A household waste heat reuse and energy storage system

An energy storage system and waste heat technology, applied in electric heating systems, household heating, household heating, etc., can solve the problems of centralized collection, transfer, phase-change heat storage and thermal energy reuse description, inability to solve scale and other problems of waste heat resources, To achieve the effect of high efficiency and flexible application, strong flexibility and high energy quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

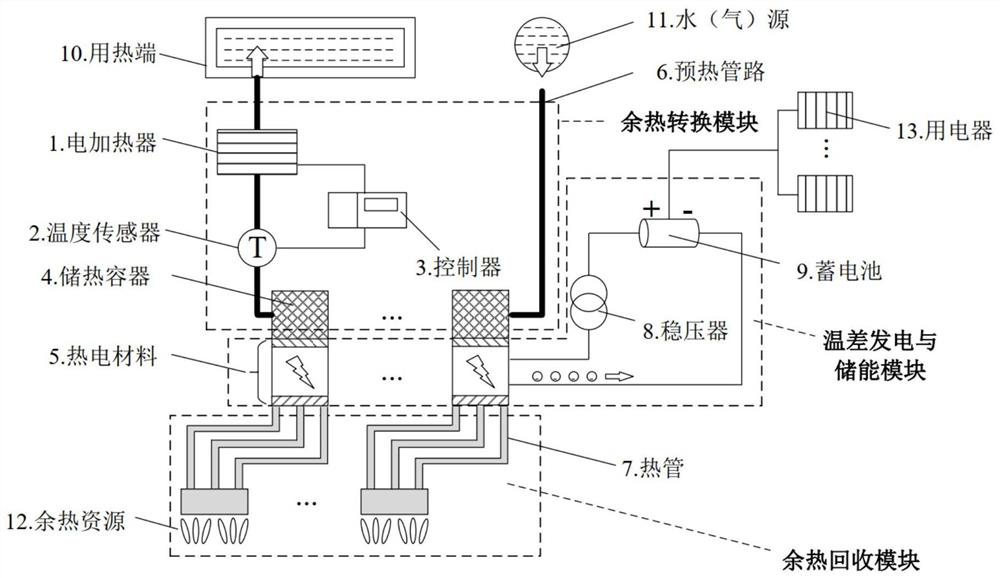

[0025] figure 1 It is a schematic diagram of the domestic waste heat reuse and energy storage system provided by the present invention.

[0026] The present invention is specifically described in conjunction with the accompanying drawings.

[0027] When electric heating or gas equipment is working, while the heating plate or flue gas is heating the pot, a large amount of waste heat energy spreads around and is transferred to the hob. In the household waste heat collection and energy storage combined system provided by the present invention, the waste heat recovery module includes at least one set of heat pipes 7, using the high-temperature base or wall surface of the electric heating or gas equipment during or after operation as the heat source, and connecting one end of the heat pipe 7 to The number and arrangement of each heat source are determined by the total number of heat sources and the power of each heat source; the waste heat is transmitted to the thermoelectric mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com