A multi-stage recovery and comprehensive utilization system of flue gas waste heat in a cogeneration power plant

A flue gas waste heat and thermoelectric technology, which is applied in the direction of combined combustion mitigation, preheating, and feed water heaters, can solve the problems of low-temperature corrosion of the air preheater, large exhaust smoke loss, and low efficiency of waste heat utilization, etc., to improve the inlet temperature , Prevent low temperature corrosion, meet the effect of heat load demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

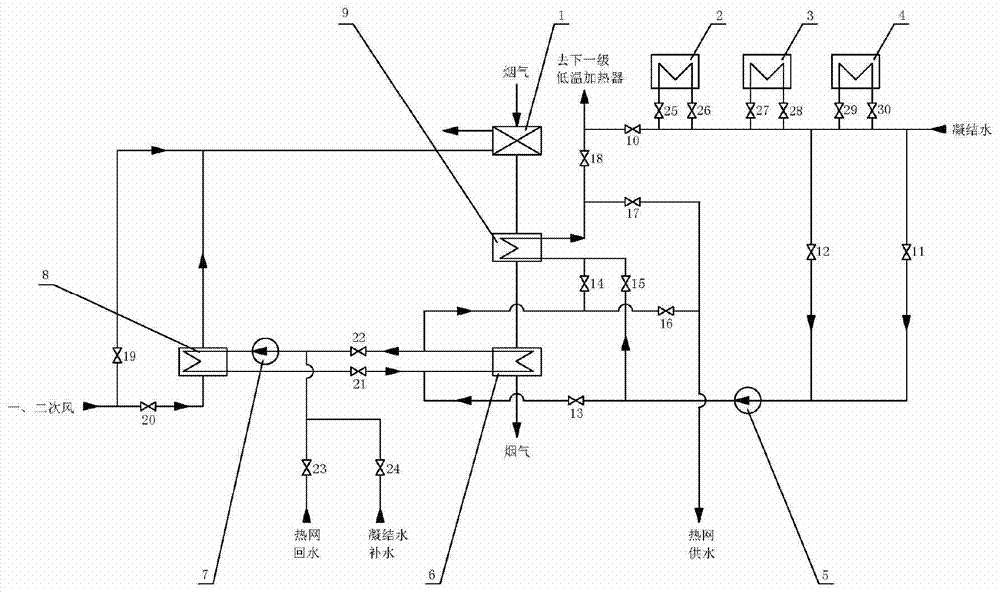

[0028] Such as figure 1 As shown, the flue gas waste heat multi-stage recovery and comprehensive utilization system of a combined heat and power plant includes an air preheater 1, a sixth low-temperature heater 2, a seventh low-temperature heater 3, an eighth low-temperature heater 4, condensate pumps 5, and two Level 1 flue gas cooler 6, closed circulation water pump 7, air heater 8, level 1 flue gas cooler 9 and related connecting pipelines, valves, etc.

[0029] Condensate water inlet is divided into two ways, through the pipe,

[0030] One path is connected to the water inlet of the condensate pump 5 through the eleventh cut-off valve 11; The primary low temperature heater is connected.

[0031] The 30th stop valve 30 is set at the entrance of the eighth low temperature heater 4, the 29th stop valve 29 is set at the outlet, the 28th stop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com