Humidity sensor film based on microregion redissolution reaction and preparation method thereof

A humidity sensor and redissolving technology, applied in the field of composite materials and humidity sensors, can solve the problems of the process method to reduce the sensor's hysteresis performance, the composite material cannot be fully dispersed, and the hysteresis performance is low, so as to improve the humidity sensitivity performance, fast Effective adjustment and improvement, easy access to materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A method for preparing a humidity sensor thin film based on a micro-region redissolution reaction, comprising the following steps:

[0041] ① Carry out standard cleaning procedures on the substrate used for film formation;

[0042] ② Preparing a thin film of the leading layer on the surface of the cleaned substrate;

[0043] ③Drying the film of the leading layer;

[0044] ④Prepare the backward layer film on the leading layer film: Drop the solution B onto the leading layer film with micron level droplets, the solute in the solution B will react chemically or ionicly with the leading layer film, after the solvent in the solution B volatilizes Finally, the backward layer film is formed.

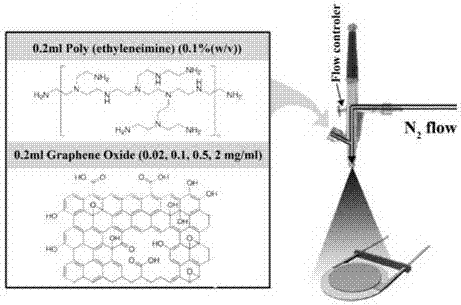

[0045] When preparing the leading layer film, solution A is added to the gas atomization spray gun or other atomization equipment, and the solution flow is generated inside the spray gun by gas atomization, so that the solution A is transformed from the original flow state into a micro...

Embodiment 1

[0052] This embodiment adopts as figure 1 The standard air-jet method is shown to prepare graphene oxide / polyethyleneimine moisture-sensitive films. Through the air-jet airbrush, the solution A and solution B added to the airbrush spray chamber are brought out by the bearing effect of the nitrogen gas flow, and are atomized in the airbrush nozzle by using the air pressure, spray the airbrush, and in the air flow And under the action of gravity, it is deposited on the surface of the device to complete the preparation of the humidity sensitive film.

[0053] In this case, a quartz crystal microbalance (QCM) device was chosen as the substrate for thin film preparation.

[0054] In this case, the moisture-sensitive materials and concentrations used are: solution A: a polyethyleneimine solution with a concentration of 0.1% (w / v) obtained by adding ultrapure water with a resistance of 15.0MΩ; solution B: a concentration of 0.1mg / ml graphene oxide solution prepared by Hummer method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com