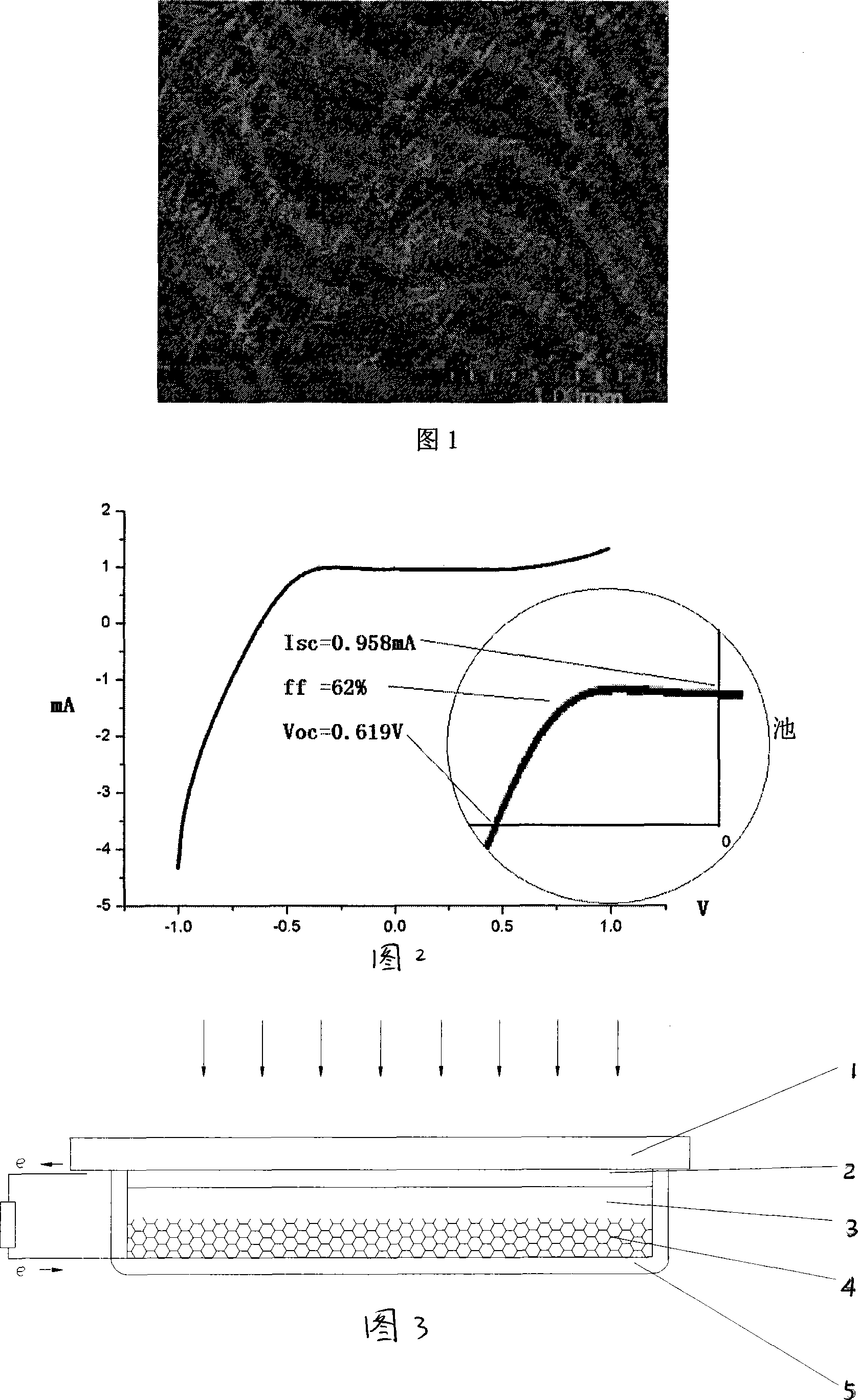

Dye sensitization nanocrystalline thin-film solar cell high pore space flexible carbon to electric pole and preparation method thereof

A technology of solar cells and sensitized nanocrystals, which is applied in the fields of nanomaterials and new energy, can solve problems such as high cost, limited catalytic area, and peeling off, and achieve the effects of reducing usage, reducing manufacturing costs, and overcoming flatness errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] (1) Preparation of Pt / C catalyst

[0024] Direct reduction of chloroplatinic acid to prepare 10% Pt / C Add 100mg of the treated carbon black to 2.5ml of isopropanol to improve its wettability, add 5ml of twice distilled water to make a suspension, and ultrasonically stir for 15min to mix evenly. Add H2PtCl6.6H20 solution containing 25mg of Pt, stir ultrasonically for 30min, raise the temperature to 80°C, keep it for 2h, adjust the pH of the solution to neutral with 1mol / LNa2CO3, use sodium formate as reducing agent, continue to stir at 80°C for 45min, and cool to Suction filter at room temperature, wash until there is no chloride ion in the filtrate, vacuum-dry the precipitate at 80°C for 12h, and then heat-treat at 800°C for 30min in flowing argon.

[0025] (2) Preparation of Pt / C catalyst by inorganic colloid method

[0026] (i) First add 0.3g solid NaHSO to 10mL 0.0125mol / L H2PtCl6 solution 3 , the reaction produces the intermediate H 3 Pt(SO 3 ) 2 OH; use 0.075m...

Embodiment 1

[0034] Example 1: Use 175c, 3MPa, 3 minutes, polytetrafluoroethylene film + hot-pressed film + carbon fiber membrane with three-dimensional porous diffusion microstructure + working electrode, and the peripheral seal is complete.

Embodiment 2

[0035] Example 2: Use 175c, 1MPa, 2 minutes, polytetrafluoroethylene film + hot-pressed film + carbon fiber membrane with three-dimensional porous diffusion microstructure + working electrode, and the peripheral seal is complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com