Patents

Literature

205results about How to "Uniform transition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

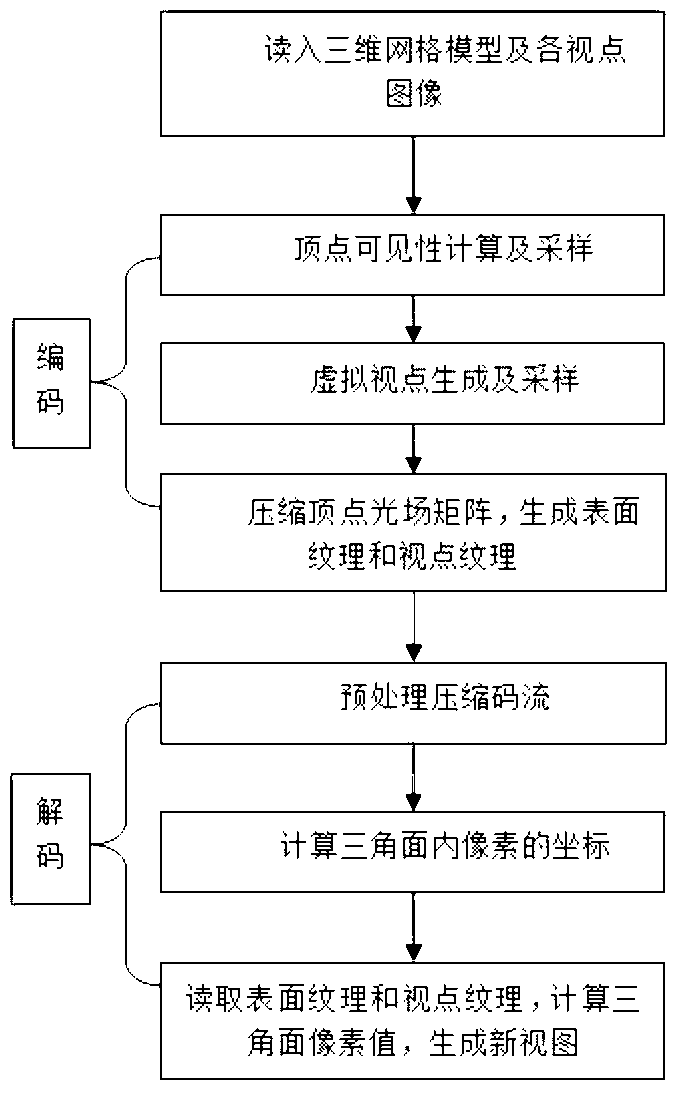

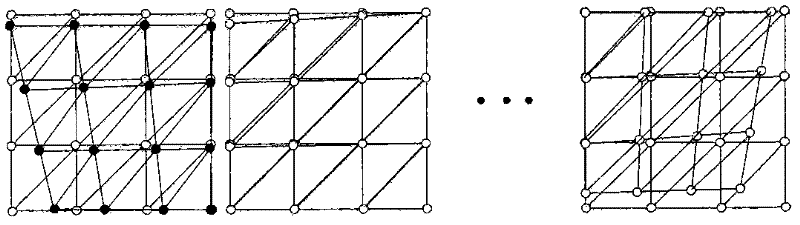

Efficient image rendering method based on modeling

ActiveCN103345771AUniform transitionEliminate texture seams3D-image renderingMatrix decompositionComputer graphics (images)

The invention provides an efficient image rendering method based on modeling. With the method, a target image under free points view points can be generated. A light field model is adopted for recording surface information of a target; on the premise that that a three-dimensional grid model of the target and an appropriate amount of view point surrounding images of the target, through determining of a visible view point list of every vertex, the view points under which sampling is performed are determined; a triangular face ring of every vertex is selected as a sampling unit, virtual view points are generated with the triangulation method, and sampling information under the virtual view points is generated according to weight interpolations; sampling matrixes of all the vertexes are compressed with a matrix decomposition and compression method to facilitate transmission of the sampling information; in order to generate the target under the free view points, the three-dimensional grid model just needs to be projected to a screen coordinate system of new view points, and then a view under the new view points can be generated through reading of the sampling information. The method not only considers the problem of handling of a lapped seam phenomenon in texture mapping, but also reduces storage space for texture information and simplifies the rendering process.

Owner:UNIV OF SCI & TECH OF CHINA

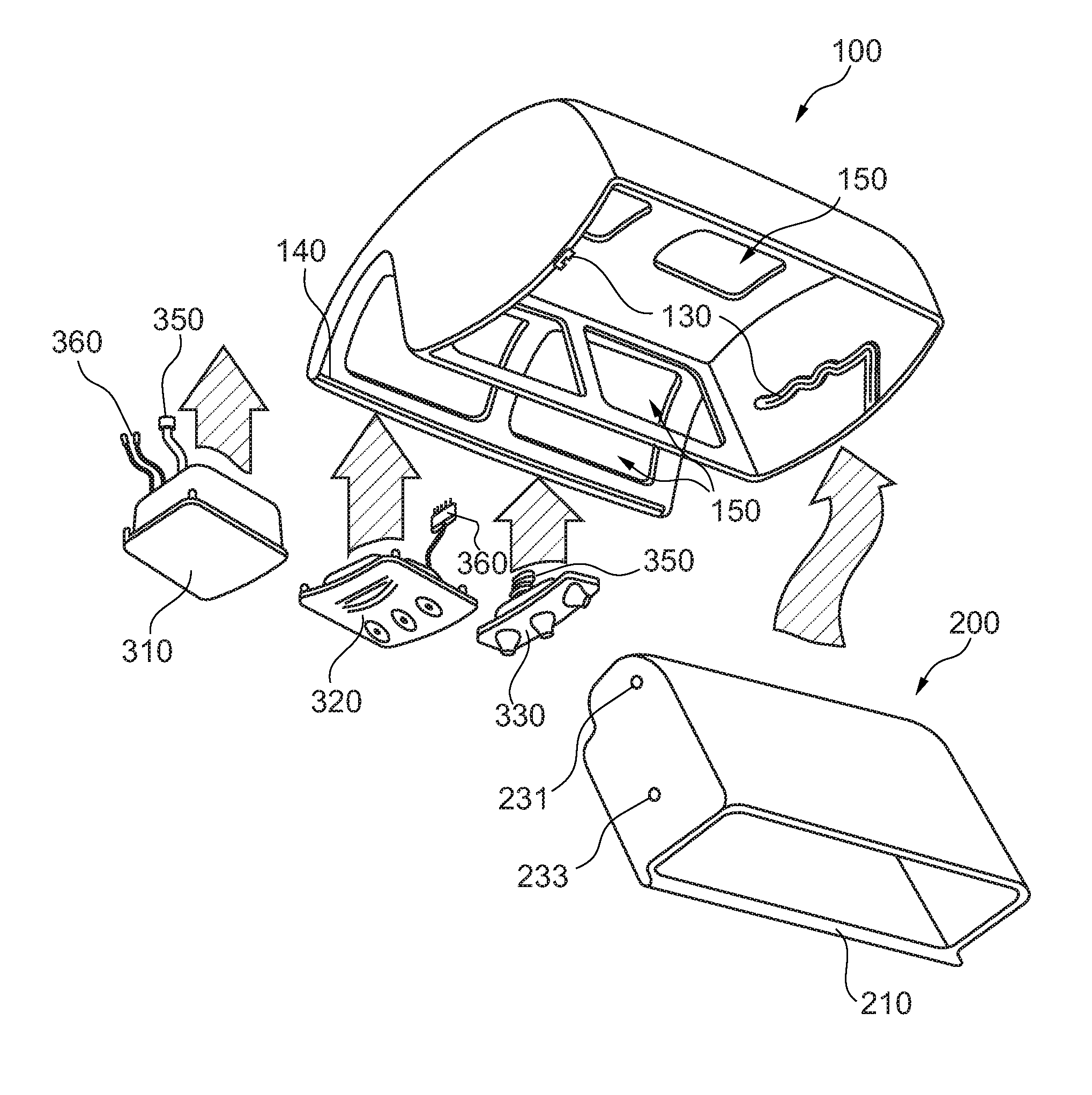

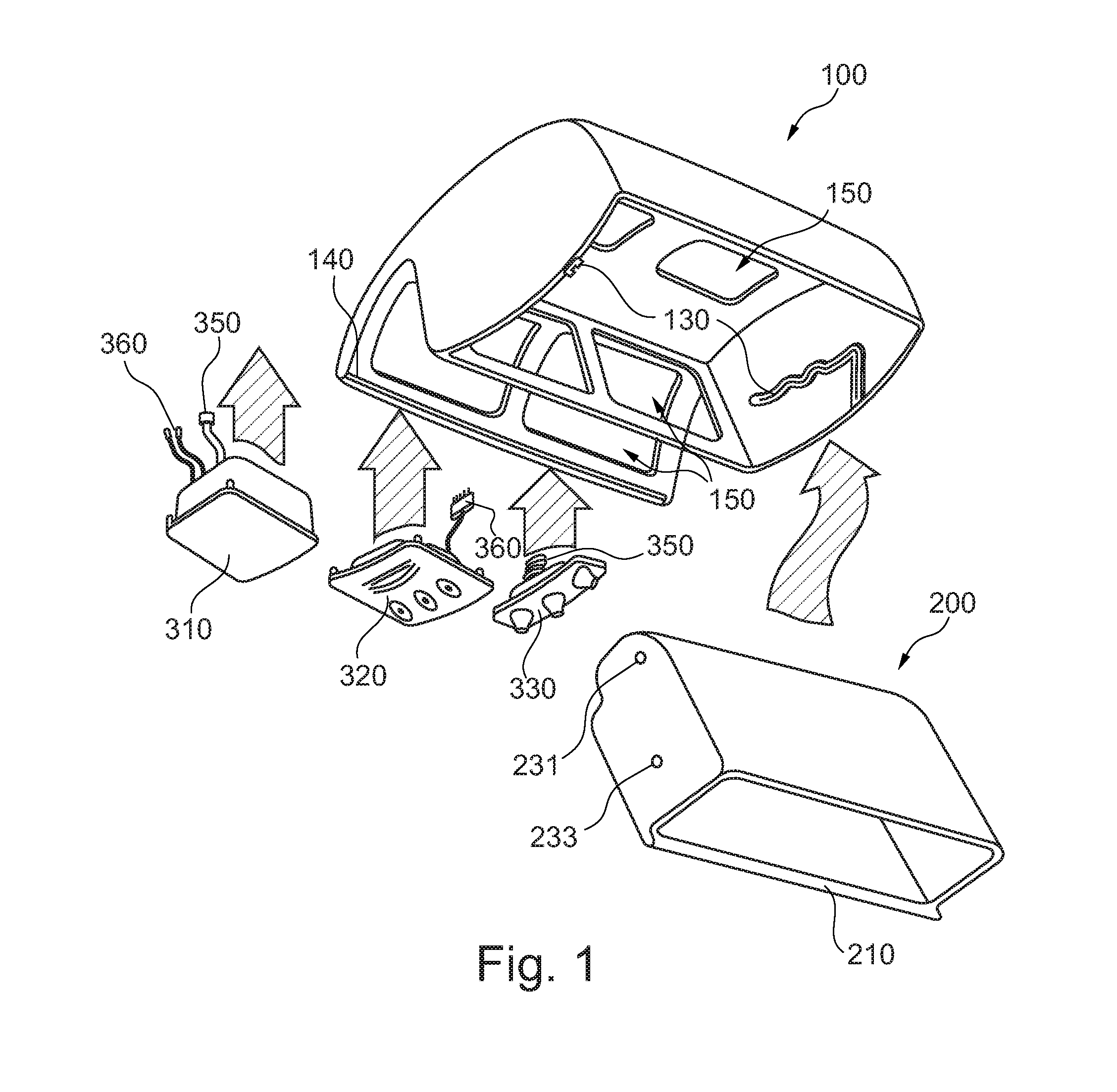

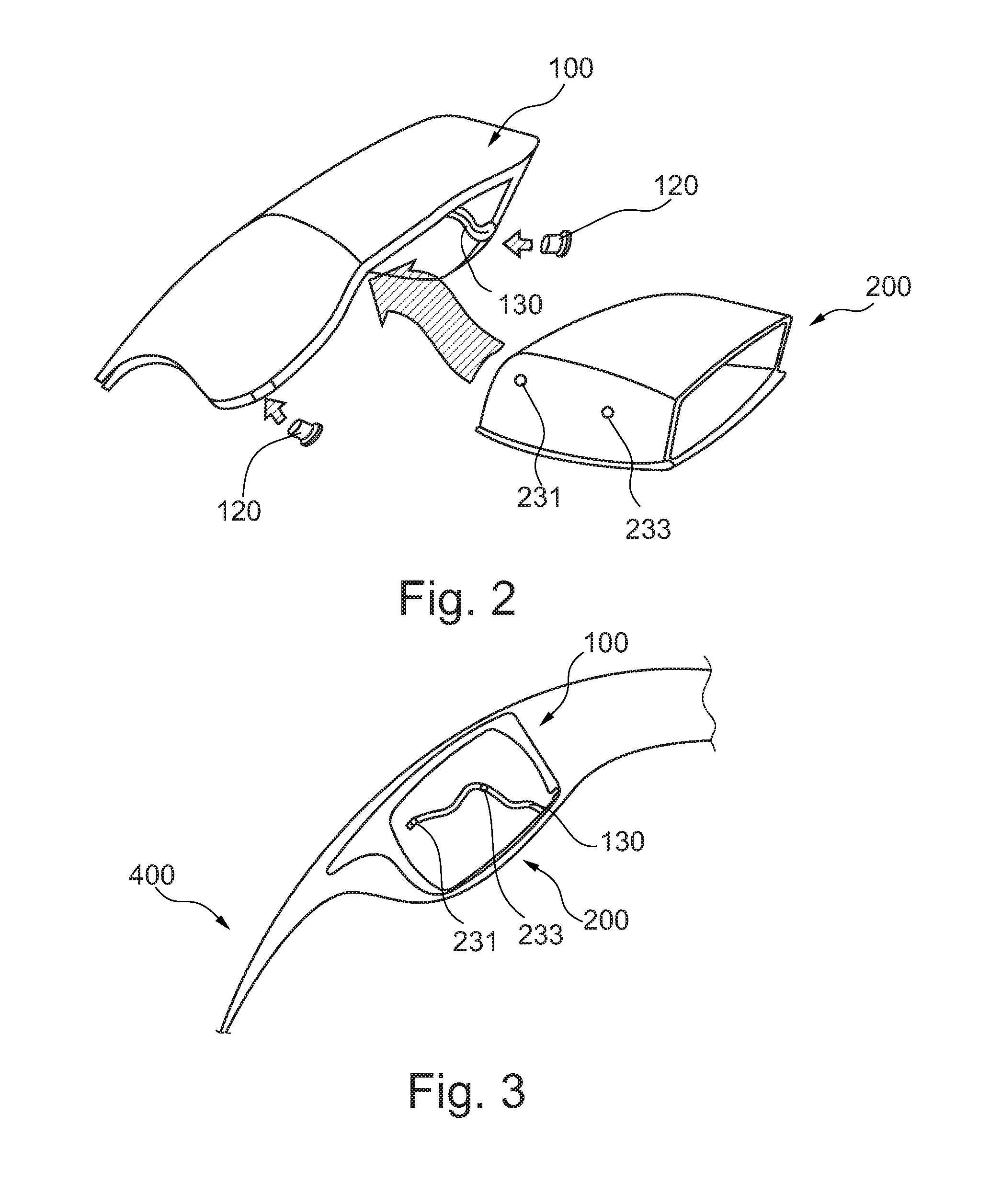

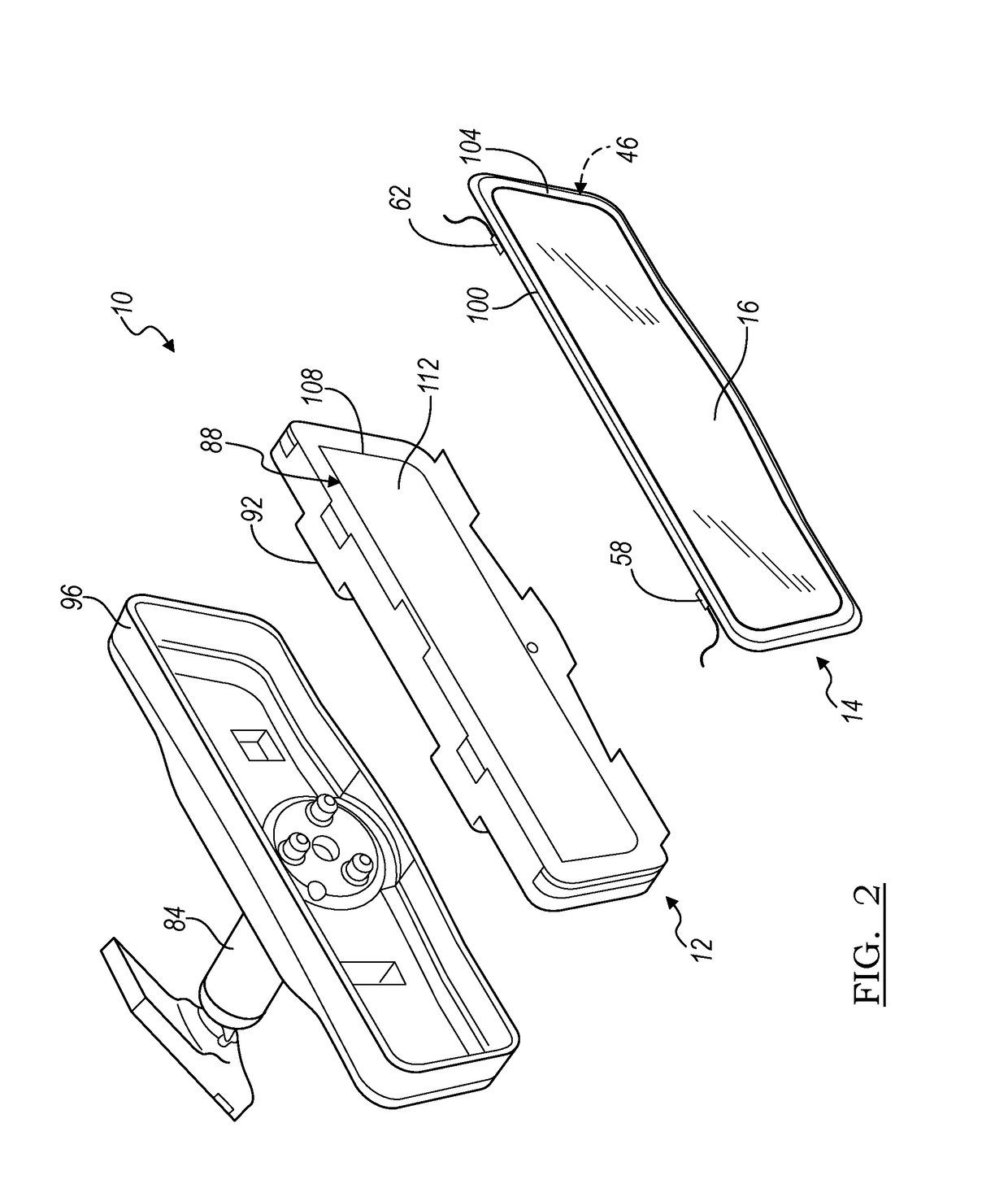

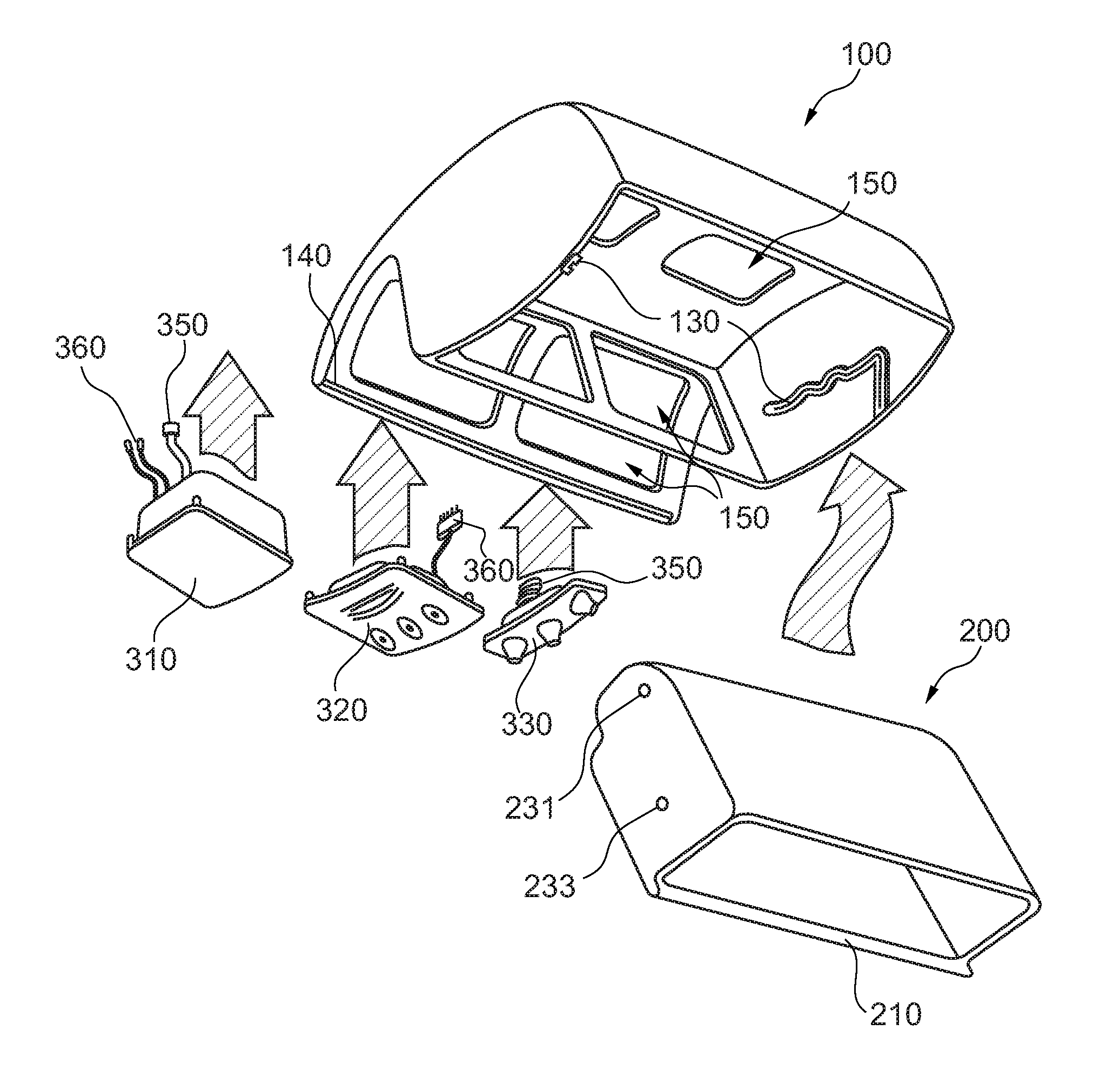

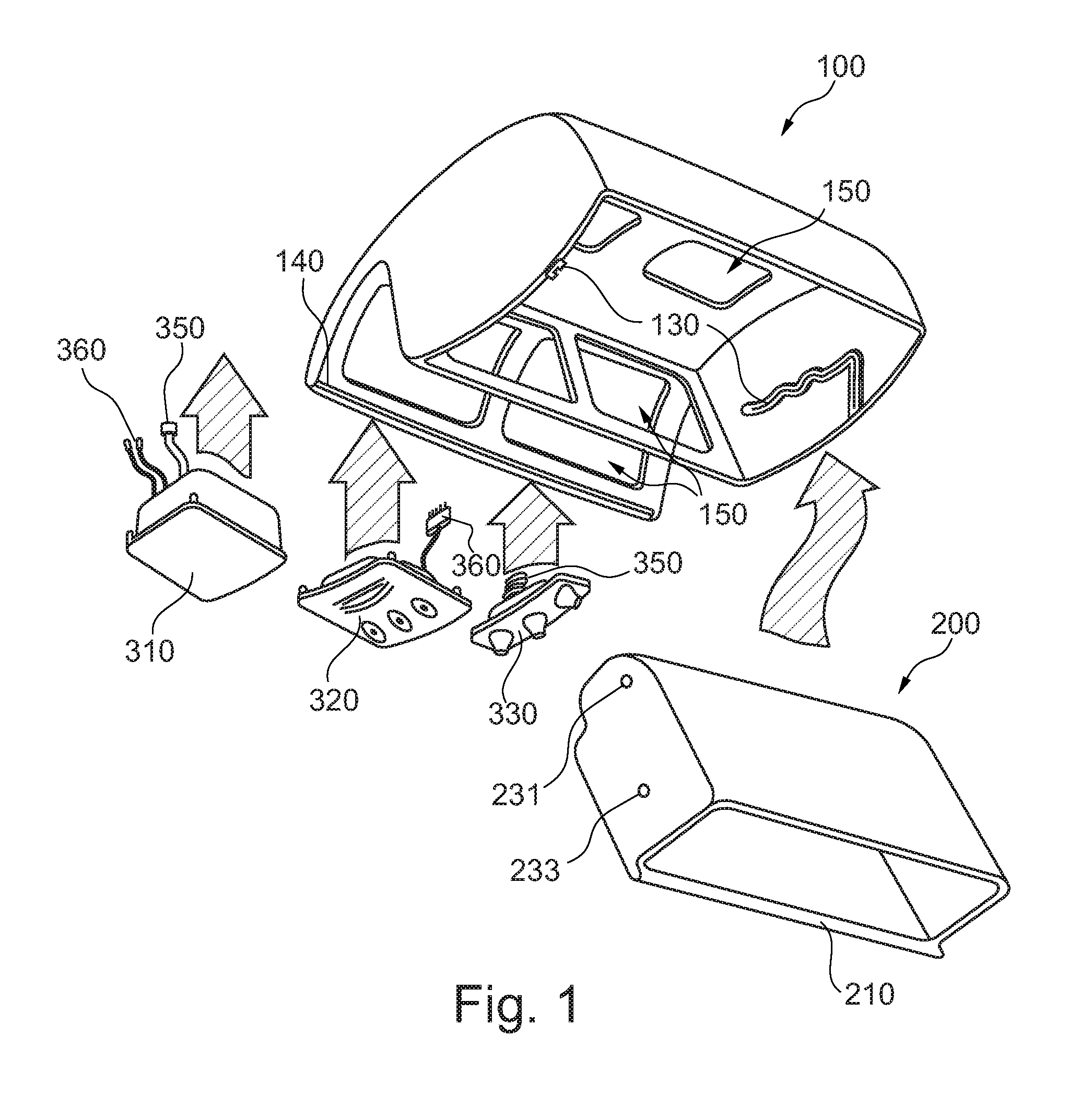

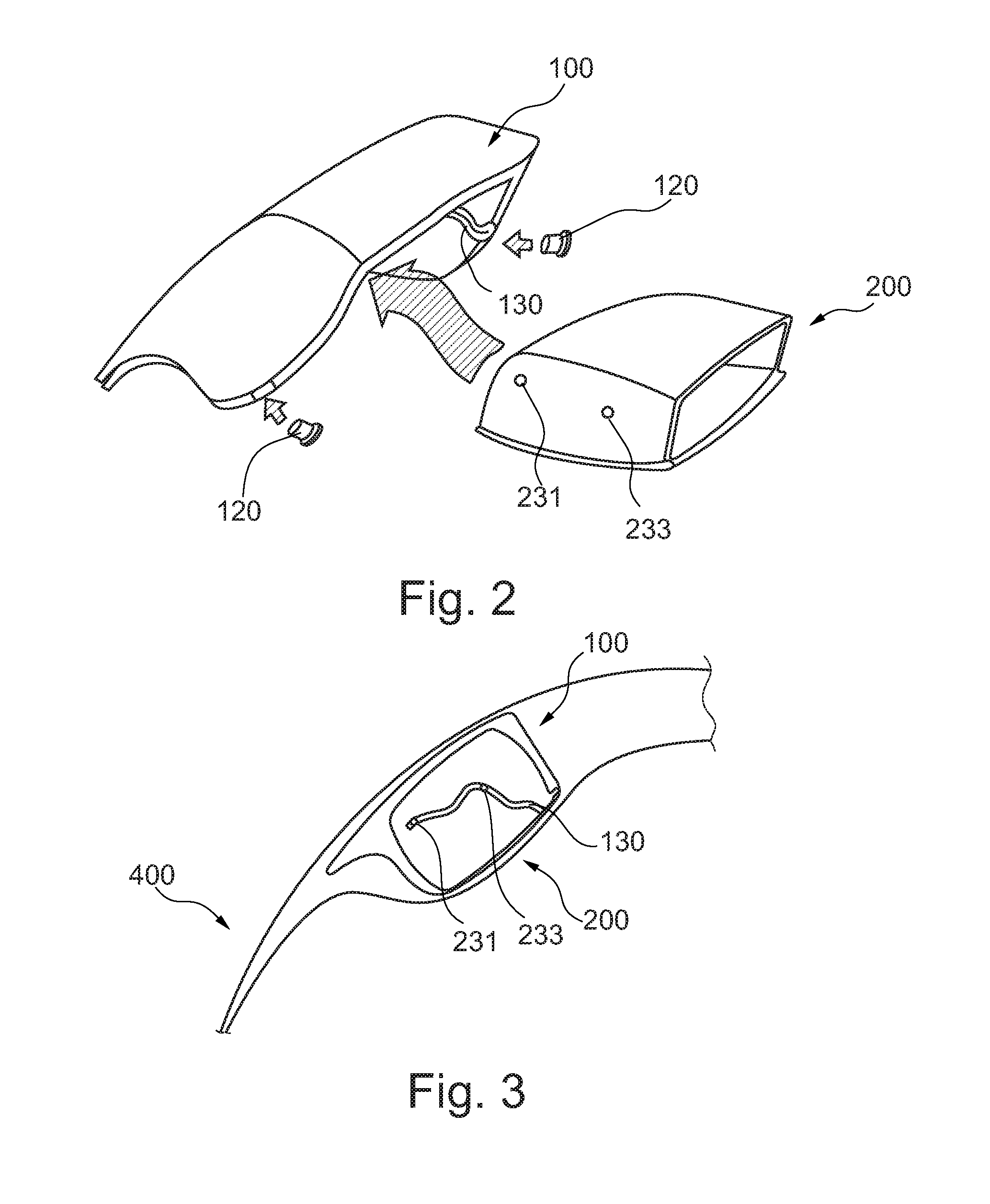

Storage compartment module with mobile storage compartment

ActiveUS20120228426A1Easy to installEasy to operateSeating arrangementsAir-treatment apparatus arrangementsEngineeringMechanical engineering

A hatrack module with a moveable hatrack comprises a housing with a hatrack accommodation space, a hatrack with laterally arranged guide elements and optionally at least one passenger service unit, wherein each guide rail is arranged on one sidewall of the hatrack accommodation space, and wherein the guide elements of the hatrack can be made to engage the guide rails on the housing.

Owner:AIRBUS OPERATIONS GMBH

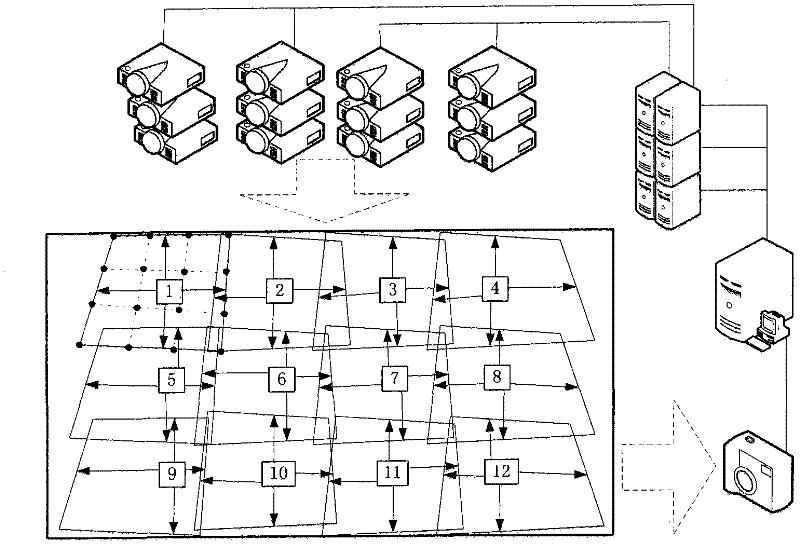

Multi-projector combined display feedback brightness correction method

InactiveCN102053812AAvoid measuring workUniform transitionTelevision system detailsColor television detailsClosed loop feedbackLarge screen

The invention discloses a multi-projector combined display based feedback brightness correction method, belonging to the field of multi-projector combined display based large-screen high-resolution display technologies. The multi-projector combined display based feedback brightness correction method is characterized by being realized in a closed-loop feedback brightness correction system consisting of a projector array, a digital camera, a server and a client computer, wherein the server obtains grids for geometry correction through the relation between a characteristic point image and characteristic points of a projection space, sends an initial template to a client, and circularly performs the process of brightness decay, projecting, image acquisition and template updating to obtain a template with corrected brightness; and the client performs geometry correction and brightness correction for every image transmitted by the server so as to obtain a seamlessly spliced big picture on a large screen. The combined display based feedback brightness correction method has the advantages of simpleness for operation and natural picture.

Owner:TSINGHUA UNIV

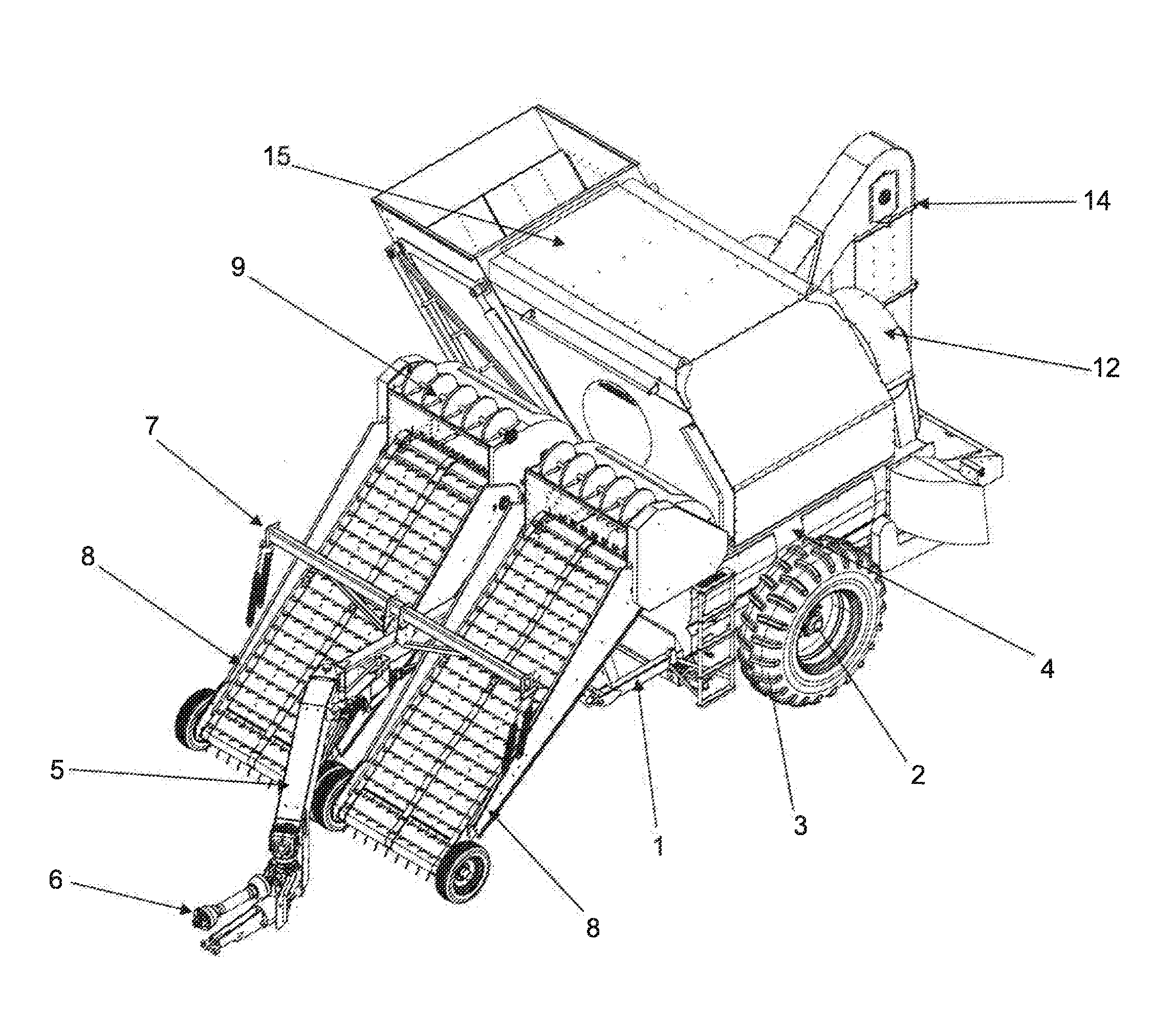

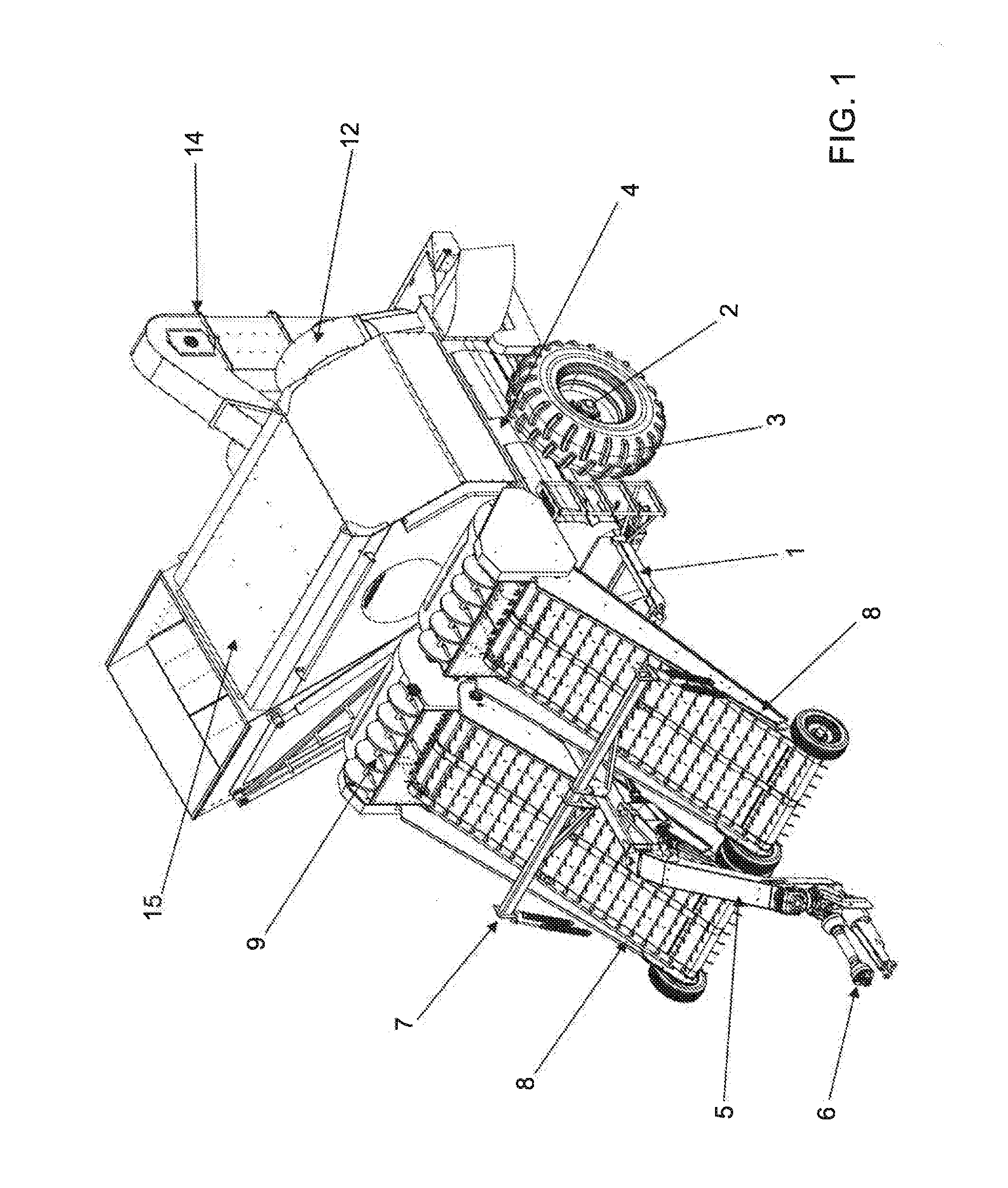

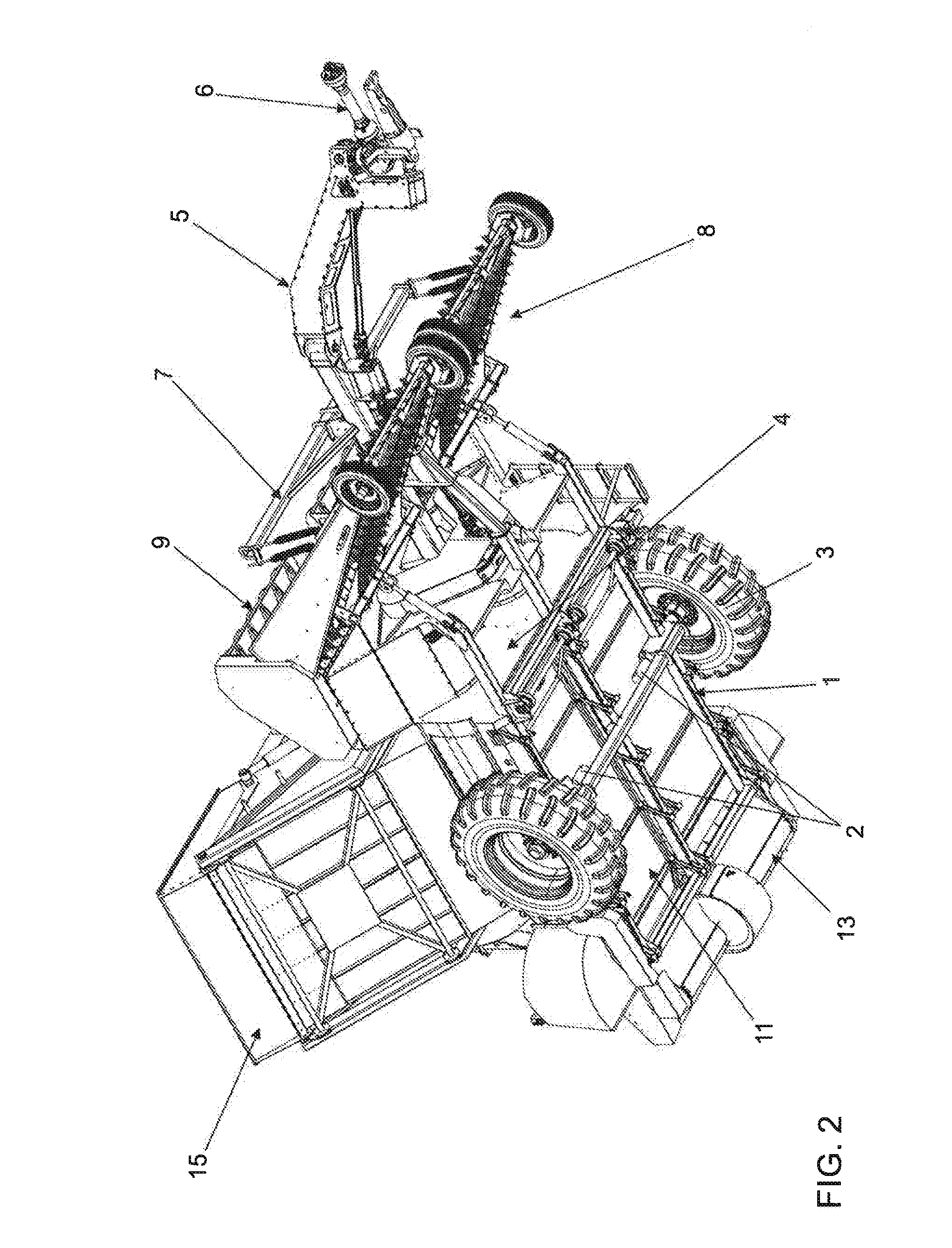

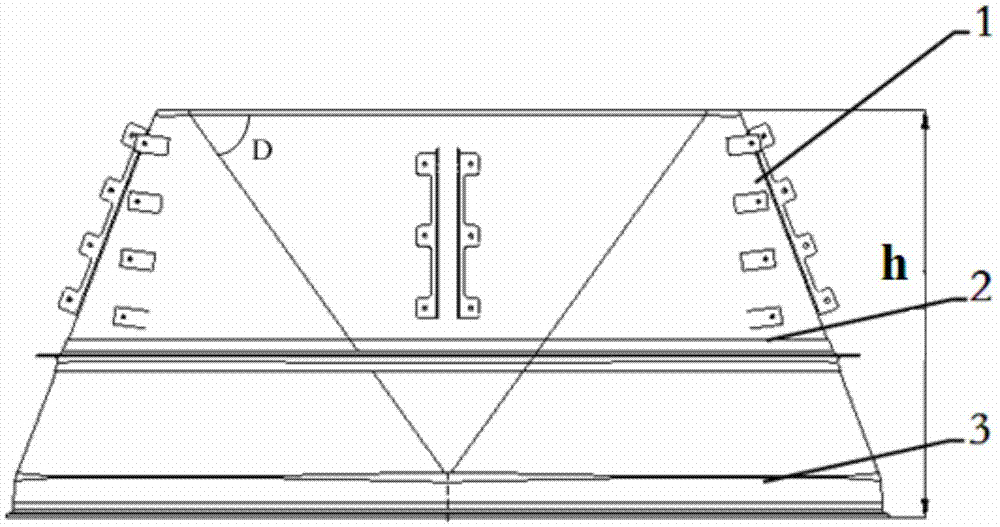

Harvester and processor for peanuts

ActiveUS20160316626A1Uniform transitionSpeed up the flowLoadersDigger harvestersAnti jammingEngineering

A harvester and processor for peanuts that comprises a drag type machine to be towed and actuated by a conventional tractor, which has various double assemblies to harvest lined up peanuts and process them through various steps of cleaning, up to the separation of the cleaned grains that are stored in an embedded tipper bucket, and to perform all this, said machine contains a chassis (1), that on its bottom side is supported by wheels (3), while on its top side is integrated with a plate body (4) forming a mono block structure for the assembling of all the embedded assemblies, starting with the frontal hitch pole (5) integrated with the transmission assembly (6) which is responsible for the actuation of various parts of the machine, specially two harvesting conveyor belts (8), anti-jamming receptive boxes (9), threshing cylinders (10), and in these cylinders starts the cleaning process together with the vibrating sieves (11) and the ventilation assembly (12), being that the cleaned fruits are delivered to a receptive chute (13), where they are collected by a bucket elevator (14) and dropped inside of a tipper bucket (15).

Owner:IND REUNIDAS COLOMBO LTD

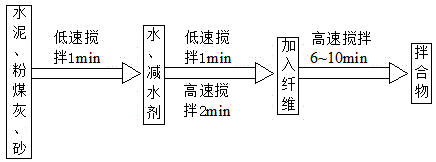

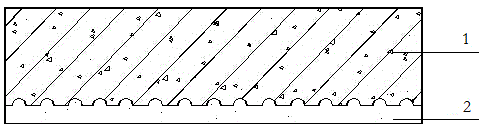

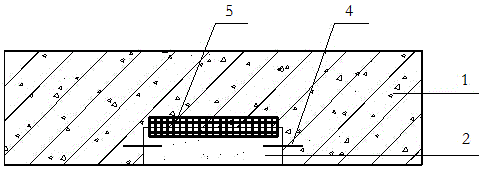

High-strength reinforced and functionally-graded concrete beam

The invention relates to a structure of a building member and a material, particularly relates to a high-strength reinforced and functionally-graded concrete beam and belongs to the technical field of building materials. The high-strength reinforced and functionally-graded concrete beam is mainly characterized in that common concrete and a high-toughness fiber-enhanced cement-based composite material are combined in a layering manner; the common concrete is adopted for the pressed area of the concrete beam; the high-toughness fiber-enhanced cement-based composite material is cast in a pulled area in the whole longitudinal-length range of the beam or the specific beam section; and interface-area treatment is adopted for a combined area of the common concrete and the high-toughness fiber-enhanced cement-based composite material. The high-strength reinforced and functionally-graded concrete beam has the advantages that uniform transition of the material system on performance is realized, discontinuous weak areas on the interface are eliminated, the bearing capability of the structure is effectively improved and the completeness and the stability of the whole structure are ensured.

Owner:YANGZHOU UNIV

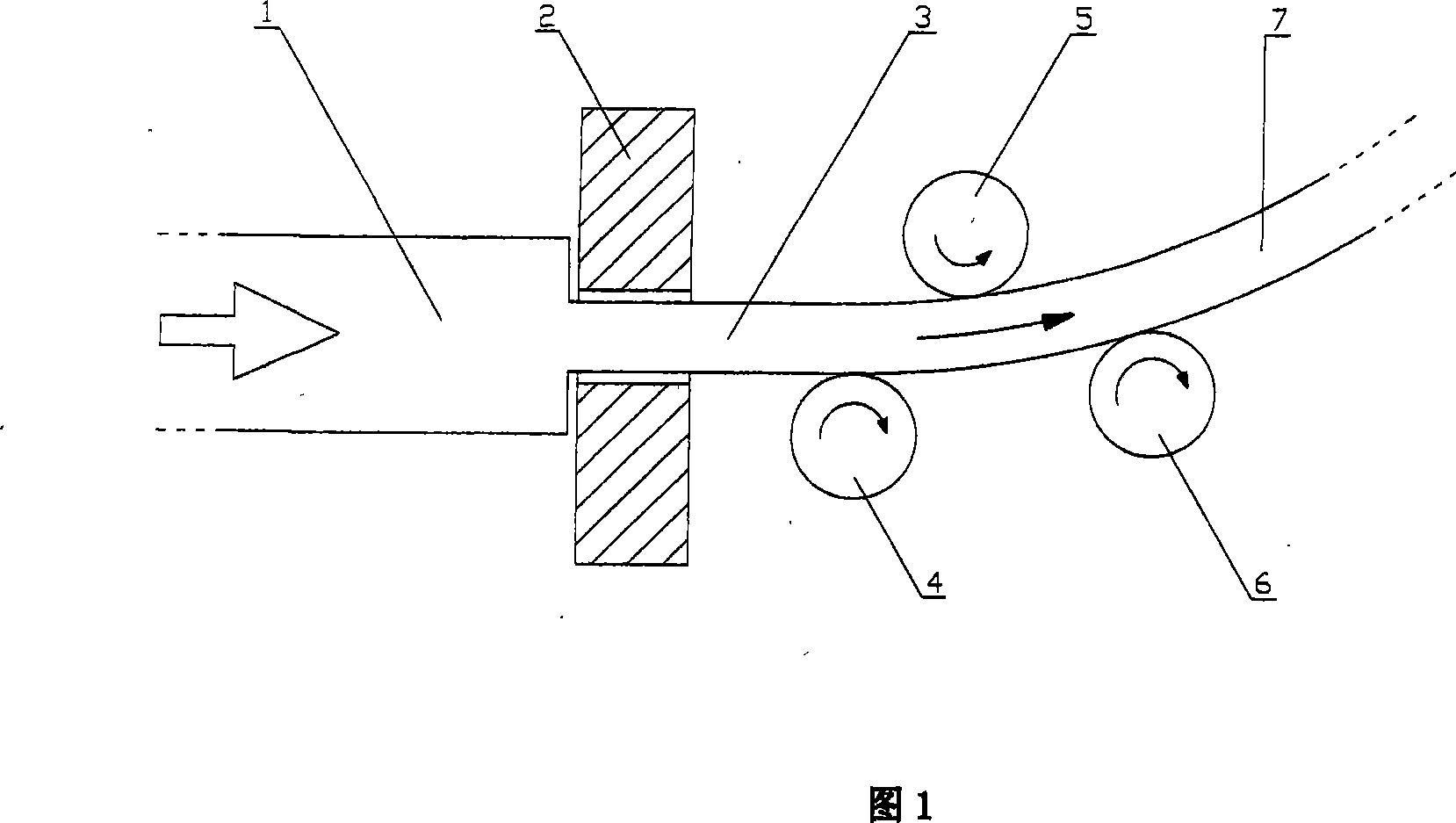

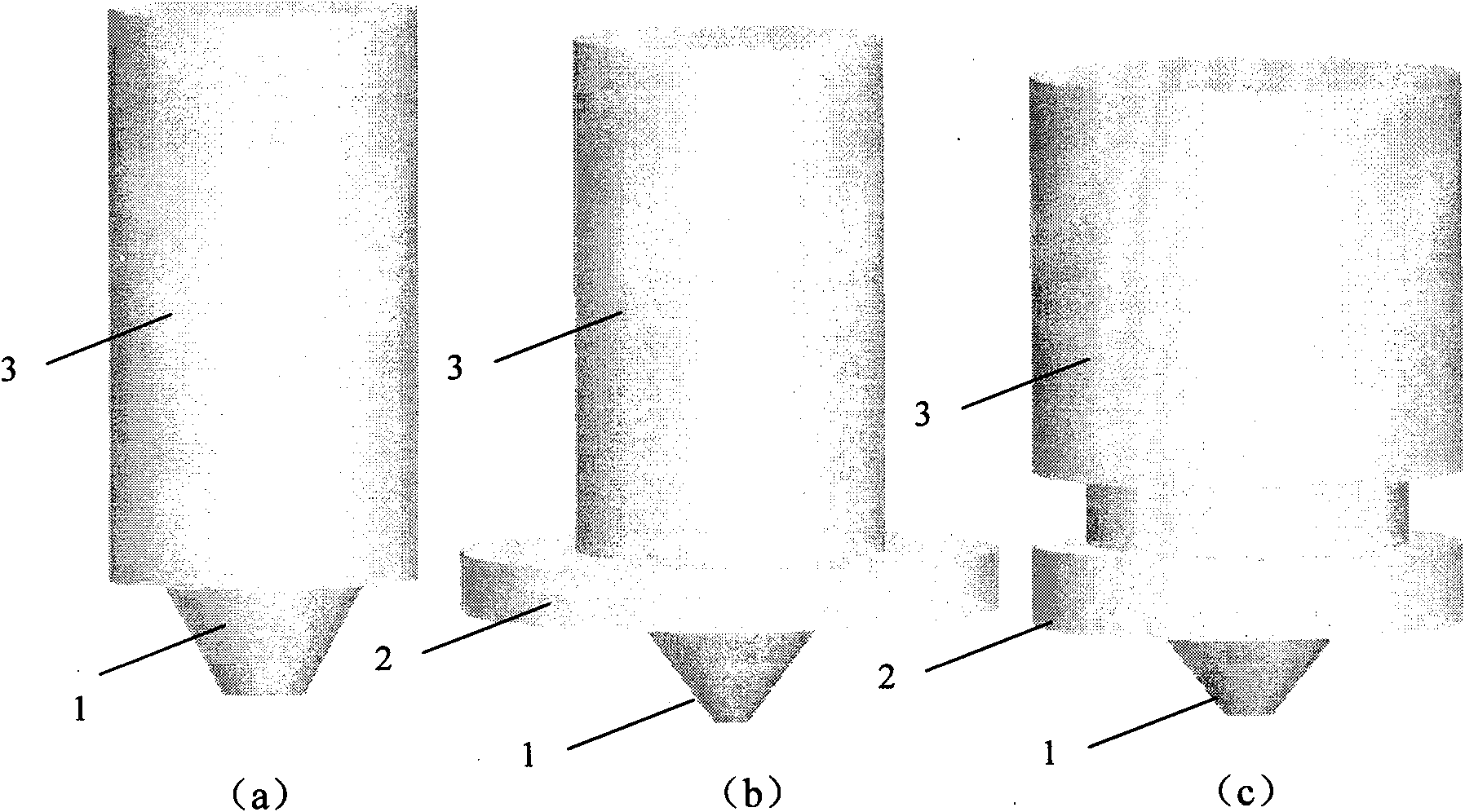

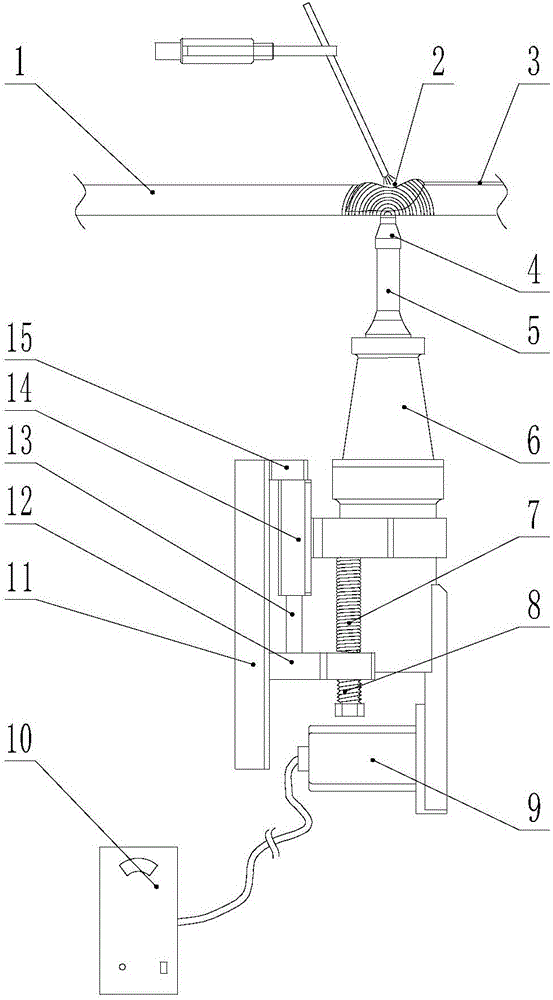

Extruding-bending integral forming method for magnesium alloy profiles

The invention relates to a technical method used for extruding-bending-integral forming of a magnesium alloy sectional material, pertaining to the technical field of plasticity processing. A set of three-wheel roll bending device is arranged near a discharge port of the original horizontal extruding machine, magnesium alloy ingot blanks are molded into the sectional material through hot extrusion, the sectional material is put into the roll bending mechanism directly before being cooled, bending moment is carried out to the sectional materials by the three roll wheels that are arranged on a same surface so as to achieve bending and molding, and the movement and position of the roll wheels are controlled to gain a bending angle and a bending radius that are required. The invention can realize the extrusion, bending and continuous molding of the magnesium alloy sectional material under the condition of only heating original ingot blanks, thereby having high production efficiency and low cost.

Owner:SHANGHAI JIAO TONG UNIV

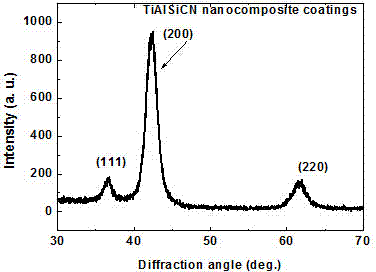

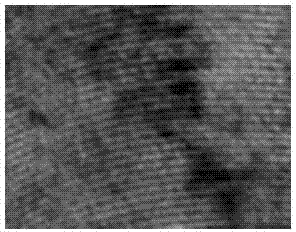

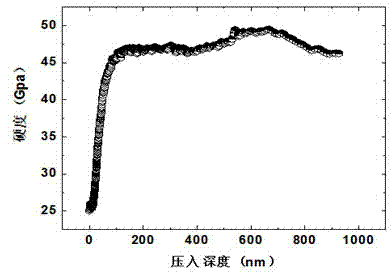

Superlubricity multilayer nano composite coating and preparation method thereof

ActiveCN104846332AReduce bond strengthReduce toughnessVacuum evaporation coatingSputtering coatingHardnessUltimate tensile strength

The invention discloses a superlubricity multilayer nano composite coating and a preparation method thereof. The coating comprises a Cr metal combination layer coated on a cutter matrix, a CrN transition layer, a gradient structure nano periodicity TiSin-TiAlN supporting layer, a nano composite TiAlSiCN functional layer and a DLC surface lubricating layer from inner to outer. The gradient structure nano periodicity TiSin-TiAlN supporting layer can greatly reduce the internal stress and improves combination intensity and toughness of a coating layer; and the DLC surface lubricating layer has low friction coefficient, can reduce abrasive wearing and increase the cutter life. The composite coating has combination force greater than 80N, internal stress less than 0.12Gpa, hardness higher than 40Pa, and friction coefficient as low as 0.2, and the cutting experiments show that the cutter life can be effectively increased. The cutter containing the coating is suitable for cutting process of an aluminum alloy and a high hardness steel material under high speed condition.

Owner:LINGNAN NORMAL UNIV

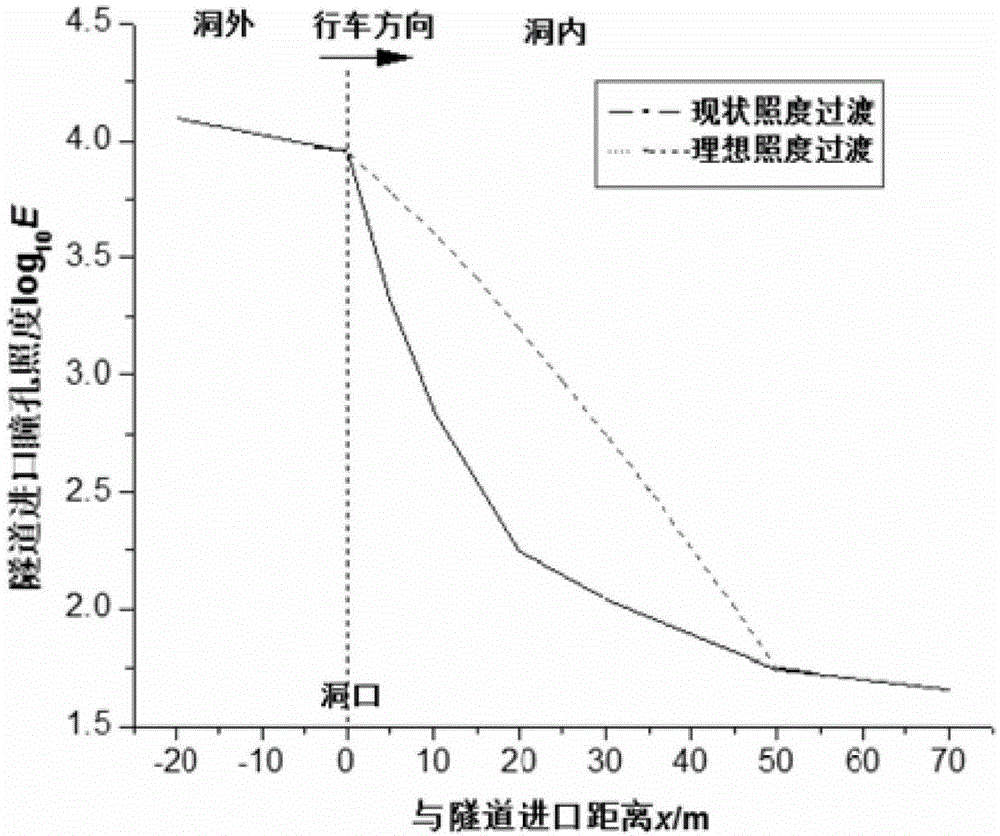

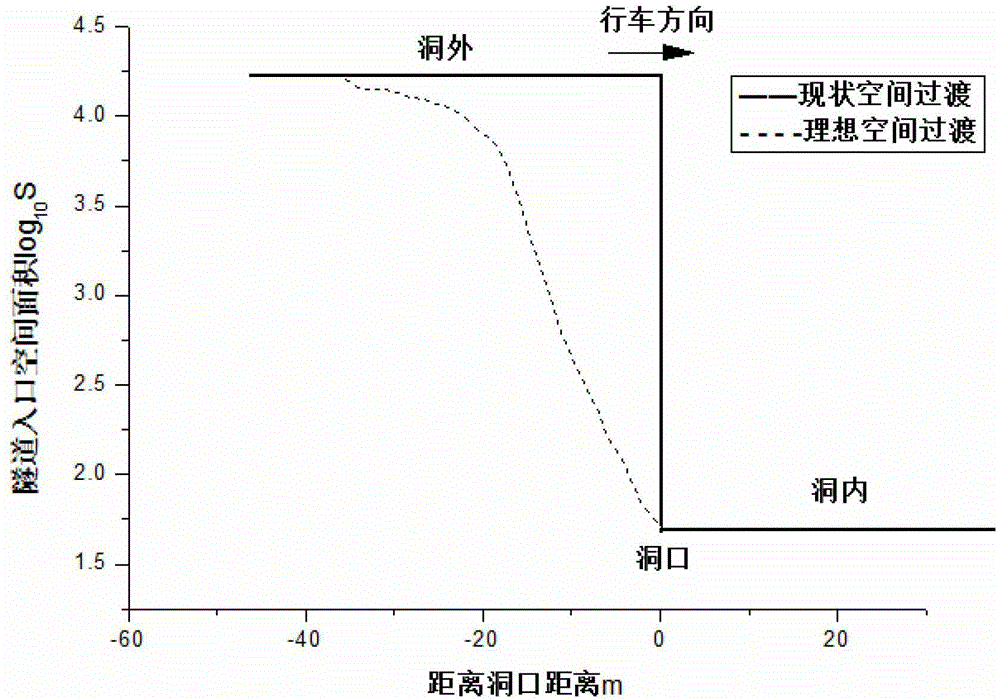

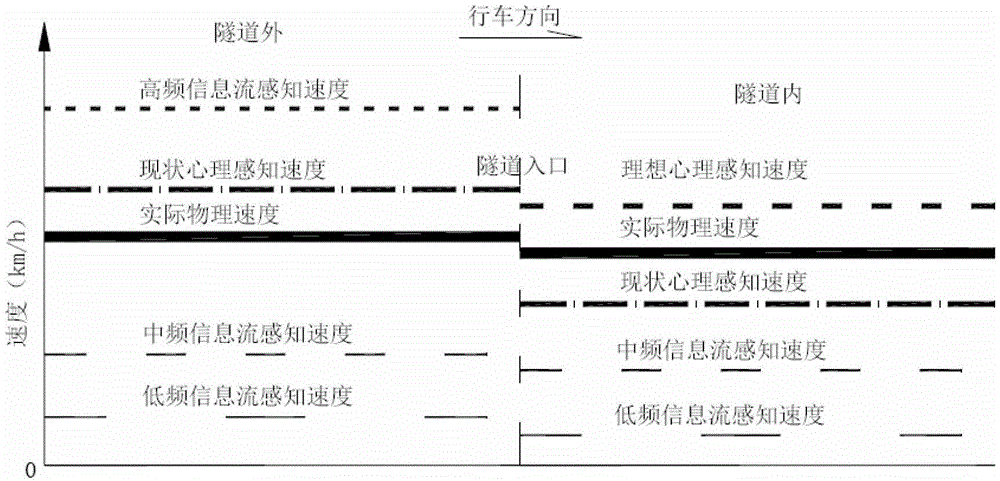

Method for designing shading transition facility for road tunnel entrance

The invention relates to a method for designing a shading transition facility for a road tunnel entrance. The facility mainly comprises transparent toughened glass plates (2), a plurality of arched steel-structure upright columns (3), cicada-wing-shaped nontransparent shading films (5) and a shading transition retroreflection system, wherein the arched steel-structure upright columns (3) are gradually heightened outwardly from tunnel cave entrance end walls (1), and horn-shaped openings are formed by the arched steel-structure upright columns (3) and the transparent toughened glass plates (2) on the upright columns; the cicada-wing-shaped nontransparent shading films are arranged on inner layers of the transparent toughened glass plates, and contour line planes and side face projections of the shading films are Boltzmann curves, and the two sides of each arched steel structure are triangularly hollowed; the retroreflection system comprises medium-frequency steel-structure upright column contour marks (7), medium-frequency guardrail contour marks (8), high-frequency guardrail facade marks (9), high-frequency pavement marking lines (10) and high-frequency pavement protrusion marks (11). The shading transition facility has the advantages that the intense transition of space, luminance and reference of the tunnel entrance can be improved, and the black-hole effect on the tunnel entrance is relieved.

Owner:WUHAN UNIV OF TECH

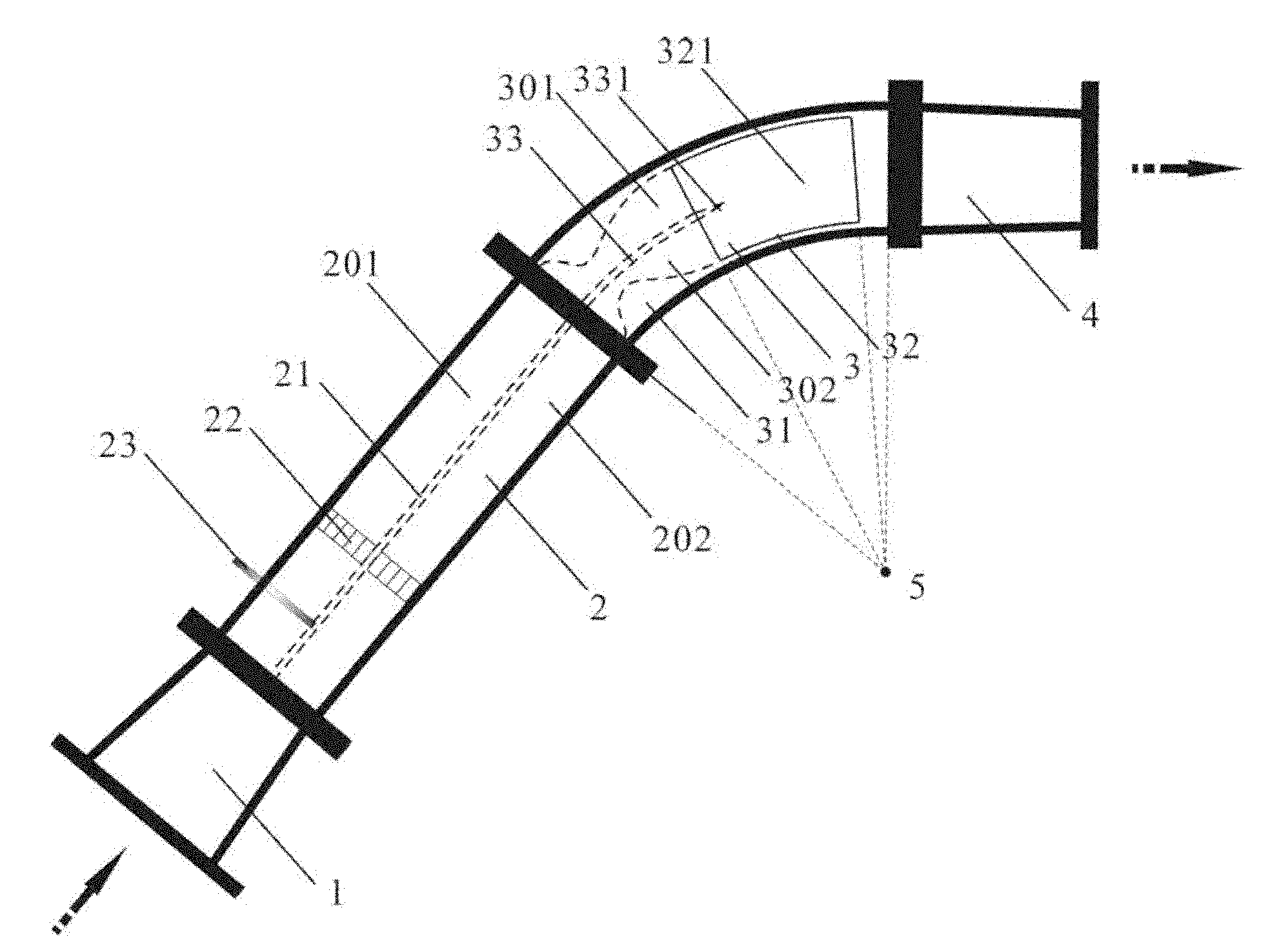

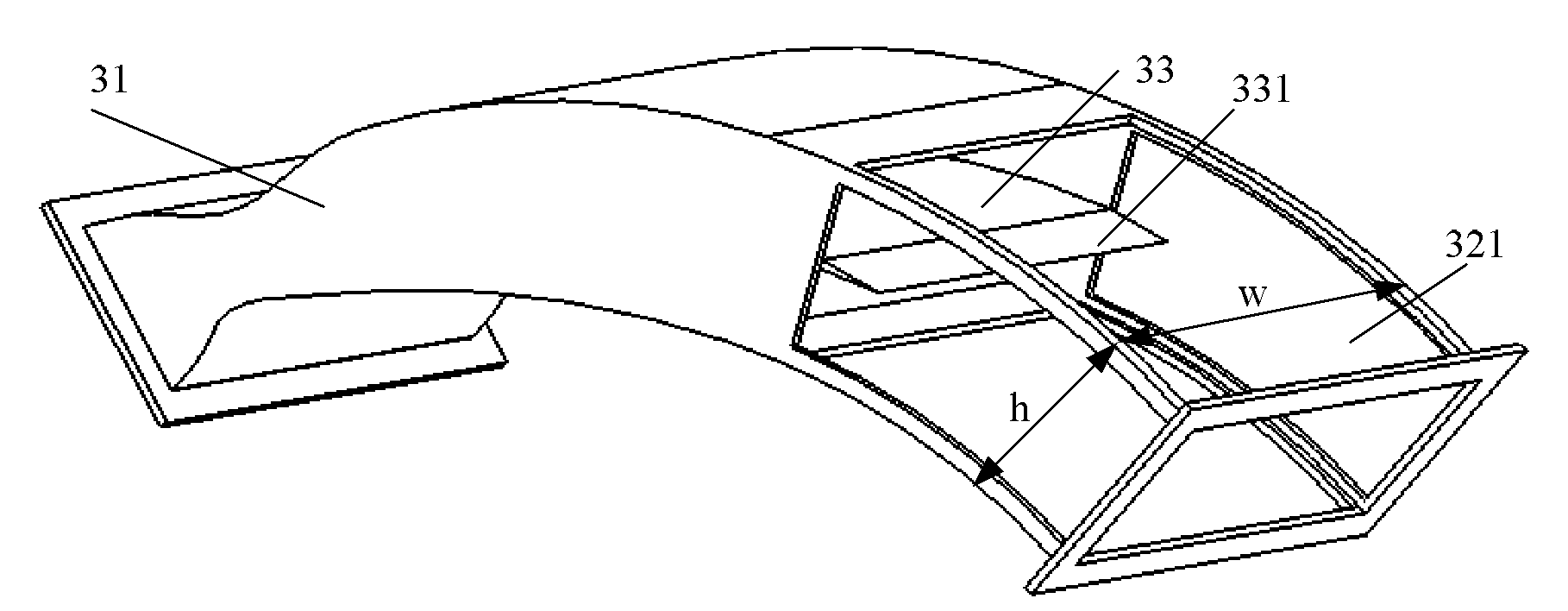

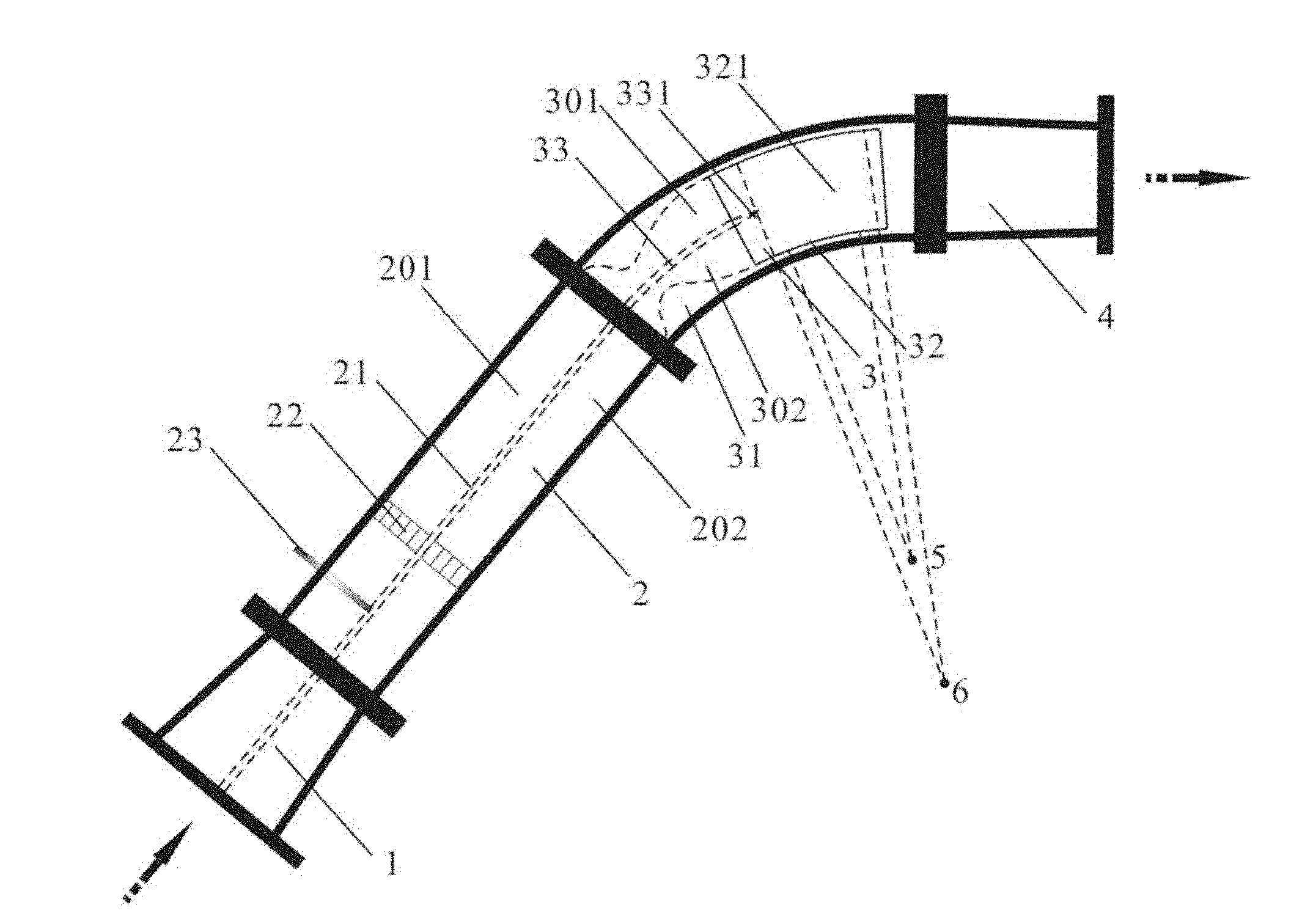

Supersonic free vortex mixing layer wind tunnel

ActiveCN102023079AFlow field characteristics researchEasy to implementAerodynamic testingEngineeringAirflow

The invention provides a supersonic free vortex mixing layer wind tunnel. The wind tunnel comprises a transition section (1), a stabilizing section (2) and a spray pipe experimental section (3), wherein the transition section (1) is used for introducing air flow; the stabilizing section (2) is connected to the downstream side of the transition section (1) and is provided with a first separation plate (21) for separating the introduced air flow into two strands of air flow; the spray pipe experimental section (3) is connected to the downstream side of the stabilizing section (2) and comprises a spray pipe part (31) and a mixing experimental part (32); a transparent window is formed on the peripheral wall of the spray pipe experimental section (3); the spray pipe part (31) has a double free vortex spray pipe structure and is used for accelerating the two strands of air flow to form a free vortex state respectively; the mixing experimental part (32) is positioned on the downstream side of the spray pipe part (31) and is used for mixing the two strands of air flow in the free vortex state to form a free vortex mixing layer, so that velocity fields of the two strands of air flow at an inlet of the experimental part of the wind tunnel meet the requirement of supersonic free vortex distribution; therefore, an ideal supersonic free vortex mixing layer can be obtained in the wind tunnel.

Owner:NAT UNIV OF DEFENSE TECH

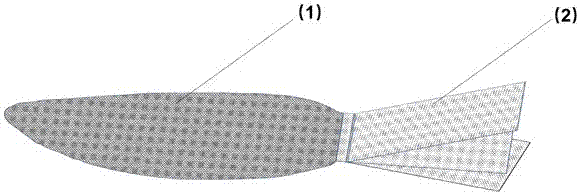

Composite material propeller blade sheet molding and transition connection technical study

The invention relates to composite material propeller blade sheet molding and transition connection technical study. The technical study includes the following steps that (1) propeller blade sheet molding is carried out, wherein a paddle die and a reinforcing material are selected and treated, a plurality of layers of carbon fiber cloth is led out from the interiors of paddles in the paddle paving design process, and die assembly, pressurizing, heating, curing and aftertreatment re carried out after paddle paving is finished; and (2) paddle and paddle hub transition connection is carried out, wherein a fixing tool is used for fixing the multiple paddles, the paddles are subject to paving design, the carbon fiber cloth led out from the interiors of the paddles is paved inside the paddles, and the carbon fiber cloth led out from the interiors of the paddles and the propeller hub are subject to co-curing. The processes of sheet molding propeller blades and transition connection are adopted, the continuity of fibers inside the paddles and the paddle hub is guaranteed, the continuity of fibers on the inner wall of the paddle hub is guaranteed, the strength of the connecting position of the propeller blade and the propeller hub is improved, the process is simple, and the reliability is high.

Owner:武汉海威船舶与海洋工程科技有限公司 +1

Surface gradual change printing technology and product thereof

The invention discloses a surface gradual change printing technology. The technology mainly comprises the following steps that firstly, printing ink is diluted, and printing ink of at least two different colors is taken to be diluted; secondly, screen inlet mixing is carried out, the diluted printing ink of the at least two different colors is guided in a blank screen printing plate and is linearly arranged according to the gradual change sequence, and a stacking layer of overlapped printing ink of two different colors is formed between adjacent printing ink of every two different colors; thirdly, stacking layer color matching is carried out, and complete mixing and color matching are carried out on the printing ink of the stacking layer through a silica gel scrapper till colors are mixed evenly; fourthly, one-time printing is carried out, a printed material is printed with a gradual change printing ink layer through the blank screen printing plate and the printing ink with even color matching on the blank screen printing plate. The non-screen-point gradual change silk-screen printing is adopted, the manufacturing procedure is simple, convenient and effective, and the product has very even transition and natural non-screen-point gradual change effects.

Owner:FUJIAN RICHES ELECTRONICS SCI & TECH

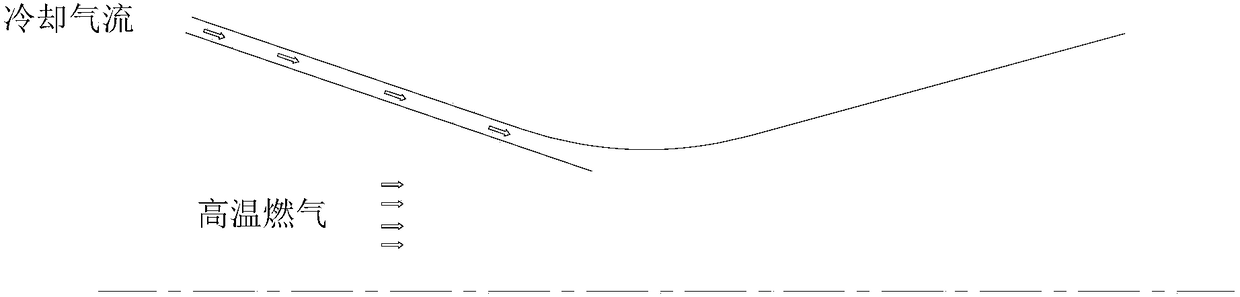

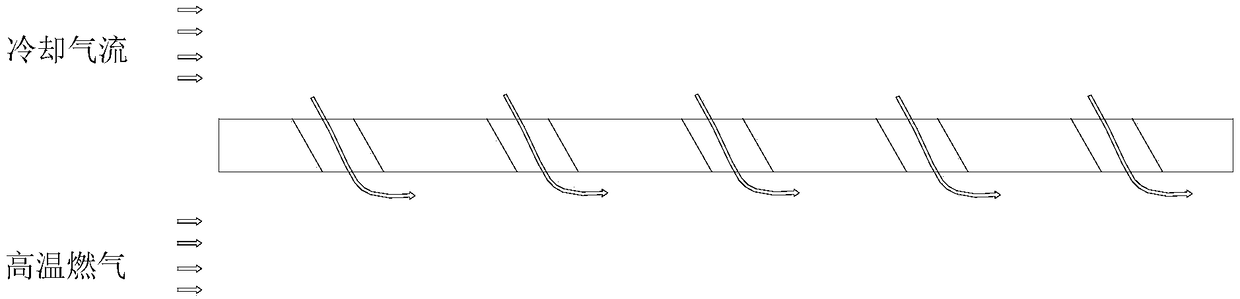

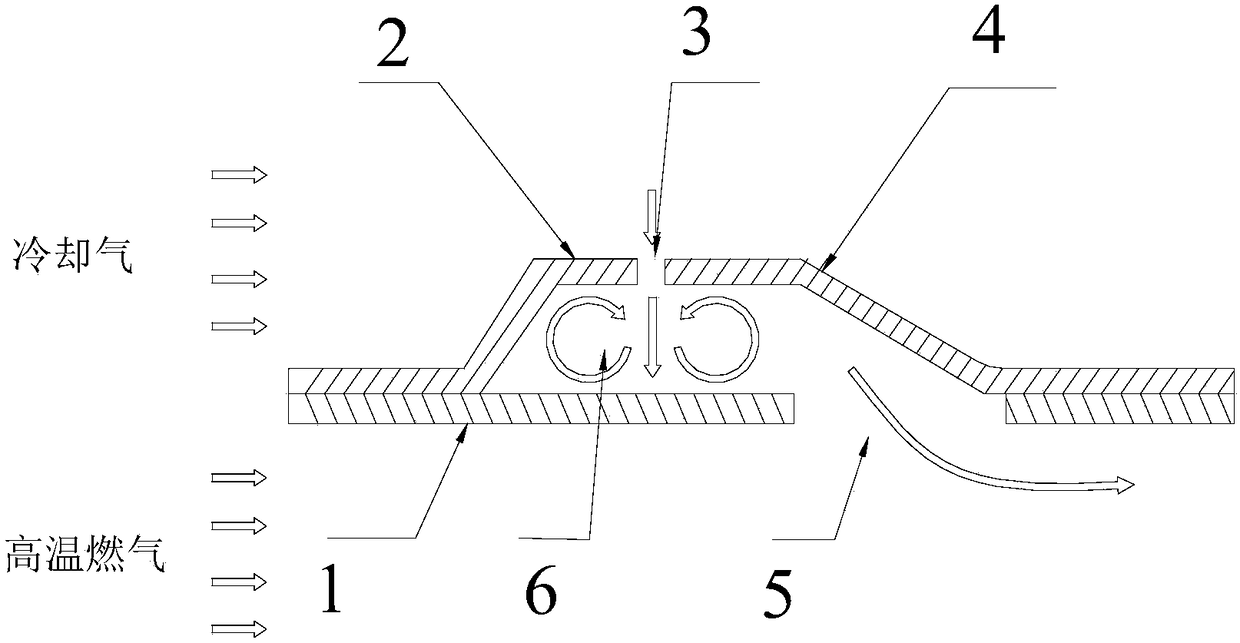

Bulging bag type cooling structure for binary spray pipe

The invention relates to a bulging bag type cooling structure used for cooling a contraction section, an expansion section and the side wall face of a binary spray pipe. The cooling structure comprising bulging bags is designed. The multiple bulging bags are formed on an upper heat isolation liner through punching, and impact holes are formed in the top ends of the bulging bags. A trapezoid air collecting cavity is formed by each bulging bag and a lower heat isolation liner, wherein the part, on the right side of the bottom of each bulging bag, of the lower heat isolation liner is provided with an air film hole. The upper heat isolation liner and the lower heat isolation liner are connected through welding. When cooling air passes through the bulging bags, convection heat exchange on the cooling air side is enhanced under the flow disturbing action of the bulging bags, the cooling air flows into the trapezoid air collecting cavities through the impact holes in the bulging bags, and impact cooling is formed for the lower heat isolation liner; and after the cooling air is decelerated and pressurized in the trapezoid air collecting cavities, the cooling air flows out of the air film holes and is converged into hot flow, an air film is formed on the inner surface of the lower heat isolation liner, and the lower heat isolation liner is protected. The structure is high in cooling efficiency and is hardly influenced by the main and secondary flow pressure ratio, and cooling structure downstream expanding-direction and axial-direction temperature distribution and transition are uniform; and the cooling air utilization is improved.

Owner:AECC SICHUAN GAS TURBINE RES INST

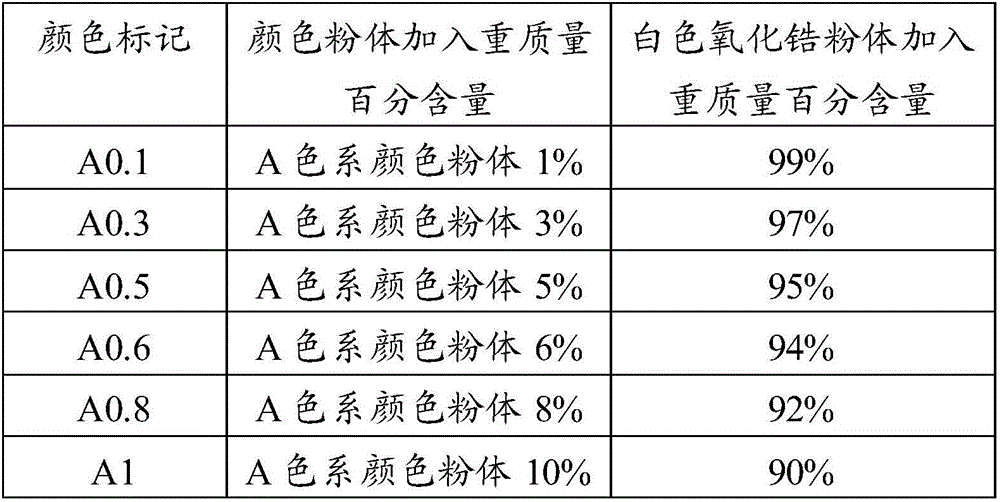

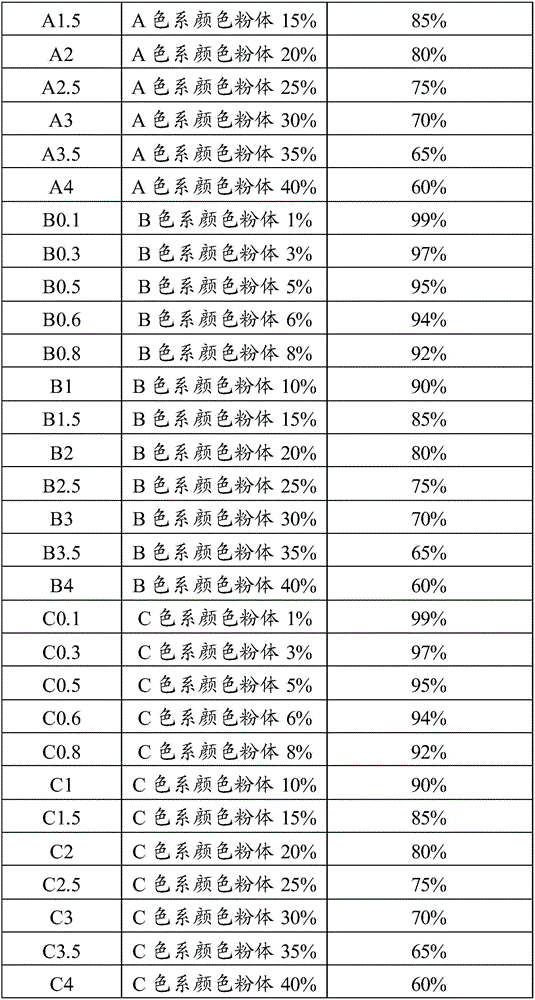

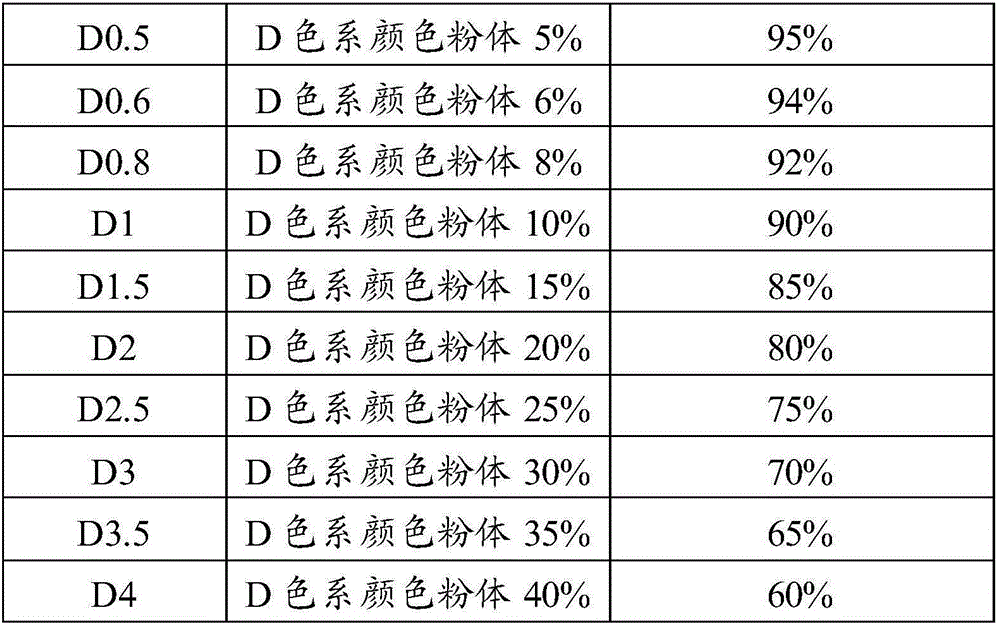

Strength and color uniform transition dentistry zirconium oxide repairing material and preparing method thereof

ActiveCN107175747AHigh strengthReduce wearCeramic shaping apparatusArtificial teethRepair materialNeck parts

The invention discloses a strength and color uniform transition dentistry zirconium oxide repairing material and a preparing method thereof. The preparing method comprises the following steps that firstly, coloring zirconium oxide powder is poured into a dry pressure die to be subjected to dry pressure forming according to the each-layer strength sequence from high to low and the color sequence from deep to shallow; secondly, after dry pressure forming, cold isostatic compaction is conducted; thirdly, after cold isostatic compaction, pre-sintering is conducted, and a raw blank is obtained; and fourthly, the raw blank is cut through CAD / CAM, finally, final sintering is conducted, and the dentistry zirconium oxide repairing material is obtained. The strength and color uniform transition dentistry zirconium oxide repairing material is formed through layering pressing of various coloring zirconium oxide powder different in strength; and the strength of a repairing body can be gradually increased from the cut end to the neck part, abrasion to adjacent teeth and jaw teeth is reduced, the strength of the neck part is high, and long bridge repairing can be conducted.

Owner:AIDITE (QINHUANGDAO) TECH CO LTD

Vibrating cladding repair technology for damaged last-stage blades of steam turbine

ActiveCN108505035AAvoid deformationAvoid crackingMetallic material coating processesSurface stressEngineering

The invention relates to the technical field of repair of blades of a steam turbine, in particular to a vibrating cladding repair technology for damaged last-stage blades of the steam turbine. Firstly, the last-stage blades of the steam turbine are heated at the low temperature, surface defect parts or damaged parts are pre-cleaned and subjected to surface detection and analysis, then, proper technological parameters are selected according to detection results, and the surface defect parts or the damaged parts are subjected to laser cladding under assistance of vibrating stress relief treatment. After cladding, samples are subjected to vibrating stress relief treatment for 20-30 min, and the residual stress of components is further eliminated. By means of the method, the surface defect orthe damaged parts of the last-stage blades of the steam turbine can be effectively repaired, and meanwhile, defects of non-uniform structure and performance distribution and the like caused by non-uniform surface stress of clad layers are overcome.

Owner:JIANGSU UNIV

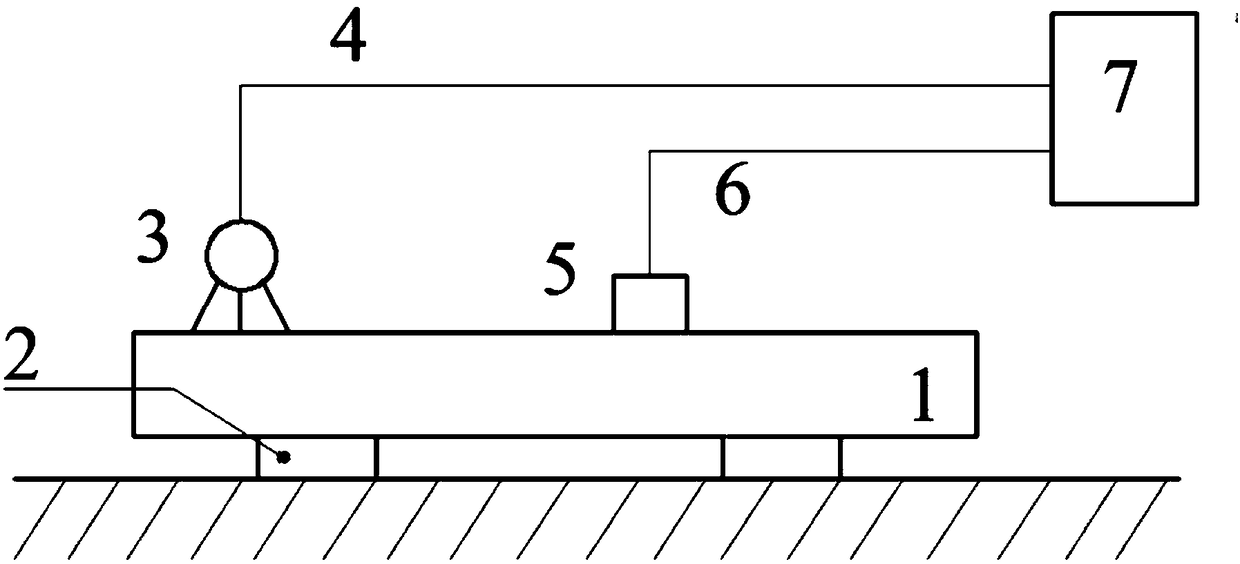

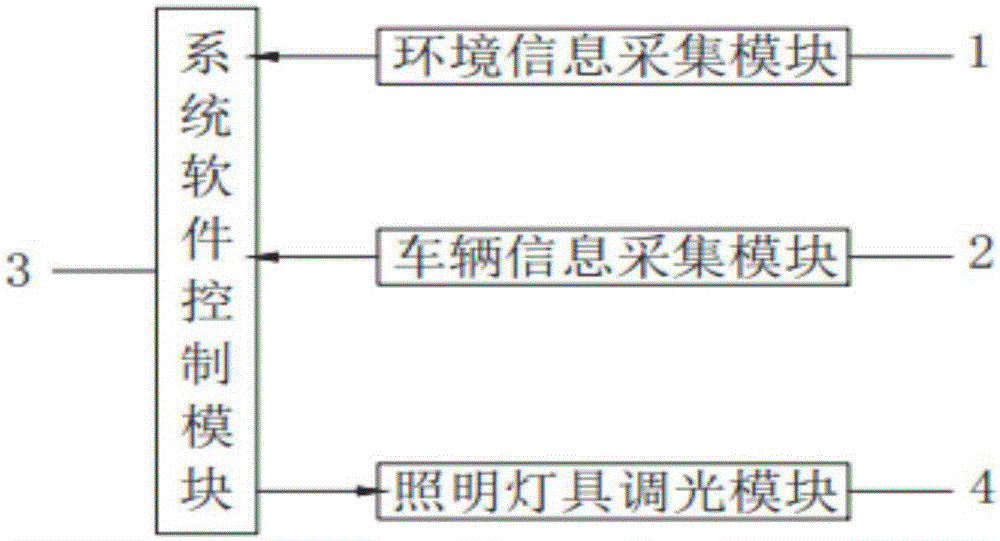

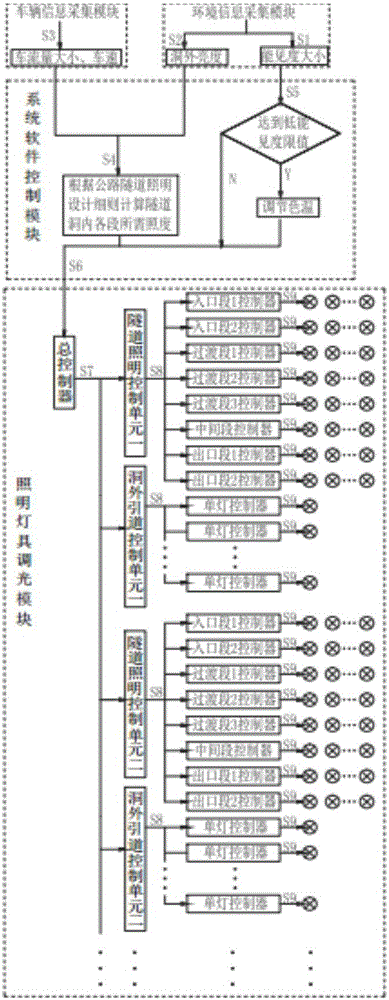

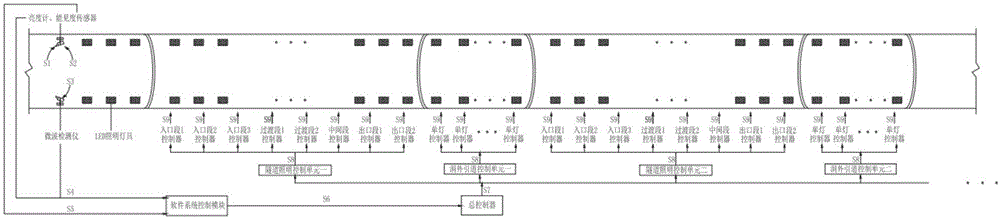

Intelligent lighting system for continuous tunnel group

ActiveCN106332345AMonitor driving speedUniform transitionElectrical apparatusElectroluminescent light sourcesIntelligent lightingVisibility

The invention discloses a tunnel lighting control system. The system comprises the steps of receiving environmental information parameters and a vehicle information parameter, calculating brightness required by each section in tunnels, judging whether to adjust color temperatures according to the environment visibility and transmitting calculated brightness values and color temperature values of the sections in the tunnels and approach sections outside holes to a lighting lamp dimming module; and receiving a dimming instruction sent by a software system control module by the lighting lamp dimming module, controlling LED lighting lamps of the sections in the tunnels to be adjusted to the brightness values and color temperature values set by the software system control module and achieving uniform transition of the lighting brightness between a last exit section and a next entrance section. The system control mode is simple and convenient; the brightness and the color temperatures of the sections in the tunnels in the holes of tunnel sections in the continuous tunnel group and the approach sections outside the holes are intelligently controlled according to different environmental parameters and traffic flow conditions; and the uniform transition of the lighting brightness of the lamps of the tunnel sections in the continuous tunnel group is ensured.

Owner:JIANGSU CHANGLU ENERGY TECH DEV CO LTD

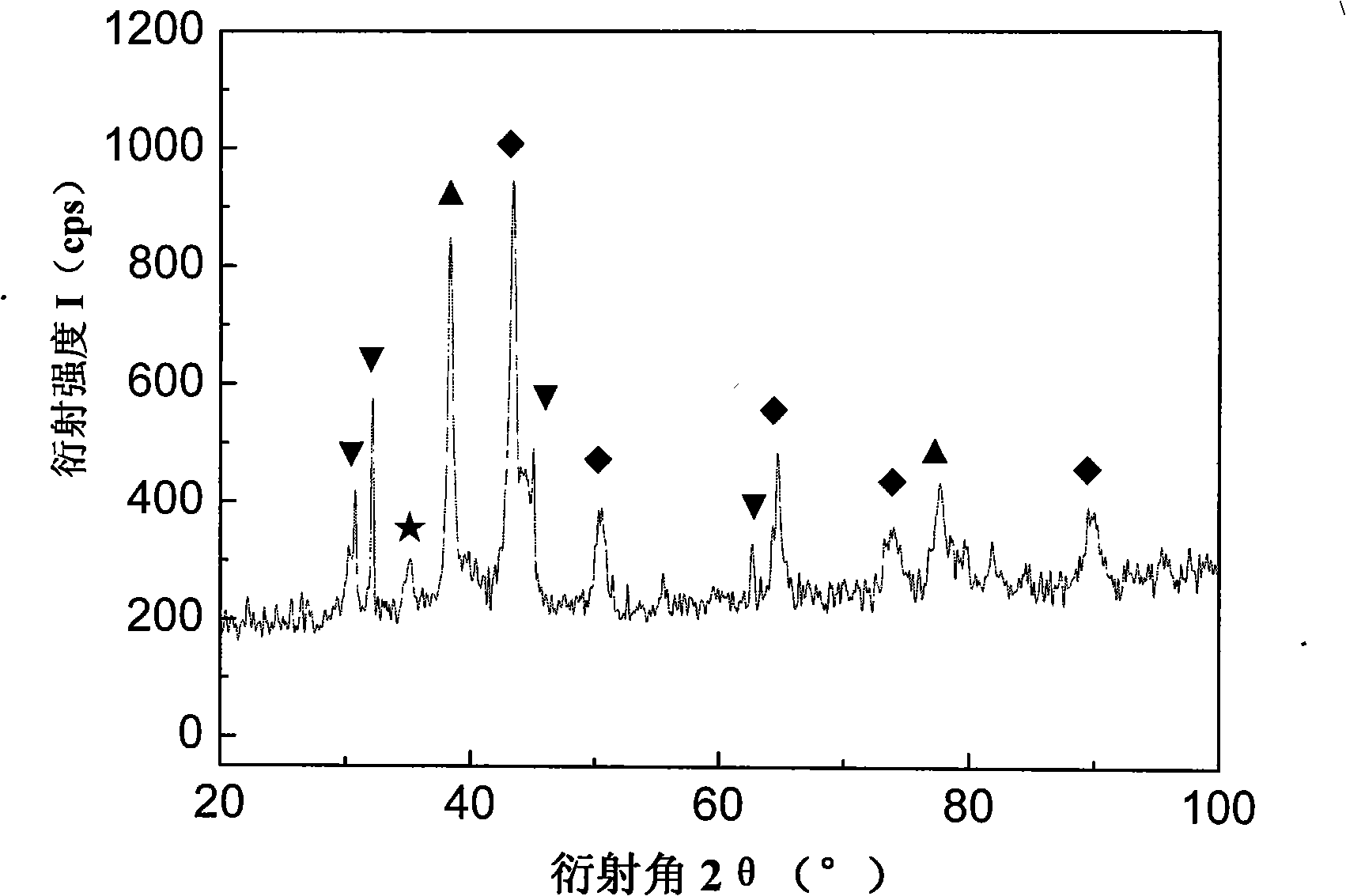

Active solder and preparation method thereof

InactiveCN101332545ALower requirementSimple processWelding/cutting media/materialsSoldering mediaSolderabilityMechanical property

The invention provides an active solder and a preparation method thereof and relates to a solder and a preparation method thereof. The method of the invention solves the problems that the preparation of the existing active solder needs to be smelted, thus influencing the weldability of the solder and the mechanical properties of joints. The solder of the invention consists of Ag, Cu, Sn and one of Ti or TiH2. In the solder of the invention, the Ag and the Cu are mixed with RE, the Sn and one of the Ti or the TiH2. The preparation method for the solder in the invention comprises the steps as follows: raw material of the active solder is added to a planetary ball mill for ball milling. After being brazed by adopting the method of the invention, the interface joint of the solder has good combination with the interface without air vent and crack, and forms a thinner responding layer with the side of mother metal, wherein, the responding layer can improve the mechanical properties of joints; and the shear strength of the soldering joint of the solder prepared by using the method of the invention can reach 11.56MPa.

Owner:HARBIN INST OF TECH

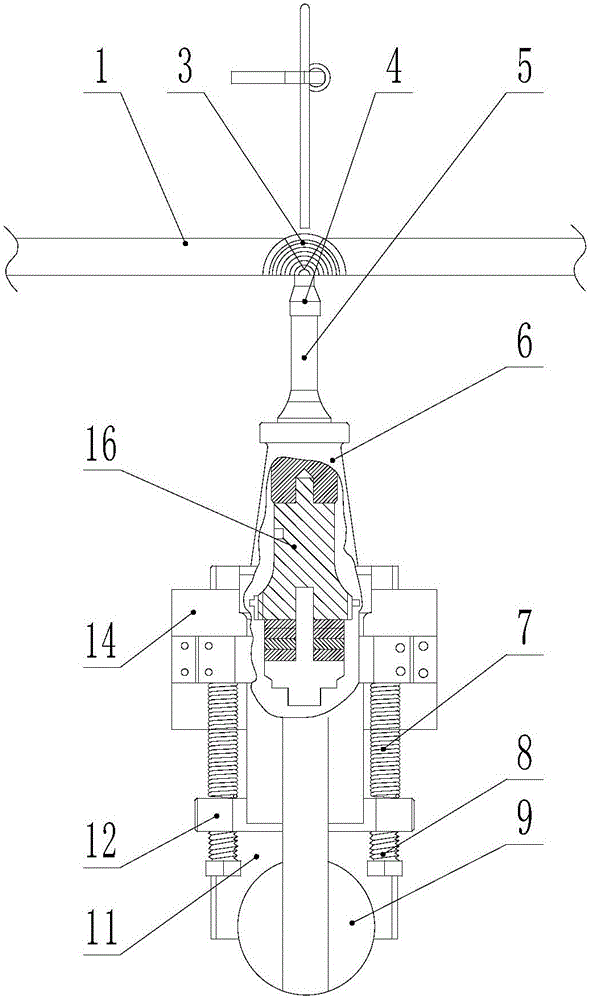

Multi-legged friction-stir welding method for improving properties of welding seam

InactiveCN101559534AUniform transitionEliminate thickness differencesNon-electric welding apparatusStress concentrationEngineering

The invention discloses a multi-legged friction-stir welding method for improving properties of a welding seam. After the welding seam is formed by stir welding by a front stirring head, the welding seam and a mother plate are rotated and squeezed by a back stirring head. The multi-legged stirring head can not only ensure smooth welding process, but also carry out rotation and squeeze to the welding seam, and smooth transition is realized between the welding seam and the mother plate so as to reduce stress concentration to the lowest or even zero. By adopting the multi-legged stirring head, smooth transition can be realized between the welding seam and the mother plate, thus eliminating the thickness difference which is peculiar to FSW.

Owner:UNIV OF SCI & TECH BEIJING

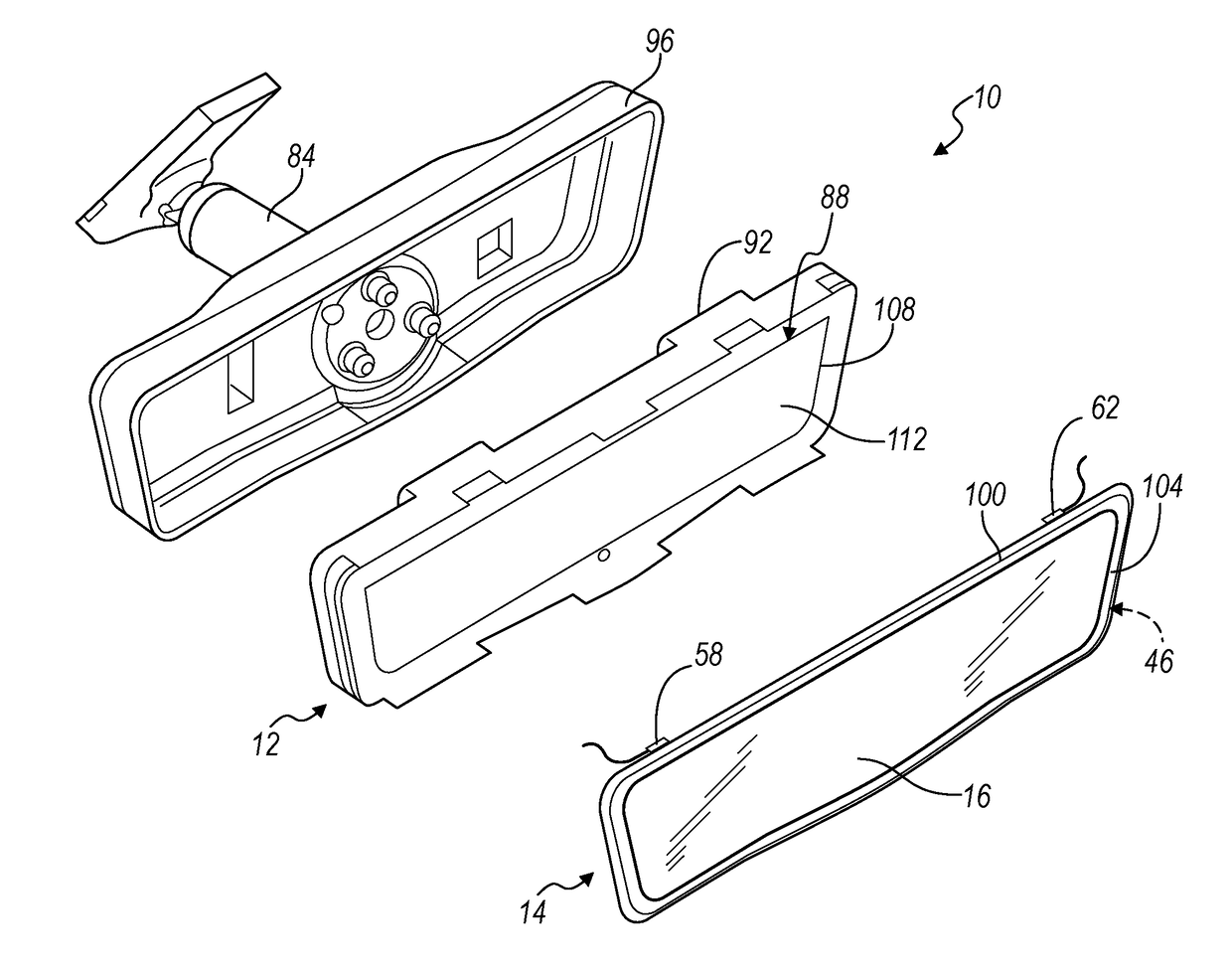

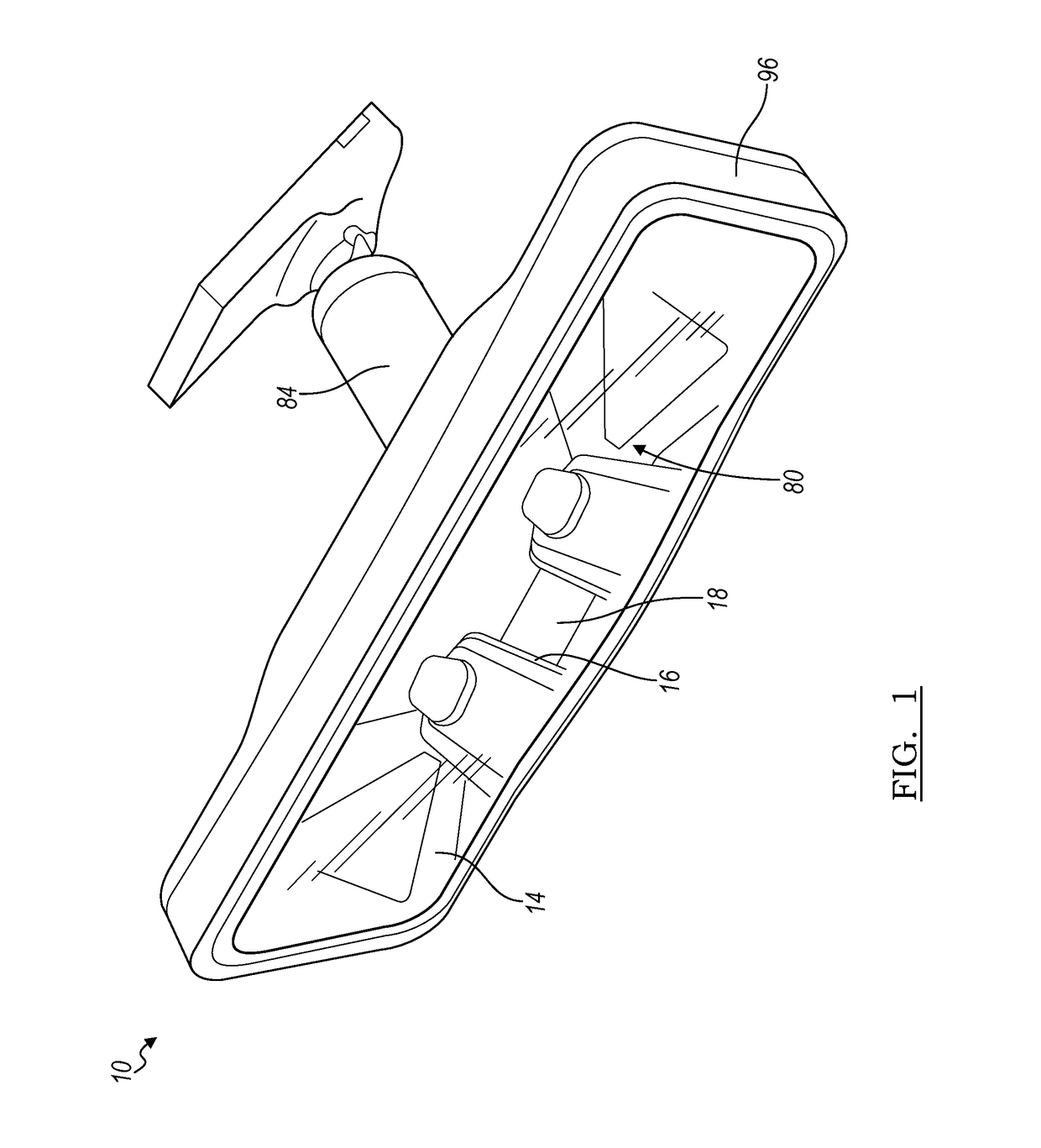

Full display mirror

ActiveUS20170088055A1Simple designSmall component sizeNon-linear opticsOptical viewingElectricityComputer module

A display mirror assembly for a vehicle is presented that includes a full display module and an electro-optic element that includes a first substantially transparent substrate having first and second surfaces disposed on opposite sides thereof. The second surface includes a first electrically conductive layer. A second substantially transparent substrate has third and fourth surfaces disposed on opposite sides thereof. The third surface includes a second electrically conductive layer. A primary seal is disposed between the first and second substrates. The seal and the first and second substrates define a cavity therebetween. An electro-optic medium is disposed in the cavity. The electro-optic medium is variably transmissive such that the electro-optic medium is operable between generally clear and darkened states. A first electrical connection and a second electrical connection are positioned on the same side of the electro-optic element.

Owner:GENTEX CORP

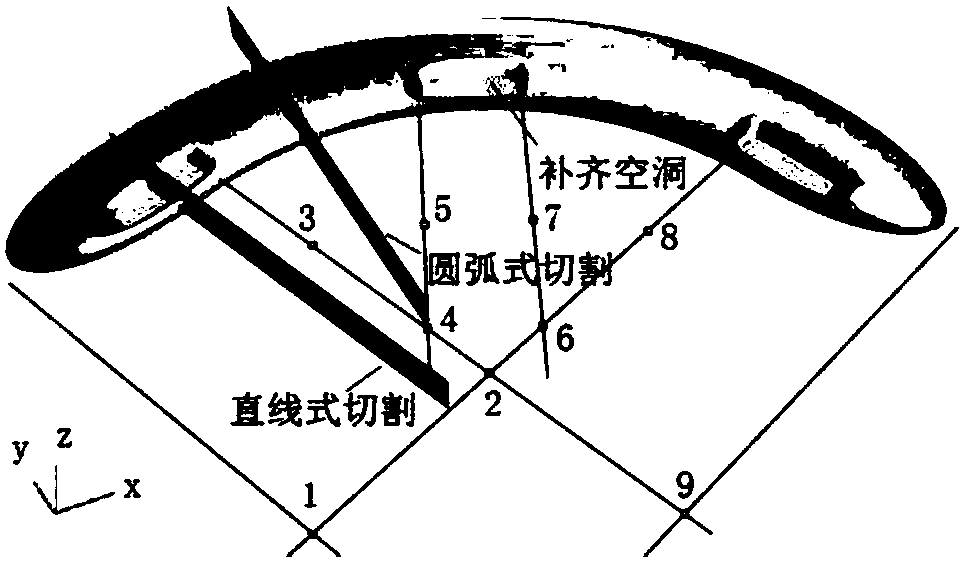

Complex free-form surface mesh generation method based on surface fitting and geodesic lines

InactiveCN107909650AResolving partitions is prone to failureSolve the adjustmentImage generation3D modellingPoint cloudFree form

The invention discloses a complex free-form surface grid division method based on surface fitting and geodesic lines, belonging to the field of architectural grid division. This method first proposes a surface-to-surface intersection method based on NURBS to obtain the N×M point cloud of the complex free-form surface, and uses the N×M point cloud as the control point to construct the NURBS surface, and then divides the pruned NURBS surface with a given number of boundaries Or divide with a given length, connect multiple boundary segment points to form a geodesic grid, and optimize and smooth to obtain the final complex free-form surface grid. The grid division method provided by the present invention can obtain grids with smooth lines and basically the same size. Compared with the multi-surface grid division method, surface fitting and geodesic grids can be used to obtain grids with smooth lines and uniform transition , has a good architectural aesthetic effect.

Owner:ZHEJIANG UNIV

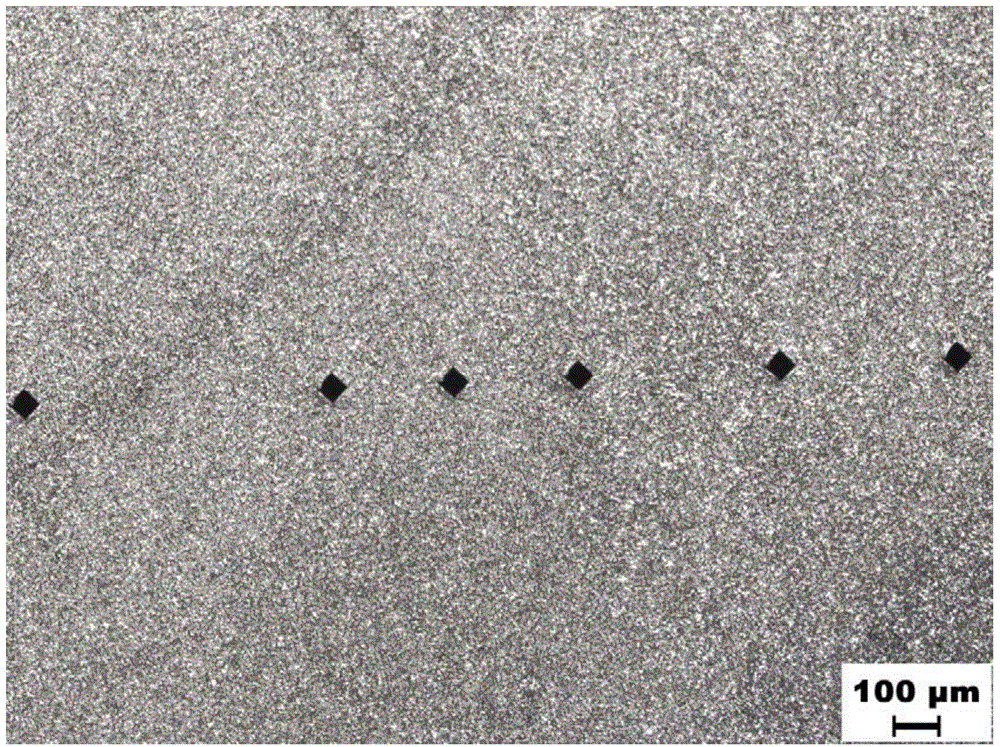

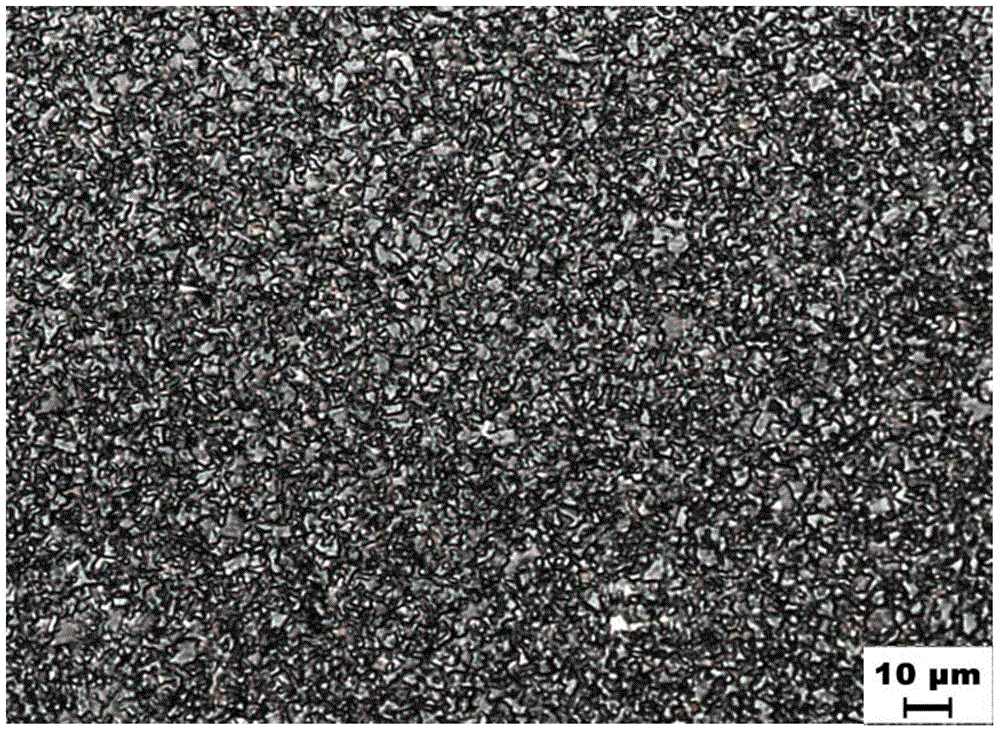

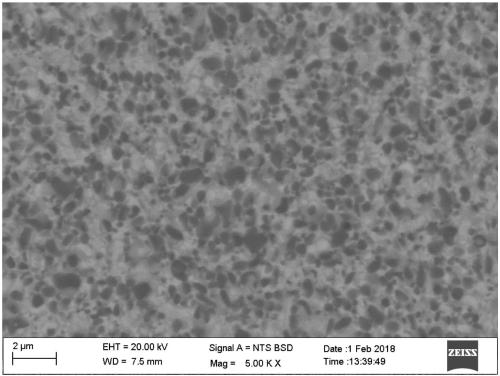

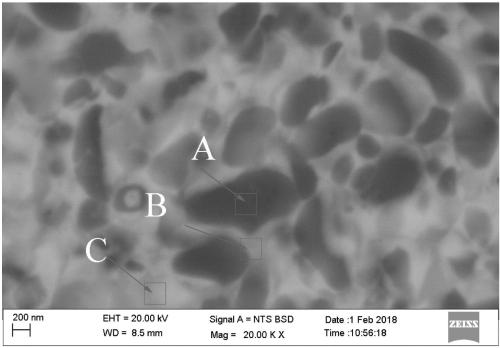

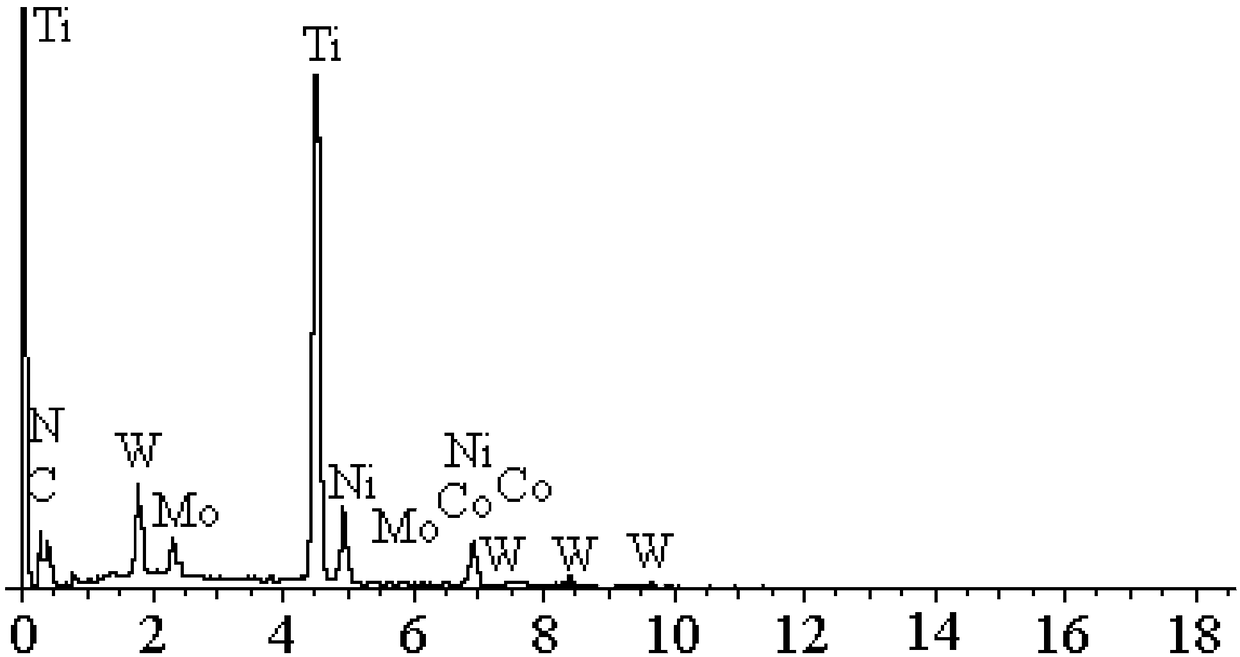

Method for molding hard alloy functionally gradient materials

ActiveCN104874797AImprove wear resistanceAccelerated corrosionTransportation and packagingMetal-working apparatusFunctionally gradient materialHardness

The invention discloses a method for molding hard alloy functionally gradient materials. The method includes mixing additives with alloy materials to obtain mixtures; carrying out compound pressure molding on the obtained mixtures in compound die groups to obtain blanks; sintering the blanks to obtain the hard alloy functionally gradient materials. The compound die groups comprise outer-layer dies with high expansion coefficients, intermediate transition-layer die groups and inner-layer dies with low expansion coefficients. The method has the advantages that the large and multi-component hard alloy functionally gradient composite materials which are of complicated contour structures and are free of obvious interfaces can be manufactured by the aid of the method; the sintered molded functionally gradient materials are provided with gradient grain structures along the thickness directions of the sintered molded functionally gradient materials, the gradient grain structures are provided with the different components, have different grain sizes and are free of obvious interfaces, and accordingly the molded hard alloy materials are excellent in comprehensive mechanical performance with high hardness, abrasion resistance, strength and toughness.

Owner:SEED TECH CORP LTD

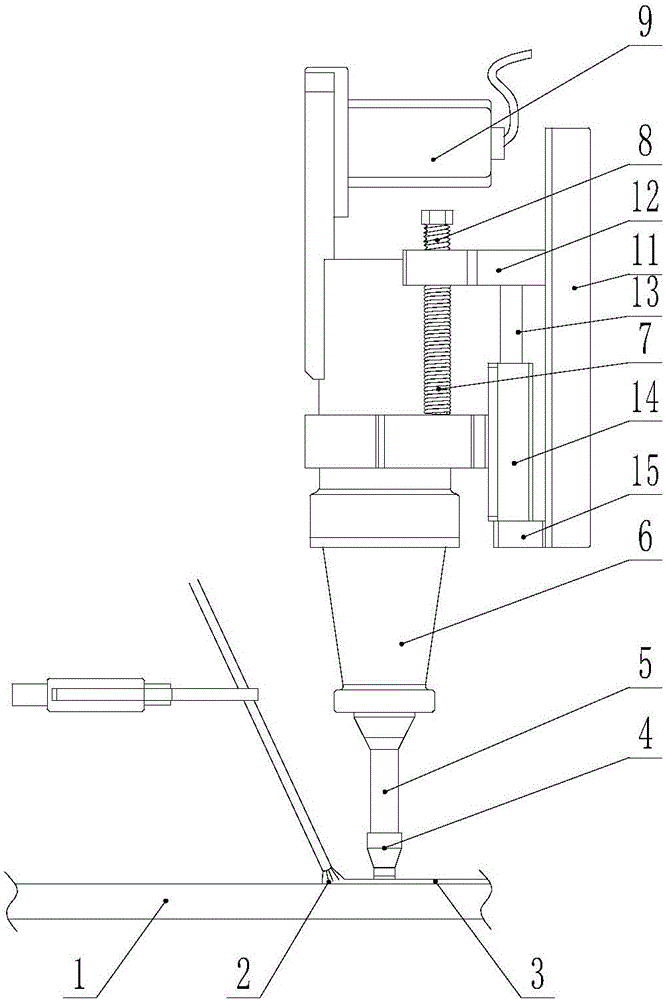

Ultrasonic vibration assisted welding method

ActiveCN105728930AIncrease the number ofInhibition of grain growthNon-electric welding apparatusMetalCrystal

The invention relates to the field of welding and in particular relates to an ultrasonic vibration assisted welding method. The method comprises the following steps: in a welding process of fusion welding, providing an ultrasonic vibration force through an ultrasonic excitation vibration device; introducing ultrasonic frequency stress wave into a welding fusion tank; finally, transmitting vibration to a welding part. With the adoption of the configuration, the quantity of crystal nucleuses can be effectively increased, the size of crystal grains is prevented from growing, dendritic crystals are crushed and a crystal shape is changed, so that condensed welding line metal crystal grains are thinned; gas, impurities and the like in the fusion tank are prompted to rapidly float up, and defects of air pores and slag adding are reduced; welding residual stress and welding deformation are reduced; components are more uniform so that a welding line metal structure is improved; a fusion region becomes narrow and is uniformly transited, and non-fusion defects are reduced; comprehensive mechanical properties of welding lines are improved through the effects above.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Dental Zirconia Restoration Material With Uniform Transition Of Strength And Color, And Preparation Method Thereof

InactiveUS20180327319A1Reduce harmHigh strengthImpression capsCeramic shaping apparatusHigh intensityCam

The application discloses a dental zirconia restoration material with uniform transition of strength and color, and a preparation method thereof. The preparation method includes the following steps: (1) pouring colored zirconia powder into a dry pressing mould in accordance with a sequence of the strength from high to low and the color from dark to light for each layer, and performing dry pressing; (2) performing isostatic cool pressing after the dry pressing; (3) performing pre-sintering after the isostatic cool pressing to obtain a greenware; and (4) performing CAD / CAM cutting on the greenware, and finally performing final sintering to obtain the dental zirconia restoration material. In the present application, the strength of a restoration can gradually increase from a cut end to the neck, the wear to adjacent teeth and jaw teeth is reduced, and long-bridge restoration can be realized due to the high strength of the neck.

Owner:AIDITE (QINHUANGDAO) TECH CO LTD

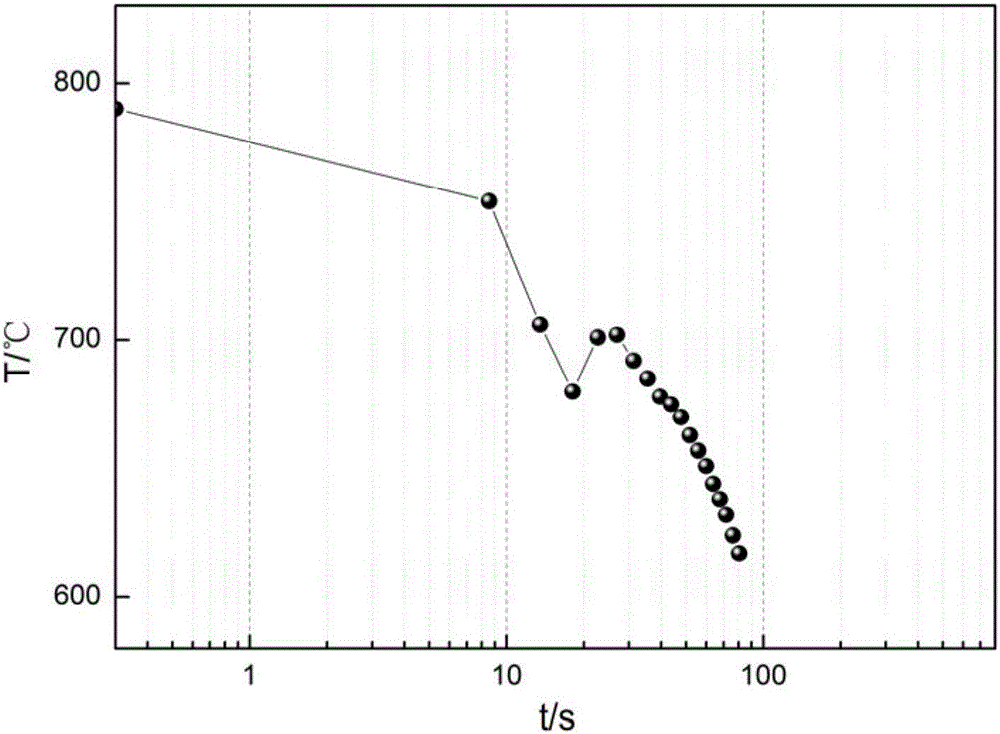

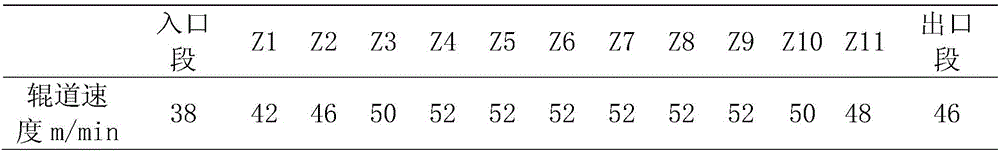

Stelmor air-cooled line controlled cooling process for improving structure and performance of spring steel 55SiCrA coil rod

ActiveCN106734261AImprove the sorbitization rateReduce the presence of retained austeniteWork cooling devicesMetal rolling arrangementsPearliteThermal insulation

The invention provides a stelmor air-cooled line controlled cooling process for improving the structure and performance of a spring steel 55SiCrA coil rod. The controlled cooling process includes the steps that the finish rolling temperature is 790-820 DEG C, the blast capacity of the front three draught fans is controlled to meet the requirement that under various specifications, the lowest temperature of the third draught fan is within 680-710 DEG C, and the cooling speed of the front two draught fans is controlled within 5-13 DEG C per second; the blast capacity of a fourth draught fan and a fifth draught fan is controlled to make the coil rod temperature rise by 10-50 DEG C; the blast capacity of a sixth draught fan and follow-up draught fans is controlled to make the cooling speed within 3 DEG C per second, after the coil rod temperature is within 670-700 DEG C, thermal insulation covers are closed, and all the thermal insulation covers are opened before the temperature range; the cooling speed in the each thermal insulation cover is controlled at 0.8-2.0 DEG C per second, the draught fans are closed, the final two thermal insulation covers are opened, and the temperature of the coil rod discharged from each thermal insulation cover is 580-630 DEG C. In the process, the 55SiCrA coil rod is uniform in structure and composed of pearlite and a small amount of ferrites, under the various specifications, the percentage of area reduction can reach 60 or above, the sorbitizing rate and the plasticity reach high standards, and the strength, the hardness and the like can meet the performance requirement.

Owner:ZENITH STEEL GROUP CORP

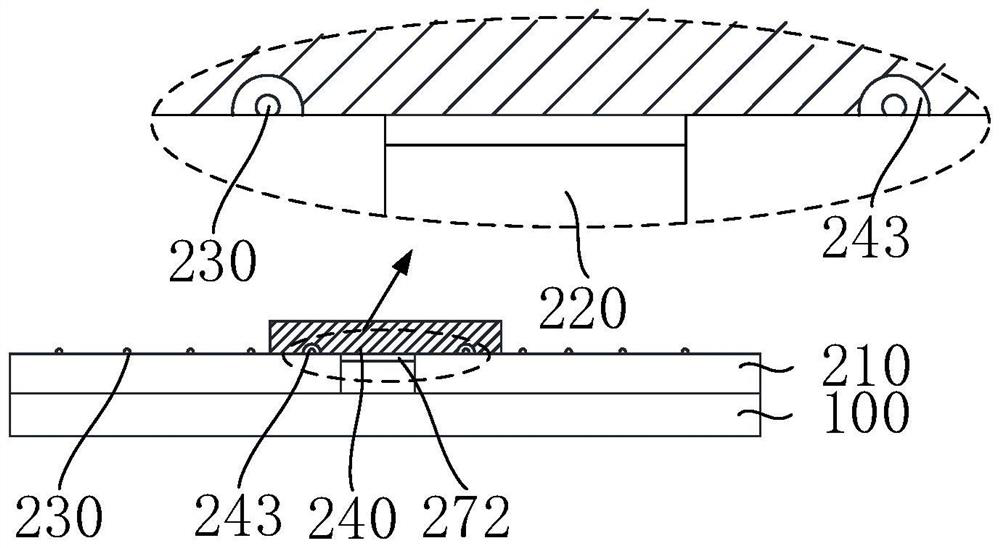

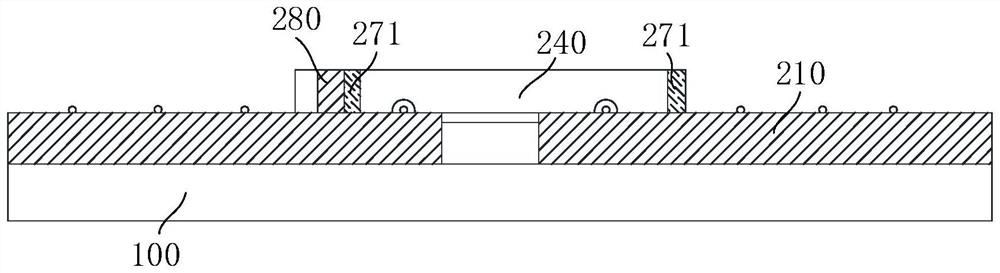

Storage compartment module with mobile storage compartment

ActiveUS8517308B2Easy to operateEasy to installSeating arrangementsAir-treatment apparatus arrangementsEngineeringMechanical engineering

A hatrack module with a moveable hatrack comprises a housing with a hatrack accommodation space, a hatrack with laterally arranged guide elements and optionally at least one passenger service unit, wherein each guide rail is arranged on one sidewall of the hatrack accommodation space, and wherein the guide elements of the hatrack can be made to engage the guide rails on the housing.

Owner:AIRBUS OPERATIONS GMBH

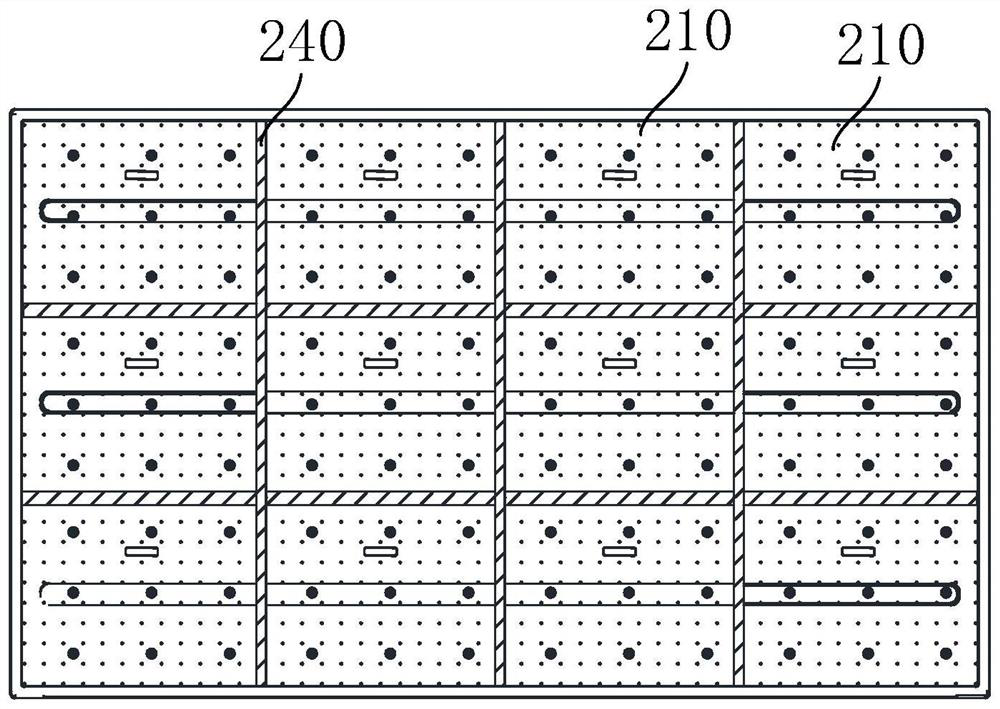

Backlight module and display device

ActiveCN114203069ALow costUniform transitionOptical light guidesIdentification meansDisplay deviceEngineering

The invention discloses a backlight module and a display device, the backlight module comprises a splicing lamp panel, the splicing lamp panel is formed by splicing a plurality of lamp panels, a gap is formed between every two adjacent lamp panels, the backlight module further comprises a diffusion plate, the diffusion plate is arranged at the position corresponding to the gap, and the diffusion plate is arranged in the position corresponding to the gap. The diffusion plate covers at least one row of light-emitting diodes on at least one lamp panel, and at least part of the light-emitting diodes on the lamp panel are not covered. The diffusion plate is arranged at the gap and covers the at least one row of light emitting diodes, close to the gap, in the at least one lamp panel, light on the lamp panel is uniformized into the diffusion plate, light transition between the gap and the lamp panel is smoother on the basis that light supplementing is conducted on the gap, and the light emitting efficiency is improved. And the manufacturing cost of the diffusion plate is lower, so that the production cost is saved.

Owner:MIANYANG HKC OPTOELECTRONICS TECH CO LTD +1

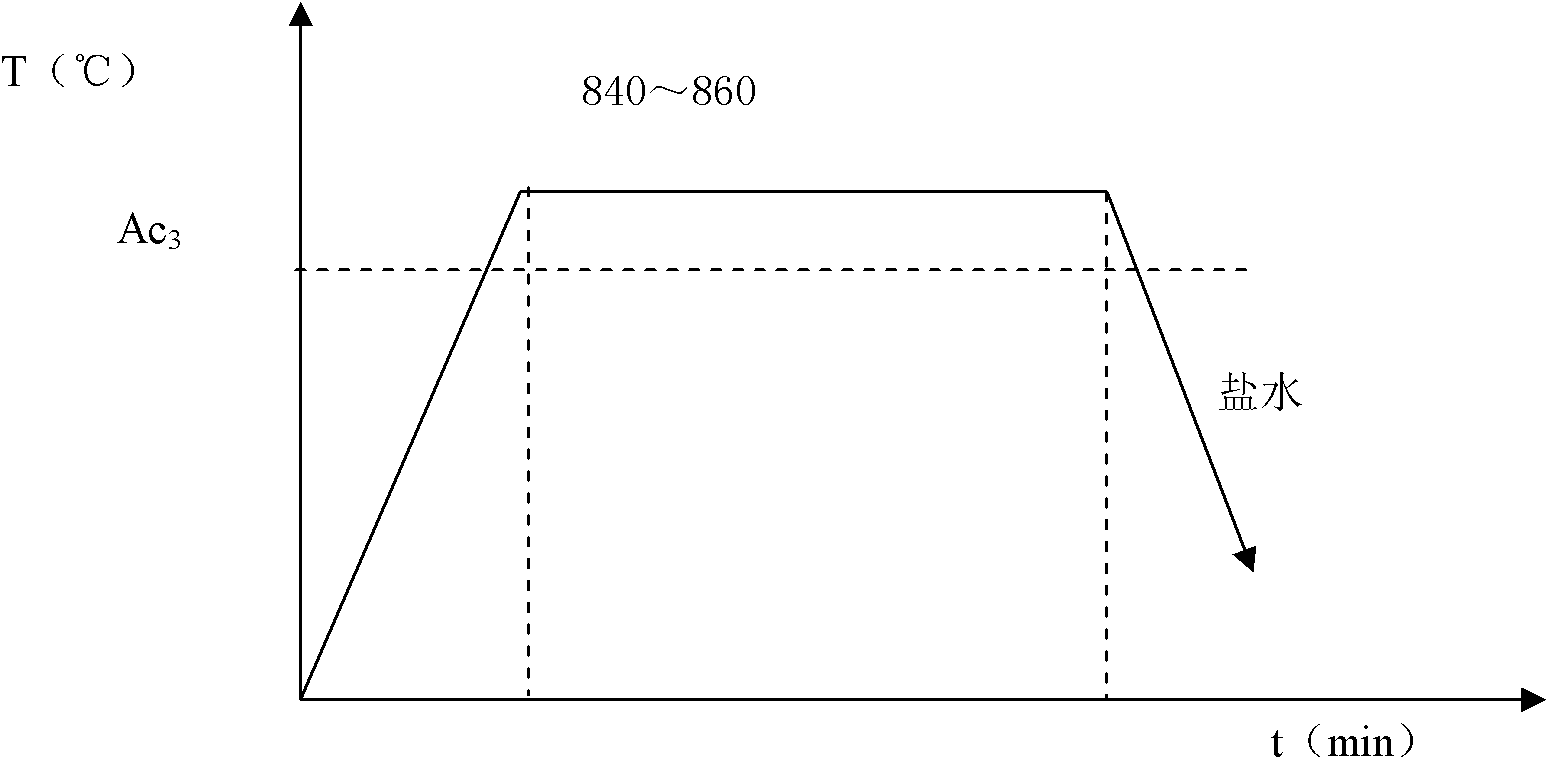

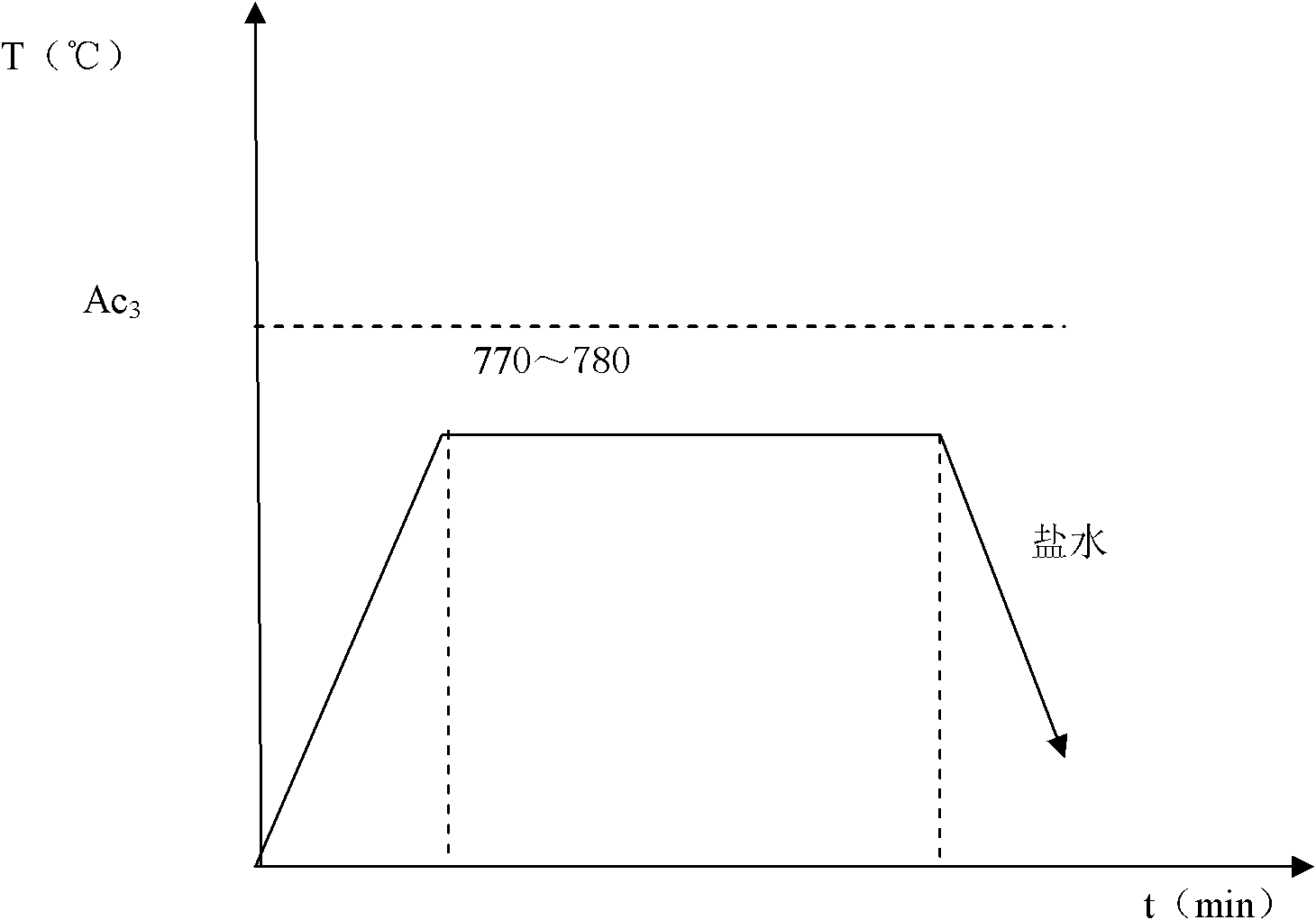

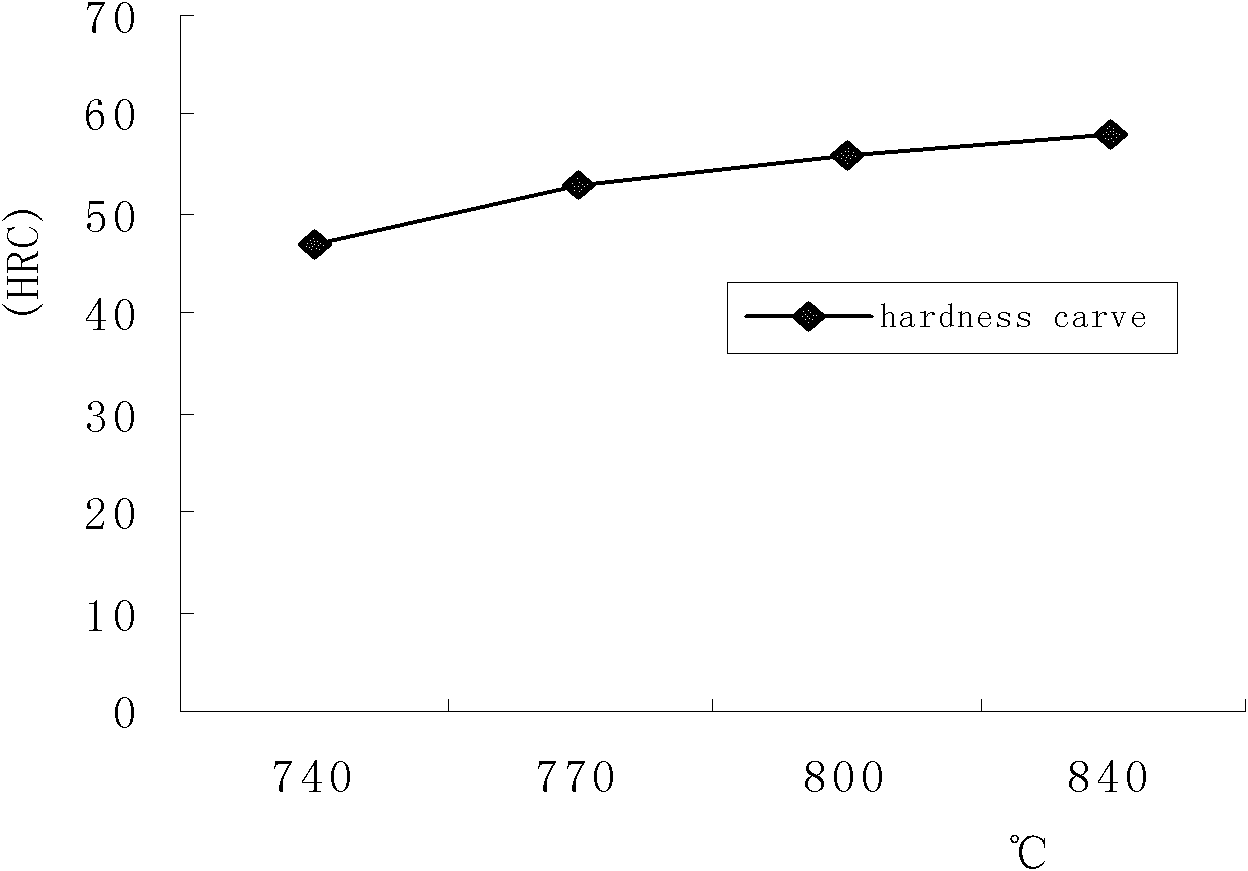

Method for quenching small-size No. 45 steel parts

InactiveCN102051453AEffectively release stressNovel methodQuenching agentsSaline waterRoom temperature

The invention relates to a method for quenching No. 45 steel, comprising the following steps: 1) heating to 770-780 DEG C, and quenching with saline water at room temperature, wherein the concentration of the saline water is 5-10%; and 2) tempering at 500-540 DEG C. The method for quenching No. 45 steel has the characteristics of fewer processing procedures, energy conservation, low cost and less deformation, and is easy to operate.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

Erbium and ytterbium containing aluminum alloy welding wire

InactiveCN106334880AHigh hardnessHigh tensile strengthWelding/cutting media/materialsSoldering mediaAlloyErbium

The invention discloses an erbium and ytterbium containing aluminum alloy welding wire which is prepared from the following components in percentage by mass: 2-3.5 percent of Mg, 0.12-0.2 percent of Ti, 0.15-0.3 percent of Cr, 0.08-0.2 percent of Mn, 0.01-0.05 percent of Ce, 0.05-0.15 percent of Te, 0.01-0.1 percent of B, 0.05-0.2 percent of Er, 0.05-0.2 percent of Yb, 0.2-0.5 percent of Zr, 0.05-0.15 percent of Ge, 0.1-0.8 percent of Sn, 0.5-2.5 percent of Mo, 1-3 percent of W, 0.5-1.5 percent of V, 4-5.8 percent of Cu, smaller than or equal to 0.3 percent of Fe plus Si, smaller than or equal to 0.2 percent of Zn, smaller than or equal to 0.05 percent of single content of other purity elements, smaller than or equal to 0.15 percent of total content of other purity elements and the balance of Al.

Owner:安徽飞弧焊业股份有限公司

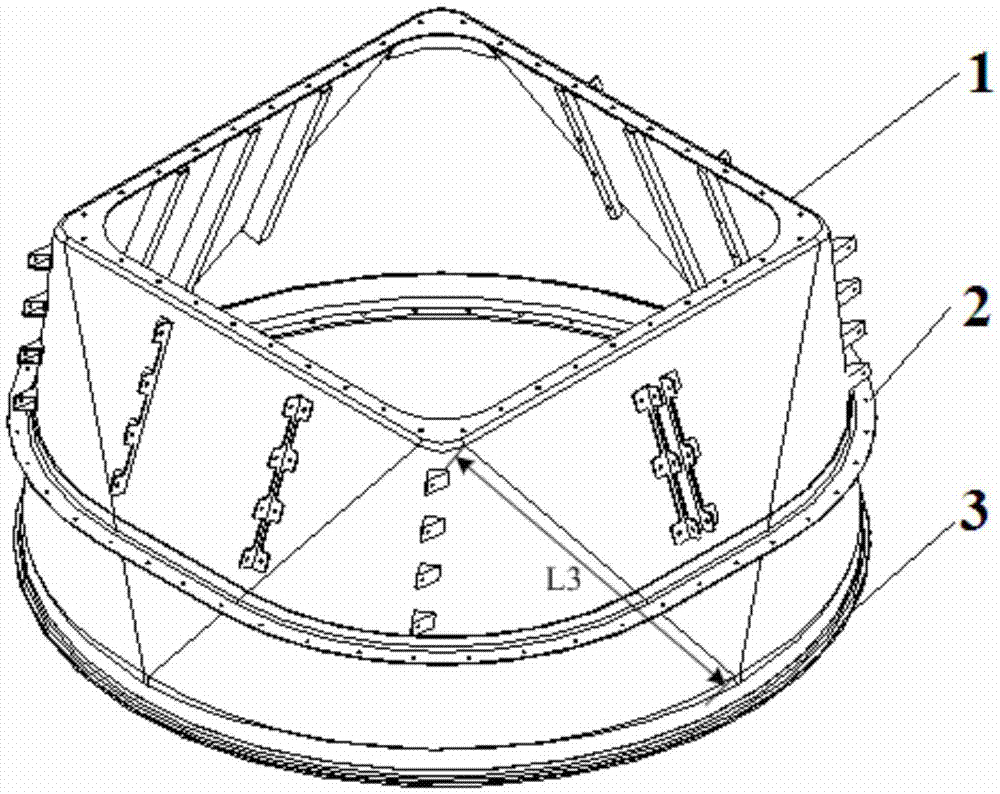

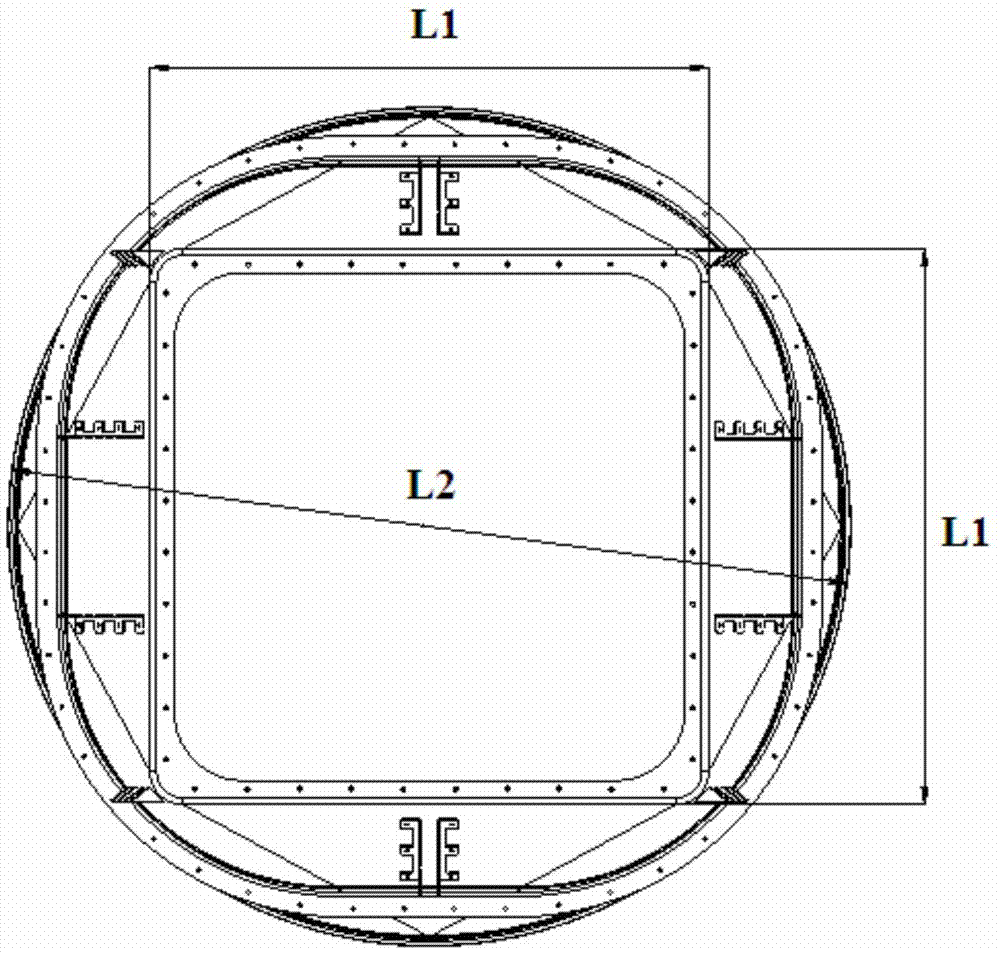

Satellite and rocket docking device

ActiveCN105438503AUniform transitionIncrease stiffnessCosmonautic vehiclesCosmonautic component separationTerra firmaConfiguration design

The invention provides a satellite and rocket docking device, and relates to the technical field of spaceflight overall configuration. The satellite and rocket docking device comprises a main cylinder, a backland plate connecting frame and a satellite and rocket docking frame, wherein the a circular opening is formed in the bottom of the satellite and rocket docking frame; a square opening is formed in the top of the main cylinder. The satellite and rocket docking frame disclosed by the invention is suitable for a total carbon fiber composite circumference transition satellite and rocket connecting device of a grillage type configuration GEO satellite platform, uniform transition of a whole satellite mechanical load from a box-shaped grillage to a circular delivery butting ring is realized, and as a corn component of the device, the grillage type satellite configuration forms a favorable force transmitting path. The rigidity, the intensity and the stability of the whole satellite device all meet design requirements, and a solid basis is established for the configuration design of the whole satellite.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

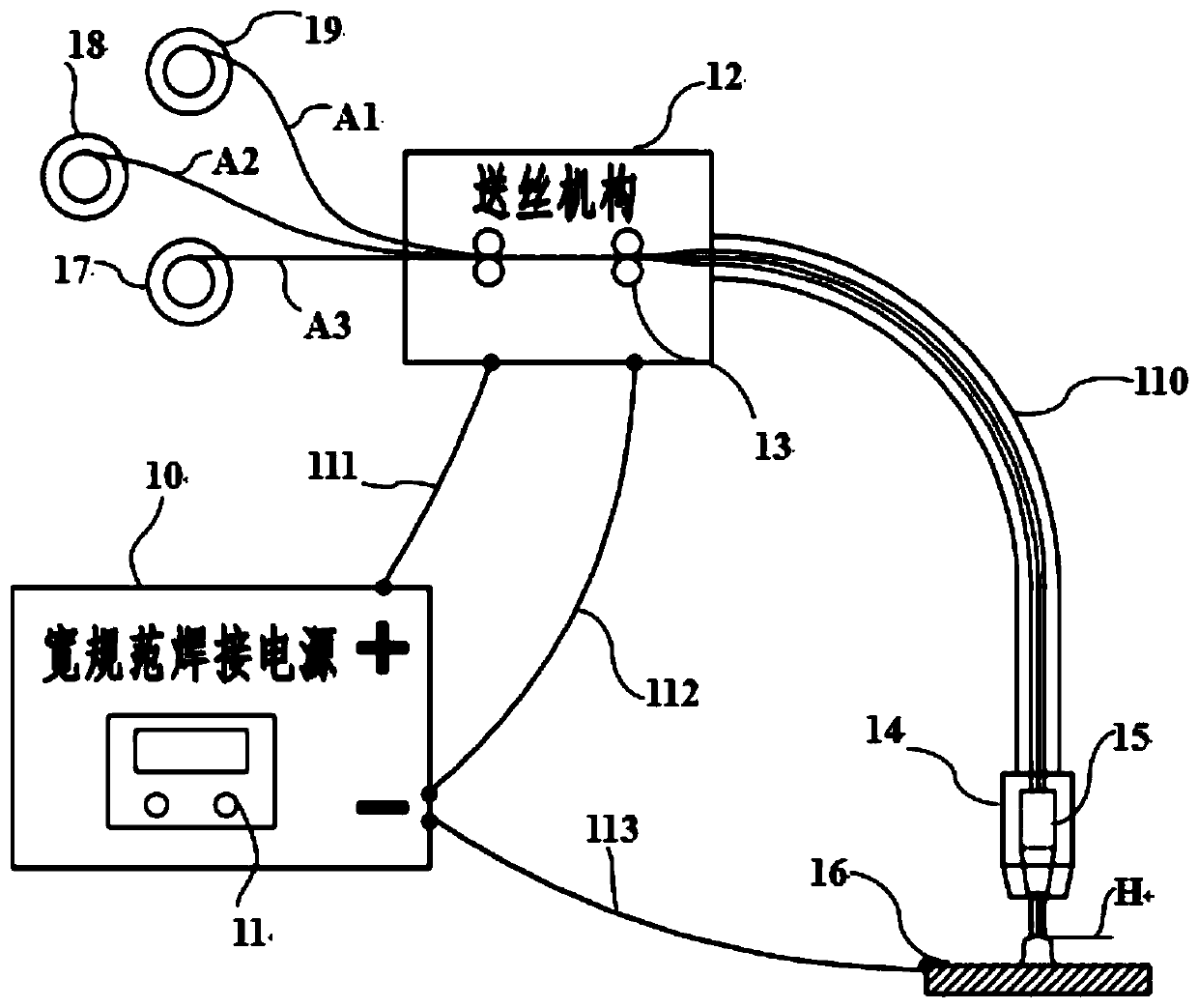

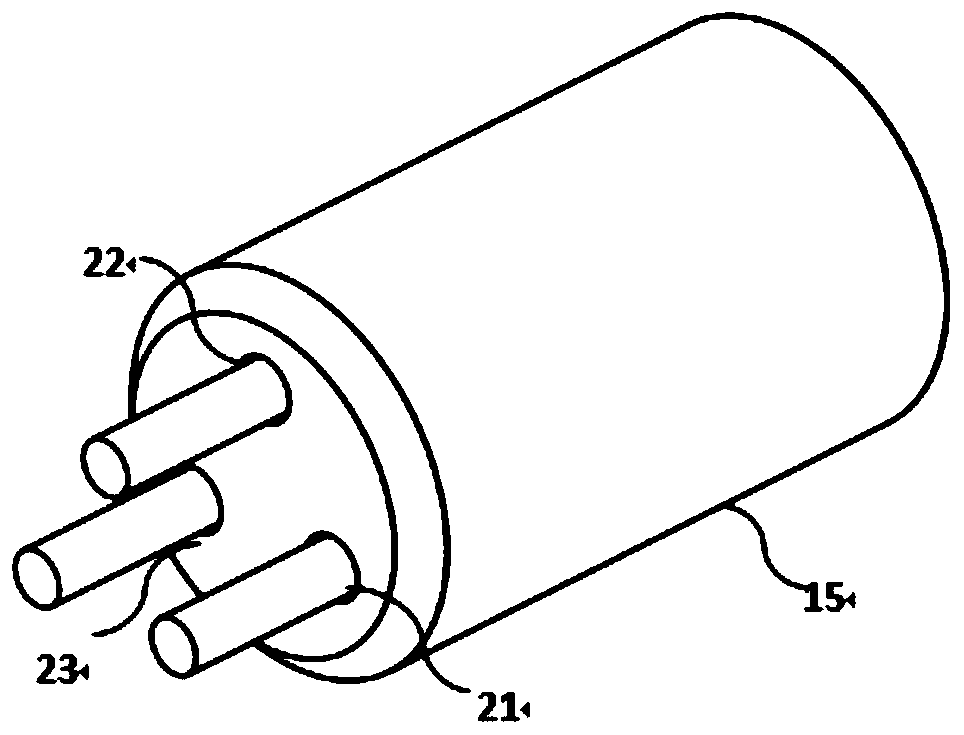

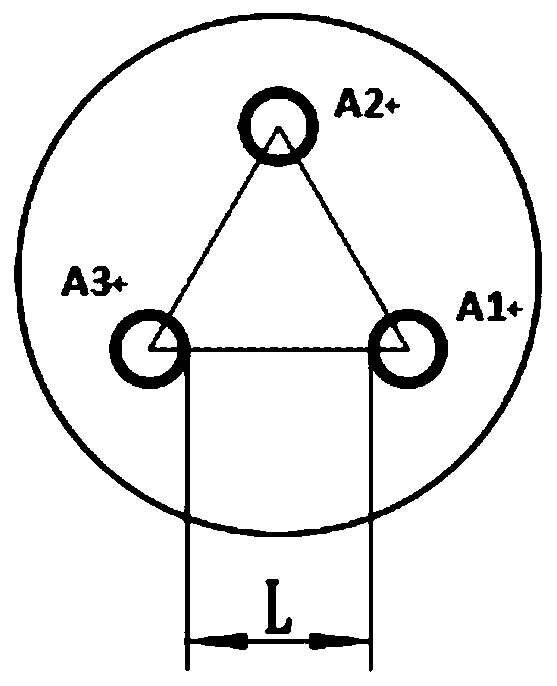

Parallel tri-wire welding system and method

PendingCN110125518ASame sizeNo arcing problemsArc welding apparatusWelding power supplySemi automatic

The invention discloses a parallel tri-wire welding system and method. The welding system comprises a wide-range welding power supply, a wire conveying mechanism with a tri-slot wire conveying wheel and a welding gun with a tri-hole conductive nozzle, wherein three welding wires are simultaneously conveyed to the welding gun through the wire conveying mechanism and separately penetrate through three independent holes which are distributed in the conductive nozzle at certain intervals; and welding waveforms output by the welding power supply are supplied to the welding wires through the conductive nozzle, and welding is carried out by simultaneously using the three wires. After the bottom ends of the three wires are molten, molten drops attract each other under electromagnetic action, and the molten drops stably and smoothly flow into a molten bath. The single-power-supply and parallel-tri-wire system has the advantages that the welding efficieny is increased, electric arc shapes and weld penetration size and contours are improved, welding flaws are reduced, and mechanical strength is improved; and at the same time, the three welding wires are stably conveyed by one wire conveying mechanism and go through one conventional welding gun, the operation is convenient, the reaching range of the welding gun is great, and manual, semi-automatic and robot welding demands can be simultaneously met.

Owner:AOTAI ELECTRIC

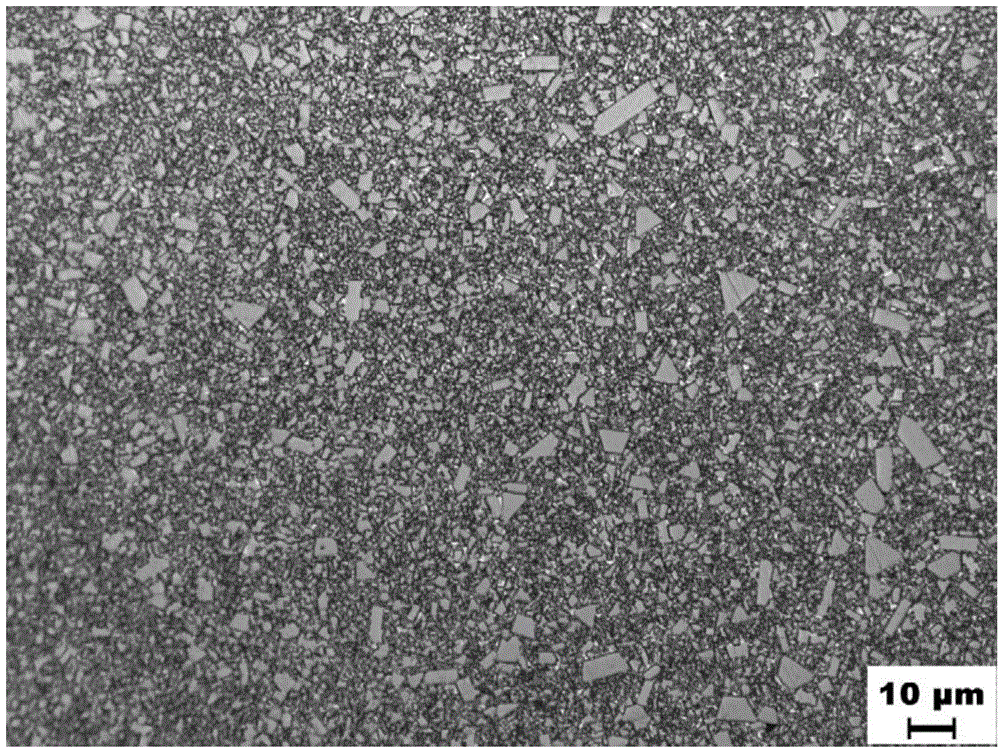

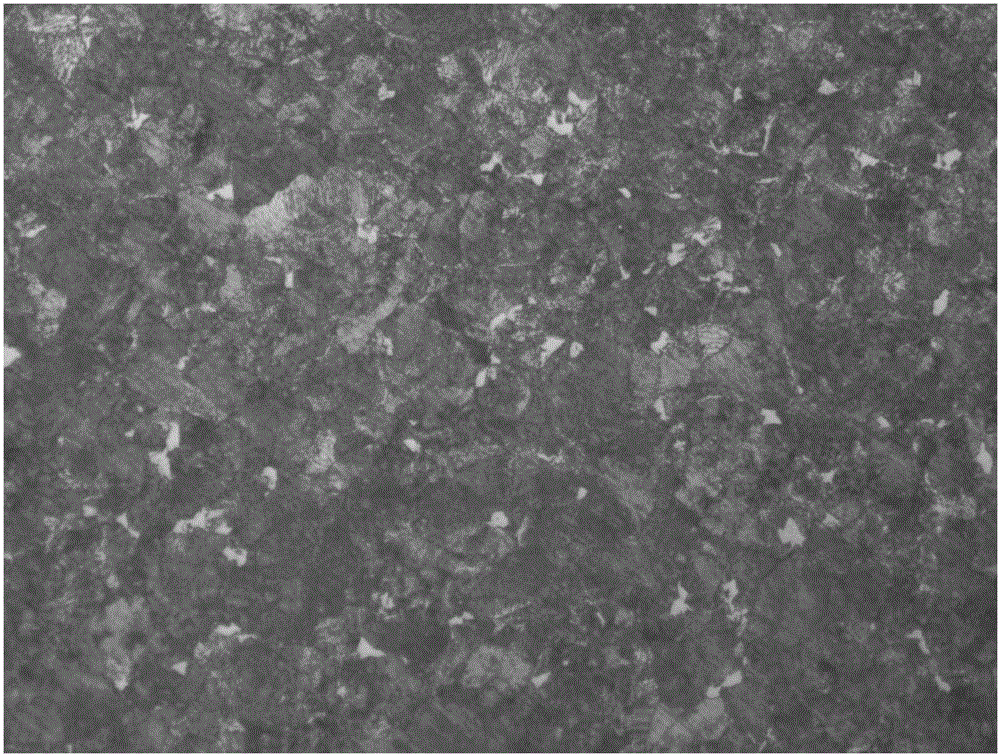

Metal ceramic alloy free of core-ring structure and preparation method thereof

ActiveCN109338193ASmall expansion coefficientRealize microcrystallization interfacial bonding methodMaterials preparationAlloy

The invention relates to the technical field of metal ceramic material preparation, and relates to a metal ceramic alloy free of a core-ring structure and a preparation method thereof. The metal ceramic alloy free of the core-ring structure comprises the following components of, in percentage by weight, 10-55% of Ti (C, N) micron powder, 10-55% of (Ti, M) (C, N) micron powder, 10-55% of Ti (C, N)sub-micron or / and nano powder, 10-55% of (Ti, M) (C, N) sub-micron or / and nano powder, 5-20% of WC, 0-30% of TiC, 0-30% of TiN, 0-20% of Co, 0-20% of Ni, 0-10% of Cr, 0-15% of Mo2C, 0-10% of TaC / NbC,0-2. 5% of VC, 0-5% of Cr2C3, and 0-1.2% of carbon black; the components are prepared into a mixture according to a certain ratio, the mixture is subjected to ball milling, sieving and mould pressingto prepare a blank, and the blank is subjected to sintering and cooling to prepare a metal ceramic material free of the core-ring structure. According to the method, a powder metallurgy method is adopted to prepare the metal ceramic alloy free of the core-ring structure, and the technological difficulty of being not easy to control the thickness of a microcosmic core-ring structure in the preparation process a traditional metal ceramic with core-ring structures is solved.

Owner:ZIGONG CEMENTED CARBIDE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com