Patents

Literature

174results about How to "Avoid Low Temperature Corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

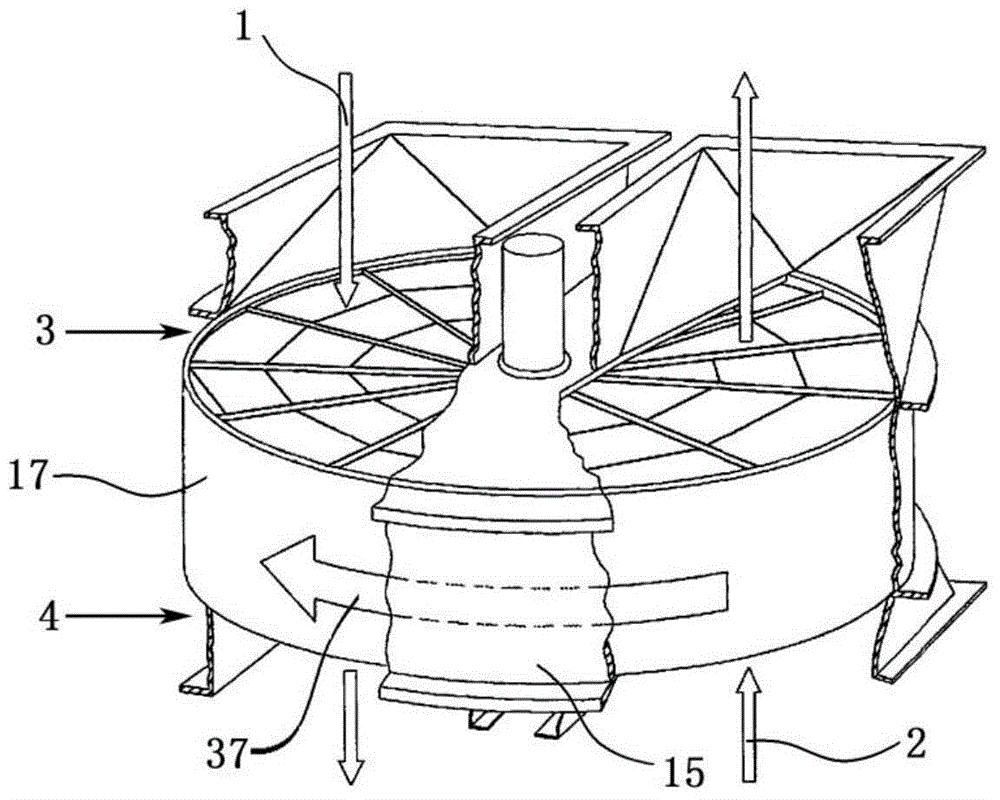

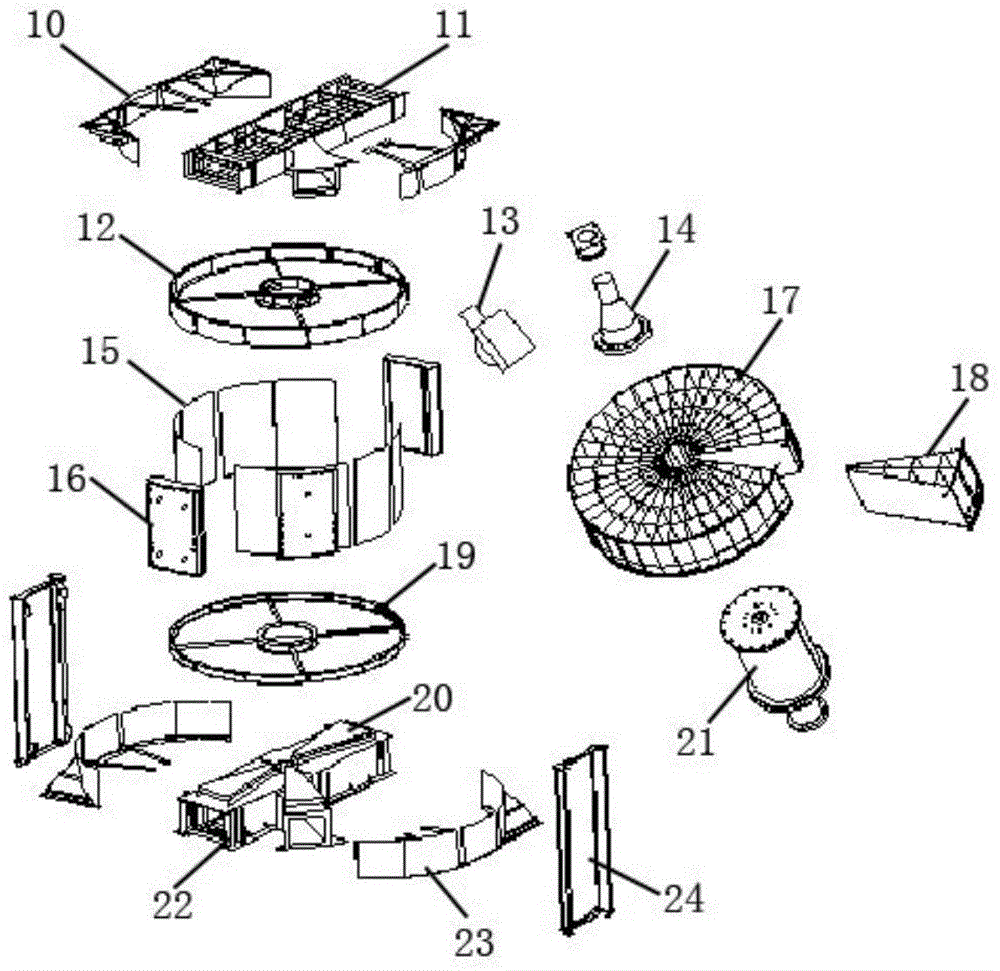

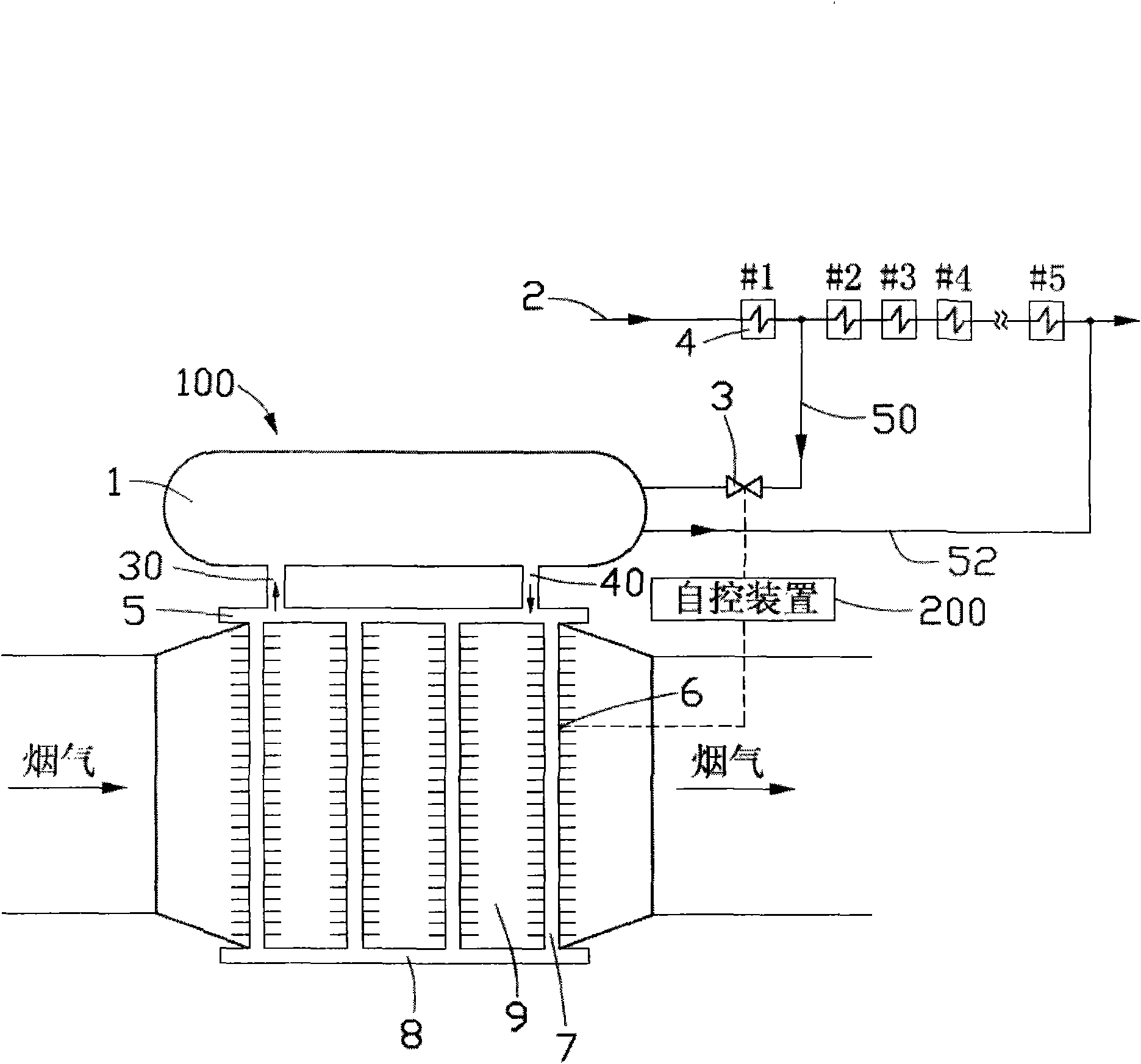

Rotary air preheater dust-blocking-prevention synergy sealing method and system

ActiveCN104949149AExtend your lifeEasy to implementCombustion processHeat exhanger sealing arrangementAir preheaterLiquid state

The invention discloses a rotary air preheater dust-blocking-prevention synergy sealing method and system. The dust-blocking-prevention synergy sealing method includes the steps that air leaked from the heat end is guided or extracted to the cold end from the heat end, and local heat exchange elements are purged and heated. The rotary air preheater dust-blocking-prevention synergy sealing system comprises a heat end primary air / smoke side sector sealing box, a heat end primary air / secondary air side sector sealing box and a cold end secondary air / smoke side sector sealing box, and further comprises a heat air leakage air flue; the heat end primary air / smoke side sector sealing box and the heat end primary air / secondary air side sector sealing box are each provided with an air inlet, one end of the heat air leakage air flue is in butt joint with the air inlets, and the other end of the heat air leakage air flue extends to a cold end secondary air highest-temperature module. By means of the rotary air preheater dust-blocking-prevention synergy sealing method and system, H2SO4 drops and liquid state NH4HSO4 are gasified while the air leaked from a preheater is reduced, and the aim of removing accumulated dust is achieved; the rotary air preheater dust-blocking-prevention synergy sealing method and system have the advantages of reducing the boiler smoke discharging temperature, restraining the accumulated dust of the preheater, reducing the air leakage rate, prolonging the service life of the heat exchange elements and the like.

Owner:南京博沃科技发展有限公司

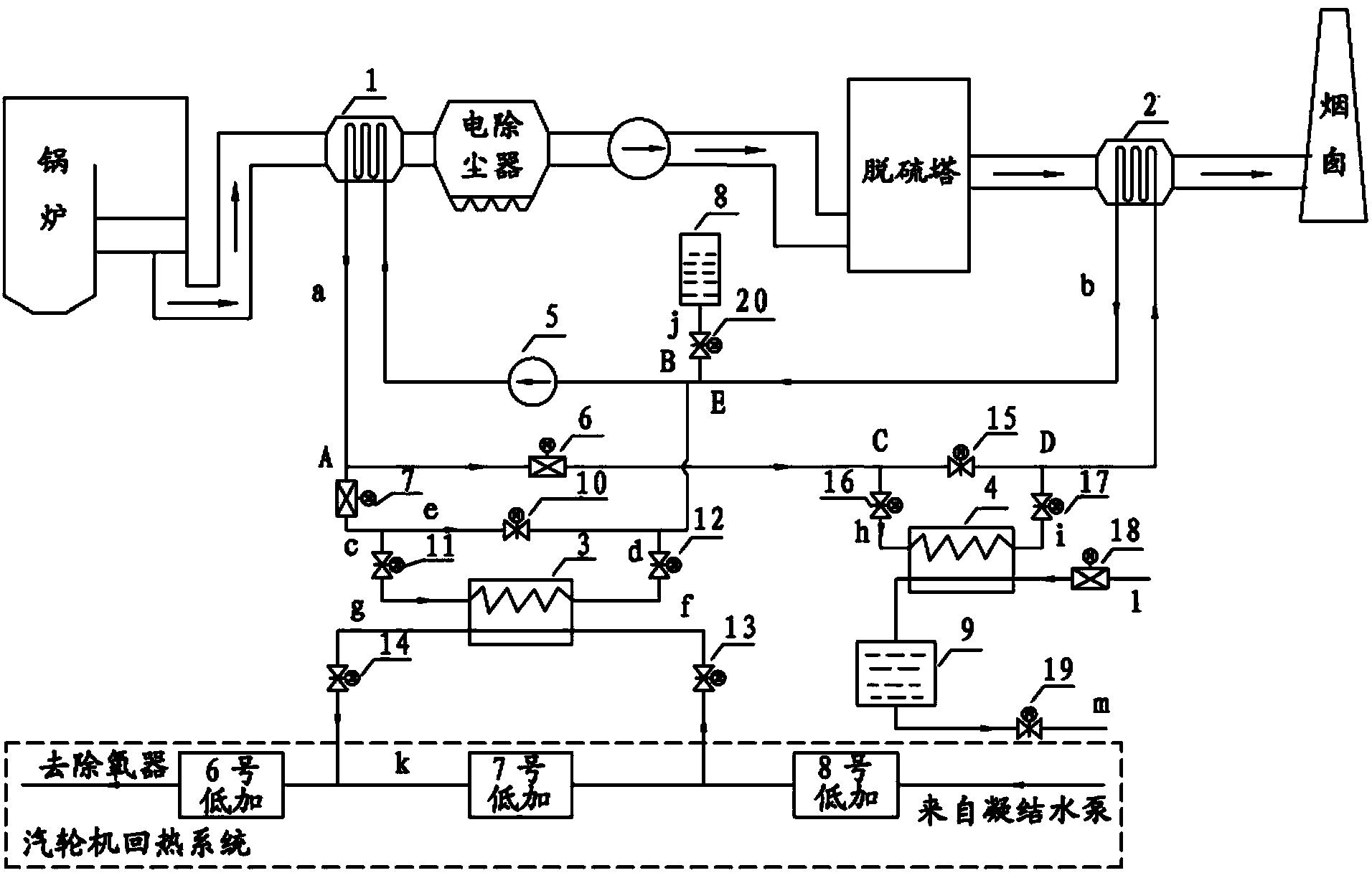

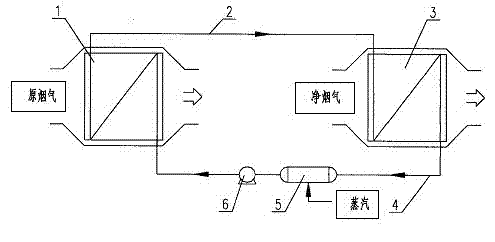

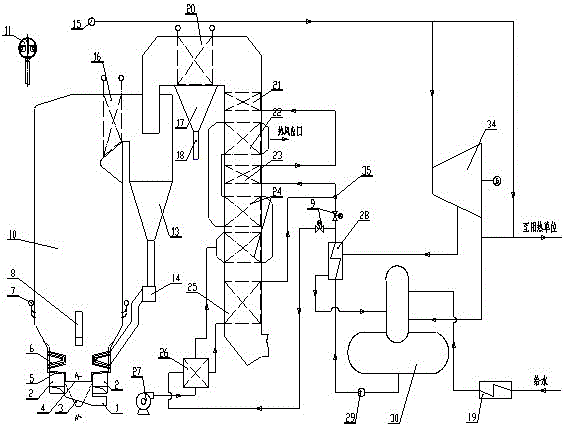

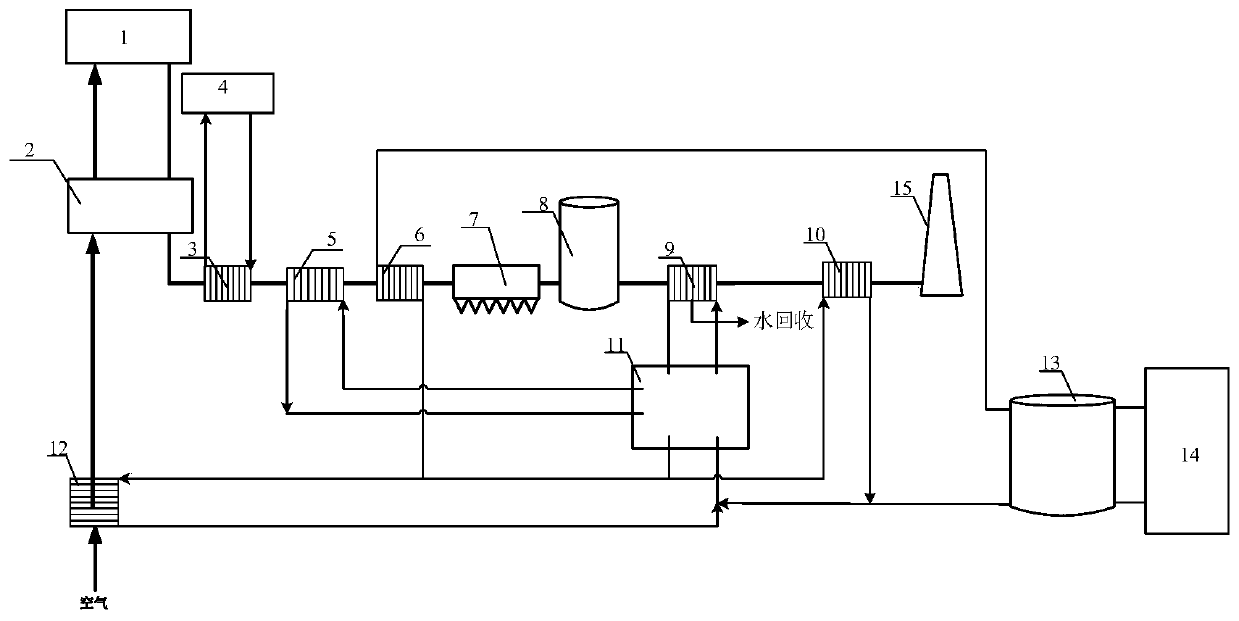

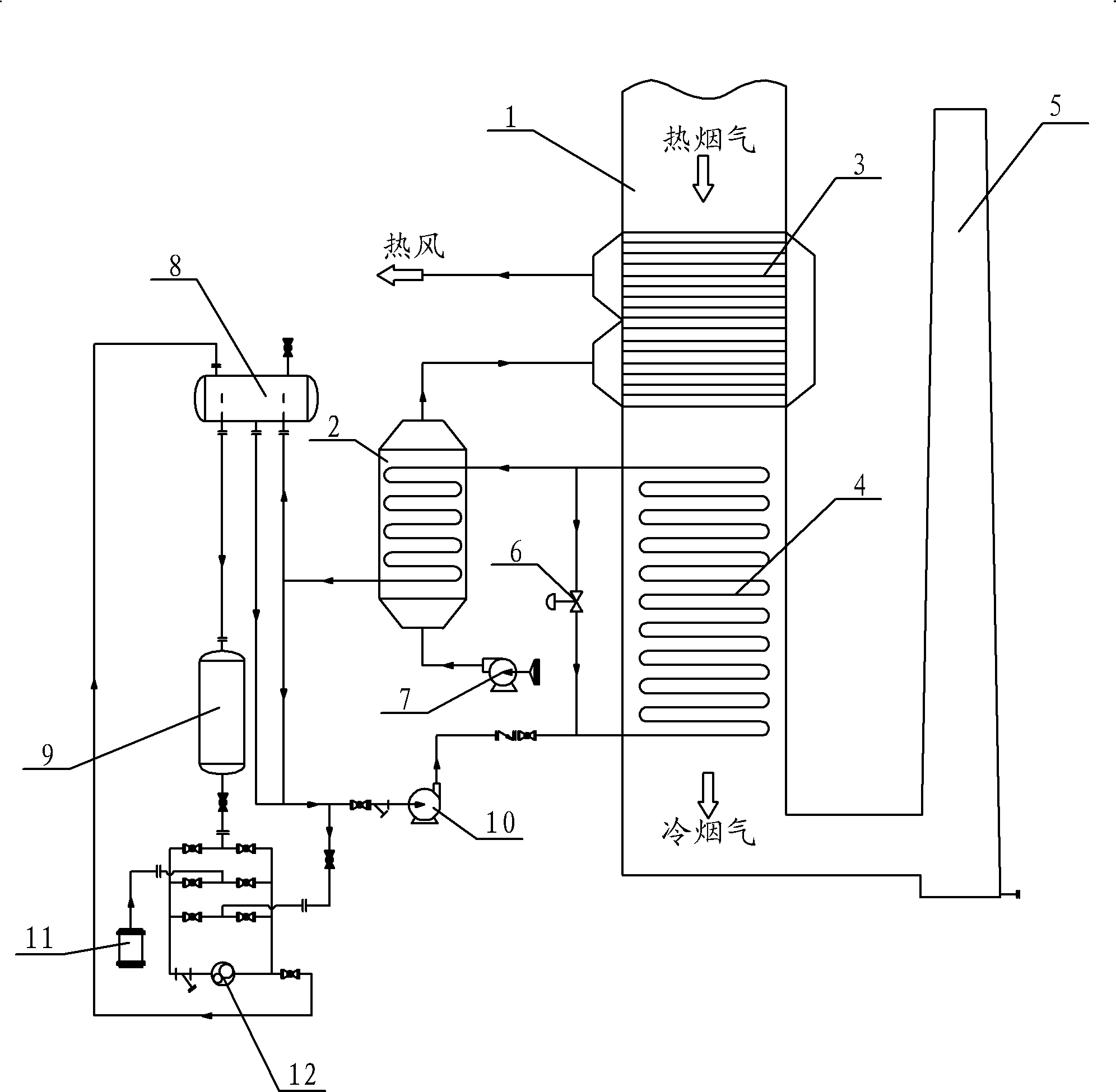

Smoke waste heat comprehensive utilization device and method

InactiveCN104048307AAvoid Low Temperature CorrosionReduce investment in anti-corrosionCombustion technology mitigationFeed-water heatersFlueChiller

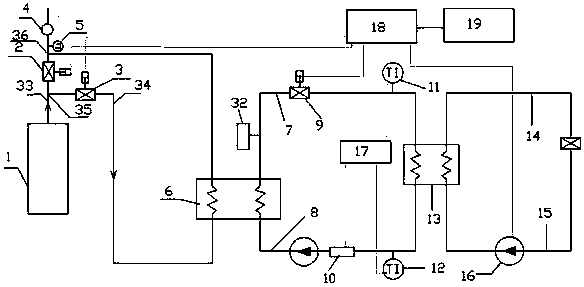

The invention discloses a smoke waste heat comprehensive utilization device and a smoke waste heat comprehensive utilization method. The device comprises a smoke cooler, a smoke heater and a closed circulation pump, wherein the smoke cooler is arranged on a flue of the smoke outlet of a boiler air pre-heater; the smoke heater is arranged on a flue of the smoke outlet of a desulphurization tower; the water outlet of the smoke cooler and the water inlet of the smoke heater are connected by a first pipeline, and the water outlet of the smoke heater and the water inlet of the smoke cooler are connected by a second pipeline, so that a closed circulation water main circuit is formed; the closed circulation pump is arranged on the closed circulation water main circuit. According to the smoke waste heat comprehensive utilization device and the smoke waste heat comprehensive utilization method, waste heat of the boiler discharged smoke of a thermal generator set is mainly used as a heat source to heat pure smoke of the smoke outlet of a wet desulphurization tower, the operation is stable, safe and environment-friendly, and the energy-saving and environment-friendly effects are excellent.

Owner:舒少辛 +1

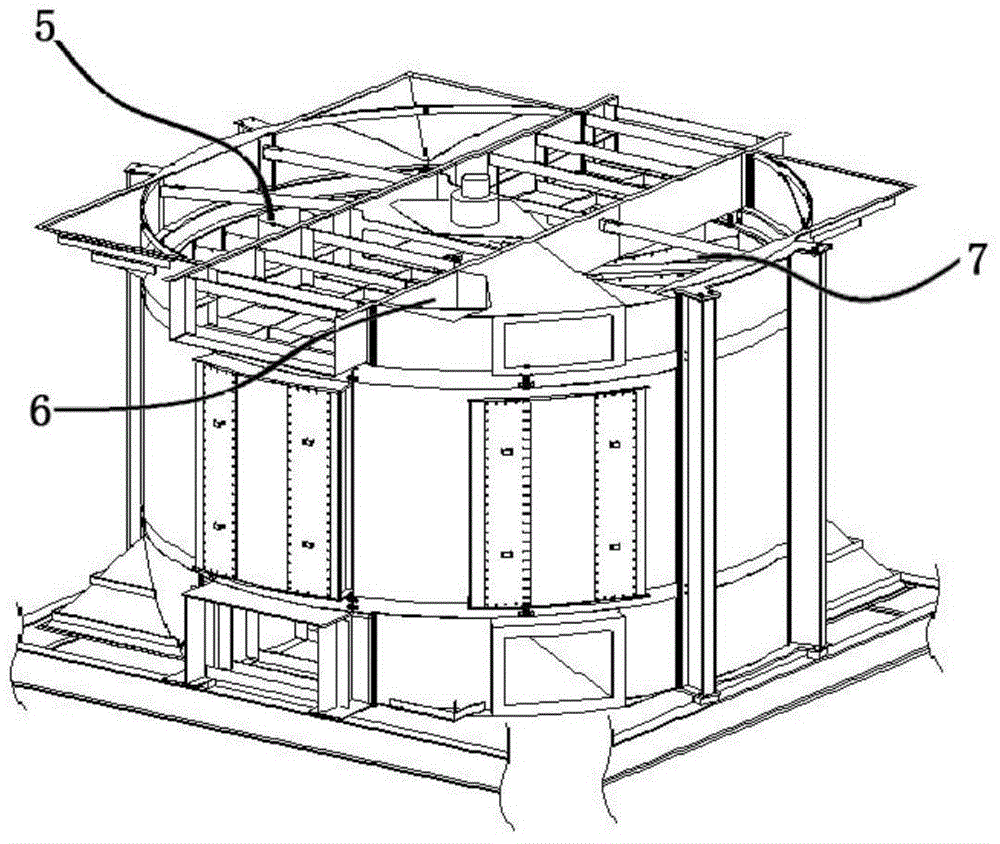

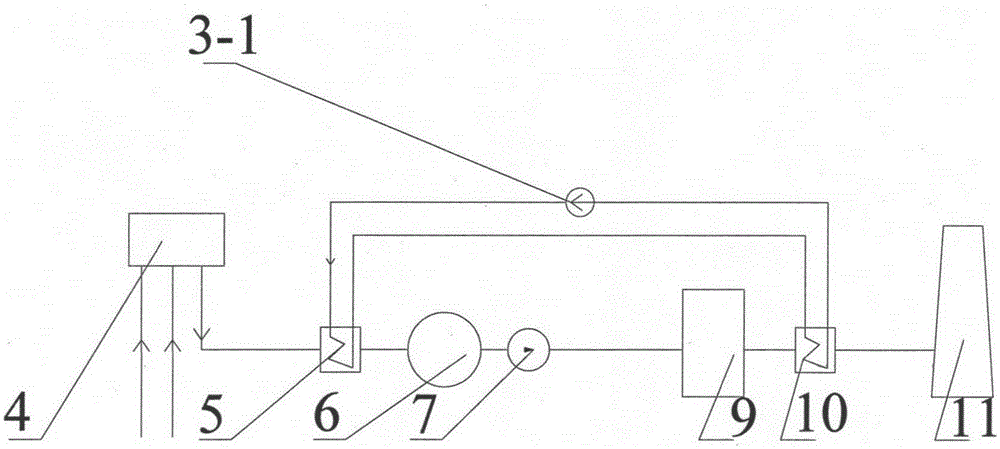

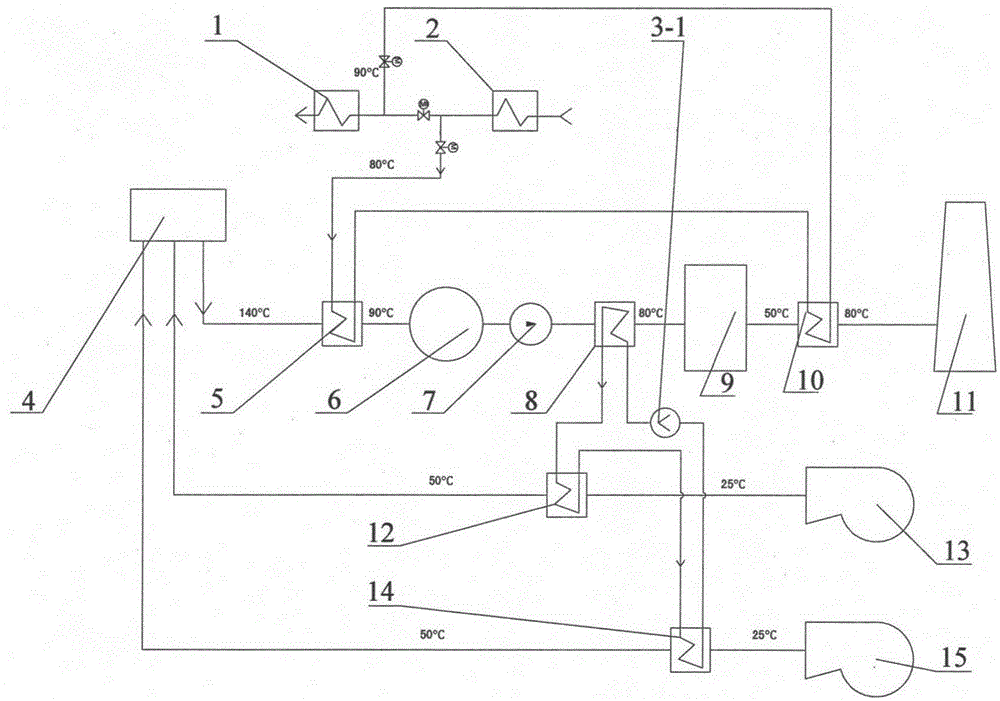

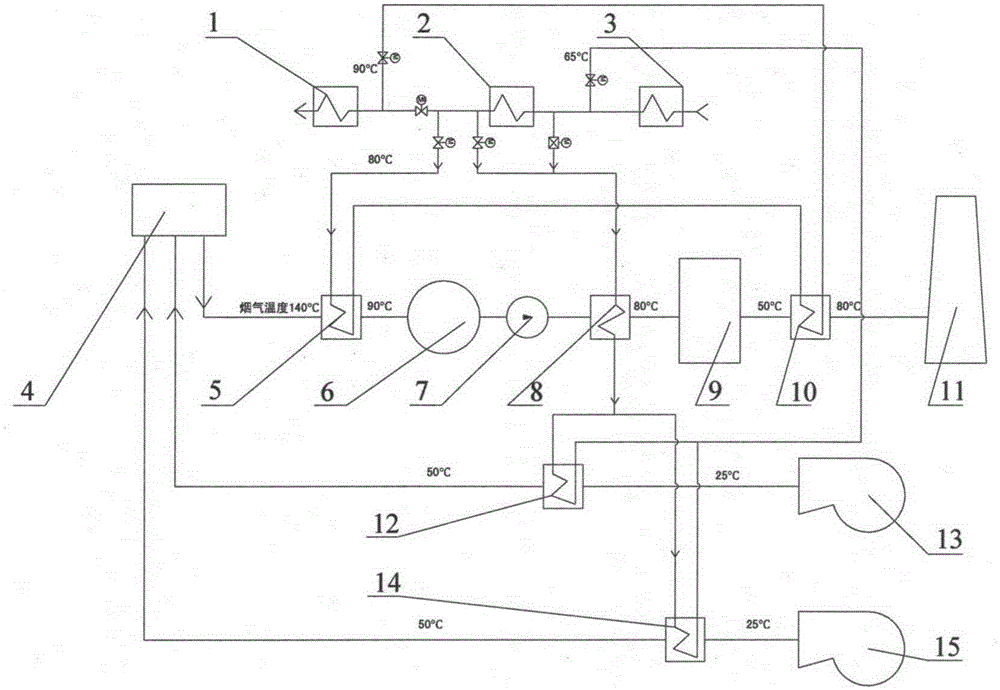

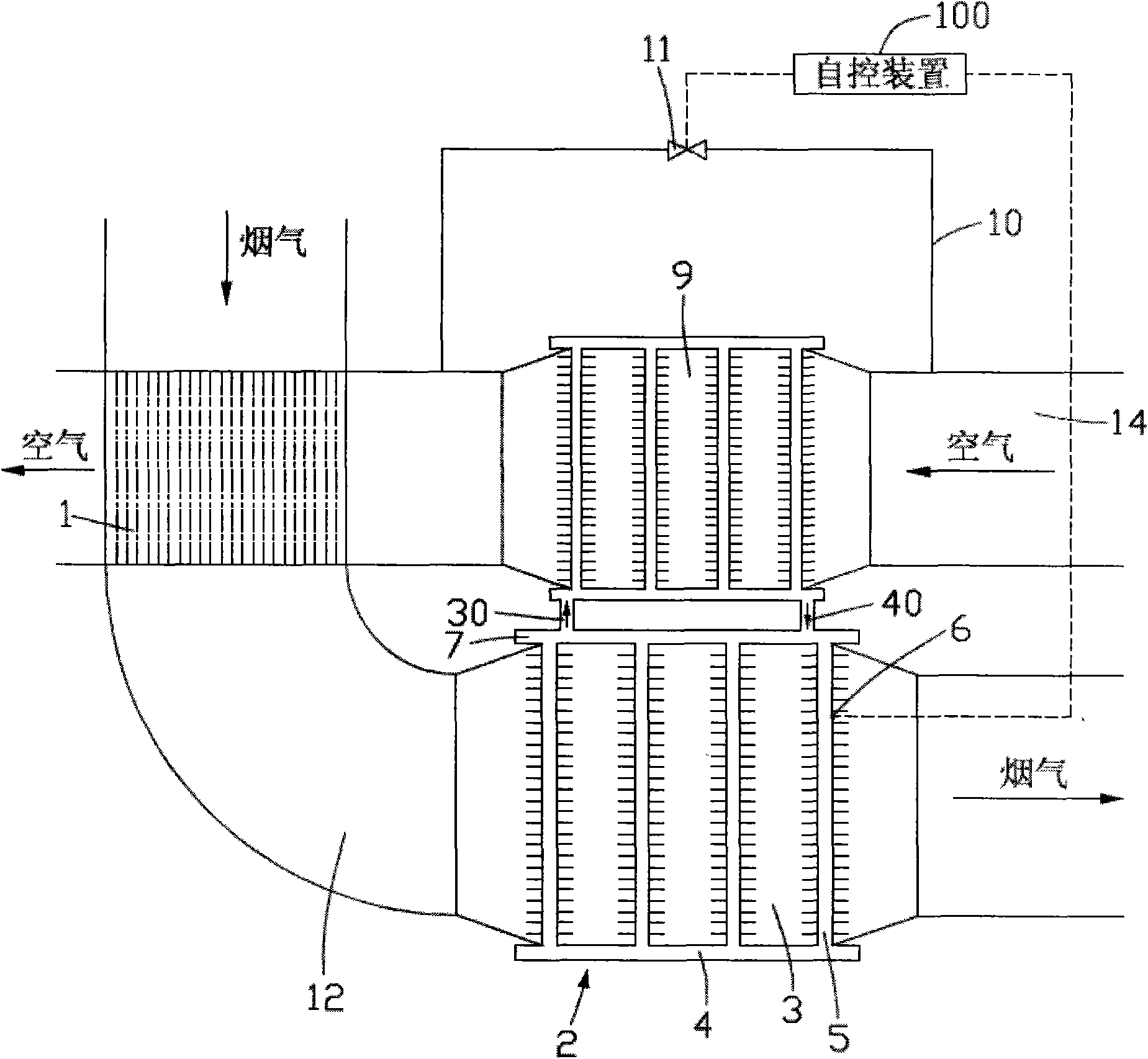

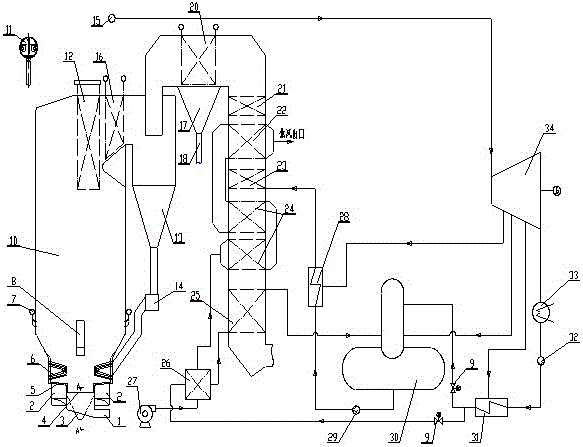

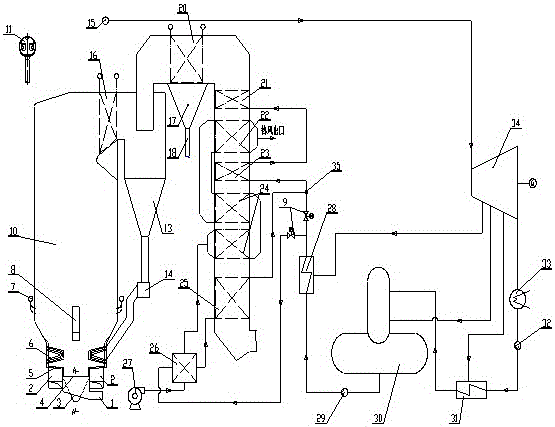

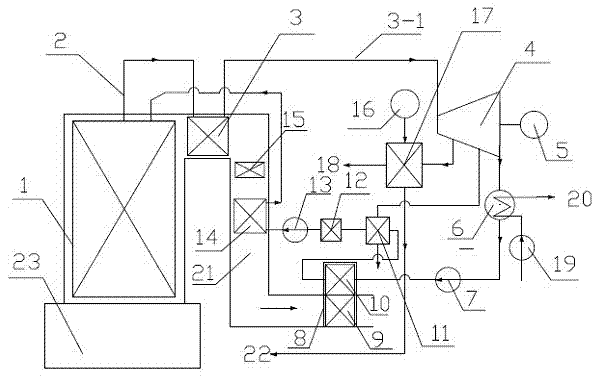

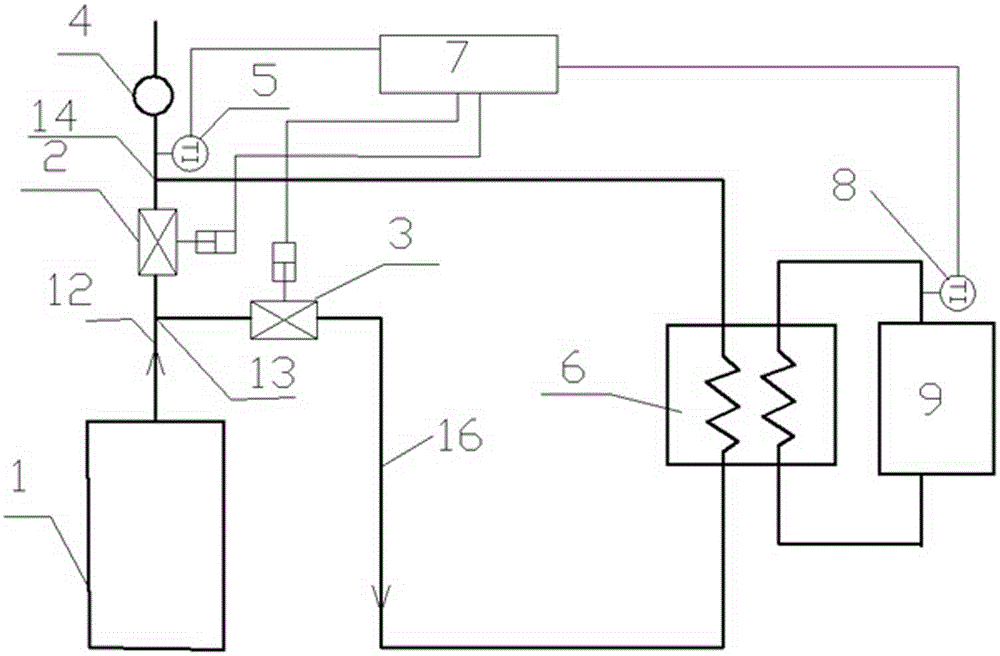

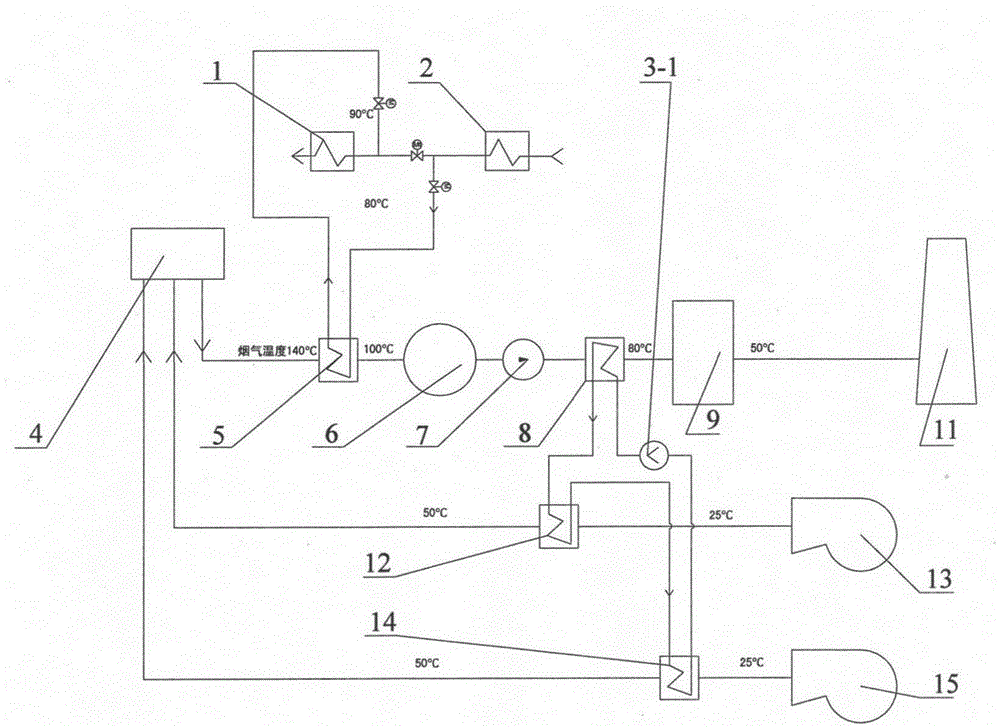

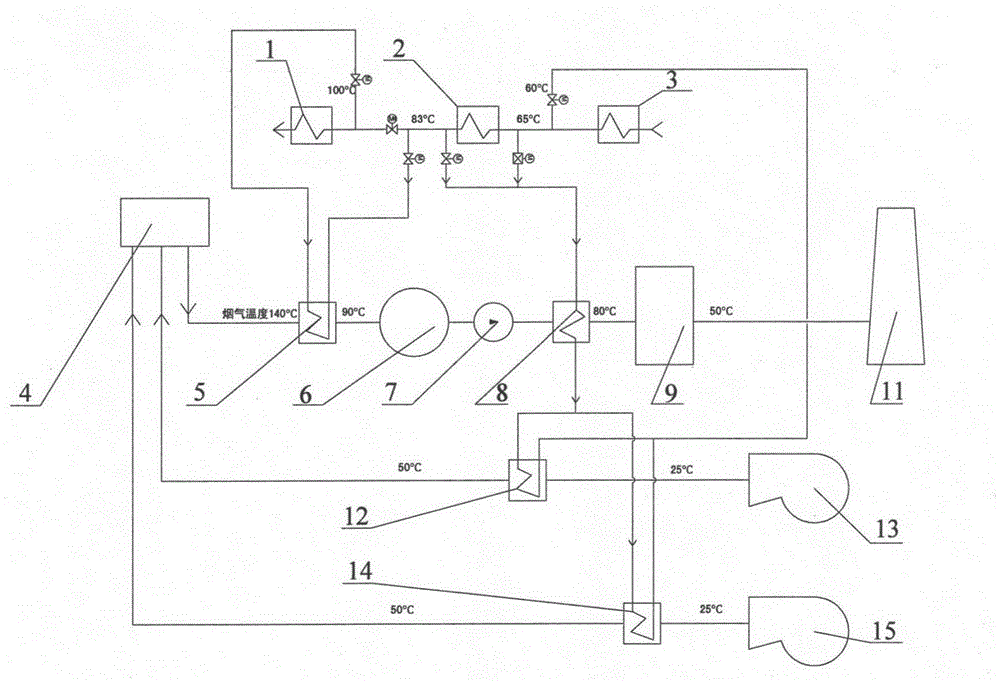

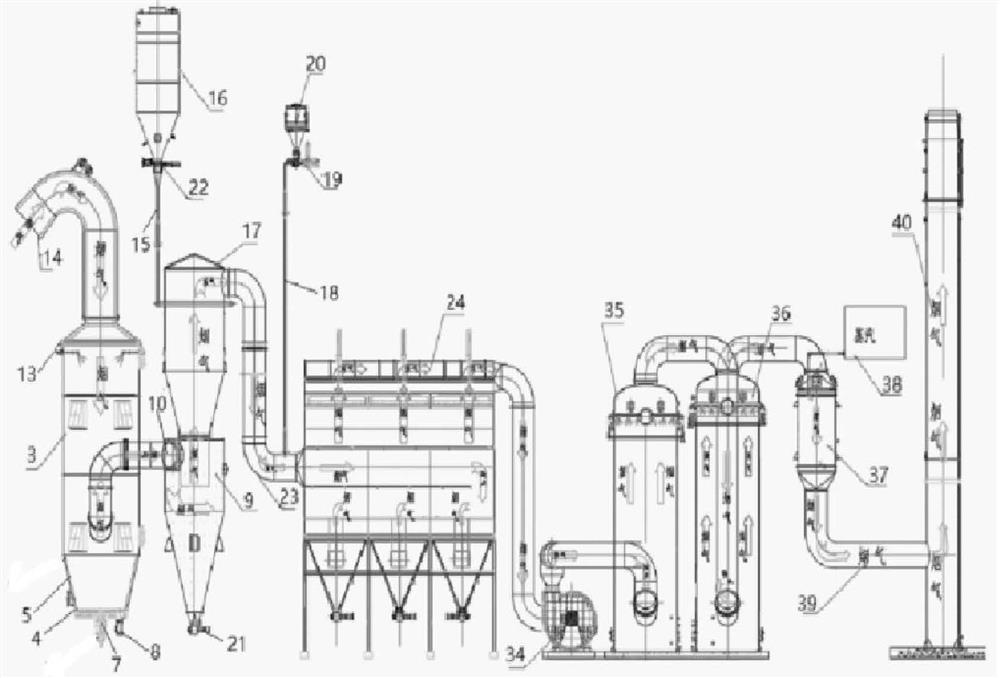

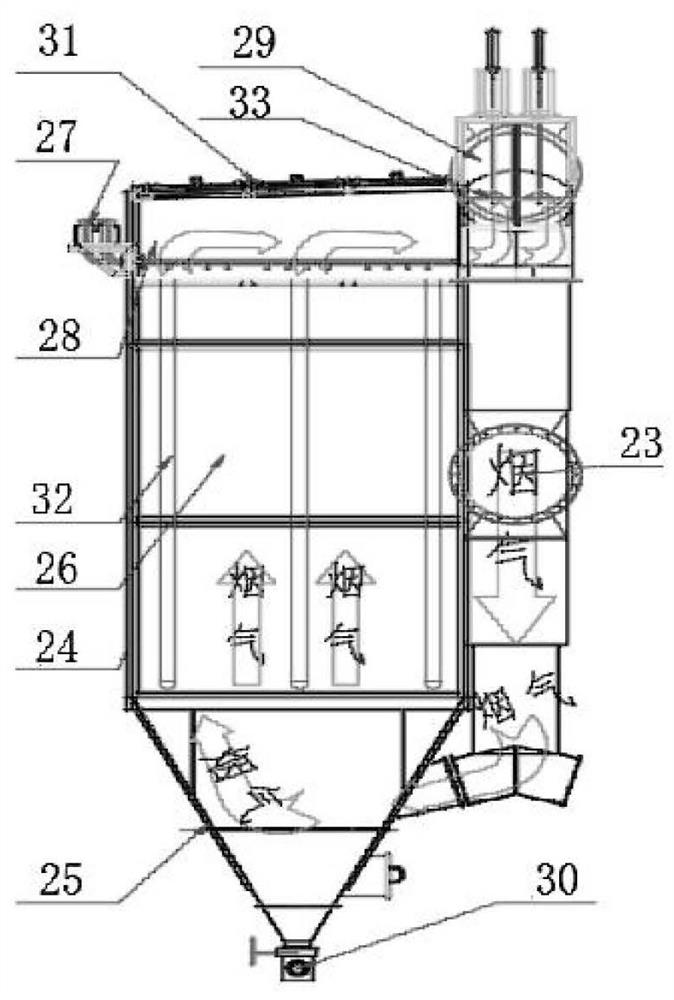

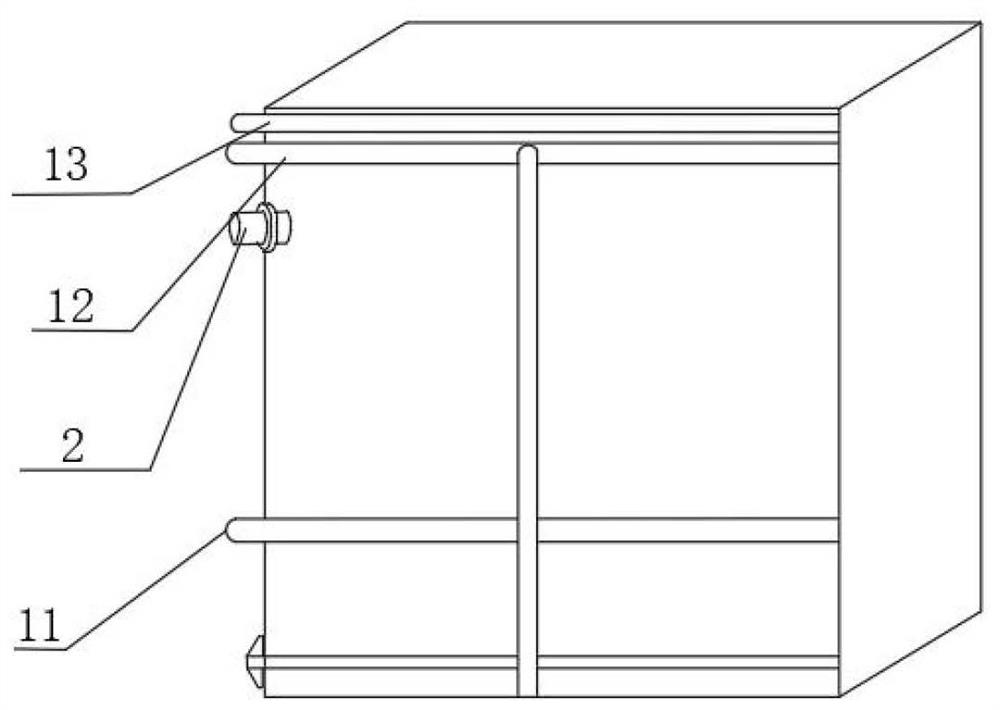

Ultralow-emission MGGH energy conservation and environmental protection equipment and method for thermal power plant

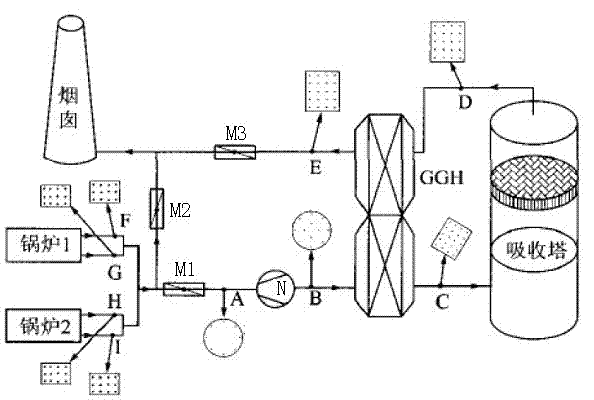

InactiveCN105240825APrevent smoke condensationAvoid flue gas low temperature corrosion phenomenonCombustion technology mitigationFeed-water heatersAutomatic controlAir heater

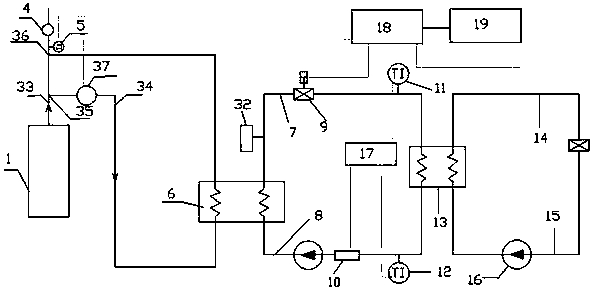

The invention discloses ultralow-emission MGGH energy conservation and environmental protection equipment for a thermal power plant. The equipment is connected with a steam pumping and heat recycling system of a steam turbine through open circulation, automatically balances smoke residual heat recycled with heat required for heating boiler inlet air, avoids smoke dew condensation, prevents smoke low-temperature corrosion, ensues that the influence of ambient temperature variation and unit load variation on the temperature of boiler exhaust smoke can be couteracted under various work conditions, and realizes automatic control on the temperature of electrostatic precipitating inlet smoke and the temperature of the boiler inlet air. The equipment can automatically balance the smoke residual heat recycling power of a low-temperature coal economizer and the boiler inlet air heating power of an air heater, and under various work conditions, can automatically control the temperature of an electrostatic precipitating smoke inlet, automatically control the air outlet temperature of the air heater and automatically control the emission temperature of a chimney. The equipment meets environmental protection requirements for smoke emission, and meanwhile, has social benefit and economical benefit of conserving coal, conserving water and reducing smoke emissions.

Owner:上海羲蓝节能环保科技有限公司

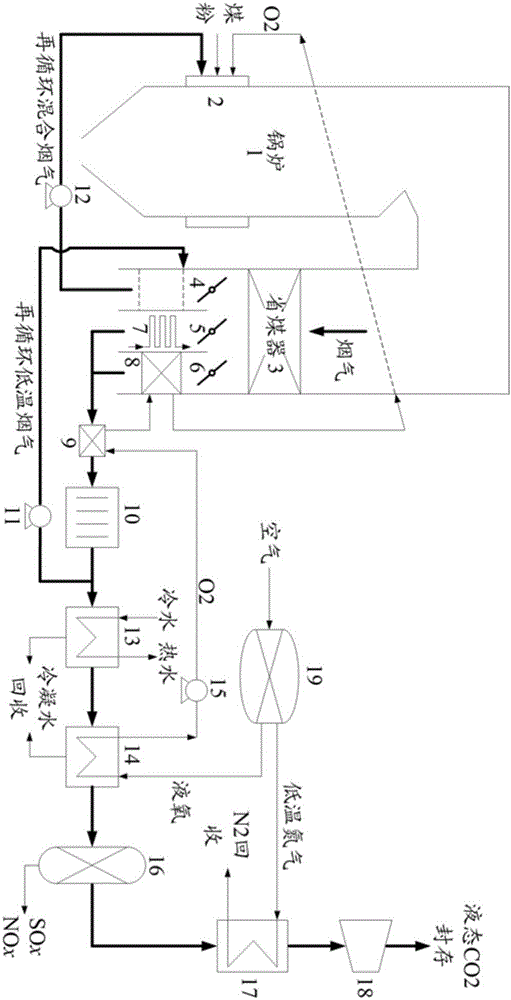

High-efficiency tail flue gas energy utilization and treatment system of oxygen-enriched combustion boiler

ActiveCN106369595AImprove adaptabilityAvoid the phenomenon of clogging the pulverized coal pipelineSolidificationLiquefactionAir preheaterWater vapor

The embodiment of the invention provides a high-efficiency tail flue gas energy utilization and treatment system of an oxygen-enriched combustion boiler. The system achieves coupling of an air separator system of the oxygen-enriched combustion boiler with a flue gas recirculation system and a tail flue gas energy recovery and treatment system; a tail flue of the boiler is divided into three parallel flues to adjust recirculating flue gas amount and temperature; the adaptability of the system to a coal type is improved; a low-pressure economizer recovers flue gas waste heat; the oxygen temperature at an outlet of an air preheater is adjusted; the three parallel flues are coupled to increase an adjustment margin of the flue gas temperature. Recirculating flue gas formed by mixing high-temperature flue gas and low temperature recirculating flue gas serves as primary air to avoid blocking of a pulverized coal pipeline due to liquefaction of accumulated steam during flue gas recirculation when the temperature of the primary air is lower; the size of the air preheater is reduced; the cost is saved; and the economy is improved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

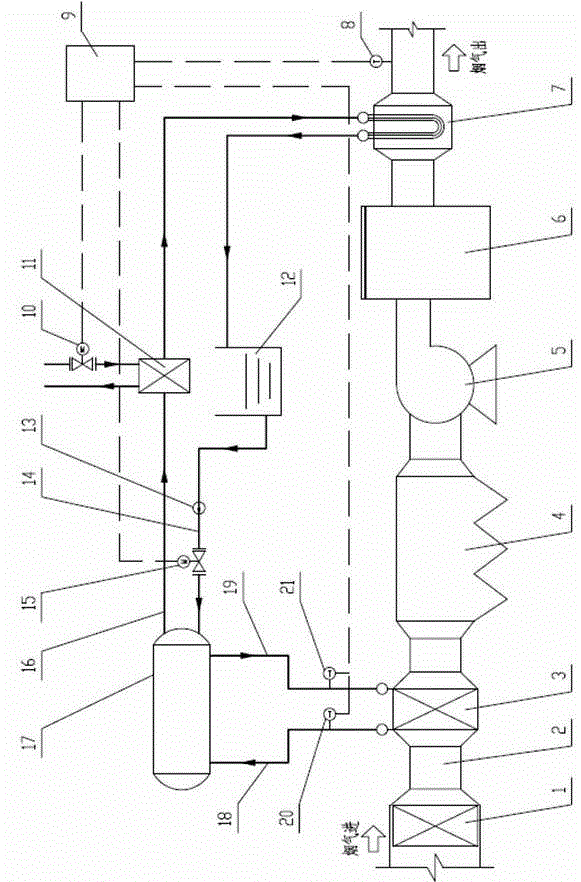

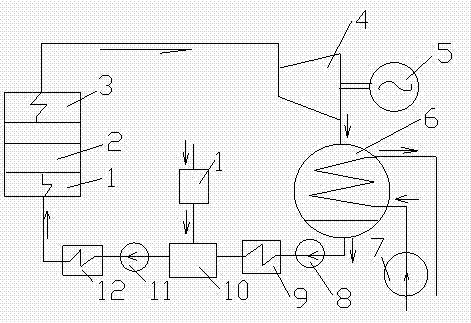

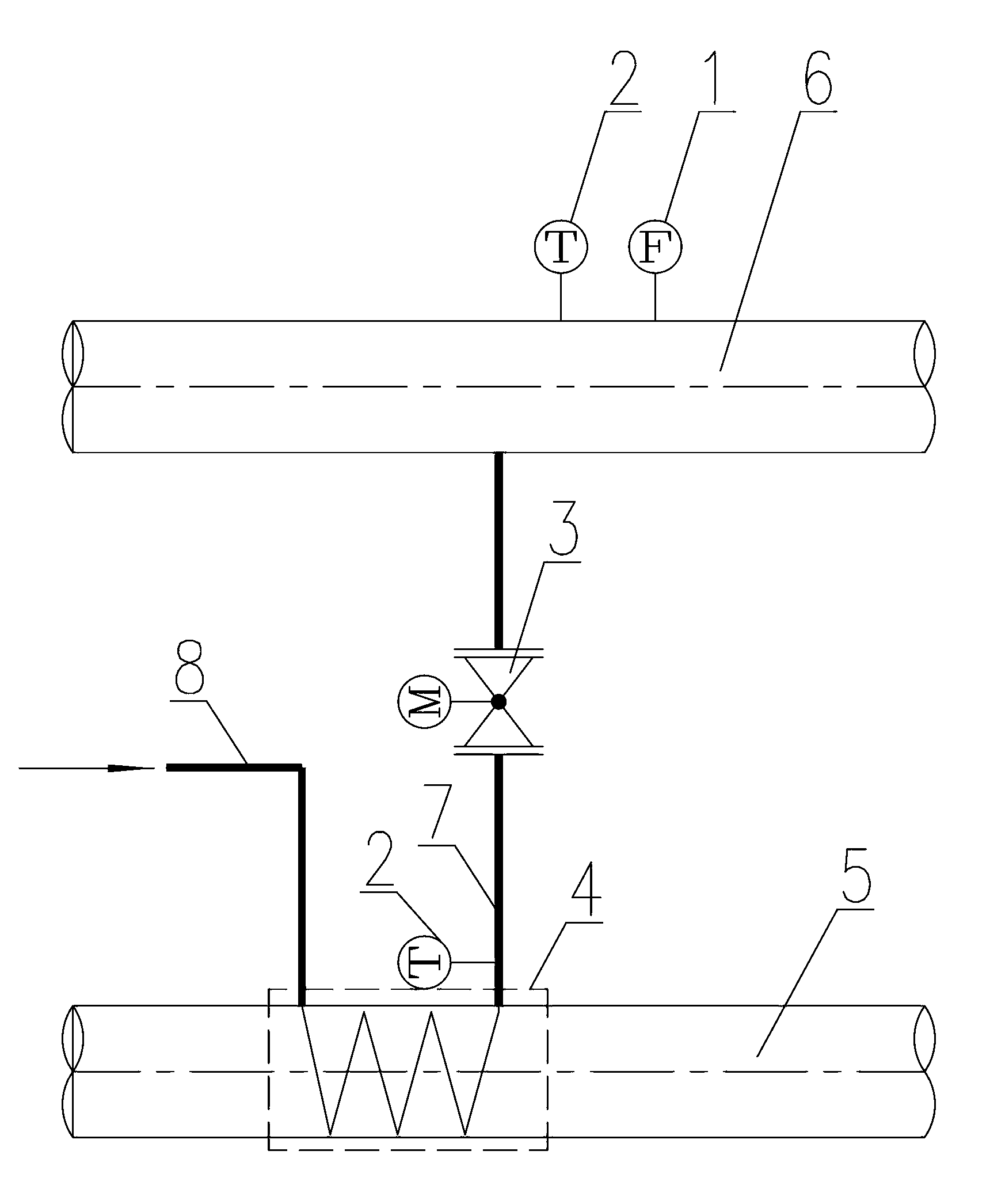

Flue gas afterheat recovery system

InactiveCN101629713AMake full use of waste heatSave heatRecuperative heat exchangersHeat recovery systemsAutomatic controlFlue gas

The invention provides a flue gas afterheat recovery system comprising a phase-change exchanger and an automatic control device which is mounted on the phase-change exchanger. The phase-change exchanger comprises a phase-change upper section and a phase-change lower section which are communicated; the phase-change upper section of the phase-change exchanger is communicated with a main condensate pipeline in a low-pressure regenerative heating system; the phase-change lower section of the phase-change exchanger is arranged in a flue gas channel; a wall temperature tester is mounted on the phase-change lower section; a signal of the wall temperature tester controls the flow of condensate entering the low-pressure regenerative heating system of the phase-change upper section of the phase-change exchanger by the automatic control device; the condensate in the automatic control device is heated after entering the phase-change upper section of the phase-change exchanger, and the heated condensate enters the main condensate pipeline in the automatic control device again. The invention saves energy and effectively utilizes flue gas afterheat to heat the condensate.

Owner:SHENZHEN ZHONGXING KEYANG ENERGY & ENVIRONMENTAL PROTECTION

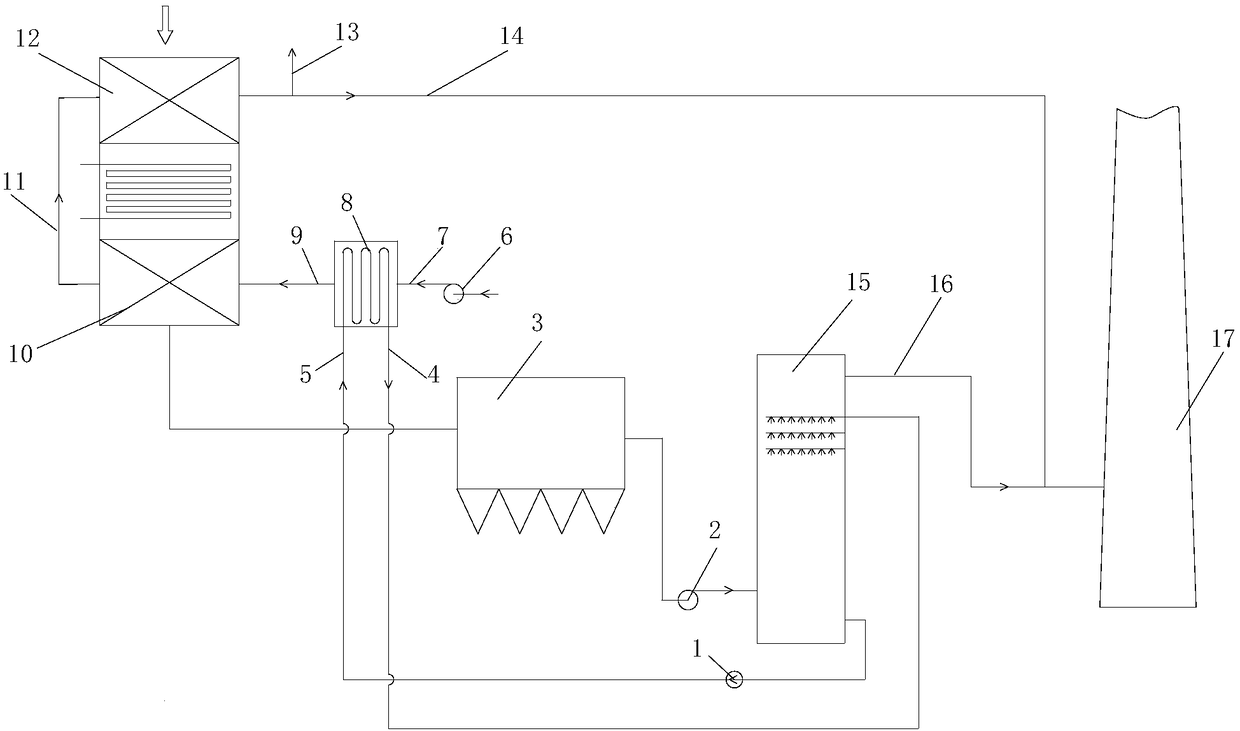

Flue gas treatment system and flue gas reheating method based on fluoroplastic heat exchanger

InactiveCN104676622ASolve the problem of low temperature corrosionAvoid Low Temperature CorrosionIndirect heat exchangersCombustion technology mitigationSteam drumTreatment system

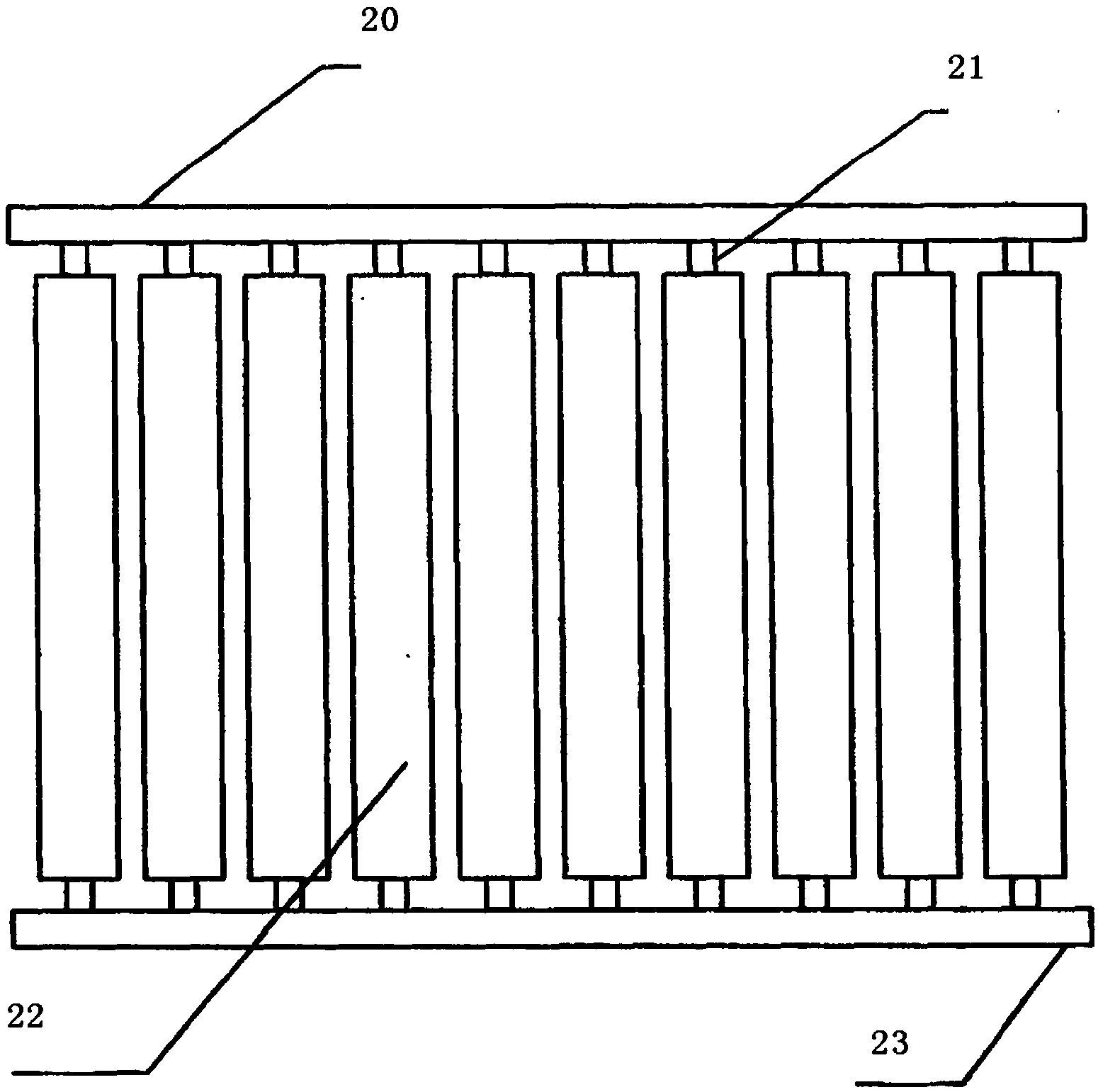

The invention relates to a flue gas treatment system and a flue gas reheating method based on a fluoroplastic heat exchanger. No flue gas treatment system and no flue gas reheating method exist to solve the problems of low-temperature corrosion, air leakage, dust deposition and scaling simultaneously at present. The flue gas treatment system disclosed by the invention is characterized by further comprising a phase-change heat exchanger, a fluoroplastic heat exchanger, a water tank, a water return pipe, a water inlet pipe, a phase-change heat exchanging steam pocket, an ascending pipe, a descending pipe and an ascending heat transfer working medium thermodetector, wherein the phase-change heat exchanging steam pocket is positioned above the phase-change heat exchanger; one end of the water return pipe is fixed on the phase-change heat exchanging steam pocket. The flue gas reheating method disclosed by the invention is characterized in that flue gas flows through the phase-change heat exchanger, condensed working medium in the phase-change heat exchanger is heated, saturated steam is generated, the saturated steam is heat-exchanged with the returned working medium, high-temperature working medium water enters the fluoroplastic heat exchanger through the water inlet pipe, and the working medium water is generated after the treated flue gas is heated. The flue gas treatment system and the flue gas reheating method based on the fluoroplastic heat exchanger have the advantage that the problems of low-temperature corrosion, air leakage, dust deposition, scaling, chimney corrosion and white smoke emission from the chimney can be solved simultaneously.

Owner:HANGZHOU HUADIAN ENERGY ENG

Flue-gas waste heat reclaiming system

InactiveCN101634457AReduce pollutionSave heatHeat storage plantsCombustion processAir preheaterAutomatic control

The invention provides a flue-gas waste heat reclaiming system which comprises a phase-change heat exchanger and an automatic control device, wherein the phase-change heat exchanger comprises a phase-change upper section and a phase-change lower section, and the automatic control device is arranged on the phase-change heat exchanger; the phase-change upper section of the phase-change heat exchanger is arranged in an air passage at the front of an inlet of an air preheater, and the phase-change lower section of the phase-change heat exchanger is arranged in a flue-gas passage; and the flow rate of air that enters into the phase-change upper section of the phase-change heat exchanger can be regulated by the automatic control device. On the one hand, the flue-gas waste heat reclaiming system utilizes flue-gas waste heat, instead of a heat source in the traditional air heater, to heat air, thereby saving energy sources; and on the other hand, the flue-gas waste heating reclaiming system regulates the air flow rate by the automatic control device and ensures that the wall temperature of the phase-change heat exchanger is always higher than the flue-gas acid dew point, thereby avoiding the low-temperature corrosion of the air preheater and the phase-change heat exchanger.

Owner:SHENZHEN ZHONGXING KEYANG ENERGY & ENVIRONMENTAL PROTECTION

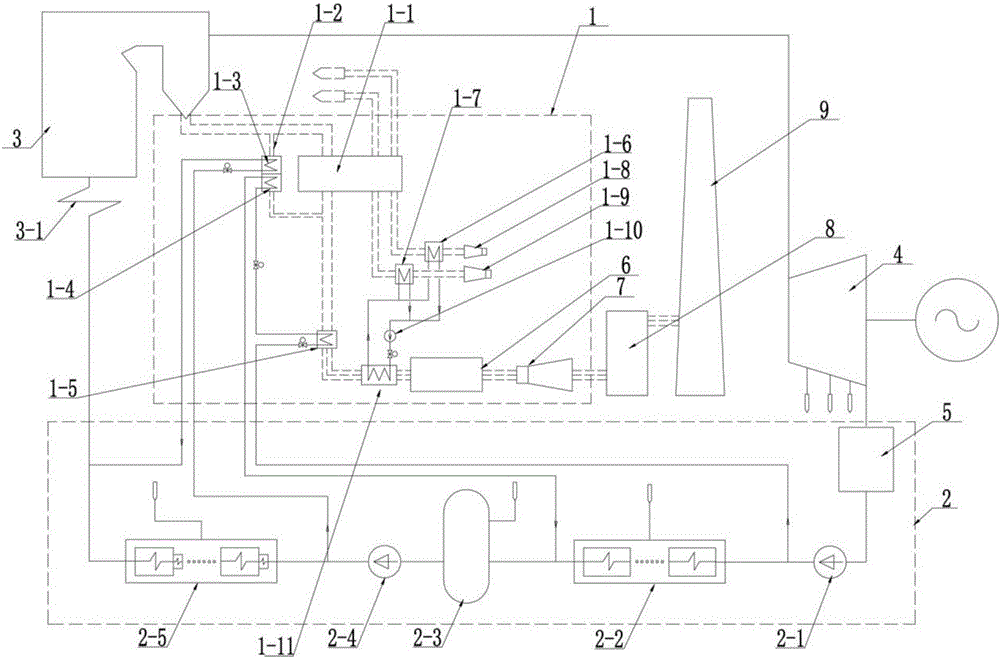

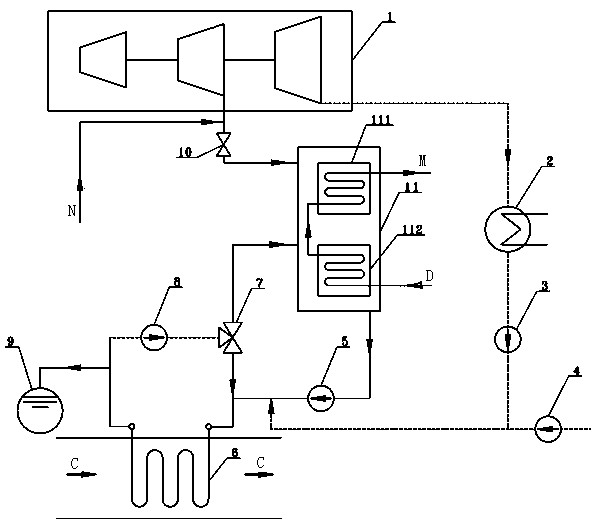

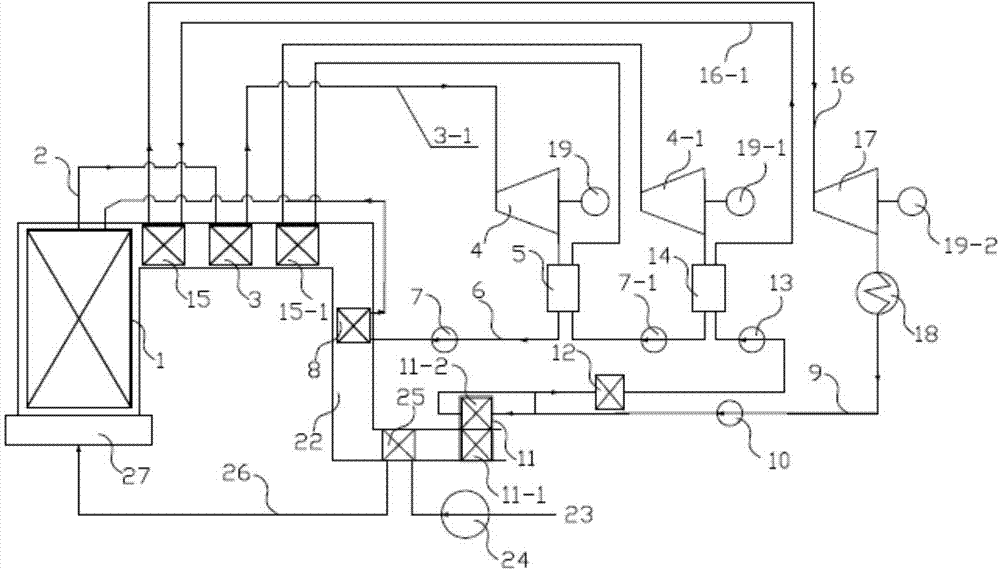

Turbine-boiler gathered heat energy circulating residual heat reuse system

ActiveCN106090880AEffective protectionImprove efficiencyCombustion processIndirect carbon-dioxide mitigationThermal energyPower equipment

The invention discloses a turbine-boiler gathered heat energy circulating residual heat reuse system and belongs to the technical field of energy conservation and emission reduction of heat energy power equipment. The system comprises a boiler, a boiler-side tail heat energy gathering flue gas system, a steam turbine and a turbine-side combined heat exchange water supply system, wherein a coal saver is arranged on the boiler; the front side of the boiler-side tail heat energy gathering flue gas system is connected to the boiler, the back side thereof is successively connected to a desulfurizing absorption tower and a chimney, the front side of the turbine-side combined heat exchange water supply system is connected to a condenser and the back side thereof is connected to the coal saver, and the boiler-side tail heat energy gathering flue gas system is connected to the turbine-side combined heat exchange water supply system through a condensed water heat exchange system and a water supply heat exchange system. The system disclosed by the invention recovers heat in the flue gas to heat boil feed water and condensed water, so as to push out highly extracted steam and lowly extracted steam, so that the steam turbine efficiency is improved; heat in the flue gas is recovered to heat air so as to improve the boiler efficiency; heat in the tail flue gas is recovered so as to improve the dedustor efficiency, the desulfuration water consumption is reduced and the energy-saving environmental-friendly contributing value is improved.

Owner:JINGNENG (XILINGUOLE) POWER CO LTD

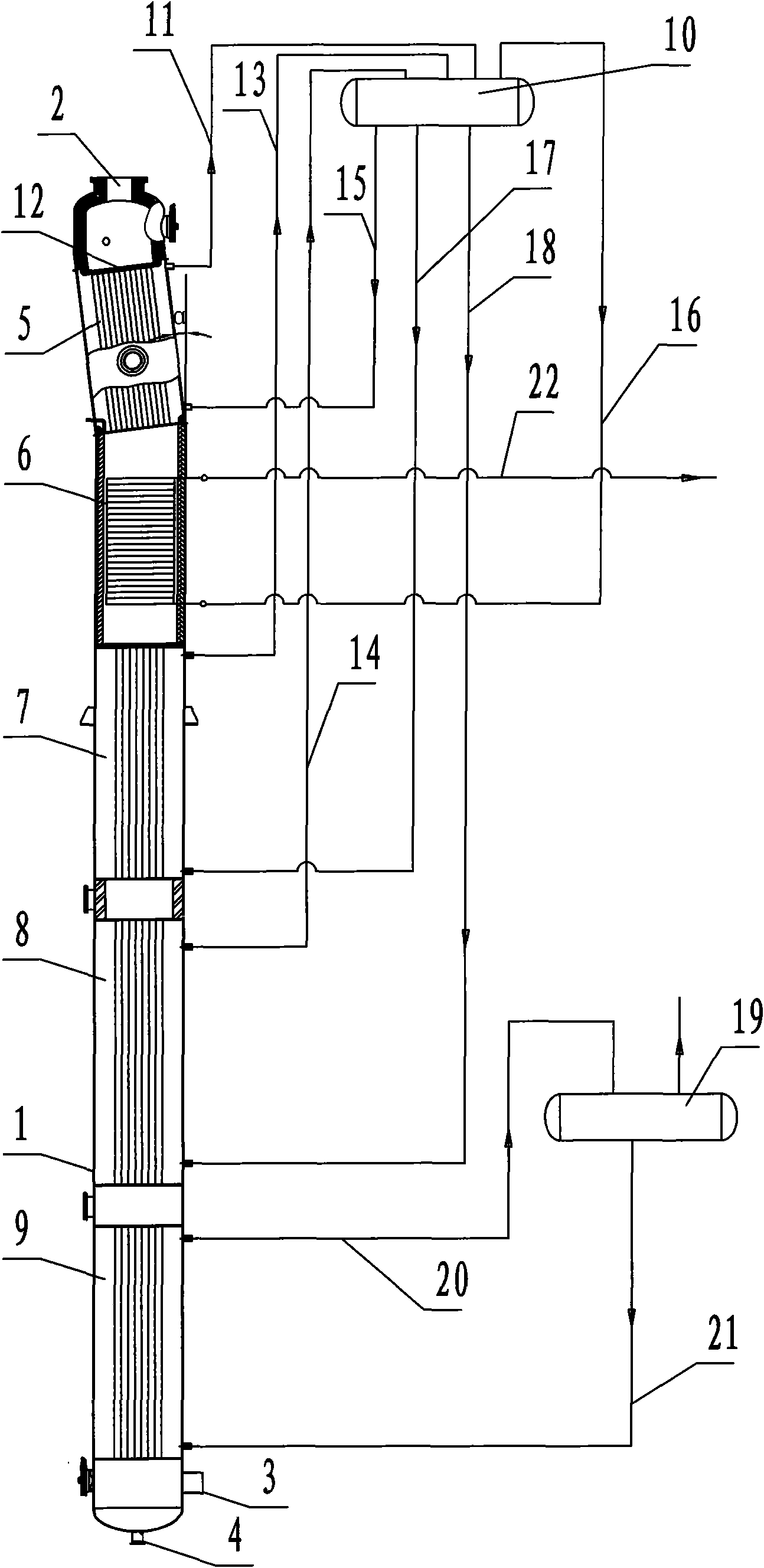

Waste-heat boiler

ActiveCN101639212AAvoid Low Temperature CorrosionSteam generation using hot heat carriersEvaporatorEngineering

The invention discloses a waste-heat boiler for a low pressure gasification device, comprising a vertical cylinder-type shell. A flue gas inlet is arranged at the upper end of the shell, a flue gas outlet and an ash outlet are arranged at the lower end, and a first middle pressure evaporator, a super-heater, a second middle pressure evaporator and a low pressure evaporator are sequentially arranged under the flue gas inlet arranged in the shell, wherein the first middle pressure evaporator, the second middle pressure evaporator and the low pressure evaporator are all fire pipe types, a lead-out pipe and a descending pipe are respectively arranged at two ends of the first middle pressure evaporator, the second middle pressure evaporator and the low pressure evaporator, the descending pipe and the lead-out pipe on the first middle pressure evaporator and the second middle pressure evaporator are respectively connected with a middle pressure steam pocket, the descending pipe and the lead-out pipe on the low pressure evaporator are connected with a low pressure steam pocket, a superheat evaporation pipe at one end of the super-heater is connected with the middle pressure steam pocket,and the other end is connected with a steam output pipe, therefore, the invention is suitable for heat energy recycle of the flue gas.

Owner:SUZHOU HAILU HEAVY IND

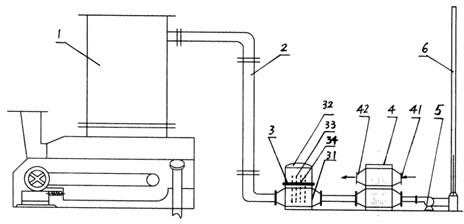

Waste heat recovering device for conduction oil furnace

InactiveCN102538203AEfficient recyclingAvoid Low Temperature CorrosionFluid heatersThermal fluidsEconomizer

The invention relates to a waste heat recovering device for a conduction oil furnace. The conduction oil furnace includes a furnace body, a heating source, a high-temperature end conduction oil circulation loop and a flue; the waste heat recovering device includes an inner circulating pipeline, a thermoregulator, a phase change heat exchanger and a coal economizer; the phase change heat exchangerincludes an evaporator and a condenser that are connected through a pipeline to form a phase change working medium circulation loop; the evaporator and the coal economizer are arranged in the flue; the condenser is arranged outside the flue; a conduction oil inlet end or a conduction oil outlet end of the furnace body is sequentially connected with the thermoregulator, the condenser and a conduction oil inlet end of the coal economizer through the inner circulating pipeline; and a conduction oil outlet end of the coal economizer is connected to the high-temperature end conduction oil circulation loop. According to the invention, the conduction oil furnace can economically operate with high heat efficiency, the problem that the waste heat of the conduction oil furnace is difficult to recover is solved, and the purposes of energy saving and consumption reducing are achieved.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

Intelligent-control efficient kiln waste heat utilization system

InactiveCN103900389AAvoid Low Temperature CorrosionBuy in timeIncreasing energy efficiencySpace heating and ventilation detailsFlueCorrosion

The invention provides an intelligent-control efficient kiln waste heat utilization system which comprises a kiln, a main flue, a bypass flue and a gas-water heat exchanger. Smoke generated by the kiln enters the gas-water heat exchanger through an inlet of the bypass flue, and the smoke after heat exchanging flows into the main flue through an outlet of the bypass flue to be discharged. A main flue adjustment valve is arranged at the position, between the inlet of the bypass flue and the outlet of the bypass flue, of the main flue and used for adjusting the amount of the smoke of the main flue; meanwhile, a bypass flue adjustment valve is arranged on the bypass flue and used for adjusting the amount of the smoke of the bypass flue. According to the intelligent-control efficient kiln waste heat utilization system, the opening degrees of the valves are adjusted, and low-temperature corrosion is avoided; meanwhile, optimization of waste heat utilization is achieved to save energy, and the environment-friendly and energy-saving aims are achieved.

Owner:SHANDONG UNIV OF TECH

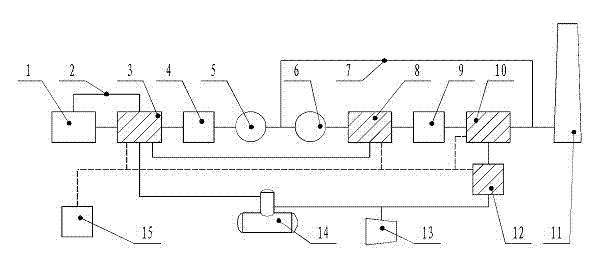

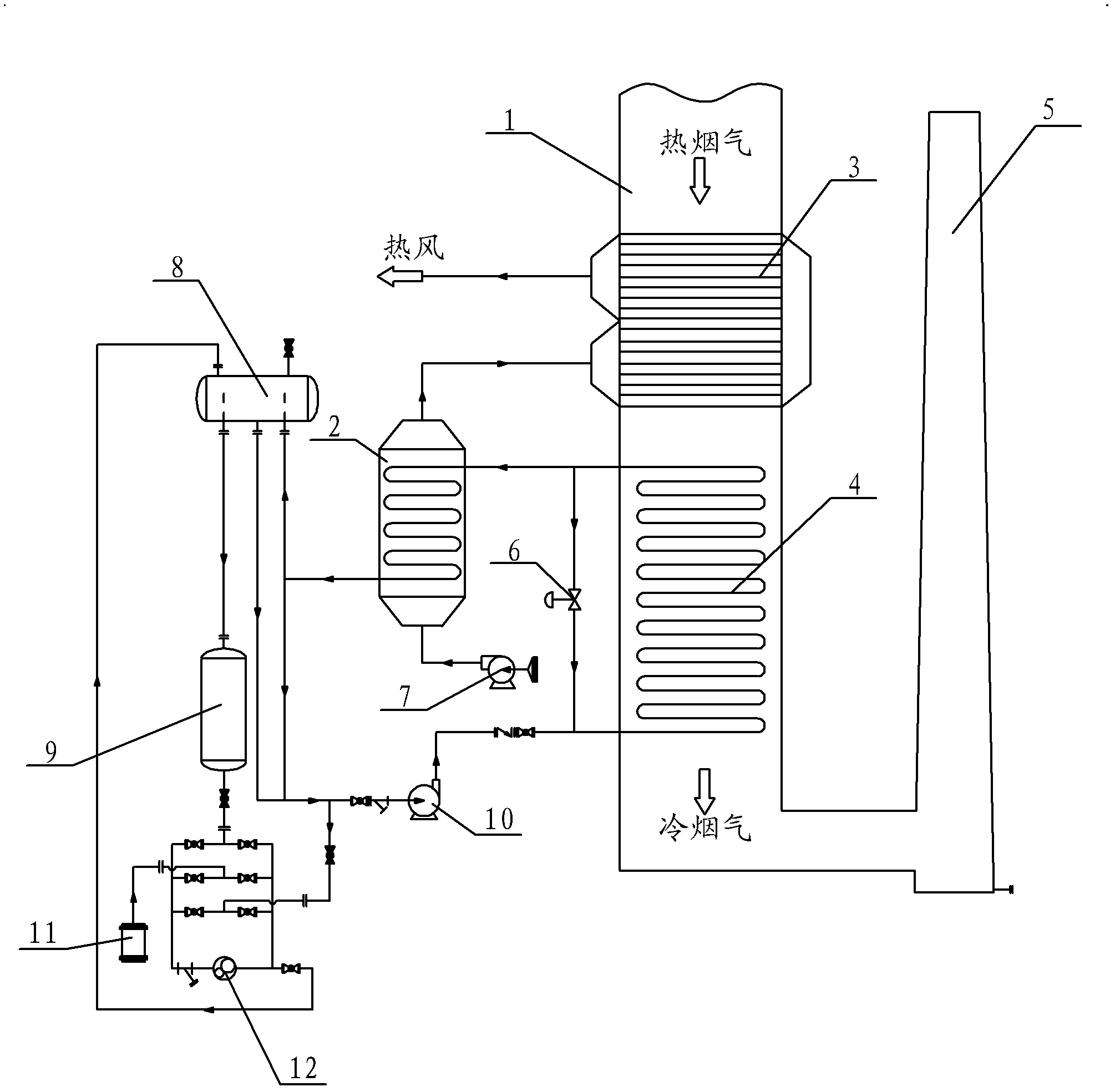

Composite phase change heat exchange system for flue gas heat recovery of boiler

InactiveCN102410549ARealize integrationEfficient recyclingLighting and heating apparatusWater savingHeat conducting

The invention discloses a composite phase change heat exchange system for flue gas heat recovery of boiler, comprising an original coal saving device of the boiler and an air pre-heater, a dust remover and a desulfurization tower; a heat conducting oil heater, a stage I composite phase changer, a stage II composite phase changer, a stage III composite phase changer, and a temperature adjusting system matched with the stage I, state II and stage III composite phase changers are disposed in the flue; the temperature adjusting system can be used for conveniently adjusting the wall surface temperature of the phase change heat exchanger; the heat conducting oil is used as the heat source of the stage III phase change heat exchanger, so as to improve the flue purity and reach the flue discharge requirement. The invention can solve the difficult problem that it is difficult to dispose the evaporation section of the heat exchange round tube in vertical flue or oblique flue, so as to realize the integrated compact arrangements of the evaporation section and condensation section of the phase change heat exchanger; the disadvantage of GGH is overcome; the hazard degree of low-temperature corrosion is decreased, so as to realize the targets of energy saving, water saving and emission reduction.

Owner:王海波

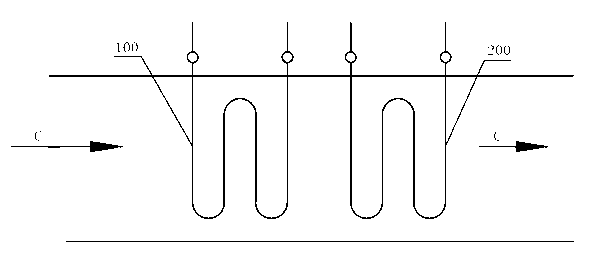

Low-pressure expanded economizer system

ActiveCN103256644ALess investmentSimple operation and maintenanceFeed water supplyHot-water central heatingEngineeringRecuperator

The invention discloses a low-pressure expanded economizer system comprising a turbine, a condenser, a condensate pump, a make-up pump, a drain pump, a low-pressure expanding economizer, a recycle pump, a low pressure steam pocket, a turn-off valve and a heat exchanger. The heat exchanger comprises a heat exchanger high-temperature section and a heat exchanger low-temperature section which are mutually communicated. Non-heating season condensate working condition is utilized as a basis and heating season heat supplying working condition is combined to combine the low-pressure expanded economizer with a smoke heating network heater (heat-supplying economizer) to form one heated surface (the low-pressure expanded economizer), and users can flexibly adjust according to heating demand and electric load condition. Compared with the prior art with the low-pressure expanding economizer and the smoke heater for heating network arranged respectively, the low-pressure expanded economizer system does not need to mount the smoke heating network heater independently, pipelines and valves needed to be arranged are reduced, the structure is simple, system reliability is high, and the problem of non-heating season burning is avoided.

Owner:HANGZHOU BOILER GRP CO LTD

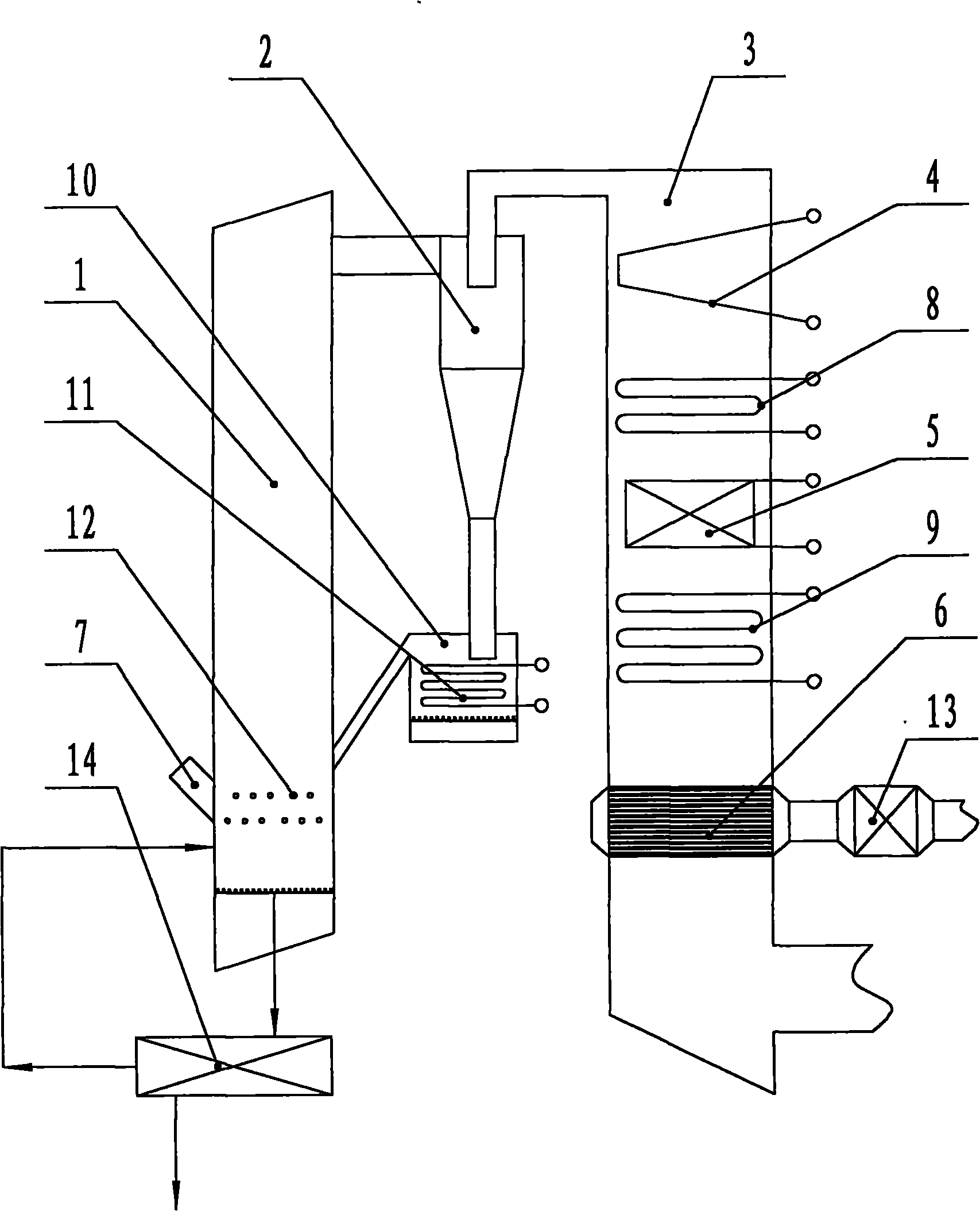

Fluidized bed biomass boiler and system capable of preventing air pre-heater from low-temperature corrosion

InactiveCN106765015AIncrease wall temperatureHigh acid dew point temperatureSteam generation plantsSteam boilersAir preheaterSlag

The invention relates to a high-low differential fluidized bed boiler and system, which combust biomass fuel and are capable of preventing an air pre-heater from low-temperature corrosion. Cold air is heated by hot water in an air-water air pre-heater and then is conveyed into a medium-temperature air pre-heater distributed on a tail flue of a boiler, so that the temperature of a metal wall of the medium-temperature air pre-heater to be higher than acid dew point temperature of flue gas, and furthermore, the low-temperature corrosion of the air pre-heater is prevented. A flue gas water feeding heater is arranged behind the air pre-heater on the tail flue of the boiler and is used for lowering flue gas temperature; meanwhile, the temperature of the air entering the flue gas water feeding heater is about 100 DEG C so that the low-temperature corrosion on the flue gas water feeding heater is also effectively avoided. The technology adopts a V-shaped air distribution plate so that problems of an existing fluidized bed biomass boiler that slag and coke are formed on a bed surface, and debris including iron nails, iron dust and the like is not easy to discharge and the like can also be effectively solved.

Owner:JIANGLIAN HEAVY IND GRP CO LTD

System and technology capable of utilizing waste heat of desulfurated slurry to prevent chimney from emitting white smoke

InactiveCN108592068ANo adverse effect on efficiencyEfficiency impactEmission preventionIndirect carbon-dioxide mitigationAir preheaterEngineering

The invention discloses a system and a technology capable of utilizing waste heat of desulfurated slurry to prevent a chimney from emitting white smoke. The system comprises a desulfurizing tower, anair heater, a high temperature air preheater and a low temperature air preheater, wherein the desulfurizing tower is connected with the air heater; desulfurated slurry from the desulfurizing tower exchanges heat with the cold air of the air heater, and the desulfurated slurry after temperature reduction returns to the desulfurizing tower; the air heater is further connected with the low temperature air preheater; the cold air passing through the air heater is heated by the desulfurated slurry and then enters the low temperature air preheater; the low temperature air preheater is connected withthe inlet of the high temperature air preheater through a pipeline; the outlet of the high temperature air preheater communicates with a boiler and the outlet flue of the desulfurizing tower; most ofhigh temperature air out of the high temperature air preheater is supplied to the boiler via a boiler hot air pipeline and provides oxygen for fuel combustion; and other small part of high temperature air enters the outlet flue of the desulfurizing tower and is mixed with wet flue gas from the desulfurizing tower in the flue to prevent the chimney from emitting white smoke.

Owner:烟台羽林节能科技有限公司

Brayton-cascade steam Rankine combined cycle power generation system

ActiveCN103075216AEfficient use ofReduce loadSteam useGas turbine plantsBrayton cycleSteam condensation

The invention relates to a Brayton-cascade steam Rankine combined cycle power generation system. The gas exhaust of a Brayton cycle is adopted as a heat source for a high-temperature end steam Rankine cycle, a steam condenser in a high-pressure end steam Rankine cycle is adopted as one of heat sources for a low-pressure end steam Rankine cycle, the latent heat of vaporization of the steam in the high-pressure end steam Rankine cycle is efficiently recovered to be used for power generation in the low-pressure end steam Rankine cycle, consequently, the load of the steam condenser of the conventional steam Rankine cycle system can be effectively reduced by more than absolute 20 percent, and by adopting a system optimization technique, the absolute thermal efficiency of the cycles of the whole system can be increased by more than 5 percent. The Brayton-cascade steam Rankine combined cycle power generation system not only can be used in the energy-saving alteration of conventional units, but also can be used in the design and construction of new units, and economic, social and environmental protection benefits are remarkable.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

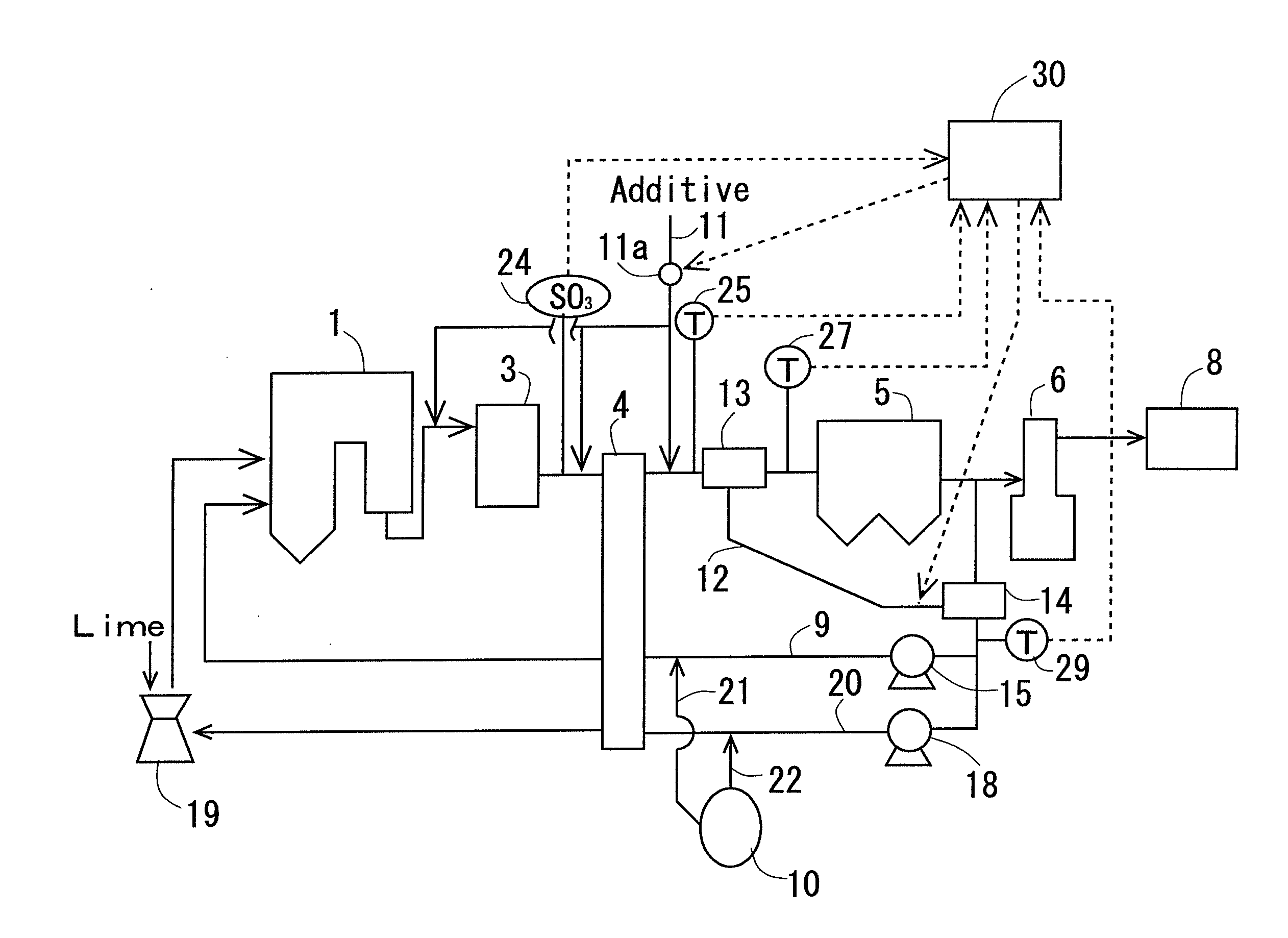

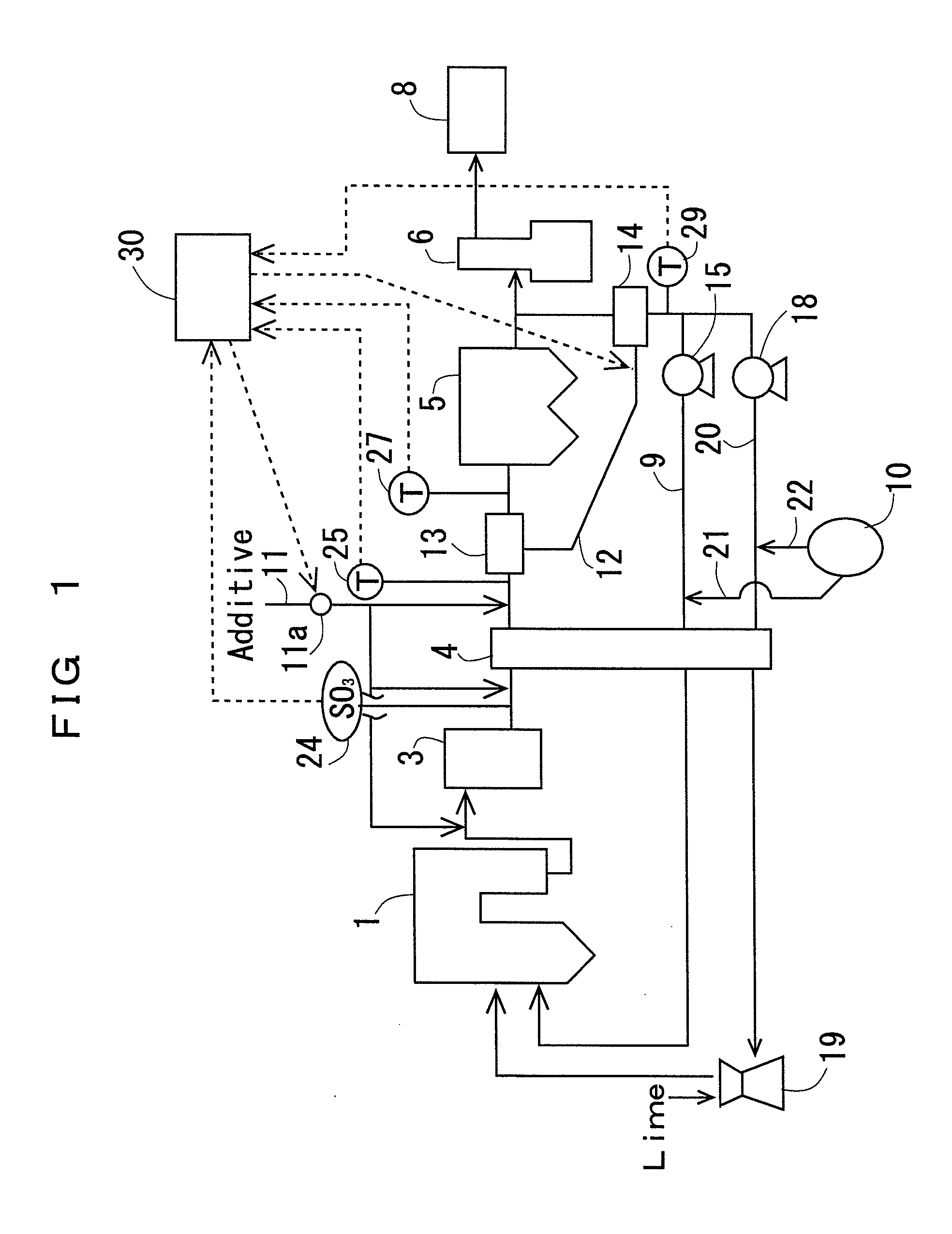

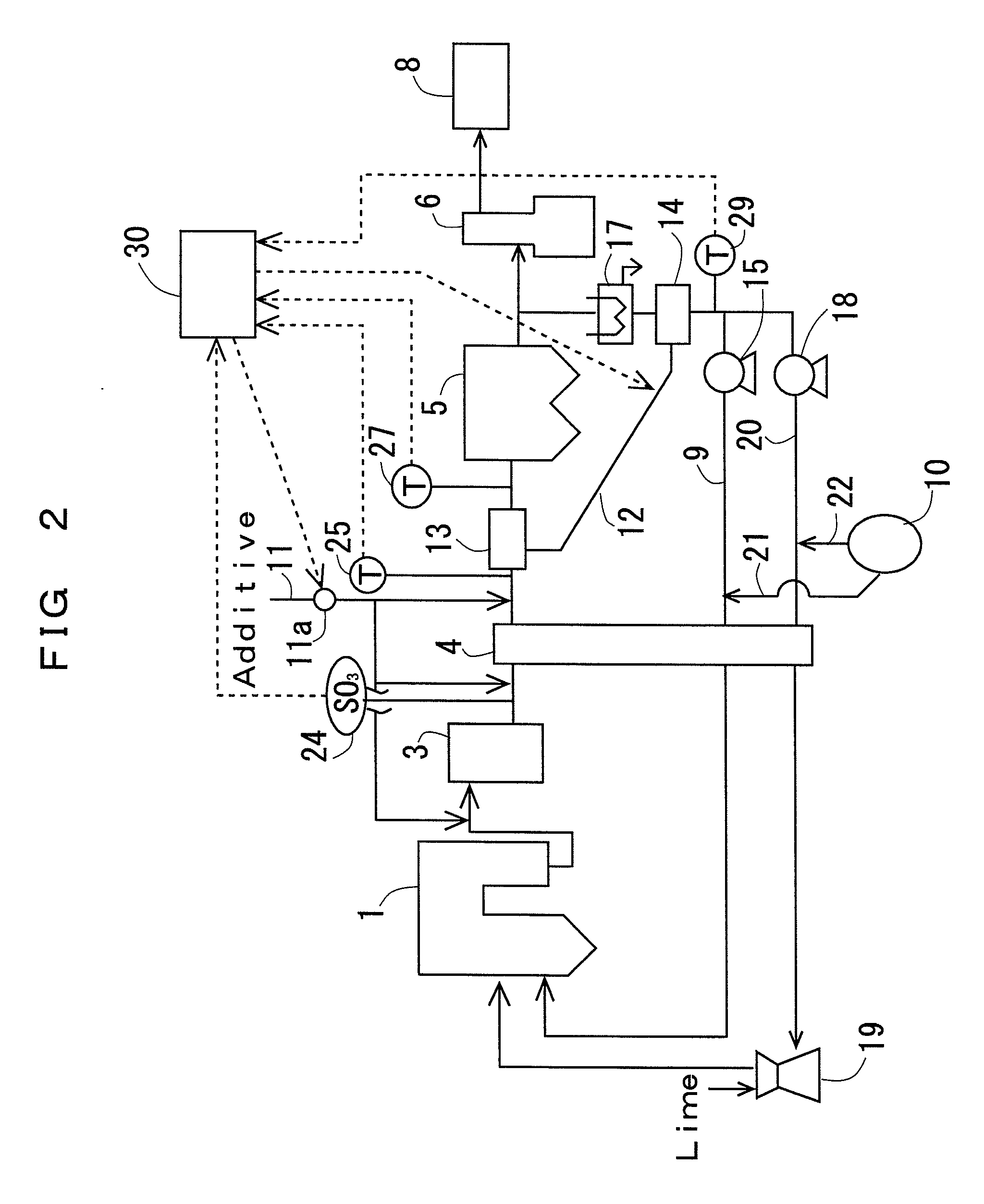

Exhaust gas treatment device for an oxygen combustion system

InactiveUS8778041B2Efficient removalAvoid corrosionCombination devicesAuxillary pretreatmentAir preheaterCombustion chamber

In an exhaust gas treatment device provided with: an exhaust gas treatment unit in which an oxygen combustion boiler 1 using coal as fuel, a denitration device 3, an air preheater 4, a dust-collection device 5, a desulfurization device 6, and a carbon dioxide recovery device 8 are sequentially arranged from the upstream side to the downstream side of an exhaust gas duct; and an exhaust gas circulation unit which branches off from the exhaust gas duct at an outlet of the dust-collection device 5 or an outlet of the desulfurization device 6 and through which the exhaust gas is preheated by the air preheater 4 and returned to the oxygen combustion boiler 1, a heat-recovery heat exchanger 13 that adjusts a gas temperature at an inlet of the dust-collection device 5 to be not greater than an acid dew point of SO3 and not lower than a water dew point is provided between the air preheater 4 and the dust-collection device 5, a reheating heat exchanger 13 that adjusts a gas temperature to be not lower than the acid dew point of SO3 is provided in the vicinity of a branch of the exhaust gas circulation unit, adjusting the gas temperature at the inlet of the dust-collection device 4 to be not greater than the acid dew point of SO3 makes it possible to prevent corrosion of pipes in the exhaust gas circulation unit and to avoid a decrease in fluidity or combustibility of the pulverized coal in the pipes in the mill.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

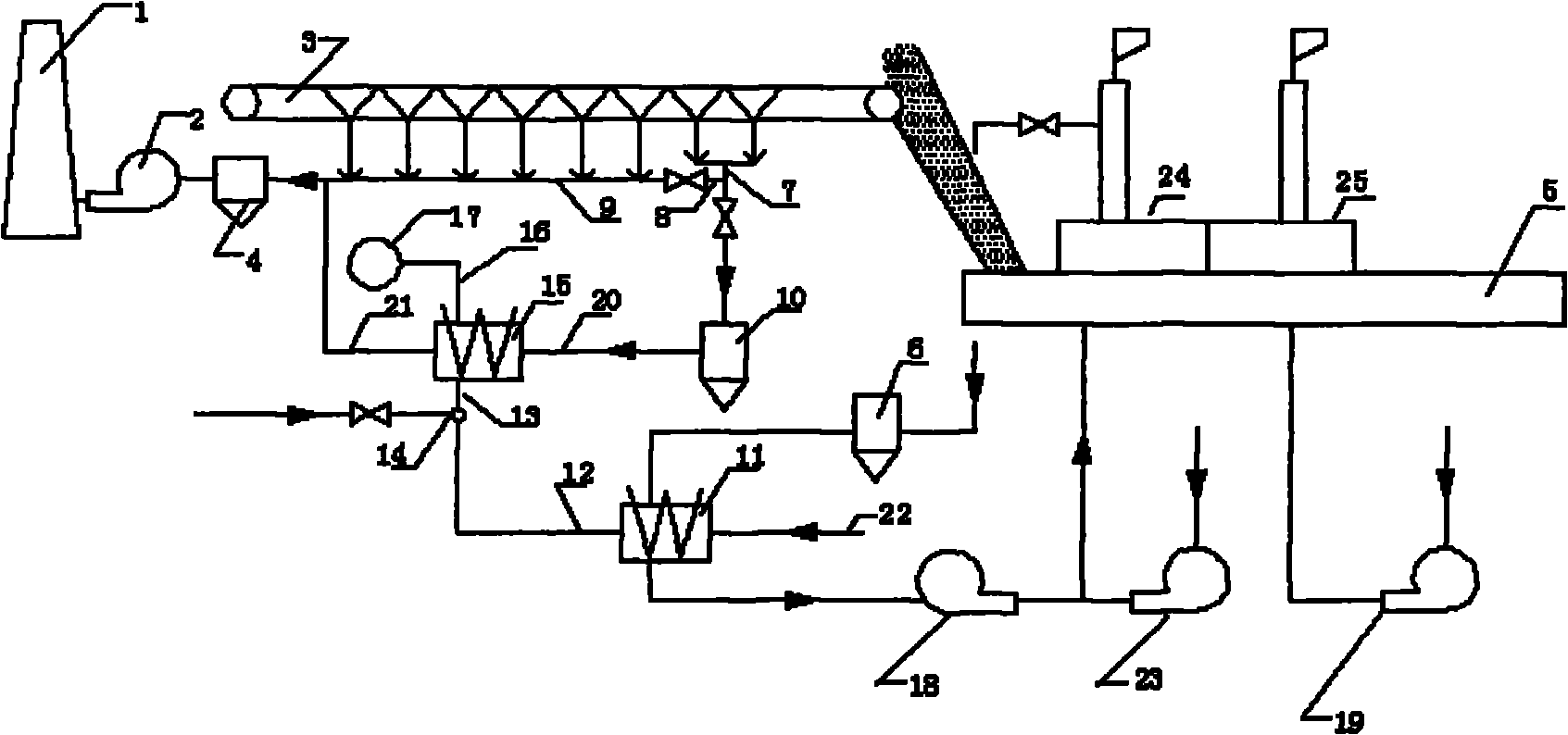

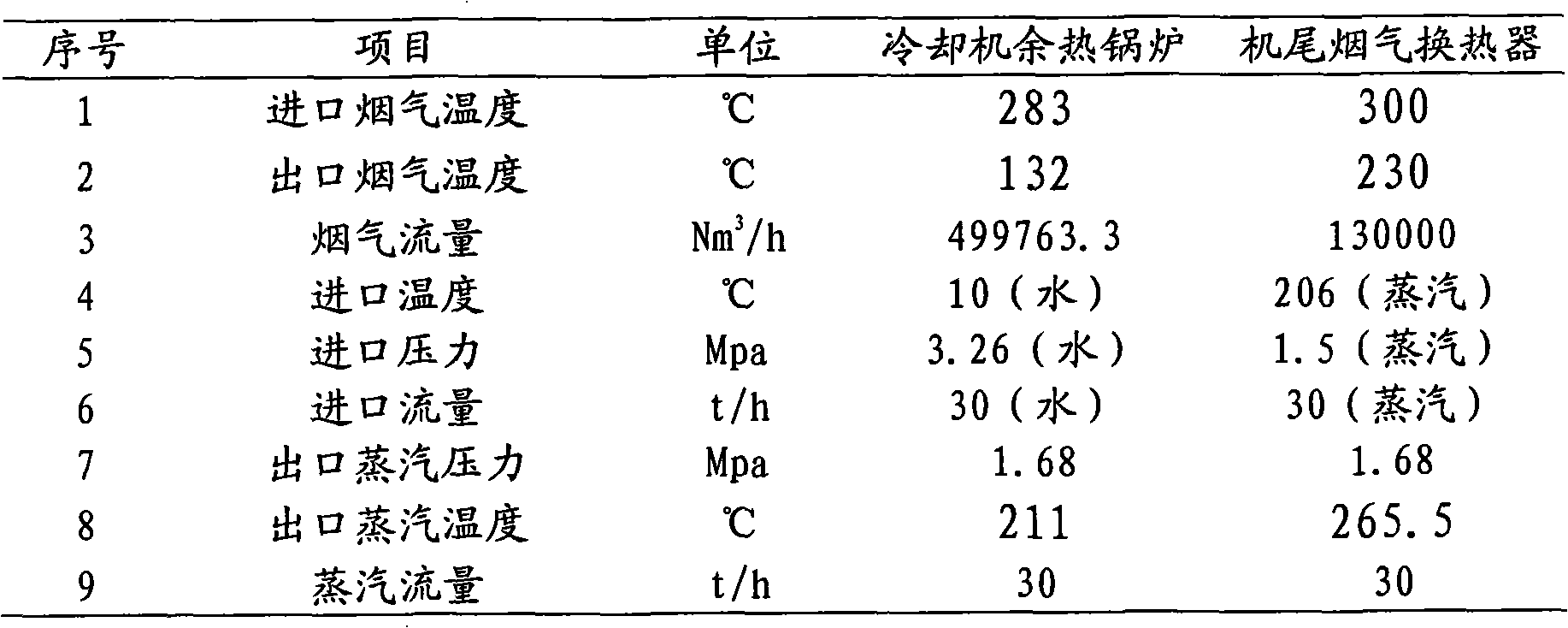

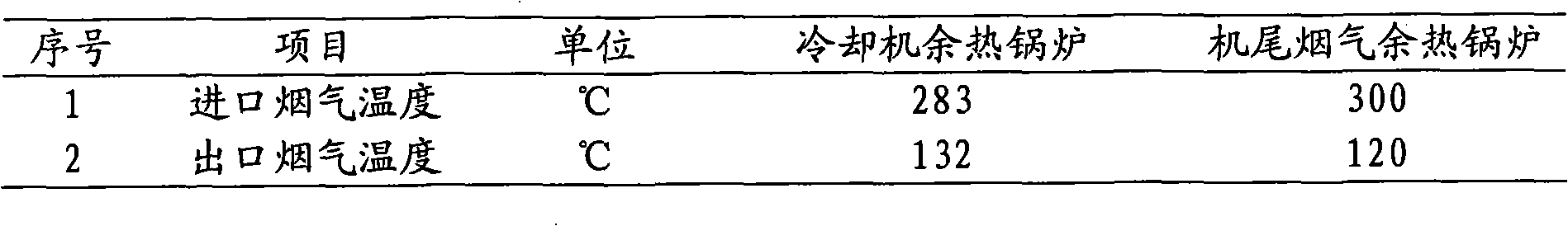

Method for overheating steam of cooler waste heat boiler and device used in same

InactiveCN101865454AIncrease the number ofQuality improvementIncreasing energy efficiencyHandling discharged materialProcess engineeringFlue

The invention discloses a method for overheating steam of a cooler waste heat boiler by using tail smoke gas waste heat of a sintering machine and a device used in the same. The device comprises a chimney, a spindle fan, a sintering machine, a large-flue dust remover, a cooler, a cooler dust remover, a sintering machine large flue, a cooler waste heat boiler, a sintering smoke gas heat exchanger, a heat user, and the like. The method mainly comprises the step of feeding the steam of the cooler waste heat boiler to the heat user via the high-quality steam formed by the sintering smoke gas heat exchanger. The method for overheating steam of the cooler waste heat boiler by using tail smoke gas waste heat of the sintering machine improves the amount and the quality of steam at the outlet of the waste heat boiler and avoids low-temperature corrosion produced in the heat exchanging process as the temperature of the steam at the inlet of the heat exchanger is far greater than that of an acid dew point of the sintering smoke gas.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Open lower temperature waste heat utilization system of ultra-clean emission coal-fired unit

PendingCN106765265AAvoid condensationAvoid Low Temperature CorrosionFeed water supplyCombustion technology mitigationGas heaterGas cooler

The invention discloses an open lower temperature waste heat utilization system of ultra-clean emission coal-fired unit, and relates to a steady controllable open MGGH system. A water outlet of a gas cooler is communicated with a gas-gas heater and a water inlet of waste heat recovery hot water mixer through pipeline systems with valves respectively, and the water inlet pipeline of the gas-gas heater is also provided with an auxiliary steam heater; the water outlet of the gas-gas heater is communicated with the water inlet of the gas cooler through a circulating water and make-up water mixer, a variable frequency booster pump and the pipeline systems with the valves; the water inlet of the circulating water and make-up water mixer is also communicated with a condensation water pipeline, and the water outlet of the waste heat recovery hot water mixer is communicated with a low-temperature heating system pipeline through at least two pipelines with the valves. In the invention, the problems that the inlet gas temperature of an electrostatic precipitator and chimney inlet gas temperature are difficult to control, the low-temperature heating adjustment of the unit is difficult to control and the disturbance is severe due to poor heat exchange effect of a plate heat exchanger in the existing MGGH technology are solved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

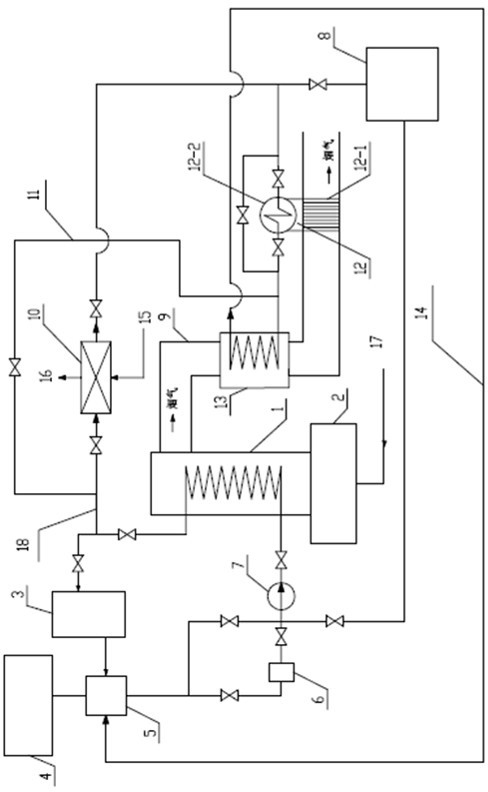

Waste heat recovery system and method for coal-fired power plant

PendingCN111486468AAvoid Low Temperature CorrosionLow temperature corrosion achievedCombustion processClimate change adaptationAir preheaterElectrolysis

The invention provides a waste heat recovery system for a coal-fired power plant. The waste heat recovery system involves a boiler, an air preheater, a plurality of coolers, a dust remover, a desulfurizing tower, a flue gas condensation heat exchanger, a flue gas reheater and a chimney which are sequentially arranged; the plurality of coolers are sequentially connected in series, the outlet temperatures of heat exchange media of the plurality of coolers are sequentially reduced, and the plurality of coolers correspond to different heat using devices; the system involves an absorption heat pump, a thermocline heat storage tank and a heat supply network, and the hot water output end of the thermocline heat storage tank communicates with the heat supply network; and heat generated by part ofthe coolers is used for driving the absorption heat pump to recover heat released in the flue gas condensation process, part of the heat generated by the heat pump is conveyed to the flue gas reheaterto be used for reheating flue gas, part of the heat is used for preheating air, and the rest part of the heat is continuously heated in part of coolers and stored in the thermocline heat storage tankto supply heat loads needed by the heat supply network. Gradient utilization of energy is achieved, energy conservation, water recovery and thermoelectric decoupling can be achieved simultaneously, and the unit waste heat and water recovery capacity and the power station operation flexibility are improved.

Owner:DATANG ENVIRONMENT IND GRP +1

Multi-working-medium backheating type Rankine cycle system

ActiveCN103114881ARaise the average heating temperatureHigh thermal efficiencyCombustion processIndirect carbon-dioxide mitigationAir preheaterEnhanced heat transfer

The invention relates to a multi-working-medium backheating type Rankine cycle system. The multi-working-medium backheating type Rankine cycle system utilizes a turbine to pump steam to heat the air and boiler feed water (or including liquid and gas fuel), so that the identical effect of heating feed water by pumping steam and cycling backheating is achieved. A smoke-air short circuit is effectively avoided by omitting an air preheater in a tail flue. Exhaust temperature is effectively lowered and low-temperature corrosion of smoke is avoided during heat transfer intensifying by arranging the air preheater outside a boiler and arranging a feed water overheater, a feed water heater and a phase change heat exchanger.

Owner:SHANDONG DAIRONG ENERGY SAVING ENVIRONMENTAL PROTECTION TECH

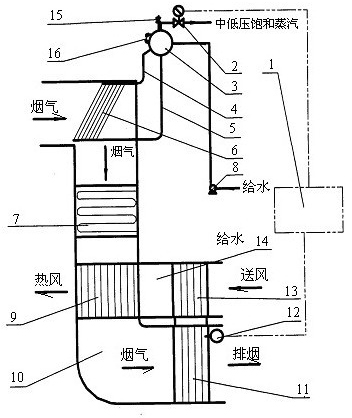

Air pre-heater system preventing low-temperature corrosion and air pre-heating method

ActiveCN102620310AReduce the temperatureNo low temperature corrosion phenomenonCombustion processIndirect carbon-dioxide mitigationAir preheaterCombustion

Provided are an air pre-heater system preventing low-temperature corrosion and an air pre-heating method. The air pre-heater system comprises a heat exchange system and a heating medium system. The heat exchange system comprises a smoke-air heat exchanger, a smoke-heating medium heat exchanger and a heating medium-air heat exchanger. The smoke-air heat exchanger and the smoke-heating medium heat exchanger are sequentially arranged in a heating furnace flue along the smoke flowing direction, and the heating medium-air heat exchanger is arranged outside the heating furnace flue. The smoke-heating medium heat exchanger, the heating medium-air heat exchanger and a heating medium system are connected in series to form a circulating system, smoke heat is transferred to a heating medium through the smoke-heating medium heat exchanger, an air inlet of the heating medium-air heat exchanger is connected with a fan, and outside air is subjected to primary heating of the heating medium-air heat exchanger, then enters the smoke-air heat exchanger to enable the air temperature to be higher than the dew-point temperature of sulfur-containing smoke and is used for supporting combustion after being subjected to secondary heating of high-temperature smoke. The phenomenon of low-temperature corrosion can be prevented, and accordingly an air pre-heater can run on line for a long period.

Owner:BIHAIZHOU BEIJING ENERGY SAVING EQUIP CO LTD

Power station boiler residual heat utilization system capable of achieving intelligent control for fan frequency

InactiveCN105202517AAvoid Low Temperature CorrosionAutomatic adjustment of heating powerCentral heating with accumulated heatBoiler controlData connectionAutomatic control

The invention provides a power station boiler residual heat utilization system capable of achieving intelligent control for fan frequency. The system comprises a boiler, a main flue, a bypass flue, a heat exchanger, a flue temperature sensor and a central controller, wherein smoke generated by the boiler enters into the heat exchanger through an inlet of the bypass flue; smoke subjected to heat exchange flows into the main flue via the outlet of the bypass flue and then is discharged; a main flue fan is arranged on the main flue; a bypass flue fan is arranged on the bypass flue; the flue temperature sensor measures the temperature of discharged smoke; the central controller is in data connection with the temperature sensor, the main flue fan and the bypass flue fan; the central controller automatically adjusts the frequency of the main flue fan and the bypass flue fan according to the exhaust gas temperature measured by the temperature sensor. According to the power station boiler residual heat utilization system, the exhaust gas temperature of smoke is automatically controlled through intelligently controlling fan frequency to adjust flow of smoke participating in residual heat utilization and heat exchange, so that low-temperature corrosion is avoided, and intelligentized adjustment of the system is realized.

Owner:ZHONGBEI UNIV

Circulating fluidized bed domestic waste incineration power generation boiler

InactiveCN101846308AIncrease disturbanceImprove heat transfer coefficientSteam boilersSteam boilers componentsSuperheaterCorrosion

The invention specifically discloses a circulating fluidized bed domestic waste incineration power generation boiler, which solves the problems of low combustion efficiency, severe corrosion and large possibility of large-area coking in the current circulating fluidized bed domestic waste incineration power generation boiler. A coal economizer comprises an upper coal economizer and a lower coal economizer, a fluidized back feeder, which is internally provided with a high temperature superheater, is arranged between the lower parts of a cyclone separator and a hearth and is also communicated with both, a plurality of secondary air jet orifices are arranged at hearth sidewall around a domestic waste feeding port, and a convective evaporation heated surface, the upper coal economizer, a lower temperature superheater, the lower coal economizer and an air preheater are sequentially arranged inside a shaft flue at the tail of the boiler from top to bottom. The circulating fluidized bed domestic waste incineration power generation boiler solves the problems of low combustion efficiency, severe corrosion and large possibility of large-area coking in the current circulating fluidized bed domestic waste incineration power generation boiler, and has the advantages of simple structure and convenient operation.

Owner:SHANXI LANTIAN ENVIRONMENTAL PROTECTION EQUIPCO

Brayton-steam Rankine-organic Rankine combined cycle power generation device

ActiveCN103089442AReduce power consumptionImprove energy savingSteam useEnergy industryOrganic Rankine cycleFlue gas

The invention relates to a Brayton -steam Rankine-organic Rankine combined cycle power generation device. Exhaust of a Brayton gas turbine serves as a heat source of steam Rankine-organic Rankine combined cycle, a condenser of the steam Rankine cycle serves as an evaporator of the organic Rankine cycle, the characteristic that the medium / low-temperature heat source has high utilization efficiency in the organic Rankine cycle is utilized, lots of latent heat of vaporization released by devaporation is used for high-efficiency organic Rankine cycle power generation, the vaporized latent heat of the steam of the steam Rankine cycle is only used for power generation, so that more that 50 degrees per tonnage steam can be recovered, the safety problem in the process of recovering flue gas waste heat in the organic Rankine cycle is solved, the smoke exhaust temperature is effectively reduced, and the low-temperature corrosion of the flue gas is avoided. The device can be used for energy conservation transformation of the conventional unit, can be used for design and construction of novel units and is obvious in economic, social and environment-friendly effects.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

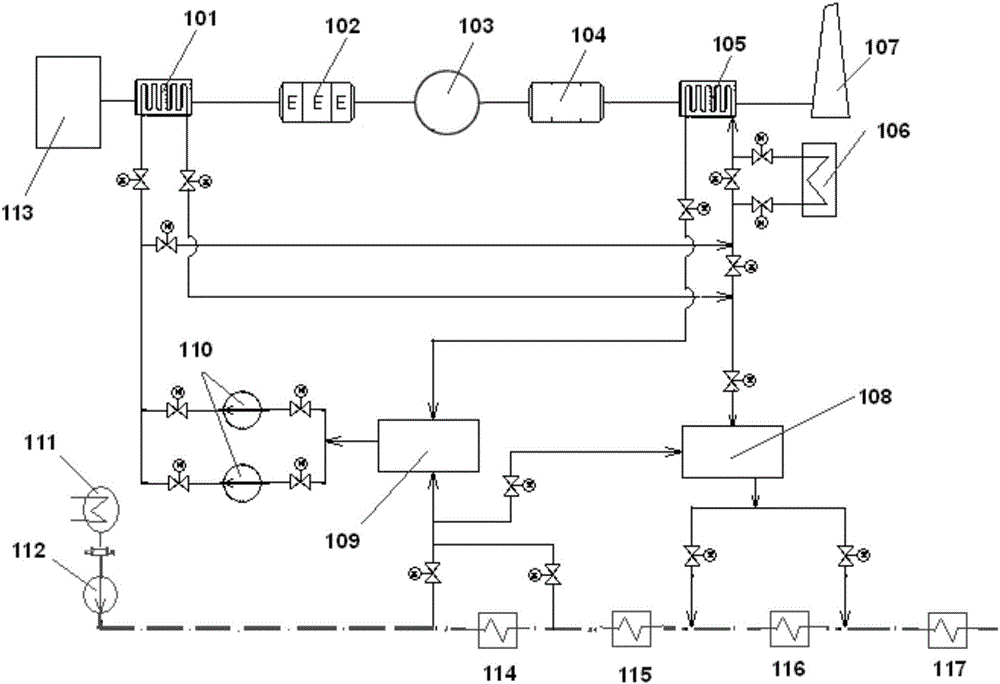

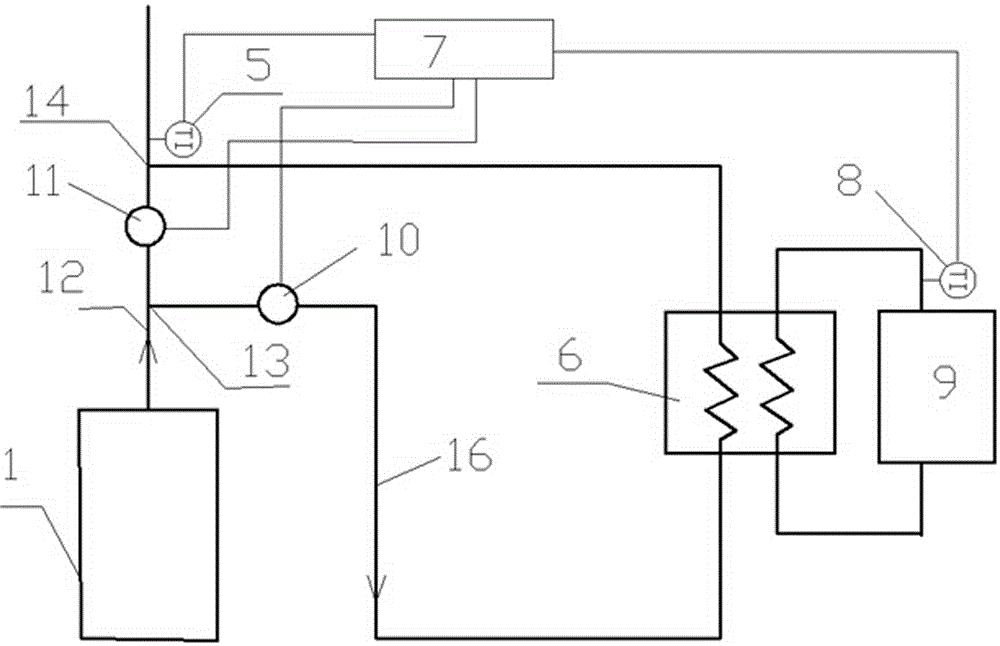

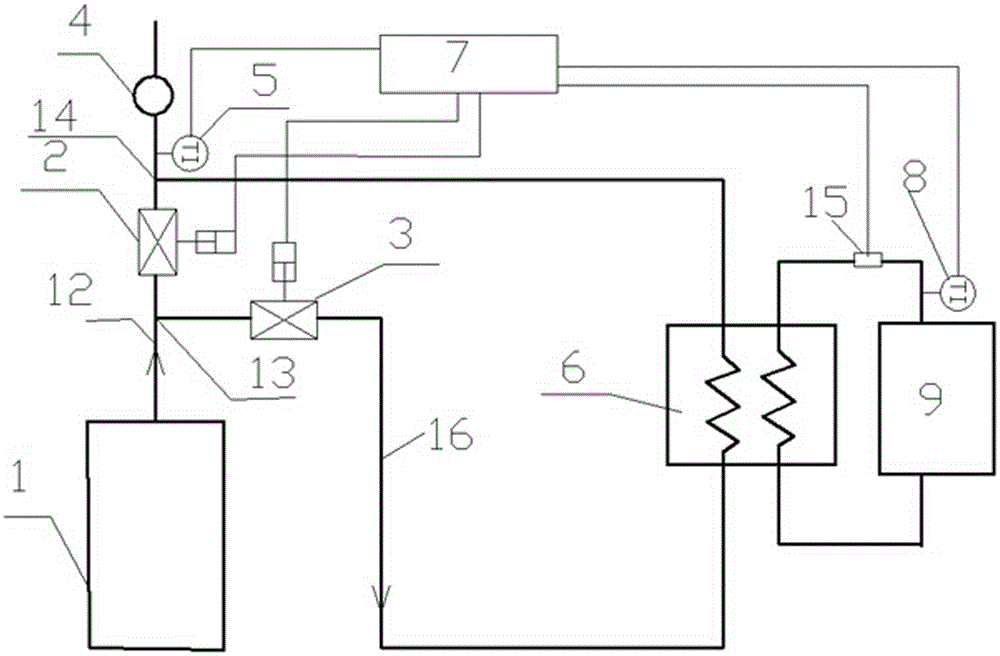

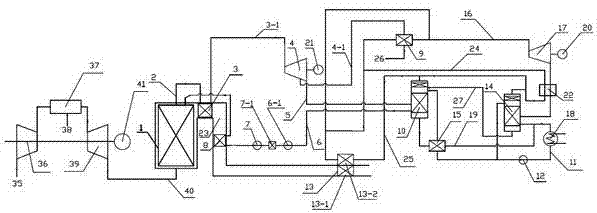

Double-circulation device and method for recovering and heating furnace-entering air through waste heat of boiler discharged smoke

ActiveCN105351915AGuaranteed safe operationAvoid condensationFeed-water heatersSocial benefitsAutomatic control

The invention provides a double-circulation device and method for recovering and heating furnace-entering air through waste heat of boiler discharged smoke. The double-circulation device is connected with a turbine steam extraction and heat return system through open circulation, and therefore recycled smoke waste heat and heat required for heating put-into-furnace air are automatically balanced, smoke is prevented from dewing, smoke low-temperature corrosion is prevented, it is ensured that the influences of environment temperature changes and unit load changes on boiler smoke discharge temperature can be offset under all working conditions, and the inlet smoke temperature of electric dust collectors and the temperature of put-into-furnace air can be automatically controlled under all the working conditions no matter how the environment temperature changes and no matter how the unit load changes. The double-circulation device and method have social benefits and economic benefits of being capable of saving coal and water and decreasing the smoke discharge amount.

Owner:上海羲蓝节能环保科技有限公司

Hazardous waste incineration line flue gas purification treatment system

InactiveCN112870946AEasy to cleanSolve the problem of incomplete purification treatmentCombination devicesGas treatmentEmission standardEngineering

The invention discloses a hazardous waste incineration line flue gas purification treatment system, which comprises a quench tower, a cyclone dust collector, a dry deacidification tower, a filter bag, a wet washing tower, an alkali liquor neutralizing tower, a steam heater and a chimney. The outer wall of the quench tower is fixedly connected with a quench tower spray gun cooling water ring pipe, a quench tower spray gun compressed air ring pipe and a quench tower spray gun protection air ring pipe, the upper end of the quench tower is provided with a quench tower flue gas inlet, and the lower end of the quench tower is provided with a spray gun compressed air inlet pipe and a quench tower spray gun protection fan. According to the hazardous waste incineration line flue gas purification treatment system, the problem that flue gas purification treatment is not thorough is solved, the process is more reasonable, more convenient and more effective, the flue gas purification treatment effect is greatly improved, and finally the flue gas reaches the national flue gas emission standard, and after flue gas generated after incineration is purified by the flue gas treatment system, the concentration meets the emission requirement, and a better use prospect is brought.

Owner:苏州巨鼎环保科技有限公司

Device for preventing wet desulfurization outlet flue from low-temperature corrosion and control method thereof

ActiveCN103007726AAvoid Low Temperature CorrosionDispersed particle separationPipe elementsFlue gasProcess engineering

The invention relates to a wet desulfurization outlet flue, and especially relates to a device for preventing the wet desulfurization outlet flue from low-temperature corrosion and a control method thereof. The device comprises a wet desulfurization outlet flue. The wet desulfurization outlet flue is provided with a flue gas analyzer and a temperature measurement instrument. The wet desulfurization outlet flue is connected with a high temperature flue by a high temperature air pipe. The high temperature flue is provided with a heat exchanger. The high temperature air pipe is connected to one end of the heat exchanger and the other end of the heat exchanger is connected to an air pipe. The device has the advantages that a temperature of flue gas in a flue is always higher than a dew point temperature of an acid; and low-temperature corrosion of a flue is avoided.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

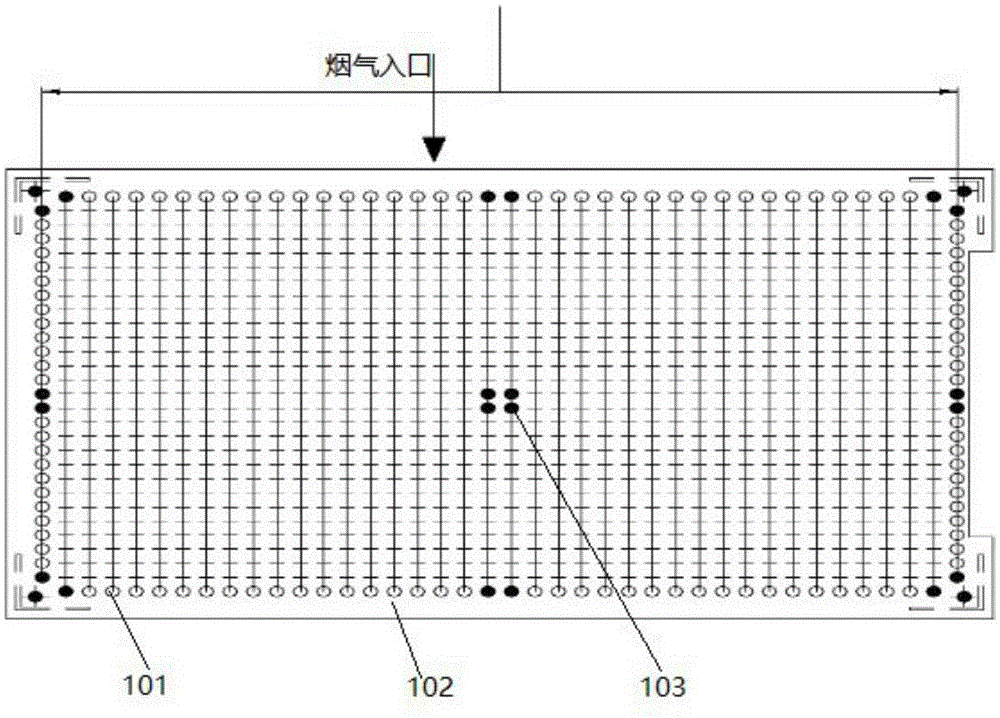

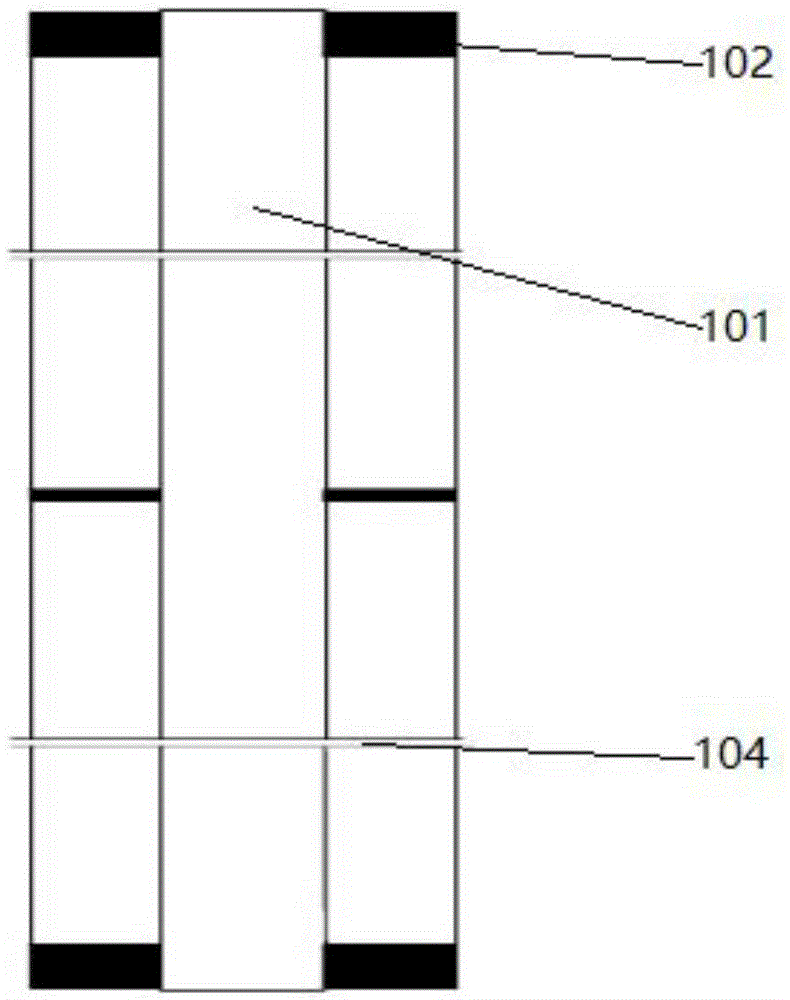

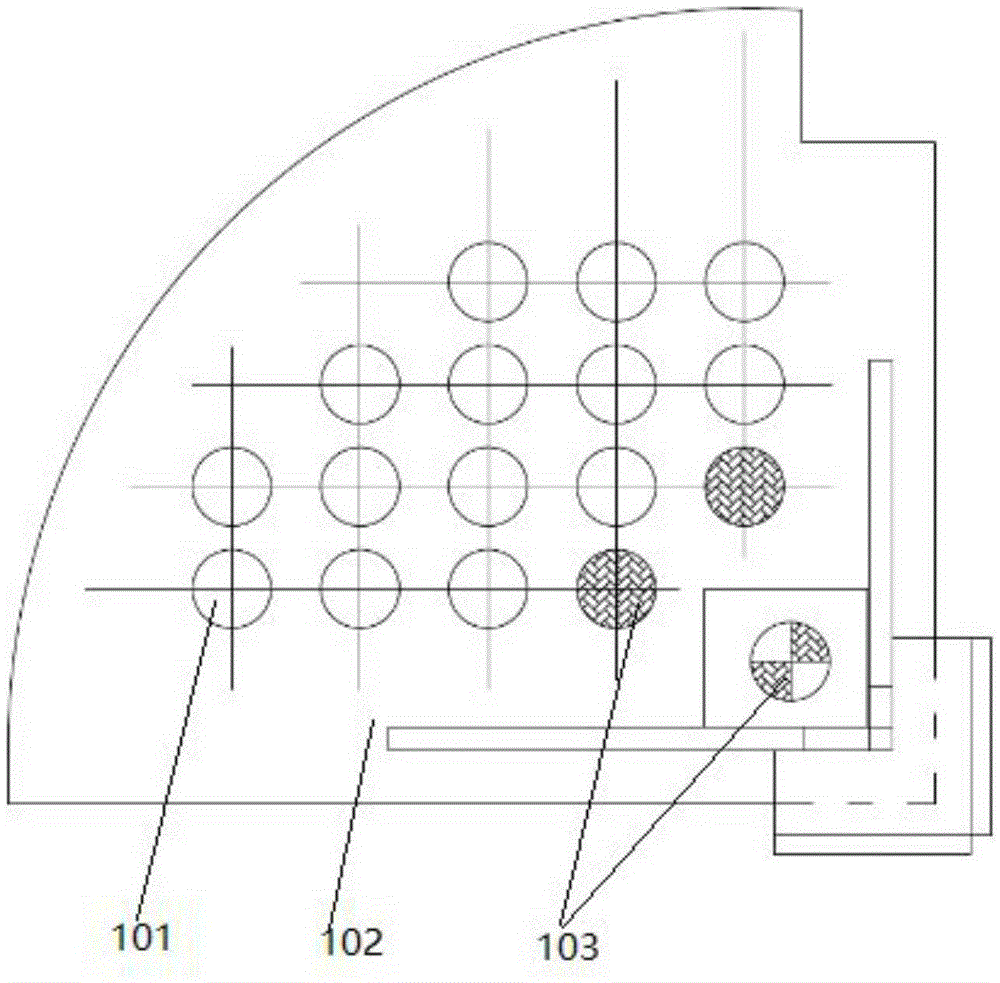

Fluoroplastic-steel air preheater with anti-corrosive and anti-blockage functions

InactiveCN105402760AAchieve anti-foulingAnti-dustingReinforcing meansCombustion processAir preheaterWorking life

The invention discloses a fluoroplastic-steel air preheater with anti-corrosive and anti-blockage functions. The fluoroplastic-steel air preheater comprises a plurality of fluoroplastic-steel tubes which are arranged at intervals in parallel and tube plates arranged at the two ends of each fluoroplastic-steel tube respectively, wherein each fluoroplastic-steel tube is produced by coating a fluoroplastic tube with a stainless steel tube; the two ends of each fluoroplastic-steel tube are fixedly connected to the corresponding tube plates through a tube expansion process respectively; and the sidewall of each fluoroplastic-steel tube faces a preheater smoke inlet. The fluoroplastic-steel air preheater disclosed by the invention can solve the easily-caused problems of low-temperature corrosion, ash attachment and slag formation, and the like of the traditional steel air preheaters, and overcomes the defect that fluoroplastic tubes are liable to generate jiggle deformation to influence working life and heat exchange performance under a smoke scouring action due to too thin tube walls in common plastic heat exchangers; and low-temperature corrosion of the air preheater can be prevented, and the fluoroplastic tube bundles can keep the original design shape and are not liable to generate jiggle deformation under the smoke scouring.

Owner:衢州佰强新材料科技有限公司

Multistage cascaded steam Rankine combined cycle power generation device

PendingCN104727870APromote circulationAbsolute Efficiency Value ImprovementIncreasing energy efficiencySteam engine plantsSteam condensationLoad following power plant

The invention relates to a multifunctional cascaded steam Rankine combined cycle power generation device. A multistage cascaded mode including a high-voltage end Rankine cycle, a middle-voltage end Rankine cycle and a low-voltage end Rankine cycle is adopted, discharged latent heat of vaporization during the vapor condensation of the high-voltage end Rankine cycle and the middle-voltage end Rankine cycle is recycled efficiently and is used for electricity generating of a Rankine cycle system, load of a condenser of a traditional steam Rankine cycle system is efficiently reduced over an absolute value of 20 percent, the system optimization technology is adopted, and the cycled absolute heating efficiency of the whole system can be improved by over 5 percent. The multifunctional cascaded steam Rankine combined cycle power generation device can be used for energy conservation transformation of an existing reheat cycle steam Rankine cycle unit and can also be used for the design and construction of a new-built unit, and the economic benefit, social benefit and environmental protection benefit are remarkable.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com