a cotio 3 Preparation method of nano-array humidity-sensitive film

A moisture-sensitive film and nano-array technology is applied in the field of moisture-sensitive film preparation to achieve the effects of short production cycle, convenient operation and improved moisture sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

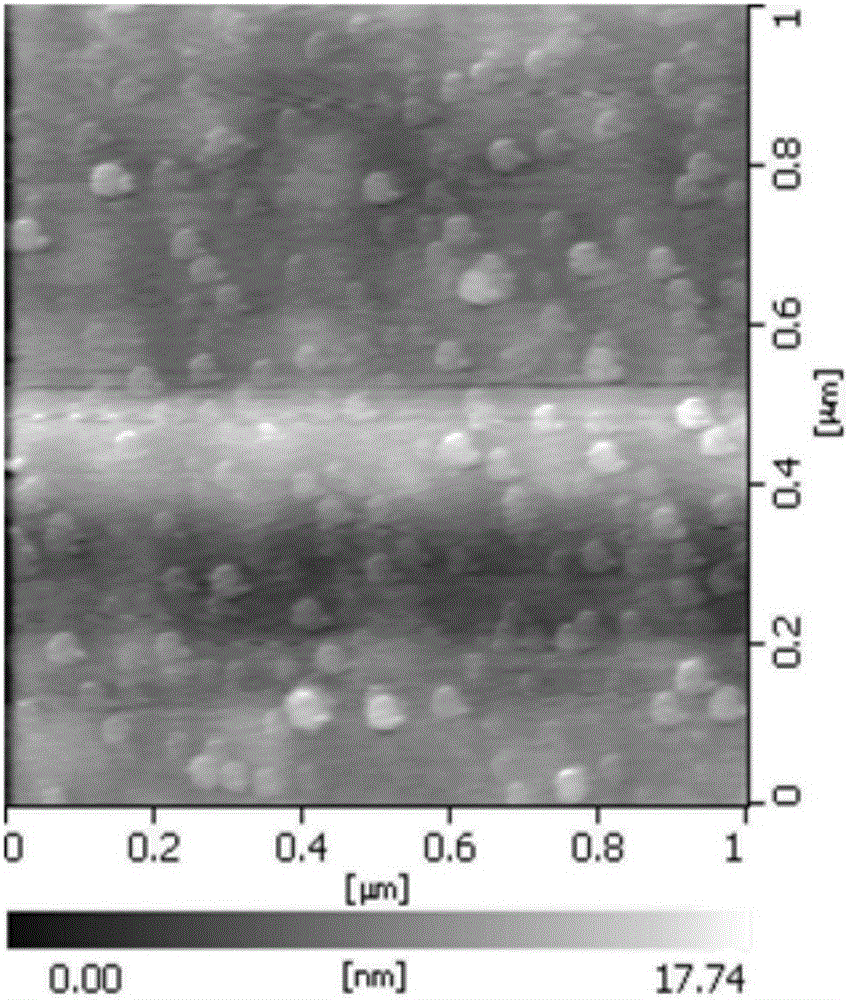

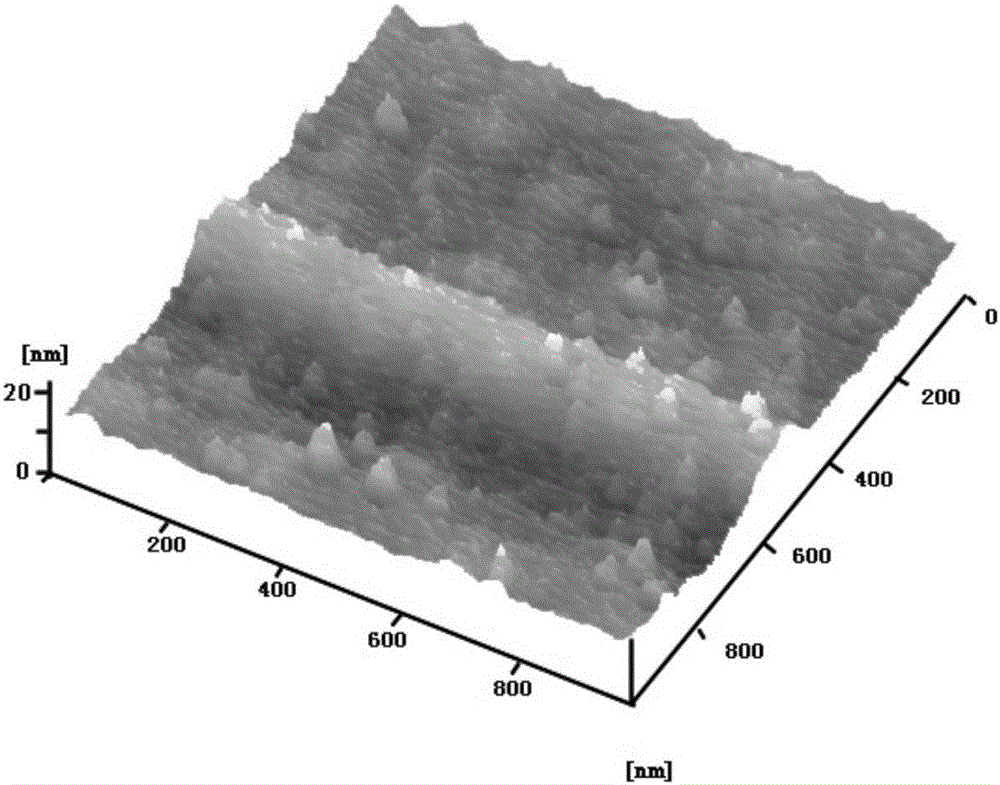

Image

Examples

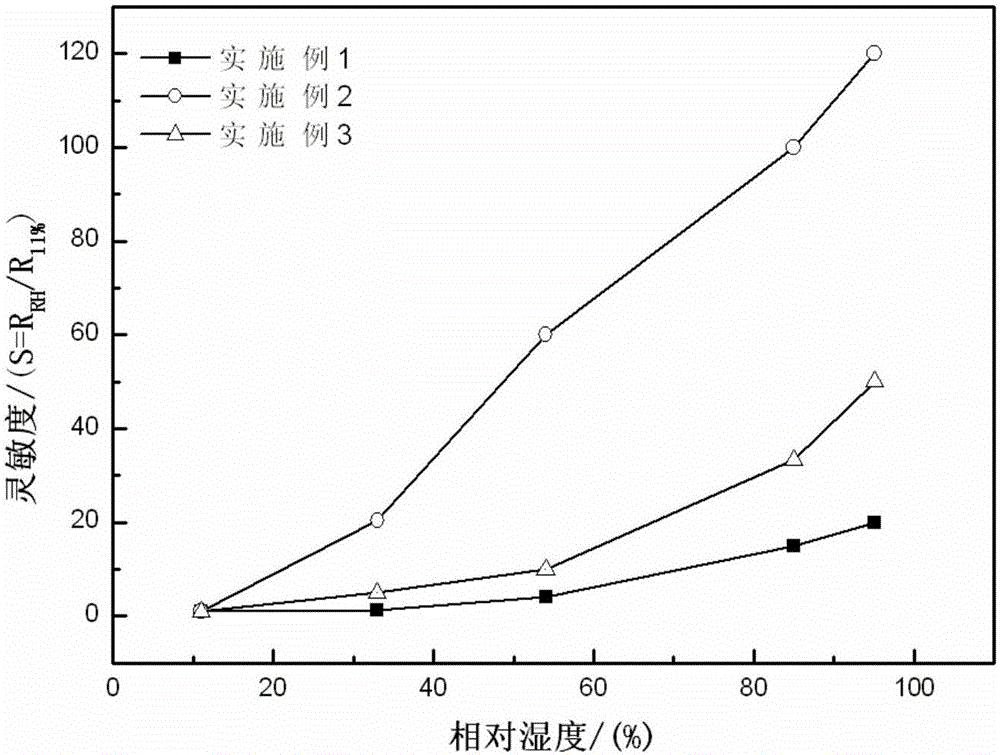

Embodiment 1

[0023] 1) Analytical pure cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) be fully dissolved in deionized water to obtain an aqueous solution of cobalt chloride, and then slowly adding TiCl with a mass concentration of 15% wherein 3 hydrochloric acid solution, magnetically stirred at room temperature to obtain a mixed solution A with a molar ratio of Co and Ti of 1:0.5; using analytically pure concentrated ammonia (NH 3 ·H 2 O) adjust the pH value of the mixed solution A to 6 to obtain a blue-purple precursor solution B;

[0024] 2) The silicon substrate was ultrasonically cleaned in analytically pure acetone and absolute ethanol for 15 minutes, and then rinsed three times with deionized water to obtain a cleaned silicon substrate;

[0025] 3) Move the precursor solution B into the hydrothermal reactor and control the filling ratio of the hydrothermal reactor at 50%, then immerse the cleaned silicon substrate in the precursor solution B, set the reaction temperature to 180°C, ...

Embodiment 2

[0030] 1) Analytical pure cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) be fully dissolved in deionized water to obtain an aqueous solution of cobalt chloride, and then slowly adding TiCl with a mass concentration of 15% wherein 3 hydrochloric acid solution, magnetically stirred at room temperature to obtain a mixed solution A with a molar ratio of Co and Ti of 1:1; using analytically pure concentrated ammonia (NH 3 ·H 2 O) adjust the pH value of the mixed solution A to 8 to obtain a blue-purple precursor solution B;

[0031]2) The silicon substrate was ultrasonically cleaned in analytically pure acetone and absolute ethanol for 15 minutes, and then rinsed three times with deionized water to obtain a cleaned silicon substrate;

[0032] 3) Move the precursor solution B into the hydrothermal reactor and control the filling ratio of the hydrothermal reactor at 65%, then immerse the cleaned silicon substrate in the precursor solution B, set the reaction temperature to 220°C, and...

Embodiment 3

[0038] 1) Analytical pure cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) be fully dissolved in deionized water to obtain an aqueous solution of cobalt chloride, and then slowly adding TiCl with a mass concentration of 15% wherein 3 hydrochloric acid solution, magnetically stirred at room temperature to obtain a mixed solution A with a Co and Ti molar ratio of 1:2; using analytically pure concentrated ammonia (NH 3 ·H 2 O) adjust the pH value of the mixed solution A to 10 to obtain a blue-purple precursor solution B;

[0039] 2) The silicon substrate was ultrasonically cleaned in analytically pure acetone and absolute ethanol for 15 minutes, and then rinsed three times with deionized water to obtain a cleaned silicon substrate;

[0040] 3) Move the precursor solution B into the hydrothermal reactor and control the filling ratio of the hydrothermal reactor at 65%, then immerse the cleaned silicon substrate in the precursor solution B, set the reaction temperature to 240°C, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com