Patents

Literature

302results about How to "Tightly wound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

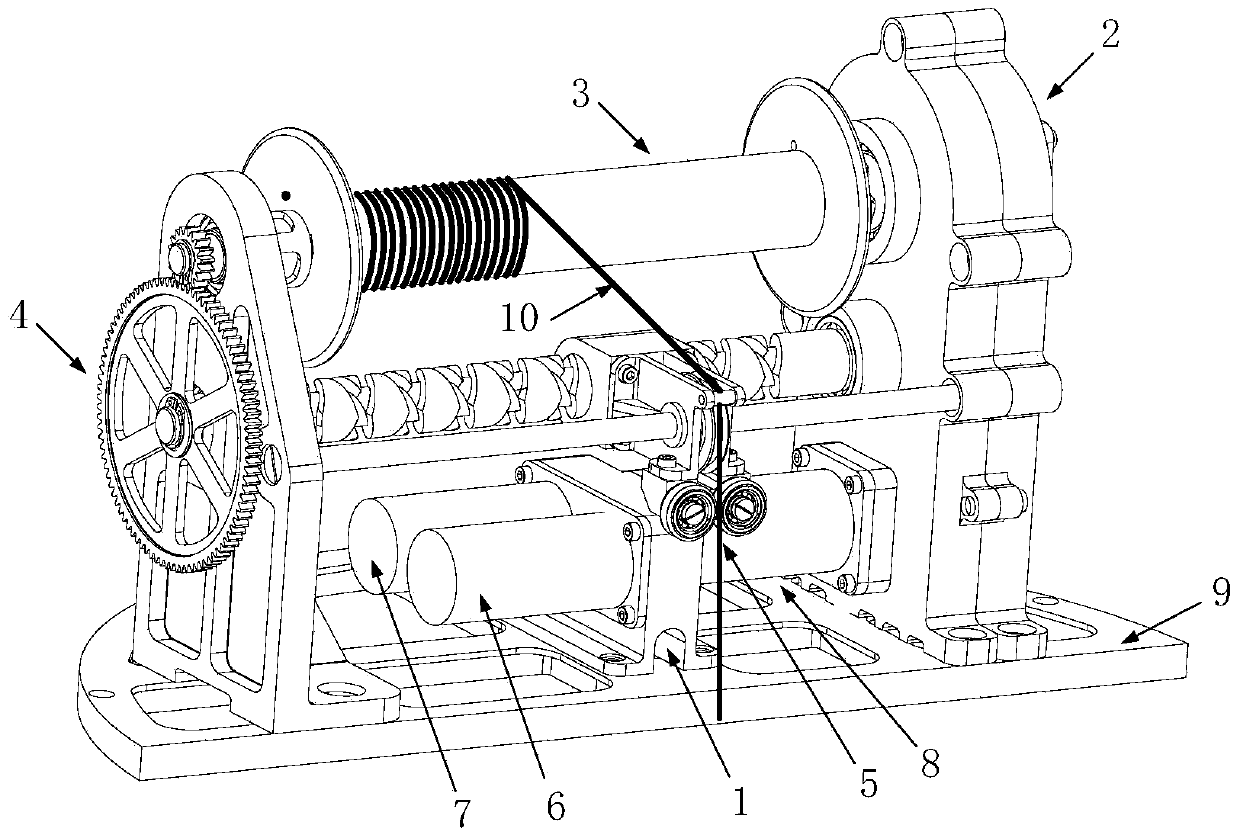

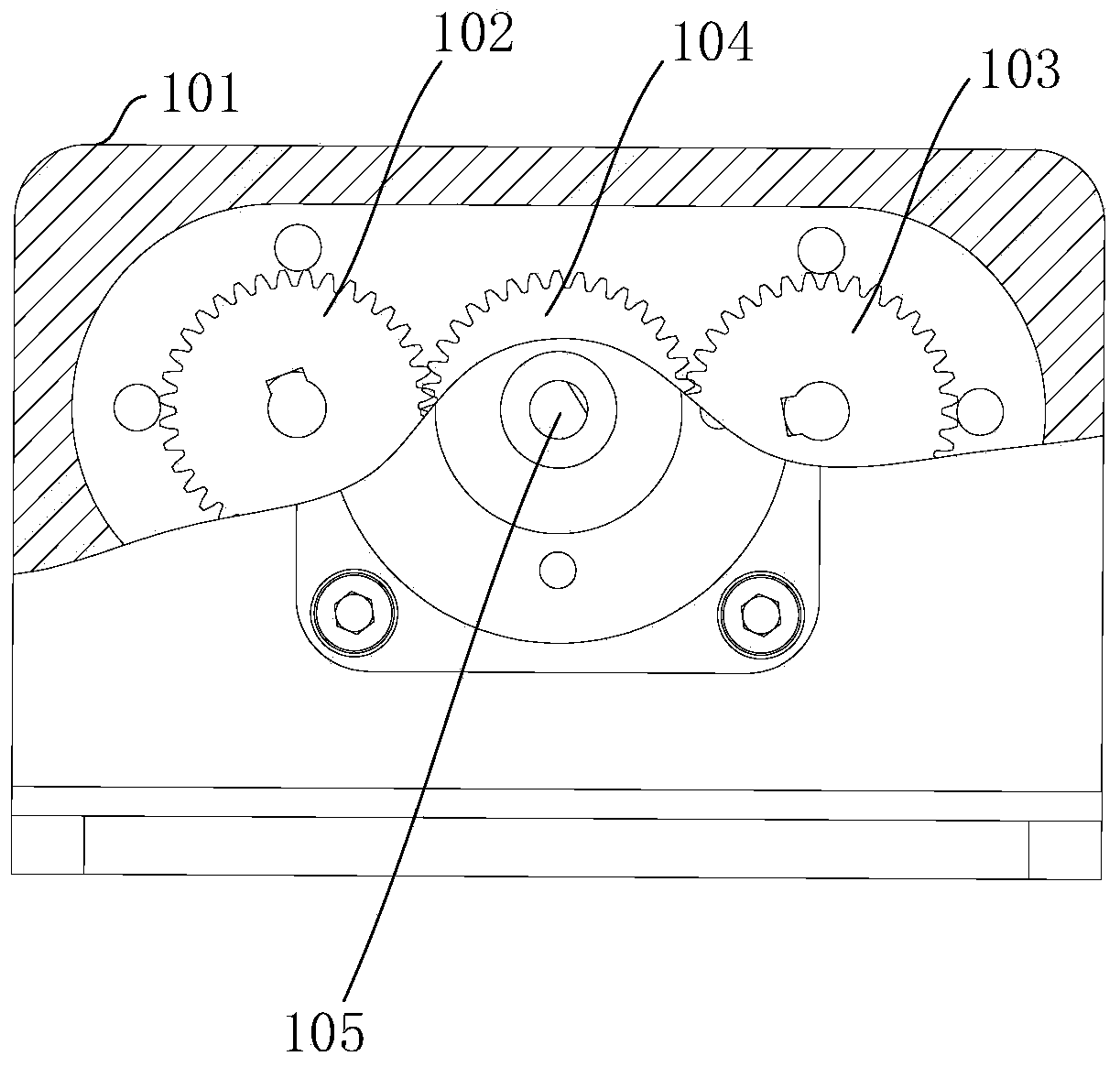

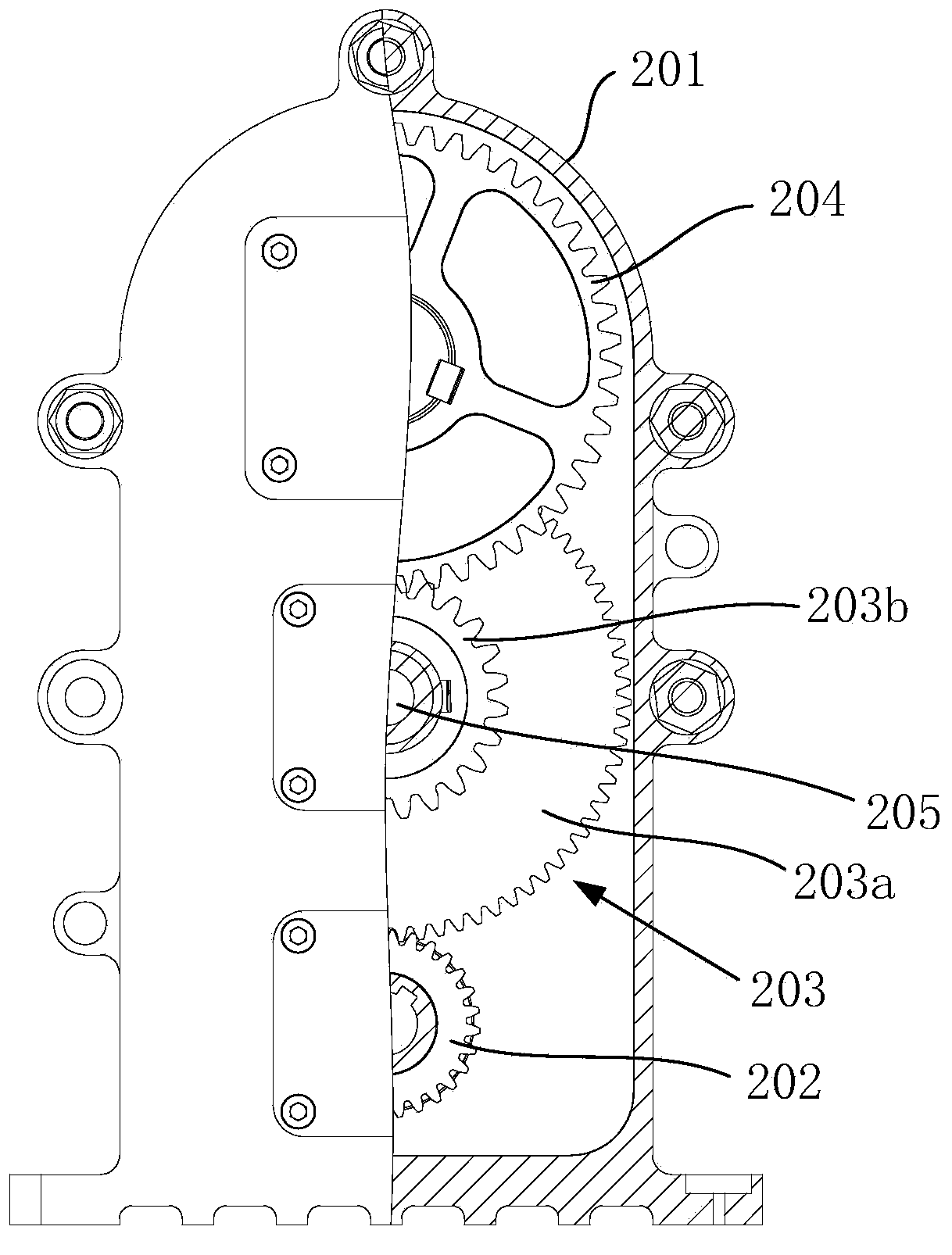

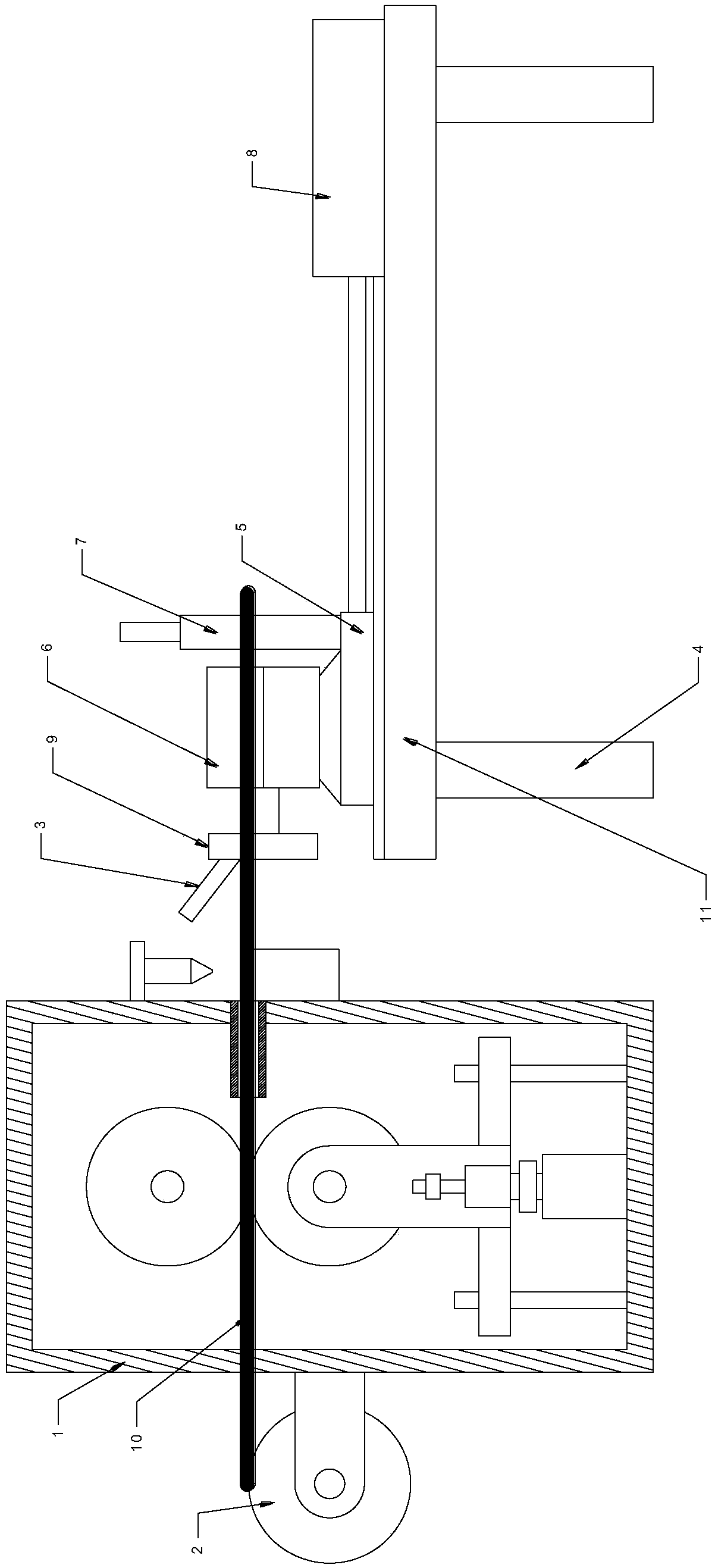

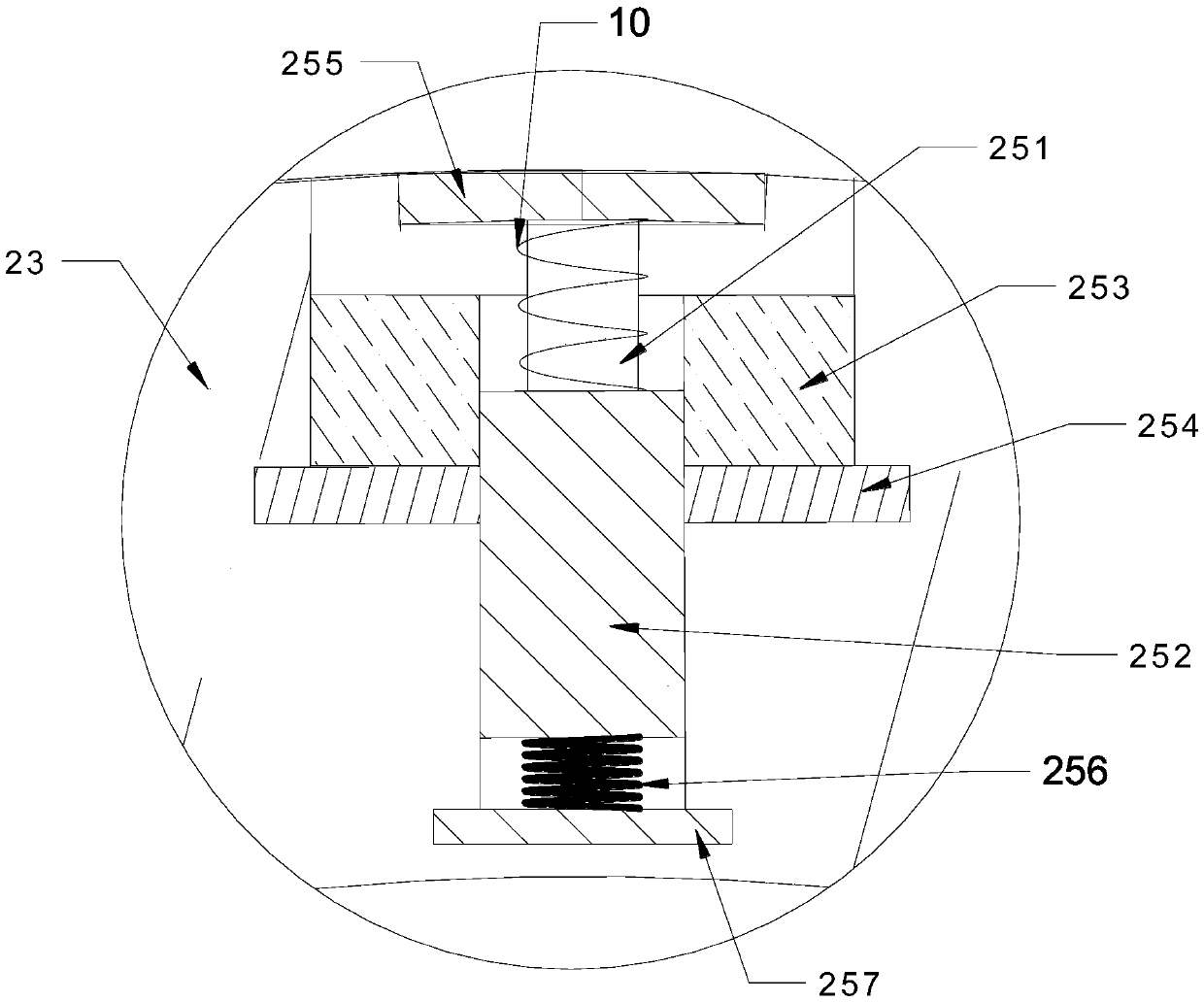

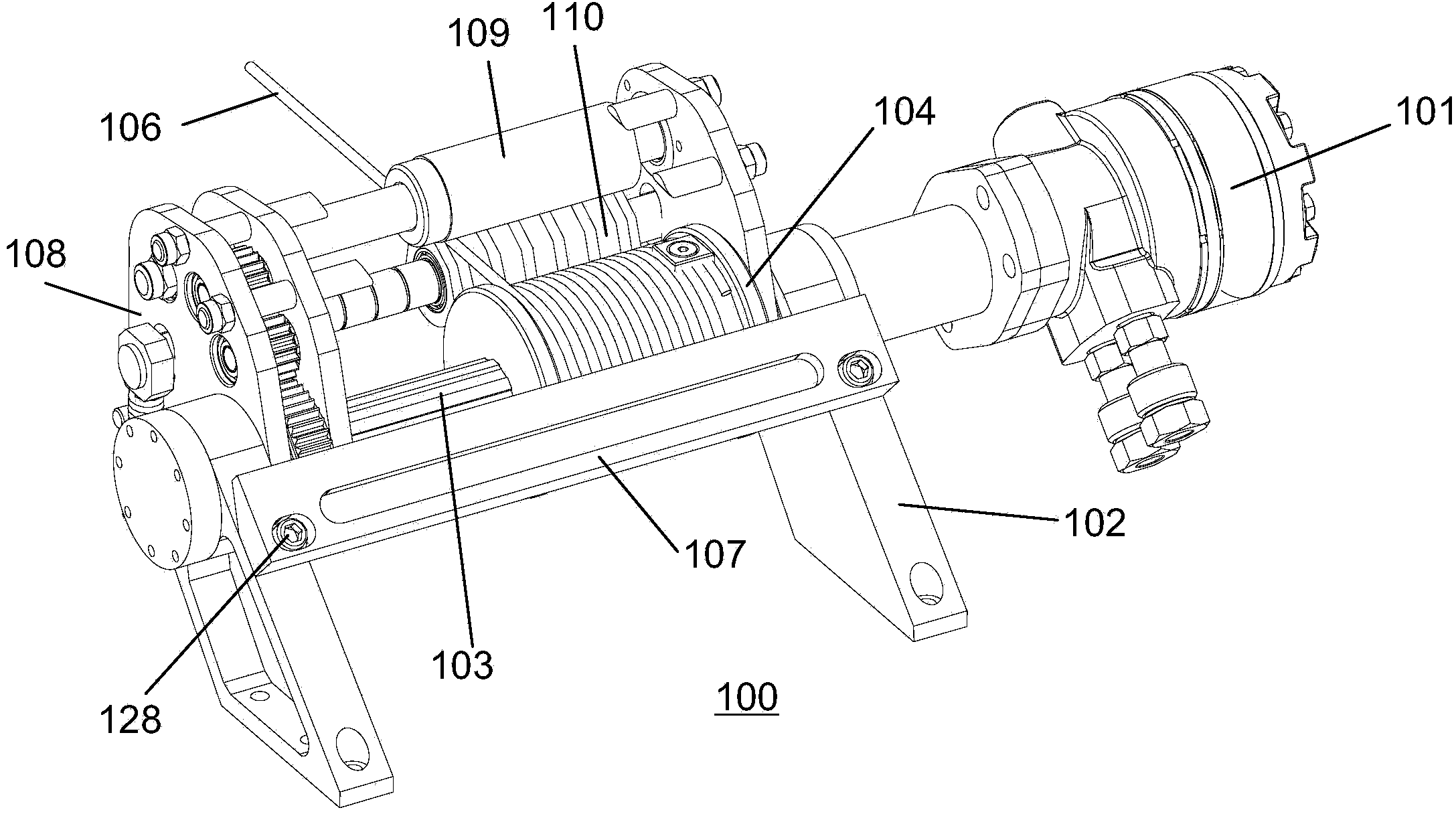

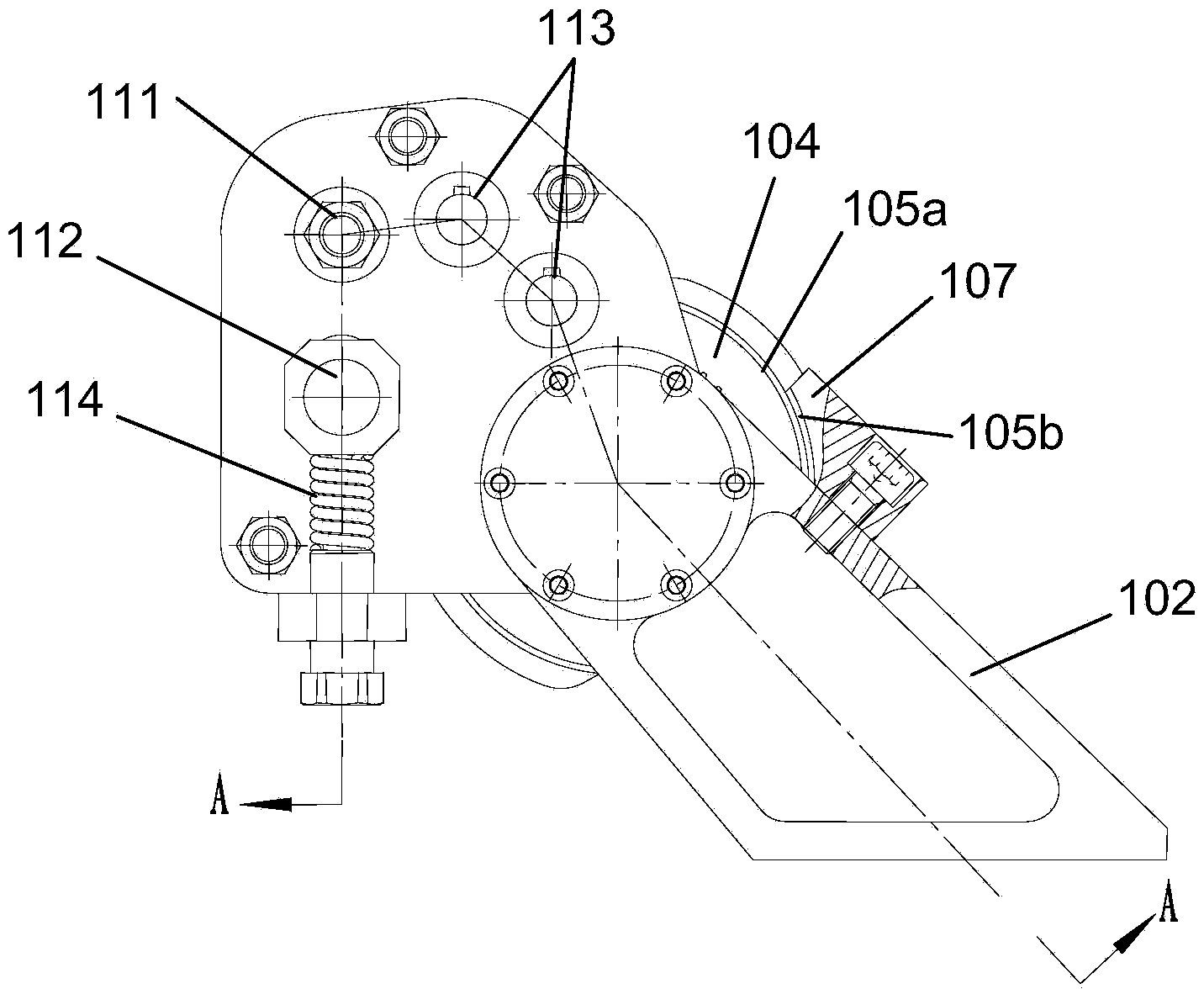

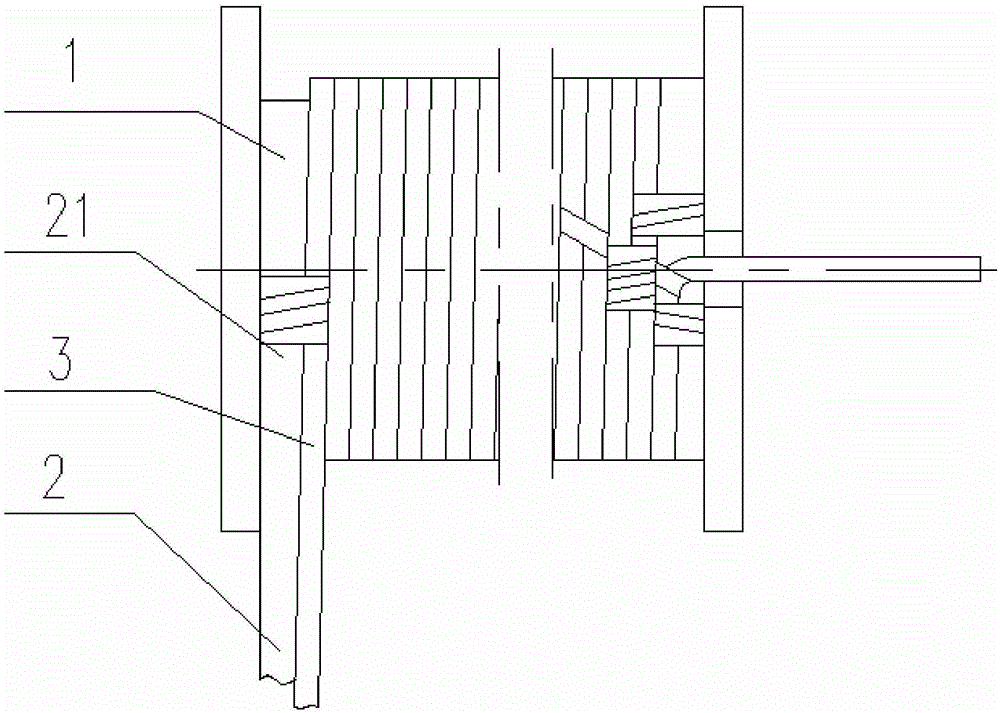

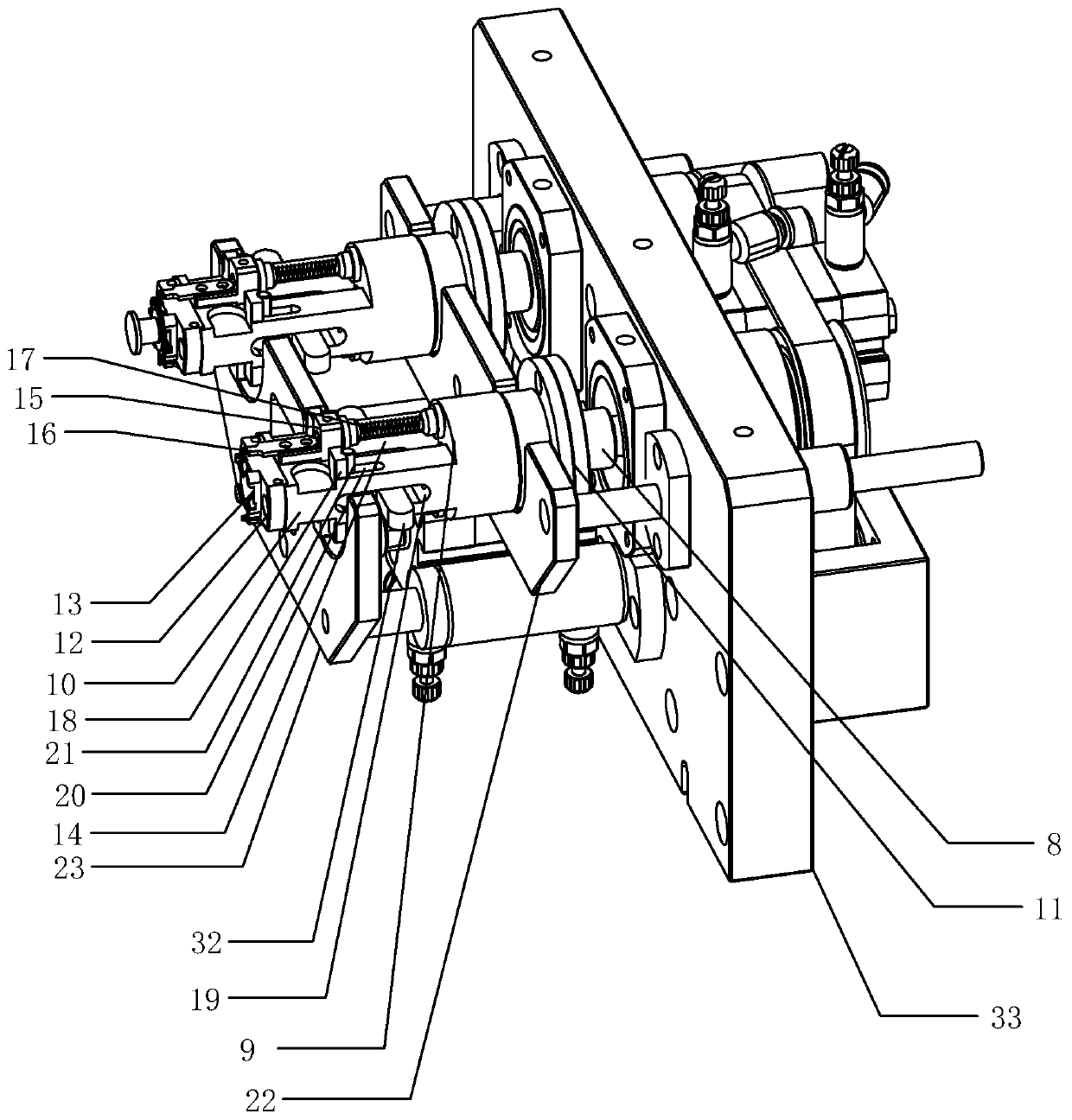

Rope drive device with reciprocating wire arrangement function

ActiveCN104192637AWith reciprocating cable functionWinding orderlyFilament handlingReciprocating motionGear wheel

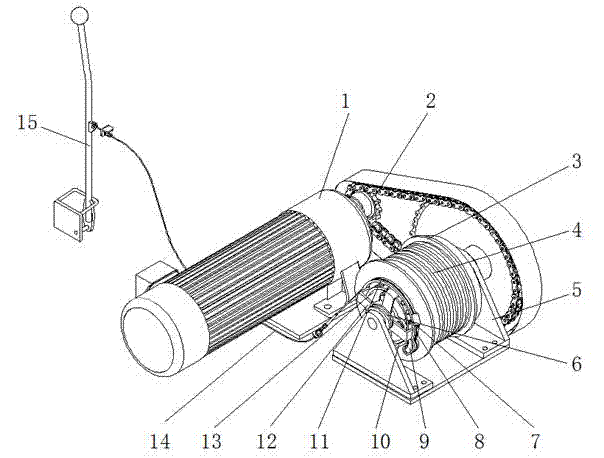

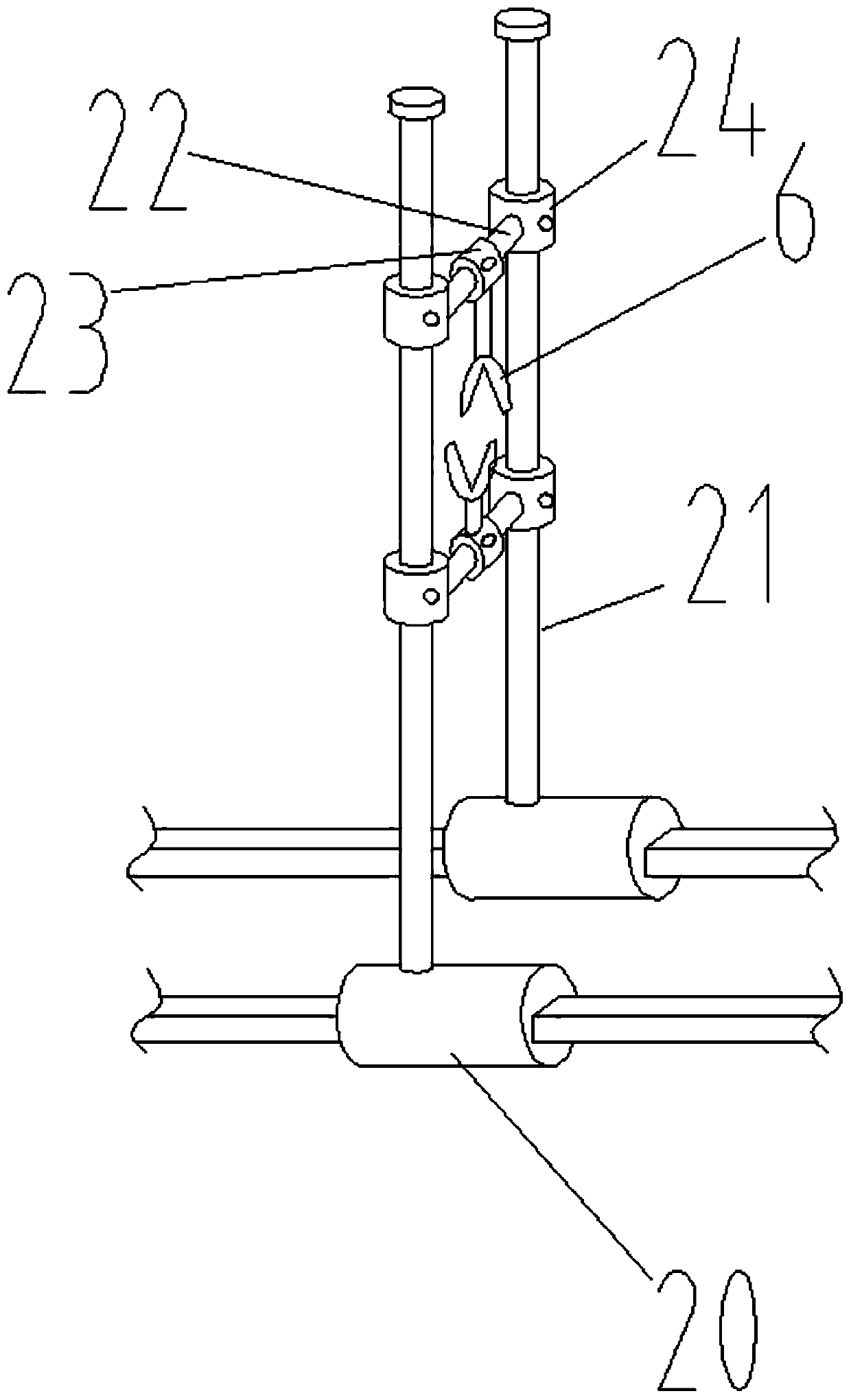

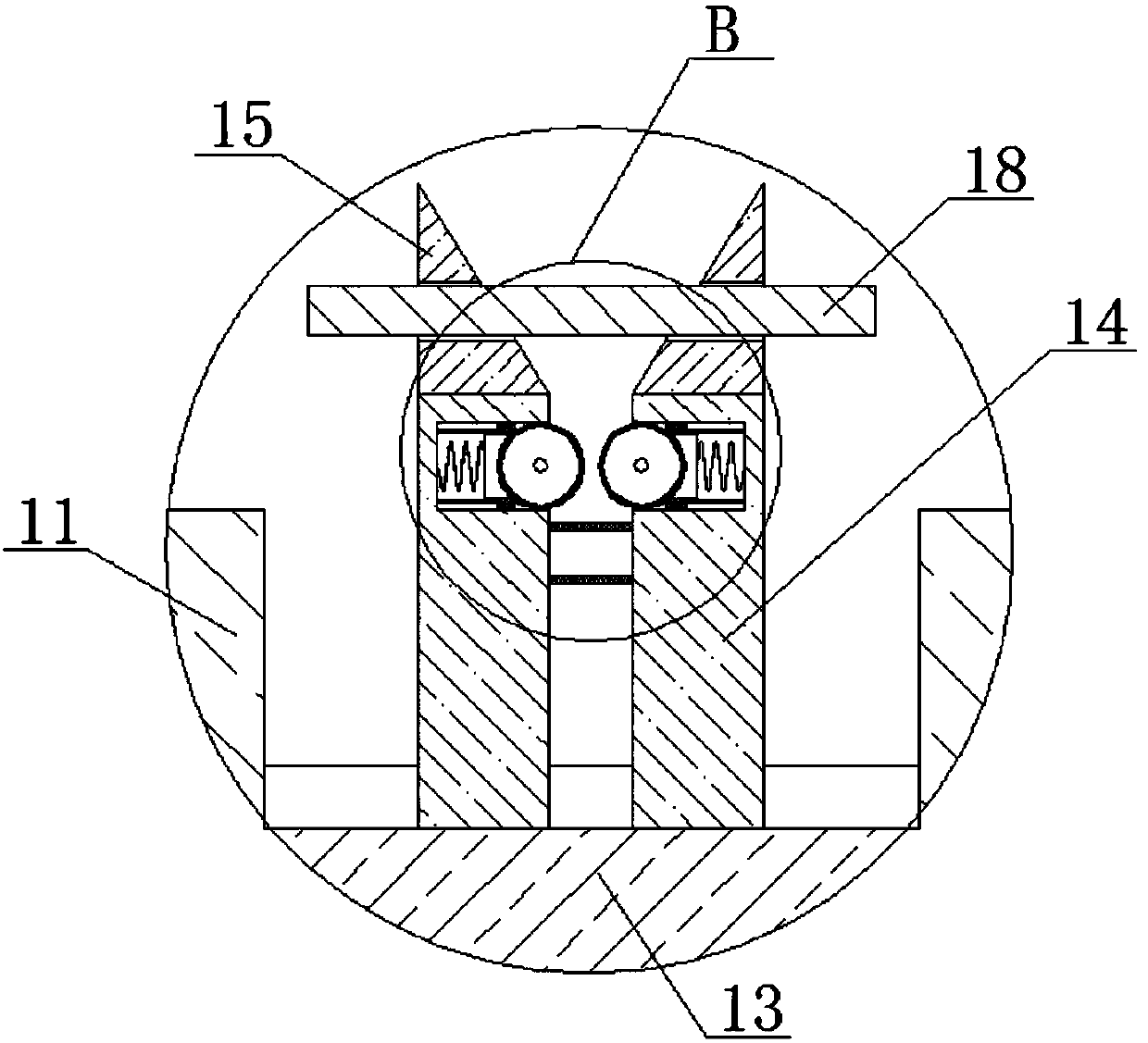

The invention discloses a rope drive device with a reciprocating wire arrangement function. The rope drive device comprises a backup motor gearbox, a rope roller reducer, a winding roller, a reciprocating screw mechanism and an arrangement guide wheel set. A driving motor is connected with an output shaft of a backup motor and an input shaft of a planetary reducer through the backup motor gearbox, so that both the driving motor and the backup motor can drive the motor gearbox to move. The rope roller reducer transmits rotation of an output shaft of the planetary reducer to the winding roller according to a specified speed ratio, and a large torque is obtained. The winding roller is mounted at an output shaft of the rope roller reducer; a drive rope is wound on and unwound from the winding roller. A reciprocating screw of the reciprocating screw mechanism is connected with the winding roller through a gear and drives a nut slider mounted on the reciprocating screw, to reciprocate. The arrangement guide wheel set is fixedly connected with the screw slider and reciprocates with the screw slider to guide the drive rope being tightly wound on the winding roller in a reciprocating manner. The rope drive device allows winding and unwinding of the rope and allows the rope to be regularly and tightly wound.

Owner:BEIHANG UNIV

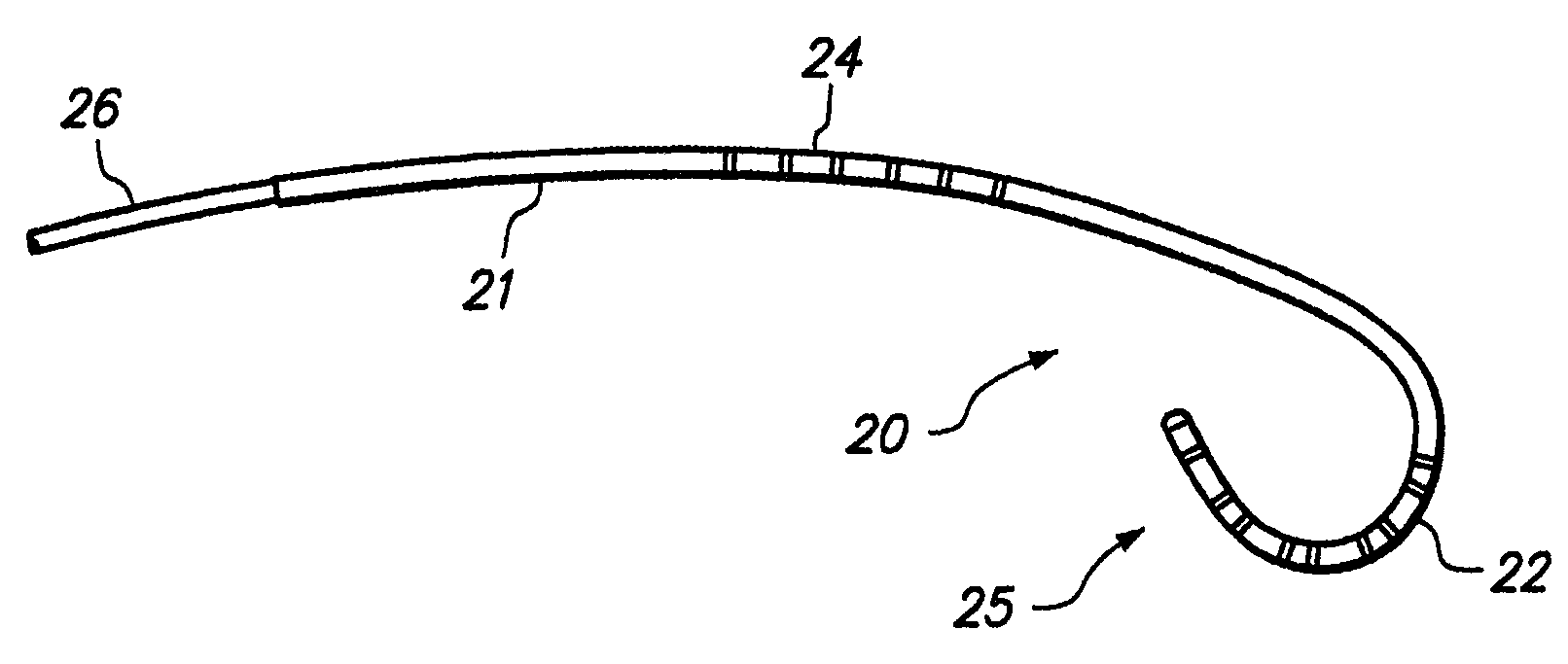

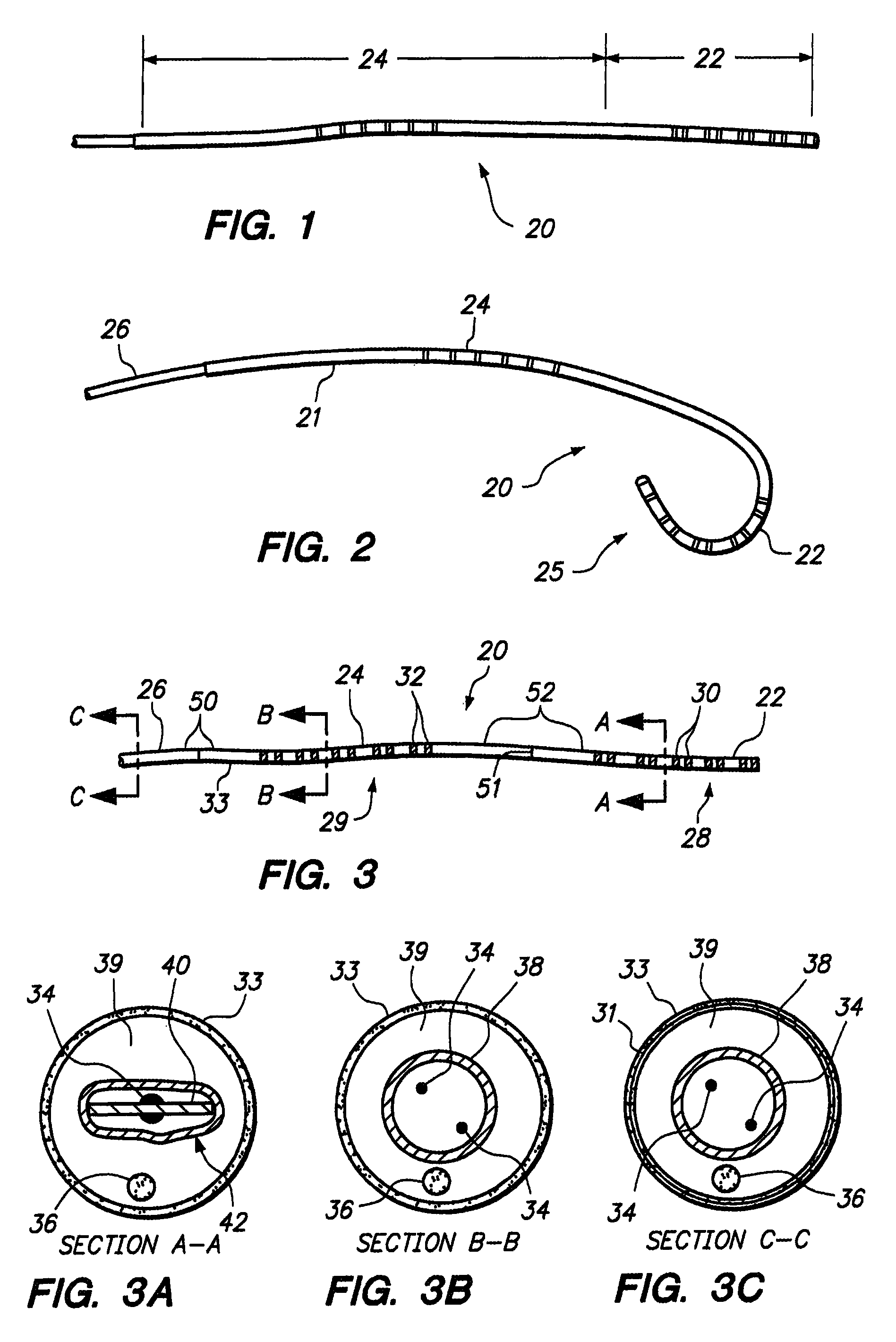

Multi-bend steerable mapping catheter

An electrophysiology catheter introduced through the groin and inferior vena cava into the right side of the heart comprises an elongate flexible shaft having a steerable distal section and a prolapsing section located proximally of the distal section. The distal section is inserted into the coronary sinus and a back-steering force is applied to the catheter to anchor the distal section therein, after which the catheter is further advanced to prolapse the prolapsing section against the high right atrium. Electrical pathways in both the coronary sinus and the high right atrium are mapped using respective electrode pairs carried on the distal and prolapsing sections of the catheter.

Owner:BOSTON SCI SCIMED INC

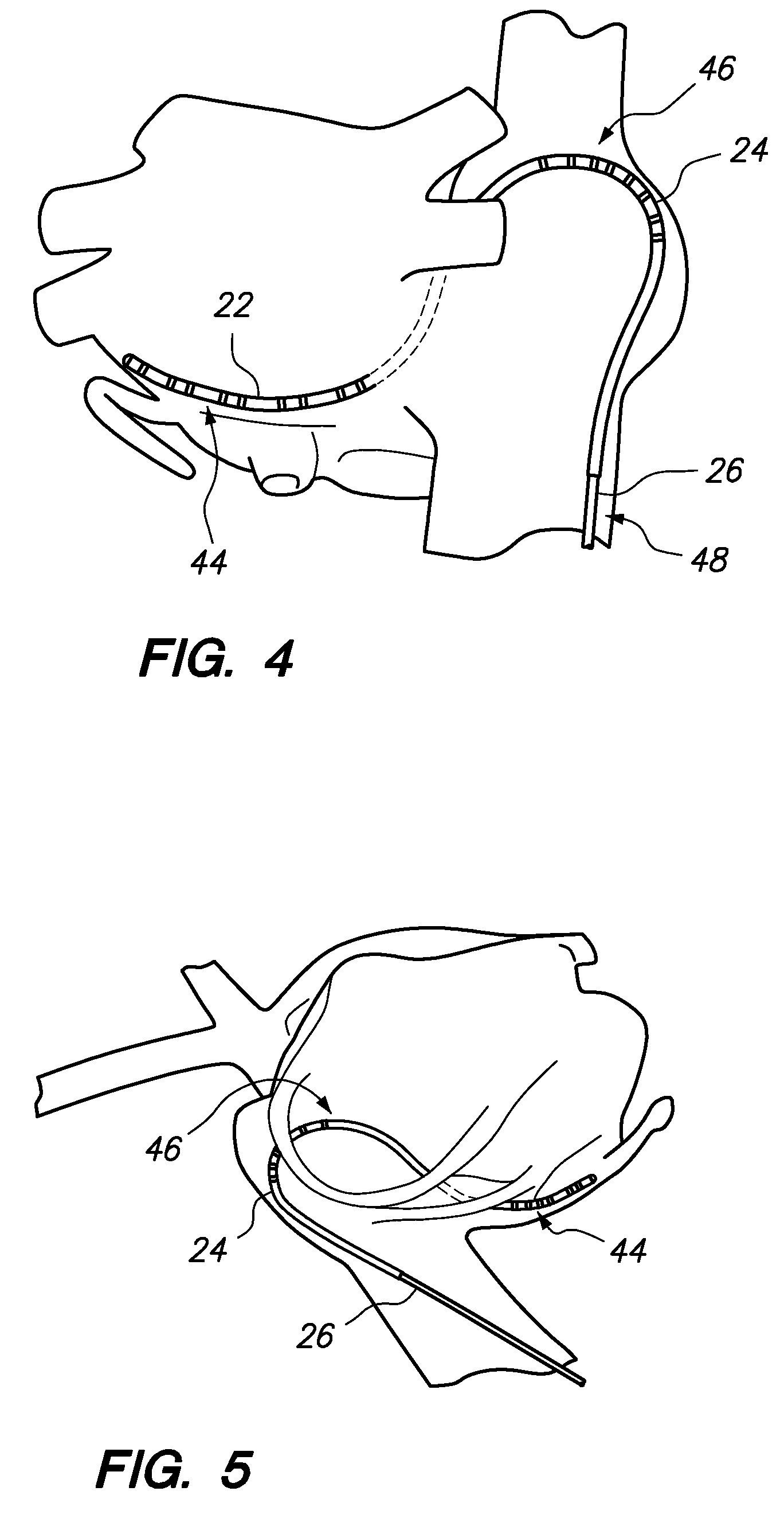

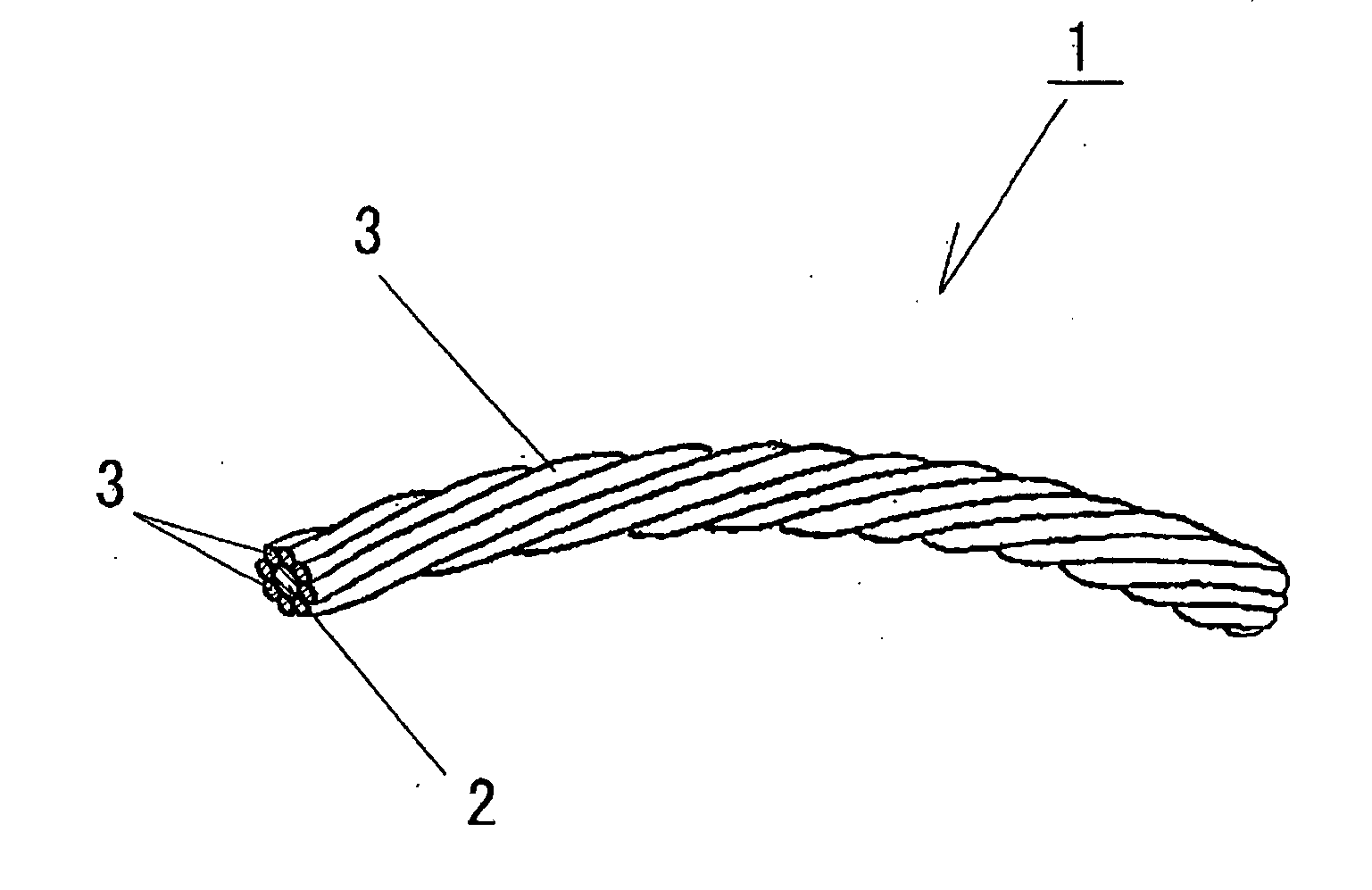

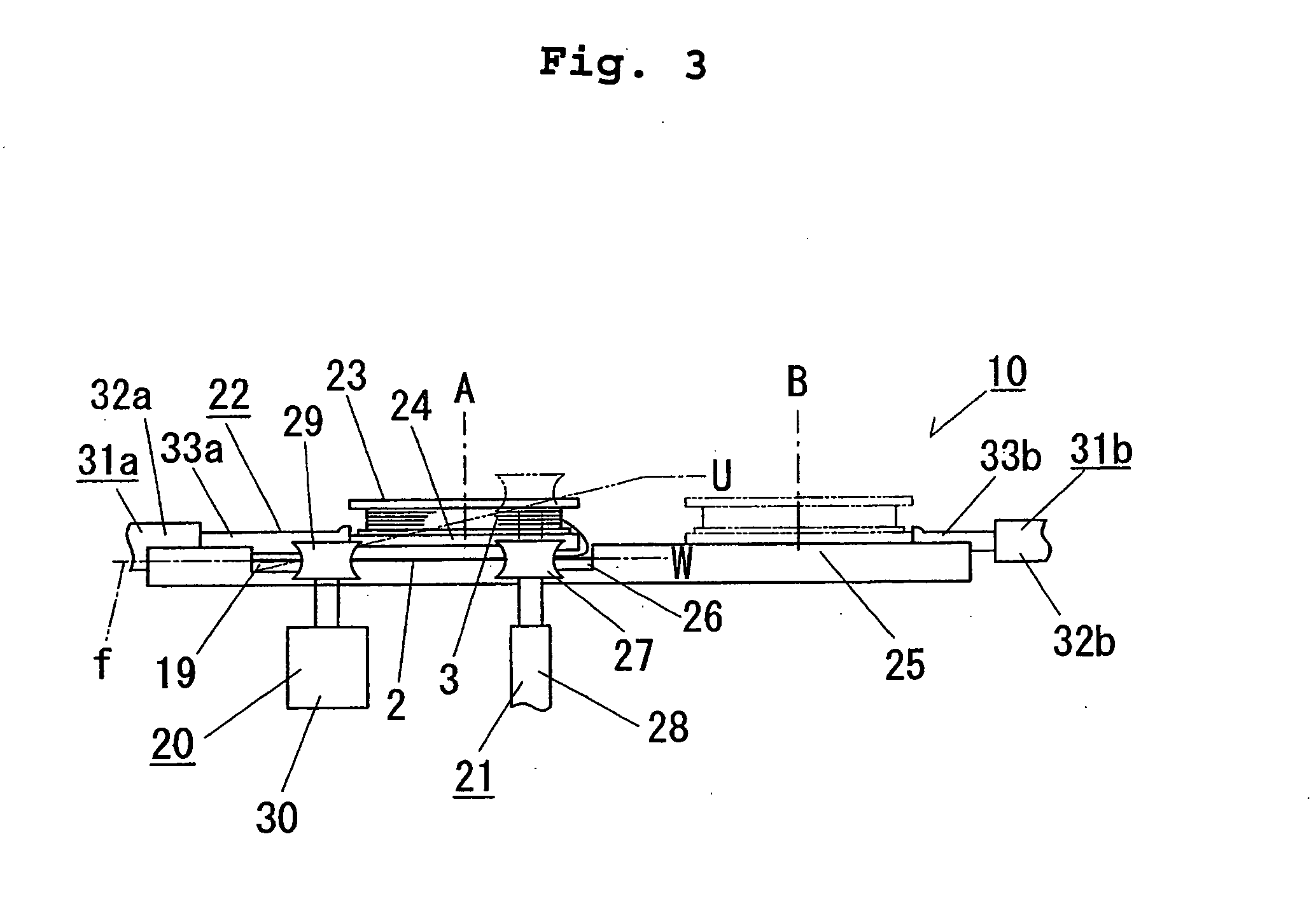

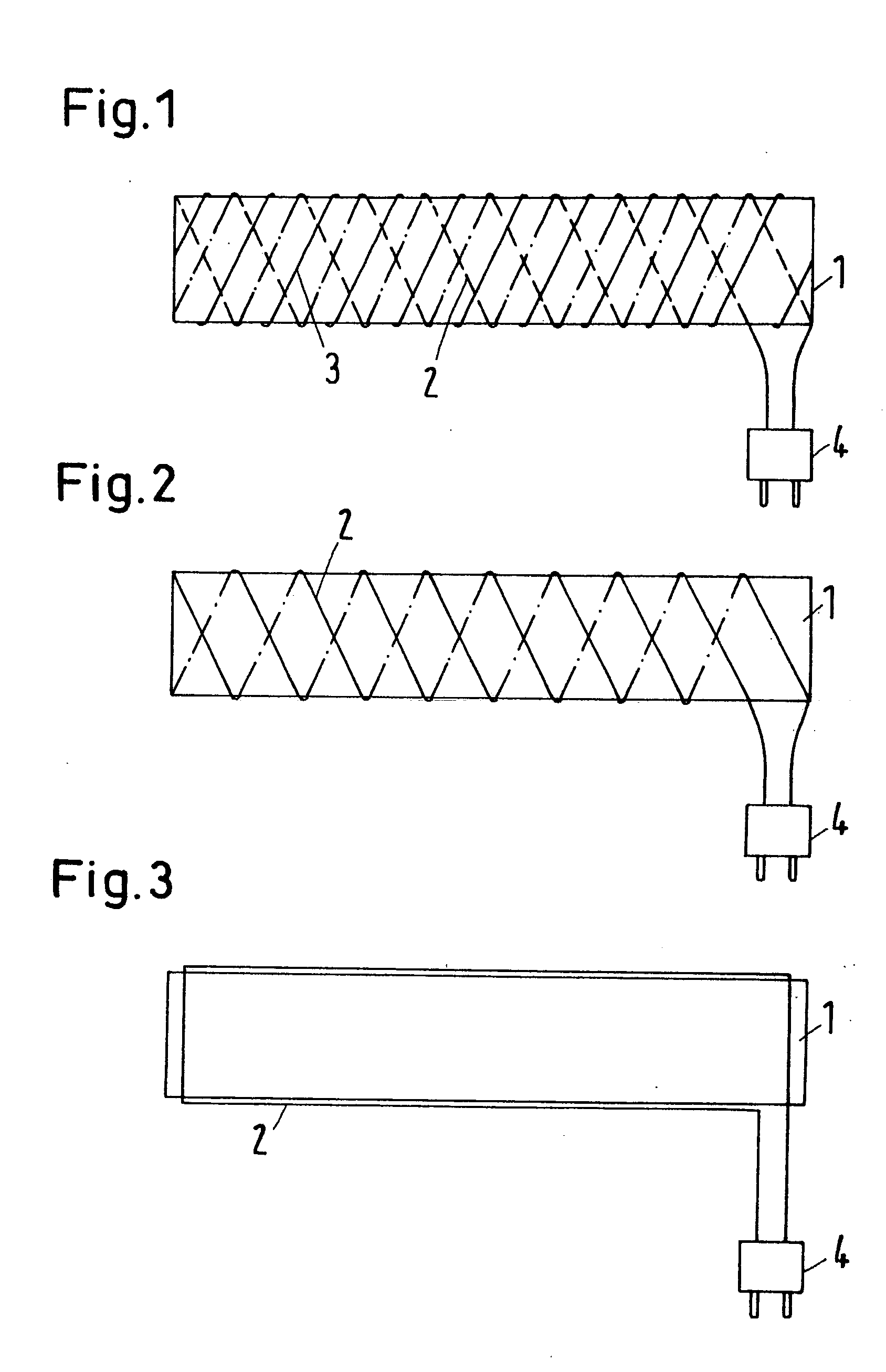

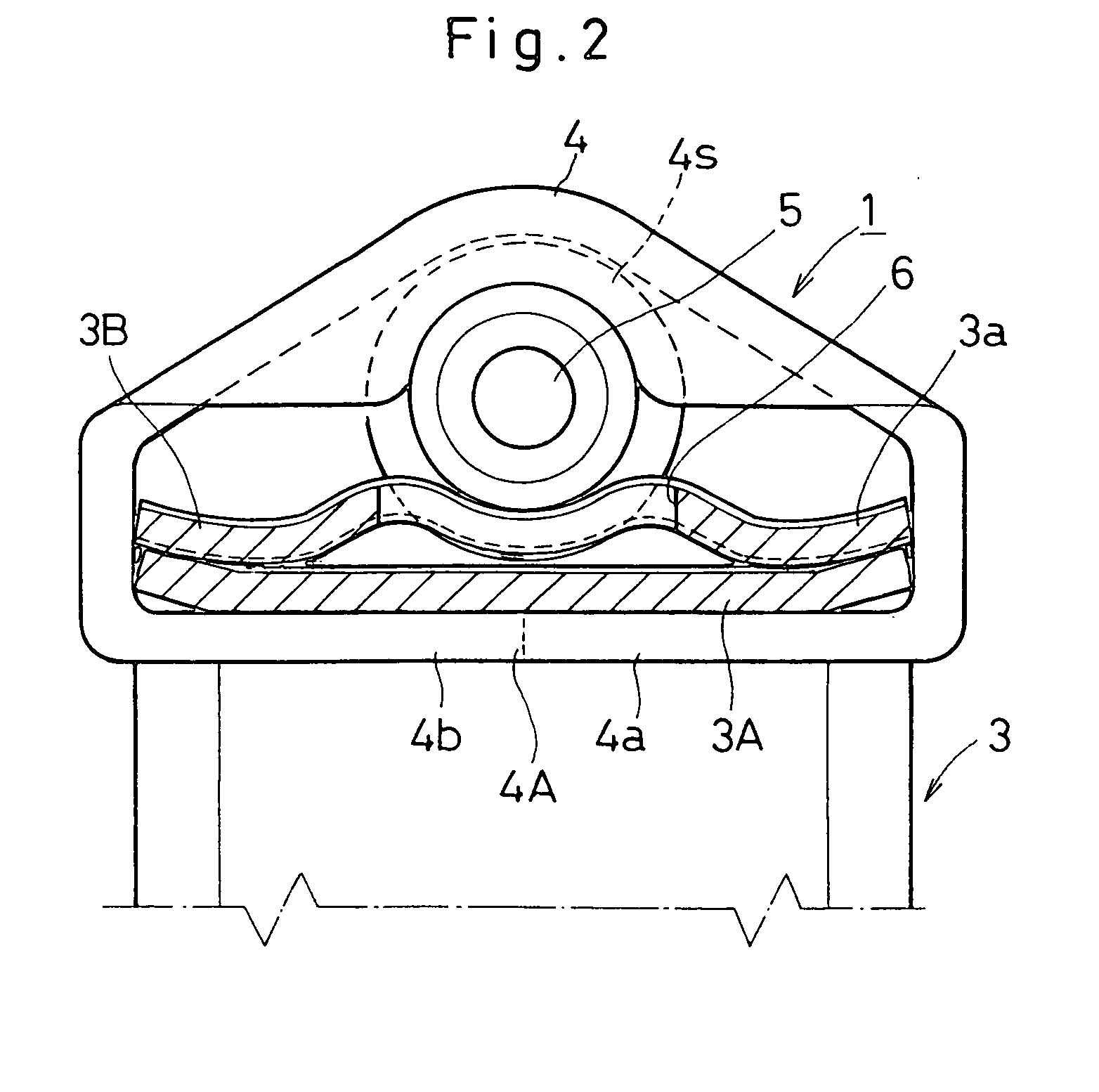

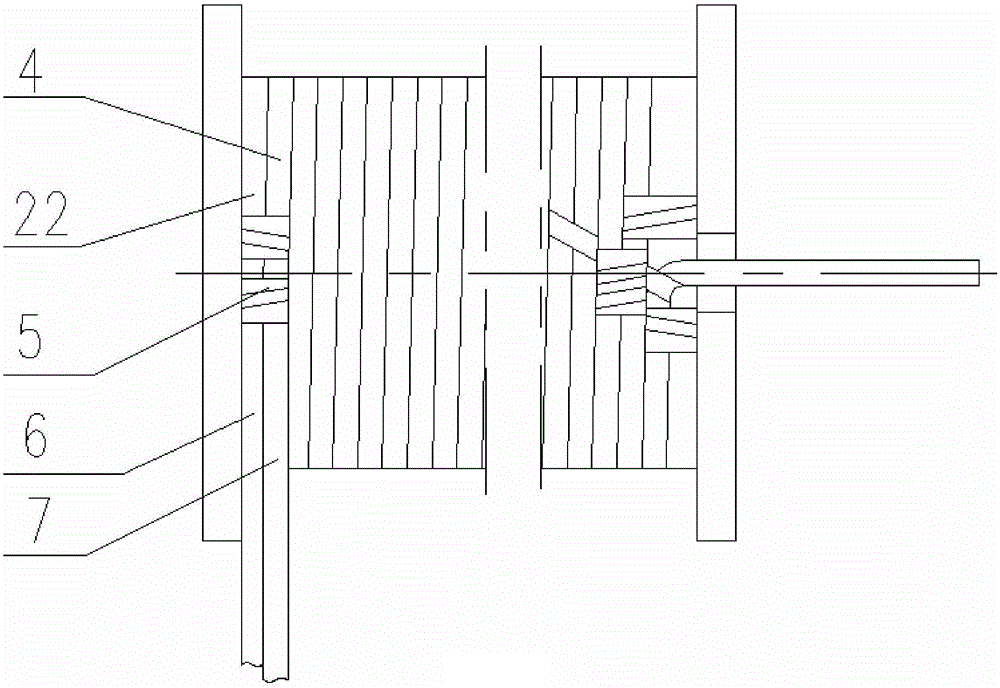

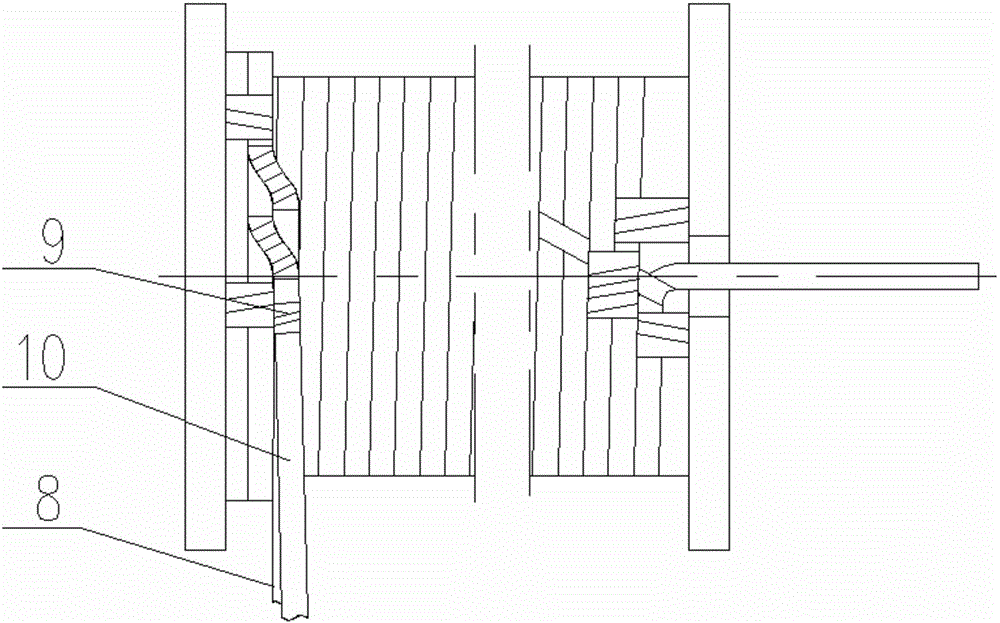

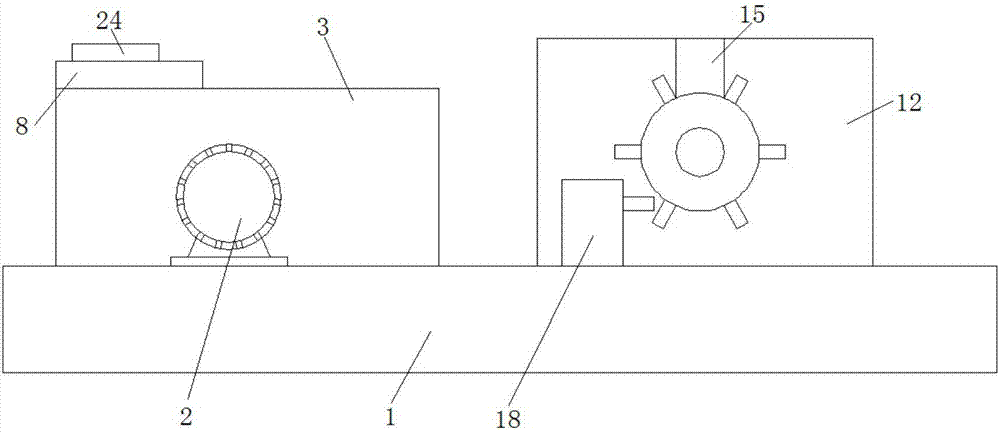

Method and apparatus of manufacturing stranded bead wire

InactiveUS20050145320A1Smoothly continuedImprove rigidityTyresTyre beadsFree rotationReciprocating motion

A method for manufacturing a stranded bead wire includes rotating an annular core wire in the circumferential direction thereof, while repeating a pseudo linear reciprocating motion of a reel around which a steel wire is wound to have an outside diameter smaller than that of the annular core wire, in which motion the reel is displaced approximately in a radial direction of the annular core wire in a way that it is relatively displaced in an approach direction on one side of a plane crossing the annular core wire, then passed through inside thereof, and displaced in a direction of distance increase on the other side of the plane, whereby the steel wire is tightly wound onto the annular core wire in a spiral pattern. A stranded bead wire manufacturing apparatus includes a core wire rotating means for rotating an annular core wire; a free rotational reel around which a steel wire is wound to have an outside diameter smaller than that of the annular core wire; and a reciprocable displacement means for repeating the pseudo linear reciprocating motion of the free rotational reel relative to the annular core wire, wherein, while the annular core wire is rotated, the free rotational reel repeats the pseudo linear reciprocating motion, whereby the steel wire is tightly wound onto the annular core wire in a spiral pattern.

Owner:NIWA SYOUKOU CO +1

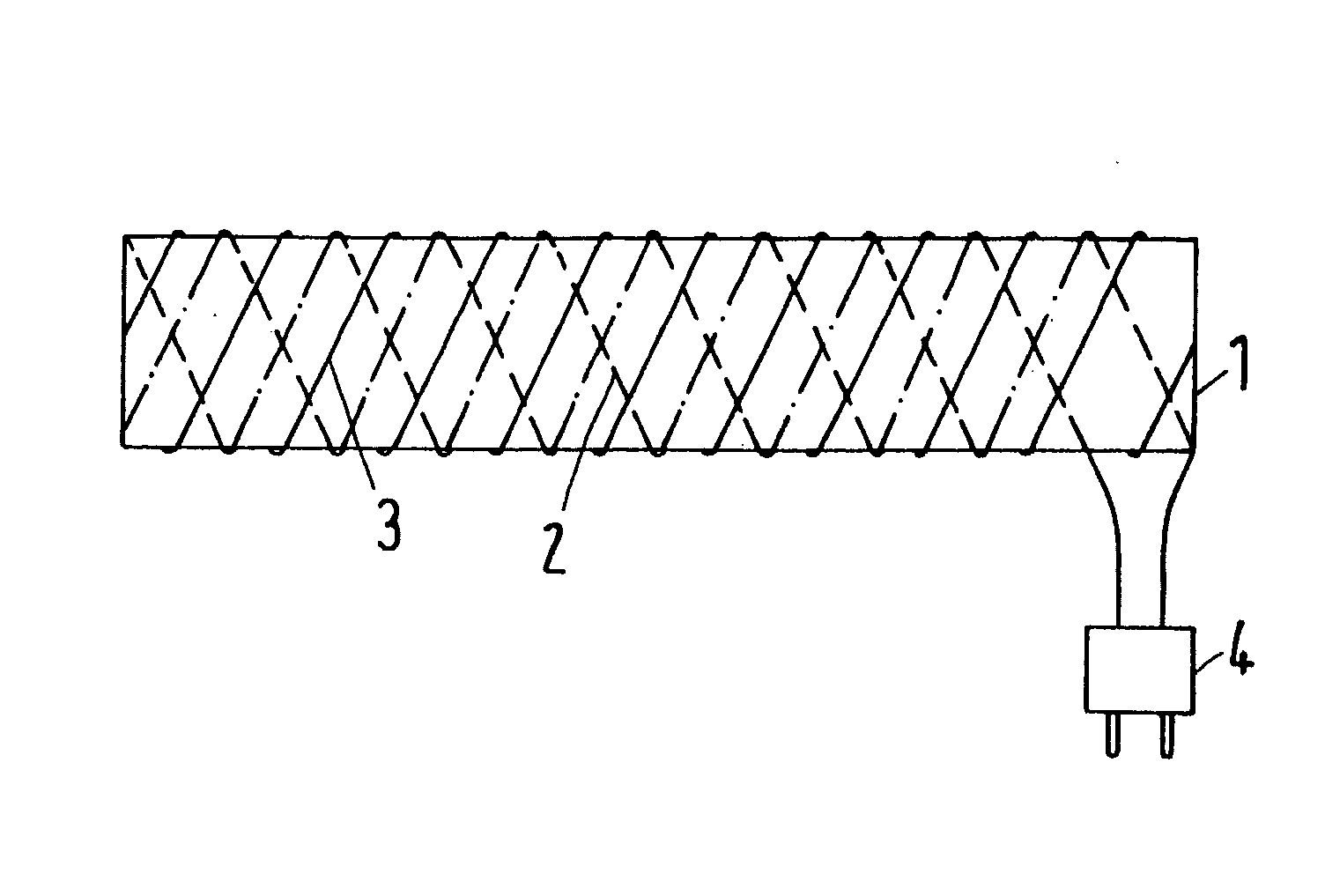

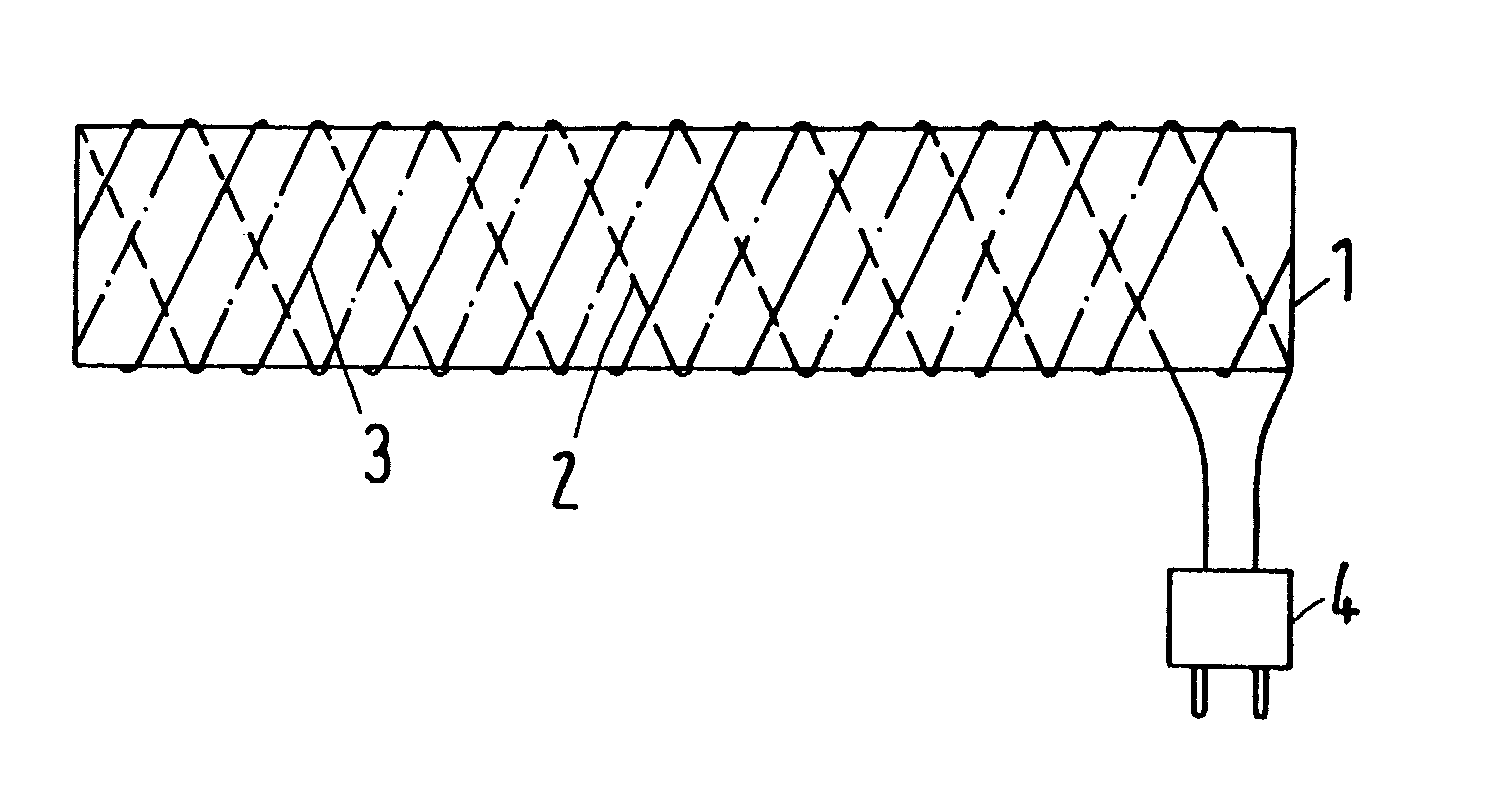

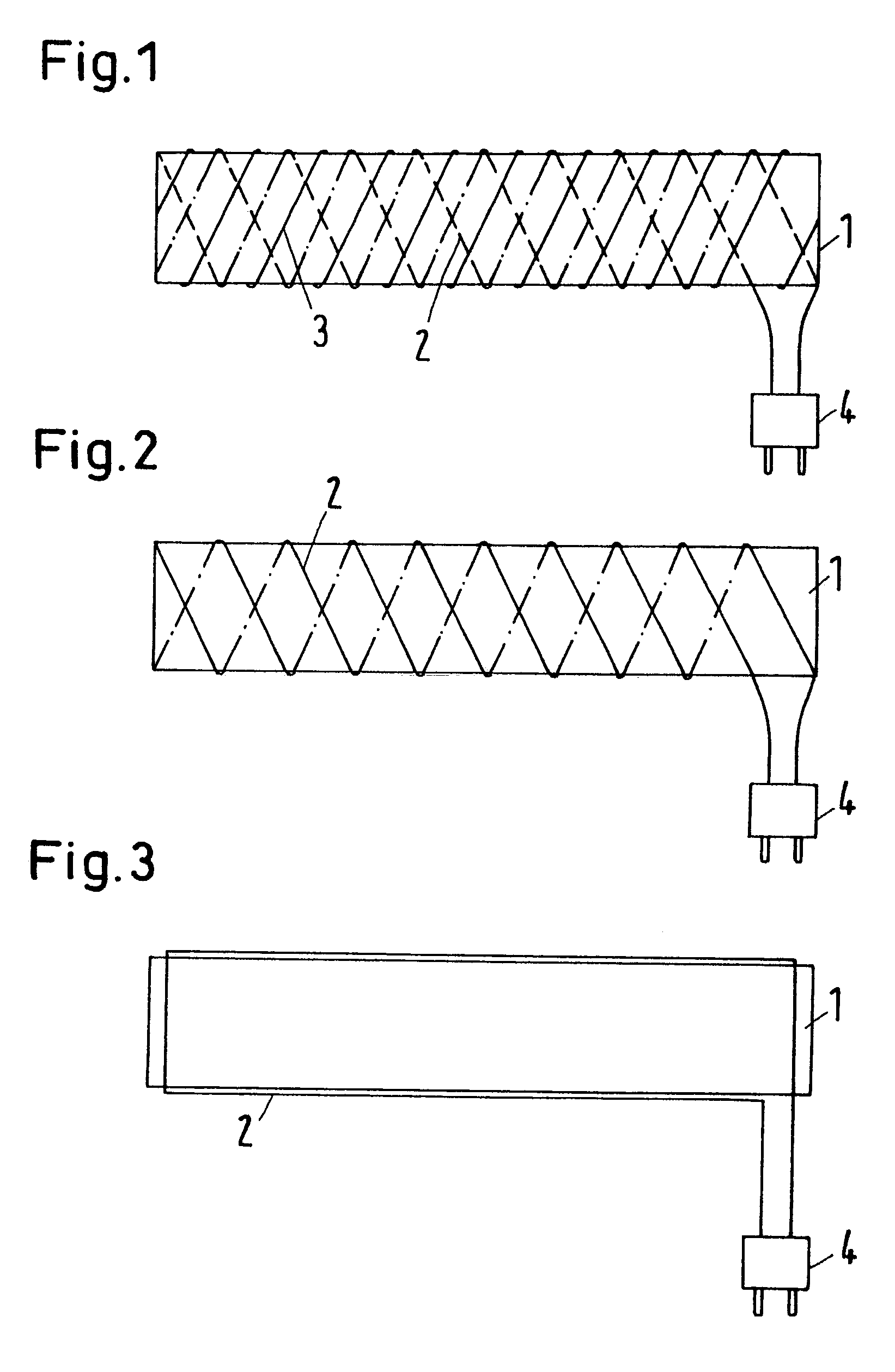

Electrically heatable liquid line

ActiveUS20050063689A1Simple to manufactureEasy to manufactureInternal combustion piston enginesExhaust apparatusLiquid lineElectricity

An electrically heatable liquid line in which a heating wire is arranged on an inner plastic layer and an electrically insulating tape is helically wound around the plastic layer and the heating wire. This object is met in the liquid line of the above-type by providing the insulating tape as an adhesive tape whose adhesive can be glued to the plastic layer.

Owner:NORMA GERMANY GMBH

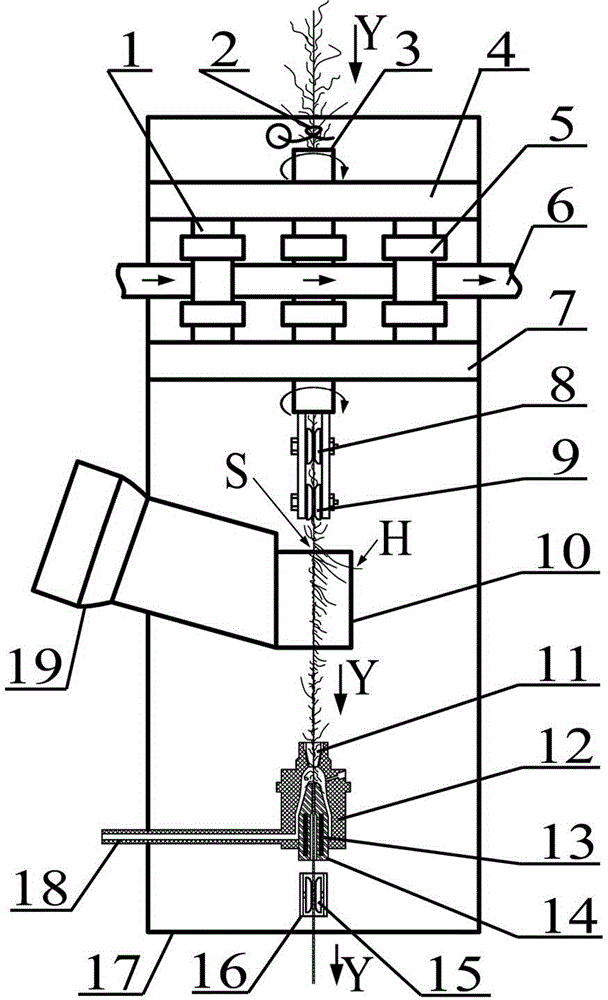

Super-smooth warping method of yarns with many drafted fibers

ActiveCN105274695AAvoid gatheringWrap tightlyWarping machinesOther manufacturing equipments/toolsFiberYarn

The invention relates to a super-smooth warping method of yarns with many drafted fibers and belongs to the textile processing technical field. According to the method of the invention, on each yarn warping mechanism of a warping machine, a false twisting device is adopted to make the trunk of a yarn rotate; a drafted fiber directional stretching device is adopted to directionally eject steam flows so as to directionally stretch the drafted fibers of the yarn, so that some of the drafted fibers of the yarn forwards and orderly wrap the trunk of the yarn, and therefore, the drafted fibers can be prevented from being entangled to from neps when randomly or vertically winding the trunk of the yarn; a drafted fiber vortex wrapping device is adopted to reversely wrap the other drafted fibers of the yarn on the trunk of the yarn, so that the other drafted fibers of the yarn and the forwards and orderly wrapped drafted fibers can be closely tangled in a cross manner; and therefore, progressive complete wrapping and cross tight wrapping of the drafted fibers of the yarns can be realized, and winding tightness and firmness of the drafted fibers can be greatly increased, and the problem of series rebound of the drafted fibers of the yarns in a warping procedure and subsequent procedures of warping can be solved, and super-smooth warping of the yarns with many drafted fibers can be realized. The device of the invention has the advantages of reasonable structure and convenient operation.

Owner:WUHAN TEXTILE UNIV

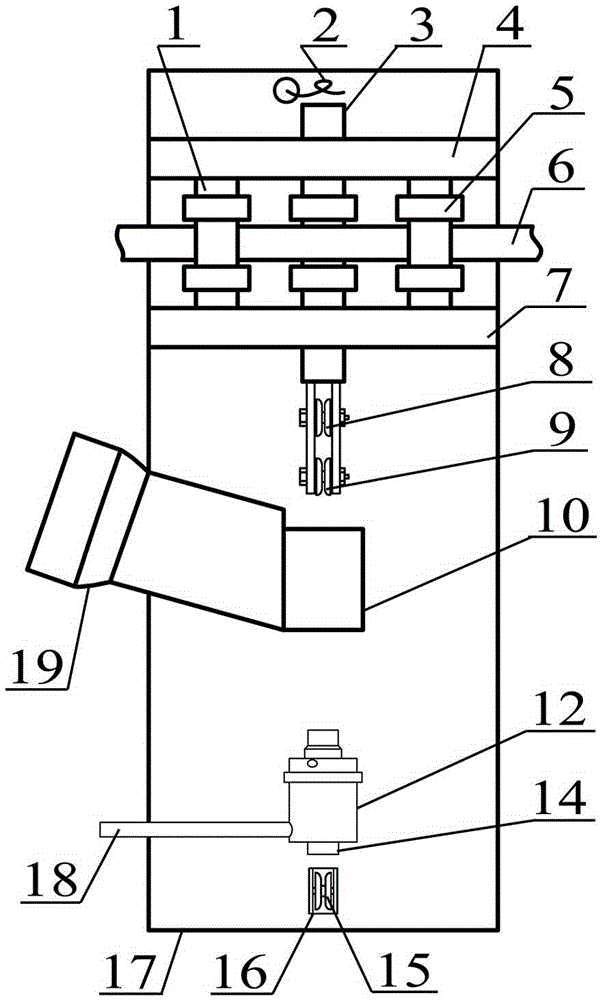

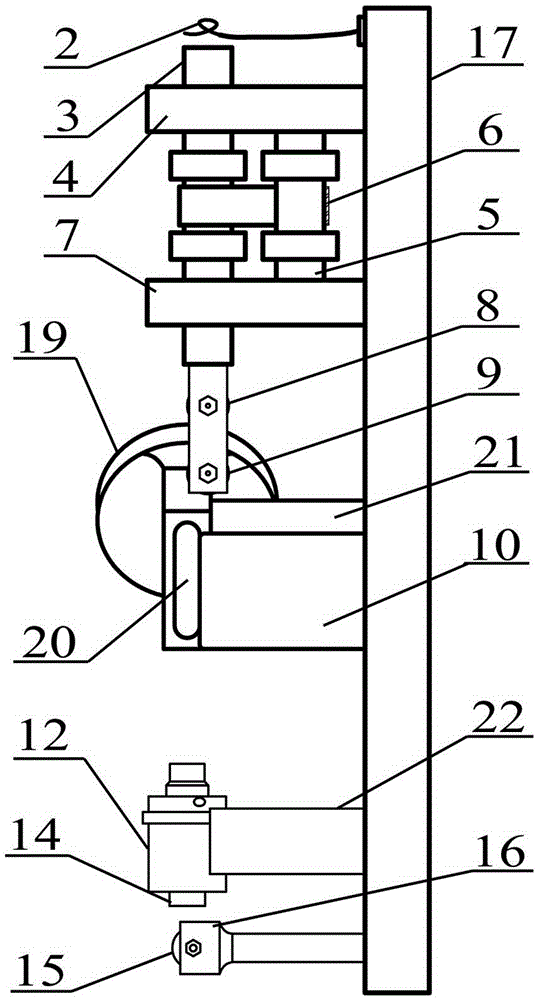

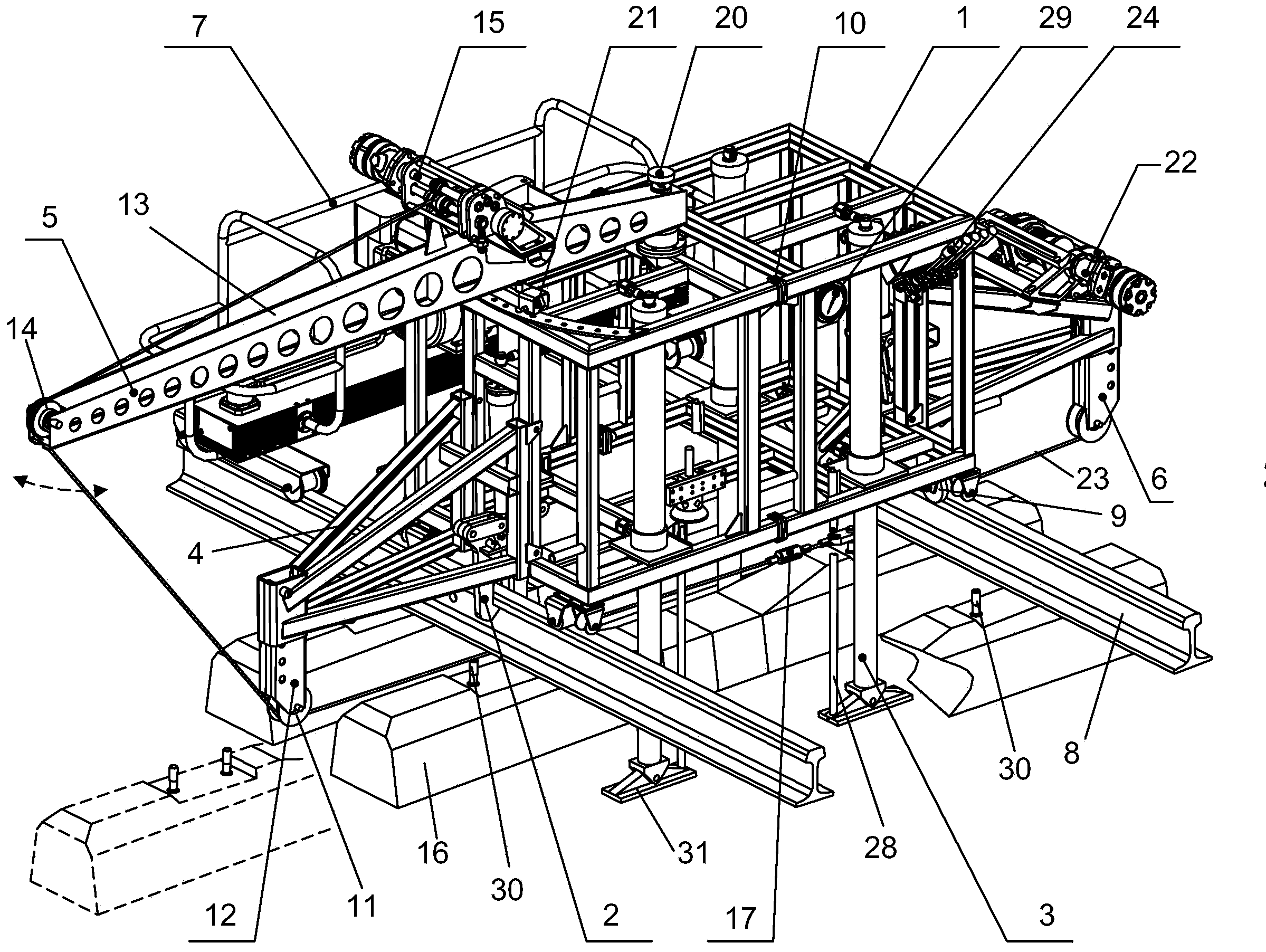

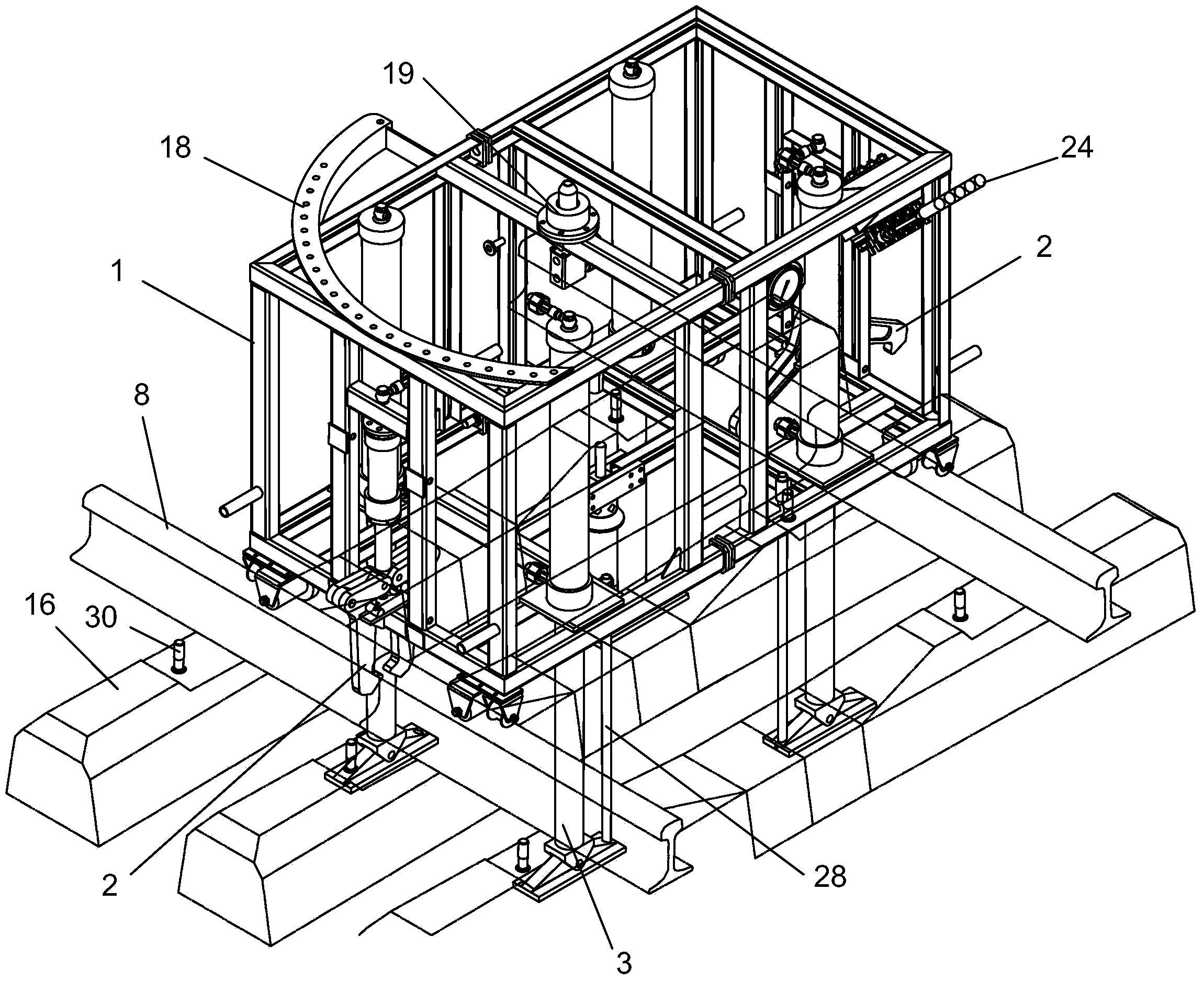

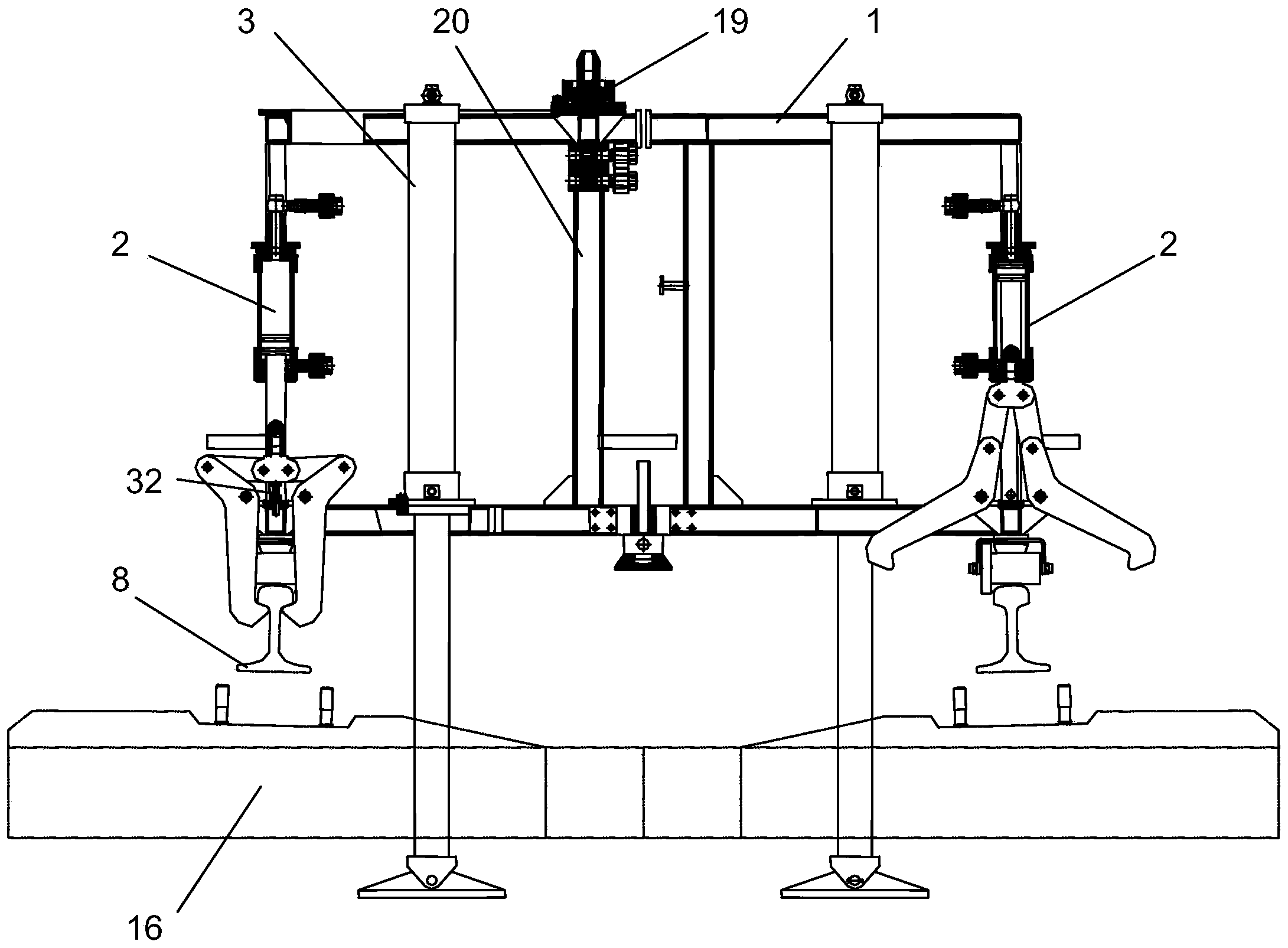

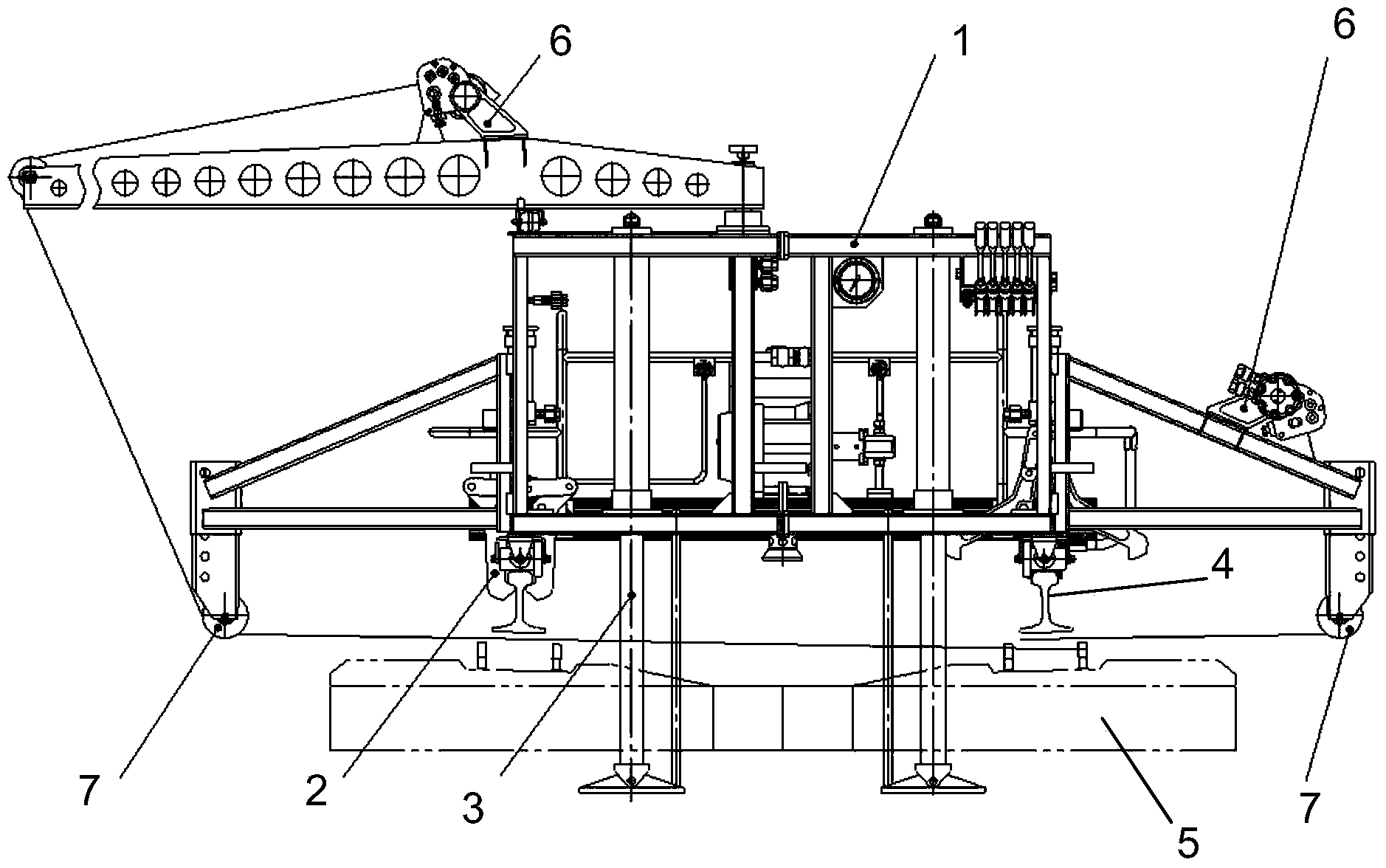

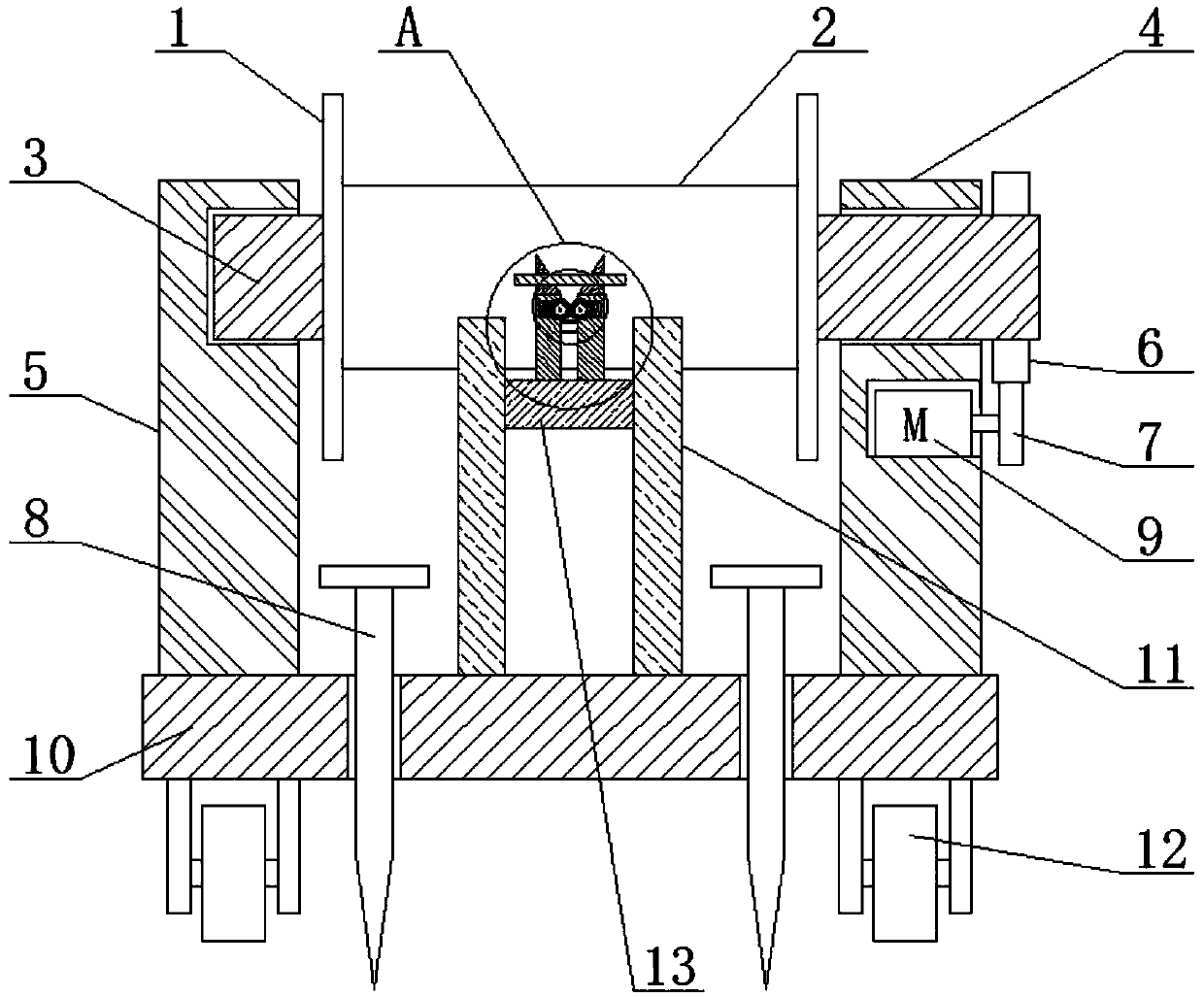

Hydraulic sleeper replacement machine and hydraulic sleeper replacement method

ActiveCN103669133AReduce labor intensityImprove work efficiencyRailway track constructionControl engineeringHydraulic pump

The invention discloses a hydraulic sleeper replacement machine. The hydraulic sleeper replacement machine comprises a main machine frame, track lifting claws, track lifting oil cylinders, an unpowered pulley support, a hydraulic lifting device, a powered pulley support, a hydraulic pump station and the like. The invention further discloses a hydraulic sleeper replacement method. According to the hydraulic sleeper replacement method, a sleeper can be pulled out and replaced through hydraulic control of the hydraulic lifting device and steel wire rope hoisting. The hydraulic sleeper replacement method is suitable for replacement of sleepers of ballasted railways and can relive labor intensity and improve working efficiency.

Owner:上海瑞纽机械股份有限公司

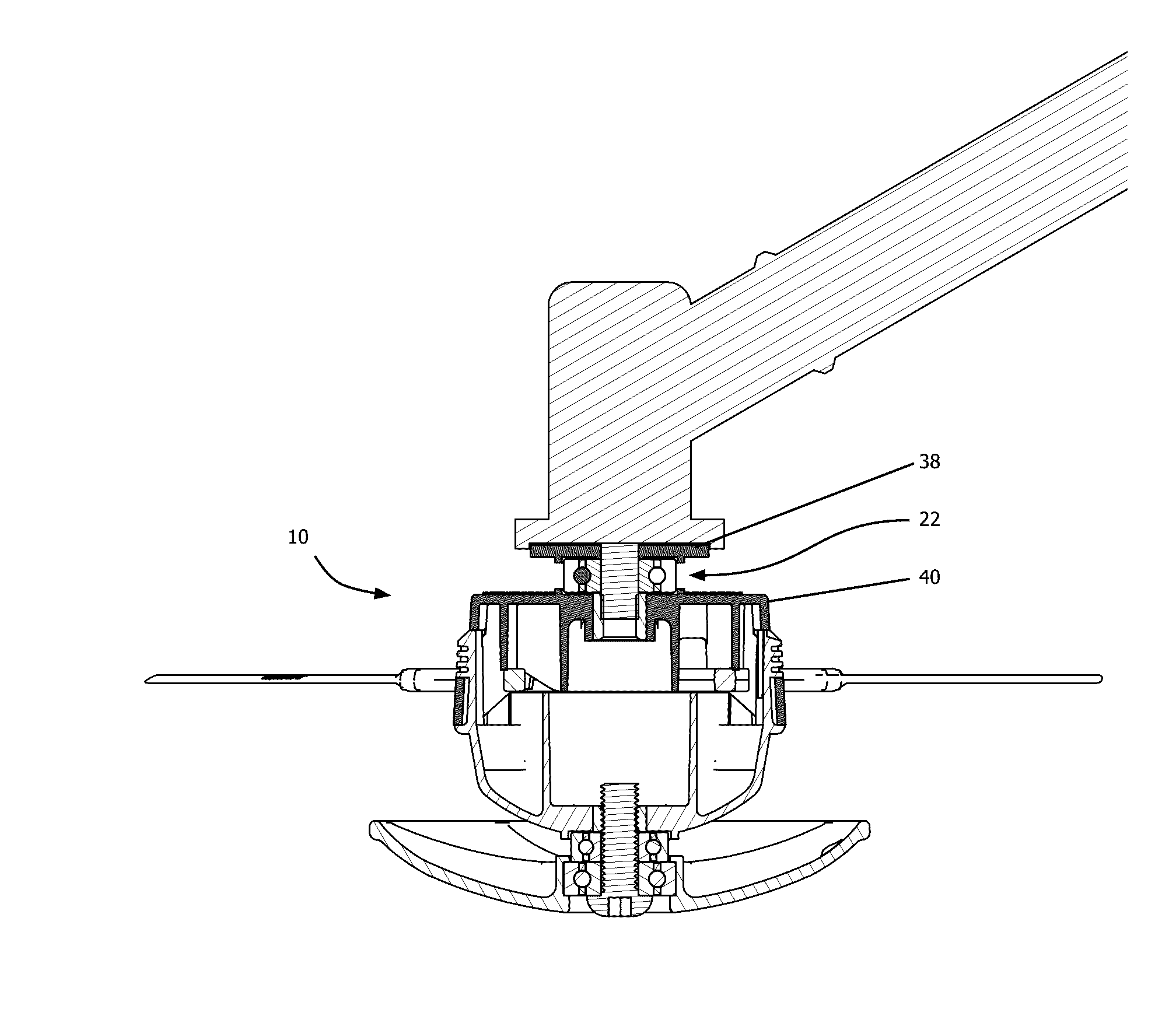

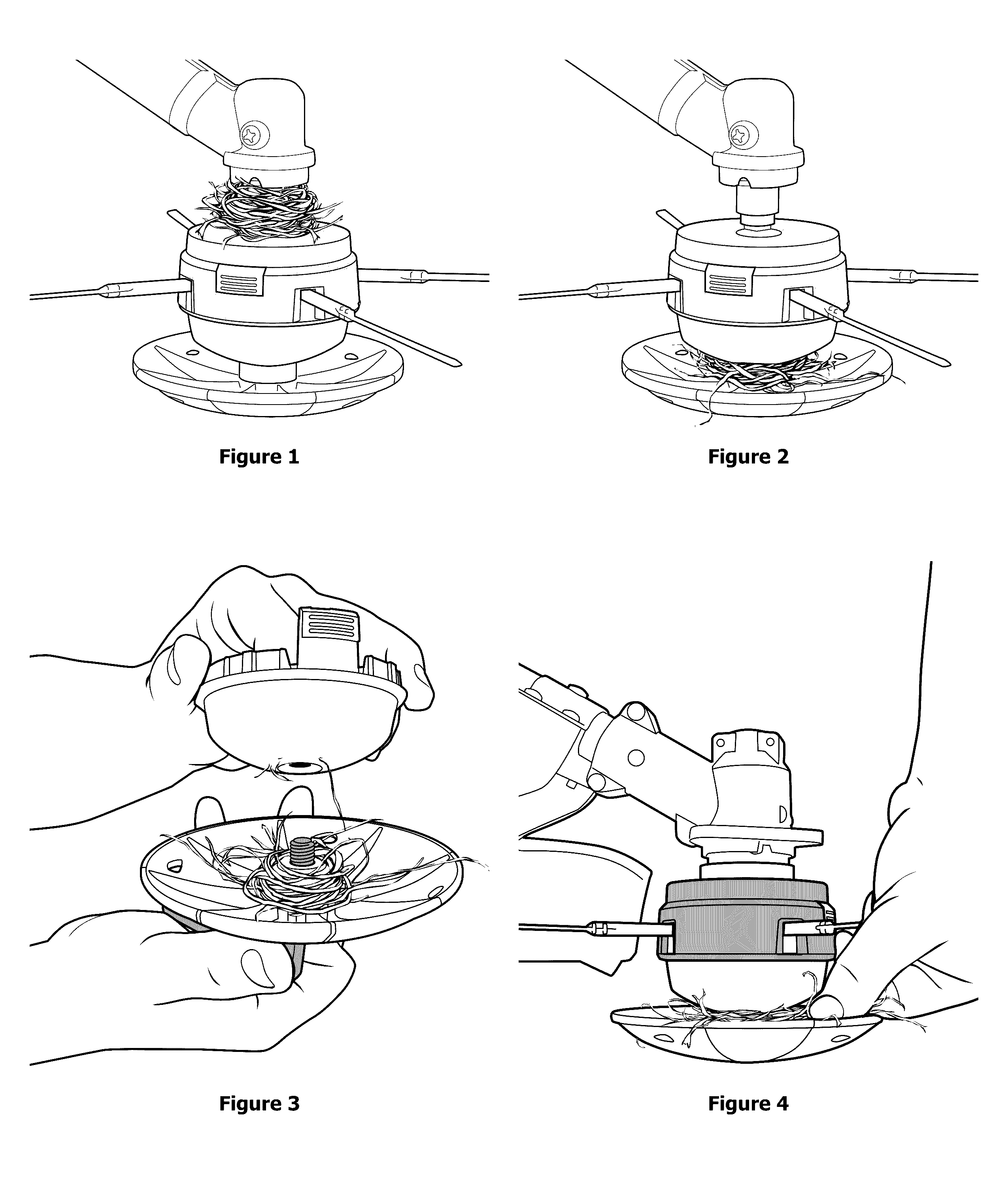

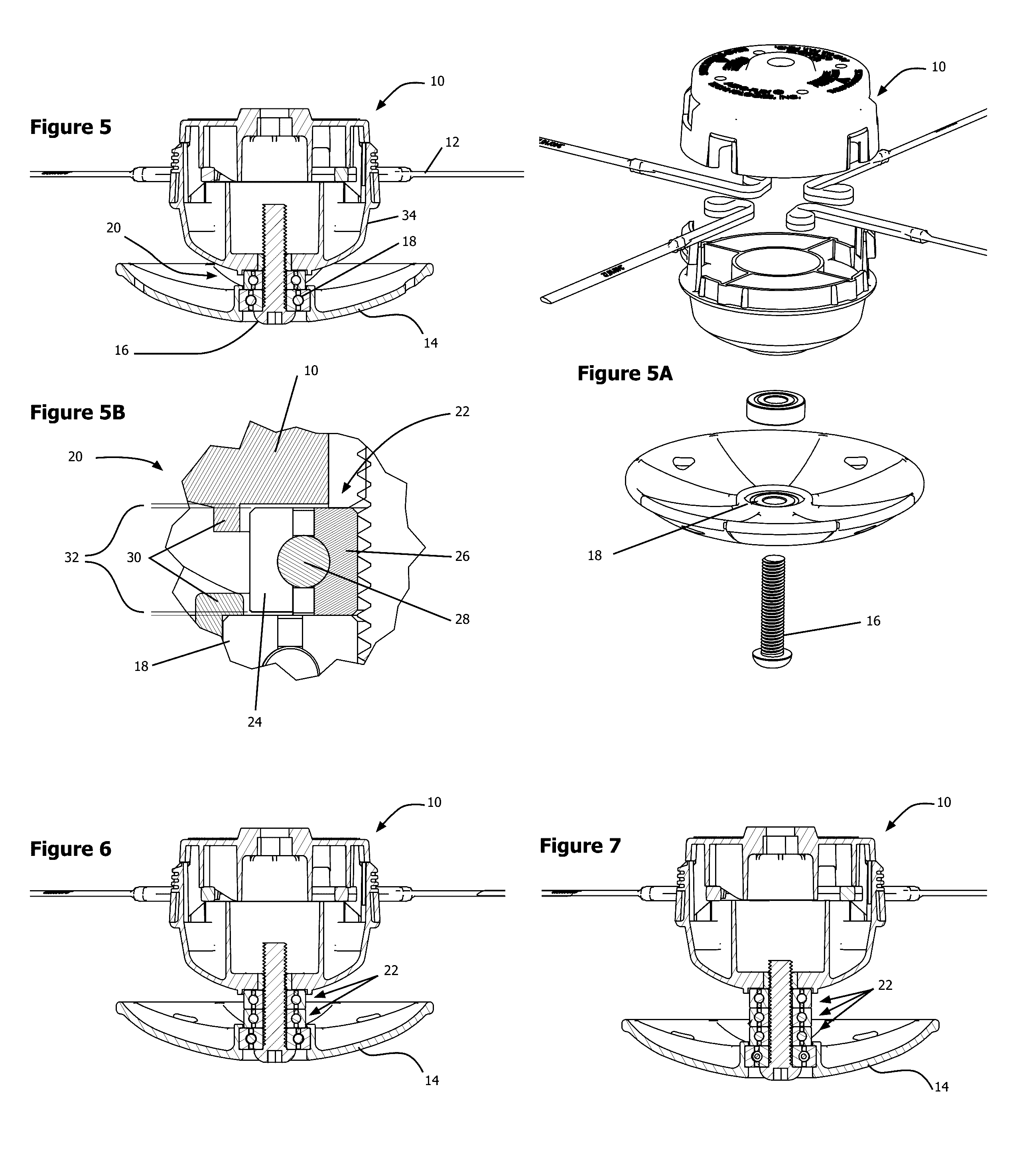

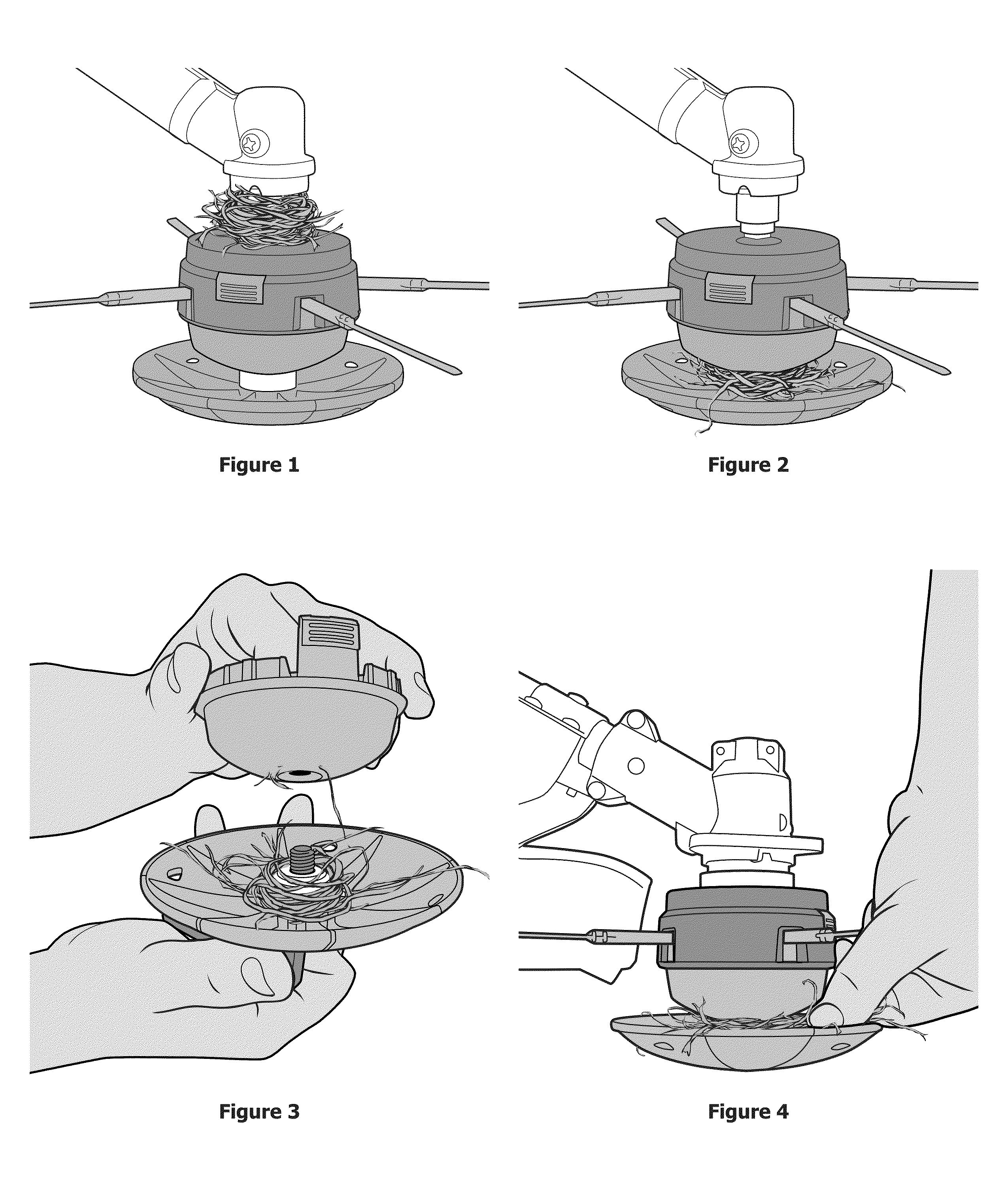

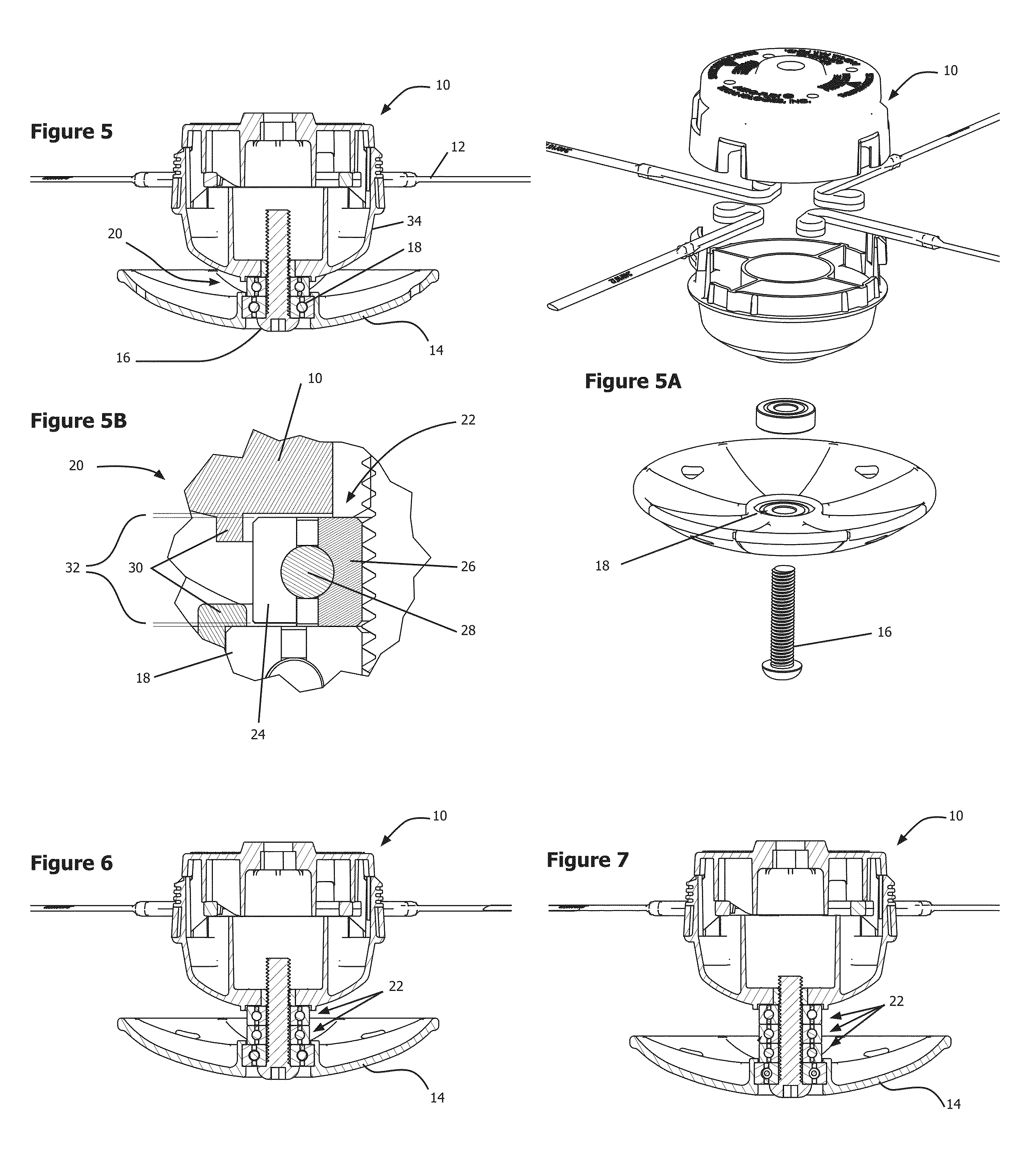

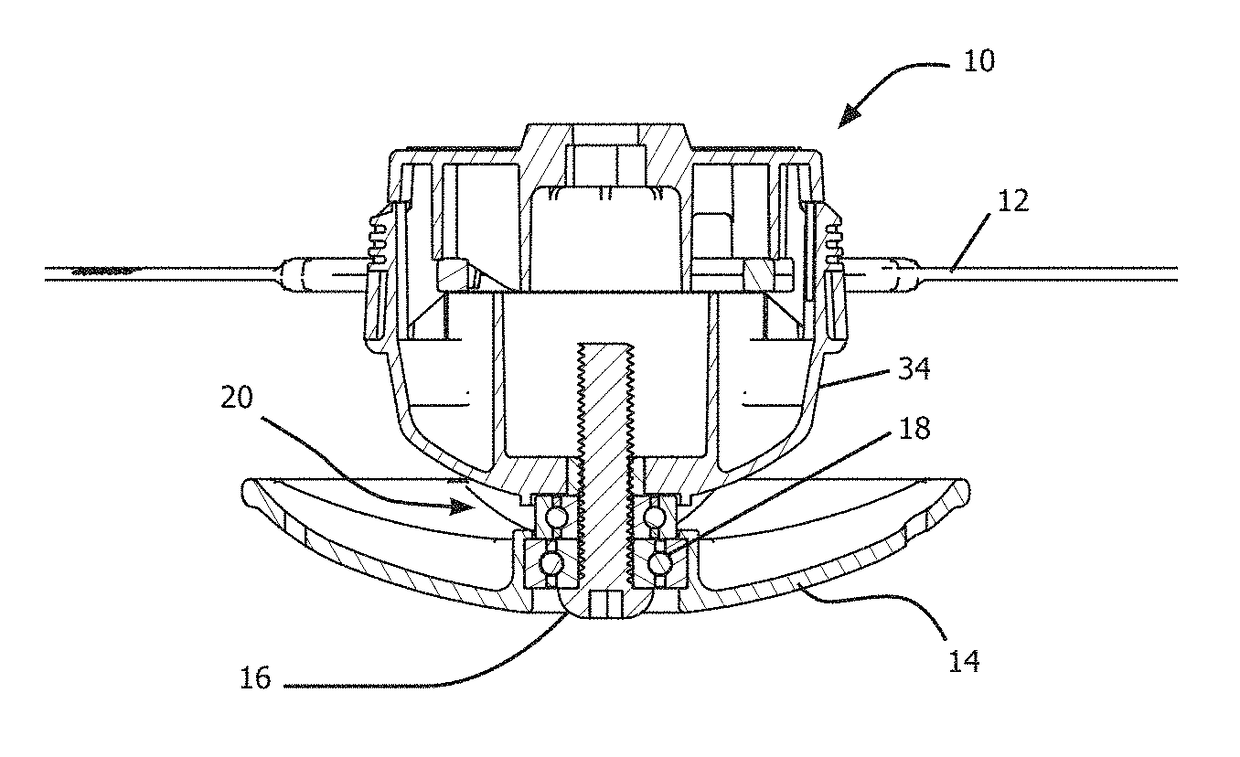

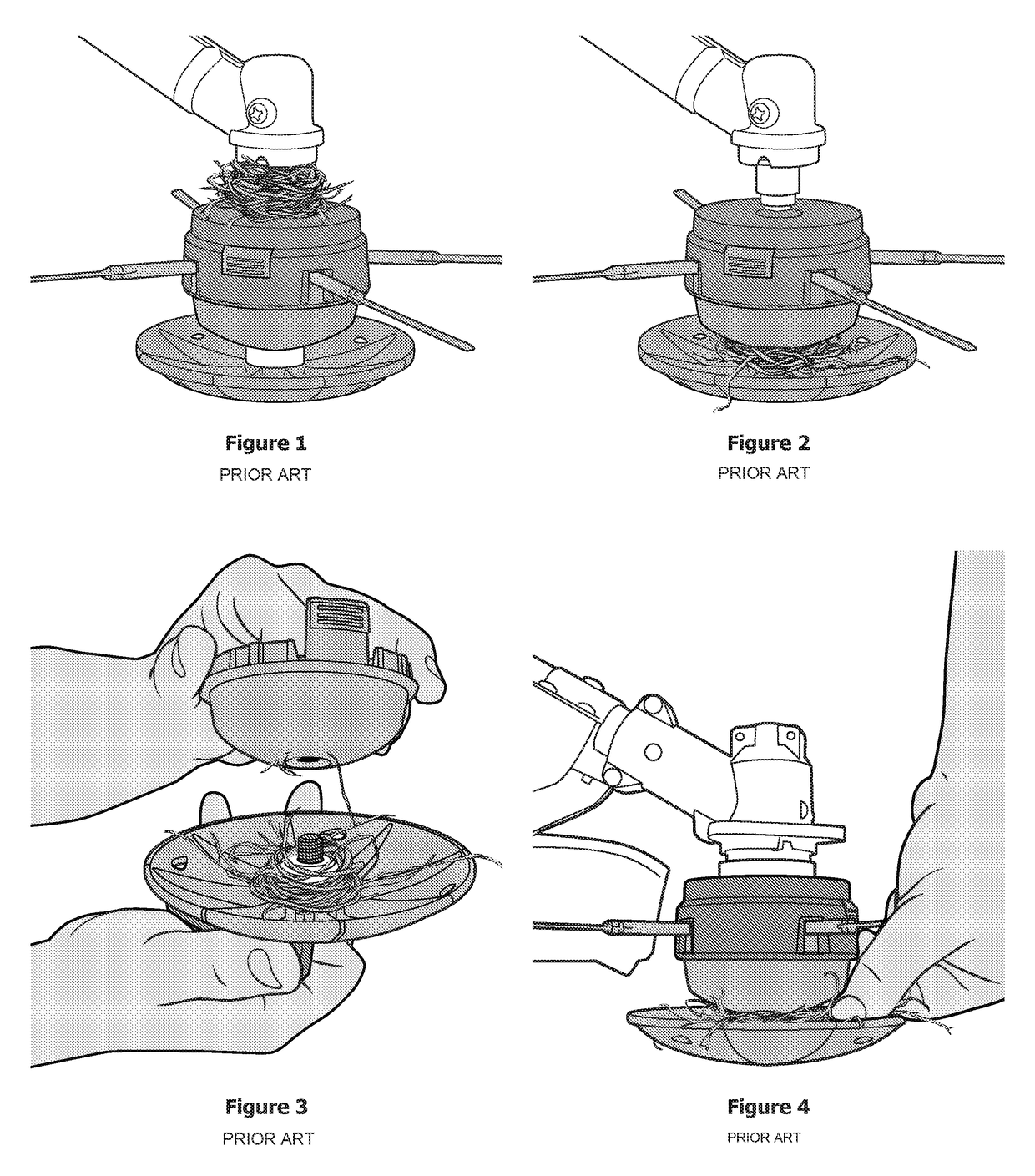

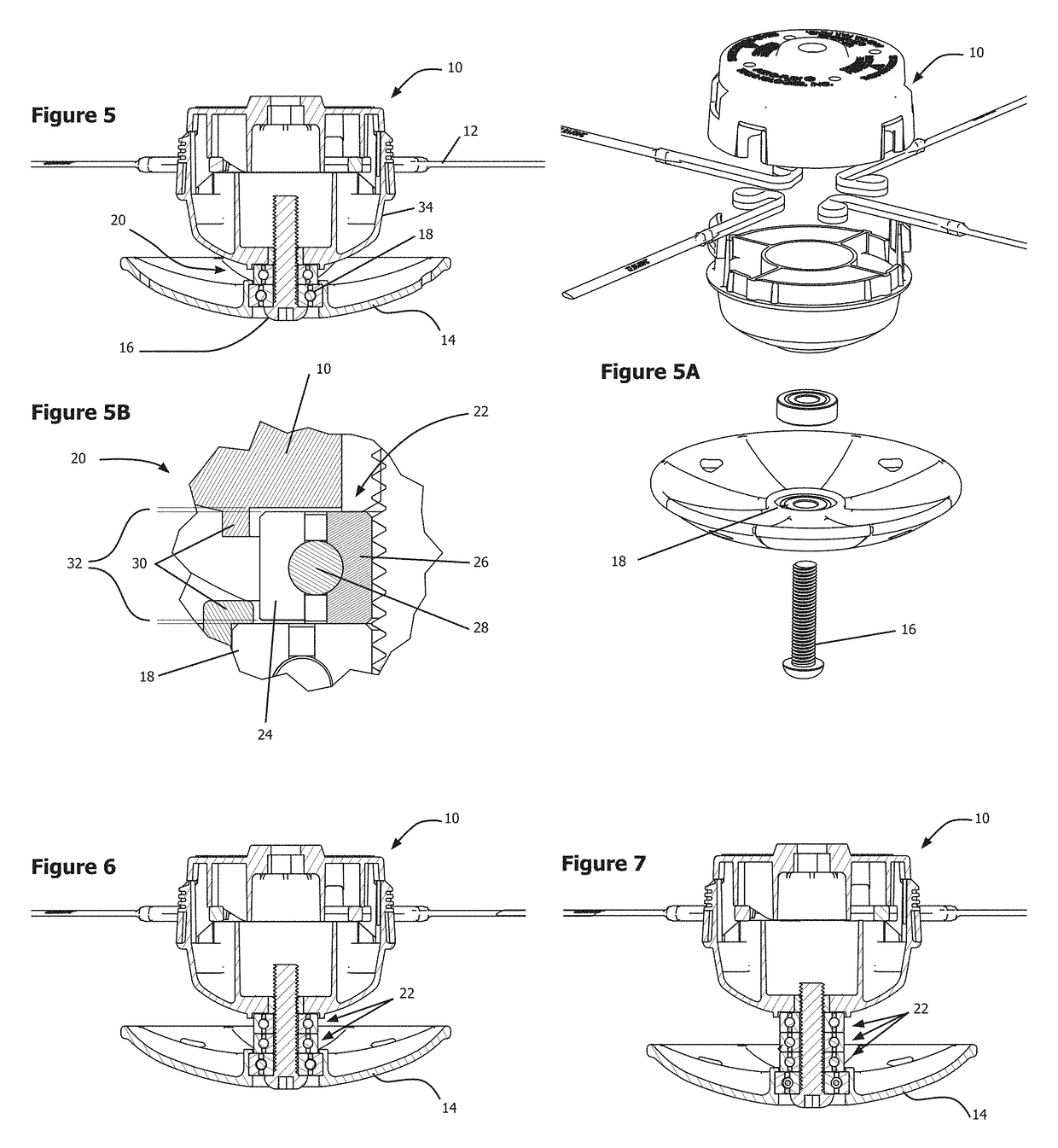

Anti-wind/Anti-wrapping assembly for trimmers

An anti-winding assembly reduces or prevents debris from winding on a trimmer and / or makes them easier to remove. The trimmer includes a trimmer head mounted to a rotatable arbor and supporting one or more cutting lines. The anti-winding assembly includes a collar positionable between the trimmer head and an adjacent trimmer component, and a shield positioned radially outward of the collar. The shield covers gaps between the collar and the trimmer head and between the collar and the adjacent trimmer component. The assembly reduces exposure to pinching gaps and to powered rotating parts that enable tight windings that can accumulate to lock trimmer rotation.

Owner:AERO FLEX TECH

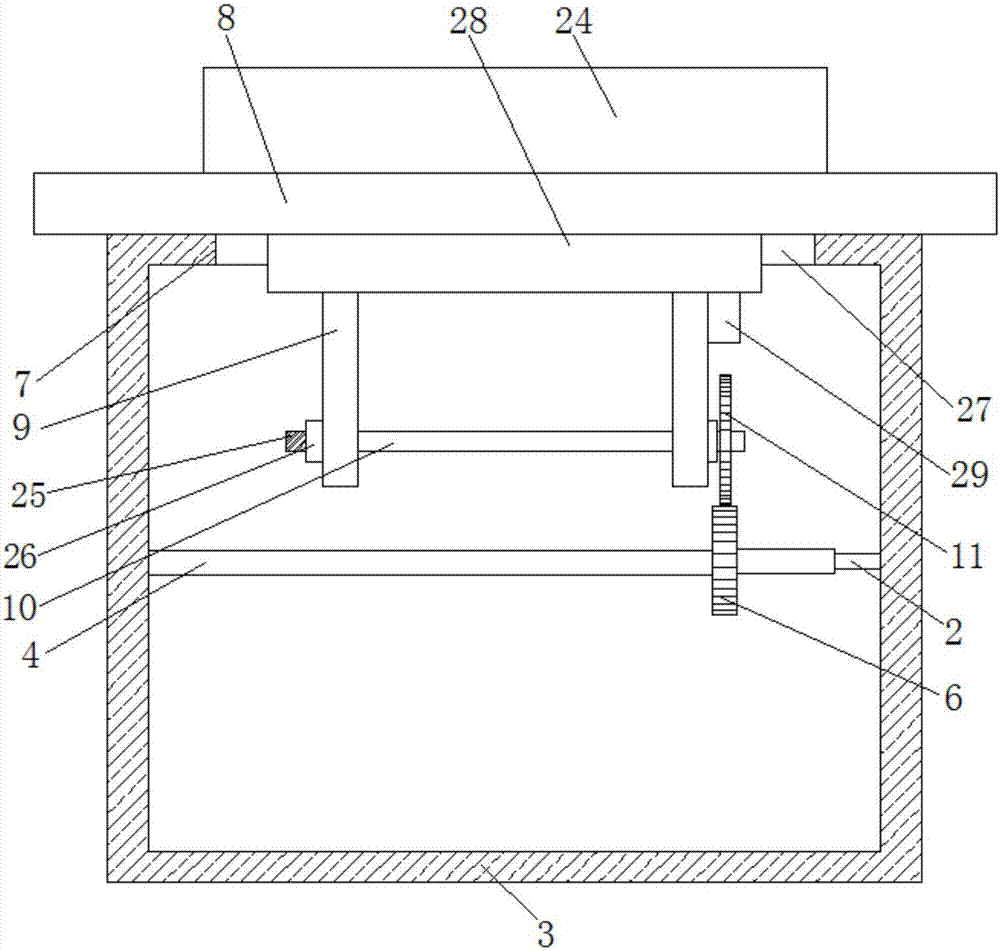

Crane winding device with steel wire rope straining mechanism

The invention discloses a crane winding device with a steel wire rope straining mechanism. The crane winding device with the steel wire rope straining mechanism comprises a winding drum part, a motor and a speed reduction system, a one-way bearing is installed in a winding drum, the inner ring of the one-way bearing is matched with a transmission shaft, and the outer ring of the one-way bearing is matched with the winding drum; the steel wire rope straining mechanism is installed on one side of the winding drum and comprises a ratchet wheel, a pawl, a support and a limiting block, the ratchet wheel is connected to an end cap of the winding drum, ratchet wheel slots are formed in the periphery of the ratchet wheel at intervals, the pawl is installed on the support, embedded into the ratchet wheel slots under the action of a compressed spring and meshed with the ratchet wheel slots, the support is provided with an arc-shaped section which is provided with a groove, a brake cable is placed in the groove, one end of the brake cable is fixedly connected with the support, and the other end of the brake cable is connected with a manipulation handle; when the handle is pressed down, the support is made to rotate in the tension direction, the winding drum rotates along with the support to strain the steel wire rope; a torsional spring is installed between the support and a bearing seat, when the handle is loosened, the support returns to the original position under the action of the torsional spring, and the limiting block is installed on the bearing seat to make the pawl break away from the ratchet wheel slots. According to the crane winding device with the steel wire rope straining mechanism, the structure is compact, the design is reasonable, and straining of the steel wire rope is safe and reliable.

Owner:SHANDONG JIANZHU UNIV

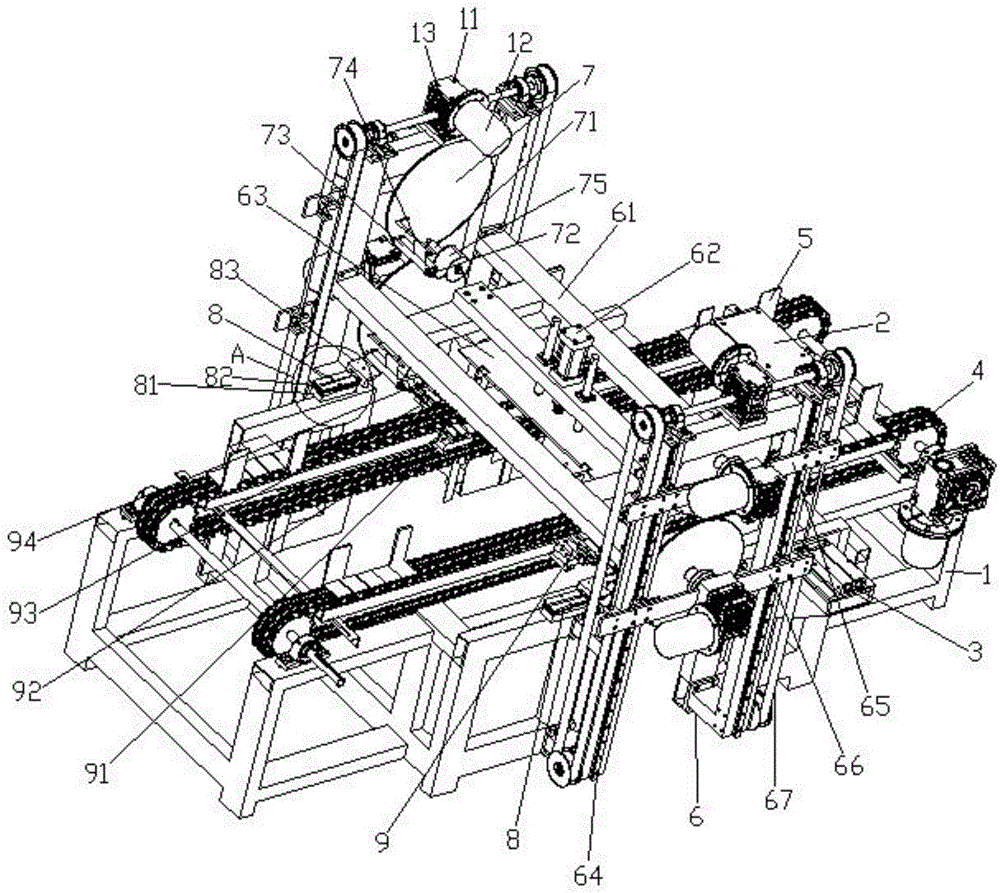

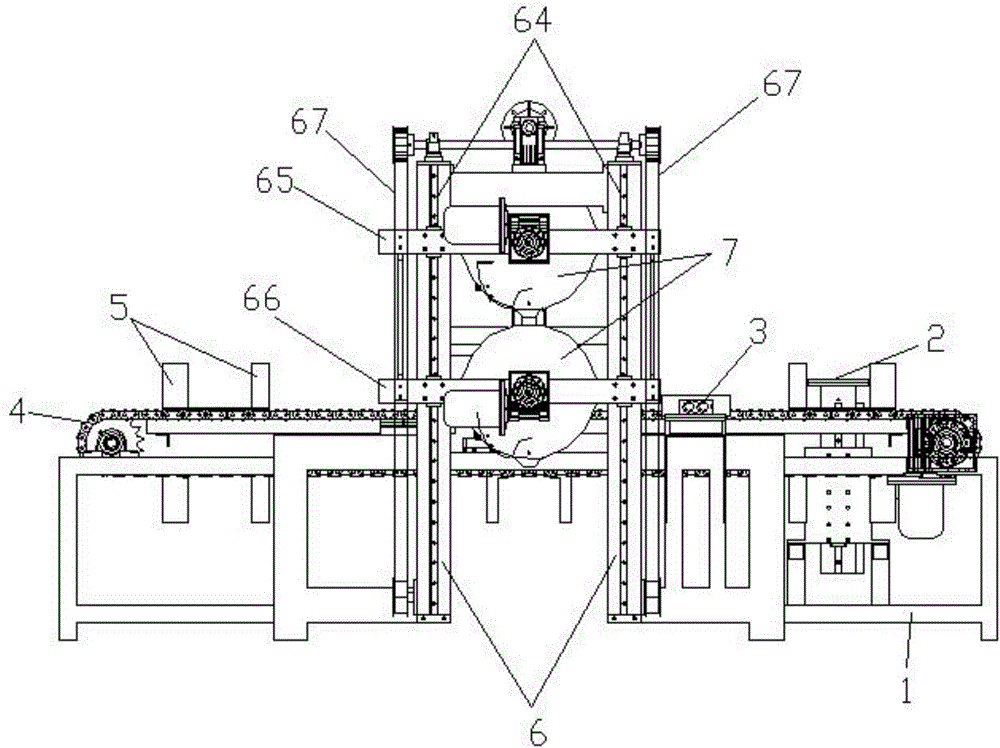

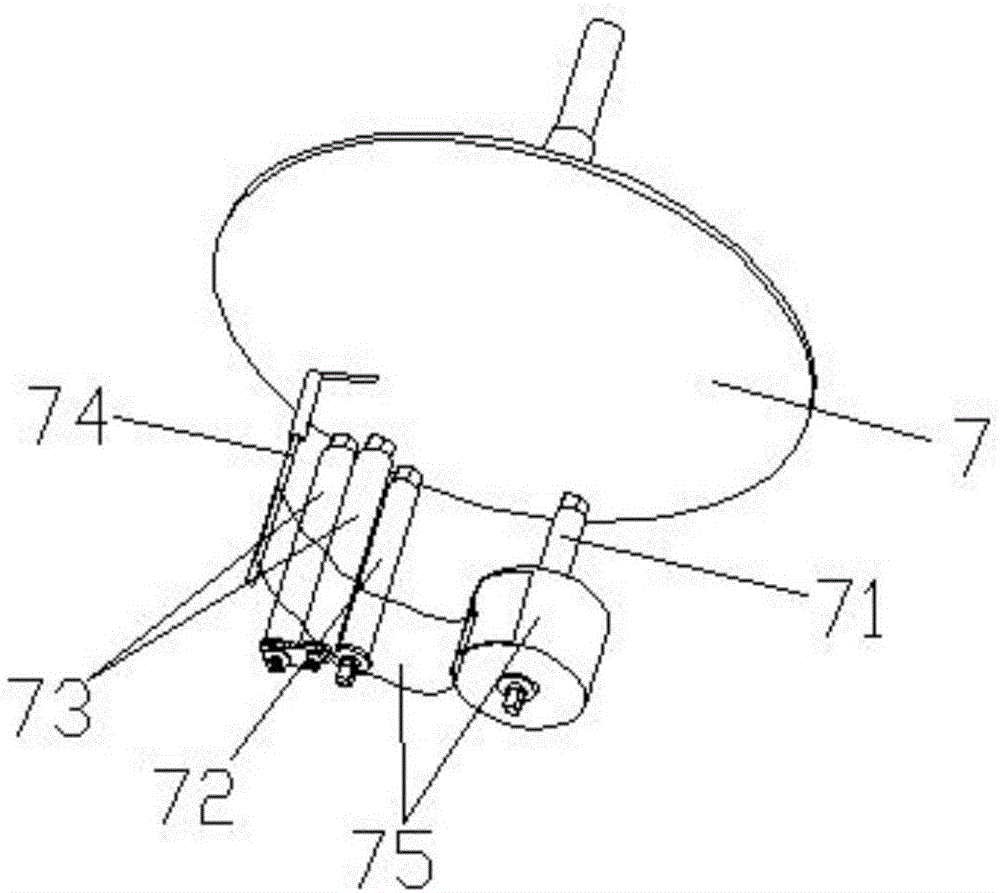

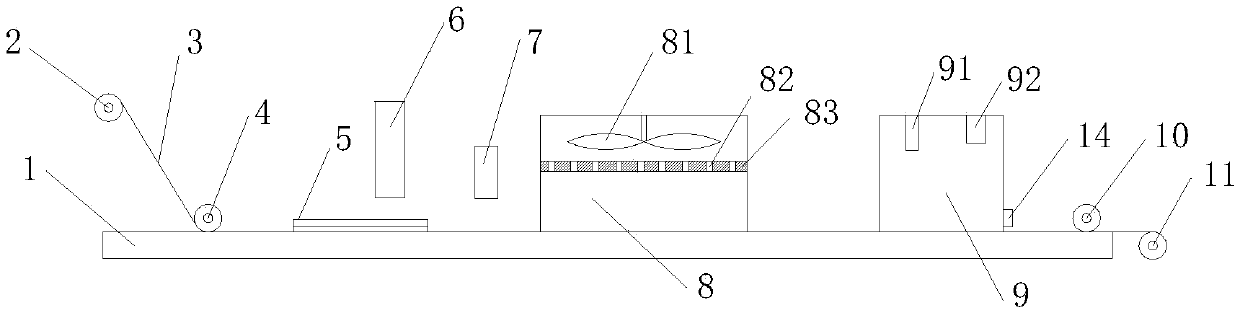

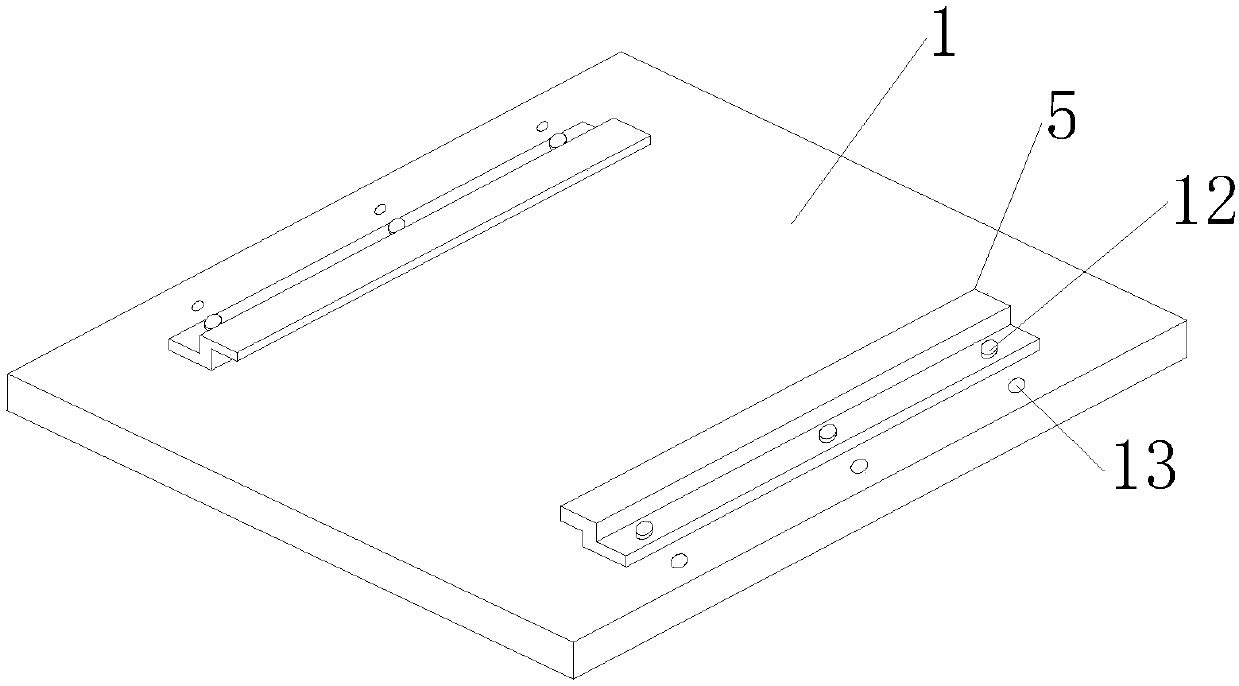

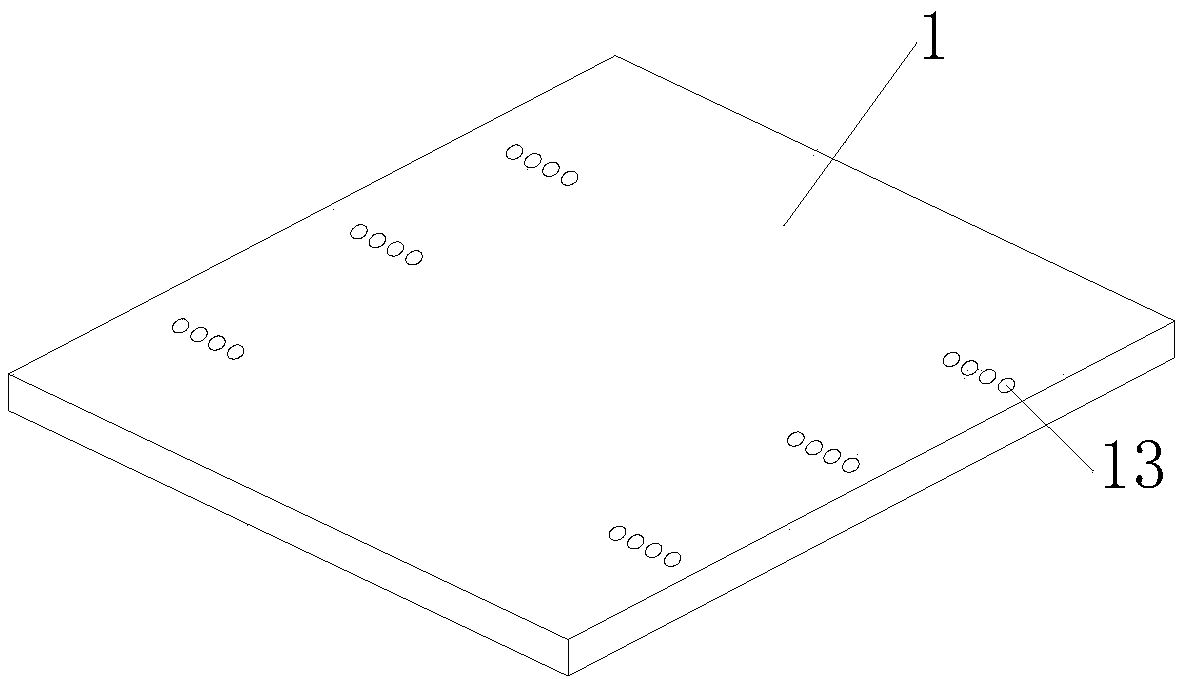

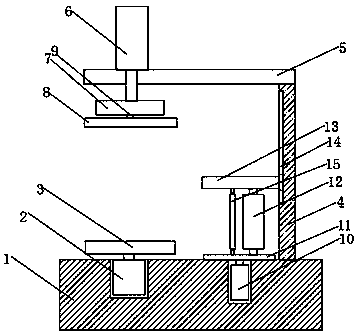

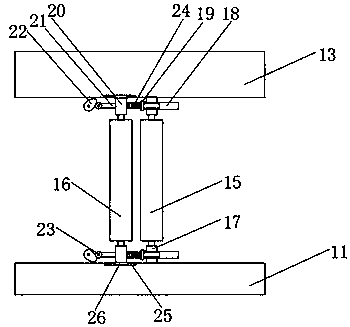

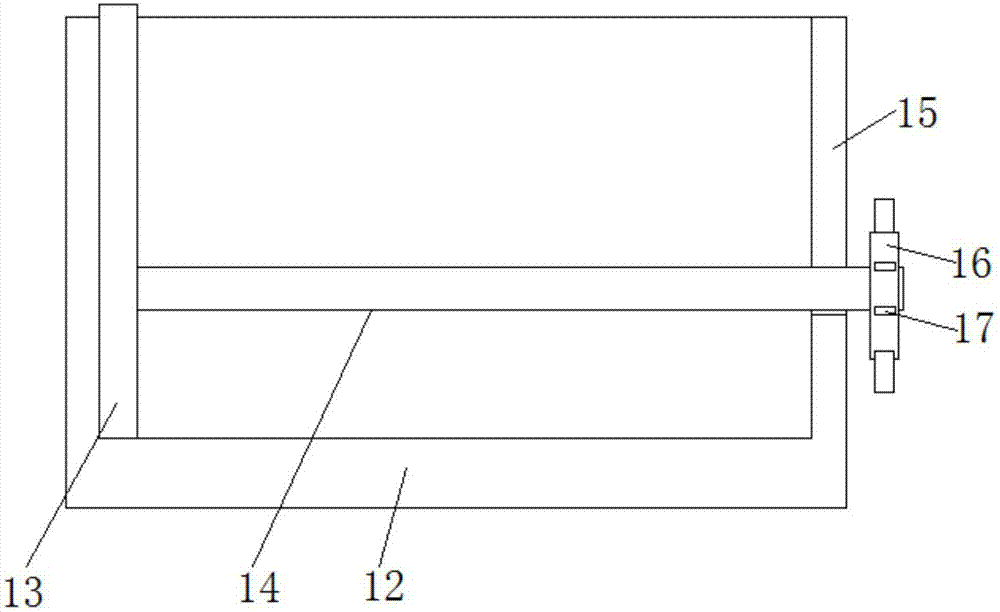

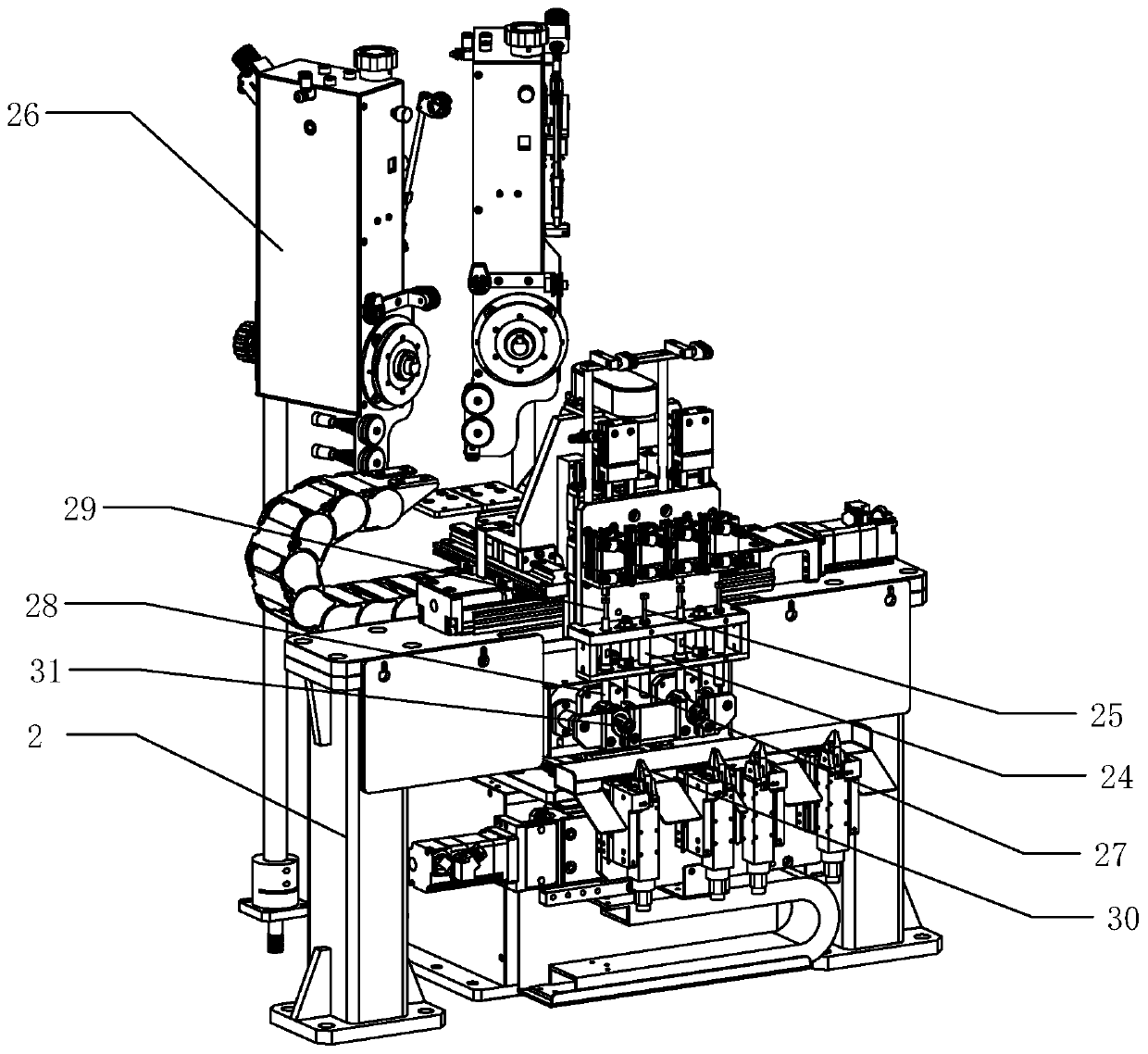

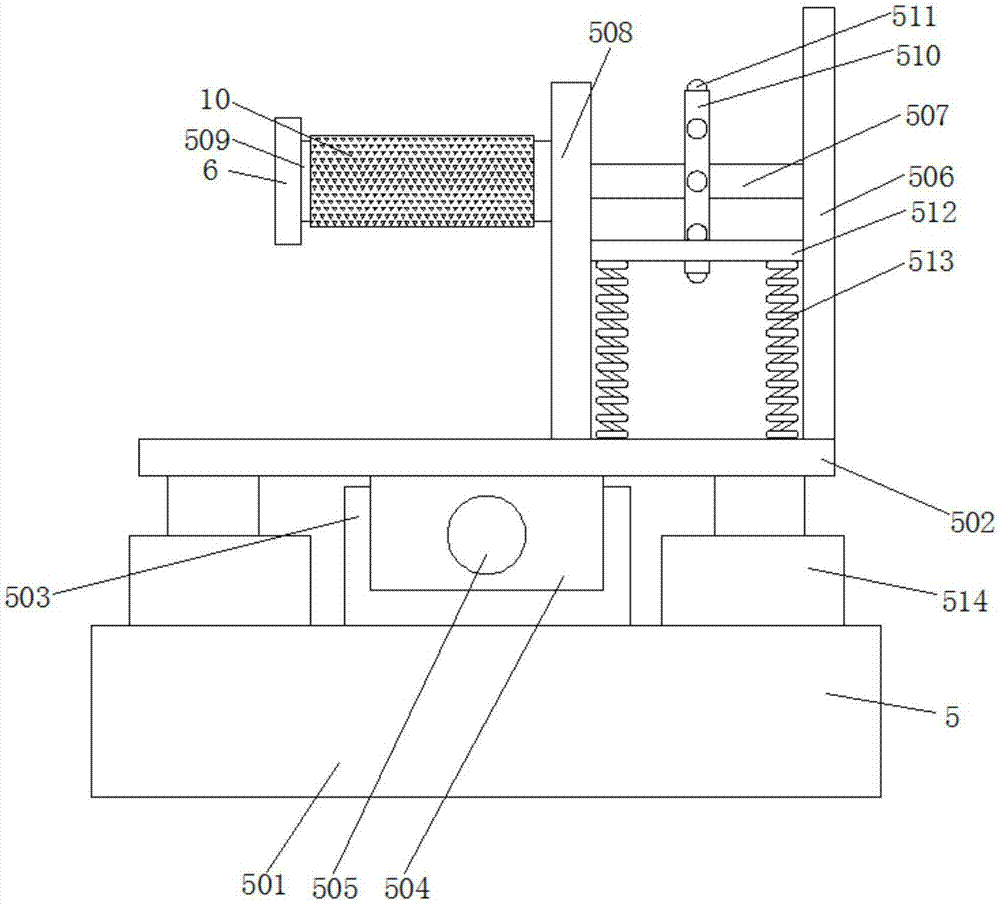

Automatic stainless steel tube winding and packaging mechanism

InactiveCN106347758AHigh degree of automationSimple and fast operationConveyor wrappingSS - Stainless steelChain link

The invention discloses an automatic stainless steel tube winding and packaging mechanism. The automatic stainless steel tube winding and packaging mechanism comprises a base, a stacking mechanism, an alignment mechanism, chain conveying lines and stainless steel tube layers and is characterized in that stop pillars are mounted on the chain conveying lines, the stainless steel tube layers are placed between the stop pillars, an automatic stainless steel tube winding and packaging mechanism body is mounted on the base and comprises winding brackets arranged on the base, a downwards pressing and fixing support is mounted between the winding brackets, a first cylinder is mounted on the downwards pressing fixing support, press plates are mounted at the front end of the first cylinder and can downwards press and fix the stainless steel tube layers, linear guideways are mounted on the winding brackets, and upper moving seat plates and lower moving seat plates are mounted on the linear guideways. The automatic stainless steel tube winding and packaging mechanism has the advantages that very little manual intervention is required, the automation degree is high, the operation is easy, labor force is reduced, the production efficiency is high, the structure is reasonable and scientific, the machine can tightly wind the stainless steel tube layers, and the sealing quality for the stainless steel tube layers is guaranteed.

Owner:佛山市虞氏科技有限公司

Processing method of steel bar cage

InactiveCN104690194ASave human effortEvenly spacedMeshed-ring wire networkNumerical controlEngineering

The invention discloses a processing method of a steel bar cage, which comprises the steps of main bar positioning, wire rod straightening, stirrup winding, carbon-dioxide arc welding, integral forming and numerical control operation. A main bar of the steel bar cage manually penetrates through a corresponding template round hole of a fixed rotary disk into a corresponding hole of a movable rotary disk for fixing; the end of a stirrup is welded on the main bar and then wound on the main bar via rotation of the fixed rotary disk and the movable rotary disk; welding is performed; and then the steel bar cage is formed. The prepared steel bar cage is uniform in spacing and high in accuracy; mechanical rotation, bar coiling and main bar winding are tight; and forming is performed and then an internal reinforcing rib is adopted, so that the concentricity of the steel bar cage is ensured.

Owner:青岛昊河水泥制品有限责任公司

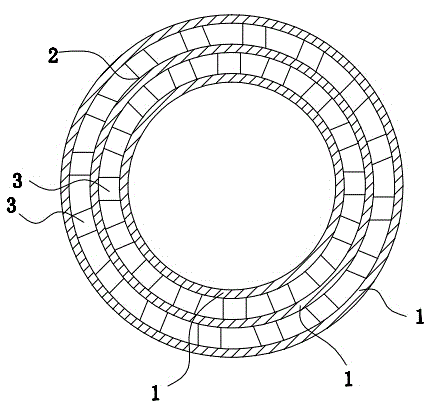

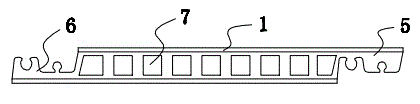

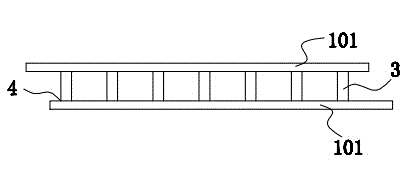

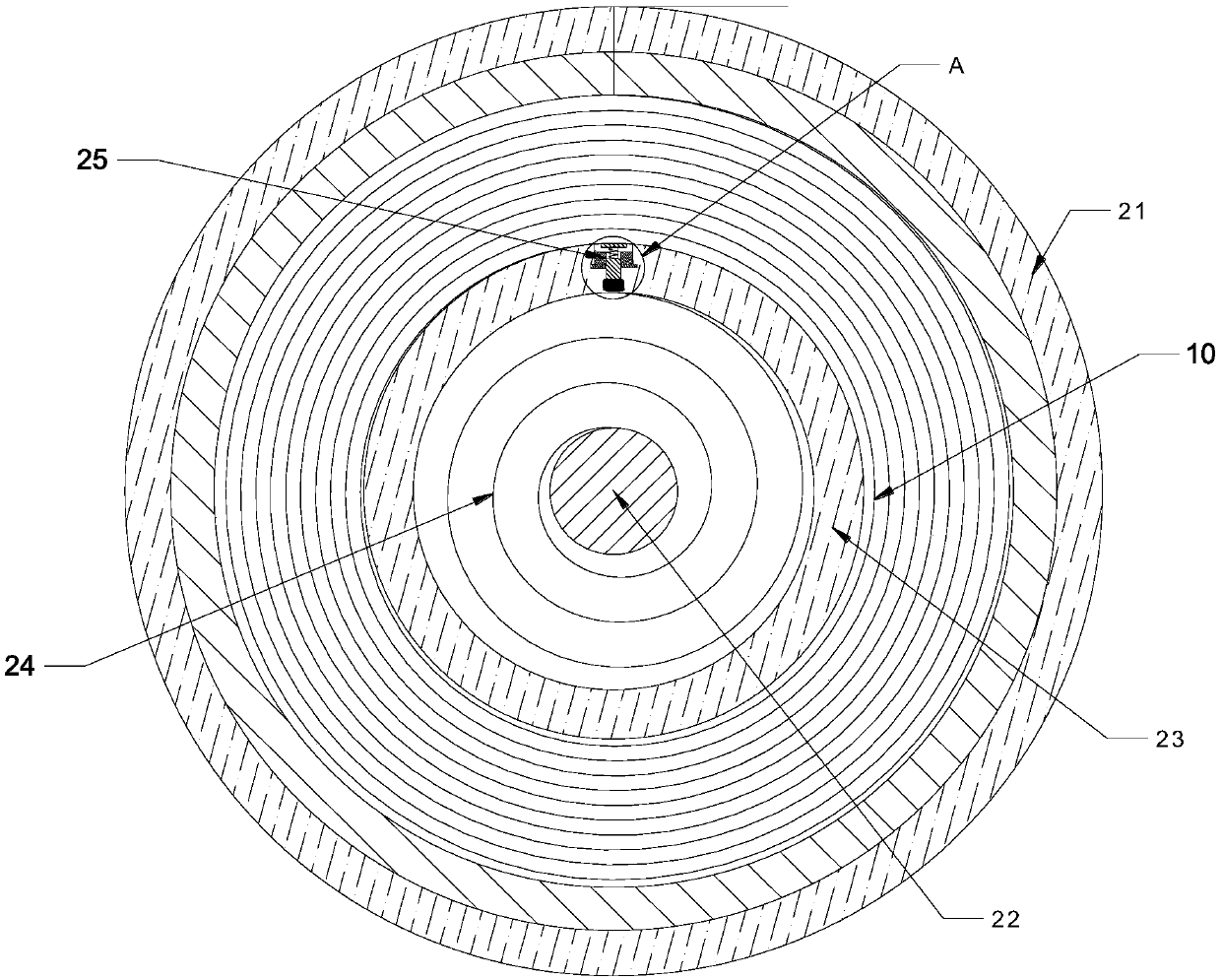

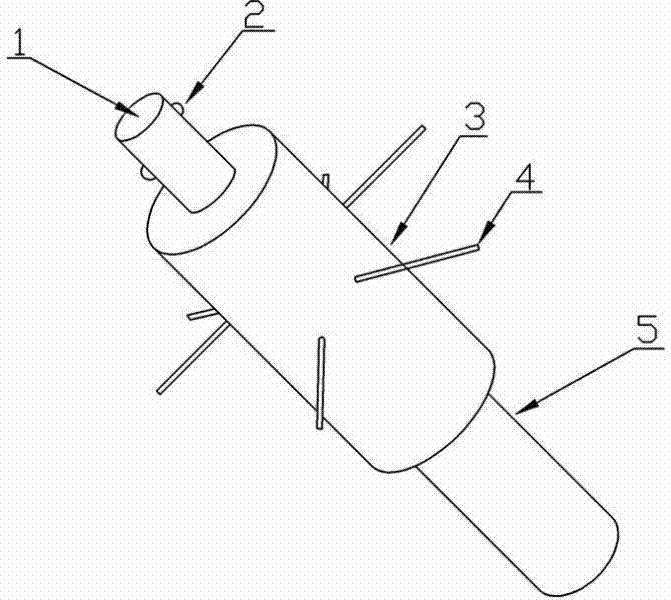

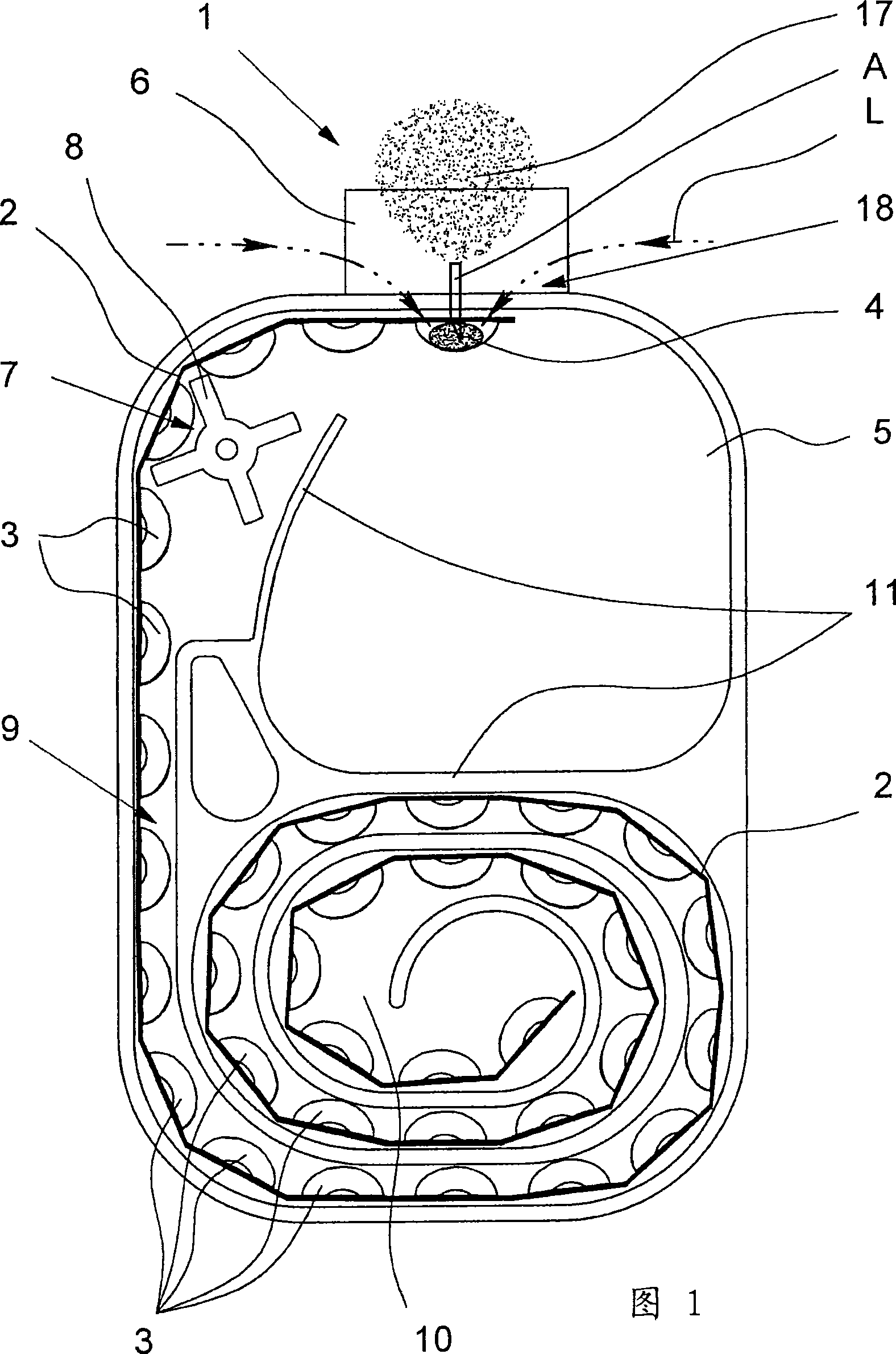

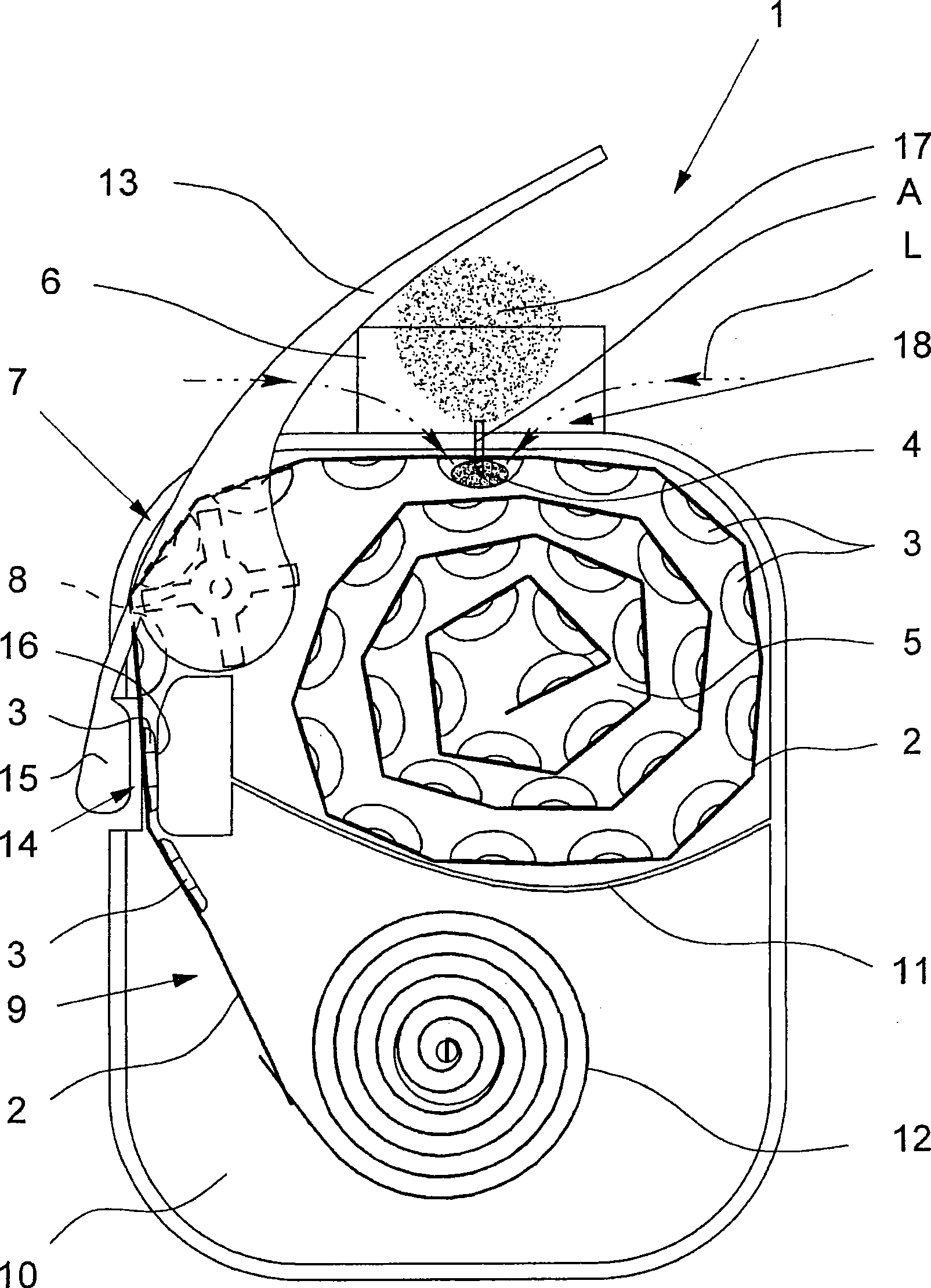

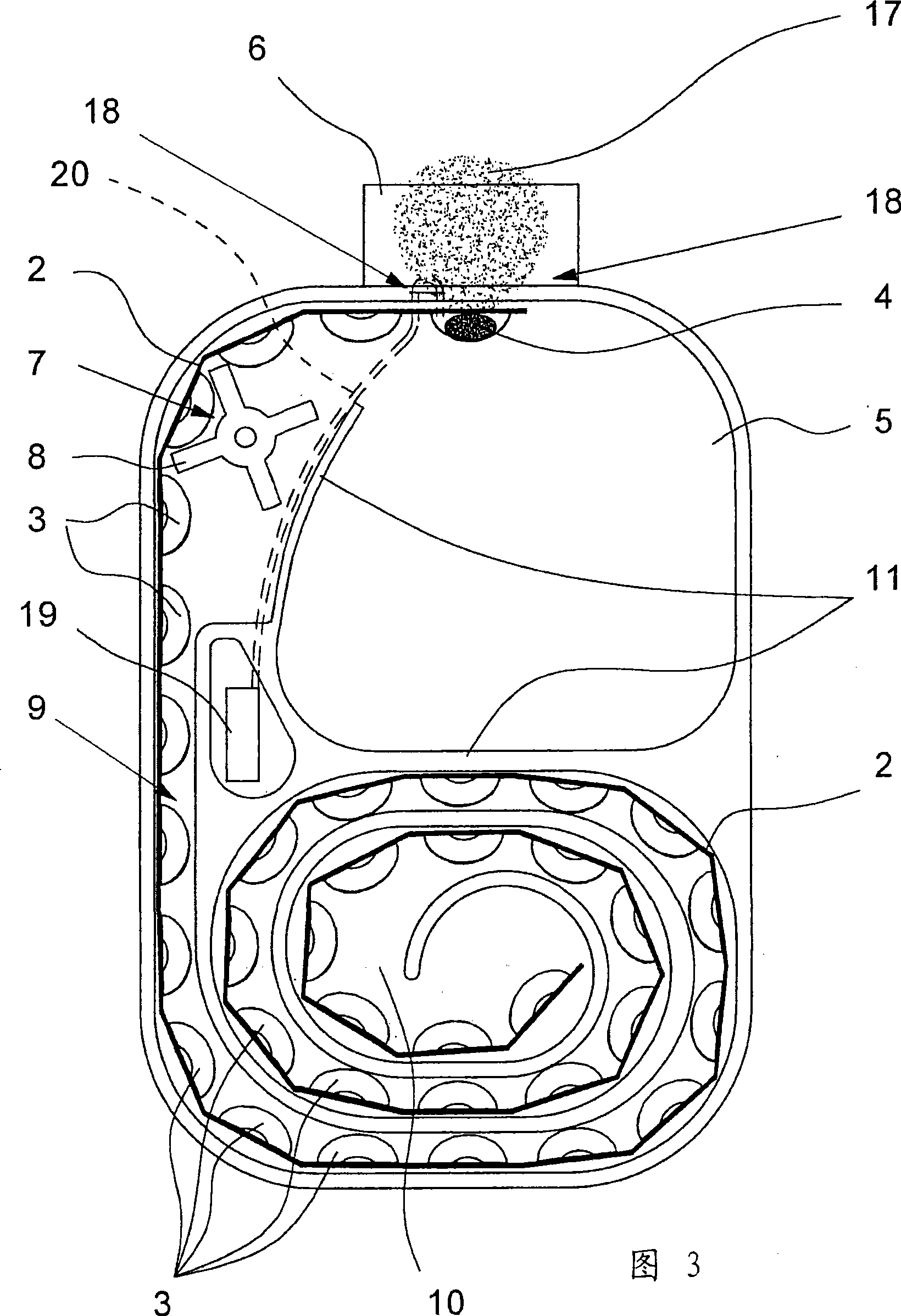

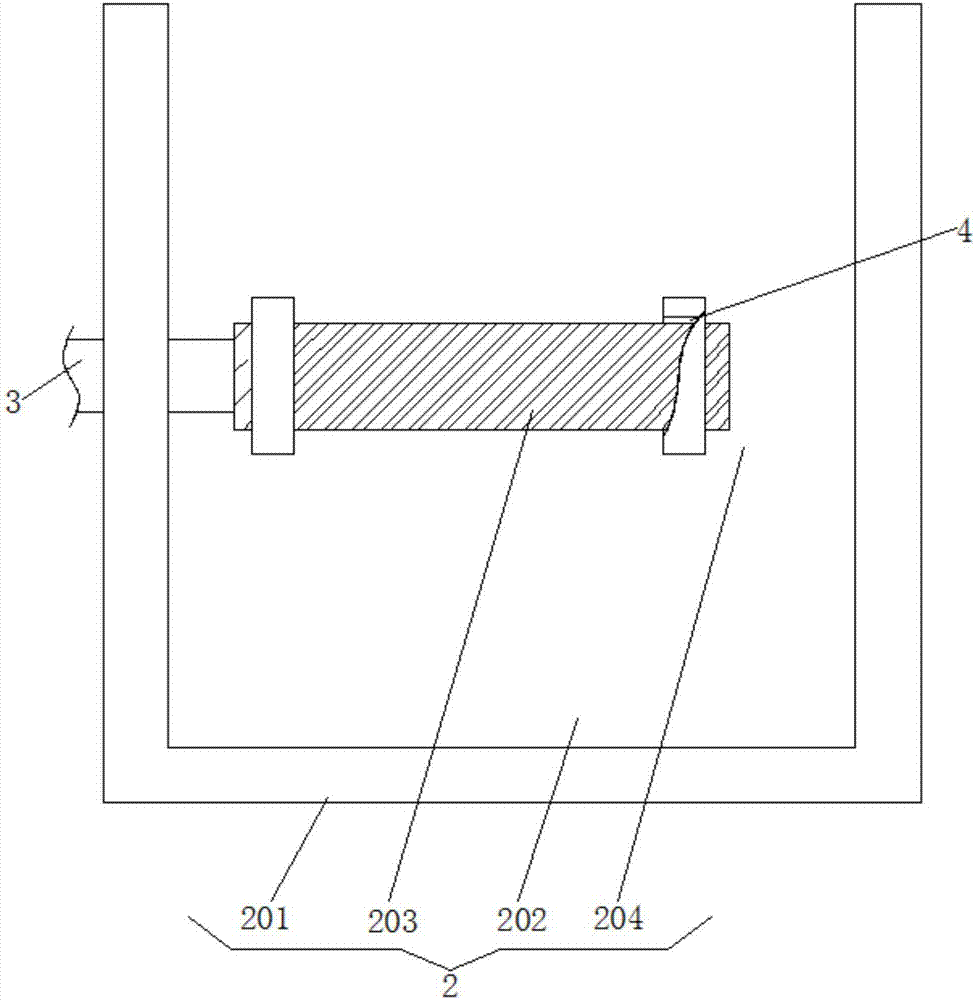

Large-diameter wound pipe and winding method thereof

ActiveCN104534188AIncrease stiffnessTightly woundRigid pipesTubular articlesWinding machineConductor Coil

The invention relates to a PVC profile spiral winding technology, namely, a large-diameter wound pipe and a winding method of the large-diameter wound pipe. The large-diameter wound pipe comprises a pipe body 2 formed by winding at least two profile blocks 1 into a whole, wherein a circular rigidity enhancement pier 3 is arranged between the two adjacent profile blocks 1. The winding method of the large-diameter wound pipe includes the steps that a spiral pipe winding machine is placed in a production workshop or on a construction site, one manufactured profile is laid on a conveying belt in front of a feed inlet of the spiral pipe winding machine, and the circular rigidity enhancement pier is placed on the upper plate face of the profile; after the circular rigidity enhancement pier is placed, another profile is laid on the top of the circular rigidity enhancement pier, and the circular rigidity enhancement pier between the two profiles and the two profiles integrally form a blank body of a plate to be wound; the spiral pipe winding machine is started, and the plate to be wound is conveyed into the spiral pipe winding machine to be wound so that the large-diameter wound pipe of the needed size can be formed. Due to the structure and the method, production cost is reduced, and circular rigidity is improved.

Owner:CHONGQING LICHENG PIPE

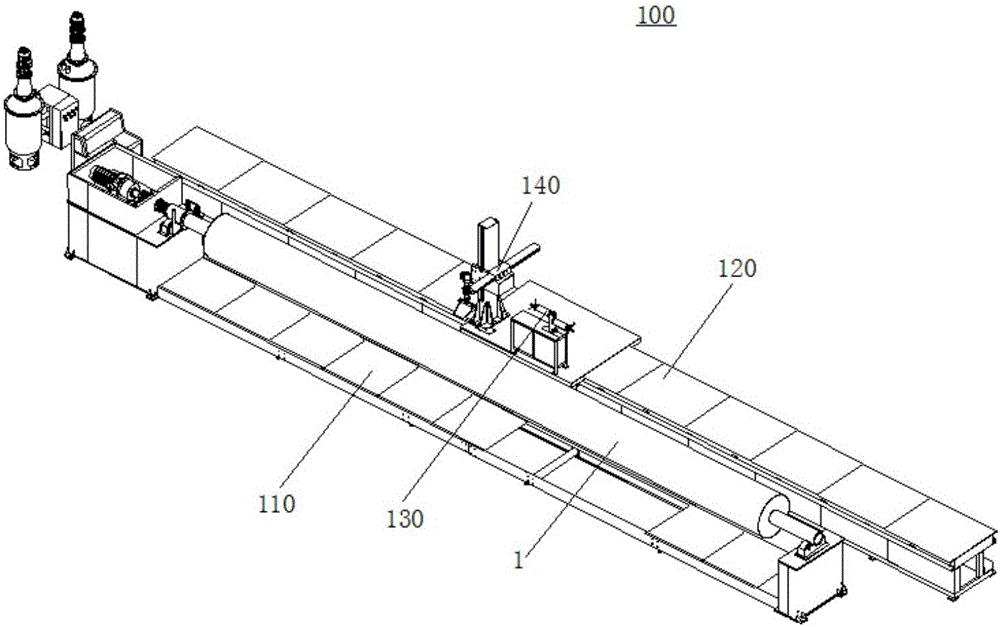

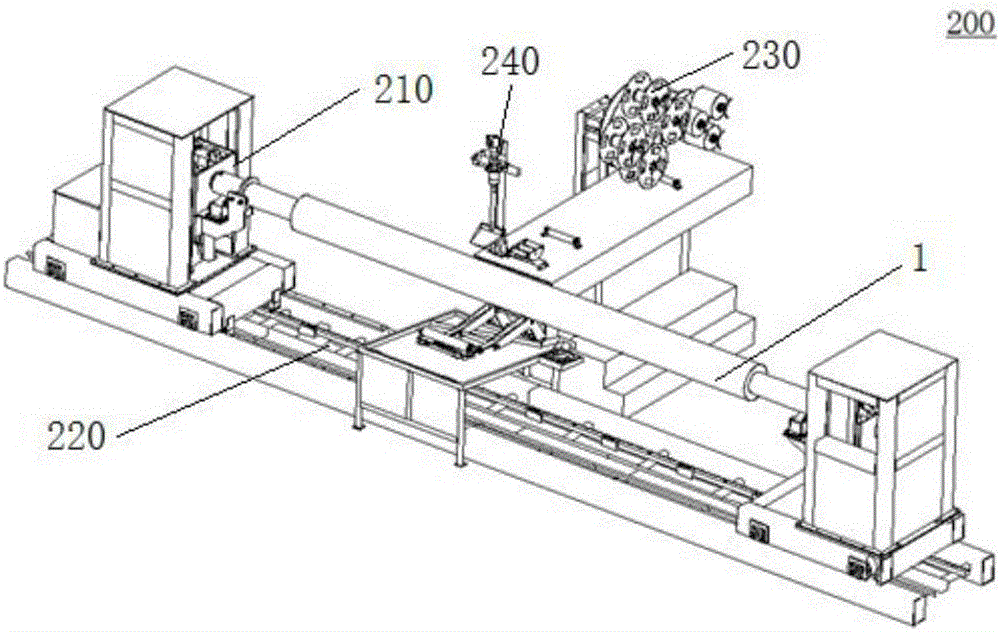

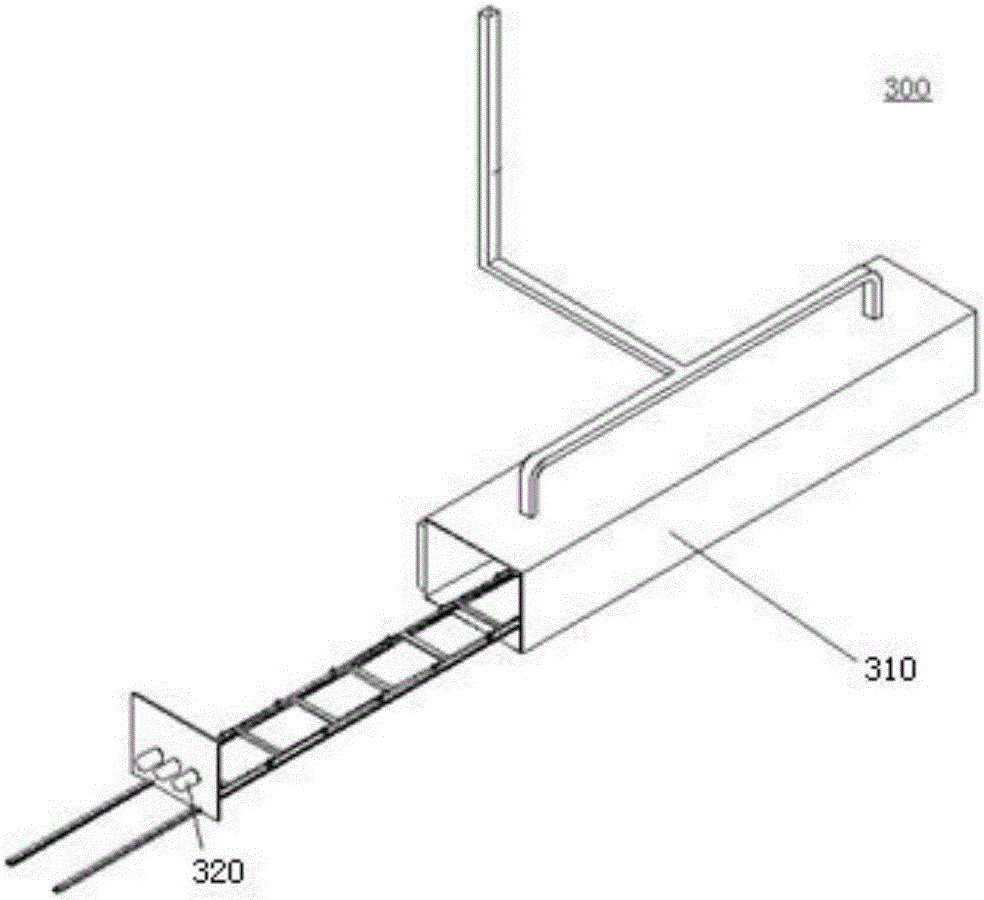

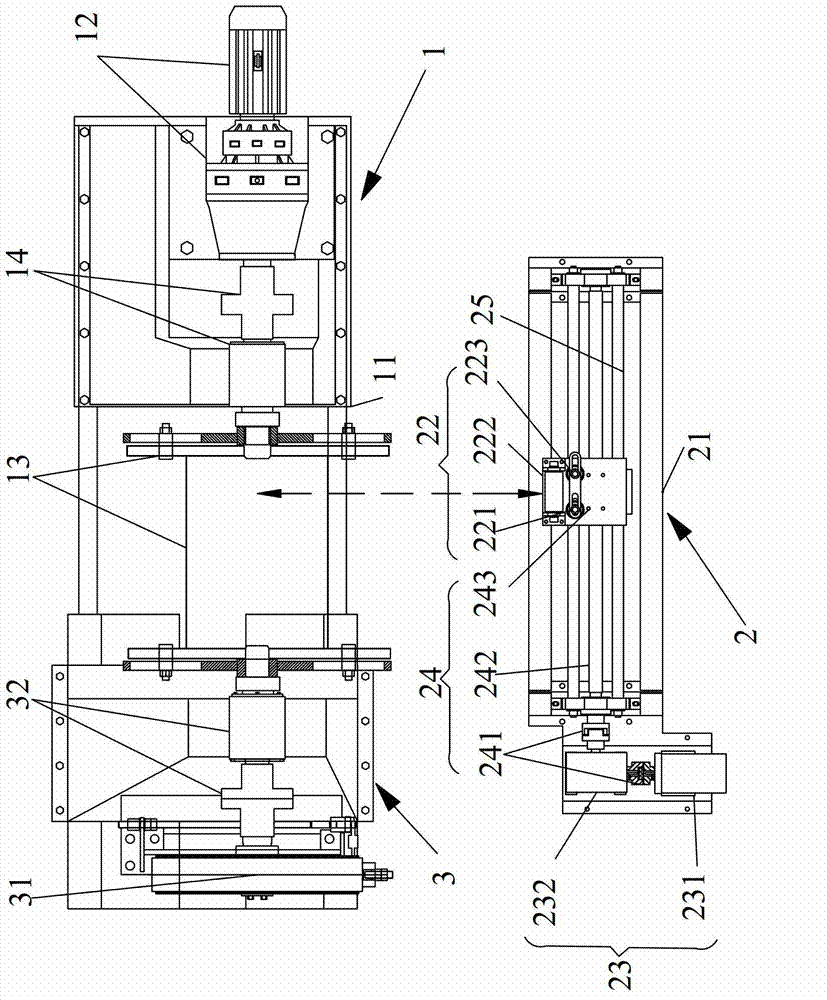

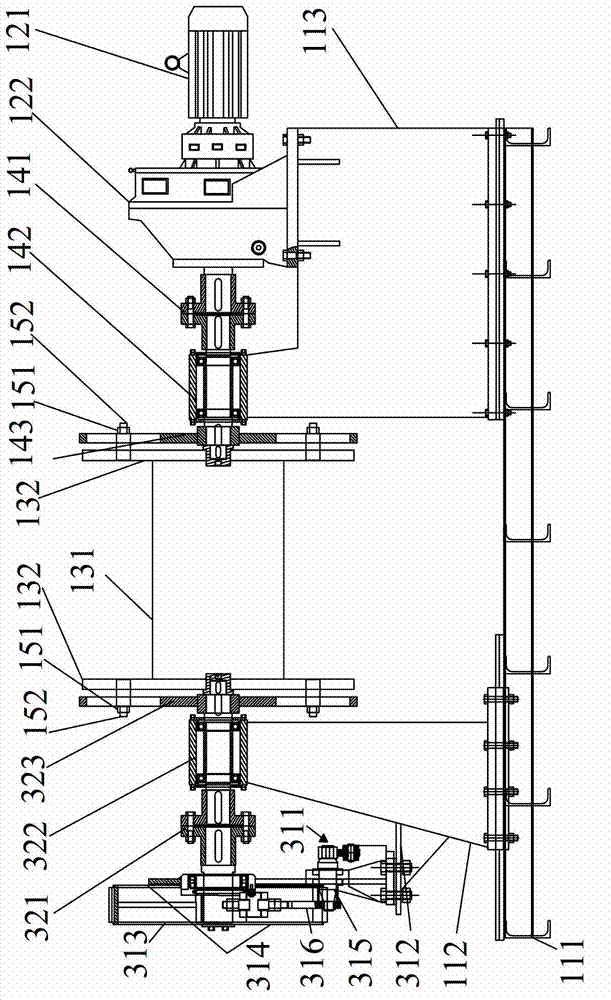

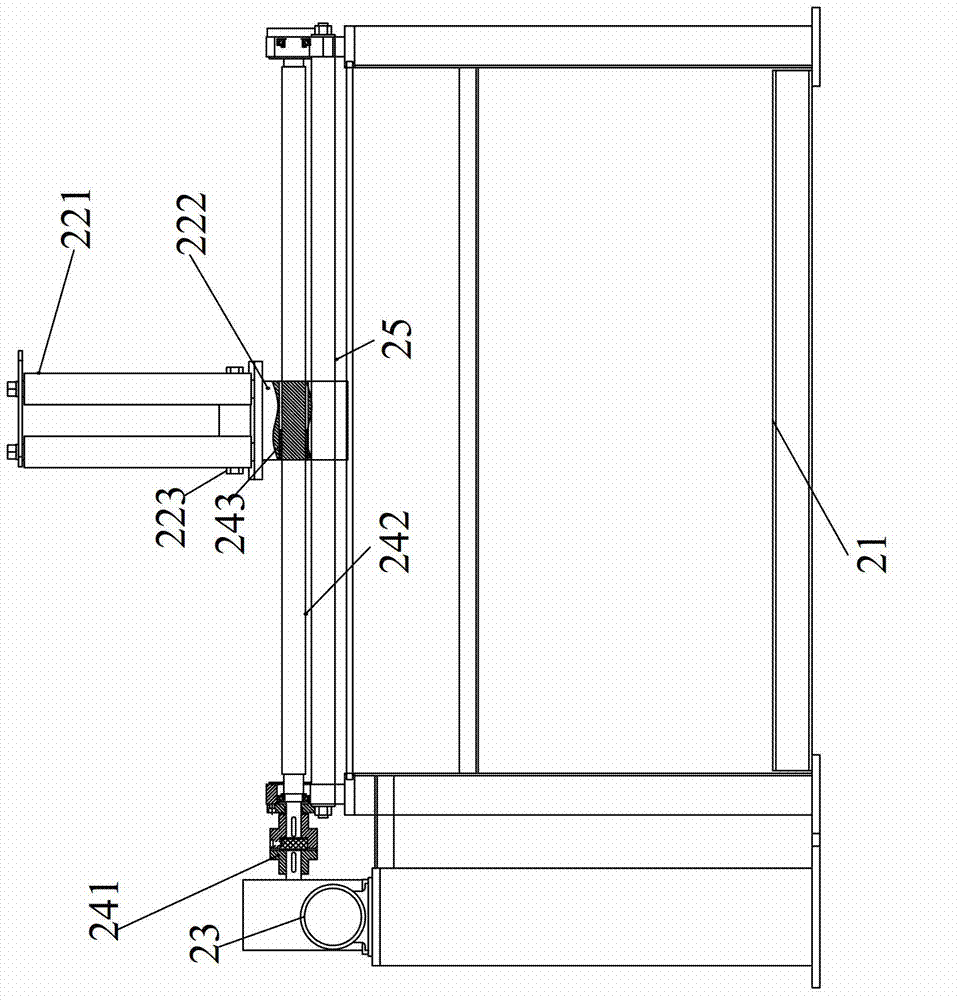

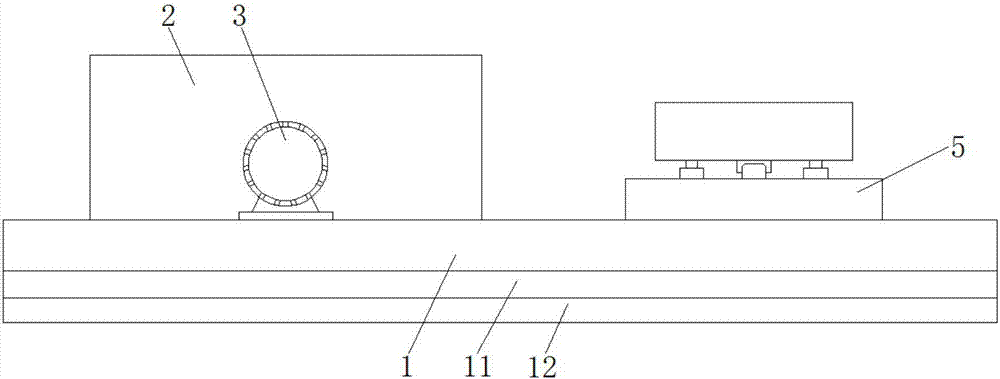

Automatic manufacturing system for manufacturing bamboo-winding composite pipe

ActiveCN105711161AEasy to manufactureSimple preparation processLamination plant layoutLaminationEngineeringPreparation procedures

The invention discloses an automatic manufacturing system for manufacturing a bamboo-winding composite pipe. The system comprises a liner layer preparation unit, a reinforcement layer preparation unit, a curing unit, a mold stripping unit, a pipe mold transfer unit and a control unit, wherein the liner layer preparation unit is used for winding a liner layer around a pipe mold; the reinforcement layer preparation unit is used for winding a reinforcement layer around the periphery of the liner layer; the curing unit is used for forming and curing the liner layer and the reinforcement layer; the mold stripping unit is used for stripping a prepared product from the pipe mold; the pipe mold transfer unit is used for conveying and transferring the pipe mold; the control unit is used for receiving operation instruction information or external instruction information of the units and controlling the units to operate correspondingly for a preparation procedure. The automatic manufacturing system is reasonable in layout due to structural improvement and layout optimization of the preparation units or mechanisms; the units are under coordinated control, so that the preparation process is simple and reasonable, and the comprehensive performance of prepared pipelines is greatly improved.

Owner:ZHEJIANG XINZHOU BAMBOO BASED COMPOSITES TECH +1

Steel wire rope auxiliary winding device

The invention discloses a steel wire rope auxiliary winding device, and belongs to the technical field of cranes. The device comprises a rope collecting mechanism and a wire arranging mechanism, wherein the rope collecting mechanism comprises a first base seat, a first drive component installed on the first base seat, a first transmission component and a tool drum rotationally installed on the base seat, and the first drive component is connected with one end of the tool drum through the first transmission component in a transmission mode; and the wire arranging mechanism comprises a second base seat, a wire arranging component, a second drive component and a second transmission component, wherein the second drive component and the second transmission component are installed on the second base seat through the second transmission component, the wire arranging component is movably installed on the second base seat and arranged relative to the tool drum, and the moving direction of the wire arranging component is same to the axis direction of the tool drum. Through the axial rotation of the tool drum, the wire arranging component transversely moves, damaged steel wire ropes are convenient to detach from a lifting drum of a crane, and the steel wire ropes are stored on the tool drum.

Owner:WUHAN MARINE MACHINERY PLANT

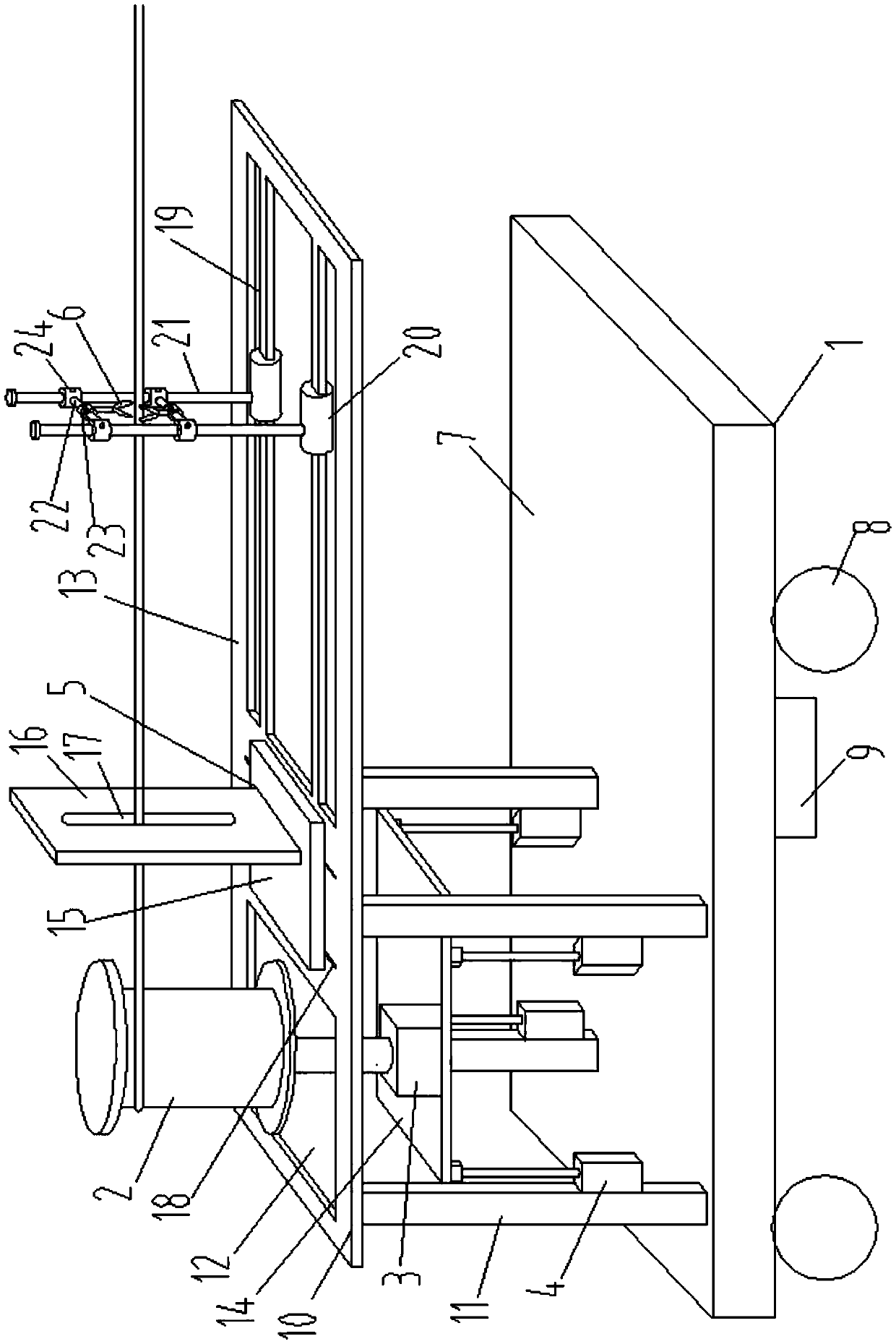

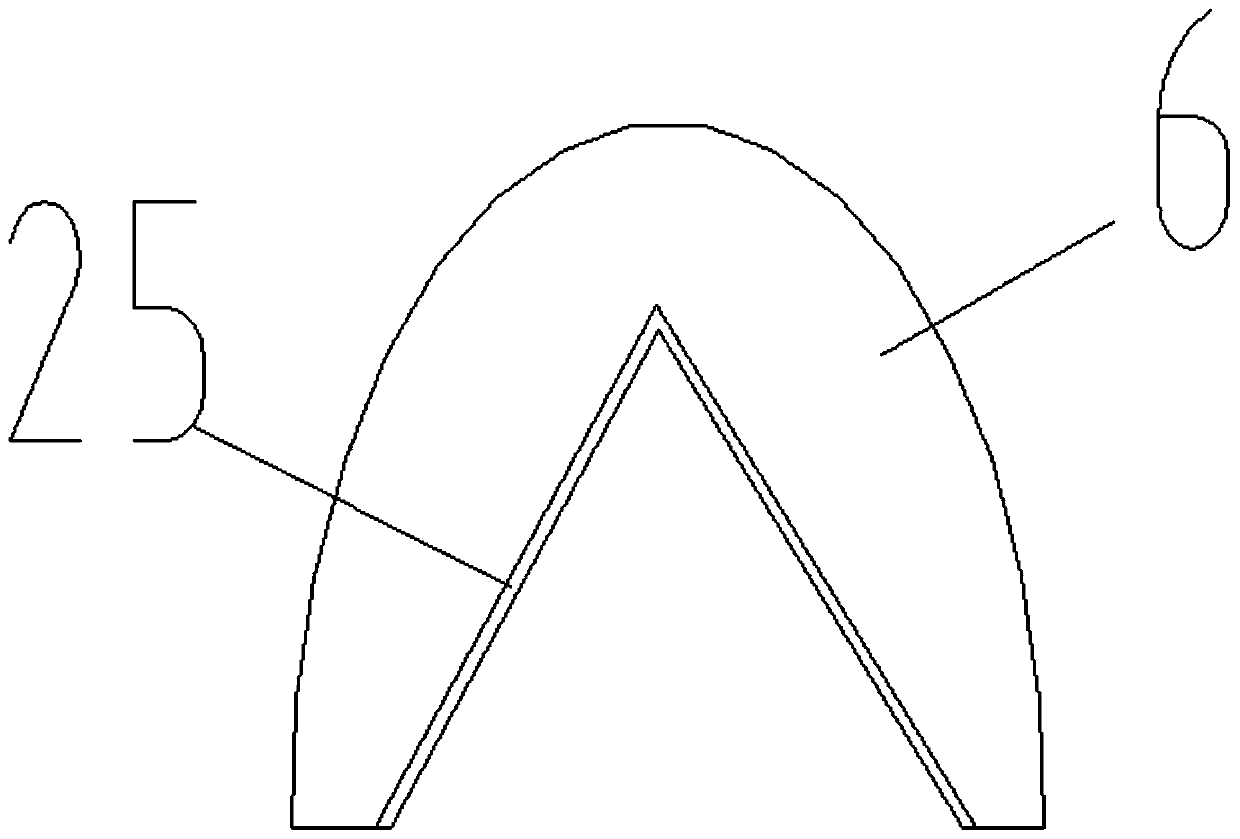

Equipment used for changing grounding wire to be spiral

The invention provides equipment used for changing a grounding wire to be spiral. The equipment comprises a first rack, a convoluting device, a winding rod, a second rack, a sliding seat, a rotary driving device, a clamping device and a horizontal driving device. The convoluting device used for convoluting the grounding wire is mounted on one side of the first rack. A supporting table is mounted on the second rack. The sliding seat capable of sliding is mounted on the supporting table. The rotary driving device is mounted on the sliding seat. The output end of the rotary driving device is connected to a rotary disc. The winding rod is mounted on the rotary disc. The clamping device is mounted on the sliding seat and used for clamping the end, away from the convoluting device, of the grounding wire. The horizontal driving device is mounted on the side, away from the convoluting device, of the sliding seat. By means of the equipment used for changing the grounding wire to be spiral, theproblems that during winding in the prior art, a grounding wire needs to be pulled and moves in the direction parallel to a central line of a wire spool relative to a winding rod, and consequentially,the winding rod and the grounding wire are prone to being damaged are solved.

Owner:STATE GRID CORP OF CHINA +1

Anti-counterfeit printing device and method

InactiveCN107554060AImprove accuracyImprove printing qualityPattern printingInksAgricultural engineeringPrinting press

The invention discloses an anti-counterfeiting printing device, comprising a printing table, a paper feed roller is connected to the entrance of the printing table, a first pressure roller is arranged at the entrance of the printing table, and a positioning block is arranged on the right side of the first pressure roller , the positioning block is provided with screws, the printing table is provided with screw holes corresponding to the screws, a printing machine is provided above the positioning block, a photoelectric sensor is provided on the right side of the positioning block, and the photoelectric sensor There is a drying chamber on the right side of the drying chamber, a fan is provided on the top of the drying chamber, a partition is provided at the lower end of the fan, a through hole is provided on the partition, and a proofreading room is provided on the right side of the drying chamber. , the interior of the pair of chambers is provided with an ultraviolet lamp and a high-speed camera, the right side of the proofreading room is provided with a punching device, the right side of the punching device is provided with a second pressure roller, and the exit of the printing table is connected with a roll roll. The invention can improve the printing efficiency of bills, and conveniently remove problematic bills.

Owner:合肥汇融文印有限责任公司

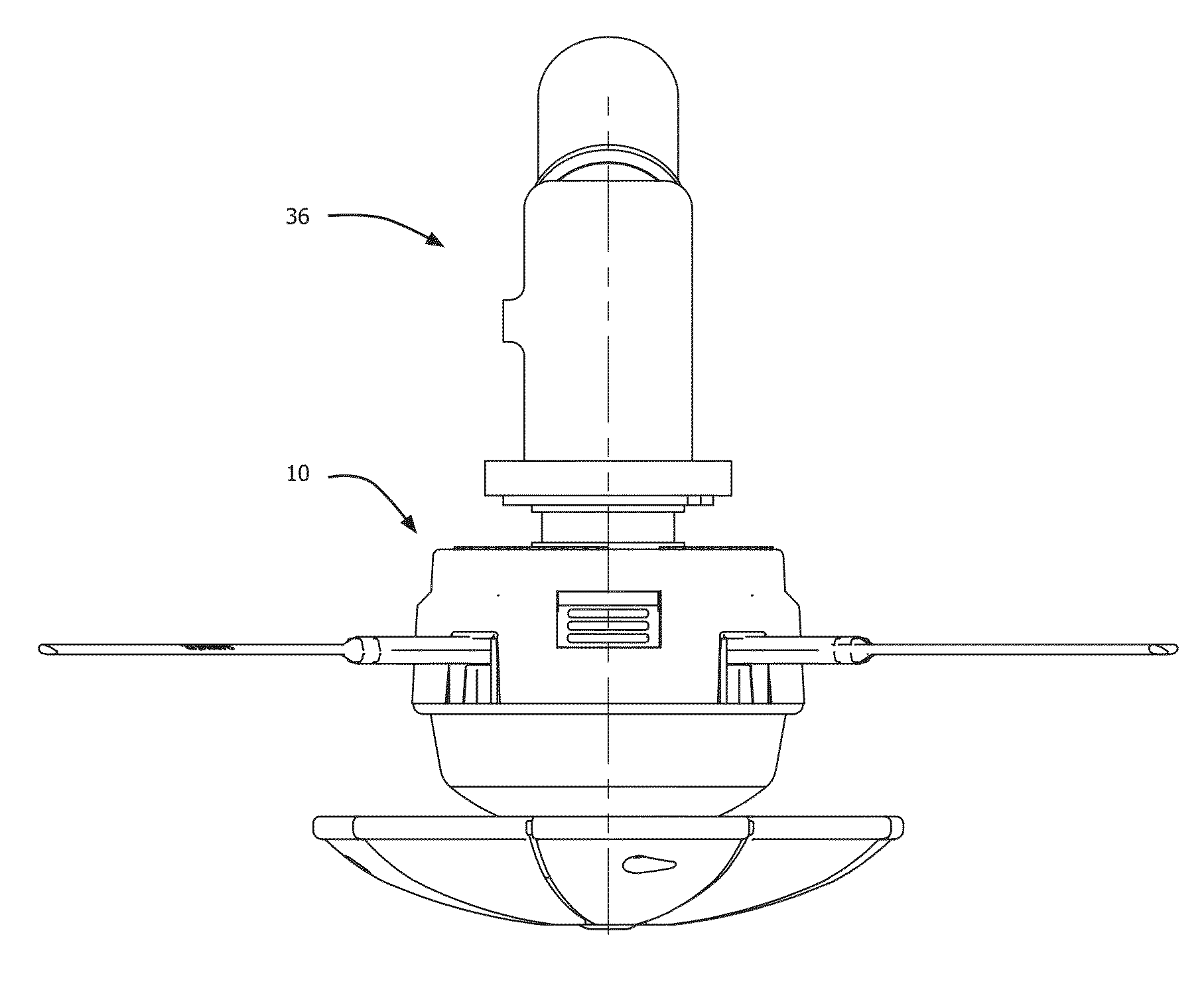

Anti-wind/Anti-wrapping assembly for trimmers

ActiveUS20160150725A1Easy to disassembleFree spinsMowersMetal working apparatusEngineeringConductor Coil

An anti-winding assembly reduces or prevents debris from winding on a trimmer and / or makes them easier to remove. The trimmer includes a trimmer head mounted to a rotatable arbor and supporting one or more cutting lines. The anti-winding assembly includes a bearing positionable between the trimmer head and an adjacent trimmer component. The bearing includes a freely rotating outer race. A shield positioned radially outward of the bearing adjacent the outer race shields gaps between the bearing and the trimmer head and between the bearing and the adjacent trimmer component. The anti-winding assembly prevents trimmed debris from being wound up near the trimmer head.

Owner:AERO FLEX TECH

Power cable take-up and pay-off device

The invention discloses a power cable take-up and pay-off device, and relates to the technical field of power cable layout. The power cable take-up and pay-off device comprises a traveling vehicle, atake-up roller, a guide frame and a cable clamp. The take-up roller is arranged on the traveling vehicle, the take-up roller is vertically arranged, the take-up roller is rotted through a first motorand lifted by an air cylinder, the guide frame is arranged on a cable take-up path on the take-up roller and is used for guiding take-up and pay-off of cables, the cable clamp is provided with two clamping heads with opposite clamping openings and facing towards the cables, the two clamping heads are arranged in a staggered mode in the direction perpendicular to the cables, and the clamping headsmove along the direction perpendicular to and parallel to the cables through a moving mechanism. The technical problems in the prior art that a cable shaft is inconvenient to transfer, the position isdifficult to adjust and the height is difficult to control during winding, the cables cannot be wound in order in the take-up process, and winding is loose are solved.

Owner:STATE GRID CORP OF CHINA +1

Novel winding machine winding method and device thereof

InactiveCN110589051AFully packagedChange gapWrapping material feeding apparatusWrapping with article rotationWinding machineElectric machinery

The invention provides a novel winding machine winding method and device thereof, and relates to the technical field of winding machines. The novel winding machine winding device comprises a base, a vertical plate is welded to one side of the top of the base, a top seat is vertically welded to the top of the vertical plate, a servo motor is embedded in one side of the interior of the base, a driving end of the servo motor penetrates through the top of the base to be fixedly connected with a rotating disc, the side, close to the vertical plate, of the interior of the base is fixedly connected with a first air cylinder, the piston end of the first air cylinder is fixedly connected with a bottom plate through the base, a top plate is arranged above the bottom plate, and a winding roller is arranged between one side of the top of the bottom plate and the top plate. By means of the arranged moving mechanism, a second tensioning roller can be driven to move, so that the distance between a first tensioning roller and the second tensioning roller is changed, so that the tensioning degree of a winding film is changed, and the object is wound more tightly.

Owner:玉门金环密封材料有限公司

Steel wire rope winding device

The invention discloses a steel wire rope winding device which comprises a power part, a fixing frame, a spline shaft, a steel wire rope reel, a nut plate, a rotary frame, a rope guiding wheel and a rope pressing wheel. The spline shaft is arranged on the fixing frame and connected with the power part, and the steel wire tope reel is movably arranged on the spline shaft in a sleeved mode. Due to the fact that the reel is meshed with the nut plate and can move along the spline shaft, when a steel wire rope is wound into or unwound out of a pulley and the reel, declination is completely avoided, in other words, the declination angle of the steel wire rope is zero degree, and therefore even if limitation of the structural size exists, for example, the center distance between the reel and the pulley is quite small, the phenomenon that due to the excessively-large declination angle of the steel wire rope, the steel wire rope is impacted and rubbed with the lateral side of a rope groove or the steel wire rope jumps out of the groove can be avoided.

Owner:上海瑞纽机械股份有限公司

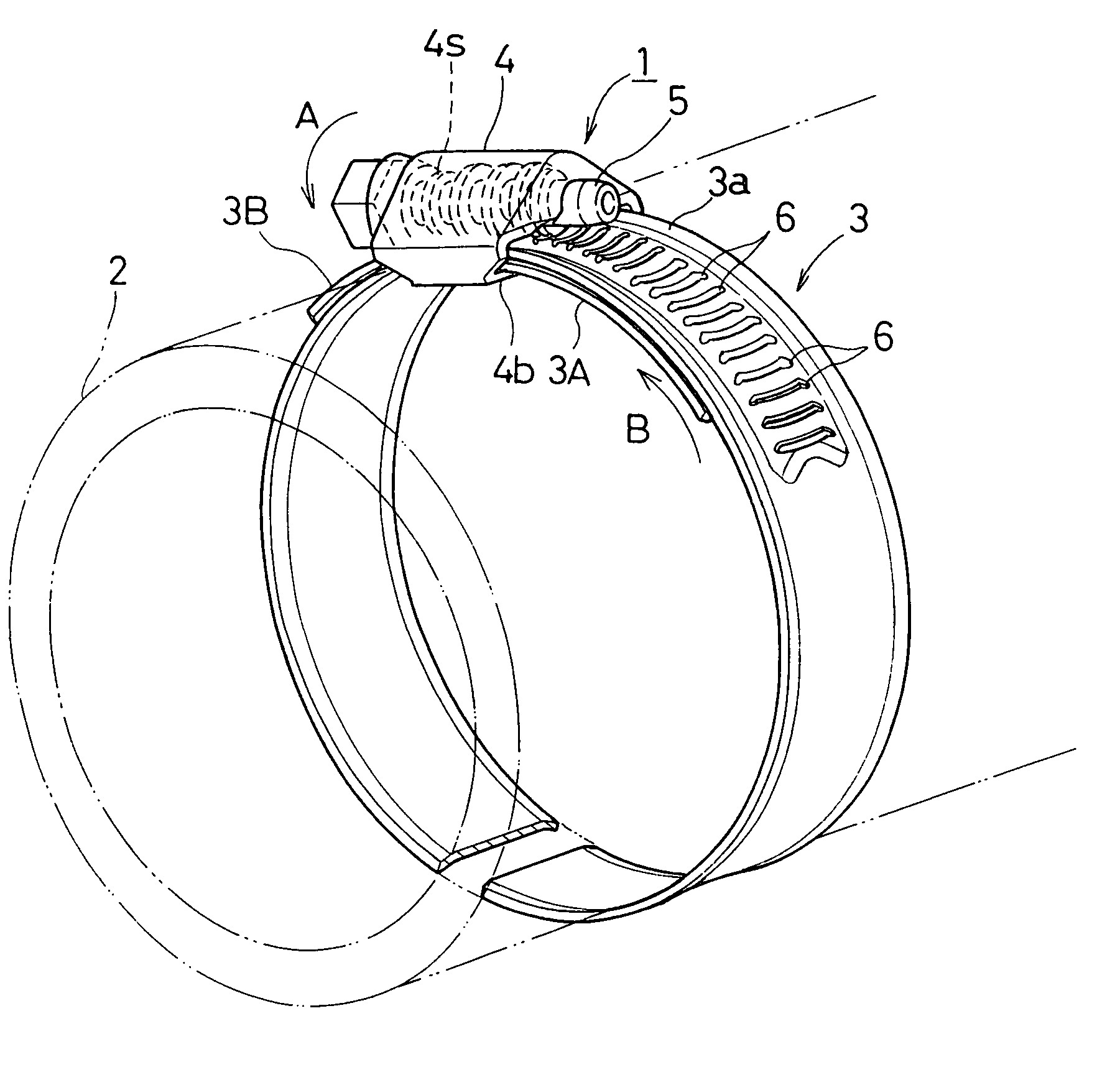

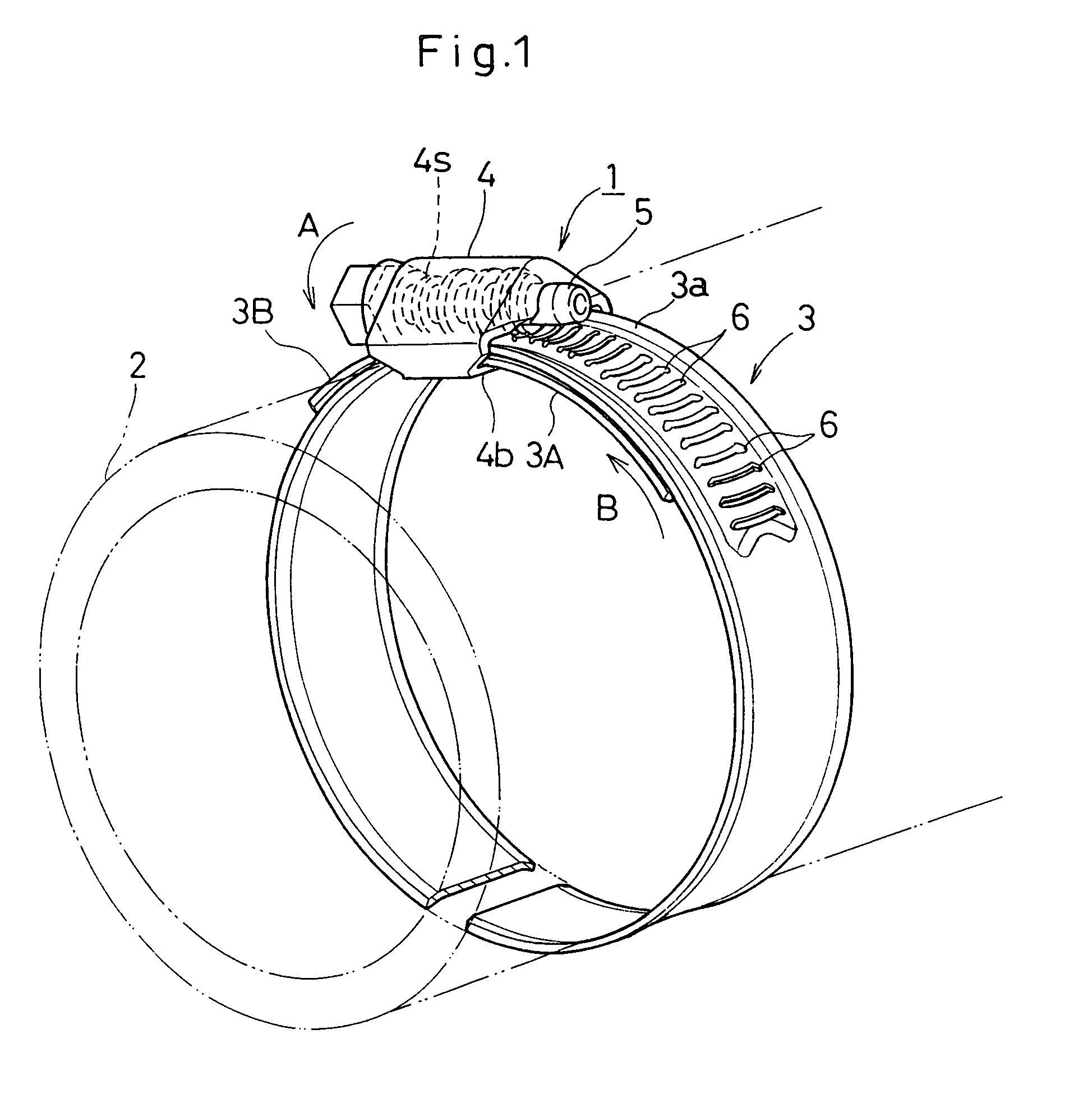

Clamp Device for Connection

InactiveUS20070283538A1Increase meshing areaTightly woundSnap fastenersFlexible elementsEngineeringElectrical and Electronics engineering

Owner:TAKAGI MFG

Anti-wind/anti-wrapping assembly for trimmers

ActiveUS9883628B2Winding and wrapping can be substantially mitigatedEasy to disassembleMowersEngineeringMechanical engineering

An anti-winding assembly reduces or prevents debris from winding on a trimmer and / or makes them easier to remove. The trimmer includes a trimmer head mounted to a rotatable arbor and supporting one or more cutting lines. The anti-winding assembly includes a bearing positionable between the trimmer head and an adjacent trimmer component. The bearing includes a freely rotating outer race. A shield positioned radially outward of the bearing adjacent the outer race shields gaps between the bearing and the trimmer head and between the bearing and the adjacent trimmer component. The anti-winding assembly prevents trimmed debris from being wound up near the trimmer head.

Owner:AERO FLEX TECH

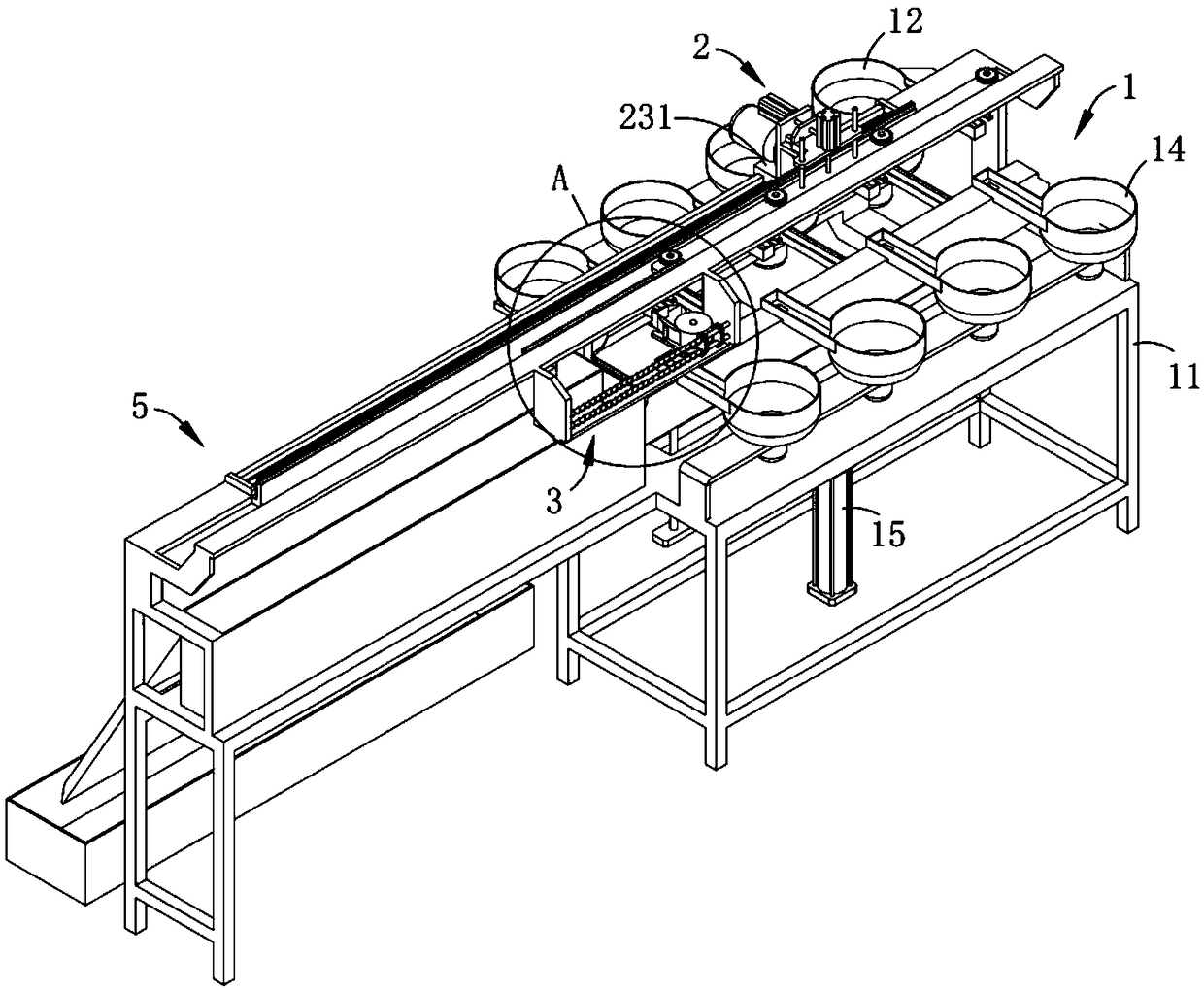

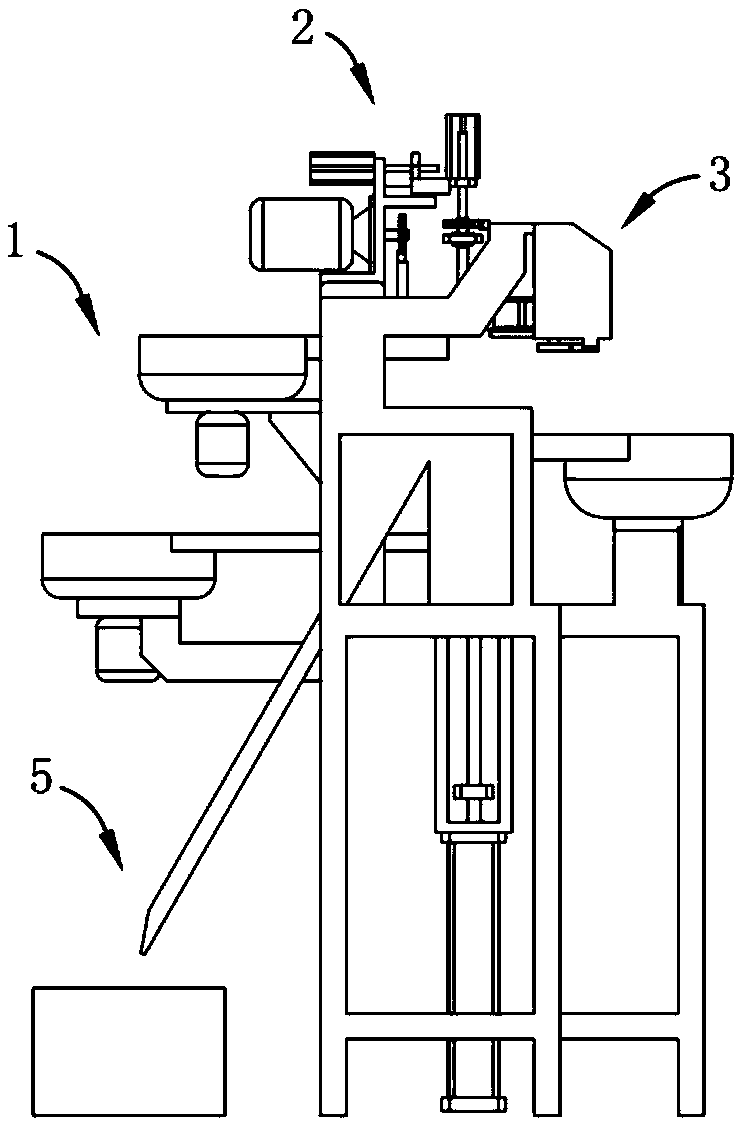

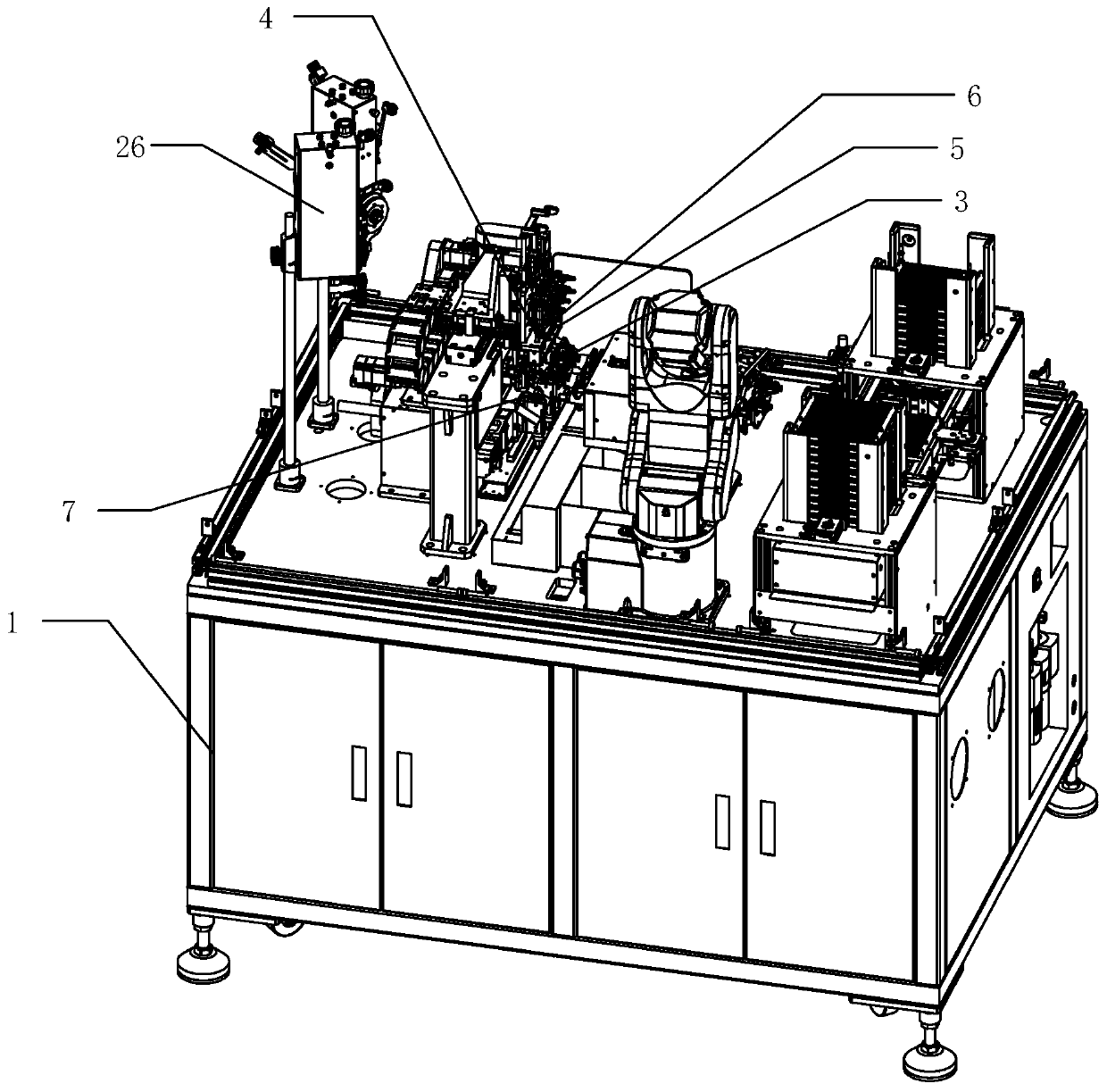

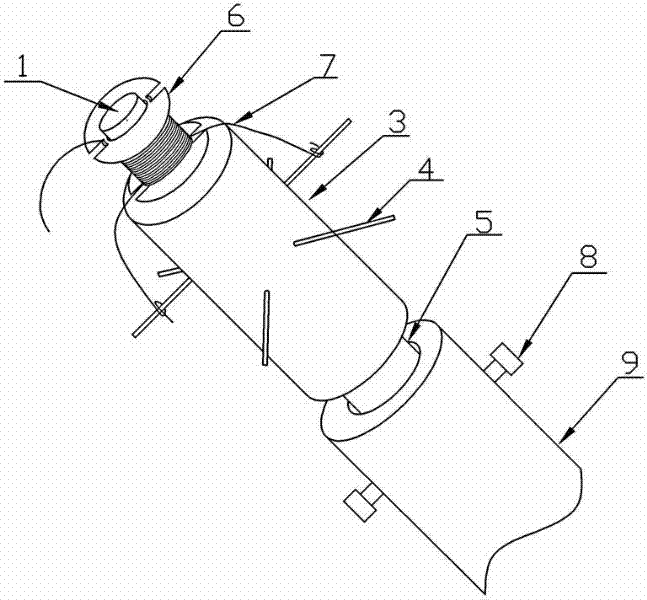

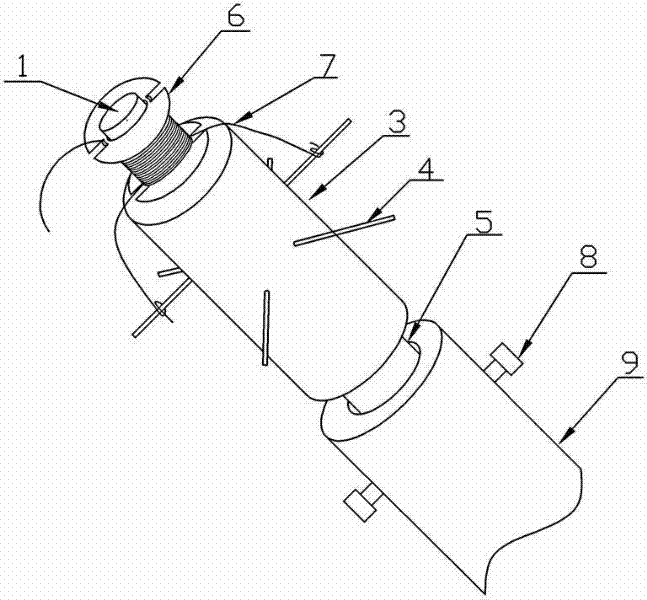

Full-automatic production line and process of inductor

InactiveCN108735490ARealize automatic film windingRealize automatic outputInductances/transformers/magnets manufactureProduction lineEngineering

The invention relates to the technical field of inductor production, and provides a full-automatic production line and process of an inductor. The full-automatic production line comprises an assemblymechanism, a transfer mechanism, a film winding mechanism and a tin dipping output mechanism, wherein the assembly mechanism comprises a rack, a sequence assembly A, a sequence assembly B, a sequenceassembly C and a jacked-up assembly, an assembly region is formed on the jacked-up assembly, the transfer mechanism comprises a positioning assembly, a telescopic assembly and a translation assembly,the film winding mechanism comprises a bearing rack, a placement assembly, a transmission assembly, a pre-tightening assembly and a cutter, the pre-tightening assembly and the positioning assembly arearranged in an interrupt contact way, and the tin dipping output mechanism comprises a tin liquid bin, a guide assembly and a receiving bin. An assembly body is driven to be interrupt transmission with the film winding mechanism by the transfer mechanism during the transferring process, a thin film is wound around the assembly body in an automatic rotation mode, automatic film winding of the assembly body during the transferring process is achieved, and the technical problem of low production efficiency caused by independence of each process in the prior art is solved.

Owner:CHANGXING SOFITEL ELECTRONICS

Winding method for multiple radial parallel winding layer distribution transformer coils

InactiveCN105702450ALow costReduce volumeInductances/transformers/magnets manufactureComplete transpositionDistribution transformer

The invention provides a winding method for multiple radial parallel winding layer distribution transformer coils. A first layer of coil is wound on a winding mold, the start end of the second last turn of the first layer is bound with a wedge-shaped end insulator, and then the last turn of the first layer is completed through parallel winding; after the coil is lifted, the coil is bound with a parallel end insulator, interlayer insulation paper is laid, and then the first turn of the second layer is completed through parallel winding; transposition is carried out on the tail of the first turn of the second layer, the start end of the second turn of the second layer is bound with a beveled jointing paperboard strip after completing transposition, a spiral line wound at the second layer is formed, and the second turn of the second layer is completed through parallel winding of a lead and the beveled jointing paperboard strip; and the lead is wound with the rest of the second layer along the spiral line. According to the winding method, two layers of coils are taken as one unit, the coil transposition is carried out on the tail of the first turn of the second layer, the height of the coil formed by winding is one turn height smaller than the height of the coil formed by middle transposition winding, 3% of the total cost of the distribution transformer is reduced and the volume of the distribution transformer is decreased.

Owner:武汉振源电气股份有限公司

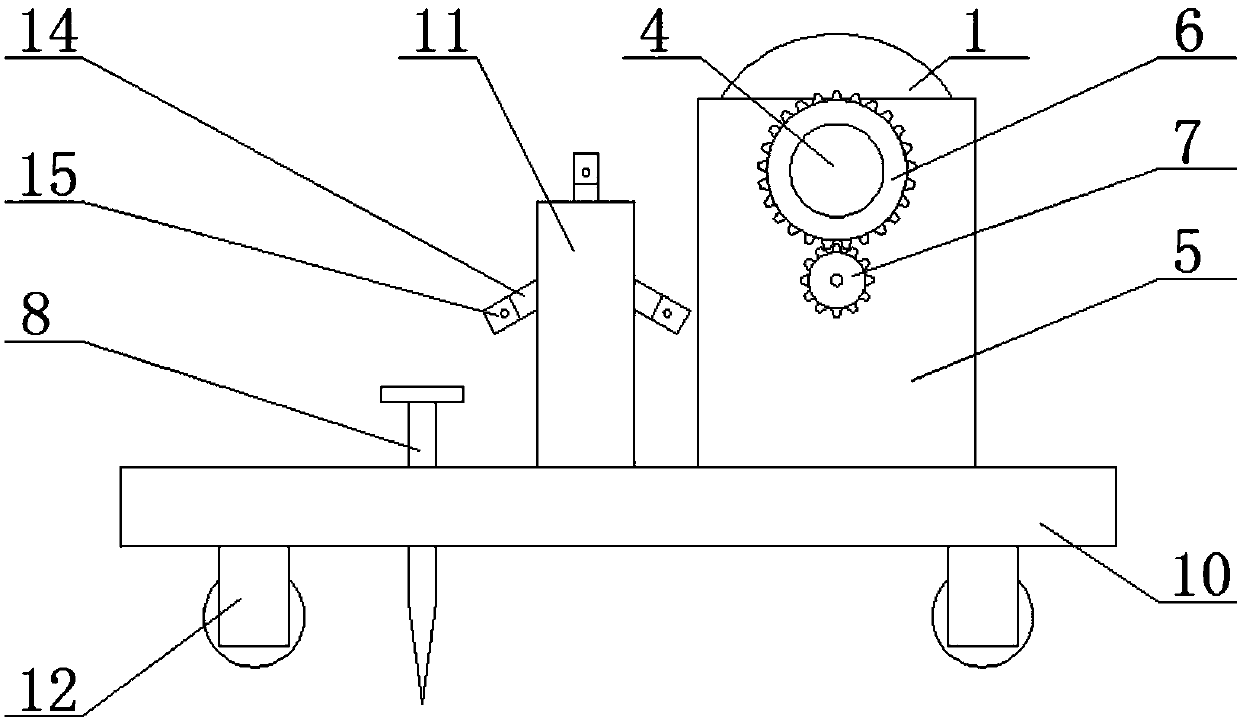

Cable stand for power construction

InactiveCN107804761AFast windingTightly woundApparatus for overhead lines/cablesEngineeringMechanical engineering

The invention discloses a wire frame for electric power construction, comprising a base, the upper end of the base is symmetrically fixedly connected with a first support and a second support, and a wire reel is arranged between the first support and the second support , the two ends of the reel are provided with annular baffles, the reel is penetrated with a first rotating shaft, the reel is fixedly sleeved on the first rotating shaft, and one end of the first rotating shaft rotates Connected in the second pillar, the other end of the first rotating shaft passes through the first pillar and is fixedly sleeved with a ring gear, the first rotating shaft is rotationally connected with the first pillar, and the side wall of the first pillar is provided with A motor is fixedly connected in the placement groove, and the end of the output shaft of the motor is fixedly sleeved with a gear corresponding to the position of the ring gear. The invention has simple structure and convenient operation, and can straighten the cable while using the motor to quickly take in and out the cable, so that the cable can be wound more compactly on the reel, saving time, labor and beauty.

Owner:CHENGDU LEYE TECH CO LTD

Electrically heatable liquid line

ActiveUS6996337B2Easy to manufactureHigh tensile strengthInternal combustion piston enginesExhaust apparatusLiquid lineAdhesive

An electrically heatable liquid line in which a heating wire is arranged on an inner plastic layer and an electrically insulating tape is helically wound around the plastic layer and the heating wire. This object is met in the liquid line of the above-type by providing the insulating tape as an adhesive tape whose adhesive can be glued to the plastic layer.

Owner:NORMA GERMANY GMBH

Winding and tightening device of fabric cloth

The invention discloses a winding device for textile cloth, which comprises a base, a motor is fixedly installed on the top of the base, and a winding box is fixedly installed on the top of the base and behind the motor through bolts, and the two sides of the winding box All are in the shape of openings, the output end of the motor runs through the winding box and is fixedly connected to one end of the rotating shaft, and the other end of the rotating shaft is movably connected to one side of the inner wall of the winding box through a shaft seat. In the present invention, by setting the placement box, the rotating rod is passed through the loosely wrapped drum to the plugboard, and then the plugboard is put into the placement box. After the plugboard is put into the placement box, the motor is started, and when the motor is working, The fabric will be separated from the slack roller and wound onto a new roller. When the fabric is detached from the slack roller, the rotating rod will be rotated, and the resistance generated by the cooperation of the rotating wheel and the fixed block will tighten the fabric. This makes the fabric more compact when wound on the new drum.

Owner:梅明会

Automatic winding machine

PendingCN110504100ATightly woundWinding tightly and orderlyCoils manufactureWinding machineWire cutting

The invention discloses an automatic winding machine. The automatic winding machine comprises a machine frame, which is provided with a rotary motor, a portal frame, a mechanical arm, and a tray support. The tray support is connected with a rotary table in a driving way, and the rotary table is provided with a winding head, which is provided with a work piece accommodating groove. The tray supportis disposed on the right side of the rotary table, and the portal frame is provided with a forward and backward translation device, which is connected with a forward and backward translation plate ina driving way. The forward and backward translation plate is provided with a left and right translation device, which is connected with a left and right translation plate in a driving way. The left and right translation plate is provided with an elevating driving device, which is connected with an elevating plate in a driving way. The elevating plate is provided with an upper wire cutting assembly, a wire leading assembly, and wire clamping assembly. A lower part of a winding head is provided with a lower wire cutting assembly. The winding efficiency is improved, and the winding is stricter and ordered, and the quality is higher.

Owner:广东昭信智能装备有限公司

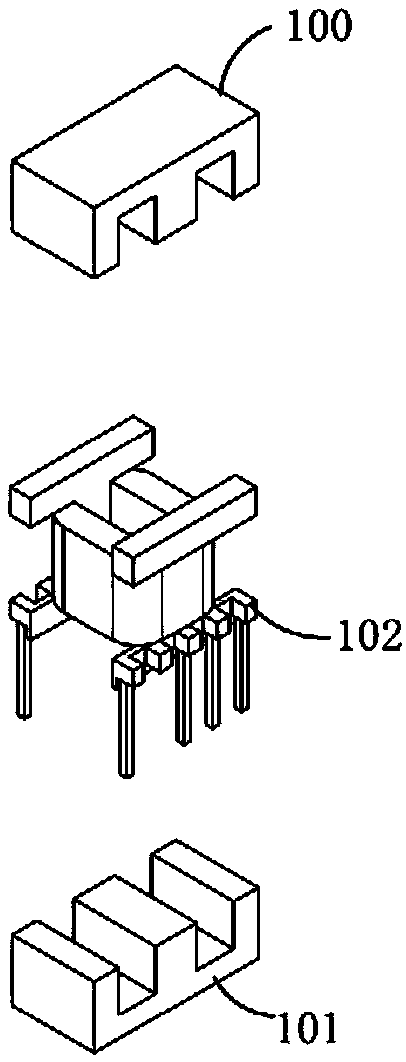

Fixing device of coil framework of miniature transformer and method for winding coils

ActiveCN102420044ATightly coupledTightly woundTransformers/inductances coils/windings/connectionsCoils manufactureTransformerSteel ball

The invention relates to a fixing device of a coil framework of a miniature transformer and a method for winding coils. The fixing device of the coil framework consists of five parts, namely a framework fixing shaft, metal springs, steel balls, a tap fixing shaft, a tap fixing pin group and a connection shaft. A transformer framework is fixed and multi-winding taps are led out and fixed, the winding level of the miniature transformer is improved, and a method which is simple, high in efficiency, high in reliability and wide in application is provided for winding of the transformer. By adoption of the fixing device, the method for winding the coils is also improved. By performing the steps of installing a winding fixing device of the miniature transformer, installing the coil framework, winding the coils and fixing winding taps, the method has the advantages that: the winding efficiency of the miniature transformer is improved; the rate of finished products is improved from about 60 percent to above 95 percent, so that wasting is avoided; a transformer manufacturing process is simple and easy to operate; manufacturing efficiency is at least doubled; and the method is wide in application.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

Inhaler

An inhaler is proposed for dispensing a powdered inhalation formulation from a blister strip with a multiplicity of blister pockets. The used part of the blister strip with emptied blister pockets is wound up by a watch spring or is pushed into a helical channel. A simple structure is thus permitted, wherein the used blister strip is separtaed from the still unused part.

Owner:BOEHRINGER INGELHEIM INT GMBH +1

Winding-uniform textile fiber winding device

InactiveCN107399638AEasy to transport and storeAvoid shakingFilament handlingTextile fiberEngineering

The invention discloses a textile fiber winding device with uniform winding, which comprises a base, a winding device is fixedly installed on the top of the base, a servo motor is fixedly installed on the top of the base, and the servo motor is located at the front of the winding device. On the surface, the top of the base and one side of the winding device are fixed with an adjustment mechanism through bolts, and the winding device includes a fixed block. In the present invention, through the cooperation of the servo motor, the winding device and the adjustment mechanism, the servo motor is started to drive the winding device to work, so that the textile fibers are wound on the winding drum, and through the reduction motor on the adjustment mechanism, the threaded rod and the nut Cooperate, so as to control the movement of the textile fiber, so that it can be evenly wound on the winding drum, and due to the cooperation of the tension rod, the rotating wheel, the lifting rod and the spring, the textile fiber is wound on the winding drum, which is more compact .

Owner:姚飞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com