A core-shell structure n-titanium dioxide@p-cobalt titanate nanocrystalline film and its preparation method

A titanium dioxide, core-shell structure technology, applied in metal material coating process, vacuum evaporation coating, coating and other directions, to achieve the effect of firm bonding, improving sensitivity, and improving gas sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

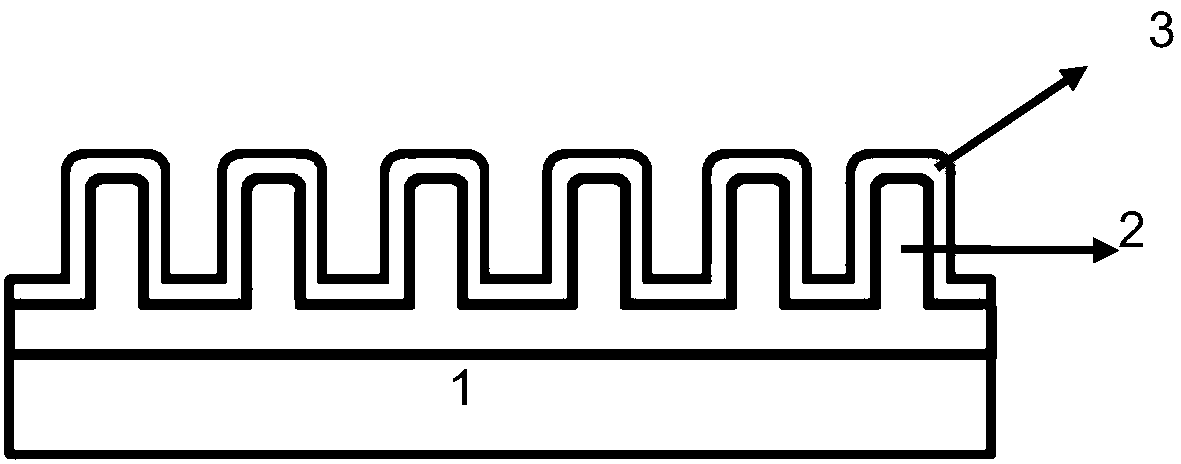

[0026] The preparation method of the present invention comprises the following steps:

[0027] (1) Install the cleaned substrate on the sample stage of the magnetron sputtering instrument, CoTiO 3 Target and TiO 2 The targets are respectively installed on two different RF target positions of the magnetron sputtering apparatus.

[0028] (2) Regulation of CoTiO 3 The angle between the normal direction of target sputtering and the substrate normal is 0°~90°, and then adjust the CoTiO 3 The distance between the target and the substrate is between 1cm and 7cm.

[0029] (3) Vacuumize to make the vacuum degree of the sputtering coating chamber reach 1.0×10 -4 Pa~9.9×10 -4 Pa, and then inject Ar gas, so that the working pressure of Ar gas in the sputtering coating chamber is 0.1Pa ~ 2Pa, CoTiO 3 The pre-sputtering of the target takes 5-15 minutes, preferably 10 minutes, and the target power is 100W-400W.

[0030] (4) Set the substrate heating program, the temperature rise rate ...

Embodiment 1

[0035] (1) Install the cleaned substrate on the sample stage, CoTiO 3 Target and TiO 2 The targets are respectively installed on two different RF target positions of the magnetron sputtering apparatus.

[0036] (2) Regulation of CoTiO 3 The angle between the normal direction of target sputtering and the substrate normal is 80°, and the CoTiO 3 The distance between target and substrate is 5cm.

[0037] (3) Vacuumize to make the vacuum degree of the sputtering coating chamber reach 1.0×10 -4 Pa, the working pressure of Ar gas in the sputtering coating chamber is 0.2Pa, CoTiO 3 The target is pre-sputtered for 10 minutes, and the target power supply is 400W.

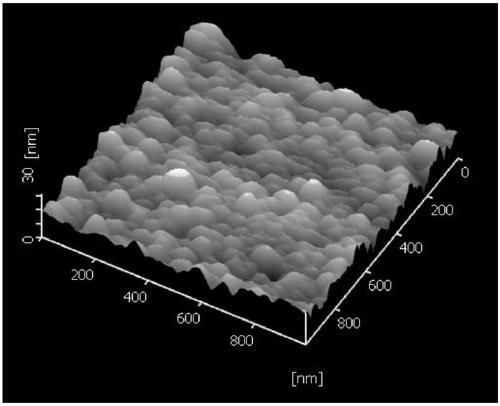

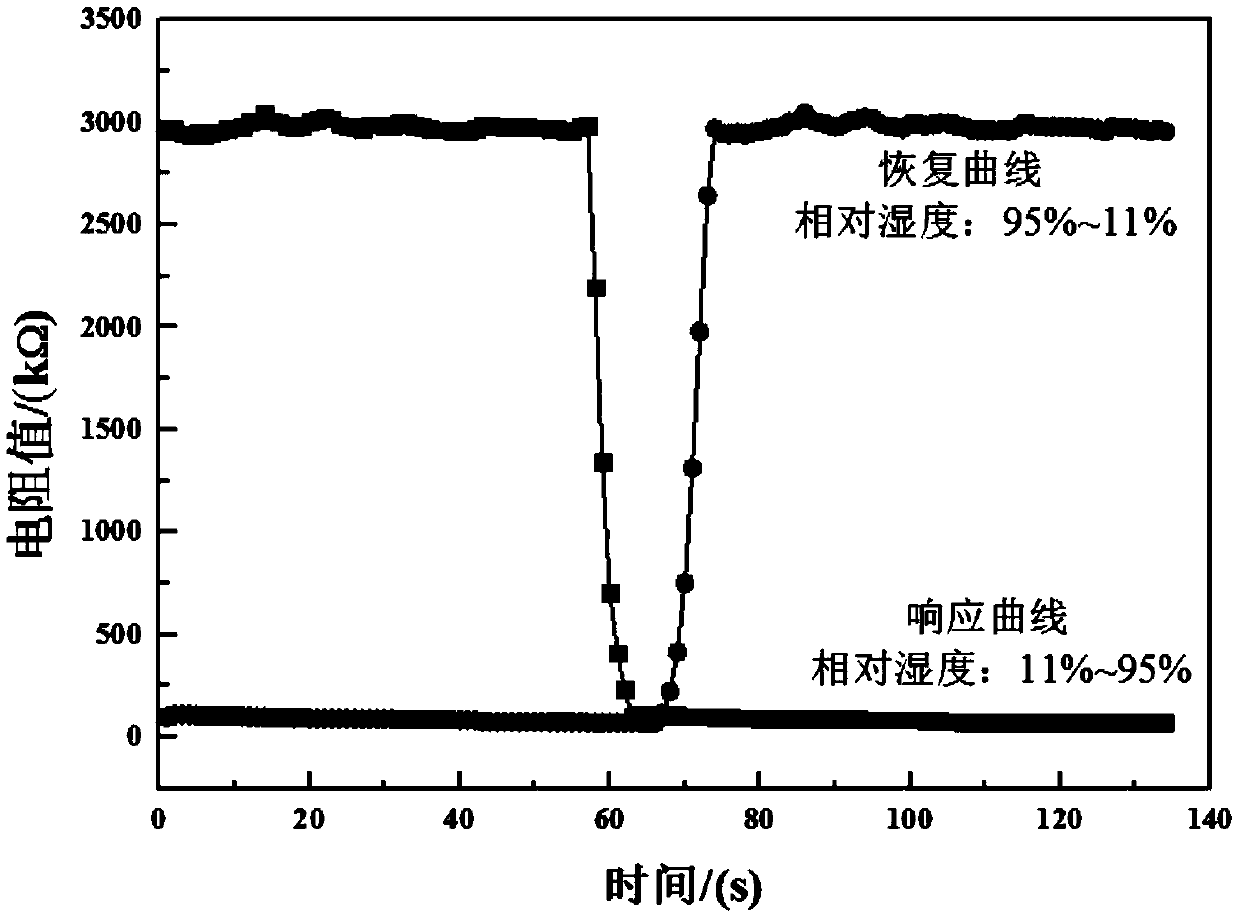

[0038] (4) Set the substrate heating program, the heating rate is 10°C / min, the temperature is raised to 400°C and kept warm. Then CoTiO 3 The target starts sputtering, the target power is 400W, the sputtering time is 90min, and CoTiO 3 Ordered nanocrystalline films after switching off CoTiO 3 target power.

[0039...

Embodiment 2

[0044] (1) Install the cleaned substrate on the sample stage, CoTiO 3 Target and TiO 2 The targets are respectively installed on two different RF target positions of the magnetron sputtering apparatus.

[0045] (2) Regulation of CoTiO 3 The angle between the normal direction of target sputtering and the substrate normal is 50°, and the CoTiO 3 The distance between the target and the substrate is 1 cm.

[0046] (3) Vacuumize to make the vacuum degree of the sputtering coating chamber reach 1.0×10 -4 Pa, the working pressure of Ar gas in the sputtering coating chamber is 0.5Pa, CoTiO 3 The target is pre-sputtered for 10 minutes, and the target power supply is 300W.

[0047] (4) Set the substrate heating program, the heating rate is 20°C / min, the temperature is raised to 400°C and kept warm. Then CoTiO 3 The target starts sputtering, the target power is 300W, the sputtering time is 90min, and CoTiO 3 Ordered nanocrystalline films after switching off CoTiO 3 target power....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com