Patents

Literature

95results about How to "Reasonable integration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

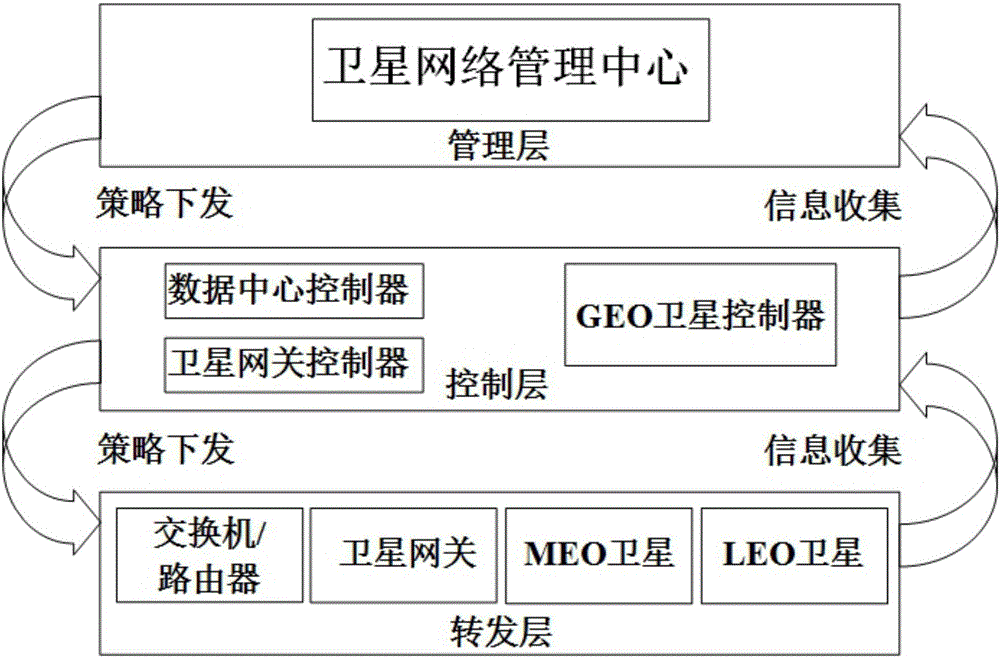

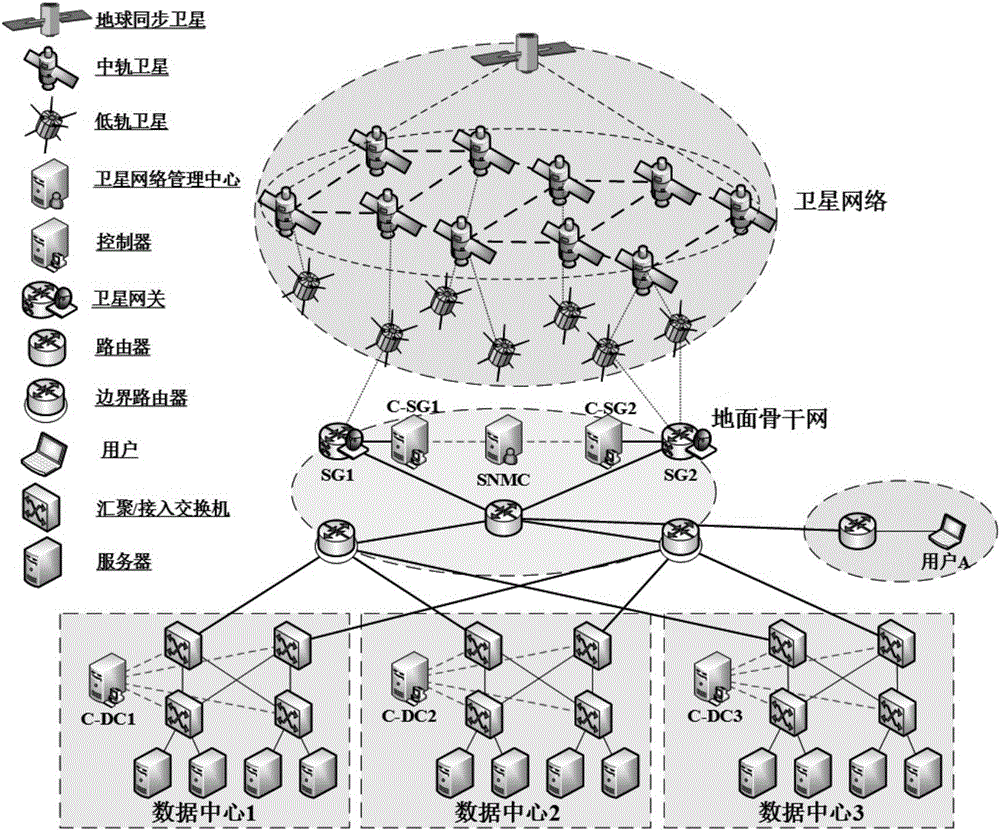

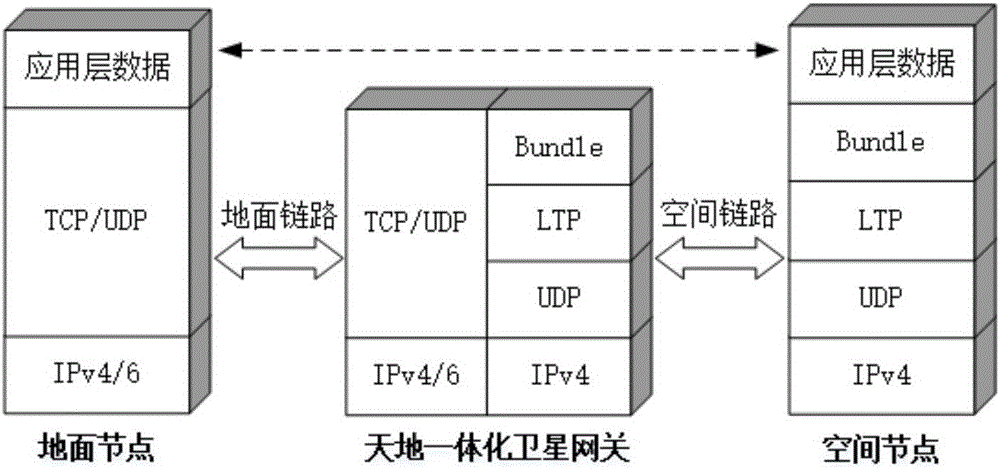

Air-ground integrated network architecture and data transmission method based on SDN and NFV technology

InactiveCN106059650AIncrease profitRealize on-demand servicesRadio transmissionData switching networksControl layerNetwork link

The invention discloses an air-ground integrated network architecture based on a software defined network and network function virtualization. According to the system architecture, the entire network consists of a ground network part and a space network part, and is divided in a unified manner into a management layer, a control layer and a forwarding layer. The management layer is responsible for registering and querying the network status and network service functions of the ground part and the space part in the air-ground integrated network and making routing, security, billing, service call and resource management strategies. The control layer consists of a ground part and a space part, and is responsible for controlling data forwarding according to the strategies of the management layer and collecting the information of network links and network service functions. The forwarding layer consists of a ground part and a space part, and is responsible for forwarding data and providing network service functions. The architecture uses a software defined network and an idea of network function virtualization, and efficient information transmission control and on-demand satellite service providing are realized in an air-ground integrated network.

Owner:BEIJING JIAOTONG UNIV

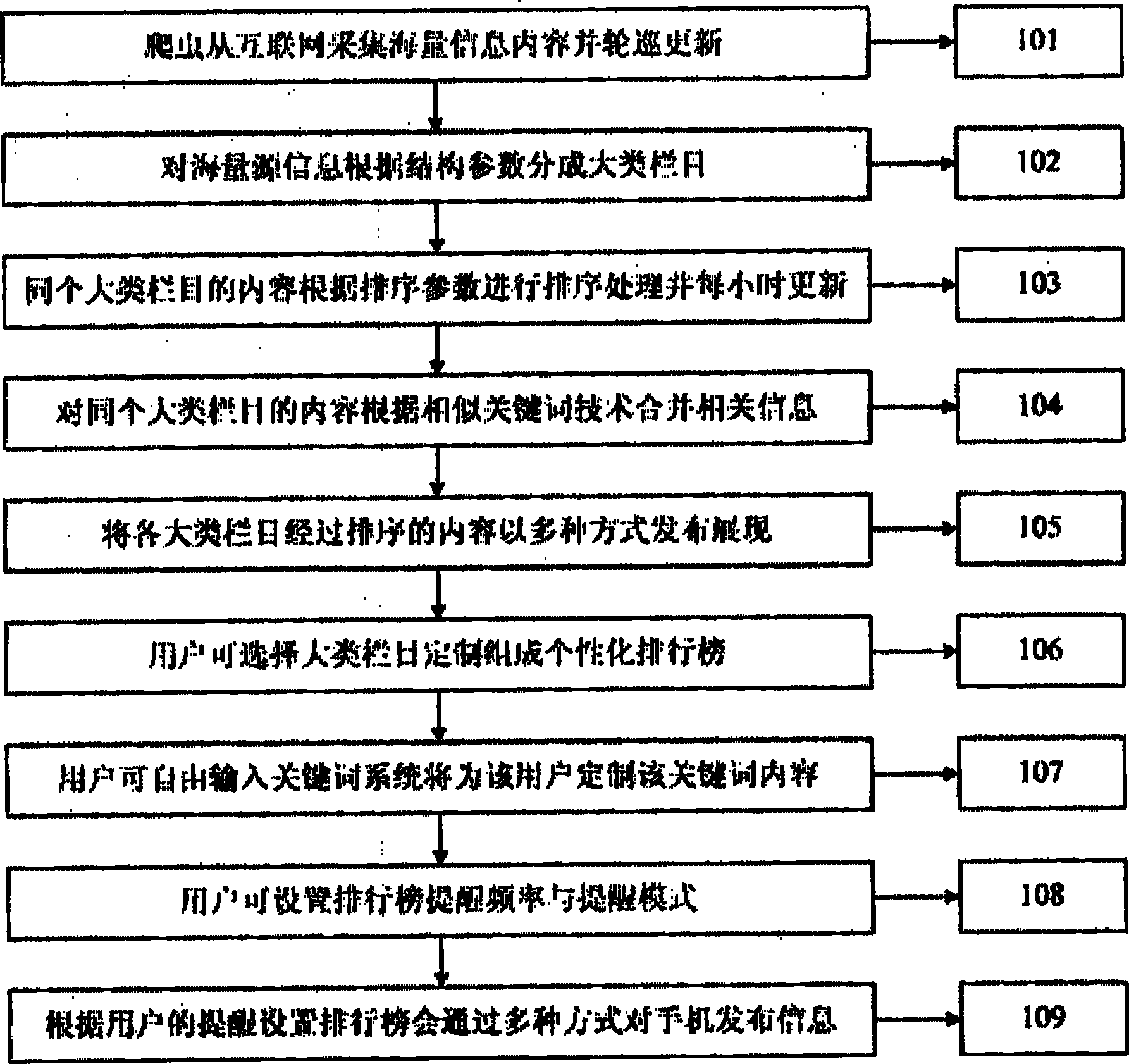

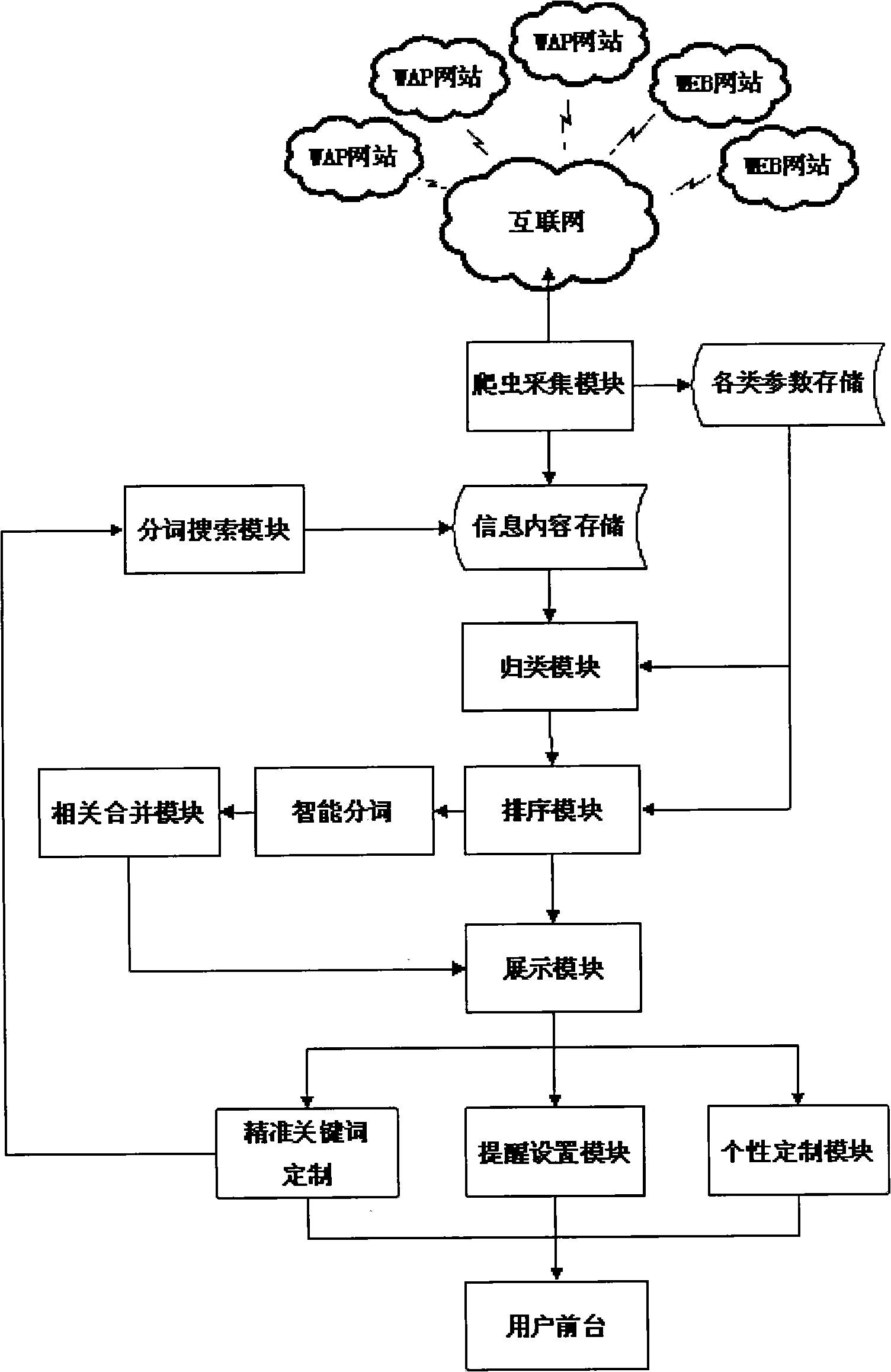

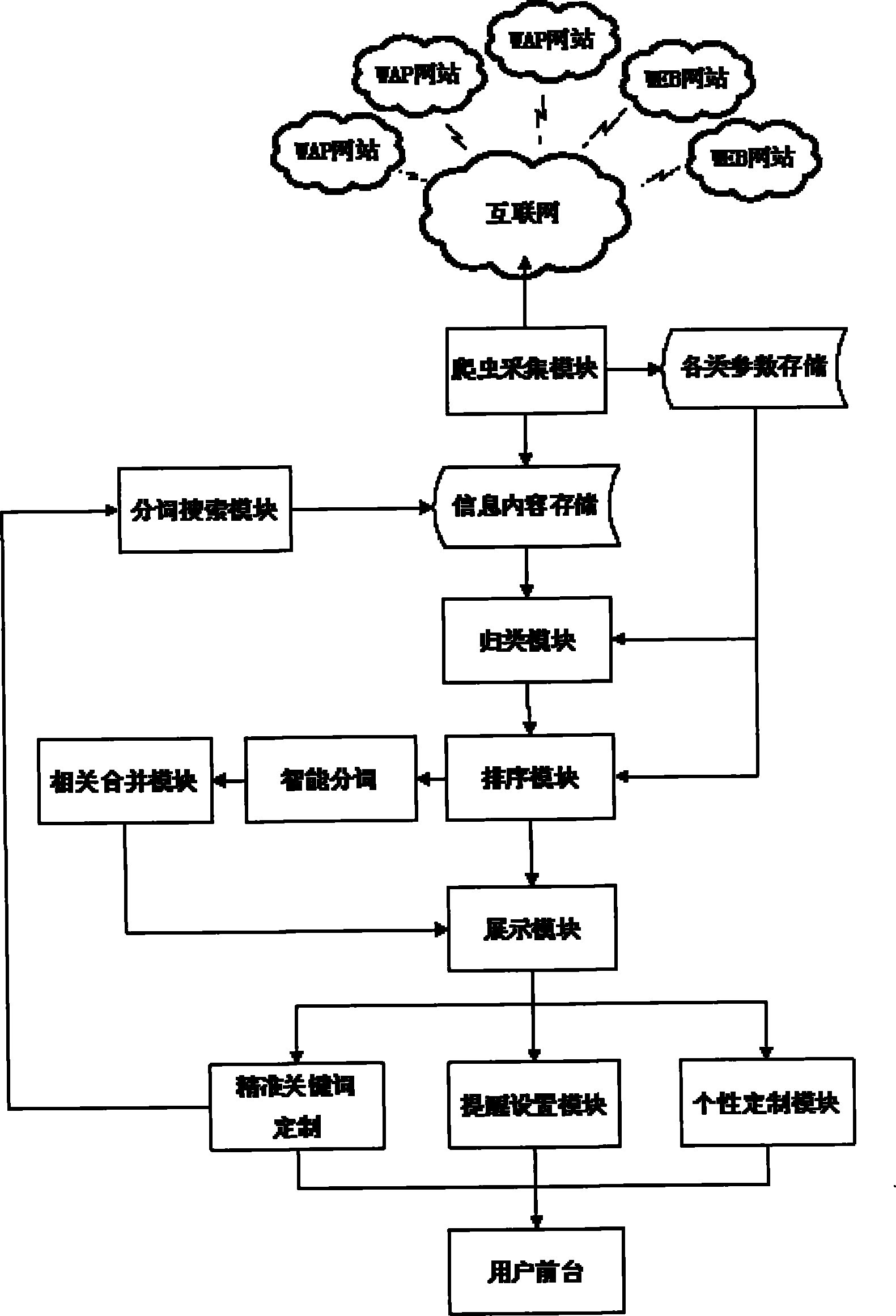

Content-aggregated wireless issuing system

InactiveCN101917456ARealize acquisitionReasonable integrationWireless network protocolsMessaging/mailboxes/announcementsPersonalizationInformation repository

The invention relates to a content-aggregated wireless issuing system. On the basis of a wireless communication network, the invention realizes magnanimous information acquisition, reasonable information integration, objective scientific sorting, personalized information exhibition and personal accurate customization, timely reminding and an issuing mode more according with a mobile phone terminal. By using the invention, a user cannot be puzzled in a magnanimous information base and can acquire the information without disperse websites; all information contents are aggregated by using a unique algorithm and is optimally-reasonably sorted and classified; the user can establish own unique information exhibition interface, only displays the contents interested per se and can customize the specific content information aiming at a certain key word; and the user do need to continuously refresh webpages for a curiously-knowing message because the system can inform the updated messages of the user by using wireless modes of the mobile phone such as MMS (Multimedia Messaging Service), WAP (Wireless Application Protocol), PUSH and SMS (Short Messaging Service) or a client and the like.

Owner:杭州热点科技有限公司

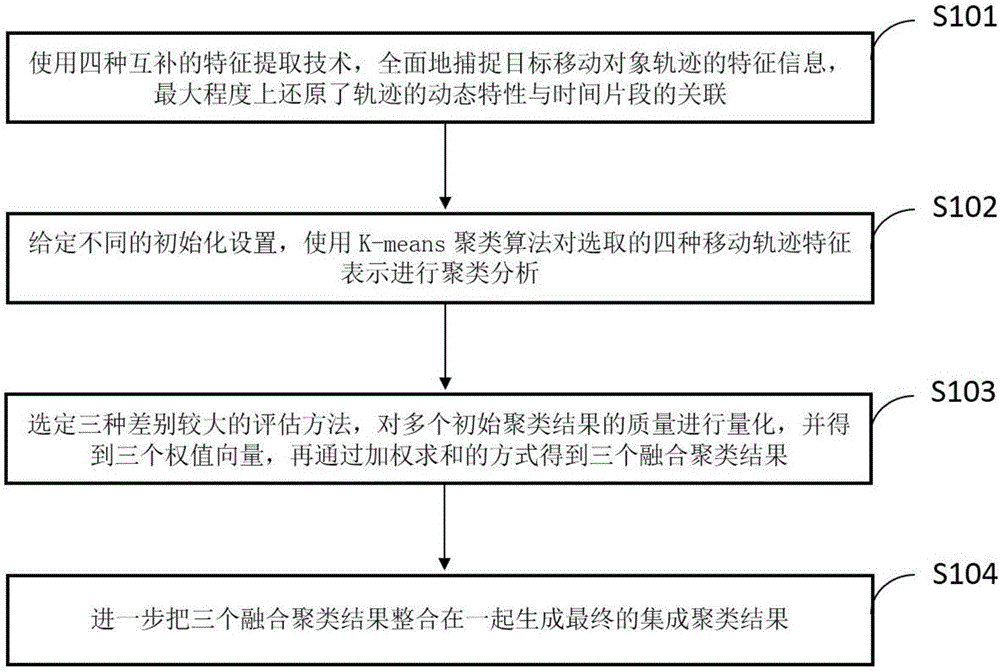

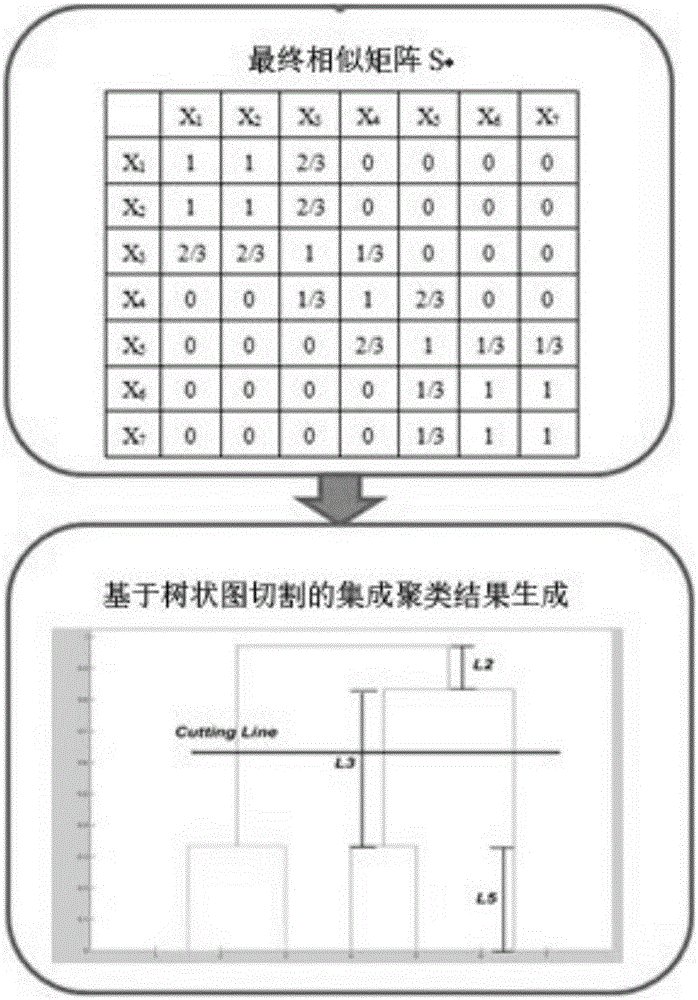

Moving object track clustering method based on multi-feature fusion and clustering ensemble

InactiveCN105843919AImprove generalization abilityImprove stabilityCharacter and pattern recognitionSpecial data processing applicationsQuality assessmentMulti feature

The invention discloses a moving object track clustering method based on multi-feature fusion and clustering ensemble. The method comprises the steps of firstly roundly capturing the feature information of the track of a target moving object; then performing clustering analysis on four selected moving track features and generating a plurality of primary clustering results by using a K-means clustering algorithm; quantizing the quality of the plurality of primary clustering results, and then obtaining three fusion clustering result by means of weighted summation; and further integrating the three fusion clustering results to generate a final integration clustering result. According to the method, the feature information of the target moving object can be comprehensively captured, relevance between the dynamic characteristic of the track and time slice can be restored to the utmost extent, and the good antijamming capability is provided; weights are distributed to the plurality of primary clustering results according to different clustering quality assessment criteria, the class number can be automatically recognized during the fusion process, and the intrinsic structure of the class cluster can be effectively captured.

Owner:YUNNAN UNIV

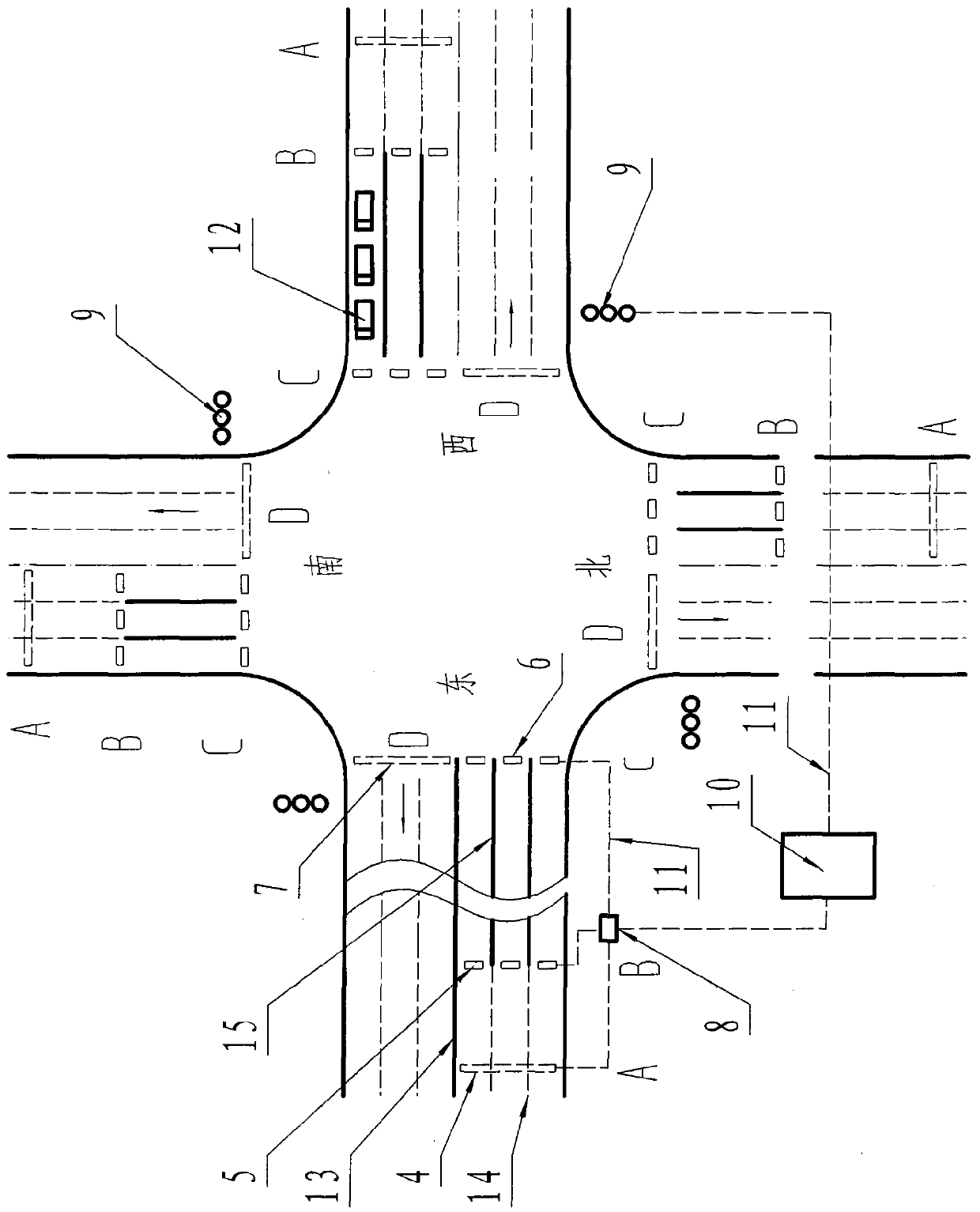

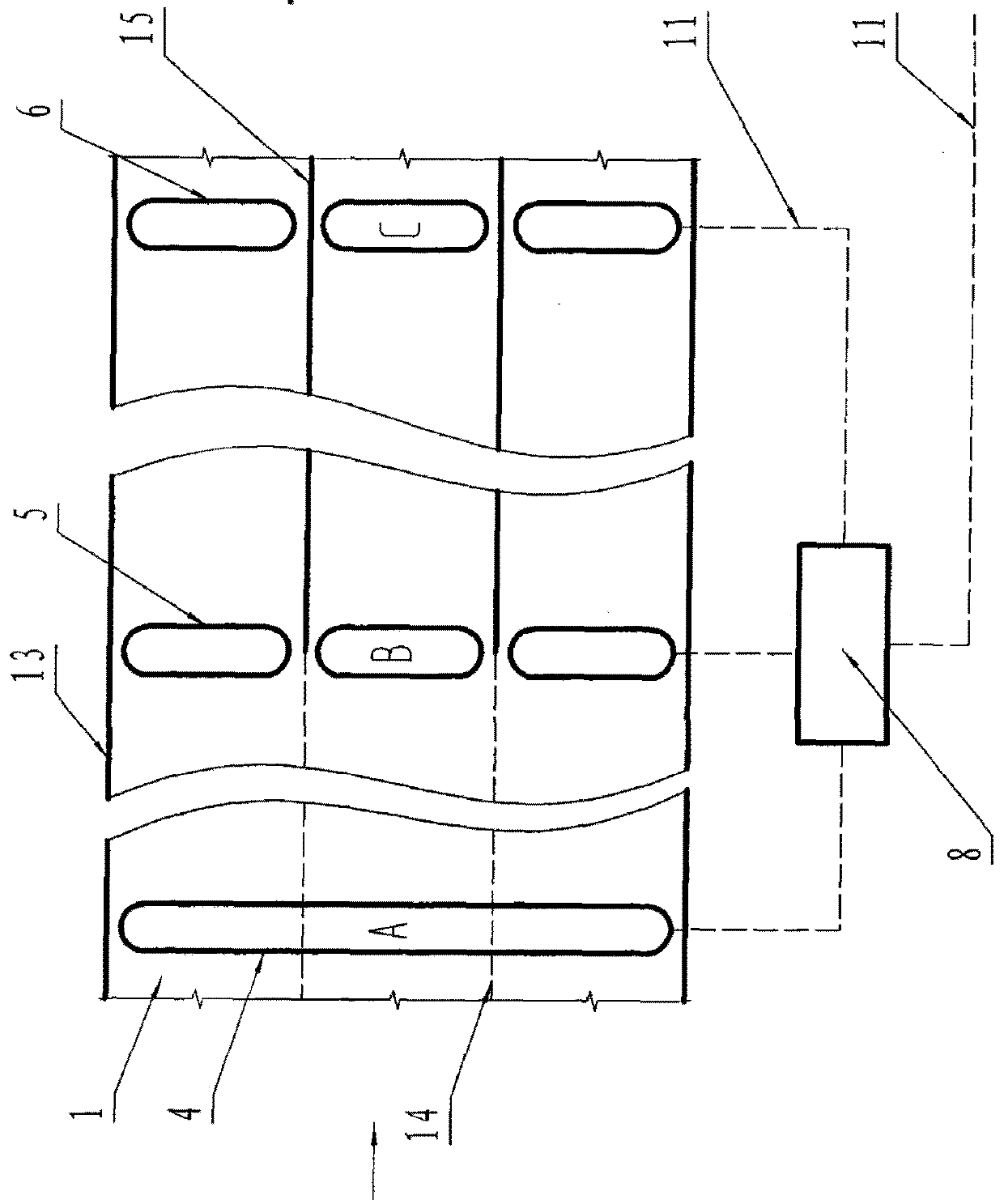

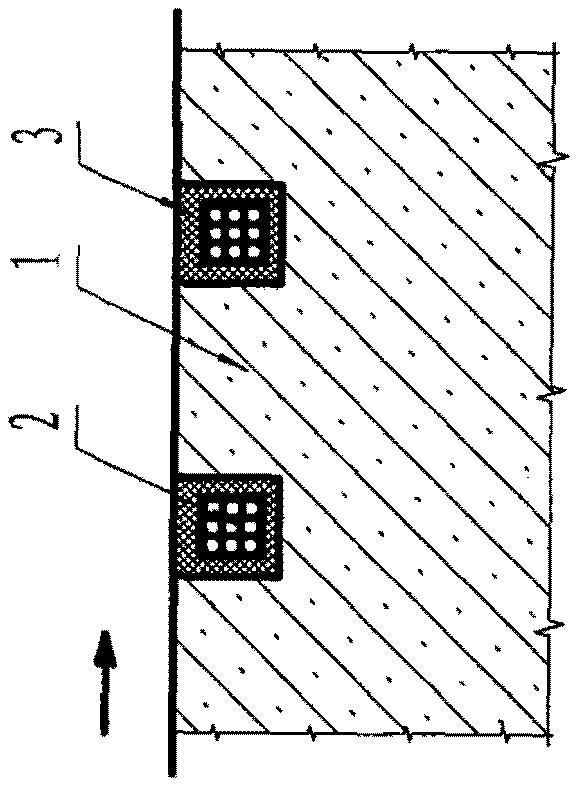

Real-time distribution control method of road traffic signal lamp

InactiveCN102194324AIncrease profitReasonable integrationControlling traffic signalsTraffic signalDistribution control

The invention relates to a real-time distribution control method of a road traffic signal lamp, electromagnetic induction signals are utilized for identifying traffic flow, real-time reasonable distribution of road resources is performed according to the traffic flow so as to achieve the purpose of realizing intelligent control of the traffic signal lamp (namely, green ratio), and the real-time distribution control method is applied in the field of management of transportation technologies of public roads and urban roads. By adopting the real-time distribution control method, the road resources and vehicle resources can be reasonably integrated, driving is safer, more convenient, fast and smooth, the labor intensity of polices and transportation management staff is effectively reduced, the waste of energy of vehicles is simultaneously reduced, and the utilization rate of the road resources and the vehicle resources is improved.

Owner:黄光佗

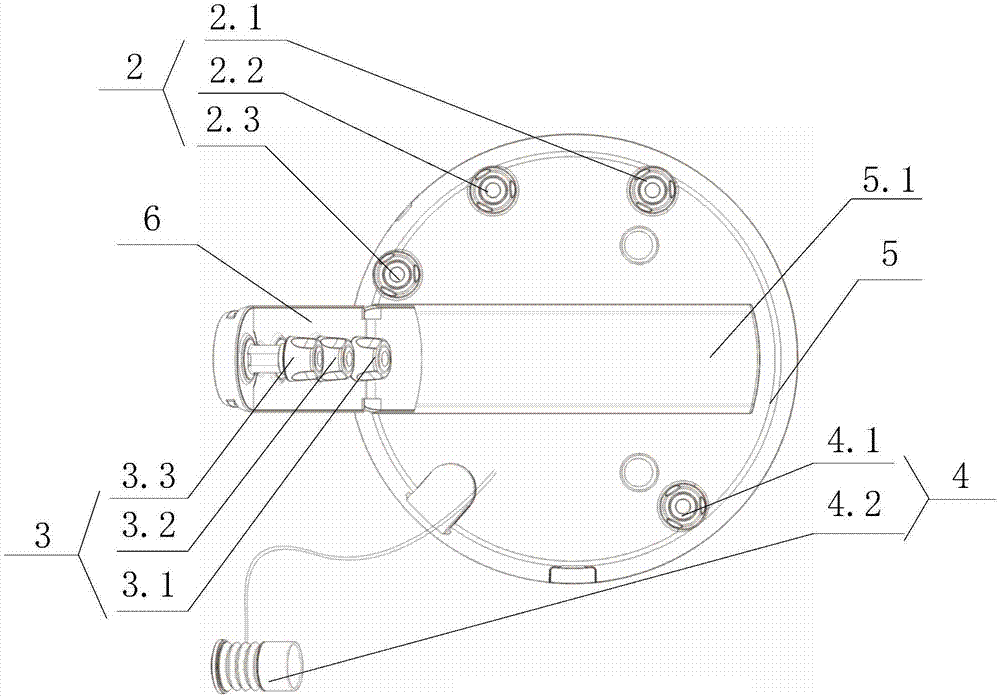

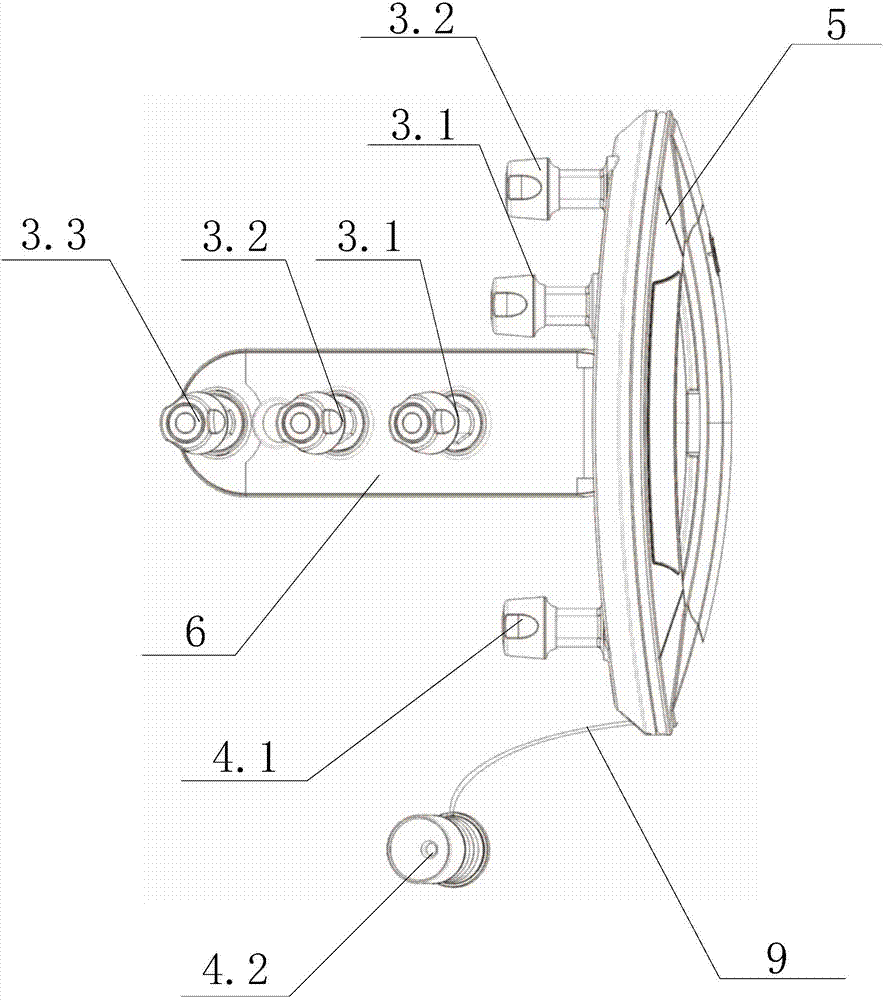

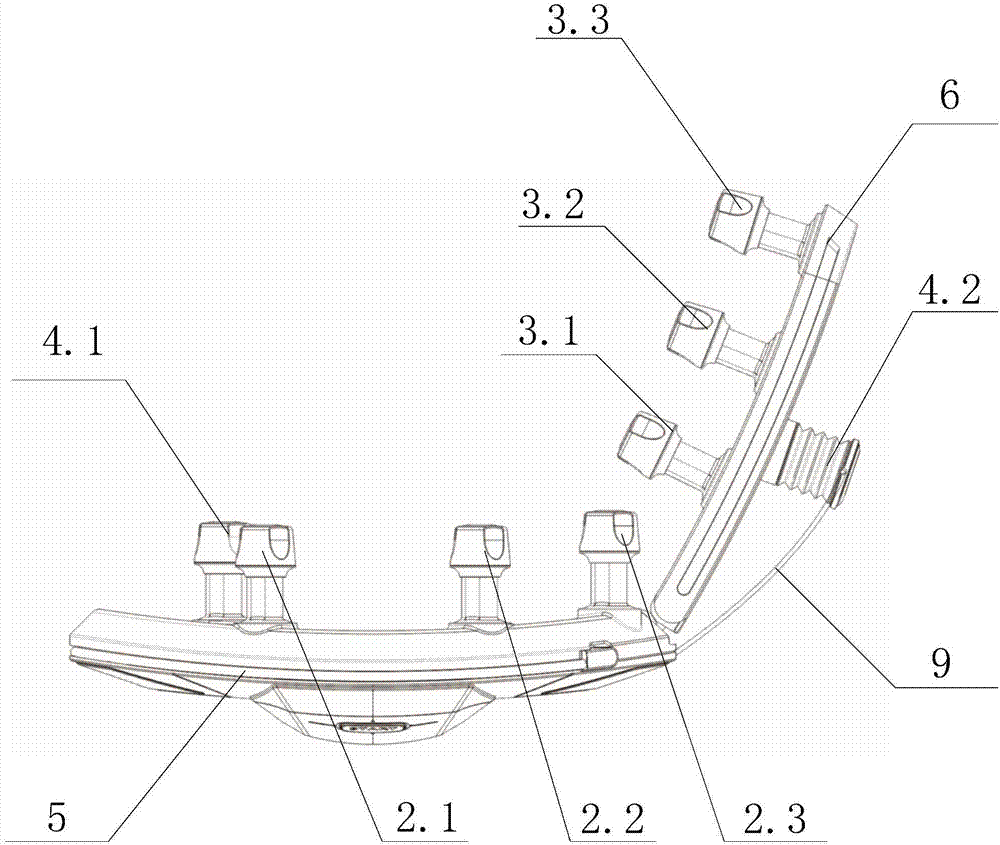

Handheld electrocardiograph detection device and electrocardiograph detection system comprising same

ActiveCN107260160AEfficient storageQuick storageEvaluation of blood vesselsSensorsEcg signalHand held

The invention relates to the technical field of a medical appliance, in particular to a handheld electrocardiograph detection device and an electrocardiograph detection system comprising the same. The handheld electrocardiograph detection device comprises a casing, a circuit board and an electrode, wherein the circuit board is connected in the casing; the electrode is connected onto the casing; the electrode and the circuit board are connected; the electrode comprises an upper limb lead electrode, a chest lead electrode, a left rib lead electrode and a lower limb lead electrode; the casing comprises a first electrode fixing element and a second electrode fixing element; the chest lead electrode and the lower limb lead electrode are connected at one side, facing the human body, of the first electrode fixing element; the left rib lead electrode is connected at one side, facing the human body, of the second electrode fixing element; and an accommodating groove is formed in one side, facing the human body, of the first electrode fixing element. The invention provides the handheld electrocardiograph detection device and the electrocardiograph detection system comprising the handheld electrocardiograph detection device. The appearance is small and ingenious; convenience and high speed are realized; the use is more convenient; the electrocardiosignal collection is accurate; and the operation by a user is simple.

Owner:北京五维康科技有限公司

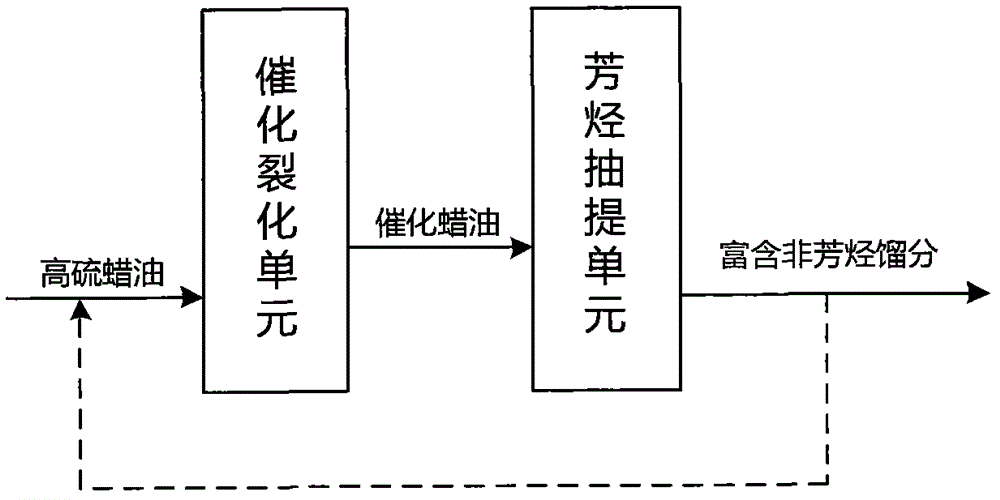

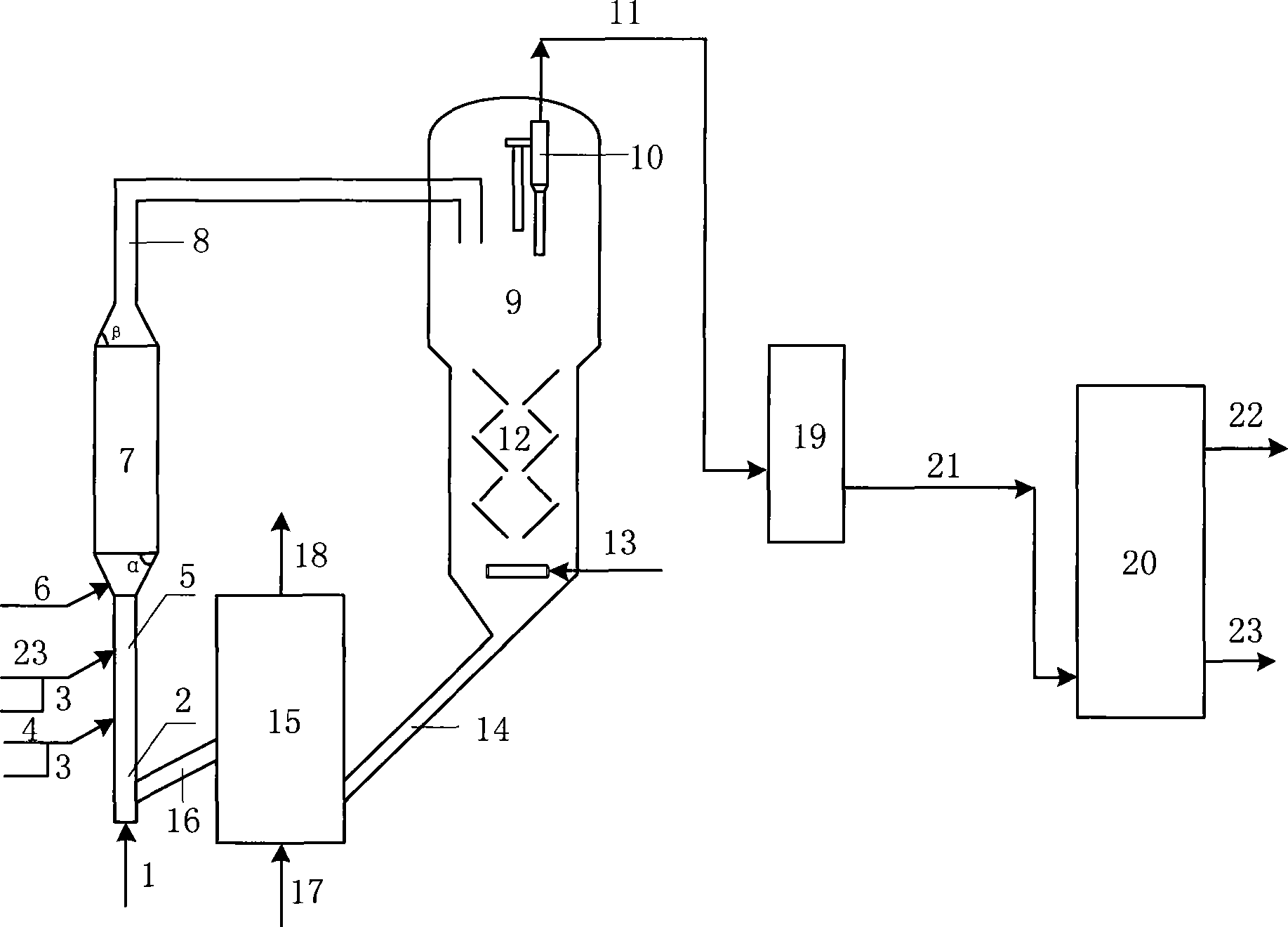

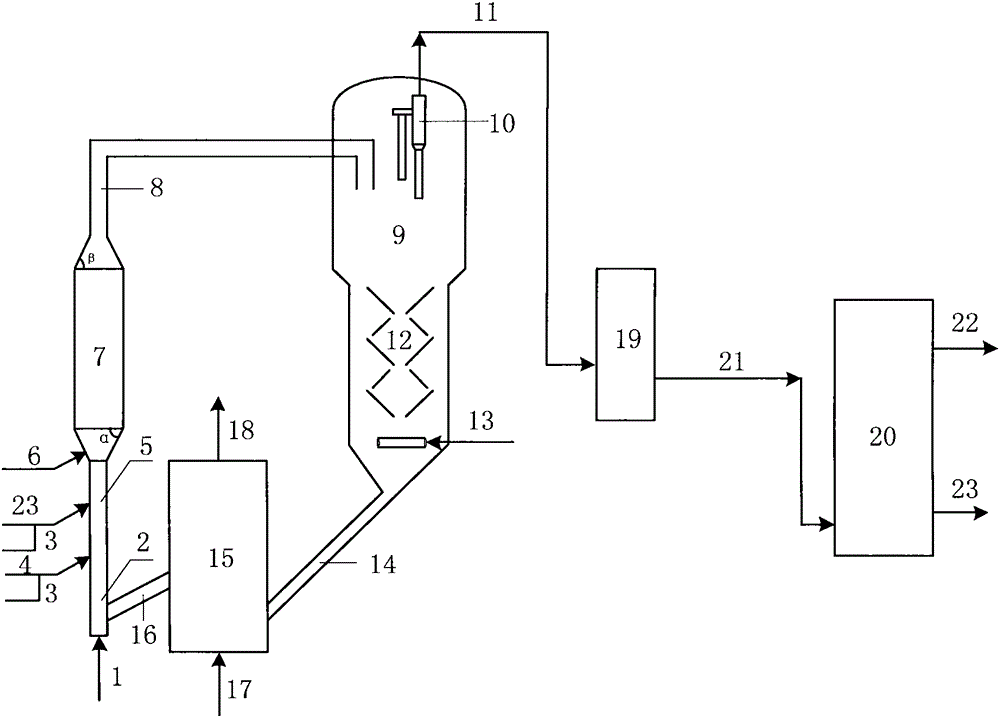

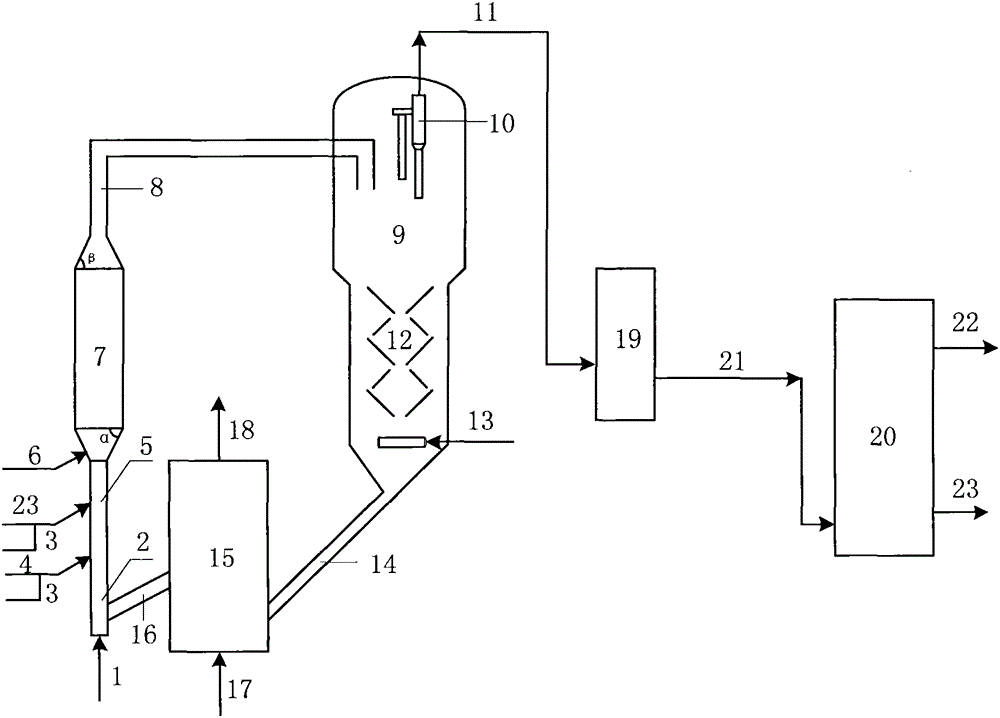

Method for highly efficient catalytic conversion of petroleum hydrocarbons

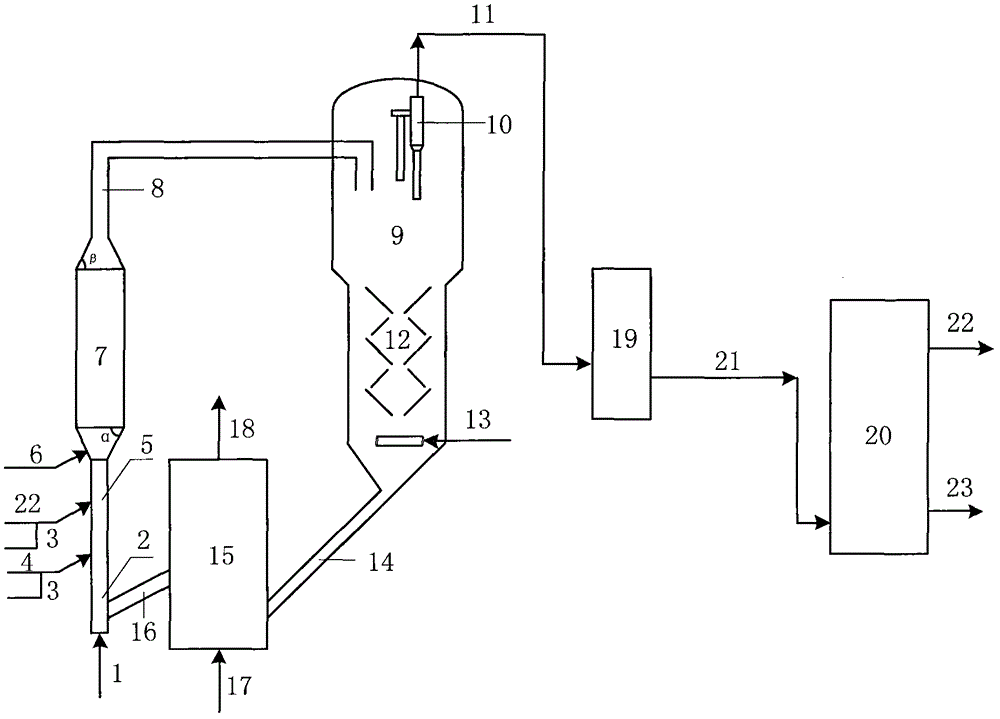

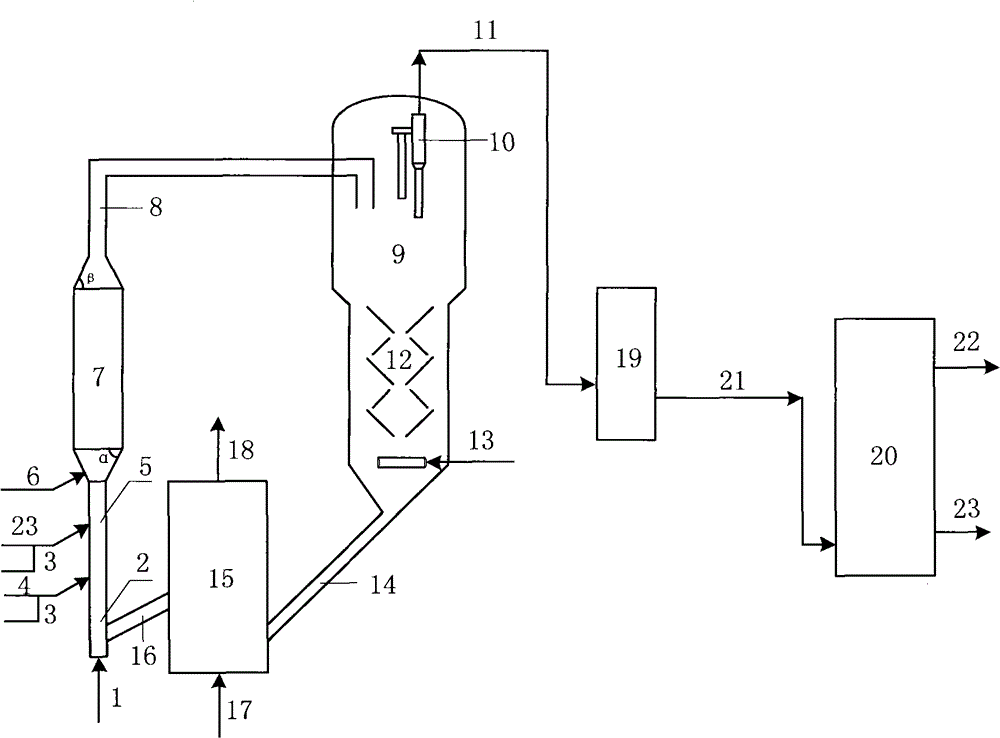

ActiveCN102796558AImprove use efficiencyReasonable integrationTreatment with plural serial stages onlyTreatment with hydrotreatment processesIsomerizationCracking reaction

The invention provides a method for highly efficient catalytic conversion of petroleum hydrocarbons. High-sulfur wax oil is contacted with a heat regenerated catalyst, which is low in equilibrium activity and relatively uniform in activity distribution, on the lower part of a catalytic cracking unit reactor for cracking reaction, the generated oil gas and a charcoal-containing catalyst ascend for selective hydrogen transfer reaction and isomerization reaction under a certain reactive environment, the reaction oil and gas are separated to obtain reaction products containing liquefied gas, gasoline and catalytic wax oil, and the spent catalyst is subjected to steam stripping and regeneration to be reused, wherein the catalytic wax oil and any processing wax oil enter an aromatic hydrocarbon separation unit to be subjected to aromatic hydrocarbon separation, and preferably the fractions richly containing the aromatic hydrocarbons are returned to a catalytic cracking unit. The method increases liquid yield and isobutene yield, improves the selectivity of propylene and provides a new path for ensuring a pollution-free oil refining process as well as pollution-free oil refining products.

Owner:CHINA PETROLEUM & CHEM CORP +1

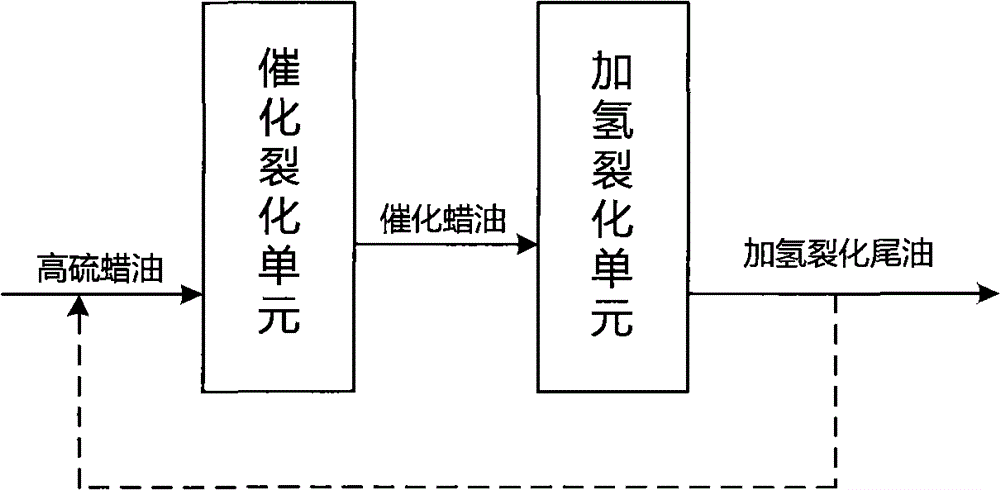

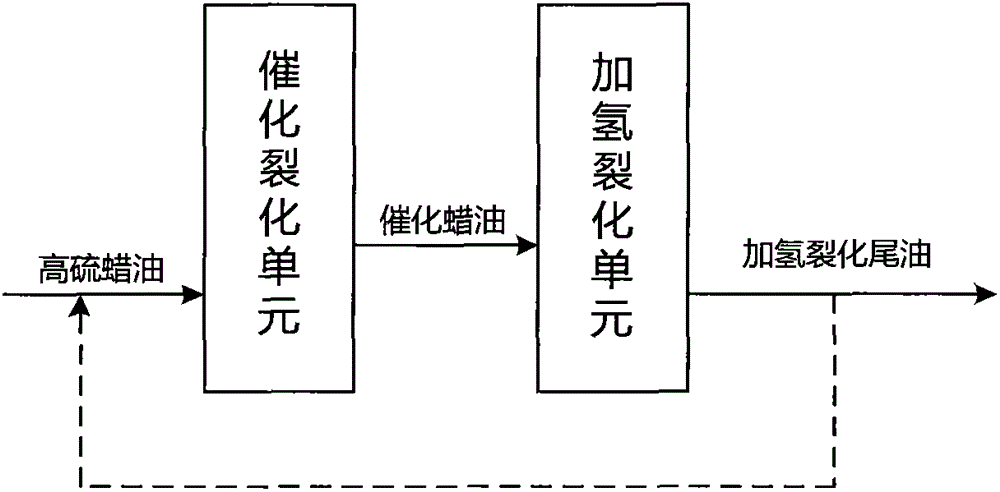

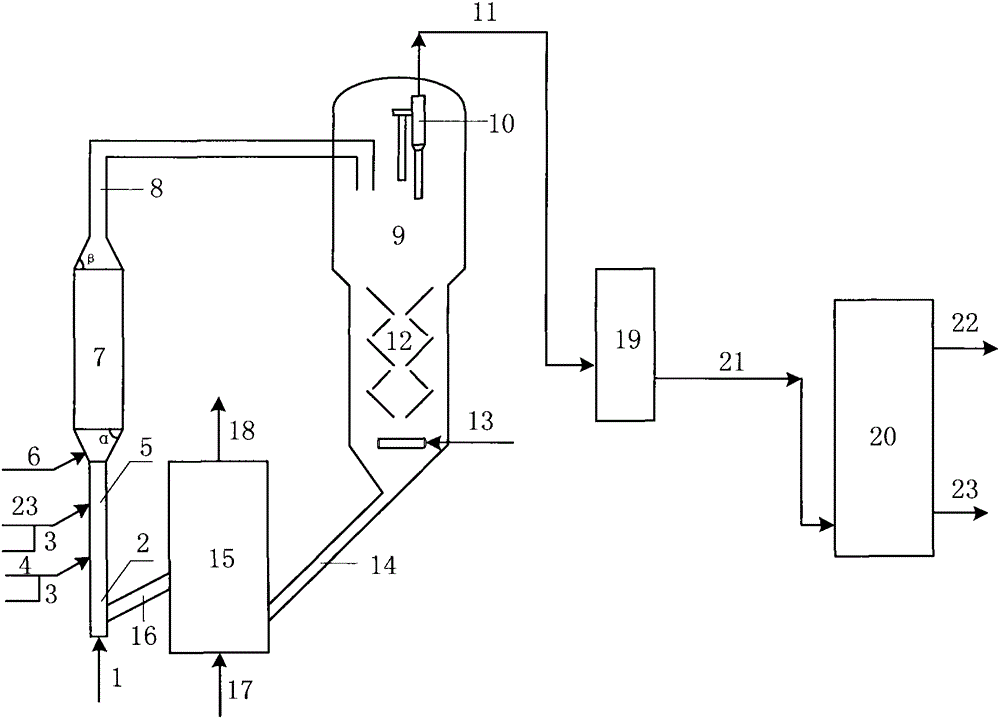

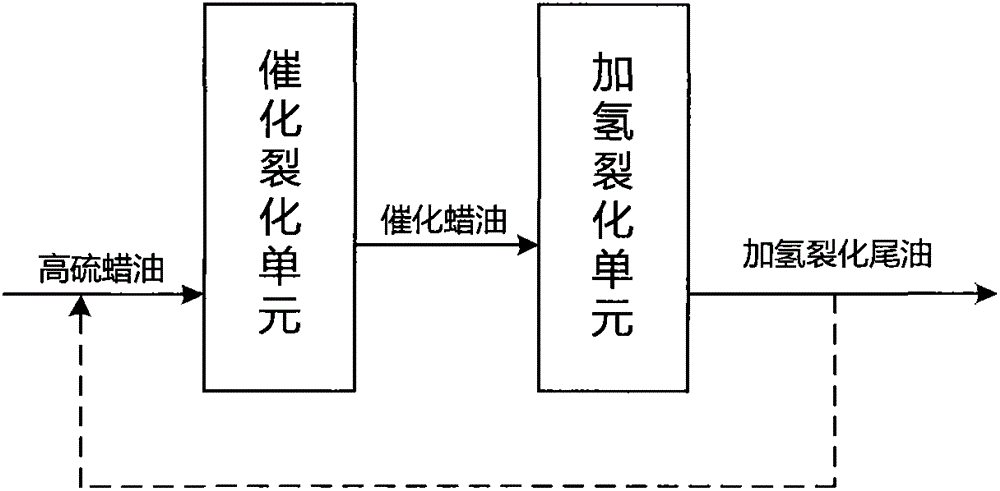

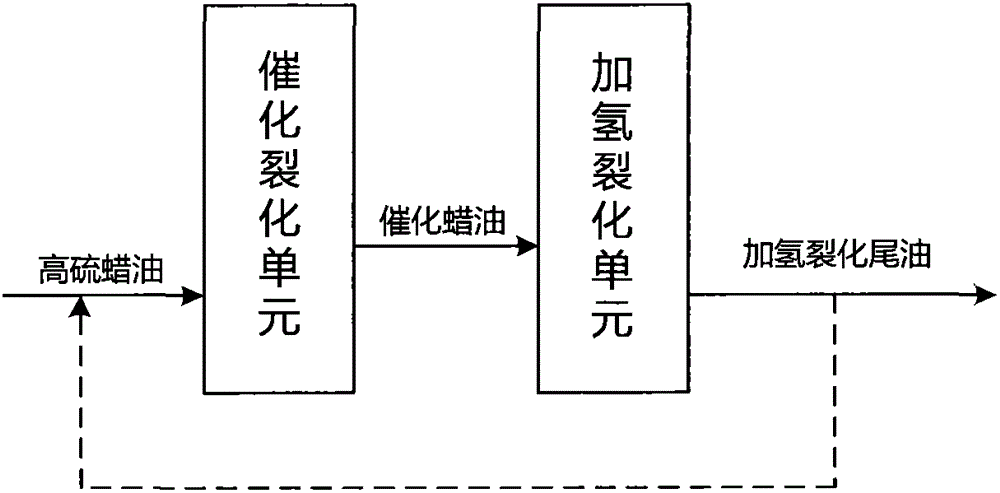

Efficient catalytic conversion method for petroleum hydrocarbon

ActiveCN103059990AImprove use efficiencyReasonable integrationTreatment with hydrotreatment processesIsomerizationLiquid gas

An efficient catalytic conversion method for petroleum hydrocarbon. High sulfur wax oil contacts with a zeolite-containing thermal regeneration catalyst with low balance activity and relatively uniform activity distribution at a lower part of a catalytic cracking unit reactor and generates a cracking reaction; the generated oil gas and a carbon-containing catalyst upstream generate a selective hydrogen transfer reaction and an isomerization reaction in a certain reaction environment; the reaction oil gas is separated to obtain reaction products containing liquefied gas, gasoline and catalytic wax oil; the spent catalyst is subjected to stripping and regeneration for recycling; the catalytic wax oil and an optional secondary processing wax oil enter into a hydrocracking unit for reaction; and preferably hydrocracking tail oil returns to the catalytic cracking unit. The method increases the yield and cetane number of diesel, and increases utilization ratio of hydrogen in the raw material, so as to save oil resource and provide a novel path for clean of a refining production process and refining products.

Owner:CHINA PETROLEUM & CHEM CORP +1

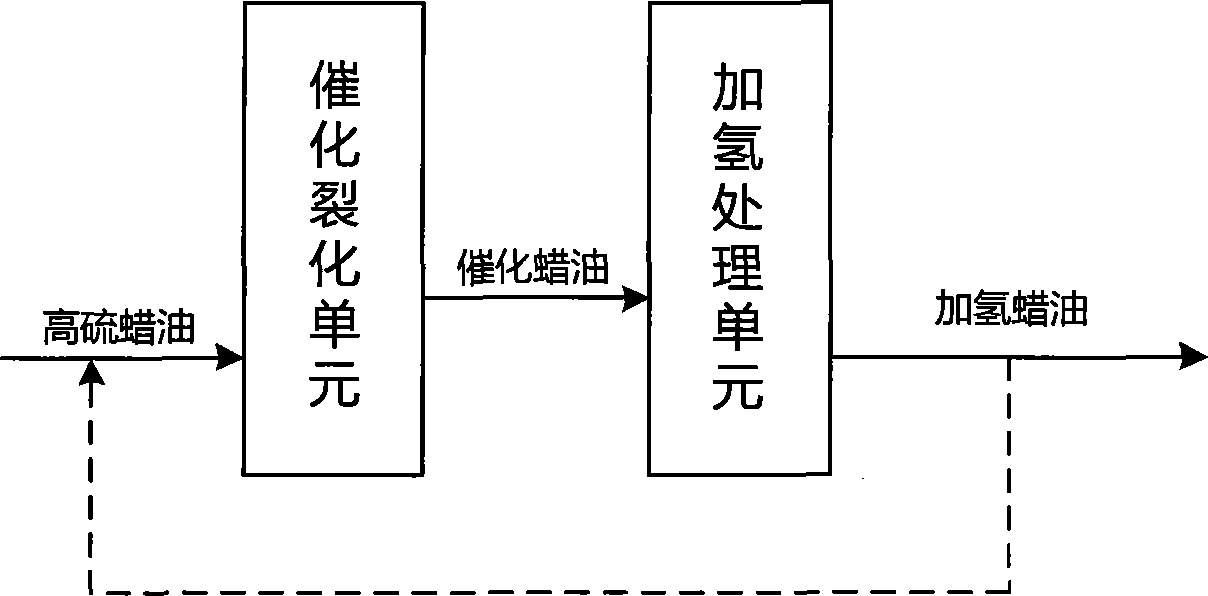

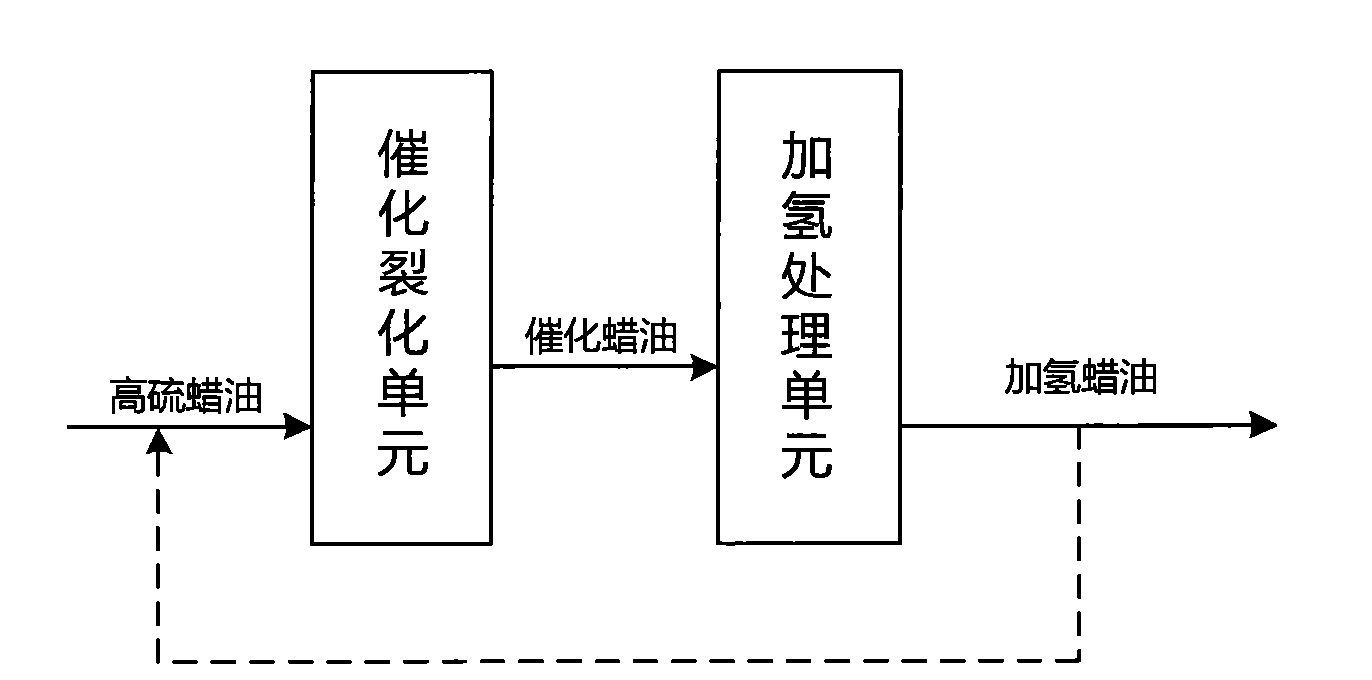

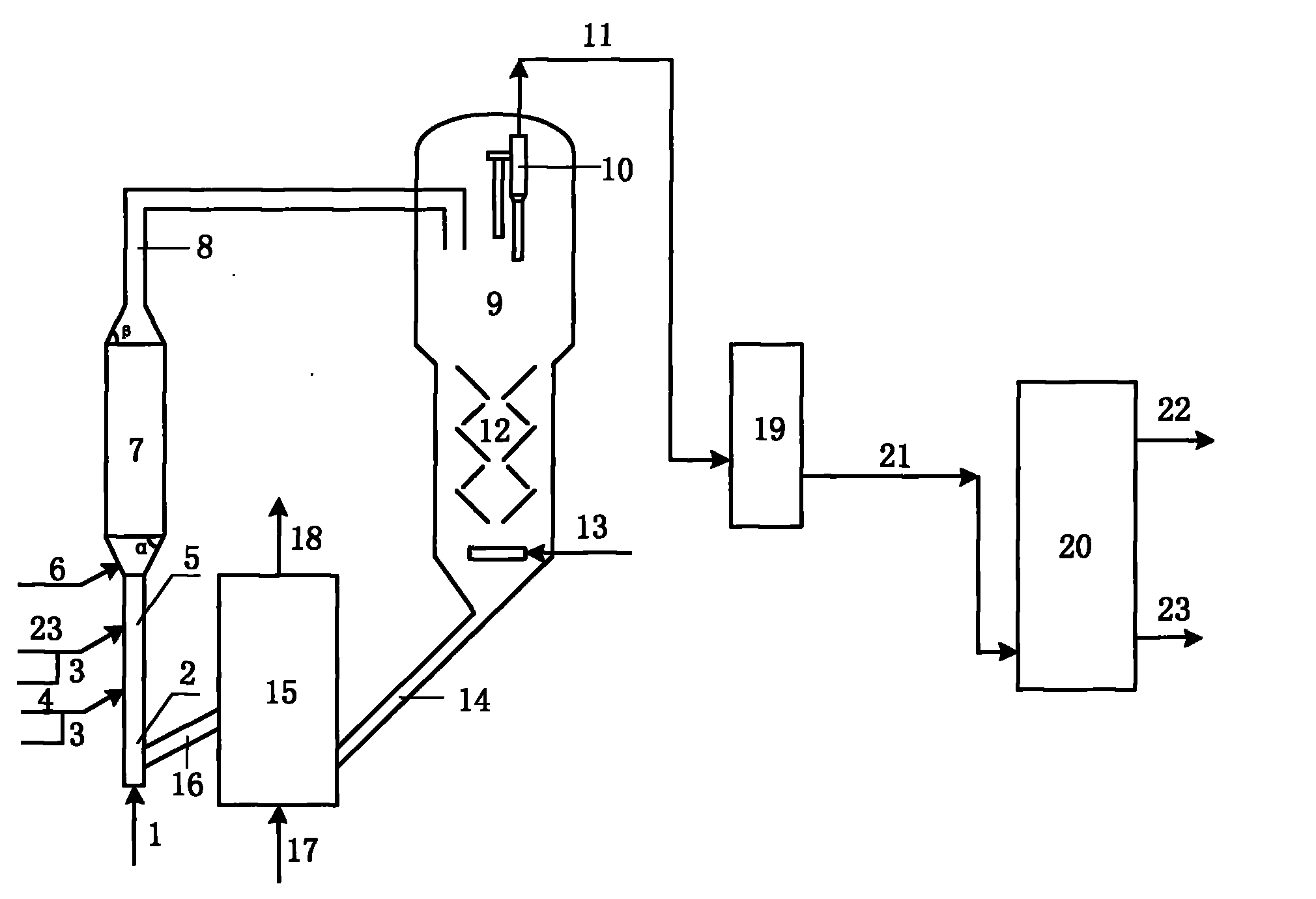

Catalytic conversion method of petroleum hydrocarbon

ActiveCN102719272AImprove use efficiencyReasonable integrationTreatment with hydrotreatment processesIsomerizationLiquid gas

The invention discloses a catalytic conversion method of petroleum hydrocarbon, characterized by contacting high-sulfur wax oil with a heat regeneration catalyst at the lower portion of a catalytic cracking unit reactor and conducting cracking reaction, letting the generated oil gas and carbon-containing catalyst upstream be subject to selective hydrogen transfer reaction and isomerization reaction under certain reaction environment, separating the reaction oil gas to obtain a reaction product containing liquefied gas, gasoline and catalytic wax oil, and letting the spent catalyst be recycled after stripping and regeneration, wherein the catalytic wax oil and optional other secondary processing wax oil enters into the hydrotreatment unit to conduct polycyclic aromatic hydrocarbons selective hydrogenation, preferably the hydrogenation wax oil returns to the catalytic cracking unit. According to the invention, the gasoline yield and propylene yield are raised, the utilization rate of hydrogen in the raw materials is raised, and simultaneously the utilization rate of hydrogen in hydrotreatment is raised, thus the petroleum resource can be saved, and the invention provides a new approach for cleaning the refining process and refined oil products.

Owner:CHINA PETROLEUM & CHEM CORP +1

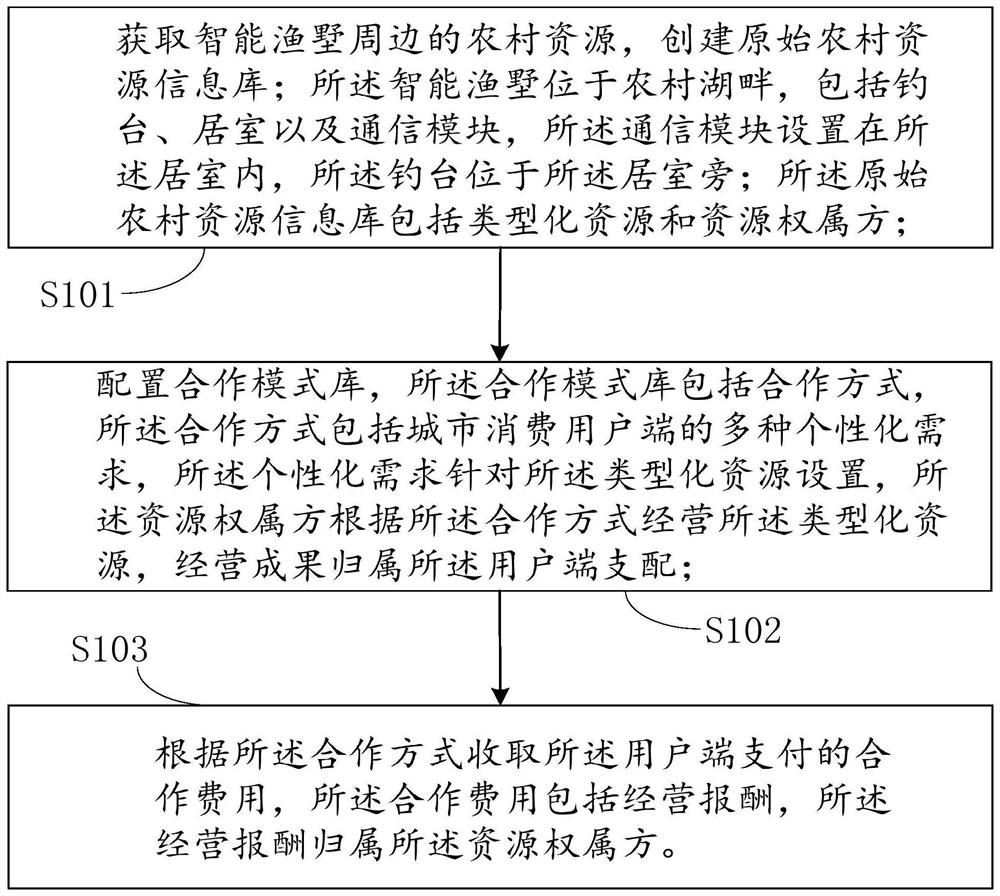

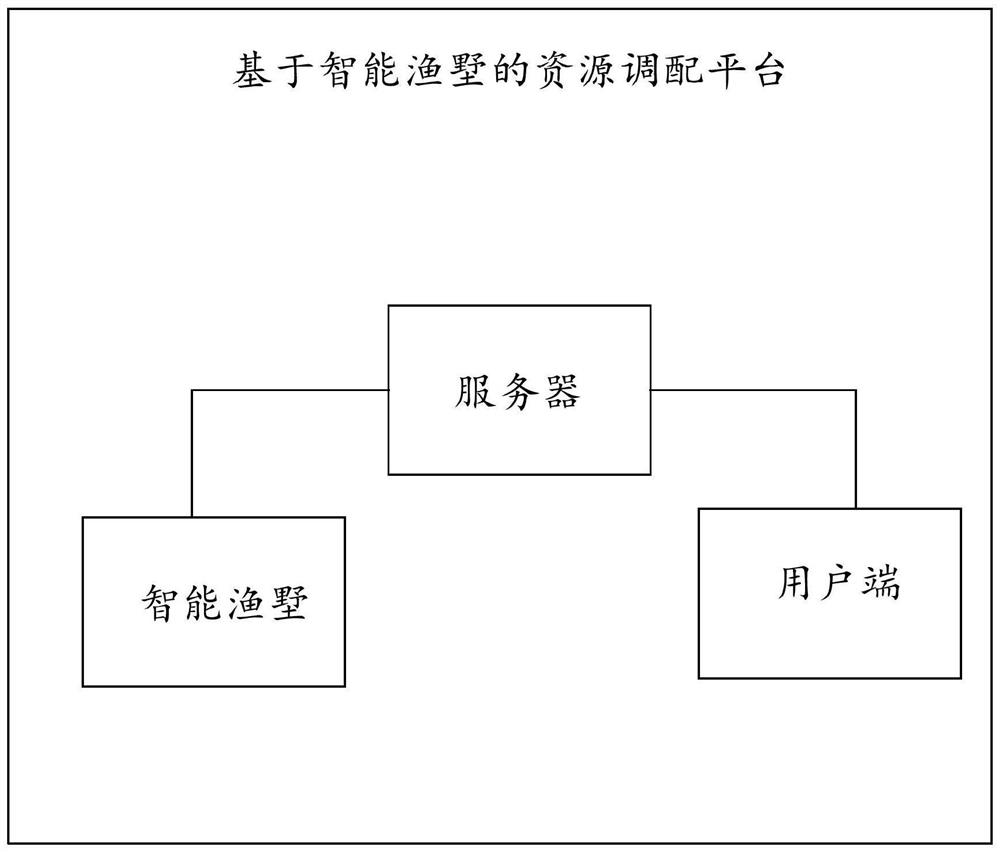

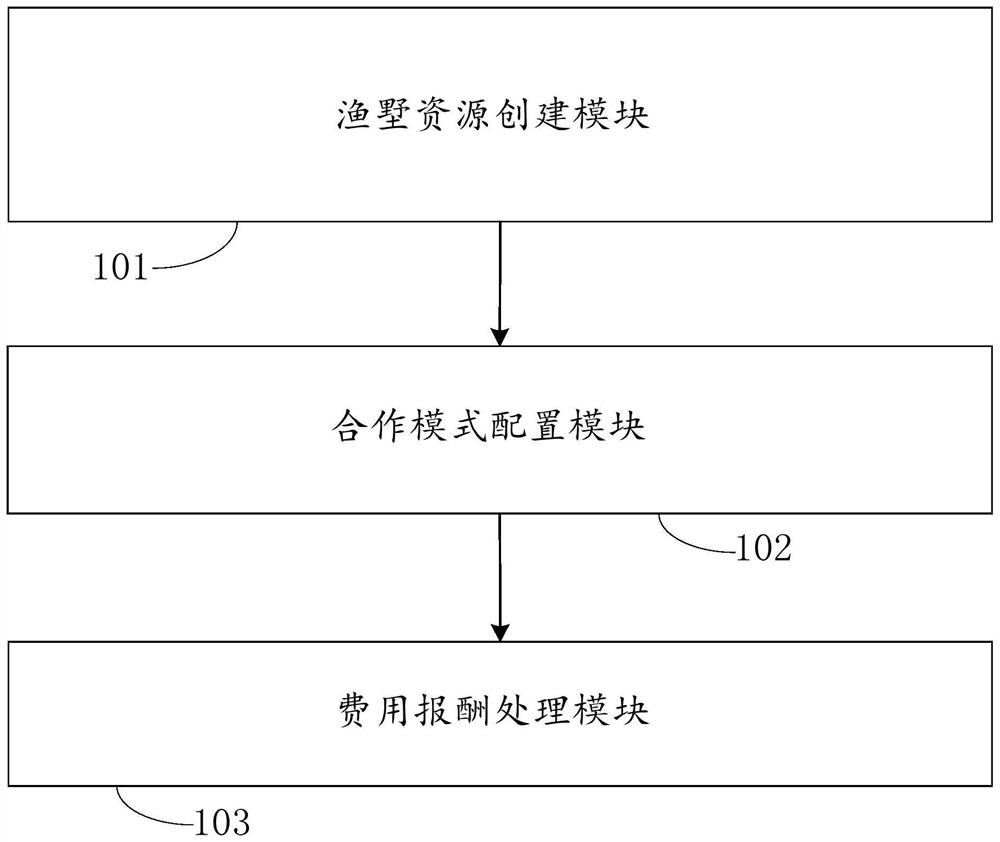

Resource allocation method and platform based on intelligent fishing villa

PendingCN114862138ARealize information sharingEfficient and precise dockingResourcesTotal factory controlPersonalizationEnvironmental geology

The invention belongs to the technical field of Internet of Things, and provides a resource allocation method and platform based on an intelligent fishing villa, which provides a plurality of personalized cooperation demands to cooperate with a resource ownership party of rural resources, so that the resource ownership party operates the rural resources according to the demands of a cooperation user side, controls an operation achievement affiliation user side and operates a reward affiliation resource ownership party. Therefore, rural resource information is accurately and efficiently mastered at the urban consumption user side, the management result is enjoyed, and consumption-to-production and consumption-to-investment are realized; the rural resource ownership party is changed from a producer to a server, works according to the demand of the urban consumption user, enjoys the cooperation cost, and achieves the effects of activating the rural resources and revitalizing the villages. In addition, the intelligent fishing villa is leisure, safe, environment-friendly and comfortable in fishing, and effective integration of rural water resources, other rural resources and urban tourism consumption resources is achieved.

Owner:深圳市聪明鱼智能科技股份有限公司

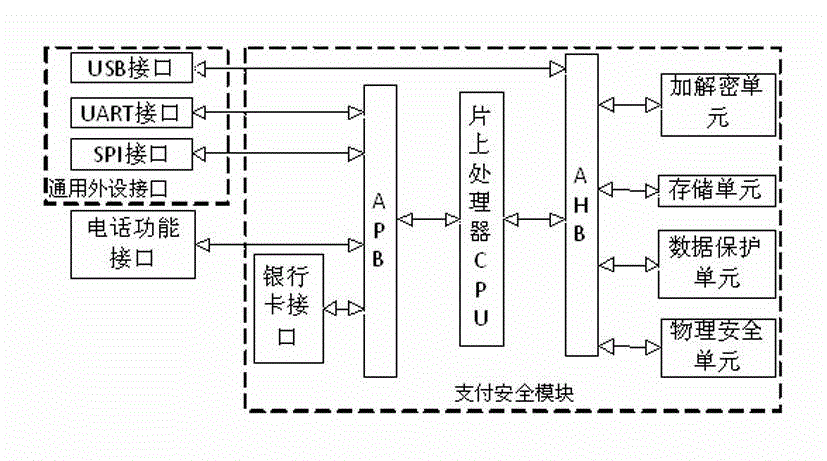

Security chip of telephone POS (point of sale)

The invention relates to a security chip of a telephone POS (point of sale). The security chip mainly comprises a payment security module, a telephone function interface and a universal peripheral interface, wherein the payment security module comprises an on-chip CPU (central processing unit). An AHB (advanced high-performance bus) connected with the CPU is used for extending a device with a high-speed bus. An APB (advanced peripheral bus) connected with the CPU is used for extending a low-speed peripheral. An encryption and decryption unit connected with the AHB is used for encryption and decryption computing. A storage unit is connected with the AHB. A data protection unit connected with the AHB is used for storing information of security data under protection. A physical security unit connected with the AHB is used for defending various physical attacks. A bank card interface connected with the APB is used for supporting reading of back card data. The universal peripheral interface connected with the AHB or the APB is used for connecting a universal peripheral. The telephone function interface connected with the APB is used for supporting related functions of telephone payment. Payment security and telephone functions are integrated to provide a solution to a single chip of the telephone POS, which supports the payment security, and the security chip is highly safe, highly integrated, low in power consumption and cost and the like.

Owner:福建睿矽微电子科技有限公司

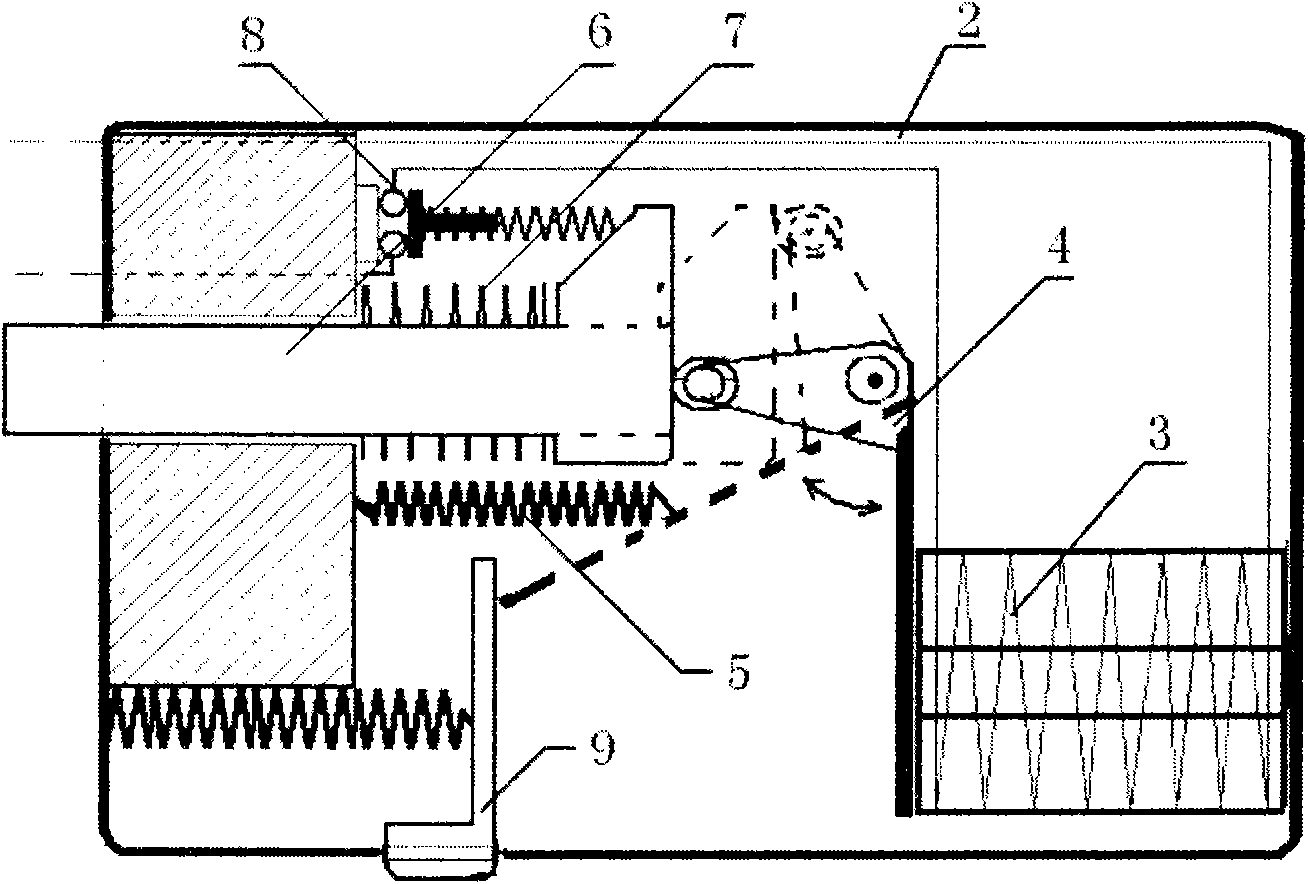

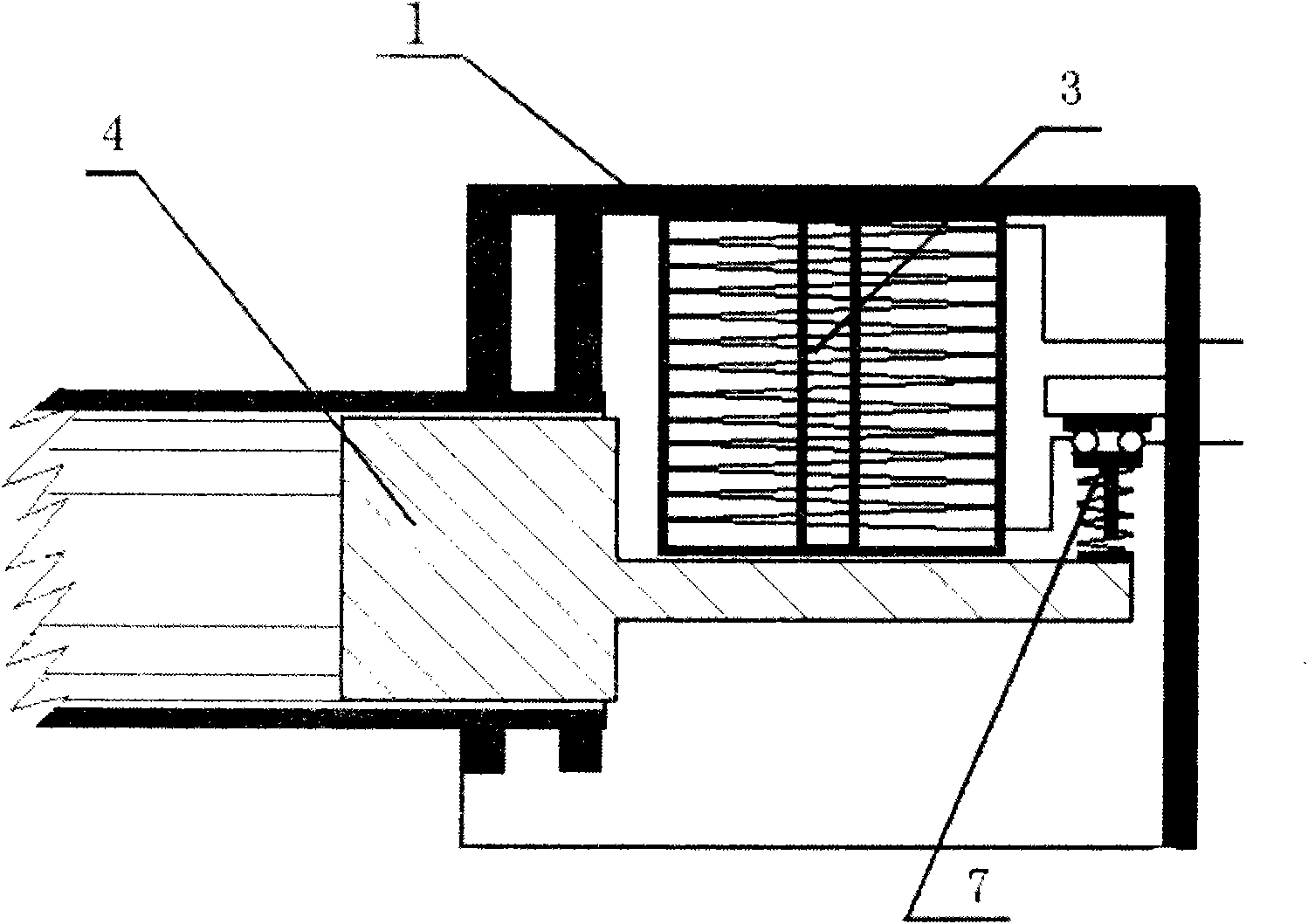

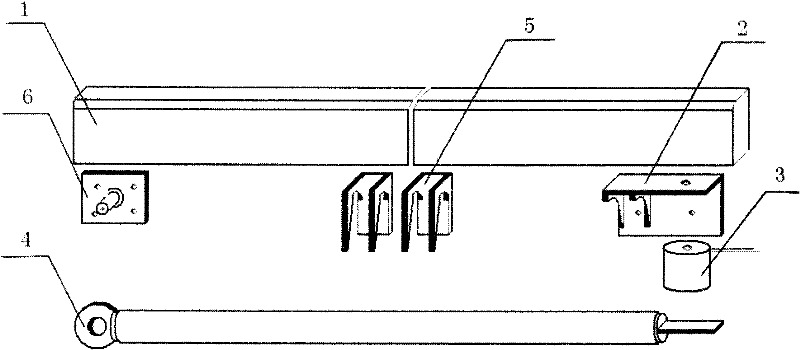

Escape door lock

InactiveCN101881107AGuaranteed anti-theft safetyStrong reliabilityNon-mechanical controlsEngineeringTouch switch

The invention provides an escape door lock which comprises a lock shell, a shell cover, a lock head outlet, a lock head, a lock head groove, an electromagnet, a touch switch, a lock machine, a shifting block, a suction plate return spring, a shifting block return spring and a lock head return spring, wherein the lock head comprises a lock head rod and a pushing block; the lock machine comprises a pushing arm and an electromagnet suction plate; the shifting block comprises a trough body and a shifting plate; the touch switch is arranged corresponding to the pushing block, the touch switch is connected with the electromagnet, and the pushing arm is hinged with the inner wall of the lock shell; a shifting notch is formed on the lock shell, and the trough body is arranged in the shifting notch; the suction plate return spring is connected between the lock shell and the electromagnet suction plate; the shifting block return spring is connected between the lock shell and the shifting plate; the lock head return spring is sleeved on the lock head rod and is propped between the lock shell and the pushing block; and the electromagnet suction plate is arranged corresponding to the shifting plate, the electromagnet suction plate is arranged corresponding to the electromagnet, and the pushing arm is pushed on the pushing block. The door lock has the advantages of convenient use, firm locking, safety and reliability and is convenient for opening a door.

Owner:马刘陈

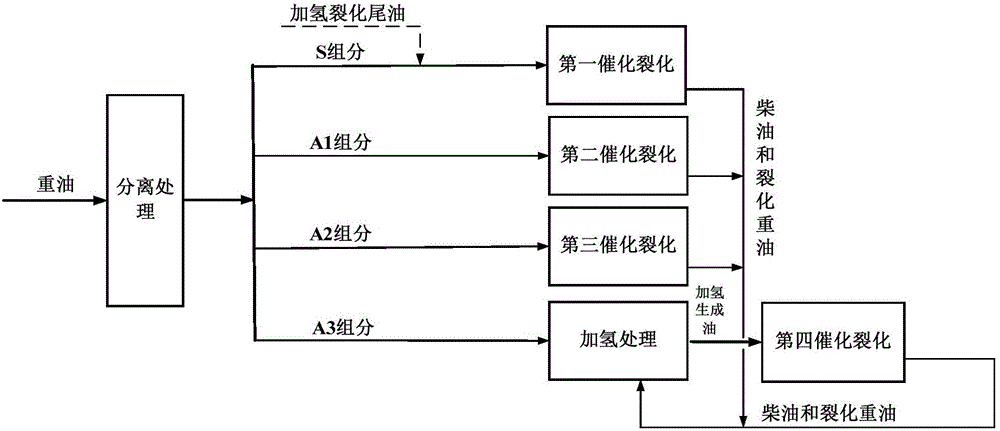

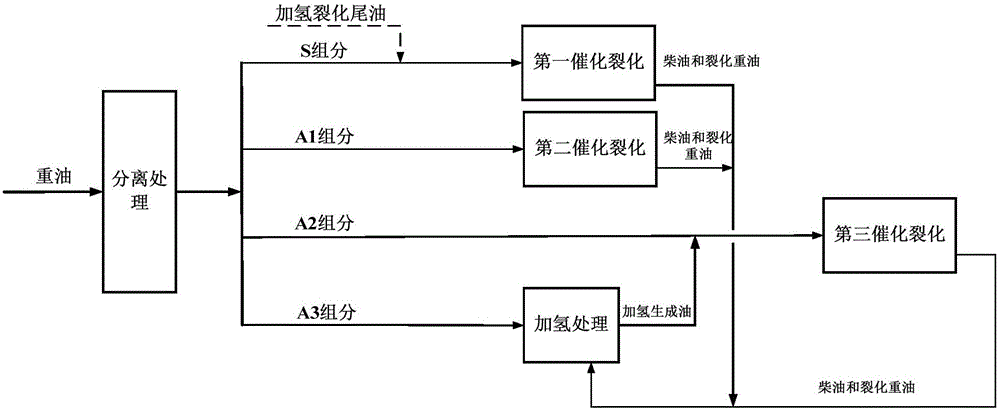

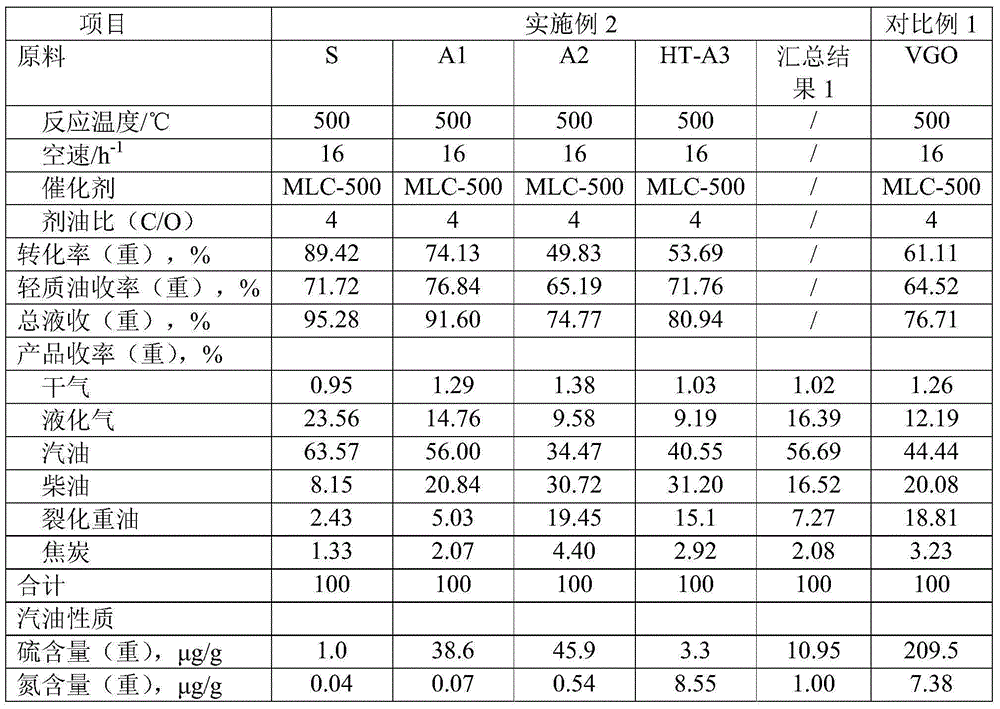

Heavy oil separation-hydrotreatment-catalytic cracking combined method

ActiveCN106467757AEliminate interactionIncrease profitTreatment with hydrotreatment processesSulfurNitrogen

The invention discloses a heavy oil separation-hydrotreatment-catalytic cracking combined method. the method comprises the following steps: a, separating heavy oil to obtain a component S, a component A1, a component A2 and a component A3; and b, carrying out a first catalytic cracking reaction on the component S obtained in the step a, so as to obtain dry gas, liquefied gas, gasoline, diesel oil, coke and cracked heavy oil; carrying out a second catalytic cracking reaction on the component A1 obtained in the step a, so as to obtain dry gas, liquefied gas, gasoline, diesel oil, coke and cracked heavy oil; carrying out a third catalytic cracking reaction on the component A2 obtained in the step a, so as to obtain dry gas, liquefied gas, gasoline, diesel oil, coke and cracked heavy oil; and carrying out a hydrotreatment reaction on the component A3 obtained in the step a under the action of a hydrotreating catalyst, so as to obtain hydrogenated oil. In comparison with the prior art, the method for heavy oil treatment and the subsequent catalytic cracking reactions has advantages of higher yield of gasoline and liquefied gas and lower sulfur / nitrogen content of gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

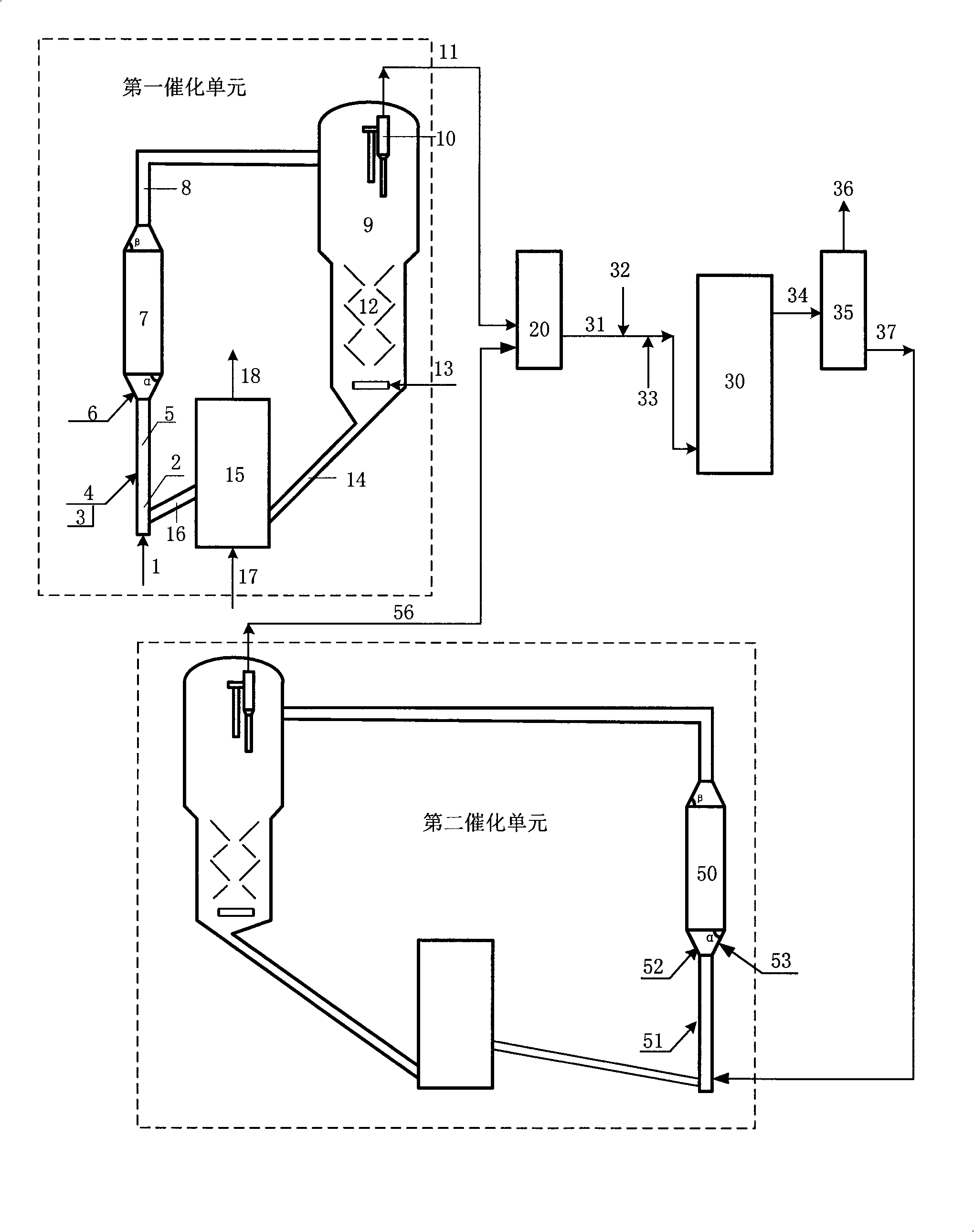

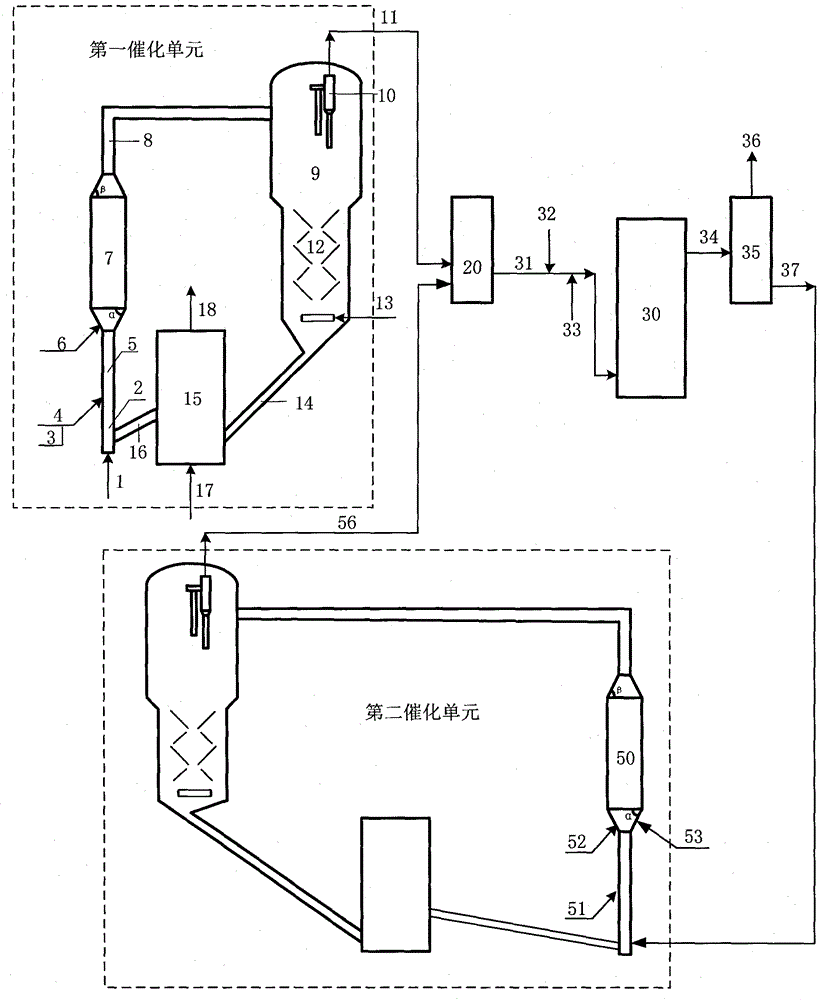

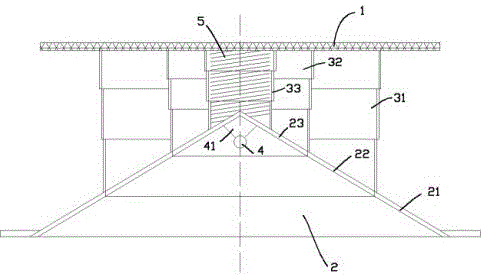

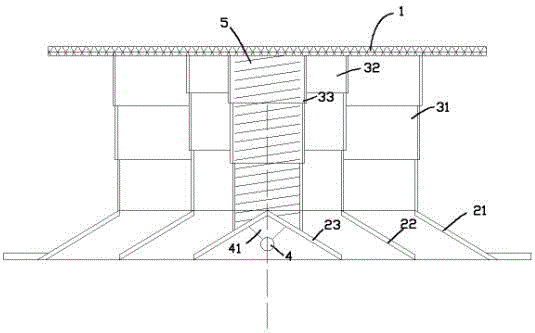

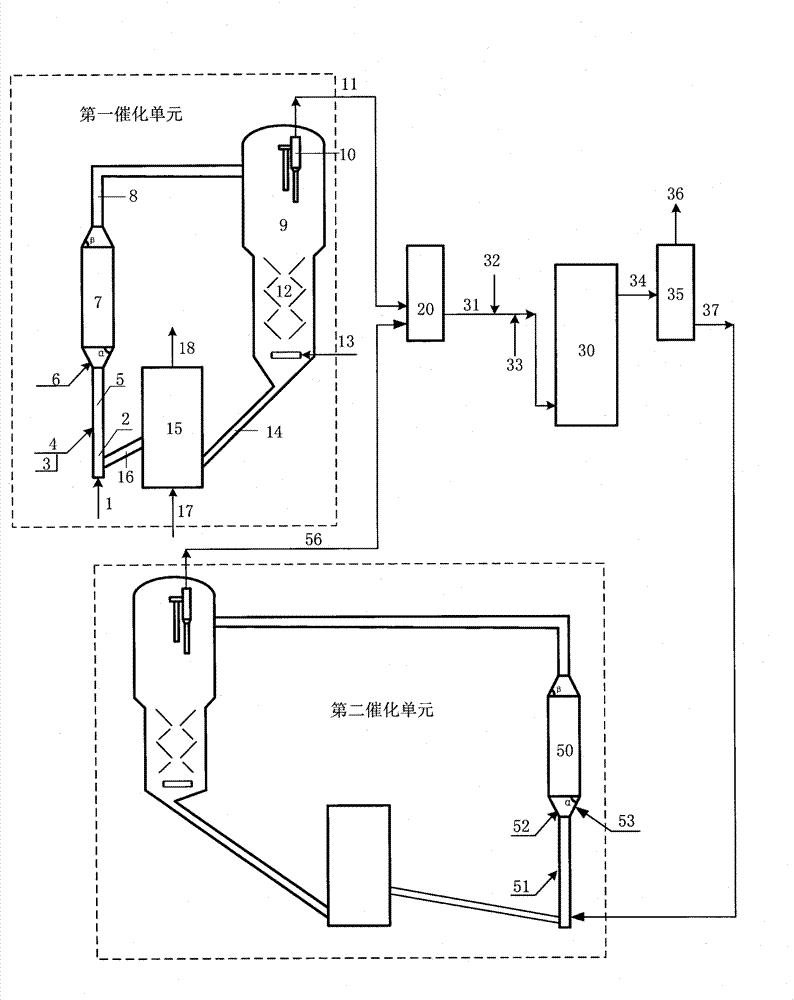

Catalytic conversion method for high sulfur wax oil

ActiveCN102911730AImprove use efficiencyReasonable integrationTreatment with hydrotreatment processesWaxIsomerization

The invention relates to a catalytic conversion method for high sulfur wax oil. The method comprises the following steps: the high sulfur wax oil and a thermal regeneration catalyst are contacted at the lower part of a first catalyst unit reactor and are subjected to a cracking reaction, and the generated oil gas and catalyst containing carbon ascend and are subjected to a secondary cracking reaction and an isomerization reaction under a certain reaction environment; the oil gas is subjected to a separation reaction to obtain a reaction product containing liquefied gas, gasoline and catalytic wax oil; a spent catalyst is subjected to steam stripping and regeneration to be recycled, wherein the catalytic wax oil and optional other secondary processed wax oil are hydrogenated; and the hydrogenated wax oil enters a second catalyst unit to be further cracked. According to the method, low carbon olefins such as propylene are furthest produced, and meanwhile the high-octane gasoline is also produced. The invention provides a new way for the cleanness of an oil refining production process and the cleanness of oil-refined products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method of petroleum hydrocarbon

ActiveCN103059993AImprove use efficiencyReasonable integrationTreatment with hydrotreatment processesIsomerizationCracking reaction

The invention discloses a catalytic conversion method of petroleum hydrocarbon. High-sulfur wax oil is contacted with a heat regeneration catalyst at the lower portion of a catalytic cracking unit reactor and subjected to a cracking reaction, wherein the heat regeneration catalyst contains macropore zeolite and mesopore zeolite, the generated oil gas and a carbon-containing catalyst go up and are subjected to a selective hydrogen transfer reaction and an isomerization reaction under a certain reaction environment, the reaction oil gas is separated to obtain a reaction product containing liquefied gas, gasoline and catalytic wax oil, and the spent catalyst is recycled for use after stripping and regeneration, wherein the catalytic wax oil and optional other secondary processing wax oil are introduced into the hydrocracking unit for reaction, and preferably the hydrocracked tail oil is returned to the catalytic cracking unit. According to the method, the diesel oil yield and the cetane number of the diesel oil are increased, the yield of low carbon olefins such as propylene and butylene are increased, the hydrogen utilization rate of the raw materials is increased, and simultaneously the utilization rate of hydrogen in the raw materials is raised, so that the petroleum resource can be saved, and the method provides a novel approach for cleaning the refining process and the refined oil products.

Owner:CHINA PETROLEUM & CHEM CORP +1

High efficiency catalytic conversion method of petroleum hydrocarbon

ActiveCN102719274AImprove use efficiencyReasonable integrationTreatment with hydrotreatment processesIsomerizationCracking reaction

The invention discloses a high efficiency catalytic conversion method of petroleum hydrocarbon, characterized by contacting high-sulfur wax oil with a heat regeneration catalyst with low equilibrium activity and relatively uniform active distribution at the lower portion of a catalytic cracking unit reactor and conducting cracking reaction, letting the generated oil gas and carbon-containing catalyst upstream be subject to selective hydrogen transfer reaction and isomerization reaction under certain reaction environment, separating the reaction oil gas to obtain a reaction product containing liquefied gas, gasoline and catalytic wax oil, and letting the spent catalyst be recycled after stripping and regeneration, wherein the catalytic wax oil and optional other secondary processing wax oil enters into the hydrotreatment unit to conduct polycyclic aromatic hydrocarbons selective hydrogenation, preferably the hydrogenation wax oil returns to the catalytic cracking unit. According to the invention, the gasoline yield, isobutene yield and total liquid yield are raised, the utilization rate of hydrogen in the raw materials is raised, and simultaneously the utilization rate of hydrogen in hydrotreatment is raised, thus the petroleum resource can be saved, and the invention provides a new approach for cleaning the refining process and refined oil products.

Owner:CHINA PETROLEUM & CHEM CORP +1

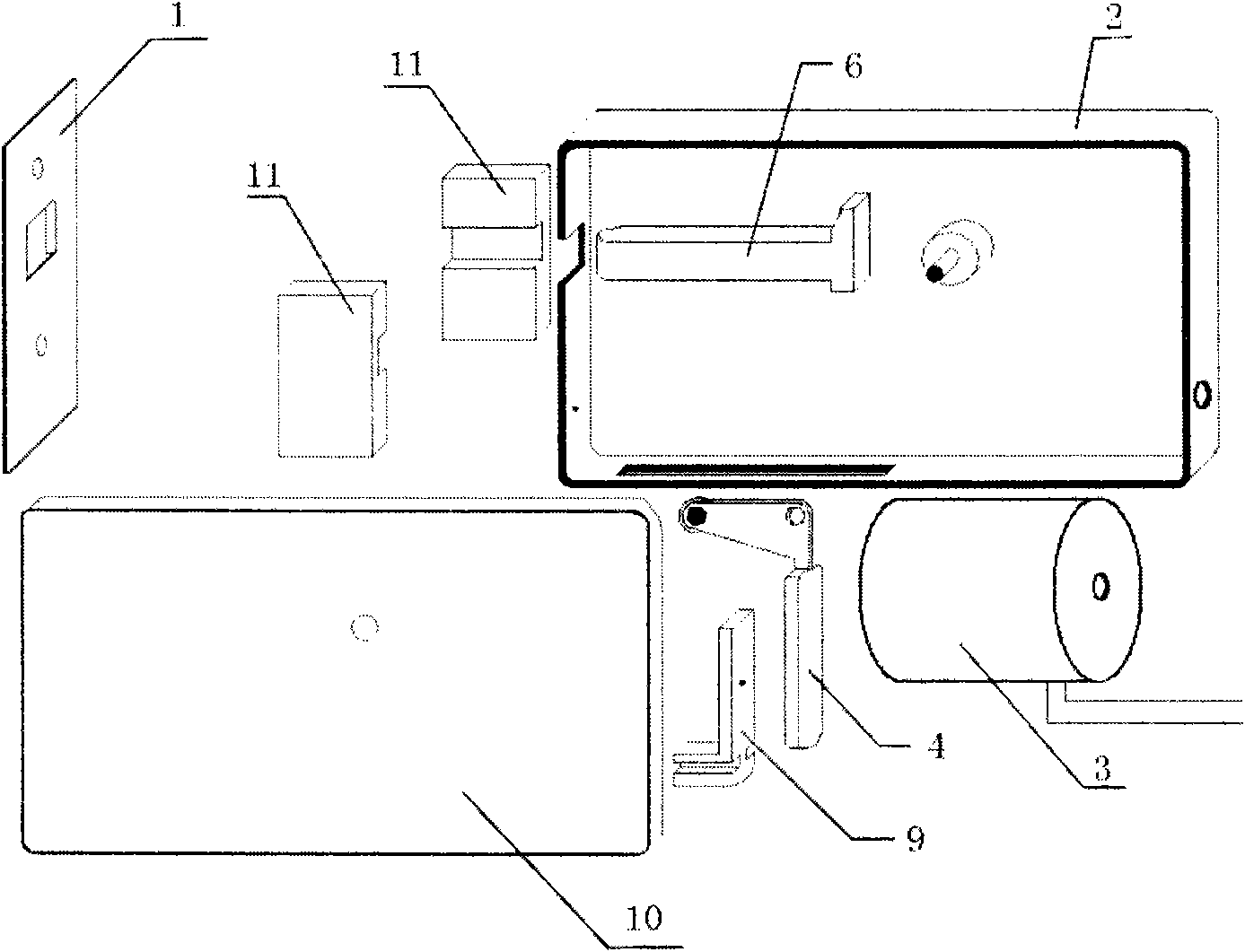

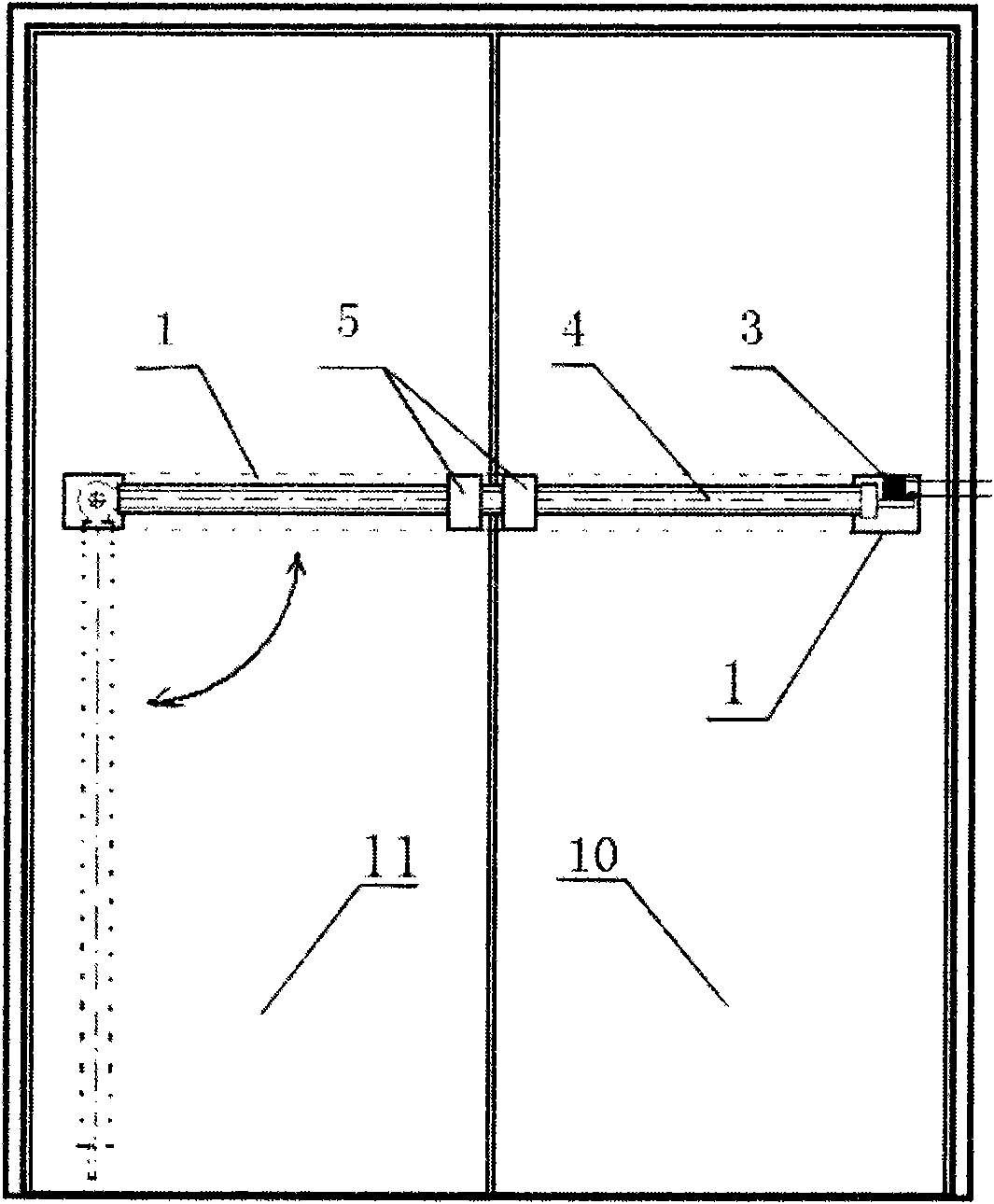

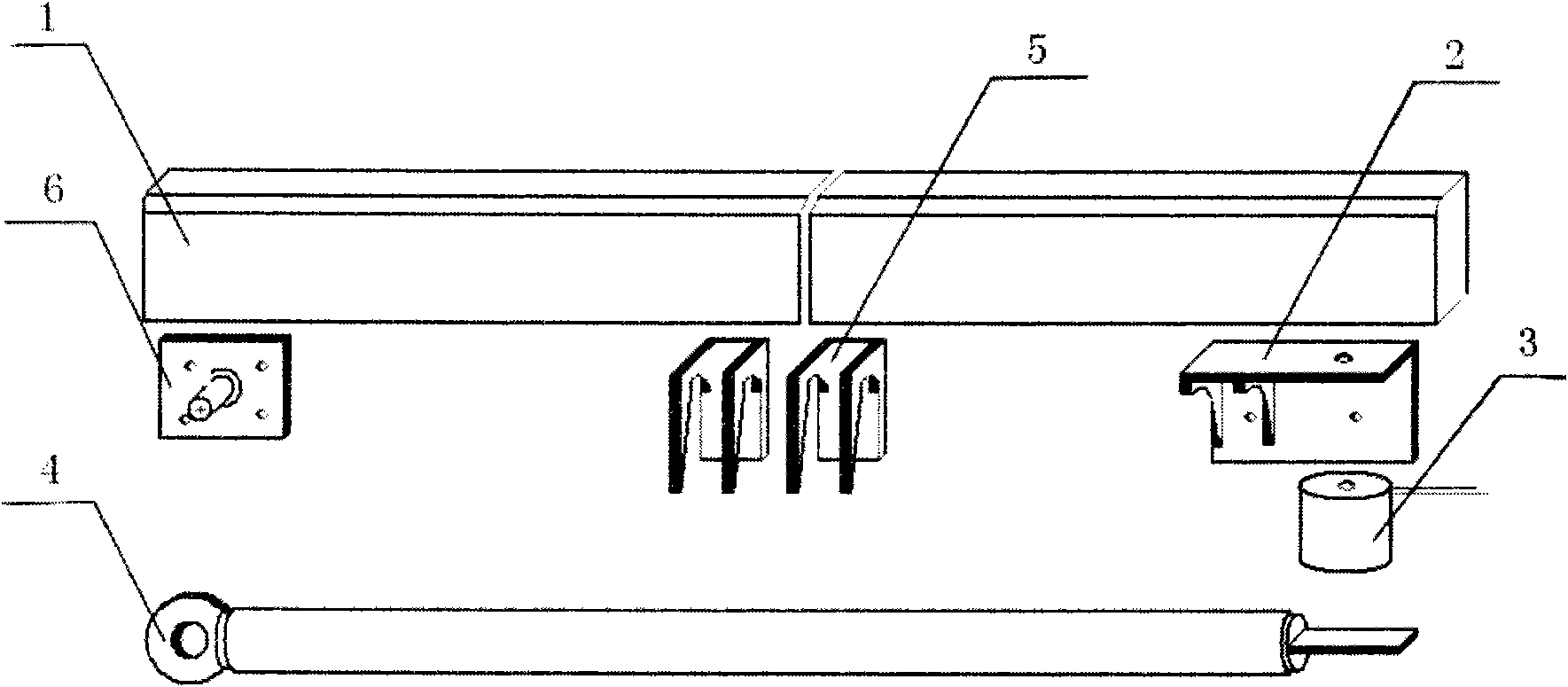

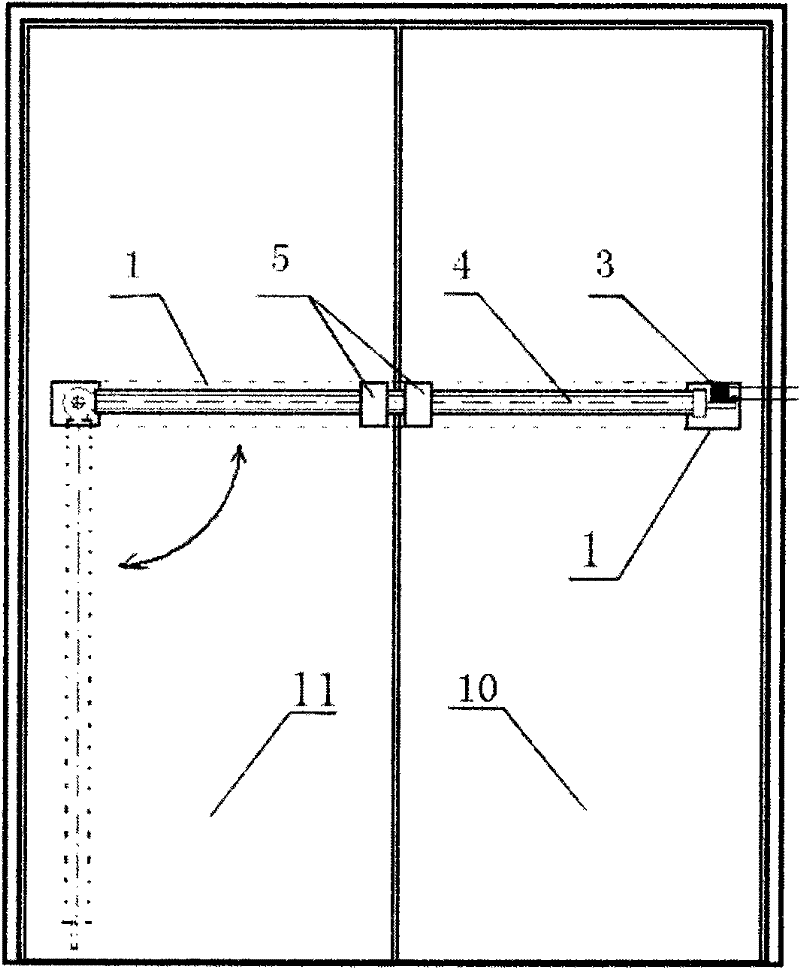

Double-door escape door lock

InactiveCN101881106AGuaranteed anti-theft safetyStrong reliabilityNon-mechanical controlsStress protectionEngineering

The invention provides a double-door escape door lock which comprises a lock groove, electromagnet, a touch switch, a strip-shaped door lever and a door lever mounting body, wherein one end of the strip-shaped door lever is articulated with the door lever mounting body, and the other end thereof is provided with an electromagnet absorbing plate; the electromagnet and the touch switch are respectively installed in the lock groove; an absorbing end of the electromagnet is arranged correspondingly to one side of the electromagnet absorbing plate; the touch switch is arranged correspondingly to one side of the electromagnet absorbing plate; the touch switch is connected in an electromagnet power supply circuit; the lock groove is internally provided with a stress protection clip which is provided with a concave-arc-shaped inner side wall; and the concave-arc-shaped inner side wall is arranged correspondingly to the strip-shaped door lever. The door lock has the advantages of simple structure, ingenious design, convenient use, firm locking, convenient and fast opening of a door, safety and reliability.

Owner:马圆棓

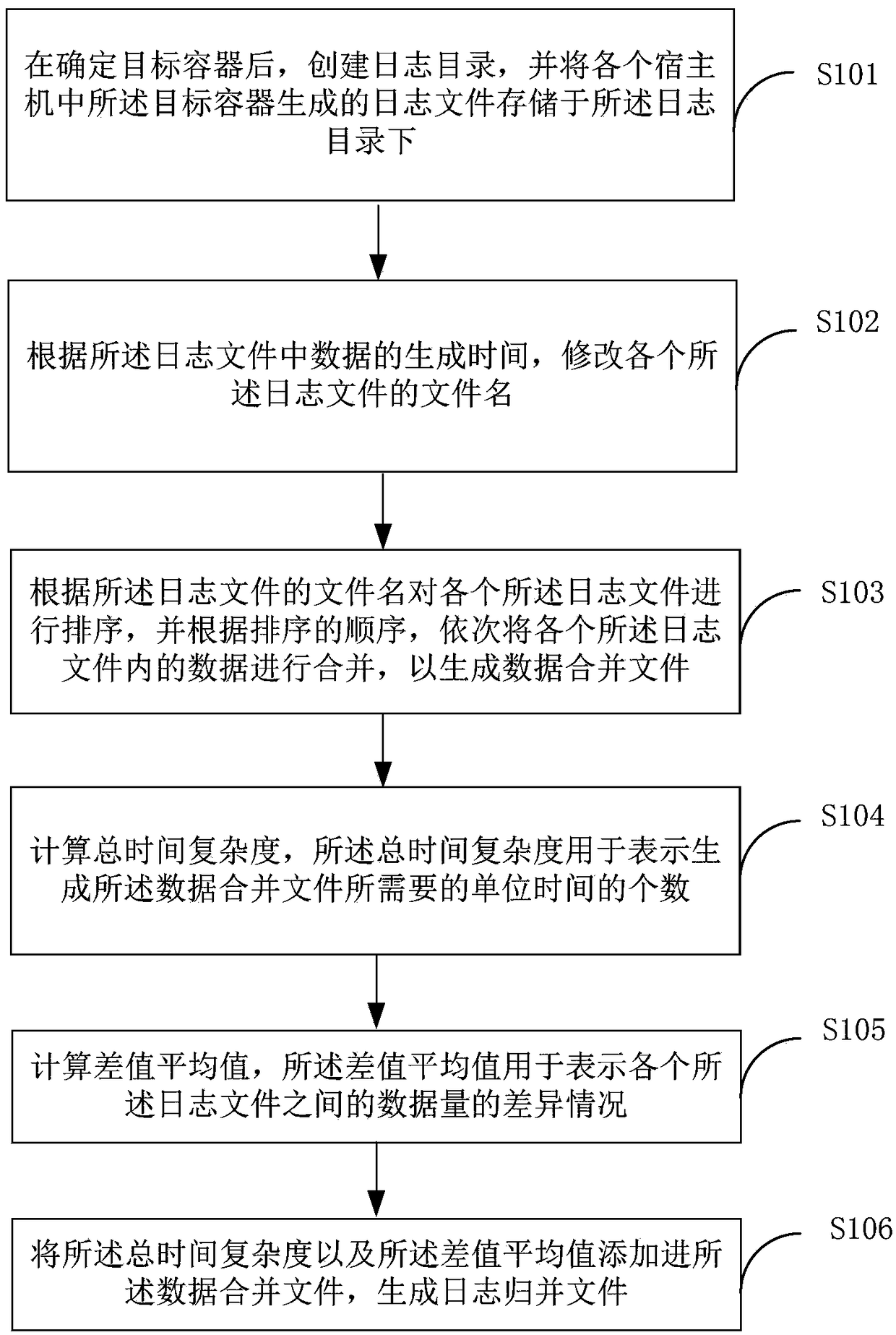

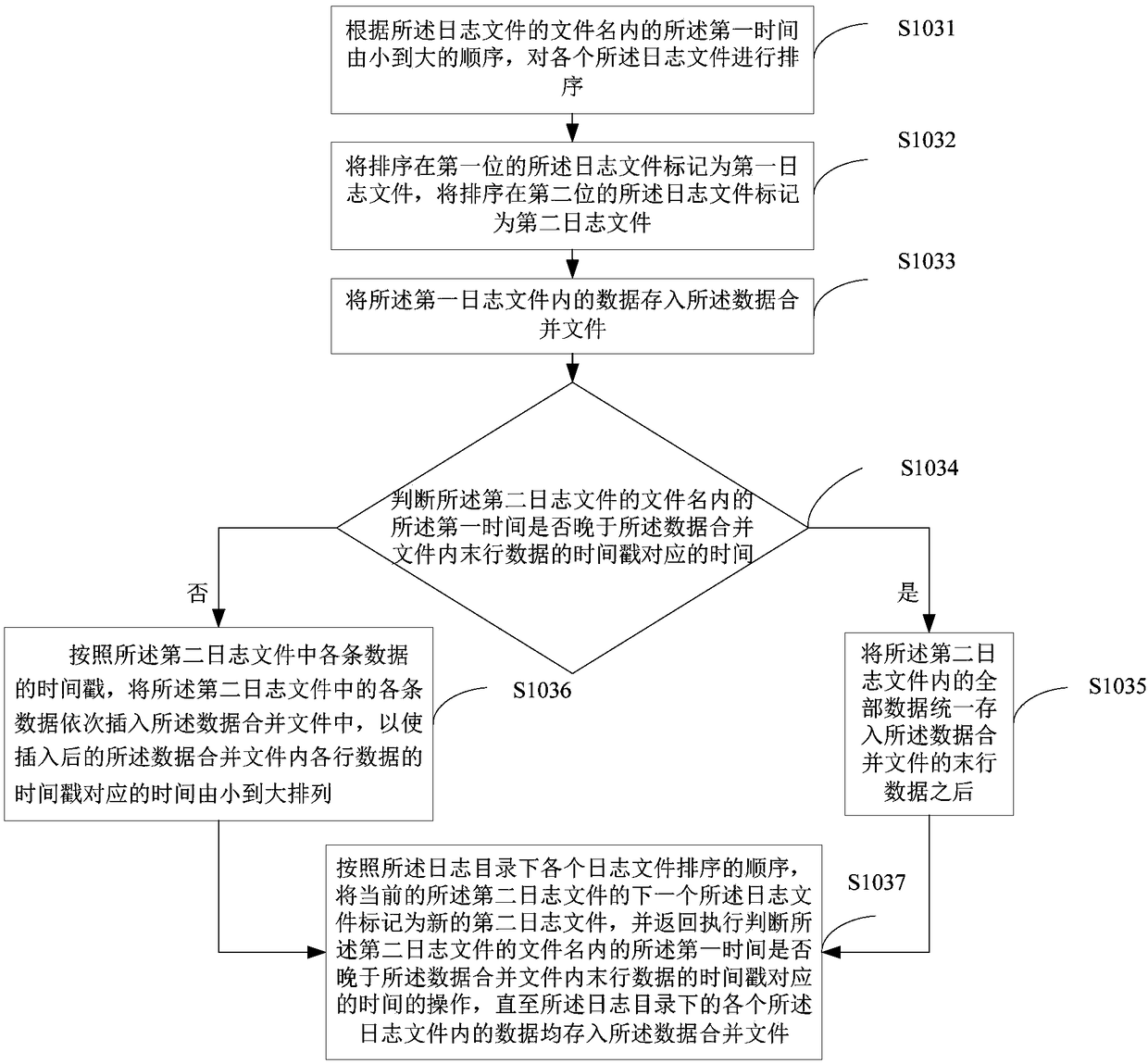

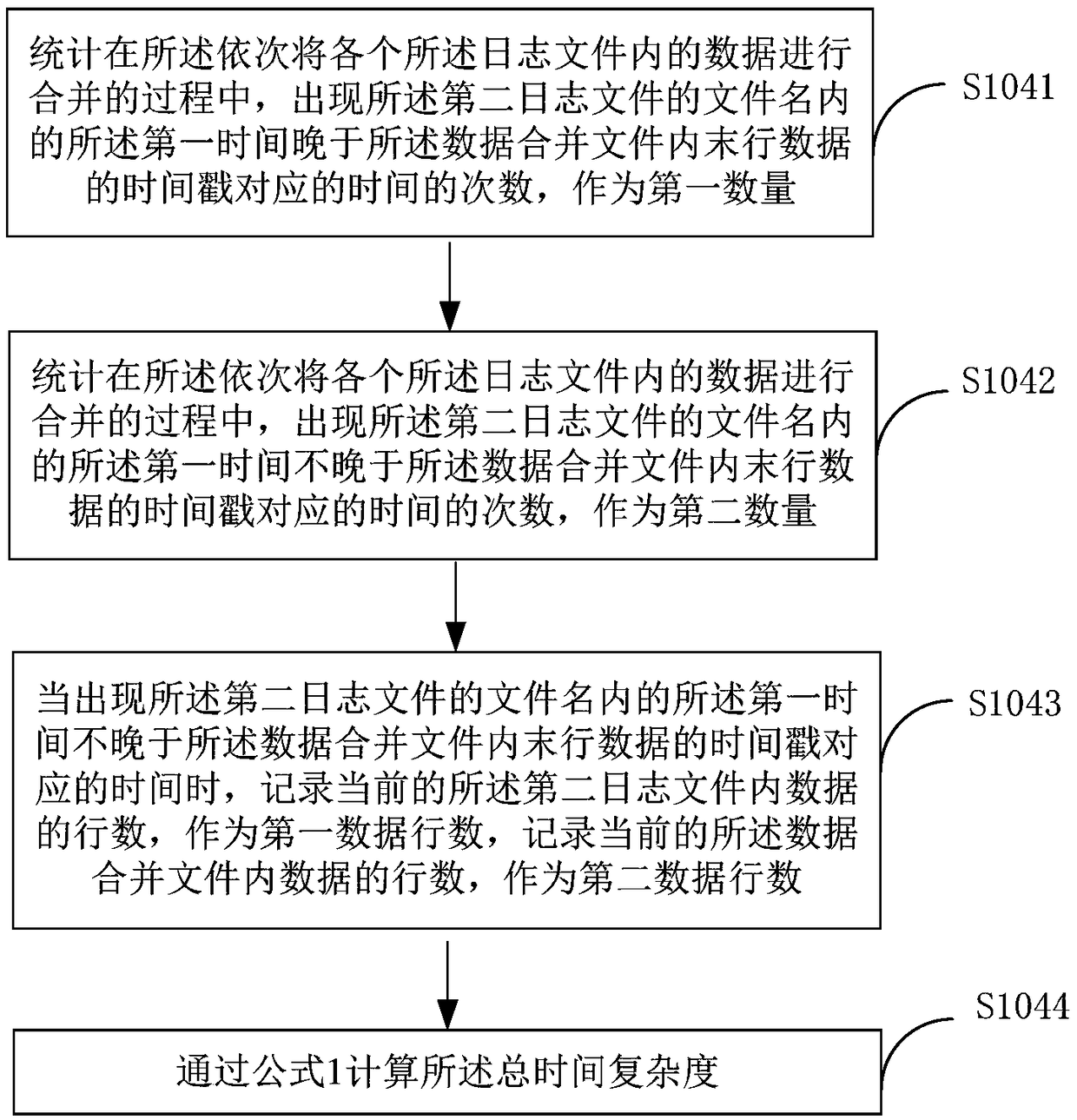

Log merging method and terminal device

ActiveCN109165201AReasonable integrationEasy to browseEnergy efficient computingSoftware simulation/interpretation/emulationTerminal equipmentTime complexity

The invention is applicable to the field of data processing, Provided are a log merging method and a terminal device. The method includes: creating a log directory after a target container is determined, and storing the log files generated by the target container in each host machine in the log directory, depending on when the data in the log file was generated, modifying a file name of each of the log files, and after sorting the individual log files based on their file names, merging the data in each log file, generating a data merge file, calculating the average of the total time complexityof the generated data merge process and the difference in the amount of data between the individual log files, and finally, adding the total time complexity and the average value of the difference into the data consolidation file to generate a log consolidation file. In this way, the reasonable integration of a large number of log files is realized, the user can conveniently browse and search thelog file information, the relevant parameters of the log file are calculated in the integration process, and thus the data utilization rate is improved.

Owner:PING AN TECH (SHENZHEN) CO LTD

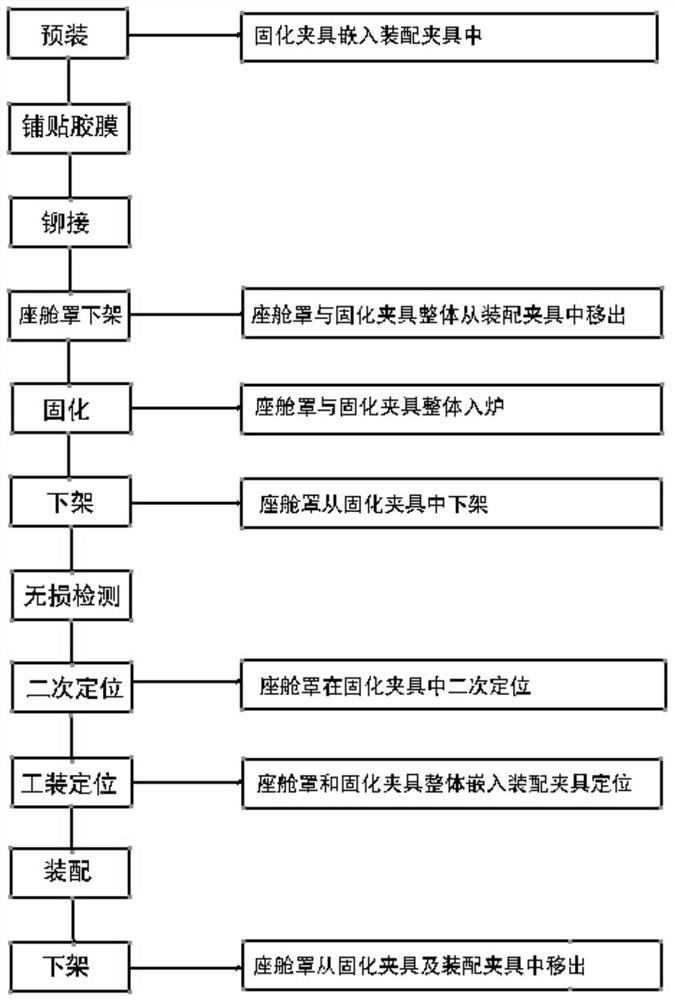

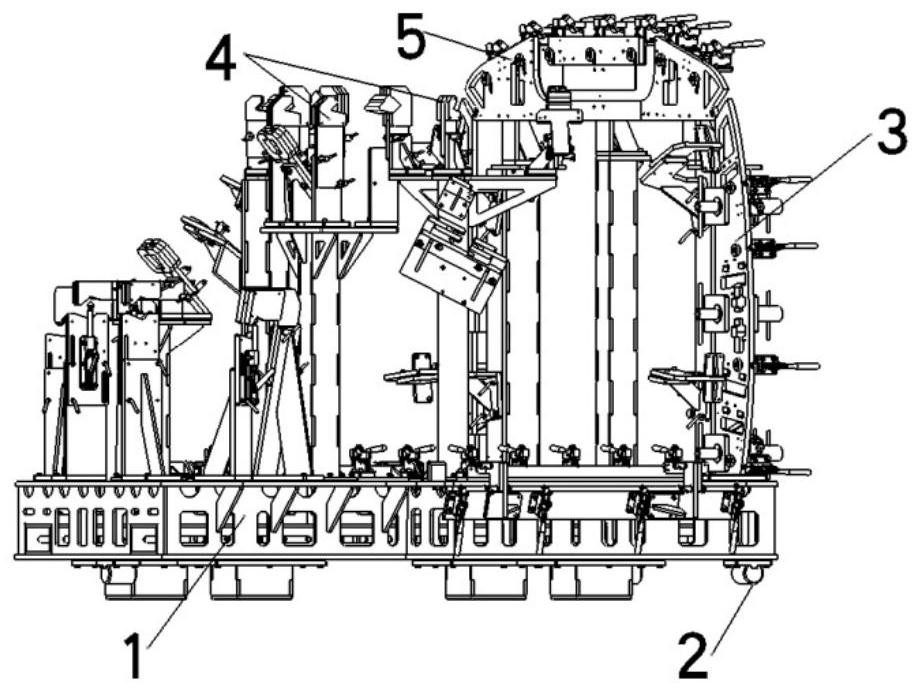

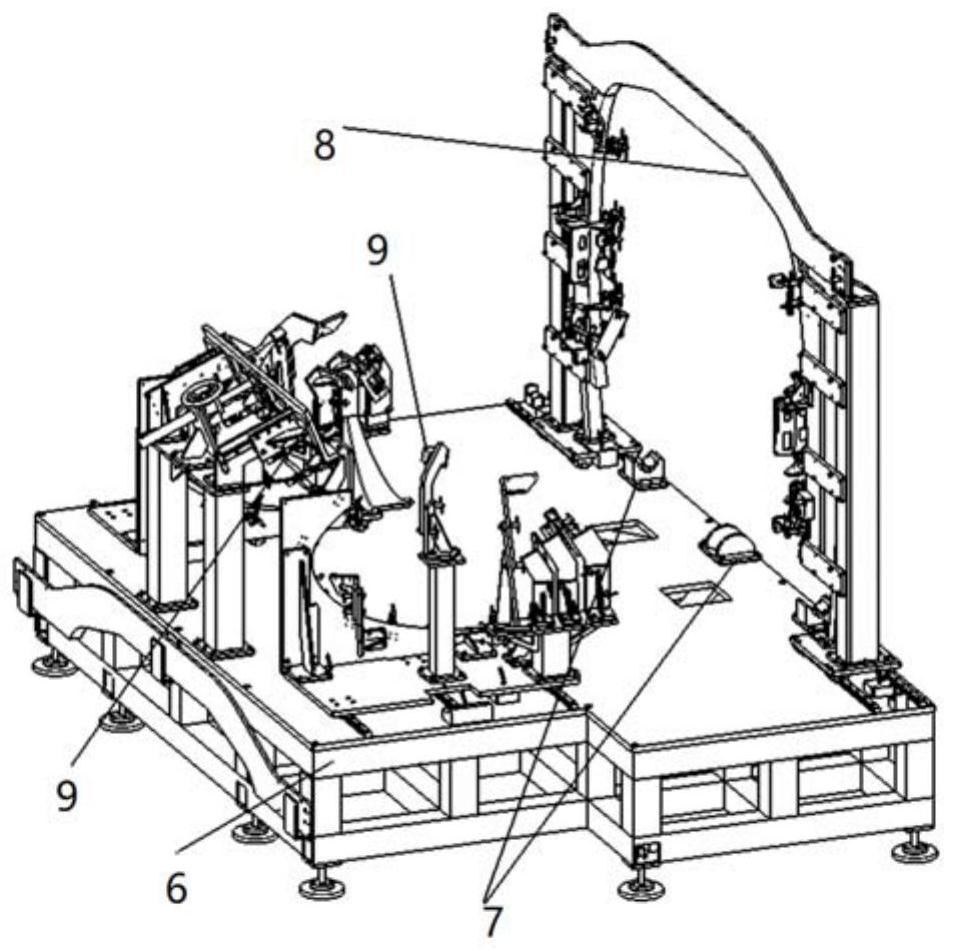

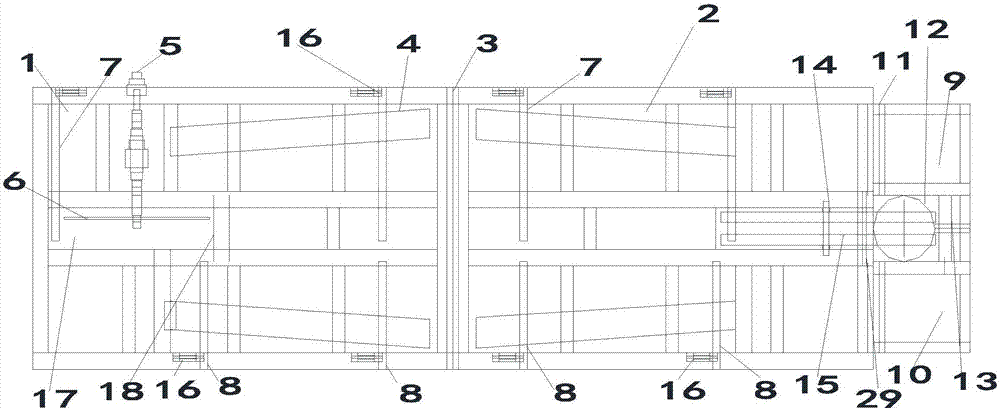

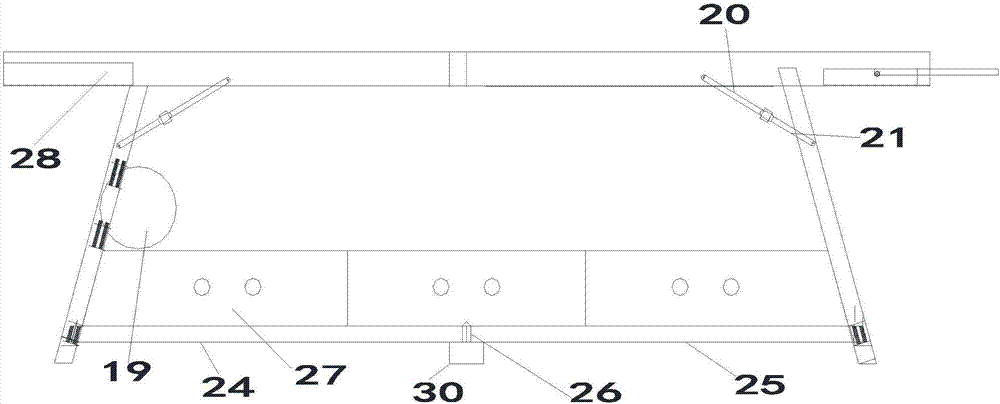

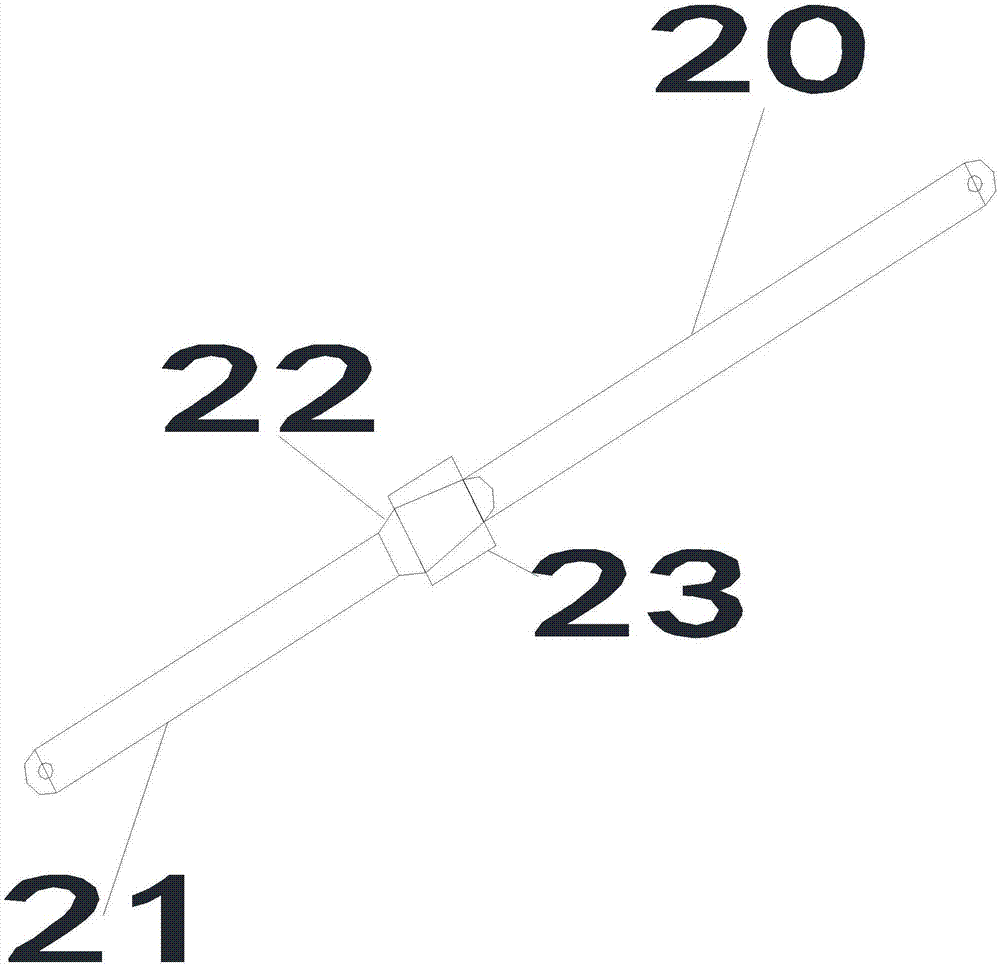

Helicopter cockpit cover gluing assembly method and clamp

ActiveCN112357112AImprove curing methodControl deformationWeight reductionAircraft assemblyButt jointAirframe

The invention belongs to the technical field of composite material assembling and manufacturing, and discloses a helicopter cockpit cover gluing assembling method and a clamp. A brand-new tool form for curing and assembling a cockpit cover is adopted, an embedded separable tool structure is provided, a simple curing bracket is changed into a curing clamp tool with an appearance clamping plate, a curing clamp and an assembling clamp form a whole in the assembling process, and the curing clamp can be separated from the assembling clamp in the curing process. An INVAR steel material with the expansion coefficient similar to that of a composite material is selected as a curing clamp tool material, and deformation of the cockpit cover in the curing process is effectively controlled; and meanwhile, the positioning reference of the cockpit cover is transferred to the curing clamp from the assembling clamp so that the unification of the positioning reference of the cockpit cover in the pre-assembling, curing and assembling processes is ensured, the off-frame frequency of the cockpit cover is reduced, and the deformation of the cockpit cover in the curing process is effectively controlled.The problems that a butt joint assembling gap between the cockpit cover and a fuselage is out of tolerance, and assembling with a cockpit door and a radome is not coordinated are solved.

Owner:哈尔滨哈飞航空工业有限责任公司

Catalytic conversion method of high-sulfur wax oil

ActiveCN102911733BImprove use efficiencyReasonable integrationTreatment with hydrotreatment processesIsomerizationCracking reaction

The invention discloses a catalytic conversion method of high-sulfur wax oil, and is characterized by comprising the following steps of: contacting the high-sulfur wax oil and a thermal regeneration catalyst with lower activity and relatively uniform activity distribution at the lower part of a catalytic unit reactor and carrying out cracking reaction, carrying out secondary cracking reaction and isomerization reaction on the generated oil gas and a carbon-containing catalyst under a certain reaction environment, separating the reaction oil gas to obtain a reaction product comprising liquefied gas, gasoline and catalytic wax oil, after stripping and regenerating a spent catalyst, circulating, hydrogenating the catalytic wax oil and the other optional secondary processing wax oil into an aromatic hydrocarbon separation unit, and further cracking the hydrogenated wax oil into a second catalytic unit. According to the method, low-carbon olefin, such as propylene and the like, can be produced furthest, and production of high-octane gasoline is both considered, so that a new way for a clean oil refining process and a clean oil refining product is provided.

Owner:CHINA PETROLEUM & CHEM CORP +1

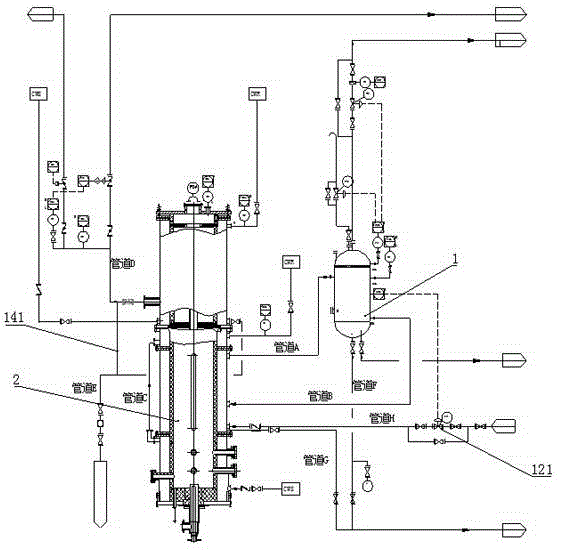

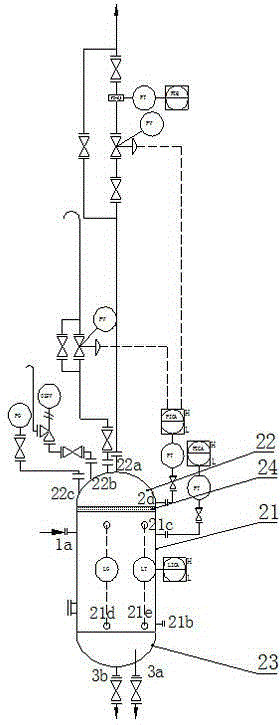

Thermal concentration system for dilute brine based on hydrogen chloride synthesis

InactiveCN104928714AReduce consumptionLow costElectrolysis componentsEnergy inputPhysical chemistryHydrogen chloride

The invention relates to a thermal concentration system for dilute brine based on hydrogen chloride synthesis. The thermal concentration system is characterized by comprising a dilute brine concentrating furnace based on hydrogen chloride synthesis, and a flash tank for concentrating dilute brine, wherein a hydrogen chloride synthesis section of the dilute brine concentrating furnace based on hydrogen chloride synthesis is provided with a cyclic-heating clamping sleeve for dilute brine; a pipeline A and a pipeline B of the cyclic-heating clamping sleeve for dilute brine are communicated with the flash tank, so that a thermal concentration circulating channel for dilute brine is formed. Through the adoption of the thermal concentration system for dilute brine based on hydrogen chloride synthesis, which is disclosed by the invention, condensed acid can be directly prepared through cooling, and saturated by-product steam can be generated through the cooperation of a jacket structure and the flash tank; besides, the dilute brine is concentrated, so that four functions of synthesizing the hydrogen chloride, preparing the acid, generating the by-product steam, and concentrating the dilute brine are integrated in the thermal concentration system; the equipment investment is greatly simplified; the resources are reasonably integrated; the cost is reduced.

Owner:NANTONG STAR GRAPHITE EQUIP CO LTD

Dietary fiber-rich blueberry dried pork slice and preparation method thereof

PendingCN114052188AUnique product lineExpand product lineFood ingredient functionsBiotechnologyMonosodium glutamate

The invention discloses dietary fiber-rich blueberry dried pork slices and a preparation method thereof, and belongs to the field of food manufacturing. The blueberry dried pork slice comprise, by weight, pork, seasonings, additives and an antioxidant. The pork is 400 parts, and the seasonings comprise 80-100 parts of sugar and 2.5-4 parts of monosodium glutamate; dietary fiber accounts for 20-25 parts; whole egg liquid accounts for 40-56 parts, fish sauce accounts for 30-50 parts blueberry jam accounts for 30-40 parts and trehalose accounts for 8-10 parts; the additives account for 15.27-22.59 parts, and the antioxidant accounts for 0.1-0.2 part. The meat flavor and the blueberry flavor are reasonably fused, the tail flavor is lasting, the taste is unique, rich dietary fibers are added into the product, the product is beneficial to health, raw material treatment is standardized, and industrial mass production is easy.

Owner:江苏骥洋食品有限公司

Double-door escape door lock

InactiveCN101881106BGuaranteed anti-theft safetyStrong reliabilityNon-mechanical controlsStress protectionEngineering

The invention provides a double-door escape door lock which comprises a lock groove, electromagnet, a touch switch, a strip-shaped door lever and a door lever mounting body, wherein one end of the strip-shaped door lever is articulated with the door lever mounting body, and the other end thereof is provided with an electromagnet absorbing plate; the electromagnet and the touch switch are respectively installed in the lock groove; an absorbing end of the electromagnet is arranged correspondingly to one side of the electromagnet absorbing plate; the touch switch is arranged correspondingly to one side of the electromagnet absorbing plate; the touch switch is connected in an electromagnet power supply circuit; the lock groove is internally provided with a stress protection clip which is provided with a concave-arc-shaped inner side wall; and the concave-arc-shaped inner side wall is arranged correspondingly to the strip-shaped door lever. The door lock has the advantages of simple structure, ingenious design, convenient use, firm locking, convenient and fast opening of a door, safety and reliability.

Owner:马圆棓

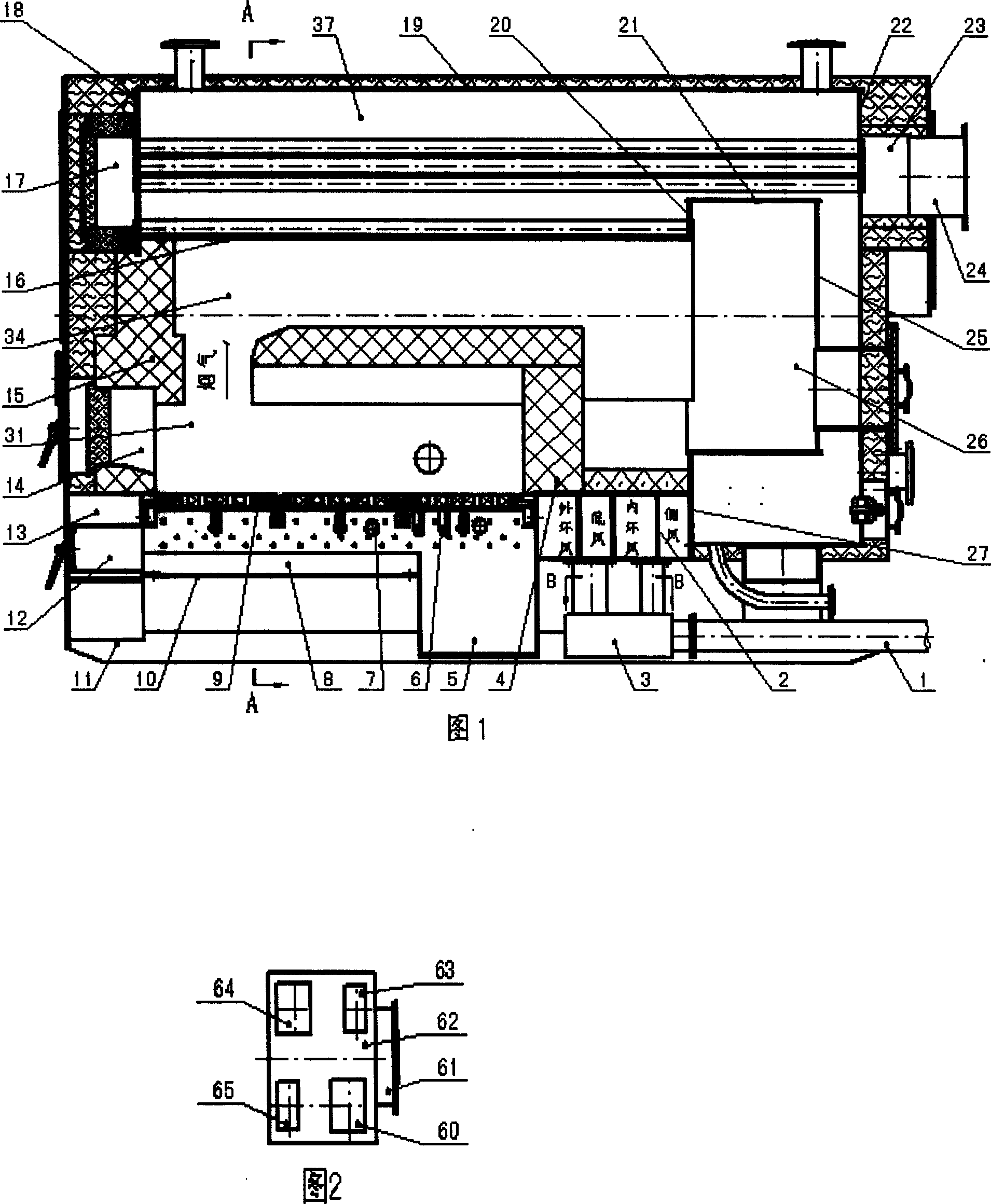

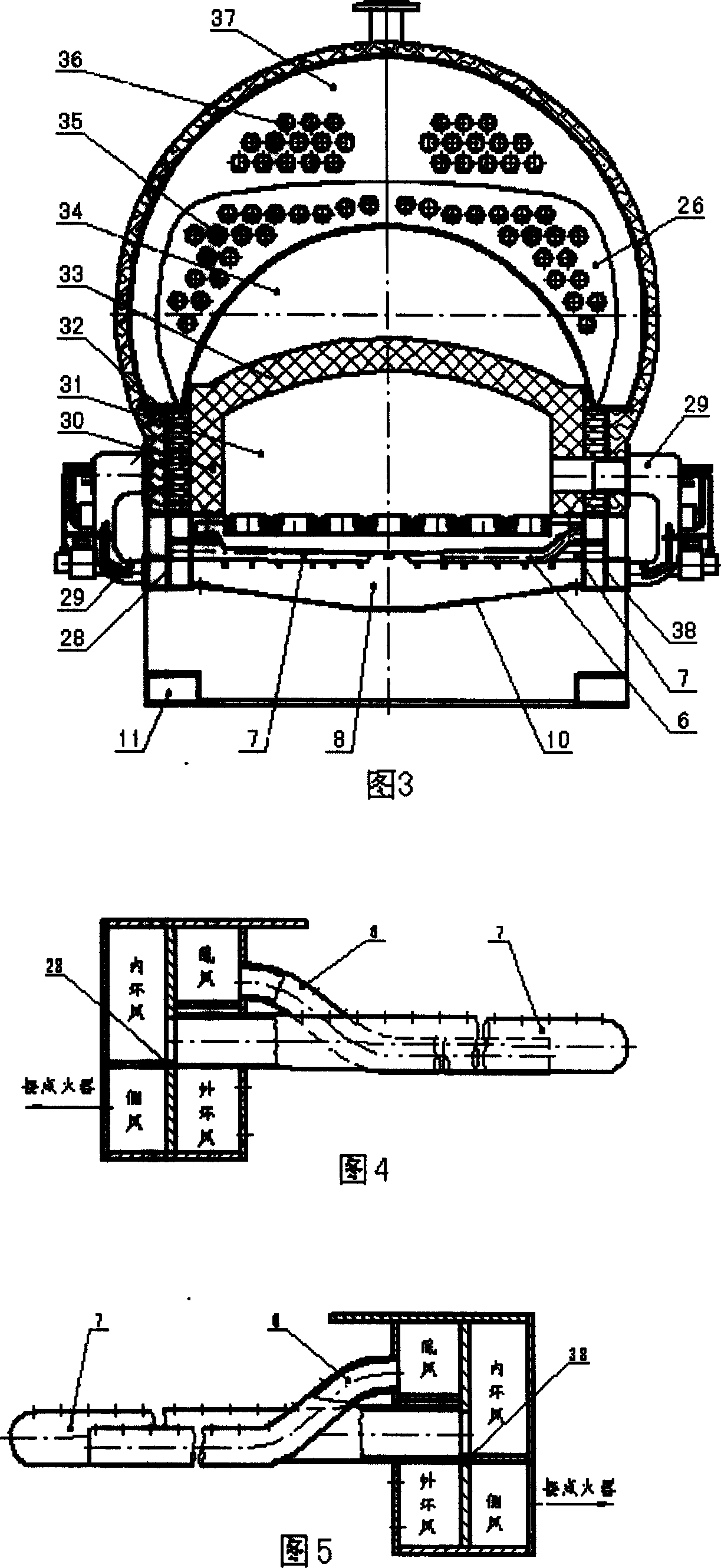

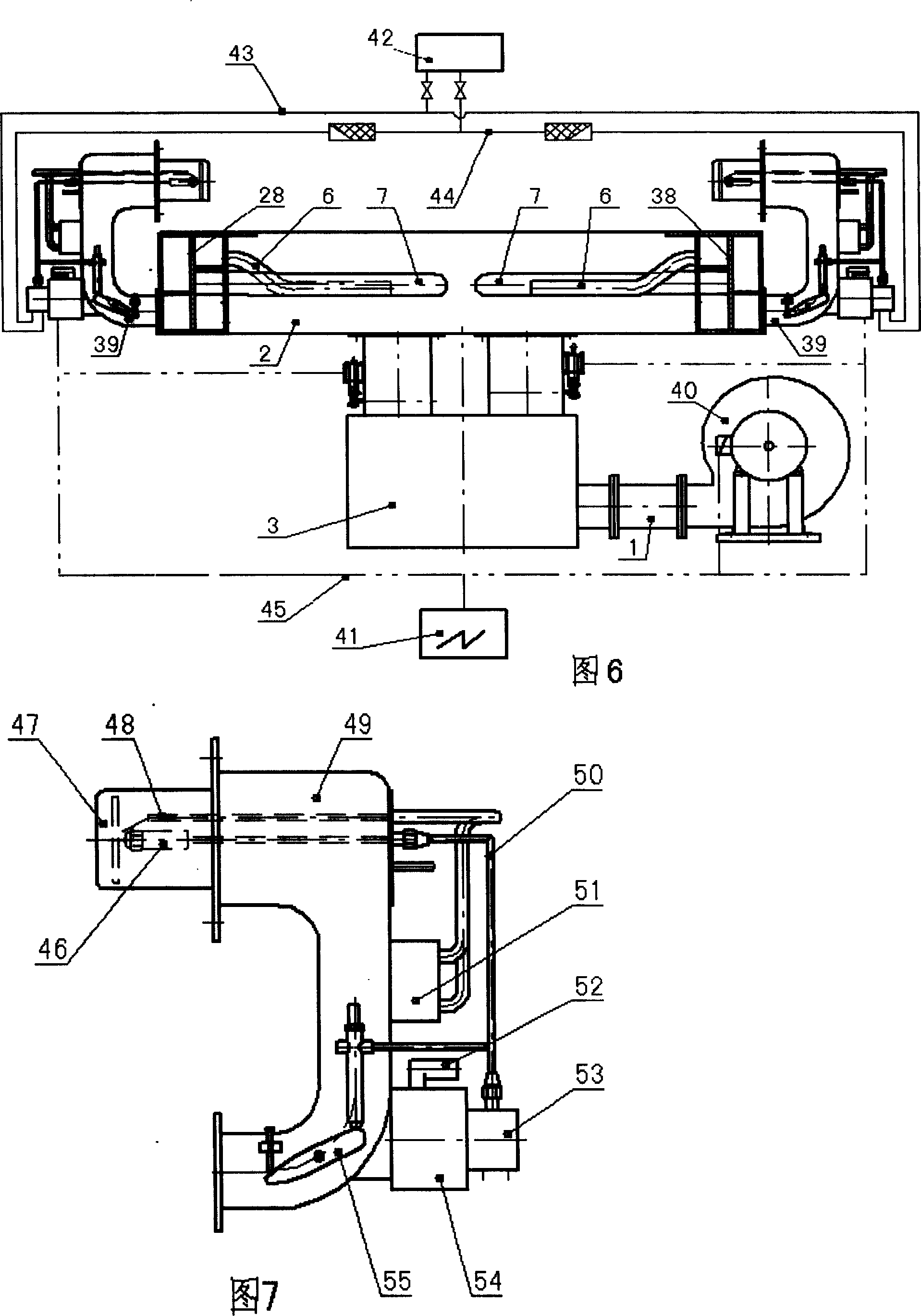

Coke boiler

InactiveCN101012926ATake advantage ofReasonable useSolid fuel combustionAir/fuel supply for combustionSolid fuelEngineering

The invention relates to a coke boiler which uses solid fuel, comprising a main body, a burner, a smoke discharger, a ventilator and an igniter. The main body is arranged with a medium room, a smoke tube, a fire box, a burning out room, and a burning room from up to down. The top and the bottom of the medium room are respectively arranged with a medium outlet and a medium inlet. The burner is formed by an air channel, an air chamber, a furnace bed, an ash chamber, and a base, while the air channel is around the air chamber and formed by front, back, left and right air channels, and front air channel is divided by the damping door into left and right air channels communicated with the outer annular air branches of left and right air channels, each outer annular air branch is arranged with a hole communicated with the air chamber. The bottom air branch and inner annular air branch of left and right air channels can guide the bottom air and inner annular air via the bottom air tube and inner annular air tube into preset area under the furnace bed. The invention has compact structure and low cost.

Owner:徐斌

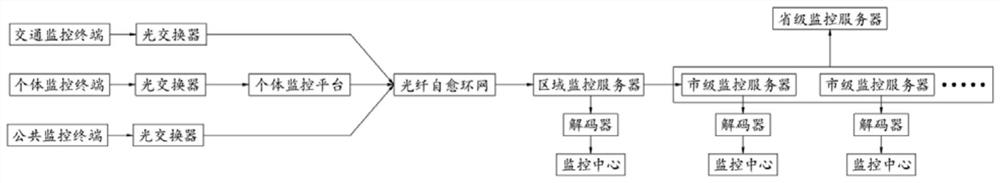

Camera searching and tracking method based on network big data

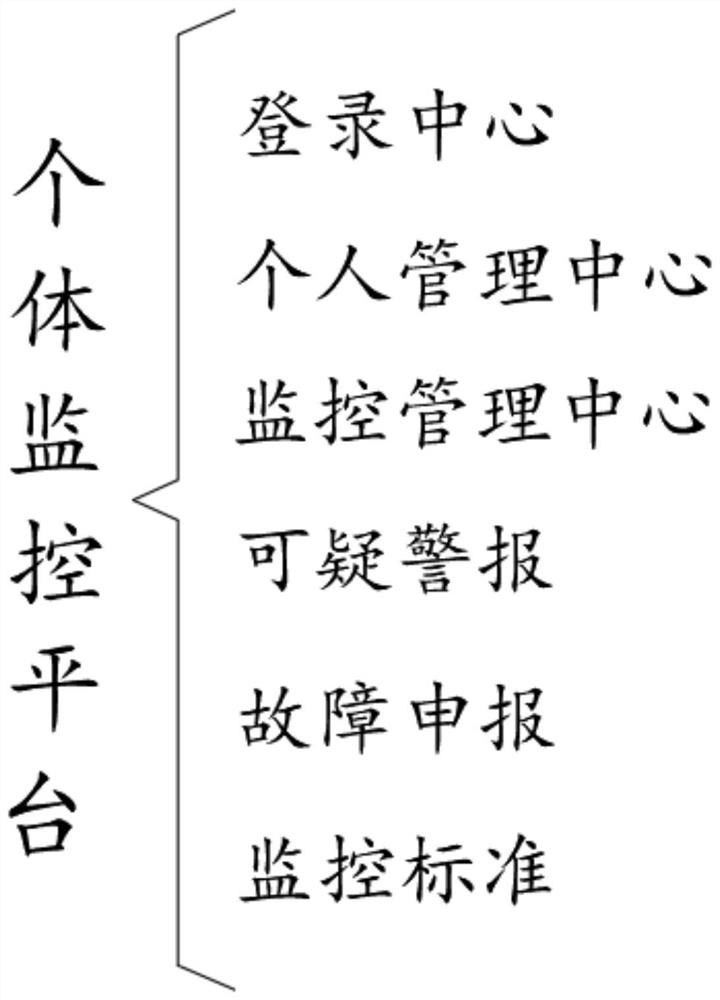

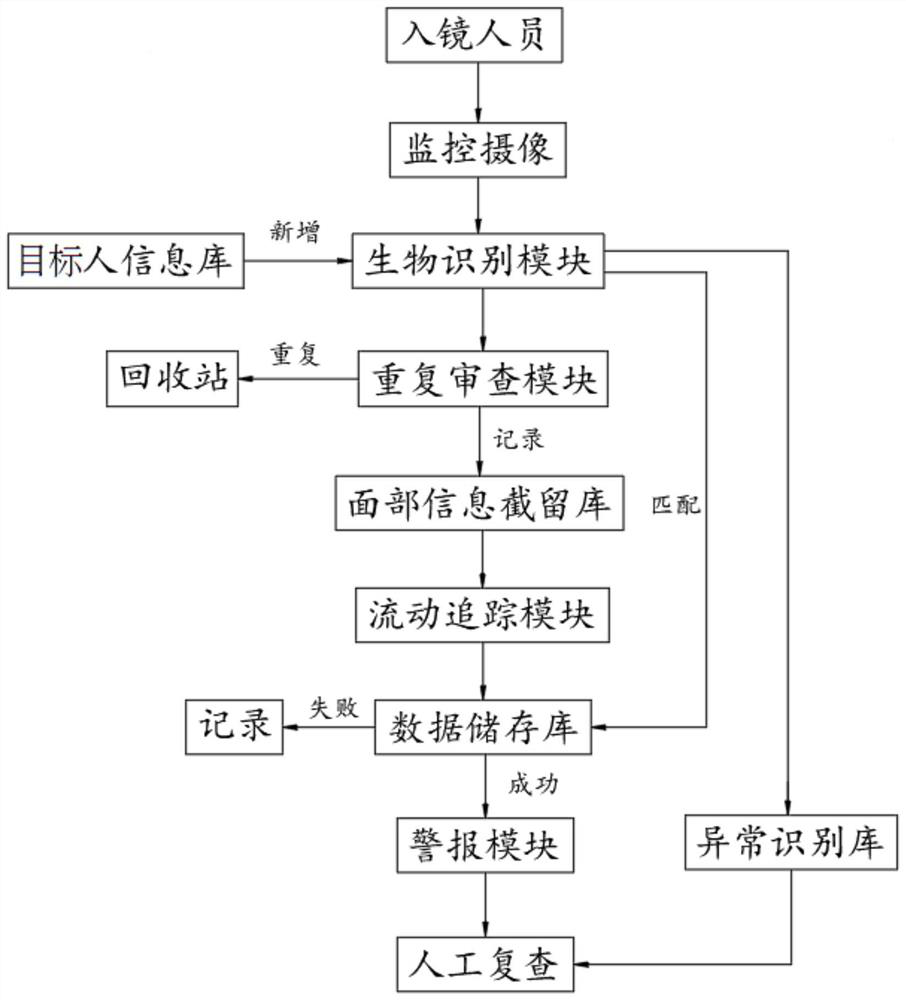

InactiveCN114170771AAchieving Regulatory IntegrationEasy to assist search and traceTelevision system detailsCharacter and pattern recognitionSurveillance cameraSelf-healing ring

The invention belongs to the technical field of searching and tracking, and particularly relates to a camera searching and tracking method based on network big data, which comprises a traffic monitoring terminal, an individual monitoring terminal, a public monitoring terminal, an individual monitoring platform, an optical fiber self-healing looped network, a regional monitoring server and a municipal monitoring server, the traffic monitoring terminal, the individual monitoring terminals and the public monitoring terminal are all connected with light exchangers, the individual monitoring terminals are gathered and connected to the individual monitoring platform through the light exchangers, and the optical fiber self-healing looped network collects information of the light exchangers and the individual monitoring platform and transmits the information to the regional monitoring server. According to the invention, through the individual monitoring platform, the information of the monitoring cameras installed by the individual households can be connected to the individual monitoring platform, the individual monitoring platform carries out integrated management on the individual households and transmits the monitoring information to the regional monitoring server at the same time, so that on-site operation of workers is not needed, and timely searching and tracking are facilitated.

Owner:南京瑞斌商贸有限公司

Effective catalytic conversion method of petroleum hydrocarbon

ActiveCN103059992AImprove use efficiencyReasonable integrationTreatment with hydrotreatment processesIsomerizationLiquid gas

The invention discloses a catalytic conversion method of petroleum hydrocarbon. High-sulfur wax oil is contacted with a heat regeneration catalyst at the lower portion of a catalytic cracking unit reactor and subjected to a cracking reaction, wherein the heat regeneration catalyst has relatively low activity and contains macropore zeolite and mesopore zeolite, the generated oil gas and a carbon-containing catalyst go up and are subjected to a selective hydrogen transfer reaction and an isomerization reaction under a certain reaction environment, the reaction oil gas is separated to obtain a reaction product containing liquefied gas, gasoline and catalytic wax oil, and the spent catalyst is recycled for use after stripping and regeneration, wherein the catalytic wax oil and optional other secondary processing wax oil are introduced into the hydrocracking unit for reaction, and preferably the hydrocracked tail oil is returned to the catalytic cracking unit. According to the method, the diesel oil yield and the cetane number of the diesel oil are increased, the mass percentages of low carbon olefins such as propylene and butylenes in the liquefied gas are increased, the hydrogen utilization rate of the raw materials is increased, and simultaneously the utilization rate of hydrogen in the raw materials is raised, so that the petroleum resource can be saved, and the method provides a novel approach for cleaning the refining process and the refined oil products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Effective catalytic conversion method of petroleum hydrocarbon

ActiveCN103059995AImprove use efficiencyReasonable integrationTreatment with hydrotreatment processesIsomerizationPetroleum

The invention discloses a catalytic conversion method of petroleum hydrocarbon. High-sulfur wax oil is contacted with a heat regeneration catalyst at the lower portion of a catalytic cracking unit reactor and subjected to a cracking reaction, wherein the heat regeneration catalyst has relatively low activity and coarse particle size distribution and contains macropore zeolite and mesopore zeolite, the generated oil gas and a carbon-containing catalyst go up and are subjected to a selective hydrogen transfer reaction and an isomerization reaction under a certain reaction environment, the reaction oil gas is separated to obtain a reaction product containing liquefied gas, gasoline and catalytic wax oil, and the spent catalyst is recycled for use after stripping and regeneration, wherein the catalytic wax oil and optional other secondary processing wax oil are introduced into the hydrocracking unit for reaction, and preferably the hydrocracked tail oil is returned to the catalytic cracking unit. According to the method, the diesel oil yield and the cetane number of the diesel oil are increased, the mass percentages of low carbon olefins such as propylene and butylenes in the liquefied gas are increased, the hydrogen utilization rate of the raw materials is increased, and simultaneously the utilization rate of hydrogen in the raw materials is raised, so that the petroleum resource can be saved, and the method provides a novel approach for cleaning the refining process and the refined oil products.

Owner:CHINA PETROLEUM & CHEM CORP +1

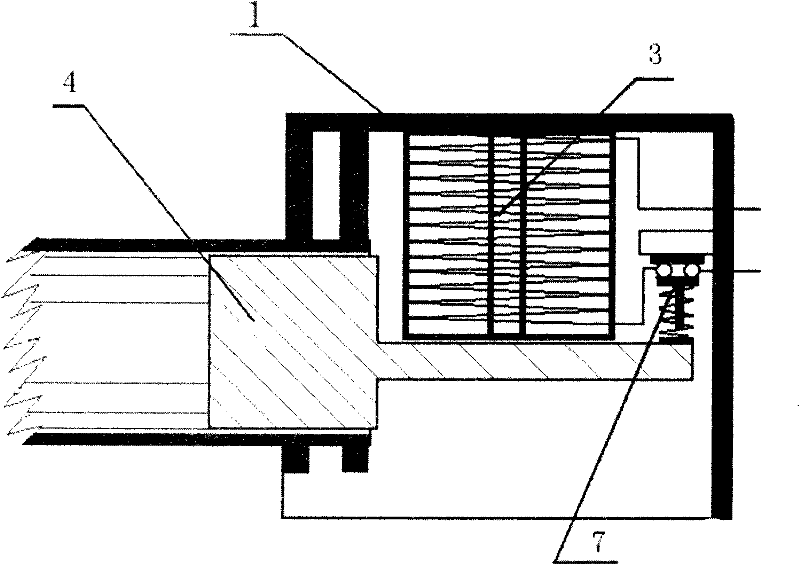

Multifunctional woodworking operation platform

InactiveCN107053362AReasonable integrationEasy to useMulti-purpose machinesCircular discAgricultural engineering

The invention discloses a multifunctional woodworking operation table, which comprises a left table top and a right table top, the left table top and the right table top are connected through a main table hinge, the left table top and the right table top are respectively provided with folding feet, and the side of the left table top is provided with a drill bit, There is a circular saw in the middle part of the left table, two table telescopic rods are provided on the front side of the left table and the right table, two telescopic rods are installed on the rear side of the left table and the right table, and the right table is right. The first engraving machine table and the second engraving machine table are respectively arranged on the side, and the first engraving machine table and the second engraving machine table are connected with the right table through hinges, and the first engraving machine table and the second engraving machine table are provided with There is an engraving machine installation part, the front part of the engraving machine installation part is an auxiliary table, and the engraving machine installation part is connected with the hanger bar through a rotating shaft. The invention has the characteristics of simple structure, low cost, good folding performance, strong stability, effective and reasonable integration of various machines, convenient use and the like.

Owner:厉旭民

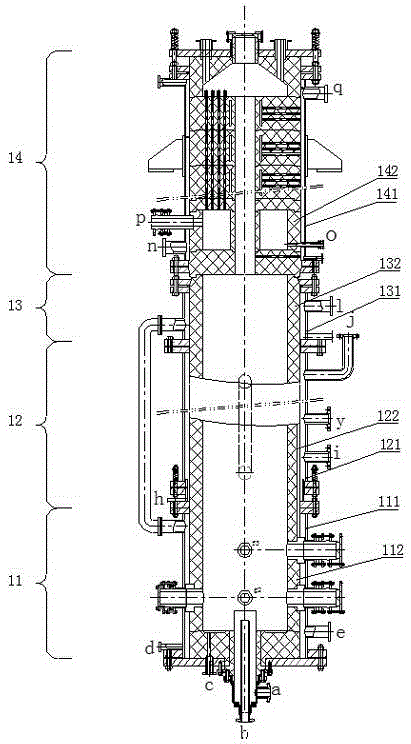

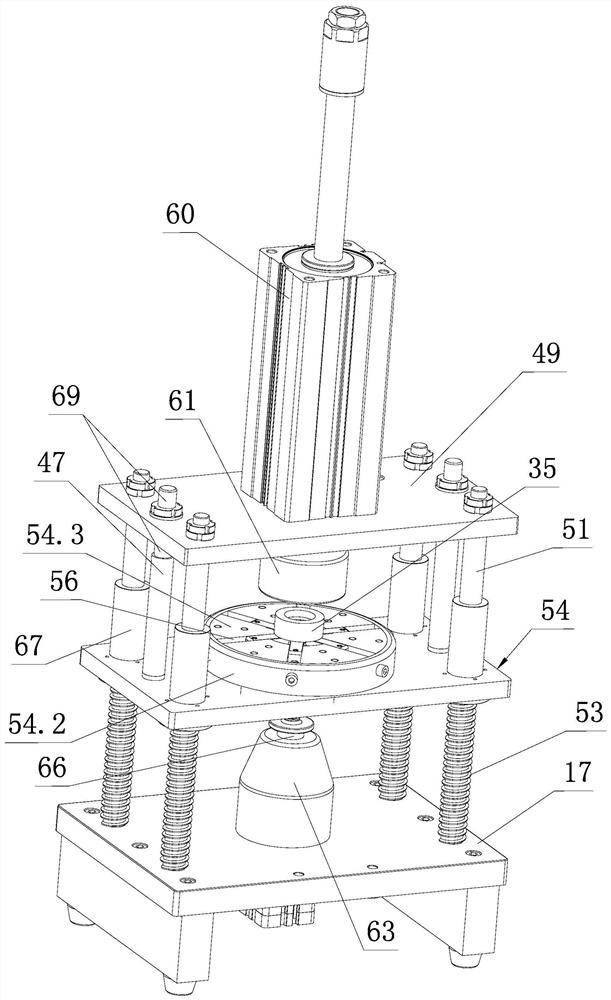

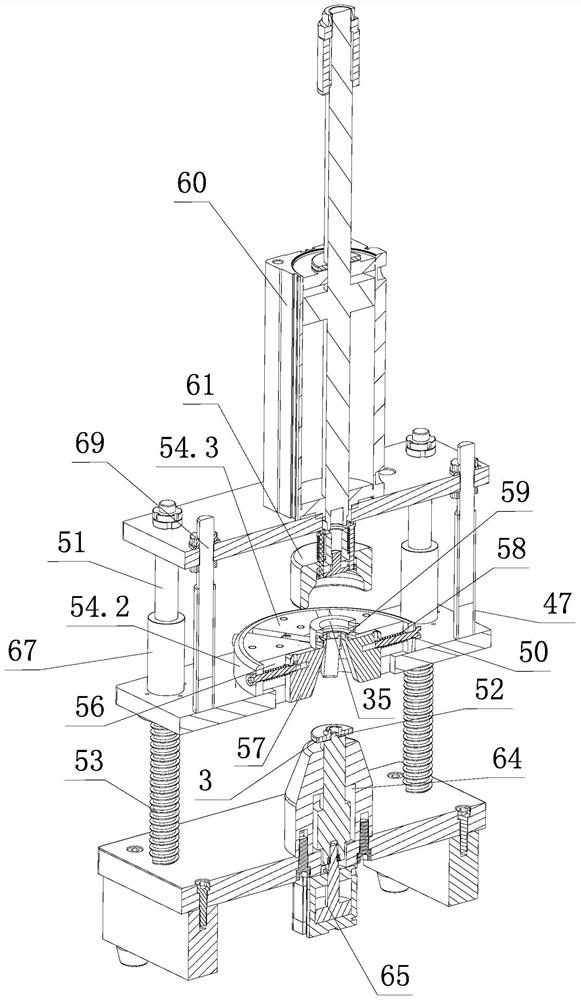

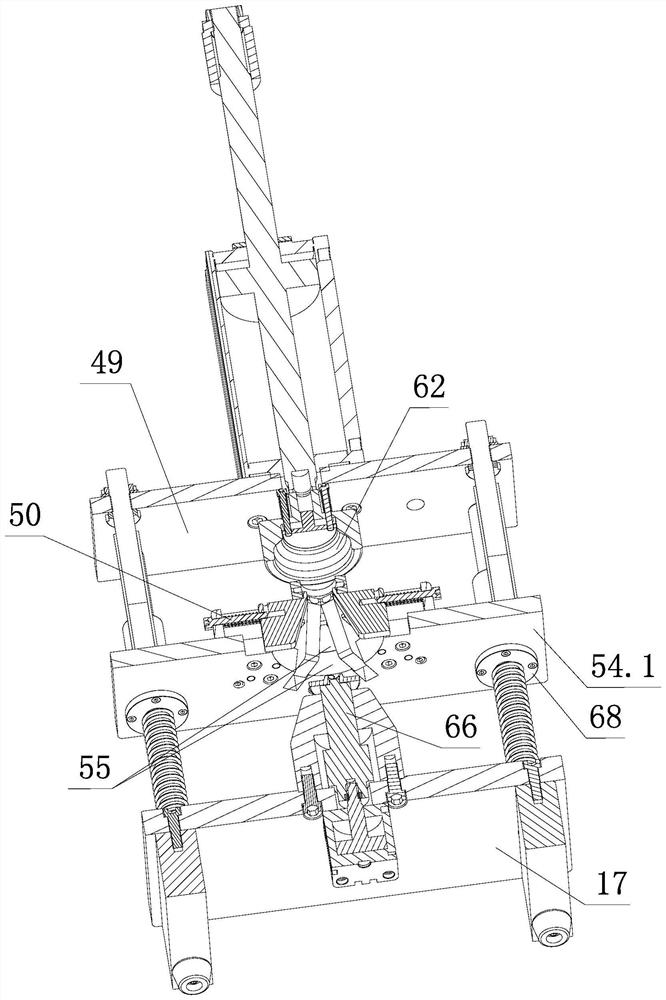

Automatic press-fitting line for shock absorber buffer inner core piece

ActiveCN112518293ASolve the problem of installation positioningReasonable integrationMetal working apparatusEngineeringWorkbench

The invention discloses an automatic press-fitting line for a shock absorber buffer inner core piece. The automatic press-fitting line comprises press-fitting equipment, a first feeding device and a second feeding device. The press-fitting equipment comprises an upper plate, a workbench and stand columns. The upper plate and the workbench are fixed through the stand columns. Each stand column is sleeved with a main compression spring and is in sliding fit with a lifting table, and the lifting tables are placed on the main compression spring. The lifting table is provided with a center hole anda radial sliding groove, wedge-shaped supporting blocks and reset compressed springs are arranged in the radial sliding groove in a sliding fit mode, the inner side faces of the wedge-shaped supporting blocks protrude out of the hole wall of the center hole, hook blocks protrude out of the top faces of the wedge-shaped supporting blocks, the polyurethane ring of the inner core piece is placed onthe lifting table, and all the hook blocks extend into the polyurethane ring. The upper plate is provided with a pressing driving cylinder used for pressing the lifting table, a conical head is arranged on the workbench, the workbench is provided with a jacking driving cylinder, a piston rod of the jacking driving cylinder is connected with a first jacking head, and the metal supporting piece of the inner core piece is placed on the first jacking head. The automatic press-fitting line can achieve automatic feeding and automatic clamping assembly.

Owner:NINGBO PREMIUM AUTOMOTIVE PARTS

Integrated air conditioner air outlet LED lamp

ActiveCN106322706AUniform and highly reflectiveFusion wellAir conditioning systemsSemiconductor devices for light sourcesEngineeringLED lamp

The invention provides an integrated air conditioner air outlet LED lamp. The integrated air conditioner air outlet LED lamp comprises a ventilation substrate and light reflecting subsections capable of being axially spliced into a light reflecting cover; the axial lengths of the light reflecting subsections are equal; the light reflecting subsections are connected to the ventilation substrate through telescopic pipes correspondingly; when all the telescopic pipes stretch to the outer extreme positions, projections of the light reflecting subsections on the axis of the light reflecting cover coincide with one another; a ventilation louver structure is formed by the light reflecting subsections; the light reflecting subsection minimum in radial size is conical; an LED lamp bulb is fixed to the inner side of the conical light reflecting subsection; the interior or the exterior of each telescopic pipe is further provided with a tension spring, wherein each tension spring axially extends and the two ends of each tension spring are connected with the ventilation substrate and the corresponding light reflecting subsection correspondingly; when the air outflow air force action of an air conditioner is not borne by the light reflecting subsections, the tensile force of the tension springs makes the telescopic pipes shortened to the inner extreme positions, and at the moment, the light reflecting subsections are just spliced into the light reflecting cover. The integrated air conditioner air outlet LED lamp can make illumination generated by the LED lamp bulb fully and uniformly projected to the indoor space.

Owner:江苏汉威电子材料有限公司

Catalytic conversion method for high sulfur wax oil

ActiveCN102911735BImprove use efficiencyReasonable integrationTreatment with hydrotreatment processesLow activityIsomerization

The invention relates to a catalytic conversion method for high sulfur wax oil. The method comprises the following steps: the high sulfur wax oil and a thermal regeneration catalyst which has lower activity and relative uniform distribution of activity are contacted at the lower part of a first catalytic cracking unit reactor and are subjected to a catalytic cracking reaction, and the generated oil gas and catalyst containing carbon ascend and are subjected to a secondary cracking reaction and an isomerization reaction under a certain reaction environment; the oil gas is subjected to a separation reaction to obtain a reaction product containing liquefied gas, gasoline and catalytic wax oil; a spent catalyst is subjected to steam stripping and regeneration to be recycled, wherein the catalytic wax oil and optional other secondary processed wax oil are hydrogenated; and the hydrogenated wax oil enters a second catalytic cracking unit to be further cracked. According to the method, low carbon olefins such as ethylene, propylene and the like are furthest produced, and meanwhile the high-octane gasoline is also produced. The invention provides a new way for the cleanness of an oil refining production process and the cleanness of oil-refined products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com