Nano toughening NdFeB magnetic material and preparation method thereof

A magnetic material, neodymium-iron-boron technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of large remanence reduction, easy pulverization and corrosion, low Curie temperature point, etc., to achieve remanence reduction Less, good machinability, avoid the effect of growing up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

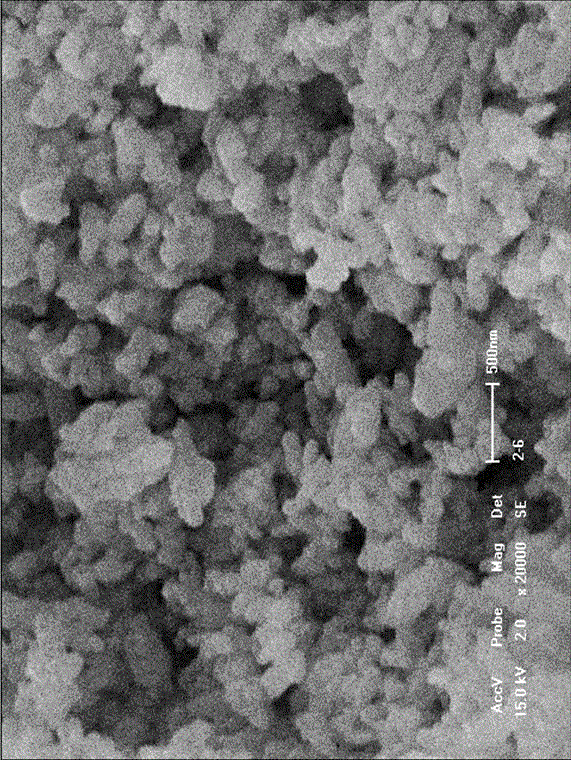

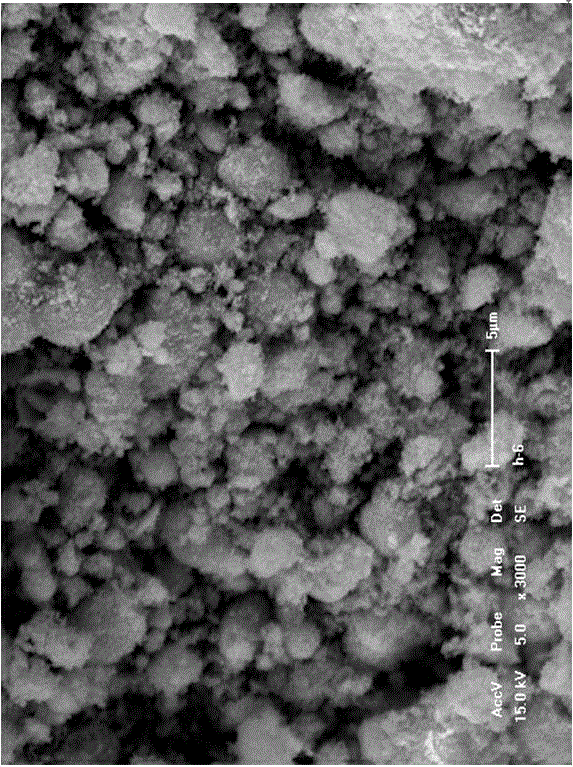

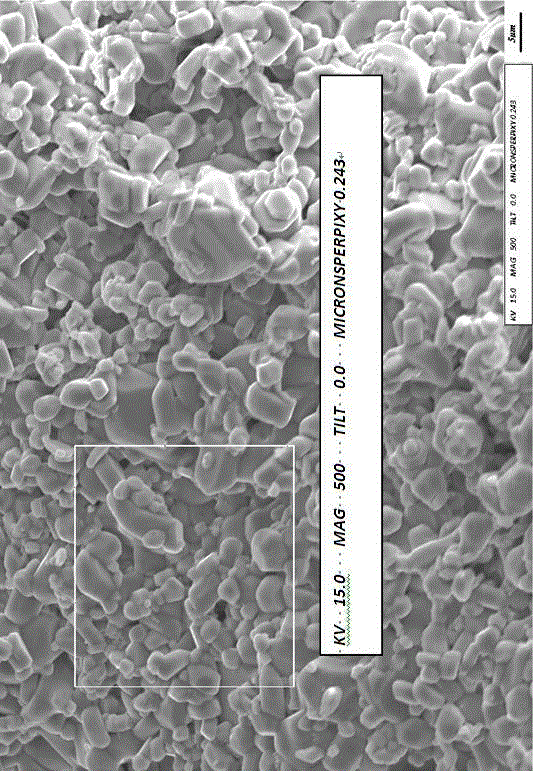

[0033] First use the arc method to process Al, Cu, Nb, Co, Ga, Mn, Ti, Zr, Ni, Mo into nano-materials with a particle size of 40-60nm; then Nd alloy 300.0kg, B 10.8kg, metal Fe 686.4 kg, Mn 0.1kg, Ti 0.1kg, Zr 0.1kg, Ni 0.1kg, Mo 0.1kg The main phase of NdFeB was prepared by SC-HD process, and the vacuum was 3.0×10 -1 Melted under Pa to form thin slices with a thickness of 0.25-0.35 mm, the thin slices absorb hydrogen at room temperature for 2.5 hours in the reaction kettle of the hydrogen crushing furnace, and then heat to 550-650 ° C for 6.5 hours to dehydrogenate, and prepare a particle size of 60-80 mesh Coarse particles for spare;

[0034] The above-mentioned coarse particles are ground by a QLM-400 jet mill under a working pressure of 0.8 MPa to a fine powder with an average particle size of 3.0-4.0 μm; then, in an argon protective atmosphere, compoundly add Al to the fine powder by the jet method 0.5kg, Cu 0.6kg, Nb 0.4kg, Co 0.4kg, Ga 0.4kg, and uniformly mixed in a m...

Embodiment 2

[0042] The difference from Example 1 is that the alloy flakes absorb hydrogen at room temperature for 2.5 hours in the reaction kettle of the hydrogen crushing furnace, heat and dehydrogenate for 6 hours; uniformly mix for 3 hours; the size of the green body is 60×60×60 mm, and other process routes are the same as in the example 1. Refer to Table 1 for the amount of raw materials input.

[0043] The material parameter relevant to this embodiment is similar to embodiment 1, omitted.

Embodiment 3

[0045] The difference from Example 1 is that the alloy flakes absorb hydrogen at room temperature for 3 hours in the reaction kettle of the hydrogen crushing furnace, heat and dehydrogenate for 7 hours; uniformly mix for 2 hours; the size of the green body is 70×70×70mm, and other process routes are the same as in the example 1. Refer to Table 1 for the amount of raw materials input.

[0046] The material parameter relevant to this embodiment is similar to embodiment 1, omitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com