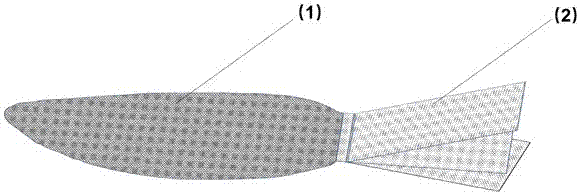

Composite material propeller blade sheet molding and transition connection technical study

A technology of composite materials and molding process, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of reduced propeller strength, high overall molding and winding costs, and difficulty in demoulding, so as to achieve smooth blade surface and enhanced strength , Transition uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific technical solutions of the present invention are further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, rather than constituting a limitation on their rights.

[0029] A kind of slice molding of composite material propeller blade comprises the following steps:

[0030] (1) Selection and processing of blade molds and materials:

[0031] (1.1) The blade mold is divided into an upper mold and a lower mold, and the material is metal;

[0032] (1.2) Before lamination, use water, ethanol, acetone and other solvents to wash off the dust, oil stains, organic matter and other impurities on the surface of the mold. After drying, apply a release agent or wax on the surface of the blade mold to evenly coat the gel coat resin. Spray on the surface of the mold, place it, and set it aside;

[0033] (1.3) Selection of reinforcement materials: choose fiber cloth and prepreg with e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com