Cross-scale micro-nano-scale in-situ composite load mechanical performance testing platform

An in-situ composite and test platform technology, applied in the electromechanical field, can solve problems that do not involve in-situ observation and nanoscale mechanical properties of materials, and achieve rich test content, controllable deformation/displacement/load rate, and test high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

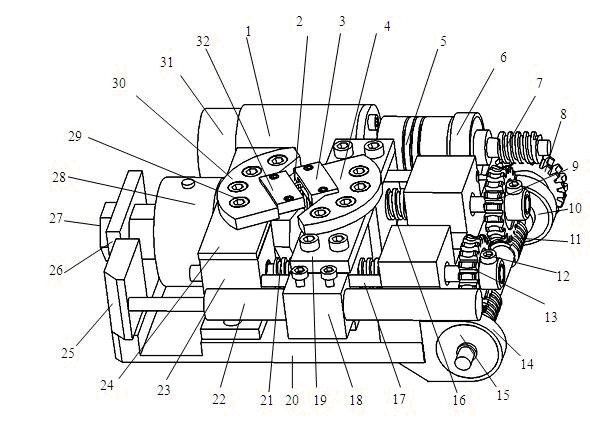

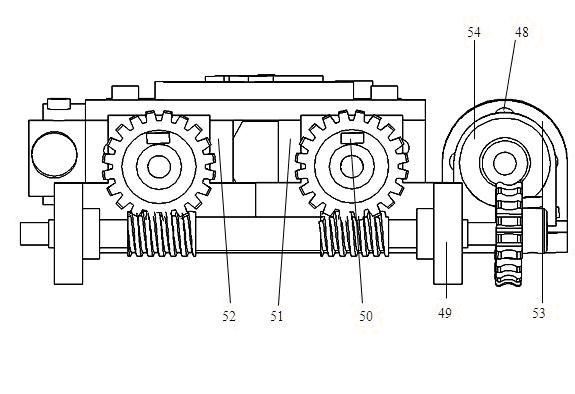

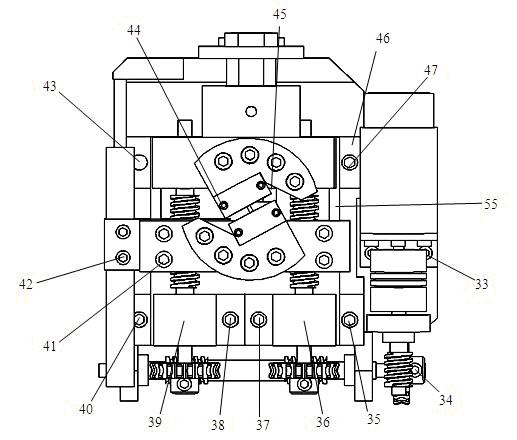

[0024] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0025] see Figure 1 to Figure 9 , the cross-scale micro-nano-scale in-situ composite load mechanical performance testing platform of the present invention includes a precision drive and transmission unit, a signal detection and control unit, clamping, connection and support units; the precision drive and transmission unit is: DC The servo motor 1 is connected with the first-stage worm 7 through the elastic coupling 5 and provides power output, and the power is transmitted to the precision ball screw I, II 16, 21 through the first-stage worm gear pair and the second-stage worm gear pair, And further, precise linear reciprocating motion is output by screw square nuts I, II 51, 52;

[0026] The signal detection and control unit includes a precision contact capacitive displacement sensor 22, a pull pressure sensor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com