Parallel tri-wire welding system and method

A welding system and welding method technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of insufficient filler wire melting, welding defects, insufficient energy, etc., and achieve good accessibility, low cost, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

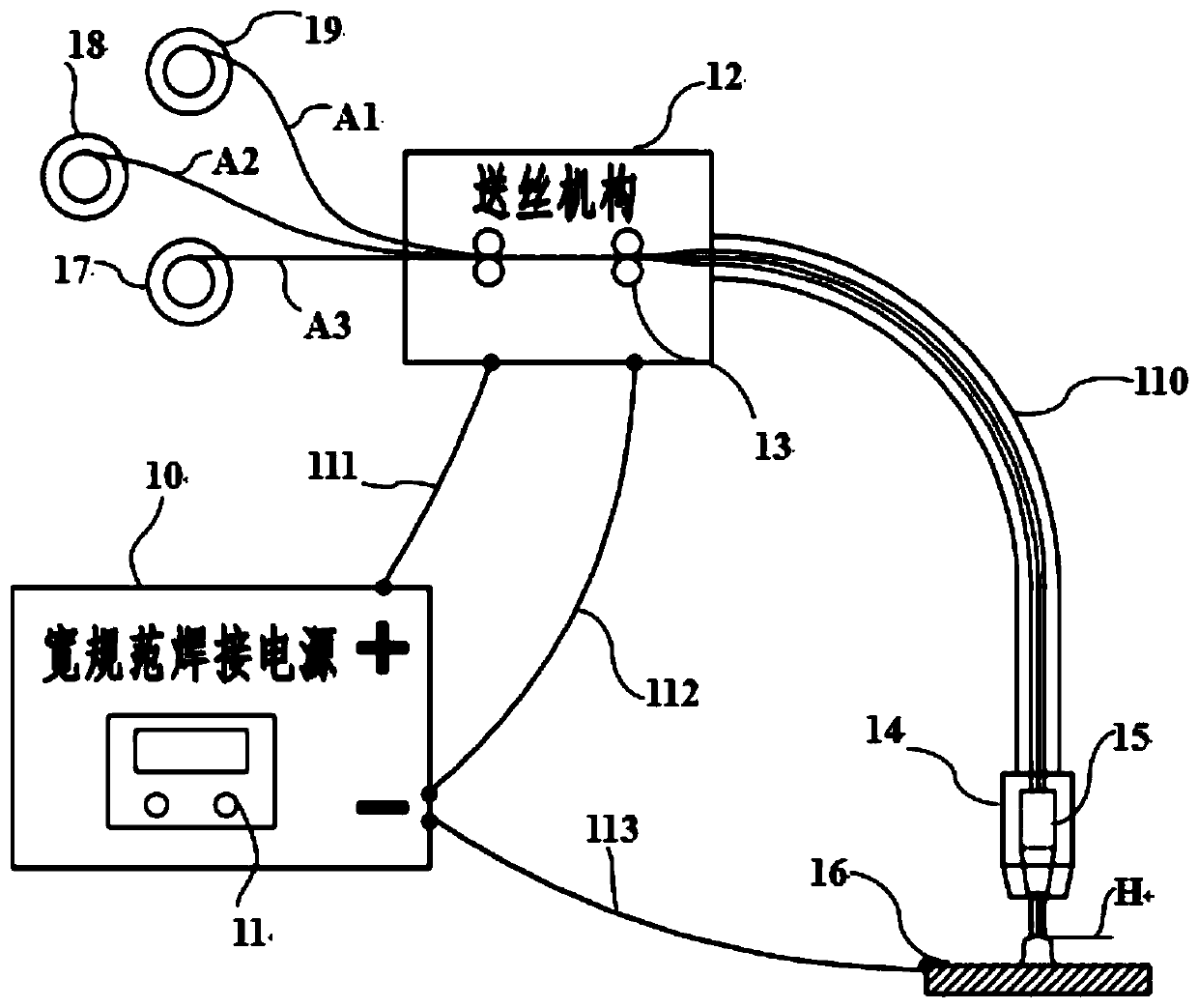

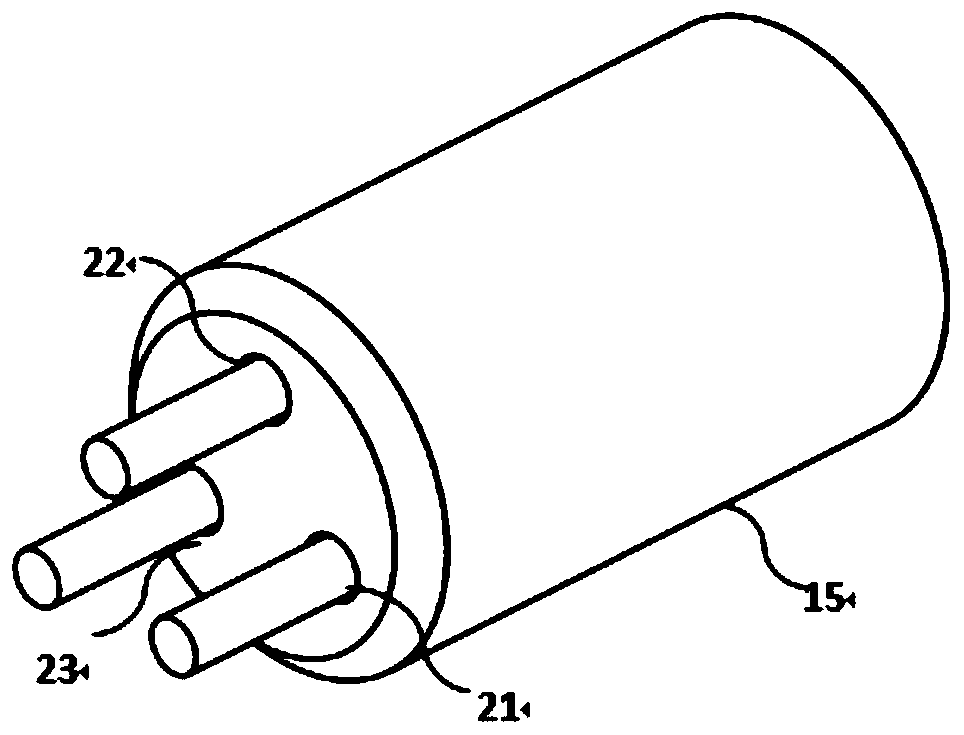

[0047] In one or more embodiments, a parallel three-wire welding system is disclosed, see figure 1, mainly includes: a wide specification welding power supply 10 and a control system 11 for controlling the output of the welding power supply, a wire feeding mechanism 12 with a three-slot wire feed wheel 13, a conventional welding torch 14 with a three-hole contact tip assembly 15 and welding Base material 16. The welding power supply 10 is connected to the wire feeding mechanism through the wire feeding machine control cable 111, and the wire feeding mechanism is connected to the welding torch through the wire feeding tube, and the welding torch passes through one pole of the output electrode of the wide specification welding power supply. The welding cable 110 attached with the shielding gas hose is connected, and the other pole of the output electrode of the wide specification welding power supply is connected to the base metal 16 to be welded through the base metal cable 113...

Embodiment 2

[0070] In one or more embodiments, a method of parallel three-wire welding is provided, comprising:

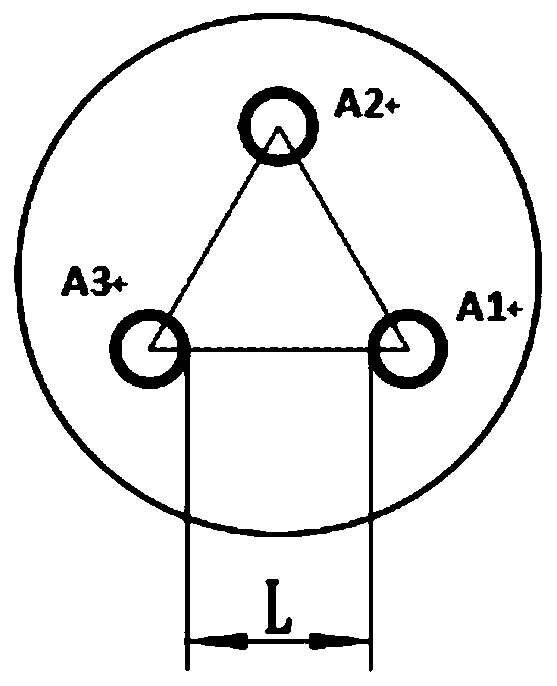

[0071]The output current waveform is provided to the contact tip through a wide range welding power supply; wherein the contact tip includes a first outlet hole, a second outlet hole and a third outlet hole; the first outlet hole, the second outlet hole and the third outlet hole are separated from each other, And the projection points of the centers of the first outlet hole, the second outlet hole and the third outlet hole on the surface of the workpiece are three vertices of an equilateral triangle, so that the distance between the three welding wires is L;

[0072] The wire feeding mechanism provides the first welding wire to the contact tip, and the first welding wire is delivered through the first outlet hole;

[0073] The wire feeding mechanism provides the second welding wire to the contact tip, and the second welding wire is delivered through the second outlet hole;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com