Fluidized bed biomass boiler and system capable of preventing air pre-heater from low-temperature corrosion

An air preheater, biomass boiler technology, applied in the direction of preheating, steam boiler, feed water heater, etc., can solve problems such as low temperature corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

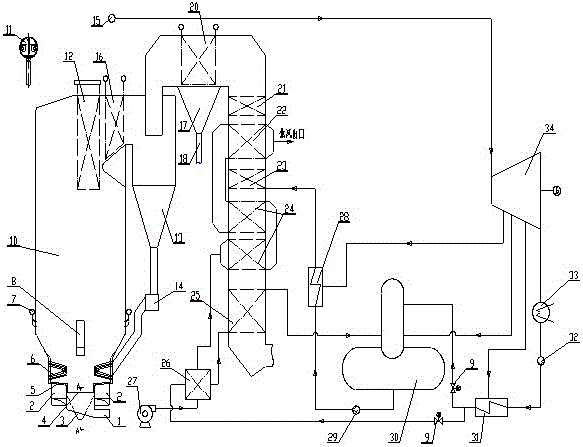

[0036] Specific implementation mode one: combine figure 1 Explain, the air preheater low-temperature corrosion prevention fluidized bed biomass boiler and system with material external circulation belt separator 13 and feeder 14 in this embodiment, the system includes a high-speed bed air chamber 1, a low-speed bed air chamber 2. V-shaped slag discharger 3. High-speed bed V-shaped air distribution plate 4. Low-speed bed air distribution plate 5. Soaking heating surface 6. Secondary air pipe 7. Feeding pipe 8. Regulating valve 9. Furnace chamber 10. Drum 11. Three-stage superheater 12, separator 13, feeder 14, steam collector 15, secondary superheater 16, horizontal flue ash collection hopper 17, ash discharge pipe 18, primary superheater 20, high temperature province Coal heater 21, high temperature air preheater 22, low temperature economizer 23, medium temperature air preheater 24, flue gas feed water heater 25, gas water air preheater 26, fan 27, high pressure heater 28, bo...

specific Embodiment approach 2

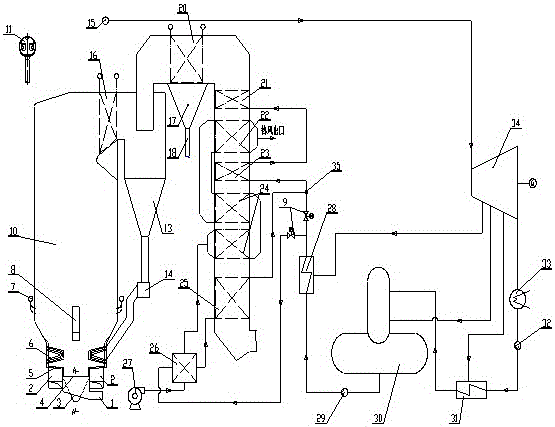

[0039] Specific implementation mode two: combination figure 2 Explain, the air preheater low-temperature corrosion prevention fluidized bed biomass boiler and system with material external circulation belt separator 13 and feeder 14 in this embodiment, the system includes a high-speed bed air chamber 1, a low-speed bed air chamber 2. V-shaped slag discharger 3. High-speed bed V-shaped air distribution plate 4. Low-speed bed air distribution plate 5. Soaking heating surface 6. Secondary air pipe 7. Feeding pipe 8. Regulating valve 9. Furnace chamber 10. Drum 11. Separator 13, feeder 14, steam header 15, secondary superheater 16, horizontal flue ash collecting hopper 17, ash discharge pipe 18, primary superheater 20, high temperature economizer 21, high temperature air Preheater 22, low temperature economizer 23, medium temperature air preheater 24, feed water flue gas heater 25, gas water air preheater 26, fan 27, high pressure heater 28, boiler feed water pump 29, deaerator 3...

specific Embodiment approach 3

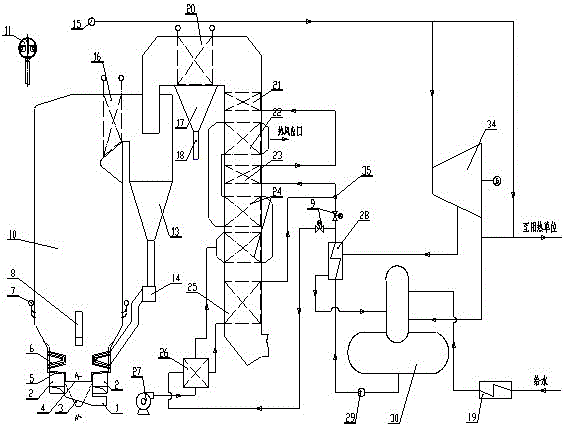

[0042] Specific implementation mode three: combination image 3Explain, the air preheater low-temperature corrosion prevention fluidized bed biomass boiler and system with material external circulation belt separator 13 and feeder 14 in this embodiment, the system includes a high-speed bed air chamber 1, a low-speed bed air chamber 2. V-shaped slag discharger 3. High-speed bed V-shaped air distribution plate 4. Low-speed bed air distribution plate 5. Soaking heating surface 6. Secondary air pipe 7. Feeding pipe 8. Regulating valve 9 Furnace chamber 10, Drum 11 , separator 13, feeder 14, steam header 15, secondary superheater 16, horizontal flue ash collecting hopper 17, ash discharge pipe 18, make-up water heater 19, primary superheater 20, high temperature and coal saving 21, high temperature air preheater 22, low temperature economizer 23, medium temperature air preheater 24, flue gas feed water heater 25, gas water air preheater 26, fan 27, high pressure heater 28, boiler f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com