Complex free-form surface mesh generation method based on surface fitting and geodesic lines

A technology of surface fitting and grid division, which is applied in the directions of instruments, computing, image data processing, etc., can solve the problems of unsatisfactory grid division effect, and achieve good architectural aesthetics and smooth lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

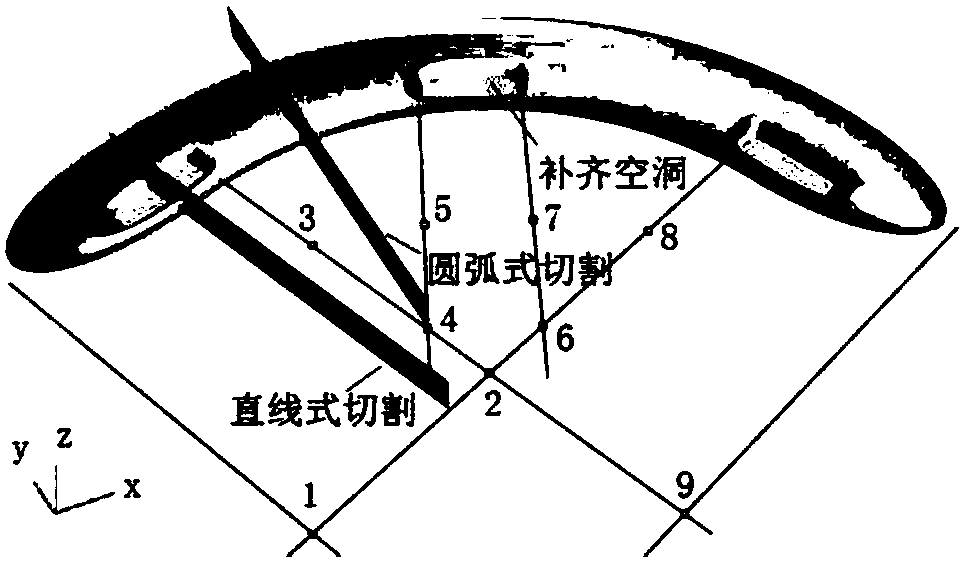

[0056] Such as figure 1 As shown, it is a complex free-form surface, which is composed of multiple NURBS clipping surfaces, and it is impossible to obtain better meshing results by conventional methods. Taking this curved surface as an example, the specific implementation of the complex free-form surface meshing method (surface-surface intersection method) based on surface fitting and geodesics in the present invention will be described below.

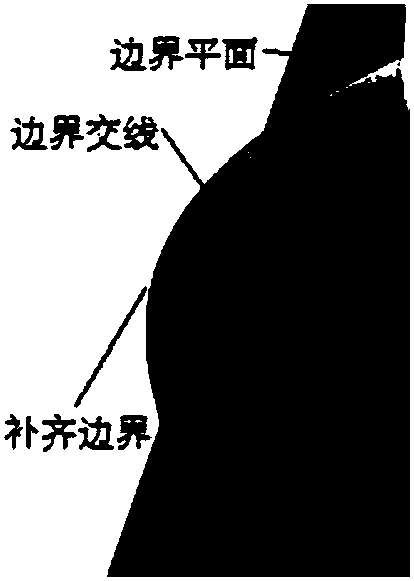

[0057] 1) Fill the holes on the surface. When there is a hole inside the complex free-form surface, in order to ensure that the intersection line between the plane and the curved surface can be fitted as a curve on the plane, the hole is filled with a plane. Such as figure 1 As shown, there are three holes in the surface, which are filled by three planes to form a continuous surface without holes.

[0058] 2) Select the plane cutting method. Use N planes distributed in a path array to cut the longitudinal section of the NURBS surfa...

Embodiment 2

[0091] In this example, for Figure 16 The surface shown is meshed, and the surface is composed of three surfaces, and the fitting surface is as follows Figure 17 shown. After utilizing the aforementioned method of the present invention to process it (the specific method is as described above, no more details), the generated geodesic line is as follows Figure 18 As shown, and further use the kangaroo plug-in in Rhino software to smooth the grid as shown in Figure 19 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com