Patents

Literature

186 results about "Nanocrystalline thin films" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical synthesis of monodisperse and magnetic alloy nanocrystal containing thin films

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

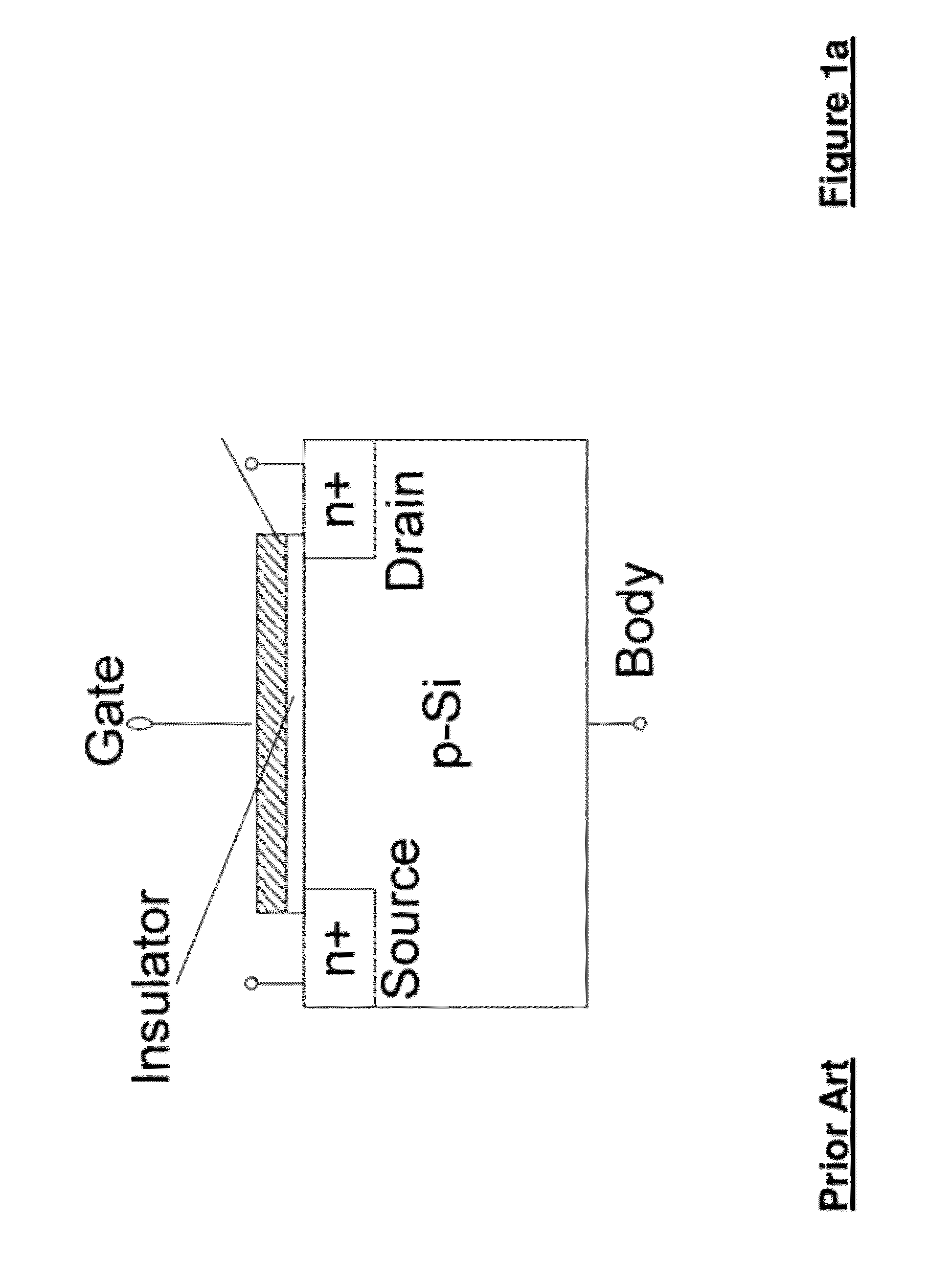

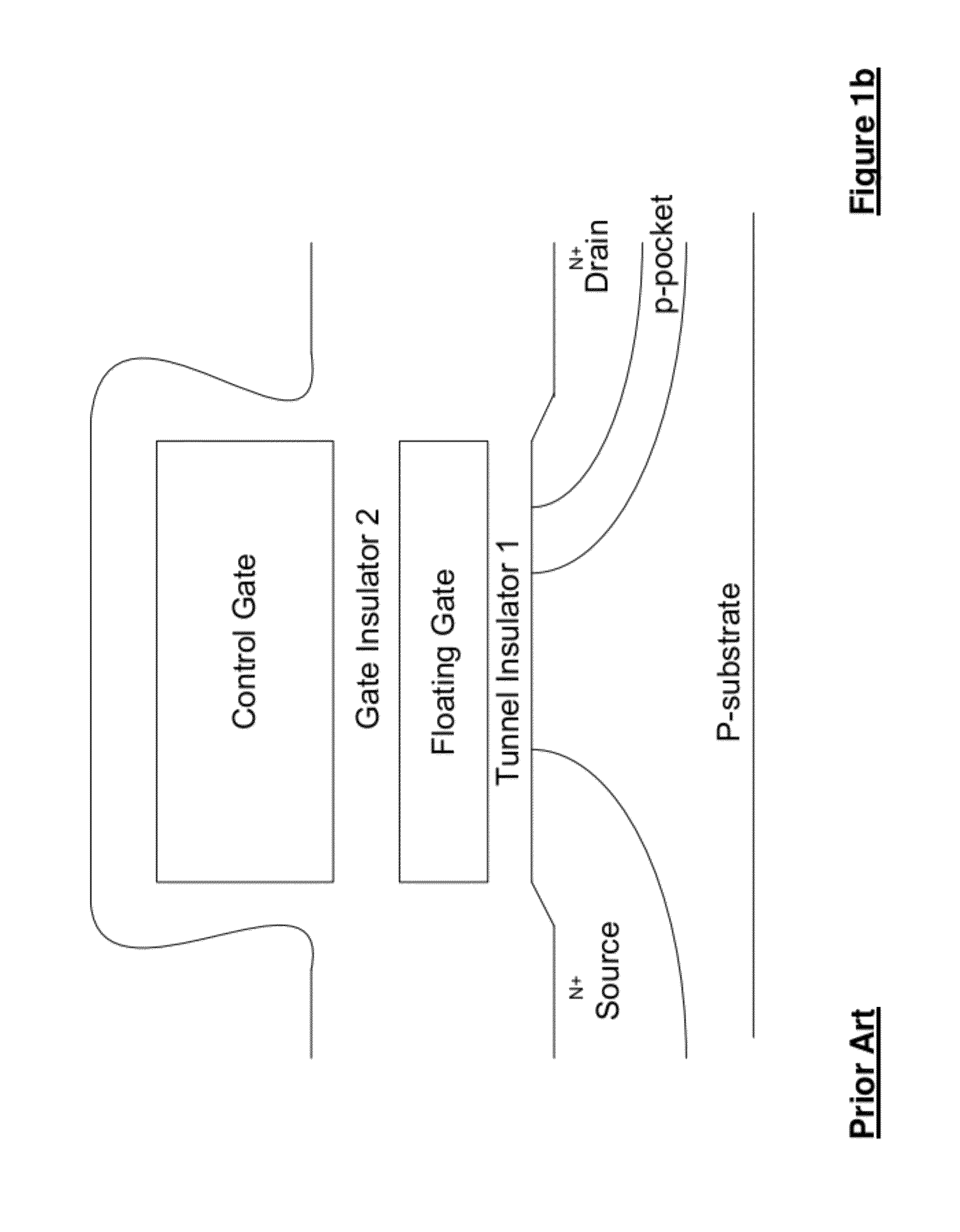

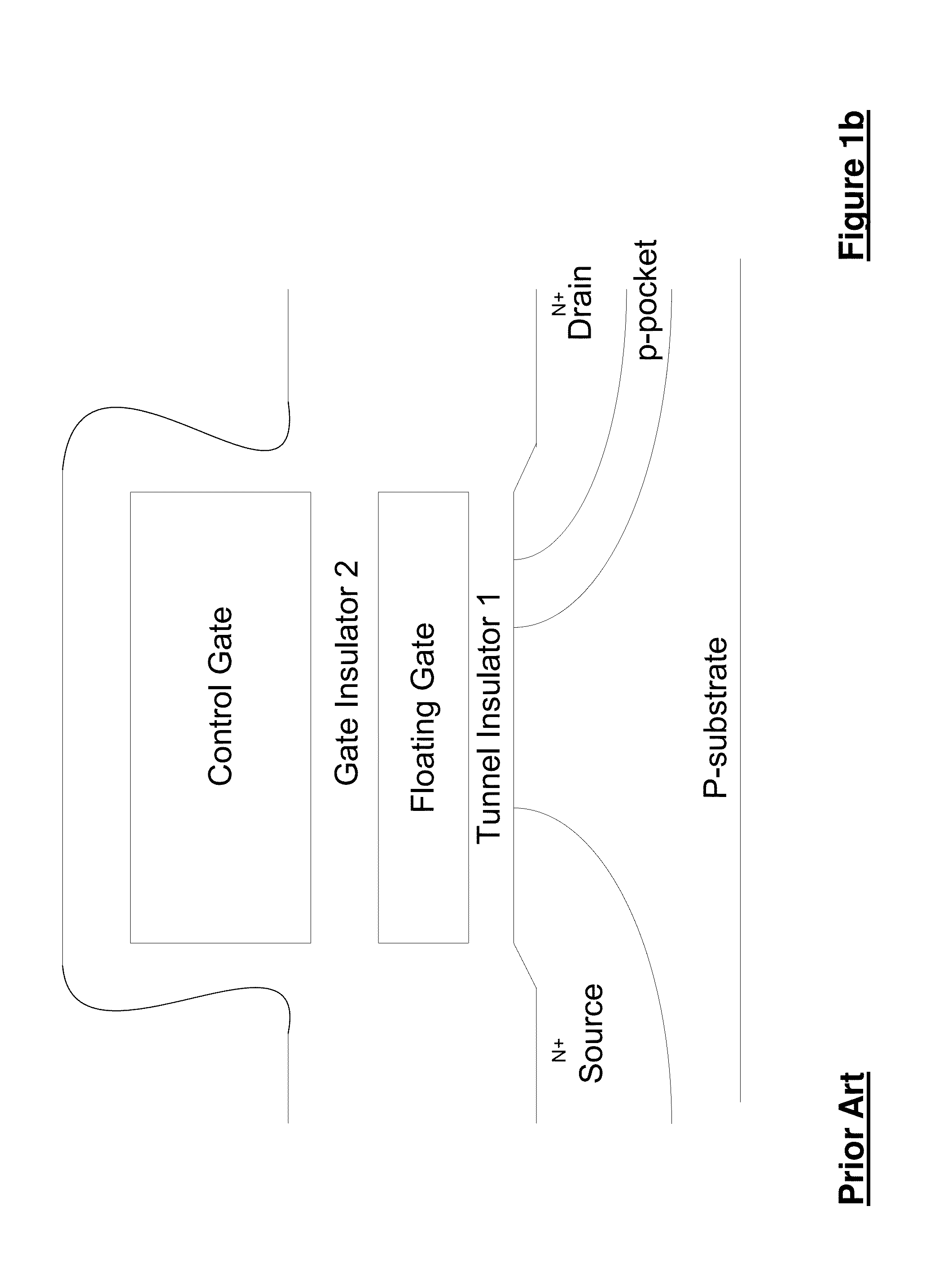

Quantum dot channel (QDC) quantum dot gate transistors, memories and other devices

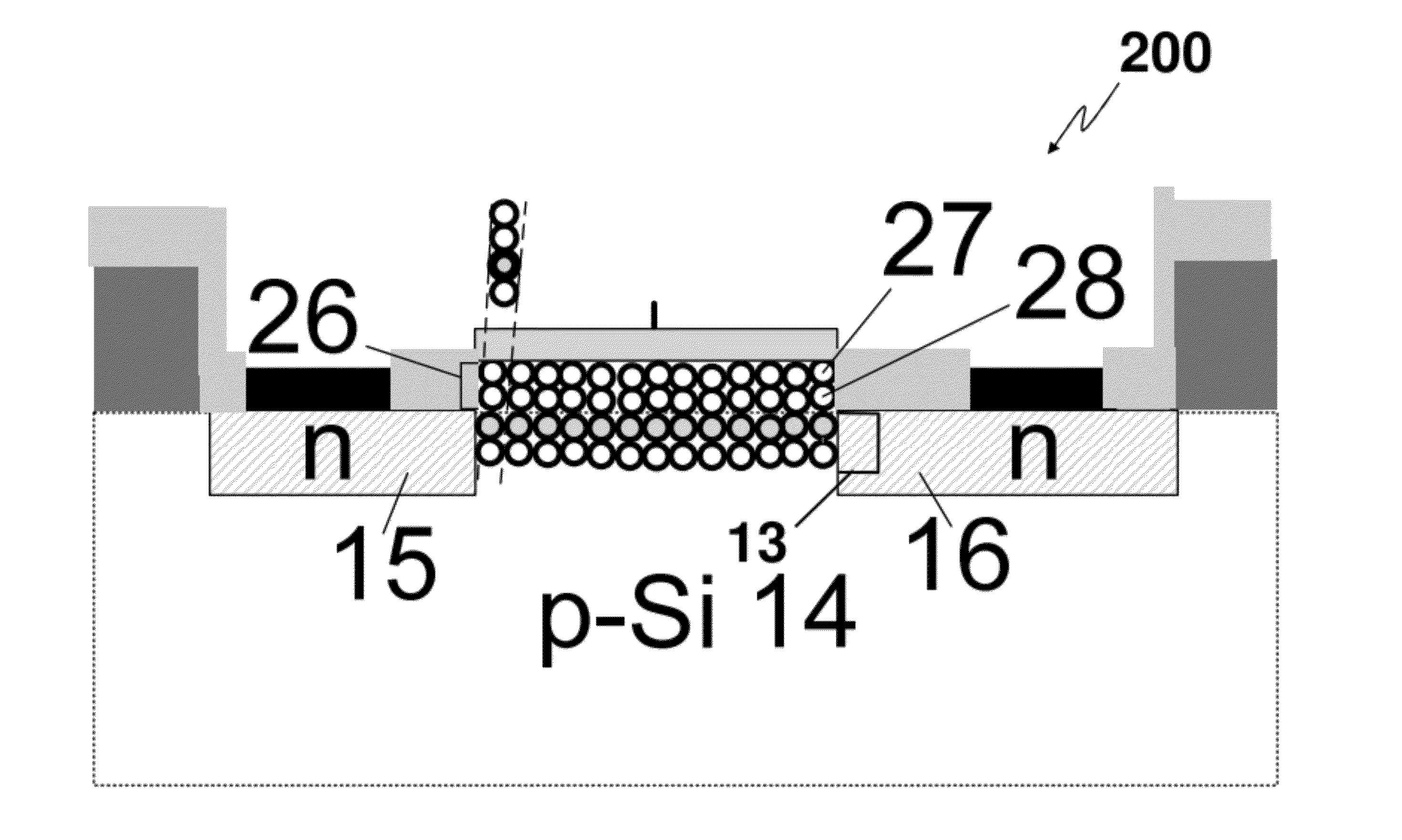

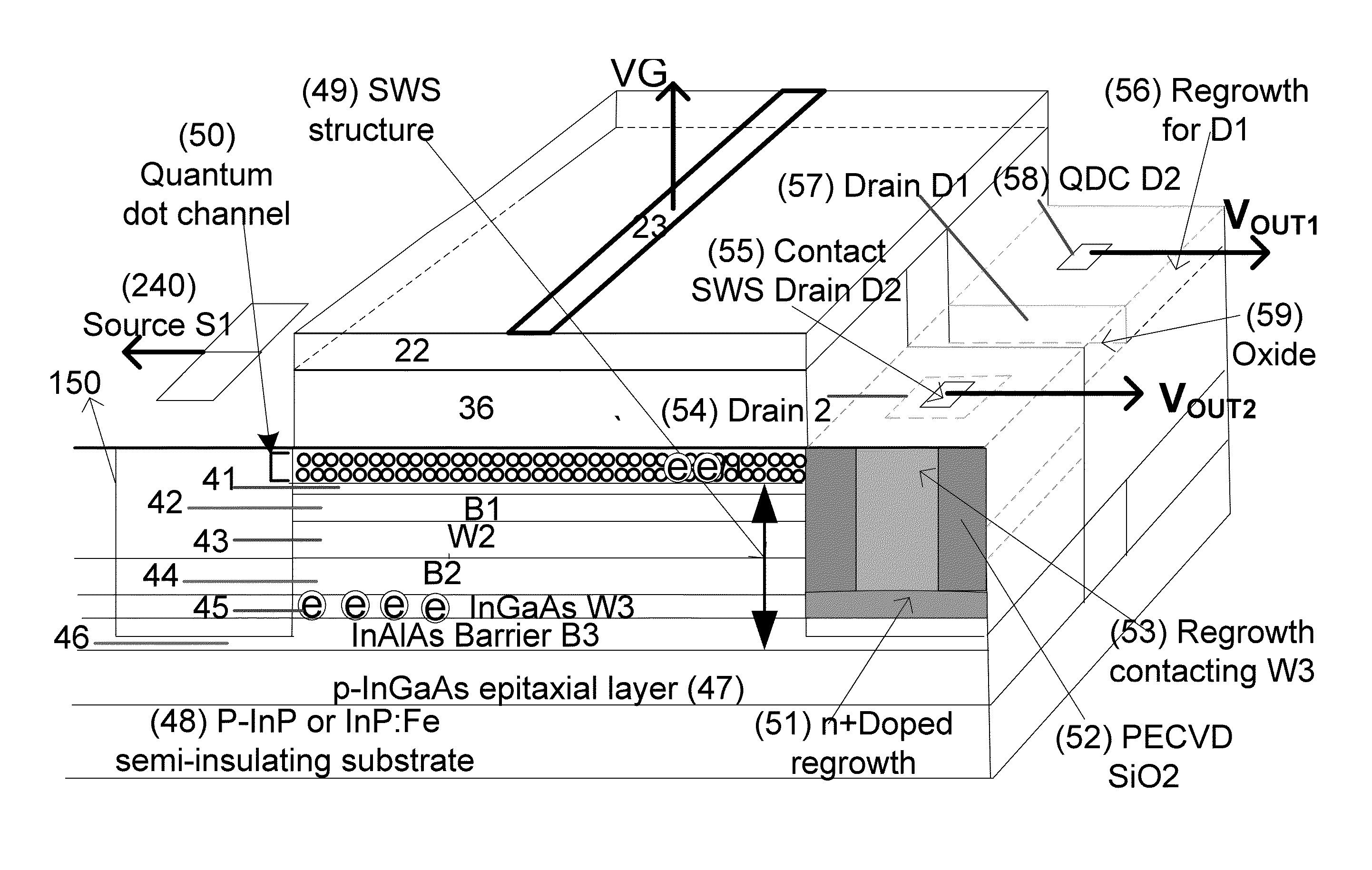

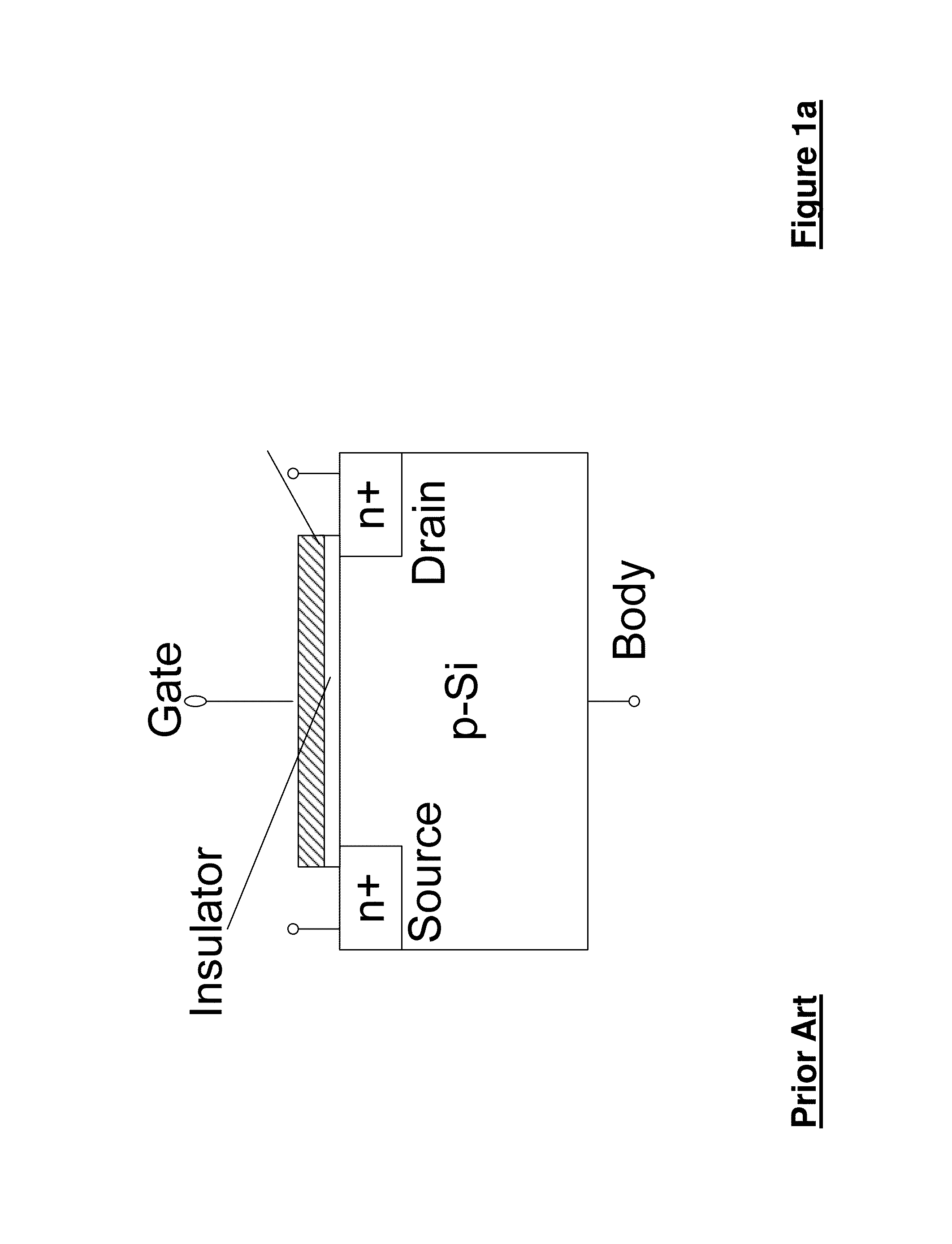

This invention describes a field-effect transistor in which the channel is formed in an array of quantum dots. In one embodiment the quantum dots are cladded with a thin layer serving as an energy barrier. The quantum dot channel (QDC) may consist of one or more layers of cladded dots. These dots are realized on a single or polycrystalline substrate. When QDC FETs are realized on polycrystalline or nanocrystalline thin films they may yield higher mobility than in conventional nano- or microcrystalline thin films. These FETs can be used as thin film transistors (TFTs) in a variety of applications. In another embodiment QDC-FETs are combined with: (a) coupled quantum well SWS channels, (b) quantum dot gate 3-state like FETs, and (c) quantum dot gate nonvolatile memories.

Owner:JAIN FAQUIR CHAND

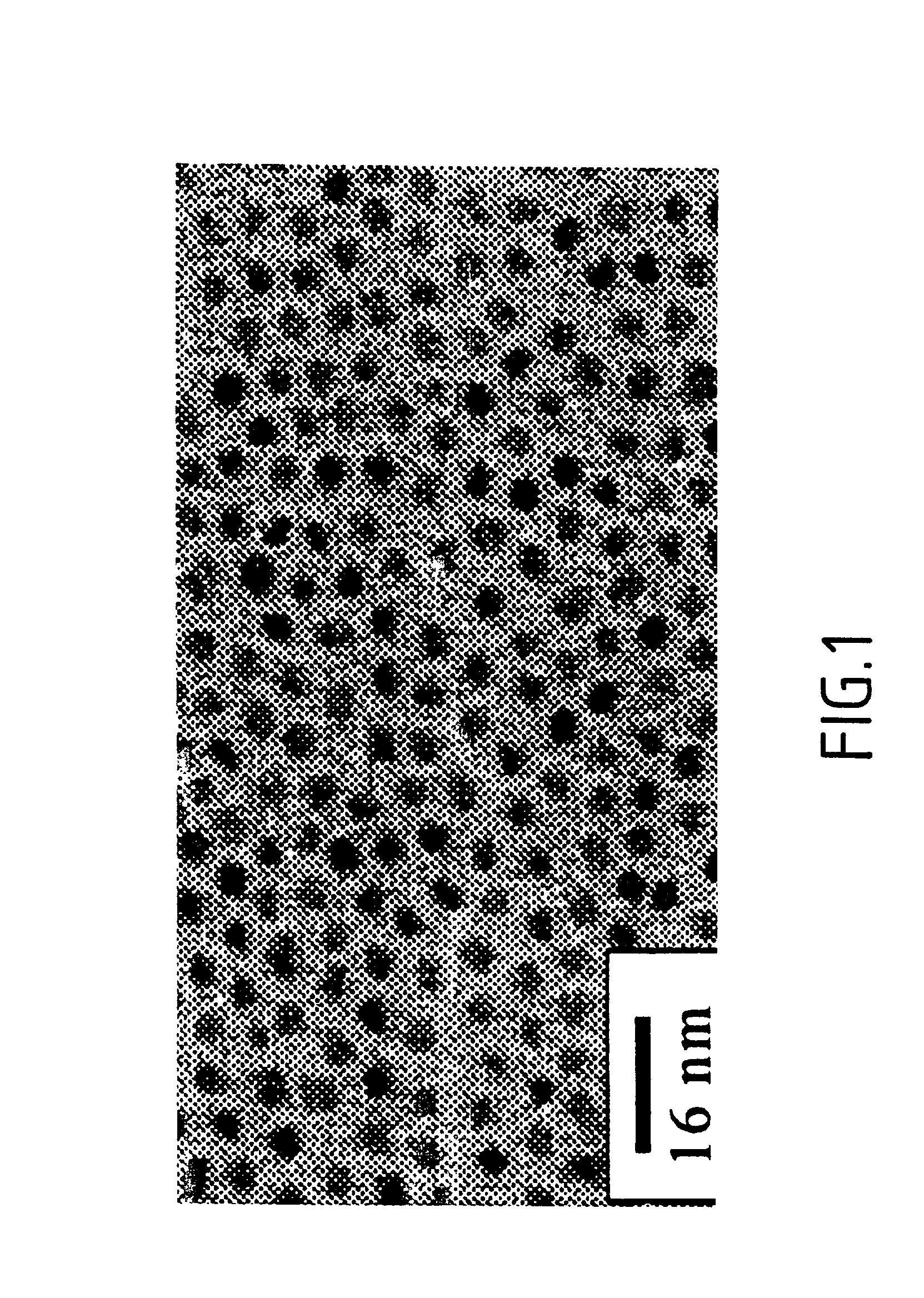

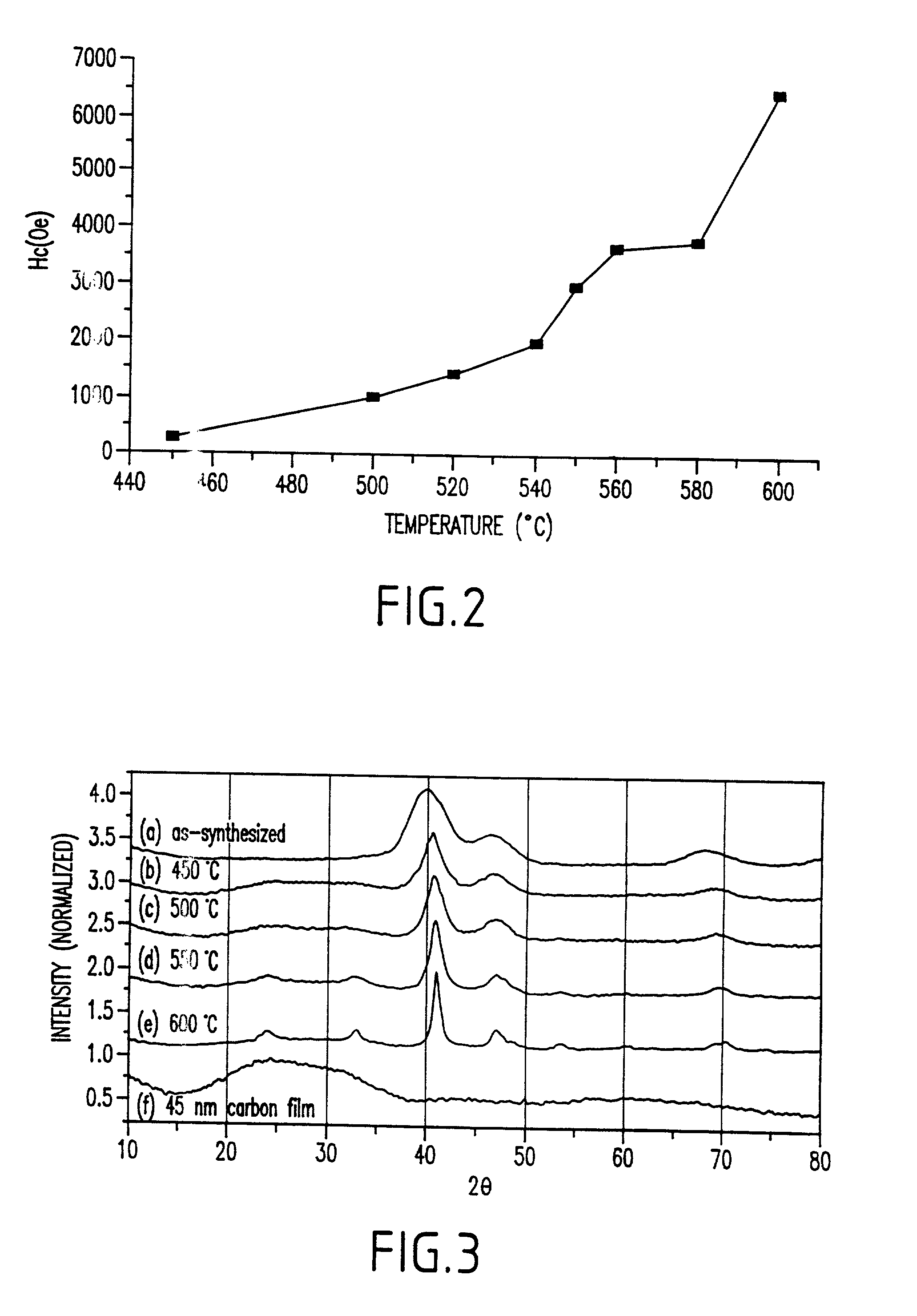

Chemical synthesis of monodisperse and magnetic alloy nanocrystal containing thin films

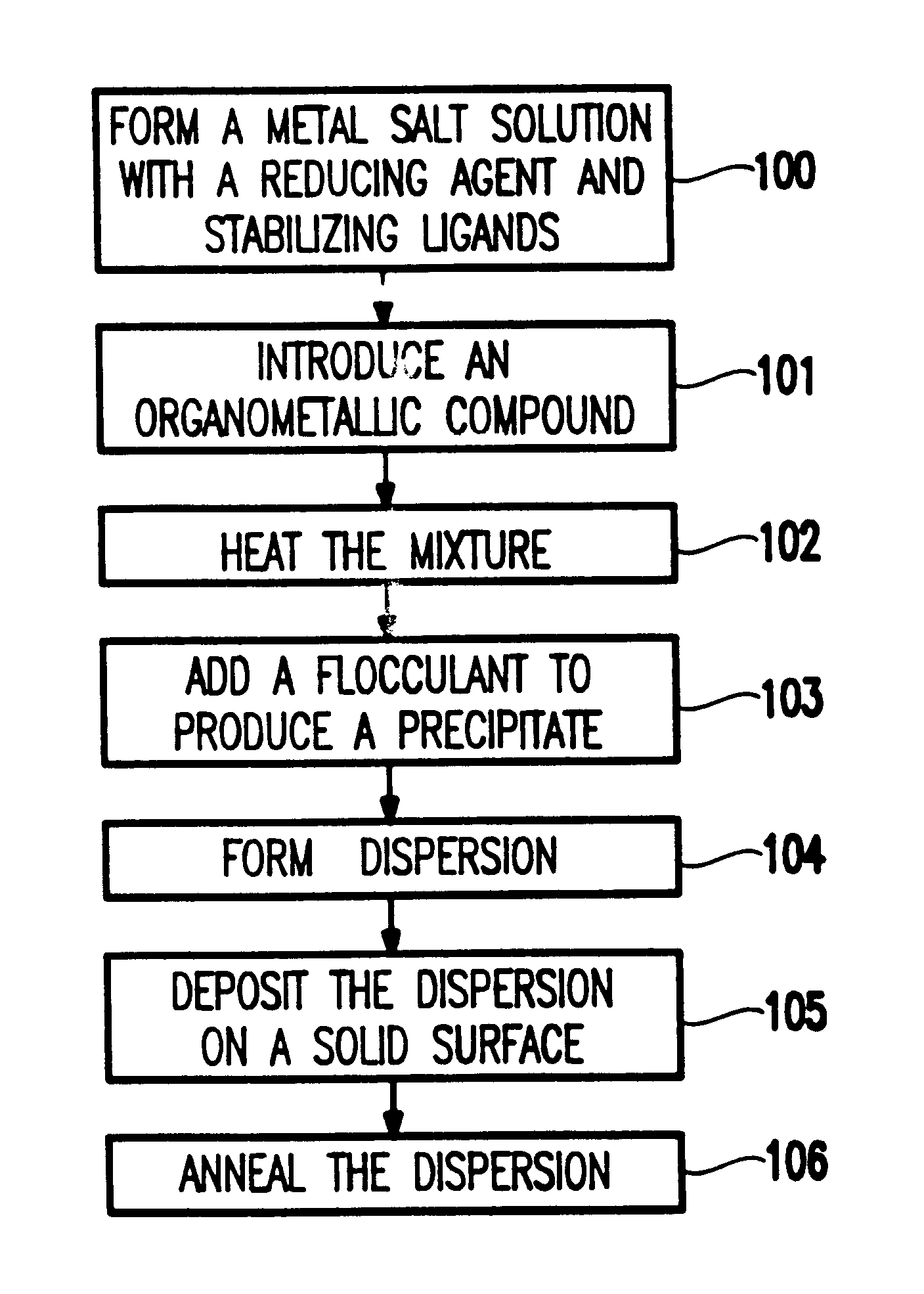

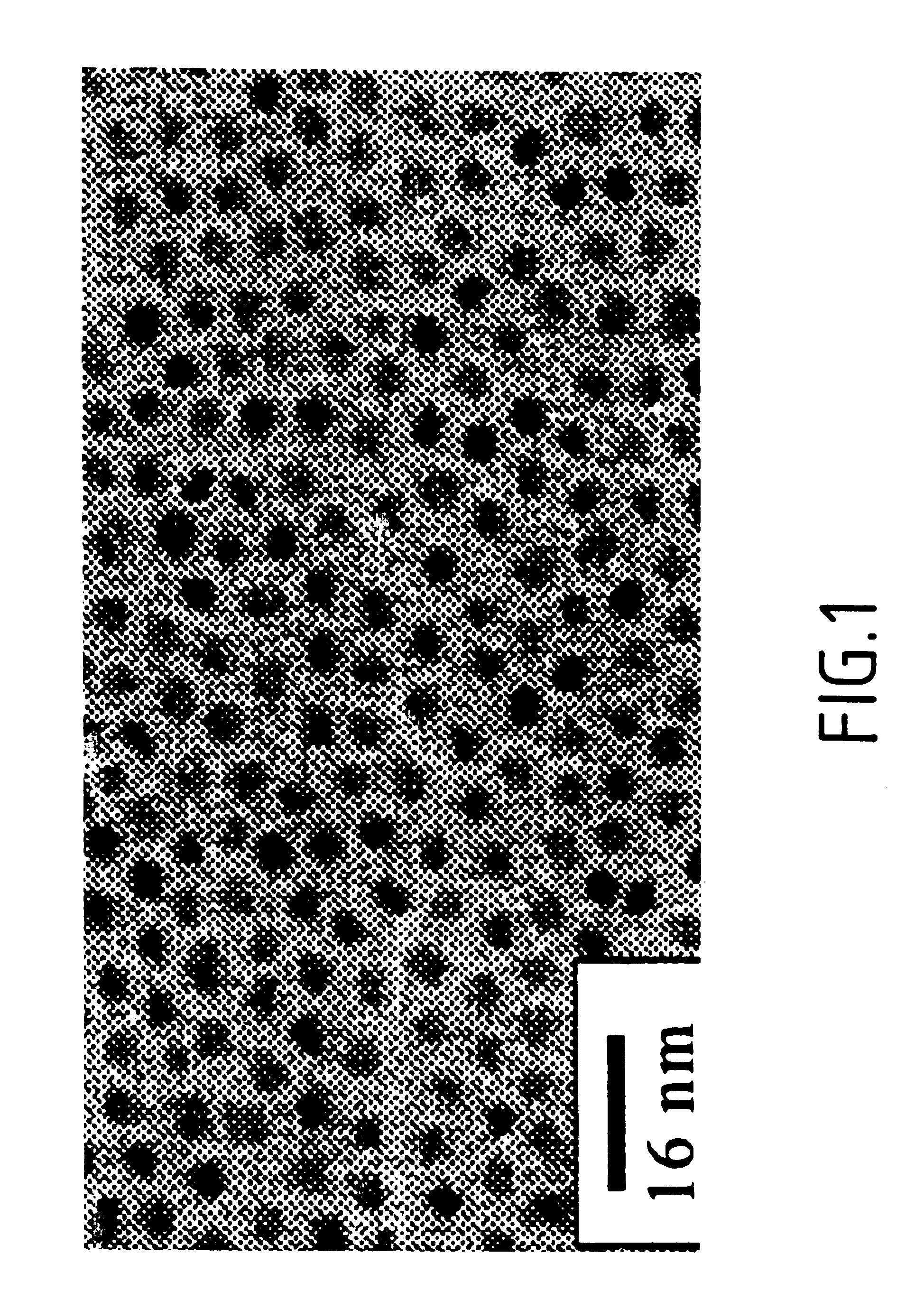

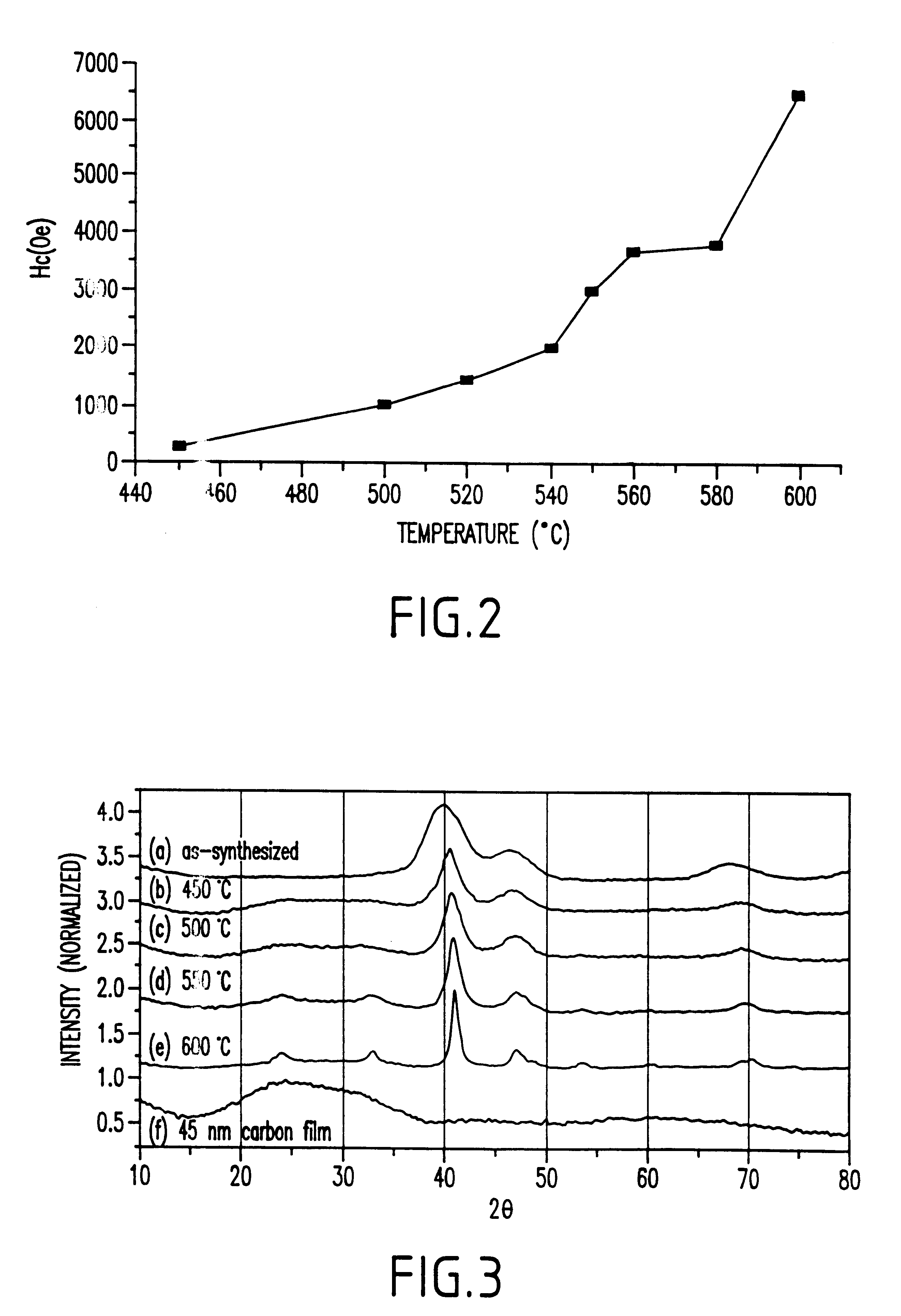

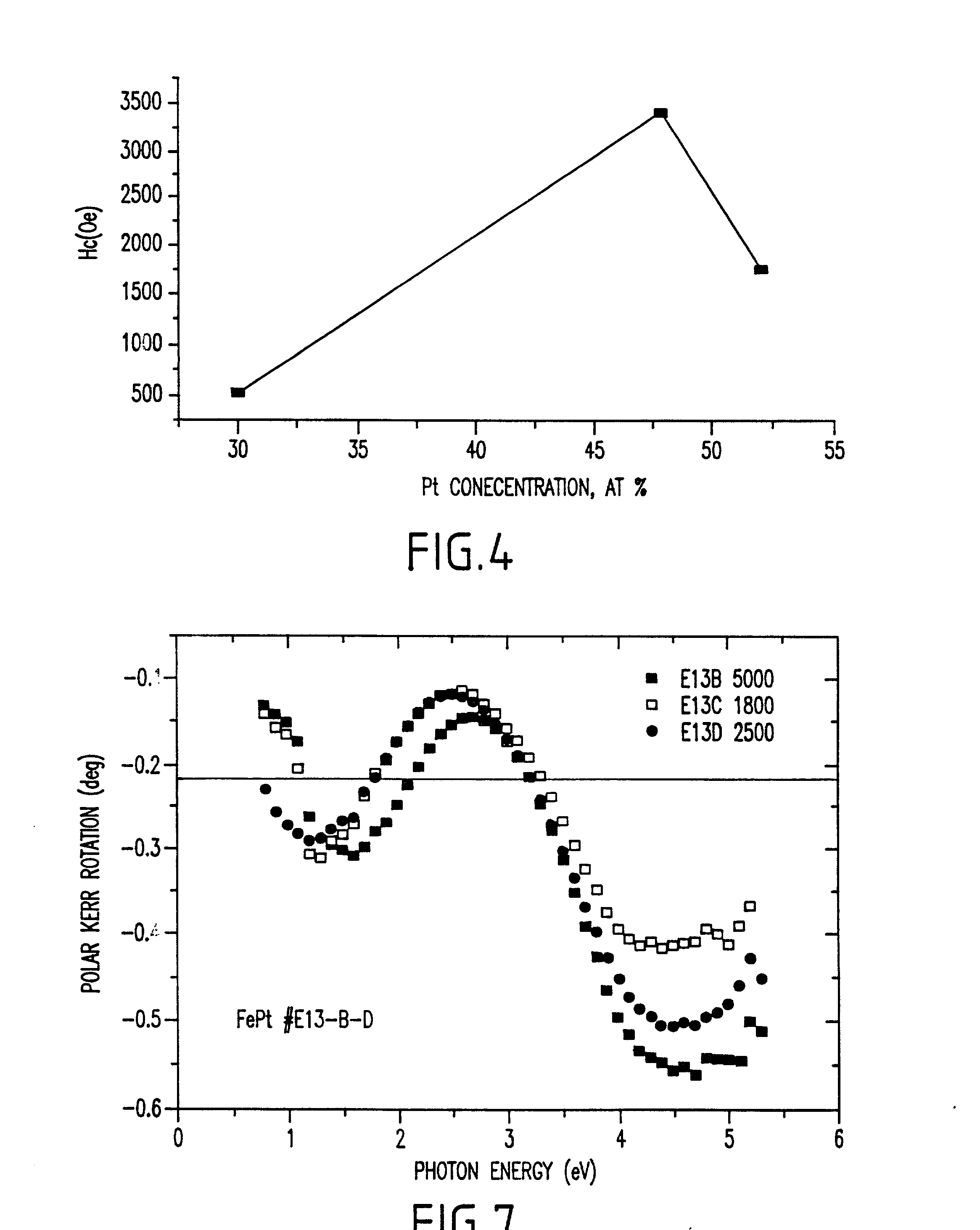

A method and structure for forming magnetic alloy nanoparticles includes forming a metal salt solution with a reducing agent and stabilizing ligands, introducing an organometallic compound into the metal salt solution to form a mixture, heating the mixture to a temperature between 260° and 300° C., and adding a flocculent to cause the magnetic alloy nanoparticles to precipitate out of the mixture without permanent agglomeration. The deposition of the alkane dispersion of FePt alloy particles, followed by the annealing results in the formation of a shiny FePt nanocrystalline thin film with coercivity ranging from 500 Oe to 6500 Oe.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

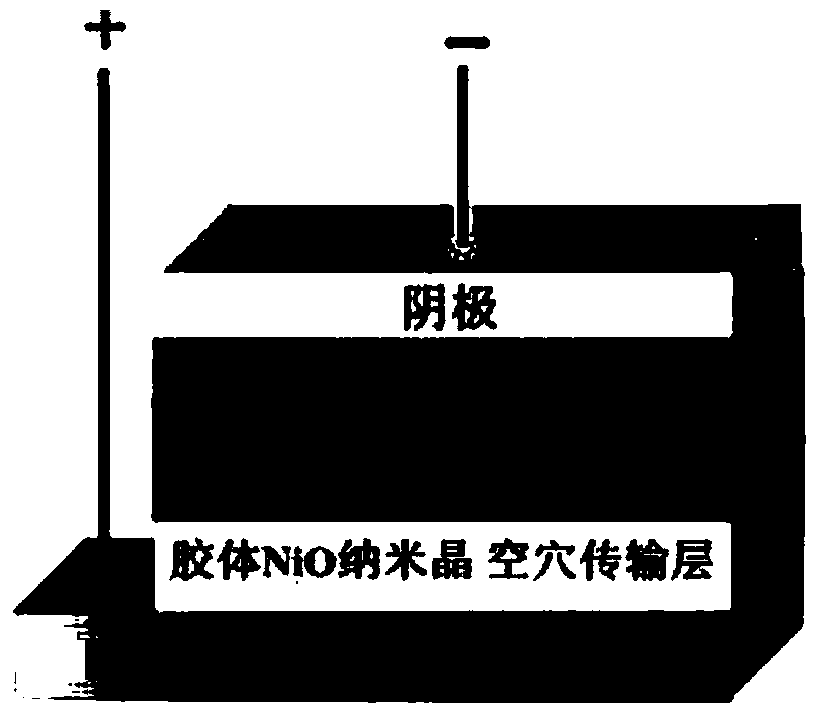

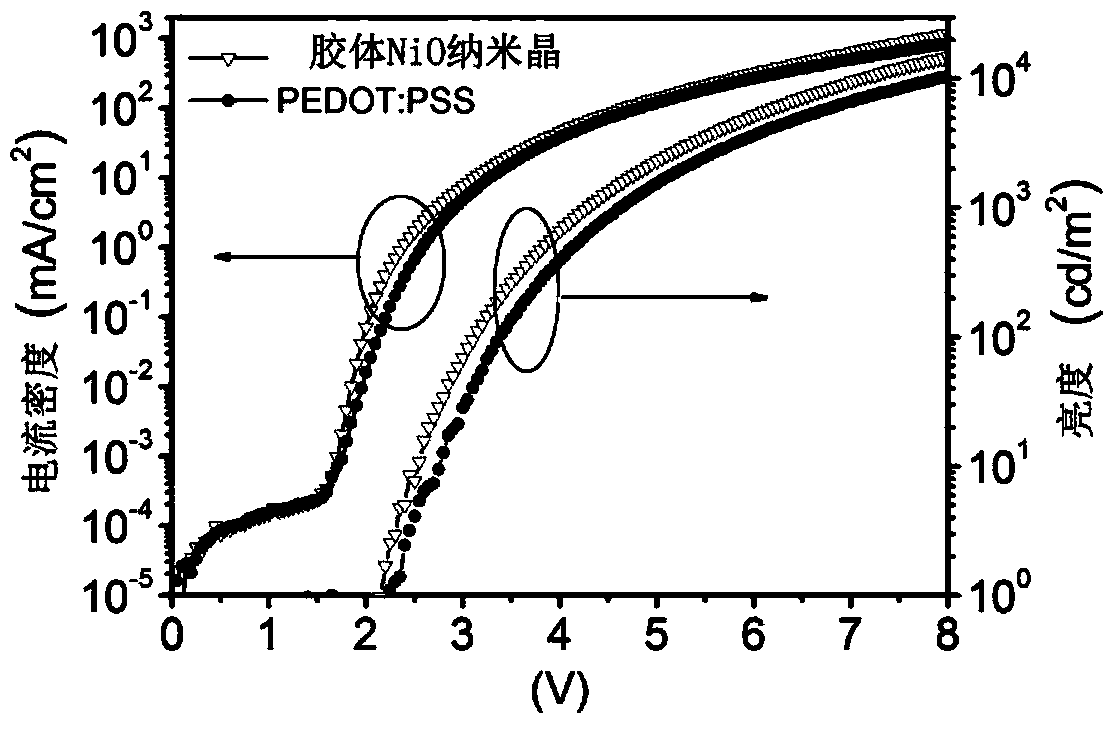

Photoelectric device with colloid NiO nanocrystalline film as hole transport layer and manufacturing method thereof

ActiveCN103840047ASimple preparation processLow costFinal product manufactureSolid-state devicesManufacturing technologyTransport layer

The invention discloses a photoelectric device with a colloid NiO nanocrystalline film as a hole transport layer. The photoelectric device is sequentially provided with an anode, the hole transport layer, an active layer, an electronic transport layer and a cathode from bottom to top. The hole transport layer is the colloid NiO nanocrystalline film. The invention further discloses a manufacturing method of the photoelectric device. The manufacturing technology is simple, saves cost and is particularly suitable for manufacturing the flexible photoelectric component. Manufactured colloid NiO nanocrystalline has the performance of solid nano NiO material and the characteristic of being processed by the adoption of a low-temperature solution technology, the film is higher in stability and working function, enables hole transport to be easier and not only can reduce interface resistance of the device, but also can obviously improve the efficiency of hole transport as the hole transport layer, so that the performance of the photoelectric device is improved.

Owner:ZHEJIANG UNIV

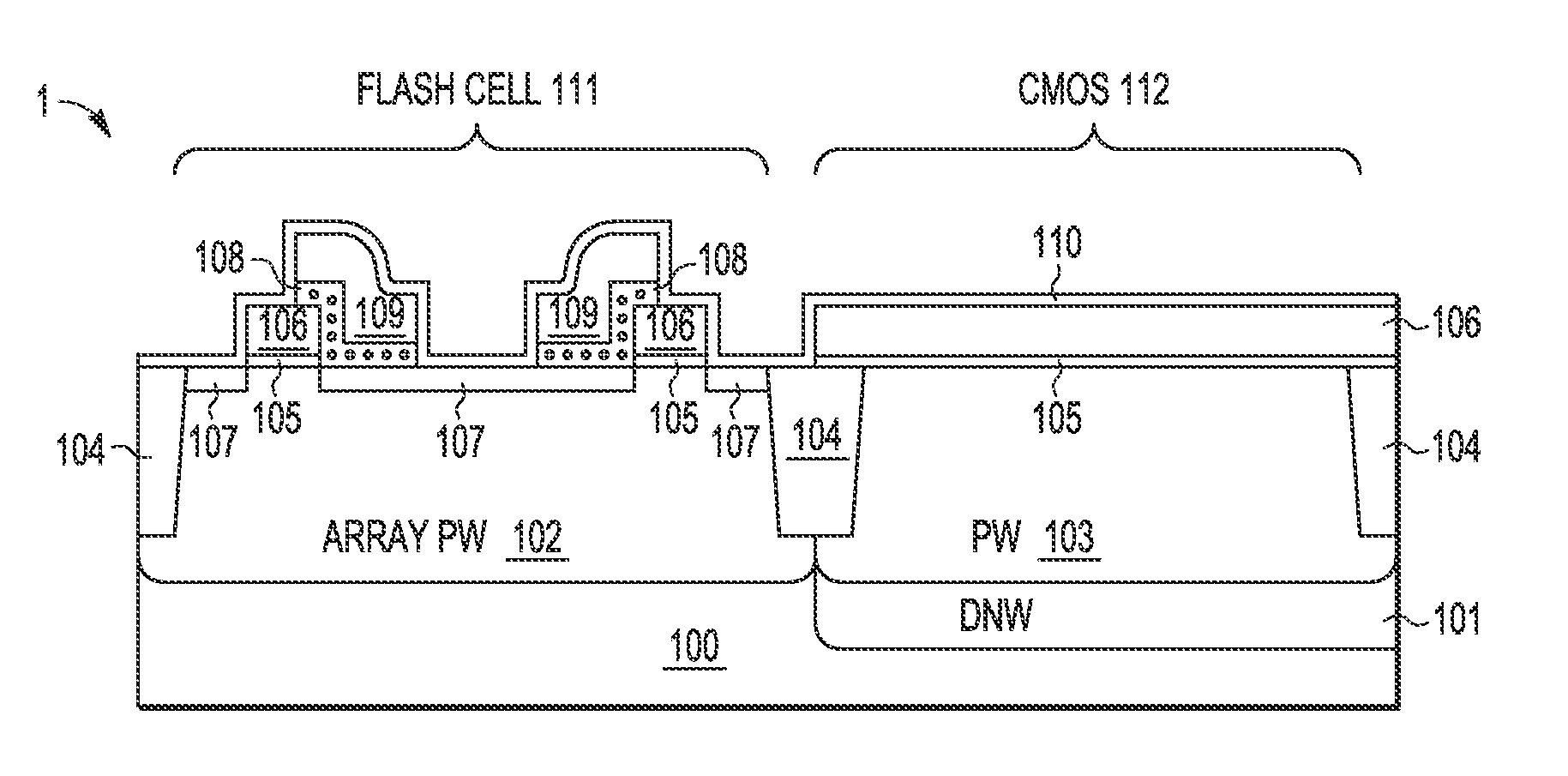

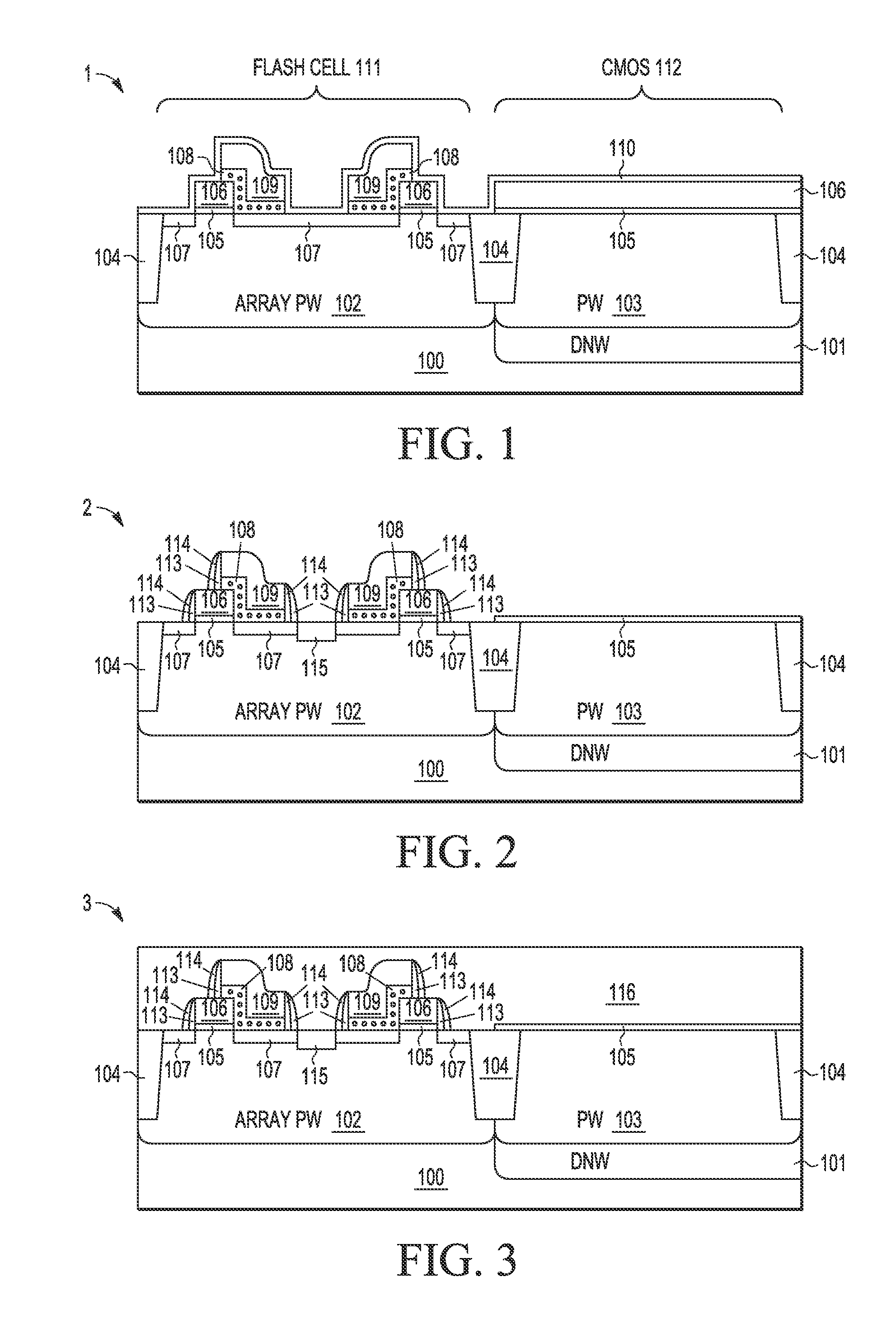

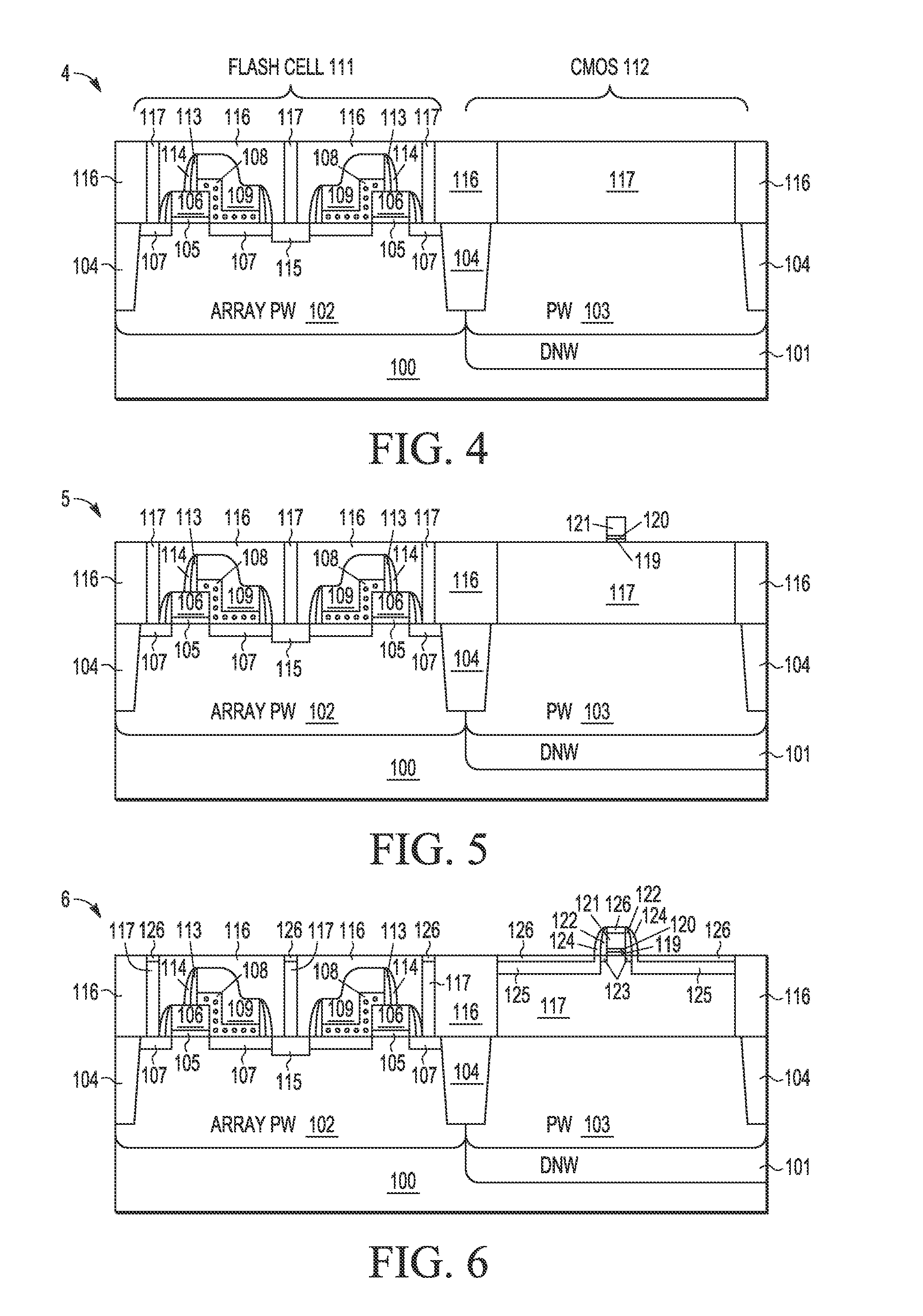

Method to Form a Polysilicon Nanocrystal Thin Film Storage Bitcell within a High K Metal Gate Platform Technology Using a Gate Last Process to Form Transistor Gates

ActiveUS20150054044A1Solid-state devicesSemiconductor/solid-state device manufacturingDielectricEngineering

A process integration is disclosed for fabricating non-volatile memory (NVM) cells (105-109, 113-115) on a first flash cell substrate area (111) which are encapsulated in one or more planar dielectric layers (116) prior to forming an elevated substrate (117) on a second CMOS transistor area (112) on which high-k metal gate electrodes (119-120, 122-126, 132, 134) are formed using a gate-last HKMG CMOS process flow without interfering with the operation or reliability of the NVM cells.

Owner:NXP USA INC

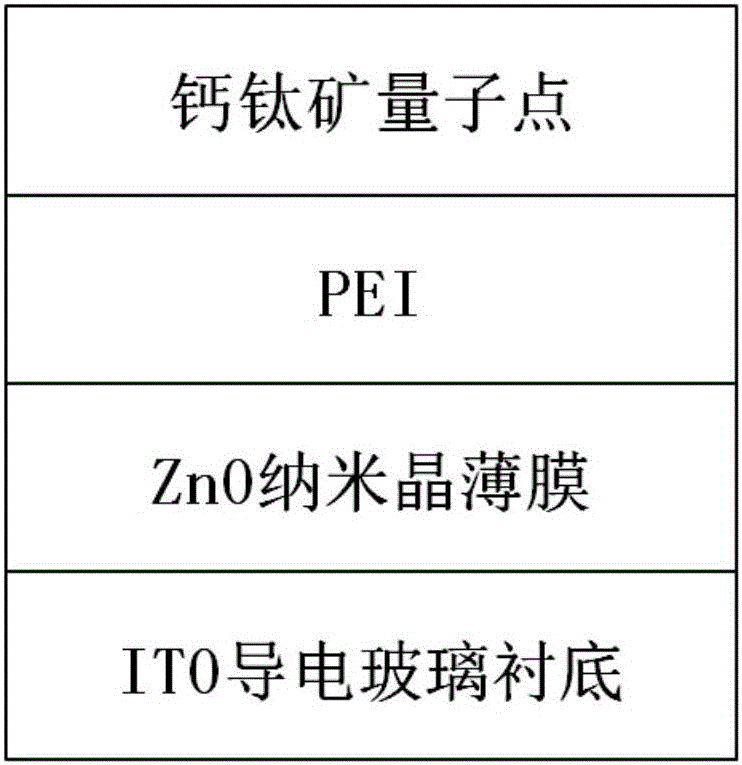

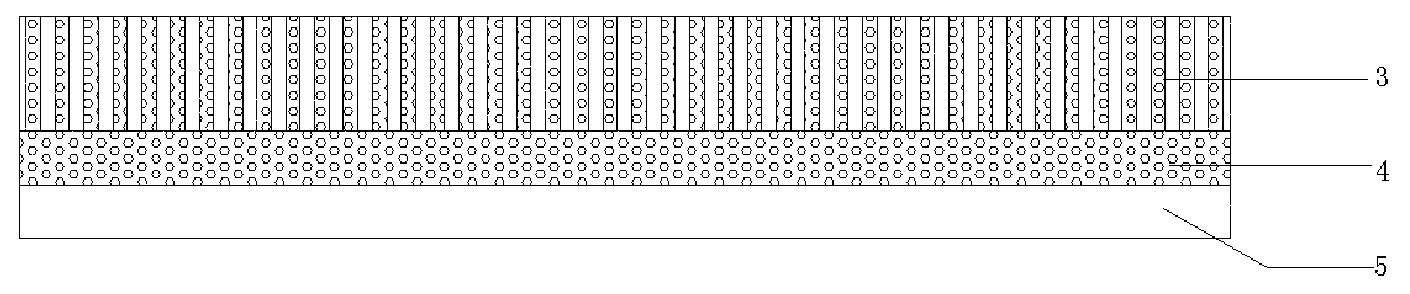

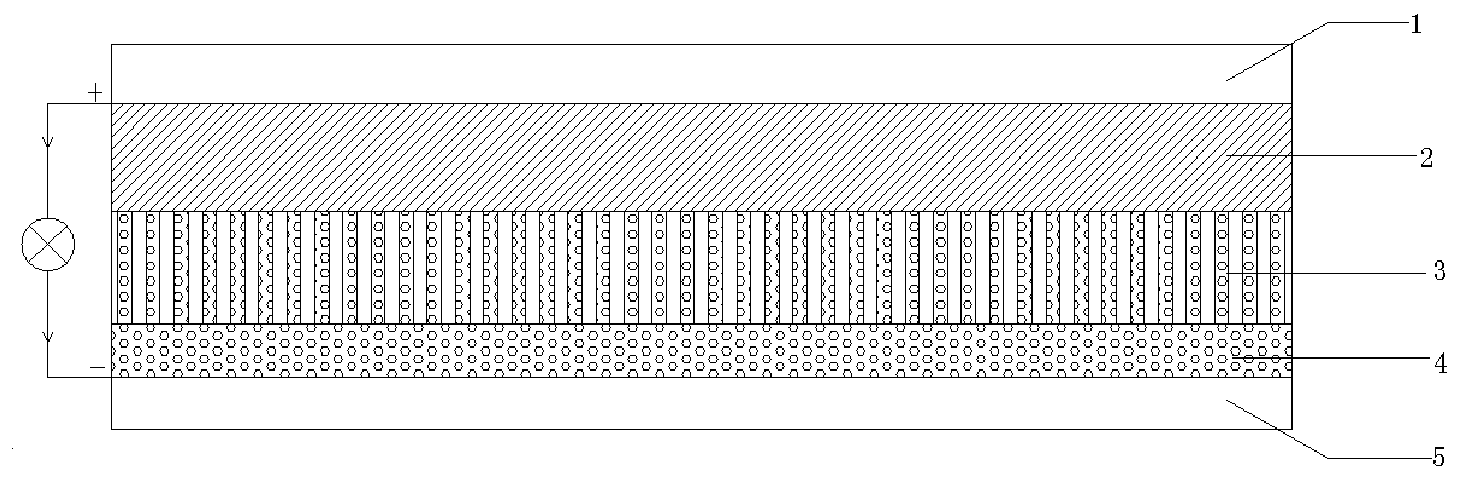

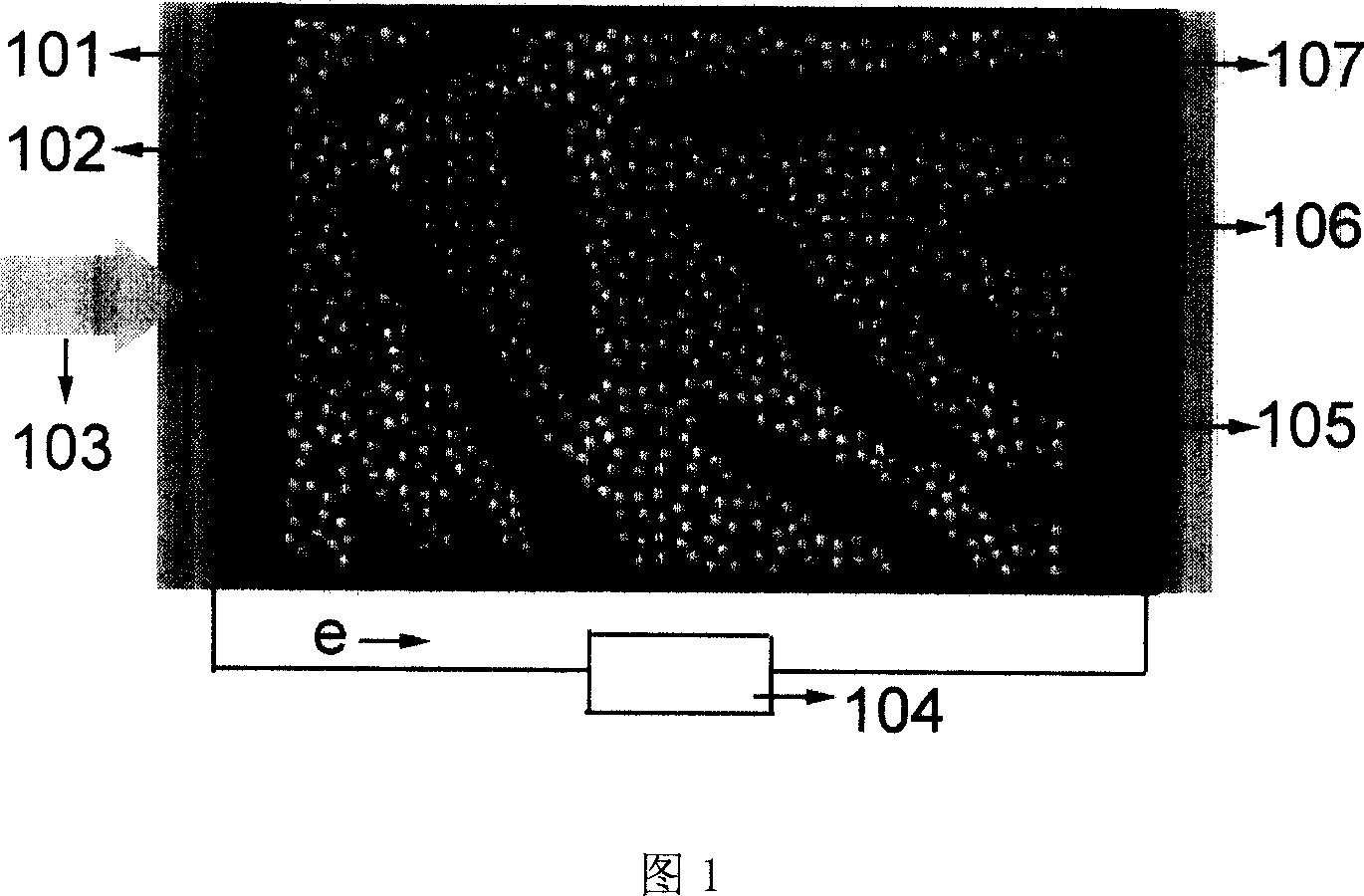

PEI (polyethyleneimine) based high-efficiency perovskite quantum dot light-emitting thin film and preparation method thereof

InactiveCN105720205AHigh fluorescence quantum yieldHigh crystallinitySolid-state devicesSemiconductor/solid-state device manufacturingQuantum yieldIndium tin oxide

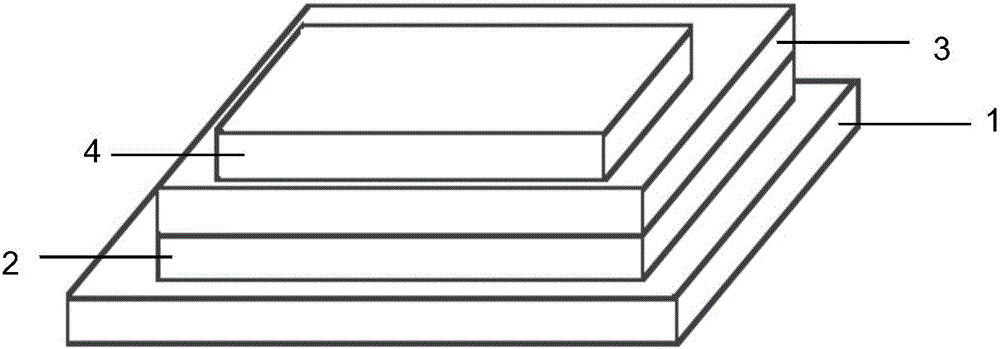

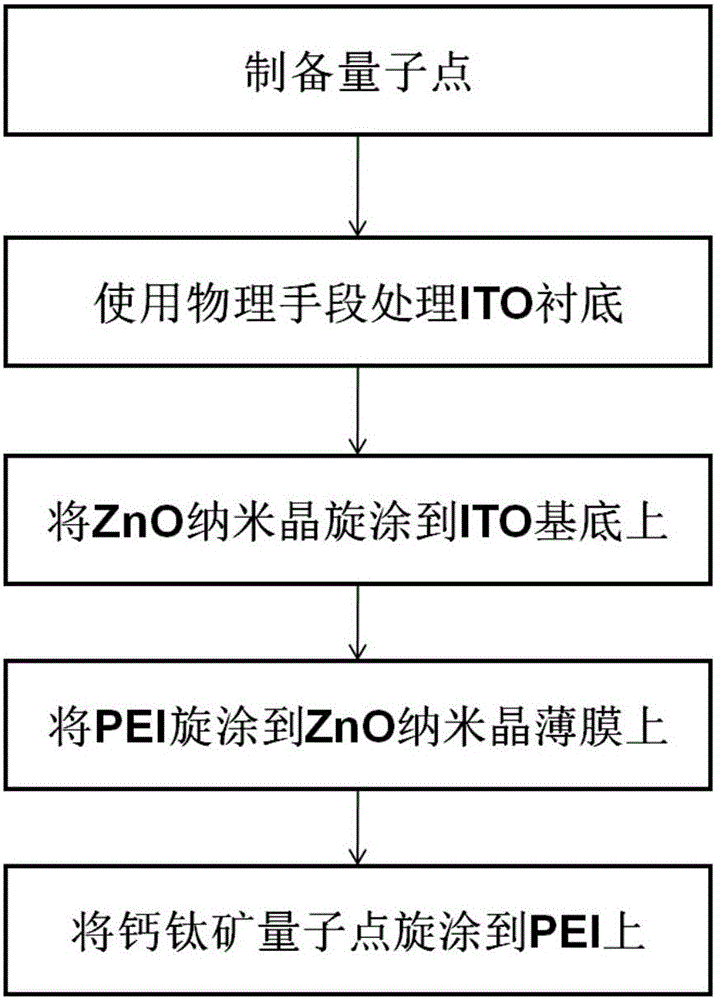

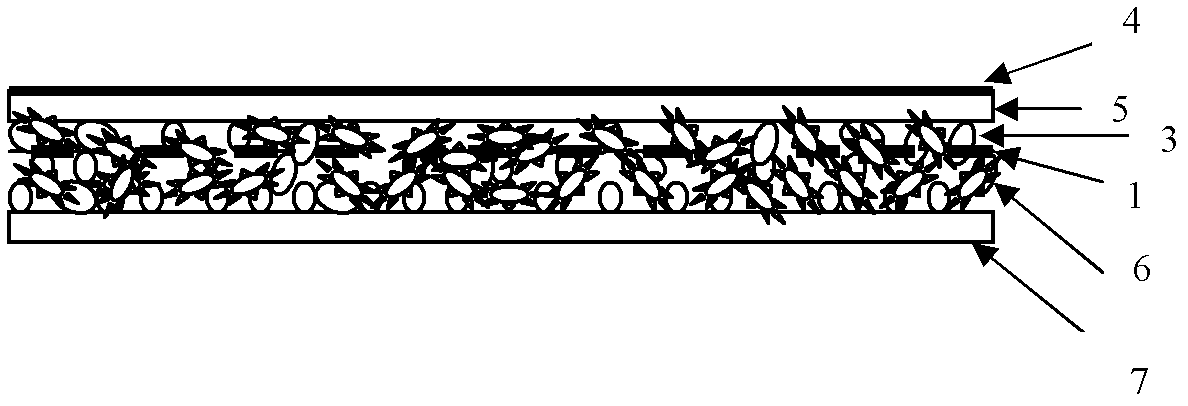

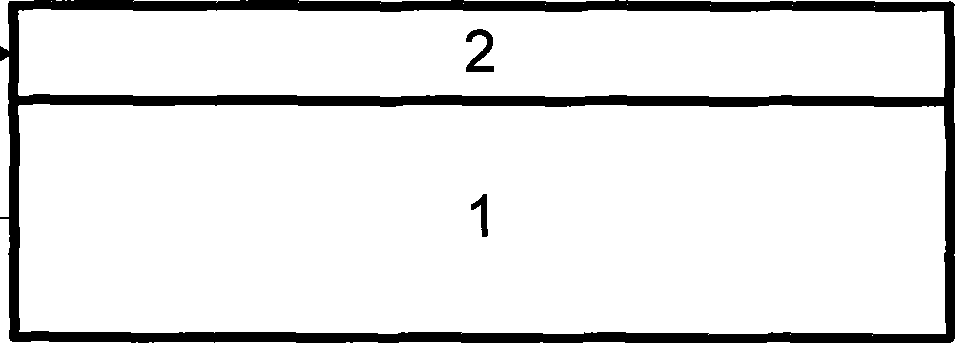

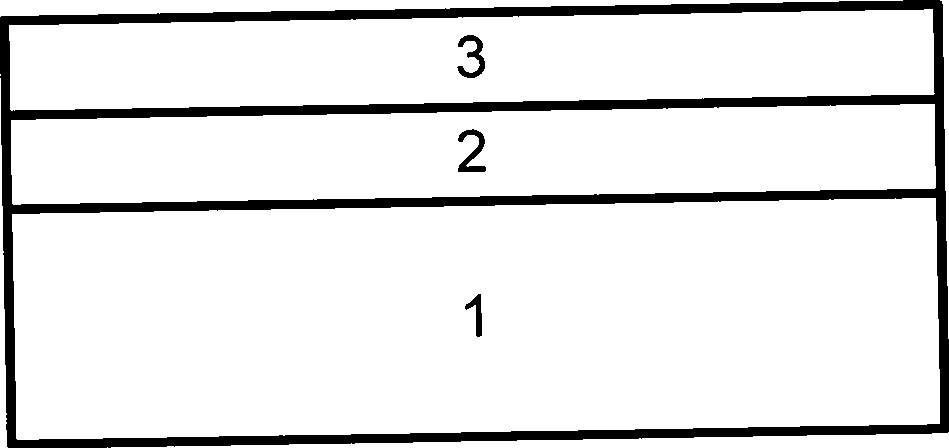

The invention mainly relates to a novel light-emitting thin film, and particularly relates to a PEI (polyethyleneimine) based high-efficiency perovskite quantum dot light-emitting thin film and a preparation method thereof. PEI and ZnO are used as electron transporting layers; and the perovskite quantum dot light-emitting thin film is used as a fluorescent layer. The PEI based high-efficiency perovskite quantum dot light-emitting thin film structurally comprises a substrate (1) formed by an ITO (indium tin oxide) thin film, a ZnO layer (2) deposited on the substrate, a PEI layer (3) spin-coated on a ZnO nanocrystalline thin film, and perovskite quantum dots (4) spin-coated on the ZnO nanocrystalline thin film coated with PEI, wherein the ZnO layer and the PEI layer are combined into an electron migration layer together; and the inorganic cesium lead halide perovskite quantum dots are used as a light-emitting layer (4). Compared with fluorescence quantum yield of a perovskite quantum dot light-emitting thin film prepared by an existing process, fluorescence quantum yield of the perovskite quantum dot light-emitting thin film prepared by the preparation method disclosed by the invention can be improved by 2 to 3 times.

Owner:JILIN UNIV

Quantum dot channel (QDC) quantum dot gate transistors, memories and other devices

This invention describes a field-effect transistor in which the channel is formed in an array of quantum dots. In one embodiment the quantum dots are cladded with a thin layer serving as an energy barrier. The quantum dot channel (QDC) may consist of one or more layers of cladded dots. These dots are realized on a single or polycrystalline substrate. When QDC FETs are realized on polycrystalline or nanocrystalline thin films they may yield higher mobility than in conventional nano- or microcrystalline thin films. These FETs can be used as thin film transistors (TFTs) in a variety of applications. In another embodiment QDC-FETs are combined with: (a) coupled quantum well SWS channels, (b) quantum dot gate 3-state like FETs, and (c) quantum dot gate nonvolatile memories.

Owner:JAIN FAQUIR CHAND

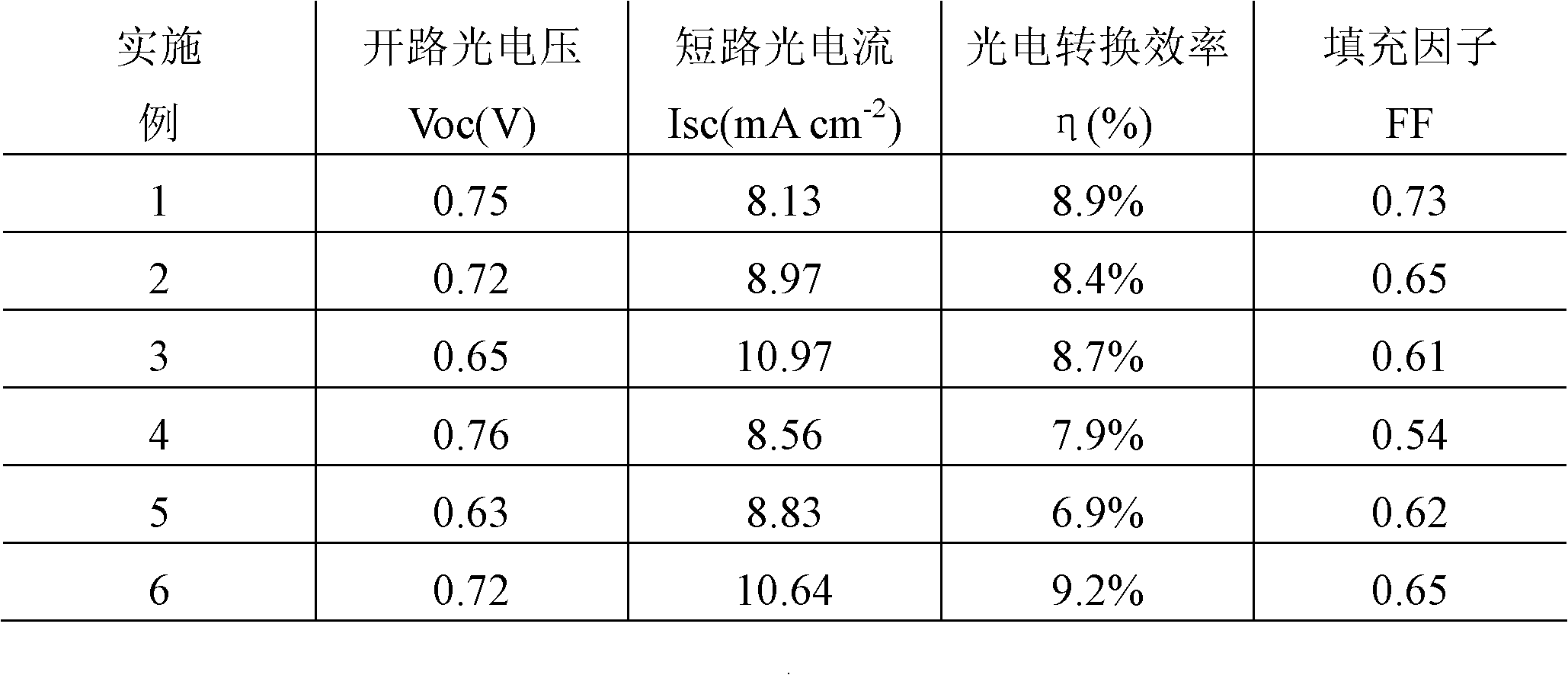

Method for preparing modified titanium dioxide nanotube dye-sensitized photoanode thin film

InactiveCN102122580ABroaden the absorption bandImprove photoelectric conversion efficiencyLight-sensitive devicesFinal product manufactureTio2 nanotubeSlurry

The invention discloses a method for preparing a modified titanium dioxide nanotube dye-sensitized photoanode thin film, and belongs to the field of dye-sensitized solar cells. The method comprises the following steps of: mixing titanium salt solution and a dopant to prepare doped titanium dioxide sol A; preparing titanium dioxide nanotubes by a hydrothermal synthesis method; dipping the titanium dioxide nanotubes in metal or non-metal dopant solution to obtain titanium dioxide nanotube powder B; mixing the powder B and the sol A and fully grinding to obtain titanium dioxide nanocrystalline slurry C; coating the sol A onto a conductive substrate and drying; coating the obtained nanocrystalline slurry C onto the conductive substrate on which the sol A is coated to obtain a titanium dioxide nanotube thin film electrode D; drying the D and performing thermal treatment to obtain a doped titanium dioxide nanotube nanocrystalline thin film electrode E; and soaking the E in ethanol solution of 4,4'-dicarboxylic bipyridyl ruthenium, washing with absolute ethanol and drying with nitrogen gas. The method has the advantages of simple preparation process, high repeatability and low cost.

Owner:BEIJING UNIV OF CHEM TECH +1

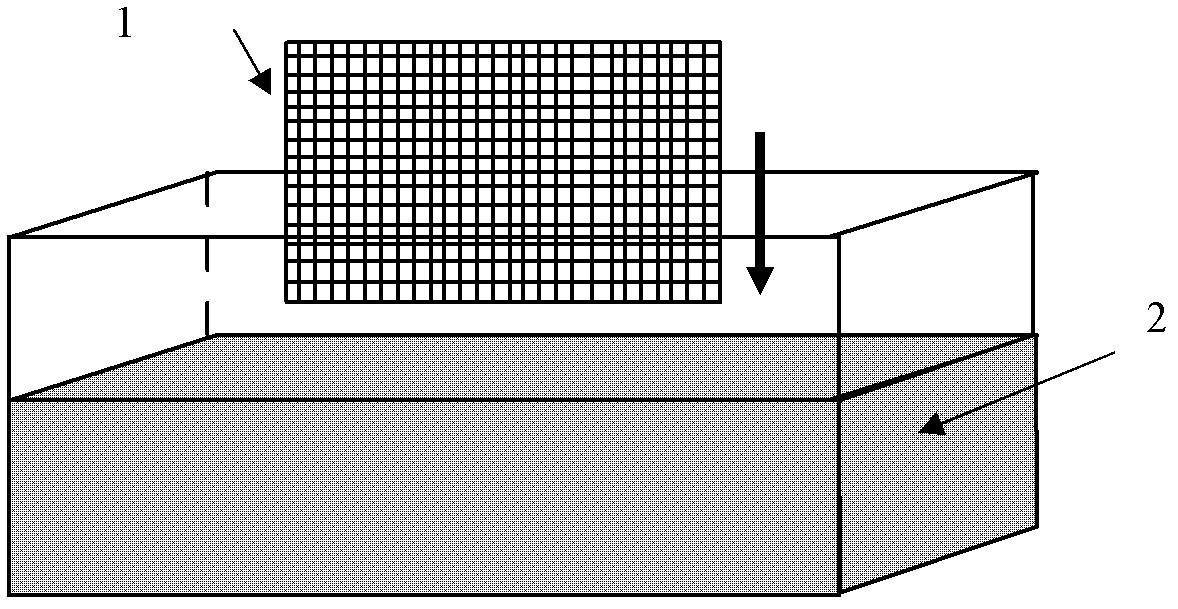

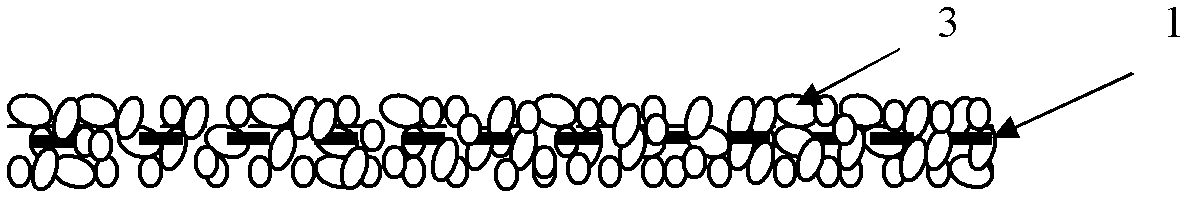

Flexible dye-sensitized nanocrystalline organic photovoltaic cell photoanode and preparation method thereof

ActiveCN102290249ADoes not reduce conductivityDoes not reduce light transmissionLight-sensitive devicesSolid-state devicesDye absorptionSlurry

The embodiment of the invention discloses a preparation method of a light anode of a flexible dye sensitized nano crystalline organic photovoltaic cell. The method comprises the following steps: dipping or spraying a uniform nano crystalline slurry on a flexible antioxidant metal wire mesh selected as a substrate, thus forming a nano crystalline thin film on the surface of the wire mesh; carryingout high-temperature heat treatment on the substrate attached with the nano crystalline thin film, thus preparing the metal wire mesh with the porous nano crystalline thin film; and then soaking the metal wire mesh with the porous nano crystalline thin film in a dye solution, thus realizing the dye sensitive effect on the nano crystalline thin film. The invention also discloses a light anode and a photovoltaic cell which are obtained according to the preparation method. According to the scheme provided by the invention, under the condition that the electric conductivity and transmission of light of the light anode can not be lowered, the DSSC (dye sensitized solar cell) has a flexible characteristic, and the nano crystalline thin film is subjected to high-temperature sintering treatment, thus the porous nano crystalline thin film is obtained, and the capability of dye absorption is improved, so that the assembled cell has the performance of higher photoelectric conversion efficiency.

Owner:苏州恒久光电科技股份有限公司 +1

Nanocrystalline film and its low temperature preparing method

ActiveCN101143357AHigh strengthEasy thickness controlPolycrystalline material growthFinal product manufactureReaction temperatureSlurry

The present invention relates to a nano-crystal thin film and a low temperature preparation method. The thin film is provided with graded structure and uses nano-crystal titania particles of different sizes as raw materials to add specific chemical bonds or function masses to the surfaces of the nano-crystal particles through a method of surface modification. The materials are mixed in inorganic or organic solution to be prepared into carcass slurries before graded, which are made into films on a flexible conductive basement or any other basement through a simple film making method. Under a low reaction temperature, the particles in the thin films are well connected through chemical sintering, and the nano-crystal particles are connected through good chemical bonds. The whole thin film is provided with high mechanical strength. Flexible dye sensitization solar energy batteries, which are assembled from the thin films, are provided with the high photoelectric conversion efficiency. The thin film and the low temperature preparation method is predicated to be provided with a wide application prospect in photoelectric transformation and photo-catalyst fields.

Owner:TSINGHUA UNIV

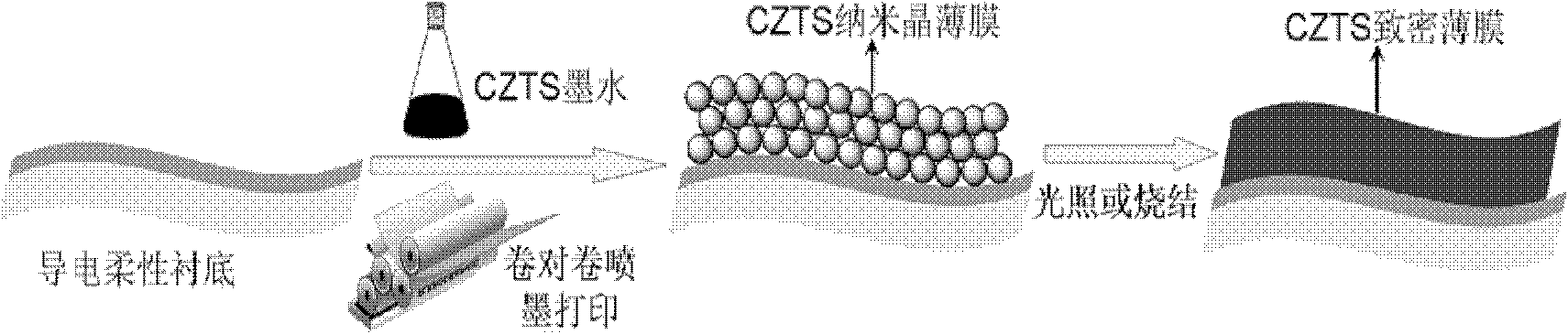

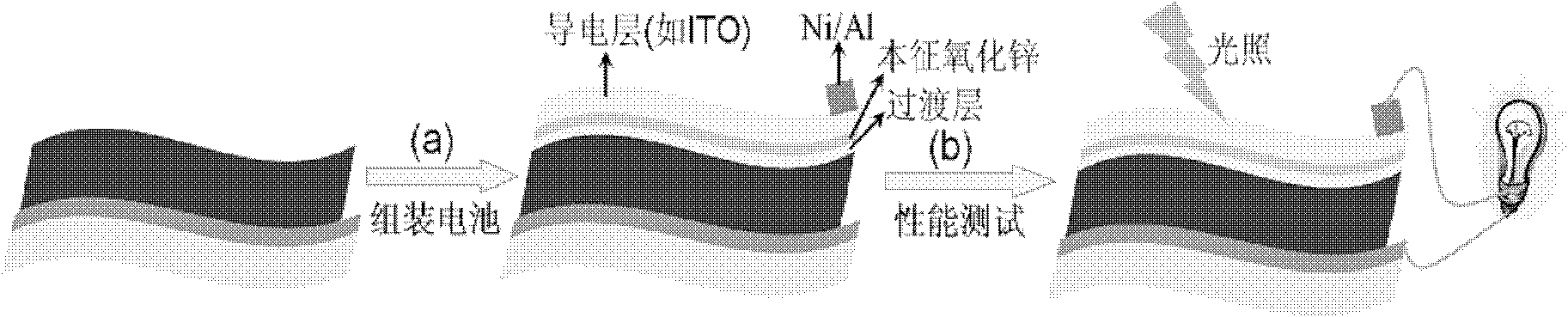

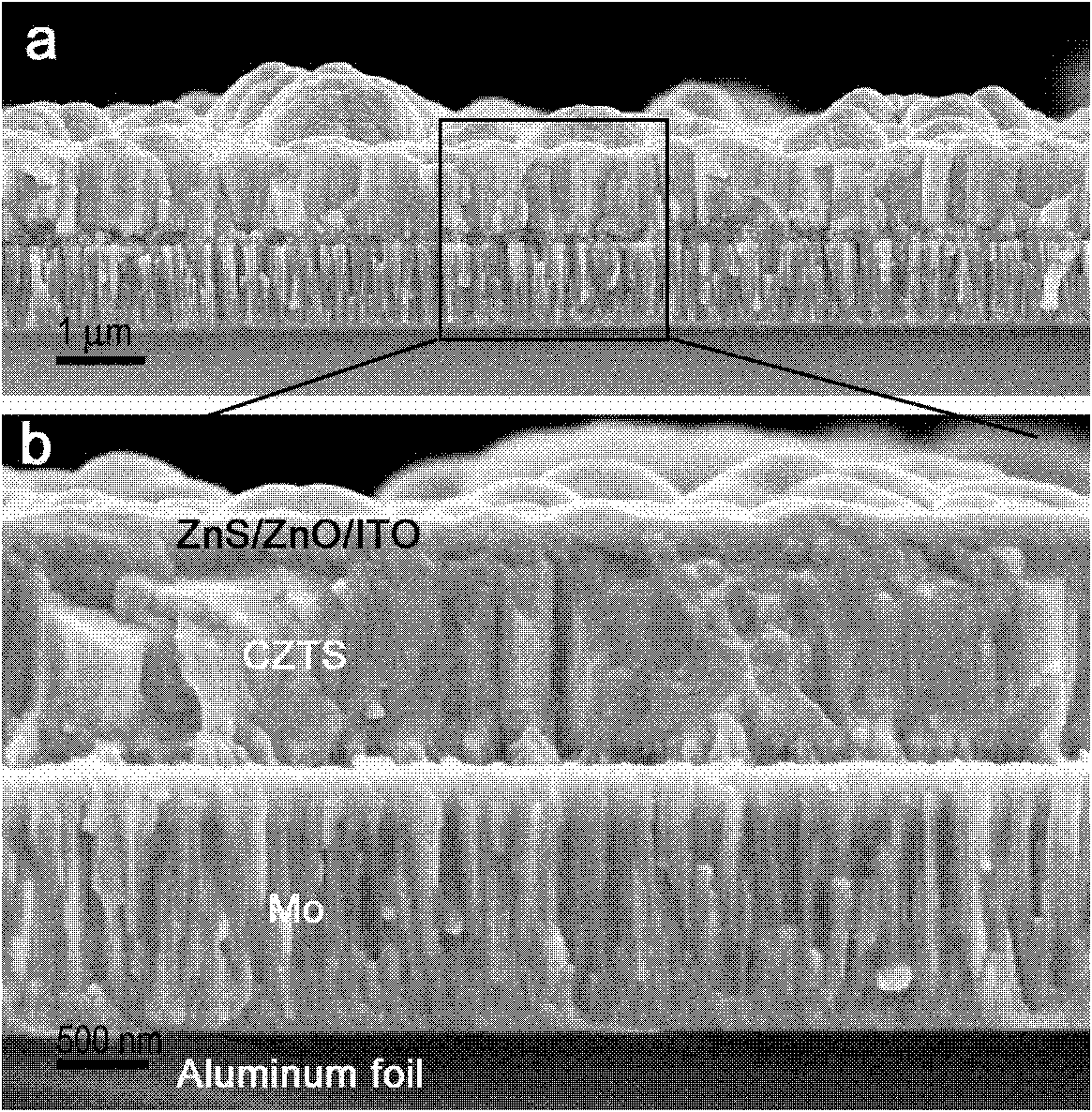

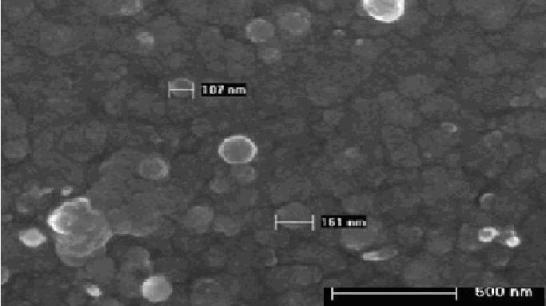

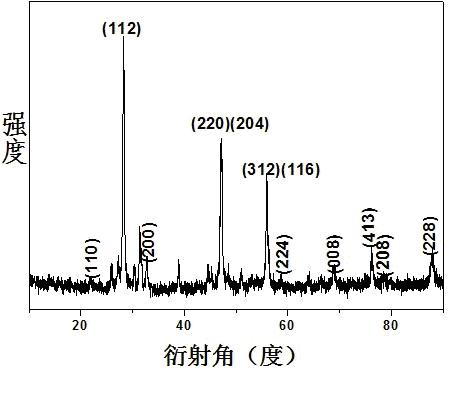

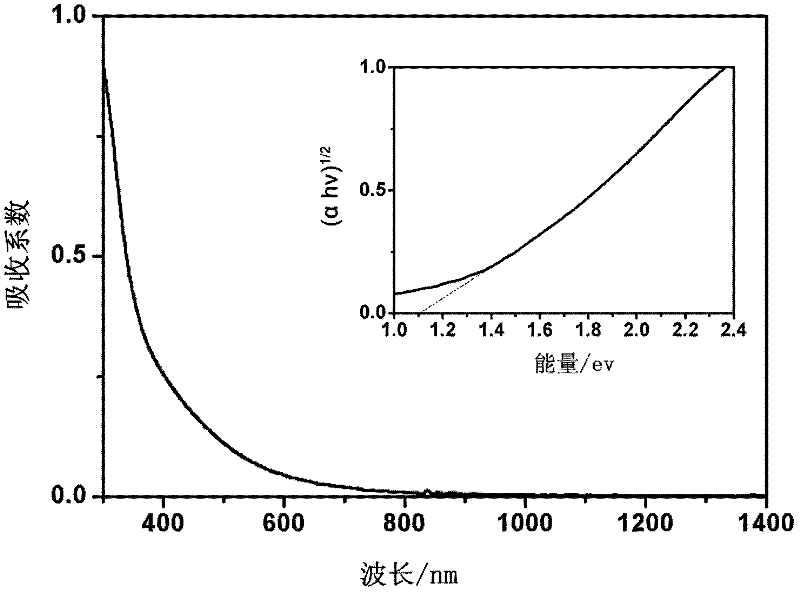

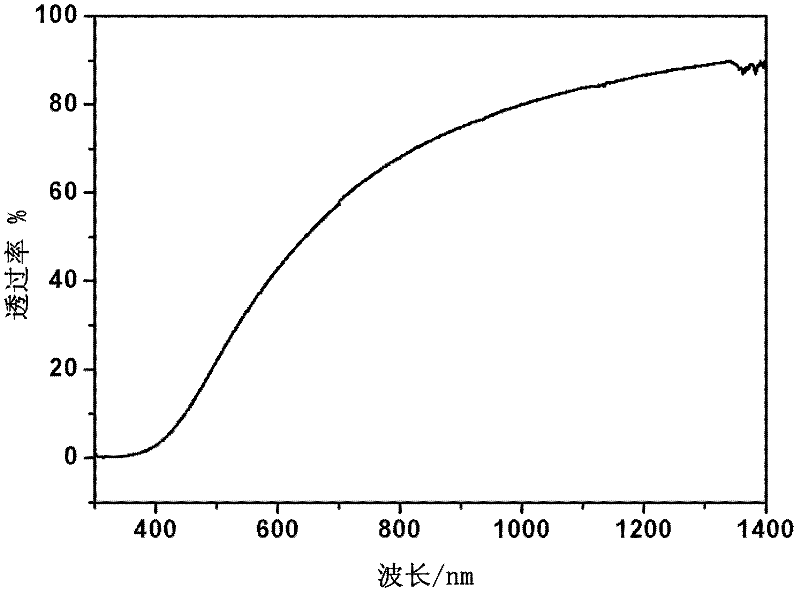

Method for preparing Cu2ZnSnS4 nanocrystalline thin-film solar cell

InactiveCN102201498AReduce weightGood dispersionFinal product manufactureNanotechnologyIntrinsicsNanocrystalline thin films

The invention relates to a method for preparing a Cu2ZnSnS4 nanocrystalline thin-film solar cell, which comprises the following steps of: performing chemical bath deposition on a ZnS film to form a buffer layer by taking molybdenum-plated metal aluminum as a flexible substrate and a film prepared from hydrophilic Cu2ZnSnS4 nanocrystalline as an absorption layer; and assembling the solar cell by performing magnetron sputtering on intrinsic ZnO, ITO and Ni-Al electrodes. By the method, vacuum equipment is not required, production cost is reduced, and convenience is brought to mass production; raw materials for preparing the Cu2ZnSnS4 solar cell are environment-friendly materials and have low prices, so that the cost of the solar cell is reduced to the great extent; and the method has a good application prospect.

Owner:DONGHUA UNIV

Blanket type light anode for dye sensitized solar cell and preparation method thereof

InactiveCN101950687AImprove photoelectric conversion efficiencyEfficient separationLight-sensitive devicesFinal product manufactureElectronic transmissionBoundary potential

The invention relates to a blanket type light anode for a dye sensitized solar cell and a preparation method thereof, which belong to the technical field of solar cells. In the blanket type light anode for the dye sensitized solar cell, a layer of blanket type structure, namely a titanium dioxide nano linear array film is increased on the basis of the conventional multiporous titanium dioxide nanocrystalline film light anode. Due to the existence of a titanium dioxide nano linear array, more fuel sensitizing agents can be adsorbed; at the same time, because multiporous titanium dioxide nanocrystal interfaces are greatly reduced, crystal boundary potential barriers which need to be overcome during electronic transmission are reduced to accelerate the effective separation of photoelectron-cavity pairs in dye molecules; the multiporous titanium dioxide nanocrystalline film at the bottom can effectively reduce leakage current and dark current; and the blanket type light anode for the dye sensitized solar cell provided by the invention has higher photoelectric conversion efficiency. The preparation method has the advantages of simpleness, mild reaction condition and safe and reliable process.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

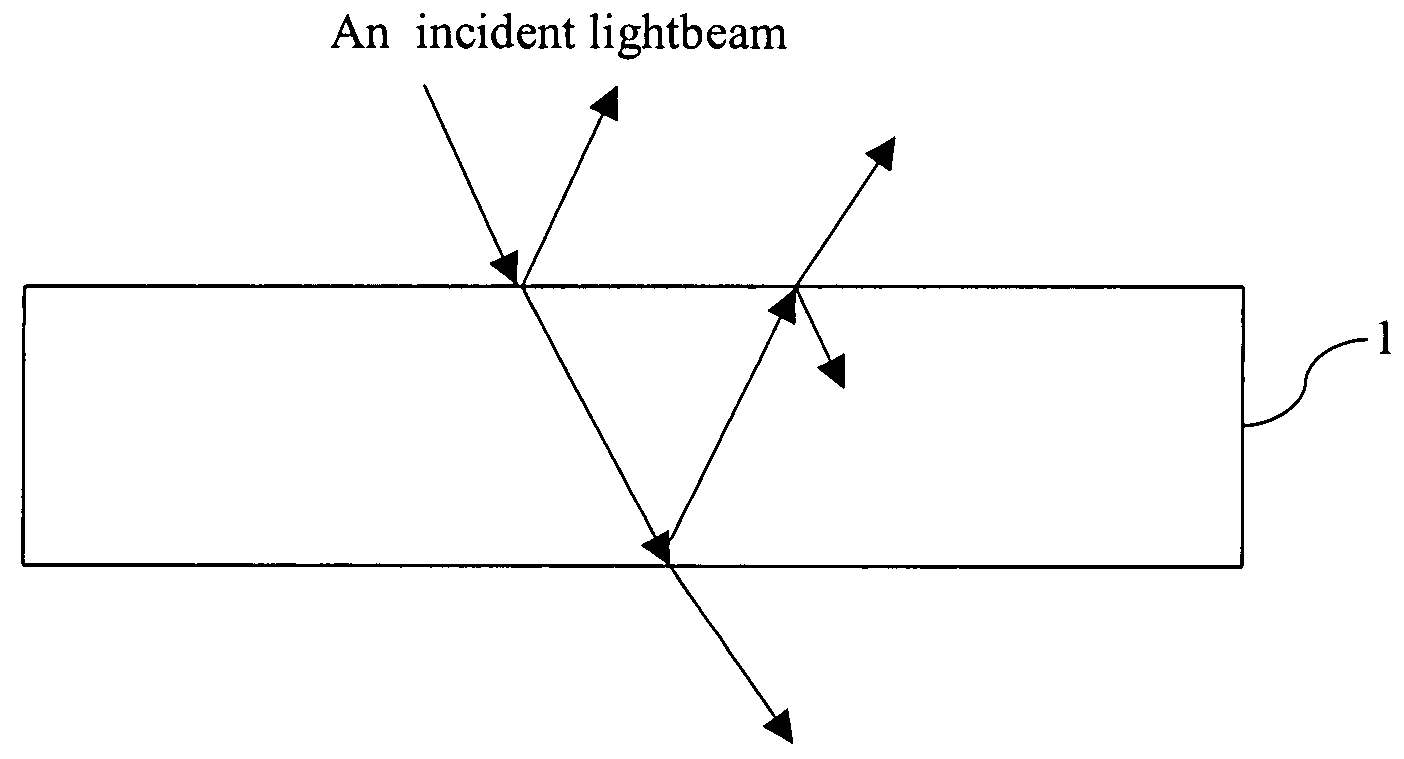

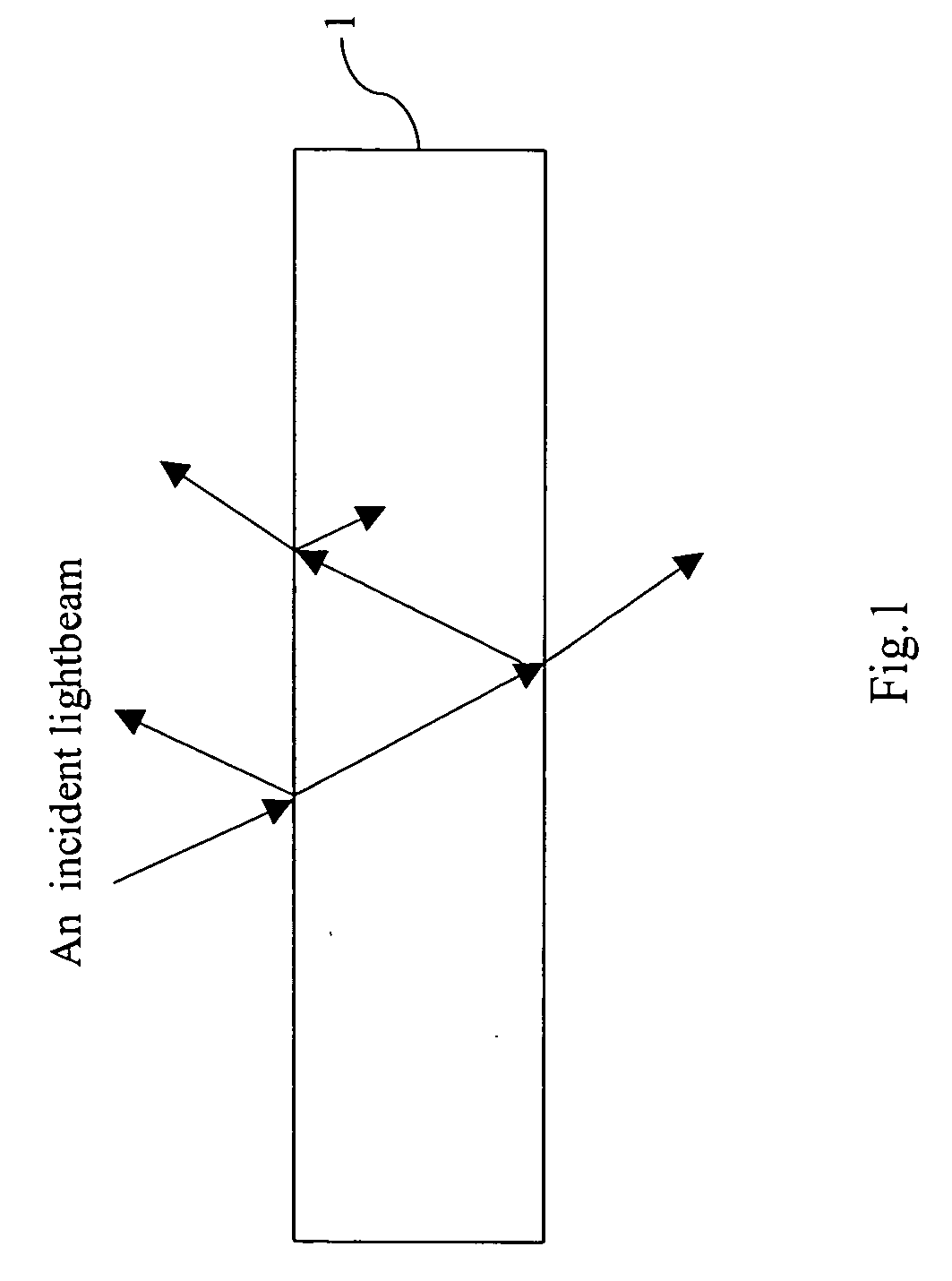

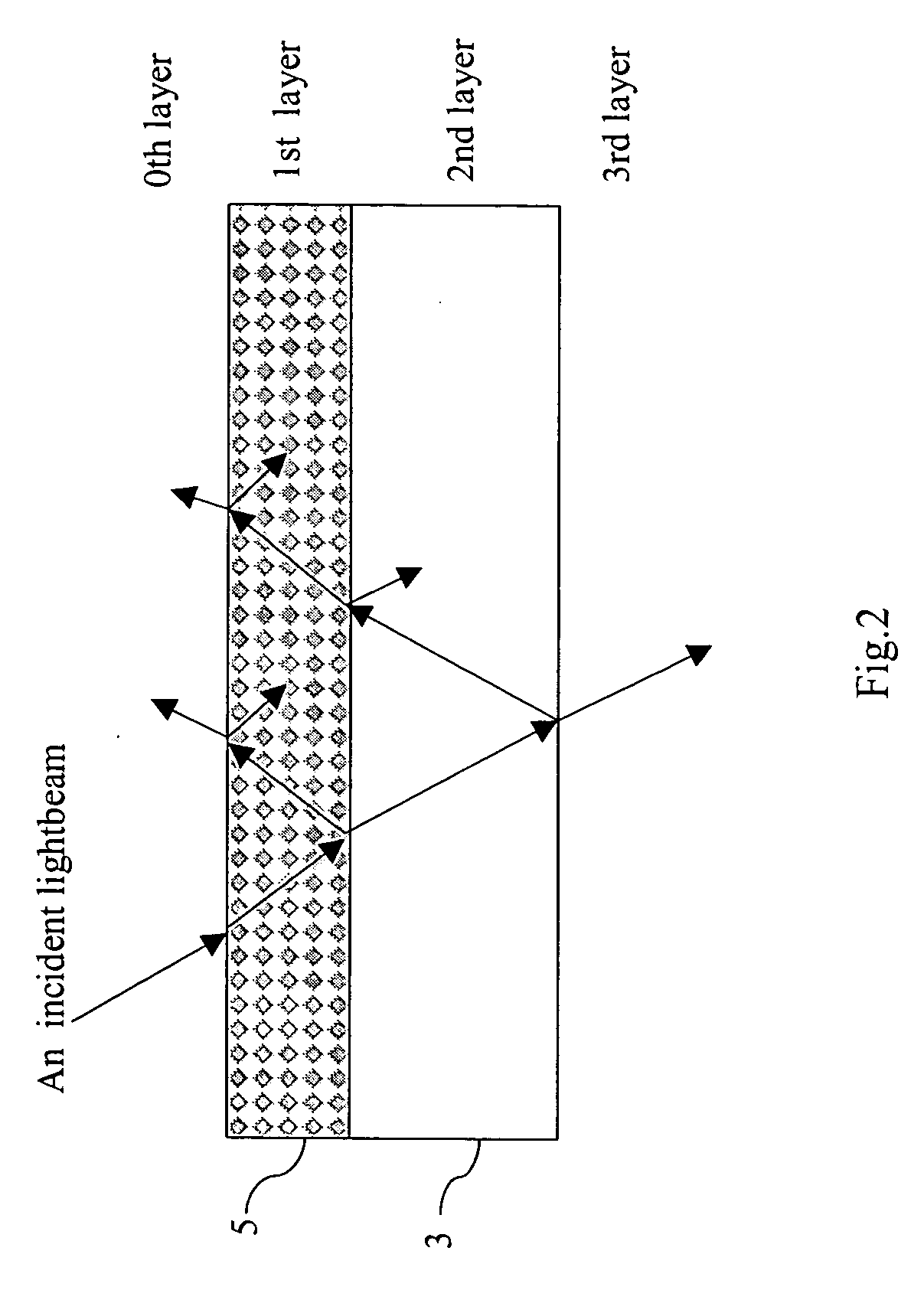

Optical method to monitor nano thin-film surface structure and thickness thereof

A method to monitor a nanocrystalline film surface structure and the thickness thereof uses the surface structure characteristics of the vapor deposition nanocrystalline thin films having the low volume fraction to make a nanocrystalline thin film become a nonhomogeneous double-layer structure comprising a dense bottom layer having high index of refraction and a surface layer having the low volume fraction. The optical module of this double-layer structure can be used to simulate the characteristics of the nanocrystalline structure. That is to say, in the thin film deposition manufacturing process, if the thin film structure satisfies the optical module of the double-layer structure, this means it has the nanocrystalline characteristic. Hence, in the manufacturing process, use the optical instruments to measure the thin film and the substrate and to calculate the optical parameters; thus a nanocrystalline film surface structure and the thickness thereof can be precisely monitored immediately.

Owner:GRACE SEMICON MFG CORP

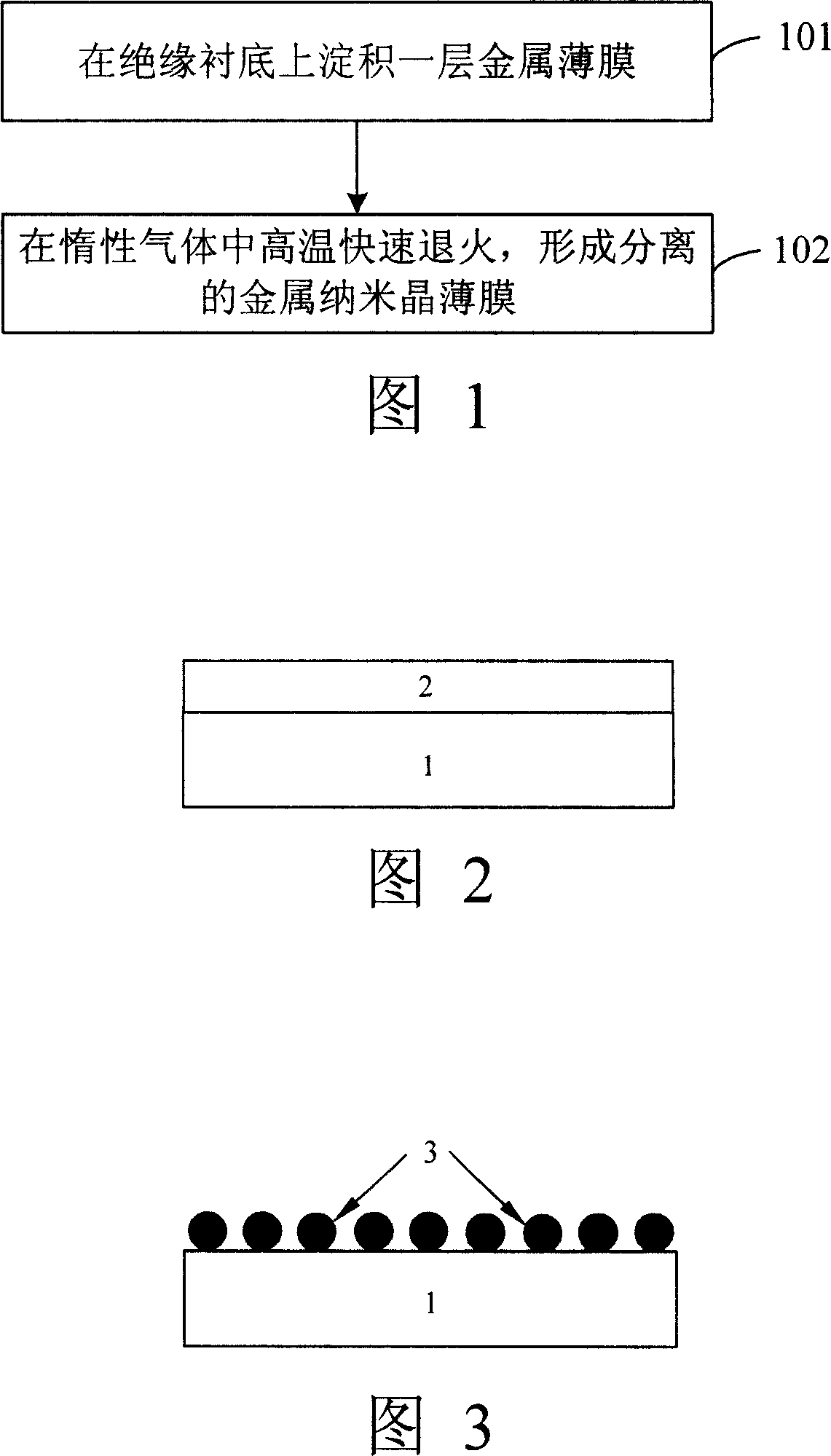

Method for preparing metal nano-crystal thin film

ActiveCN101122006AGood charge trappingImprove featuresVacuum evaporation coatingSputtering coatingCharge retentionNanocrystal

The invention discloses a method of preparing a metal nano-crystal film, which includes: A. a layer of metal film is deposited on an insulating substrate; B. conductin fast annealing with high temperature in the inert gas, so as to form the separated metal nano-crystal film. The metal nano-crystal film prepared by the invention has very good charge retention and storage characteristics as well as processing compatibility with traditional silicon planes, and is very applicable in preparing high-performance semiconductor memory components. The method of preparing a metal nano-crystal film provided by the invention greatly simplifies the preparing technology, reduces the preparing cost, improves the technological stability and preparing efficiency, and is very good for wide promotion and application of the invention.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

New structure crystal silicon solar energy battery

InactiveCN1949545AImprove absorption rateAvoid the effects of boron-oxygen defectsPhotovoltaic energy generationSemiconductor devicesNanocrystalline siliconP type silicon

The invention is a crystalline silicon solar battery adopting emission region on film silicon back, belonging to a new structured photovolt battery, and its key point is depositing a layer of silicon film on the back to form heterogeneous PN junction on an N-type monocrystalline silicon substrate so as to replace the homogenous PN junction on the right side of a battery, prepared by routine diffusion, where the deposited silicon film can noncrystalline, microstalline, or nanocrystalline film; the heterogenerous PN junction forming method can directly deposit a P-type silicon film on the N-type monocrystalline silicon, and can firstly deposit a layer of intrinsic silicon film on the N-type monocrystalline silicon and then deposit the P-type silicon film. Thus, the battery efficiency can reach above 20%.

Owner:BEIJING SOLAR ENERGY INST

Production method of dye-sensitized TiO2 film based gas sensor

The invention discloses a production method of a dye-sensitized TiO2 film based gas sensor. The method comprises steps of: choosing a substrate suitable for subsequent film plating; preparing electrodes on the substrate through a film plating method; preparing a nanocrystalline TiO2 film on the substrate with electrodes by a magnetron sputtering method; selecting a suitable dye sensitizing material according to gas to be tested and dissolving the dye sensitizing material in a compatible solvent to prepare a dye solution; immersing the nanocrystalline TiO2 film into the dye solution for 12-8 h; taking out the nanocrystalline TiO2 film; removing impurities with ethanol; and drying and baking in an oven at 30-80 DEG C for 1-5 h. According to the invention, the nanocrystalline TiO2 film is employed as the substrate material, and the dye sensitizing material is employed as a sharpening material; dye molecules encapsulate the TiO2 molecules while filling gaps between the TiO2 crystals; and the gas sensor can be used for qualitative and quantitative analysis on gas at room temperature through changes of the sensor resistance, and has high sensitivity and wide detection range.

Owner:JIANGSU UNIV

Dye sensitization nanocrystalline thin-film solar cell high pore space flexible carbon to electric pole and preparation method thereof

InactiveCN101140956AReduce manufacturing costReduce thicknessLight-sensitive devicesElectrode manufacturing processesComposite filmNanocrystalline thin films

A highly porous flexible carbon counter electrode used for solar battery of the dye sensitize amino-quinoline thin film is provided, which comprises an composite film composed by a carboform membrane layer with a microstructure of three dimensional porous diffusion and polyafluortetraethylene thin membrane layer; a titanium dioxide semiconductor expanded film equipped on the said composite film as the working electrode of the semiconductor. The preparation method of the electrode is: greying the arboform membrane and platinum black to the nanometer-carried; sensitizing the counter electrode used of the solar battery with the dye of the composite film, which forms dye sensitize solar battery with the working electrode of the semiconductor oxide based on the rigid stratum; greying the arboform membrane and platinum black to the nanometer-carried, which is composed with the polyafluortetraethylene thin membrane to form a composite film, which forms dye sensitize solar battery with the working electrode of the semiconductor oxide based on the rigid stratum.

Owner:NANJING UNIV

Preparation method for ZnO nanocrystalline thin-film transistor type UV detector

ActiveCN105655442AReduce dark currentThe synthesis method is simpleMaterial nanotechnologyFinal product manufactureResponse sensitivityPower flow

The invention discloses a preparation method for a ZnO nanocrystalline thin-film transistor type UV detector. The UV detector successively comprises a low-resistance Si layer, a SiO2 insulating layer, a ZnO nanocrystalline layer and an Au electrode from bottom to top. The preparation method comprises the steps of firstly, preparing a ZnO nanocrystalline colloid dispersed phase; secondly, conducting the spin coating process of the colloid dispersed phase on the SiO2 surface of Si / SiO2, and then annealing; finally, plating the Au electrode to complete the preparation of the UV detector. Compared with a traditional UV detector, the above UV detector prepared through the above method is low in dark current, high in response sensitivity, quick in response time, simple in structure and low in manufacturing cost. Therefore, the method has an important application value in the fields of military, civilian and special aspects.

Owner:ZHEJIANG UNIV

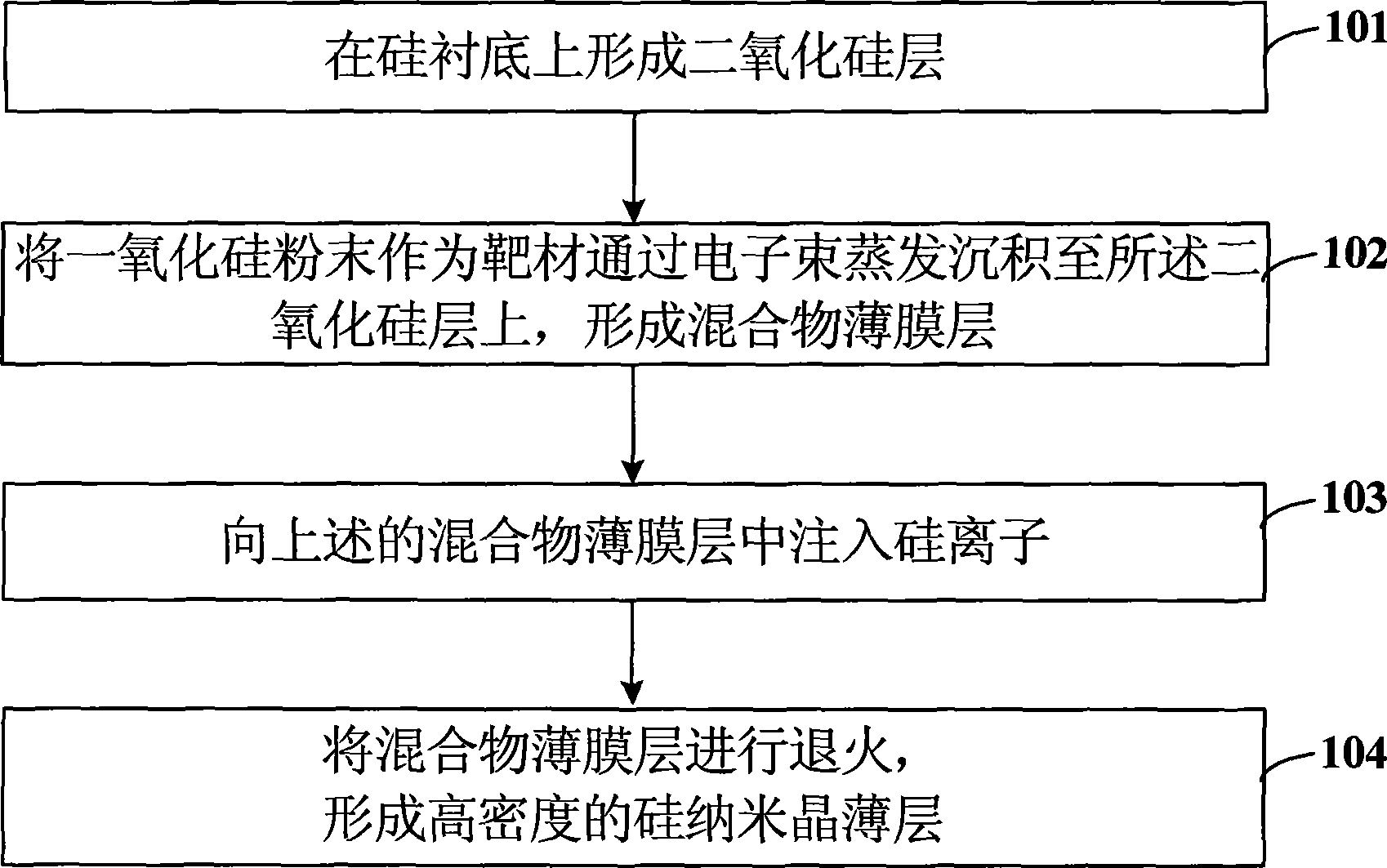

Method for preparing high-density silicon nano-crystalline film

InactiveCN101414552AThe process steps are simpleVersatileSemiconductor/solid-state device manufacturingSilicon monoxideEvaporation

The invention relates to a preparation method of a high-density silicon nano-crystalline thin film, and the preparation method comprises: a silicon dioxide layer is formed on a silicon substrate; silicon monoxide is taken as a target material to be deposited on the silicon dioxide layer by the electron beam evaporation method, thereby forming a mixture thin film layer; silicon ions are implanted in the mixture thin film layer; and the mixture thin film layer is annealed to form the high-density silicon nano-crystalline thin film layer. The preparation method prepares the high-density silicon nano-crystalline thin film by the electron beam evaporation of the silicon monoxide and the ion implantation method for matching, thereby having the advantages of simple process steps, multiple purposes and ability of being compatible with the traditional Si-based CMOS technology. The surface density of the silicon nano-crystalline which is prepared by using the method can be up to 10<12>cm<minus 1> level, and the diameter of particles is in the range of 5-8nm. The preparation method is mainly applied in the preparation of key components of the third generation of silicon-based solar cell chips, silicon single electron devices, single electron memories, silicon nano-crystalline floating gate memories and other aspects, thereby being applicable to the requirements on large-scale production.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

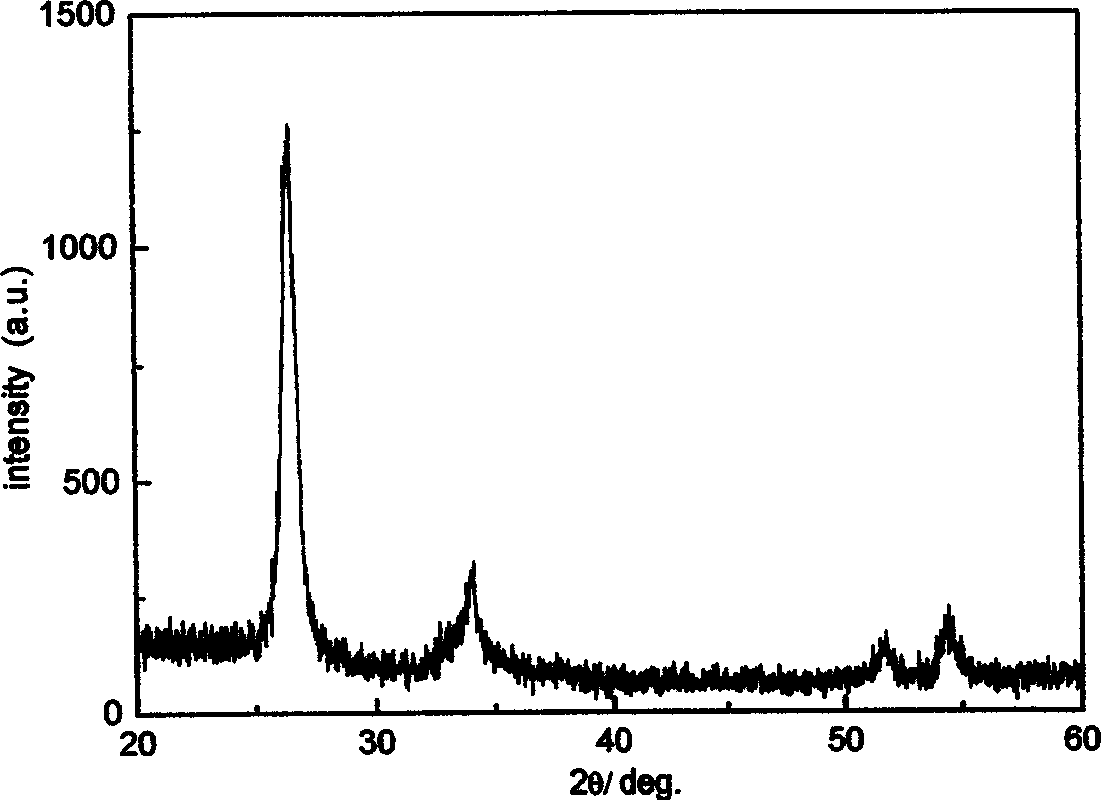

Process for preparing tin oxide nanocrystalline thin films

InactiveCN1544692AThickness is easy to controlNo crackSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingTin dioxidePotassium

The invention discloses a stannum dioxide nano crystal state film preparing method, including the following steps; (1) washing the surface of a substrate; (2) placing the substrate in the mixed solution of oil of vitriol and oxydol to hydroxylate the surface; (3) dipping the substrate X(CH2)nSi(OH3)3, X(CH2)nSiCl3 or HS(CH2 m solution for soaking, so as to form an organic molecular self-composing single-layer film on the surface; (4) soaking the substrate with mercaptoand alkyl groups as head groups by the mixed solution of oxydol and acetic acid; or soaking the substrate with ethylene as head group by saturated potassium monopersulfate solution, so as to functionalize organic molecular self-composing layer on the surface; (5) dipping the substrate in SnCl4 HCl solution or SnF2 boric acid solution to make a stannum dioxide nano crystal state film. It provides a functionalized surface liquid-phase deposition technique and the prepared products have rutile crystal shaped structure.

Owner:TIANJIN UNIV

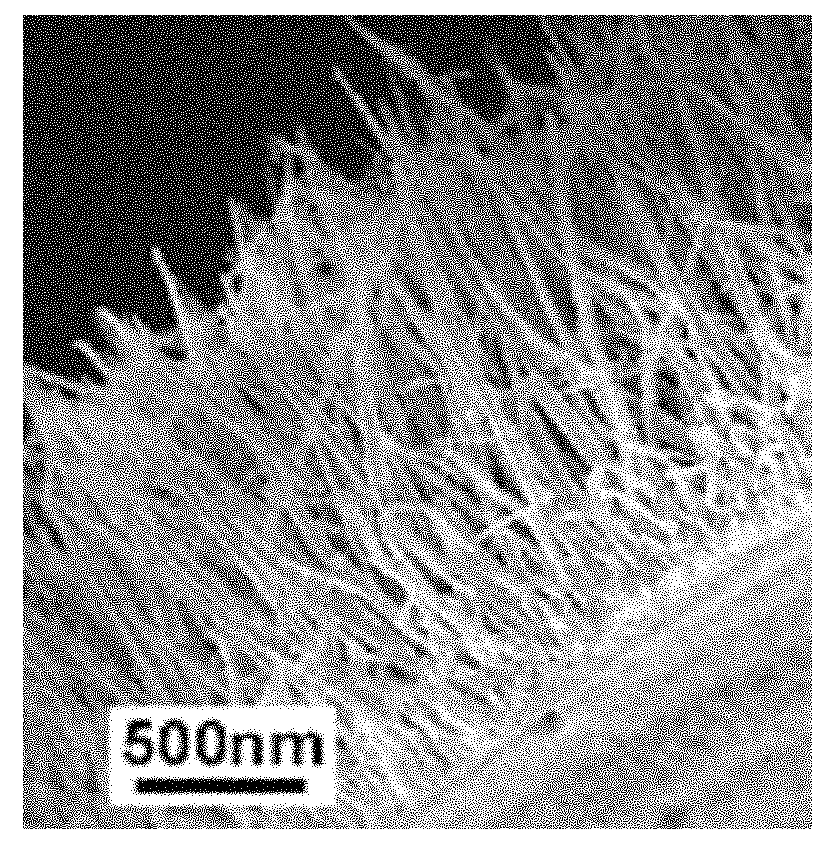

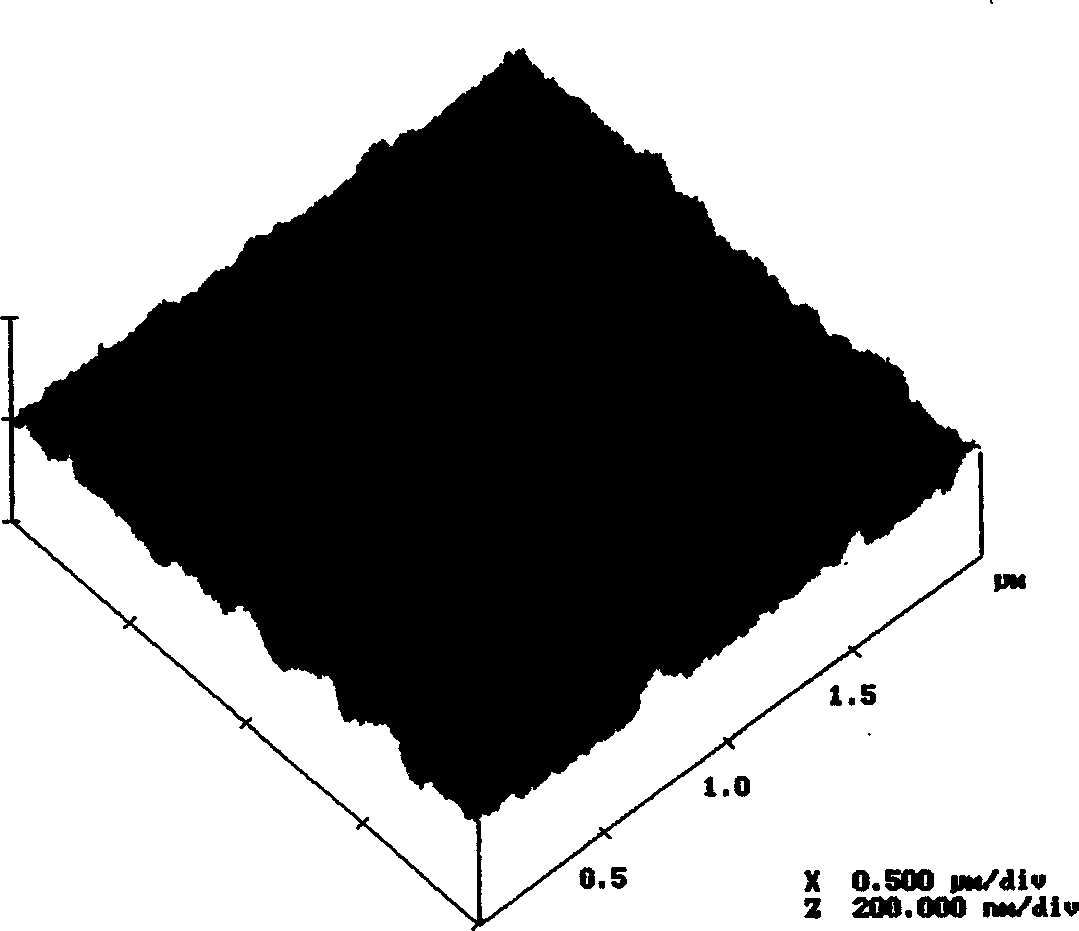

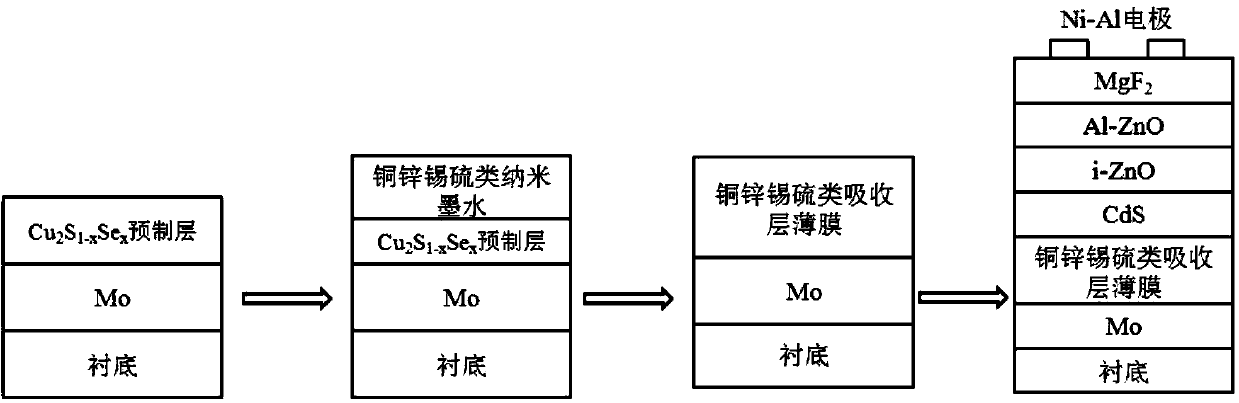

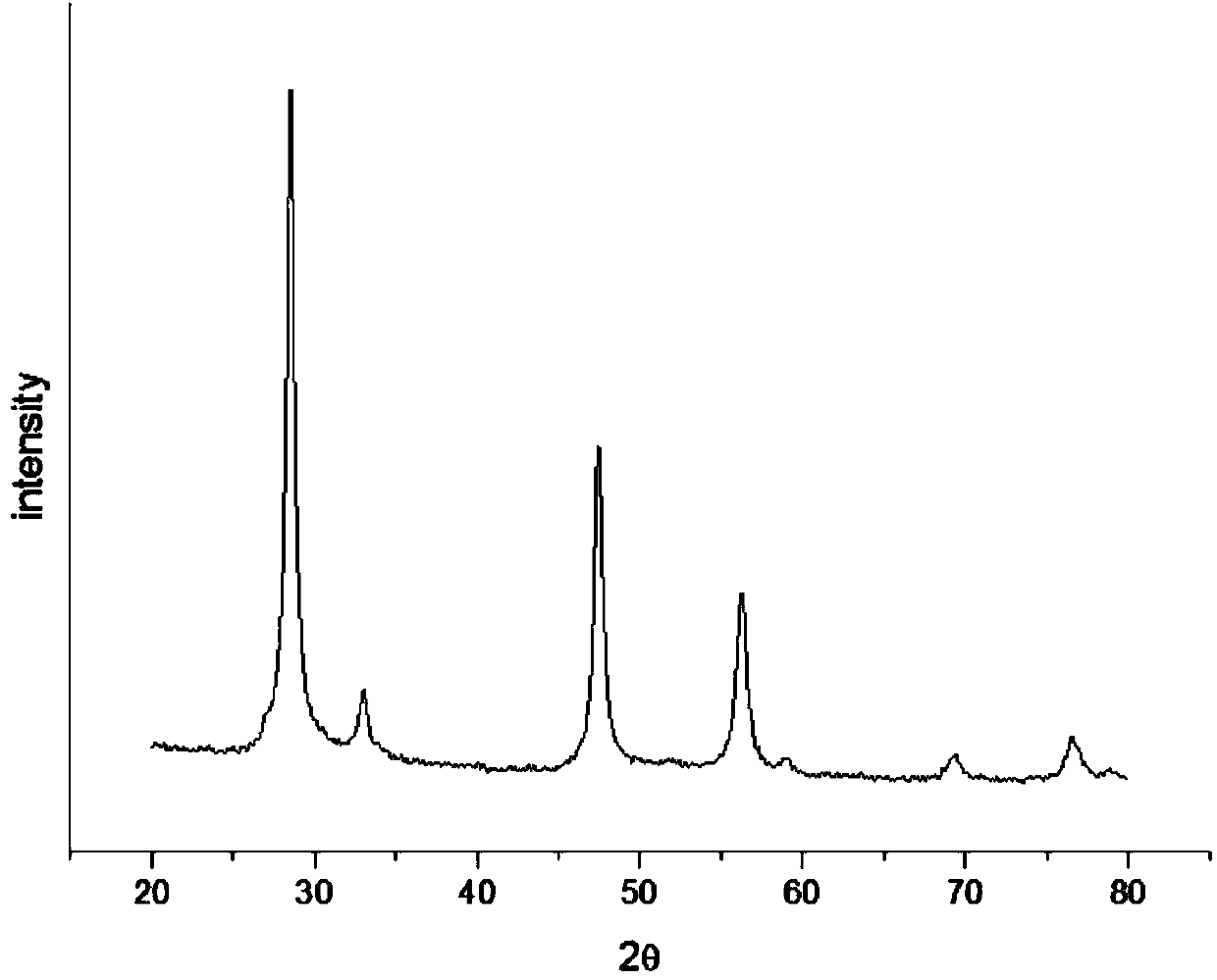

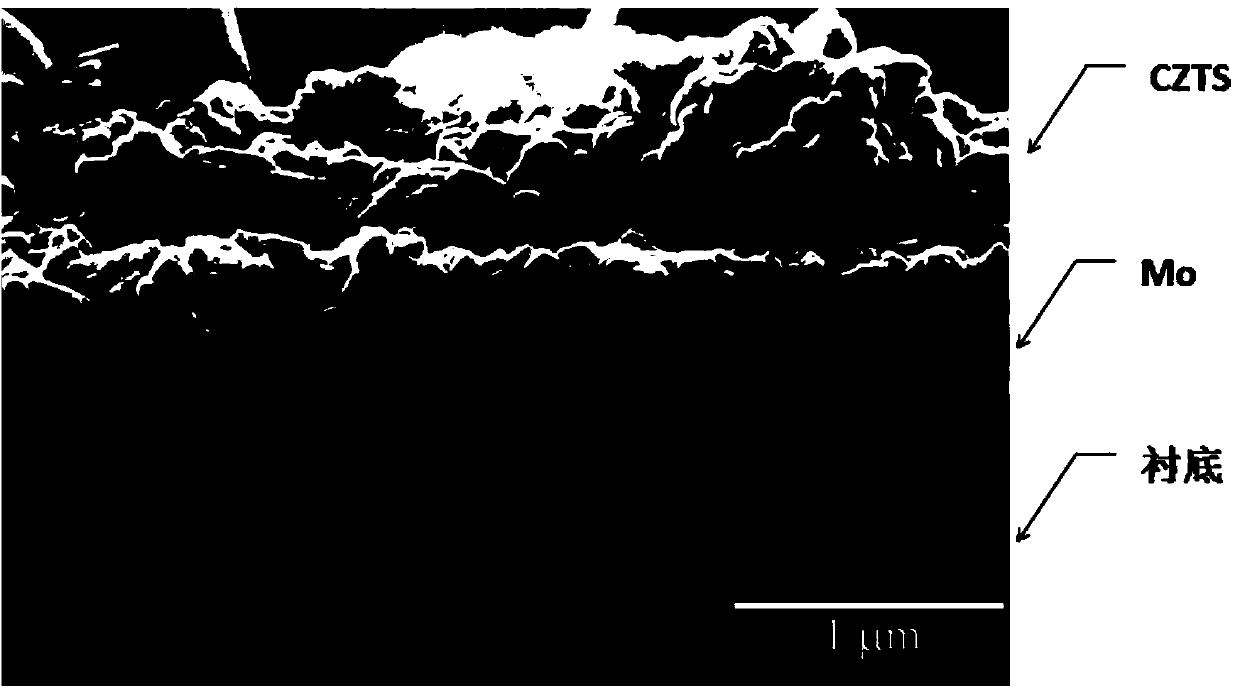

Method for preparing copper-zinc-tin-sulfur thin-film solar cell through interfacial modification

InactiveCN103746034AStrong adhesionImprove efficiencyFinal product manufacturePhotovoltaic energy generationChemical reactionContact layer

The invention relates to the technical field of solar cells, and discloses a method for preparing a copper-zinc-tin-sulfur thin-film solar cell through interfacial modification. The copper-zinc-tin-sulfur thin-film solar cell is of a multi-layer film structure, and comprises a substrate, an Mo back contact layer, a copper-zinc-tin-sulfur light absorption thin-film layer, a CdS buffer layer, a ZnO window layer, an MgF2 anti-reflecting film and an Ni-Al metal gate electrode. According to the method, through interfacial modification, a Cu2S1-xSex pre-fabricating layer is prepared on the Mo back contact layer, wherein x is greater than or equal to 0 and smaller than or equal to 1; copper-zinc-tin-sulfur nano-ink is used for film forming on the pre-fabricating layer, so that diffusion confusion and chemical reaction of the Cu2S1-xSex pre-fabricating layer and a copper-zinc-tin-sulfur nanocrystalline thin-film are realized through high-temperature annealing technology; on the basis that other impurity elements are not introduced, the disadvantage that copper-zinc-tin-sulfur nanocrystalline is low in film-forming adhesive force is effectively overcome, and a copper-zinc-tin-sulfur light absorption thin-film layer with good crystallinity, uniform appearance, single phase and high adhesive force is obtained, thus the copper-zinc-tin-sulfur thin-film solar cell with high efficiency is prepared.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

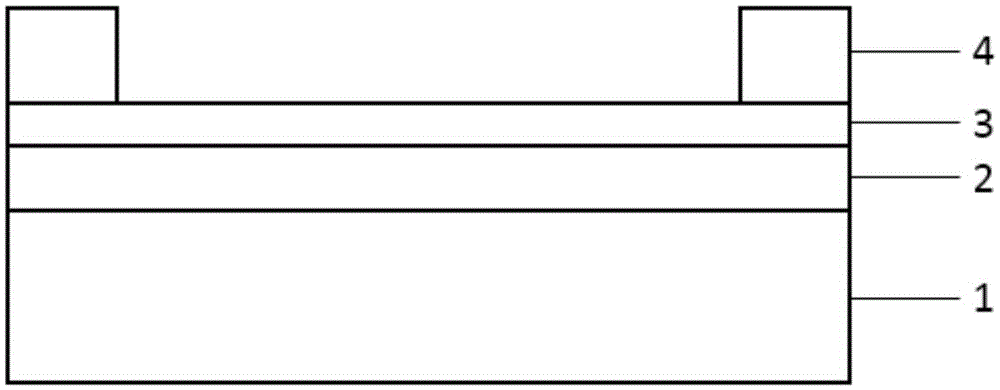

Dye-sensitized solar battery of nano-crystalline thin film and method for making same

InactiveCN101013730AImproved interface contactImprove responseLight-sensitive devicesFinal product manufactureSolid state electrolyteEngineering

Owner:FUDAN UNIV

Preparation of nano crystal film of rare earth doped strontium cerate

InactiveCN1584114AImprove compactnessImprove conductivityPolycrystalline material growthSolid/suspension decomposition chemical coatingWater bathsRare earth

A method for preparing rare earth doped strontium cerate nanometer crystal thin film by organic polymer presoma method is disclosed. It is prepared by: preparing initial solution with cerous nitrate, strontium nitrate or strontium acetate, rare earth oxide as raw materials, determining the proportion by prepared thin film composition, the composition of thin film is SrCe1-xRExO3, the range of x volume is 0.02-0.20, concentration of initial solution is 0.1-0.4mol / L, taking ethylene as complexant, the adding account of ethylene is 2-6 times of metal ionic total account, mixing and supersonic oscillating, heating in water bath under 50-100deg.C, adjusting PH value, the system being heated reacting to produce organic polymer, film coating with 1500-3000rpm circulating speed on required chip by glue equalizer when viscosity reaching 100-300cP, infrared drying or vacuum drying, second film coating, drying until reaching the required thickness, and producing nanometer crystal thin film under 900deg.C reacting.

Owner:SHANGHAI UNIV

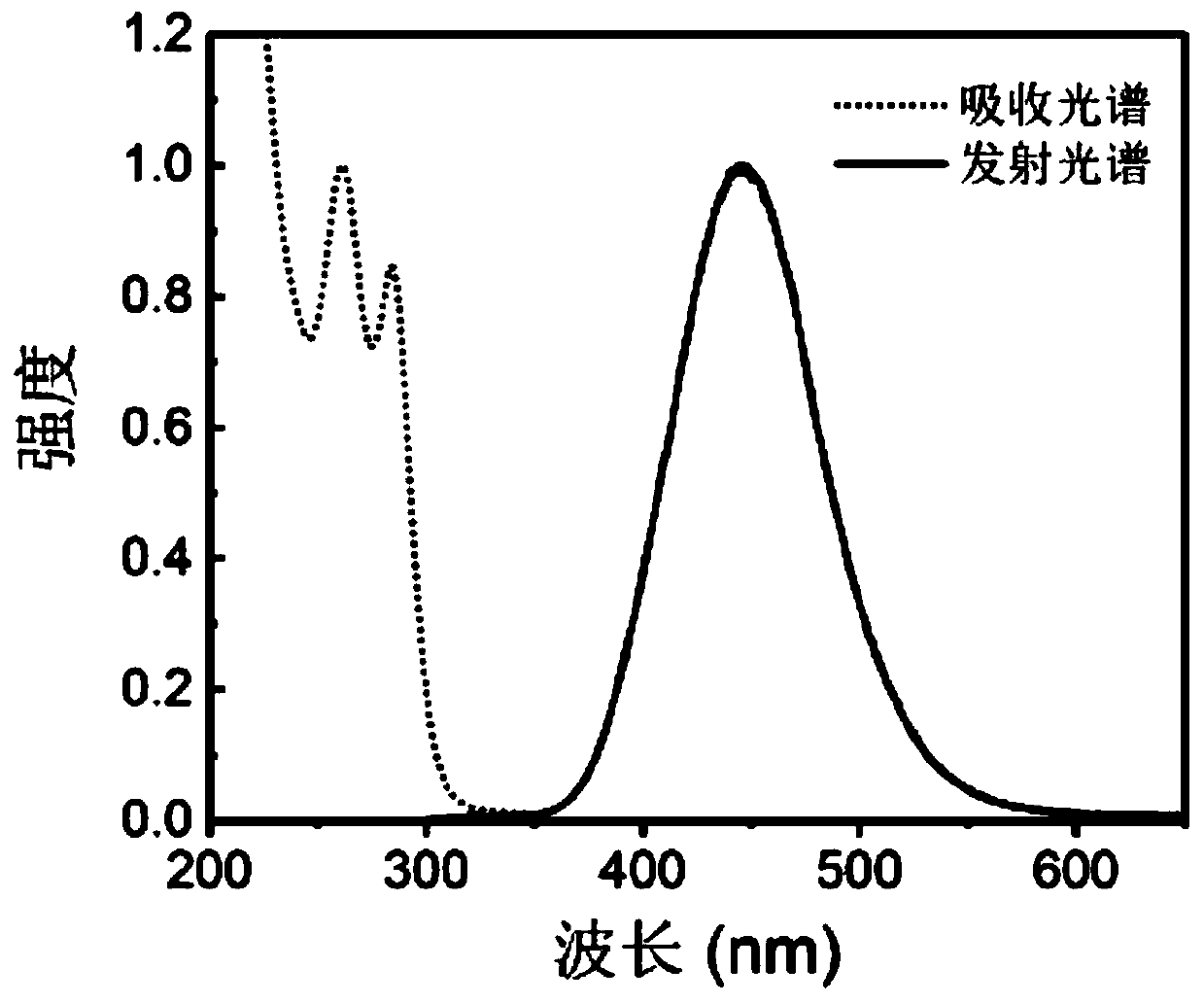

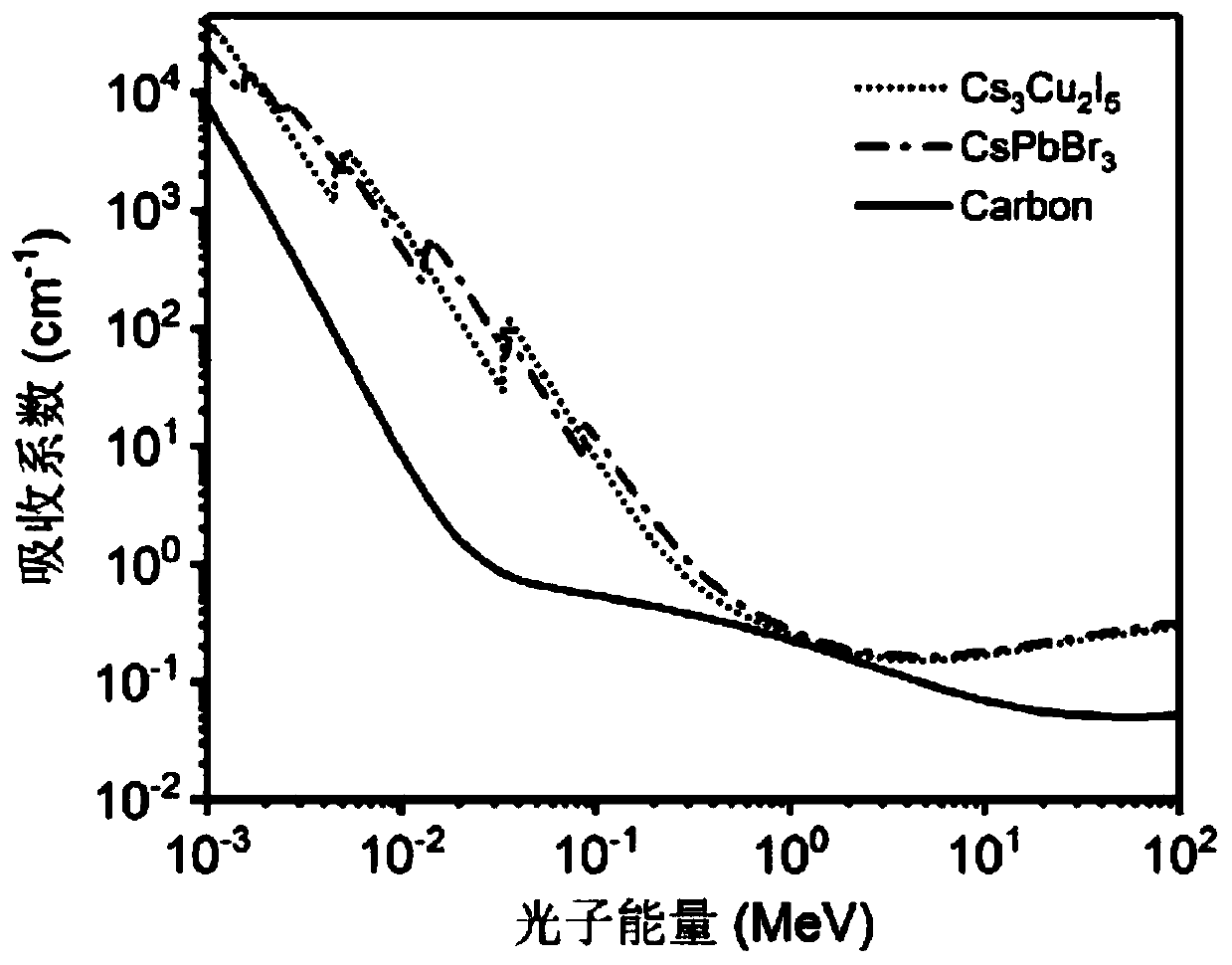

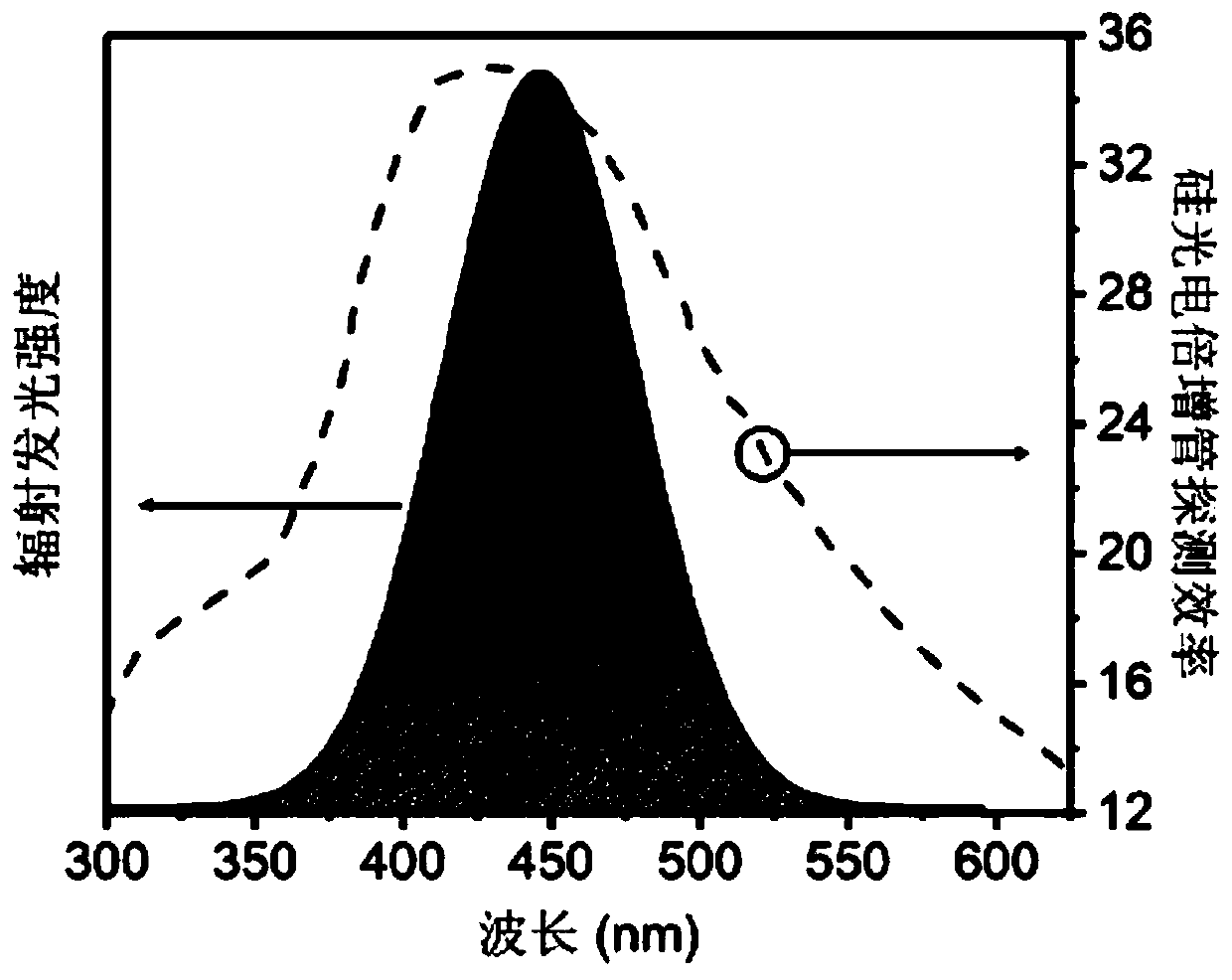

Application of non-self-absorption nanocrystalline as scintillator and preparation method of non-self-absorption nanocrystalline

InactiveCN111348675ALow costExperiment operation is simpleNanoopticsX/gamma/cosmic radiation measurmentMedical diagnosisGlass sheet

The invention belongs to the technical field of application of all-inorganic metal halide nanocrystals, and discloses application of a non-self-absorption nanocrystal as a scintillator and a preparation method of the non-self-absorption nanocrystal. The chemical general formula of the nanocrystal is Cs3Cu2X5, and X is selected from Cl, Br and I. The preparation method of the scintillator comprisesthe following steps: coating a glass sheet with an organic solution of Cs3Cu2X5 nanocrystalline, and naturally volatilizing an organic solvent in air to form a Cs3Cu2X5 nanocrystalline film which canbe used as the scintillator. The Cs3Cu2X5 nanocrystalline thin film is prepared to serve as a scintillator to be applied to X-ray imaging, the efficient scintillation performance is shown, and meanwhile the Cs3Cu2I5 nanocrystalline scintillator is applied to X-ray imaging, and the very high resolution is shown as high as 0.32 mm. The preparation method is simple in preparation process, easy to implement and low in cost, and has important application value and important prospect in medical diagnosis, national defense industry and manufacturing industry. And meanwhile, the defects of the traditional lead-containing halogen perovskite nanocrystalline can be overcome.

Owner:HUAZHONG UNIV OF SCI & TECH

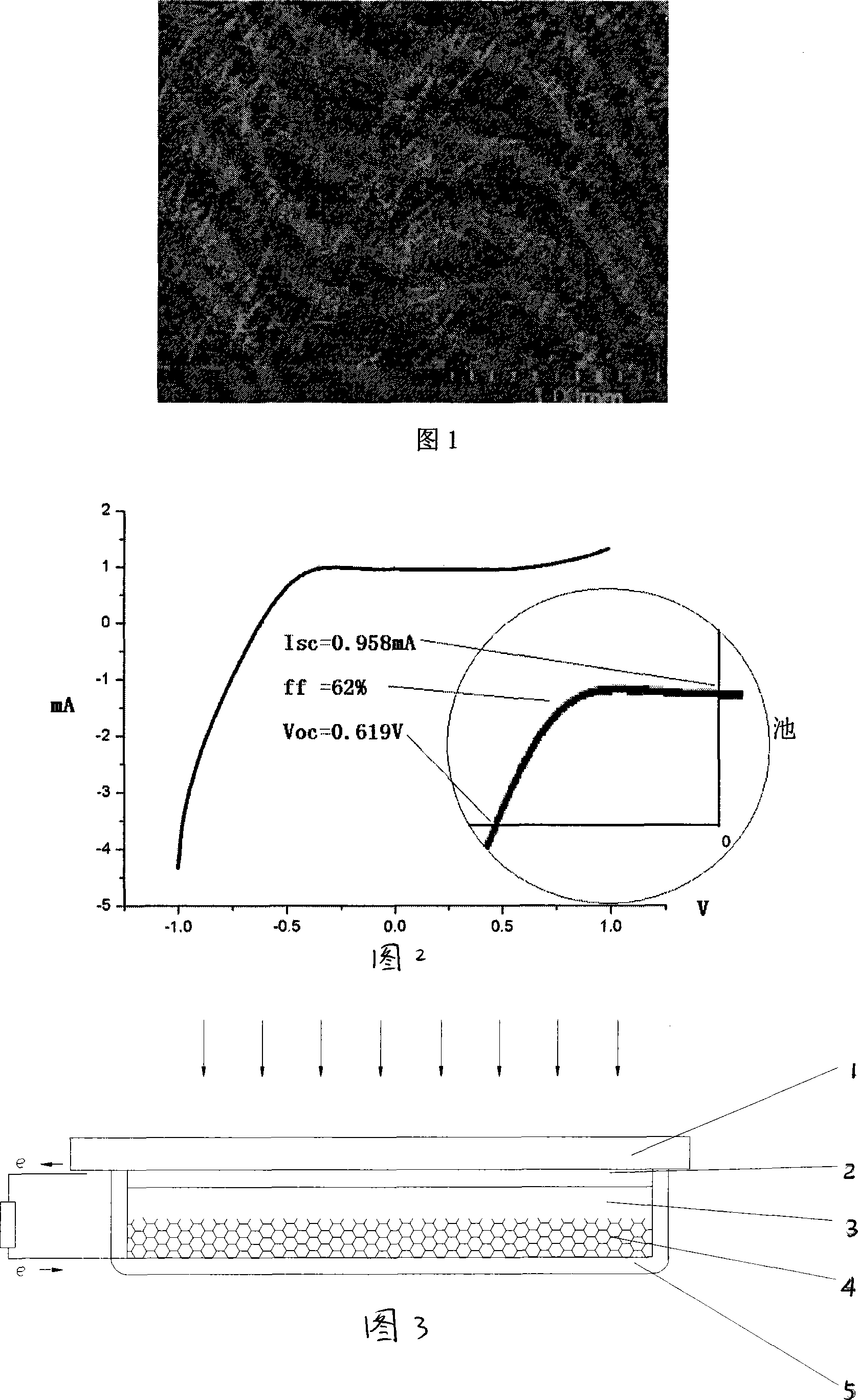

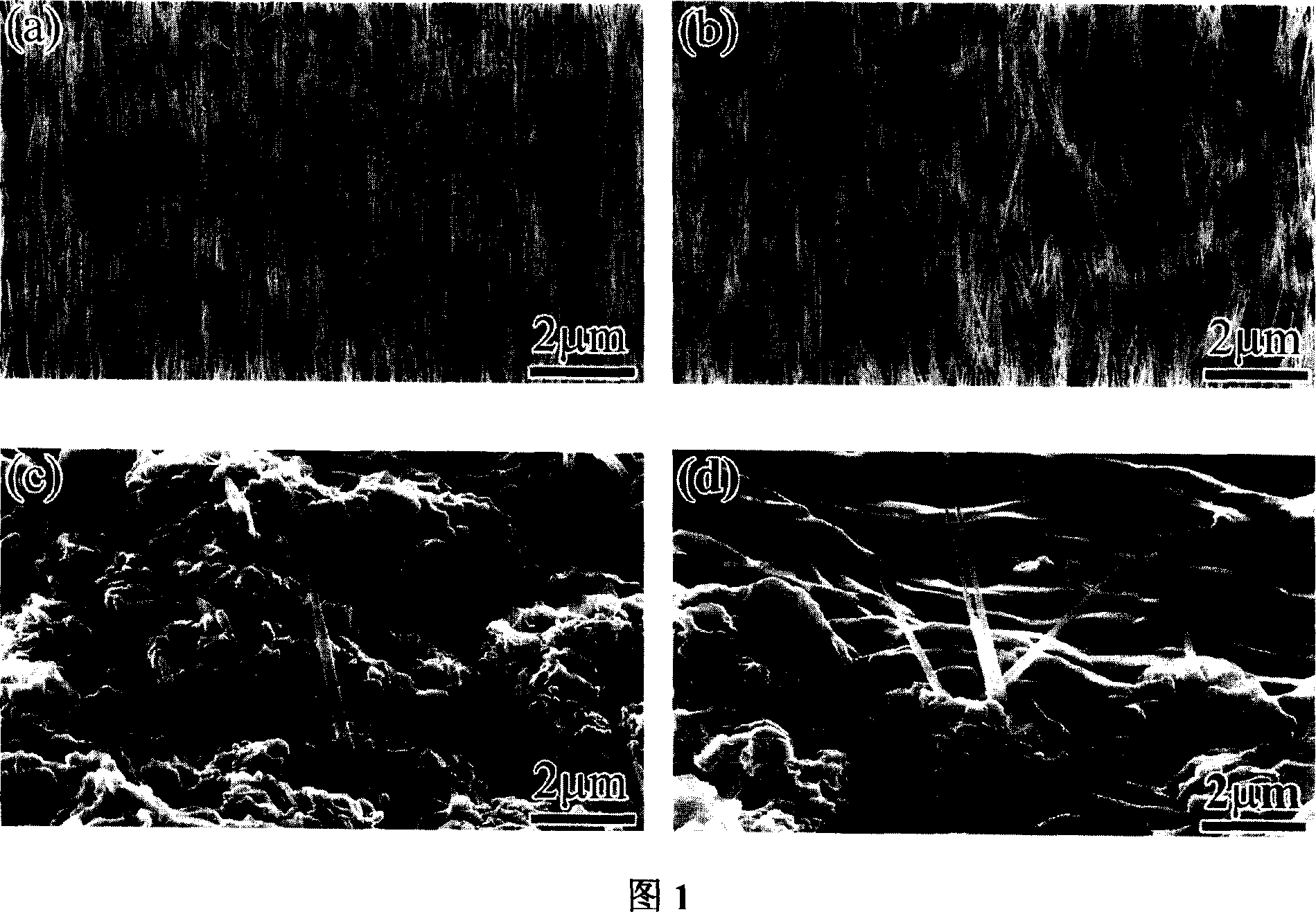

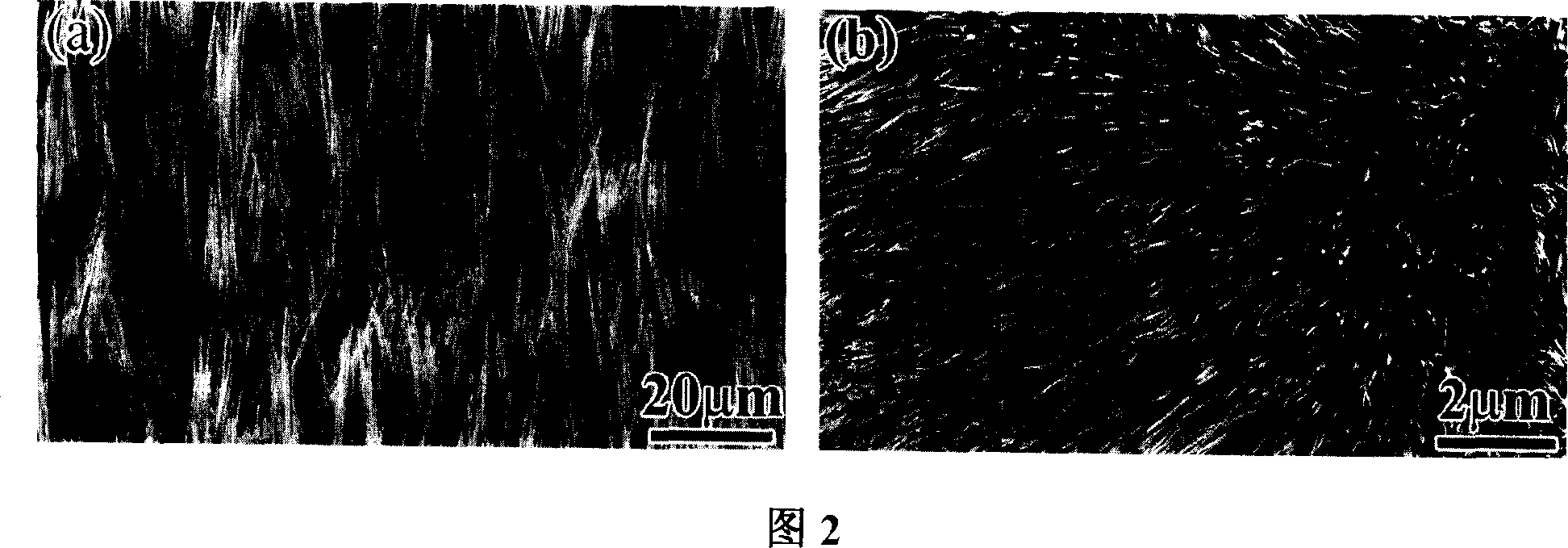

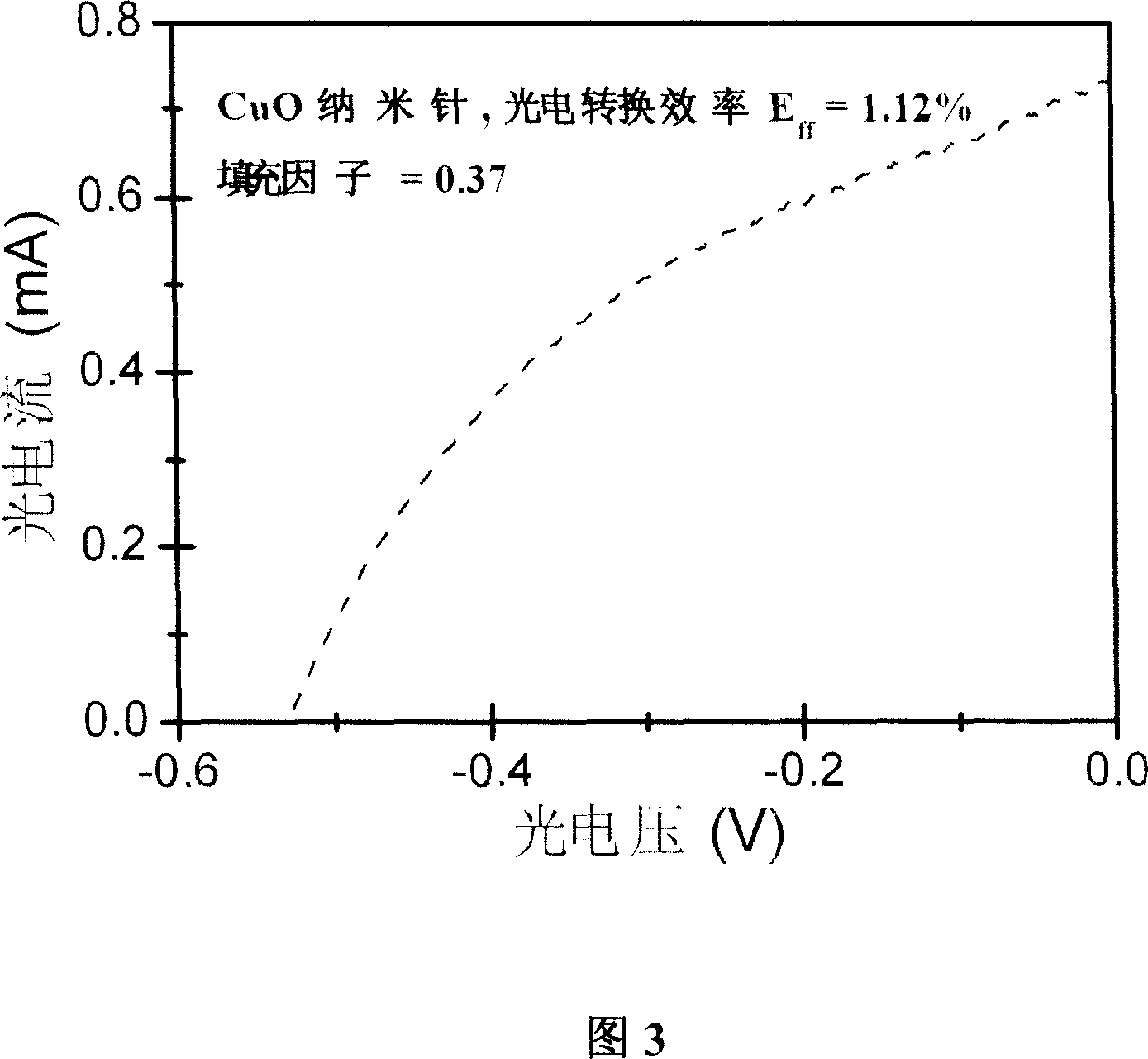

Use of CuO nano-needle/Cu base-plate material in solar dye battery

InactiveCN101030606ASimple processHigh degree of controllabilityLight-sensitive devicesFinal product manufactureWork functionDeposition process

The invention is concerned with one dimension CuO Nano-needle / Cu substrate material and the application in dye solar cells. The material is produced with pulse electrolysis deposition process. Electrolysis deposit one layer of nanocrystalline Cu film on Cu substrate, put this film into heating stove to get one dimension CuO Nano-needle material under 750+ / -50 DEG C for 1 to 2 hours. Take the one dimension CuO Nano-needle / Cu substrate material as cathode material to solar cell with TCO Conducting glass / TiO2 nanocrystalline / dry / CuO Nano-needle / Cu substrate, and test its efficiency of light to electricityeta. For the work function of CuO(Phi=5.3eV) is close to Pt(Phi=5.65eV), and P type of CuO has high hole mobility (0.1cm<2>V<-1>S<-1>), so it can be used as cathode material to solar cell instead of Pt to greatly reduce the cost, for better application and spread of solar cell.

Owner:WUHAN UNIV OF TECH

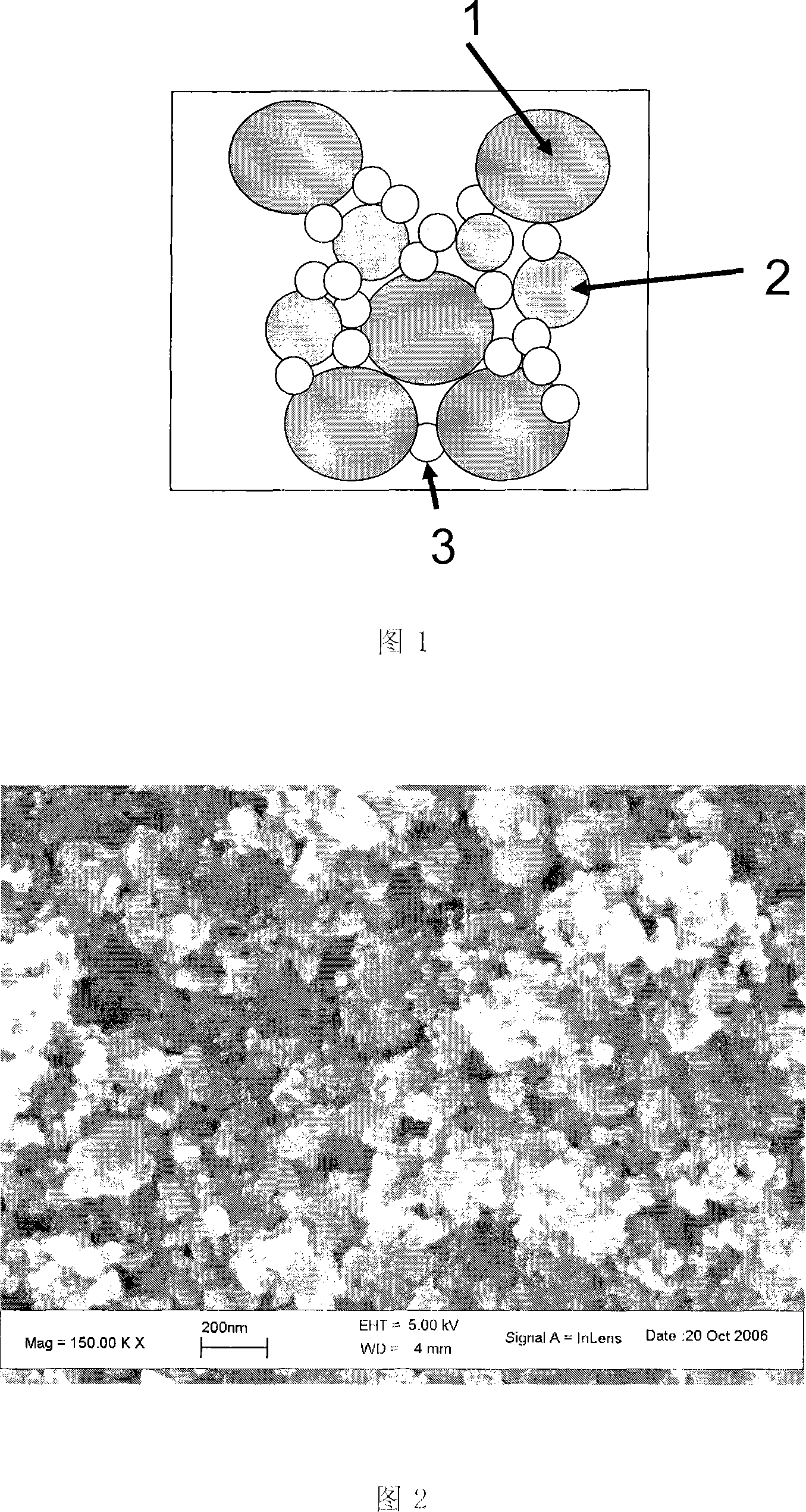

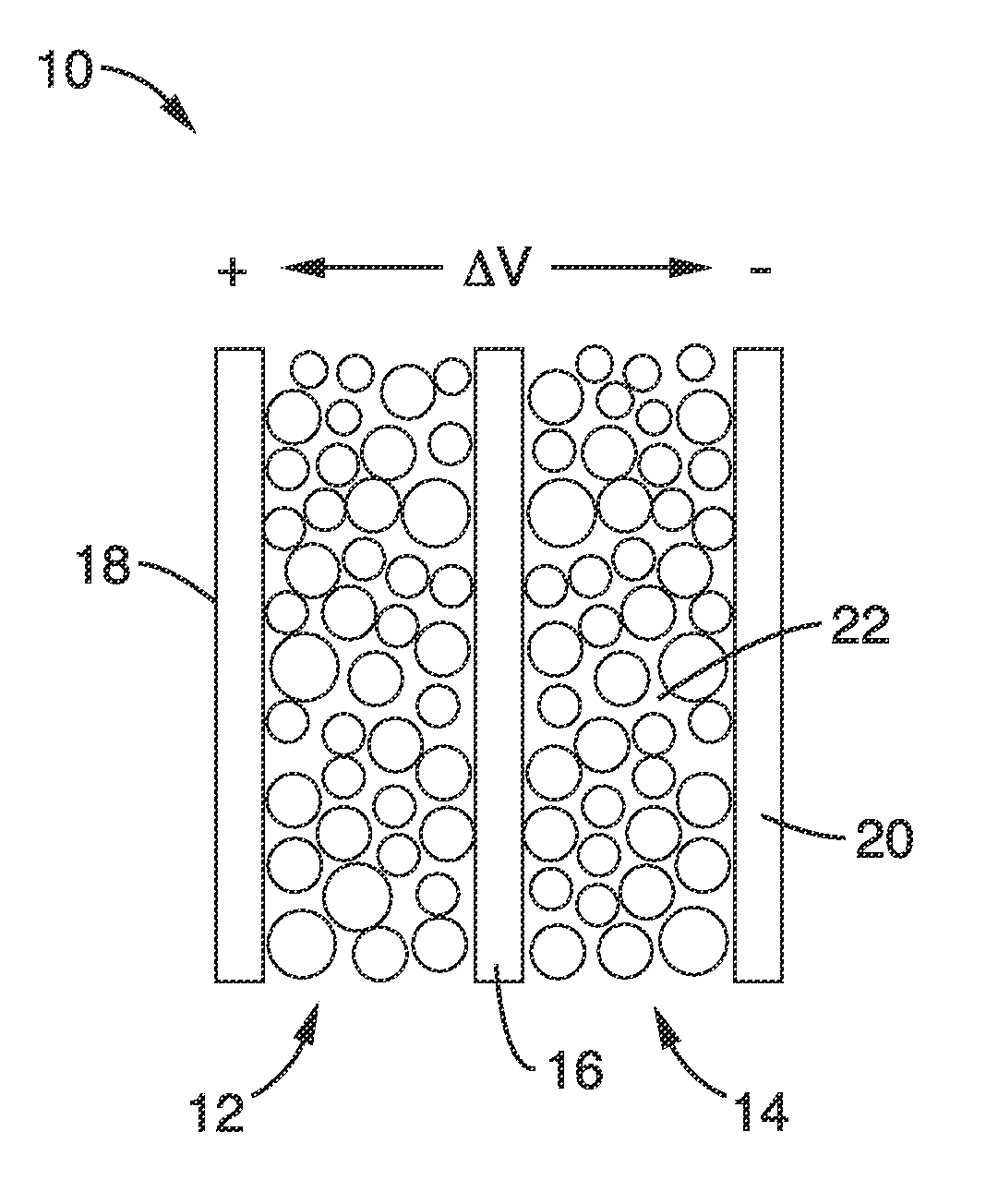

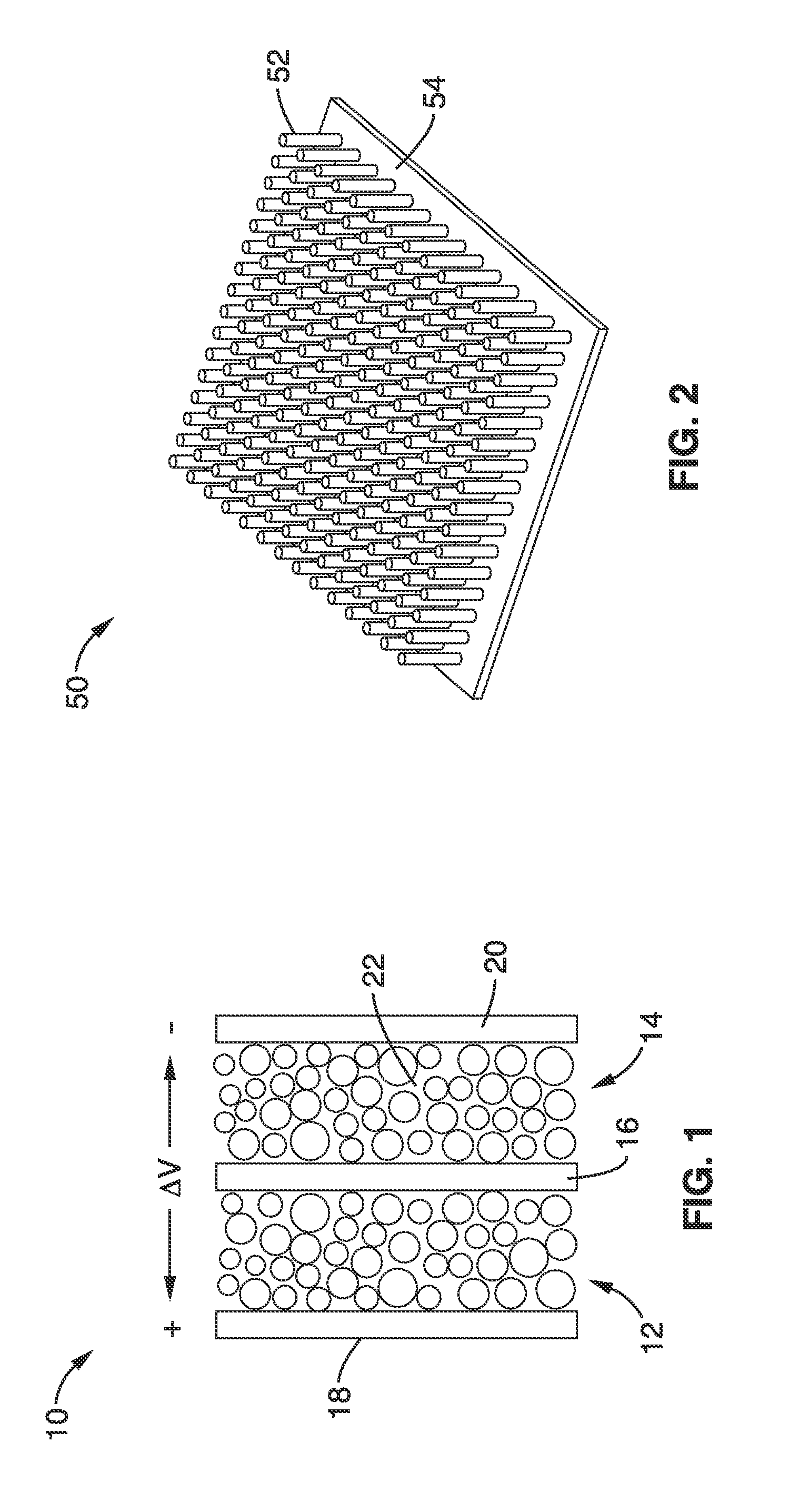

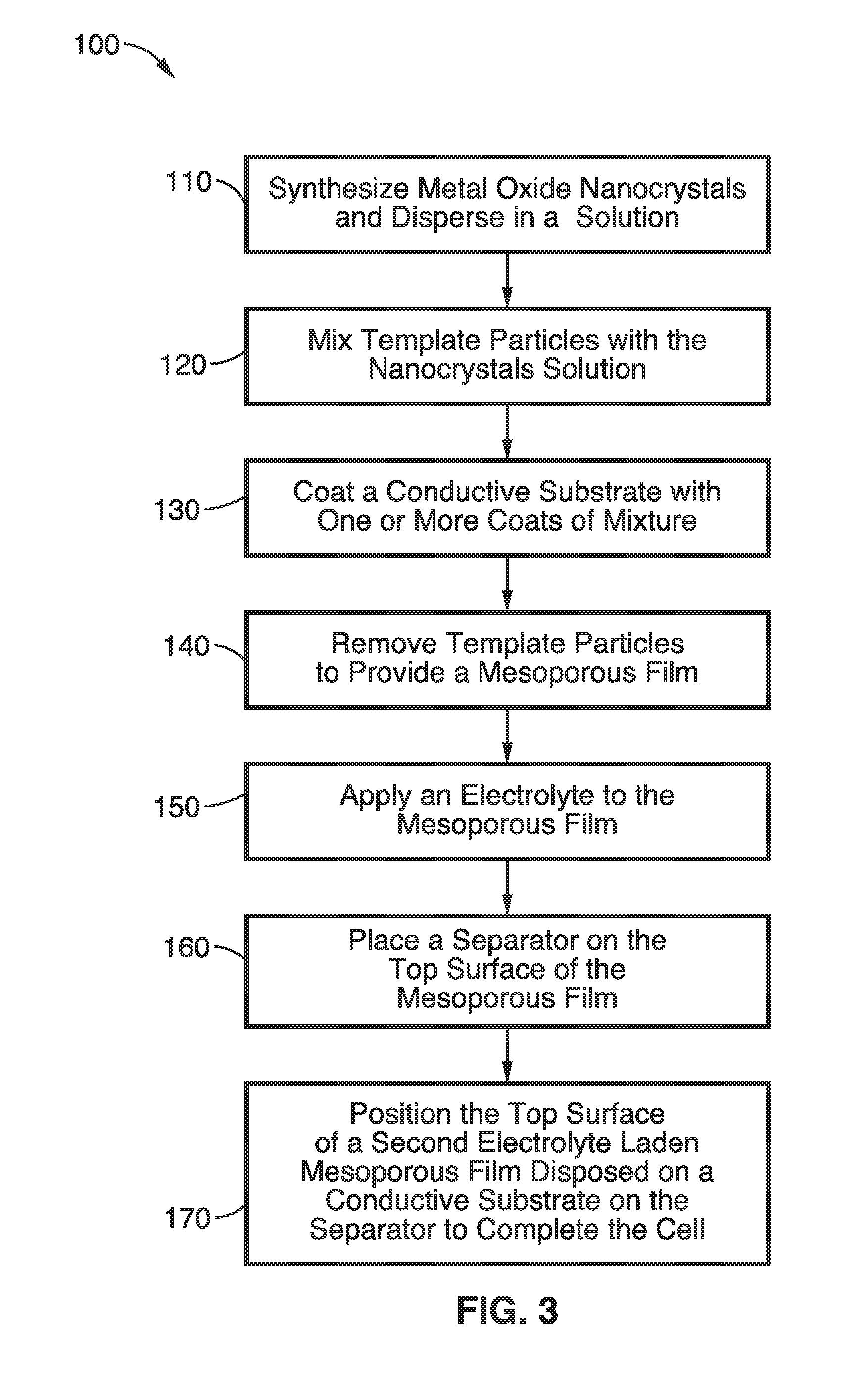

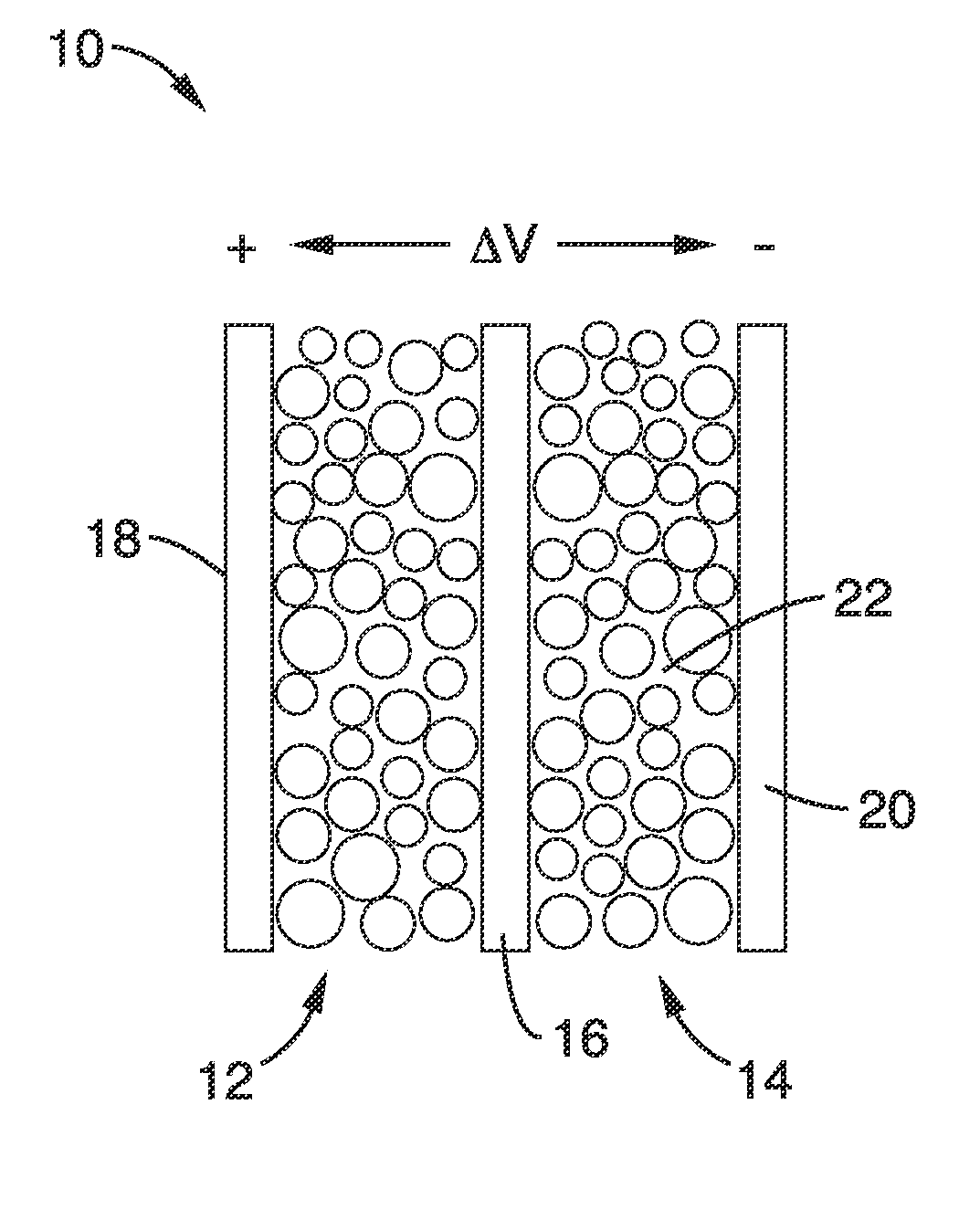

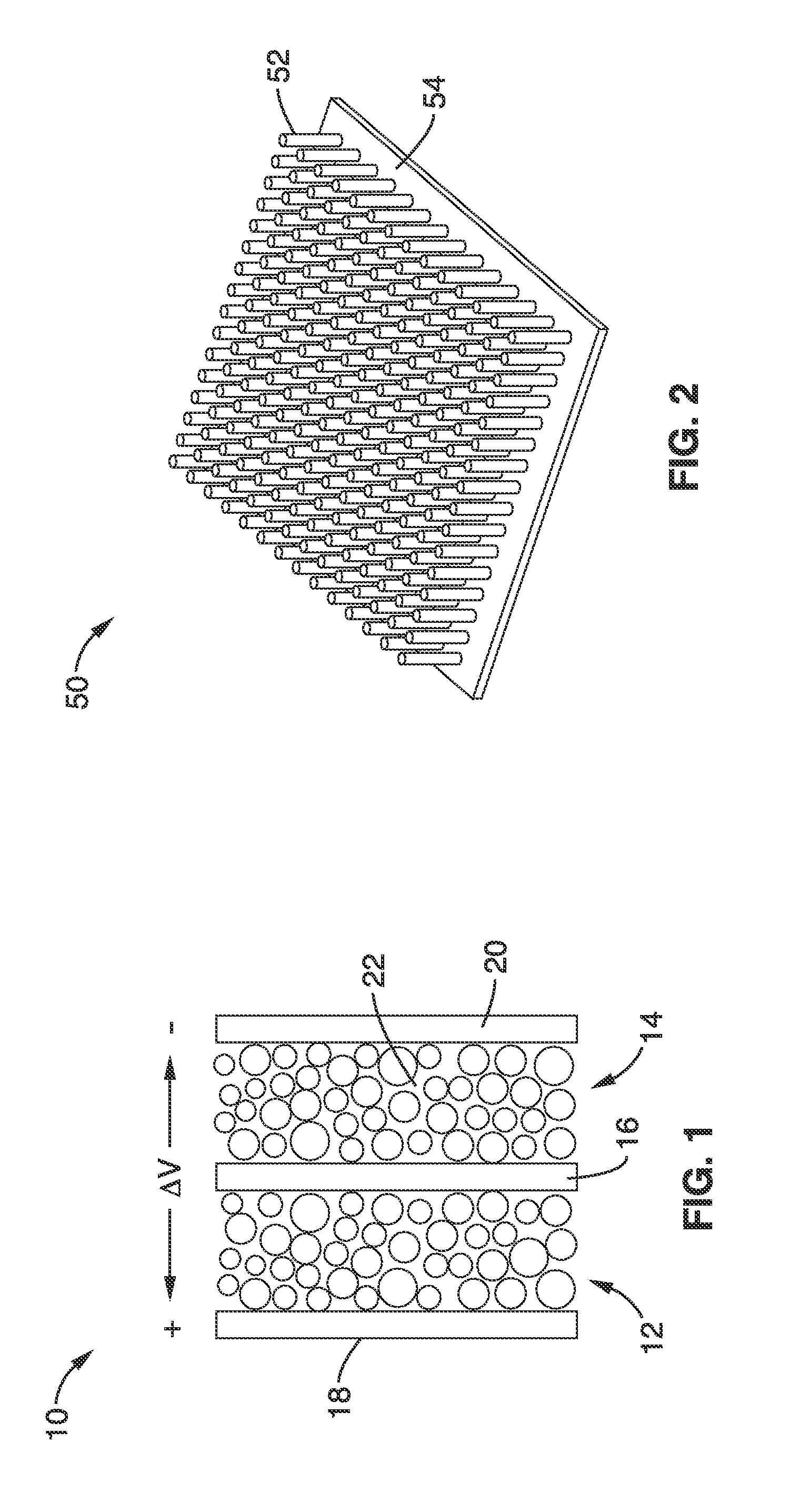

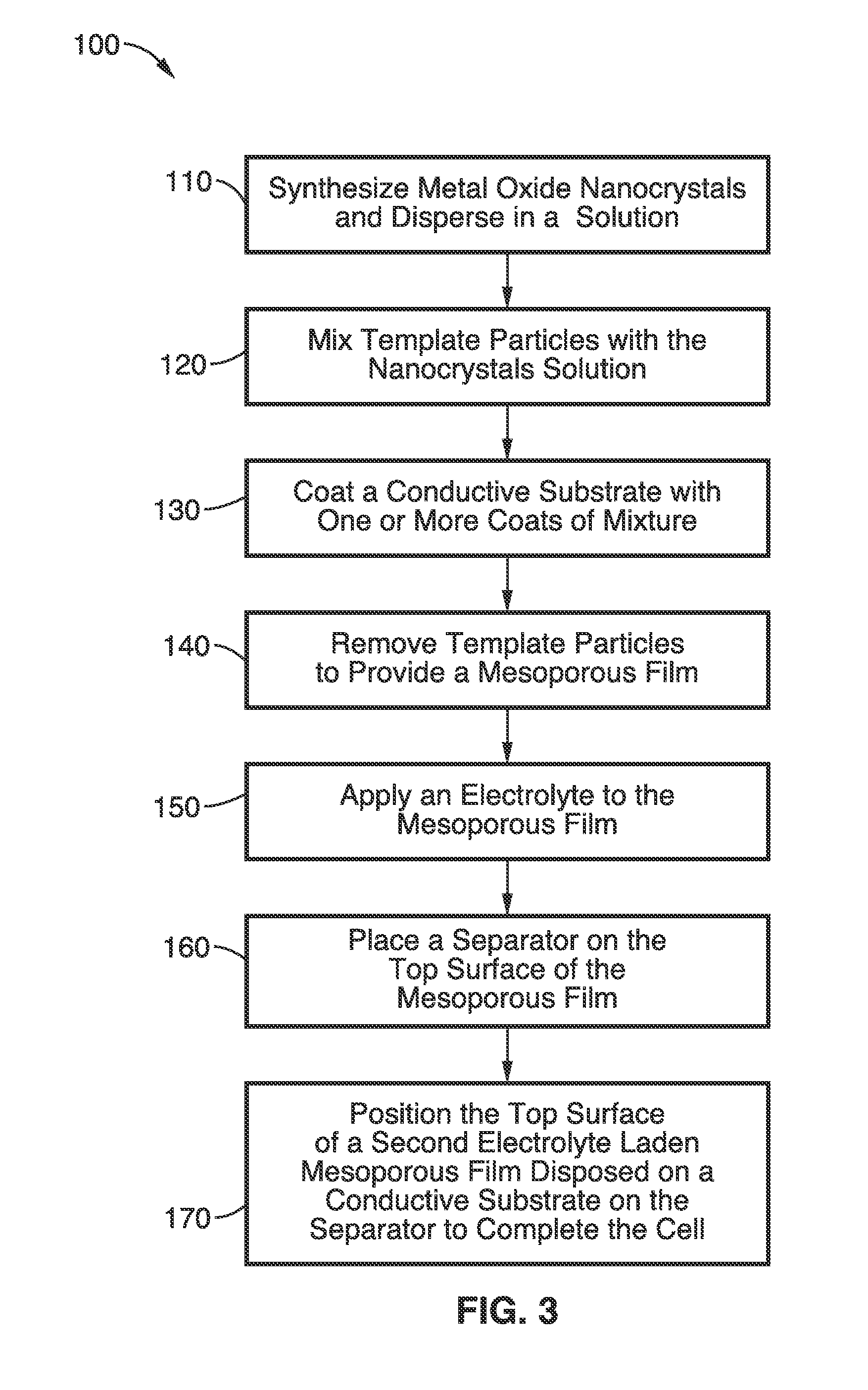

Mesoporous nanocrystalline film architecture for capacitive storage devices

ActiveUS20120026644A1Without energy densityHigh rateNanotechHybrid capacitor electrodesCapacitanceCapacitive storage

A mesoporous, nanocrystalline, metal oxide construct particularly suited for capacitive energy storage that has an architecture with short diffusion path lengths and large surface areas and a method for production are provided. Energy density is substantially increased without compromising the capacitive charge storage kinetics and electrode demonstrates long term cycling stability. Charge storage devices with electrodes using the construct can use three different charge storage mechanisms immersed in an electrolyte: (1) cations can be stored in a thin double layer at the electrode / electrolyte interface (non-faradaic mechanism); (2) cations can interact with the bulk of an electroactive material which then undergoes a redox reaction or phase change, as in conventional batteries (faradaic mechanism); or (3) cations can electrochemically adsorb onto the surface of a material through charge transfer processes (faradaic mechanism).

Owner:RGT UNIV OF CALIFORNIA

Mesoporous nanocrystalline film architecture for capacitive storage devices

ActiveUS8675346B2Without energy densityHigh rateNanotechLiquid electrolytic capacitorsCapacitancePath length

A mesoporous, nanocrystalline, metal oxide construct particularly suited for capacitive energy storage that has an architecture with short diffusion path lengths and large surface areas and a method for production are provided. Energy density is substantially increased without compromising the capacitive charge storage kinetics and electrode demonstrates long term cycling stability. Charge storage devices with electrodes using the construct can use three different charge storage mechanisms immersed in an electrolyte: (1) cations can be stored in a thin double layer at the electrode / electrolyte interface (non-faradaic mechanism); (2) cations can interact with the bulk of an electroactive material which then undergoes a redox reaction or phase change, as in conventional batteries (faradaic mechanism); or (3) cations can electrochemically adsorb onto the surface of a material through charge transfer processes (faradaic mechanism).

Owner:RGT UNIV OF CALIFORNIA

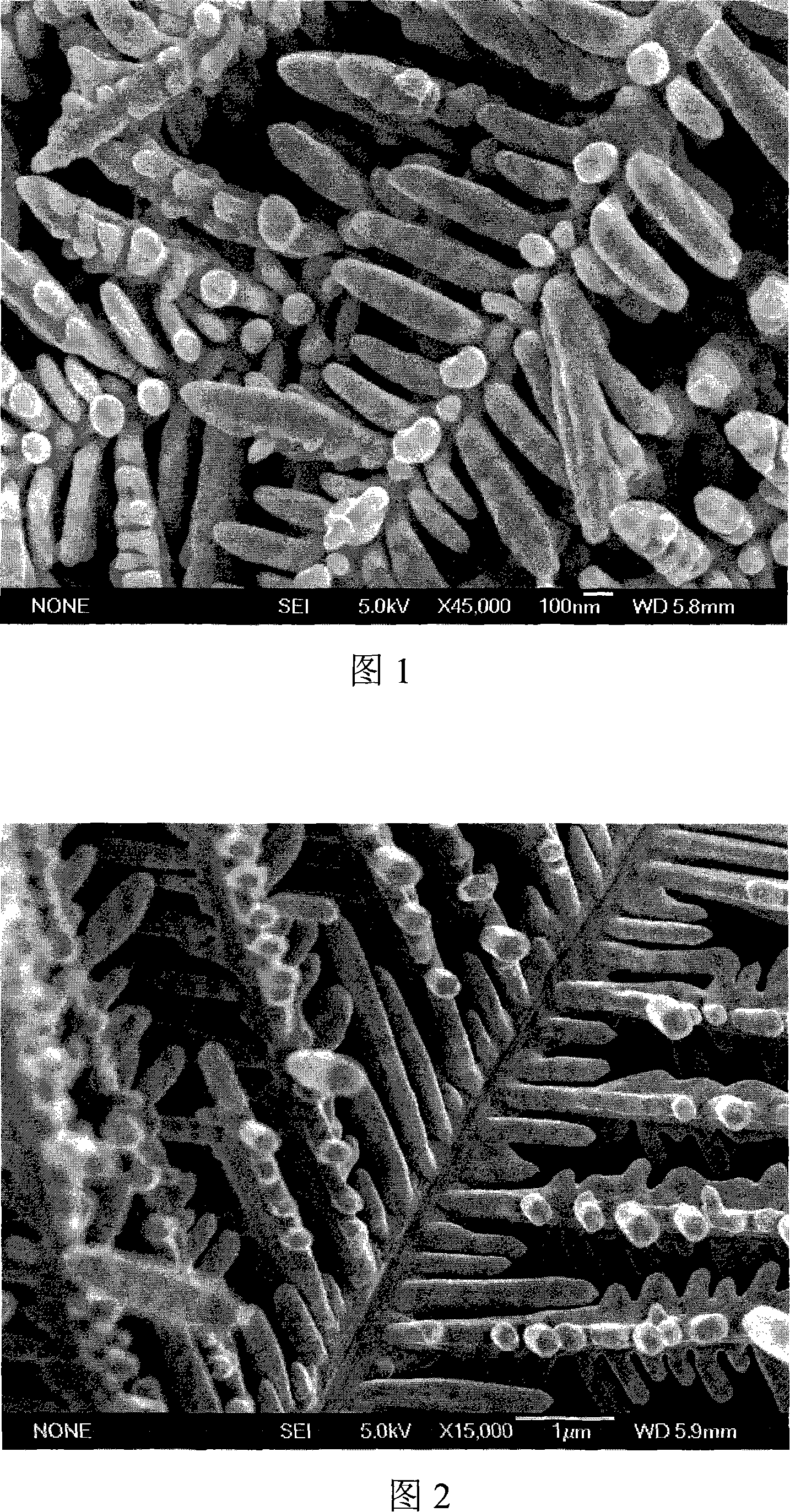

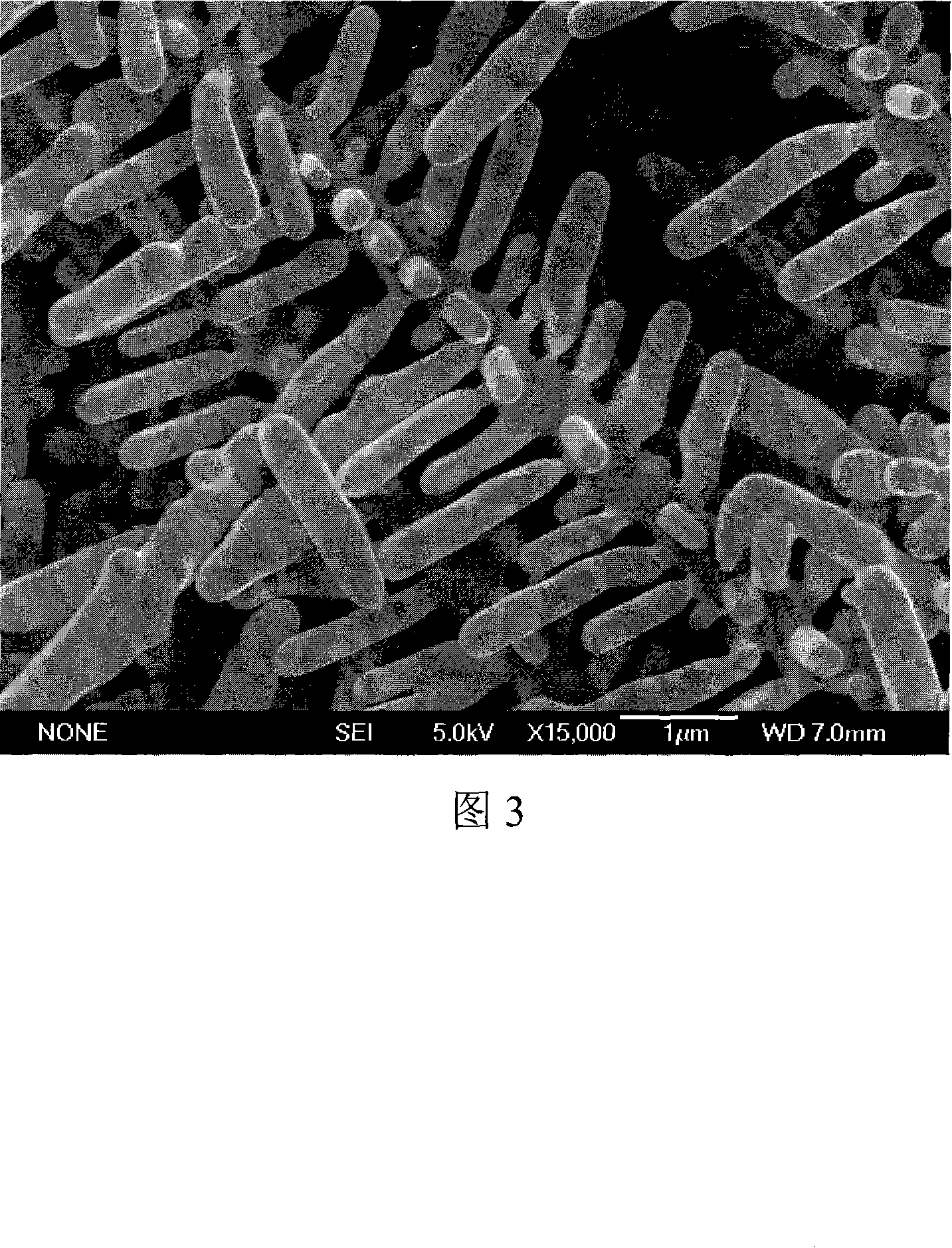

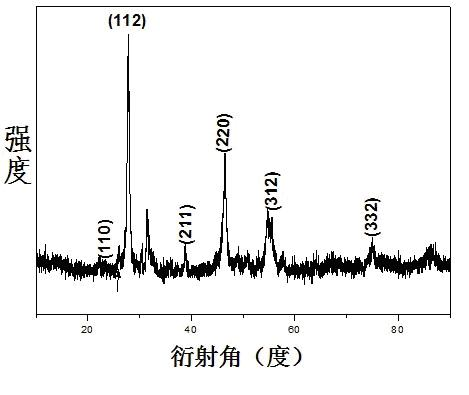

Dendritic silver selenide nano crystal thin film material and preparation method

InactiveCN101121504ARapid responseEasy to operateNanostructure manufactureSilve compoundsChemical reactionSolvent

A dendritic silver selenide nano-crystalline thin film material and the preparation method are provided. The making method of the present invention is that a substrate material with a metal silver surface, a simple substance selenium powder and an organic alcohol solvent are put into a reaction kettle of a polytetrafluoroethylene and react at a temperature between 120 DEG C and 180 DEG C. The dendritic silver selenide nano-crystalline thin film material is formed at the original place on the metal silver surface of the substrate material and cools down to the room temperature after the reaction is over. The production is cleaned with a waterless ethanol and dried under the temperature of 50 DEG C. The substrate material is the metal silver foil, of which the surface is plated with a layer of semiconductor silicon wafers of the nano metal silver, a conductive glass ITO and others. The present invention directly produces the silver selenide nano-crystalline thin film at the original place on the substrate of metal silver surface by one-step reaction and takes the simplest organic alcohol as the reaction medium; therefore the environment is moderate. Any additive and surfactant are not used and the subsequent purification step is not needed but the crystalline shape is still perfect. With the quick reaction and the convenient operation, the present invention has a broad industrial application foreground.

Owner:XUCHANG UNIV

The water bath preparation method of cu2znsns4 or cu2cdsns4 nanocrystalline film

InactiveCN102275980AEasy to prepareSynthesis temperature is lowTin compoundsWater chlorinationTin(II) chloride

The invention discloses a low-temperature preparation method of a Cu2ZnSnS4 or Cu2CdSnS4 nanocrystalline film with low cost and high quality, comprising the following steps of: firstly adding a certain amount of copper sulphate, zinc chloride or cadmium chloride, stannous chloride and thioacetamide into a beaker with deionized water, letting glass which undergoes ultrasonic cleaning by the use ofalcohol, acetone and deionized water vertically suspend inside the beaker; adding dropwisely a diluted hydrochloric acid solution into the beaker to adjust the pH value and make the solution to stay in the acid condition; heating up and reacting for a certain time at a certain stirring rate, carrying out annealing treatment on the glass, on which the Cu2ZnSnS4 or Cu2CdSnS4 nanocrystalline film grows, in Ar and H2S(5%) atmospheres to finally obtain the high-quality Cu2ZnSnS4 or Cu2CdSnS4 nanocrystalline film. The invention has the following advantages: the nanocrystalline preparation method issimple; the synthesis temperature is low; the cost of precursor materials is low; and the nanocrystalline film prepared is uniform and compact. The Cu2ZnSnS4 or Cu2CdSnS4 nanocrystalline film prepared in the invention can be used as an absorbed layer for photovoltaic devices or a good thermoelectric material.

Owner:SHANGHAI UNIV

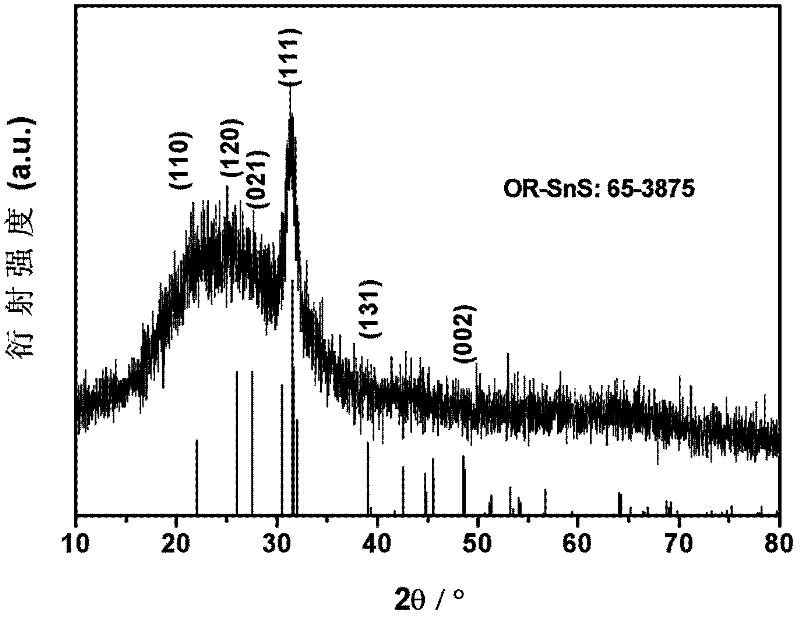

SnS nanocrystalline thin film preparation method

The invention discloses a SnS nanocrystalline thin film preparation method, which adopts an ink method. The preparation method comprises two steps: (1) preparation of SnS nanocrystalline ink including preparing a Sn-source precursor solution and a S-source precursor solution, respectively adding the S-source precursor solution and high-temperature injecting the Sn-source precursor solution into a three-neck flask, refluxing in the N2 atmosphere to prepare a SnS nanocrystalline solution, centrifugally cleaning the nanocrystalline solution with absolute ethanol, and ultrasonically dispersing in absolute ethanol to obtain the ink; (2) thin film preparation including soaking a glass substrate in the nanocrystalline ink, and preparing the thin film by dip-coating method. The preparation method is simple, and can control the formation and growth speed of crystal nucleus. Additionally, the preparation method is easy in controlling stoichiometric ratio, and is suitable for preparation of multicomponent thin film.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com