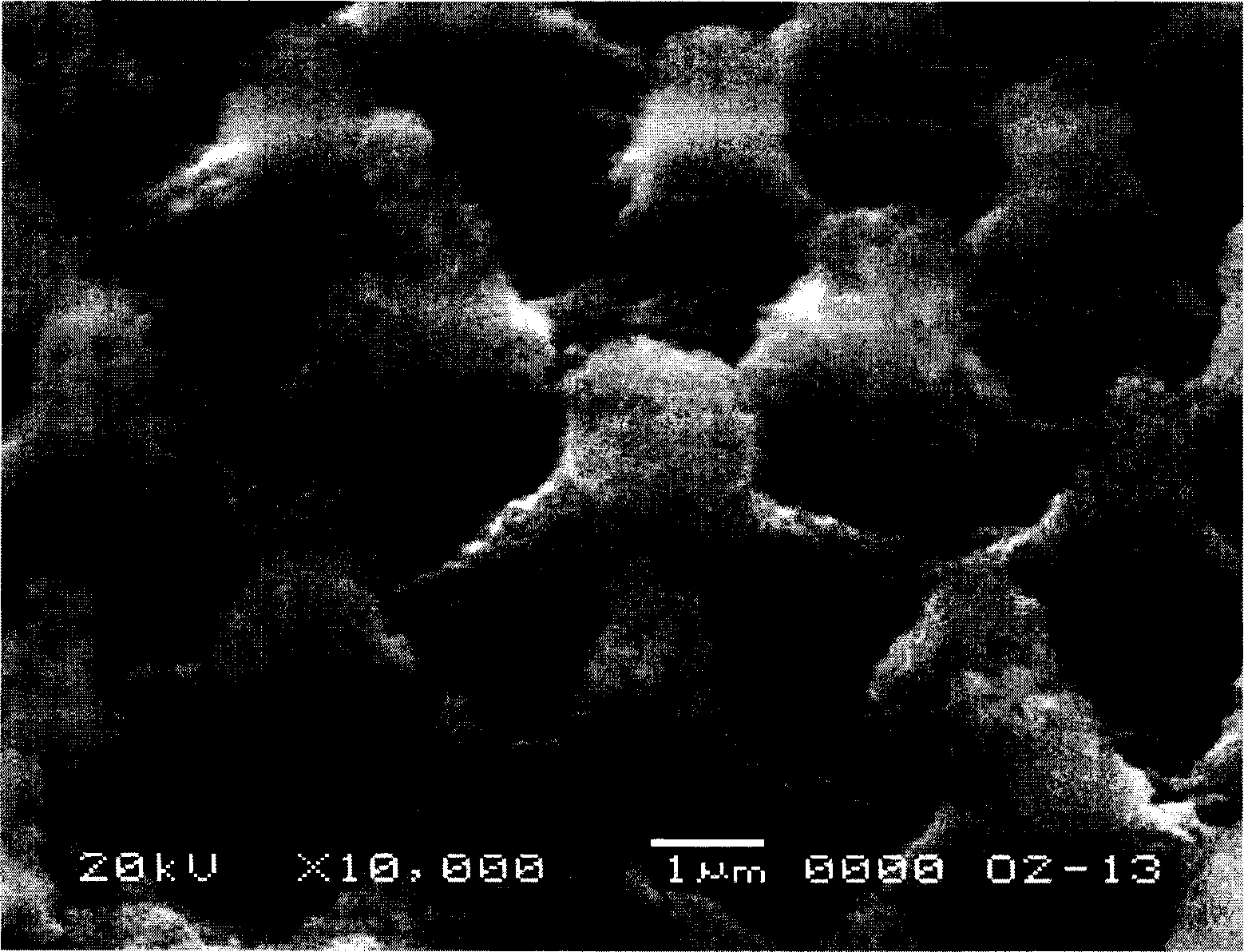

[0014] (2) Prepare the microemulsion in this ratio: TrintonX-100: n-hexanol: cyclohexane=1: 1: 1 (volume ratio), then add to the mixed solution (NH 4 ) 2 SO 4 ·FeSO 4 ·6H 2 O: in hydrazine hydrate=1:1 (molar ratio), react in hydrothermal reactor for 1 hour, temperature 120 ℃, naturally cool after reaction;

[0015] (3) Utilize the spin coater to control the rotation speed of 1000 rpm to wrap the Fe in the microemulsion 3 o 4 Nanoparticles are sprayed on silicon nanohole arrays;

[0016] (4) The annealing temperature is 200°C, the annealing time is 1 hour, and finally Fe 3 o 4 / Si-NPA nanocomposites. Made Fe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com