A kind of preparation method of moisture sensitive sensing film

A technology of sensing film and moisture sensitivity, applied in the field of preparation of moisture-sensitive sensing film, can solve the problems of poor humidity sensitivity, easy detachment of the moisture-sensitive film, and insufficient environmental protection materials, so as to improve the humidity sensitivity, The effect of low substitution degree and easy film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of embodiment 1 water-soluble cellulose acetate

[0026] Take 1.8mL of valeryl chloride and slowly add it dropwise to 30g of ionic liquid 1-ethyl-3-methylimidazolium acetate, take 1.00g of cotton linter cellulose and infiltrate it into the above solvent system. Magnetic stirring was carried out to obtain a transparent, viscous and completely dissolved cellulose solution, and under the condition of continuous magnetic stirring, the reaction was kept at 70°C for 12 hours. After the reaction, the system was poured into 200ml of ethanol to terminate the reaction, and then repeatedly washed with a large amount of ethanol and filtered until the ionic liquid and unreacted reagents were cleaned to obtain a pure cellulose product, which was verified to be soluble in water.

Embodiment 2

[0035] The preparation method of embodiment 2 moisture-sensitive sensing film

[0036] S 1 1. Take 1.8mL of valeryl chloride and slowly add it dropwise to 30g of ionic liquid 1-ethyl-3-methylimidazole acetate, take 1.00g of linter cellulose and infiltrate it into the above solvent system. Under magnetic stirring, a transparent, viscous, and completely dissolved cellulose solution was obtained. Under the condition of continuous magnetic stirring, the reaction was maintained at 70° C. for 12 hours. After the reaction, pour the system into 200ml of ethanol to terminate the reaction, then repeatedly wash and filter with a large amount of ethanol until the ionic liquid and unreacted reagents are cleaned to obtain a pure cellulose acetate product;

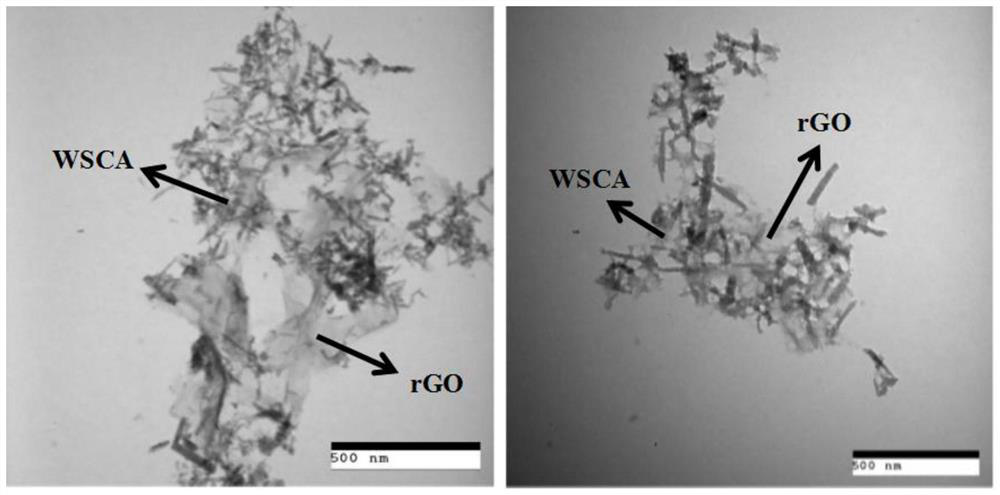

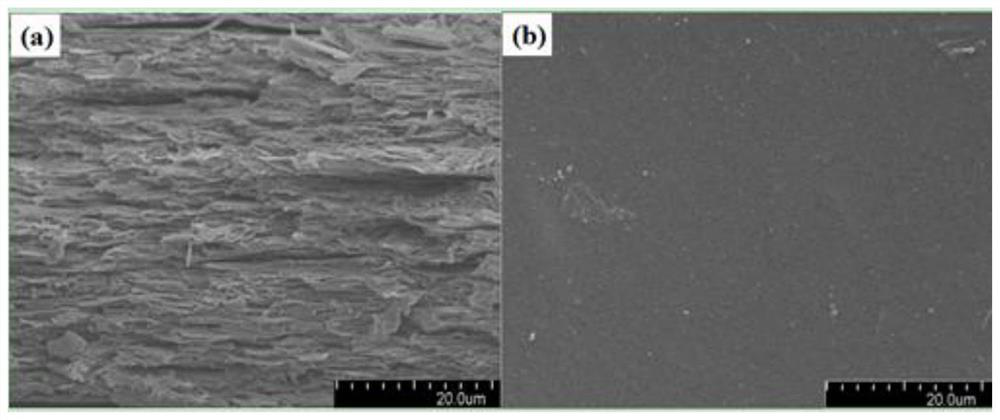

[0037] S 2 1. Take a certain mass of WSCA to prepare 10mL of a 1% aqueous solution, weigh 0.0025g of rGO to prepare a 0.25mg / mL aqueous solution, add the graphene aqueous solution to the prepared WSCA solution, and perform ultrasonic t...

Embodiment 3

[0045] The preparation method of embodiment 3 moisture-sensitive sensing film

[0046] S 1 1. Take 1.5mL of valeryl chloride and slowly add it dropwise to 30g of ionic liquid 1-ethyl-3-methylimidazolium acetate, take 0.6g of woody cellulose and intrude into the above solvent system, under the condition of 63℃ oil bath Magnetic stirring was carried out to obtain a transparent, viscous, and completely dissolved cellulose solution. Under the condition of continuous magnetic stirring, the reaction temperature was maintained for 9 hours. After the reaction, pour the system into 200ml of ethanol to terminate the reaction, then repeatedly wash and filter with a large amount of ethanol until the ionic liquid and unreacted reagents are cleaned to obtain a pure cellulose acetate product;

[0047] S 2 1. Take a certain mass of WSCA to prepare 20mL of a 0.5% aqueous solution, weigh 0.0005g of rGO to prepare a 0.25mg / mL aqueous solution, add the graphene aqueous solution to the prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com