Full-automatic production line and process of inductor

A fully automatic, production line technology, applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve problems such as low production efficiency, and achieve high production efficiency, increased rotational resistance, reliable assembly and winding quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

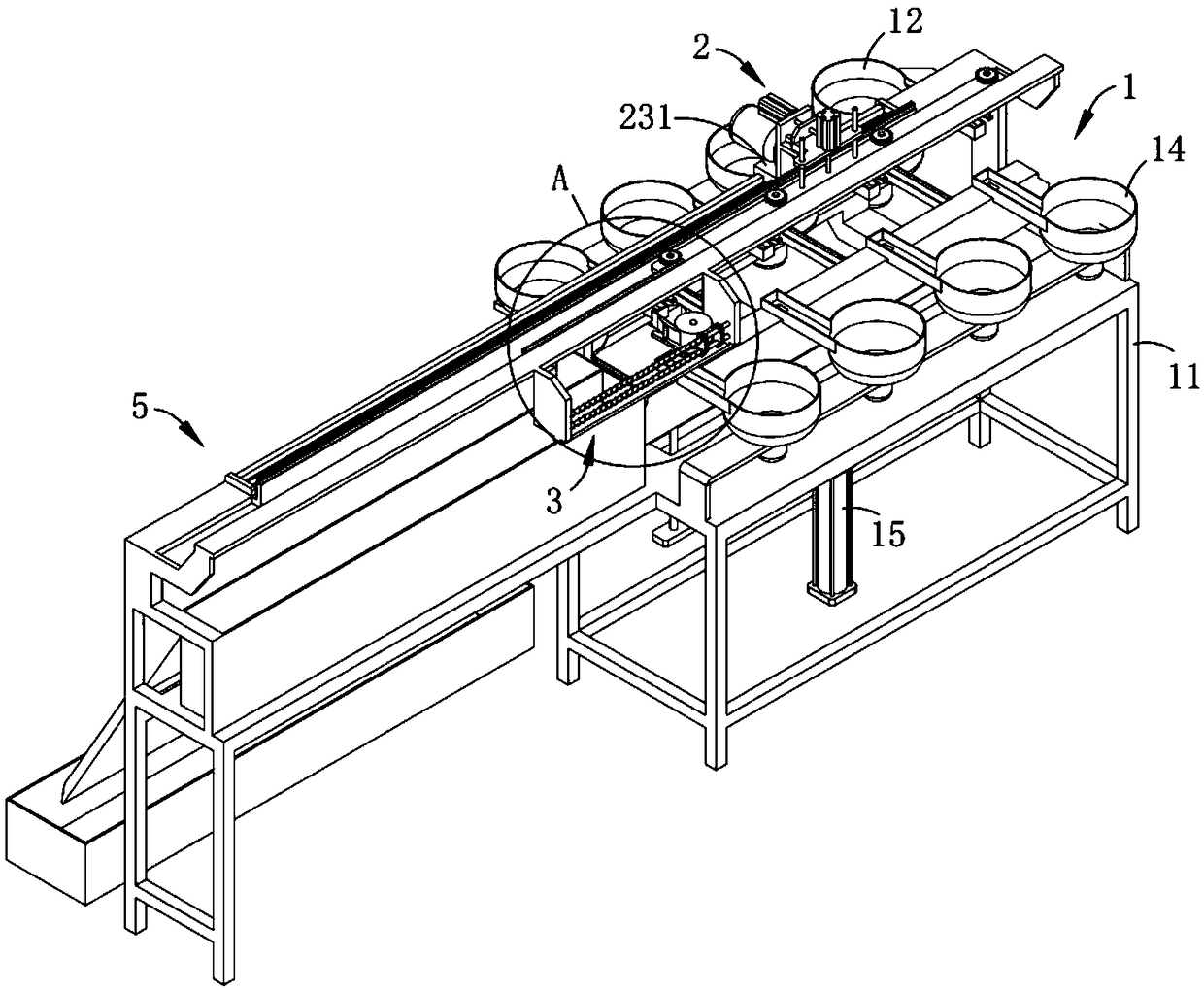

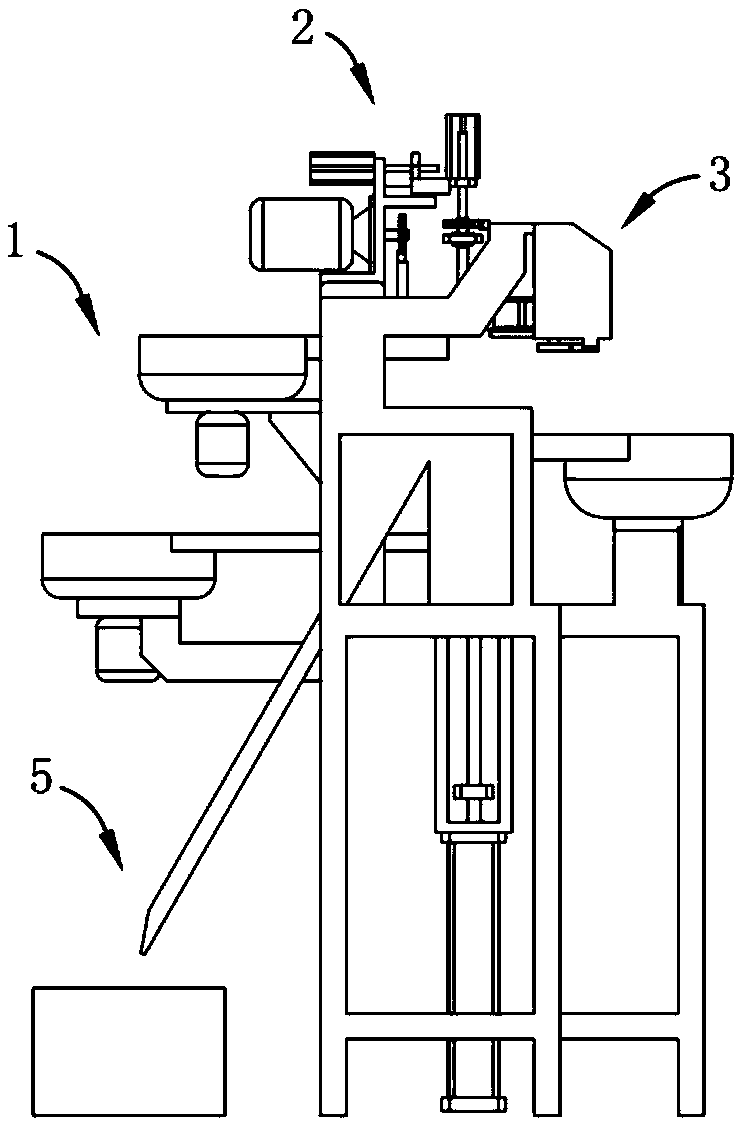

[0046] Such as figure 1 , 2 , 3, 4, 5, 6 and 7, a fully automatic production line for inductance, including:

[0047] Assembling mechanism 1, described assembling mechanism 1 comprises frame 11, is arranged on this frame 11 and the sorting component A12 that is arranged on this frame 11 and distributes sequentially from top to bottom, sorting component B13, sorting component C14 and is arranged below described sorting component C14 and The jacking assembly 15, the assembly area 16 is formed above the jacking assembly 15; the so...

Embodiment 2

[0058] Such as Figure 9 and 10 As shown, the parts that are the same as or corresponding to those in the first embodiment adopt the reference numerals corresponding to the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below; the differences between the second embodiment and the first embodiment The location is: the film winding mechanism 3 also includes a film release assembly 36 arranged on the carrier 31 , the film release assembly 36 is located below the placement seat 321 , and it includes a set coaxial with the positioning column 322 And the friction wheel 361 that is fixedly connected, and the friction block 362 that is located on one side of the friction wheel 361 and is in intermittent contact with it; when working, when the placement component 32 is driven by the positioning part 213 to move along the output direction of the assembly body 10, through The friction block 362 is in contact with the friction w...

Embodiment 3

[0063] According to the manual attached Figure 12 A fully automatic production process for inductors in this embodiment is described.

[0064] The present invention also provides a fully automatic production process for inductors, comprising the following steps:

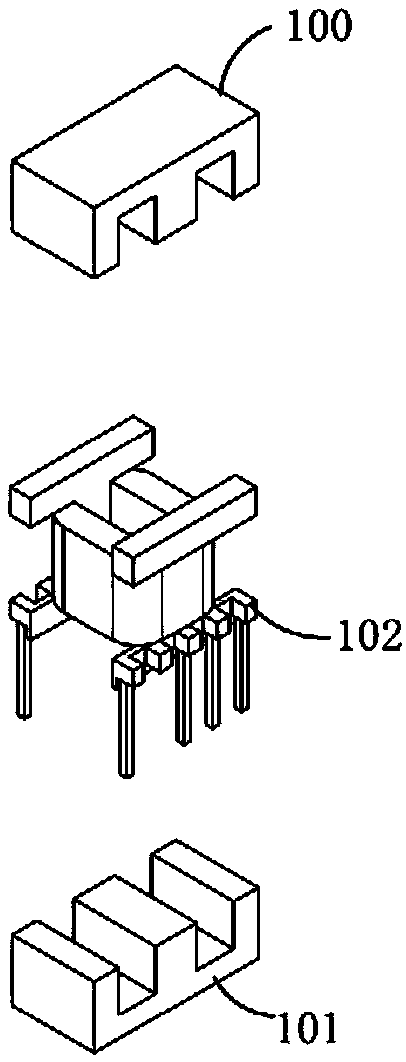

[0065] (a) Sorting part, the magnetic core A100, the magnetic core B101 and the coil body 102 are sorted sequentially through the sorting component A12, the sorting component B13, and the sorting group C14 respectively;

[0066] (b) Assembling part, after step a, move down the positioning slot 2133 on the positioning assembly 21 to magnetically absorb the magnetic core A100 into the positioning slot 2133 and then move up, and then move up through the telescopic assembly 22 The magnetic core A100 is translated to the top of the jacking assembly 15, and the magnetic core B101 and the coil body 102 are sequentially pushed into the magnetic core A100 by the jacking assembly 15 from bottom to top to fit with it, forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com