Patents

Literature

168results about How to "Solve the peeling problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

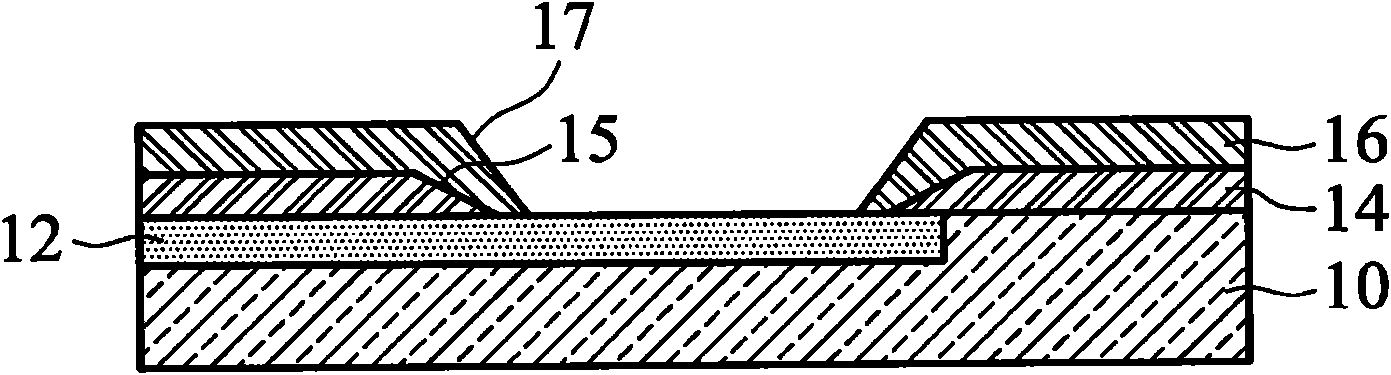

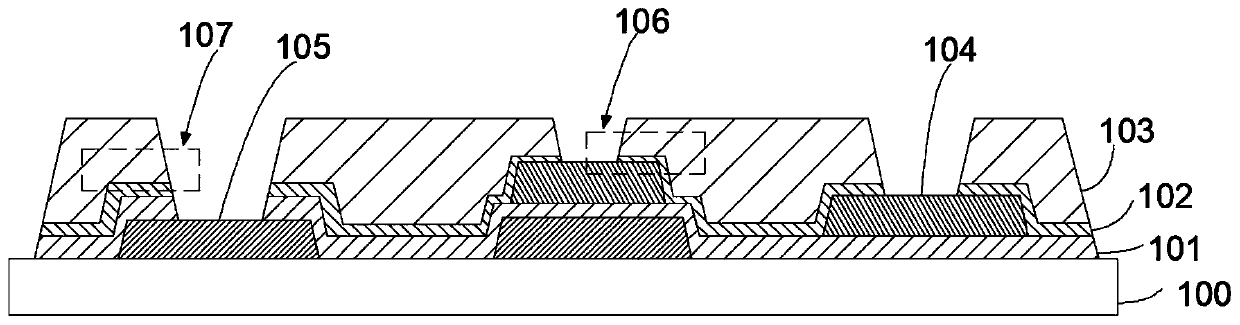

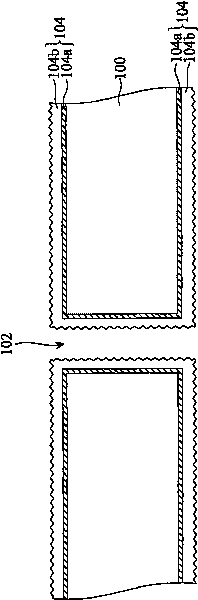

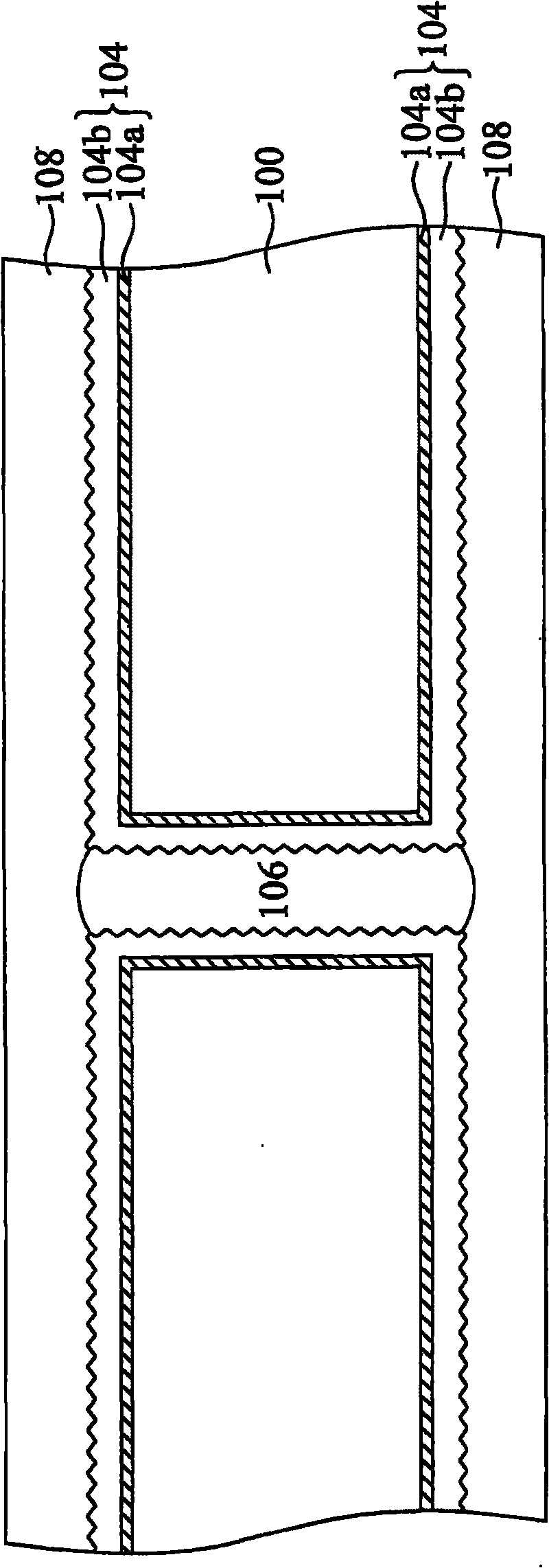

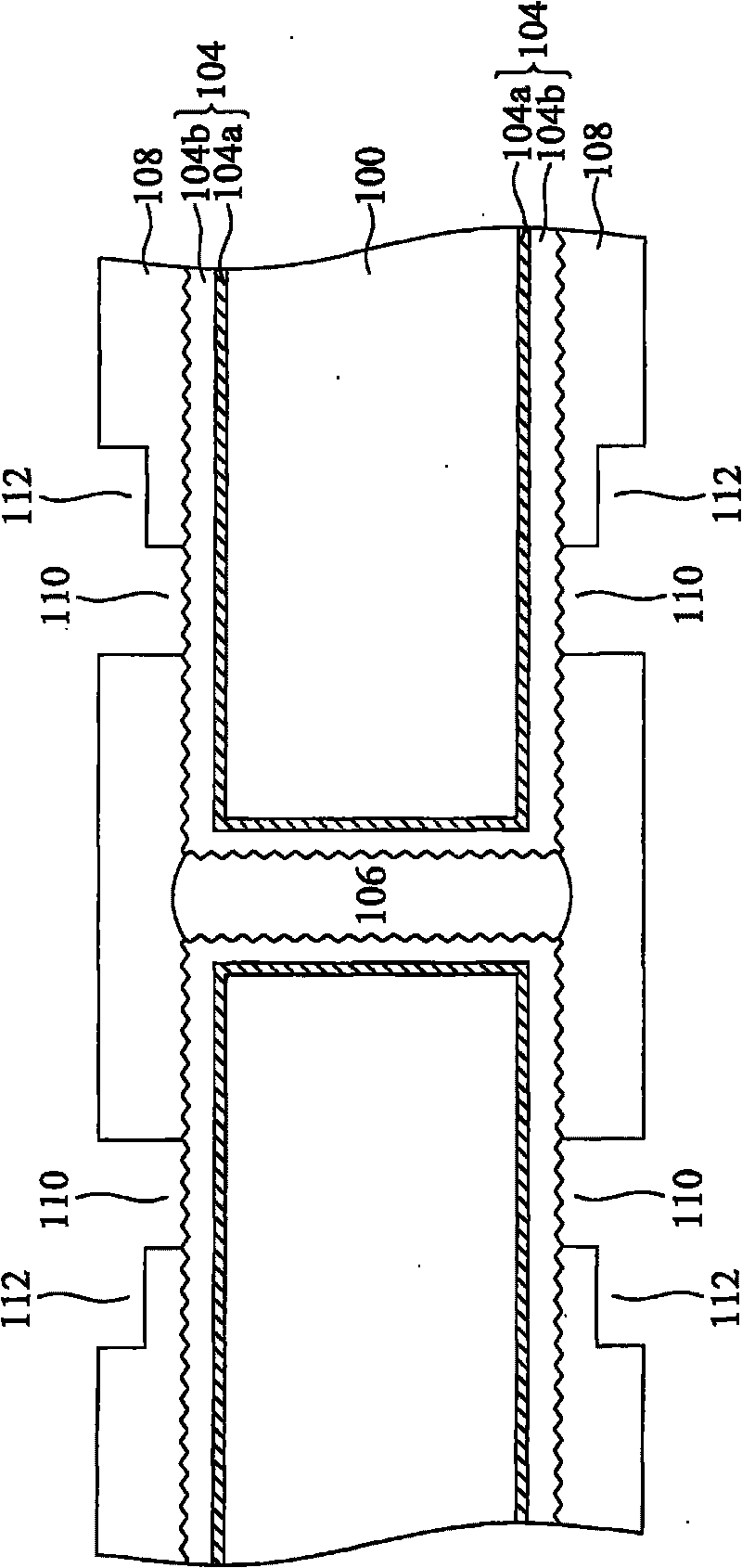

Integrated circuit element and forming method of bumping block structure

ActiveCN102237316APrevent oxidationExcellent adhesionSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorFilling materials

The invention provides an integrated circuit element and a forming method of a bumping block structure. The integrated circuit element comprises a semiconductor substrate, a bumping block metal layer disposed on the semiconductor substrate, a copper column which is disposed on the bumping block lower metal layer and has a side wall surface and an upper surface, and a protection layer which is disposed on the side wall surface and the upper surface of the copper column. The protection layer is a nickel-containing layer, including phosphor with content being less than 0.01 weight%. The invention provides a copper column bumping block, having a side wall protection layer formed by an electrolytic metal layer. The electrolytic metal layer is an electrolytic nickel layer, an electrolytic gold layer, an electrolytic copper layer or an electrolytic silver layer, preventing the copper column side wall from oxidation, and increasing the adhesion strength between the copper column side wall and the bottom filler materials formed afterwards. The bumping block can prevent stress to be concentrated on one point, resolving the problem that the bumping blocks are peeled off or delaminated from the copper column side wall.

Owner:TAIWAN SEMICON MFG CO LTD

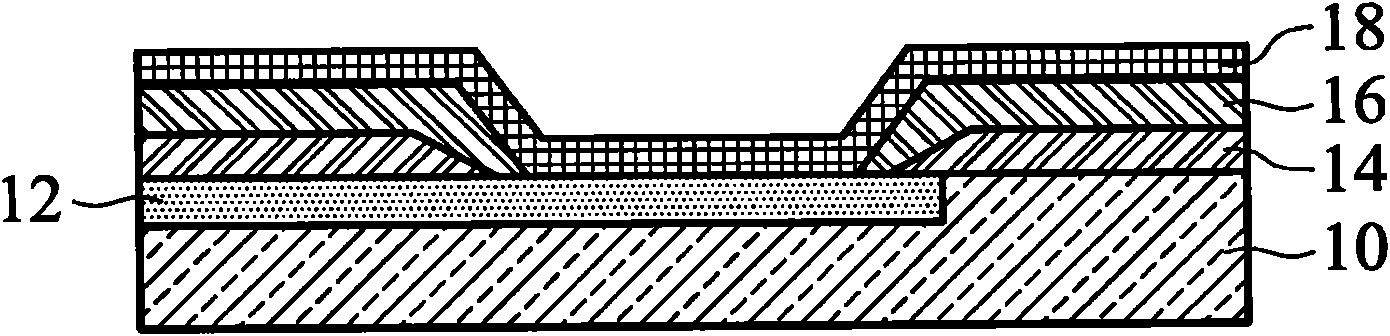

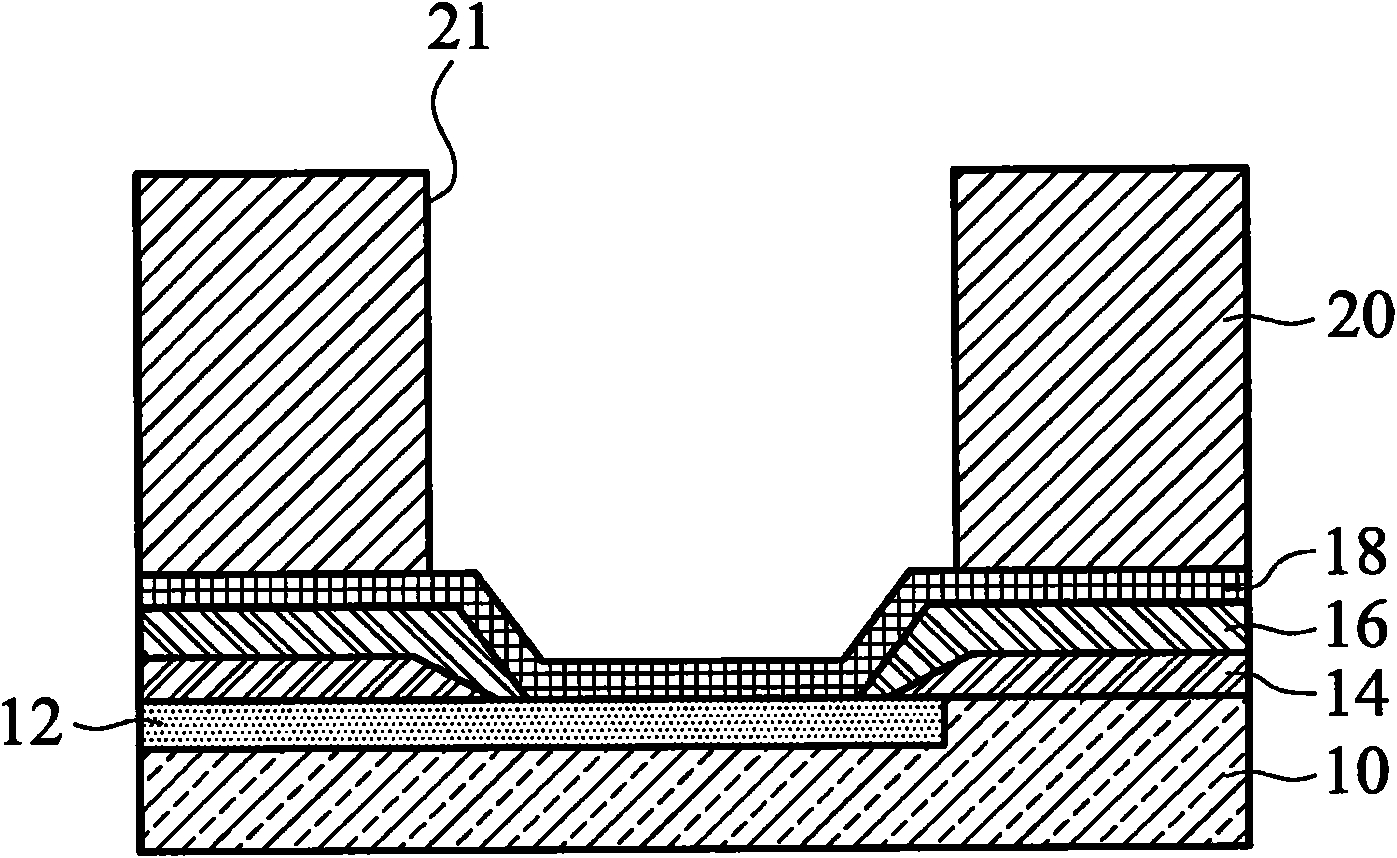

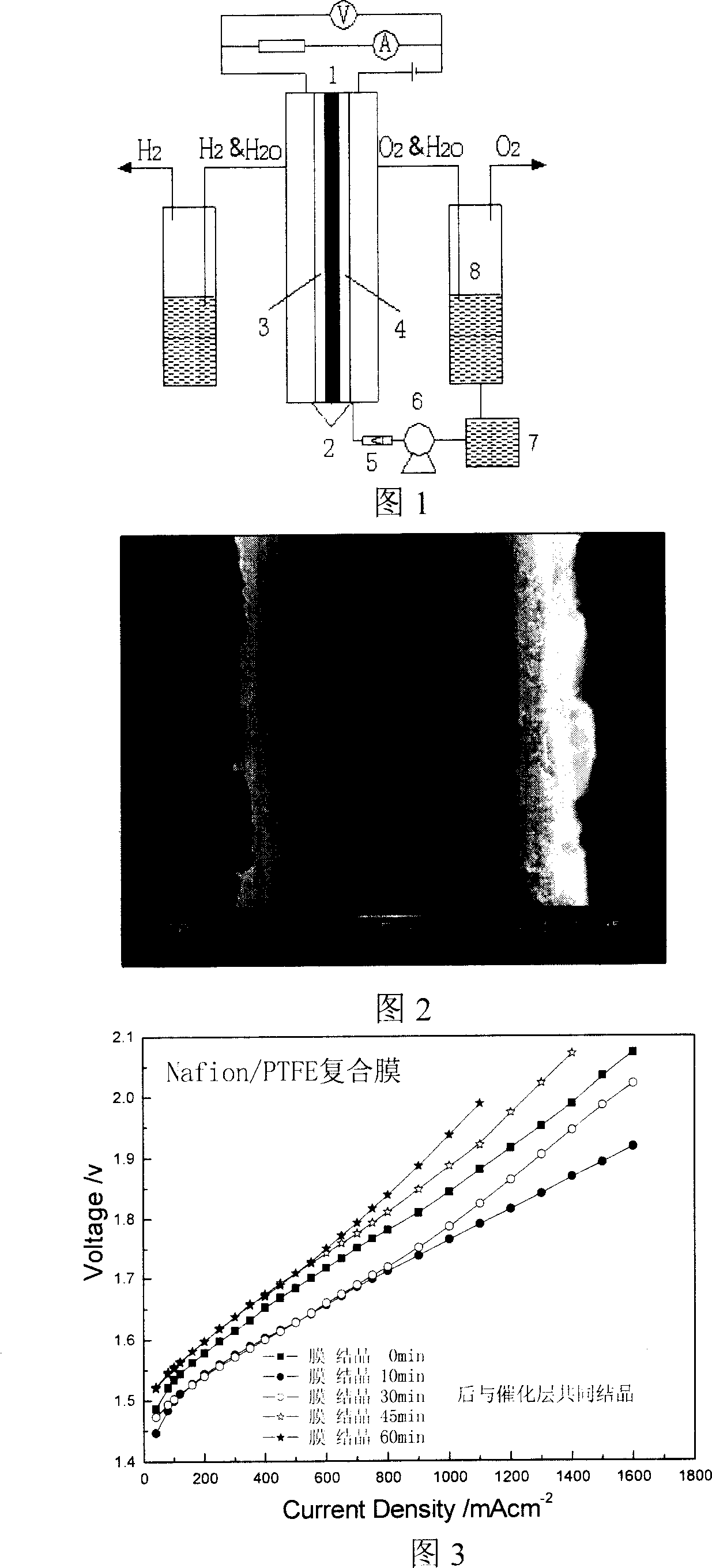

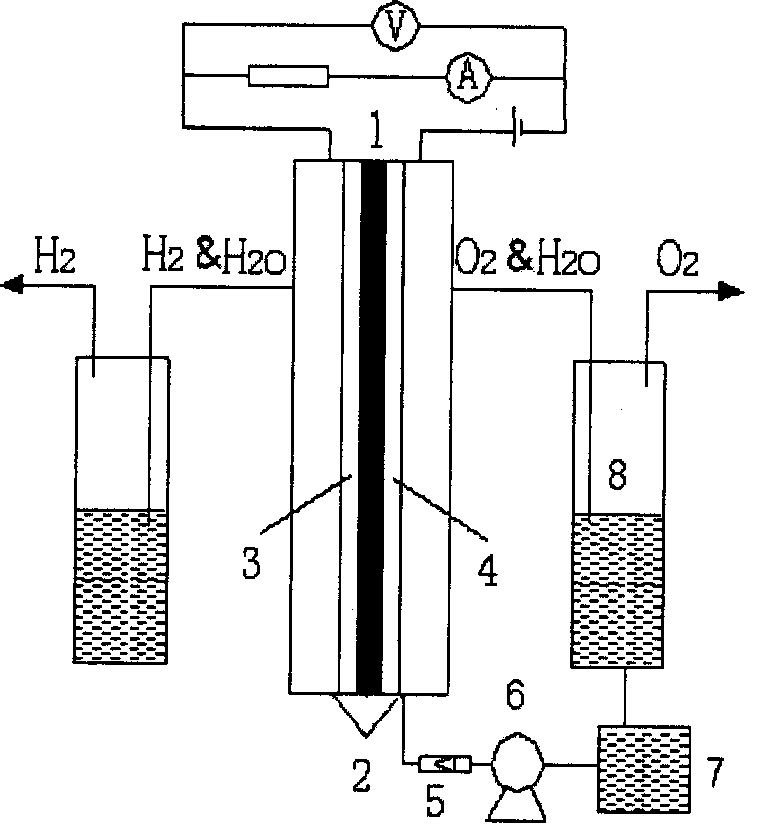

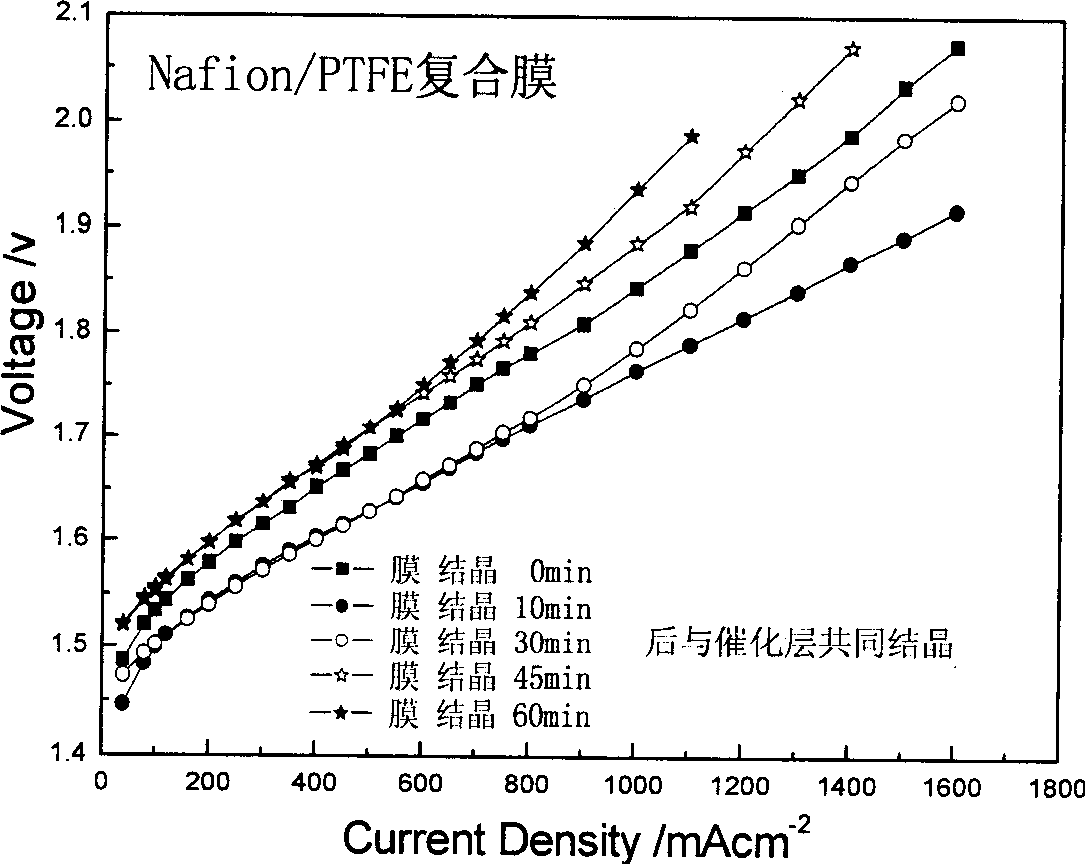

Preparation method of film electrode for solid polymer electrolyte water electrolysis

The invention relates to a method for preparing membrane electrode for solid polymer water electrolyte. It evaporates solid polymer electrolyte solution and forms film, couples catalytic layer composed of catalyst and solid polymer electrolyte on two sides to form integrated membrane electrode, then crystalizes membrane electrode to realize co-crystallization for solid polymer electrolyte. The combination between membrane and catalytic layer is tight and the stratification between membrane and electrode caused by gas evolution and wahsing during water electrolysis process is solved. The invention can produce solid polymer water electrolyte with high performance, high stability and high durability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

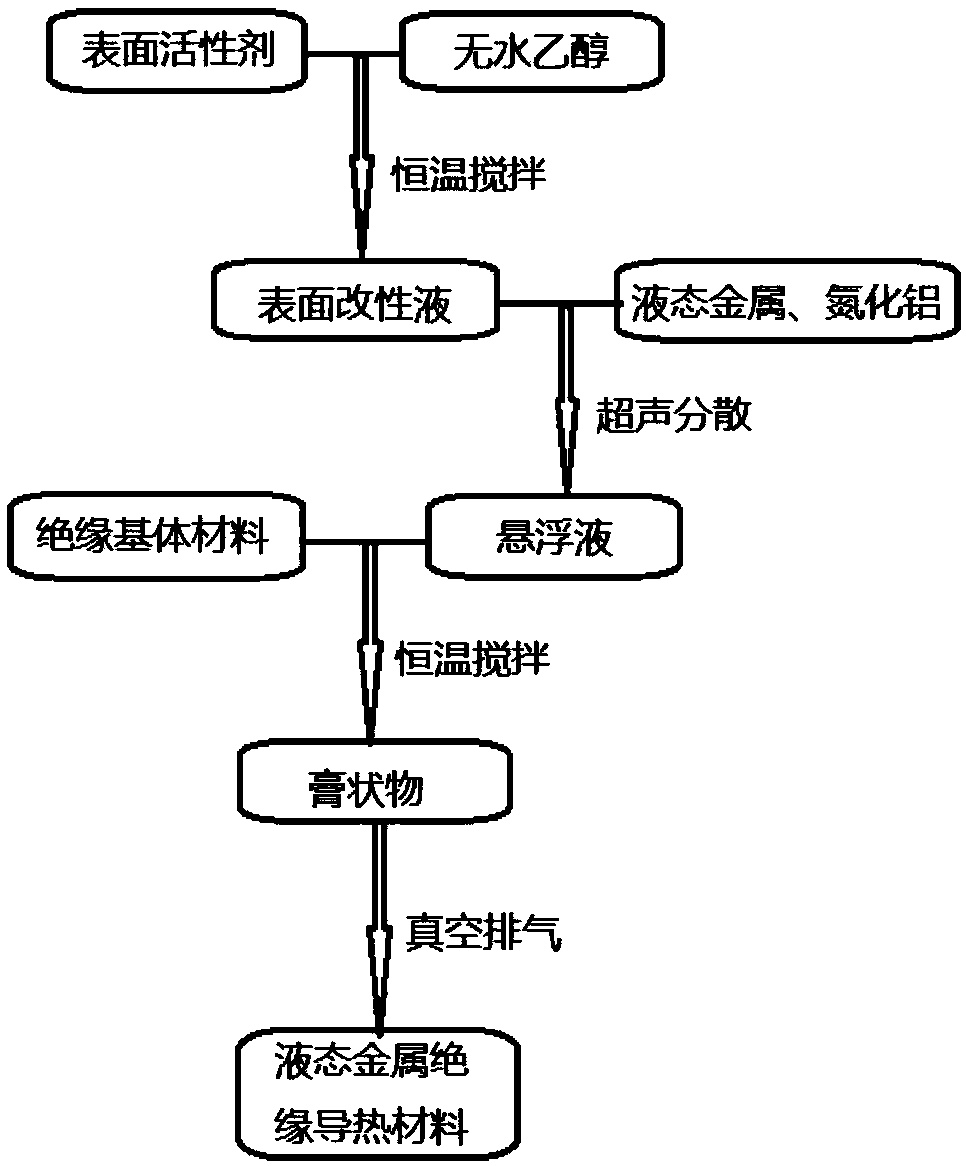

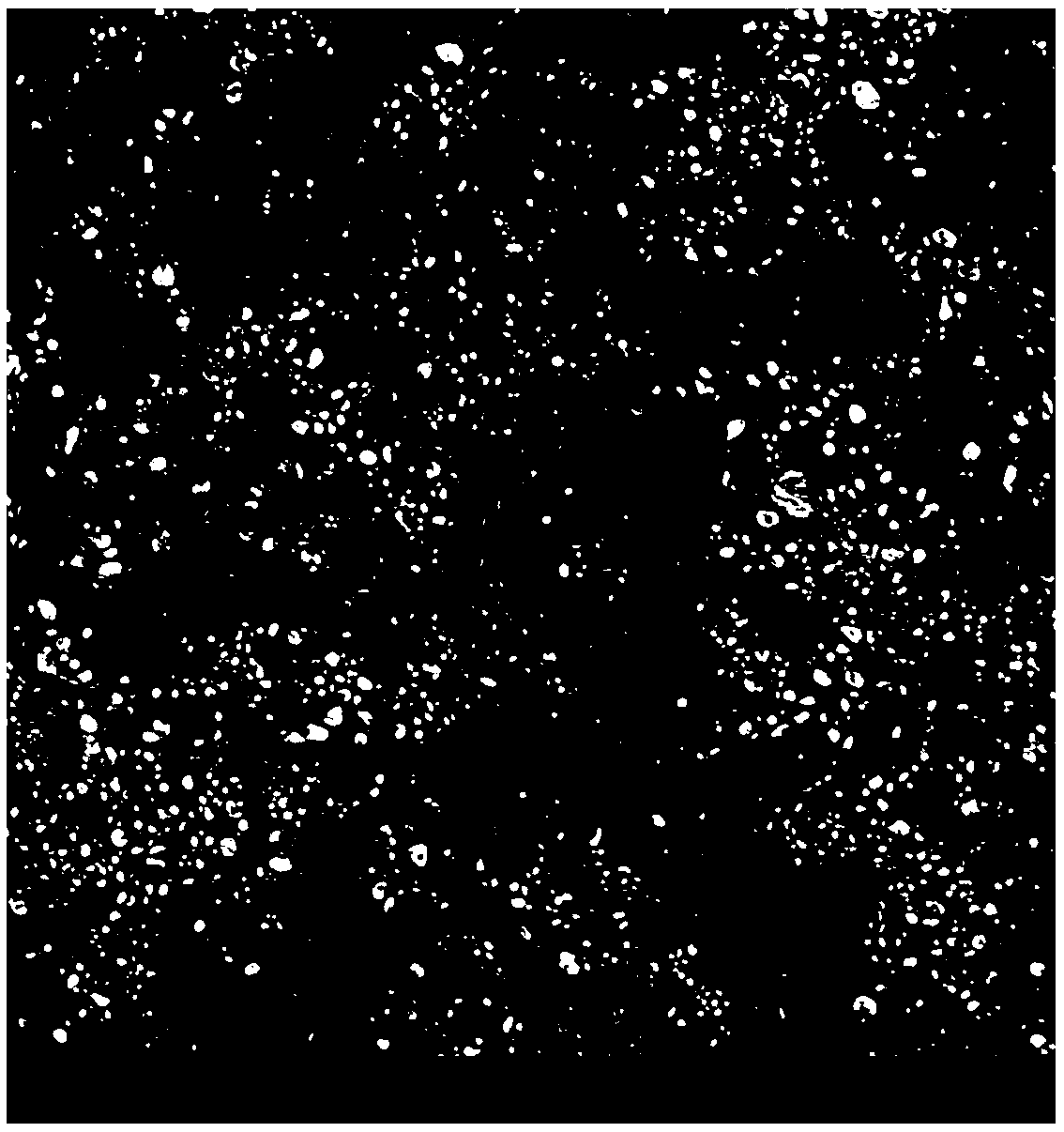

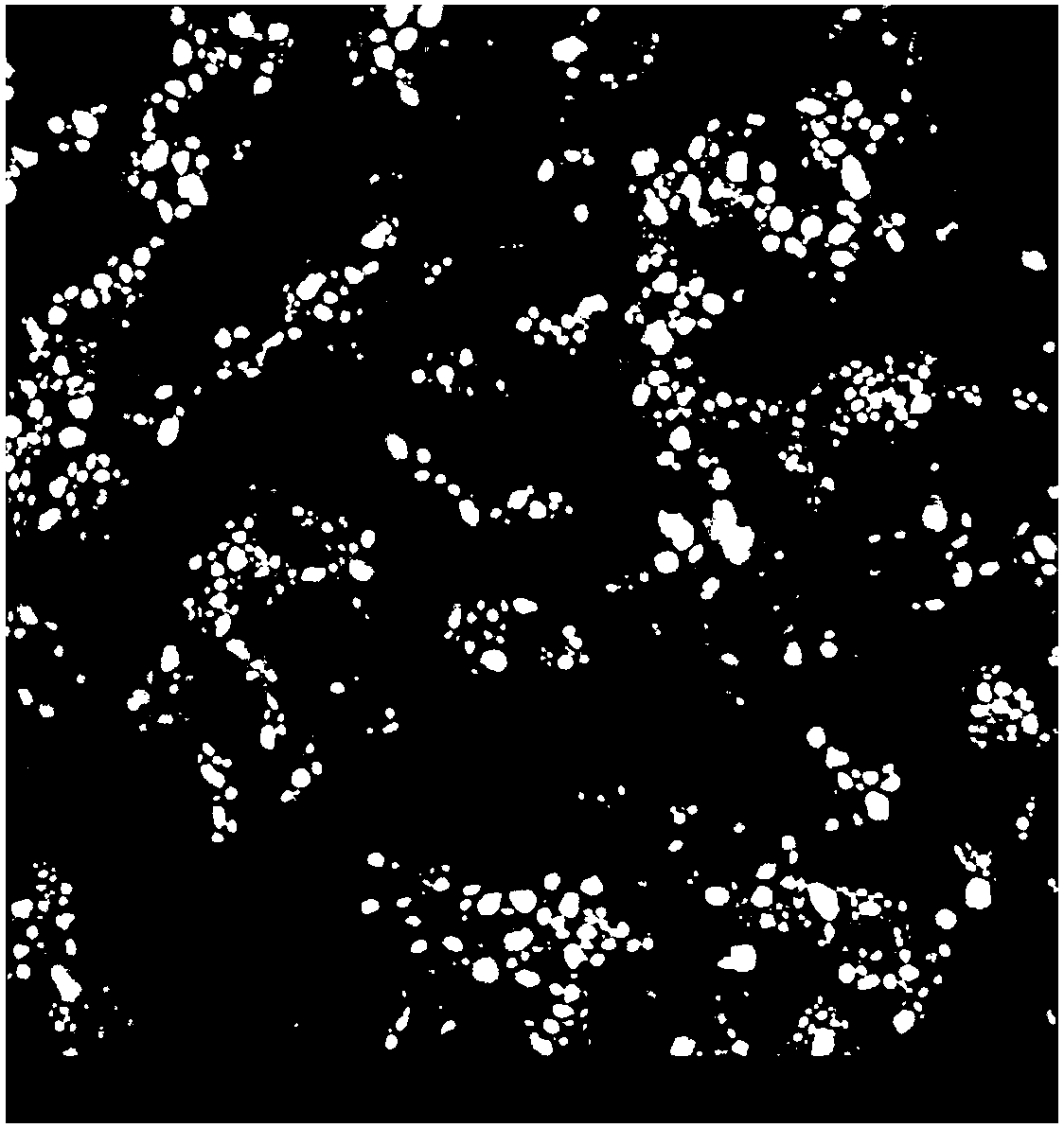

Liquid metal insulation and heat-conduction material and preparation method thereof

ActiveCN108129841AImprove insulation performanceImprove thermal conductivityHeat-exchange elementsCoatingsAnhydrous ethanolAlloy

The invention relates to a liquid metal insulation and heat-conduction material. The liquid metal insulation and heat-conduction material comprises a liquid metal and an insulation matrix material, the liquid metal is modified with a surface modification solution, and is uniformly dispersed in the insulation matrix material in a nano-level liquid droplet form, the liquid metal is metal or alloy having a melting point being 7-200 DEG C, and the surface modification solution is prepared through adding a surfactant into anhydrous ethanol. The liquid metal insulation and heat-conduction material prepared in the invention can guarantee a good insulation property, makes the volume resistivity equal to or more than 10<10> omega.m, has a high heat conduction property, allows the heat conductivityto reach 3.4 W / m.K or more, overcomes the defect of poor stability in the prior art, well meets the requirements of electronic devices for high performances and good heat dissipation property, has anexcellent application prospect, and promotes the further development and application of liquid metal thermal interface materials.

Owner:YUNAN JINGCHUANG LIQUID METAL THERMAL CONTROL TECH RES & DEV CO LTD

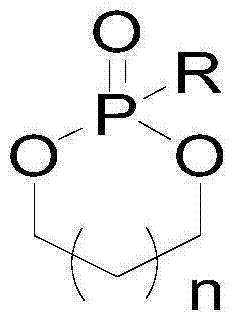

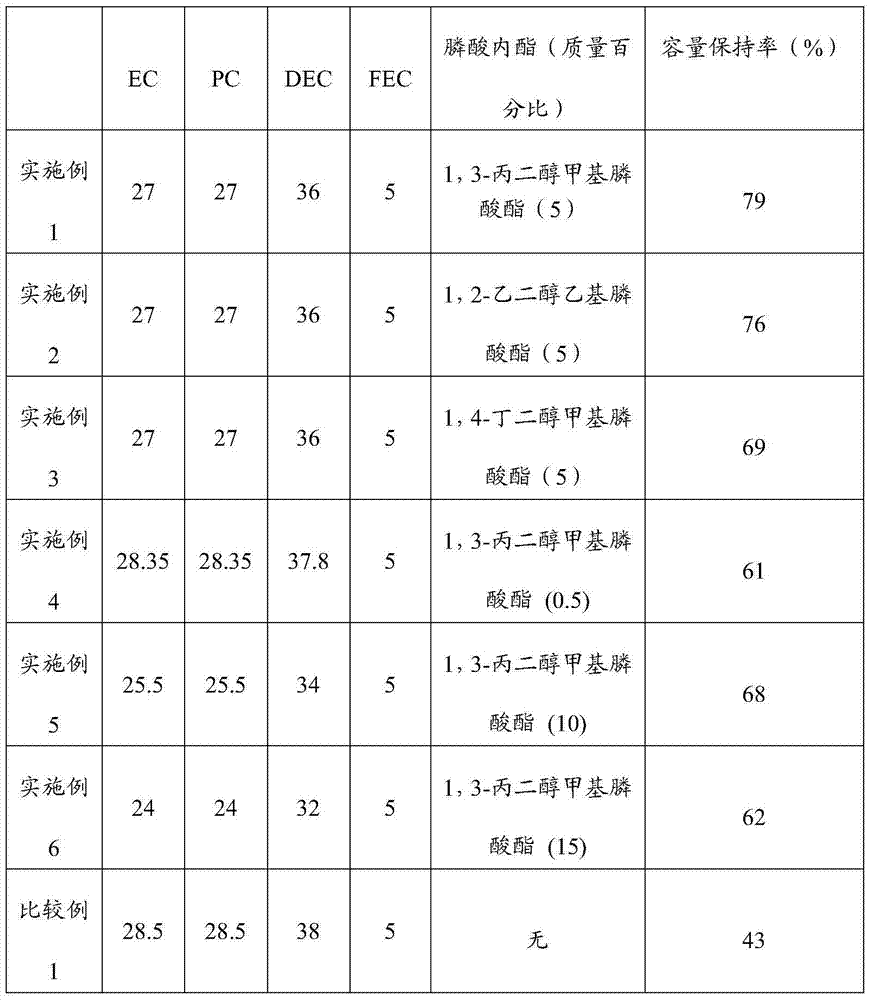

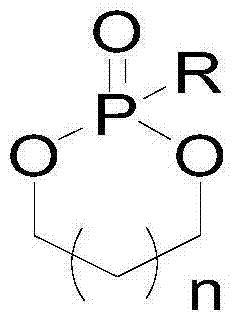

Lithium ion secondary battery electrolyte

InactiveCN103887563AImprove initial discharge capacityImprove cycle lifeSecondary cellsOrganic electrolytesPhosphoric Acid EstersSolid state electrolyte

The invention discloses lithium ion secondary battery electrolyte comprising a non-aqueous solvent and lithium salt dissolved into the non-aqueous solvent, wherein non-aqueous solvent contains cyclic phosphoric ester accounting for 0.5-15% of the total mass of non-aqueous solvent. Cyclic phosphoric ester has the structural formula as the specification, wherein n is an integer ranging from 0 to 2, and R is a straight-chain or branched-chain alkyl from C1 to C4. A functional additive used by the lithium ion secondary battery electrolyte has a relatively high reduction potential and can be used for forming a layer of compact and stable solid electrolyte passive film (SEI) in the first charging process, so that the co-intercalation of propylene carbonate (PC) to graphite can be effectively inhibited, the initial discharging capacity of a battery can be effectively increased, the cycle life of the battery can be effectively prolonged, and the high-and-low temperature performance of the battery can be effectively improved.

Owner:XIAMEN SHOUNENG TECH

All-solid mixed-potential NOx sensor and preparation method thereof

InactiveCN101706470ASolve the peeling problemStable working signalMaterial analysis by electric/magnetic meansScreen printingRepeatability

The invention discloses an all-solid mixed-potential NOx sensor prepared on the basis of spark plasma sintering technology. The NOx sensor consists of an electrolyte layer, a sensing electrode layer, a reference electrode and a working electrode, wherein the multilayer composite consisting of the electrolyte layer and the sensing electrode layer is directly sintered by the spark plasma sintering technology; and the reference electrode layer and the working electrode layer, which have screen pores, are directly printed in the centers of the upper and lower surfaces of the composite by screen printing. As the NOx sensor is manufactured by the spark plasma sintering technology, the sensing electrode layer and the electrolyte layer of the sensor are well combined without problems of flying up, cracking and the like and have the characteristics of good repeatability, stable performance, simple manufacturing process, short manufacturing period, small volume, quick response and the like. The NOx sensor of the invention can detect NOx concentration ranging from 1 to 75 percent and give a response within 2 minutes and is suitable for the detection of the NOx concentration in a wide range.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

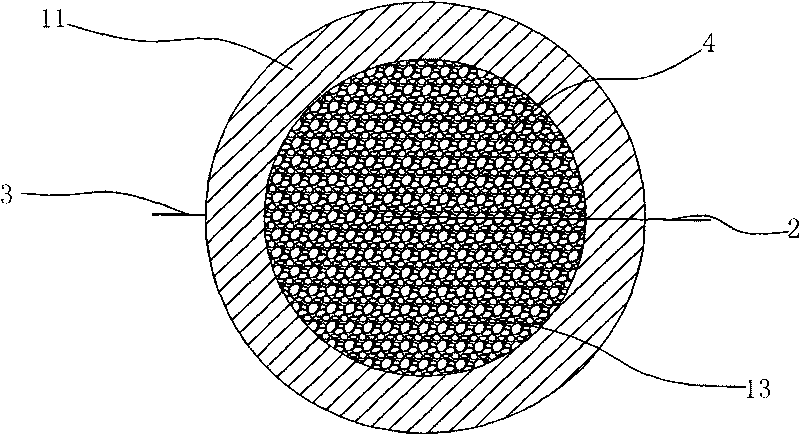

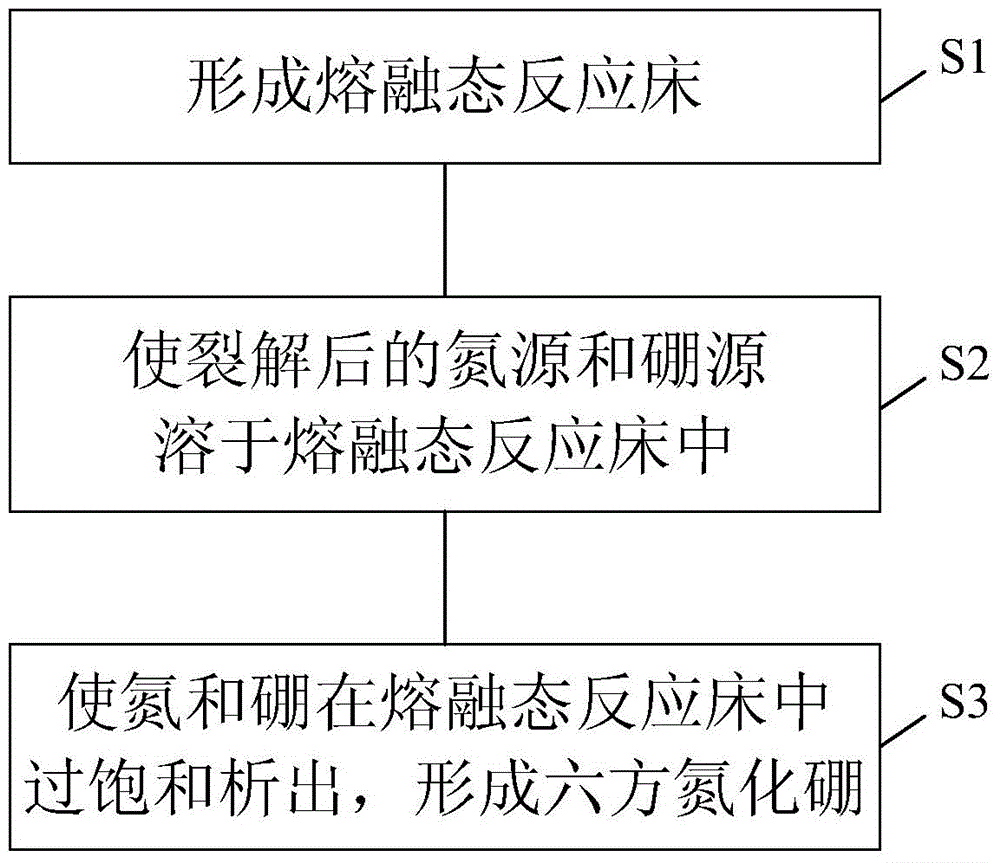

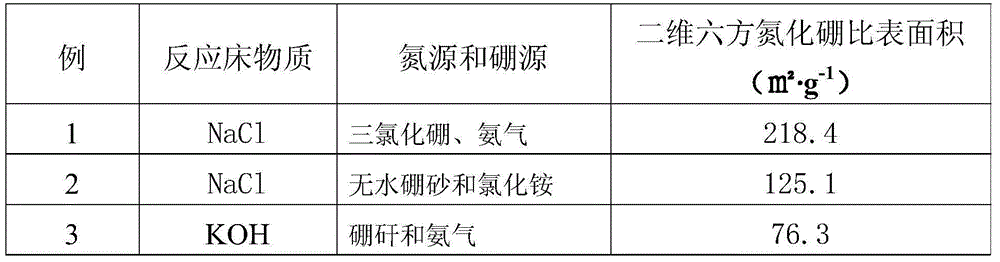

Method for preparing two-dimensional hexagonal boron nitride by using molten state reaction bed

ActiveCN104860273ASolve the peeling problemQuality improvementNitrogen compoundsMolten stateHexagonal boron nitride

The present invention provides a method for preparing two-dimensional hexagonal boron nitride by using a molten state reaction bed. The method comprises: 1) forming a molten state reaction bed; 2) dissolving a cracked nitrogen source and a cracked boron source in the molten state reaction bed; and 3) making the nitrogen and the boron be subjected to supersaturated precipitation in the molten state reaction bed so as to form the two-dimensional hexagonal boron nitride on the molten state reaction bed. According to the present invention, the method has characteristics of low cost, high efficiency and low pollution, the prepared two-dimensional hexagonal boron nitride has the good quality, and the difficult problem of the two-dimensional hexagonal boron nitride peeling and transfer in the engineering technology can be solved.

Owner:孙旭阳

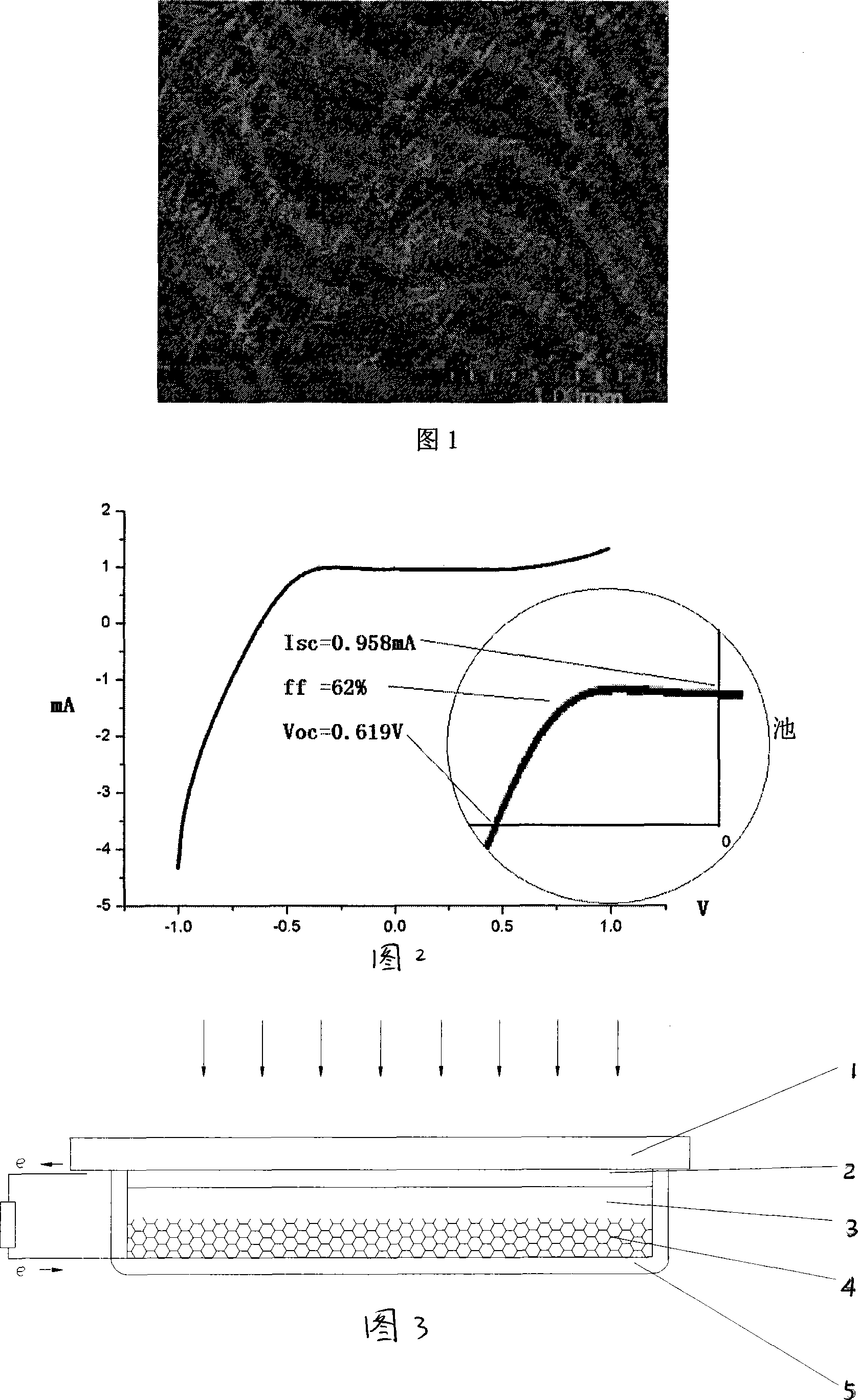

Dye sensitization nanocrystalline thin-film solar cell high pore space flexible carbon to electric pole and preparation method thereof

InactiveCN101140956AReduce manufacturing costReduce thicknessLight-sensitive devicesElectrode manufacturing processesComposite filmNanocrystalline thin films

A highly porous flexible carbon counter electrode used for solar battery of the dye sensitize amino-quinoline thin film is provided, which comprises an composite film composed by a carboform membrane layer with a microstructure of three dimensional porous diffusion and polyafluortetraethylene thin membrane layer; a titanium dioxide semiconductor expanded film equipped on the said composite film as the working electrode of the semiconductor. The preparation method of the electrode is: greying the arboform membrane and platinum black to the nanometer-carried; sensitizing the counter electrode used of the solar battery with the dye of the composite film, which forms dye sensitize solar battery with the working electrode of the semiconductor oxide based on the rigid stratum; greying the arboform membrane and platinum black to the nanometer-carried, which is composed with the polyafluortetraethylene thin membrane to form a composite film, which forms dye sensitize solar battery with the working electrode of the semiconductor oxide based on the rigid stratum.

Owner:NANJING UNIV

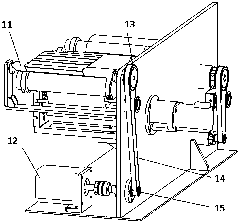

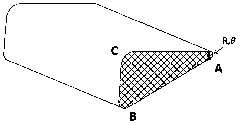

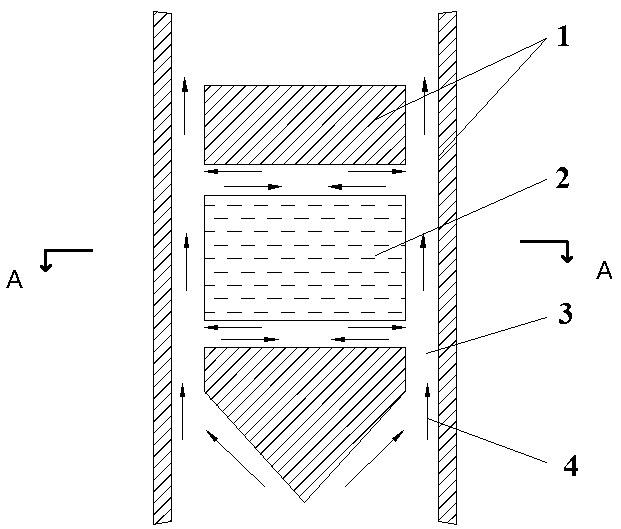

Stripping device and stripping method of multilayer flexible film

ActiveCN103991269AMeet the requirements of processing conditionsOptimize geometryLamination ancillary operationsLaminationEngineeringThin membrane

The invention provides a stripping device of a multilayer flexible film. A stripping knife of the stripping device is of a columnar structure with a circular bead polygonal cross section, and is provided with a plurality of arc stripping surfaces with different bending radiuses and bending angles; during use, different stripping surfaces can be selected according to different films for stripping and processing without replacing the stripping knife, and thus the application range of the stripping knife is greatly enlarged; a relationship theory of a geometrical parameter and a stripping effect of the stripping knife is further applied, and an optimal stripping knife structure is designed and optimized, and thus optimal stripping quality and stripping efficiency are achieved; the stripping device is simple in structure and low in cost, and has a wide application prospect in the field of packaging of a large-area flexible device.

Owner:HUAZHONG UNIV OF SCI & TECH

Composite material of ultra-branched organic montmorillonite / heat vulcanization type silicon rubber, and preparation method

InactiveCN101050317ASolve the peeling problemSolving Dispersion ProblemsPigment treatment with non-polymer organic compoundsPolymer scienceChemical reaction

This invention discloses a method for preparing hyperbranched organic montmorillonite / heat-curing silicone rubber composite. The composite is composed of: methylvinylsilicone raw rubber 80-90 parts, 2, 4-di-tert-butyl peroxy hexane 0.5-0.8 part, and hyperbranched organic montmorillonite 10-20 parts. The hyperbranched organic montmorillonite is dispersed in the polymer matrix in nanoscale lamellar state, which can exhibit good small size effect, interfacial effect and quantum tunneling effect, thus the chemical reaction contact surface area and activity of the hyperbranched organic montmorillonite are significantly increased. The composite has obviously improved tensile strength and elongation at break than silicone rubber added with organic montmorillonite. The tensile strength is near that of silicone rubber added with gaseous white carbon black.

Owner:SHANGHAI UNIV OF ENG SCI

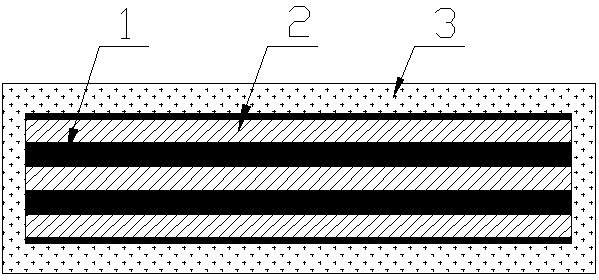

Fabric laminated flame-retardant conveyor belt for coal mines

The invention discloses a fabric laminated flame-retardant conveyor belt for coal mines. The fabric laminated flame-retardant conveyor belt for coal mines is characterized in that the framework material, the cover adhesive formulation and the adhesive sticker formulation are improved and a flame-retardant fabric layer having certain flame retardant property is taken as the framework material, and therefore, the safety performance index is satisfied, and the problems of easy deflection and large elongation of an integer core belt. Besides, the rubber-plastic CPE (Chlorinated Polyethylene) is introduced into the cover adhesive formulation so that the flowing property of the cover adhesive at high temperatures can be improved; a flame-retardant lubricant MB-202 is added so that the temperature rise rate can be reduced, and the friction temperature not exceeding 325 DEG C of a roller is guaranteed. In the adhesive sticker formulation, a plurality of adhesives are combined so that the adhesive strength can be improved, and moreover, the scaling problem is solved.

Owner:YANKUANG GRP CO LTD +1

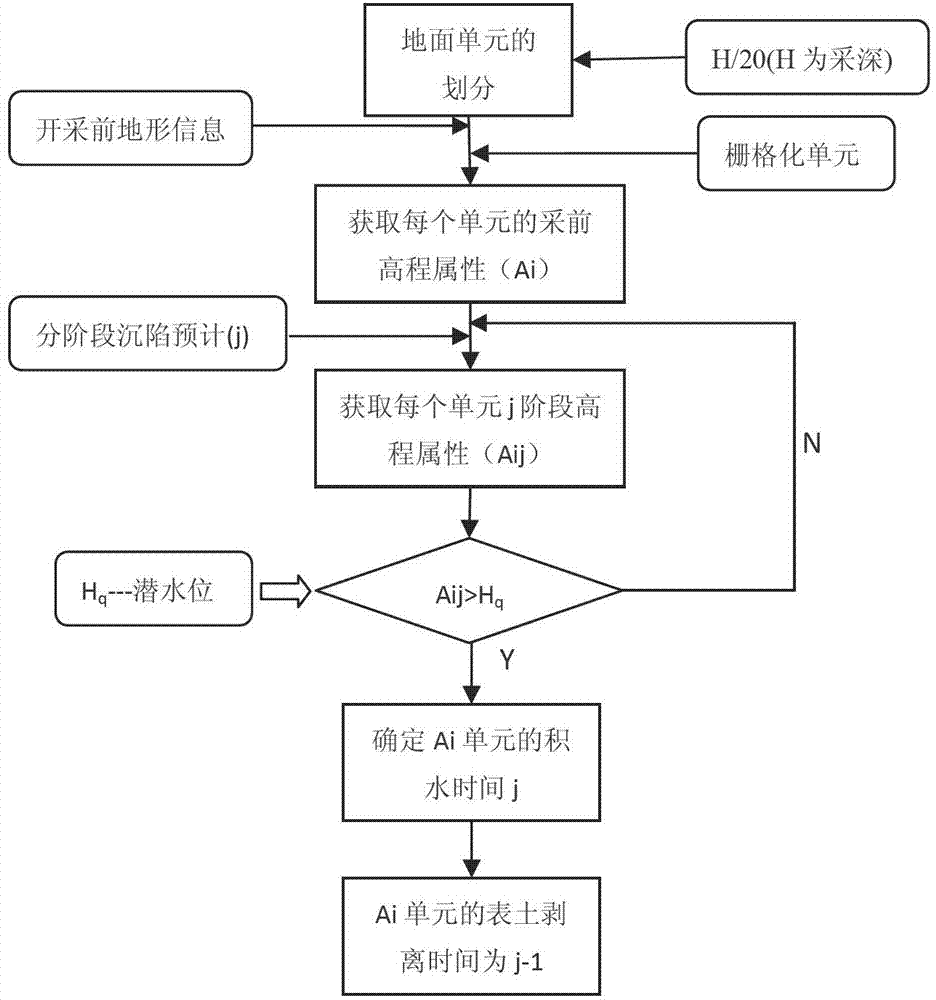

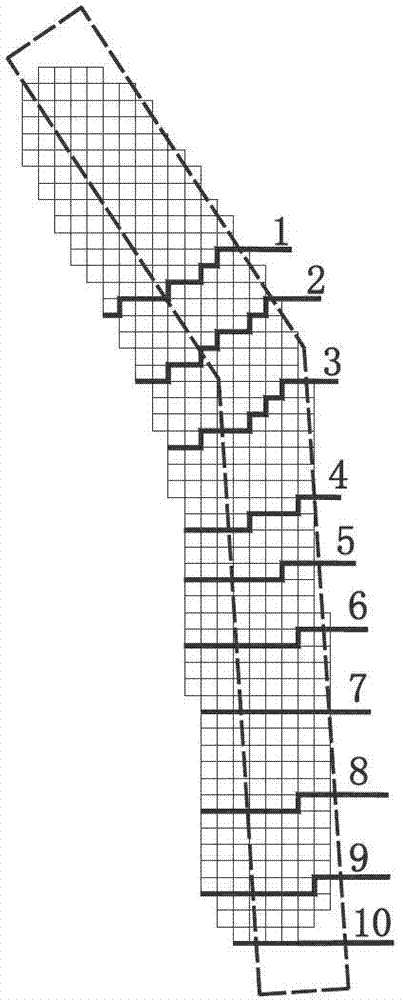

Method for confirming coal mining sunken surface soil peeling space time based on geographic information system (GIS) grid unit

ActiveCN102889083AAvoid influenceSolve the problem of topsoil strippingUnderground miningSurface miningSoil scienceWater level

The invention relates to a method for confirming a coal mining sunken surface soil peeling space time based on a geographic information system (GIS) grid unit, belonging to the fields of mining technology, soil utilization and soil rehabilitation. The method comprises the following steps: classifying ground units, obtaining ground elevation information of every ground unit before exploring, predicting sunken by stages; obtaining the elevation property at every predict stage of every ground unit, and confirming the water accumulation time of every ground unit, thereby confirming the time of peeling surface soil of every ground unit. Through classifying the ground unit and combining the underground exploring stage, the water accumulating time of any ground unit and the time of surface soil peeling time are determined, thus the time and place of performing the surface soil peeling activity can be confirmed clearly; the method is simple and easy to understand and convenient to perform the actual construction operation, thus the surface soil protection work of a high diving water level mine zone can be specifically carried out at a fixed quantity; the method provides the guarantee for the soil rehabilitation at the later period and is beneficial to improve the rehabilitation plowing rate, and accelerate the sustainable utilization and development of the soil resource in the mine lot.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

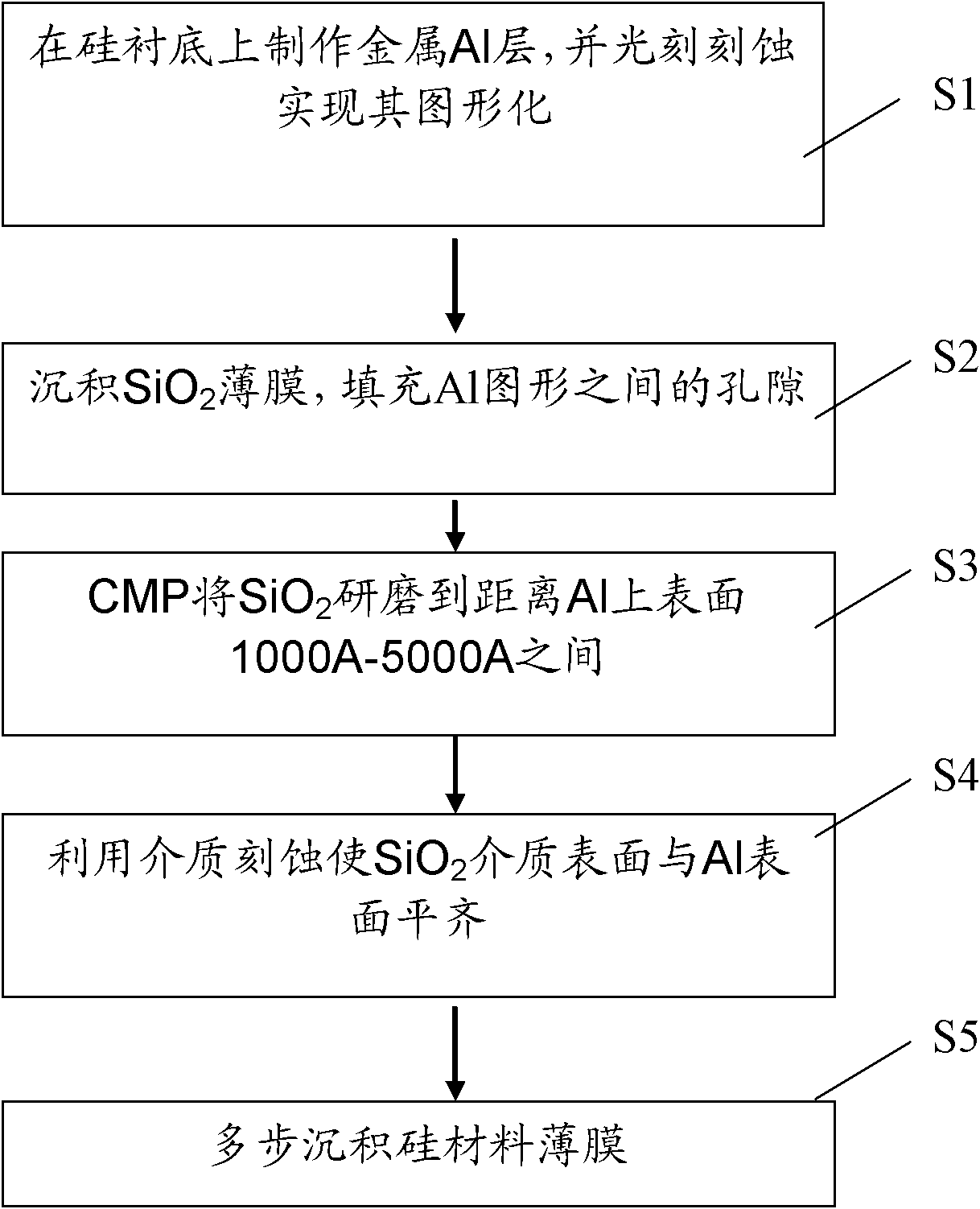

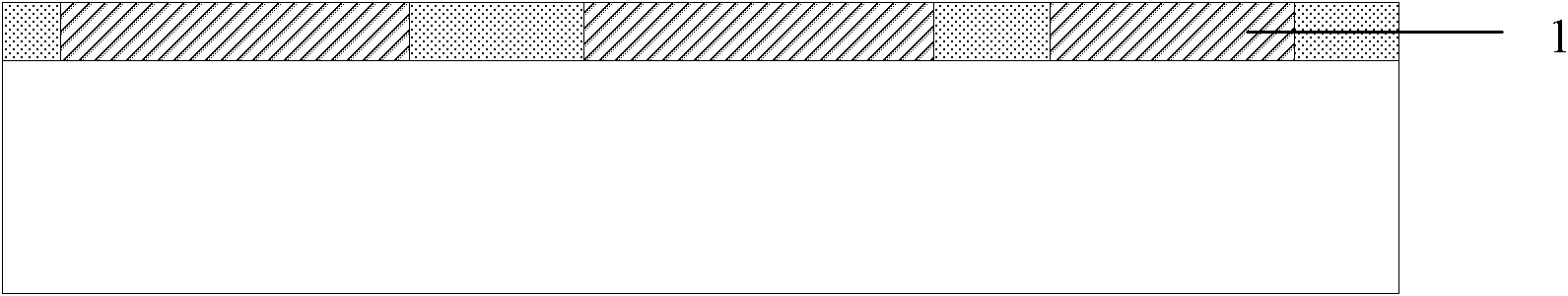

Manufacturing method of sacrifice layer of MEMS (Micro-electromechanical System)

ActiveCN102205942AIncrease contactImprove performanceDecorative surface effectsChemical vapor deposition coatingAmorphous siliconMaterials science

The invention discloses a manufacturing method of a sacrifice layer of an MEMS (Micro-electromechanical System). The method comprises the following steps of: metal layer forming; silicon wafer surface processing before sacrifice layer deposition, used for improving the surface characteristics of a silicon wafer; supported hole patterning for patterning a supported hole in a sacrifice layer; and sacrifice layer postprocessing for processing the sacrifice layer to form a surface film on the surface of the sacrifice layer. The formed surface film covers the sacrifice layer effectively for solving the problem that the film strips off from the sacrifice layer because of H overflow, thereby improving the performance, the yield and the reliability of related MEMS products.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

Anti-corrosion paint, application thereof and pipeline coating

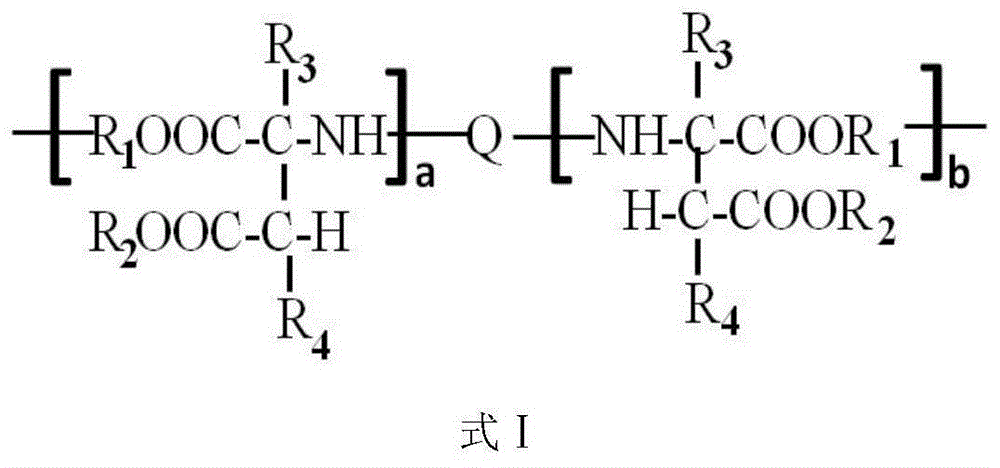

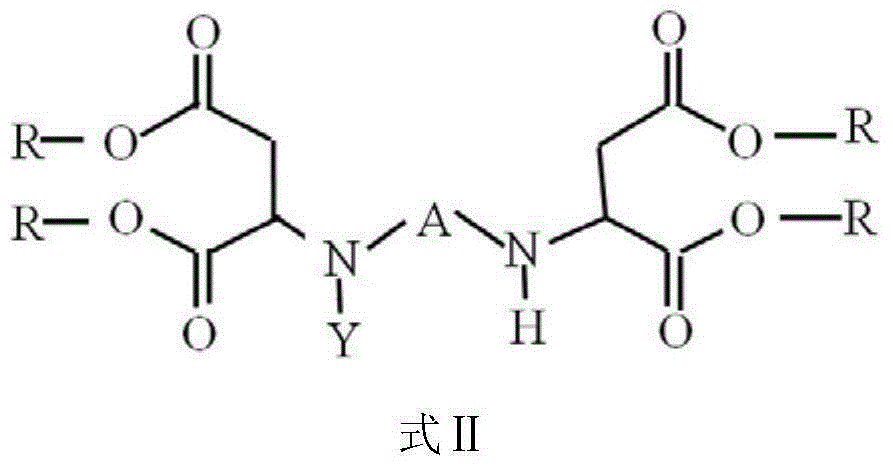

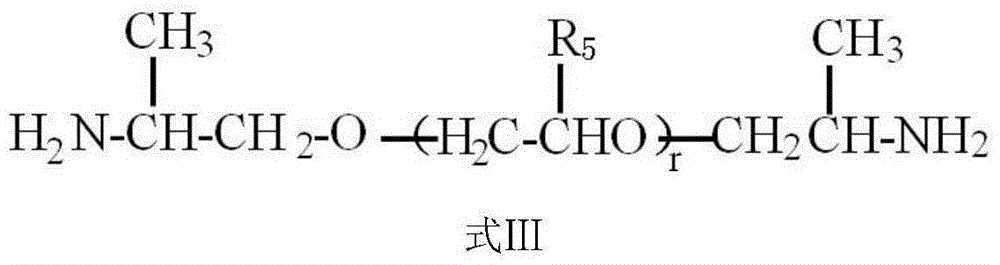

ActiveCN105199573AIncrease chain lengthImprove low temperature toughnessAnti-corrosive paintsPolyurea/polyurethane coatingsPrepolymerPolyaspartic acid

The invention provides anti-corrosion paint, an application thereof and a pipeline coating. The anti-corrosion paint comprises a first component and a second component, wherein the first component comprises polyether amine, first modified polyaspartic acid ester and second modified polyaspartic acid ester, and the second component comprises isocyanate and / or a prepolymer thereof. Compared with traditional polyaspartic acid ester urea paint, by means of the added polyether amine component, ether linkage with good flexibility can be introduced in a final cured resin molecular chain, and the chain length and the low-temperature toughness of the cured resin molecular chain are improved; by means of added second modified polyaspartic acid ester, increase of the heat-resistant temperature as well as improvement of weather resistance, smoothness and scratching resistance of the coating is facilitated. When the anti-corrosion paint is matched with a fusion bonded epoxy powder bottom coating, the problems of stripping and joint coating stripping in application of a polyethylene anti-corrosion layer of a conventional pipeline as well as poor high temperature cathodic stripping resistance of a polyuria coating can be solved very well.

Owner:北京碧海云智新材料技术有限公司

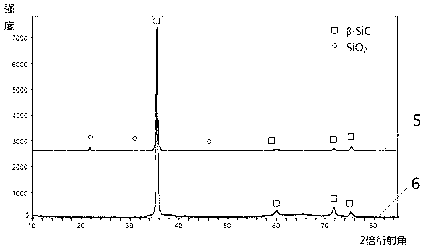

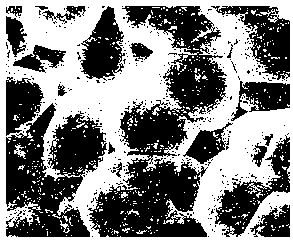

C/SiC coating with pore structure and preparation method thereof

InactiveCN103290386AImprove antioxidant capacityImprove thermal shock resistanceChemical vapor deposition coatingInterface layerDeposition process

The invention discloses a C / SiC coating with a pore structure and a preparation method of the same. The prepared C / SiC coating material is closely combined with the matrix, and is divided into a typical three-region structure, wherein the three regions include an interface combination region, a pore transition region and an outer layer compact region, and many pores with the diameter of 3-20 micrometers are distributed in the area between the compact outer layer and the interface layer of the coating. The preparation technology provided by the invention is used for preparing the C / SiC coating with a pore structure, of which the diameter is 3-20 micrometers, in a self-designed slot type deposition chamber, by controlling the slot size to be 2-8mm, using MTS as an SiC source gas, using H2 as MTS carrier gas and using H2 and Ar as conditioning gases. A large flow negative pressure rapid deposition technology is used, the reactant gases rapidly pass through the slot to realize deposition. For the C / SiC coating with the pore structure prepared by the invention, the bonding strength of the coating and the matrix is improved, the coating fissure caused by heat stress is remitted to a great extent, and the usability of the coating is improved greatly. Meanwhile, the problems of long cycle and limit on size in gas phase coating preparation of the normal technology are solved.

Owner:CENT SOUTH UNIV

Coloring process of whole body of fiber cement external wall panel

The invention discloses a coloring process of the whole body of a fiber cement external wall panel, comprising the following steps of: (1) doping blended inorganic pigments into the raw material powder for producing the fiber cement external wall panel, enabling the blended inorganic pigments to be absorbed on the surfaces of other granules through high-speed stirring to achieve the purpose of sufficient dispersion, and then stirring by adding water; (2) carrying out kneading and mixing processes on raw materials, and then enabling the raw materials to enter an extruder for extrusion molding;(3) carrying out steam ordinary-pressure curing and autoclave curing on a product in a still kettle to accelerate and enhance the strength of the product; and (4) finally processing the surface of the product, and spraying colorless clearwater paint. The invention enables the whole body of the fiber cement external wall panel to have one color, fresh and lovely luster and elegant appearance and endure high temperature without color fading by adding the inorganic pigments to the fiber cement external wall panel and adopting a customized production and curing process, thereby solving the problems of easy ageing, color fading and stripping of a surface coating of the traditional external wall panel colored by using paint.

Owner:BEIJING NEW BUILDING MATERIALS PLC +1

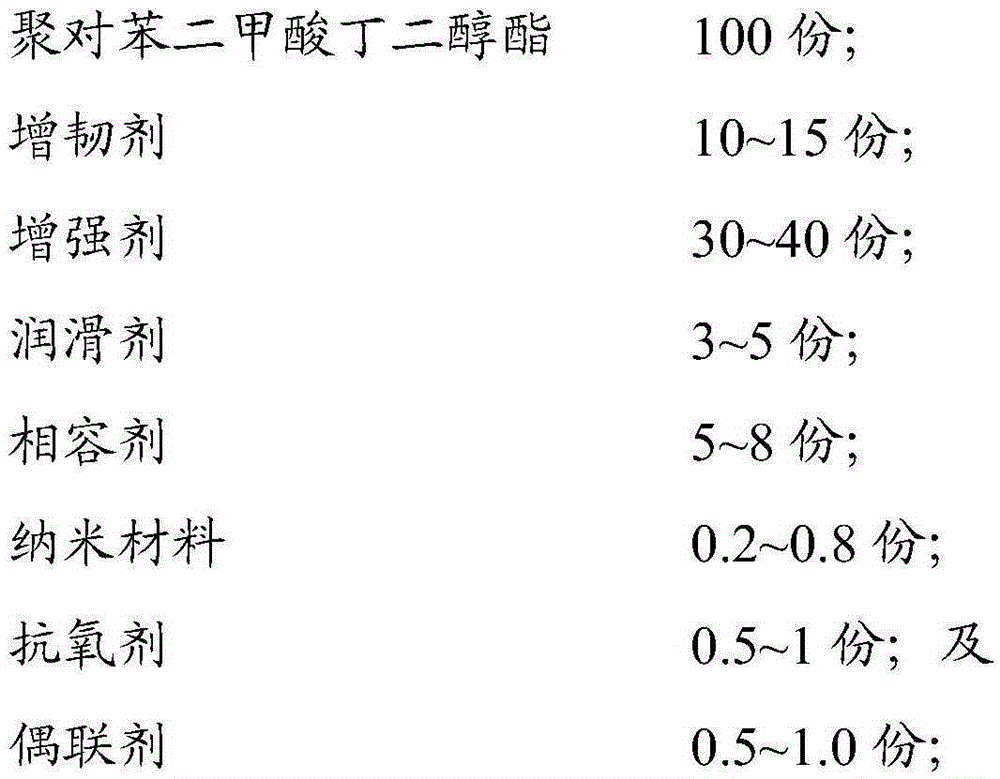

PBT composite material used for NMT forming and preparation method thereof

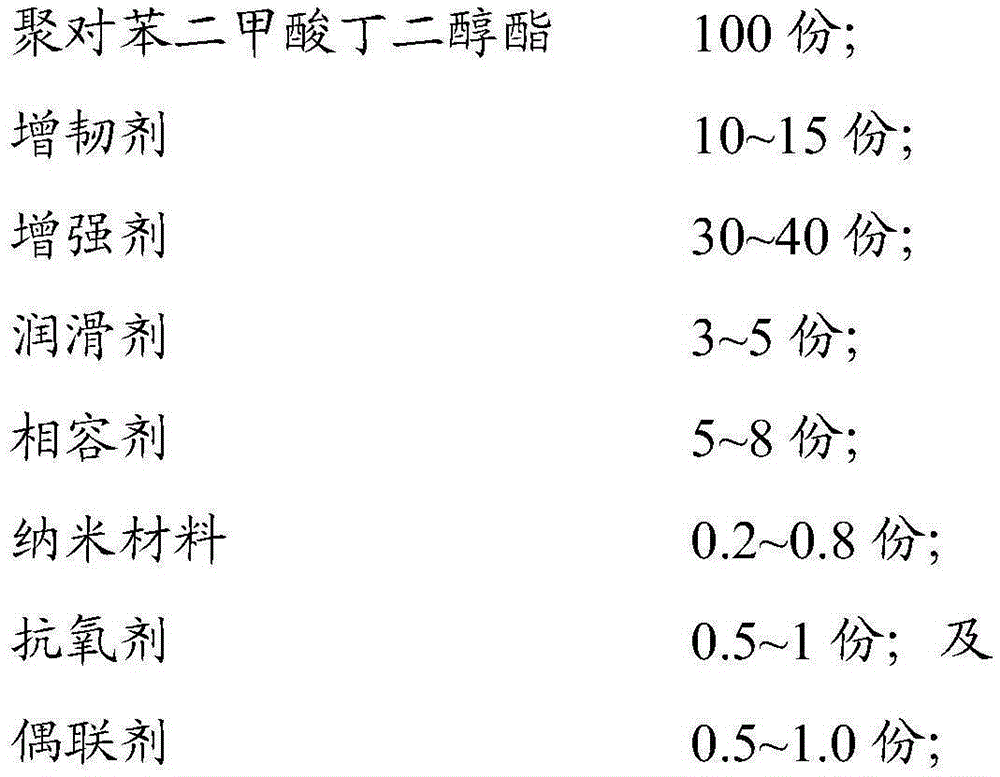

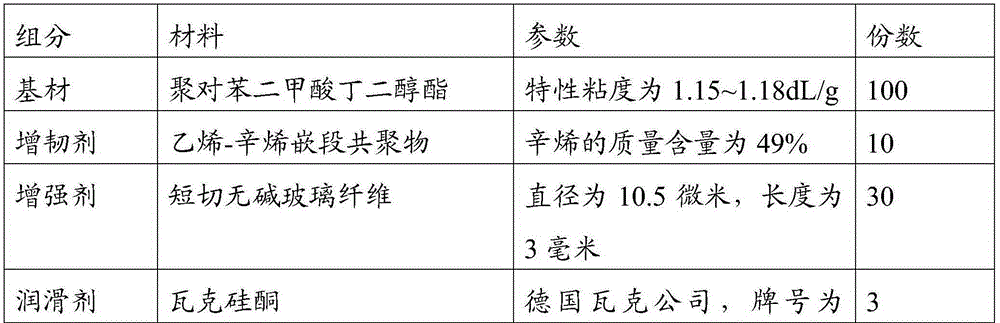

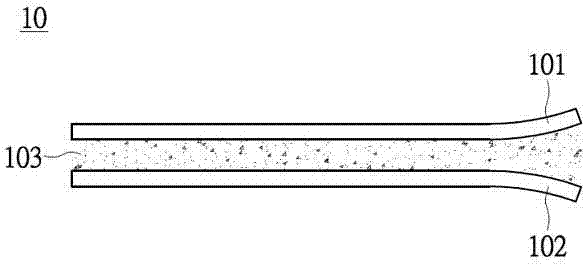

The invention relates to a PBT composite material used for NMT forming and a preparation method thereof. The PBT composite material used for NMT forming is characterized by being prepared from, by mass, 100 parts of polybutylene terephthalate, 10-15 parts of flexibilizers, 30-40 parts of reinforcing agents, 3-5 parts of lubricating agents, 5-8 parts of compatilizers, 0.2-0.8 part of nano materials, 0.5-1 part of antioxidants and 0.5-1 part of coupling agents. The nano materials are prepared from at least one of nano alumina, nano magnesia and nano iron oxide. The reinforcing agents are prepared from glass fibers. The PBT composite material used for NMT forming can be applied to NMT forming.

Owner:SHENZHEN XINGSHENGDI NEW MATERIALS

Manufacturing procedure of electronic substrate, manufacturing procedure of display panel and applied adhesive

ActiveCN104765178ASolve the peeling problemAvoid errorsEster polymer adhesivesHydrocarbon polymer adhesivesAdhesiveLiquid state

The invention provides a manufacturing procedure of an electronic substrate, a manufacturing procedure of a display panel and the applied adhesive. For the display panel, the manufacturing procedure comprises the steps of firstly preparing a first hard type substrate and a second hard type substrate coating liquid adhesives on surfaces then arranging dissolution removing agent on the adhesives so that adhesive dry films with adhesion ability are formed on the adhesives combining a first base material and a second base material by the adhesive dry films and the second substrate is combined to the second hard type substrate by the adhesive dry film. The formed two panel modules and display materials therebetween are adhered and laminated via frame glue so that a display panel is formed. Light is emitted on the display panel, so the adhesive dry films loose adhesion ability. Thus, the first hard type substrate and the second hard type substrate can be easily moved and the display panel can be formed.

Owner:ZHEJIANG KUOSEN FINE CHEM TECH

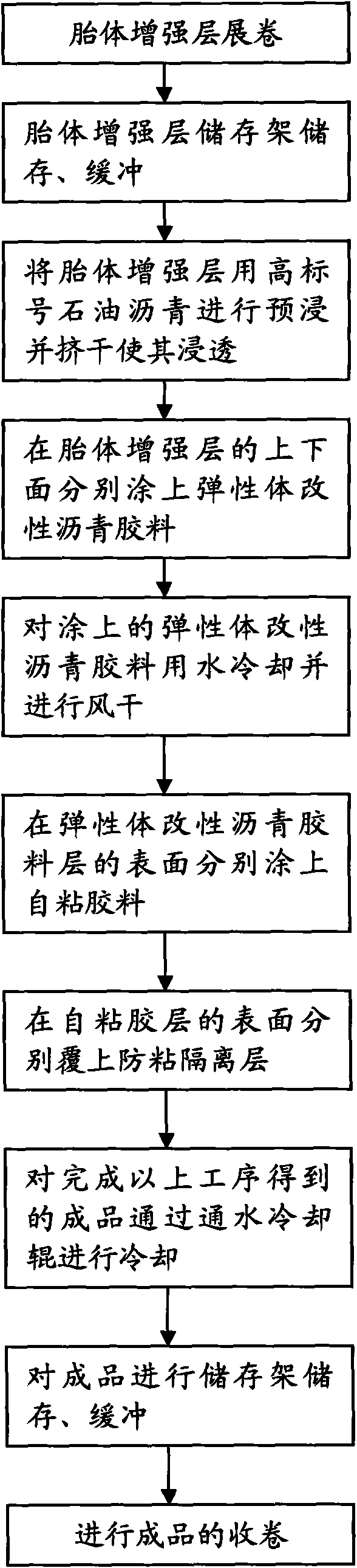

Preparation method of elastomer modified asphalt waterproof roll capable of being placed in wet

InactiveCN101769046AConstruction safetyConstruction environmental protectionLamination ancillary operationsRoof covering using flexible materialsElastomerBituminous waterproofing

The present invention discloses a preparation method of elastomer modified asphalt waterproof roll capable of being placed in wet, comprising the following steps: uncoiling a carcass reinforcement layer, storing the carcass reinforcement layer on a store frame, buffering, pre-impregnating the carcass reinforcement layer by high-grade petroleum asphalt and squeezing to dry for complete impregnation, coating an elastomer modified asphalt glue stock on the upper and the lower surfaces of the carcass reinforcement layer, cooling the elastomer modified asphalt glue stock by water and performing air drying, coating a self-adhesive glue stock respectively on the surface of the elastomer modified asphalt glue stock layer, covering a conglutination resistant isolation layer respectively on the surface of the self-adhesive glue stock layer, cooling the product after the processes above by a flow-through cooling roll, storing the product on a store frame, buffering and finally coiling the product. The roll of the invention has low preparation cost, good stability of structure and thermal expansivity, security construction, environmental protection and reliable adhesion. The adhesion between the self-adhesive glue stock and the elastomer modified asphalt glue stock is strong and the roll prepared has reliable waterproof effect.

Owner:浙江天信建材有限公司

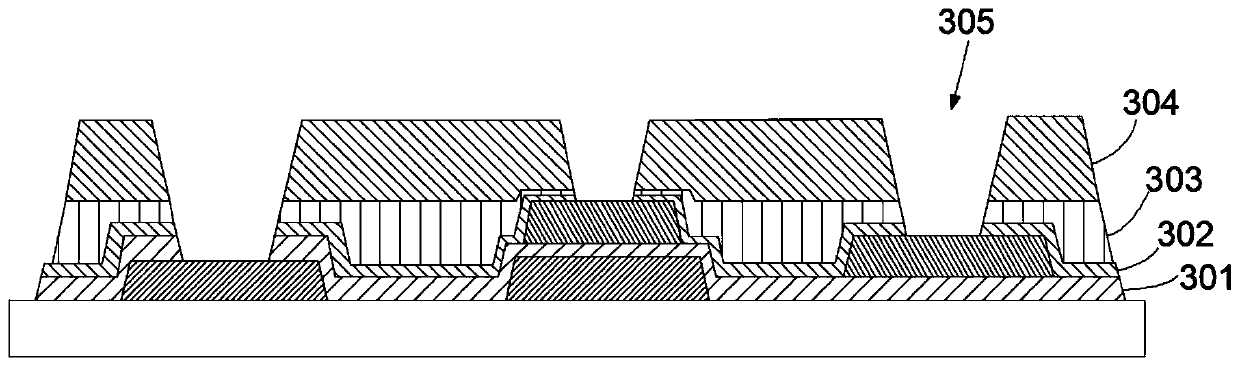

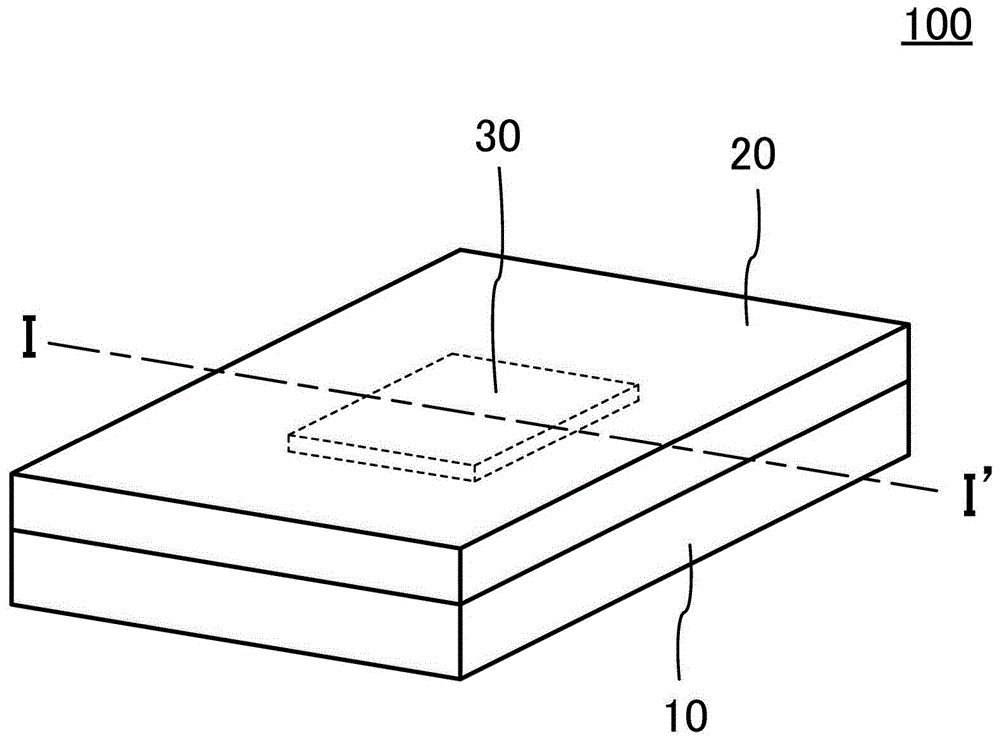

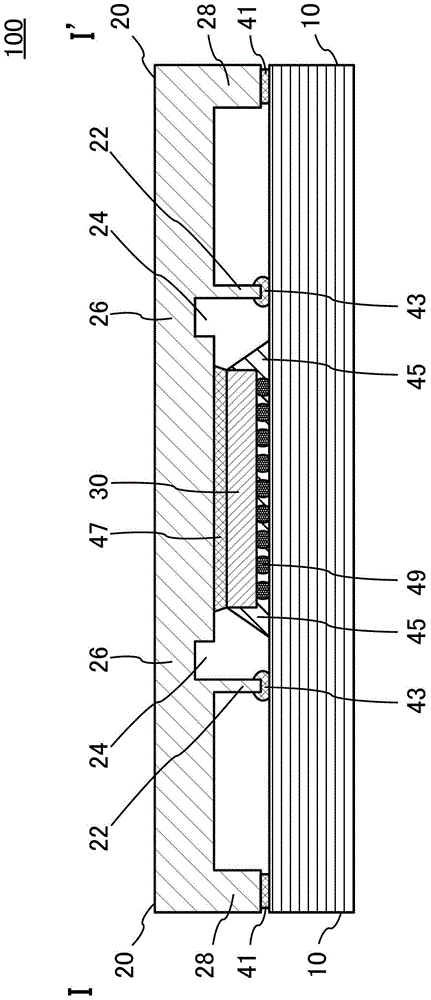

Display panel and preparation method of display panel

InactiveCN109991789AReduce stressImprove electrical and yieldNon-linear opticsStress ProblemComputer science

The invention provides a display panel and a preparation method of the display panel. The display panel comprises a substrate, a device layer on the substrate and a flat layer on the device layer; thedisplay panel further comprises a color resistance layer; and the color resistance layer is arranged between the device layer and the flat layer. Through extending the color resistance layer in a display area to a surrounding gate driving area, the terrain is more flat when the color resistance layer is arranged on the flat layer, so that the stress problems at the wide edges of metal wires are reduced and the condition of flat layer stripping is avoided.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

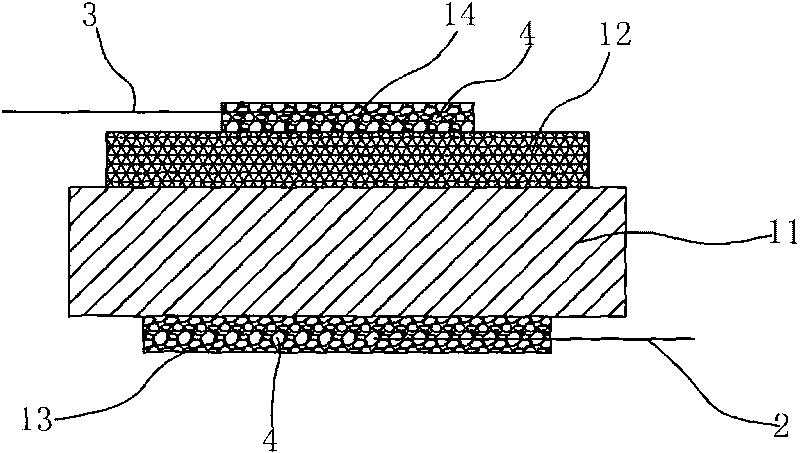

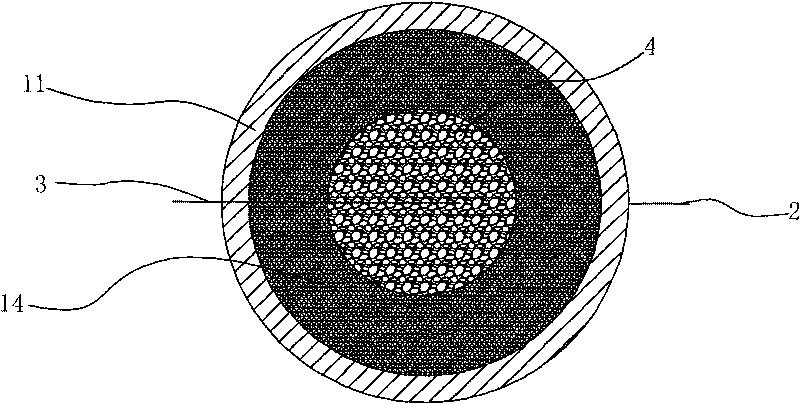

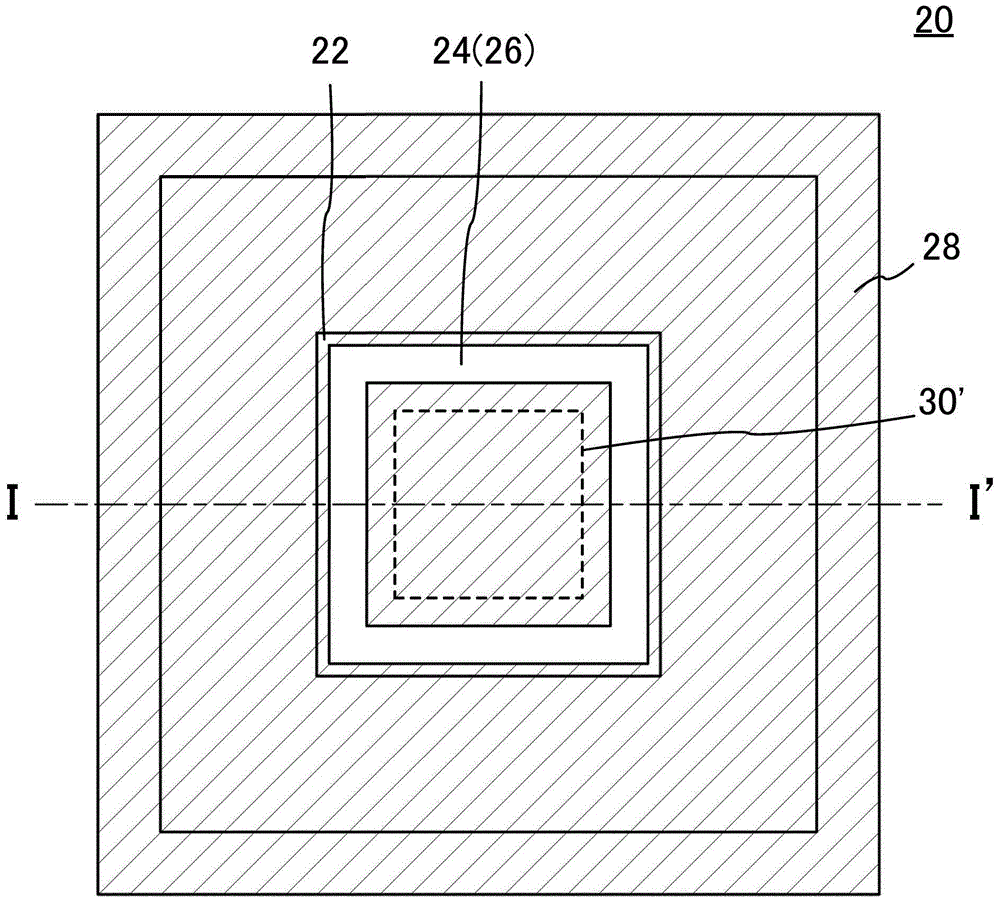

Semiconductor device

ActiveCN105870080ASolve the peeling problemSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

The objective of the invention is to overcome a problem that an adhesion part between a heat sink and a substrate peels off because the heat sink configured to a semiconductor chip and the substrate expands or contracts along with heat. A semiconductor device includes a substrate whose surface is made of an insulation material, a semiconductor chip flip-chip connected on the substrate, and a heat sink bonded to the semiconductor chip via a thermal interface material and fixed to the substrate outside the semiconductor chip, wherein the heat sink has a protrusion part protruding toward the substrate and bonded to the substrate via a conductive resin between a part bonded to semiconductor chip and a part fixed to the substrate and the heat sink has a stress absorbing part. According to the semiconductor device, the protrusion part of the heat sink is prevented from being peeled off due to heat expansion or heat contraction from the substrate at the part where the protrusion part of the heat sink is bonded to the substrate.

Owner:AMKOR TECH JAPAN INC

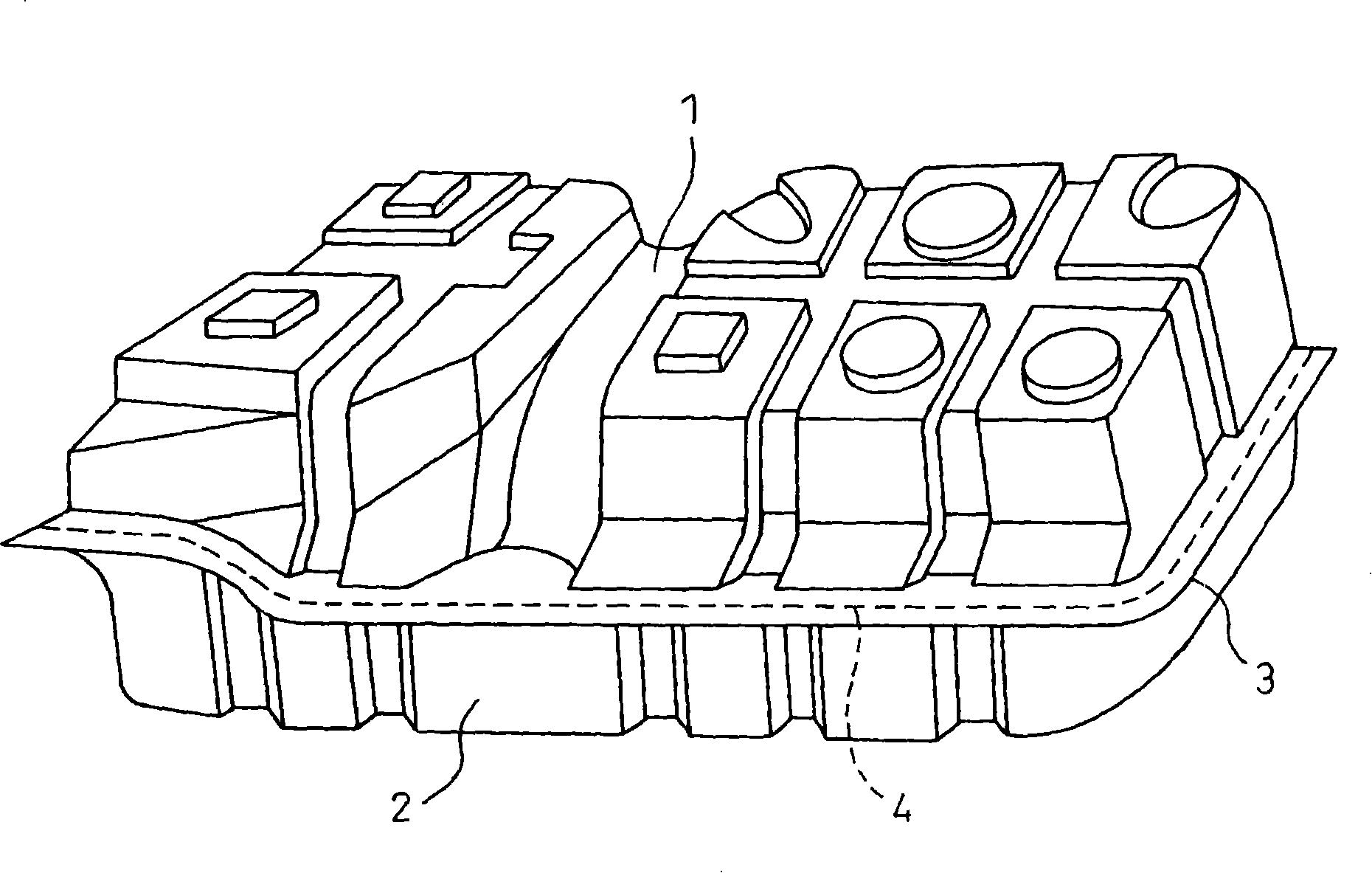

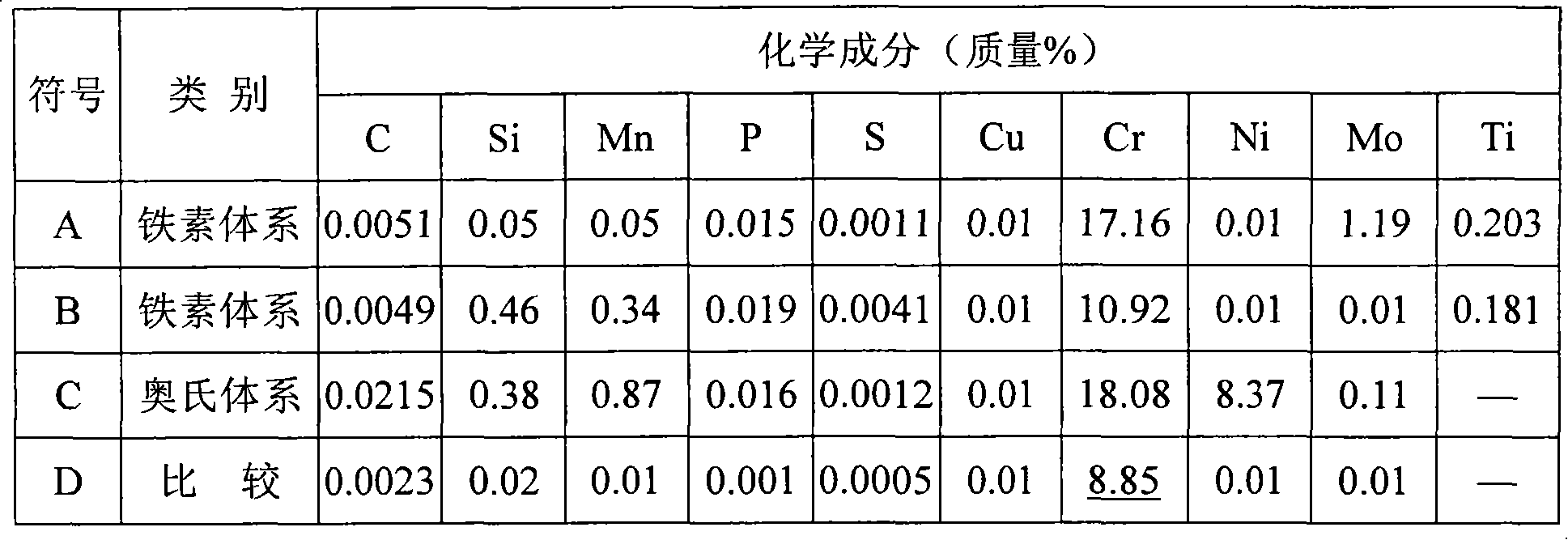

Surface-treated stainless-steel sheet with excellent corrosion resistance in salt damage environment for automotive fuel tank

InactiveCN101213323AImprove corrosion resistanceReduce thicknessHot-dipping/immersion processesLiquid surface applicatorsAlloyAutomotive fuel

A surface-treated stainless-steel sheet with excellent corrosion resistance in a salt damage environment for automotive fuel tanks, characterized by comprising: a ferritic stainless-steel sheet base containing 10.0-25.0 mass% chromium and having an average r value of 1.4 or higher and an overall elongation of 30% or higher or an austenitic stainless-steel sheet base containing 10.0-25.0 mass% chromium and having an overall elongation of 45% or higher and a degree of work hardening of 400 N / mm<2> or lower; and a deposit layer formed over a surface of the base in an amount of 5-80 g / m<2>, the deposit layer containing 5-13 mass% silicon, with the remainder being unavoidable impurities and aluminum. It is further characterized in that the alloy layer formed between the deposit layer and the base iron has a thickness smaller than 5.0 [mu]m, and that it has, formed on the deposit layer, a lubricant coating film which comprises a soluble resin and a lubricity-imparting agent, the amount of the agent being 1-30 mass% based on the soluble resin, and has a coefficient of friction of 0.15 or lower.

Owner:NIPPON STEEL & SUMIKIN STAINLESS STEEL CORP

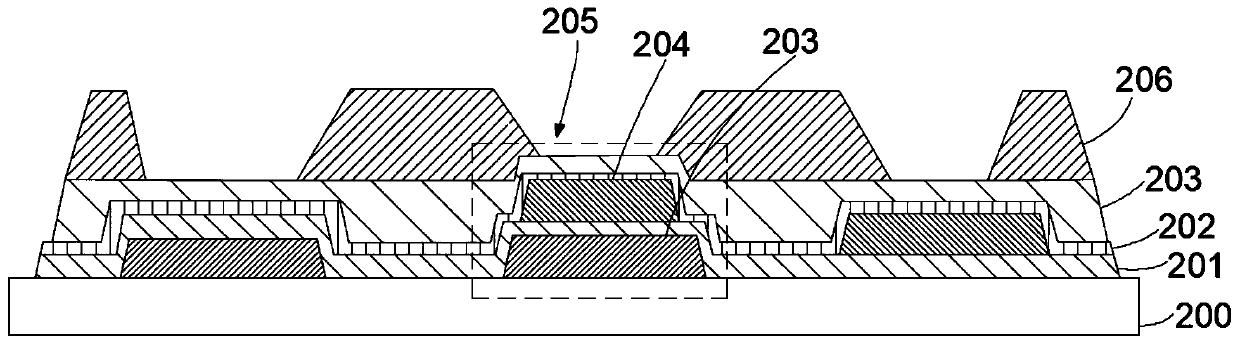

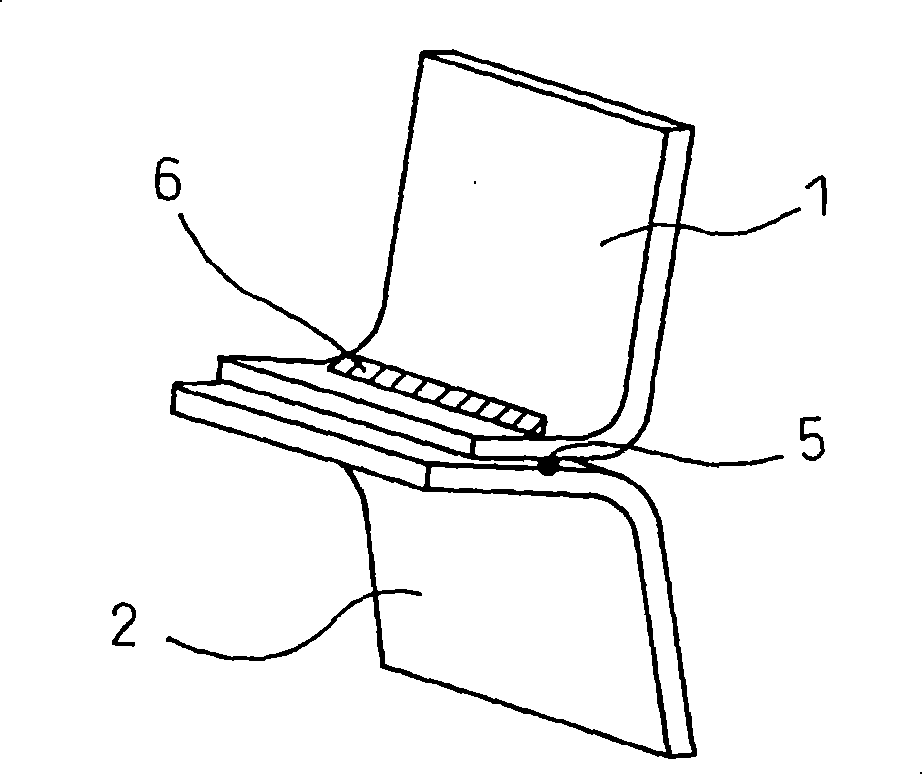

Molding structure and method for laser-assisting base plate line

ActiveCN101765341AEliminate image transfer processThe process steps are simpleInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsInsulation layerOptoelectronics

The invention provides a molding structure and a method for a laser-assisting base plate line; wherein the method comprises the following steps: providing a circuit base plate provided with multiple via holes; forming a first metal layer on the multiple via holes and the circuit base plate; forming a dielectric layer coating the first metal layer; carrying out laser hole drilling to form multiple via holes and grooves in the dielectric layer, wherein the multiple via holes expose the first metal layer, the multiple grooves are arranged above the via holes; forming a second metal layer between the multiple via holes and the multiple grooves to electrically connect the second metal layer to the first metal layer. The invention has the following advantages of saving publicly known image transferring process, simplifying processing steps and lowering processing cost, increasing binding force between the metal layers and the dielectric layer and solving the problem that the line is peeled off due to bad binding force between the line and an insulation layer.

Owner:NAN YA PRINTED CIRCUIT BOARD CORPORATION

Preparation method of film electrode for solid polymer electrolyte water electrolysis

The invention relates to a method for preparing membrane electrode for solid polymer water electrolyte. It evaporates solid polymer electrolyte solution and forms film, couples catalytic layer composed of catalyst and solid polymer electrolyte on two sides to form integrated membrane electrode, then crystalizes membrane electrode to realize co-crystallization for solid polymer electrolyte. The combination between membrane and catalytic layer is tight and the stratification between membrane and electrode caused by gas evolution and wahsing during water electrolysis process is solved. The invention can produce solid polymer water electrolyte with high performance, high stability and high durability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

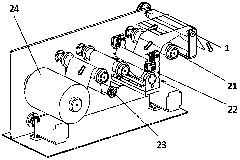

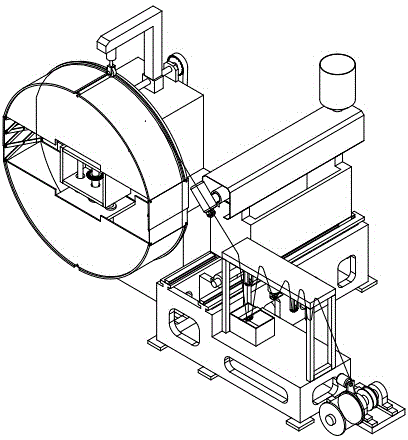

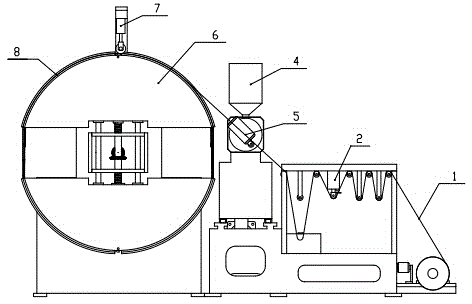

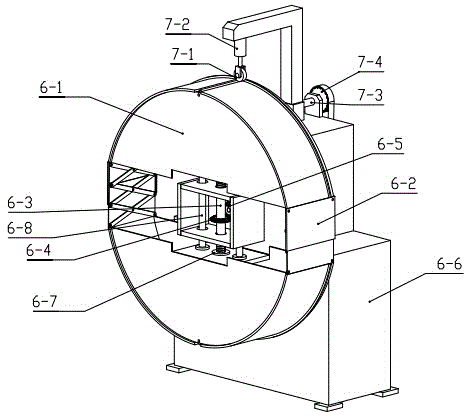

Manufacturing device of wire cord fabric for rubber track and manufacturing method

The invention discloses a manufacturing device of a wire cord fabric for a rubber track; the manufacturing device comprises a steel wire tightening mechanism, an extruder and a roller mechanism; a steel wire rope bypasses the steel wire tightening mechanism, so that the steel wire rope has tensile force; the steel wire rope passes through a mouth mould of the extruder, so that a layer of rubber wraps the surface of the steel wire rope to form a rubber coated cord thread; the rubber coated cord thread is wound on a rotary cylinder by the roller mechanism in the rotating process; an extruder moving mechanism is arranged on the extruder; the extruder moving mechanism is capable of driving the extruder to axially move along the roller mechanism; a pressing mechanism is arranged above the roller mechanism; the pressing mechanism is pressed on the rubber coated cord thread on the rotary cylinder; and therefore, the wire cord fabric for the rubber track is formed. According to the invention, automatic production of the wire cord fabric can be realized; and the produced cord fabric can be ensured to accord with use requirements. The invention further discloses a manufacturing method of the wire cord fabric for the rubber track.

Owner:日照纬润机电科技有限公司

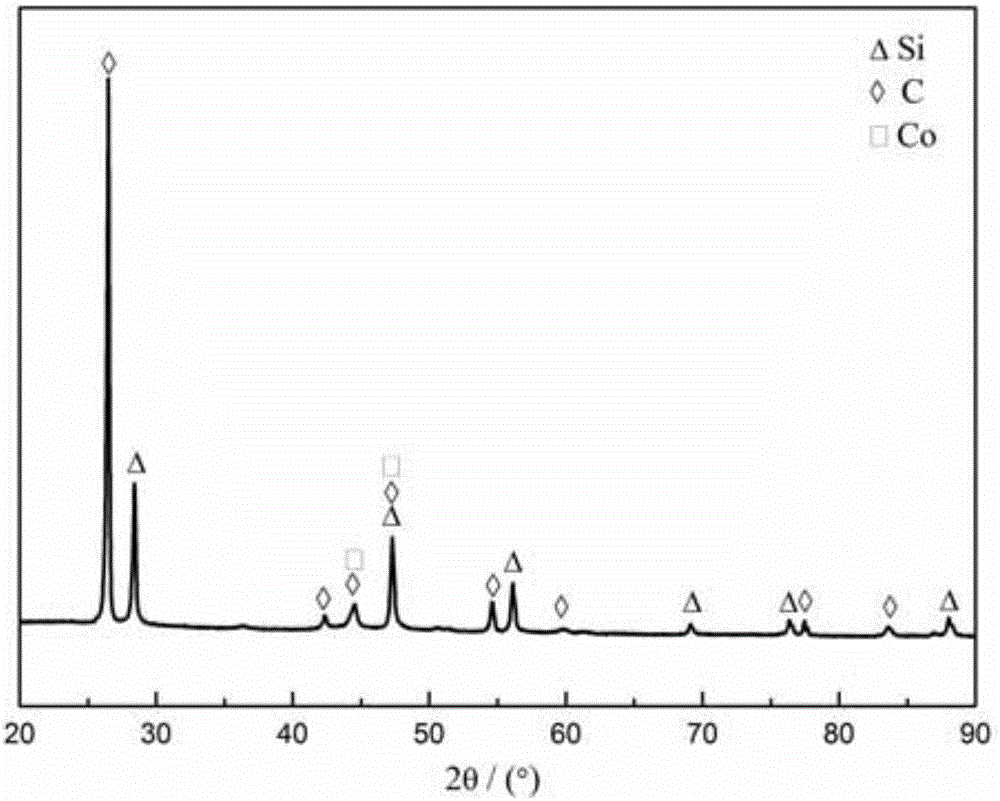

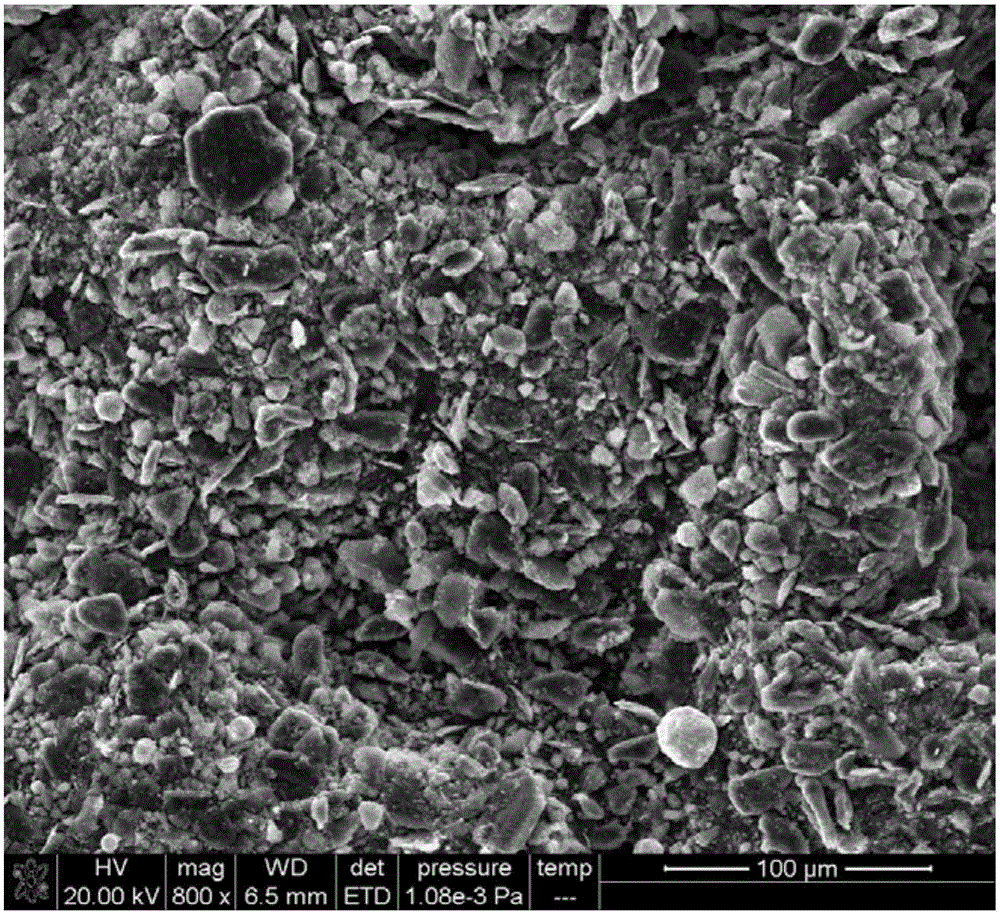

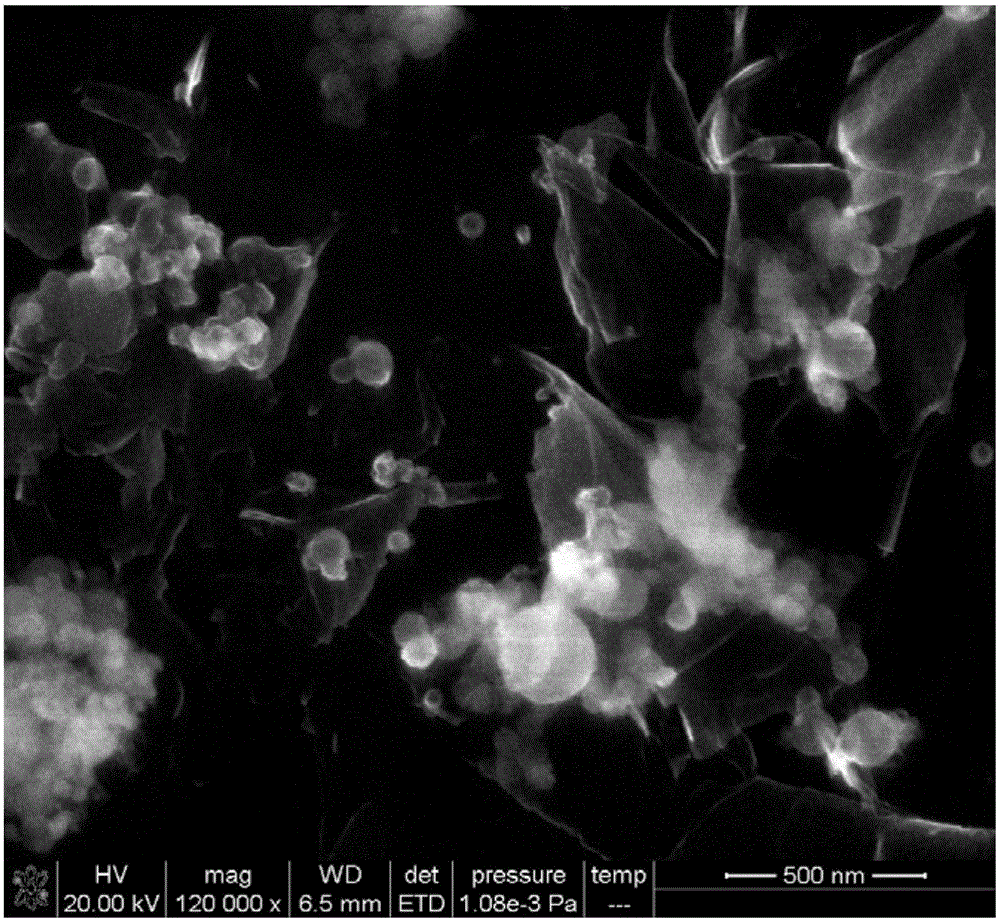

Silicon-cobalt-carbon composite material for negative electrode of lithium ion battery and preparation method of silicon-cobalt-carbon composite material

ActiveCN105742589ASolve the peeling problemIncrease capacityMaterial nanotechnologyCell electrodesCarbon compositesCitrinin hydrate

The invention discloses a silicon-cobalt-carbon composite material for a negative electrode of a lithium ion battery and a preparation method of the silicon-cobalt-carbon composite material. The preparation method comprises the following steps of uniformly dispersing nanometer silicon powder in water to obtain a nanometer silicon powder dispersing solution; adding a cobalt source into the nanometer silicon powder dispersing solution, dissolving the cobalt source, adding citric acid monohydrate, dissolving the citric acid monohydrate, adding graphite, and uniformly mixing the graphite to obtain a mixed solution; adjusting pH of the obtained mixed solution to be 2-5, precipitating a metal cobalt complex wrapping nanometer silicon powder particles from the surface of graphite powder particles to obtain a colloidal solution; carrying out drying and thermal processing on the obtained colloidal solution to obtain the silicon-cobalt-carbon composite material, wherein the mass ratio of the nanometer silicon powder to the cobalt source is (1:1) to (1:2), the mass ratio of the citric acid monohydrate to the cobalt source is (1:1) to (1:2), and the mass ratio of the nanometer silicon powder to graphite is (1:3) to (1:10). The silicon-cobalt-carbon composite material is environmental-friendly and is low in cost, the initial reversible capacity of the battery also can be effectively improved, and the cycle lifetime of the battery can be effectively prolonged.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

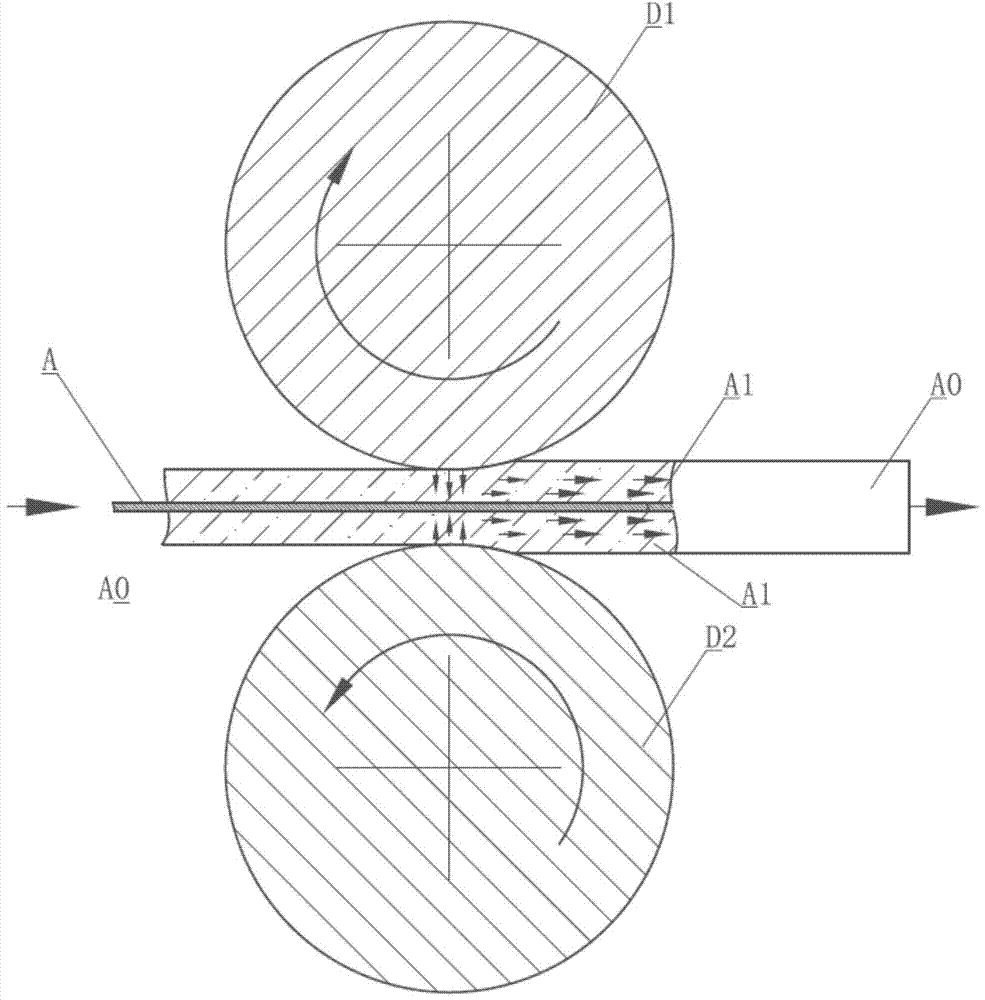

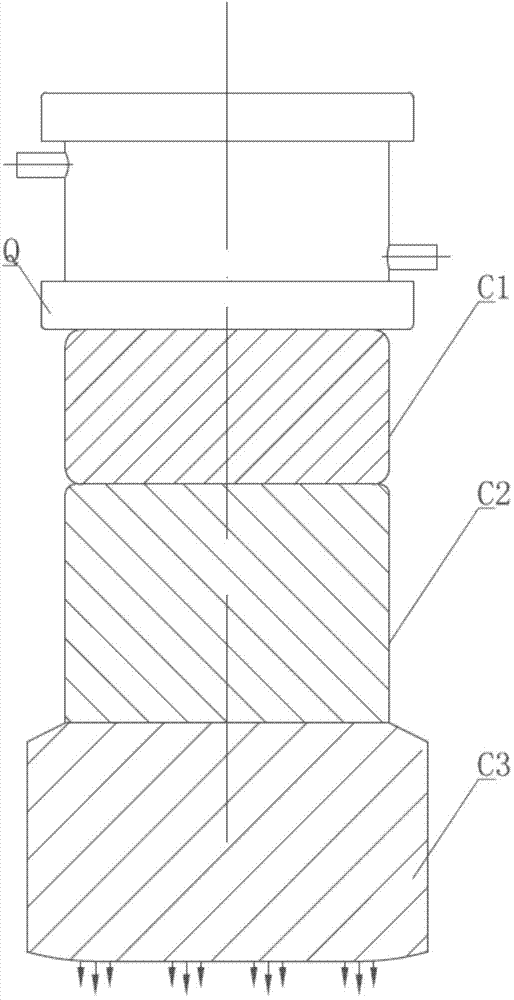

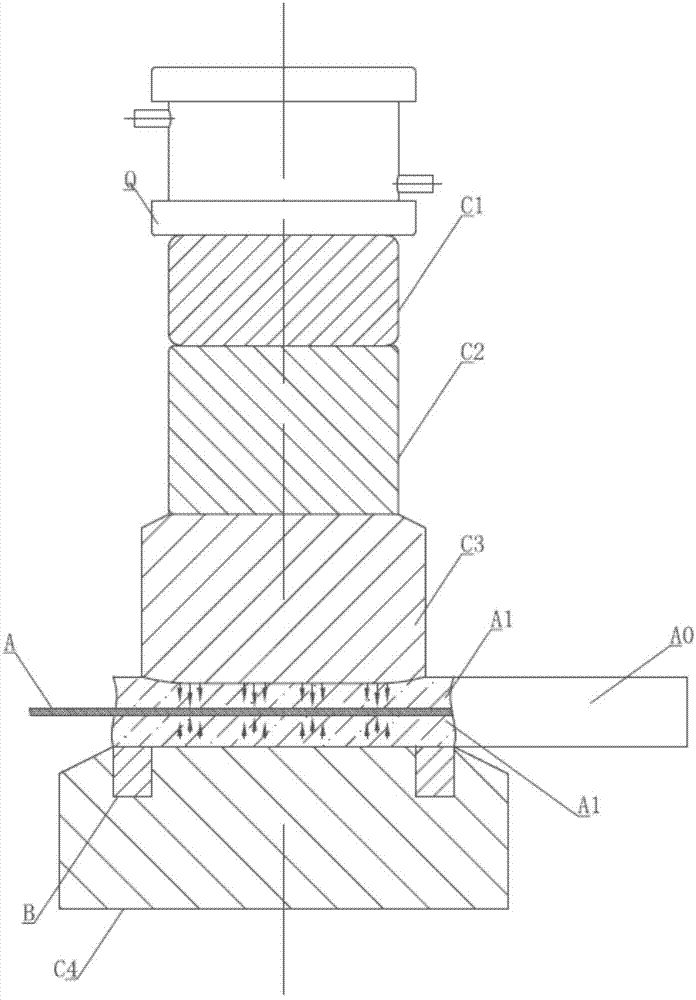

Ultrasonic film-rolling machine for wave lithium ion battery pole pieces

InactiveCN103943823AOvercome the defect of parallel slipSolve the peeling problemElectrode rolling/calenderingUltrasonic sensorTransformer

An ultrasonic film-rolling machine for wave lithium ion battery pole pieces consists of an unreeling motor (F), an ultrasonic rolling assembly, a frame (J) and a reeling motor (S). The ultrasonic rolling assembly is formed by successively connecting a cylinder (Q), an ultrasonic transducer (C), an amplitude transformer (C2) and a film-rolling pressure head (C3). An anvil block (C4) is arranged below the film-rolling pressure head (C3). A film-rolling station is disposed between the film-rolling pressure head (C3) and the anvil block (C4). The wave energy amplitude of a longitudinal wave is utilized and transmitted to lithium ion battery coating pole pieces, under the pressure intensity effect of the cylinder, the particle sections of the lithium ion battery coating pole pieces are subjected to resultant force compression of the longitudinal wave impulse and the cylinder pressure intensity in the thickness direction; and by utilizing the resultant force of a transverse wave impulse and the cylinder pressure intensity, the particles of the lithium ion battery coating pole pieces are mutually extruded, so that the coating pole pieces have no parallel slip during rolling, and the bonding structure of the coatings and current collectors is not destroyed.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

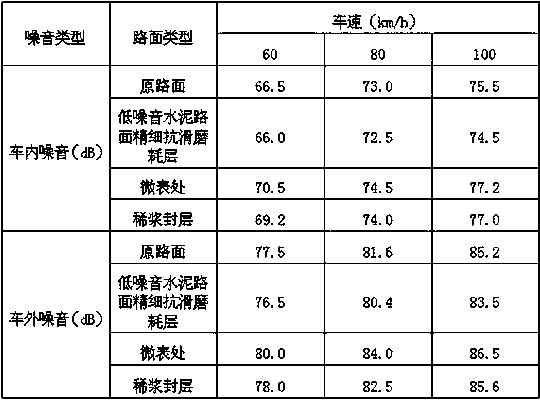

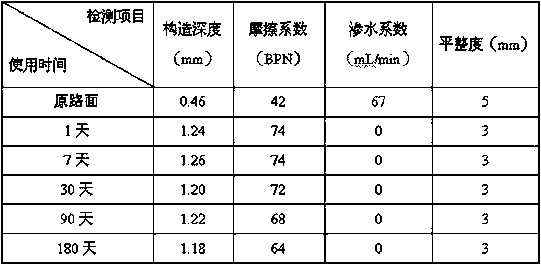

Low-noise cement pavement fine friction course and construction method

The invention discloses a low-noise cement pavement fine friction course and a construction method. The low-noise cement pavement fine friction course is prepared by performing two-layer paving on fine aggregate I, fine aggregate II, an epoxy adhesive, a curing agent and a stabilizer in parts by weight. The construction method comprises the following steps: closing a construction section, polishing the old cement pavement, repairing local diseases and cleaning the pavement; uniformly performing in-place mixing on the epoxy adhesive and the curing agent according to the designed ratio by adopting a synchronous chip seal vehicle, respectively performing layered paving on the fine aggregate I and fine aggregate II, rolling for 1-2 times by adopting a pneumatic-tired roller, and forming an epoxy anti-slide thin layer; spraying the stabilizer onto the epoxy anti-slide thin layer by adopting an asphalt distribution truck after the epoxy anti-slide thin layer is consolidated, performing curing molding and quality inspection, and handing over for later use after qualified. The low-noise cement pavement fine friction course disclosed by the invention has the advantages of being excellent innoise reduction and flatness, high in cement pavement affinity, excellent in adhesive property and the like, the surface structure of the old cement pavement can be rapidly repaired, and the pavementskid resistance and road appearance can be improved.

Owner:CHONGQING SINCERE BOND PAVEMENT MATERIALS

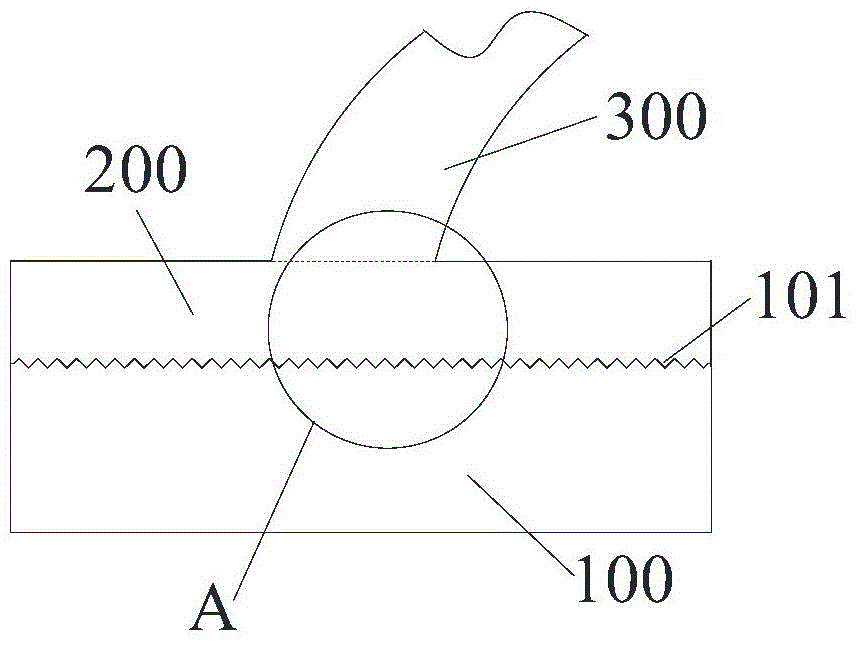

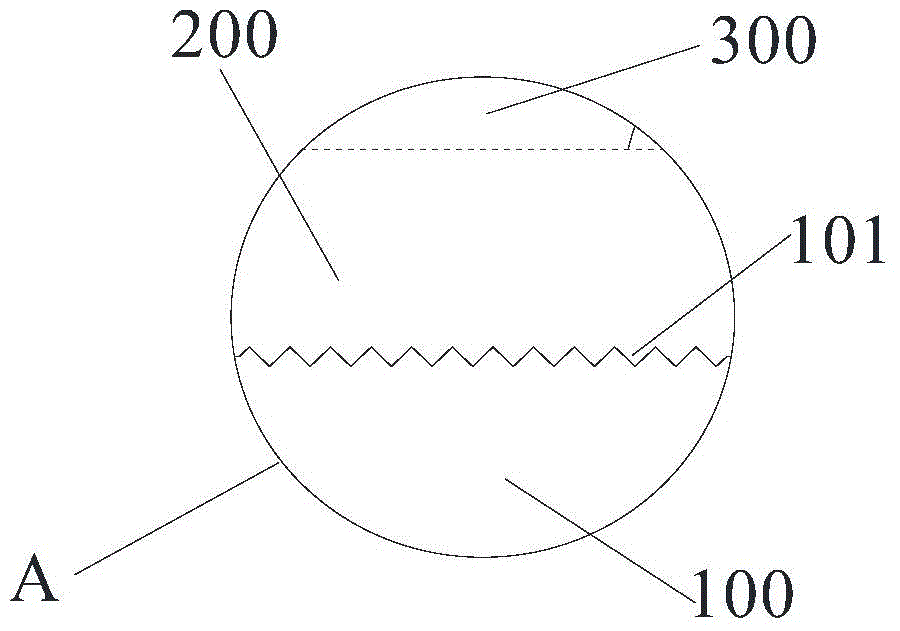

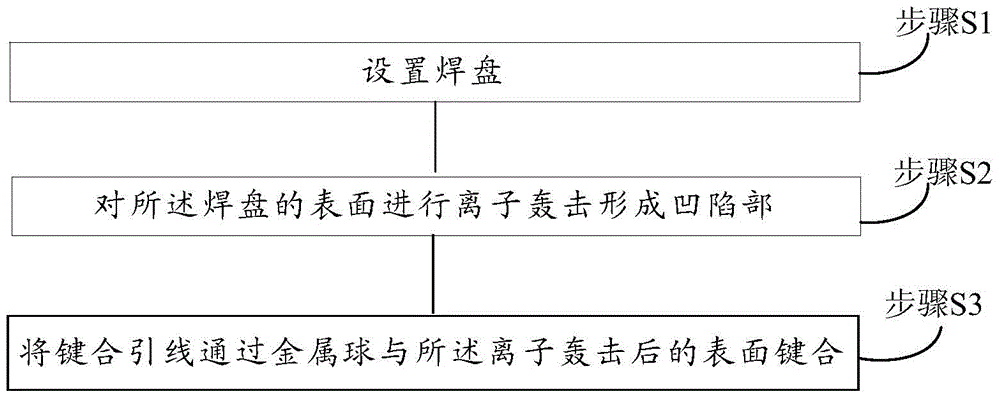

Wire bonding structure and wire bonding method

ActiveCN105097742AImprove surface structureIncrease contact areaSemiconductor/solid-state device detailsSolid-state devicesLead bondingStructure and function

The invention provides a wire bonding structure and a wire bonding method. The wire bonding structure comprises a pad, a metal ball, and a bonding wire, wherein the metal ball is fixed on the pad; the bonding wire and the metal ball are arranged in an integrated mode; and the surface where the pad and the metal ball are contacted is provided with multiple depressions. As the surface where the pad and the metal ball are contacted is provided with multiple depressions, the contact area between the pad and the metal ball is increased; curved surface contact replaces the original plane contact, resistance when the pad and the metal ball are separated is increased, and the separation problem of the two can be effectively solved; and in addition, only the surface structure of the pad is improved, the fact that a huge amount of heat is formed due to processes such as high-temperature heating and electroplating does not happen, a newly-formed semiconductor device structure is not influenced at all, and the original structure and functions of a chip can be ensured.

Owner:SEMICON MFG INT (SHANGHAI) CORP

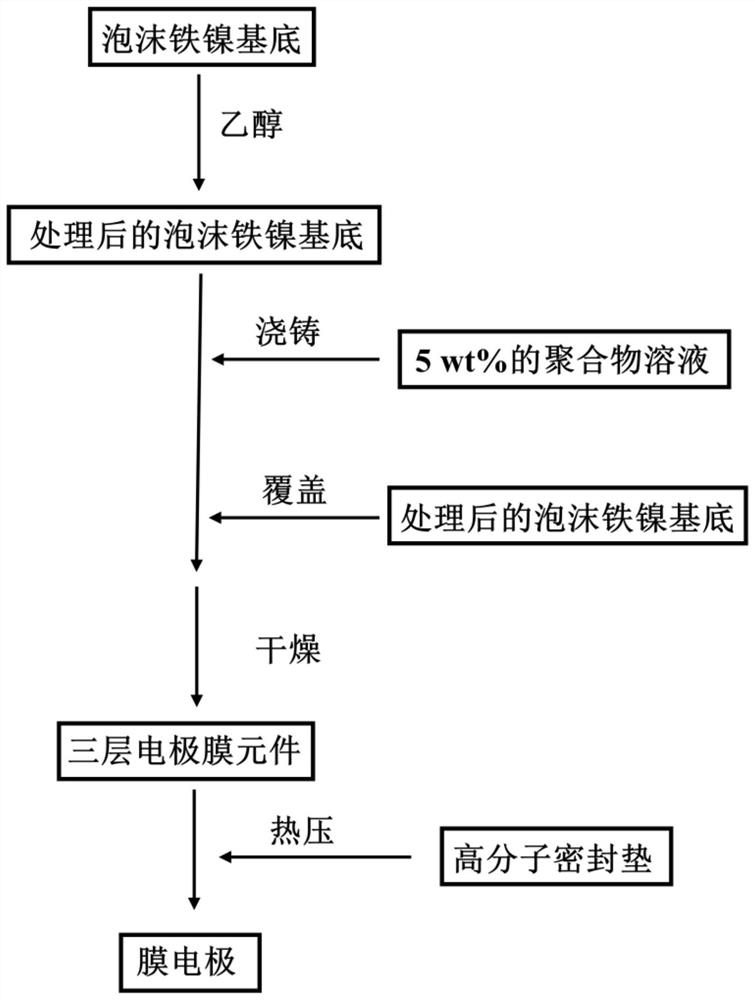

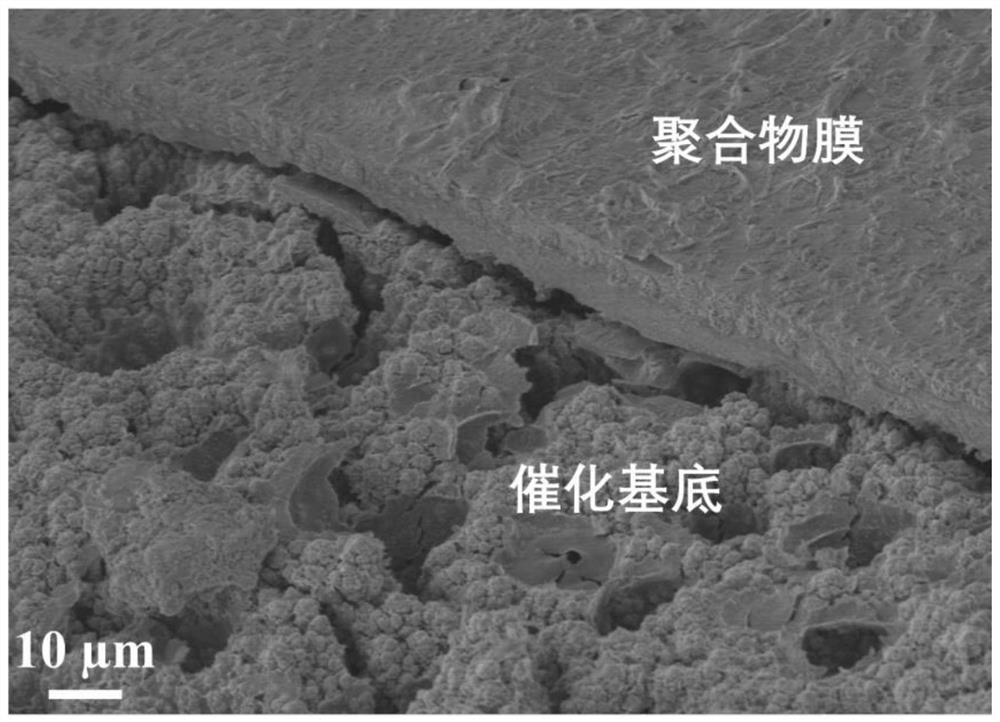

Preparation method and application of self-supporting ordered structure membrane electrode

InactiveCN113161590ALarge interface area and stabilityImprove performanceCellsFinal product manufacturePtru catalystCatalytic function

The invention discloses a preparation method and application of a self-supporting ordered structure membrane electrode, and belongs to the technical field of electro-catalysis membrane reactors. The method comprises: taking a porous structure solid material with an electro-catalysis function as a catalytic electrode; preparing a polymer of an ion conducting membrane into a polymer solution; salivating the polymer solution on the surface of the solid material to form a uniform thin layer, so that the surface is completely covered, the holes of the solid material are infiltrated, the interface area of the solid material and the polymer solution is increased, and active sites of the electrocatalyst are fully exposed; and covering another solid material on the polymer thin layer, heating and drying, and sealing to obtain the membrane electrode. According to the invention, the thickness of the film can be reduced by regulating and controlling the thickness of the film casting liquid coating, the ultrathin film with the bent surface is formed, the film is tightly attached along the uneven electrode surface, and the bonding firmness is enhanced; and the membrane electrode is of a three-dimensional surface structure, a larger interface area is provided, ion transfer is facilitated, and the performance of the membrane electrode is improved.

Owner:TSINGHUA UNIV

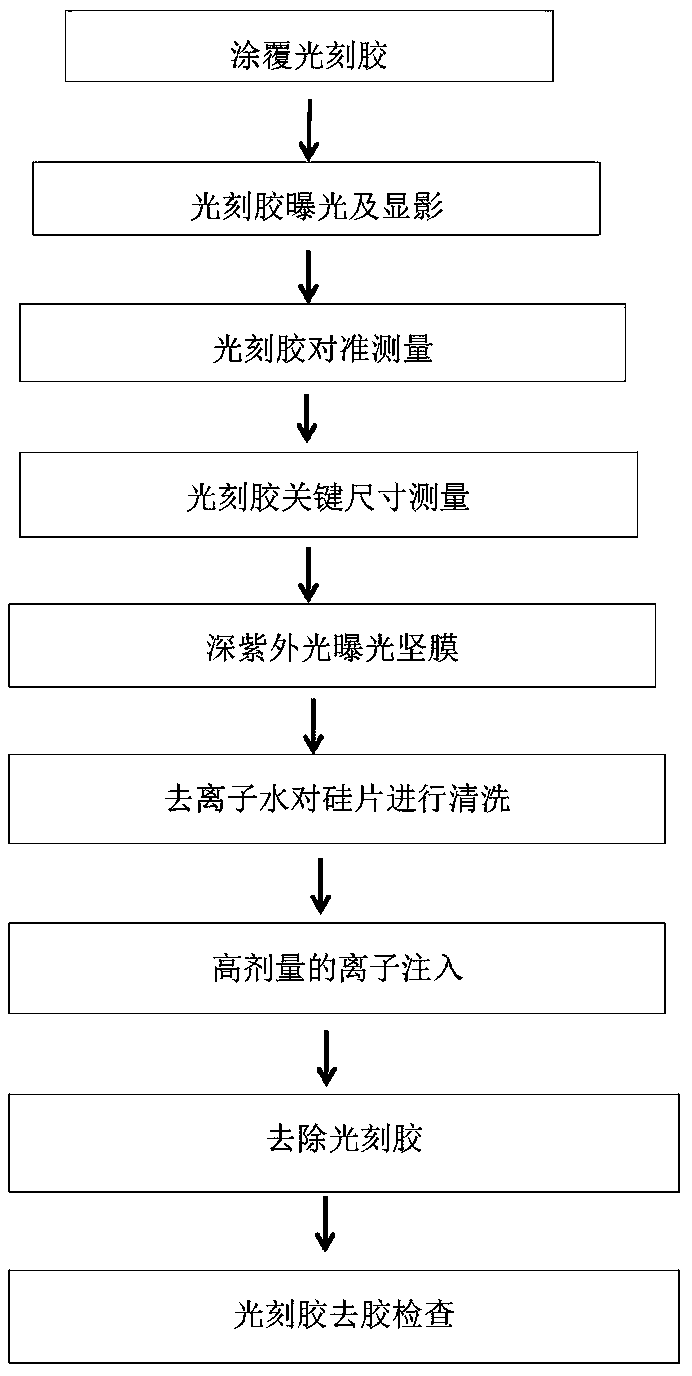

Method for enhancing adhesion of photoresist after developing

InactiveCN107942623ASolve the peeling problemImprove adhesionSemiconductor/solid-state device manufacturingPhotosensitive material processingDimension measurementHigh dosage

The invention discloses a method for enhancing adhesion of a photoresist after developing. The method comprises the steps of 1, performing coating on the photoresist; 2, performing exposure and developing on the photoresist; 3, performing aligned measurement on the photoresist; 4, performing critical dimension measurement on the photoresist; 5, performing UVQ; 6, performing cleaning and wetting ona silicon wafer by deionized water; 7, performing high-dosage ion injection; 8, removing the photoresist; and 9, performing adhesive-removing examination on the photoresist. According to the method for enhancing adhesion of the photoresist after developing, cleaning and wetting of the silicon wafer by deionized water is added after the photoresist is completely developed, so that high adhesion between the photoresist and the silicon wafer can be ensured, the problem of photoresist peeling in high-dosage injection can be solved, and process margin is improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com