Patents

Literature

30results about How to "Improve energy quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

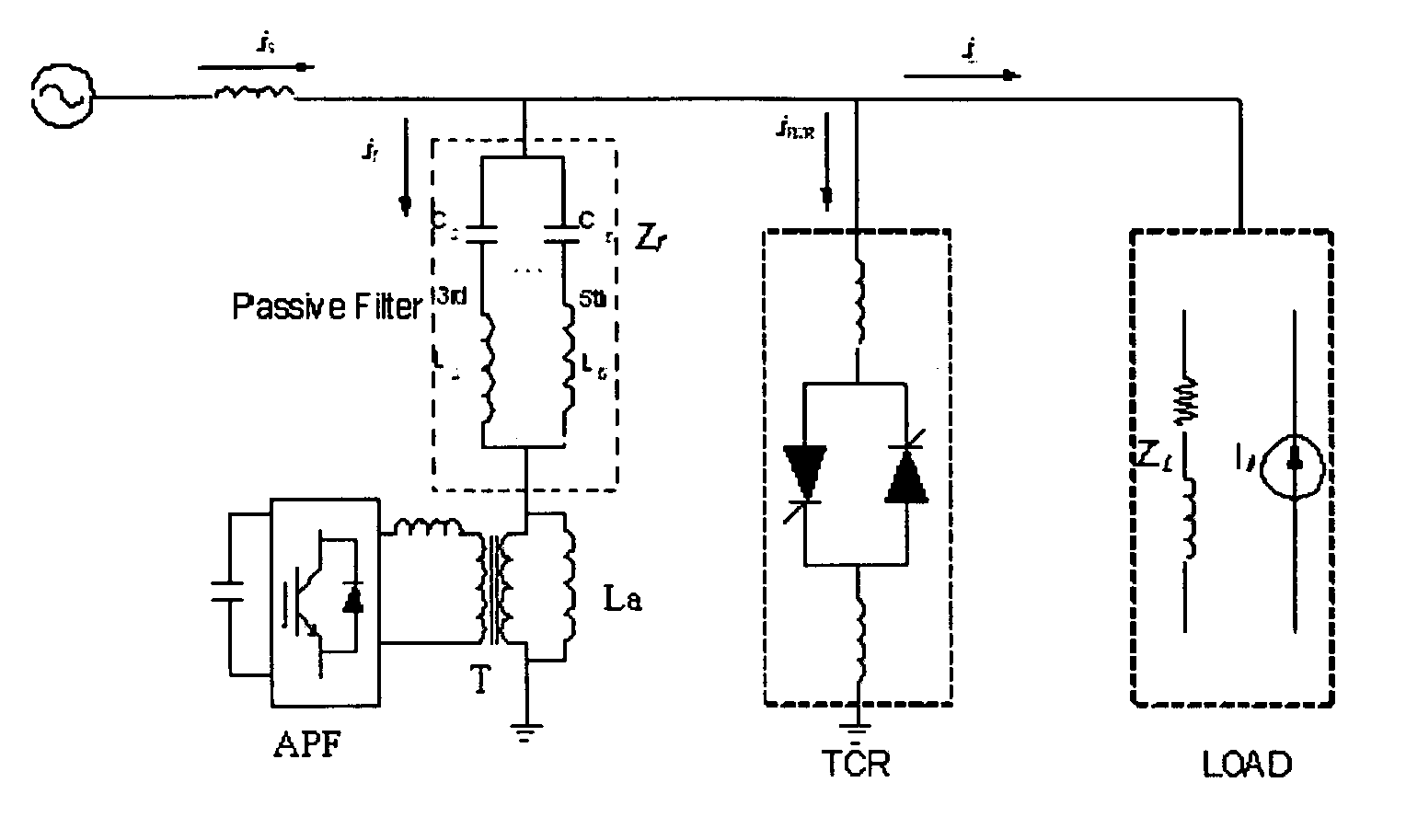

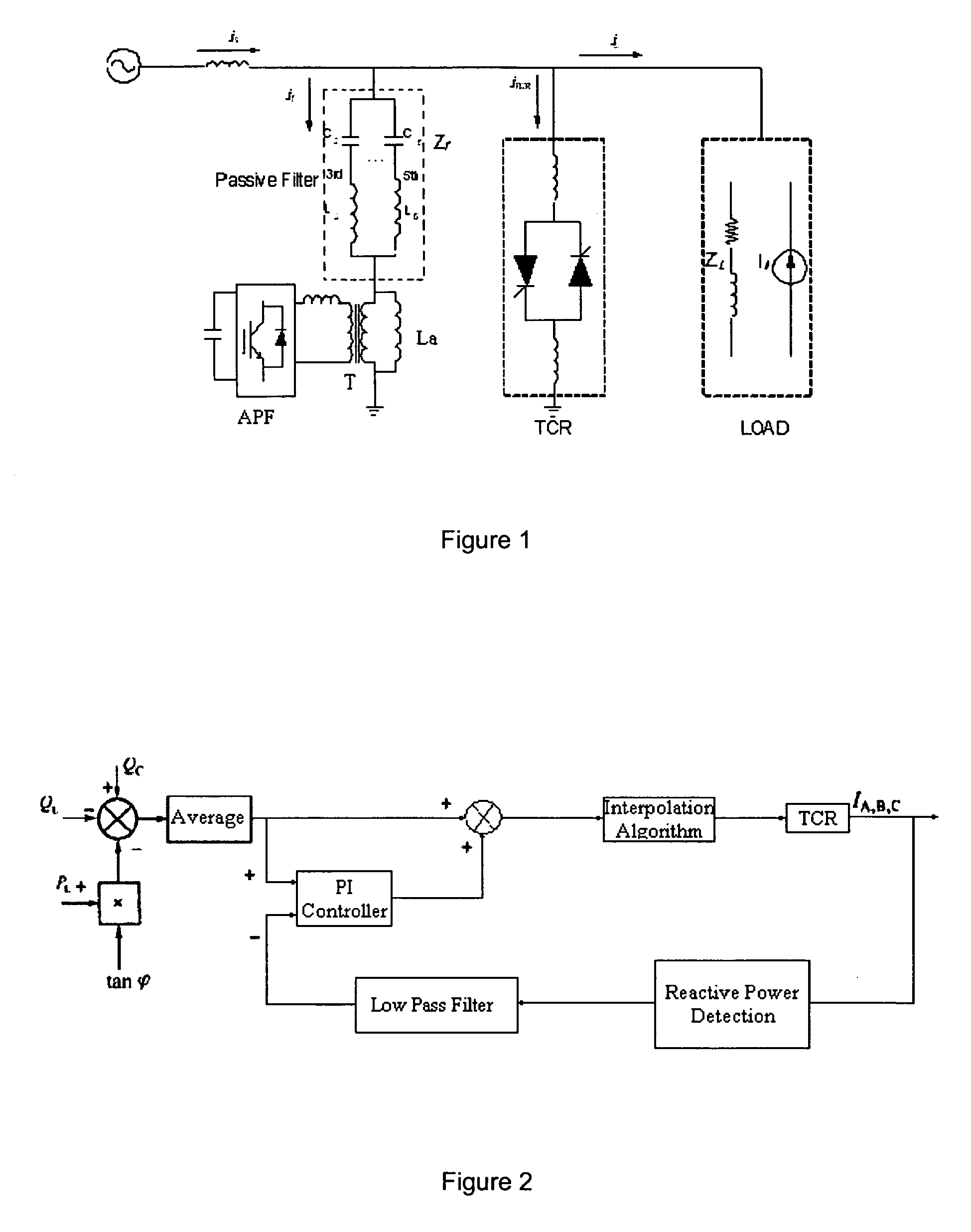

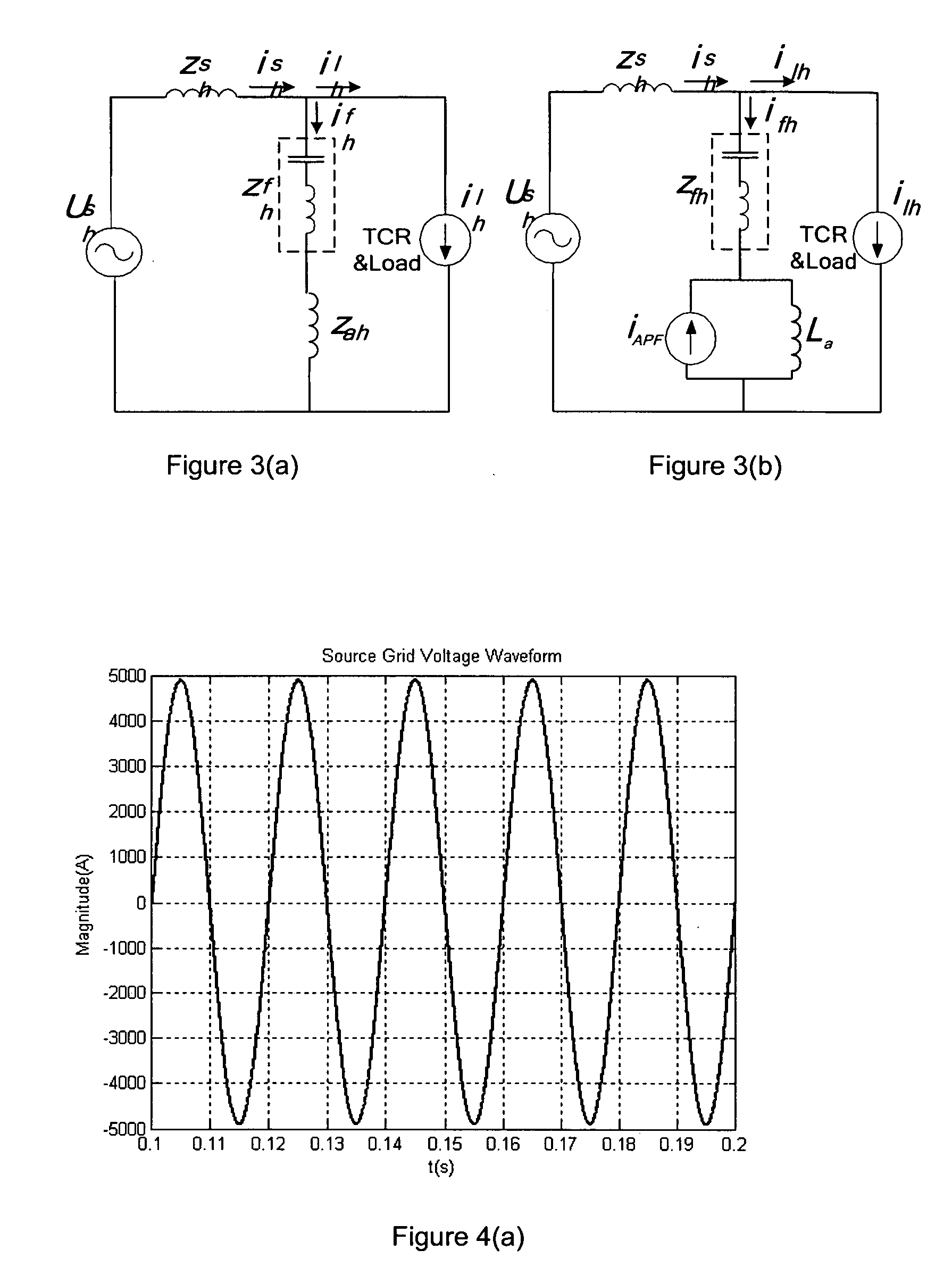

Comprehensive power quality controller for substation in power system

InactiveUS20070014132A1Small capacityCost muchFlexible AC transmissionActive power filteringPower gridPassive filtering

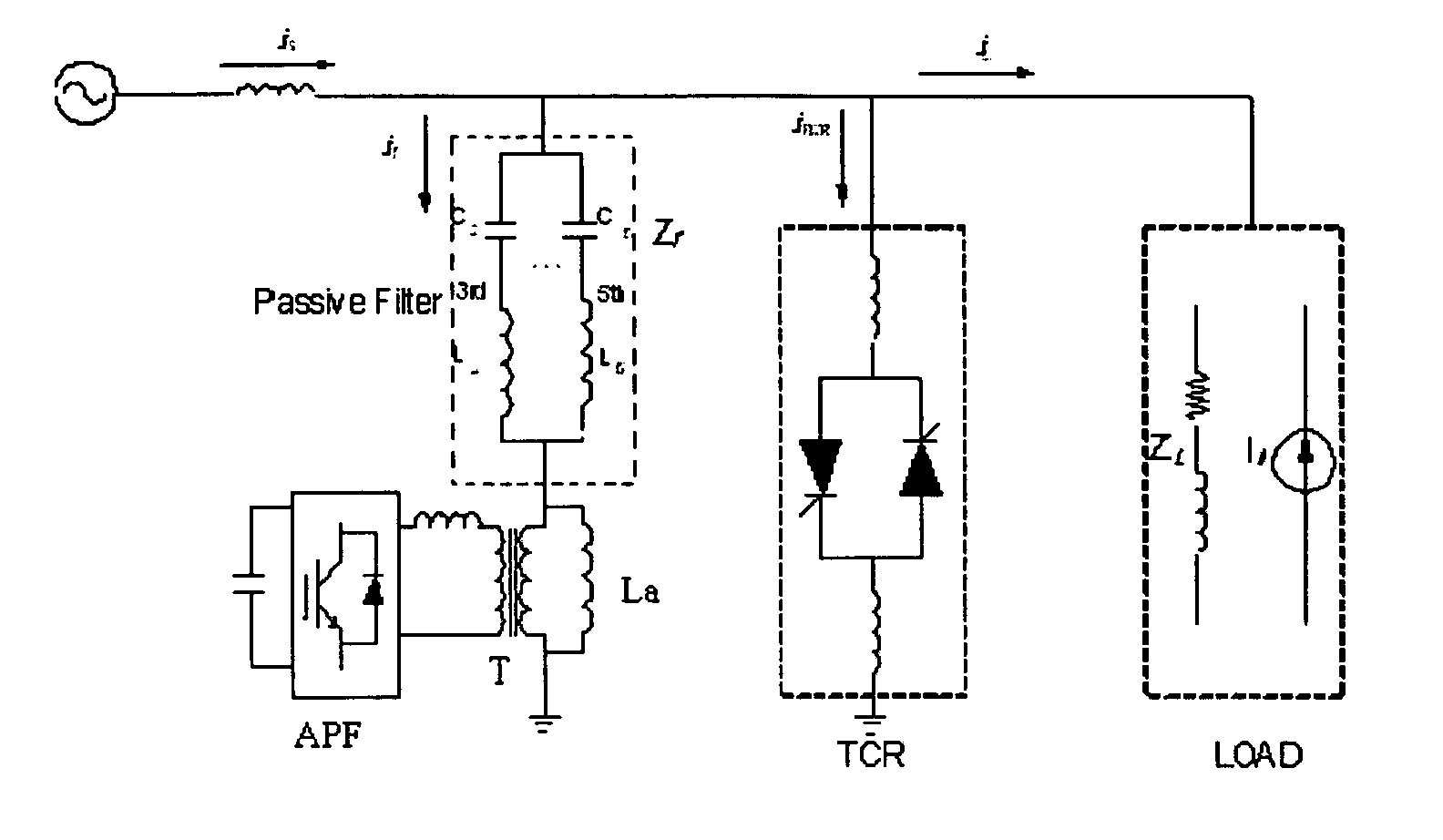

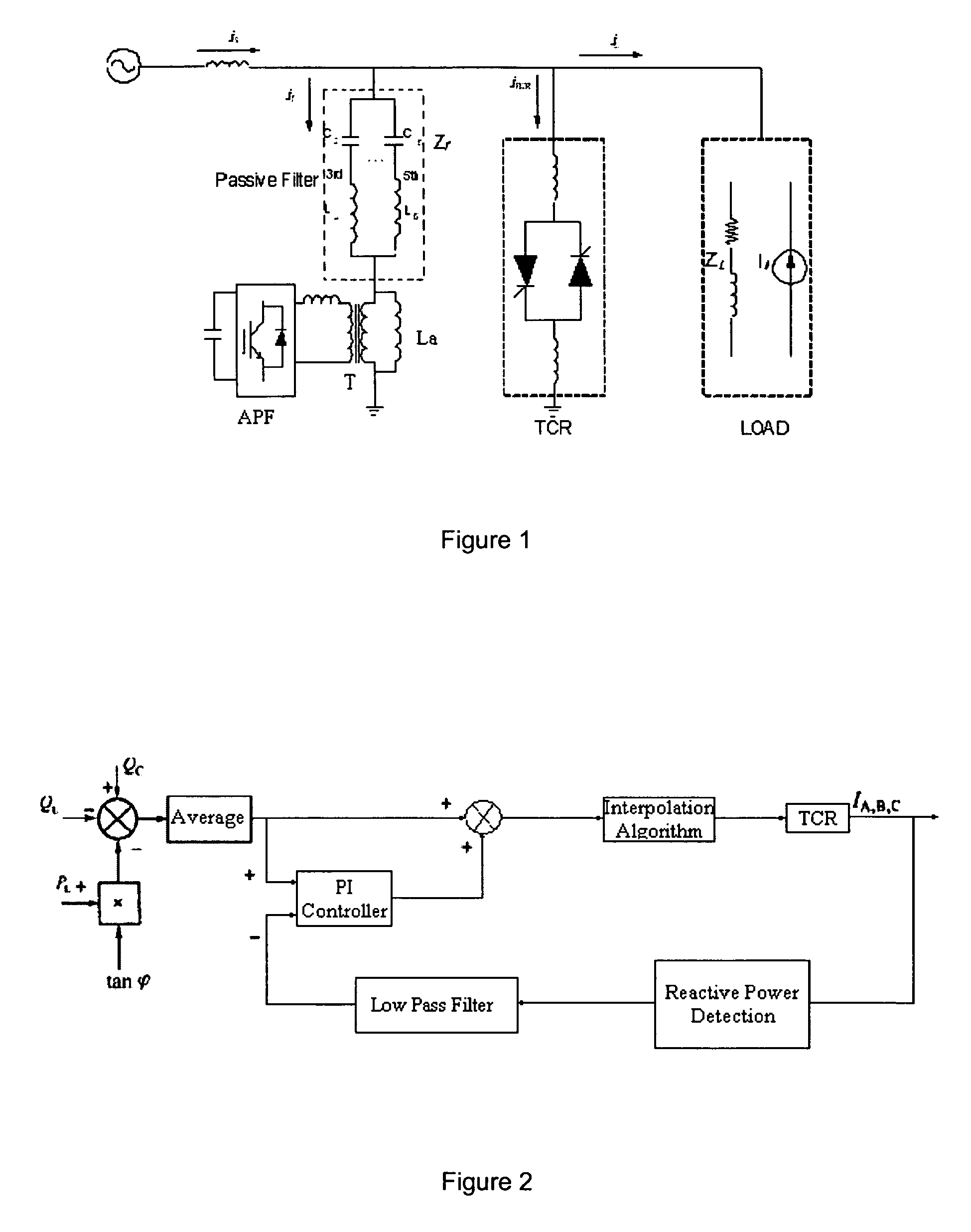

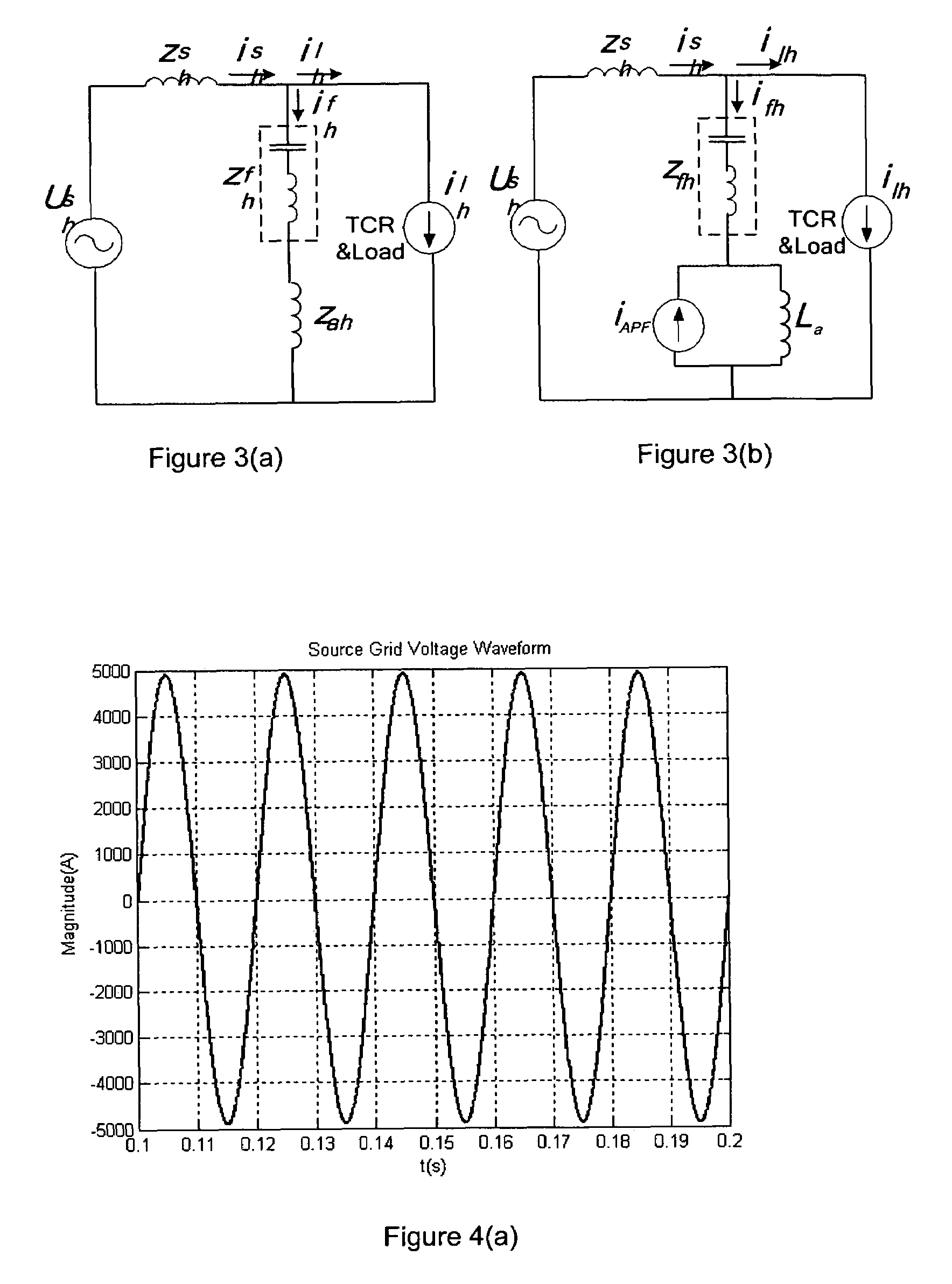

This invention disclosed is a comprehensive power quality controller for substation in the electric power system and includes a Thyristor Controlled Reactor (TCR), pure tuned passive filter Zf, additional inductor L active power filter (APF), and a coupling transformer. The Thyristor Controlled Reactor (TCR) provides inductive reactive power and controls the active power filter (APF) as the current source, it is connected with the additional inductor La in parallel via the coupling transformer, then connected to the passive filter Zf in serial to consist a hybrid power filter system, which is connected to the power grid via the circuit breaker or thyristor. The comprehensive filter system provides required capacitive reactive power and filters the harmonic produced by the load and TCR system itself. Because the capacity of the active power filter (APF) is very small which is less than 1% of the harmonic source capacity, so it is a solution with low cost but simple and reliable control mode. It can suppress influence on the passive filter by the “background harmonic” of the substation and prevent the resonance occurred between the passive filter and power grid impedance.

Owner:XI AN JIAOTONG UNIV

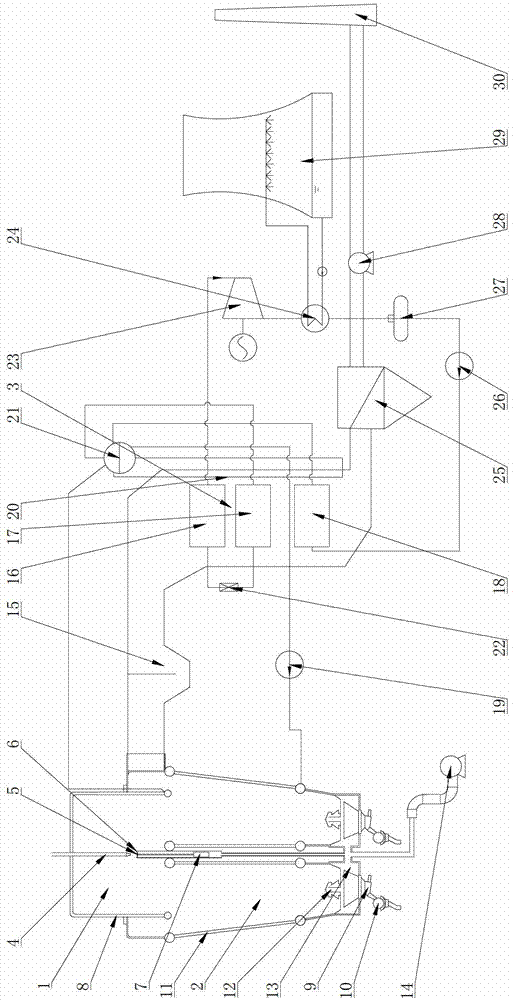

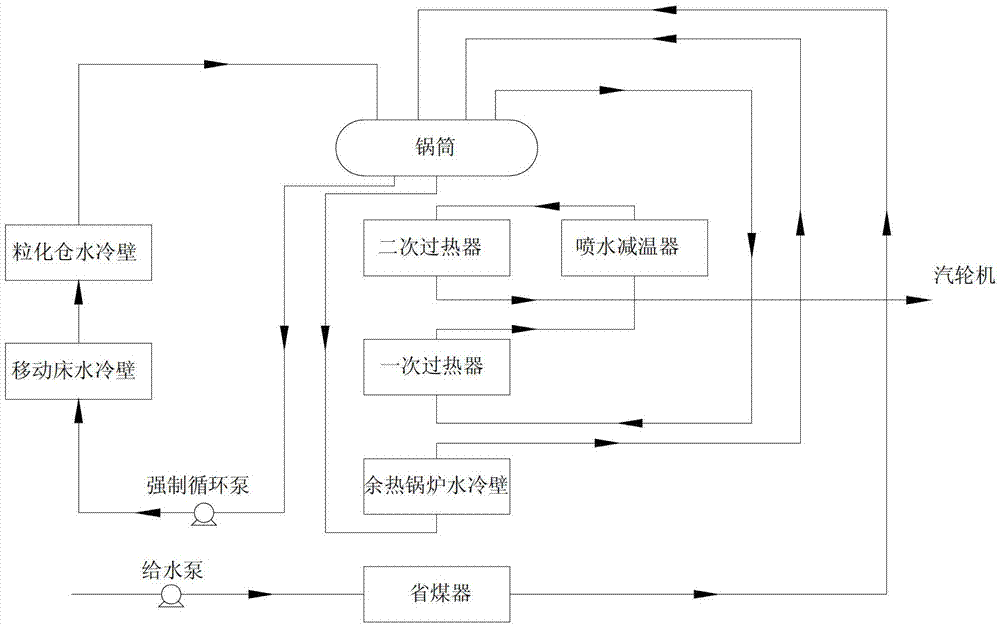

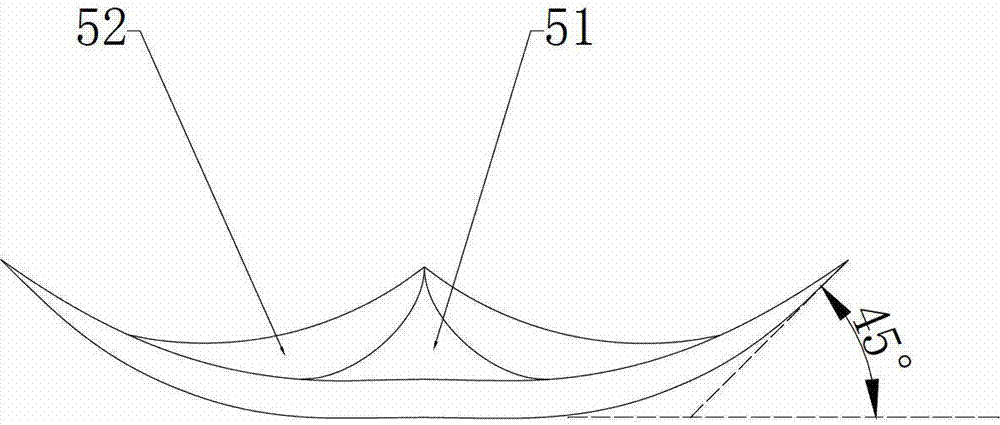

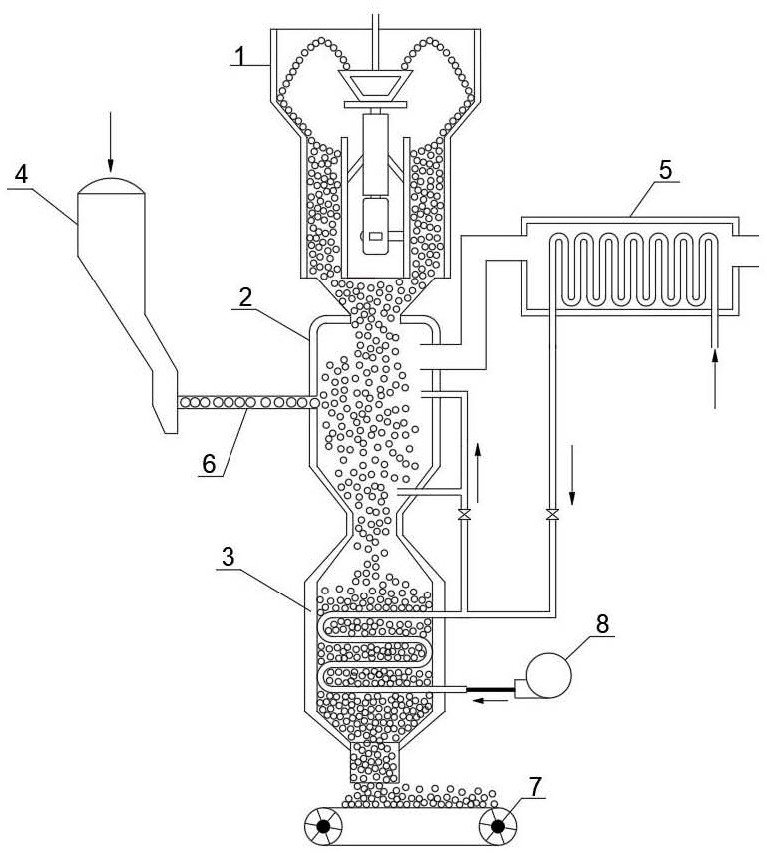

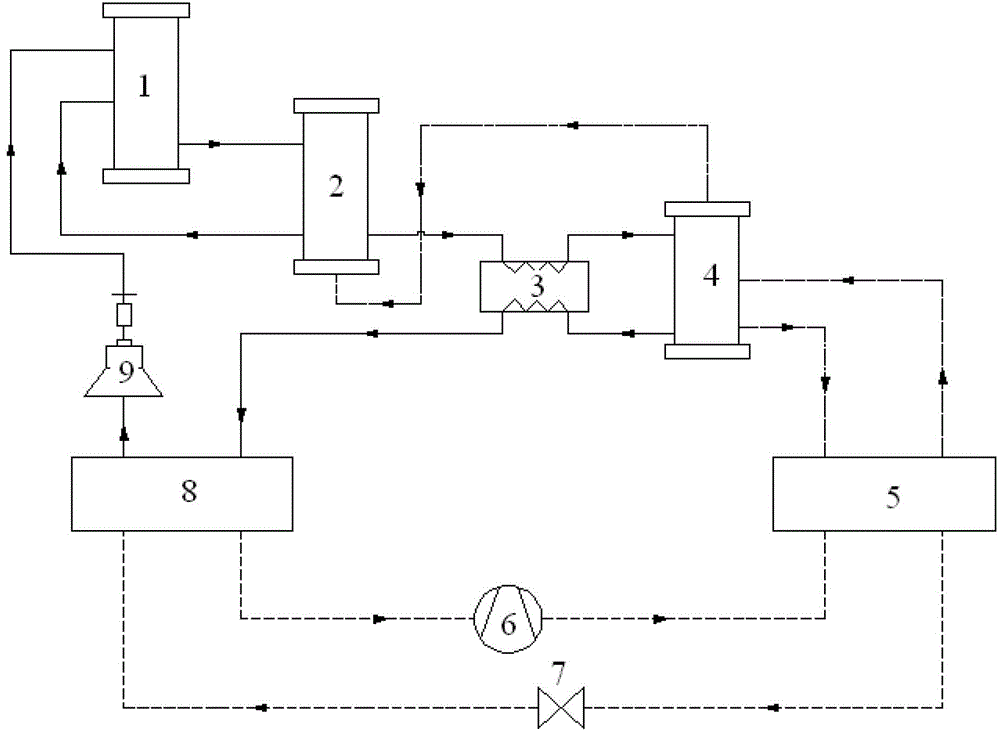

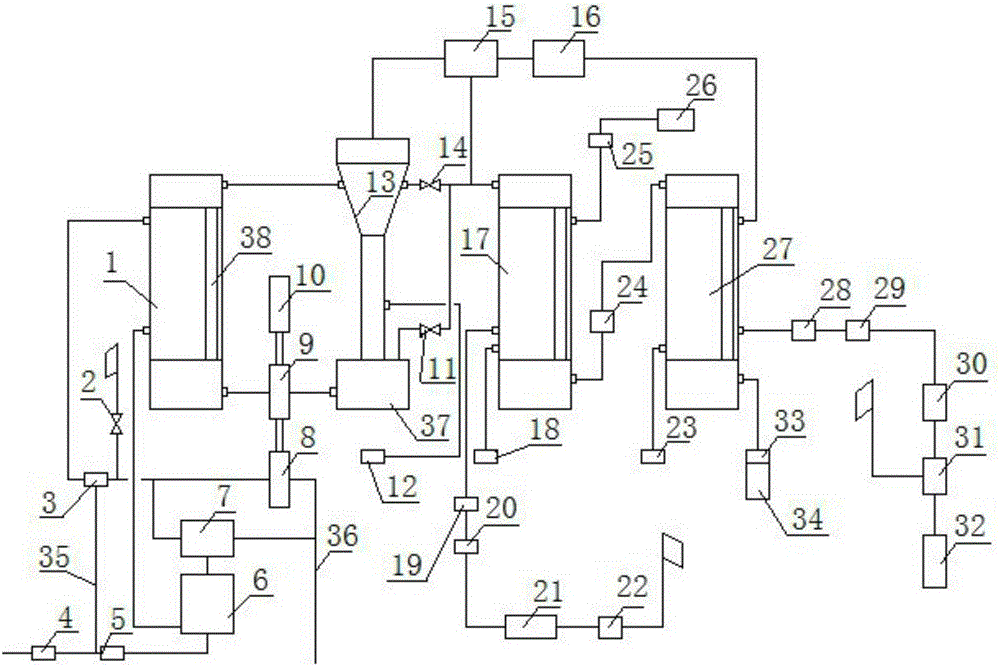

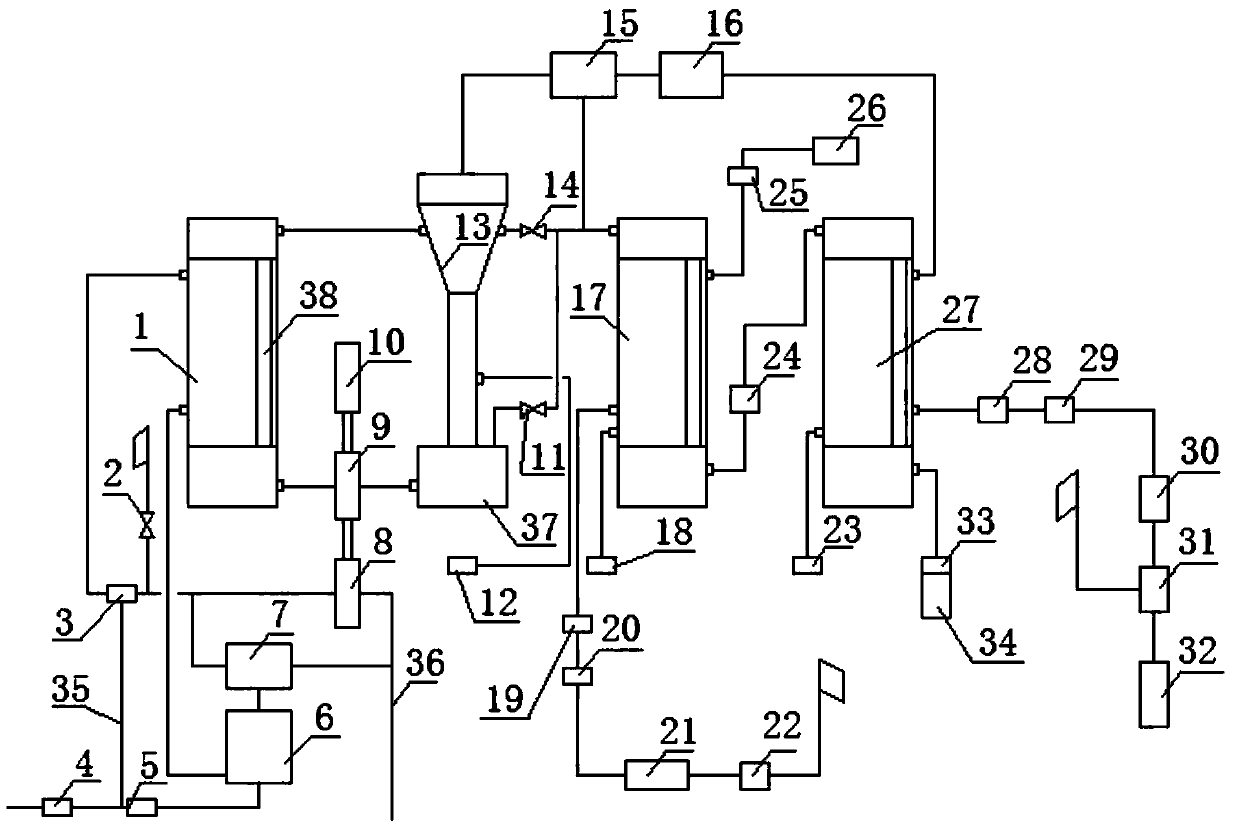

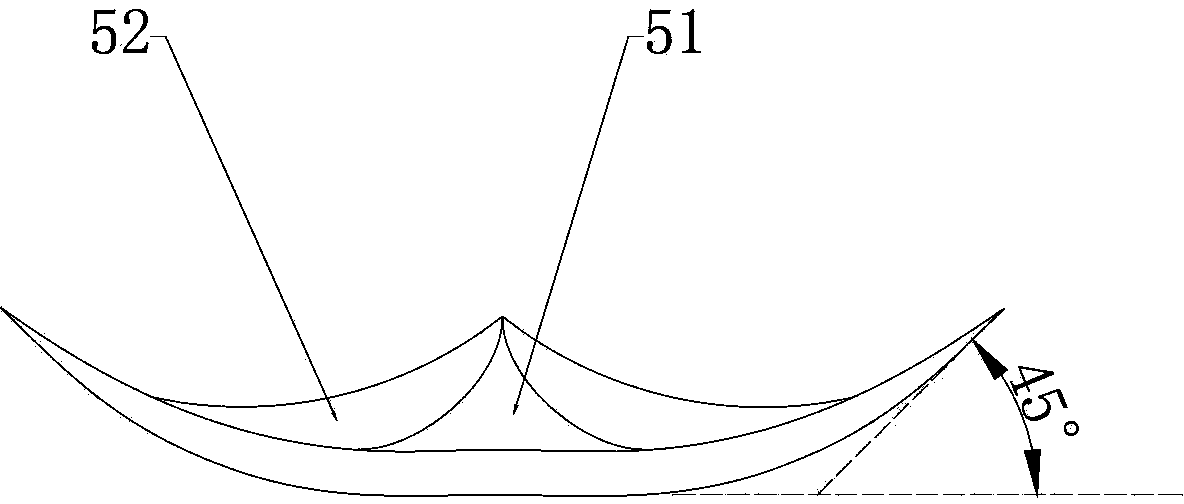

Afterheat recovery system and method of dry granulating liquid slag

ActiveCN102827969AEasy to diluteImprove granulation effectIncreasing energy efficiencyRecycling and recovery technologiesRecovery methodLiquid slag

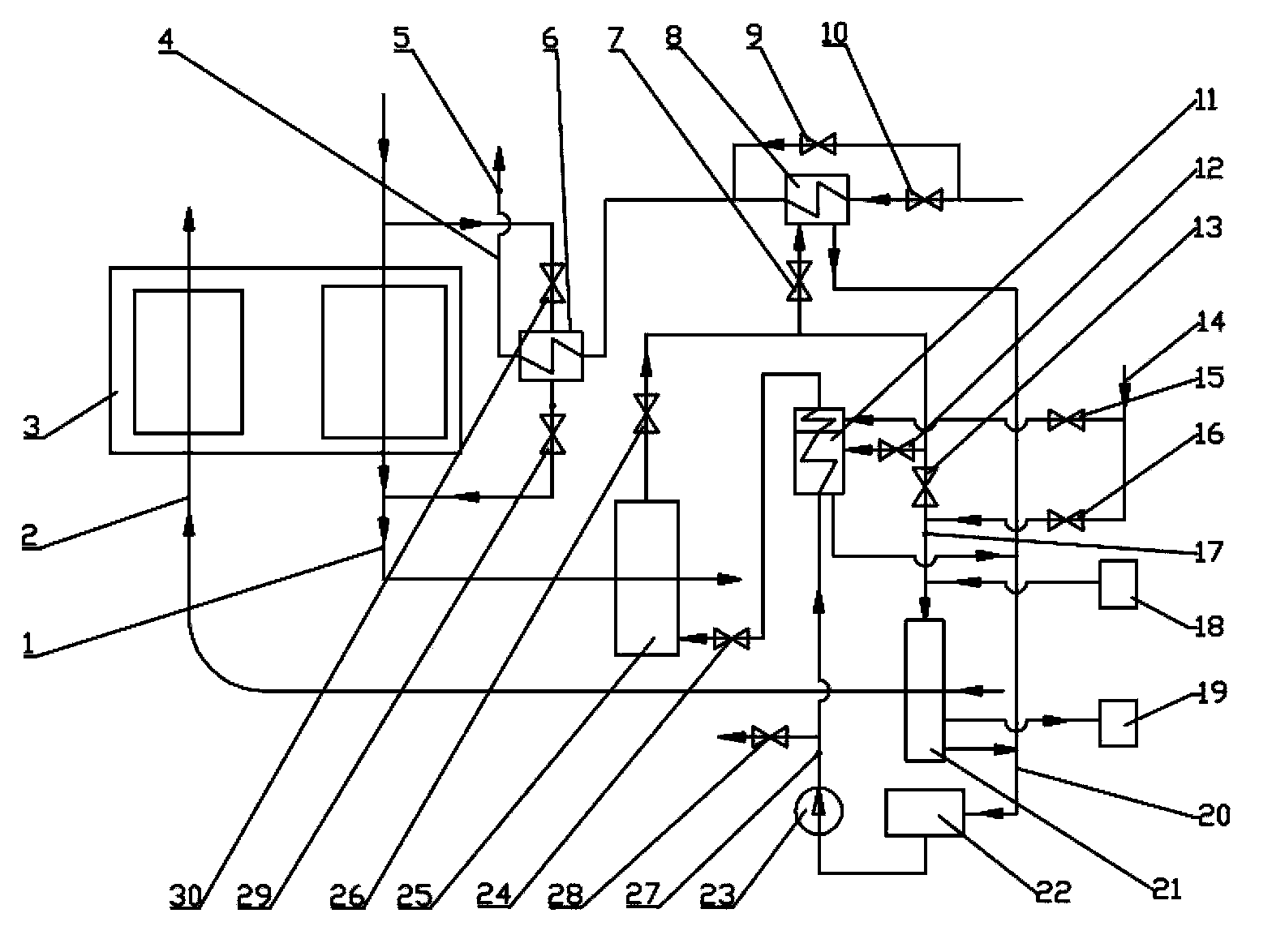

The invention discloses an afterheat recovery system and an afterheat recovery method of dry granulating liquid slag. The system comprises a granulating cabin, a moving bed and an afterheat recovery system, the inner surface of the granulating cabin is provided with a granulating cabin water cooling wall, the center of the top of the granulating cabin is provided with a slag pipe, the slag pipe extends into the granulating cabin, the lower part of the tail end of the slag pipe is provided with a centrifugal granulator, the centrifugal granulator is connected with a motor arranged at the lower part of the centrifugal granulator, the lateral side of the centrifugal granulator is provided with an air supply pipeline, an annular air opening is formed between the centrifugal granulator and the air supply pipeline, the lower part of the granulating cabin is provided with the moving bed, the inner surface of the moving bed is provided with a moving bed water cooling wall, the top of the moving bed is provided with an air outlet, the bottom of the moving bed is provided with a slag discharge device, an air inlet device is arranged above the slag discharge device, the afterheat recovery system comprises a primary dust remover, an afterheat boiler, a secondary dust remover, an exhaust fan and a chimney which are connected in sequence, and the primary dust remover is connected with the air outlet arranged at the top of the moving bed. The system and the method effectively solve the problems of heat recovery and furnace slag granulation of equipment such as a blast furnace.

Owner:XI AN JIAOTONG UNIV +1

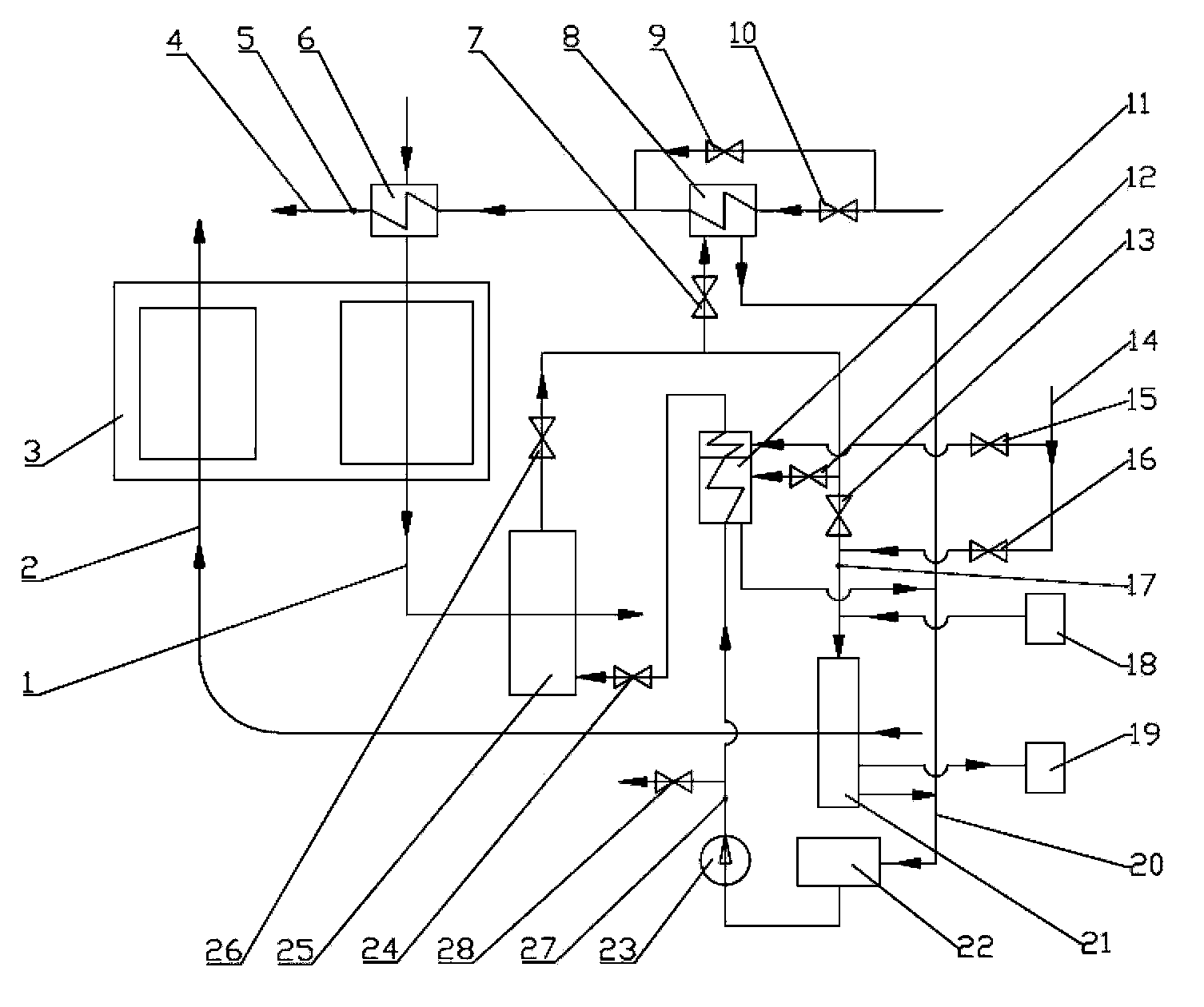

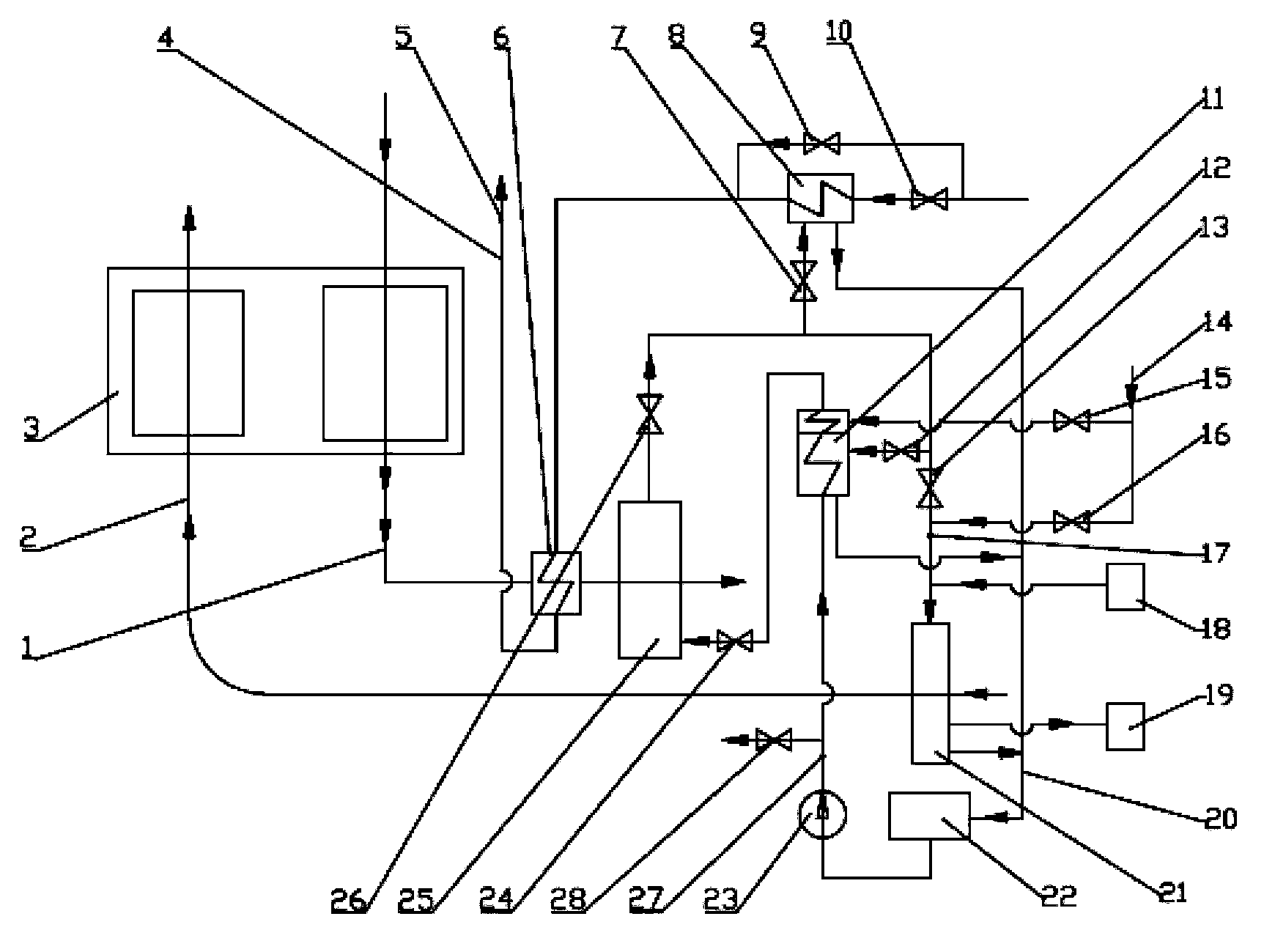

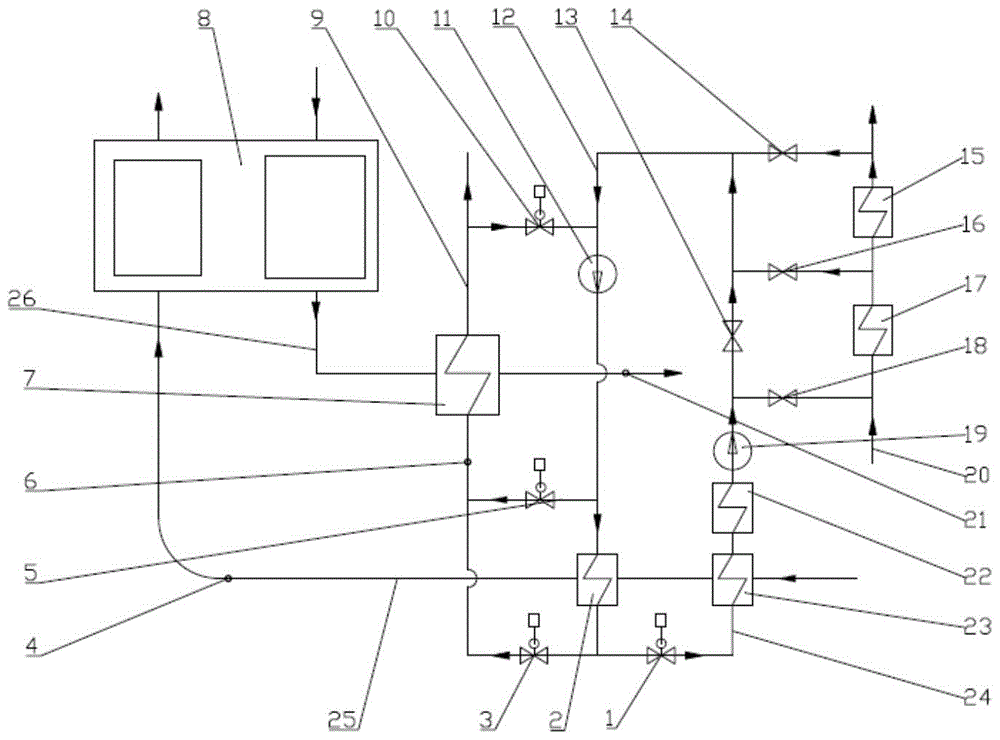

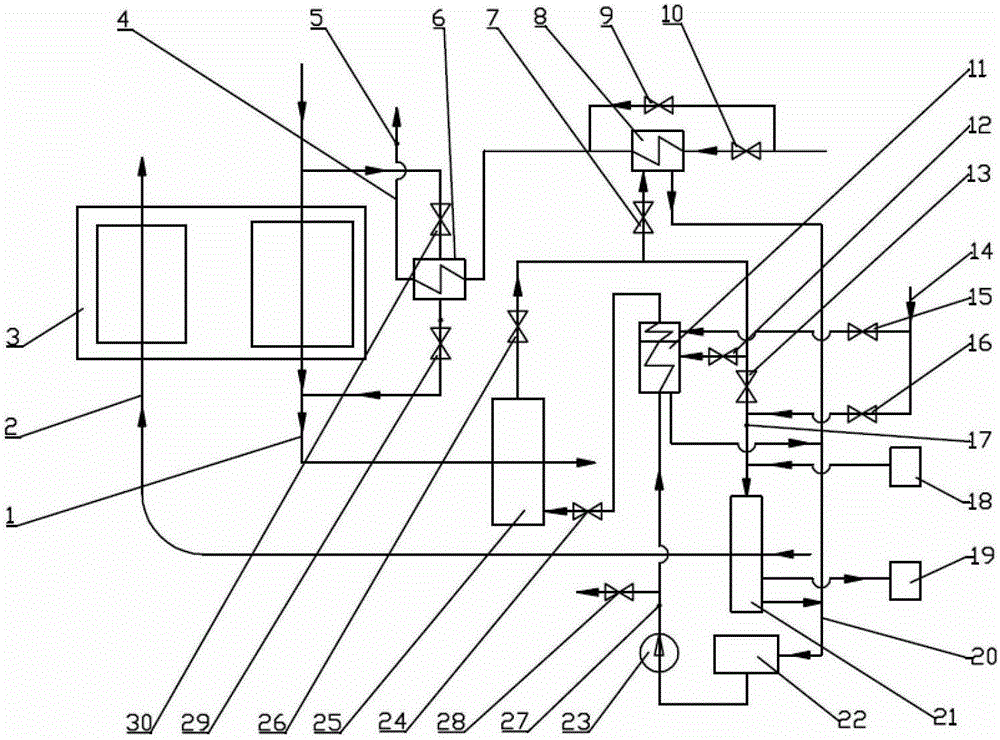

Sub-control phase-change heat exchange system and method based on grading combination heat exchange

InactiveCN103808178AIncrease temperatureImprove energy qualityIndirect heat exchangersAir preheaterHigh energy

The invention discloses a sub-control phase-change heat exchange system based on grading combination heat exchange. The sub-control phase-change heat exchange system comprises a flue, an air channel, an air pre-heater, an external water pipeline, a steam supply valve of a low-temperature water heater, the low-temperature water heater, a water inlet valve of the low-temperature water heater, a steam-liquid heat exchanger, a steam supply valve of the steam-liquid heat exchanger, a steam supply valve of an air channel heat exchanger, an external steam supply valve of the air channel heat exchanger, a main water draining pipeline, the air channel heat exchanger, a water tank, a water pump, a water inlet valve of a flue heat exchanger, the flue heat exchanger, and a steam outlet valve of the flue heat exchanger. According to the sub-control phase-change heat exchange system, heat release exchangers which utilize the waste heat of recycled flue gas are arranged in a grading combination mode; according to different situations such as ambient air temperature, operating conditions and the like, the waste heat can be utilized to heat boiler supplied air, condensed water on the side of a steam turbine and the like in a combination mode; meanwhile, the temperature of the condensed water is improved through grading heating, higher energy quality is obtained, and the optimal economic benefit of recycling the waste heat is achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Comprehensive power quality controller for substation in power system

InactiveUS7352597B2Improve energy qualityImprove securityFlexible AC transmissionActive power filteringPower qualityElectric power system

This invention disclosed is a comprehensive power quality controller for substation in the electric power system and includes a Thyristor Controlled Reactor (TCR), pure tuned passive filter Zf, additional inductor L active power filter (APF), and a coupling transformer. The Thyristor Controlled Reactor (TCR) provides inductive reactive power and controls the active power filter (APF) as the current source, it is connected with the additional inductor La in parallel via the coupling transformer, then connected to the passive filter Zf in serial to consist a hybrid power filter system, which is connected to the power grid via the circuit breaker or thyristor. The comprehensive filter system provides required capacitive reactive power and filters the harmonic produced by the load and TCR system itself. Because the capacity of the active power filter (APF) is very small which is less than 1% of the harmonic source capacity, so it is a solution with low cost but simple and reliable control mode. It can suppress influence on the passive filter by the “background harmonic” of the substation and prevent the resonance occurred between the passive filter and power grid impedance.

Owner:XI AN JIAOTONG UNIV

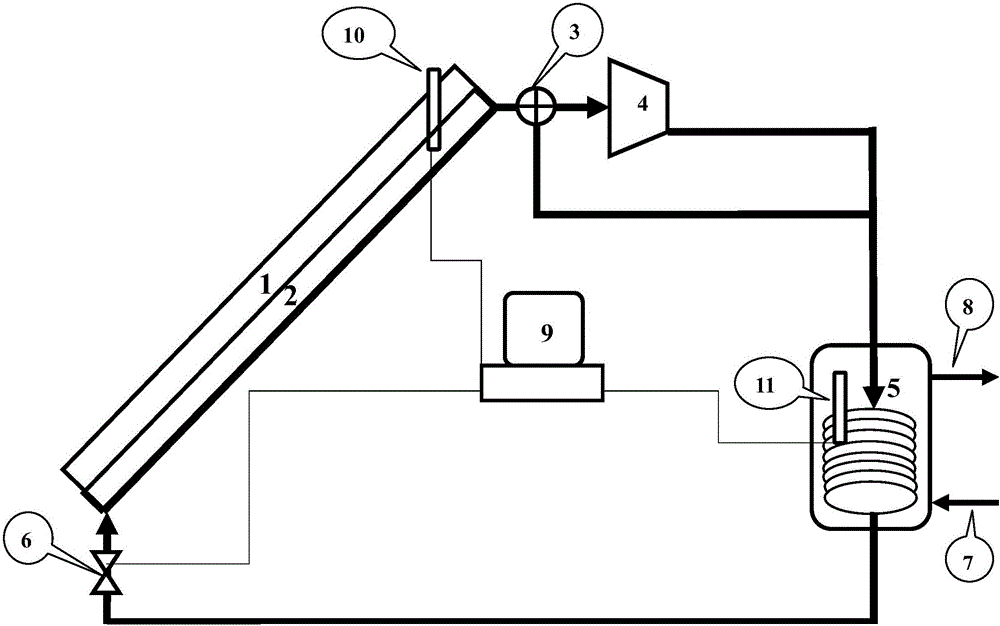

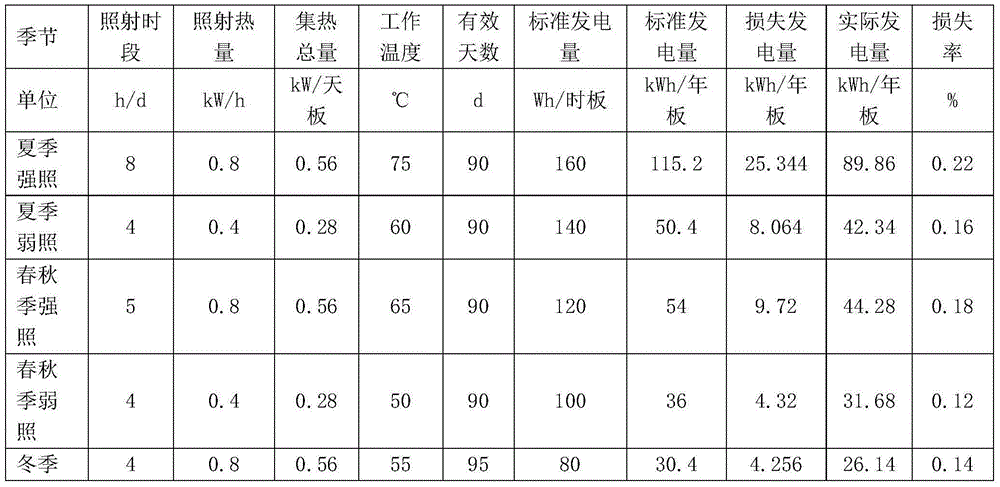

Heat pump cooling/heating system of solar photovoltaic power generation system

InactiveCN105071767AIncrease working temperatureTake advantage ofHeat pumpsPhotovoltaicsThermal energyQuality level

The invention discloses a heat pump cooling / heating system of a solar photovoltaic power generation system, comprising a solar photovoltaic panel and a working medium evaporator arranged below the solar photovoltaic panel. The working medium evaporator is sequentially connected with a three-way reversing valve, a working medium compressor, a working medium condenser and an electronic expansion valve to form a circulation loop. A working medium thermometer is arranged on the working medium evaporator. A hot water thermometer is arranged inside the working medium condenser. The working medium thermometer, the hot water thermometer and the electronic expansion valve are connected with a main control computer. While that the solar photovoltaic system works at optimal temperature is ensured, cooled heat can be recycled for heating, the solar energy utilization rate of the original system is improved greatly, the operation mode of solar photovoltaic power generation operation all the year is optimized, and the utilization rate of solar energy throughout the year is maximized. Moreover, the quality of energy can be improved through use of heat pumps, cooled heat at low temperature can be improved to a higher quality level to meet the requirements of life and heating temperature, and low-quality heat is recycled all year round.

Owner:TIANJIN UNIV

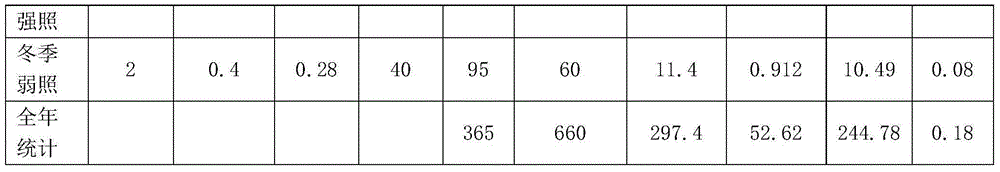

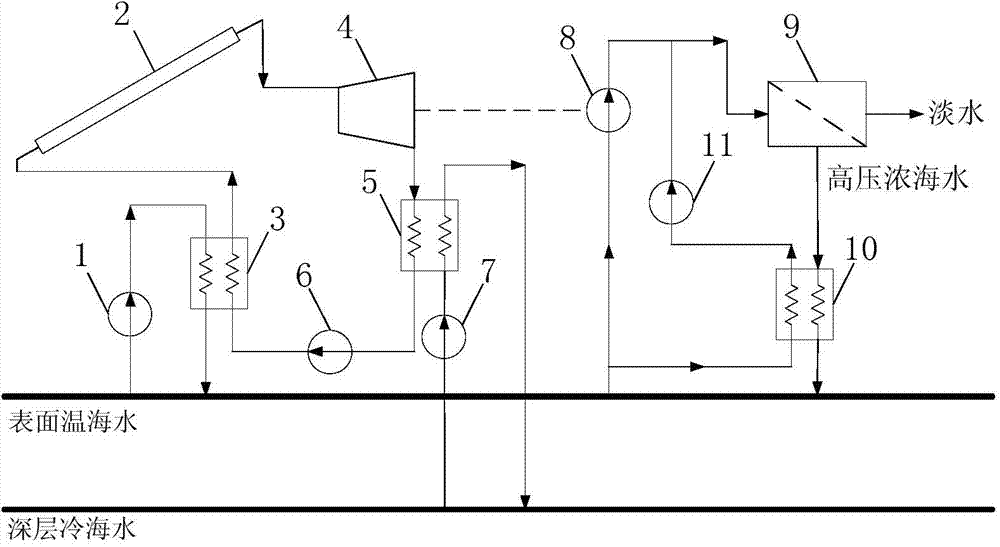

Seawater desalination system driven by combination of solar energy and ocean thermal energy

InactiveCN103758712AImprove utilization efficiencyImprove energy qualityFrom solar energySteam engine plantsThermal energyWorking fluid

The invention relates to a seawater desalination system driven by combination of solar energy and ocean thermal energy. The seawater desalination system comprises a heat source circulating loop, a power circulating loop, a cold source circulating loop and a seawater desalination loop. The power circulating loop comprises an organic turbine utilizing cycle working fluids to act. The heat source circulating loop comprises a warm water pump for pumping warm seawater. The output end of the warm water pump supplies the heat source for evaporating cycle working fluids through an evaporator. The cold source circulating loop comprises a cold water pump for pump cold seawater. The output end of the cold water pump the cold source for condensing the cycle working fluids through a condenser. The seawater desalination loop is a reverse osmosis desalination system which comprises a high-pressure pump and a reverse osmosis device. The power output end of the organic turbine is connected with the drive shaft of the high-pressure pump. Solar energy collectors are disposed in the heat source circulating loop or the power circulating loop. The solar energy collectors are connected between the warm water pump and the evaporator or between the evaporator and the organic turbine.

Owner:XI AN JIAOTONG UNIV

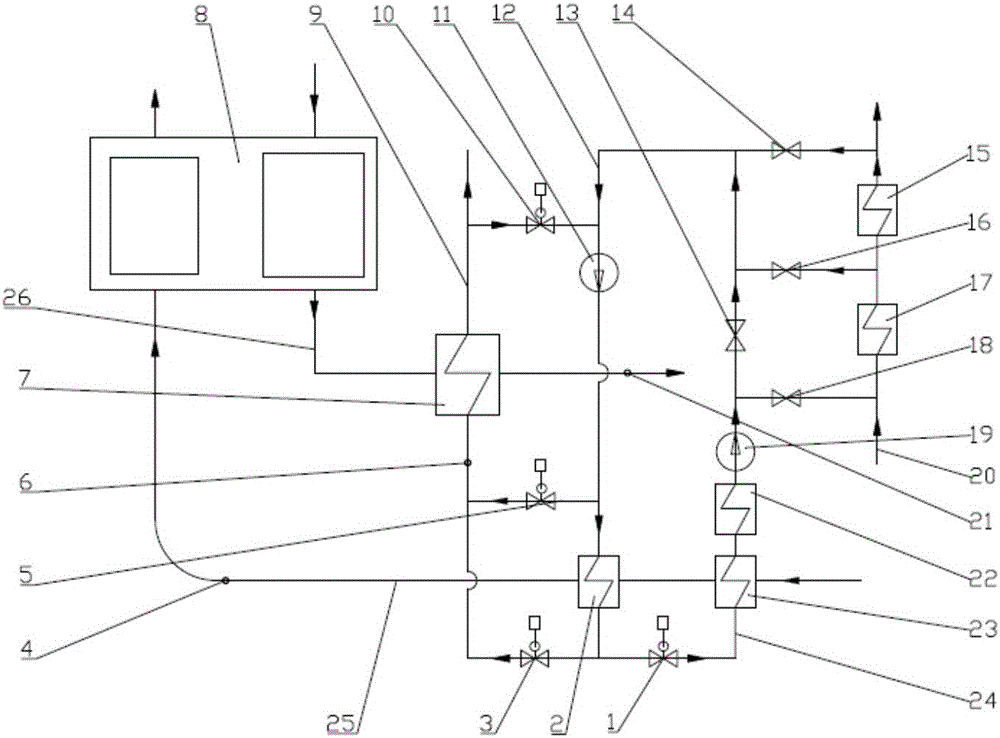

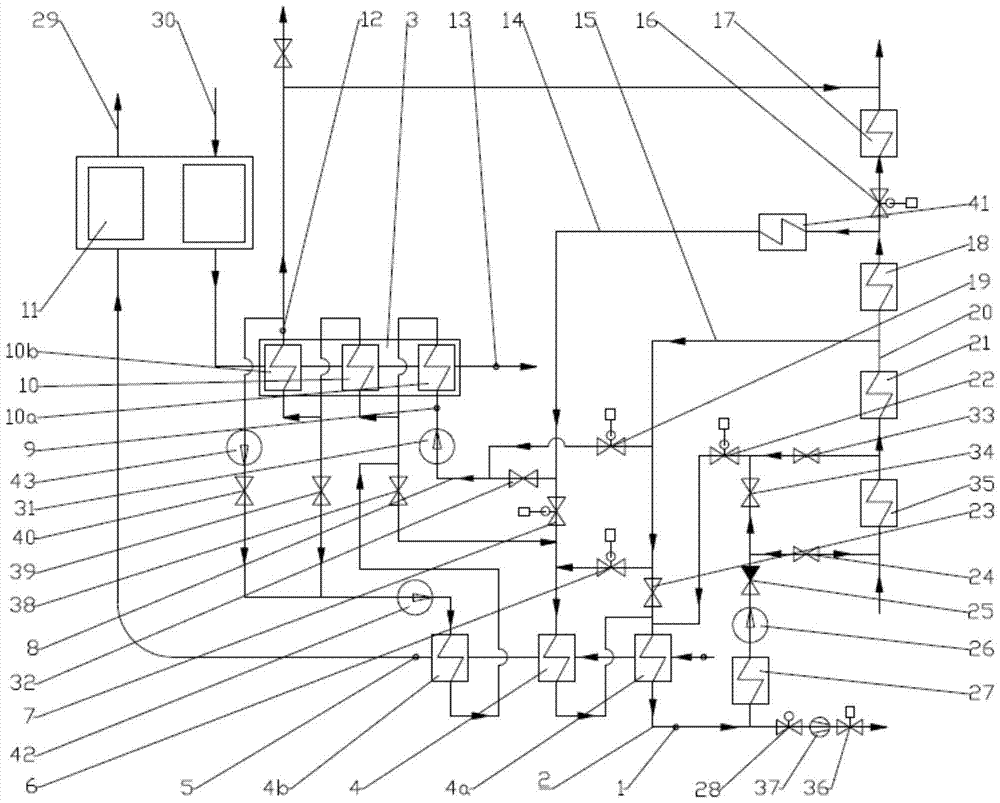

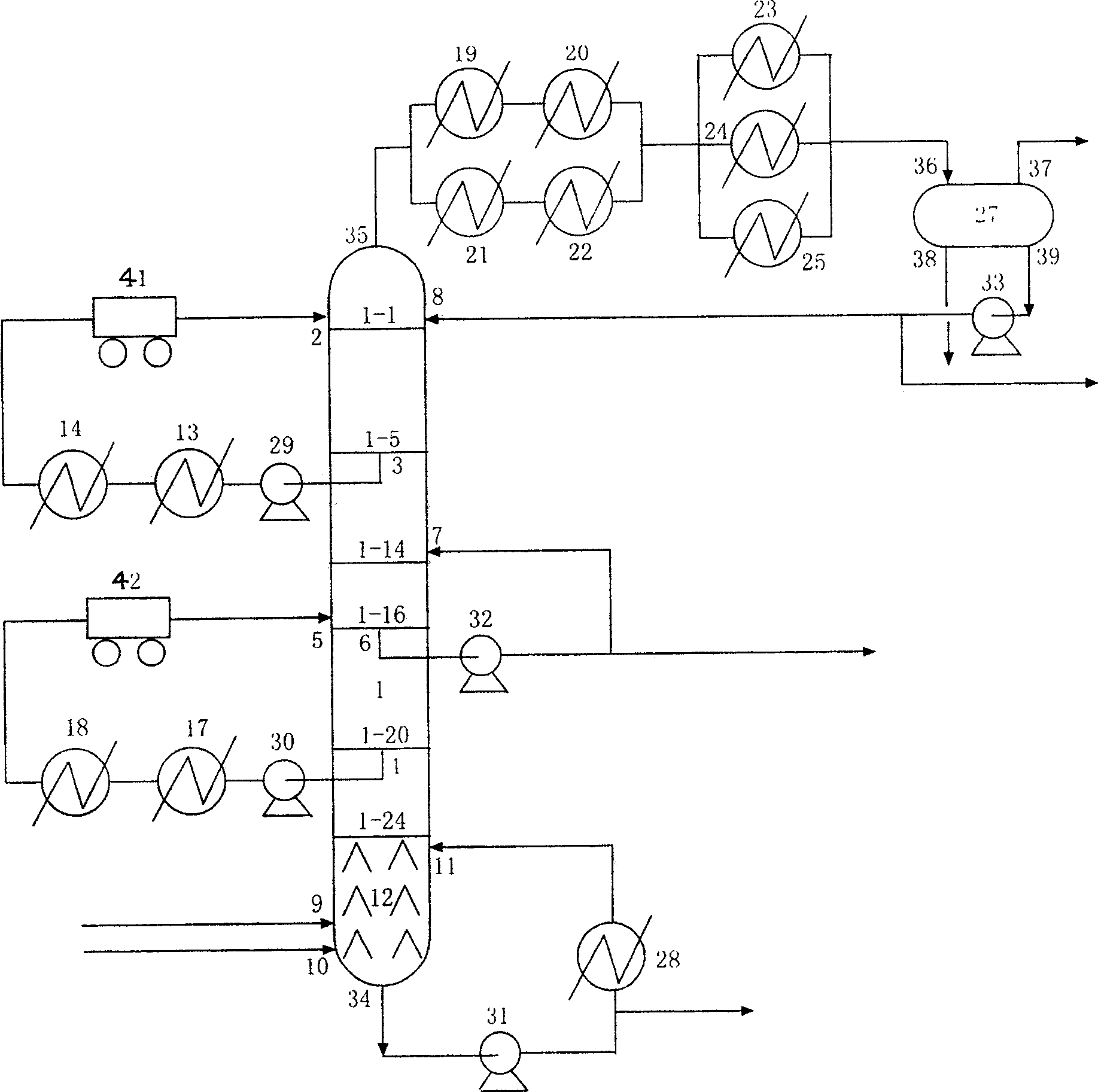

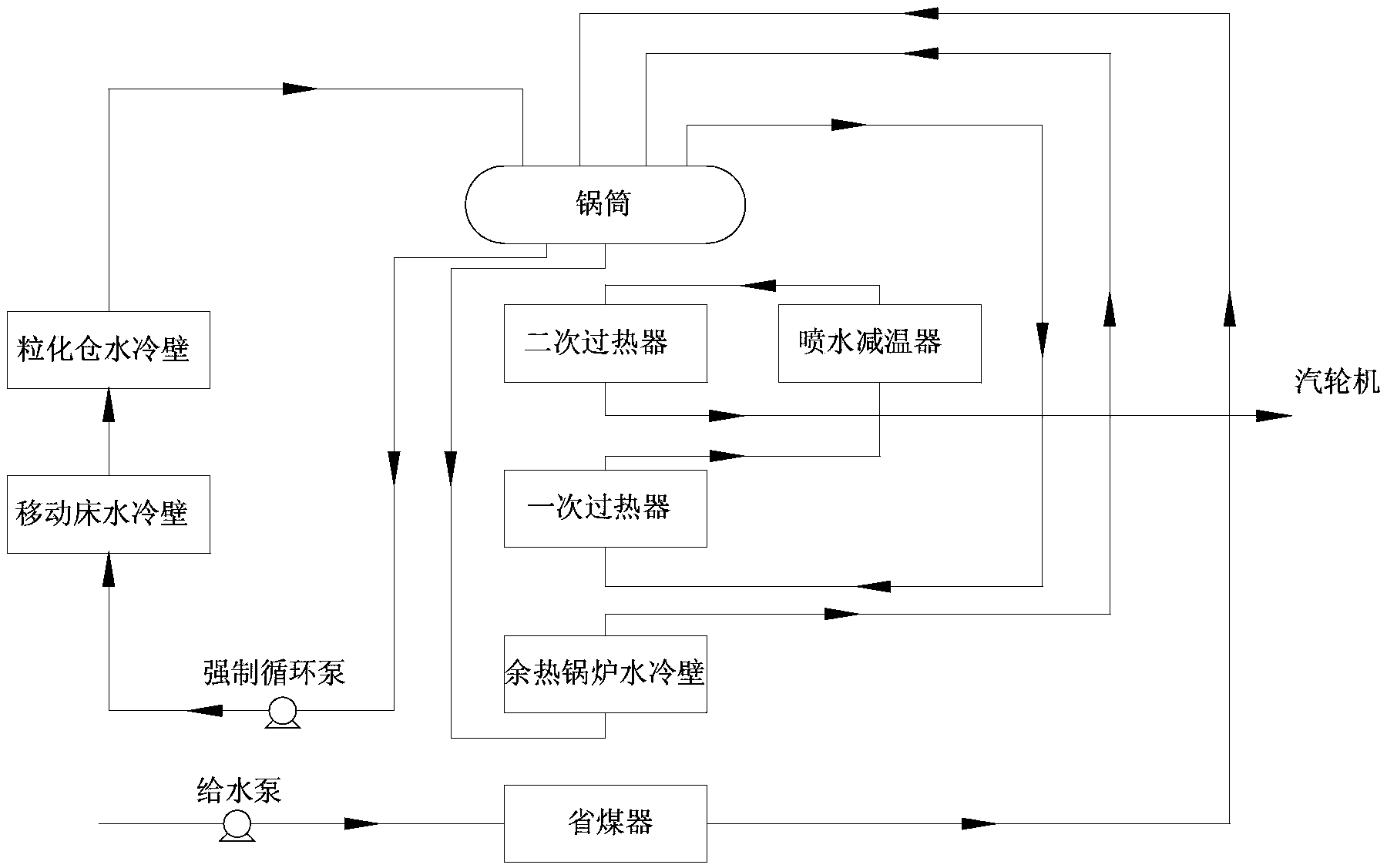

Comprehensive gradient utilization system of recovered heat and waste heat of thermal power generation

InactiveCN105333450ABest Cascade UtilizationImprove energy qualityIndirect carbon-dioxide mitigationAir/fuel supply for combustionAir preheaterEngineering

The invention relates to a comprehensive gradient utilization system of recovered heat and waste heat of thermal power generation. The comprehensive gradient utilization system comprises an air pre-heater subsystem, a main condensation water subsystem, a medium temperature condensation water supply subsystem, a low temperature condensation water supply subsystem, a smoke cooling condensation water subsystem and an air heating condensation water subsystem. The air pre-heater subsystem is connected with the smoke cooling condensation water subsystem, the medium temperature condensation water supply subsystem, the low temperature condensation water supply subsystem and the air heating condensation water subsystem and then is connected to the main condensation water subsystem in a collected mode.

Owner:郝江平

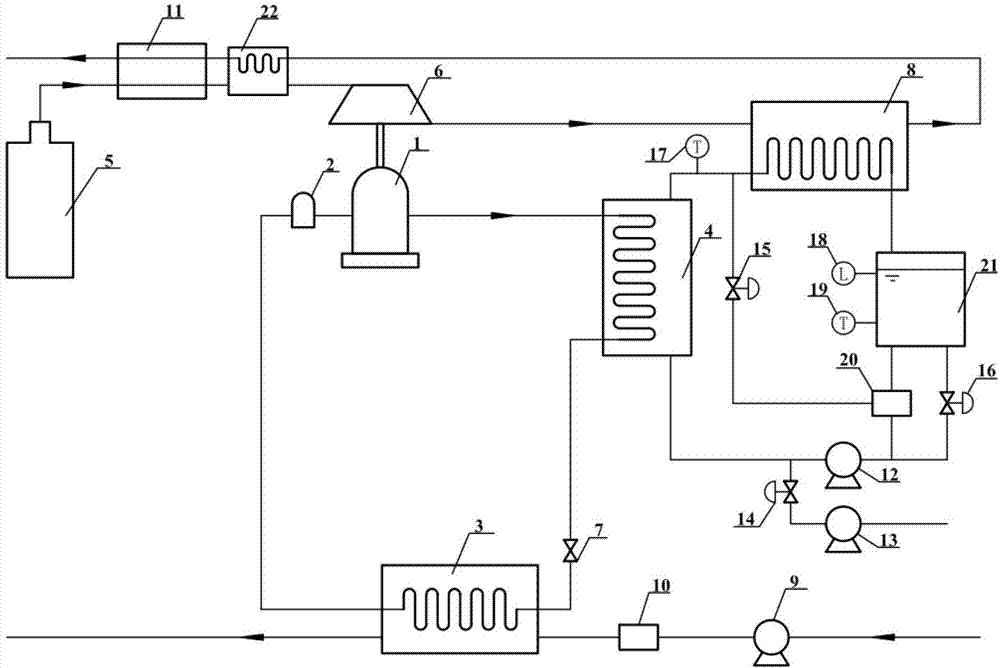

Sewage energy and biogas energy combined heat pump heating system

InactiveCN103244986AImprove energy qualitySave electricityHeat pumpsHot-water central heatingElectromagnetic valveHeat pump

The invention aims at providing a sewage energy and biogas energy combined heat pump heating system. Biogas enters a biogas engine through a preheater to be burned, passes a water / waste gas heat exchanger and is discharged after passing the preheater; sewage enters a sewage evaporator through a sewage pump and is discharged after heat exchanging; a bent shaft of a compressor is connected with a power shaft of the biogas engine, refrigerant is added in the sewage evaporator, and the refrigerant after absorbing heat of the sewage and being evaporated is inhaled by the compressor after passing a gas-liquid separator and returns the sewage evaporator after passing a condenser; and a heating circulation pump is communicated with a circulating water replenishing pump, a first electromagnetic valve is mounted between the heating circulation pump and the circulating water replenishing pump, and water enters the condenser and the water / waste gas heat exchanger sequentially through the heating circulation pump for heat exchanging and is stored in a heat storage water tank which is communicated with a user. By the sewage energy and biogas energy combined heat pump heating system, electric energy is saved, environmental pollution is small, residual heat of waste gas of the biogas engine and domestic sewage source with a lot of heat energy are recycled simultaneously, so that improvement of energy quality is realized.

Owner:HARBIN ENG UNIV

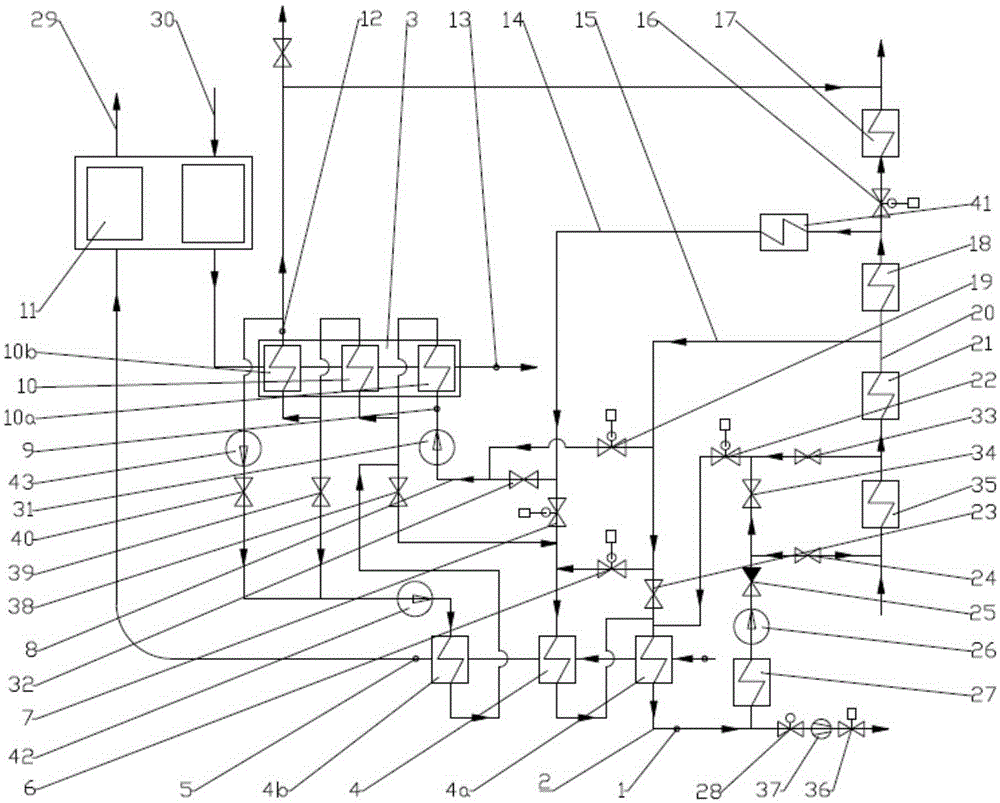

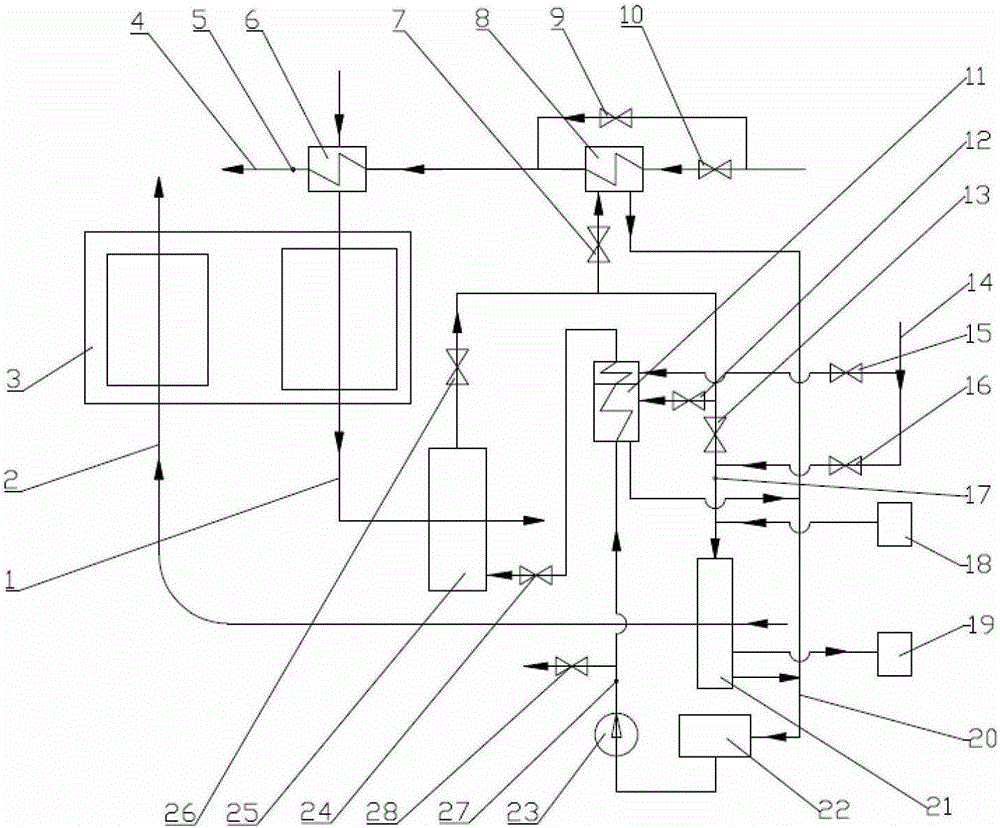

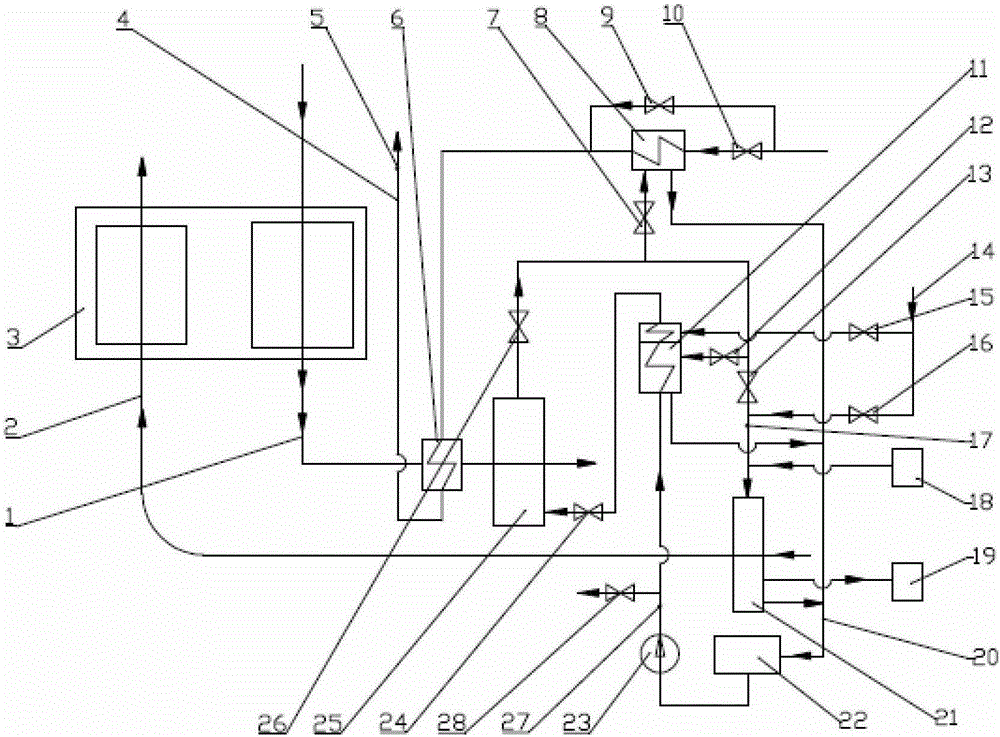

Adjustable boiler air preheating system and method integrating heat regeneration and waste heat utilization

InactiveCN105091020AIncrease independenceBest Cascade UtilizationCombustion processSteam useEngineeringRecuperator

The invention belongs to the fields of thermal power generation and the like and particularly relates to an adjustable boiler air preheating system and method integrating heat regeneration and waste heat utilization. According to the adjustable boiler air preheating system and method, air preheating, waste heat utilization and regenerative heat cycling are made to be combined organically; heat-transmission cycling condensate water is divided into a large open cycle in which a bypass low-pressure heater extrudes a steam turbine to perform high-parameter steam extraction and a small closed cycle in which the low-pressure heater (or an added heat exchanger) is used for absorbing heat to increase low-parameter steam extraction; heat flow is divided according to the temperature level difference, heat source and cold source resources are dynamically and sufficiently used, optimal gradient utilization of heat energy in the power generation thermodynamic cycle is achieved, the energy use quality is improved, and energy losses are reduced. According to the adjustable boiler air preheating system and method, the operation mode of the system can be optimized and adjusted automatically according to the change of the operation condition so that gradient utilization of energy of different qualities can be achieved and energy losses can be reduced, and the thermodynamic cycle efficiency and the system economy are maximized.

Owner:郝江平

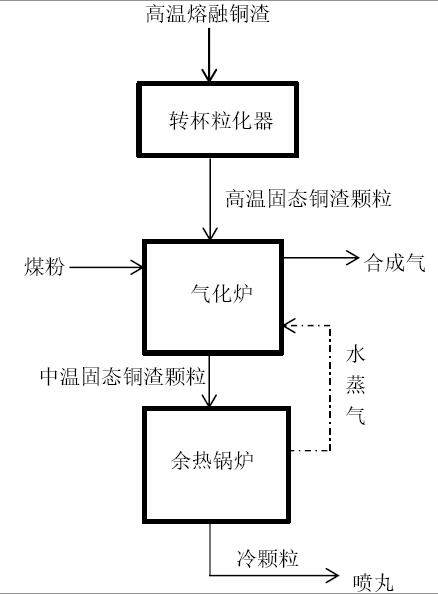

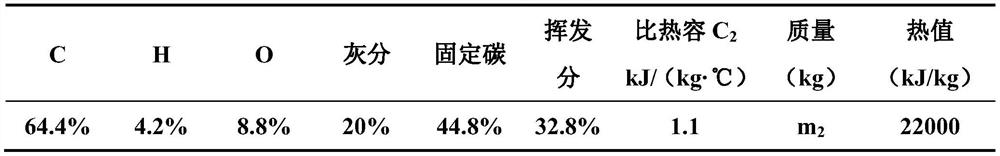

Device system and method for gradient absorption of copper slag waste heat based on coal gasification reaction

PendingCN111733322AEmission reductionSolve resource processingEnergy inputGasification processes detailsSyngasMetallurgy

The invention discloses a device system and method for gradient absorption of copper slag waste heat based on a coal gasification reaction. The method comprises the steps of carrying out copper slag granulation, carrying out the coal gasification reaction, carrying out waste heat recovery through a waste heat boiler and the like. The method specifically comprises the following steps that copper slag is prepared into high-temperature spherical slag particles, and the slag particles gradually provide heat for the coal gasification reaction and the waste heat boiler process; pulverized coal is subjected to heat exchange with the slag particles and is subjected to the gasification reaction under the action of a water vapor and a gasifying agent to absorb the heat of the slag particles so as togenerate synthesis gas containing CO, H2 and CH4; and cold water absorbs heat through heat exchange with the slag particles and is converted into water vapor to serve as the gasifying agent for the gasification reaction. According to the device system and method, the solid slag particle waste heat recovery efficiency is improved to 75% or above, and meanwhile high resource utilization of the coaland copper slag is achieved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

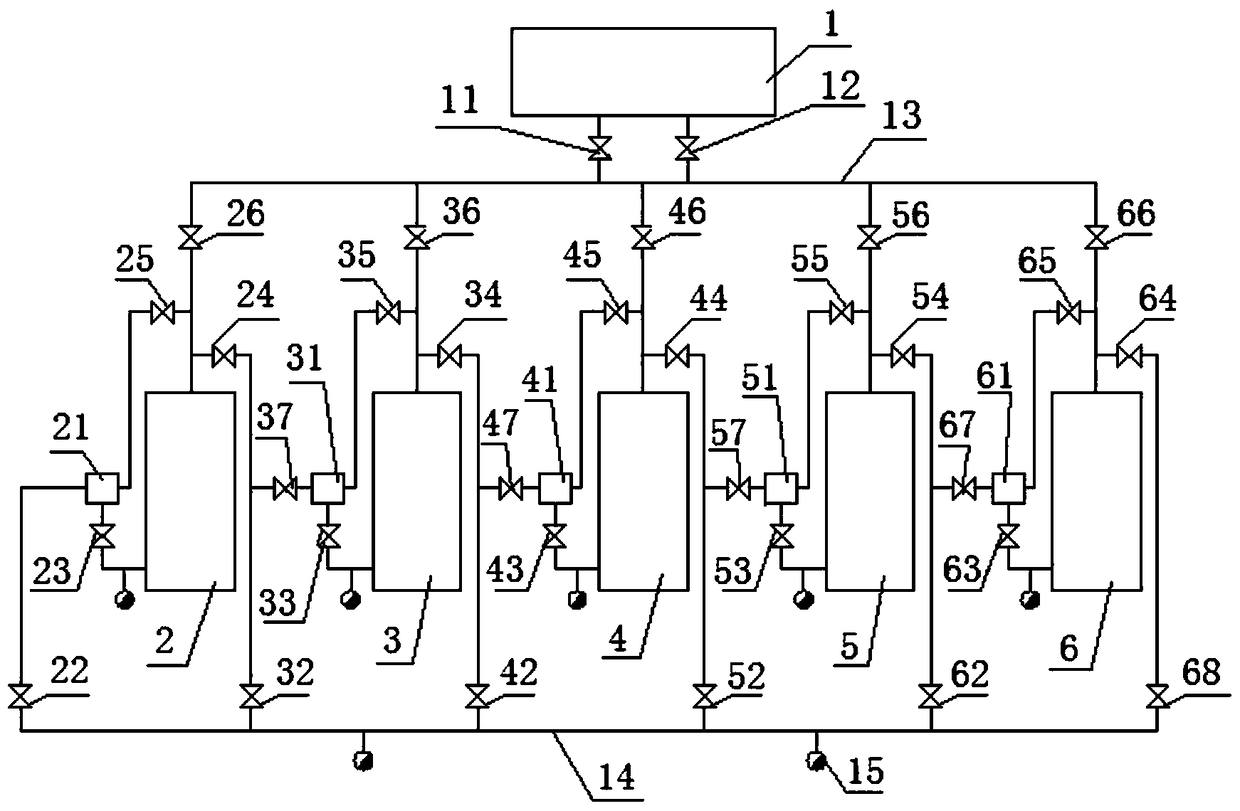

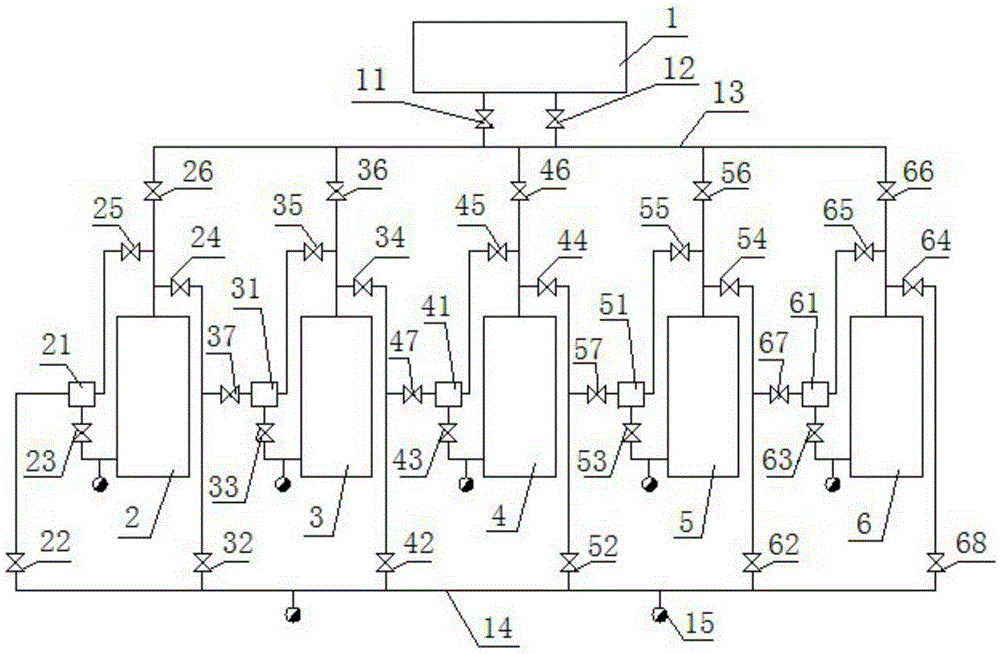

An autoclave system for the production of phosphogypsum autoclaved bricks

InactiveCN105291257BAchieve recyclingReduction of recycling energy consumptionCeramic shaping apparatusPressure riseBrick

The invention discloses a still kettle system for producing ardealite steam-pressing bricks. The still kettle system comprises a heat main steam source collecting box, a still kettle A, a still kettle B, a still kettle C, a still kettle D, a still kettle E, a steam source distribution pipe, a dead steam distribution pipe, a steam-steam pumping pipe A, a steam-steam pumping pipe B, a steam-steam pumping pipe C, a steam-steam pumping pipe D and a steam-steam pumping pipe E, wherein the main steam source collecting box is connected with the steam source distribution pipe through a steam source main valve A and a steam source main valve B; inlets of the still kettle A, the still kettle B, the still kettle C, the still kettle D and the still kettle E are connected with the steam source distribution pipe and the dead steam distribution pipe; outlets of the still kettle A, the still kettle B, the still kettle C, the still kettle D and the still kettle E are connected with the steam-steam pumping pipe A, the steam-steam pumping pipe B, the steam-steam pumping pipe C, the steam-steam pumping pipe D and the steam-steam pumping pipe E. Dead steam of the still kettles are subjected to temperature rise and pressure rise respectively through the steam-steam pumping pipes and then is gathered into the dead steam distribution pipe, therefore the dead steam can be recycled instead of being discharged, the recycling effect is better, and the maximum recycling and reusing purposes are achieved.

Owner:GUIZHOU KAILIN GRP CO LTD

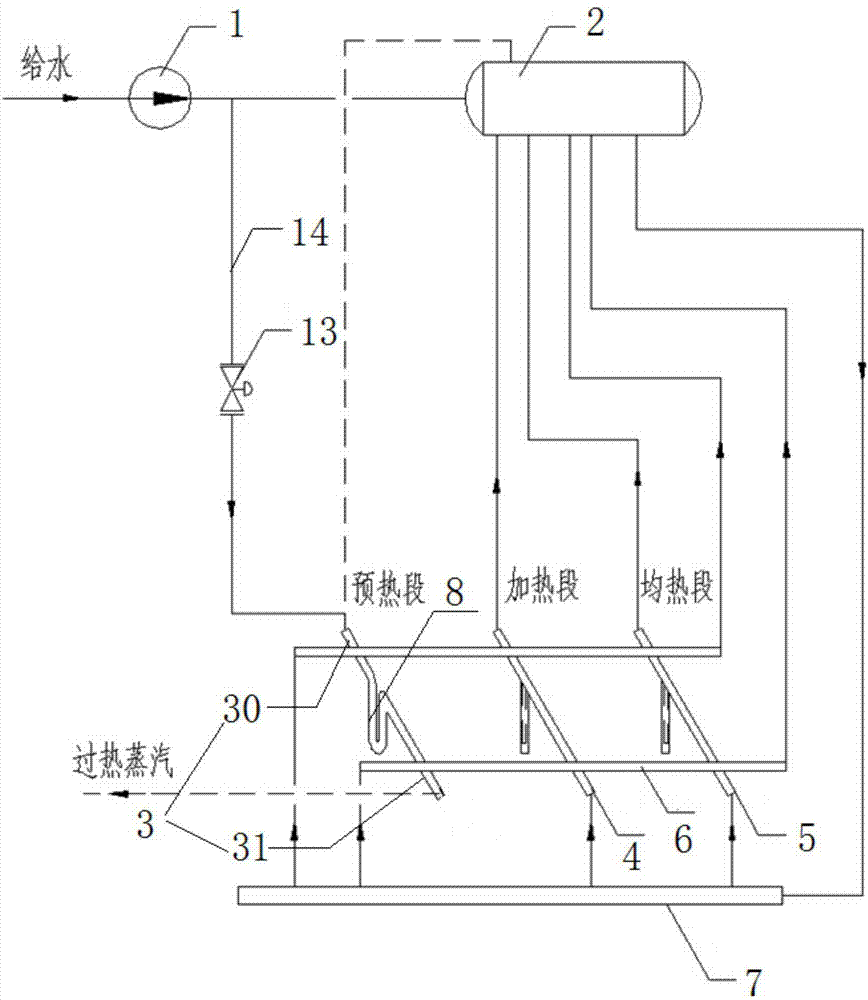

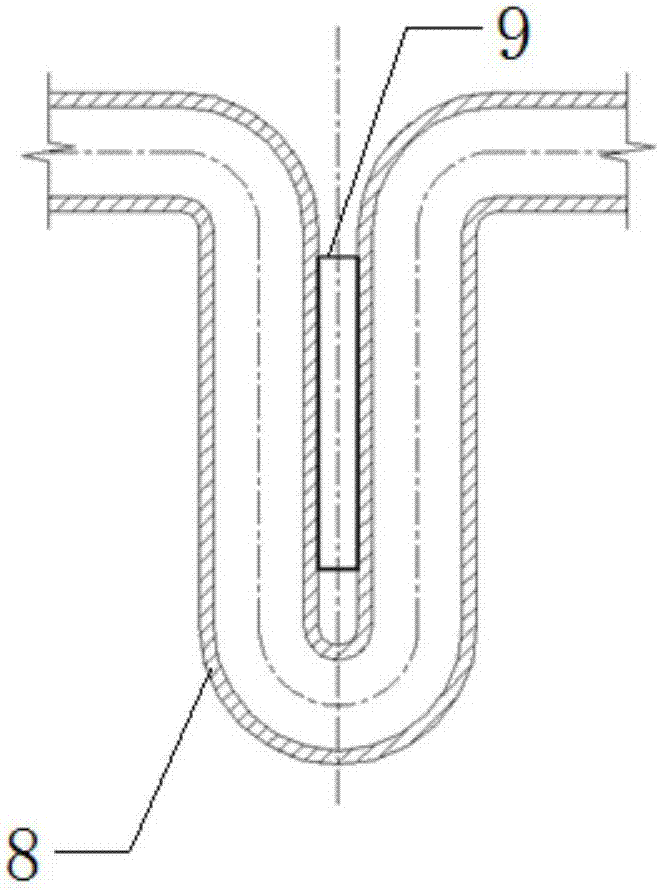

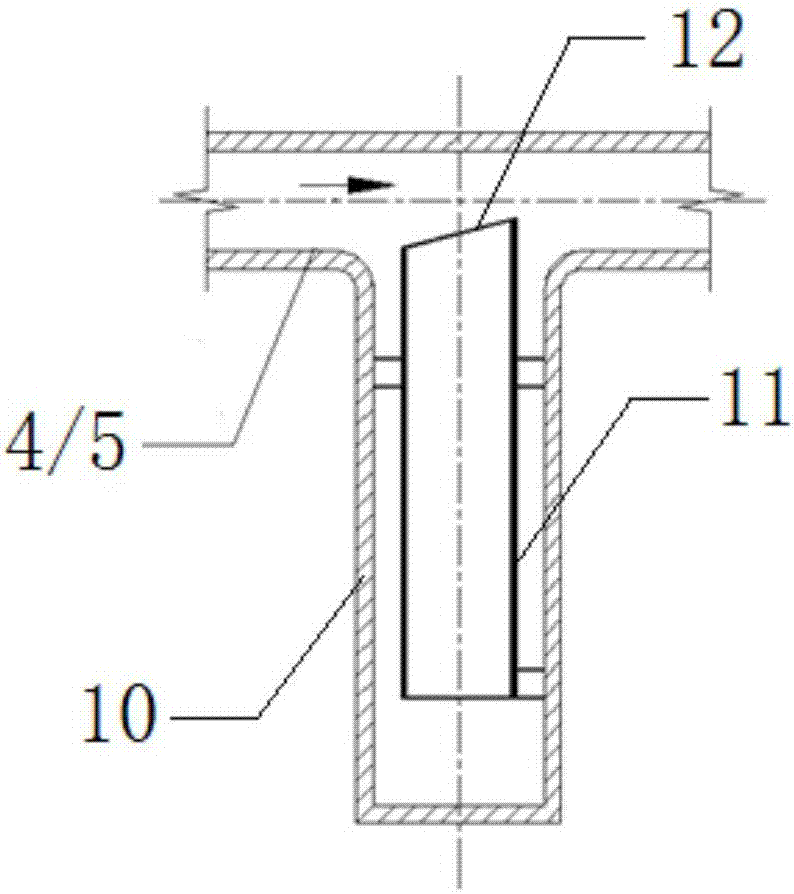

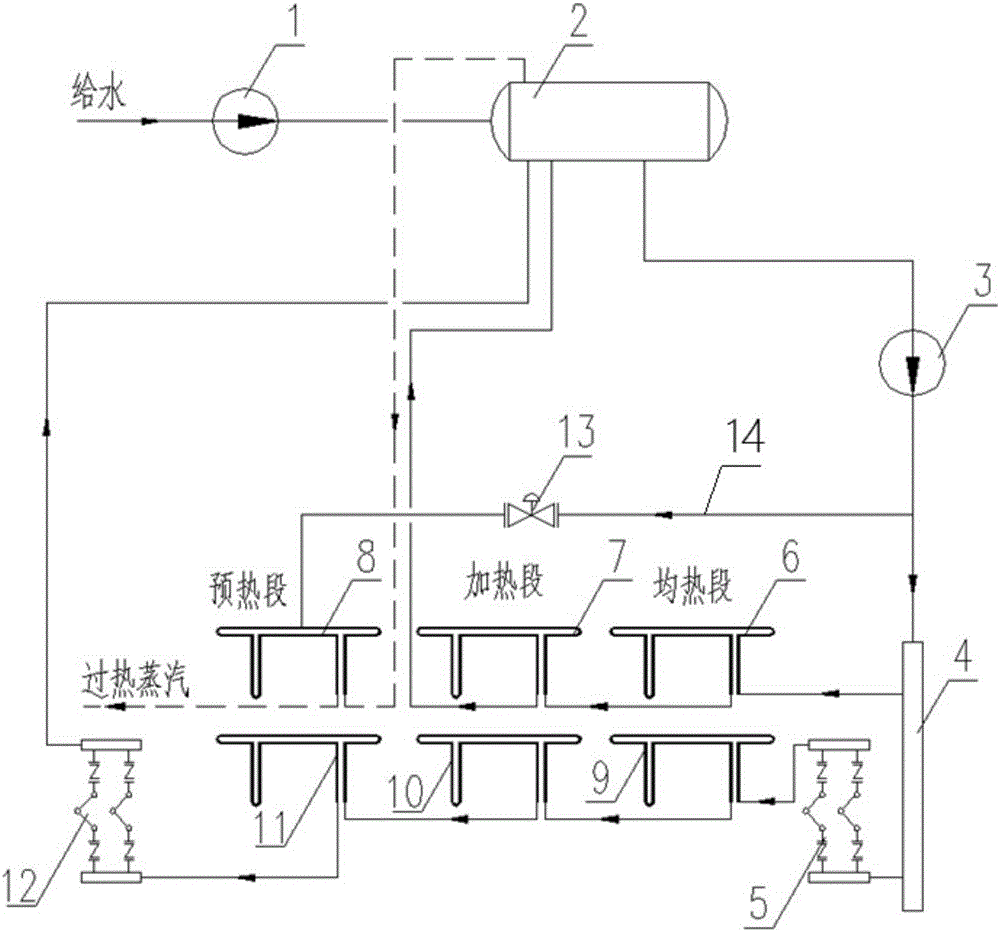

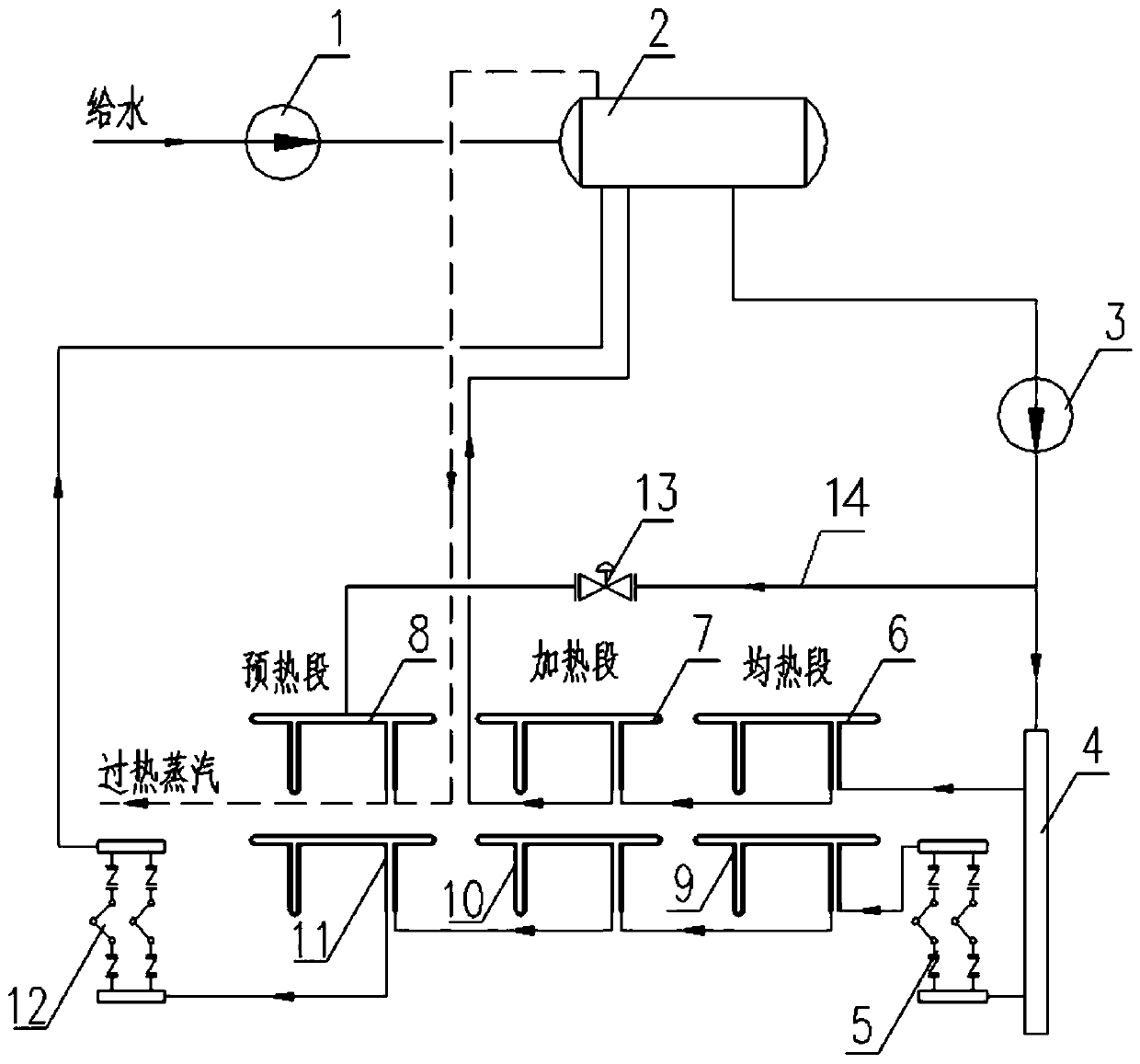

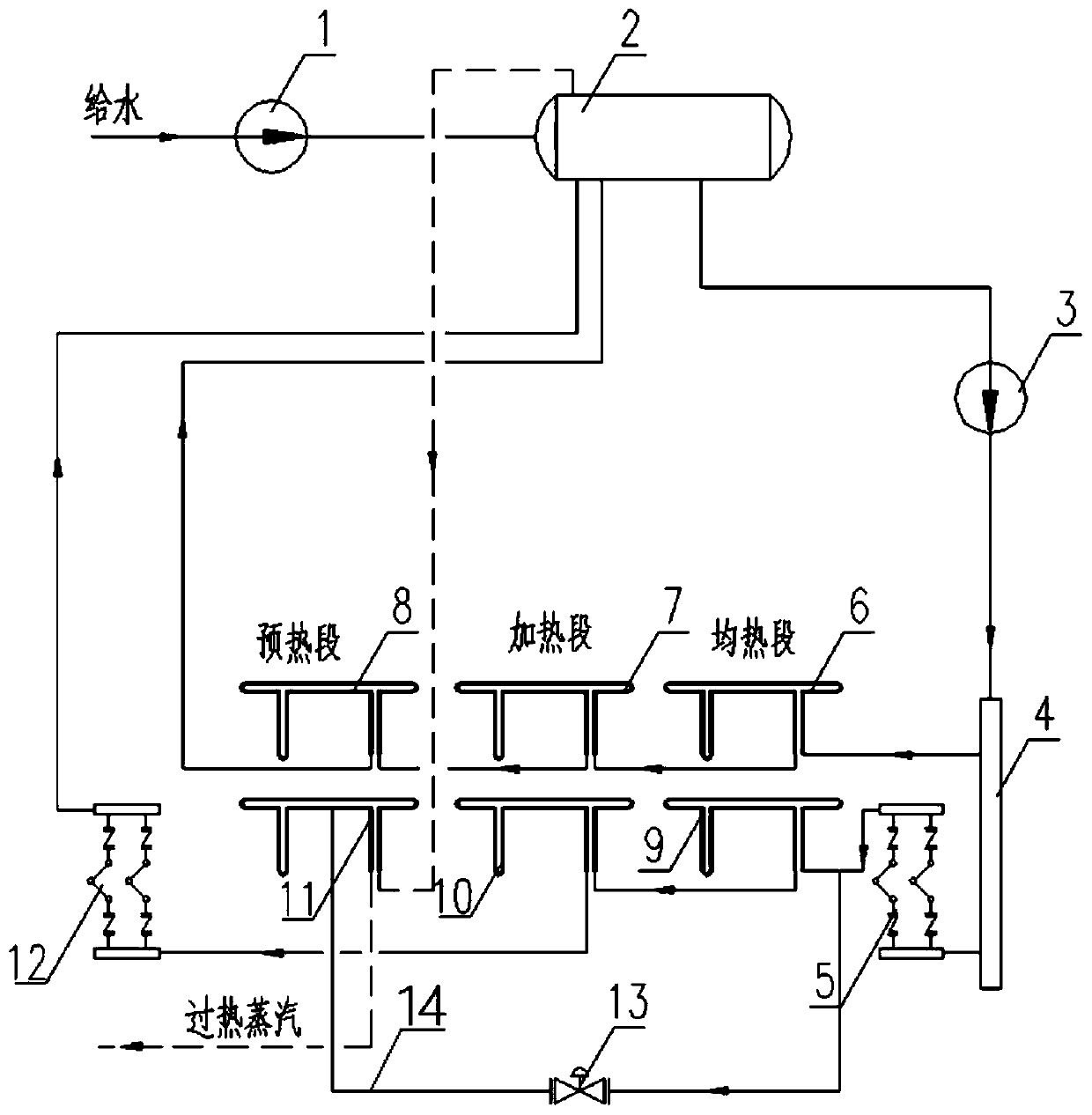

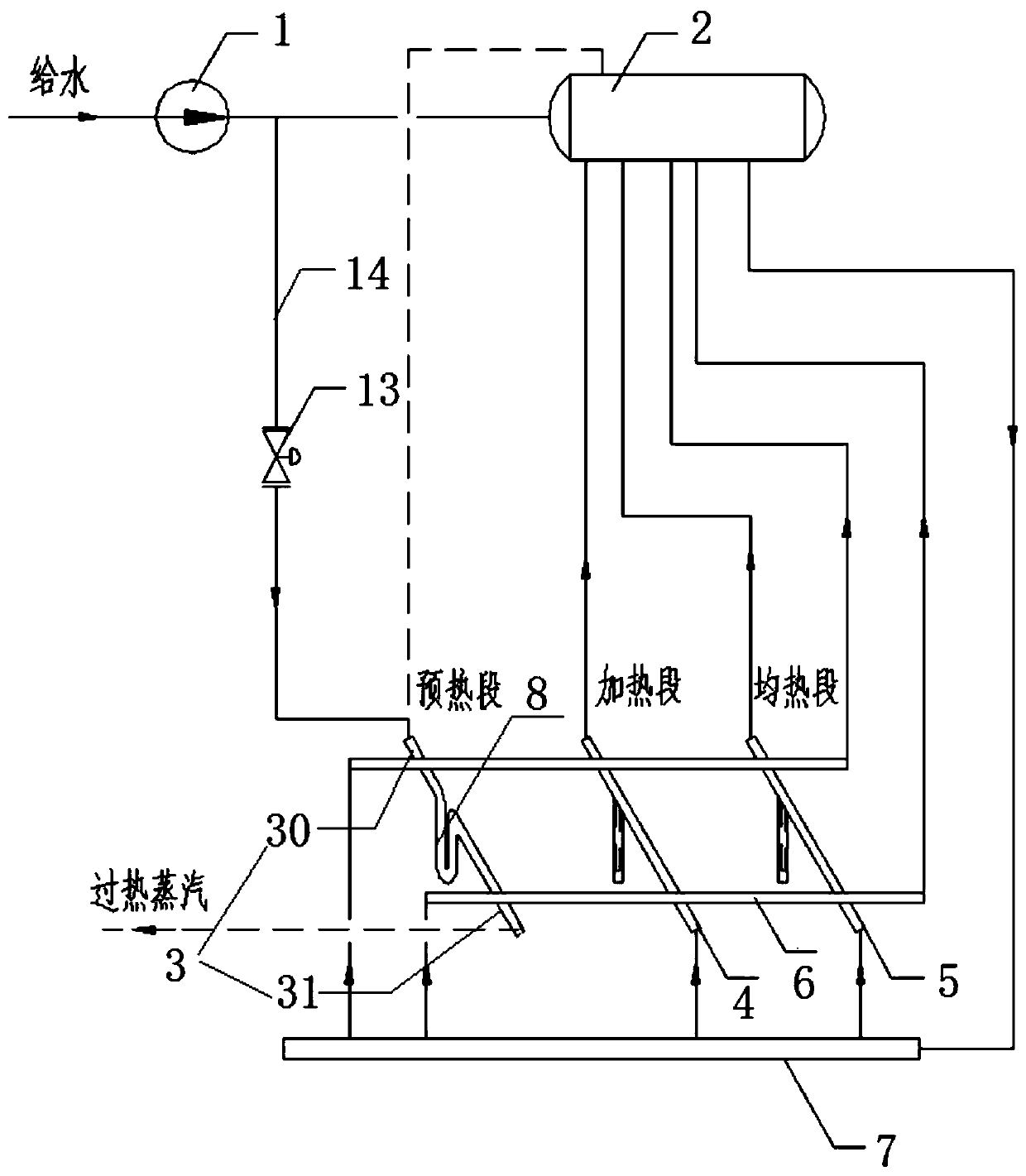

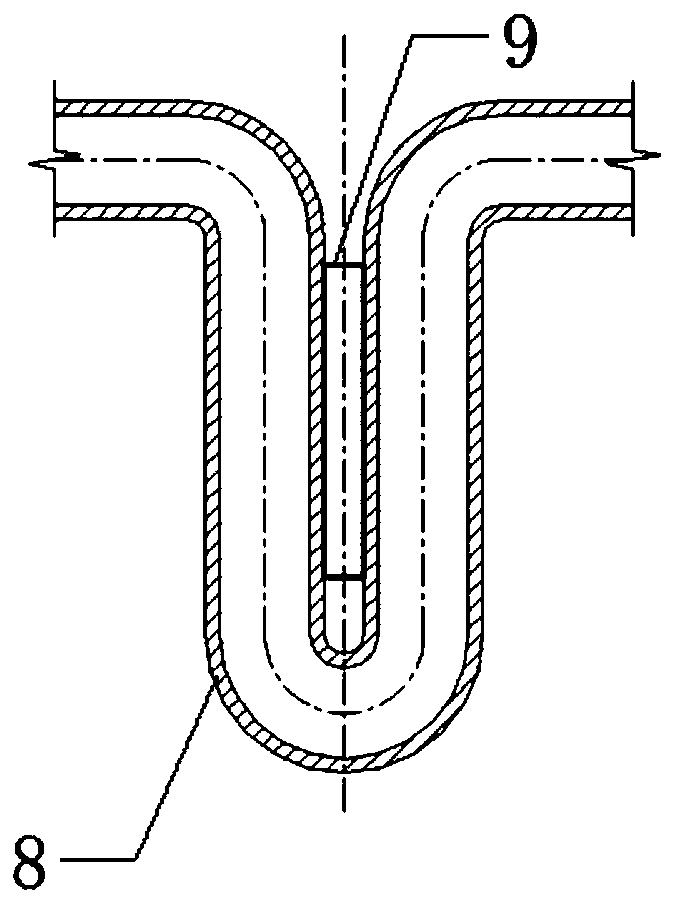

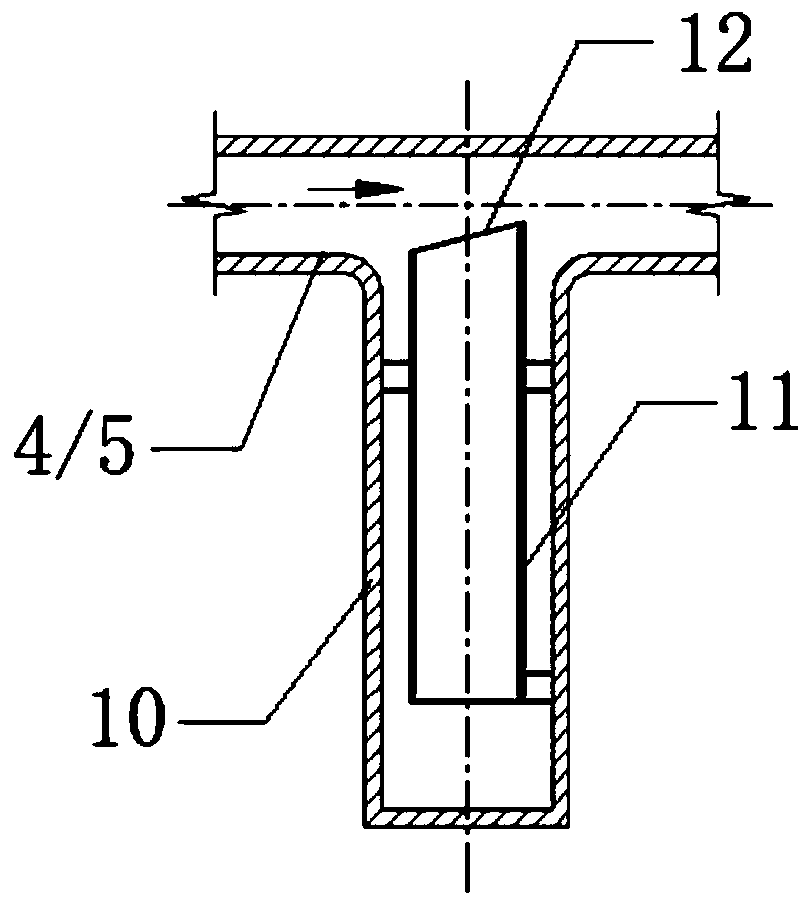

Evaporation cooling device with superheated steam producing function for pusher-type heating furnace

ActiveCN107543421AImprove energy qualityReduce consumptionIncreasing energy efficiencySteam generation using hot heat carriersEvaporationEnergy quality

The invention provides an evaporation cooling device with the superheated steam producing function for a pusher-type heating furnace. The evaporation cooling device comprises a water feed pump, a steam pocket, a preheating section transverse water pipe, a preheating section, and at least one of a heating section transverse water pipe, a heat uniformizing section transverse water pipe and a crossing water pipe. A water feeding inlet of the steam pocket communicates with a water outlet of the water feed pump. The preheating section is arranged in a furnace hearth of the heating furnace, a steaminlet of the preheating section communicates with a steam outlet of the steam pocket, and a steam outlet of the preheating section communicates with a superheated steam pipe network outside the heating furnace. The heating section transverse water pipe is arranged in a heating section, the heat uniformizing section transverse water pipe is arranged in a heat uniformizing section, and the crossingwater pipe is arranged in the furnace hearth of the heating furnace and transversely crosses the preheating section, the heating section and the heat uniformizing section. A water inlet of at least one of the heating section transverse water pipe, the heat uniformizing section transverse water pipe and the crossing water pipe communicates with a circulating water outlet of the steam pocket, and awater outlet of at least one of the heating section transverse water pipe, the heat uniformizing section transverse water pipe and the crossing water pipe communicates with a steam-water mixture inletof the steam pocket. The energy quality of waste heat recovery of the heating furnace is improved, and the fuel consumption of the heating furnace is also reduced.

Owner:HUATIAN ENG & TECH CORP MCC

Still kettle system for producing ardealite steam-pressing bricks

InactiveCN105291257AReduce energy consumptionImprove energy qualityCeramic shaping apparatusGypsumPressure rise

The invention discloses a still kettle system for producing ardealite steam-pressing bricks. The still kettle system comprises a heat main steam source collecting box, a still kettle A, a still kettle B, a still kettle C, a still kettle D, a still kettle E, a steam source distribution pipe, a dead steam distribution pipe, a steam-steam pumping pipe A, a steam-steam pumping pipe B, a steam-steam pumping pipe C, a steam-steam pumping pipe D and a steam-steam pumping pipe E, wherein the main steam source collecting box is connected with the steam source distribution pipe through a steam source main valve A and a steam source main valve B; inlets of the still kettle A, the still kettle B, the still kettle C, the still kettle D and the still kettle E are connected with the steam source distribution pipe and the dead steam distribution pipe; outlets of the still kettle A, the still kettle B, the still kettle C, the still kettle D and the still kettle E are connected with the steam-steam pumping pipe A, the steam-steam pumping pipe B, the steam-steam pumping pipe C, the steam-steam pumping pipe D and the steam-steam pumping pipe E. Dead steam of the still kettles are subjected to temperature rise and pressure rise respectively through the steam-steam pumping pipes and then is gathered into the dead steam distribution pipe, therefore the dead steam can be recycled instead of being discharged, the recycling effect is better, and the maximum recycling and reusing purposes are achieved.

Owner:GUIZHOU KAILIN GRP CO LTD

A system for comprehensive cascade utilization of heat recovery and waste heat in thermal power generation

InactiveCN105333450BBest Cascade UtilizationImprove energy qualityIndirect carbon-dioxide mitigationAir/fuel supply for combustionAir preheaterEngineering

The invention relates to a comprehensive gradient utilization system of recovered heat and waste heat of thermal power generation. The comprehensive gradient utilization system comprises an air pre-heater subsystem, a main condensation water subsystem, a medium temperature condensation water supply subsystem, a low temperature condensation water supply subsystem, a smoke cooling condensation water subsystem and an air heating condensation water subsystem. The air pre-heater subsystem is connected with the smoke cooling condensation water subsystem, the medium temperature condensation water supply subsystem, the low temperature condensation water supply subsystem and the air heating condensation water subsystem and then is connected to the main condensation water subsystem in a collected mode.

Owner:郝江平

An adjustable boiler air preheating system and method for integrated heat recovery and waste heat utilization

InactiveCN105091020BIncrease independenceBest Cascade UtilizationCombustion processSteam useThermal energyEngineering

The invention belongs to the fields of thermal power generation and the like and particularly relates to an adjustable boiler air preheating system and method integrating heat regeneration and waste heat utilization. According to the adjustable boiler air preheating system and method, air preheating, waste heat utilization and regenerative heat cycling are made to be combined organically; heat-transmission cycling condensate water is divided into a large open cycle in which a bypass low-pressure heater extrudes a steam turbine to perform high-parameter steam extraction and a small closed cycle in which the low-pressure heater (or an added heat exchanger) is used for absorbing heat to increase low-parameter steam extraction; heat flow is divided according to the temperature level difference, heat source and cold source resources are dynamically and sufficiently used, optimal gradient utilization of heat energy in the power generation thermodynamic cycle is achieved, the energy use quality is improved, and energy losses are reduced. According to the adjustable boiler air preheating system and method, the operation mode of the system can be optimized and adjusted automatically according to the change of the operation condition so that gradient utilization of energy of different qualities can be achieved and energy losses can be reduced, and the thermodynamic cycle efficiency and the system economy are maximized.

Owner:郝江平

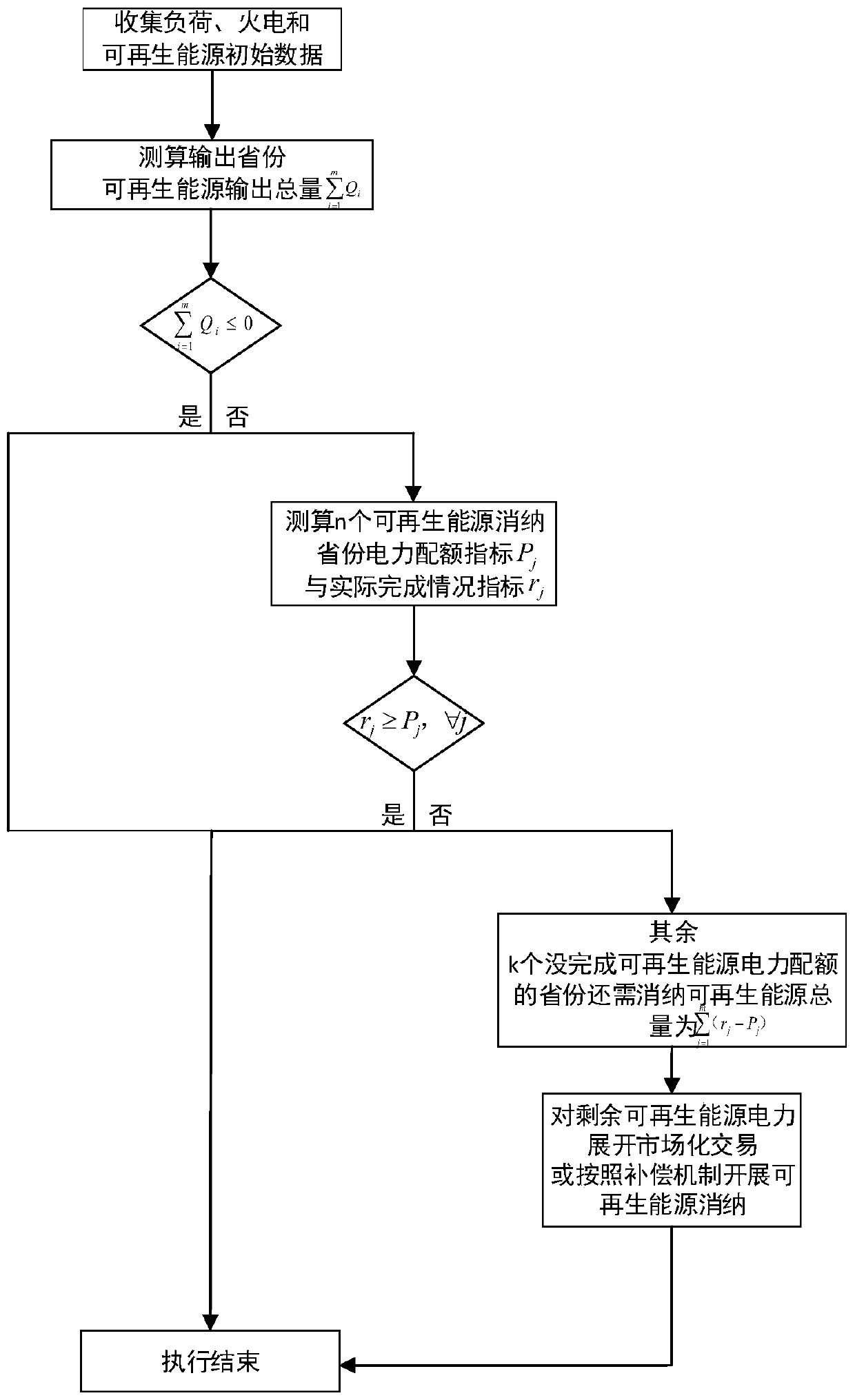

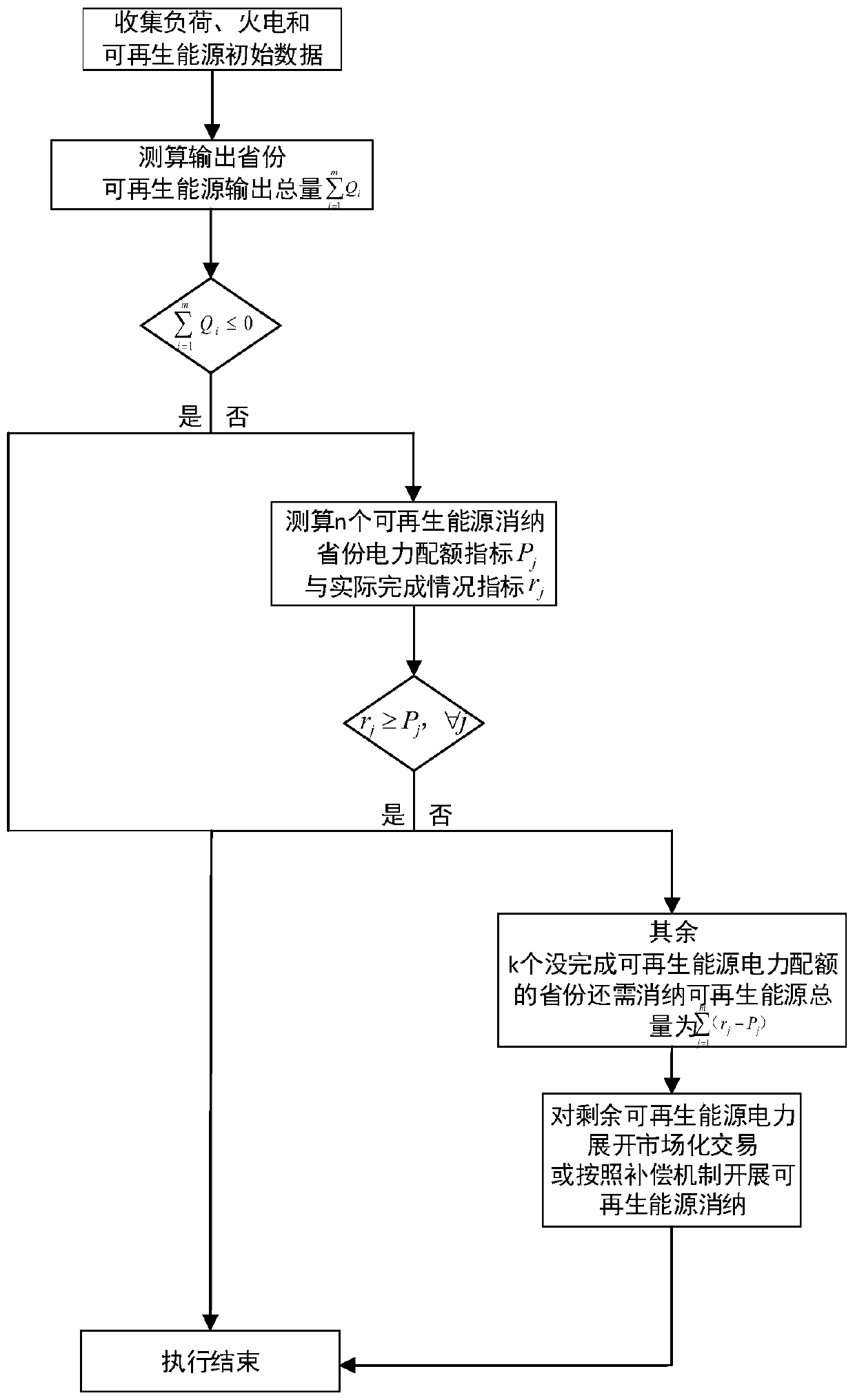

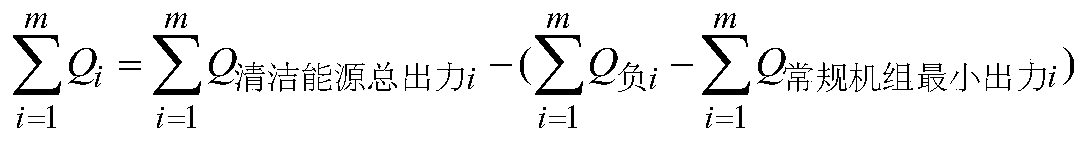

Quota system-considered renewable energy source distribution and consumption method

ActiveCN109980697APromote end-use electricityOptimize market resource allocationSingle network parallel feeding arrangementsRenewable energyEngineering

The invention discloses a quota system-considered renewable energy source distribution and consumption method. According to the method, the output conditions of renewable energy source output provinces and the consumption conditions of renewable energy source consumption provinces are judged on the basis of analyzing the output data and load data of a unit. The process of judging the renewable energy source consumption conditions comprises the steps of judging whether the output provinces deliver renewable energy sources or not according to cross-province renewable energy source delivery electric quantities; determining the consumption conditions of the consumption provinces according to renewable energy source electric quota indexes of the consumption provinces and practical completion condition indexes of the renewable energy source electric quotas; and for the residual renewable energy source after completing the renewable energy source electric quota indexes, carrying out market transaction or continuously carrying out renewable energy source consumption according to a compensation mechanism. The method is capable of providing reference for how to carry out maximum consumptionof cross-province renewable energy sources, is beneficial for improving the renewable energy source utilization rate, and is capable of solving the wind and light abandoning problems to a certain extent.

Owner:国家电网有限公司华中分部

System for recycling waste heat produced by methyl-diethanolamine (MDEA) decarburization process by using ultra high temperature heat pump

InactiveCN102895843BImprove energy efficiency ratioEmission reductionHeat pumpsDispersed particle separationEnergy qualityProduct gas

The invention discloses a system for recycling waste heat produced by a methyl-diethanolamine (MDEA) decarburization process by using an ultra high temperature heat pump. The system mainly comprises two procedures of MDEA decarburization and ultra high temperature heat pump working media. In the system, an evaporator of an ultra high temperature heat pump unit replaces original cooling water to decrease the temperature of a barren solution of the decarburization process to a required temperature, and the cooled barren solution absorbs CO2 of process gases; and a condenser of the ultra high temperature heat pump unit replaces original high temperature vapor. According to the system for recycling the waste heat produced by the MDEA decarburization process by using the ultra high temperature heat pump, by means of an ultra high temperature heat pump technology, technical bottlenecks of temperature limitation of original high temperature heat pumps are broken through, and recycling ranges of low temperature waste heat are greatly expanded. The ultra high temperature blending working media are used, and the waste heat produced by the MDEA decarburization process is utilized so that energy qualities are improved to meet requirements of high temperature heat required when an MDEA decarburization solution is regenerated. By means of the system, energy utilization ratios of the process are improved, and good energy-saving and economical effects are achieved.

Owner:TIANJIN UNIV

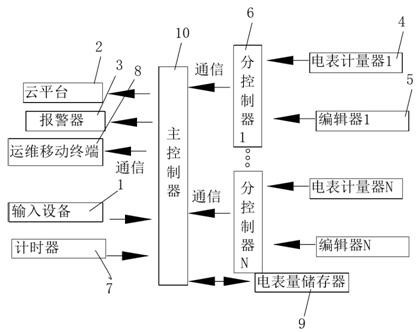

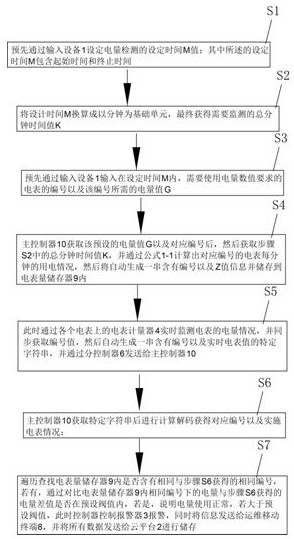

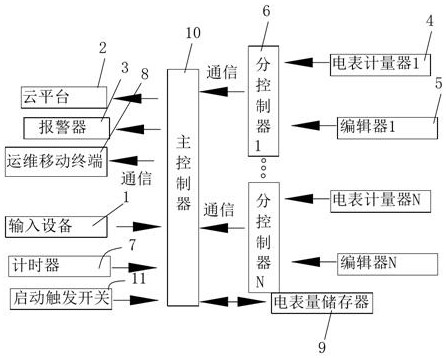

Smart electric energy management system and management method thereof

PendingCN112150787AImprove management levelPrevent electricity theftElectric signal transmission systemsData processing applicationsNetwork connectionControl engineering

The invention discloses a smart electric energy management system. The smart electric energy management system comprises the following equipment: input equipment, an alarm, more than one electric meter counter, more than one editor, more than one sub-controller, a timer, an operation and maintenance mobile terminal, an electric meter quantity storage device and a main controller, wherein the morethan one electric meter counter is arranged in each electric meter and used for monitoring the electric quantity condition of the electric meter in real time; the more than one editor is arranged in each electric meter and used for displaying the number of the electric meter; the more than one sub-controller is arranged in each electric meter and used for acquiring the number information and the electric quantity information of the electric meter; and the main controller is electrically connected with the electric meter quantity storage device, the input equipment, the alarm and the timer, isin communication connection with the operation and maintenance mobile terminal and the sub-controller, and is also in network connection with a cloud platform. The invention further discloses a smartelectric energy management method. The smart electric energy management system and the smart electric energy management method monitor the electric quantity in real time, and improve the energy management efficiency.

Owner:新优(宁波)智能科技有限公司

Energy source recovery system for ammonium phosphate production

InactiveCN105293460AAchieve recyclingAvoid noise pollutionPhosphatesChemical industryPhosphoric acidEngineering

The present invention discloses an energy source recovery system for ammonium phosphate production. The energy source recovery system comprises a first heat exchanger, a temperature reducing device, a condensed water tank, a phosphoric acid circulating pump, a hot acid flash evaporation chamber, a second heat exchanger, a third heat exchanger and a hot acid middle tank, wherein the lower end of the first heat exchanger is respectively connected to the outlet pipe of the phosphoric acid circulating pump and the water inlet pipe of the condensed water tank, the upper end is respectively connected to the outlet pipe of the temperature reducing device and the inlet pipe of the hot acid flash evaporation chamber, the temperature reducing device is connected to the condensed water tank through a temperature reducing water pipe, the inlet pipe of the phosphoric acid circulating pump is connected to the outlet pipe of the hot acid middle tank, the outlet pipe of the phosphoric acid circulating pump is connected to the lower inlet pipe of the first heat exchanger, both sides on the upper portion of the hot acid flash evaporation chamber are respectively connected to the acid outlet pipe of the first heat exchanger and the upper portion sealing head acid outlet pipe of the second heat exchanger, and the top portion gas outlet pipe of the hot acid flash evaporation chamber is connected to the upper portion of the third heat exchanger sequentially through a re-blocking foam removing device and a pressurization device. With the energy source recovery system of the present invention, the exhaust steam energy quality is effectively re-utilized, and the production cost is substantially reduced.

Owner:GUIZHOU KAILIN GRP CO LTD

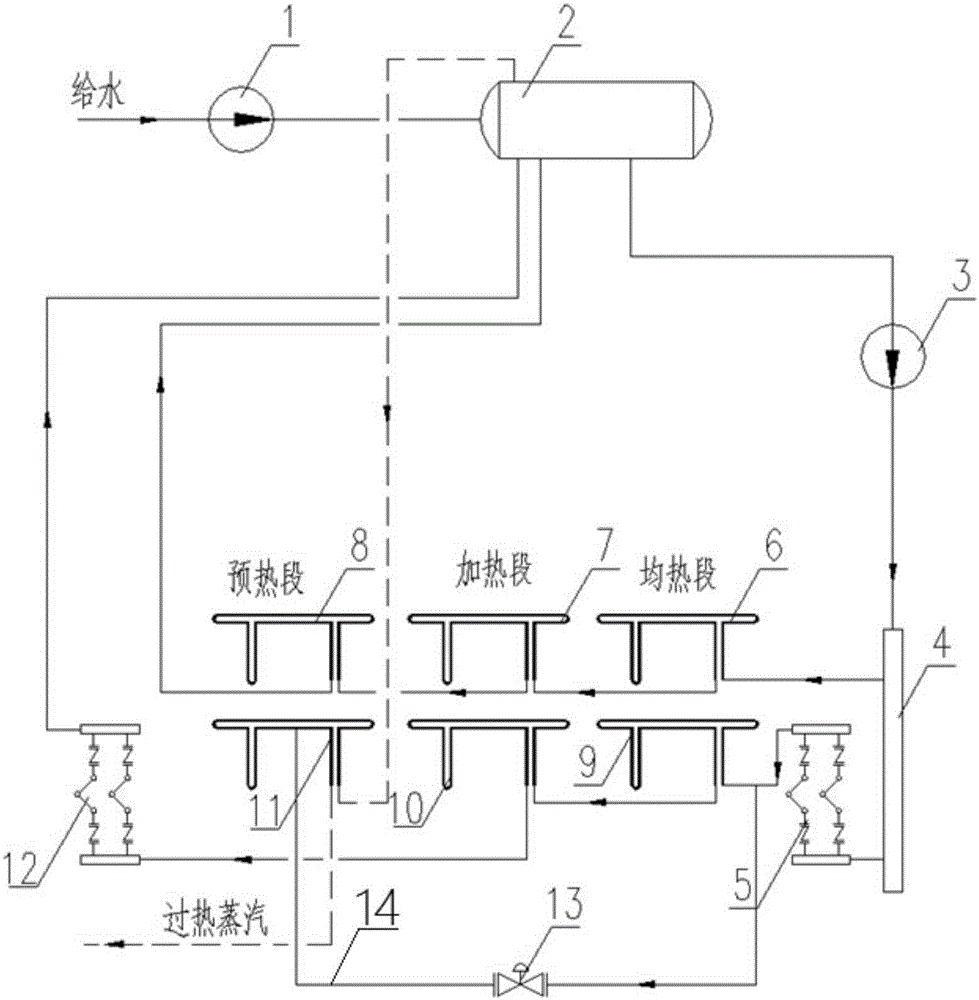

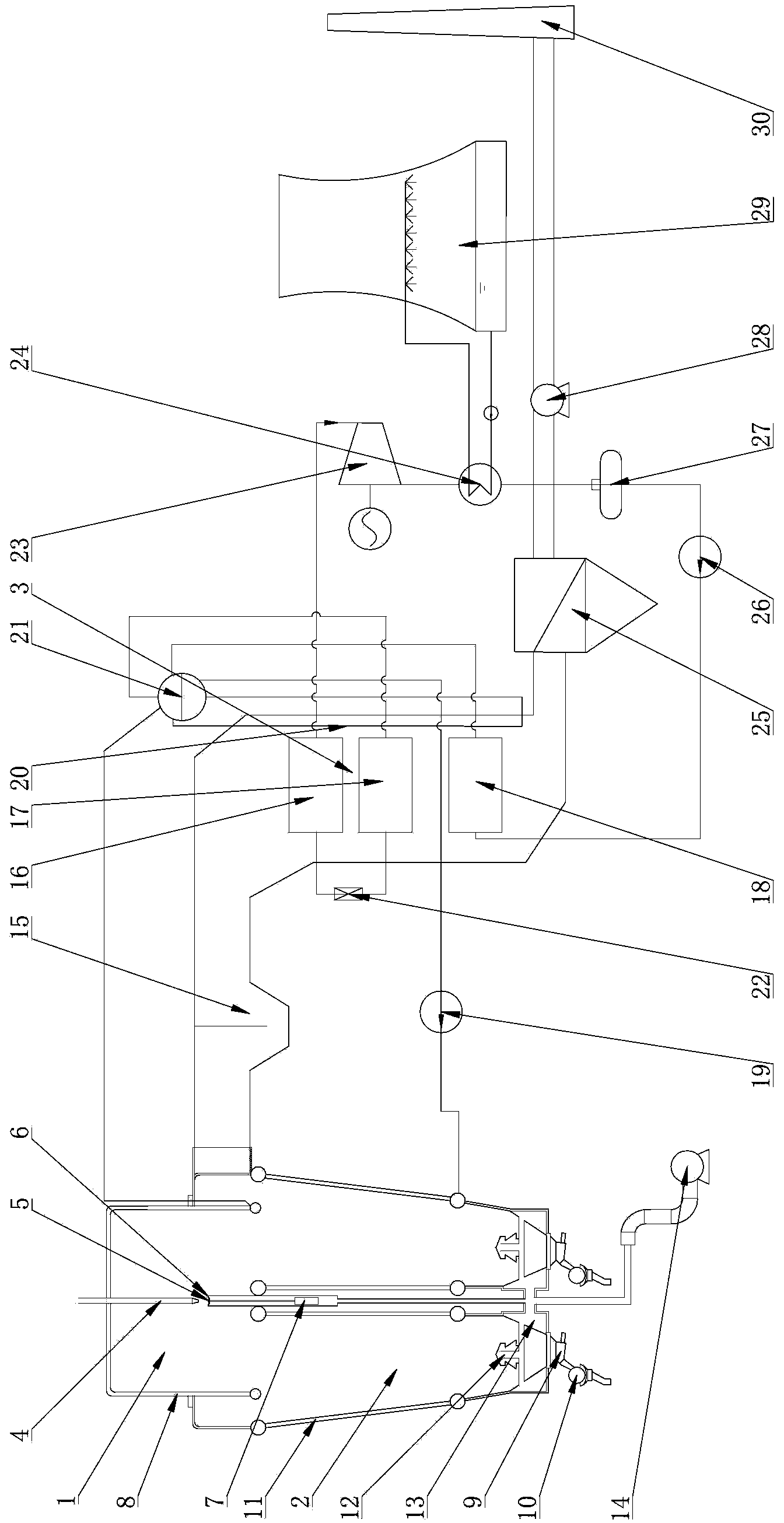

Stepping type heating furnace vaporization cooling device capable of generating superheated steam

ActiveCN107525411AImprove energy qualityReduce consumptionIncreasing energy efficiencySteam generation using hot heat carriersHearthEnergy quality

The invention provides a stepping type heating furnace vaporization cooling device capable of generating superheated steam. The stepping type heating furnace vaporization cooling device comprises a water feed pump, a steam pocket communicating with the water feed pump, a superheated steam generation water beam, a circulating water pump connected with the steam pocket and a steam-water mixture generation water beam. The superheated steam generation water beam is arranged on a preheating section fixed beam or a preheating section stepping beam in a hearth of a heating furnace, a steam inlet of the superheated steam generation water beam is connected with a steam outlet of the steam pocket, and a steam outlet of the superheated steam generation water beam communicates with an external superheated steam pipe net. The circulating water pump is connected with the steam pocket. The steam-water mixture generation water beam is arranged on a fixed beam or a movable beam in the hearth, a water inlet of the steam-water mixture generation water beam communicates with a water outlet of the circulating water pump, and a water outlet of the steam-water mixture generation water beam communicates with a steam-water mixture inlet of the steam pocket. The superheated steam generation water beam and the steam-water mixture generation water beam are arranged on the different fixing beams or movable beams in the hearth of the hearing furnace. According to the stepping type heating furnace vaporization cooling device capable of generating the superheated steam, the energy quality of waste heat recovery of the stepping type heating furnace is improved, and fuel consumption of the stepping type heating furnace is reduced.

Owner:HUATIAN ENG & TECH CORP MCC

Evaporation cooling device for walking heating furnace producing superheated steam

ActiveCN107525411BImprove energy qualityReduce consumptionIncreasing energy efficiencySteam generation using hot heat carriersThermodynamicsHearth

The invention provides a stepping type heating furnace vaporization cooling device capable of generating superheated steam. The stepping type heating furnace vaporization cooling device comprises a water feed pump, a steam pocket communicating with the water feed pump, a superheated steam generation water beam, a circulating water pump connected with the steam pocket and a steam-water mixture generation water beam. The superheated steam generation water beam is arranged on a preheating section fixed beam or a preheating section stepping beam in a hearth of a heating furnace, a steam inlet of the superheated steam generation water beam is connected with a steam outlet of the steam pocket, and a steam outlet of the superheated steam generation water beam communicates with an external superheated steam pipe net. The circulating water pump is connected with the steam pocket. The steam-water mixture generation water beam is arranged on a fixed beam or a movable beam in the hearth, a water inlet of the steam-water mixture generation water beam communicates with a water outlet of the circulating water pump, and a water outlet of the steam-water mixture generation water beam communicates with a steam-water mixture inlet of the steam pocket. The superheated steam generation water beam and the steam-water mixture generation water beam are arranged on the different fixing beams or movable beams in the hearth of the hearing furnace. According to the stepping type heating furnace vaporization cooling device capable of generating the superheated steam, the energy quality of waste heat recovery of the stepping type heating furnace is improved, and fuel consumption of the stepping type heating furnace is reduced.

Owner:HUATIAN ENG & TECH CORP MCC

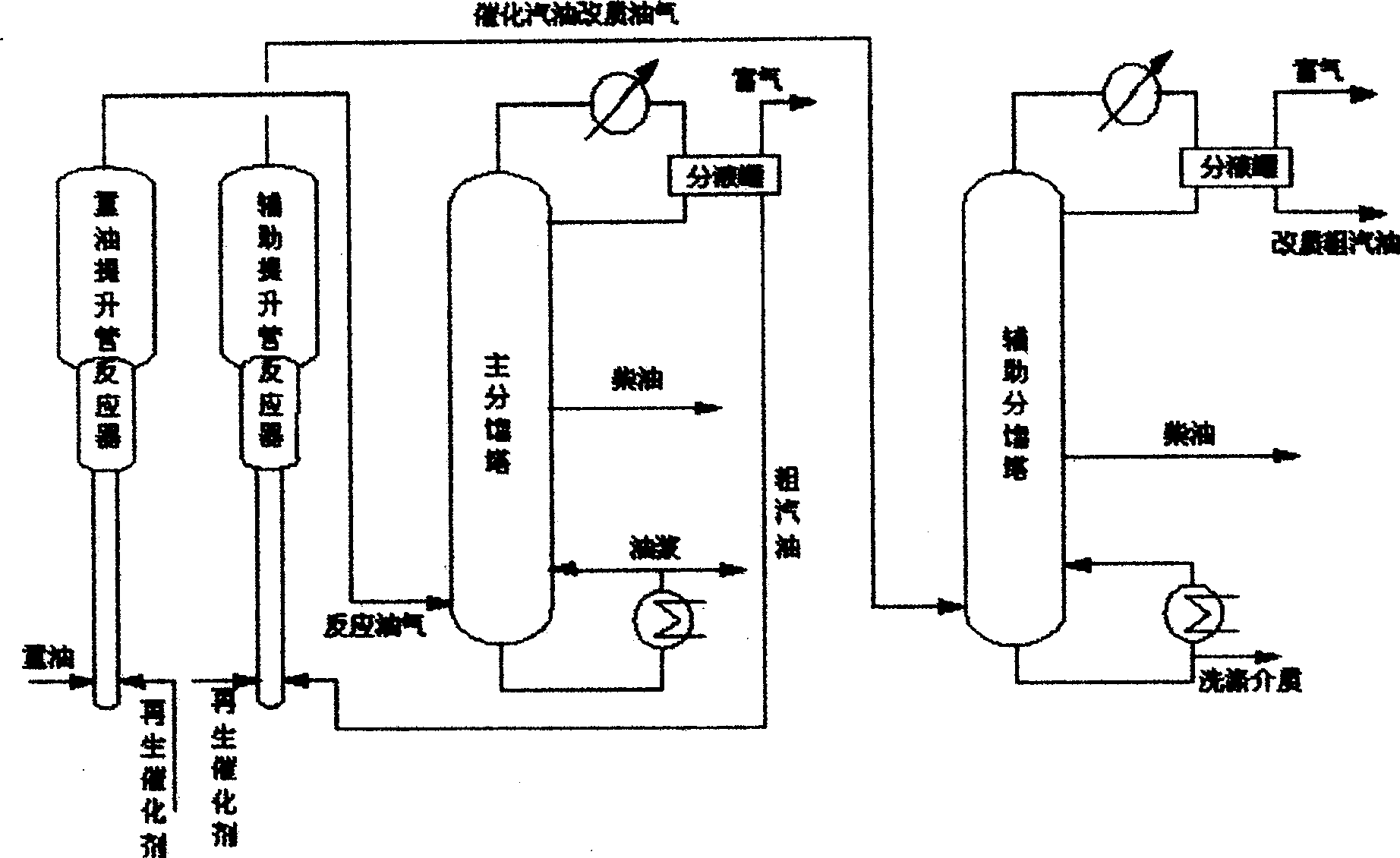

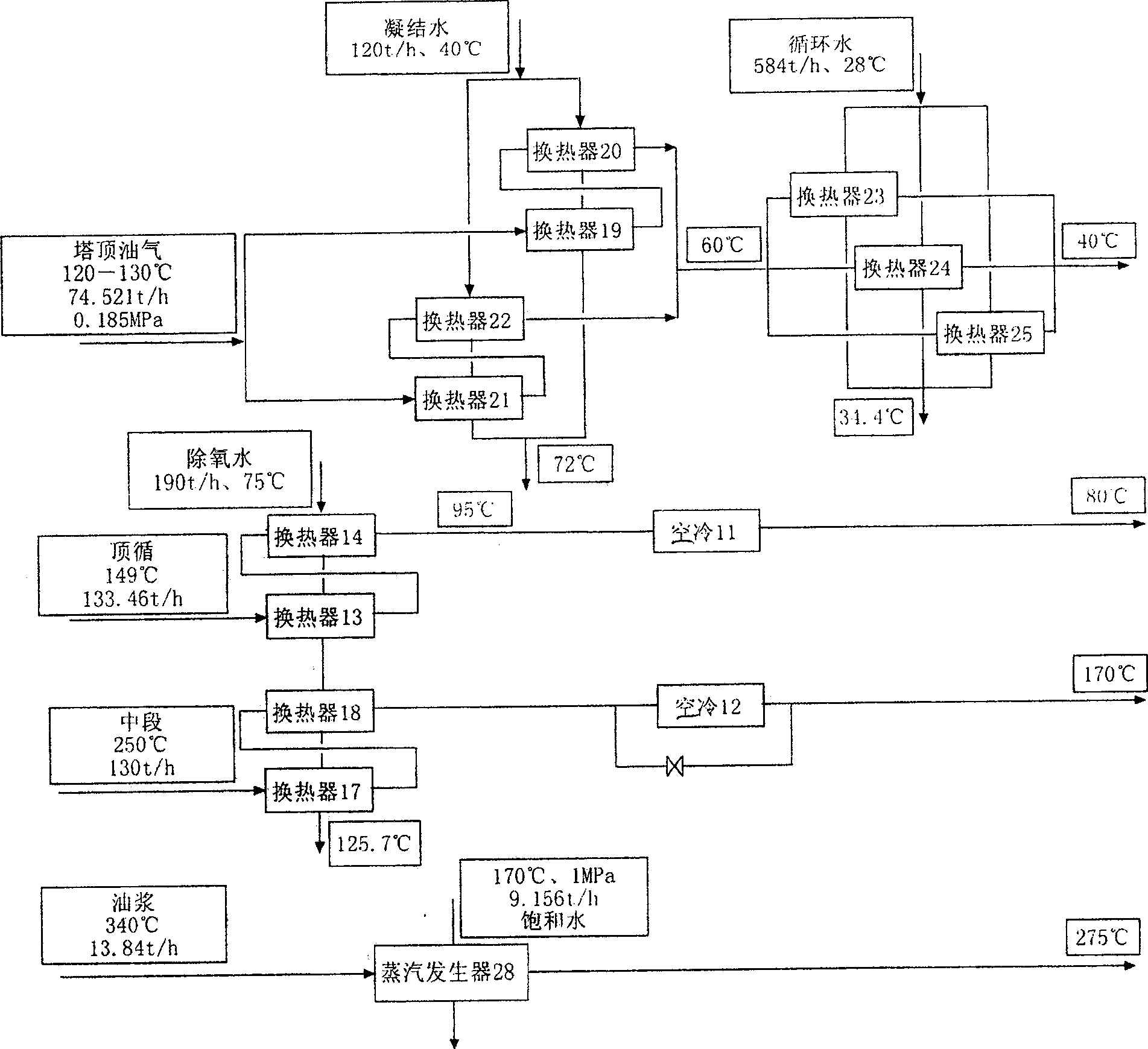

Auxiliary fractional tower and its gasoline catalyzing and olefine reducing modification process

InactiveCN100519699CSimple structureOptimize energy distributionHydrocarbon distillationGasolineCoke

Owner:SOUTH CHINA UNIV OF TECH

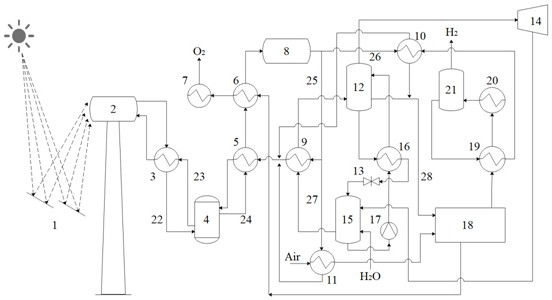

A high-temperature solid oxide water electrolysis hydrogen production system and process coupled with solar amino thermochemical energy storage and Karina cycle

ActiveCN113322475BReduce energy absorption gradeReduce the cost of concentrating heatSolar heating energyElectrolysis componentsElectrolysed waterProcess engineering

The invention discloses a high-temperature solid oxide water electrolysis hydrogen production system and process coupled with solar amino thermochemical energy storage and Karina cycle, the system includes amino thermochemical energy system, Karina cycle system and high-temperature solid oxidation Water electrolysis hydrogen production system, the amino thermochemical energy system and the high temperature solid oxide water electrolysis hydrogen production system realize heat exchange connection through the sixth heat exchanger, the third heat exchanger and the seventh heat exchanger, the amino thermochemical The heat exchange connection between the energy system and the Kalina cycle system is realized through the fifth heat exchanger, and the Kalina cycle system is connected with the high-temperature solid oxide water electrolysis hydrogen production system to provide raw materials for the high-temperature solid oxide water electrolysis hydrogen production system. The present invention can reduce the cost of concentrating and heat collection, reduce the loss of energy storage, and improve the cycle efficiency of power generation and the hydrogen production efficiency of electrolyzed water by reducing the energy absorption grade, storing at normal temperature, and improving the energy release grade.

Owner:ZHEJIANG UNIV OF TECH

A split-controlled phase change heat system and heat transfer method based on hierarchical combined heat transfer

InactiveCN103808178BIncrease temperatureImprove energy qualityIndirect heat exchangersAir preheaterHigh energy

The invention discloses a sub-control phase-change heat exchange system based on grading combination heat exchange. The sub-control phase-change heat exchange system comprises a flue, an air channel, an air pre-heater, an external water pipeline, a steam supply valve of a low-temperature water heater, the low-temperature water heater, a water inlet valve of the low-temperature water heater, a steam-liquid heat exchanger, a steam supply valve of the steam-liquid heat exchanger, a steam supply valve of an air channel heat exchanger, an external steam supply valve of the air channel heat exchanger, a main water draining pipeline, the air channel heat exchanger, a water tank, a water pump, a water inlet valve of a flue heat exchanger, the flue heat exchanger, and a steam outlet valve of the flue heat exchanger. According to the sub-control phase-change heat exchange system, heat release exchangers which utilize the waste heat of recycled flue gas are arranged in a grading combination mode; according to different situations such as ambient air temperature, operating conditions and the like, the waste heat can be utilized to heat boiler supplied air, condensed water on the side of a steam turbine and the like in a combination mode; meanwhile, the temperature of the condensed water is improved through grading heating, higher energy quality is obtained, and the optimal economic benefit of recycling the waste heat is achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

An energy recovery system for ammonium phosphate production system

InactiveCN105293460BAchieve recyclingAvoid noise pollutionPhosphatesChemical industryPhosphoric acidEnergy quality

The present invention discloses an energy source recovery system for ammonium phosphate production. The energy source recovery system comprises a first heat exchanger, a temperature reducing device, a condensed water tank, a phosphoric acid circulating pump, a hot acid flash evaporation chamber, a second heat exchanger, a third heat exchanger and a hot acid middle tank, wherein the lower end of the first heat exchanger is respectively connected to the outlet pipe of the phosphoric acid circulating pump and the water inlet pipe of the condensed water tank, the upper end is respectively connected to the outlet pipe of the temperature reducing device and the inlet pipe of the hot acid flash evaporation chamber, the temperature reducing device is connected to the condensed water tank through a temperature reducing water pipe, the inlet pipe of the phosphoric acid circulating pump is connected to the outlet pipe of the hot acid middle tank, the outlet pipe of the phosphoric acid circulating pump is connected to the lower inlet pipe of the first heat exchanger, both sides on the upper portion of the hot acid flash evaporation chamber are respectively connected to the acid outlet pipe of the first heat exchanger and the upper portion sealing head acid outlet pipe of the second heat exchanger, and the top portion gas outlet pipe of the hot acid flash evaporation chamber is connected to the upper portion of the third heat exchanger sequentially through a re-blocking foam removing device and a pressurization device. With the energy source recovery system of the present invention, the exhaust steam energy quality is effectively re-utilized, and the production cost is substantially reduced.

Owner:GUIZHOU KAILIN GRP CO LTD

Afterheat recovery system and method of dry granulating liquid slag

ActiveCN102827969BEasy to diluteImprove granulation effectIncreasing energy efficiencyRecycling and recovery technologiesRecovery methodLiquid slag

The invention discloses an afterheat recovery system and an afterheat recovery method of dry granulating liquid slag. The system comprises a granulating cabin, a moving bed and an afterheat recovery system, the inner surface of the granulating cabin is provided with a granulating cabin water cooling wall, the center of the top of the granulating cabin is provided with a slag pipe, the slag pipe extends into the granulating cabin, the lower part of the tail end of the slag pipe is provided with a centrifugal granulator, the centrifugal granulator is connected with a motor arranged at the lower part of the centrifugal granulator, the lateral side of the centrifugal granulator is provided with an air supply pipeline, an annular air opening is formed between the centrifugal granulator and the air supply pipeline, the lower part of the granulating cabin is provided with the moving bed, the inner surface of the moving bed is provided with a moving bed water cooling wall, the top of the moving bed is provided with an air outlet, the bottom of the moving bed is provided with a slag discharge device, an air inlet device is arranged above the slag discharge device, the afterheat recovery system comprises a primary dust remover, an afterheat boiler, a secondary dust remover, an exhaust fan and a chimney which are connected in sequence, and the primary dust remover is connected with the air outlet arranged at the top of the moving bed. The system and the method effectively solve the problems of heat recovery and furnace slag granulation of equipment such as a blast furnace.

Owner:XI AN JIAOTONG UNIV +1

Evaporation cooling device for pusher type heating furnace producing superheated steam

ActiveCN107543421BImprove energy qualityReduce consumptionIncreasing energy efficiencySteam generation using hot heat carriersEvaporationEnergy quality

The invention provides an evaporation cooling device with the superheated steam producing function for a pusher-type heating furnace. The evaporation cooling device comprises a water feed pump, a steam pocket, a preheating section transverse water pipe, a preheating section, and at least one of a heating section transverse water pipe, a heat uniformizing section transverse water pipe and a crossing water pipe. A water feeding inlet of the steam pocket communicates with a water outlet of the water feed pump. The preheating section is arranged in a furnace hearth of the heating furnace, a steaminlet of the preheating section communicates with a steam outlet of the steam pocket, and a steam outlet of the preheating section communicates with a superheated steam pipe network outside the heating furnace. The heating section transverse water pipe is arranged in a heating section, the heat uniformizing section transverse water pipe is arranged in a heat uniformizing section, and the crossingwater pipe is arranged in the furnace hearth of the heating furnace and transversely crosses the preheating section, the heating section and the heat uniformizing section. A water inlet of at least one of the heating section transverse water pipe, the heat uniformizing section transverse water pipe and the crossing water pipe communicates with a circulating water outlet of the steam pocket, and awater outlet of at least one of the heating section transverse water pipe, the heat uniformizing section transverse water pipe and the crossing water pipe communicates with a steam-water mixture inletof the steam pocket. The energy quality of waste heat recovery of the heating furnace is improved, and the fuel consumption of the heating furnace is also reduced.

Owner:HUATIAN ENG & TECH CORP MCC

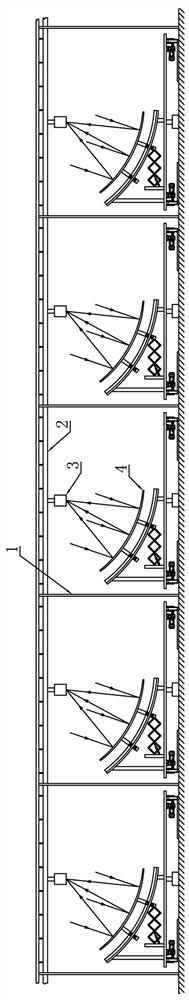

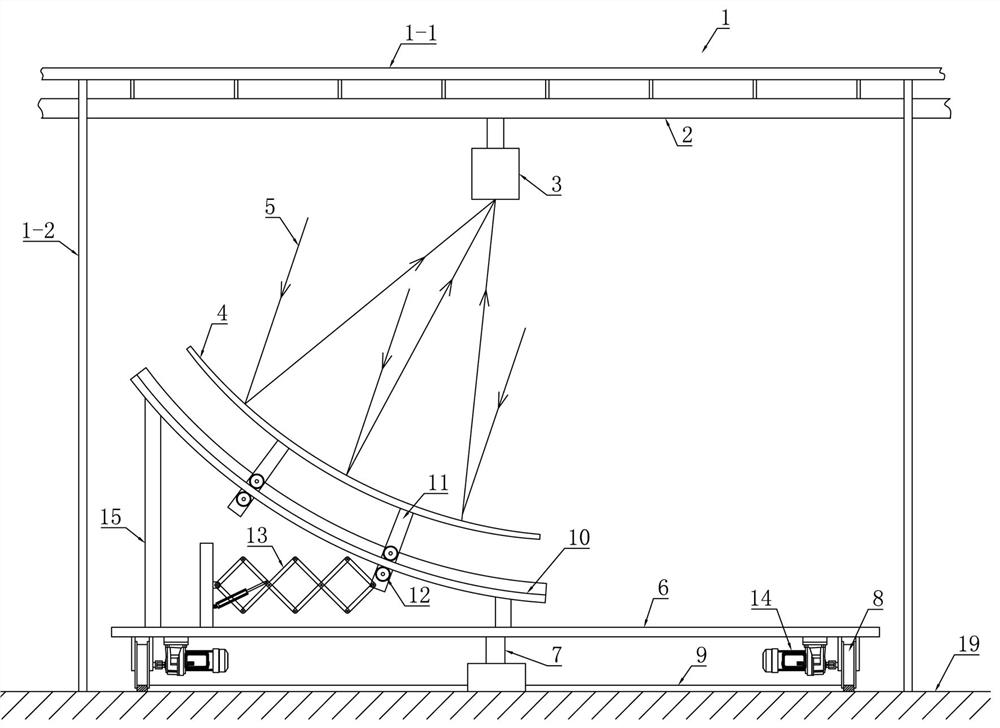

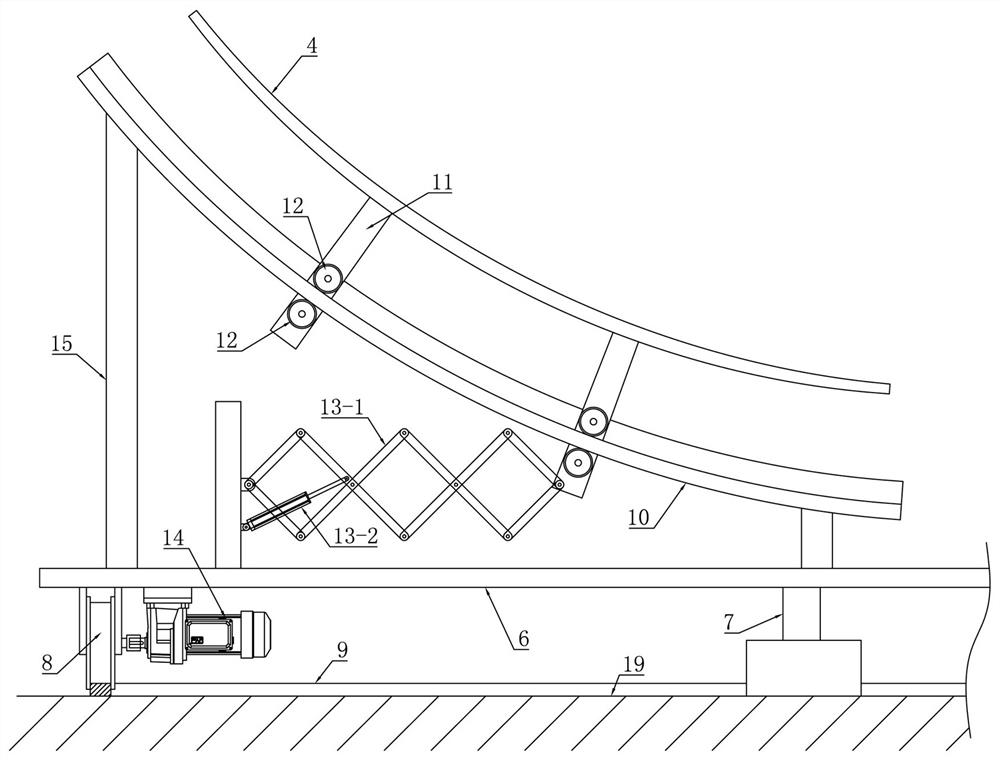

Array type fixed collector rotating parabolic solar energy concentration and heat collection system

ActiveCN111089431BFirmly connectedHigh collector temperatureSolar heating energySolar heat collector controllersCondenser (heat transfer)Collector device

The invention relates to an array-type fixed heat collector rotating parabolic solar energy concentration and heat collection system, which breaks through the development bottleneck of high cost of solar thermal power generation by virtue of its high performance and low cost. It includes several concentrating and heat-collecting units connected in series / parallel; the concentrating and heat-collecting unit includes a bracket, a heat transfer pipe fixed on the support, a heat collector fixedly connected to the heat transfer pipe, and a rotating parabolic reflective condenser And a tracking system supporting the rotating parabolic reflective condenser; the focus of the rotating parabolic reflective condenser is located on the heat collector; the tracking system includes driving the rotating parabolic reflective condenser to move up and down with its focus as the center to track the sun's altitude angle A variable vertical rotation mechanism, and a horizontal rotation mechanism that drives the rotating parabolic reflective condenser to rotate horizontally on the axis of the vertical line passing through the focus point downward to track the change of the azimuth angle of the sun.

Owner:贾英洲

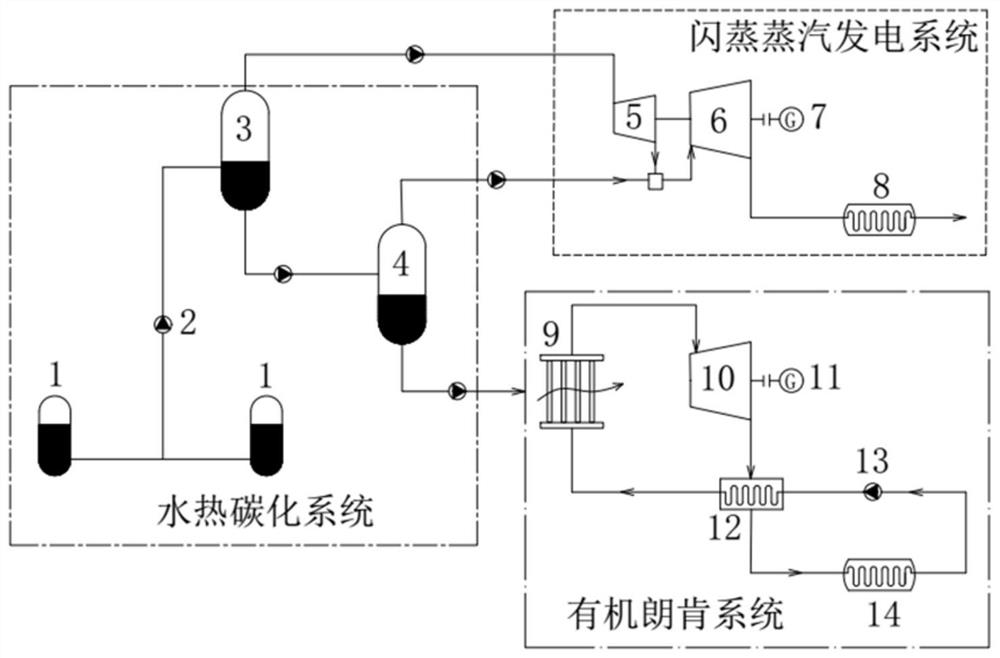

Hydrothermal Carbonization Coupled Double Flash-Organic Rankine Cycle Power Generation System and Power Generation Method

ActiveCN110513156BReduce lossReduce moisture contentBiofuelsSteam useOrganic Rankine cycleSteam power

The invention discloses a hydrothermal carbonization coupled double flash-organic Rankine cycle power generation system and method, including a hydrothermal carbonization system, a flash steam power generation system and an organic Rankine cycle system, and the reaction kettle is connected to the first stage through a slurry pump The flash tank, the concentrated slurry outlet of the first flash tank is connected to the second flash tank, the steam outlet of the first flash tank is connected to the first turbine, the steam outlet of the second flash tank is connected to the first turbine The exhaust steam outlet of the flat machine is connected to the second-stage turbine, and the first-stage turbine and the second-stage turbine coaxially drive the first generator to generate electricity; the concentrated slurry outlet of the second-stage flash tank is connected to the evaporator, The steam outlet of the organic working medium of the evaporator is connected to the turbine, and the turbine drives the second generator to generate electricity. The invention efficiently realizes the quality improvement and utilization of the waste heat of the hydrothermally carbonized slurry product, and significantly reduces the moisture content of the hydrothermally carbonized slurry product and the subsequent mechanical dehydration amount and dehydration energy consumption.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

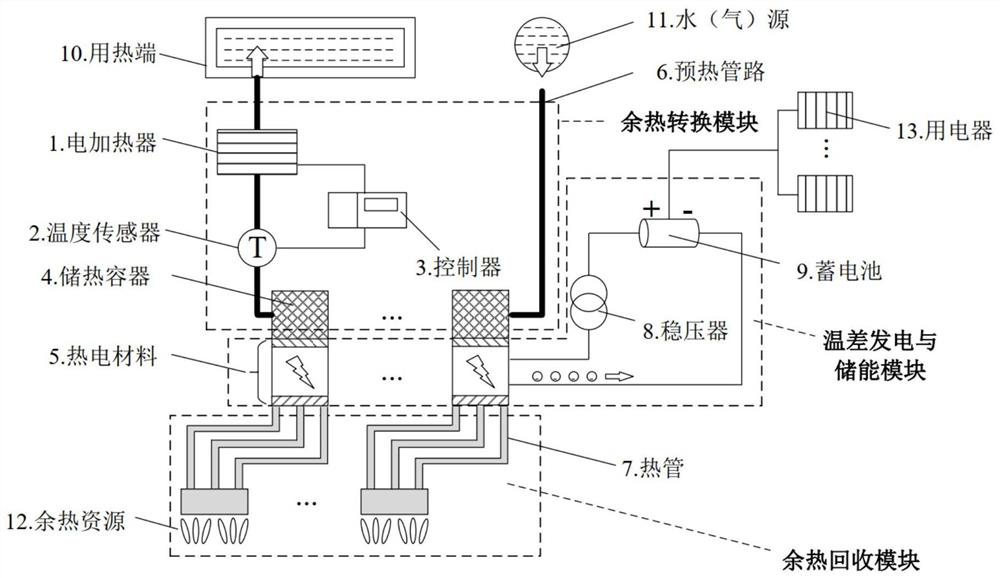

A household waste heat reuse and energy storage system

ActiveCN112539444BRealize acquisitionAchieve recyclingBatteries circuit arrangementsDomestic stoves or rangesThermoelectric materialsEnvironmental geology

The invention relates to a household waste heat reuse and energy storage system. The system includes a waste heat recovery module, a thermoelectric power generation and energy storage module, and a waste heat conversion module. The waste heat recovery module can collect the waste heat energy generated by various household appliances and electrical equipment, and the waste heat can be transmitted to the hot end of the thermoelectric material through a short distance through the heat pipe; the thermoelectric power generation and energy storage module includes thermoelectric materials, batteries and voltage regulators Part of the heat transmitted through the heat pipe can be converted into electrical energy by thermoelectric materials and stored in the battery, which can provide a stable DC power supply for small electrical appliances. The waste heat conversion module includes one or more sets of phase change medium heat storage containers, which are attached to the cold end of the thermoelectric material, and connected to the preheating pipeline in series or parallel, and part of the heat is transferred from the heat pipe to the thermoelectric material and then transferred to the thermoelectric material. into the phase change medium container, and then heat the water source or air source in the preheating pipeline.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com