Manufacturing device of wire cord fabric for rubber track and manufacturing method

A technology of steel cord and rubber track, which is applied in the manufacture of steel cord for rubber track and the field of manufacturing equipment for steel cord for rubber track, can solve the problems of high labor intensity, messy arrangement, uneven force, etc., and achieve automatic production, The effect of uniform glue covering and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

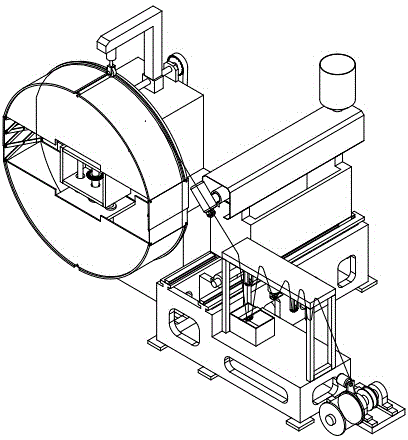

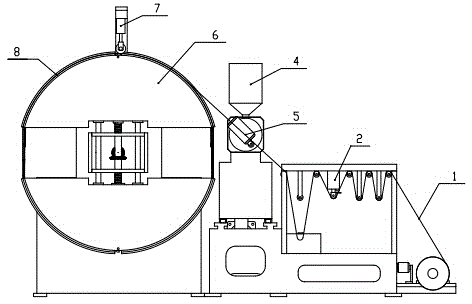

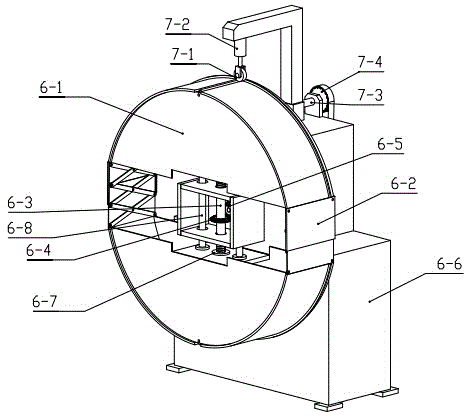

[0040] Such as figure 1 , figure 2 As shown, the manufacturing device of the steel cord for rubber crawler of the present invention comprises a steel wire tensioning mechanism 2, an extruder 4, and a roller mechanism 6, and the steel wire rope 1 bypasses the steel wire tensioning mechanism 2, so that the steel wire rope 1 has tension; the steel wire rope 1 Pass through the die 5 of the extruder 4, so that the surface of the steel wire rope 1 is coated with a layer of rubber to become a rubber-coated cord 8;

[0041] The roller mechanism 6 is arranged on the frame 6-6, and the roller mechanism 6 can rotate around its horizontal axis; the roller mechanism 6 winds the rubber-coated cord 8 onto the rotating cylinder 6-1 during the rotation process;

[0042] The extruder 4 is provided with an extruder moving mechanism; the extruder moving mechanism can drive the extruder 4 to move axially along the roller mechanism 6;

[0043] A pressing mechanism 7 is arranged above the roller ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com