Patents

Literature

1602results about "Organic fertiliser apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

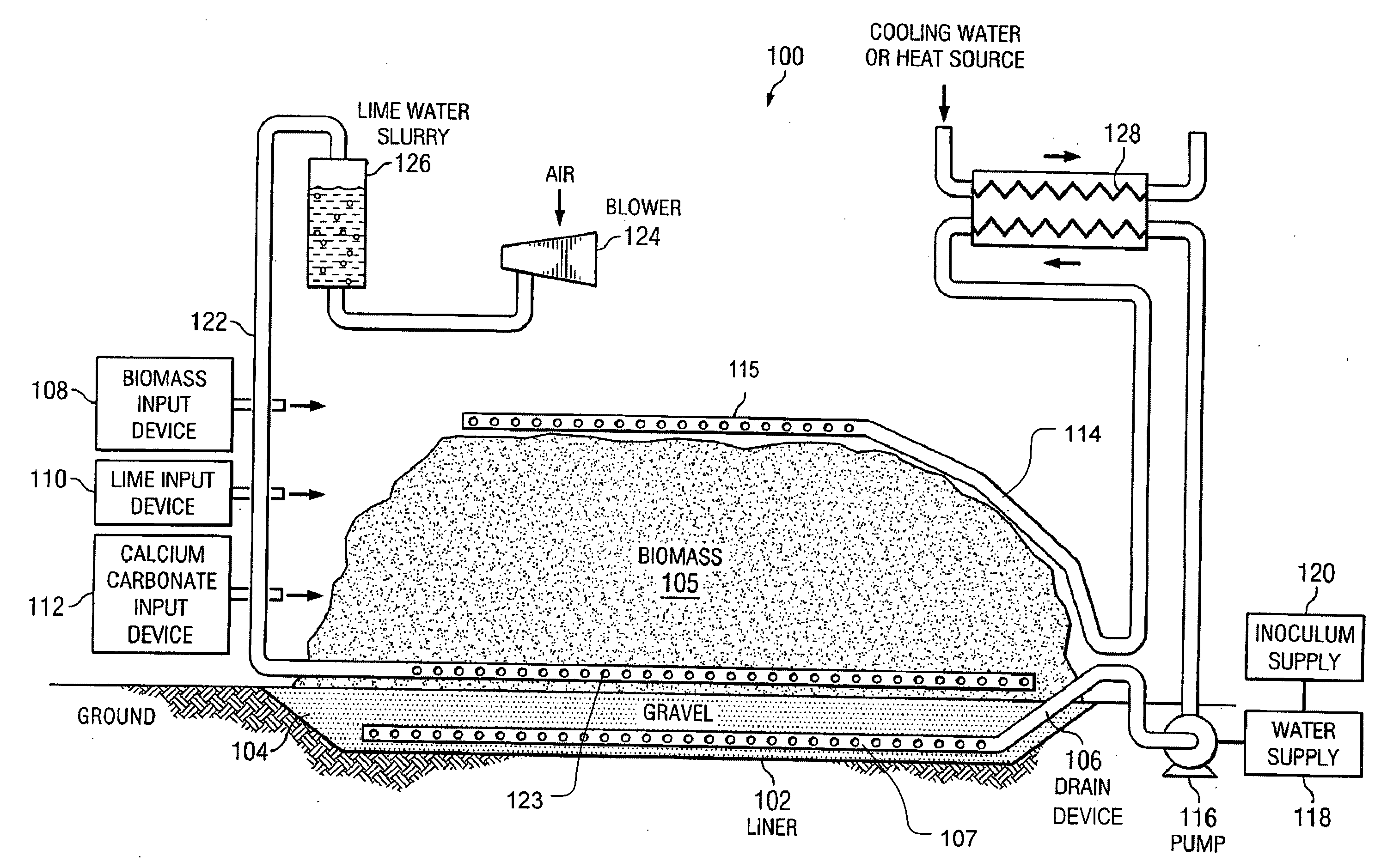

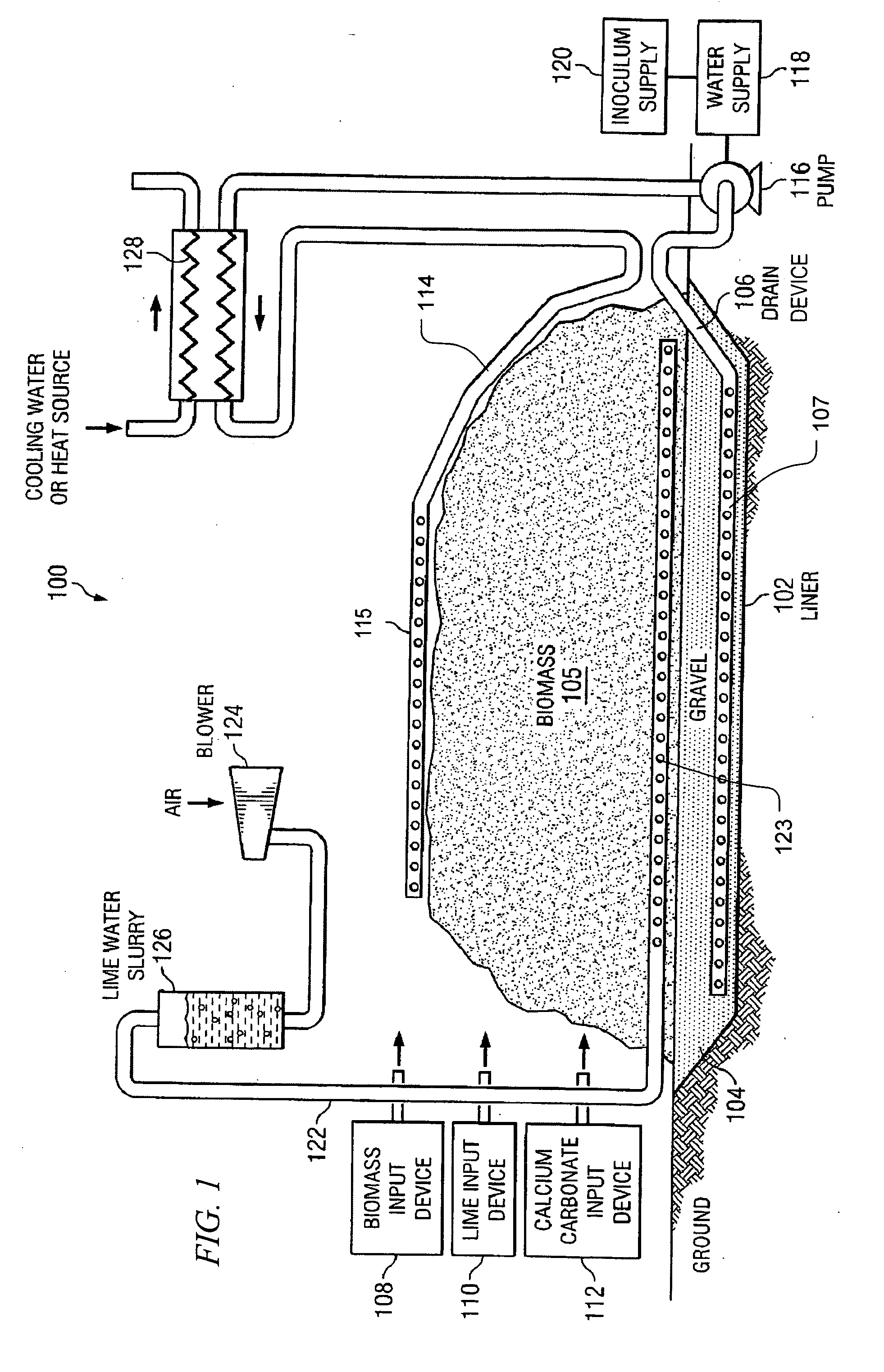

System and method for processing biomass

InactiveUS20060188980A1Low costBioreactor/fermenter combinationsBio-organic fraction processingEngineeringFluid input

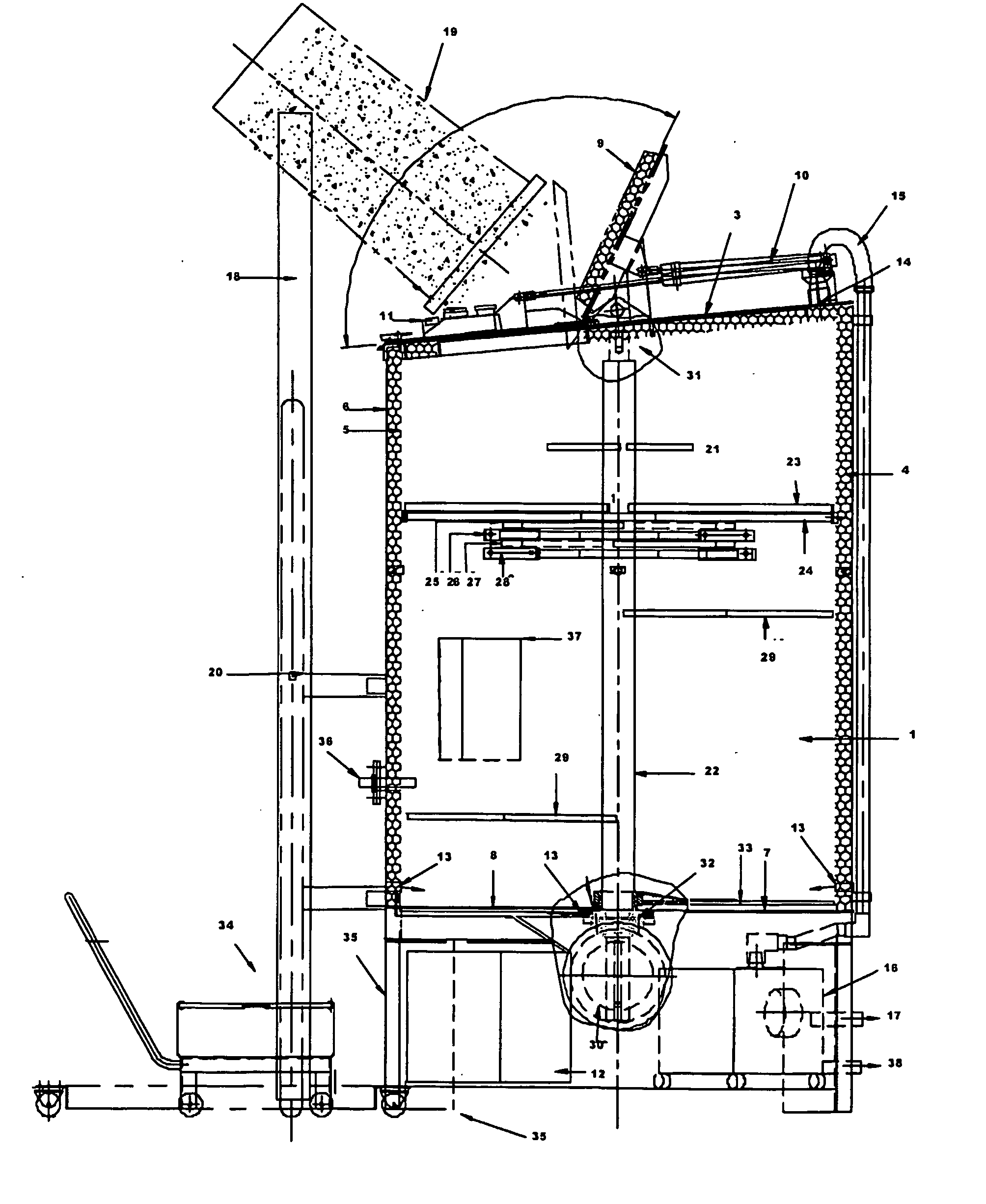

According to one embodiment of the invention, a system for processing biomass comprises a chamber, a biomass input device, a fluid input device, and a retrieval device. The chamber is defined by at least a bottom, at least one wall, and a cover supported by the at least one wall. The biomass input device operable to deliver biomass into the chamber to form a biomass pile. The fluid input device is operable to deliver fluid into the chamber to the biomass pile. The retrieval device operable to receive fluid from the chamber.

Owner:TEXAS A&M UNIVERSITY

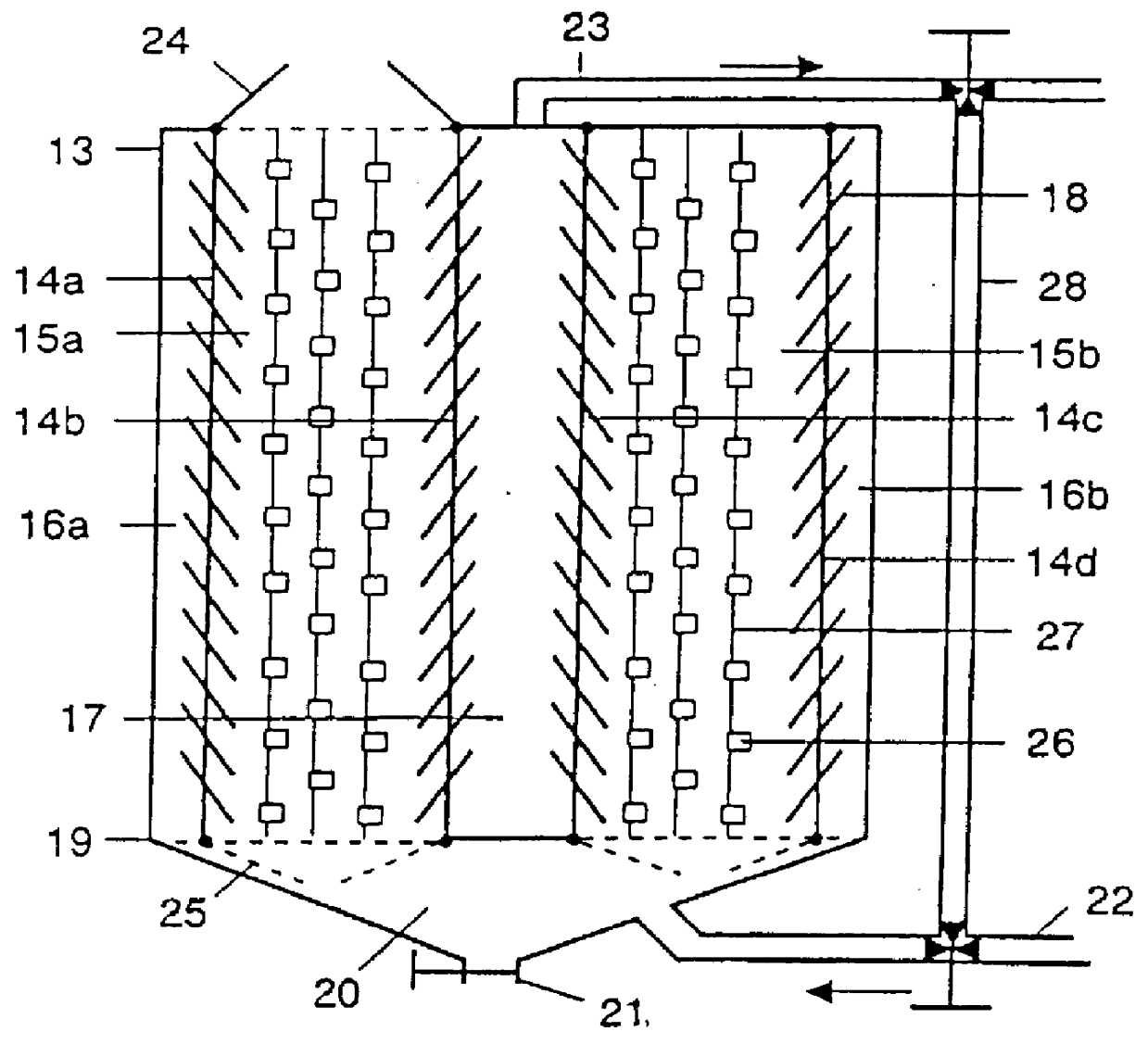

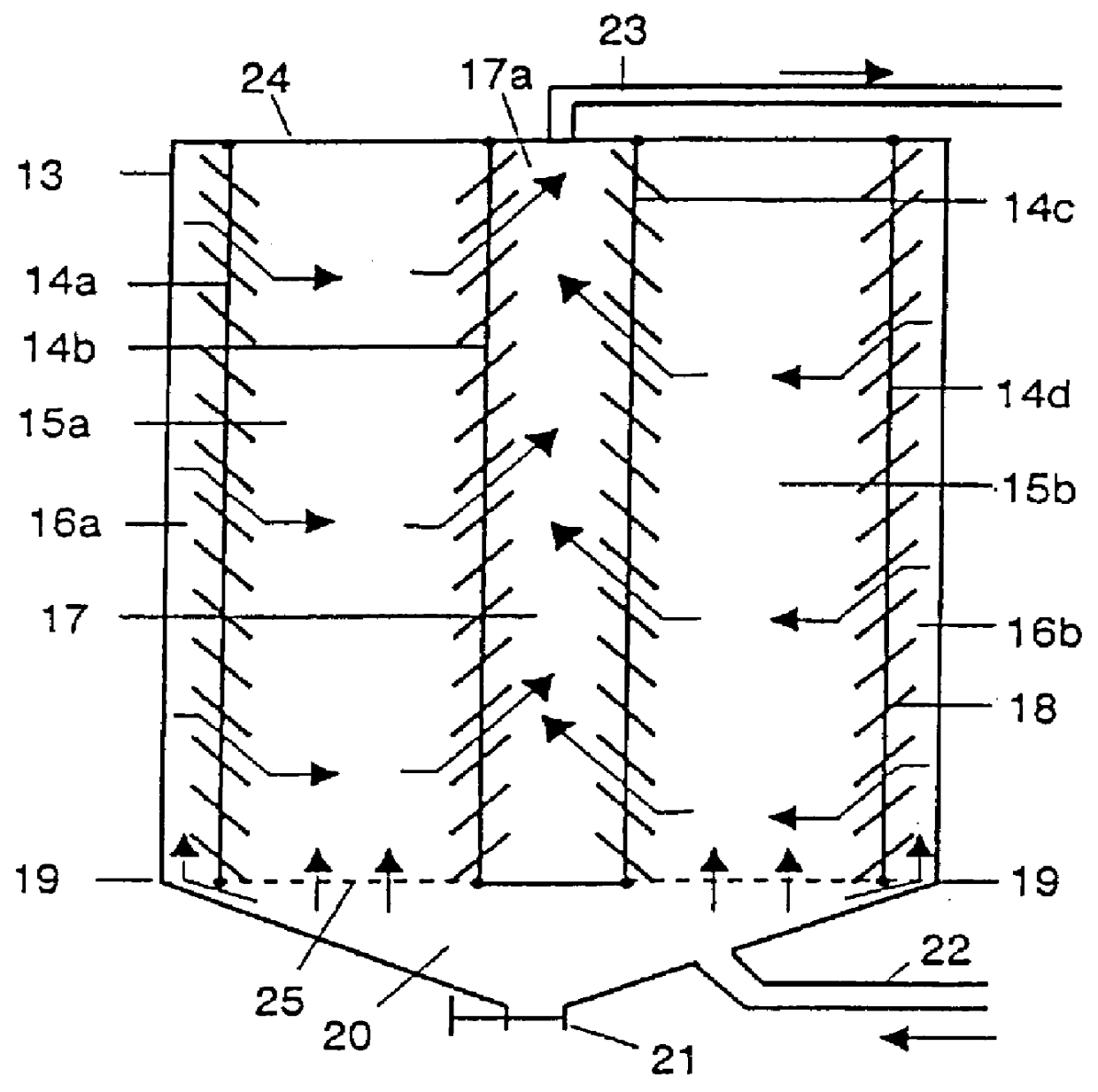

Device and process for the aerobic treatment of organic substances

InactiveUS6065224ABio-organic fraction processingDrying solid materials with heatEngineeringVenetian blinds

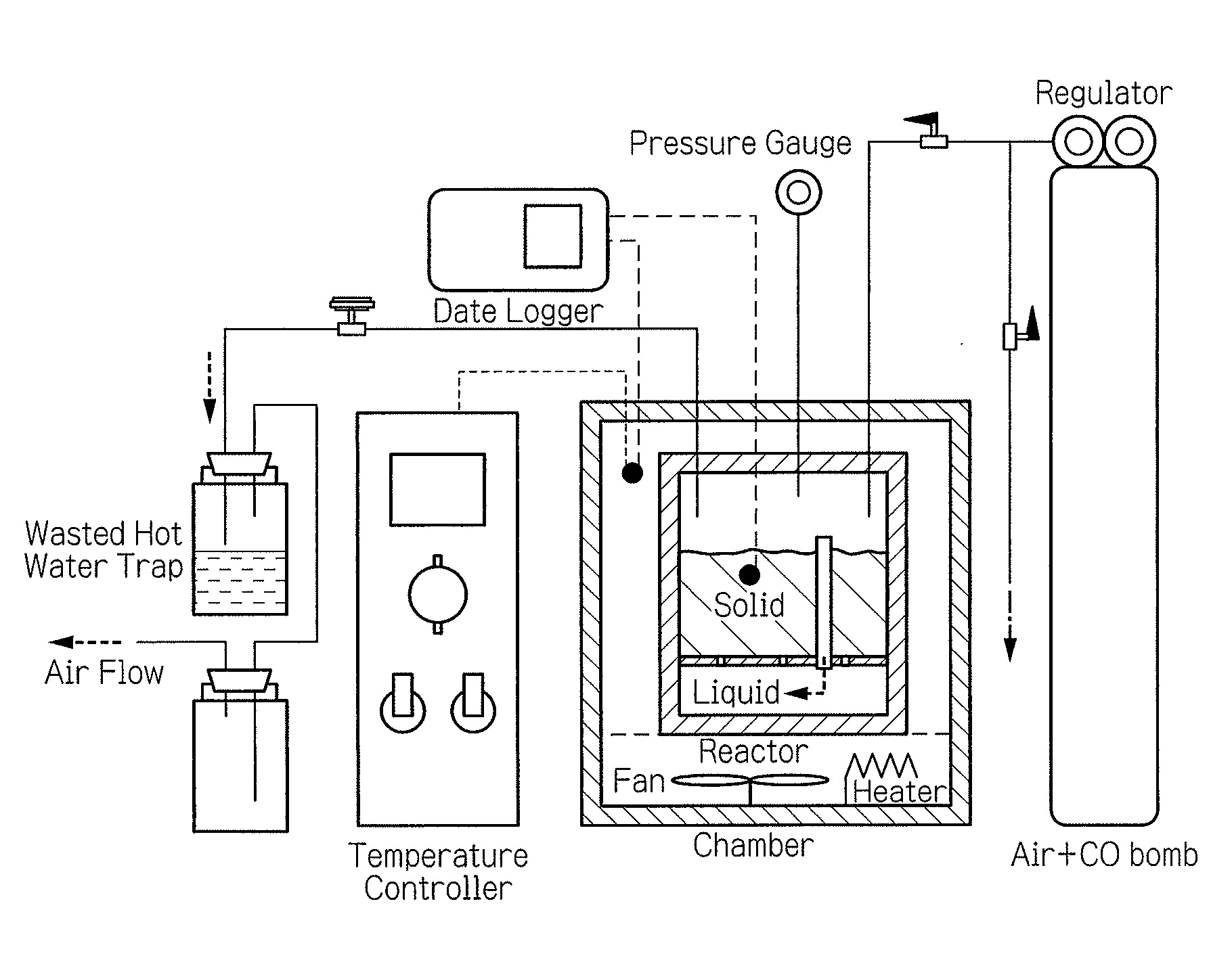

PCT No. PCT / EP96 / 00110 Sec. 371 Date Jul. 10, 1998 Sec. 102(e) Date Jul. 10, 1998 PCT Filed Jan. 11, 1996 PCT Pub. No. WO97 / 25295 PCT Pub. Date Jul. 17, 1997A device for the aerobic treatment, conditioning and / or drying of moist, substantially solid or paste-like, at least partly organic material, has a vessel containing paired, Venetian-blind-like walls, with adjustable blades, forming at least one reaction chamber, at least one air inlet chamber and at least one air discharge chamber, and containing supports which are in spatially staggered array inside the reaction chamber in such a way that they provide the best possible pressure relief for the filling. The invention also relates to a process using said device.

Owner:INTERLICENSE DEN HAAG

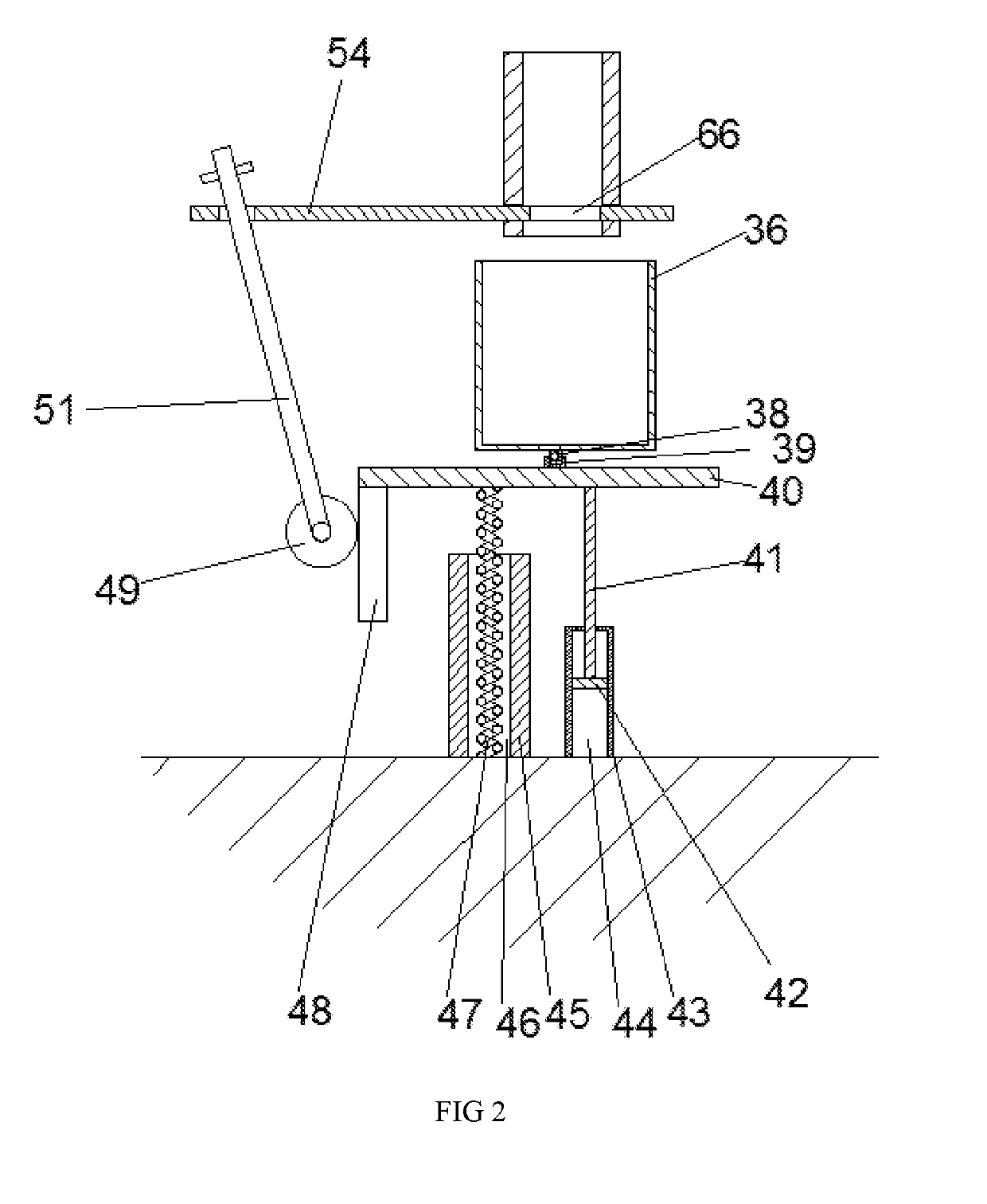

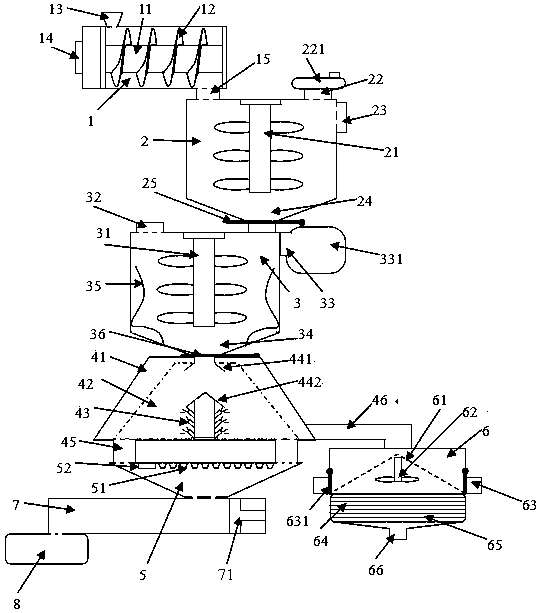

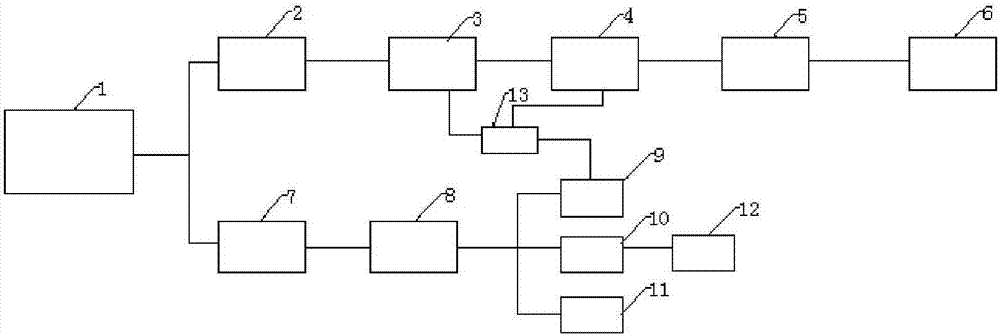

Method and device for high-temperature rapid fermentation on agricultural waste to produce organic fertilizer

ActiveCN104609916ANo secondary pollutionNo smellBio-organic fraction processingOrganic fertiliser apparatusAutomatic controlMicrobial agent

The invention discloses a method and a device for high-temperature rapid fermentation on agricultural waste to produce an organic fertilizer. The device comprises a material storage system, a heating system, a stirring system, a dehumidification and biodeodorization system, an oxygenation system, a feeding and discharging system and electric automatic control systems, wherein the material storage system comprises a U-shaped fermentation tank and an overall rack; the heating system comprises a heating insulating jacket, heat-conducting oil and an electric heating tube; the stirring system comprises a gear motor, a stirring shaft and a dual-layer spiral mixing blade; dehumidification and biodeodorization system comprises a dehumidifier and a biodeodorization filter material; the oxygenation system comprises an air compressor and an oxygen delivery pipeline; the feeding and discharging system comprises a feeding hole and a discharge hole; the electric automatic control systems of various units are uniformly connected to an electric control box. According to the method and the device, agricultural waste and thermophilic composite microbial agents can be evenly stirred and mixed, and are rapidly heated, so that the temperature in the device reaches 80-100 DEG C; harmful microorganisms and pathogens in the waste can be effectively inactivated; meanwhile, the activity of the thermophilic composite microbial agents is activated; and the organic fertilizer product is produced within 9 hours.

Owner:天津市生态环境科学研究院

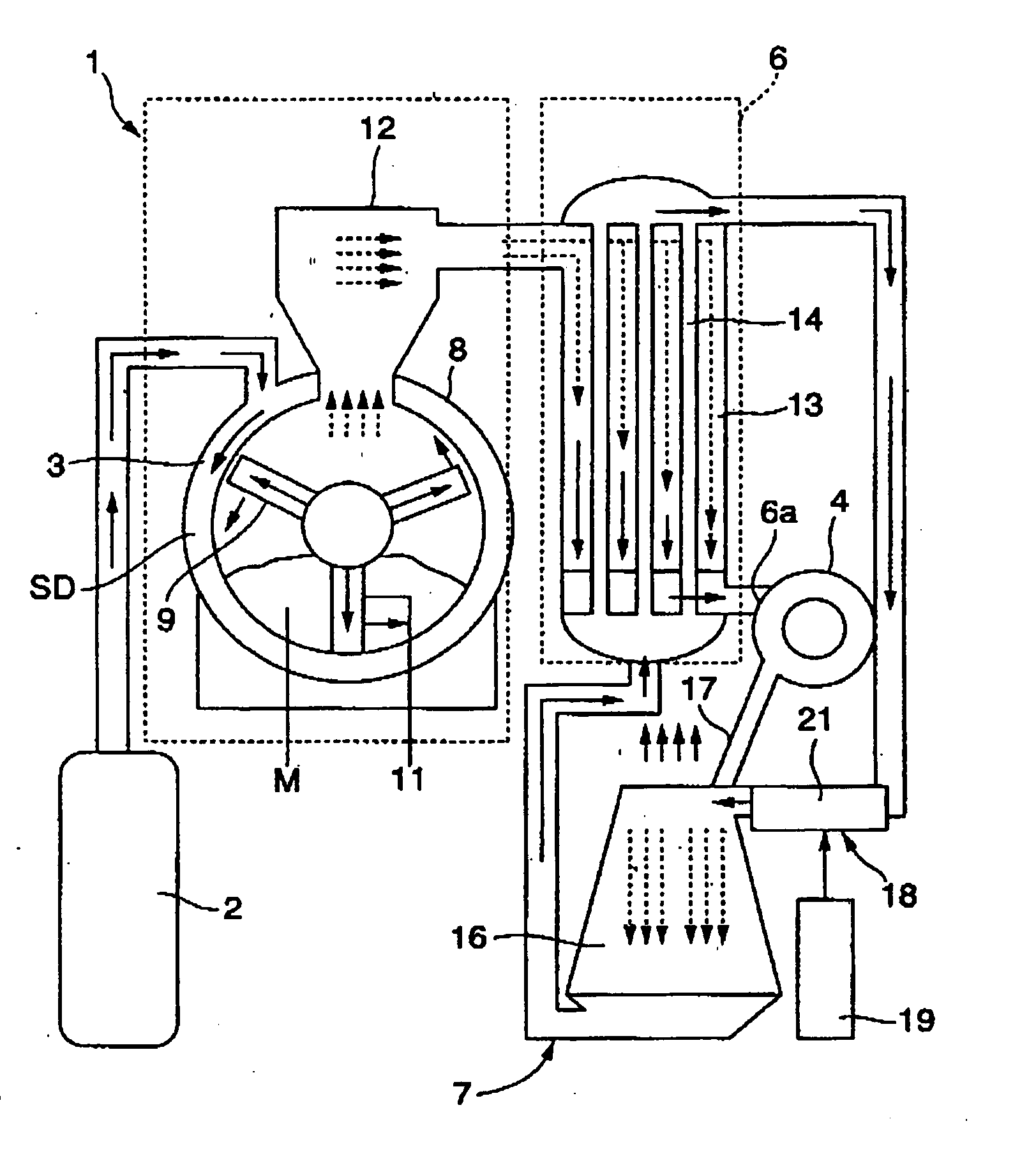

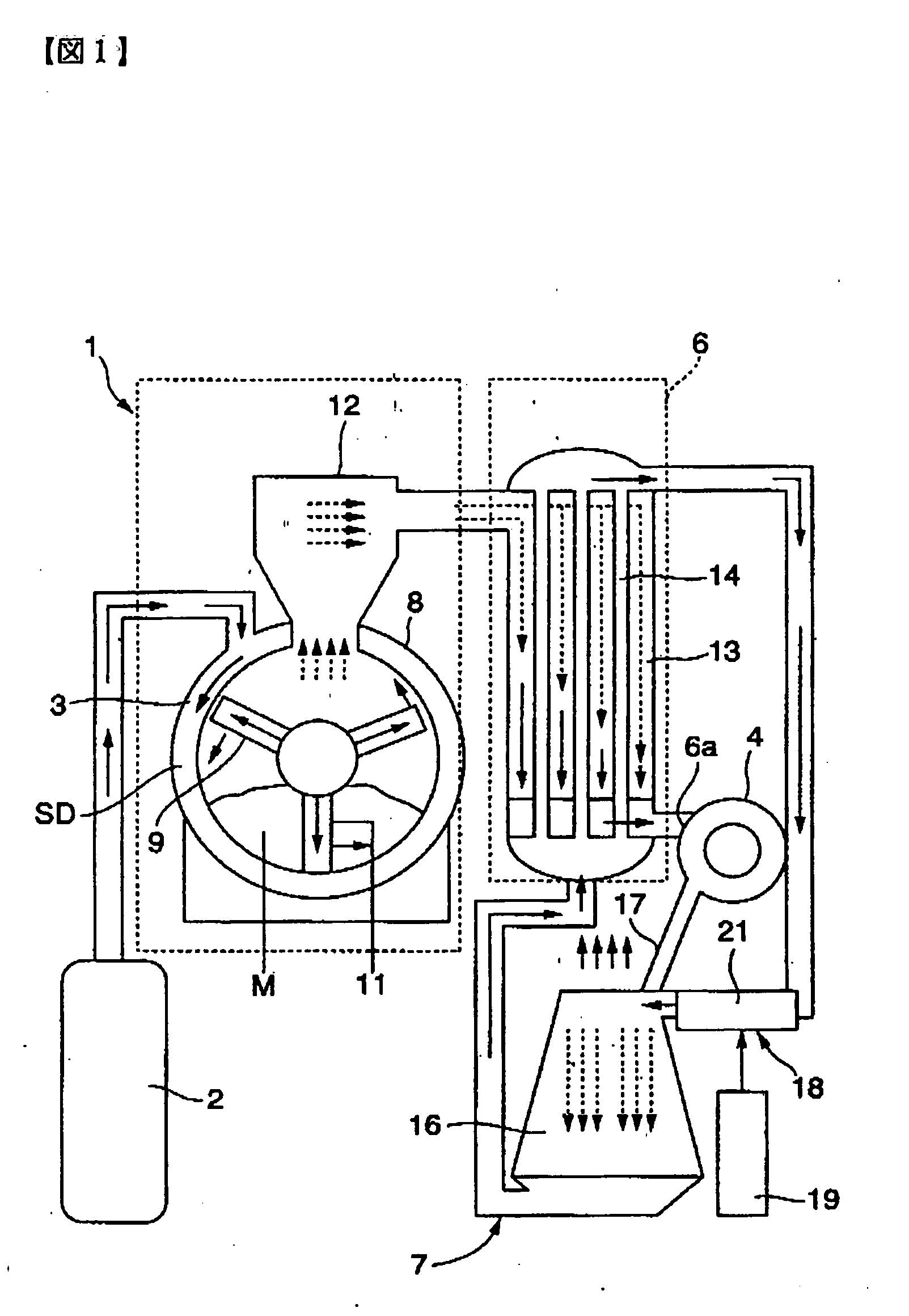

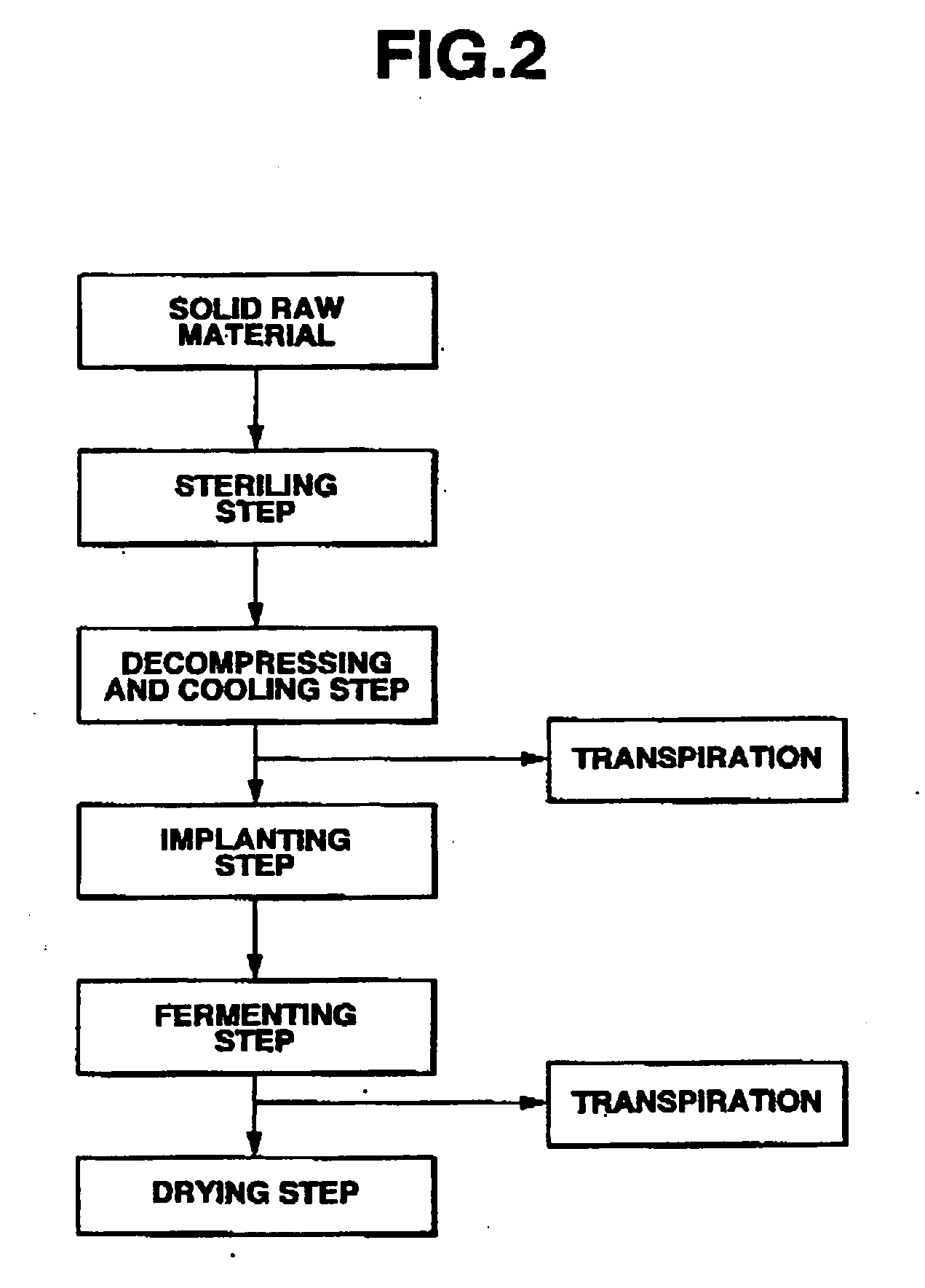

Method and apparatus for producing organic fertilizer

InactiveUS20050044911A1Short timeImprove efficiencyBioreactor/fermenter combinationsBio-organic fraction processingBoiling pointDecomposition

Disclosed is an manufacturing method of organic fertilizer of the present invention, wherein moisturized organic wastes and microbe, which decomposed organic materials so as to compost, are mixedly contained in a container (3) which can be sealed but also freely opened and closed, the container (3) is heated as well as decompressed by closing the container (3), the boiling point of water in the container (3) is set below the fermentation heat of the organic wastes caused by the microbe in decomposing the organic materials, and the moisture in the organic wastes in the container (3) ins vaporized and exhausted, whereby an organic fertilizer is manufactured by the decomposition of the organic materials. Thereby, a technique where the process to manufacture the organic fertilizer from organic wastes is efficiently conducted in a short period of time is provided.

Owner:JAPAN NOBLE SYST

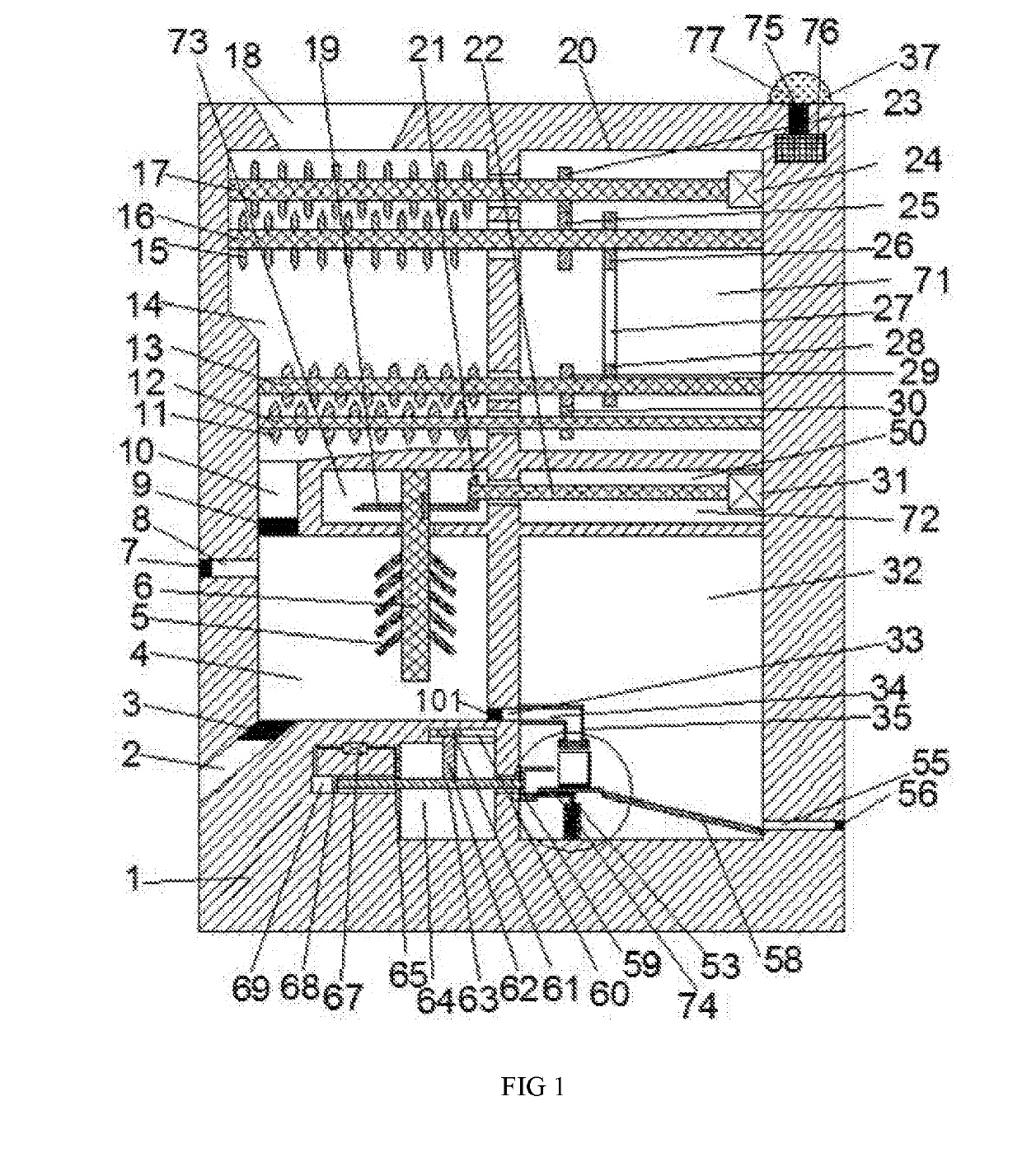

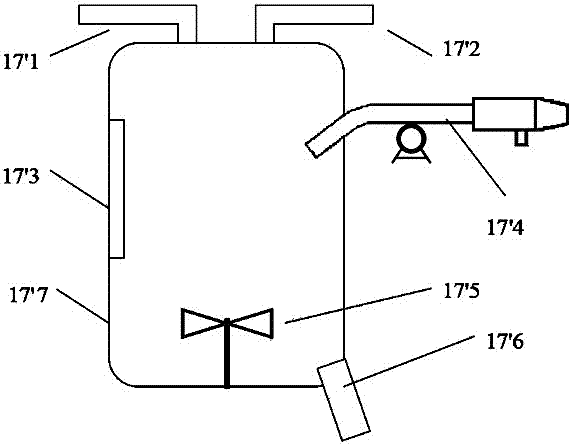

Environmentally Friendly Fertilizer Device Based on Big Data

ActiveUS20190135709A1Simple structureEasy to operateBio-organic fraction processingProductsEngineeringMechanical engineering

The invention discloses an environmentally friendly fertilizer device based on big data, comprising a work box and a crushing space set in the work box, wherein a crushing driving space is set in one end wall of the crushing space, wherein a crushing mechanism is set in the crushing driving space; by turning on a first electromagnetic switch, the kitchen garbage enters the crushing space from the feed inlet, so the kitchen garbage is crushed by the crushing space. A transmission space is arranged in the lower end wall of the crushing space, and a driving space is set in the lower end wall of the crushing driving space; a stirring space is set in the lower end wall of the transmission space; the crushed kitchen garbage enters the stirring space through a circulation pipeline and is stirred by the stirring mechanism, thereby the kitchen garbage can be fully fermented.

Owner:GE GUOSONG

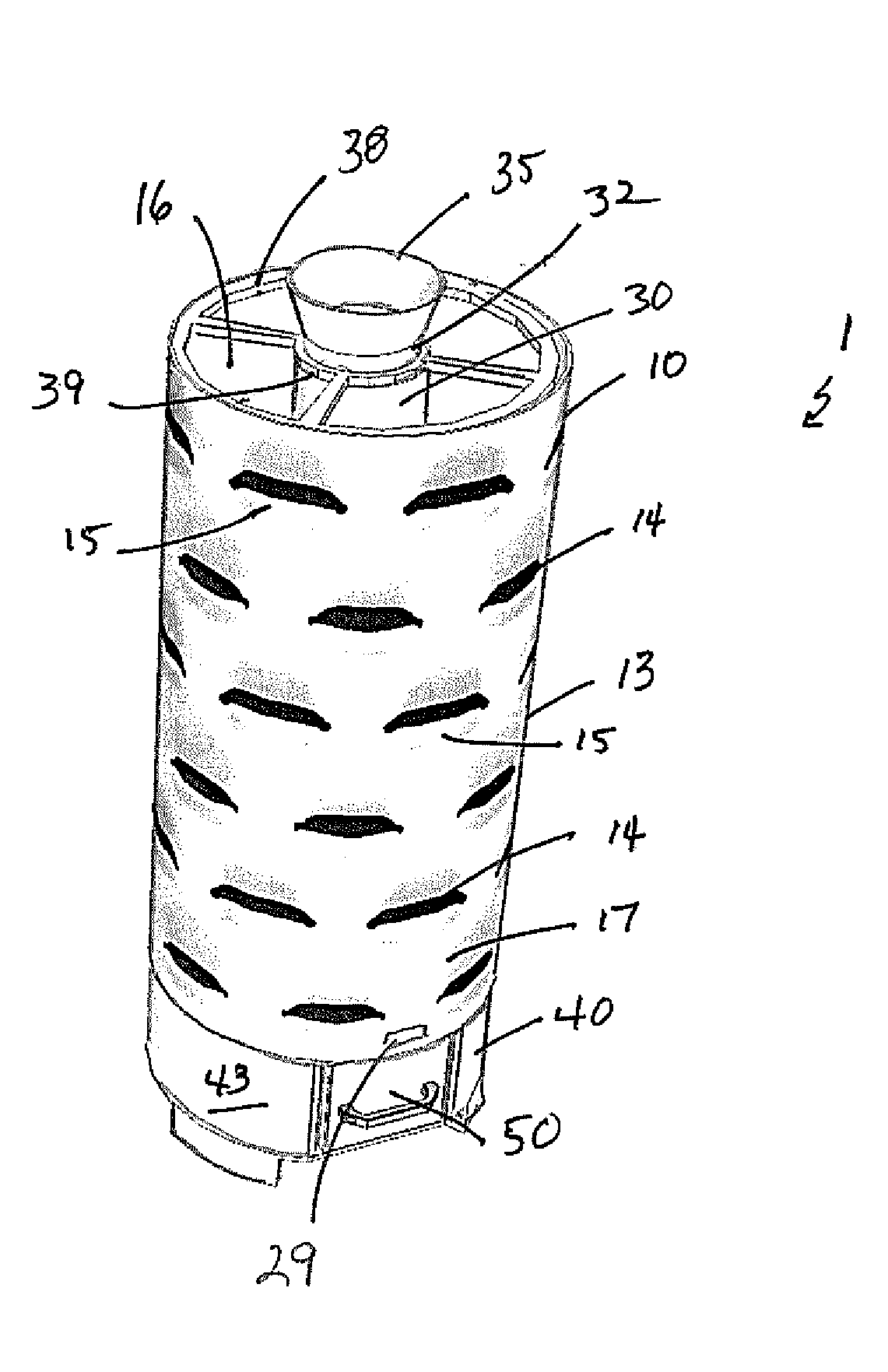

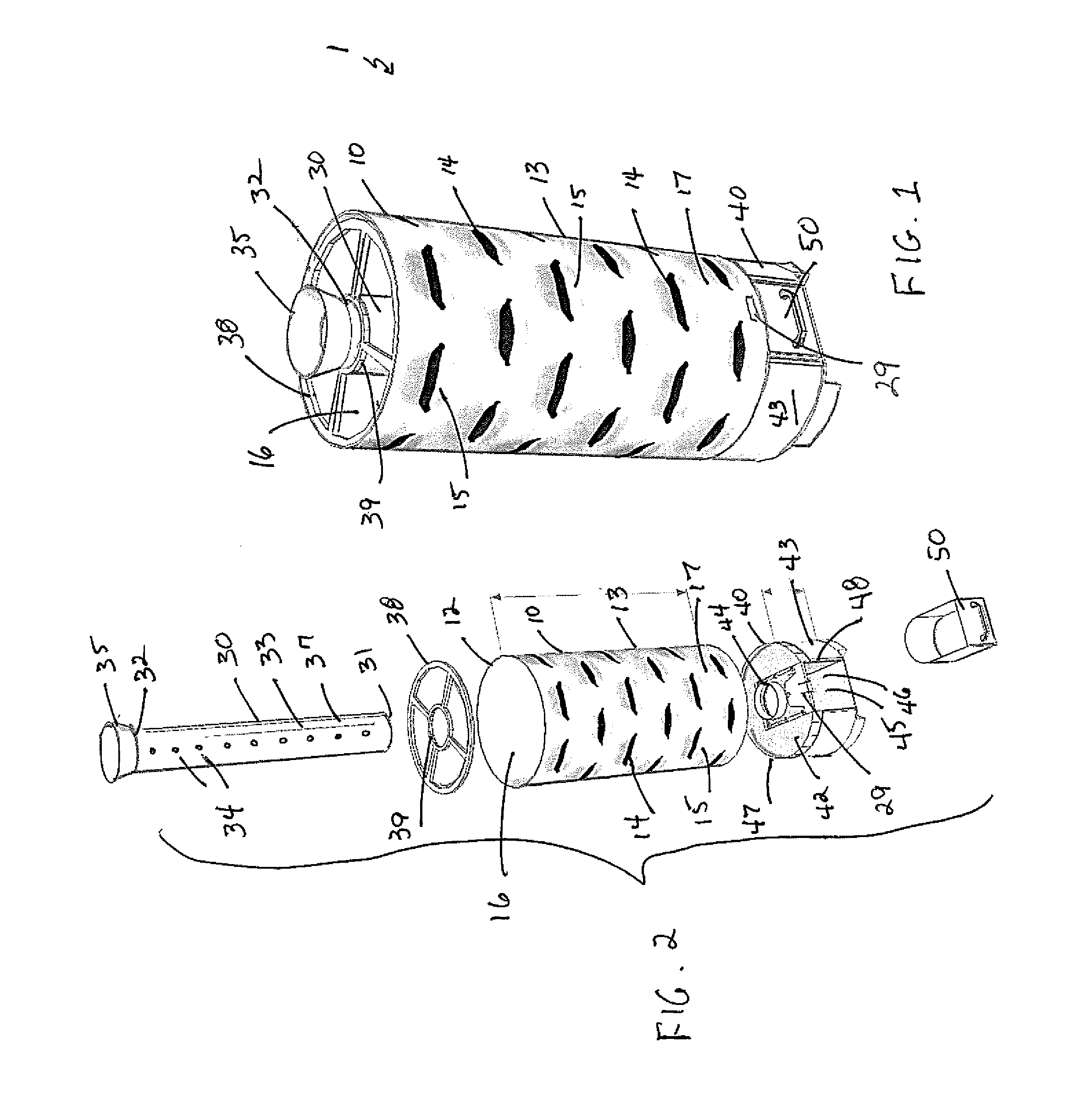

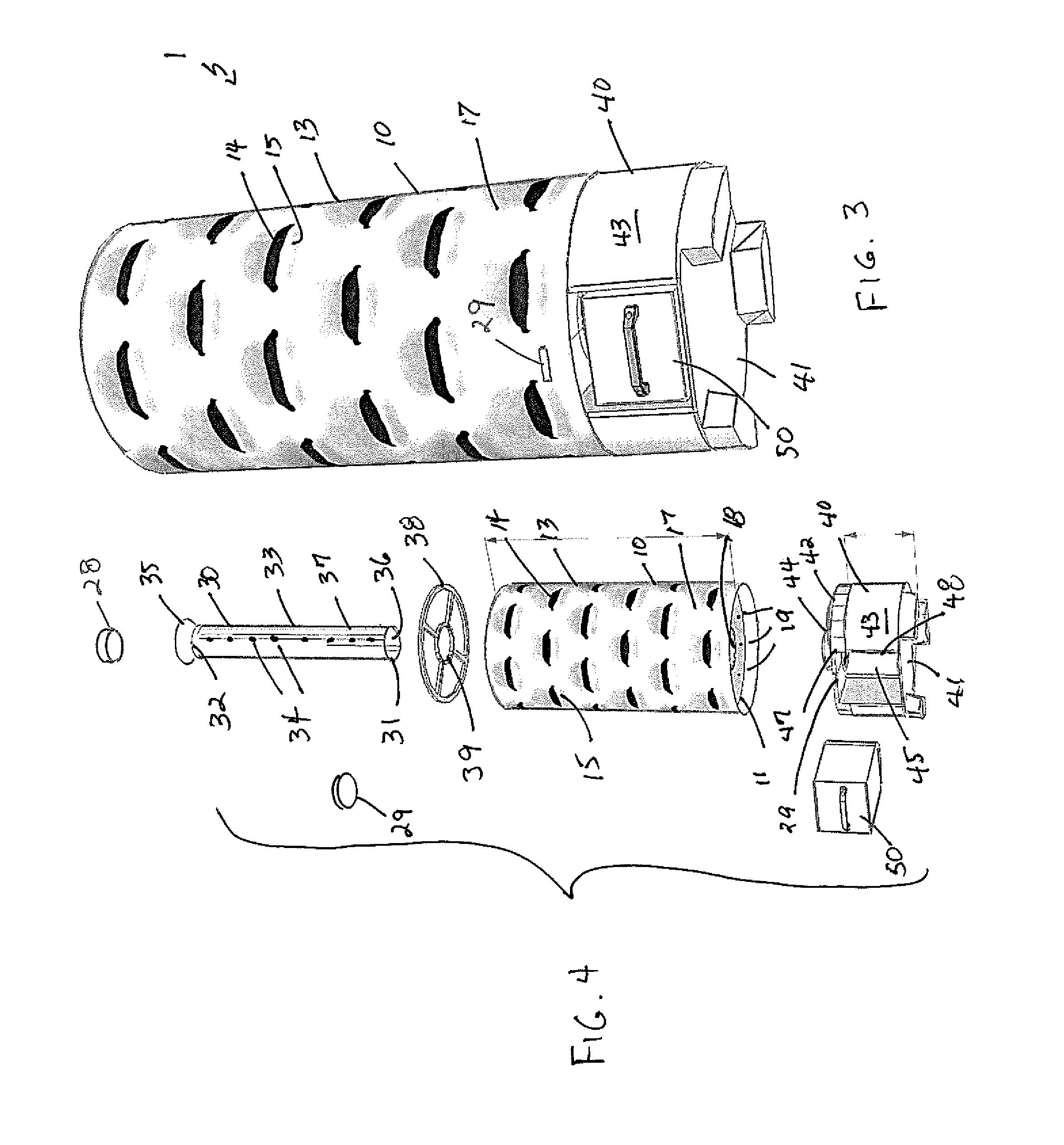

Composting Garden Container

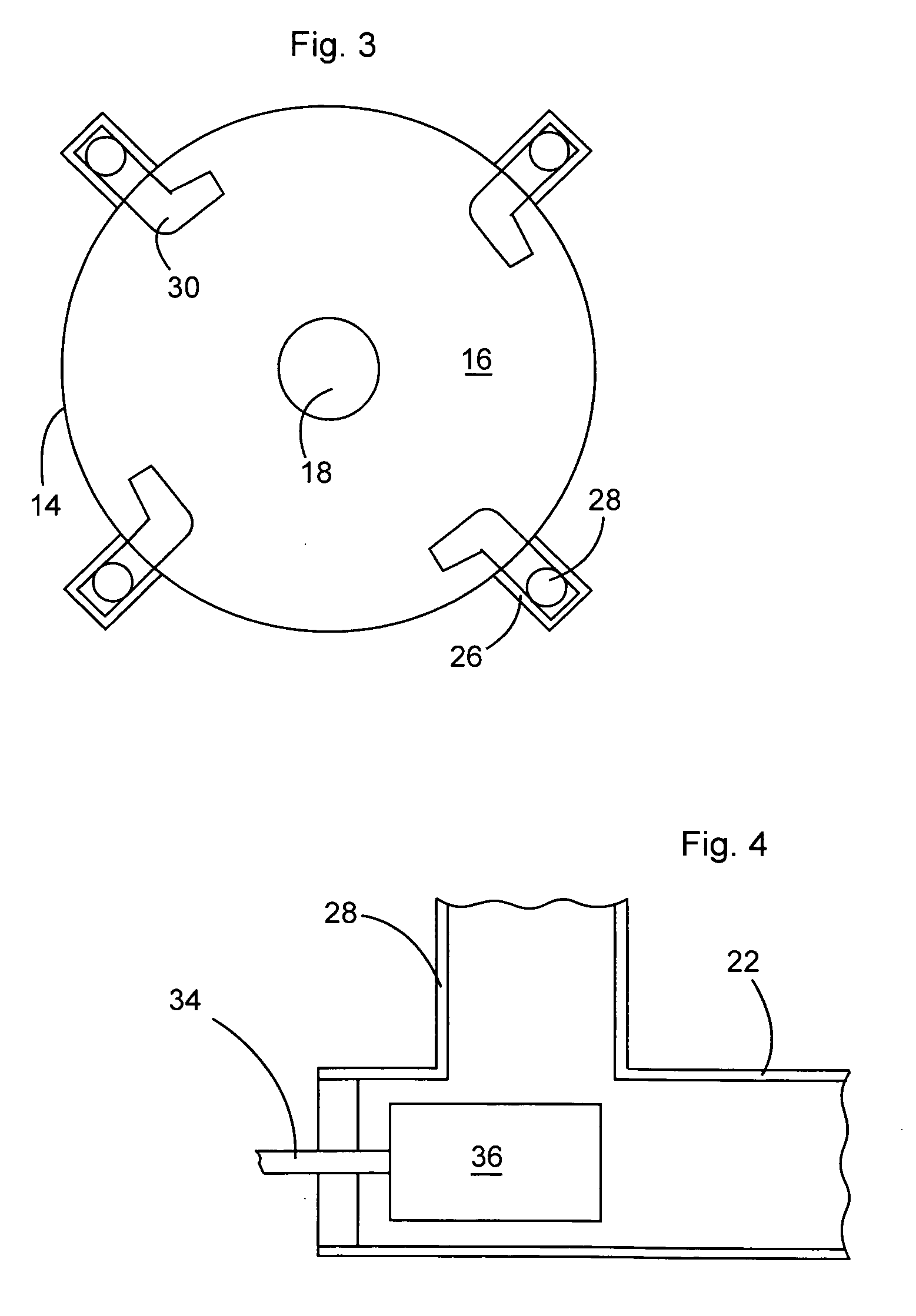

A planter in the form of a tower planter having an internal vertical composting capability is provided. The planter has a hollow, vertical, outer cylindrical barrel with a plurality of openings formed about its cylindrical side. A hollow inner cylindrical composting tube having a plurality of perforations formed in its cylindrical wall is provided. The space formed between the inner tube and barrel wall is filled with growing medium. The inner tube is filled with compost material. A removable container is placed at the bottom of the tube and barrel, said container adapted to capture water draining out from the tube and barrel, as well, as periodically receiving compost from the compost tube.

Owner:CUDMORE COLIN

Kitchen garbage disposal method

ActiveCN107824601AImprove processing efficiencyFull recoveryBio-organic fraction processingSolid waste disposalLitterReclaimed water

The invention relates to a kitchen garbage disposal method. The kitchen garbage disposal method adopts a kitchen garbage disposal device which comprises a crushing chamber, a disinfection chamber, a fermentation chamber, a separation chamber, a drying chamber, a sewage treatment cavity, a compression chamber and an organic fertilizer storage box. Through such steps as crushing, disinfection, fermentation, solid-liquid separation, sewage treatment, drying, compression and storage, solids of kitchen garbage form an organic fertilizer, liquid is processed to obtain reclaimed water, produced gas forms marsh gas, and therefore, full recycling and reusing of kitchen garbage are truly realized.

Owner:广东人峰实业有限公司

Composting device

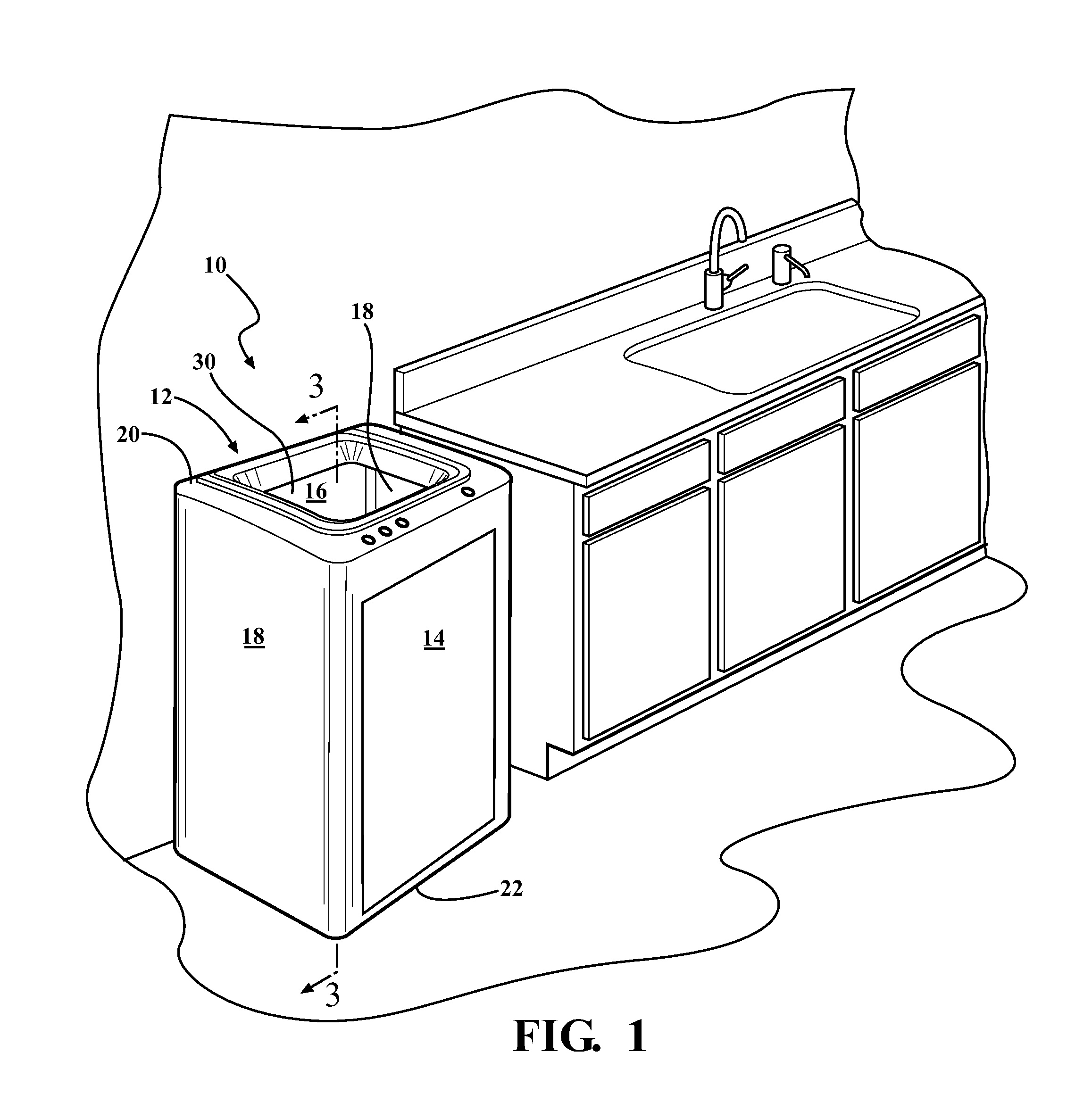

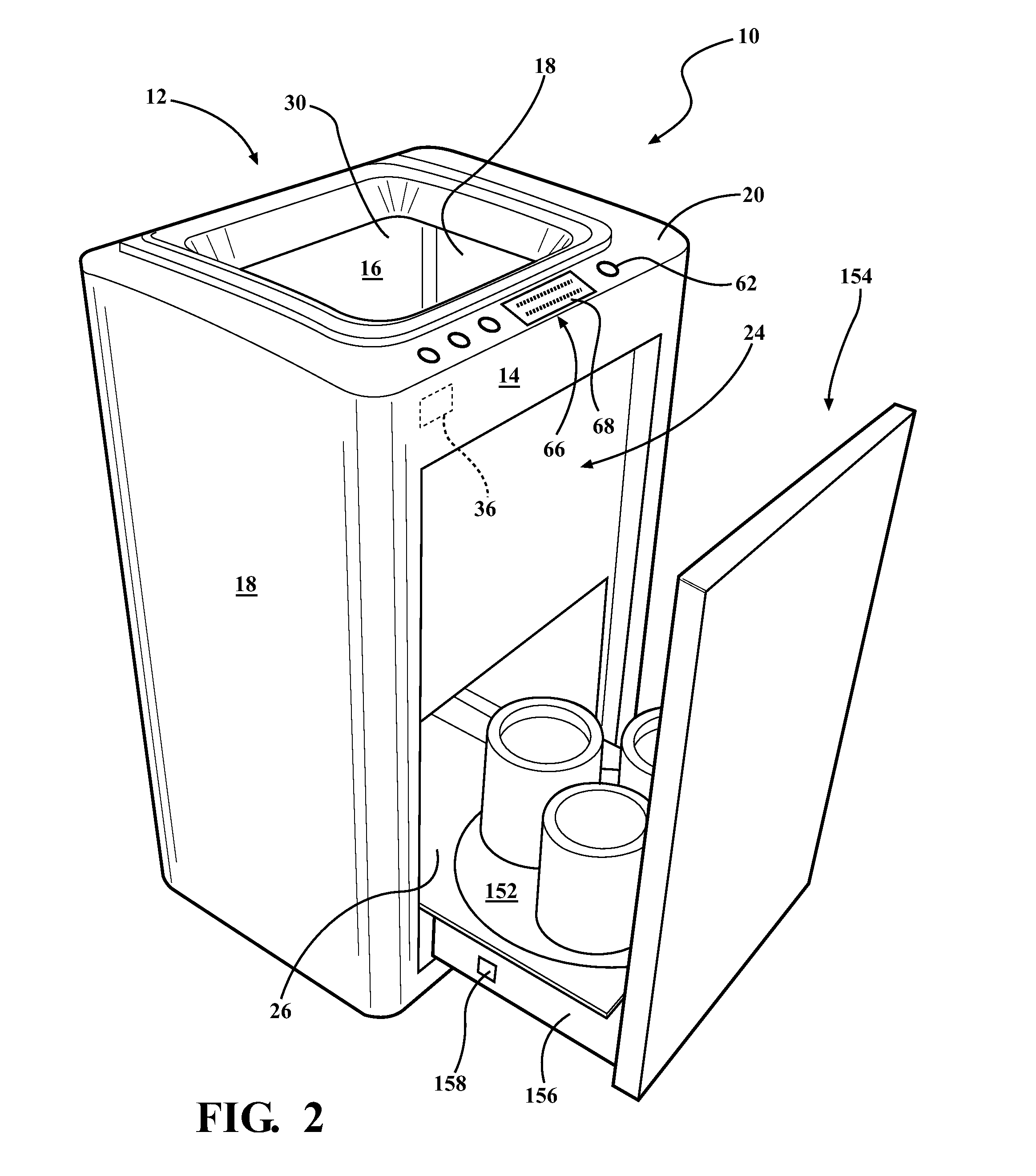

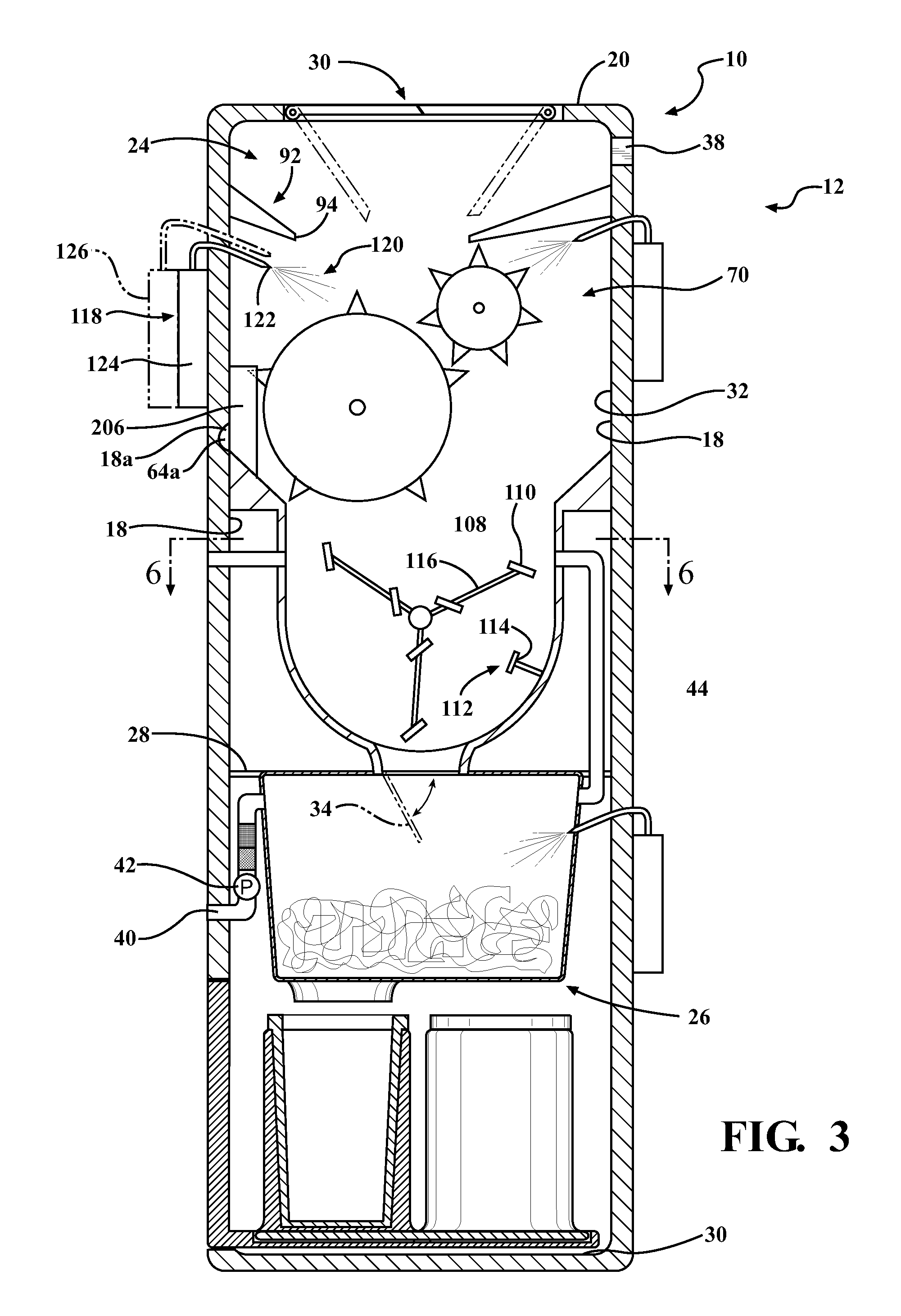

A device for transforming refuse into compost according to a cycle of operation has a cabinet, a first chamber, a first reducing mechanism in the hopper, a transfer mechanism disposed in a conduit from the first chamber to an outlet, a motor beneath the first chamber and the transfer mechanism, a container beneath the outlet to receive ground refuse from the outlet, wherein the container is accessible from outside the cabinet, and a cleaning mechanism operative to clean the first chamber.

Owner:WHIRLPOOL CORP

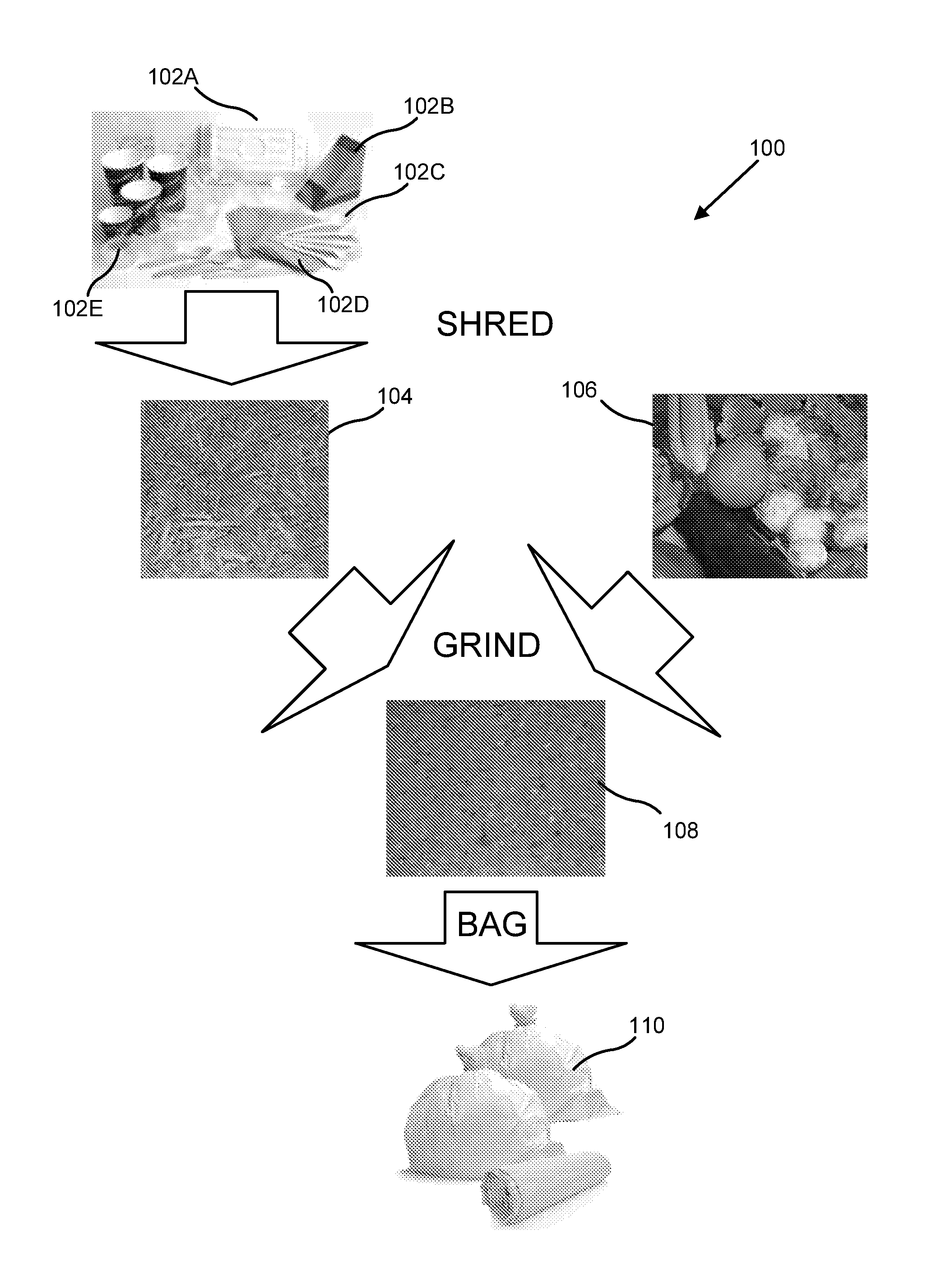

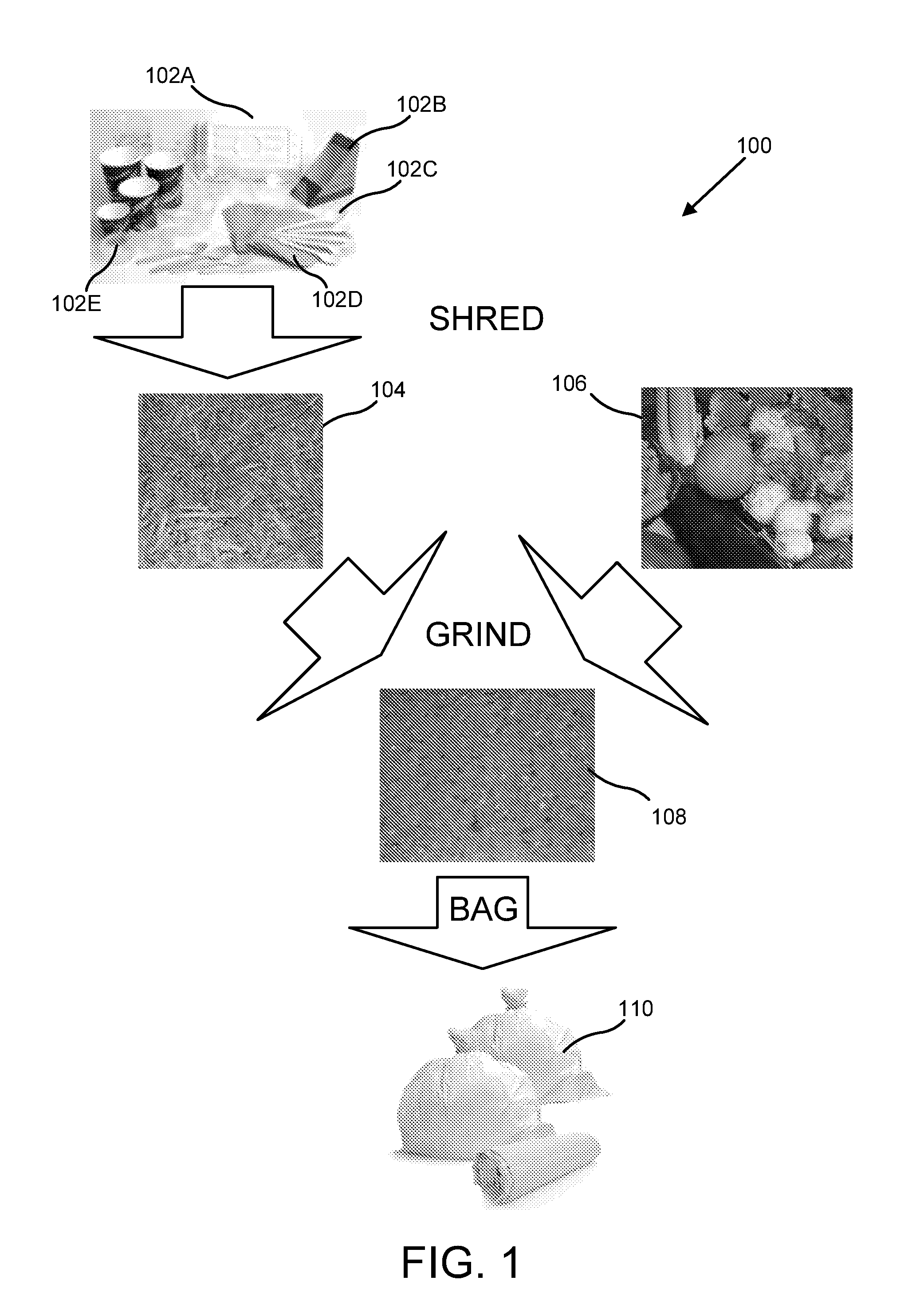

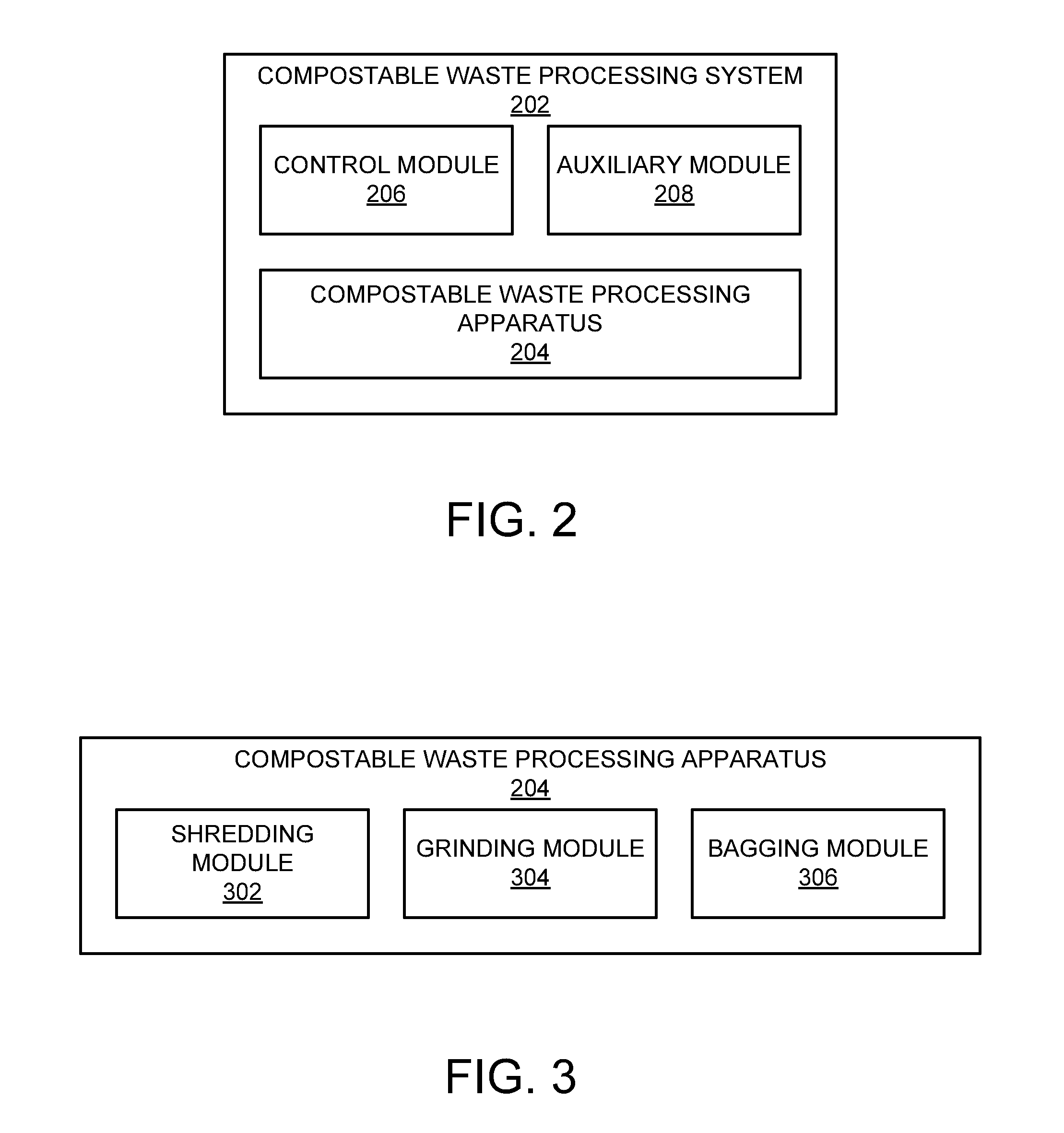

Apparatus, system, and method for compostable waste processing

InactiveUS20110101137A1Overcomes shortcomingLower the volumeProductsBio-organic fraction processingParticulatesWaste processing

An apparatus, system, and method to process compostable waste. The apparatus includes a shredding module, a grinding module, and a bagging module. The shredding module may operate to shred non-food compostable waste into shredded waste. The grinding module may operate to combine the shredded waste with food waste into combined waste, add water to the combined waste if an insufficient moisture condition exists for further processing, and grind the combined waste into particulate waste. The bagging module may operate to bag the particulate waste into a compostable bag.

Owner:LANGSTON JODY

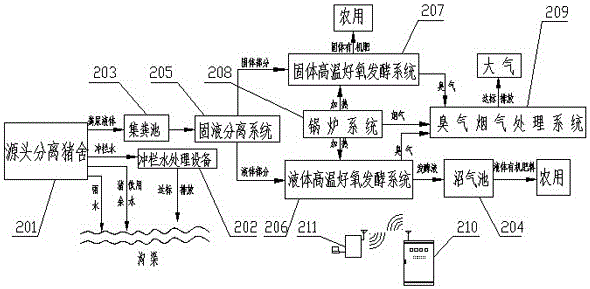

Concentrated harmless treatment method for excrements of breeding industry

InactiveCN106882981APromotes anaerobic fermentationReduce adverse effectsBio-organic fraction processingAnimal corpse fertilisersBiotechnologyFeces

The invention relates to a concentrated harmless treatment method for excrement of the breeding industry, particularly relates to a method for concentrated harmless treatment of livestock excrements to produce methane and an organic fertilizer and harmless treatment of sick and dead animal bodies to produce the organic fertilizer, and belongs to technique and equipment required in the fields of resources and environments. The method comprises four parts of excrement treatment, production of the organic fertilizer, treatment of sick and dead livestock, and intelligent control; the four parts are mutually related and mutually complement functionally, the methane can provide energy to conveniently realize high temperature sterilization, the fermentation of the organic fertilizer also requires the temperature, meanwhile, an organic fertilizer fermentation strain is also helpful for making the fertilizer through fermenting the sick and dead livestock in the later period, and the intelligent control is central nervous of the system, and has huge actions on efficient treatment and improvement of the treatment efficiency. The treatment method is reasonable in structure, the system is equipped, intelligent and efficient, and the method is suitable for popularization and application.

Owner:新疆舒创环保科技有限公司

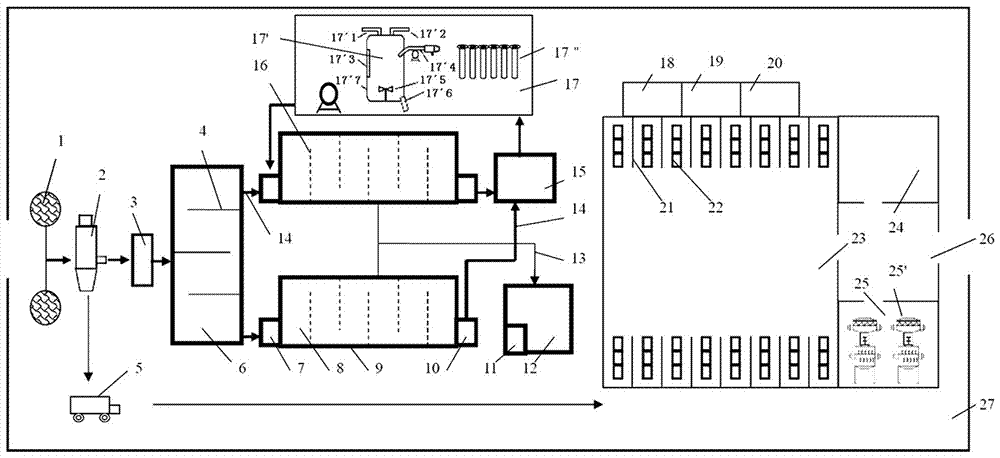

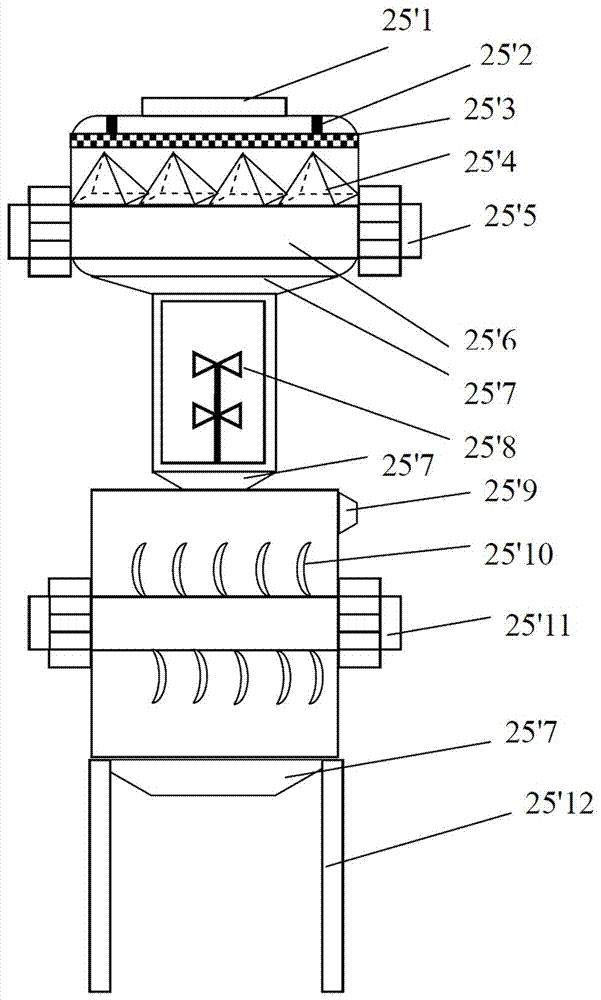

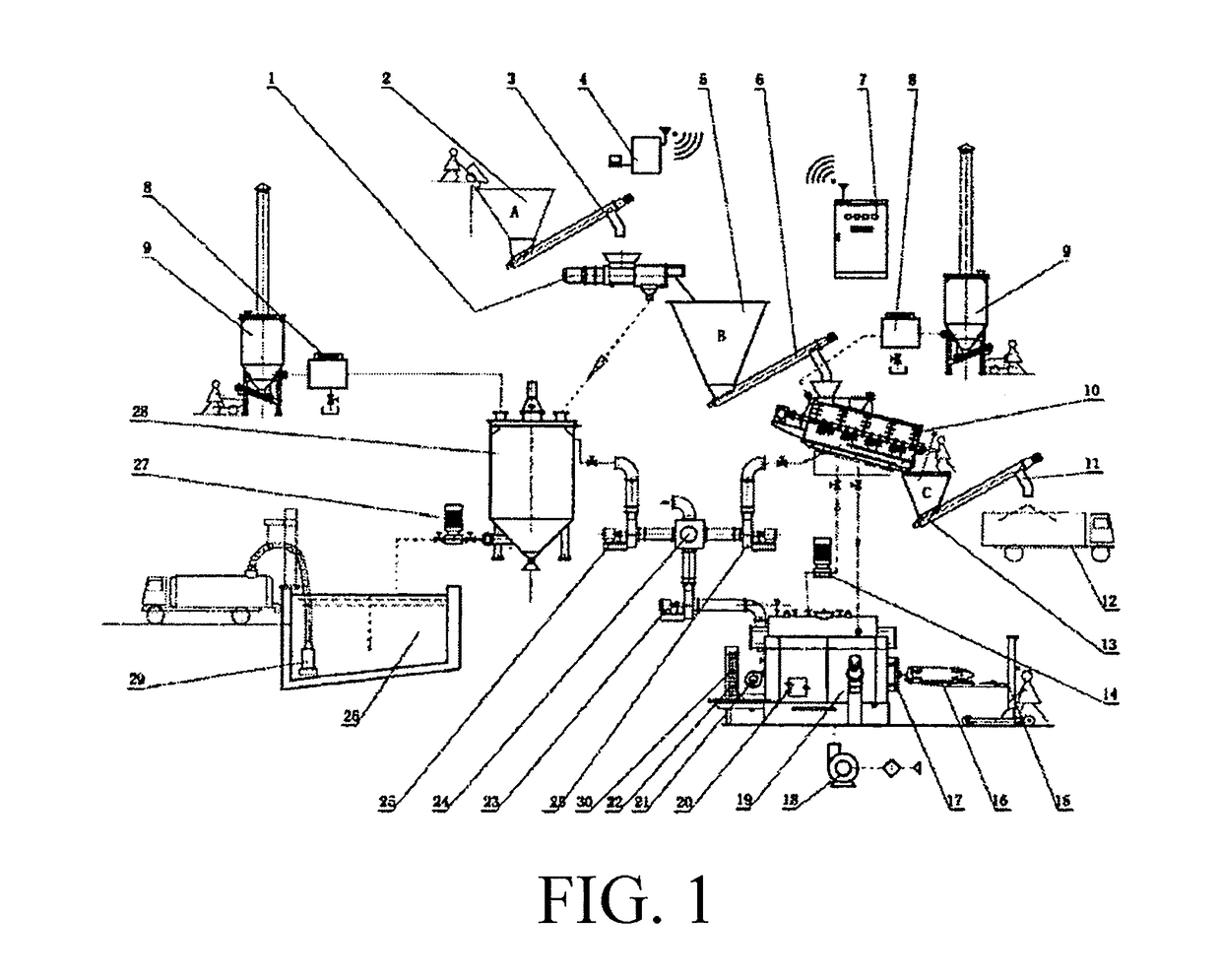

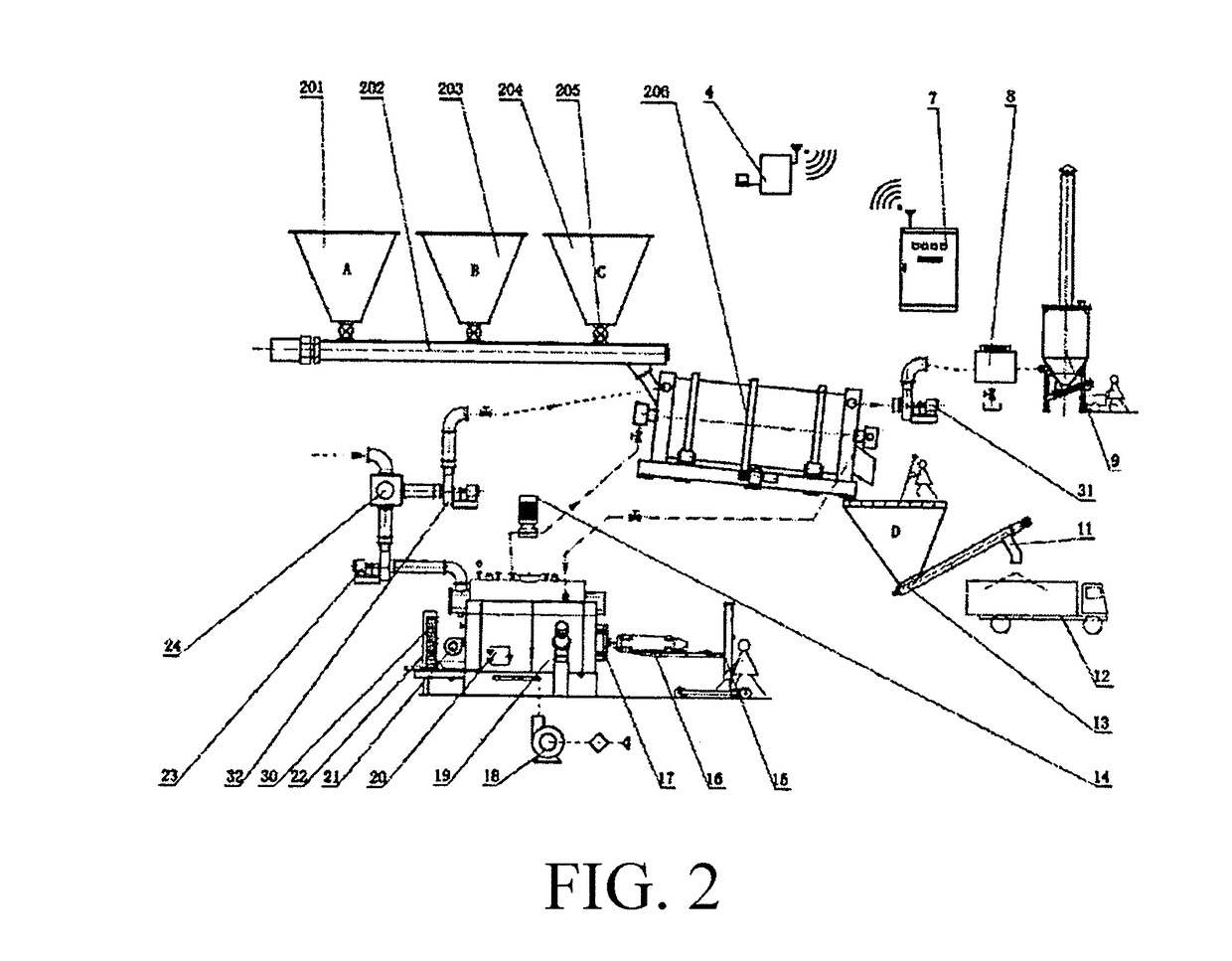

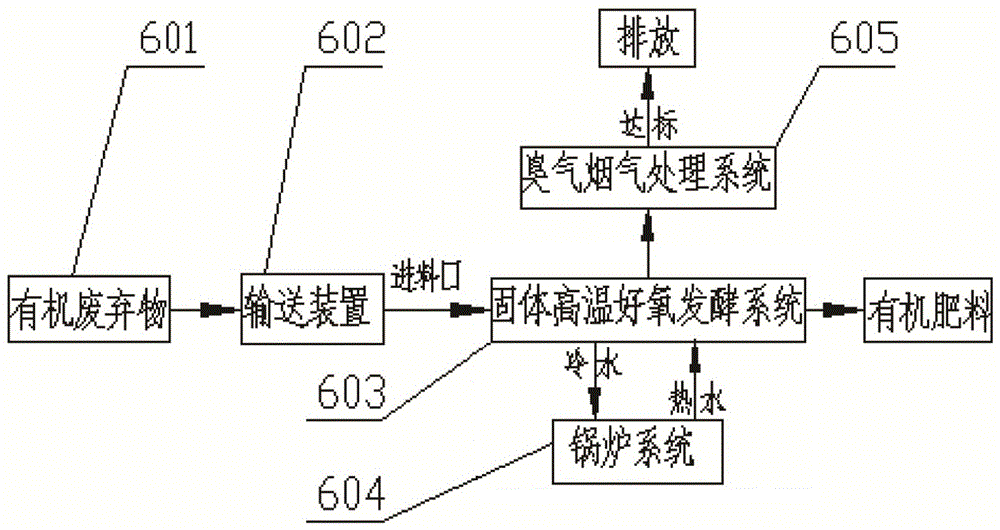

Rural bulk organic waste pollutant source comprehensive treatment system and method

ActiveUS20180148389A1Keep healthyProtect environmentBio-organic fraction processingSolid waste disposalOxygenFermentation

A rural bulk organic waste pollutant source comprehensive treatment system including a solid high-temperature aerobic fermentation reactor, a liquid high-temperature aerobic fermentation reactor and a multifunctional boiler is provided. A rural bulk organic waste pollutant source comprehensive treatment method. For excretion waste of a livestock farm adopting the technology of manure cleaning by urine submerging, a solid-liquid separation is firstly performed thereto, wherein solid is conveyed to the solid high-temperature aerobic fermentation reactor and fermented to produce solid organic fertilizers, and liquid is conveyed to the liquid high-temperature aerobic fermentation reactor and fermented to produce liquid organic fertilizers. For dry collection manure of a livestock and poultry farm, carbon-containing auxiliary materials, residues left after dead animals and household waste being incinerated by the multifunctional boiler, and ash generated by straw burning are added thereto, and then the mixture is conveyed to the solid high-temperature aerobic fermentation reactor and fermented to produce solid organic fertilizers. Exhaust fume and hot water produced by the multifunctional boiler pass through the solid high-temperature aerobic fermentation reactor and the liquid high-temperature aerobic fermentation reactor to heat the reactors and keep the reactors warm.

Owner:HUNAN SAKAL ENVIRONMENTAL SCI & TECH CO LTD +1

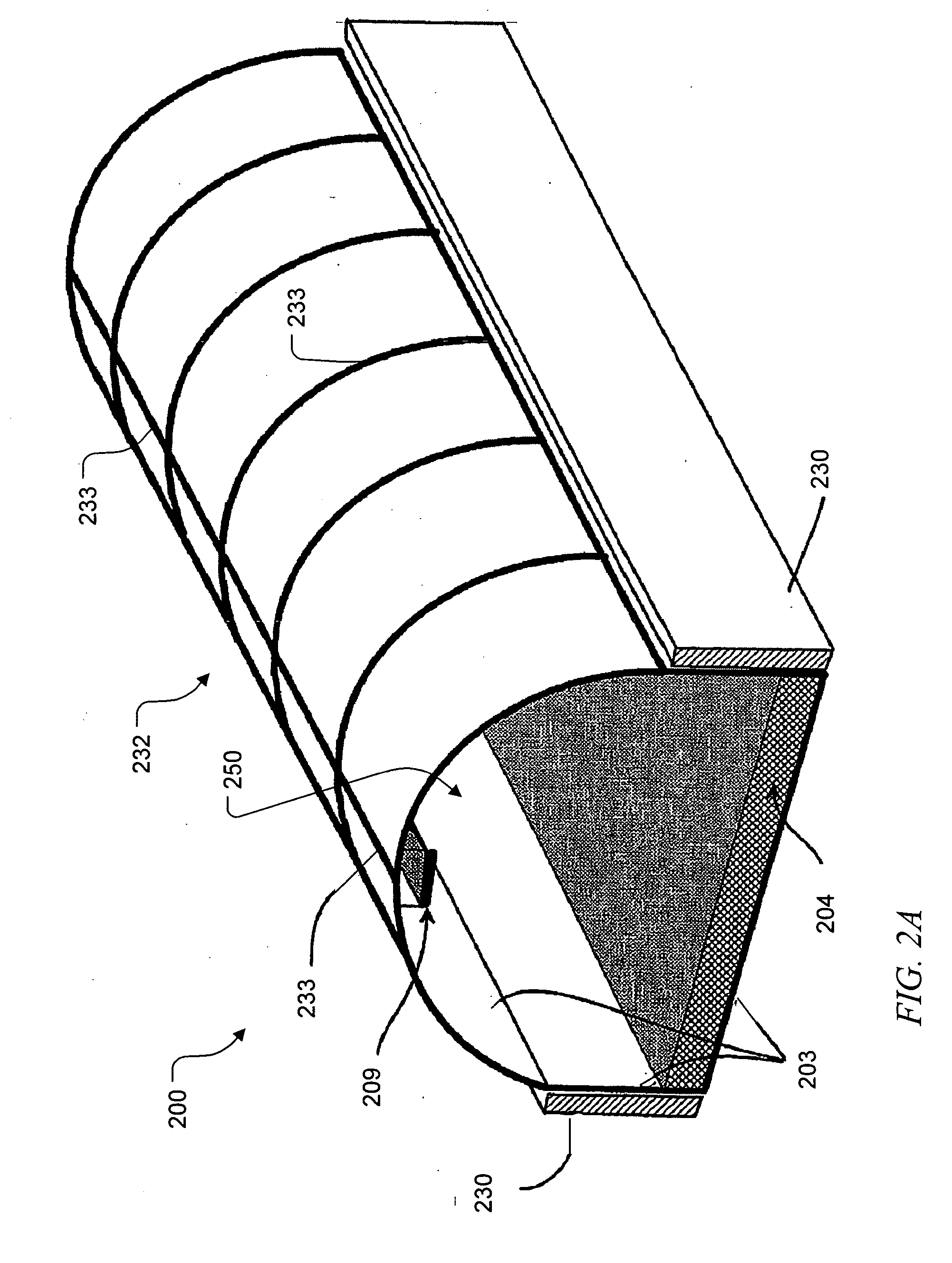

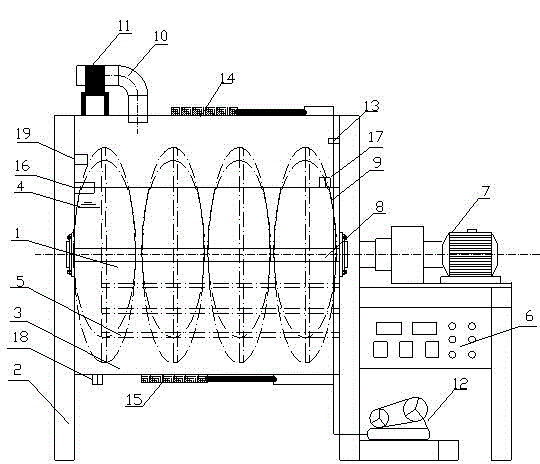

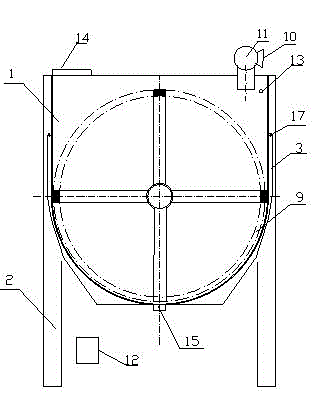

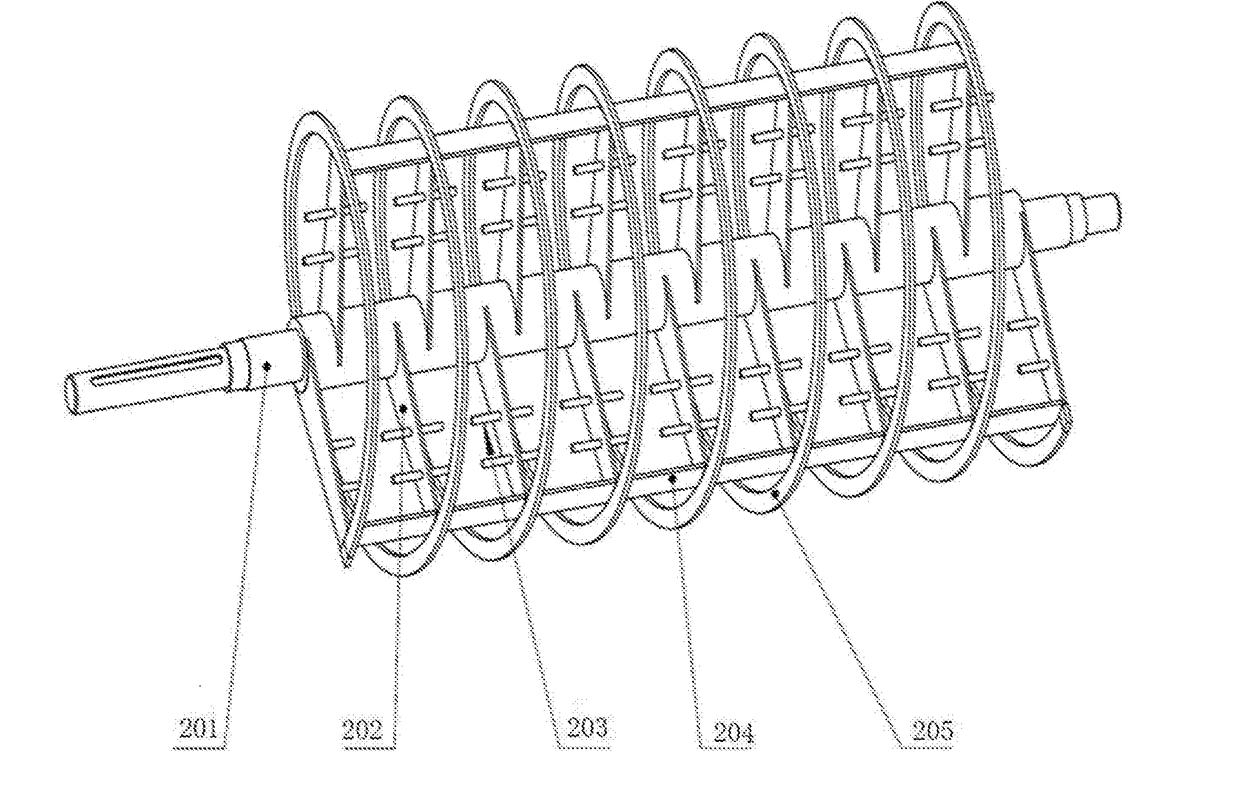

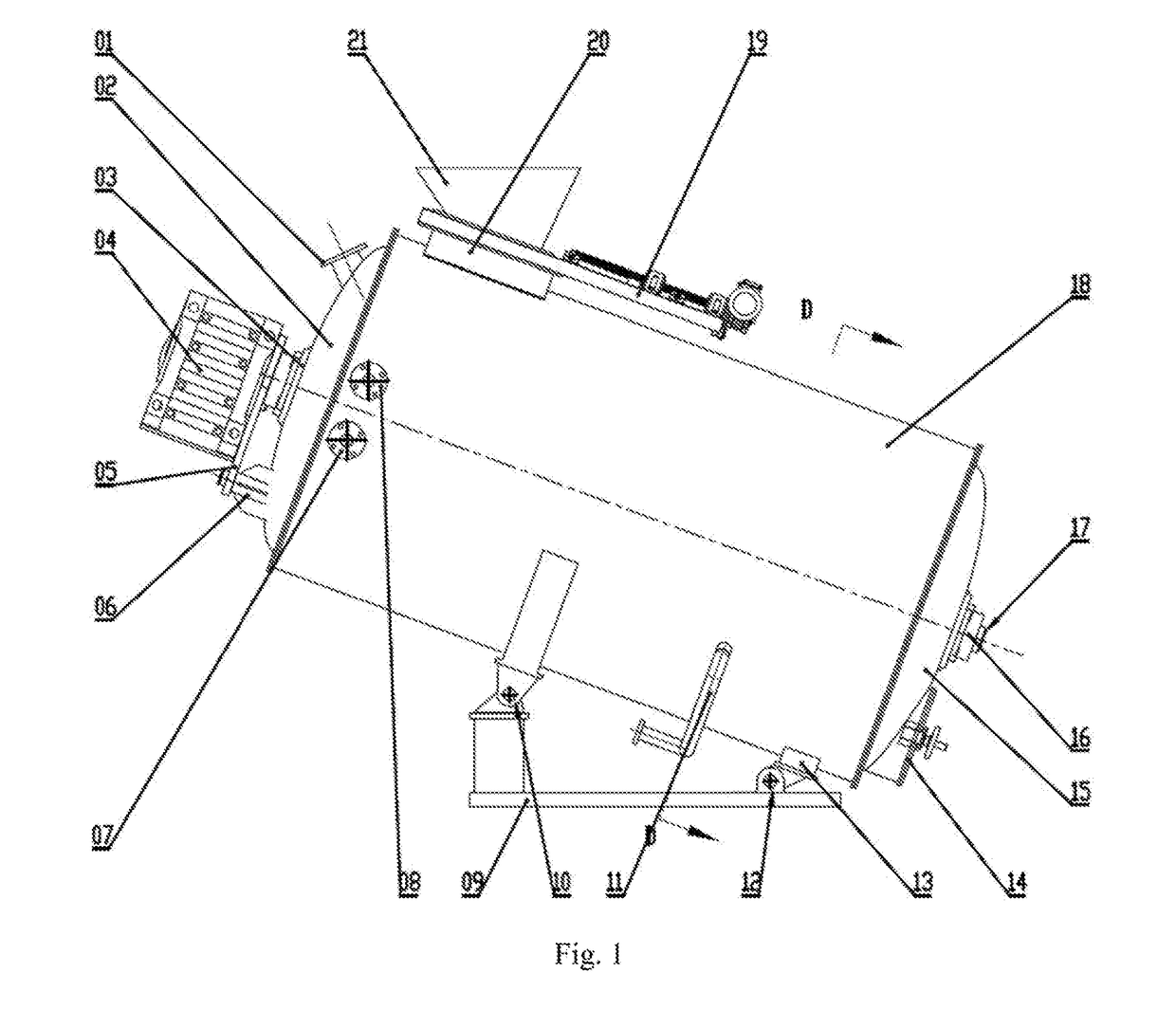

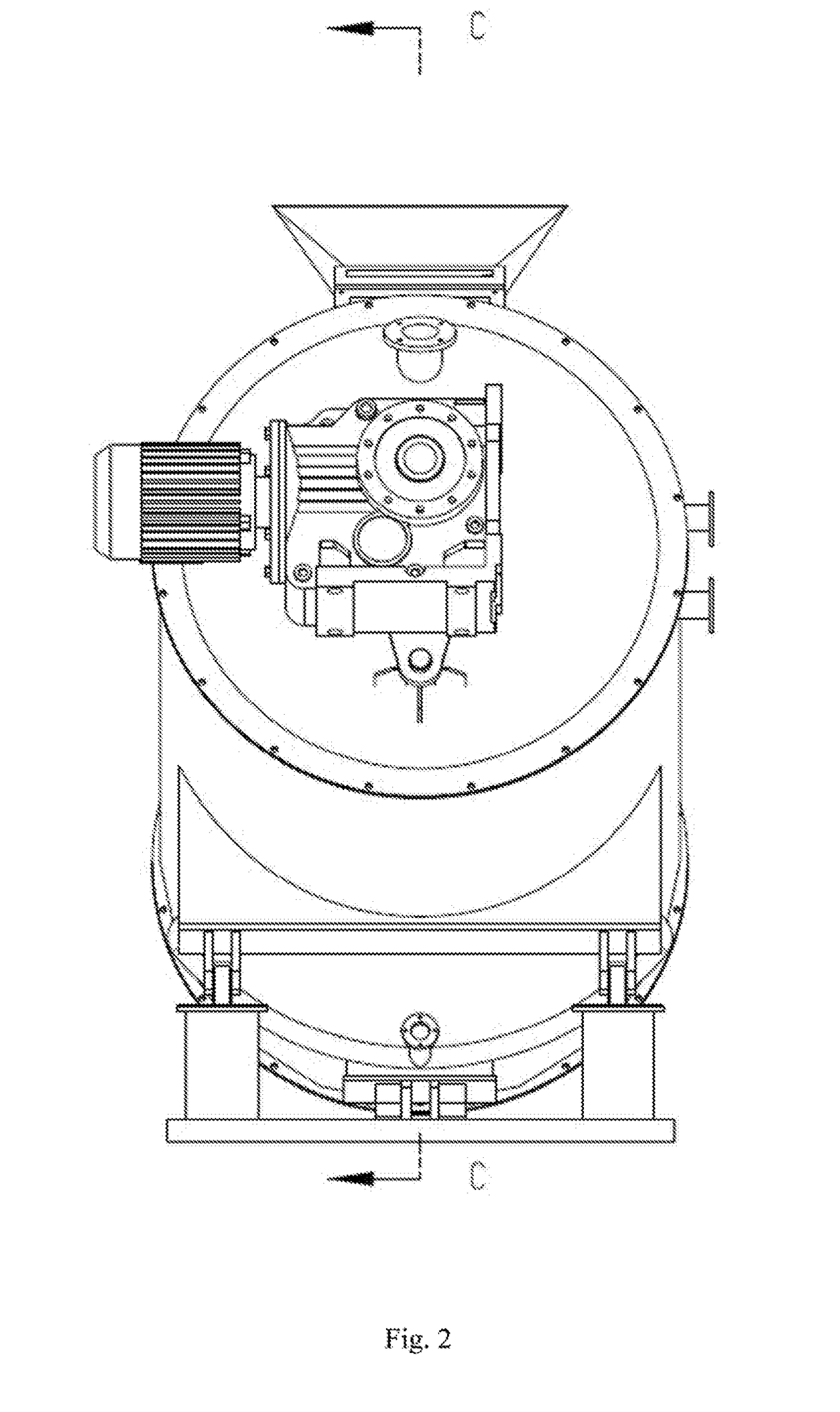

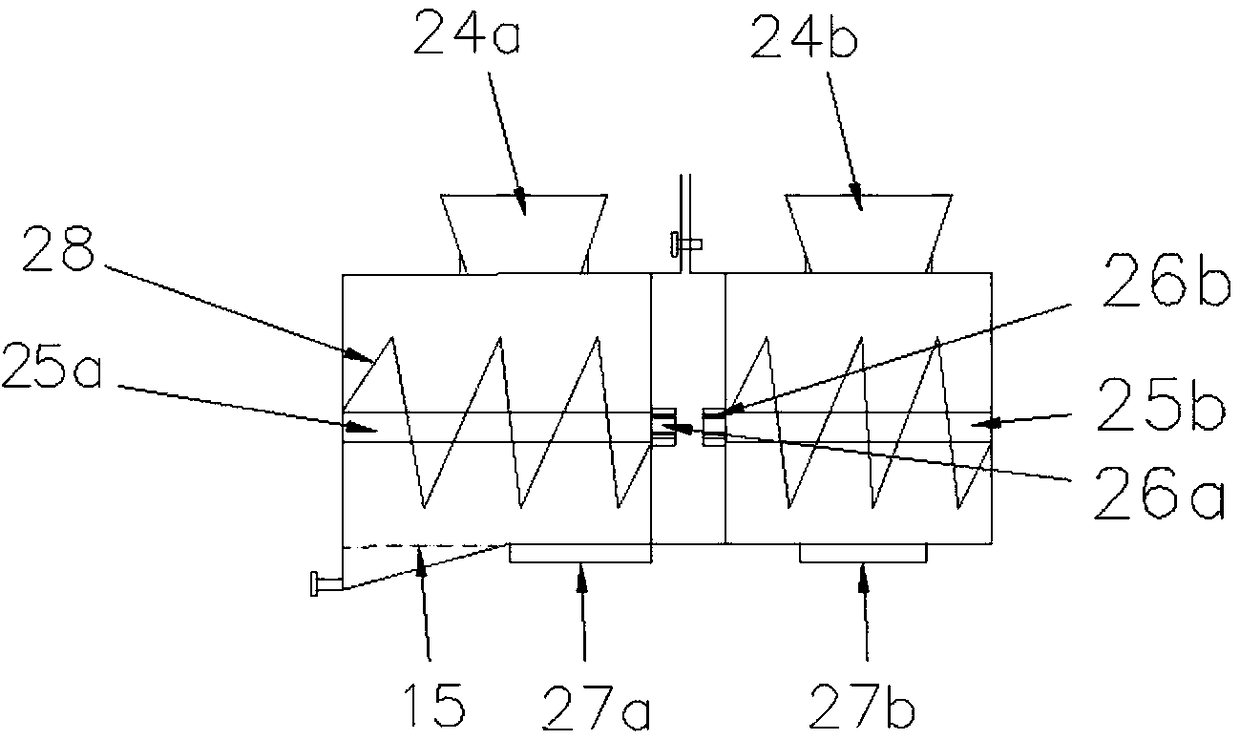

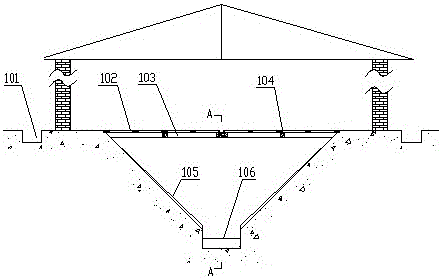

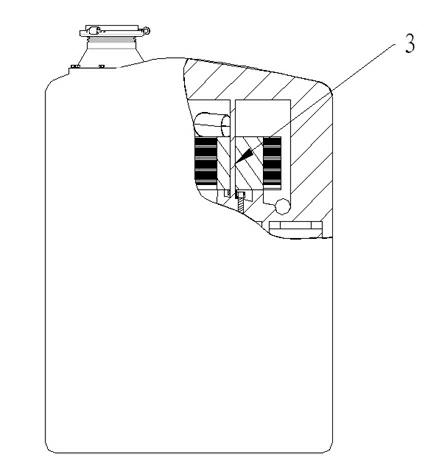

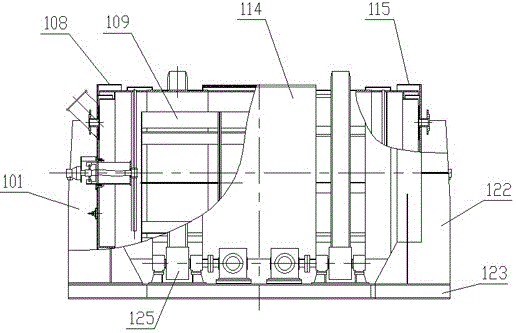

Inclined reactor of bottom gas-inlet type for aerobic fermentation and method for aerobic fermentation

ActiveUS20170226023A1Increase speedSufficient oxygenBioreactor/fermenter combinationsBio-organic fraction processingHeight differenceOxygen

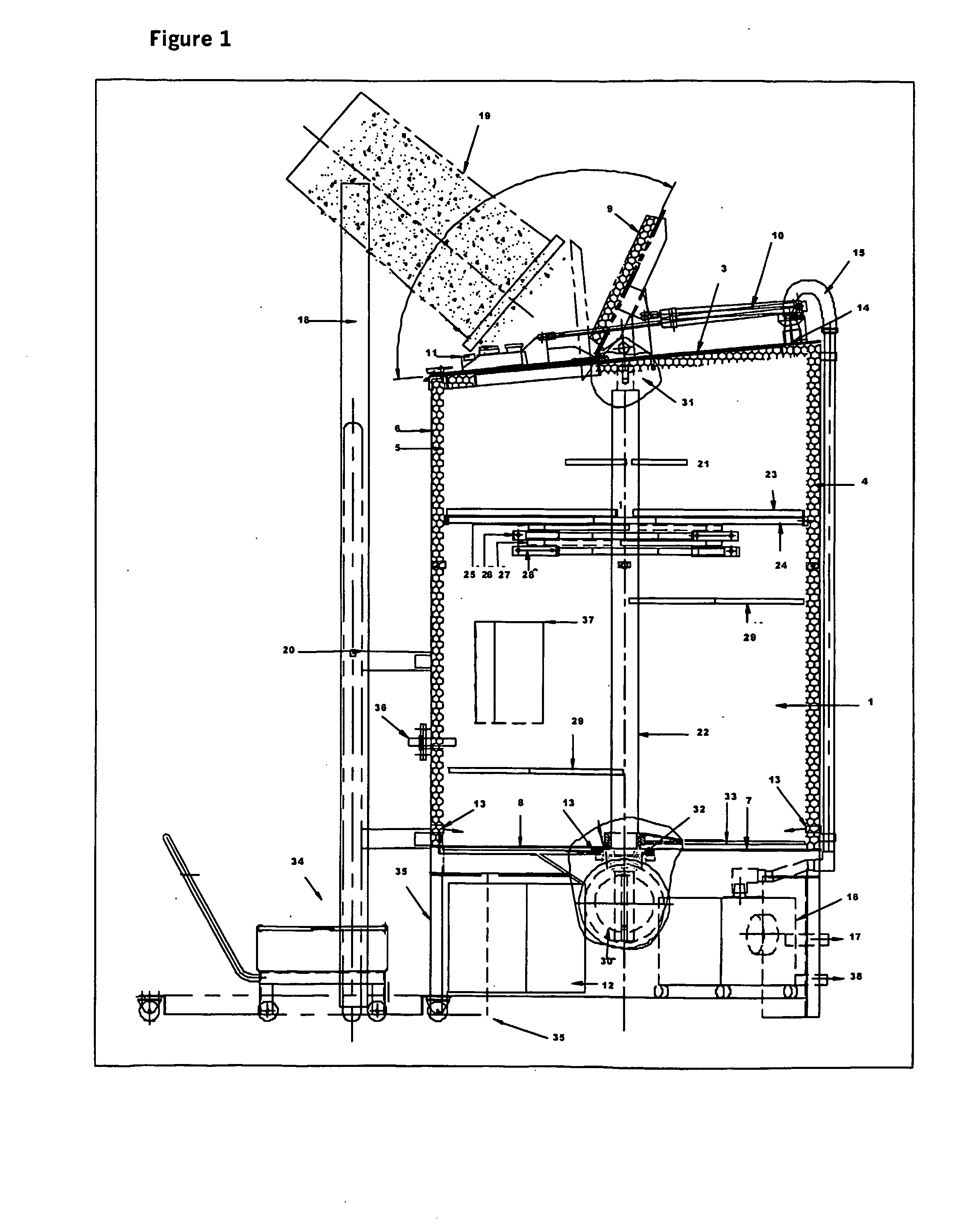

An inclined reactor of bottom gas-inlet type for aerobic fermentation and a method for aerobic fermentation are provided, a fermenter is provided with a circular inner tank, end covers and a jacket; an airtight fermentation space is formed in the fermenter by the inner tank, an upper end cover and a lower end cover; a feed opening and an exhaust outlet are arranged at an upper part of the fermenter, and a discharge opening is arranged at a lower part of the lower end cover of the fermenter; a length of the fermenter is greater than or equal to a diameter of the fermenter, the fermenter is fixed on a base having a height difference and is hence in an inclined state; an energy-saving stirrer is mounted in the fermenter, and the energy-saving stirrer is formed by connecting several groups of tangential plates or a spiral combination of tangential plates, a radial rod, a stirring rod and a stirring shaft; several groups of air chambers are arranged at an external wall at the bottom of the inner tank of the fermenter, the air chambers are arranged inside the jacket, several aeration nozzles are defined on an inner side of each air chamber, and the aeration nozzles are close to the inner tank.

Owner:HUNAN SAKAL ENVIRONMENTAL SCI & TECH CO LTD

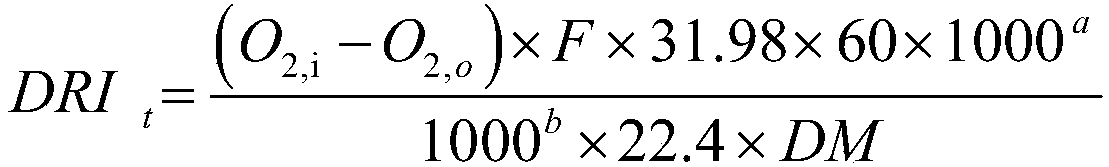

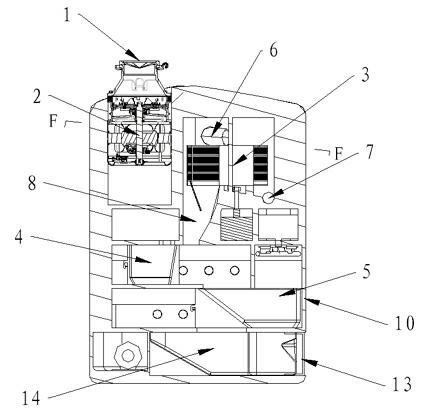

High-efficiency kitchen waste aerobic fermentation equipment

PendingCN109485475ARealize fine controlEffective fermentationBio-organic fraction processingOrganic fertiliser apparatusAutomatic controlAeration system

The invention discloses high-efficiency kitchen waste aerobic fermentation equipment. The equipment comprises a fermentation bin, a grinding and dehydrating system, a stirring and pushing system, a heating system, a biological deodorizing system, an aeration system, a water supply system and an automatic control system. According to the fermentation equipment, kitchen waste compost is divided intofour stages including grinding, heating, high temperature and curing, and parameters of the heating system, stirring system, aeration system and water supply system can be independently set in each stage, so that parameters in three bins can be finely controlled, and effective performance of fermentation can be favored; and the dynamic respiratory index DRI is applied in the kitchen waste fermentation equipment to serve as an index for measuring product maturity, and the quality of mature fertilizer can be finally guaranteed by the advanced monitoring method.

Owner:NANJING UNIV

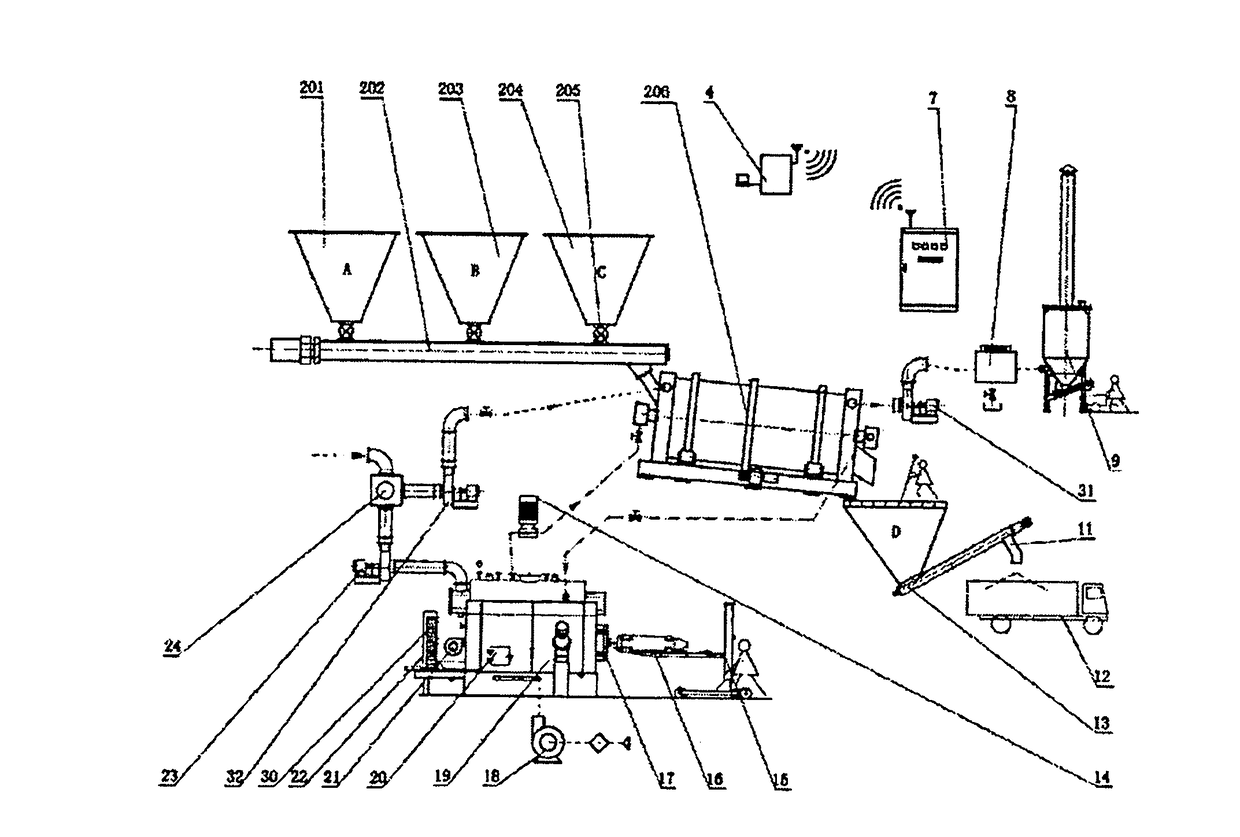

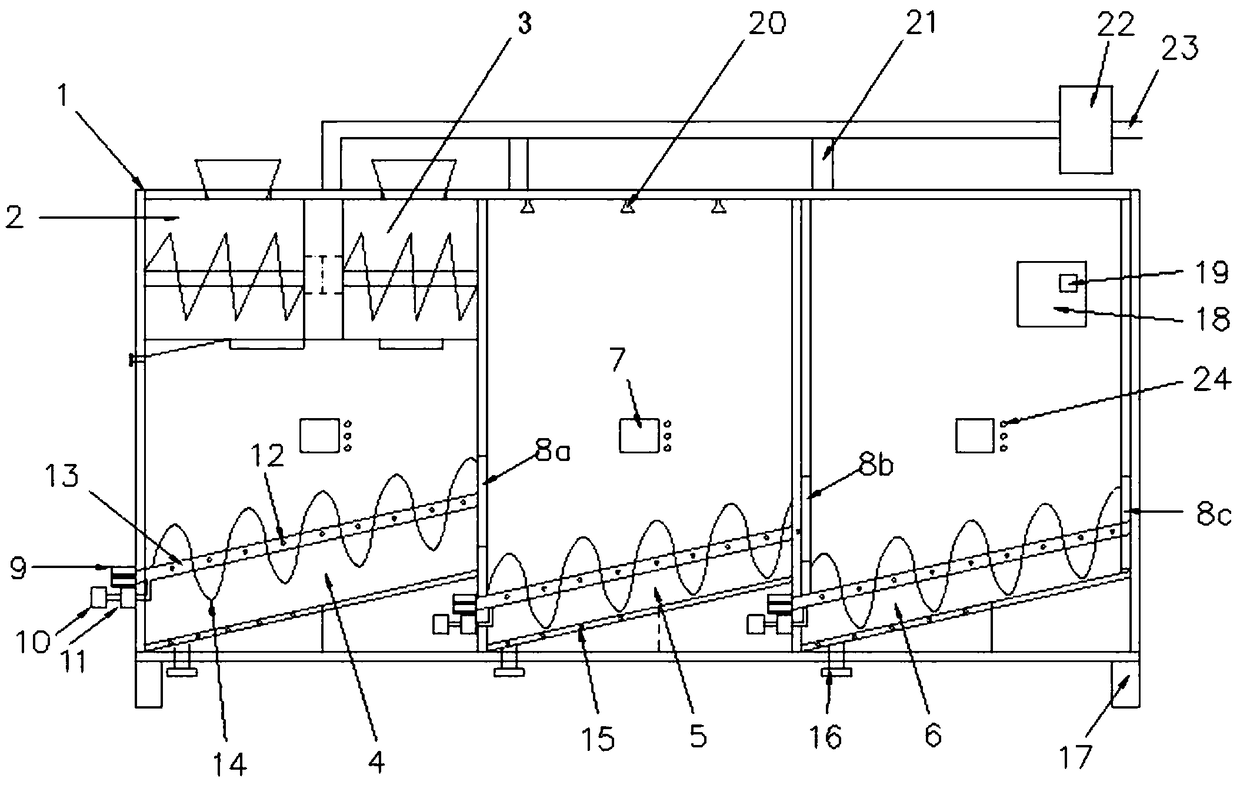

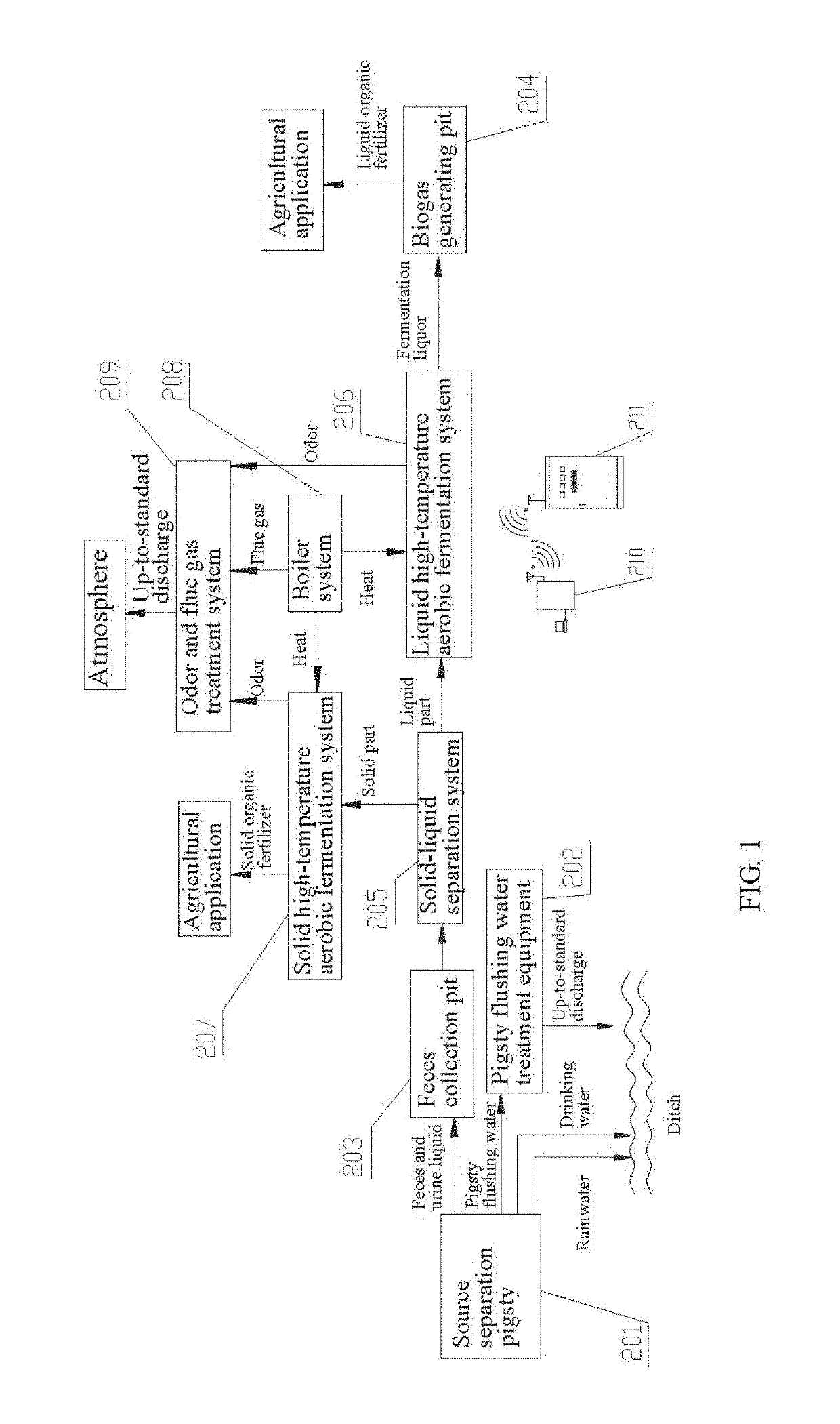

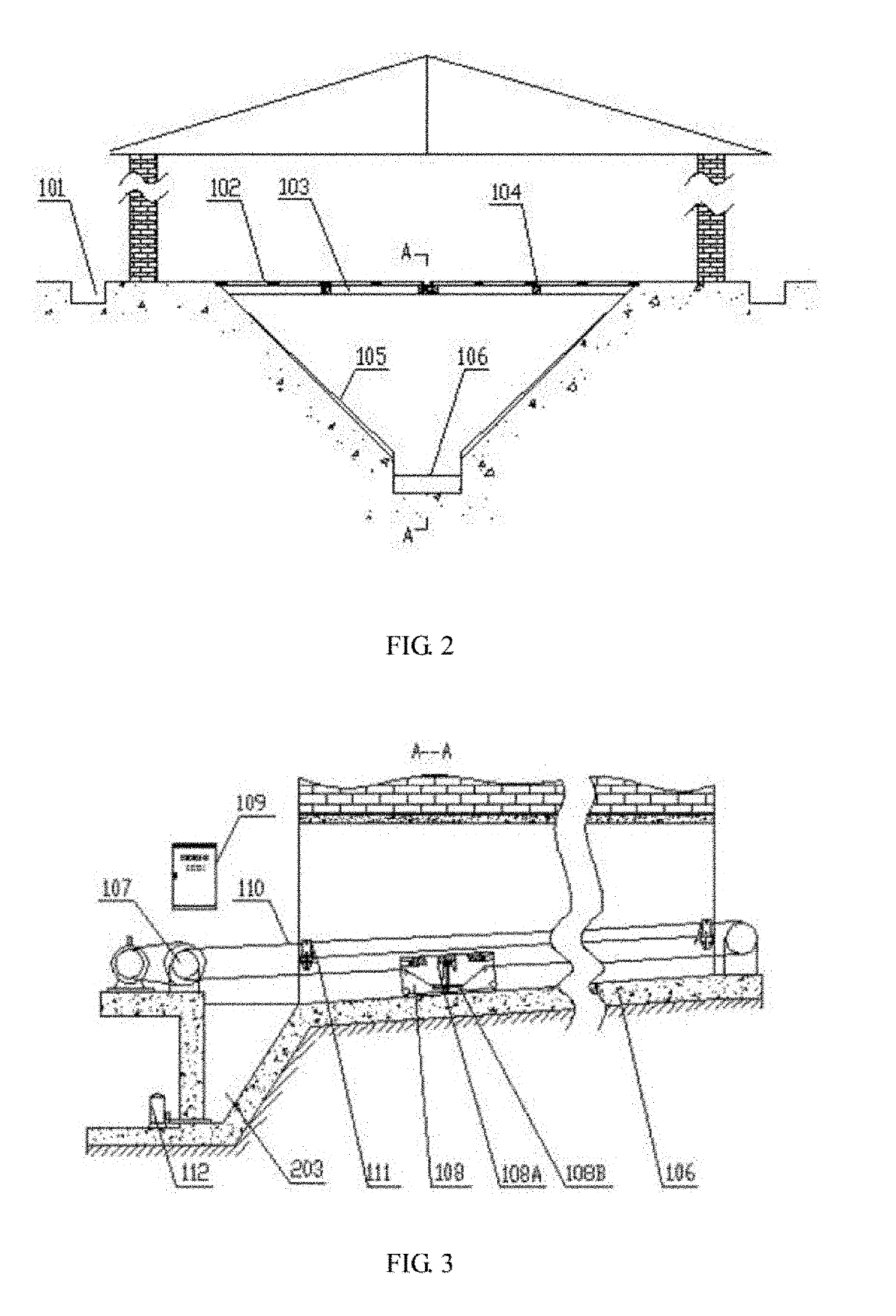

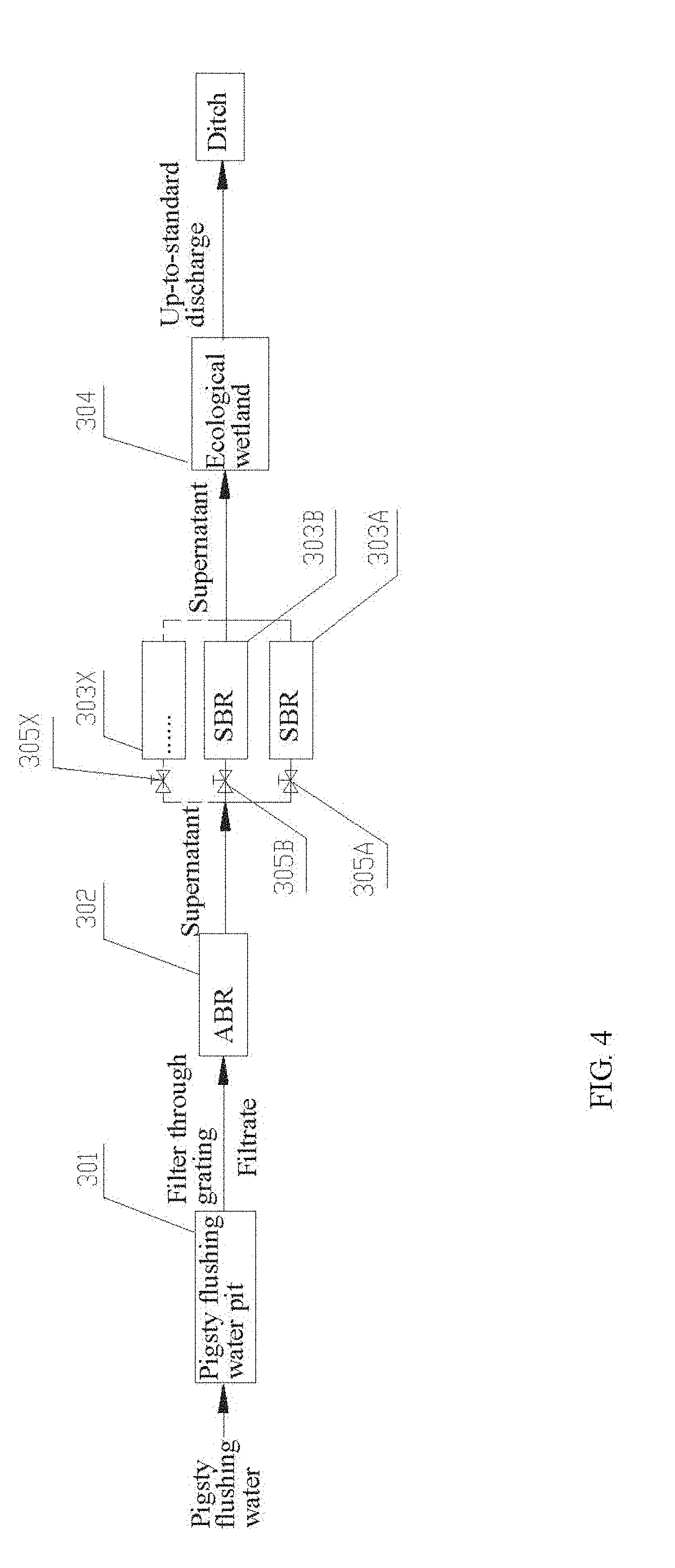

Breeding pollution comprehensive treatment system and method of large-scale pig farm

ActiveCN106824972AIn line with the cycleReduce the burden onBio-organic fraction processingSolid waste disposalPig farmsSludge

The invention discloses a breeding pollution comprehensive treatment system and method of a large-scale pig farm. The system comprises a source separation pigsty, a pigsty washing water treatment system, a solid-liquid separation system, a solid high-temperature aerobic fermentation system, a liquid high-temperature aerobic fermentation system, an odor and flue gas treatment system, a boiler system and a detection control system. The source separation pigsty is designed to be a pigsty with fecaluria separated from rainwater, pigsty washing water and drinking residual water. A sludge pump pumps the fecaluria to a solid-liquid separation device. Solids separated out from the solid-liquid separation device are conveyed to the solid high-temperature aerobic fermentation system. Liquid separated out from the solid-liquid separation device is conveyed to the liquid high-temperature aerobic fermentation system. A fermentation odor exhaust opening of the solid high-temperature aerobic fermentation system, a fermentation odor exhaust opening of the liquid high-temperature aerobic fermentation system and exhausted flue gas of the boiler system are connected with the odor and flue gas treatment system through pipelines. The boiler system comprises a boiler, a circulation pump, a hot water pipeline and a water return pipeline. Sensors of the detection control system are arranged in the above systems, and the detection control system carries out connection control over the above systems. According to the system and method, pollution of the large-scale pig farm is comprehensively treated, and zero emission, zero pollution and resourceful utilization of pollutants of the large-scale pig farm are achieved.

Owner:HUNAN SAKAL ENVIRONMENTAL SCI & TECH CO LTD +1

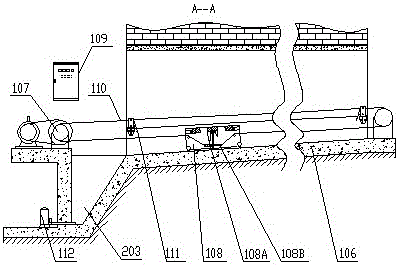

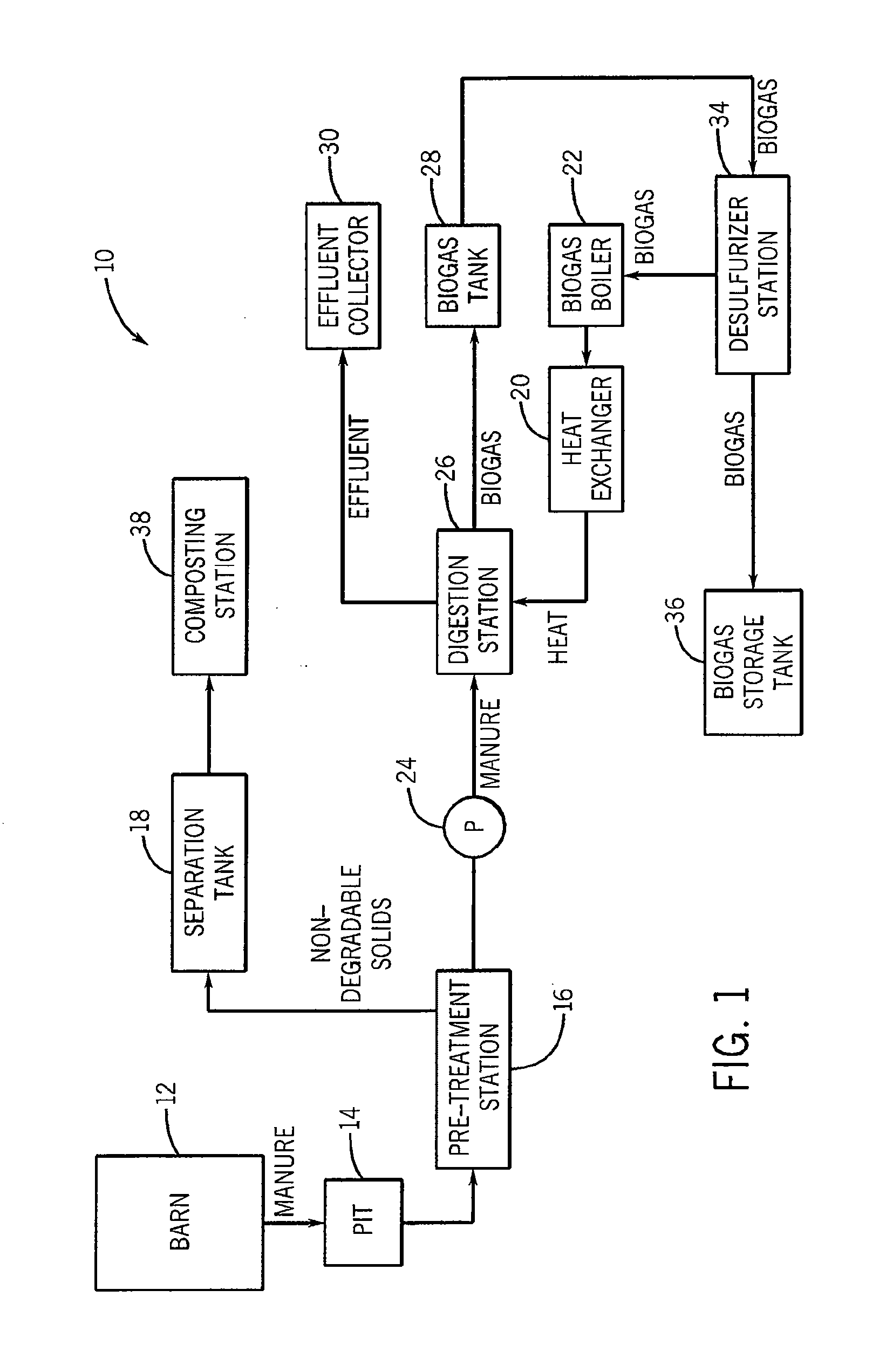

Organic Substrate Treatment System

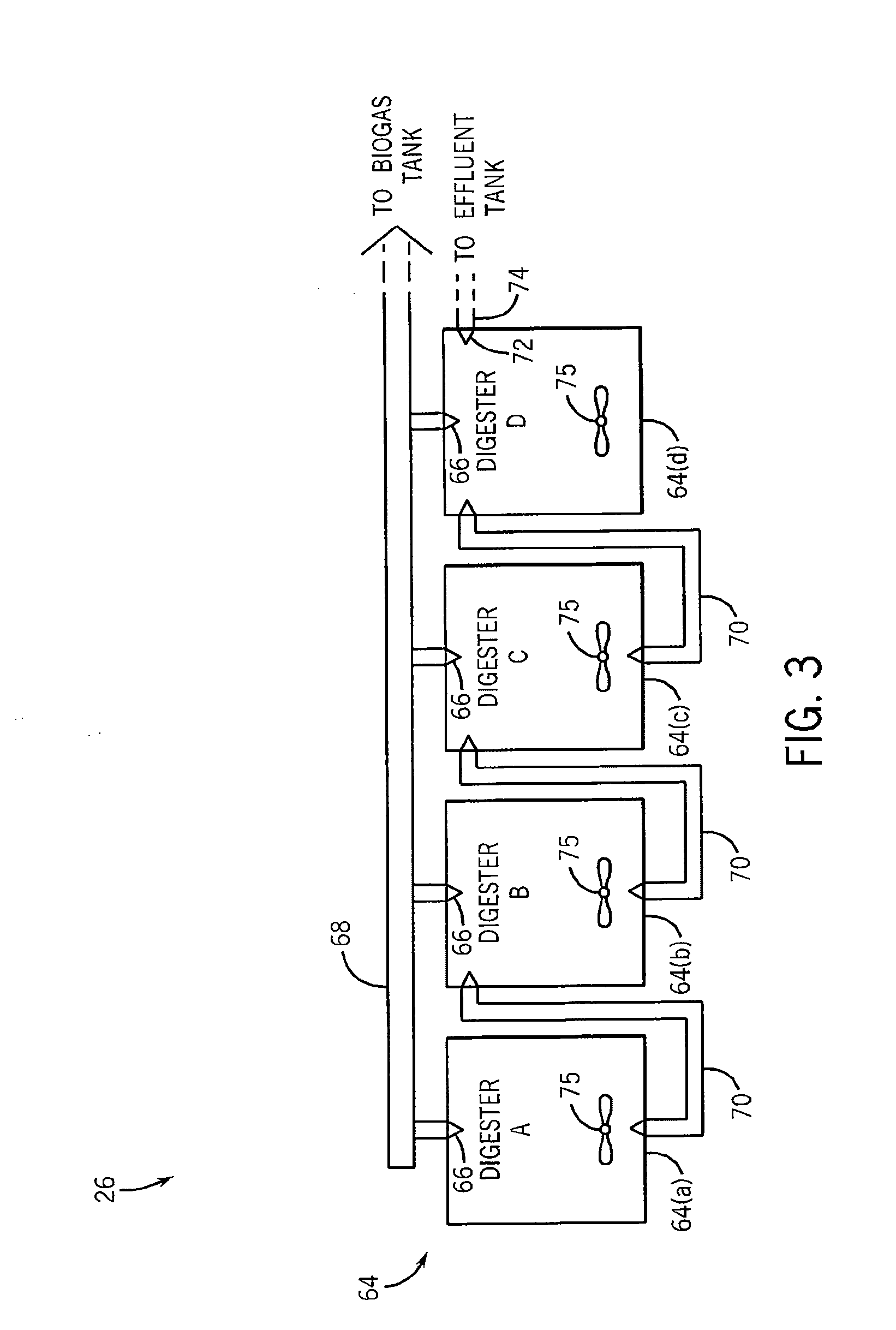

InactiveUS20110318778A1Easy injectionPromote degradationBioreactor/fermenter combinationsBio-organic fraction processingBiogas productionDigestion

The present invention is directed to an organic substrate treatment system that converts organic substrate and other organic materials to nutrient rich effluent and biogas. Using sequential degradation of the organic materials, biogas and effluent is efficiently produced with relatively short digestion times. Additives are added to the organic materials prior to anaerobic digestion to enhance biogas production. A desulfurizer may be used to clean the raw biogas so that it is suitable for use with gas engines and boilers.

Owner:ICS RENEWABLES

Fecal treatment method and system used in farm

InactiveCN107117786AAchieve multi-level efficient utilizationImprove utilizationBio-organic fraction processingExcrement fertilisersElectricitySlurry

The invention relates to the technical field of fecal treatment and in particular to a fecal treatment method and system used in a farm. The fecal treatment method comprises the following steps: performing solid-liquid separating treatment on feces to obtain solid feces and liquid feces; feeding the liquid feces into a liquid feces adjusting pond, mixing uniformly, and then feeding the feces into an anaerobic reactor for anaerobic fermentation to obtain biogas, biogas slurry and biogas residues; feeding the biogas slurry into a settling pond for precipitation separation, feeding the biogas into a biogas purifying device for purification, and generating electricity by the purified biogas through a biogas generating device; and pre-treating the solid feces, feeding the pre-treated solid feces and biogas residues jointly into a fermenting pond, adding a fermenting agent for fermentation, and after fermentation, drying and granulating the mixture to obtain a biological organic fertilizer.

Owner:CHONGQING CITY WANYUAN EGGS FOOD

Method and device for purifying and recycling organic garbage from kitchen

ActiveCN102199048AEasy to useFast filtrationProductsBio-organic fraction processingMicrobial agentLitter

The invention discloses a method for purifying and recycling for organic garbage from a kitchen and a device for purifying and recycling organic garbage from a kitchen by utilizing the same. The method comprises the following steps: step 1. pulverizing the organic garbage generated in families or kitchens; step 2. dewatering by virtue of a dewatering and separating operation chamber, and conveying to a fermenting container; step 3. adding a microbial agent, and carrying out fermenting operation; and step 4. carrying out drying and sterilizing treatment to obtain an organic fertilizer. The device for purifying and recycling the organic garbage from the kitchen comprises a pulverizing system, the dewatering and separating operation chamber, the fermenting container and a drying and sterilizing operation chamber provided with an organic fertilizer outlet. According to the invention, in-situ rapid high-efficiency fermentation of organic garbage from the kitchens can be realized, the off-odor in environment can be eliminated, the environmental pollution can be reduced, and not only can the garbage be treated, but also renewable resources are recycled, thus the device provided by the invention is clean and sanitary, and convenient for household use.

Owner:YUHUAN SENDOE SANITARYWARE

System and method for comprehensive treatment of cultivation pollution in scalable pig farm

InactiveUS20190144304A1Increase contentImprove fertilizer efficiencyBio-organic fraction processingSolid waste disposalPig farmsSludge

A system for comprehensive treatment of cultivation pollution in a scalable pig farm includes a source separation pigsty, a pigsty flushing water treatment system, a solid-liquid separation system, a solid high-temperature aerobic fermentation system, a liquid high-temperature aerobic fermentation system, an odor and flue gas treatment system, a boiler system and a test and control system. The source separation pigsty is designed into a pigsty that separates feces and urine from rainwater, pigsty flushing water and residual drinking water. The sludge pump pumps the feces and urine to the solid-liquid separation device. Solids separated by the solid-liquid separation device are conveyed to the solid high-temperature aerobic fermentation system, and liquid separated by the solid-liquid separation device is conveyed to the liquid high-temperature aerobic fermentation system. The boiler system includes a boiler, a circulating pump, a hot water pipeline and a water return pipeline.

Owner:HUNAN SAKAL ENVIRONMENTAL SCI & TECH CO LTD

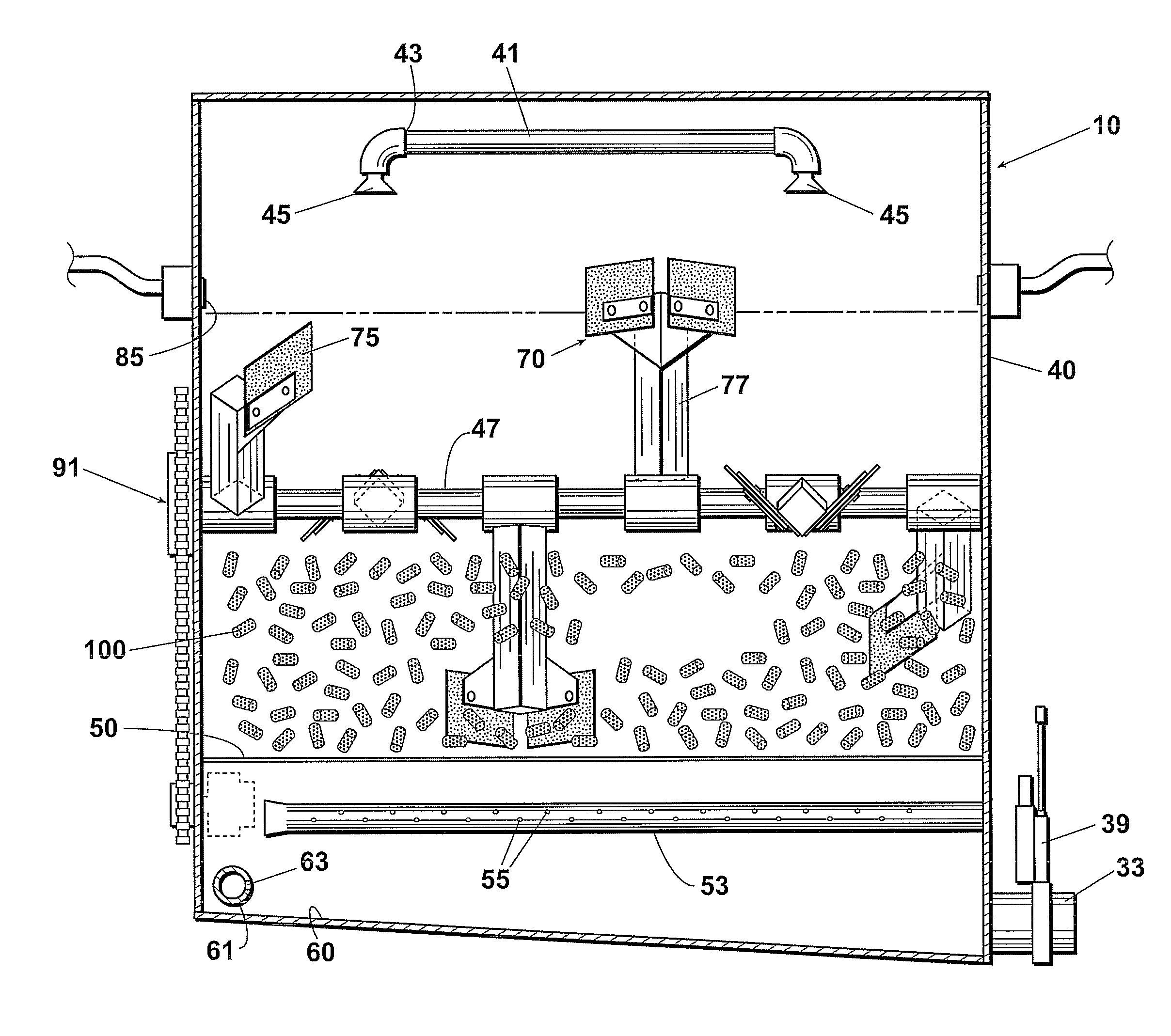

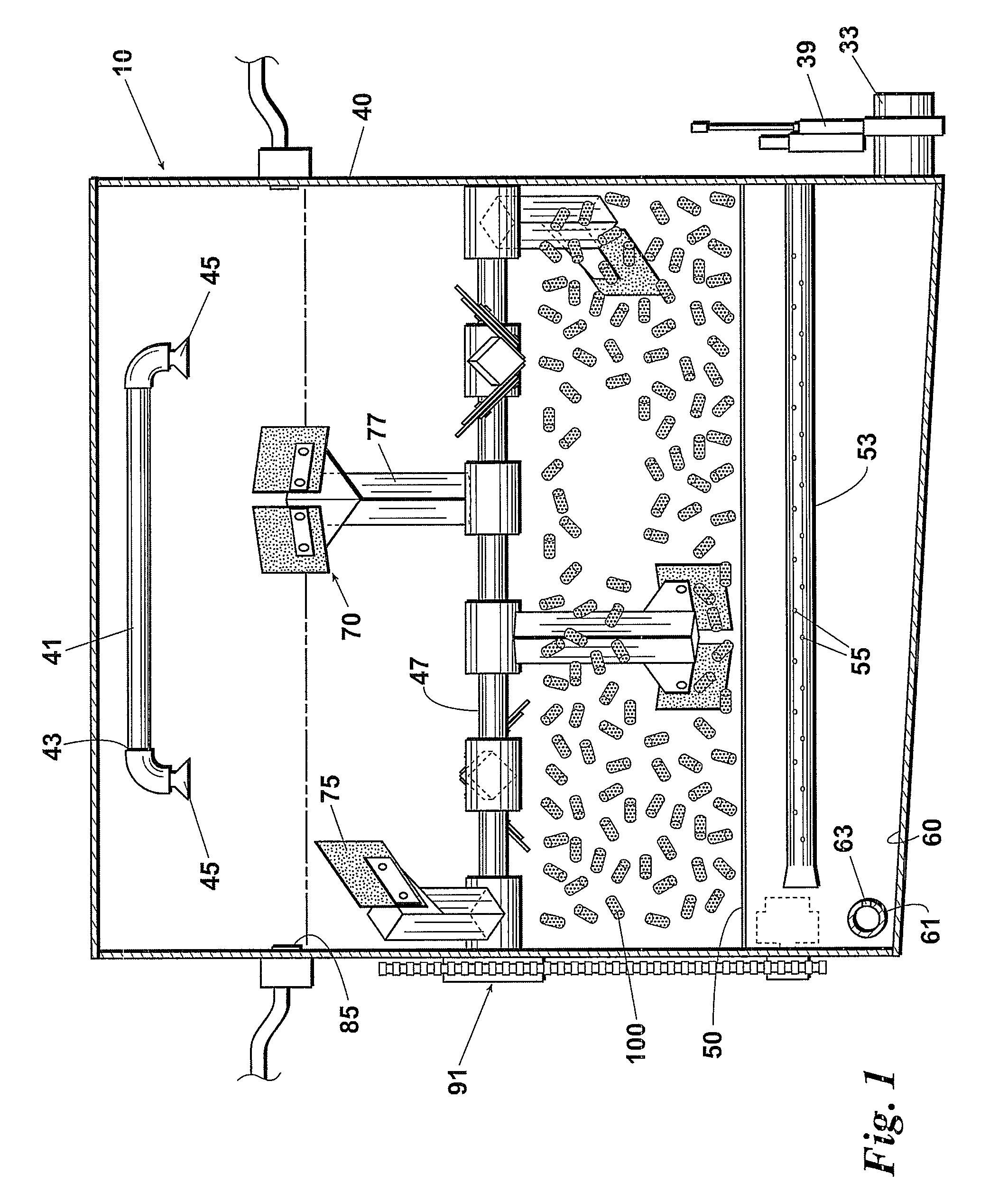

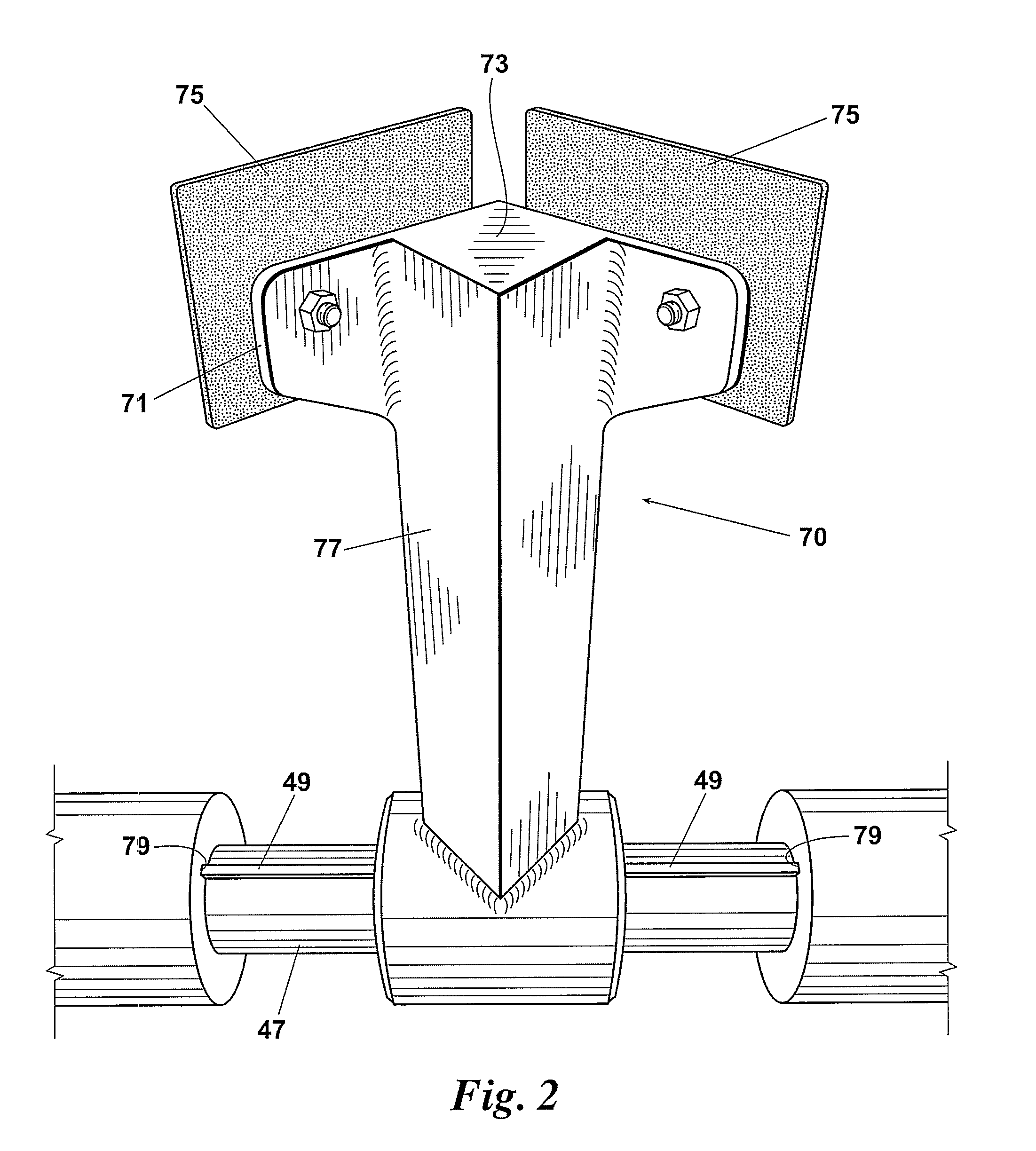

Bio-Reactor System and Method for Composting Food Waste

InactiveUS20120252107A1Low costEfficient and effective and reliableBioreactor/fermenter combinationsBio-organic fraction processingMicroorganismReactor system

A bio-reactor made according to this invention uses low temperature aerobic composting to decompose bio-compostable material. The reactor includes mixing paddles with wiper blades which aerate and agitate a set of plastic resin biochips which house microorganisms and cause the chips to come into contact with bio-compostable material. A water pipe located toward the upper portion of the bio-reactor delivers fresh or recycled water (or some mix of the two) and the bio-reactor cycles between a water cycle and a non-water cycle. Agitation also cycles on and off. Perforated bottom screens limit the size of the composted material exiting the bio-reactor. The wiper blades, which may be brushes, continually wipe the bottom screens and work to prevent blockage and build-up of debris within the bio-reactor.

Owner:TOTALLY GREEN

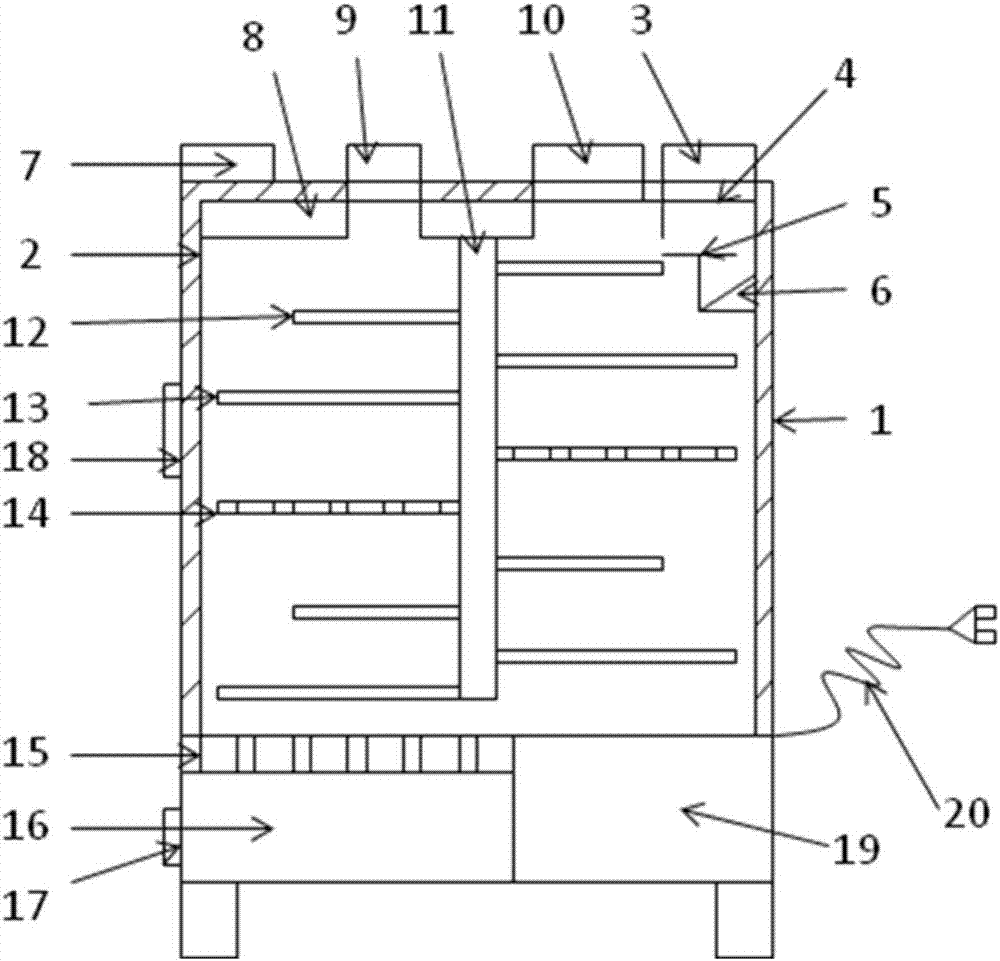

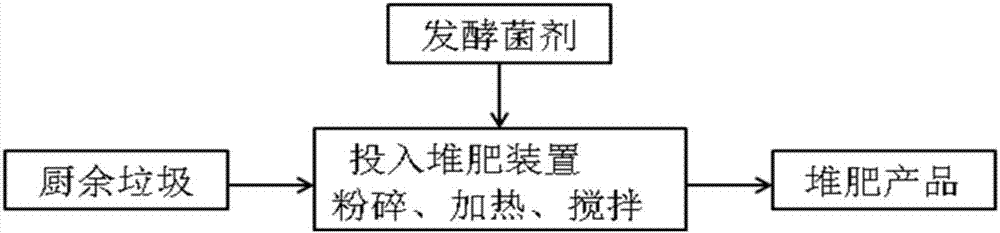

Household in-situ kitchen garbage composting device and composting treatment method thereof

InactiveCN107021795AImprove stabilityExtended stayBio-organic fraction processingClimate change adaptationLitterThermal insulation

The invention provides a household in-situ kitchen garbage composting device and a composting treatment method thereof. The composting device comprises a box body, a motor and a power supply connecting line, wherein a kitchen garbage charging hole, an operation panel, a vent hole and a bacteria solution adding hole are arranged above the box body; a heating thermal-insulation layer, a crushing device and a stirring device are arranged inside the box body. A filter plate and a composted product outlet are formed in the lower portion of the box body; staying time of large-grain-size materials can be prolonged by a stirring partition in the box body of the composting device, and stability of the composted product is improved. The composting method is simple to operate; kitchen garbage is added into a material hole, the temperature and stirring rotation speed are set, so that the composting device can integrate heating, crushing and stirring; and the composed product can be used for gardening and improving soil. The household in-situ kitchen garbage composting device can realize treatment at a kitchen garbage generating source, so that household garbage treatment load is reduced, and kitchen waste recycling is realized.

Owner:DALIAN UNIV OF TECH

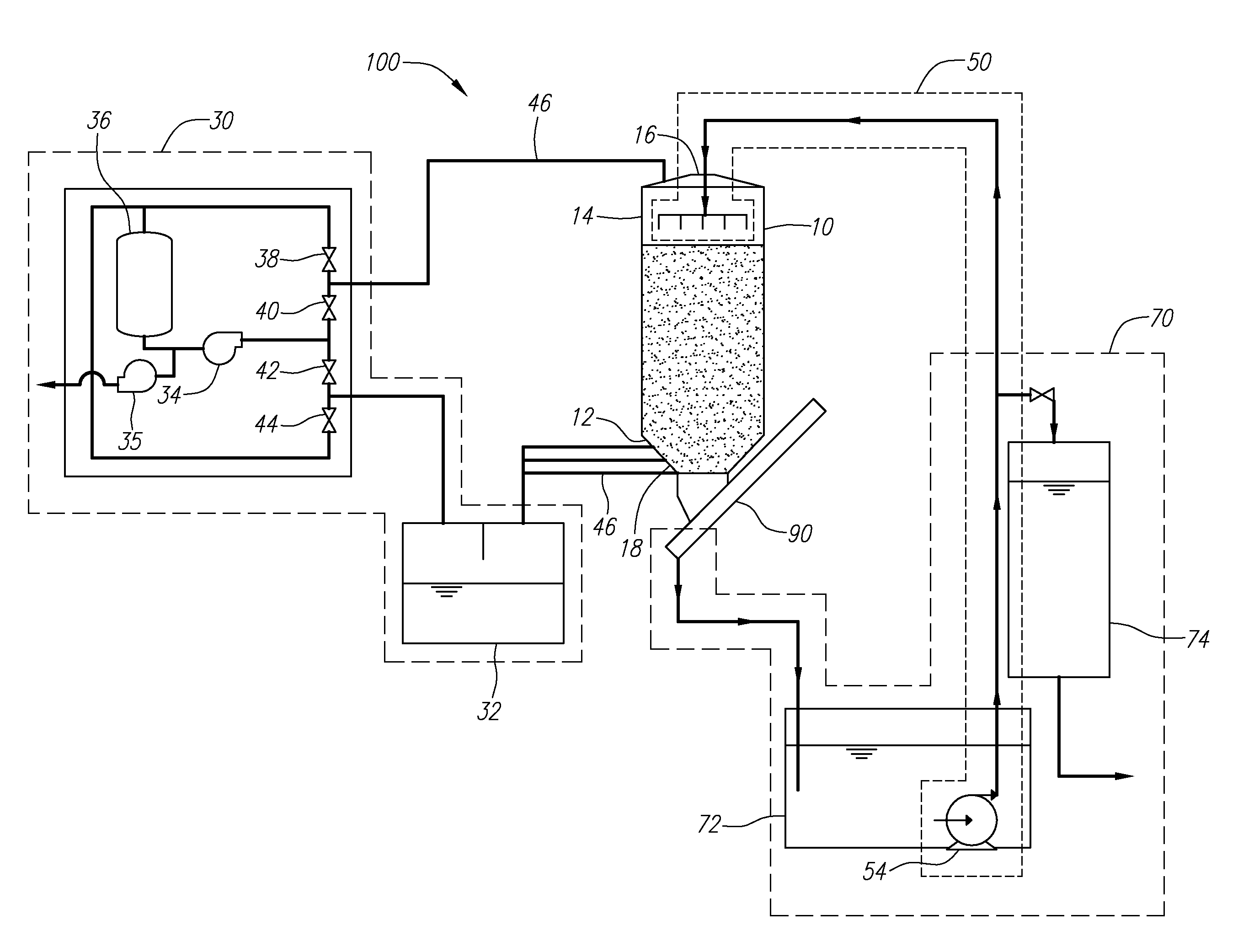

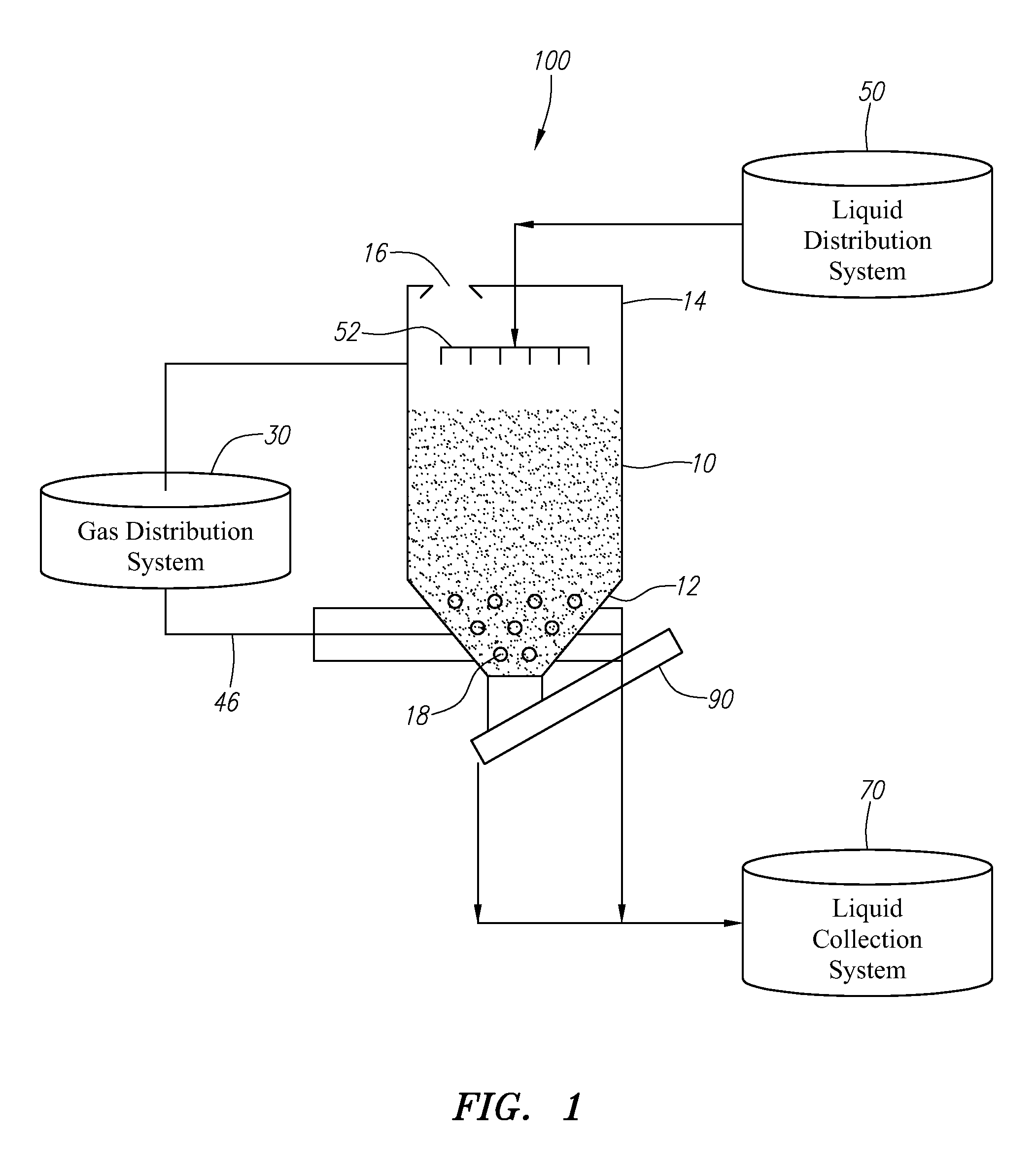

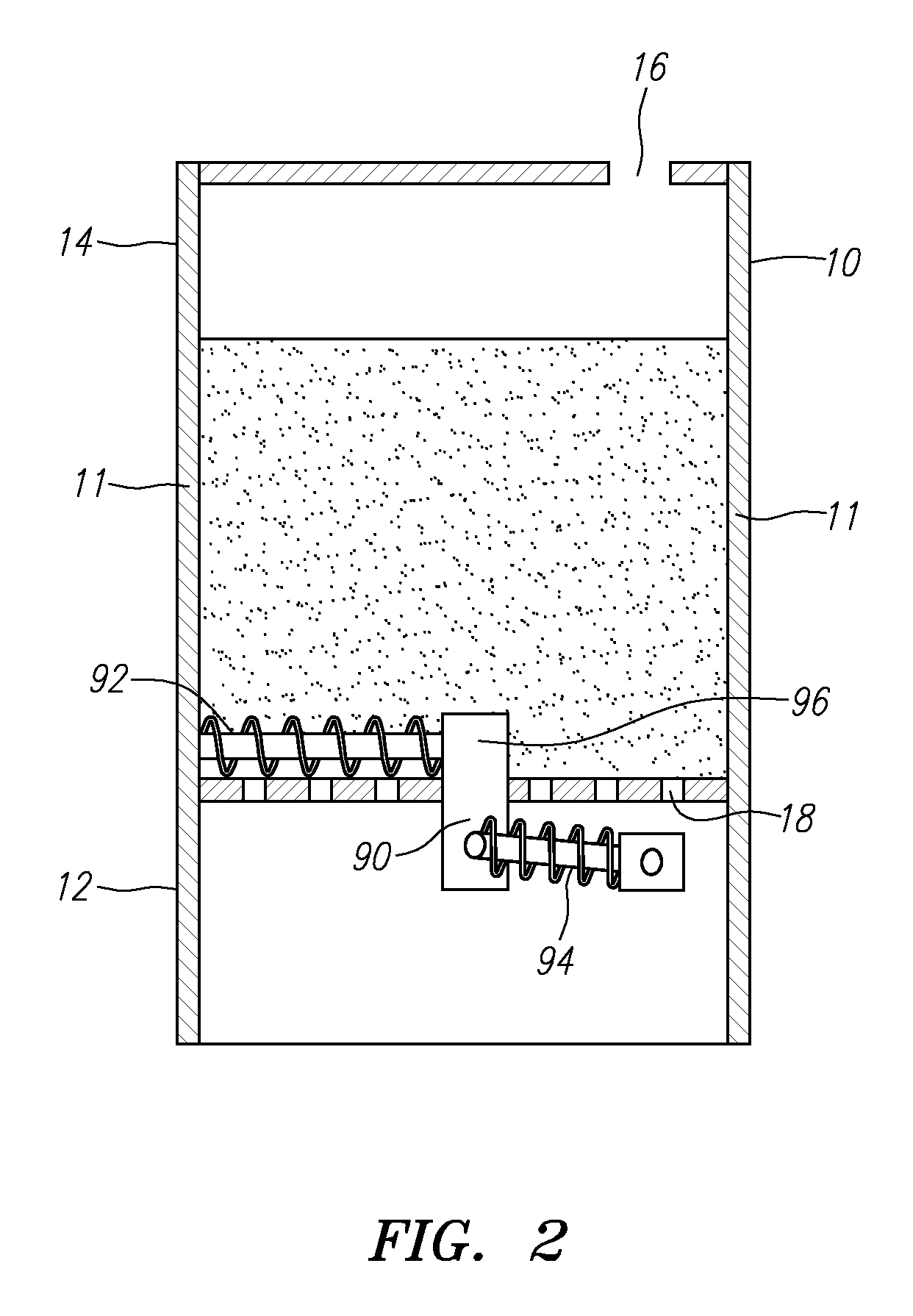

Static solid state bioreactor and method for using same

InactiveUS20100261242A1Quantity minimizationReadily and cost-effectivelyBioreactor/fermenter combinationsBio-organic fraction processingMaterial removalMarine engineering

A static solid state bioreactor and method of using same. The bioreactor comprises a vessel having an upper end and a lower end, the upper end having a sealable opening. A gas distribution system in communication with the upper end and the lower end of the vessel. A liquid distribution system in communication with the upper end of the vessel. A liquid recovery system in communication with the lower end of the vessel. A material removal system disposed at the lower end of the vessel for removing biomass from the vessel.

Owner:GEOSYNFUELS

Organic waste treatment apparatus

InactiveUS20050260744A1Effective alternativeSmall sizeBioreactor/fermenter combinationsProductsMarine engineeringWaste treatment

A composting system including a vertically-orientated vessel with a range of mechanisms attached to a vertically oriented central mounted rotating shaft, including rotatable size reduction blade(s), agitation mechanism(s), and discharge blade / mechanism(s). The composting system includes internal size reduction mechanism for reducing the size of waste and / or organic material introduced to the vessel. The composting system includes a loading hatch through which material may be introduced into the vessel, a discharge hatch through which material may be removed from the lower region of the vessel, and a source of air to maintain aerobic conditions within said vessel. When the apparatus is in use, material introduced to the vessel moves from the upper region of the vessel gravitationally and via agitation through a zone of size reduction to the lower region of the vessel. Process conditions within the vessel are controlled via intervention by an operator and via electronic control mechanism, which can monitor operating conditions such as temperature and loading rate (for example), to manage air injection, mechanical agitation and size reduction such that composting proceeds efficiently and at an optimal rate.

Owner:BIOSYS

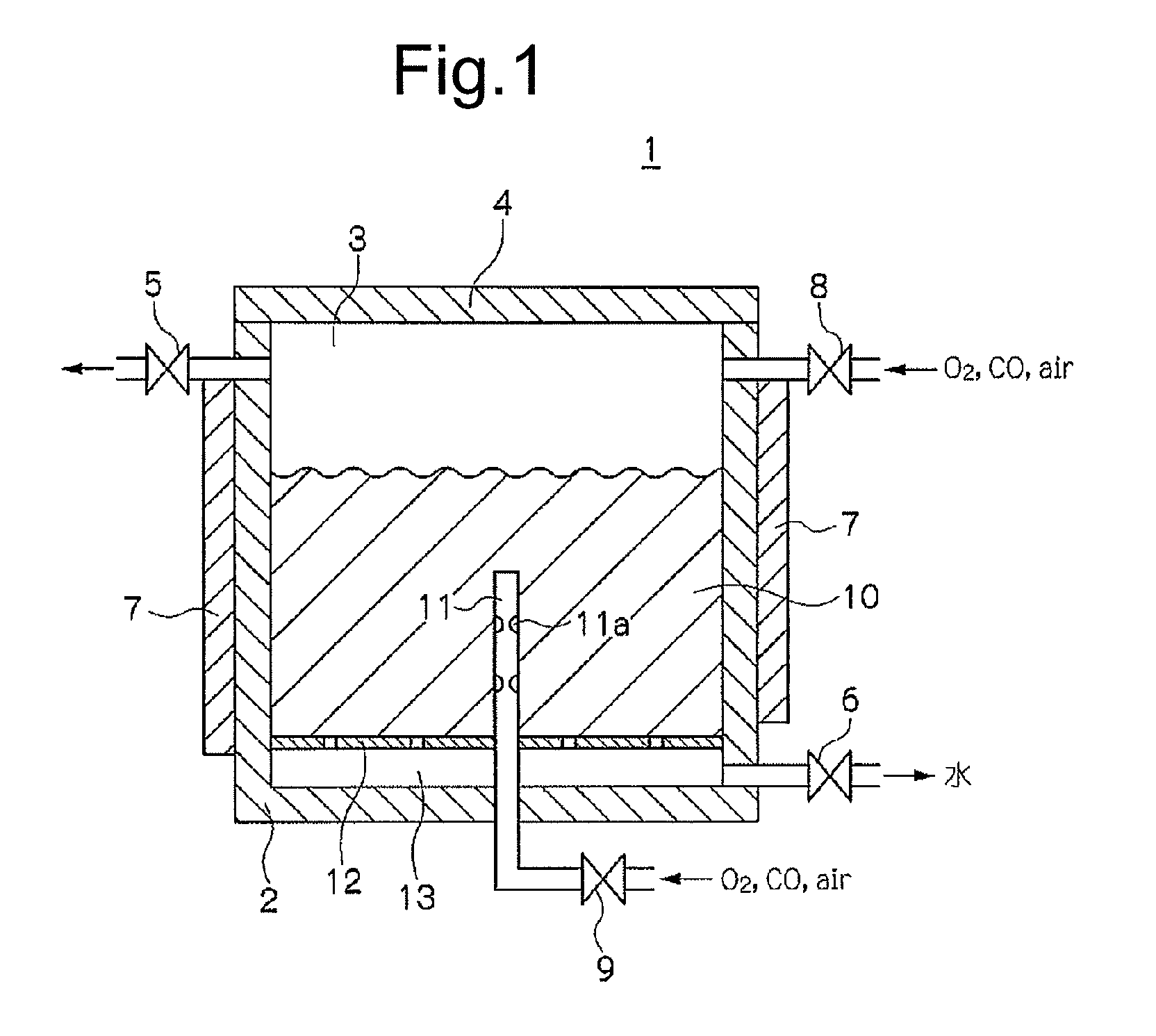

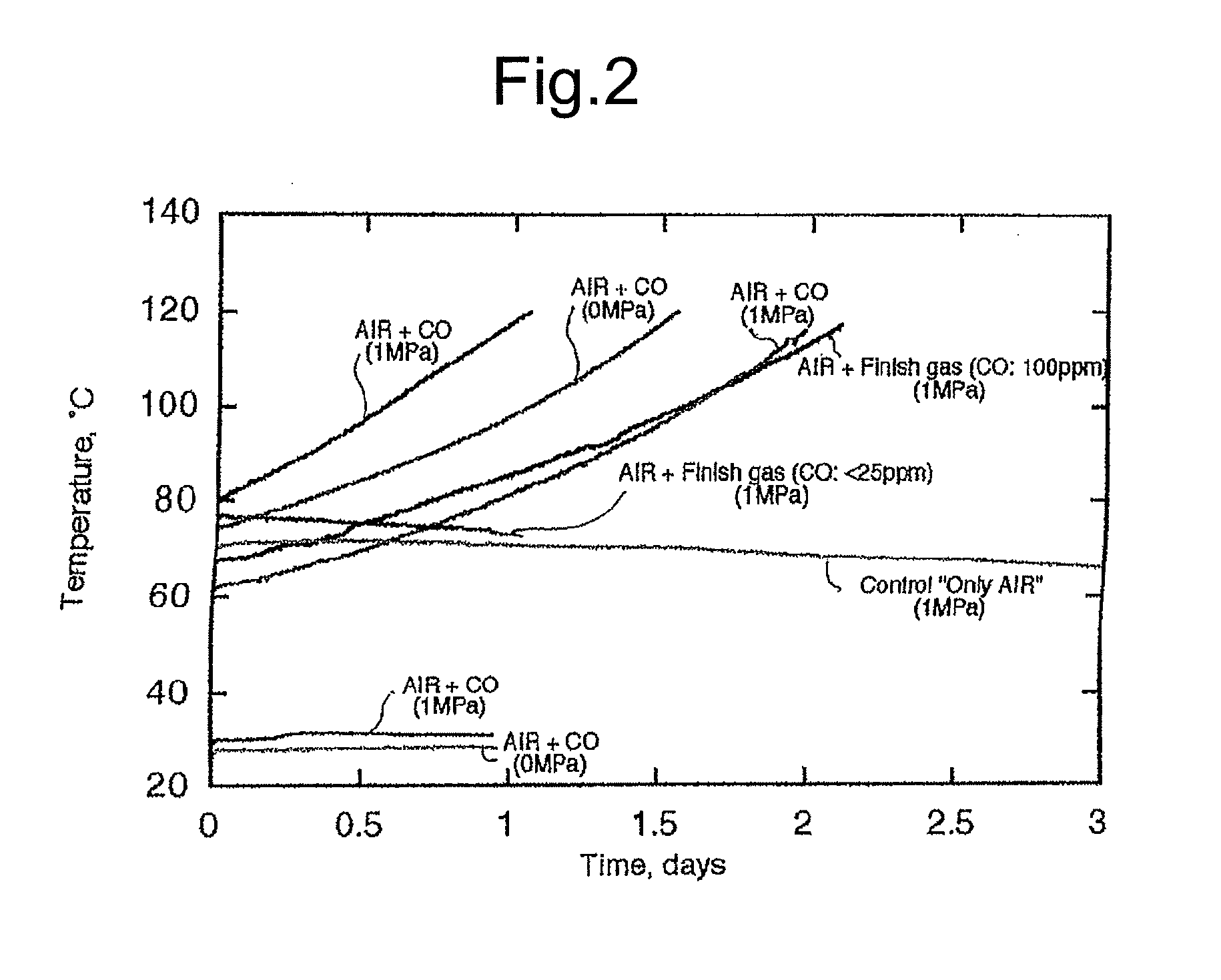

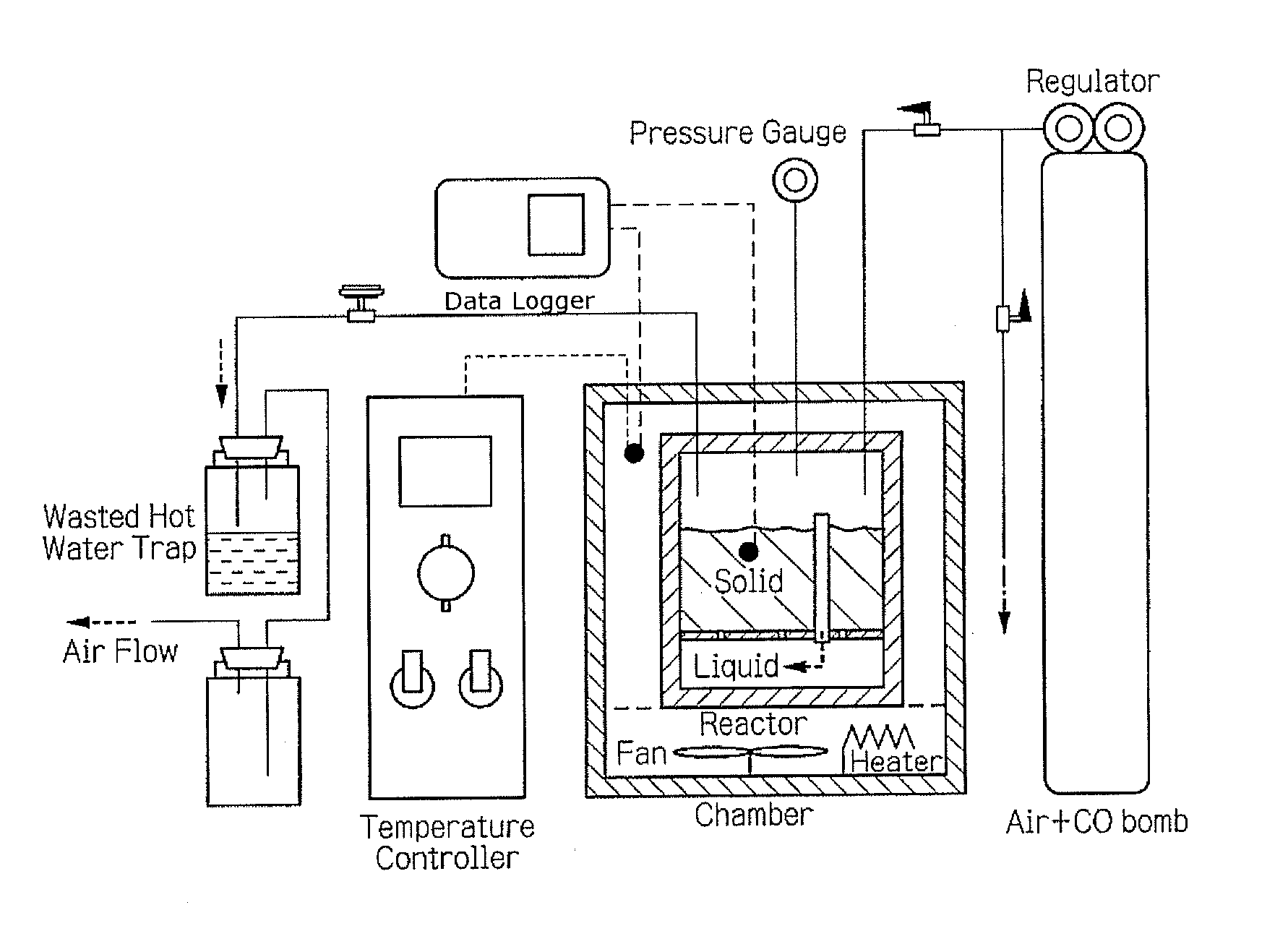

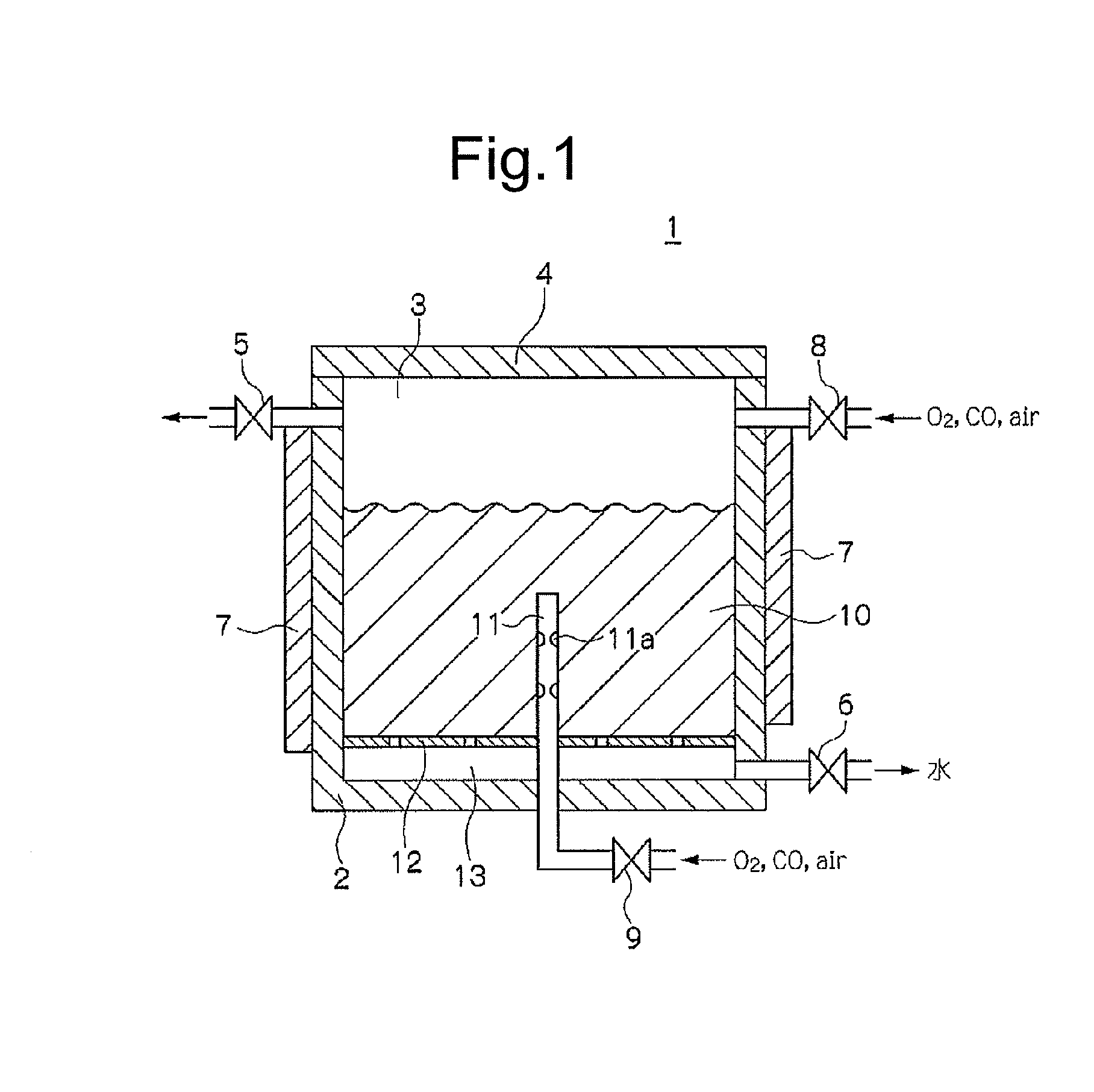

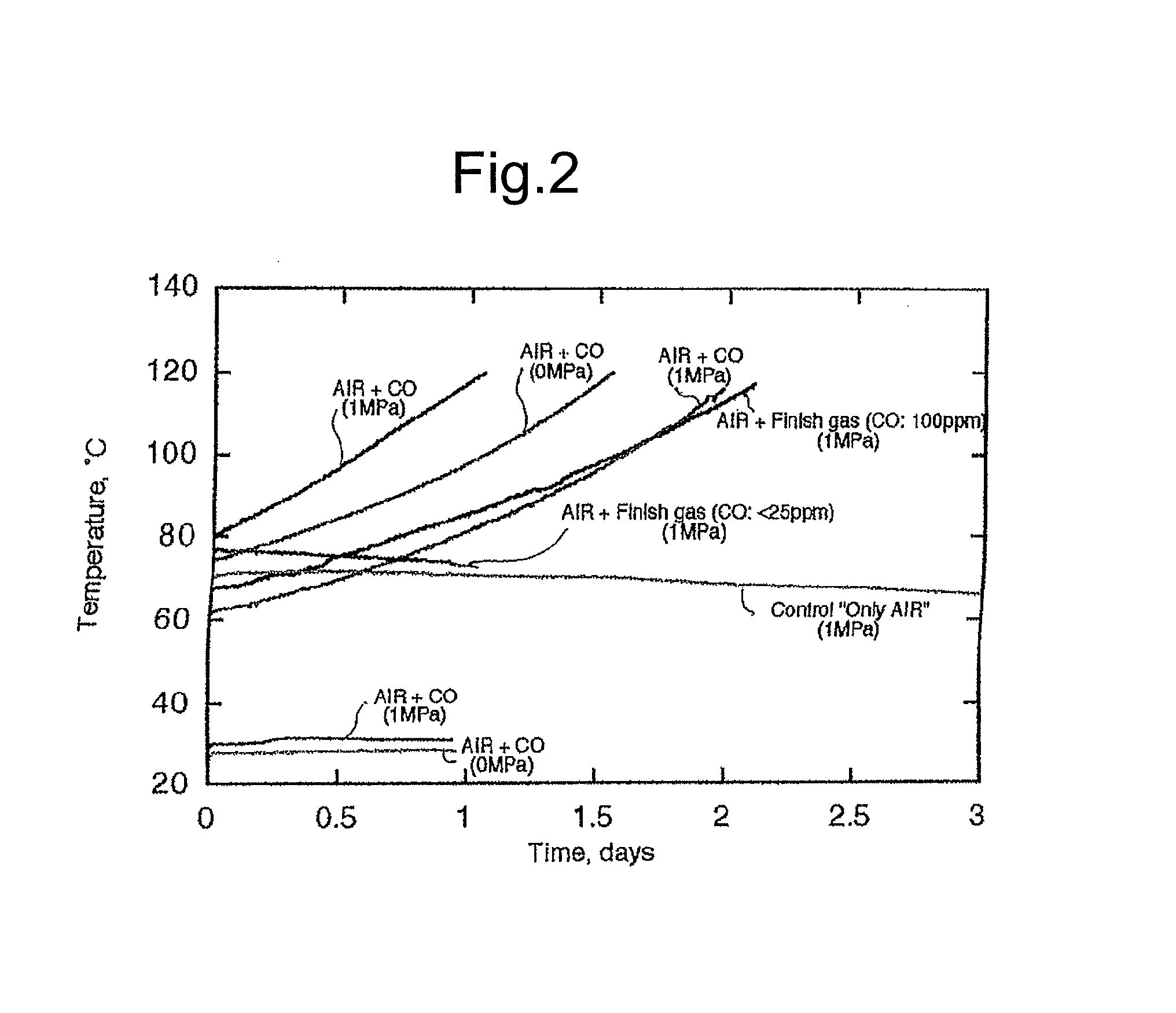

Method for treating biomass material and method for using heat energy

ActiveUS20120193212A1Material efficiencyImprove efficiencyBio-organic fraction processingSludge treatment by oxidationCarbonizationEngineering

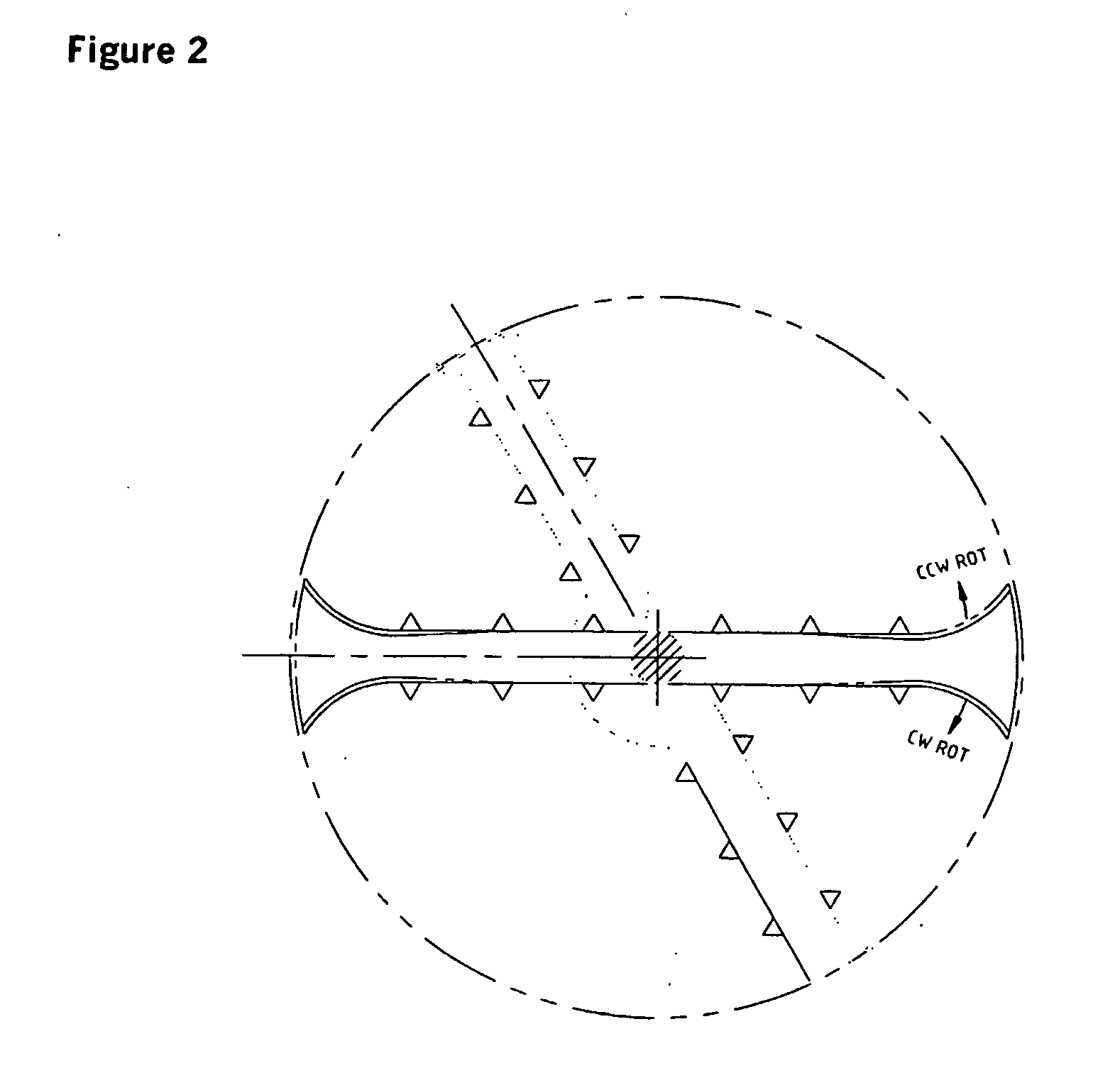

A method of treating biomass material, which can achieve volume reduction or carbonization of biomass material can be achieved at extremely low cost, is disclosed. The method of treating biomass material to achieve volume reduction or carbonization of one type or more of biomass material which is selected among food scraps, livestock excreta, agricultural waste products, marine waste products and forest waste products in a pressurizable and heatable container, includes: placing the biomass material in the container; setting an initial condition of the container after placing the biomass material, the initial condition including all of (a) an atmosphere in the container having oxygen, (b) a temperature range in the container being equal to or greater than 55 degree Celsius and equal to or less than 80 degree Celsius, (c) a pressure range in the container being equal to or greater than atmospheric pressure and equal to or less than 15 atmospheric pressure and (d) carbon monoxide concentration being equal to or greater than 100 ppm; increasing temperature of the biomass material over 80 degree Celsius under the initial condition; setting a continuation condition after initiating increase in the temperature of the biomass to over 80 degree Celsius under the initial condition, the continuation condition including (i) the atmosphere in the container having oxygen, (ii) the pressure range in the container being equal to or greater than atmospheric pressure and equal to or less than 15 atmospheric pressure and (iii) a carbon monoxide concentration in the container being equal to or greater than 100 ppm; and maintaining the continuation condition, in order to spontaneously increase temperature of the biomass material over at least 150 degree Celsius, and achieve volume reduction or carbonization of the biomass material.

Owner:TANIGURO KATSUMORI (I) (JP)

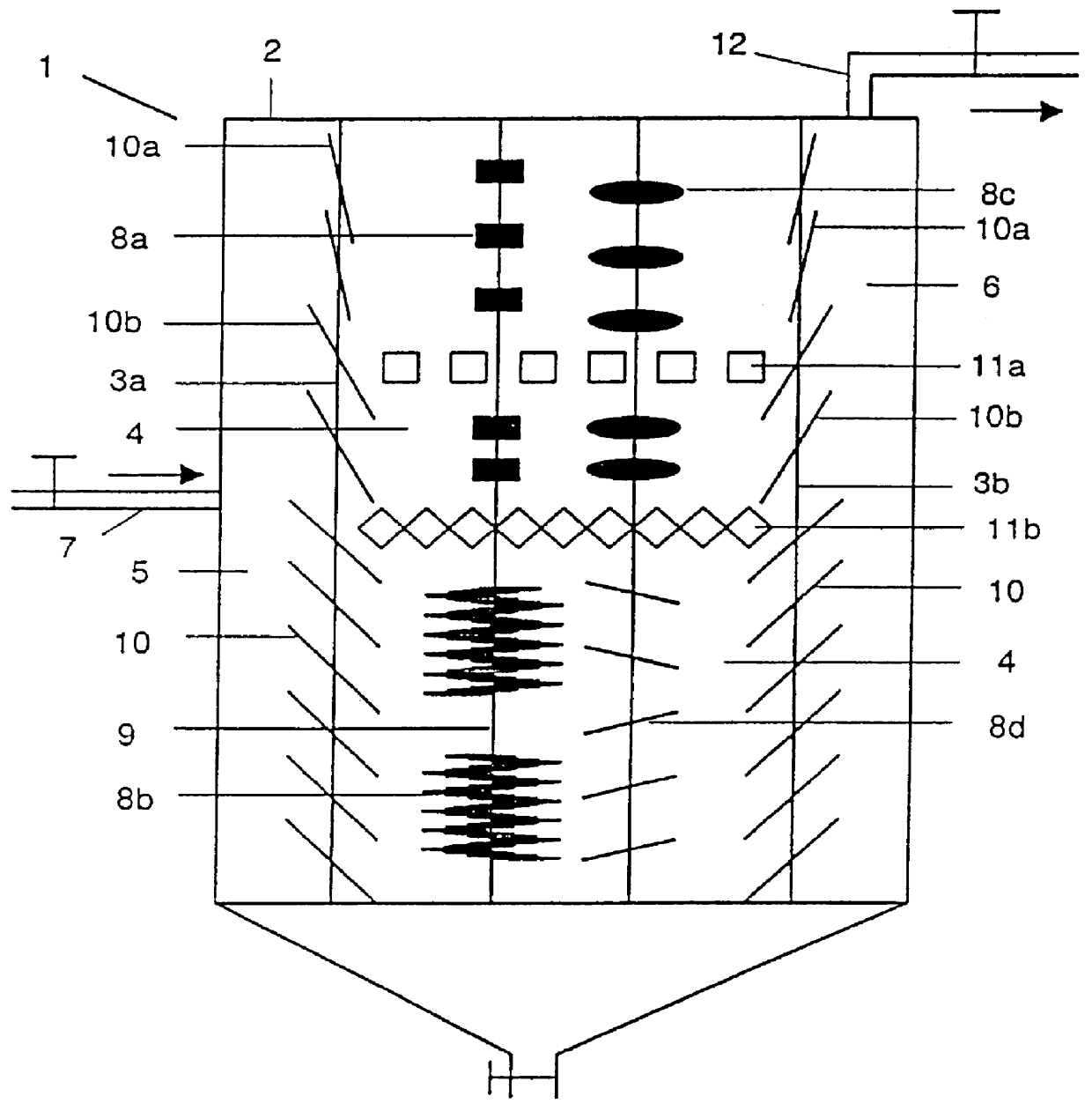

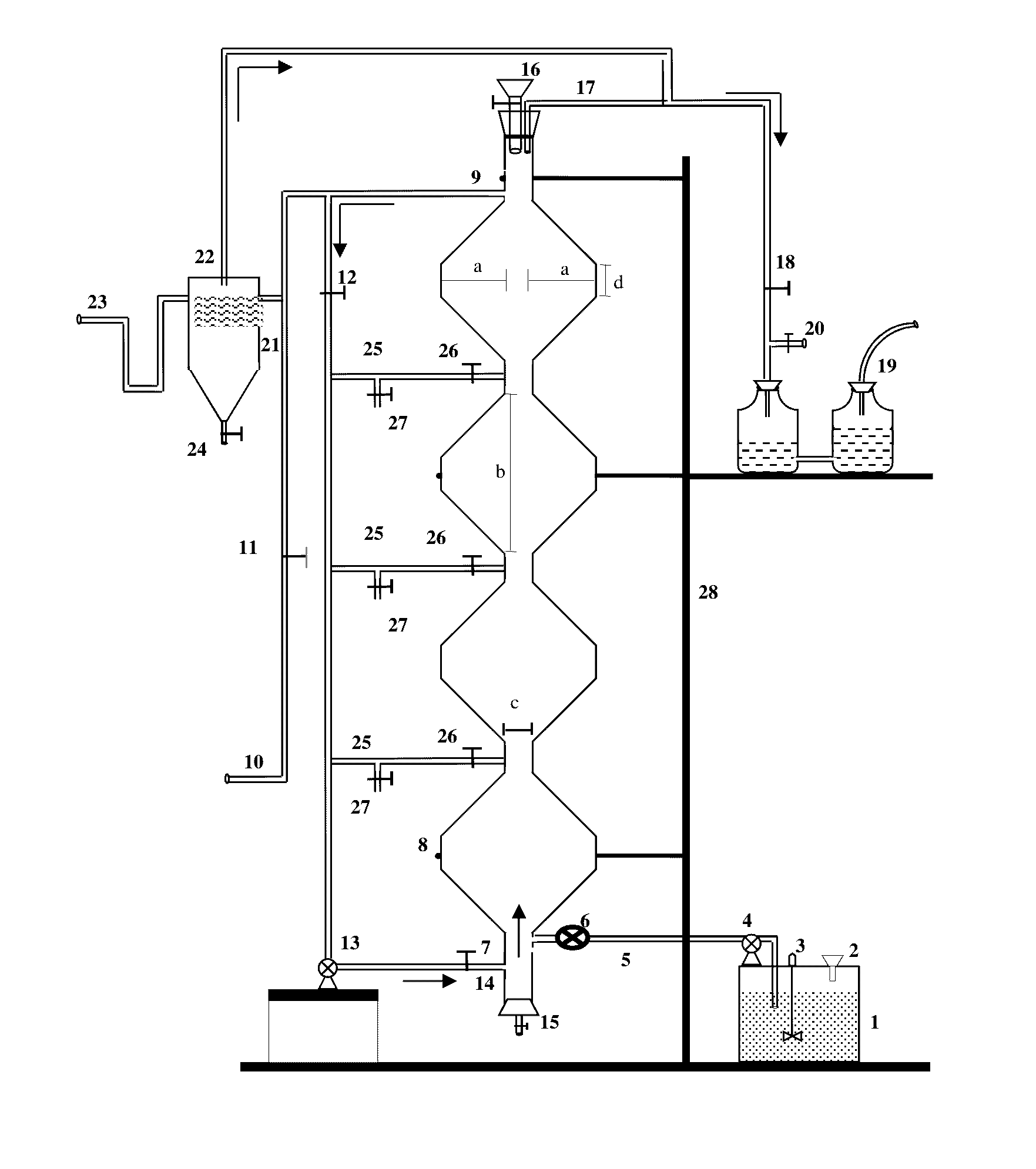

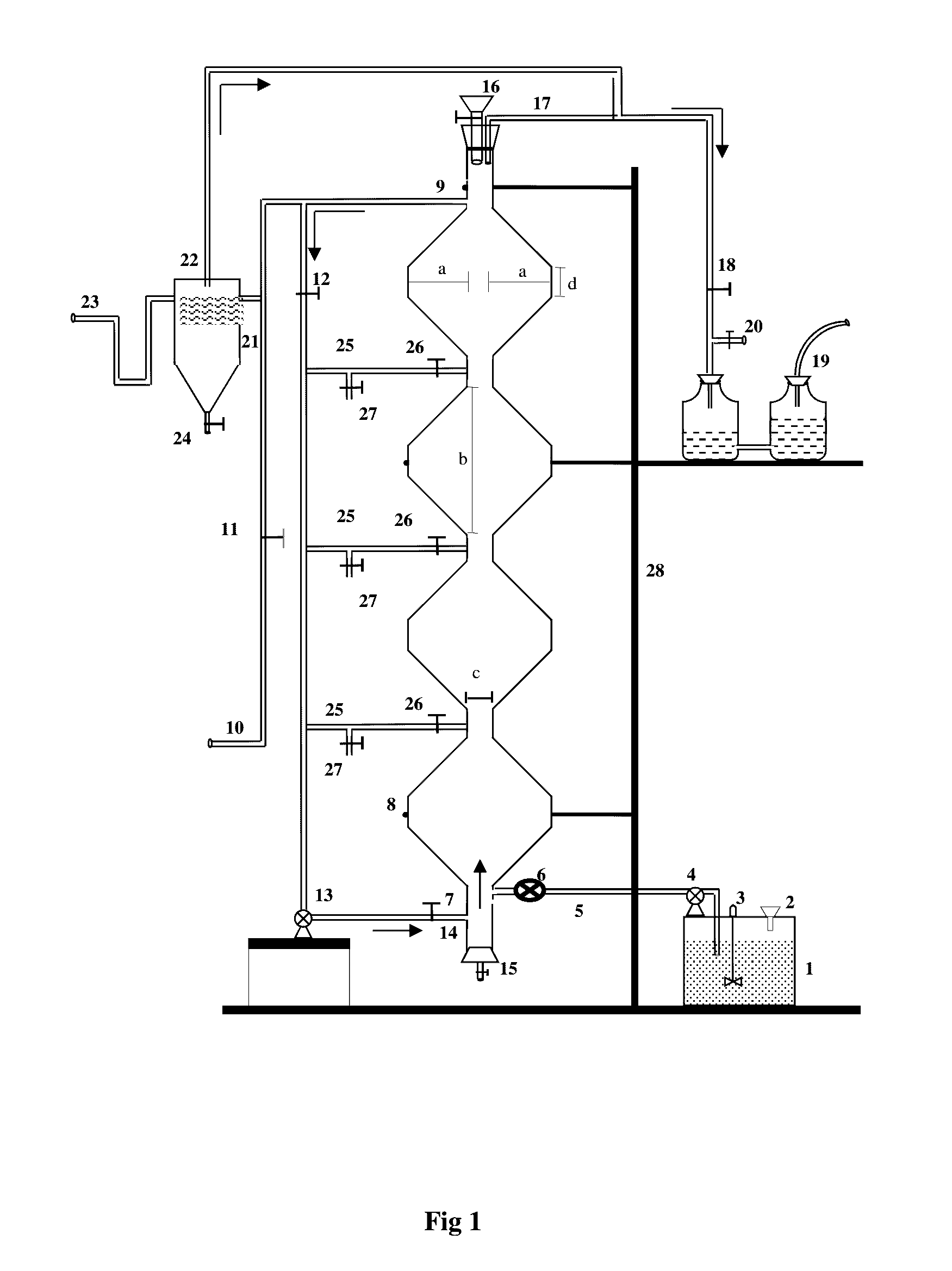

Anaerobic column reactor for biodegradation of wastes and the process thereof

ActiveUS20170050892A1Prevent escapeEnhances biomass substrate contactBioreactor/fermenter combinationsBio-organic fraction processingProcess engineeringAnaerobic reactor

The present invention relates to an anaerobic column reactor for biodegradation of wastes. Particularly the present invention relates to a process for conversion of biodegradable wastes to biogas and compost. More particularly, the present invention relates to an anaerobic reactor with unique arrangement of expanded and constricted portions alternatively placed vertically over each other which enhances the mixing pattern and thereby the mass transfer rates while controlling the biomass washout by regulating the upflow liquid velocity.

Owner:COUNCIL OF SCI & IND RES

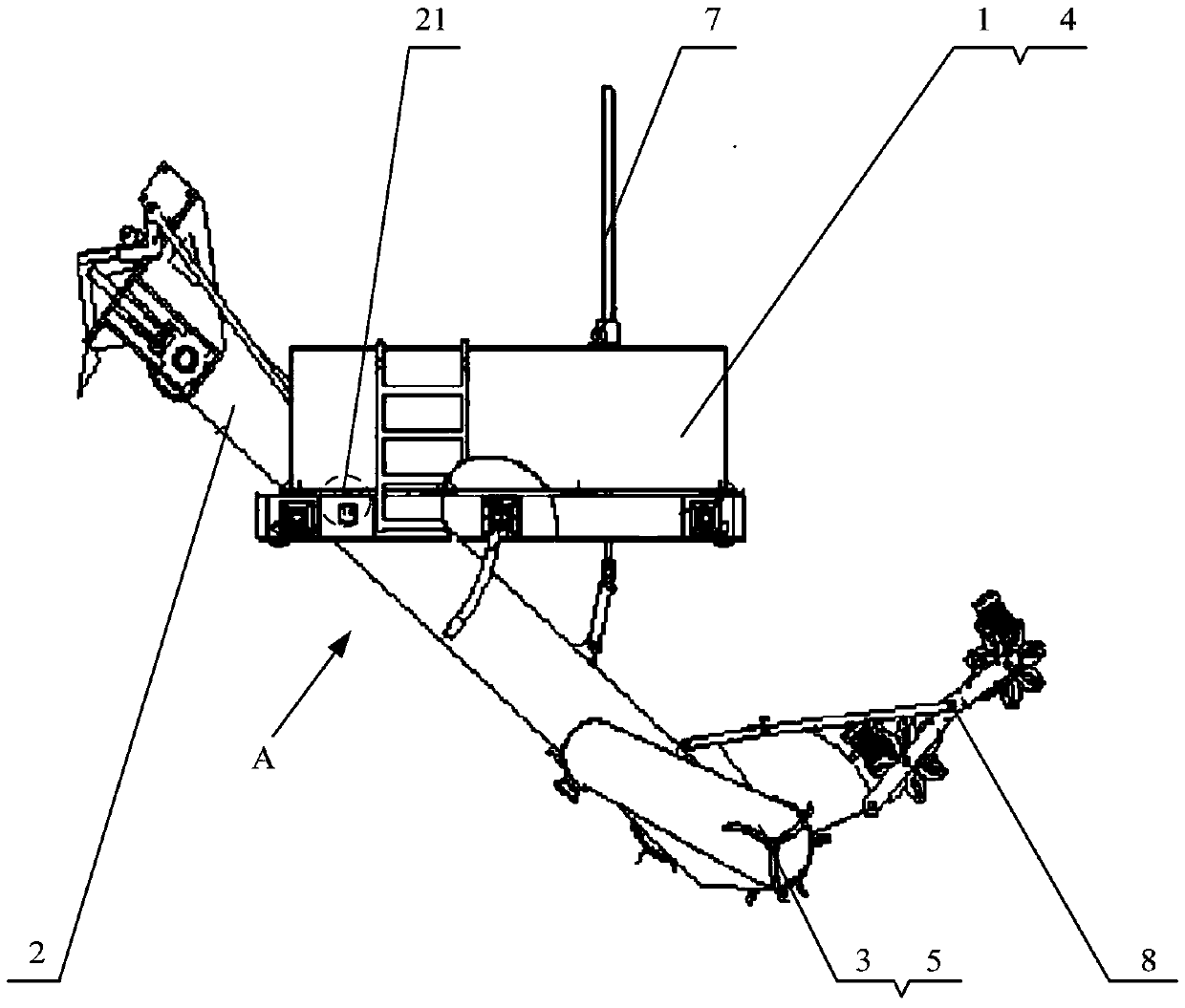

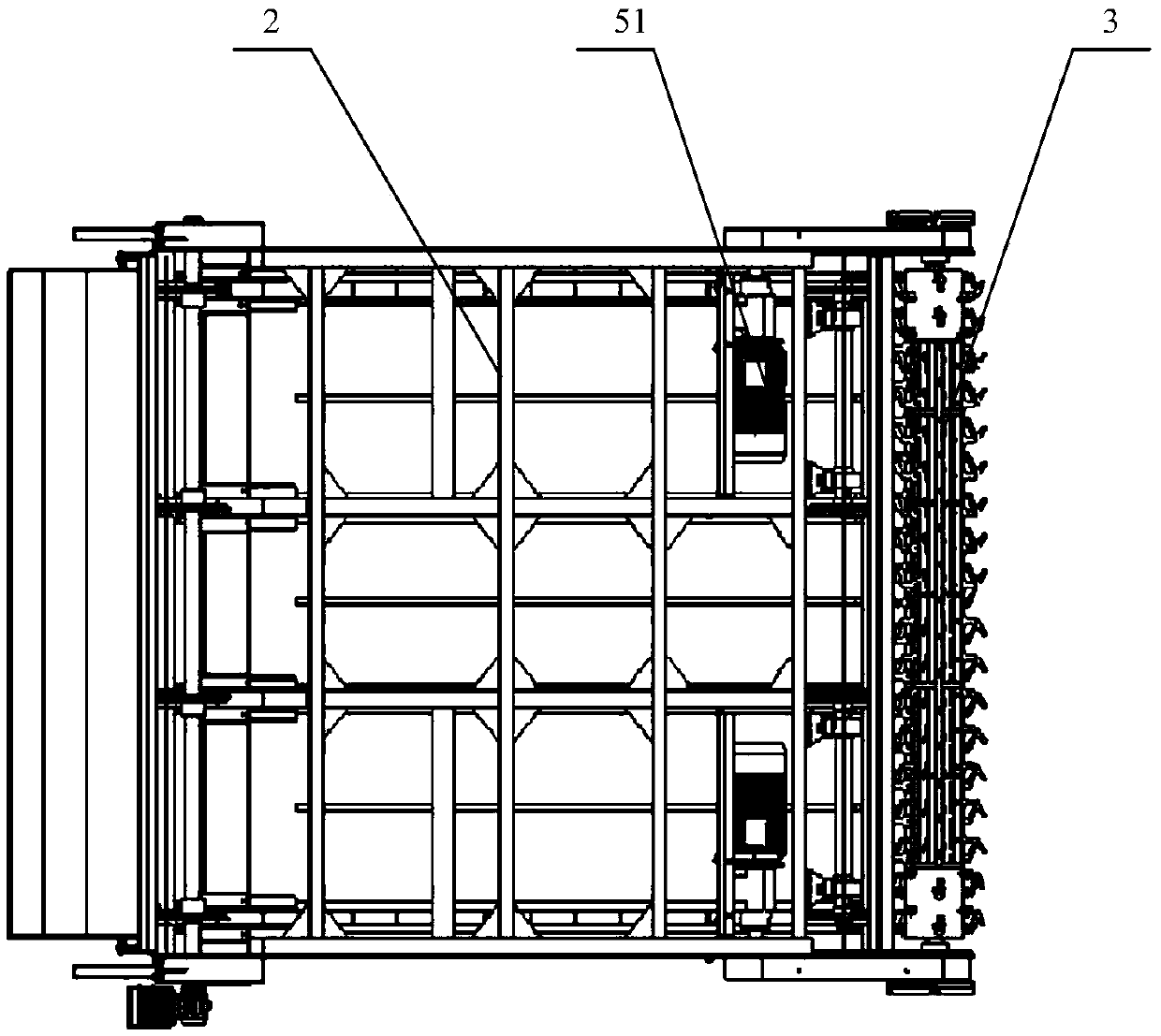

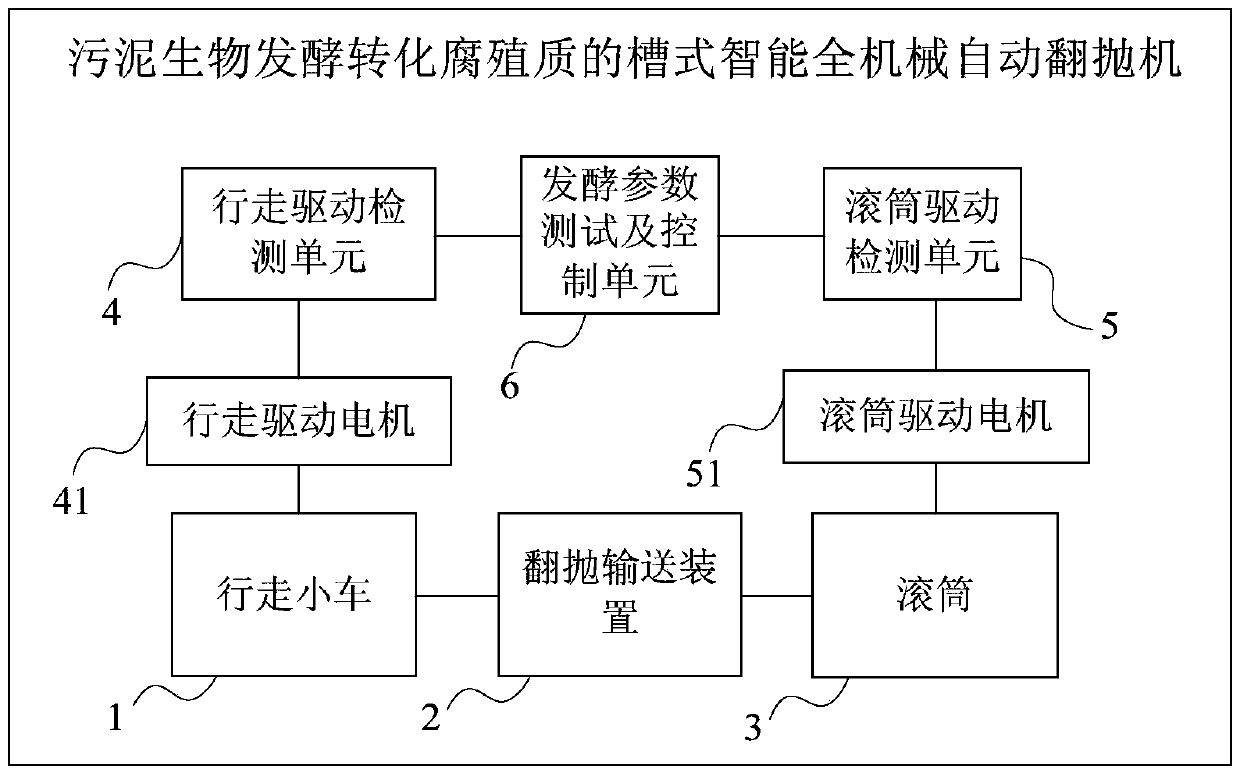

Fully-mechanical intelligent and automatic trough type compost turner with capacity of capacity of converting sludge into humus through biological fermentation

ActiveCN105503287ARealize intelligent automationReduce human inputBio-organic fraction processingClimate change adaptationElectricitySludge

The invention provides a fully-mechanical intelligent and automatic trough type compost turner with capacity of converting sludge into humus through biological fermentation. The fully-mechanical intelligent and automatic trough type compost turner with capacity of converting the sludge into the humus through biological fermentation comprises a travel trolley, a roller, a turned material conveying device, a travel drive detection unit, a roller drive detection unit and a fermentation parameter test and control unit, wherein the roller drive detection unit comprises a roller drive motor, an output end of the roller drive motor is connected with a roller shaft of the roller through a roller reducer, and the roller drive motor is used for driving the roller to rotate so as to turn materials in a fermentation trough; the fermentation parameter test and control unit is electrically connected with the travel drive detection unit and the roller drive detection unit and used for controlling output of a travel drive motor and the roller drive motor according to material resistance of the roller. The fully-mechanical intelligent and automatic trough type compost turner can realize automatic turning operation.

Owner:NANTONG ZHONGKE CHUNYUAN ENVIRONMENTAL PROTECTION EQUIP MFG CO LTD

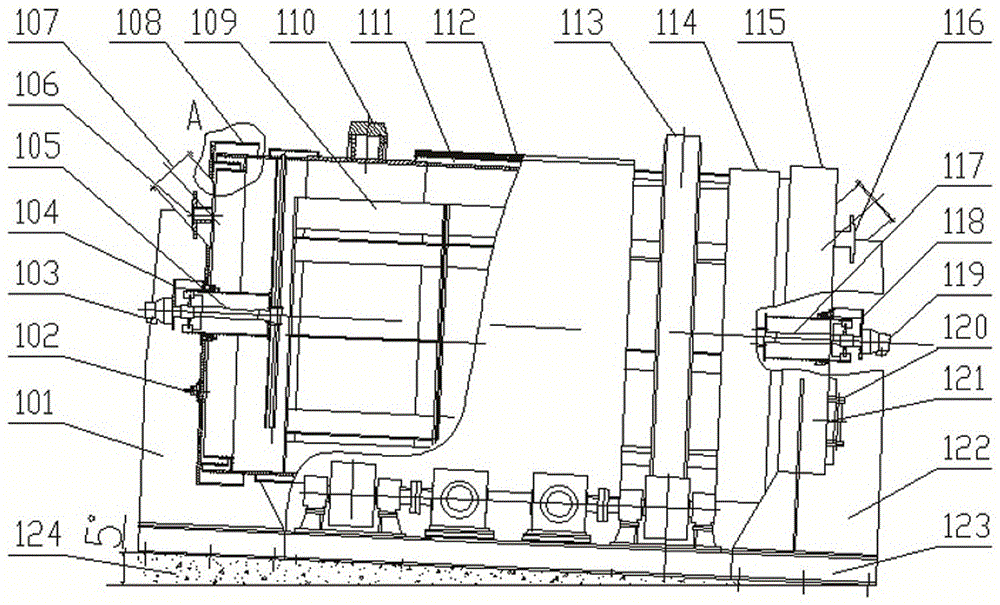

Solid high-temperature aerobic fermentation reaction system and method

ActiveCN106119105AAvoid stickingEasy to use and maintainBioreactor/fermenter combinationsBio-organic fraction processingEnvironmental resistanceSmall footprint

Owner:HUNAN SAKAL ENVIRONMENTAL SCI & TECH CO LTD +1

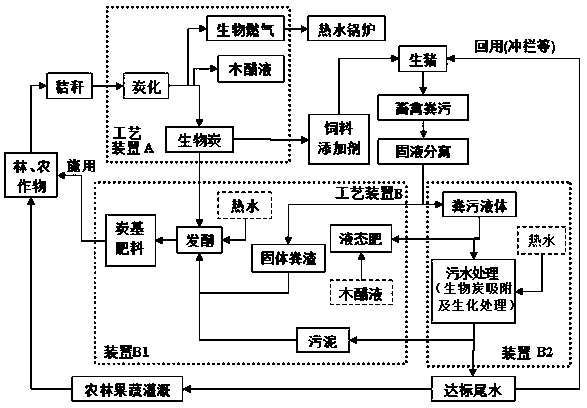

Production system for conducting comprehensive treatment and utilization on waste straw and livestock feces

ActiveCN109534636AReduce finishing costsImprove the ecological environmentBio-organic fraction processingExcrement fertilisersEcological environmentResource utilization

The invention discloses a production system for conducting comprehensive treatment and utilization on waste straw and livestock feces. According to the system, a waste biomass straw treating device and a livestock feces treating device are combined, and are comprehensively used, wherein the waste biomass straw treating device conducts pyrolysis and carbonization treatment on the waste biomass straw to obtain biochar, wood tar, wood vinegar and associated gas; the livestock feces treating device separates solid fecal residues and liquid feces from the livestock feces; the solid fecal residues enter a fermentation and fertilizer production device, the biochar is added into the fermentation and fertilizer production device, and an associated gas heat source is connected for drying to preparecarbon-based bio-organic fertilizer; the liquid feces are subjected to biochar adsorption, solid is returned to the fermentation and fertilizer production device, liquid is connected with hot water heated by the associated gas, the liquid enters a sewage biochemical treatment device, and tail water which reaches the standard is discharged. The system conducts efficient resource utilization on thelivestock feces, and efficiently treats the biomass straw, so that the overall treatment cost is reduced, double economic benefits are generated, the waste straw and the livestock feces are recycled,and the ecological environment is improved.

Owner:湖北金日生态能源股份有限公司

Method for treating biomass material and method for using heat energy

ActiveUS9139790B2Low costEasy to useBio-organic fraction processingSludge treatment by oxidationCarbonizationDegree Celsius

A method of treating biomass material includes: placing biomass material in a container; then setting an initial condition of the container including (a) an oxygen containing atmosphere, (b) a temperature range from 55 degree Celsius to 80 degree Celsius,(c) a pressure range from atmospheric pressure to 15 atmospheric pressure, and (d) carbon monoxide concentration equal to or greater than 100 ppm; increasing temperature of the biomass material over 80 degree Celsius; setting a continuation condition including (i) the oxygen containing atmosphere, (ii) the pressure range from atmospheric pressure to 15 atmospheric pressure, and (iii) a carbon monoxide concentration equal to or greater than 100 ppm; and maintaining the continuation condition, in order to spontaneously increase temperature of the biomass material over at least 150 degree Celsius, and to achieve volume reduction or carbonization of the biomass material.

Owner:TANIGURO KATSUMORI (I) (JP)

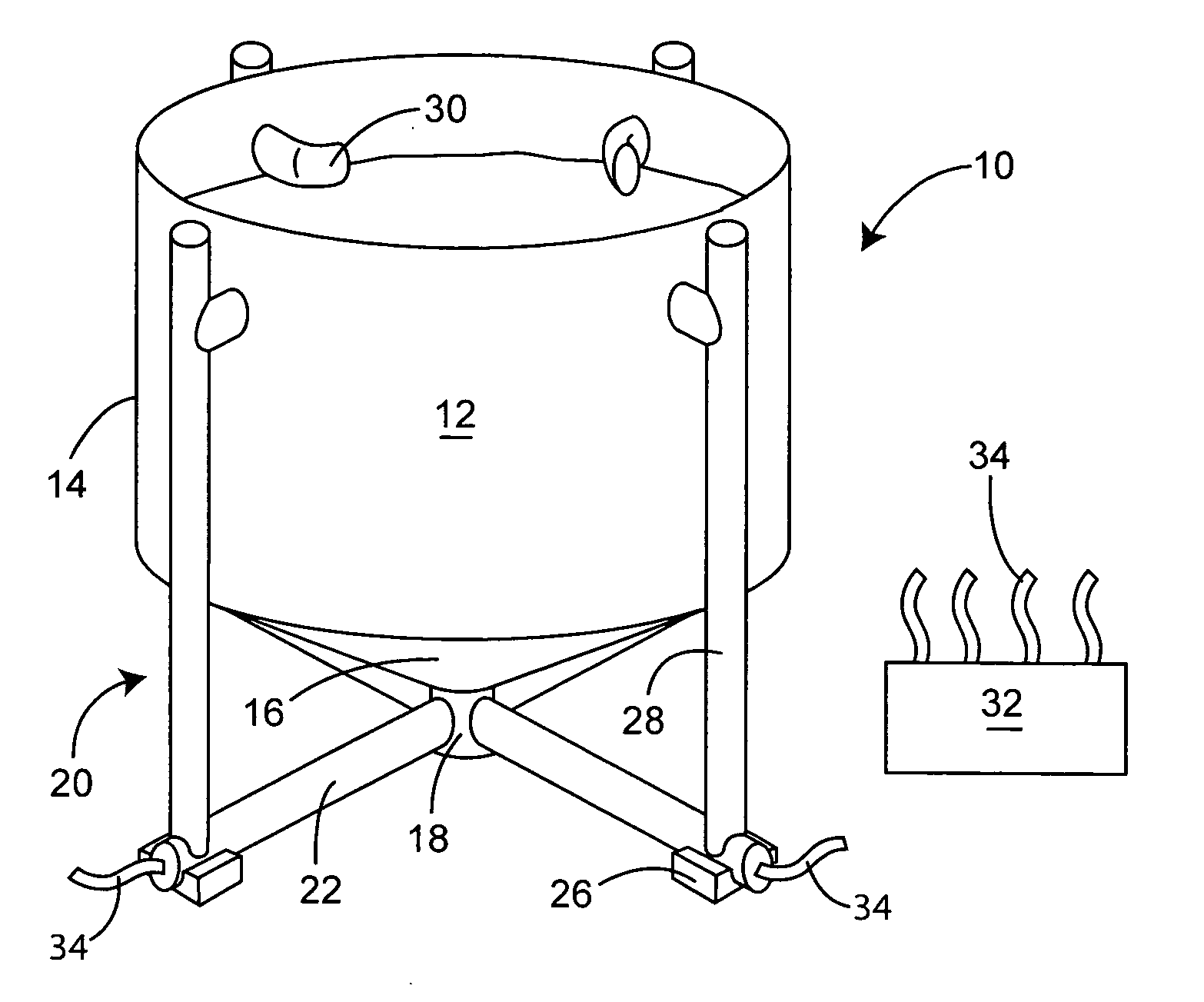

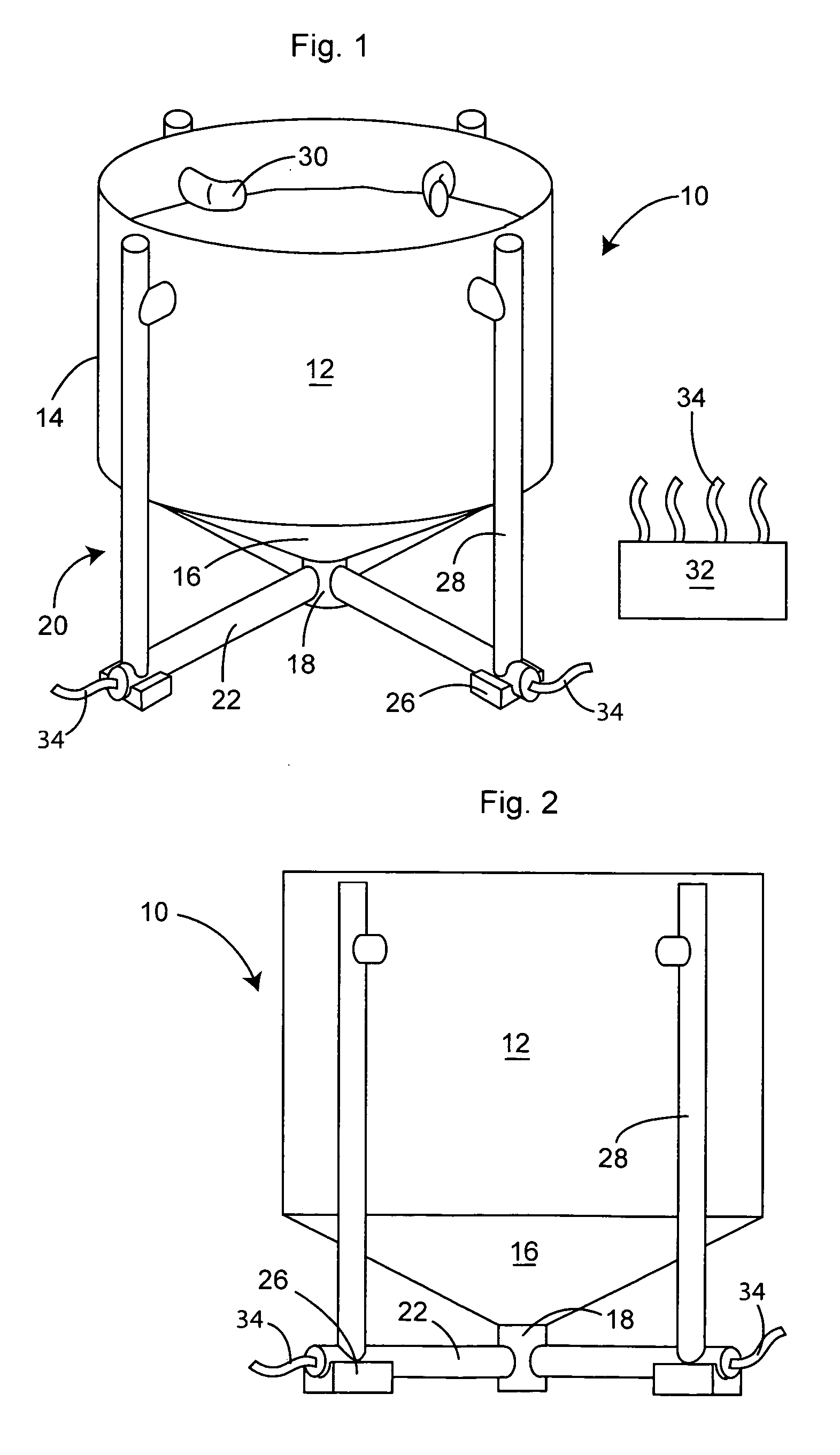

Compost tea brewer

InactiveUS20070059819A1Increase surface areaEnhancing oxygenation potentialBioreactor/fermenter combinationsBio-organic fraction processingMicroorganismWater level

An apparatus for brewing compost tea from an aqueous compost mixture using only air bubbles as a means to circulate the mixture during fermentation. The mixture is held in a tank having a continuous sidewall and a conical bottom section with a central discharge opening. A plurality of equidistant conduits extend from the tank discharge opening to discharge nozzles having discharge ends at or just above the water level in the tank. A compressed air supply is joined by air lines to air diffusers in each of the conduits. During use, air is discharged from the diffusers to continually circulate the aqueous compost mixture upwardly in said conduits from the tank discharge opening to the discharge nozzles. The microorganisms grow rapidly in the aerated water, resulting in a rich compost tea. Due to the conical tank bottom and angled nozzles, the water swirls in the tank, creating a vortex.

Owner:PROGRESSIVE GARDENS LLC

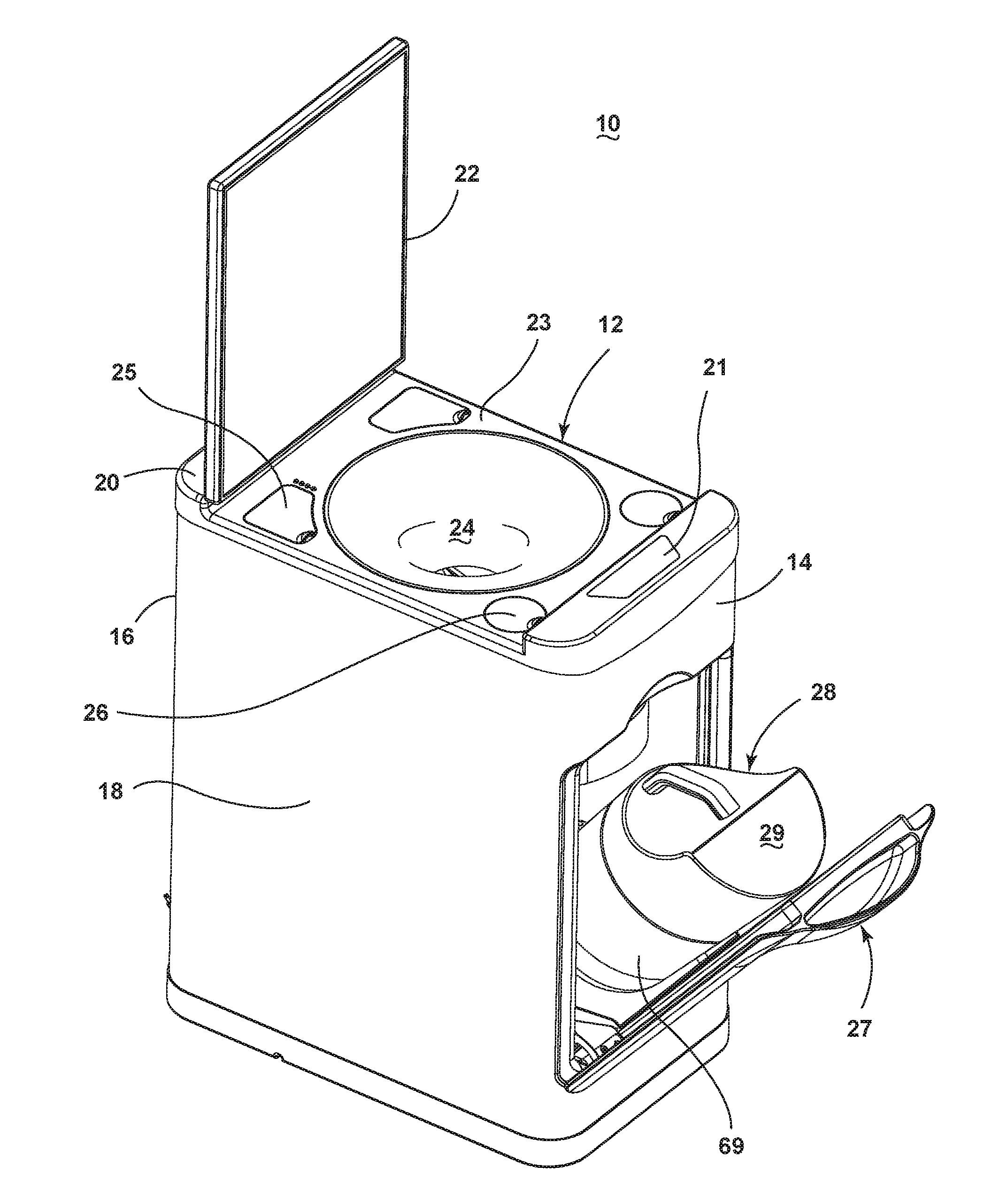

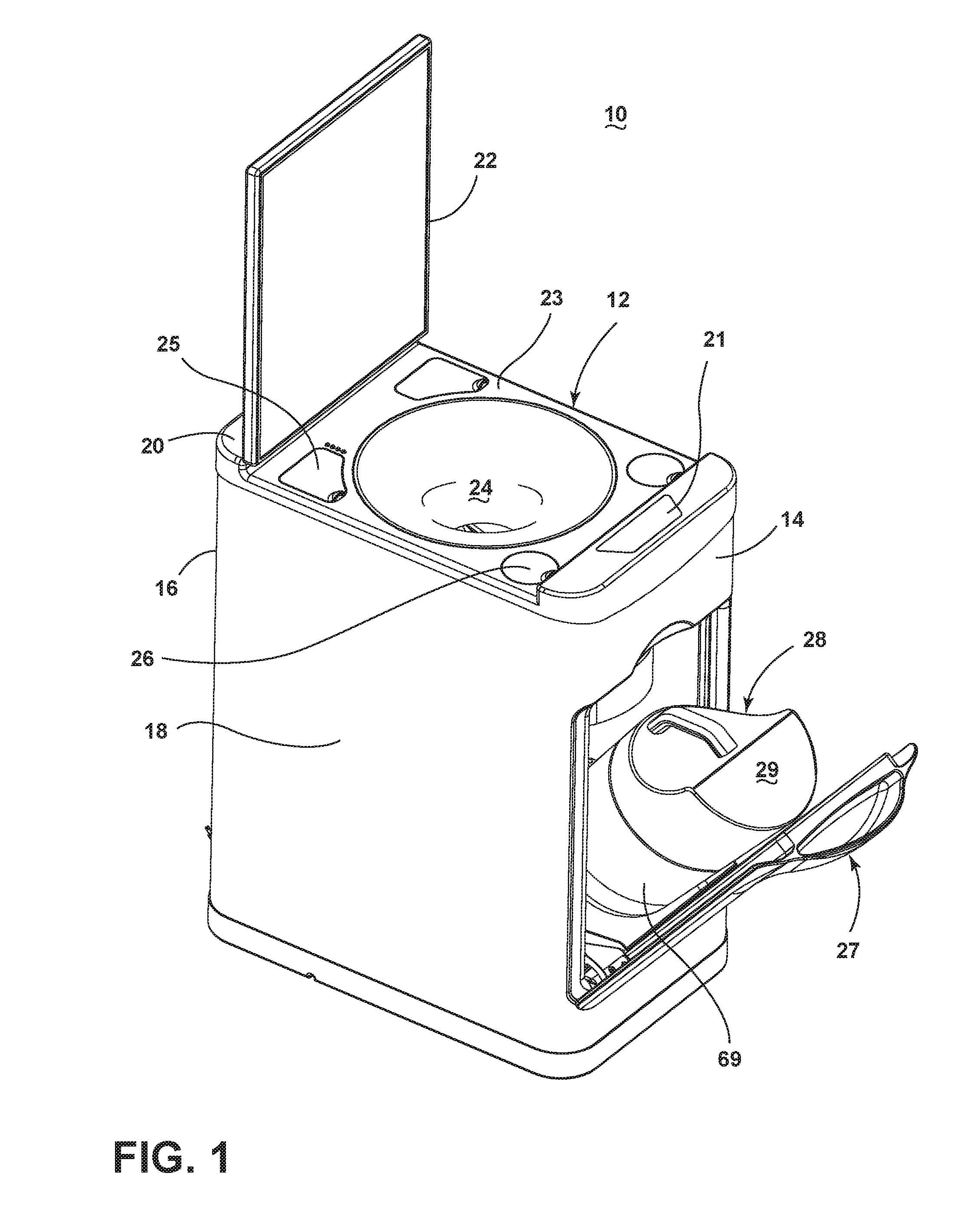

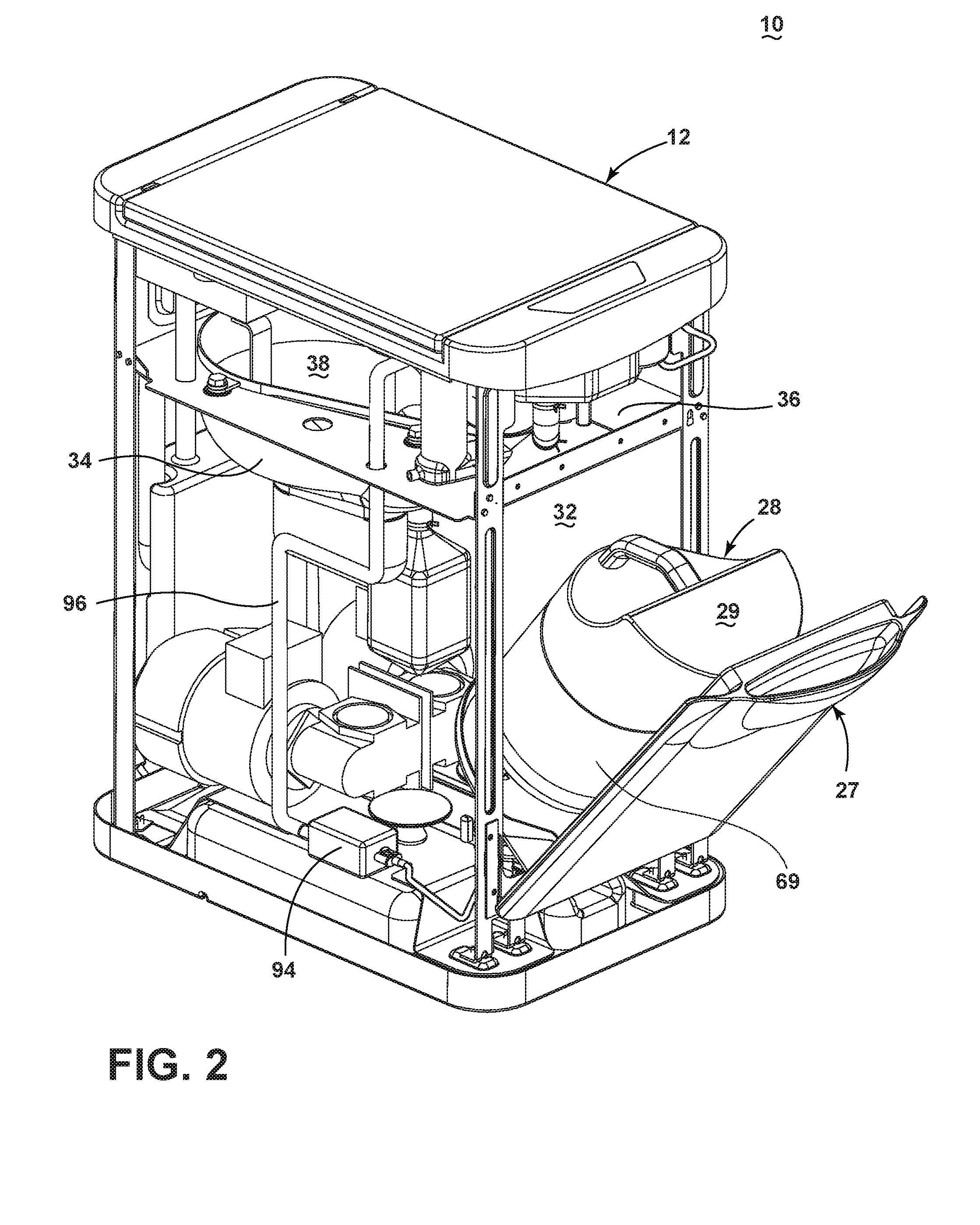

Composting device

InactiveUS20130260446A1Bioreactor/fermenter combinationsBio-organic fraction processingThermal energyEngineering

The invention relates to a device for transforming refuse into compost. The device includes a first chamber having a grinding mechanism to grind refuse. The device also includes a second chamber attached to the first chamber, and a conduit interconnecting the first chamber to the second chamber. The second chamber stores the ground refuse to promote the composting process, and the conduit allows thermal energy and moisture to be shared between the first and second chambers.

Owner:WHIRLPOOL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com