Fecal treatment method and system used in farm

A technology for manure treatment and farms, which is applied in the direction of sludge treatment, sedimentation treatment, anaerobic digestion treatment, etc. It can solve the problems of high investment and operation management costs, insufficient systematization of manure treatment, and low resource utilization rate, etc., to reduce The cost of breeding, the realization of multi-level efficient utilization, and the effect of easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

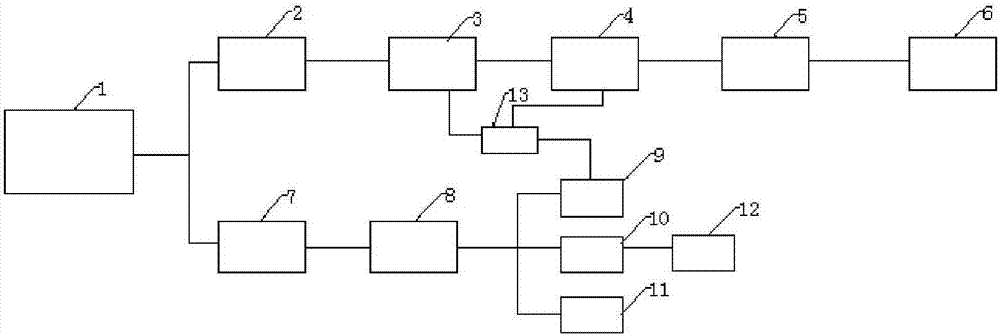

Image

Examples

preparation example Construction

[0073] In an optional embodiment, the preparation method of the bio-organic fertilizer comprises the following steps:

[0074] Pretreating the solid manure, mixing the pretreated solid manure, biogas residue, plant powder, plant ash and sludge according to the proportion, and stirring evenly to obtain a mixture;

[0075] The mixture is added to a fermenter, and fermented after adding a starter;

[0076] After the fermentation is finished, the fermented product is dried until the water content is 8% to 12%;

[0077] Add urea, chitin, chitosan and superphosphate to the dried fermented product according to the ratio, stir and mix evenly, and then send it into a granulator for granulation to obtain the bio-organic fertilizer;

[0078] Preferably, the fermentation temperature is 25-50° C.; the fermentation time is 20-30 days.

[0079] Optionally, drying the ferment to a moisture content of 8%, 9%, 10%, 11% or 12%

[0080] Optionally, the fermentation temperature is 25°C, 30°C, 3...

Embodiment 1

[0096] A method for treating manure from a farm, said method comprising the following steps:

[0097] Carry out solid-liquid separation treatment on feces to obtain solid feces and liquid feces;

[0098] The liquid manure enters the liquid manure adjustment tank for uniform mixing, removes impurities and adjusts evenly, then enters the anaerobic reactor for anaerobic fermentation, and obtains biogas, biogas slurry and biogas residue through the three-phase separator of the anaerobic reactor; The oxygen fermentation conditions are as follows: the temperature is 40° C., the time is 5 hours, and the pH value is 6.

[0099]The biogas slurry enters the sedimentation tank for sedimentation and separation, and then is transported by a power pump for planting vegetables;

[0100] The biogas enters the biogas purification device for purification, and the purified biogas generates electricity through the biogas power generation device;

[0101] The solid manure is pretreated by drying...

Embodiment 2

[0103] A method for treating manure from a farm, said method comprising the following steps:

[0104] Carry out solid-liquid separation treatment on feces to obtain solid feces and liquid feces;

[0105] The liquid manure enters the liquid manure adjustment tank for uniform mixing, removes impurities and adjusts evenly, then enters the anaerobic reactor for anaerobic fermentation, and obtains biogas, biogas slurry and biogas residue through the three-phase separator of the anaerobic reactor; The oxygen fermentation conditions are as follows: the temperature is 50° C., the time is 4 hours, and the pH value is 8.

[0106] The biogas slurry enters the sedimentation tank for sedimentation and separation, and then is transported by a power pump for planting fruit trees;

[0107] The biogas enters the biogas purification device for purification, and the purified biogas generates electricity through the biogas power generation device;

[0108] The solid manure is pretreated by dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com