Helicopter cockpit cover gluing assembly method and clamp

An assembly method and jig technology, applied in aircraft assembly and other directions, can solve the problems of repeated positioning of the cockpit cover, unified positioning reference, curing deformation, etc., and achieve the effect of solving the gap of the butt assembly, solving the key technical problems, and controlling the deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

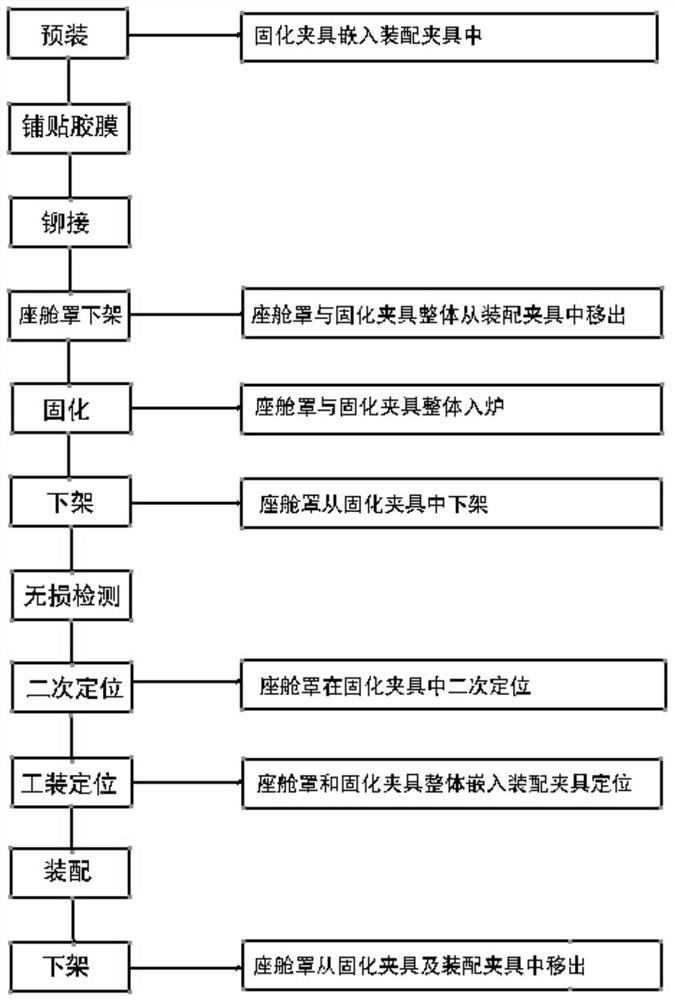

[0036] A kind of helicopter cockpit cover bonding and assembly method, such as figure 1 shown, including the following steps:

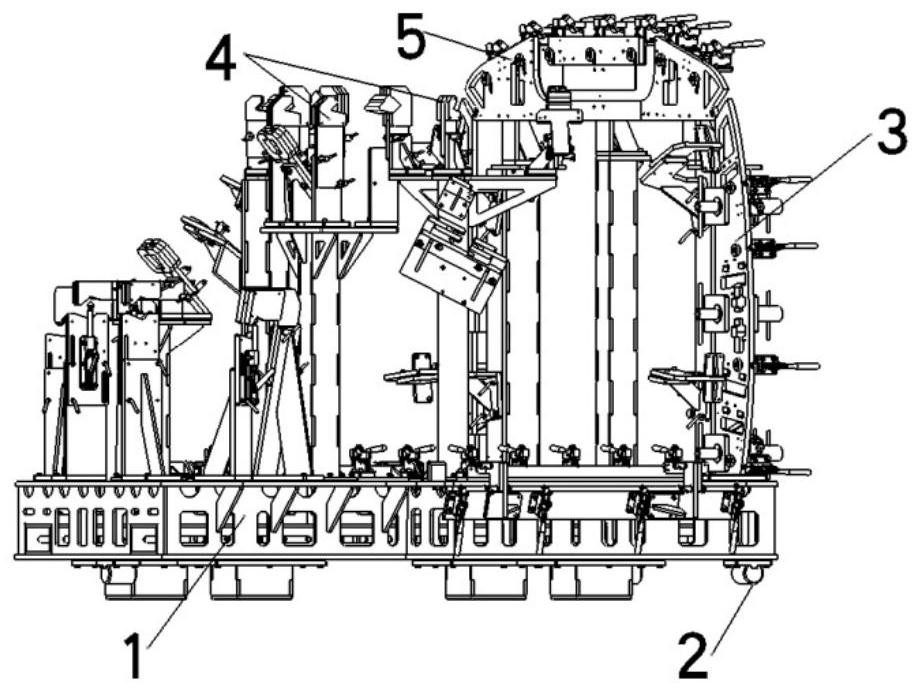

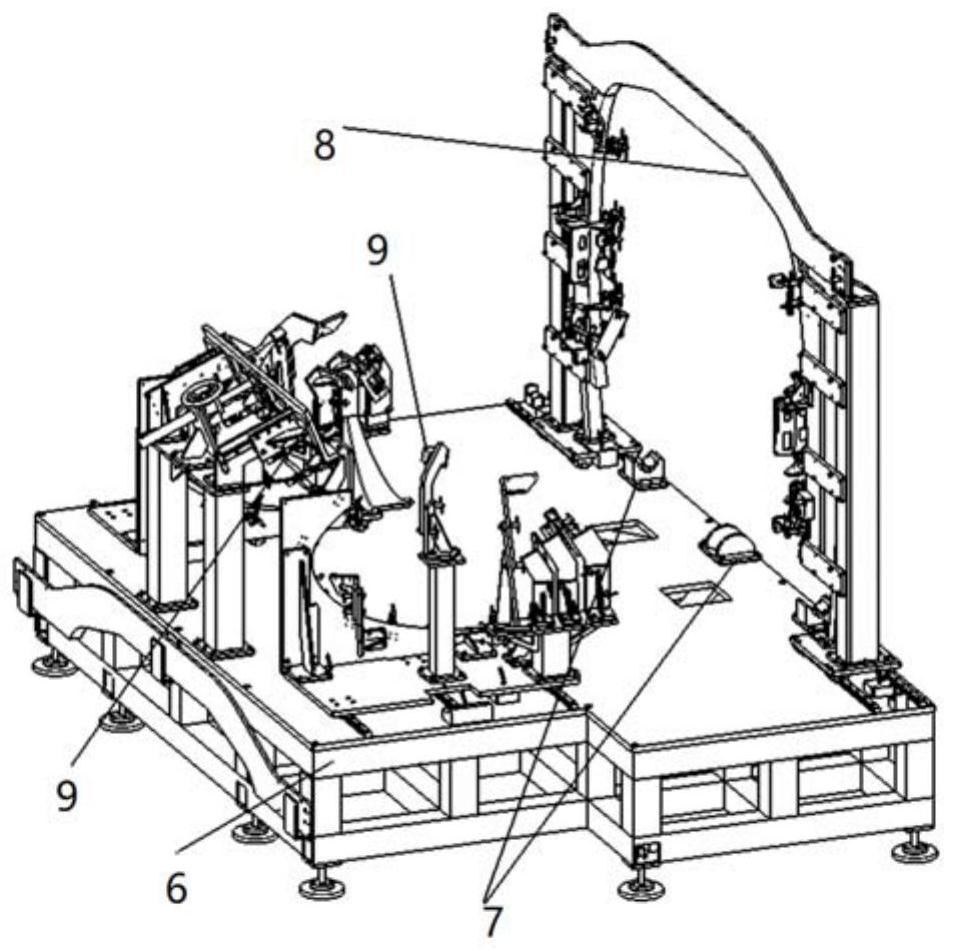

[0037] Step 1: Pre-installation: Position the left door frame frame, right door frame frame, left windshield frame, right windshield frame, upper corner joint, lower corner joint, cockpit ceiling, and ventilation pipe-shaped parts on the assembly fixture in sequence according to the positioning reference; measure each part The gap between the board and the pallet;

[0038] The second step: make the initial hole, make the left door frame frame, the right door frame frame, the left windshield frame, the right windshield frame, the upper corner joint, the lower corner joint, the cockpit ceiling, and the initial holes for connecting the ventilation pipe parts;

[0039] The third step: riveting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com