Patents

Literature

68 results about "Composite propeller" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Marine composite propellers often refer to ship propellers, usually made from fiber composites like glass or carbon fibers infused with a high-strength resin like epoxy or polyimide. These kinds of composites made are strong, light and high-tech materials. Such composite propellers can be produced in several ways, including vacuum infused molding and injection molding process, depending on size and resin viscocity.

Single-Piece Propeller And Method Of Making

A method for making a propeller product is disclosed. The propeller is formed using polyurethane cores adhered to a laminate hub to form a core assembly. An encapsulating structural laminate skin is then formed on the core assembly using a resin-transfer-molding process to create a single-piece composite propeller.

Owner:TEXTRON INNOVATIONS

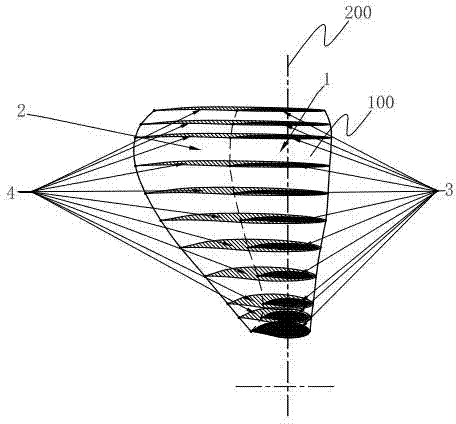

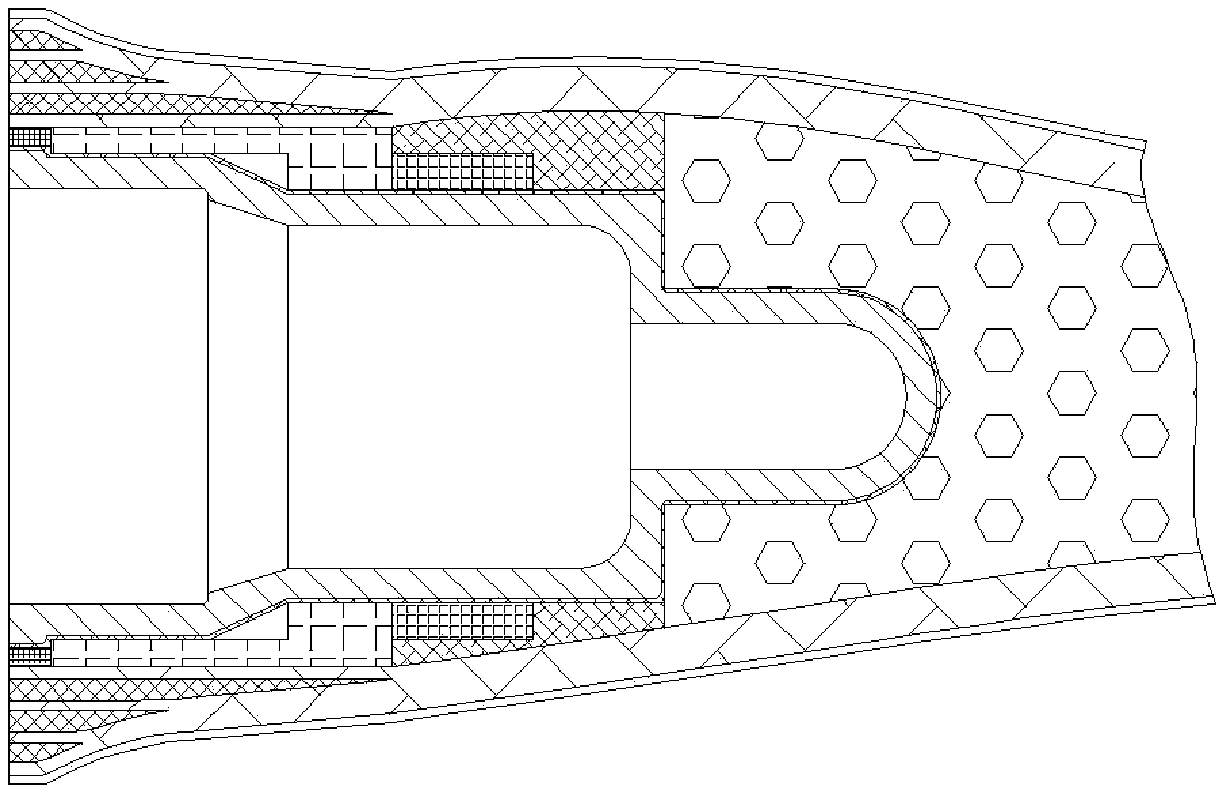

Integrally forming mould of composite propeller and manufacture method thereof

The invention relates to an integrally forming mould of a composite propeller and a manufacture method thereof, solving the problems that hubs and paddle shafting of traditional propellers vibrate, and paddle roots are easy to be damaged. In the mould, an upper mould paddle chamber is arranged on an upper mould parting curved surface, a lower mould parting curved surface that is matched with the upper-mould parting curved surface on an upper mould block is arranged on each lower mould block that is arranged on a lower mould, a lower mould paddle chamber is just opposite to the upper mould paddle chamber, each lower mould parting curved surface and seal groove on the lower mould is matched with one of the upper mould blocks, a cover plate is arranged on the upper end faces of the three upper mould blocks, and each mould block groove on the cover plate is provided with one of the upper blocks. The method comprises the following steps of: firstly, designing an aluminum sheath; secondly, manufacturing aluminum alloy hubs; thirdly, cutting pieces of upper mould fiber cloth and pieces of lower mould fiber cloth; fourthly, preparing paddles; fifthly, placing the aluminum alloy hubs; sixthly, assembling the upper and the lower moulds; seventhly, injecting epoxy resin; and eighthly, forming the mould under pressure. The invention is used for manufacturing the composite propeller.

Owner:HARBIN INST OF TECH

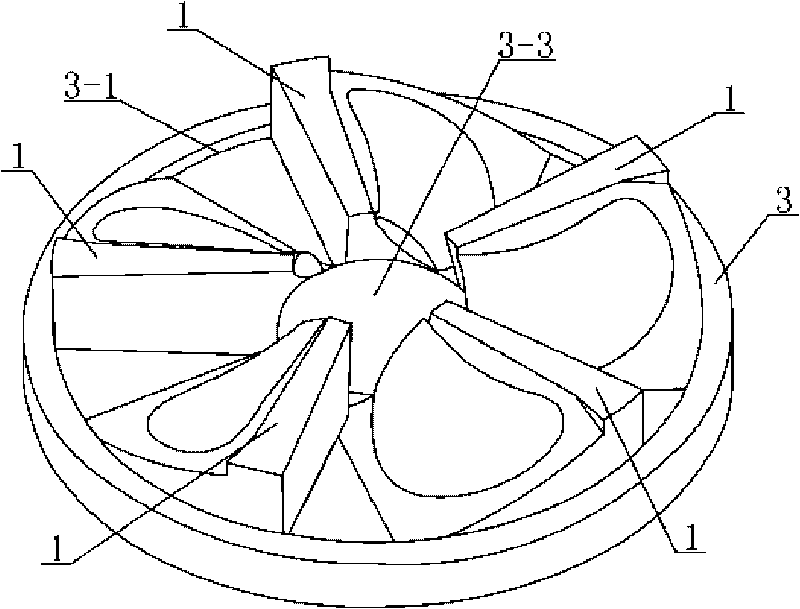

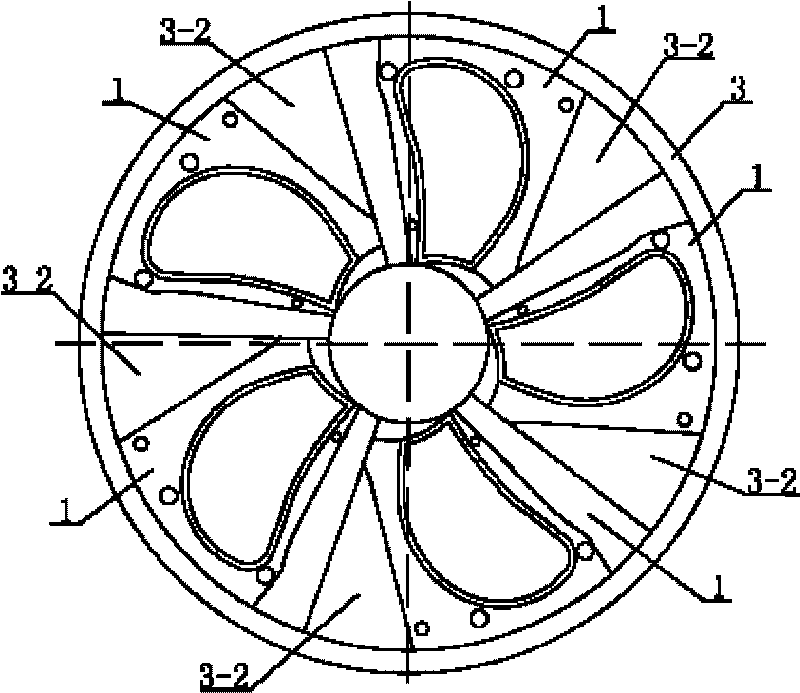

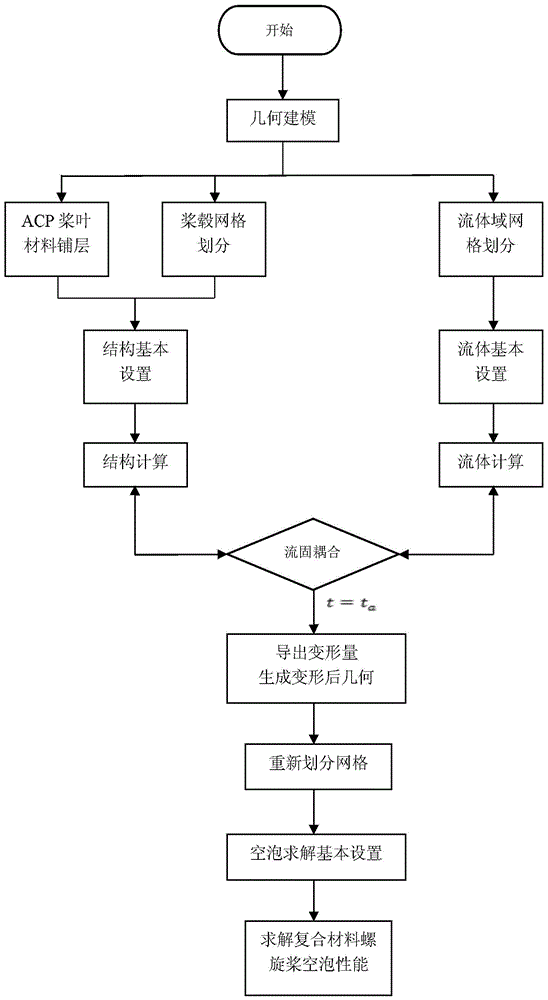

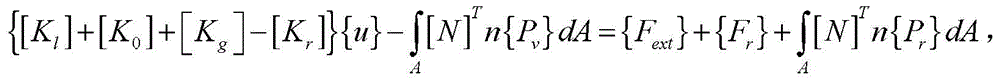

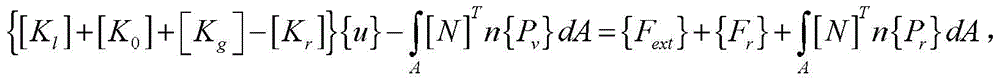

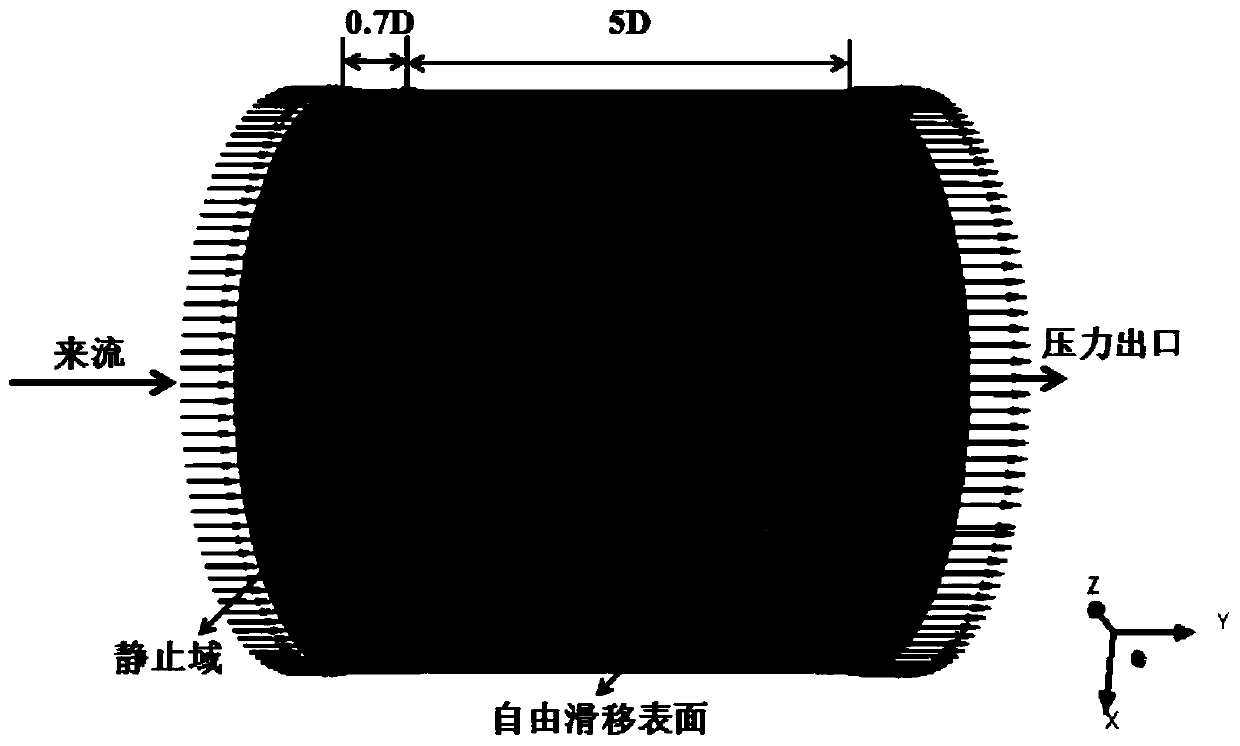

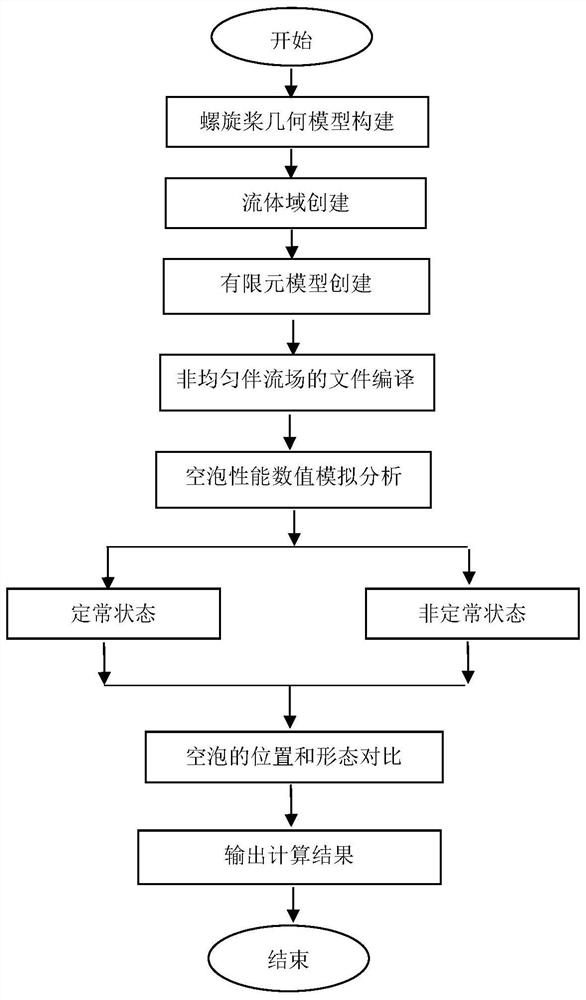

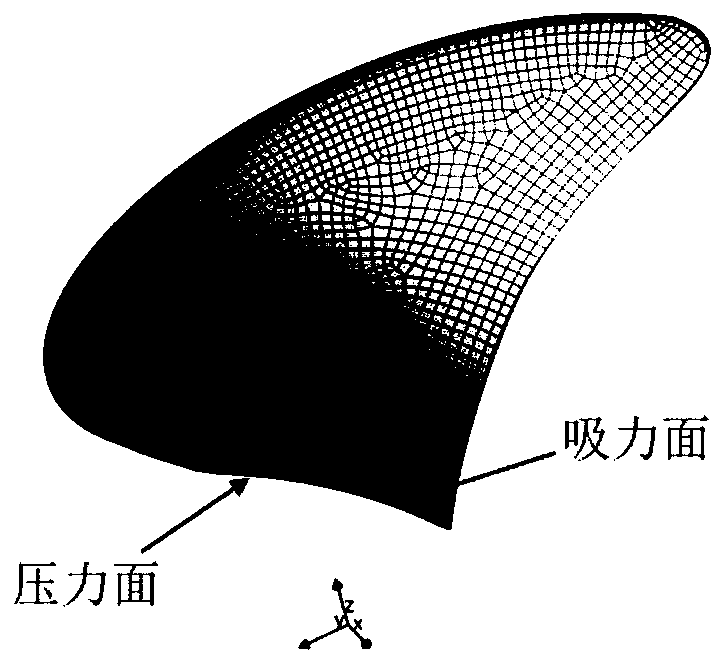

Composite material propeller cavitation performance calculation method

ActiveCN105653781AAvoid affecting propulsion performanceSolve the problem of imperfect research workSustainable transportationDesign optimisation/simulationMaterial defectComposite propeller

A composite propeller cavitation performance calculation method. The present invention relates to a composite material propeller cavitation performance calculation method. In order to solve the problem that due to generation of cavitation, the existing method will affect hydrodynamic performance of propellers, reduce propulsion efficiency, severely affect concealment of vessels, corrode surface materials of the propellers and cause surface material defects, the present invention provides a composite material propeller cavitation performance calculation method. The method comprises: establishing a geometric model; carrying out grid division; carrying out structure and fluid arrangement; carrying out structure and fluid calculation; exporting a deformed geometric model; re-dividing a grid; and carrying out cavitation performance calculation. The method provided by the present invention is applied to the field of propellers.

Owner:HARBIN INST OF TECH

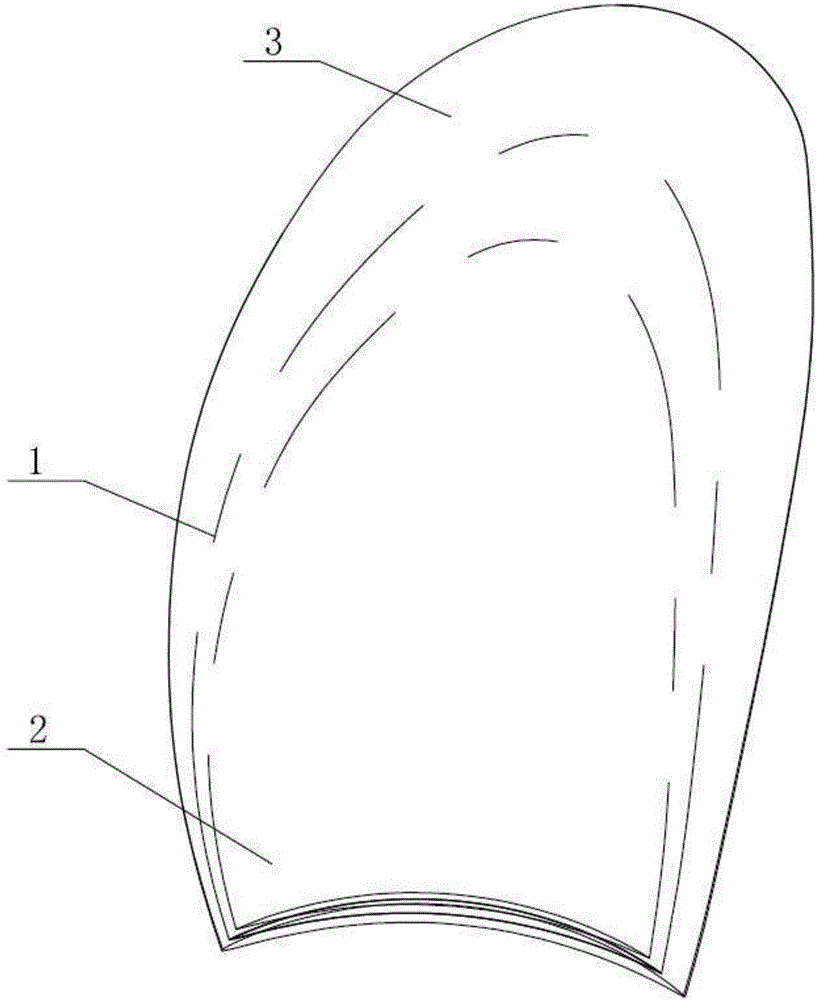

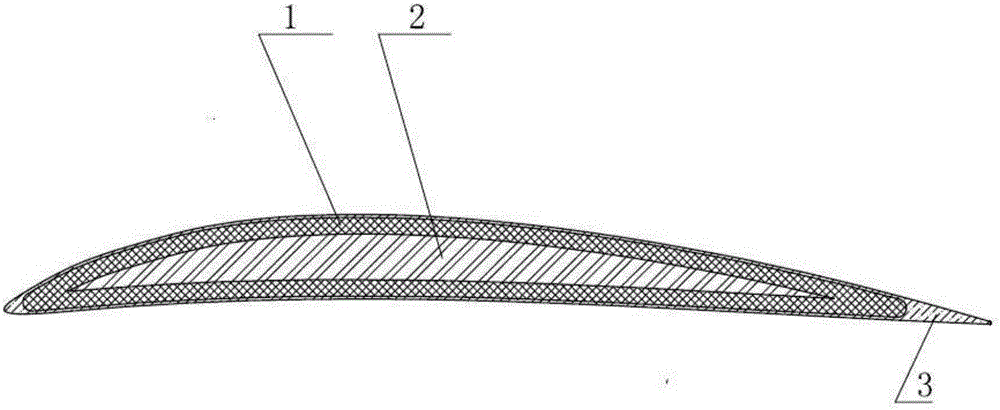

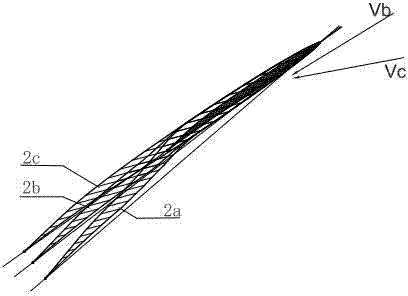

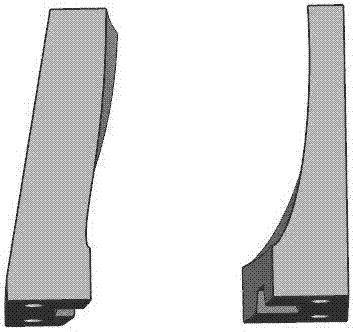

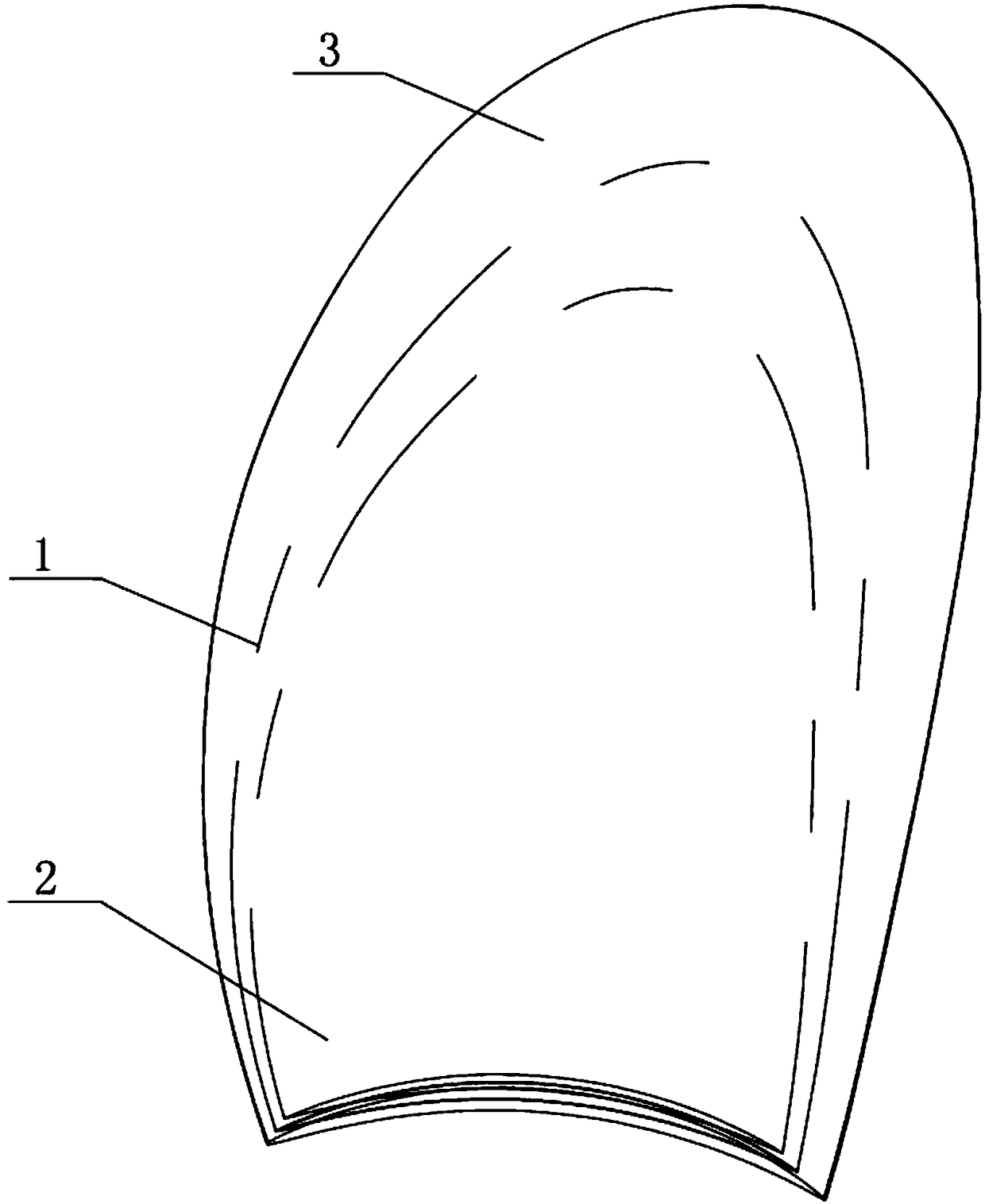

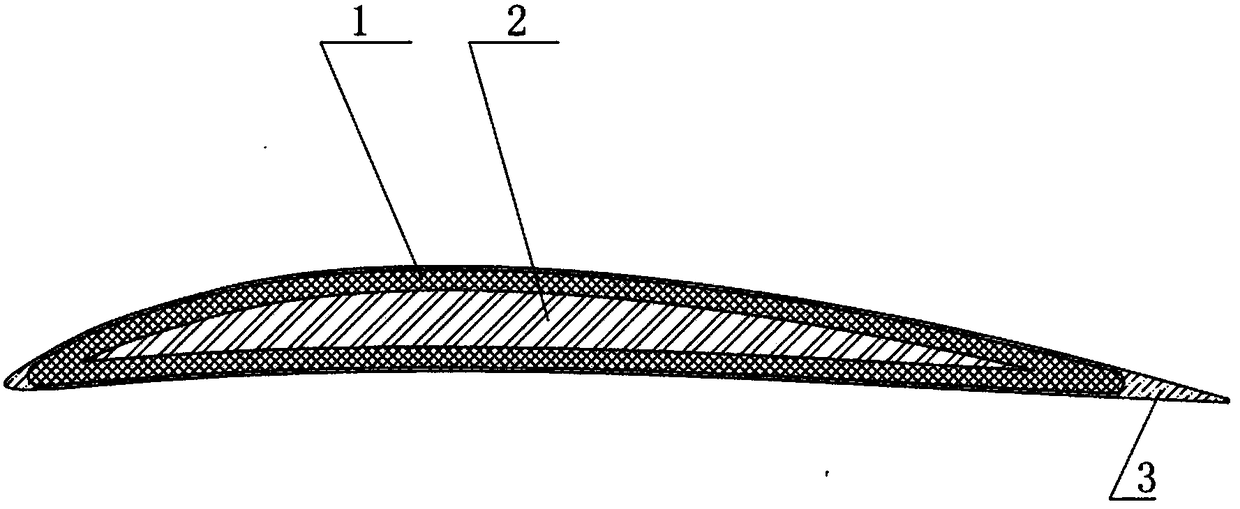

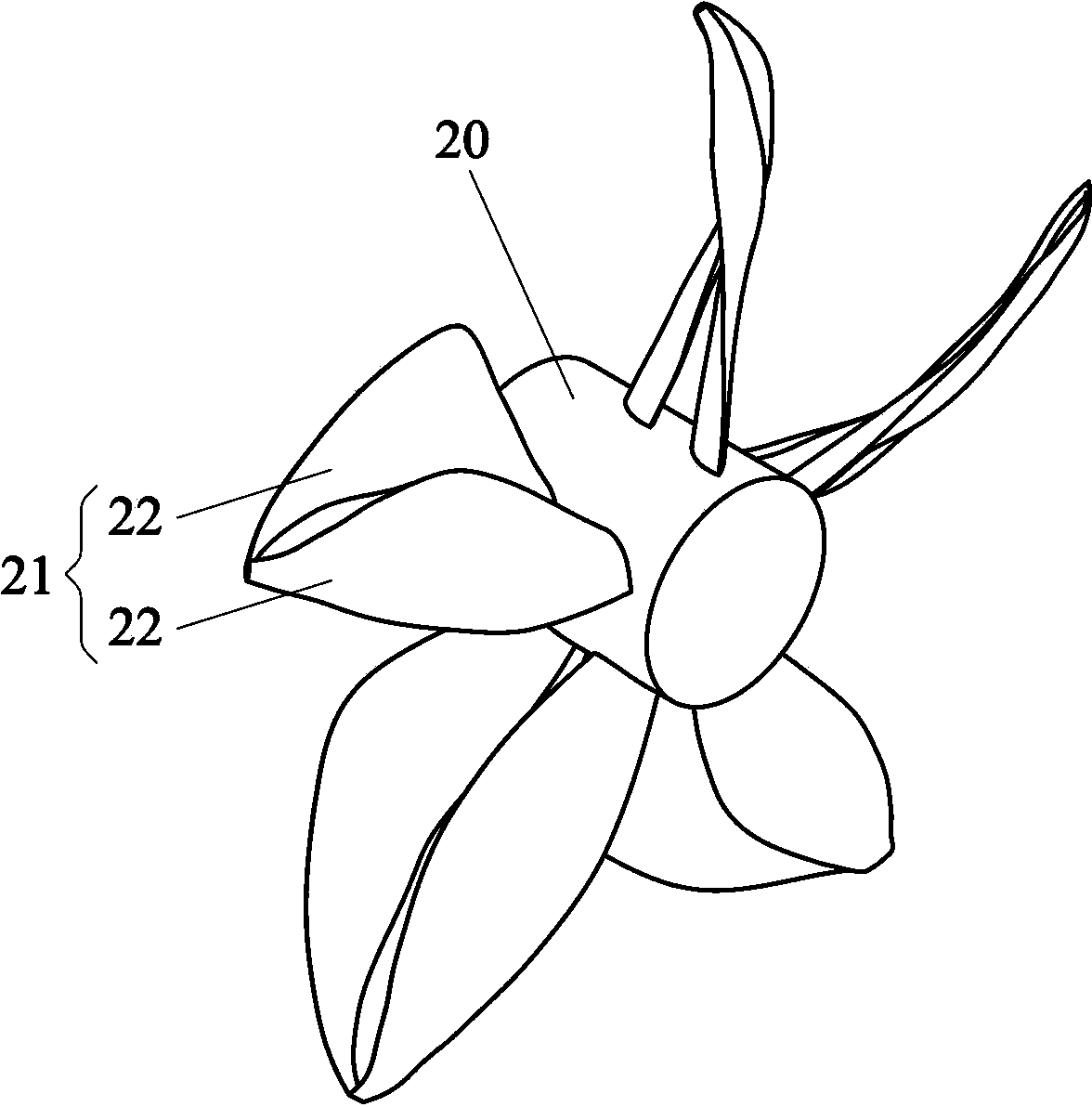

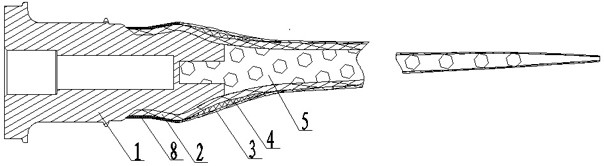

Performed composite propeller blade of ship and manufacturing method of performed composite propeller blade

The invention relates to a performed composite propeller blade of a ship and a manufacturing method of the performed composite propeller blade. Compared with a metal propeller, the preformed composite propeller blade has the advantages that the weight is low, corrosion resistance is good, the hydrodynamic performance is superior, cavitation can be delayed, cavitation corrosion is reduced, the acoustic characteristic is excellent, noise of the propeller is lowered, and the stealth performance of the ship can be easily improved. Fiber covers serve as a primary bearing mechanism, and the fiber covers are designed to be of identical thickness and cover the whole blade. By means of the performed composite propeller blade of the ship and the manufacturing method of the performed composite propeller blade, quasi two-dimensionalization of complex three-dimensional weaving is effectively achieved. The problems of delamination and stripping of guide edges and following edges of an original blade are effectively solved, the weaving difficulty is reduced, and cost is reduced; and the dead load of the propeller blade can be greatly reduced, and the appearance precision of the propeller blade is improved.

Owner:中国船舶重工集团公司第七〇二研究所

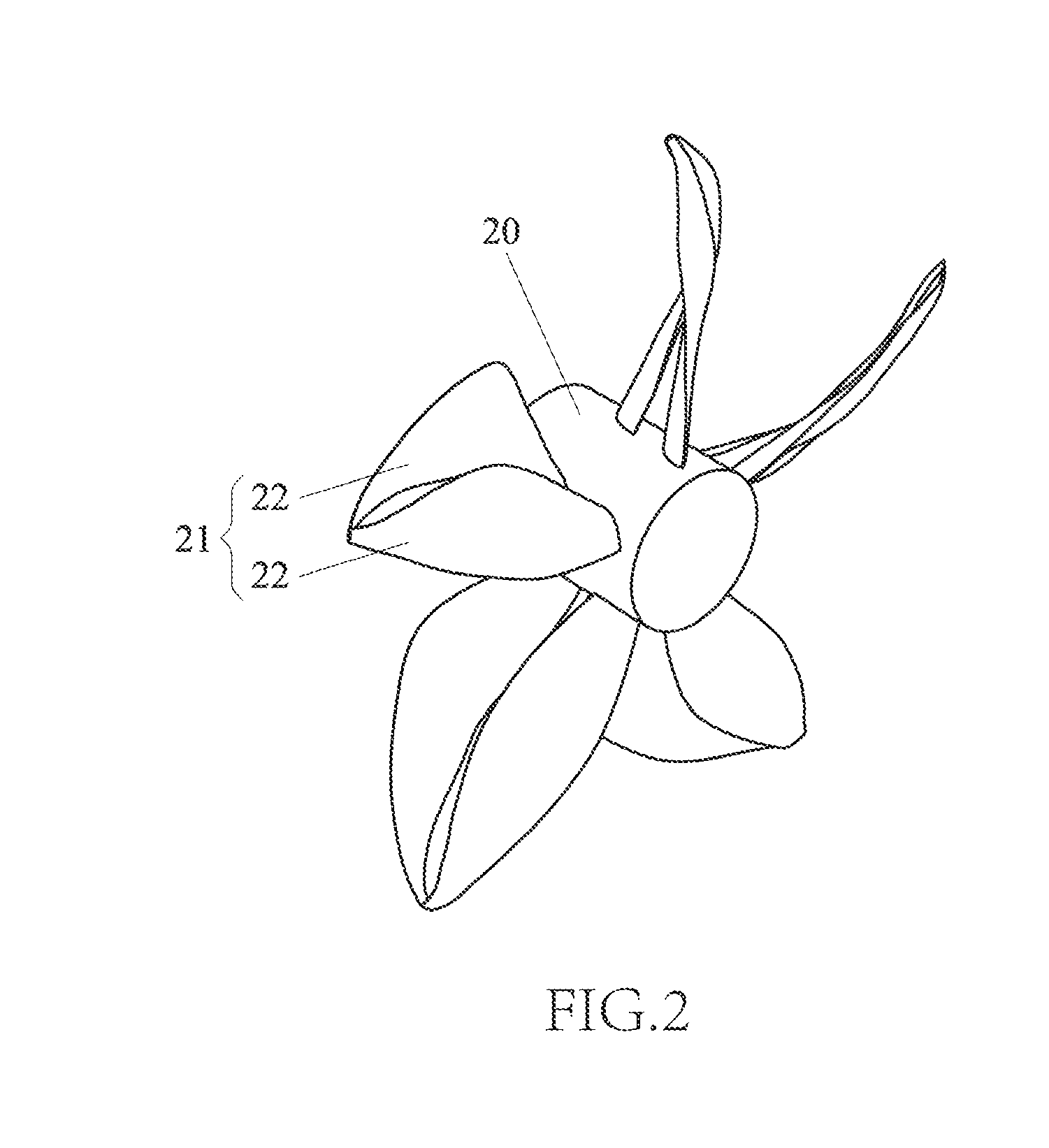

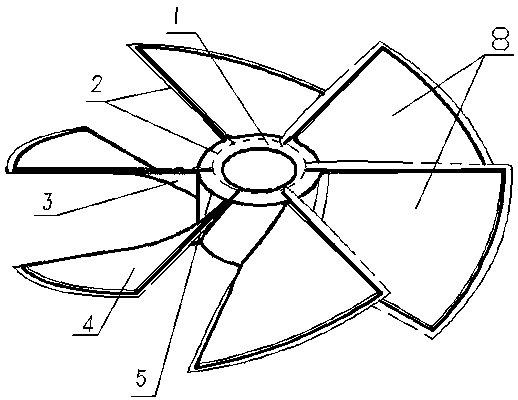

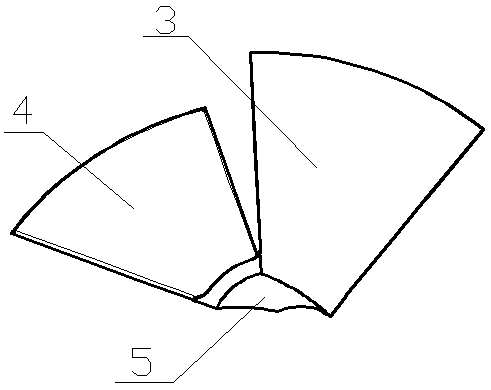

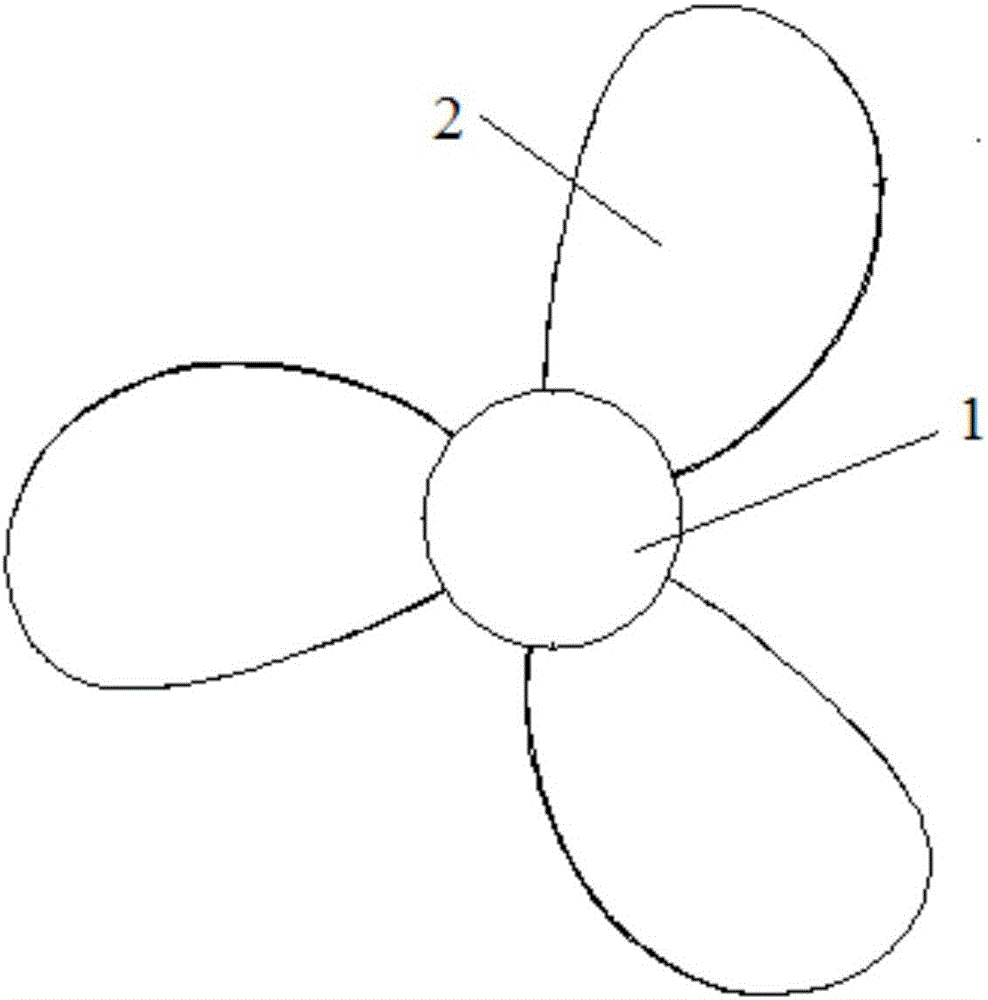

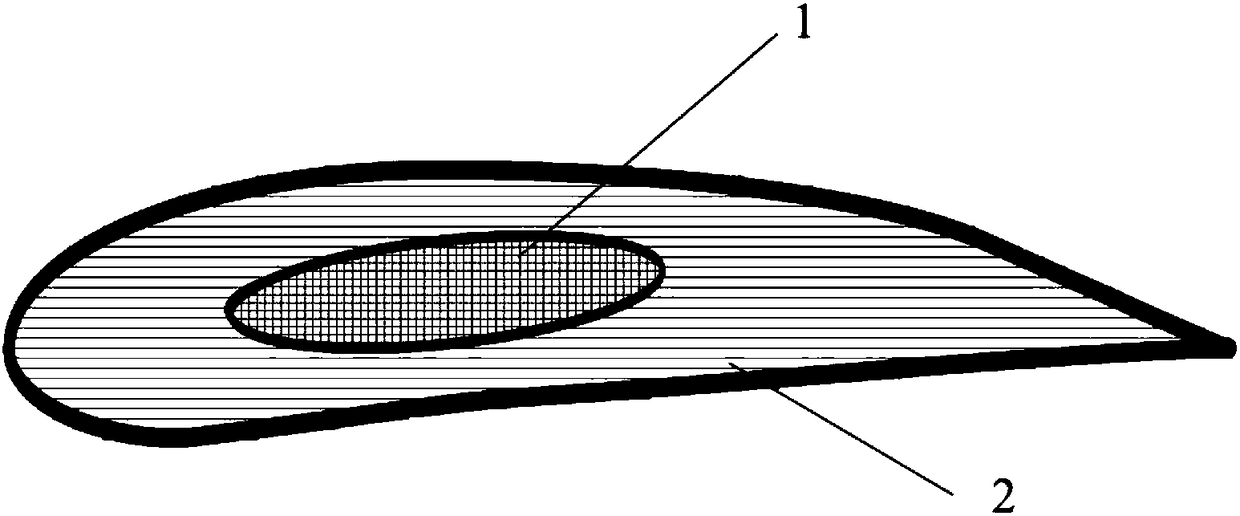

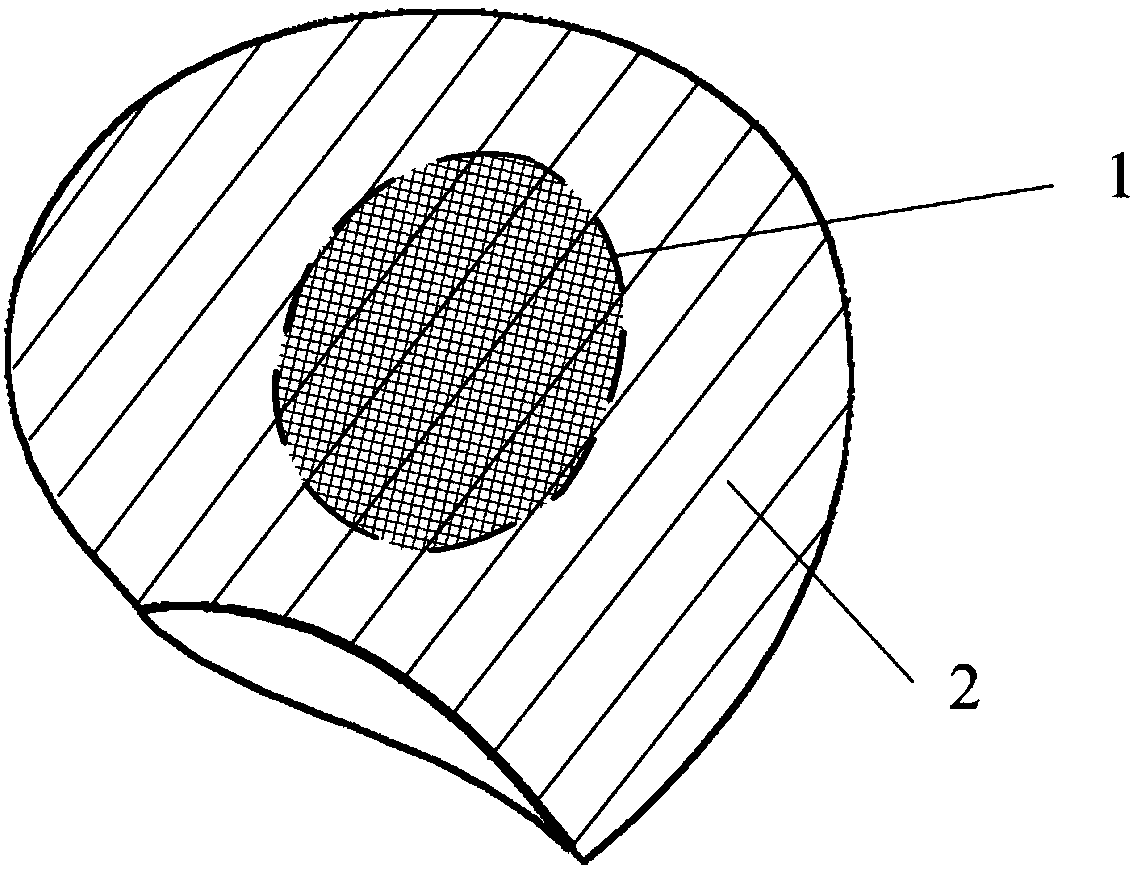

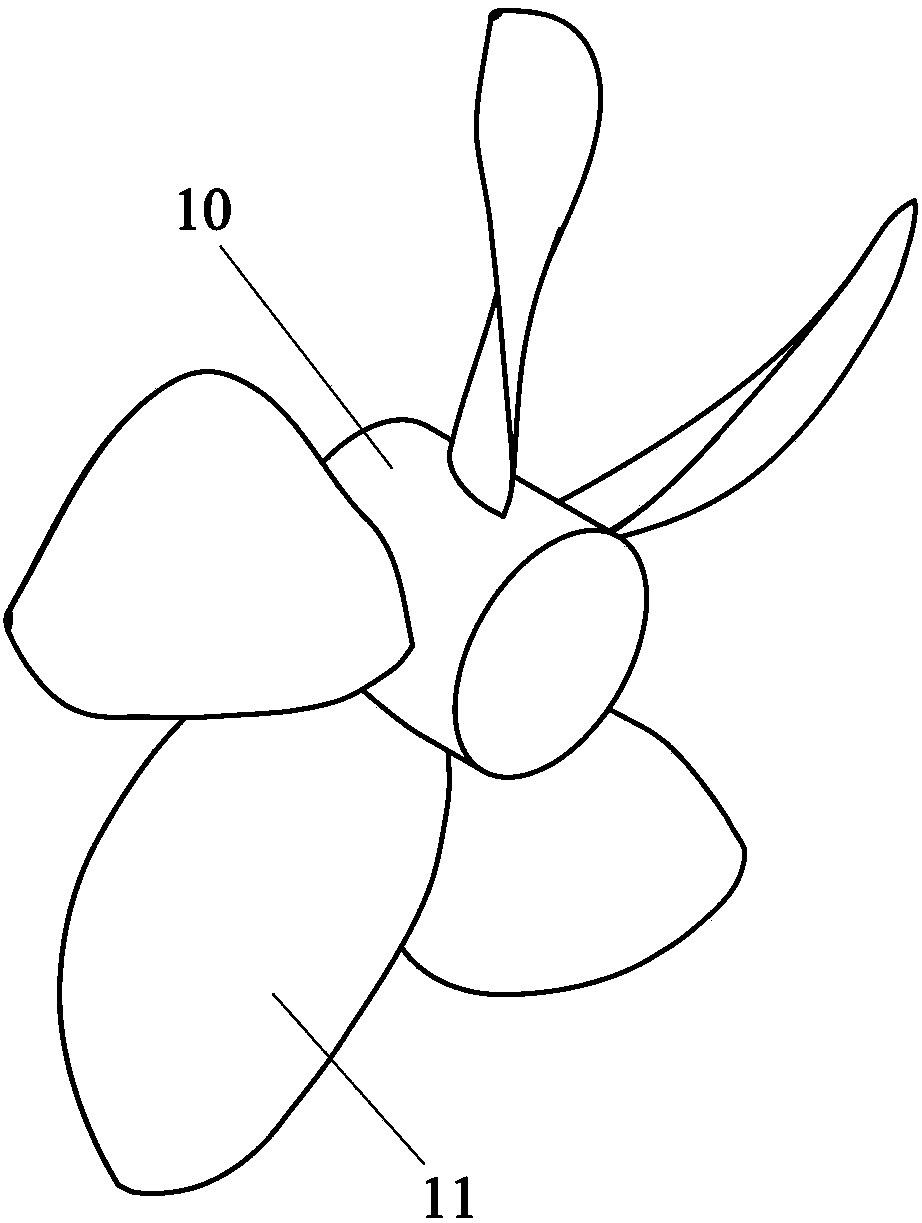

Self-adaptive biomimetic composite propeller blade

The invention relates to a self-adaptive biomimetic composite propeller blade. The body of the self-adaptive biomimetic composite propeller blade is formed by a guiding edge part and a following edge part. The self-adaptive biomimetic composite propeller blade is characterized in that the guiding edge part is arranged by taking the reference axis of a propeller as a center and provided with a rigid blade core, the rigid blade core is covered by a flexible material layer, and the flexible material layer extends along the chord length direction to form the following edge part. The self-adaptive biomimetic composite propeller blade has a simple and compact structure and is convenient to install. Due to the adoption of the self-adaptive biomimetic composite propeller blade, the overall manufacturing cost of the ship is reduced. Due to the adoption of the rigid blade core of the guiding edge part and the flexible material structure of the following edge part as well as the structure and the appearance of the propeller blade with the self-adaptive wake flow attack angle change, the violent bearing force vibration of the propeller blade working in the non-uniform wake field and the vacuole induced ship hull surface fluctuating pressure are reduced, the power of a host can be fully utilized in multiple working conditions, and the waste of the power of the conventional propeller host and the ducted propeller host can be reduced.

Owner:中国船舶重工集团公司第七〇二研究所

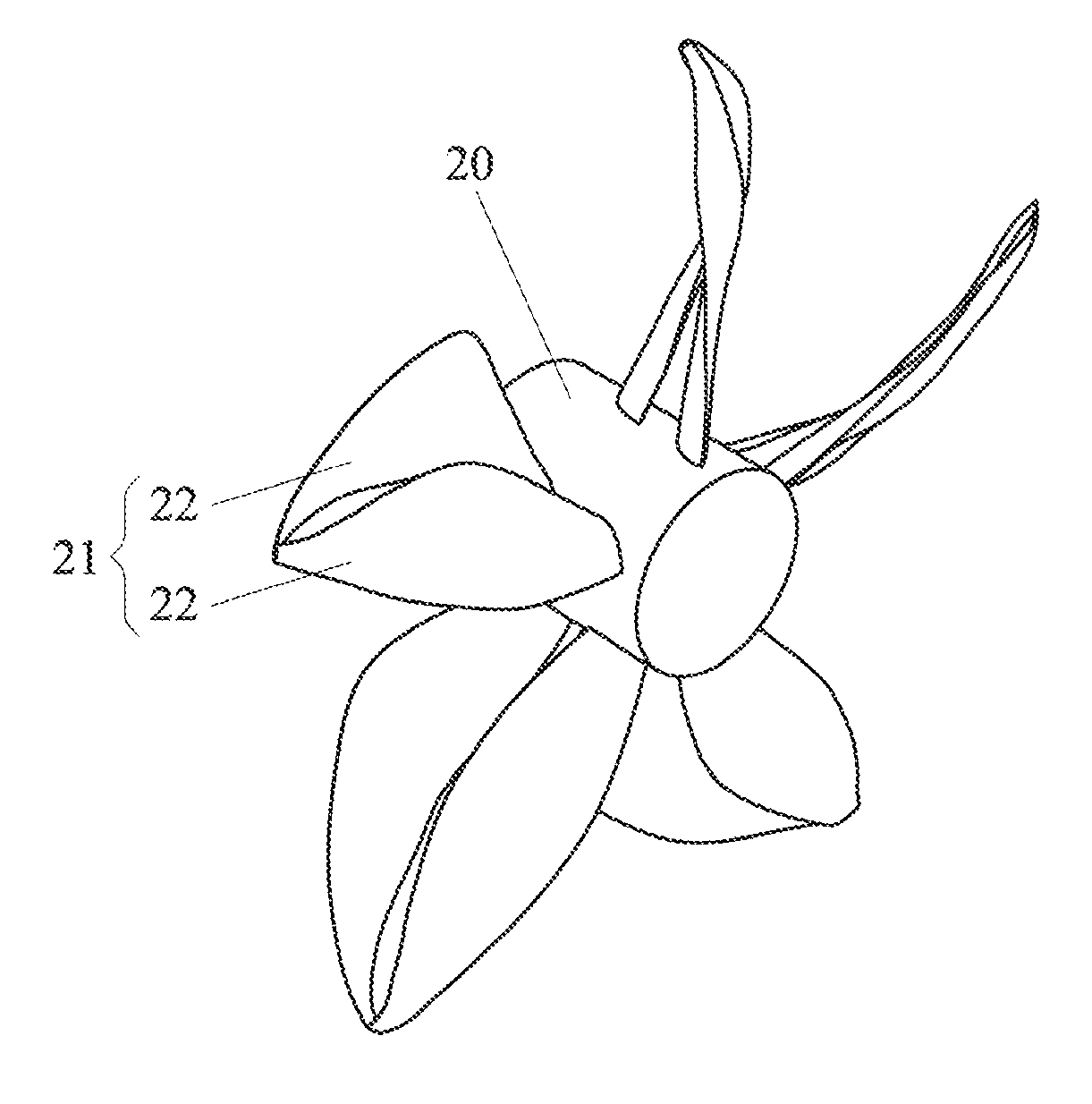

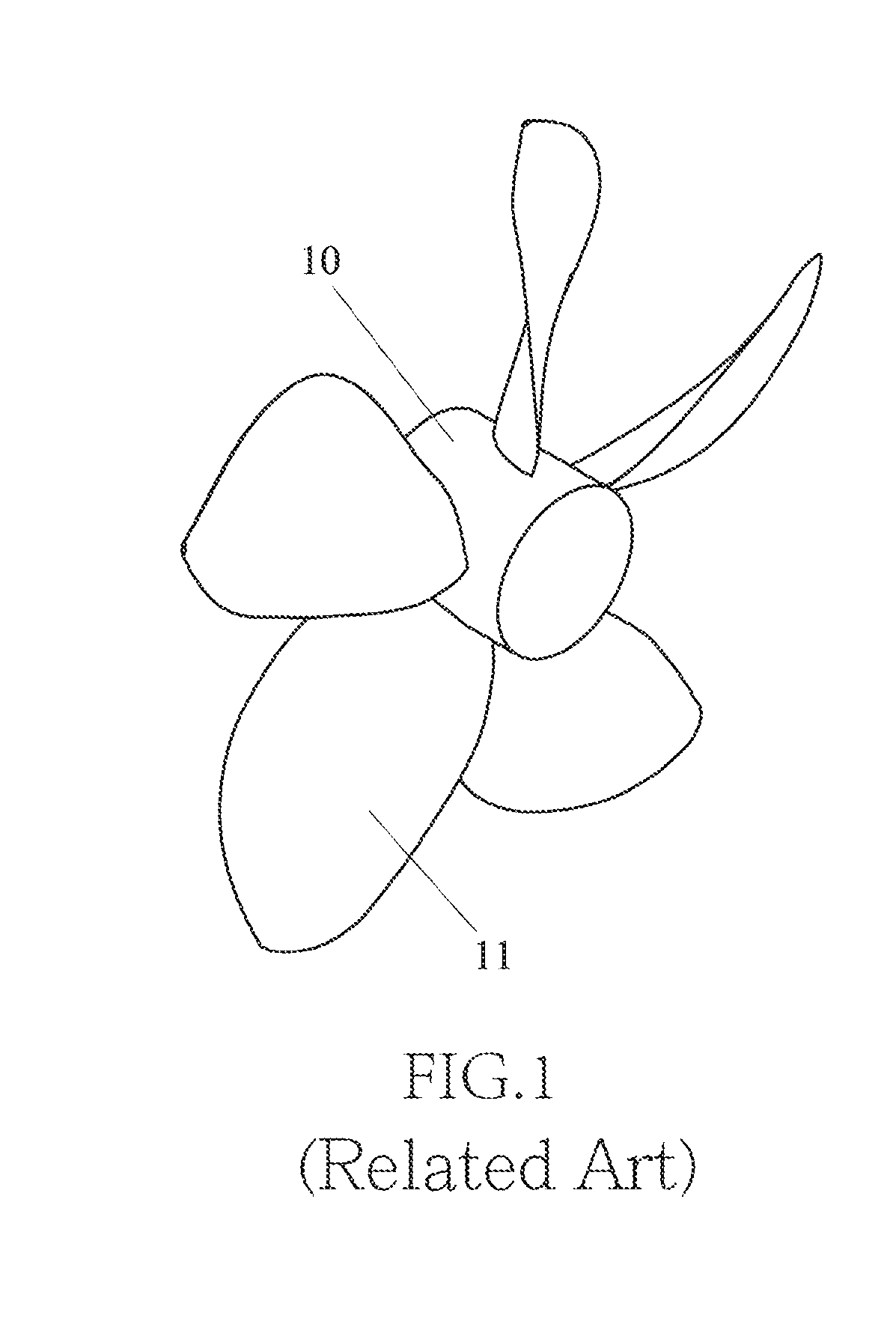

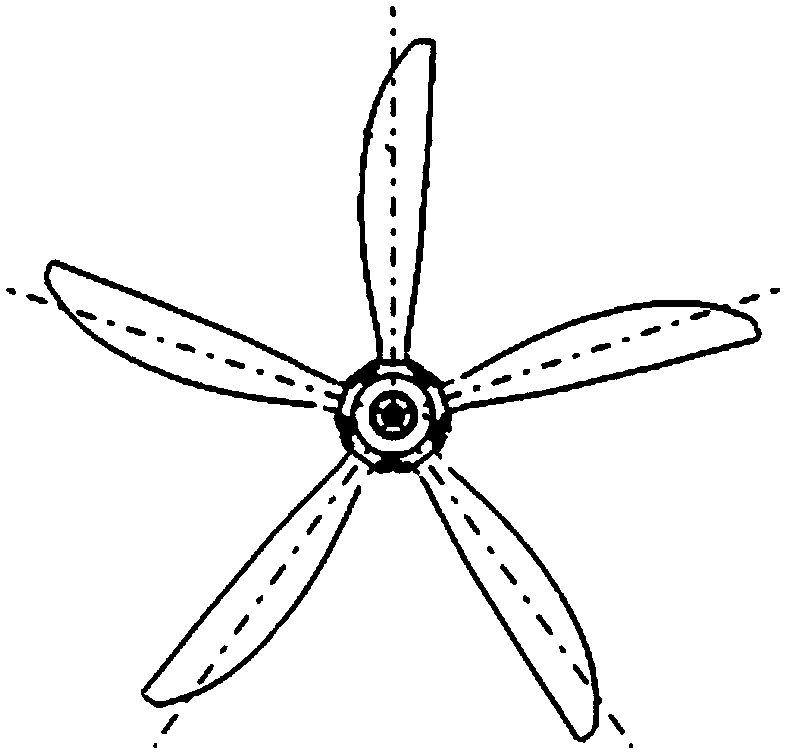

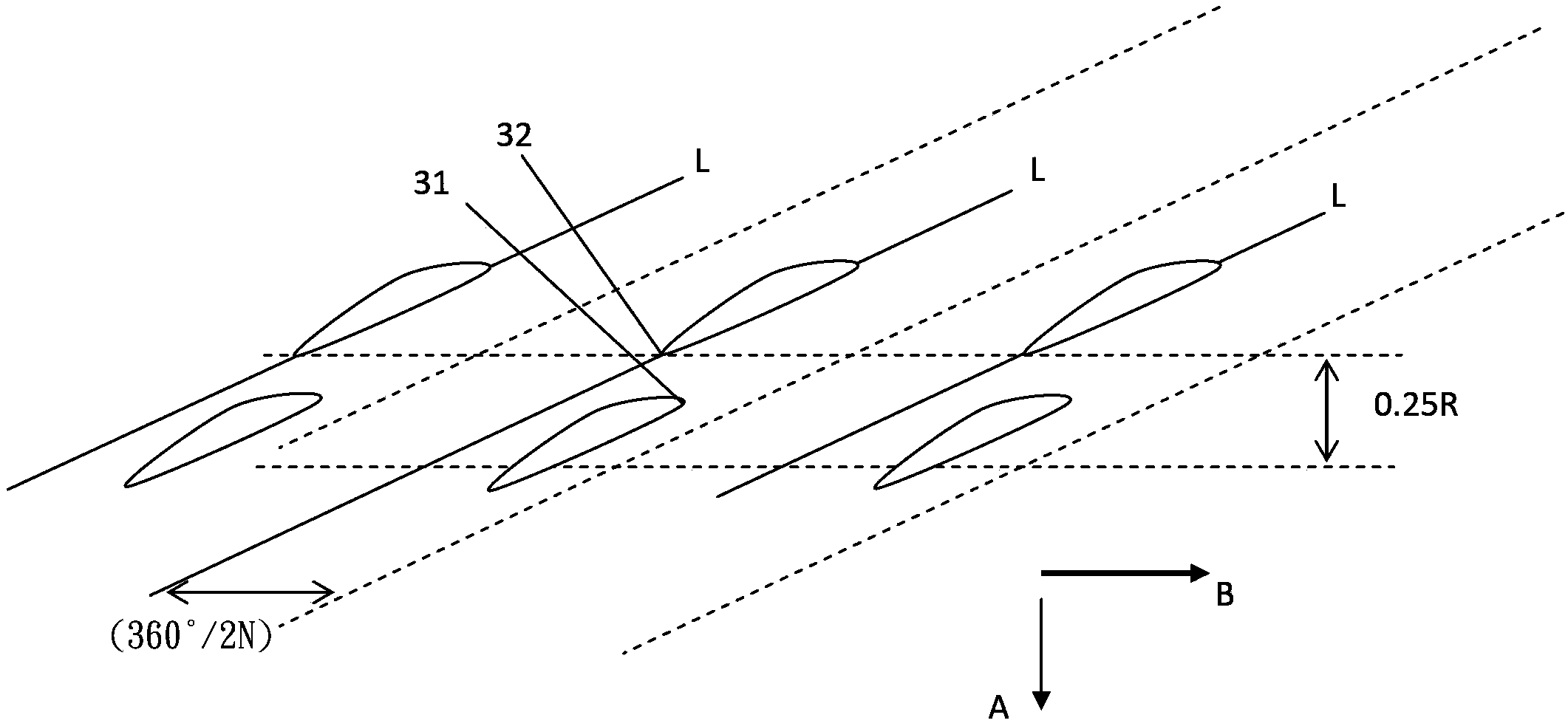

Composite propeller blade structure

InactiveUS20150037157A1Improve performanceEffectively boosting performanceRotary propellersMachines/enginesComposite propellerFront edge

A composite propeller blade structure includes at least a rotation shaft and a rotation surface on which plural blades are formed, and characterized in that: each of the blades is composed of plural blade units; and in the equivalent radius cross section of each of the blades, the installed location of a front edge of the blade unit at the downstream is defined as following: in the rotation axial direction, which is located behind a rear edge of the adjacent blade unit at the upstream, and the maximum distance thereof is not greater than 25% of the radius of the adjacent blade unit at the upstream; and in the circumferential direction, located at the pressure surface side defined on the nose-trail line of the adjacent blade unit at the upstream, and the maximum range thereof is not greater than (360° / 2N), wherein N is the quantity of the blades.

Owner:APPLIED THERMAL FLUID ANALYSIS CENT LIMITED LIABILITY

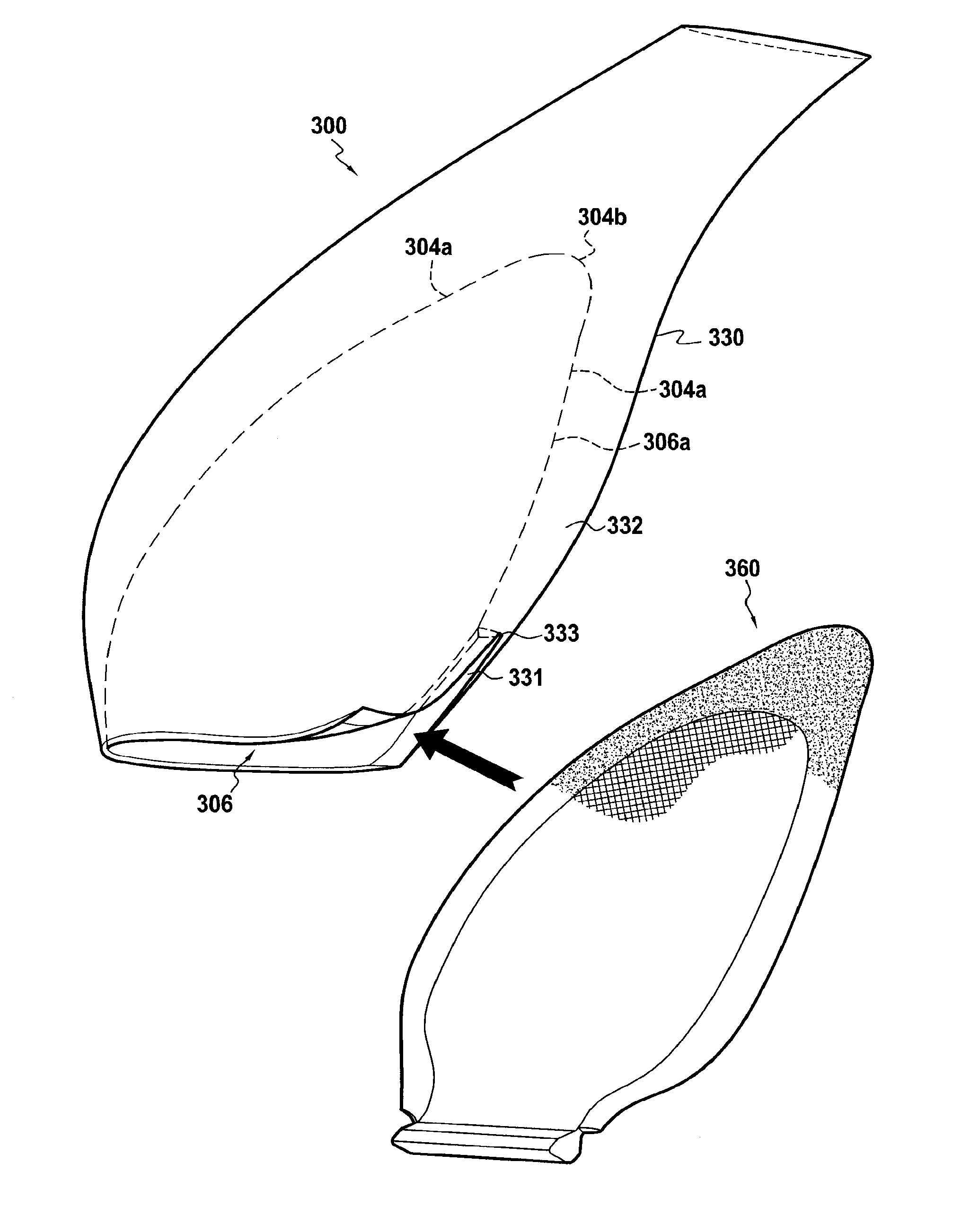

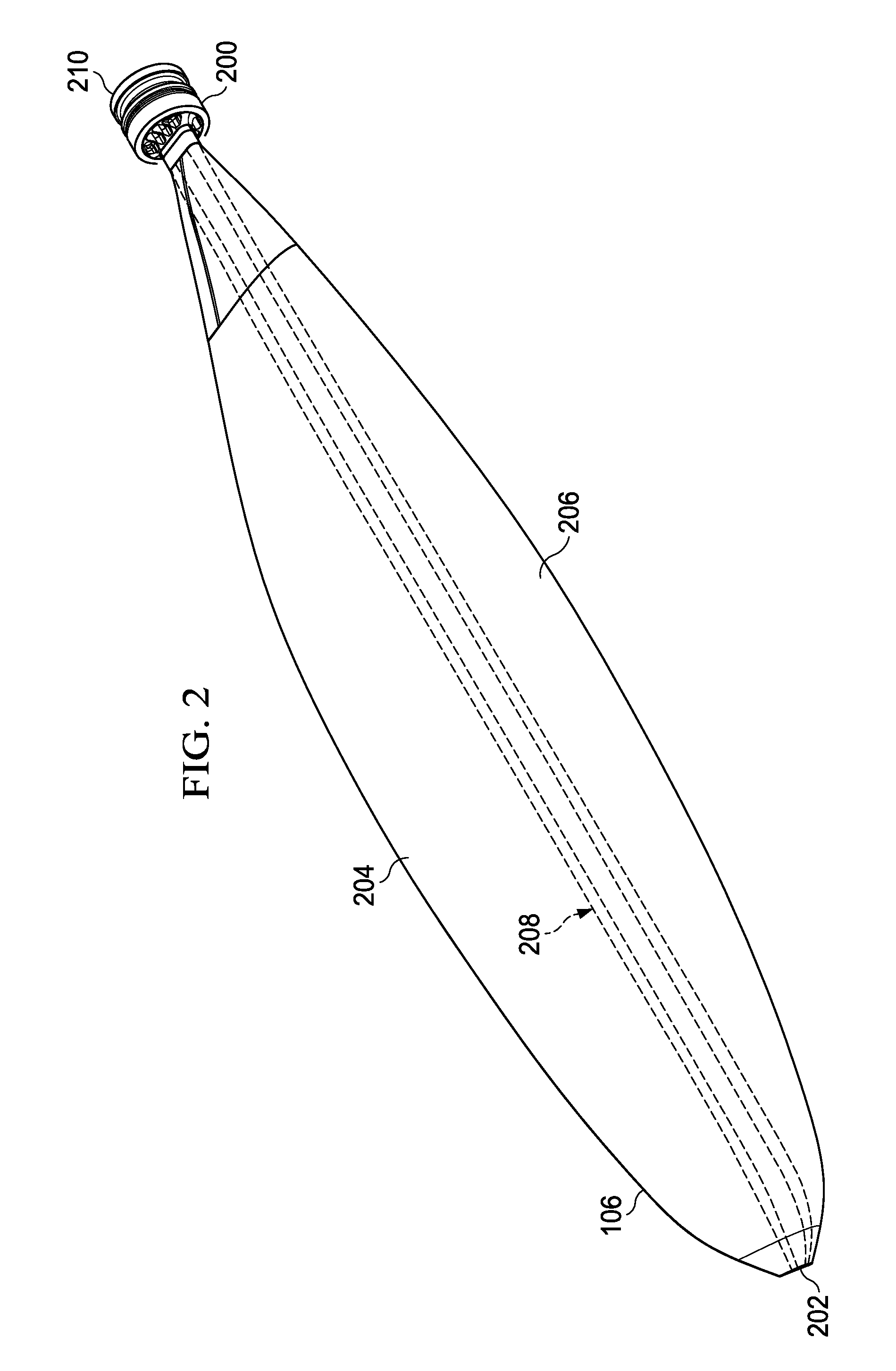

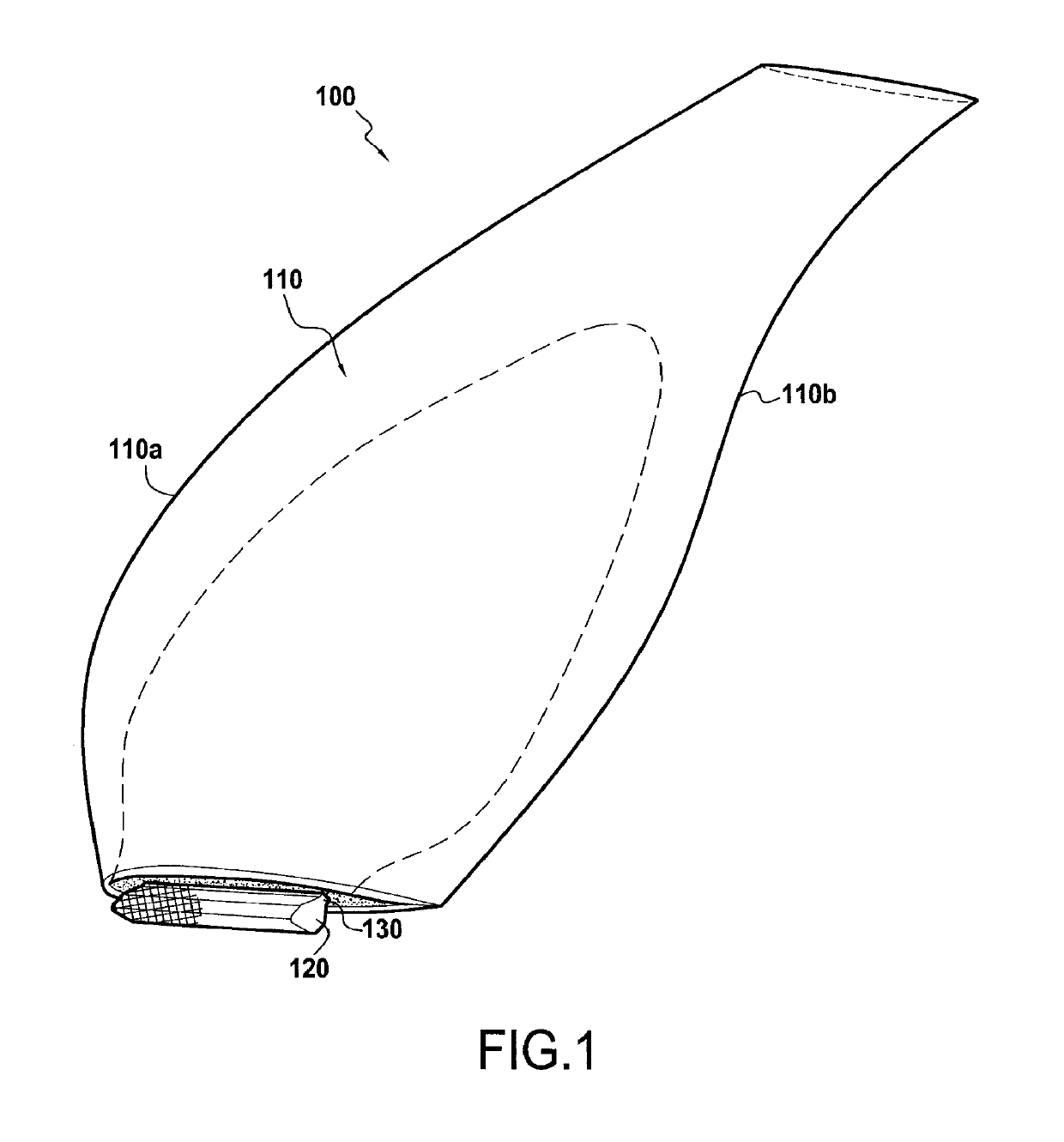

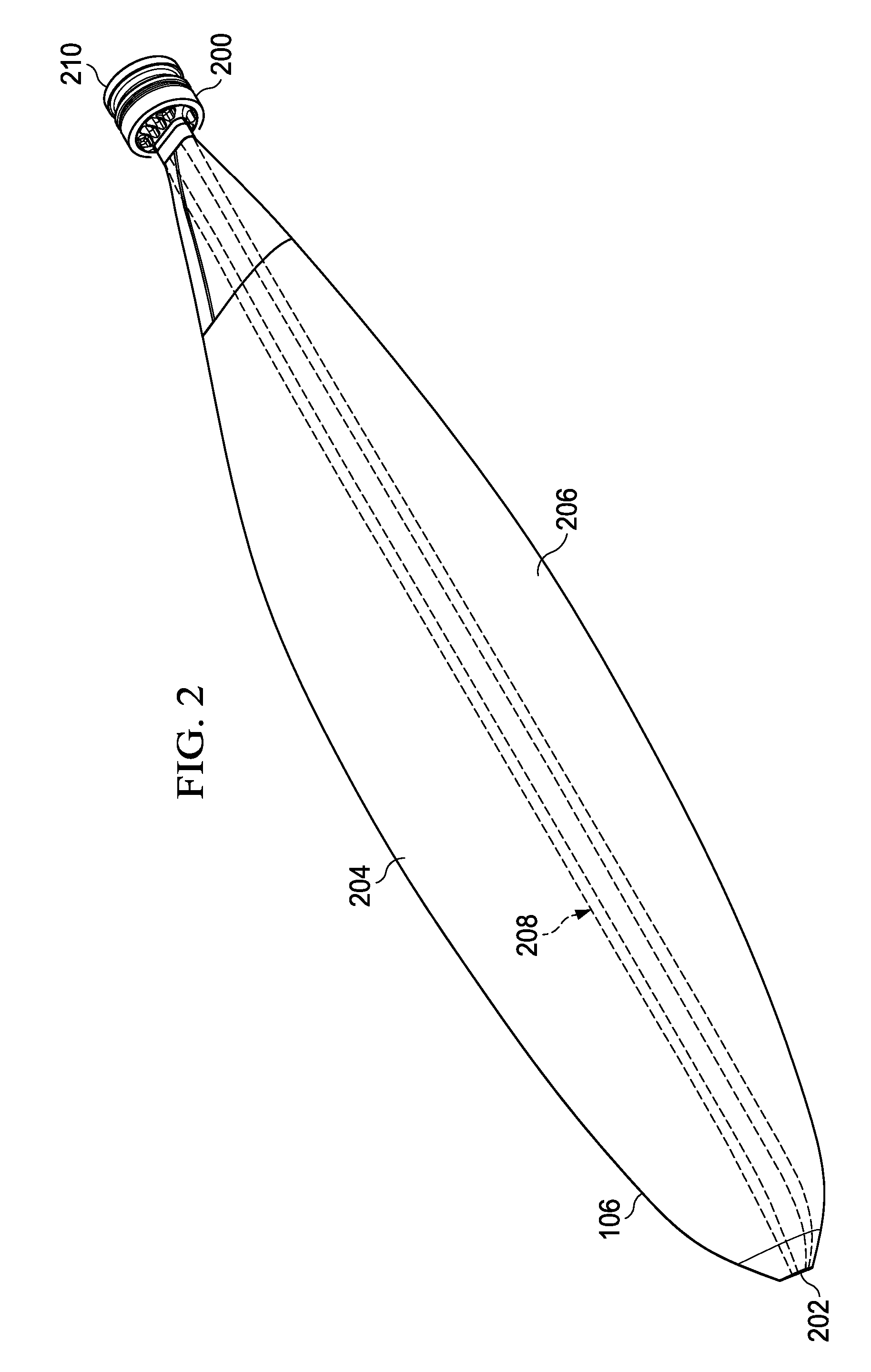

Composite propeller blade for an aircraft

ActiveUS20160159460A1High mechanical strengthEasy to holdPropellersBlade accessoriesYarnComposite propeller

An aircraft propeller blade including a streamlined structure constituted by at least one piece of fiber reinforcement obtained by three-dimensionally weaving yarns and densified by a matrix, together with a spar including an enlarged portion extending outside the fiber reinforcement and forming the root of the blade, and a shaping portion present in a housing arranged inside the fiber reinforcement. The fiber reinforcement includes a non-interlinked zone forming the housing inside the fiber reinforcement. The non-interlinked zone opens out into the bottom portion and into the rear edge of the fiber reinforcement so as to form an opening for inserting the shaping portion of the spar into the housing of the fiber reinforcement. The opening present in the rear edge of the fiber reinforcement extends over a height that is less than the height of the housing.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

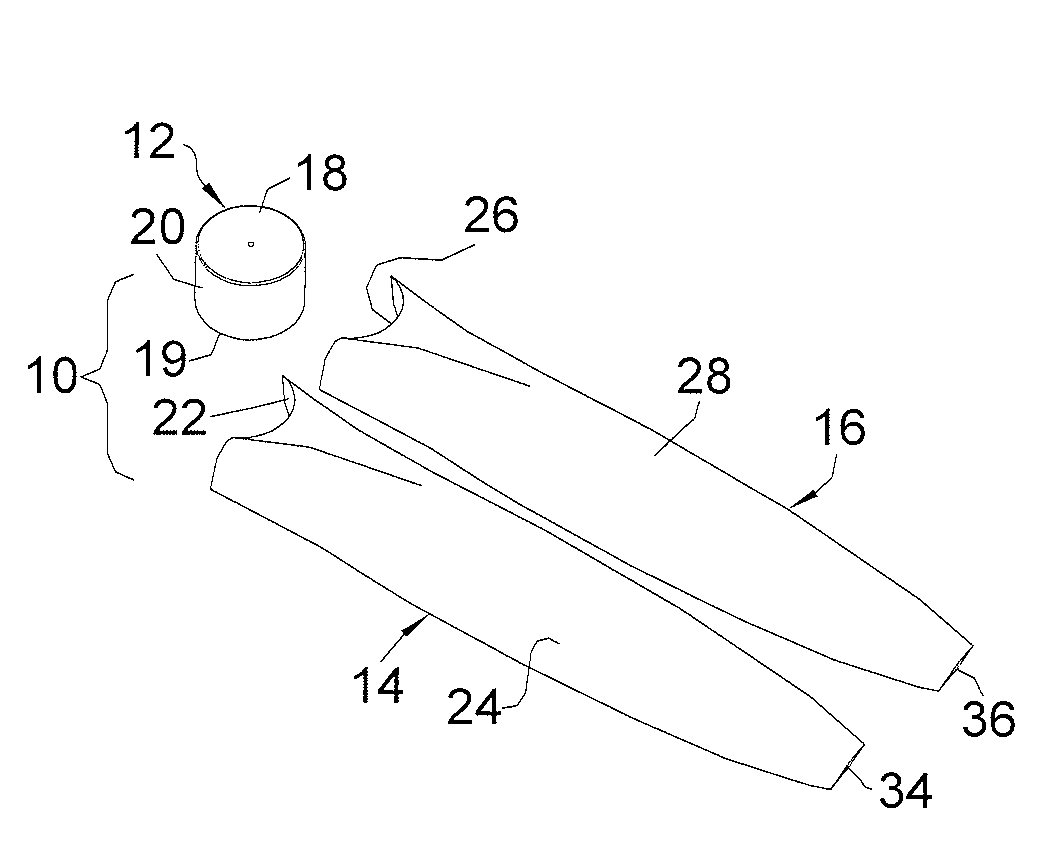

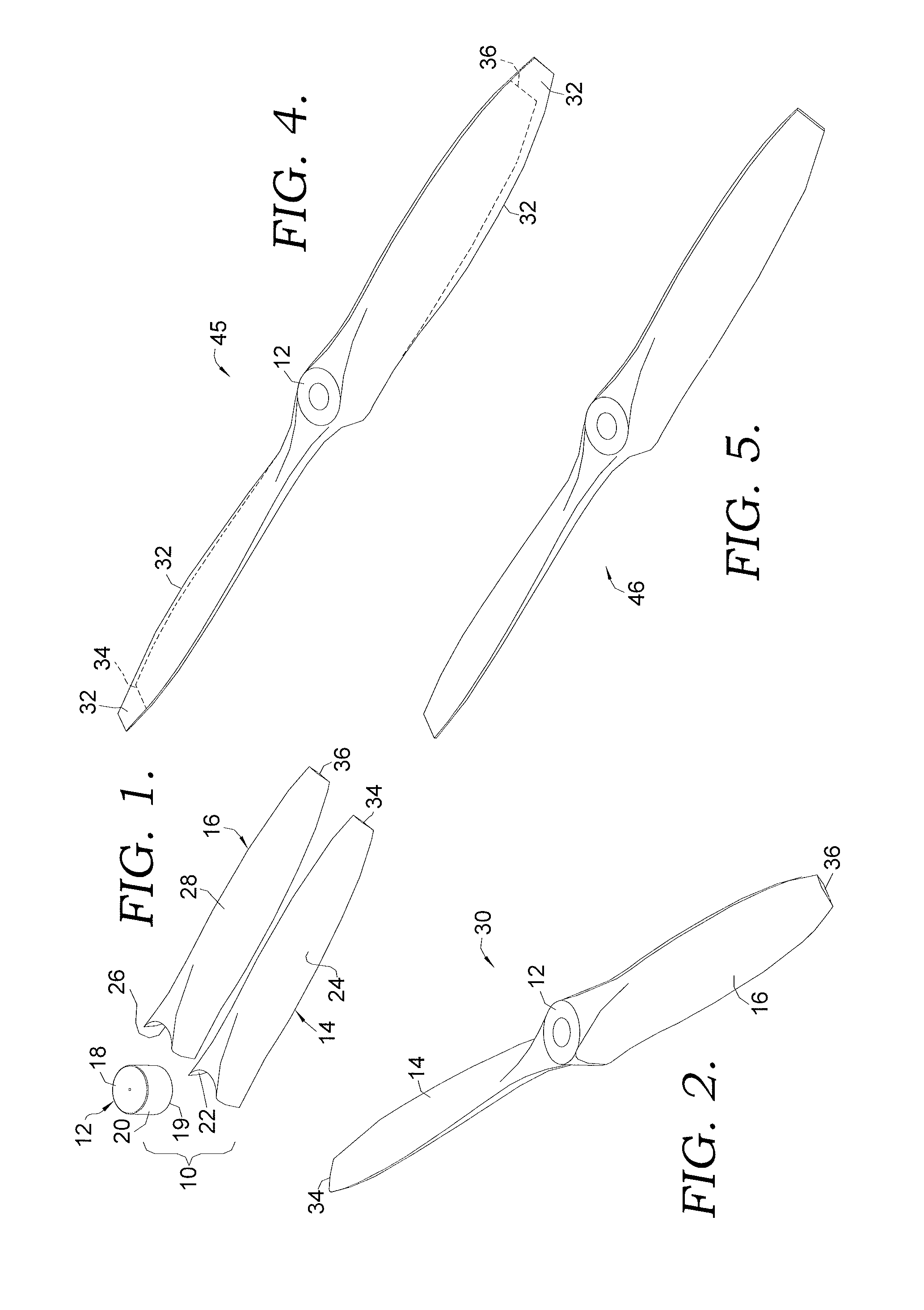

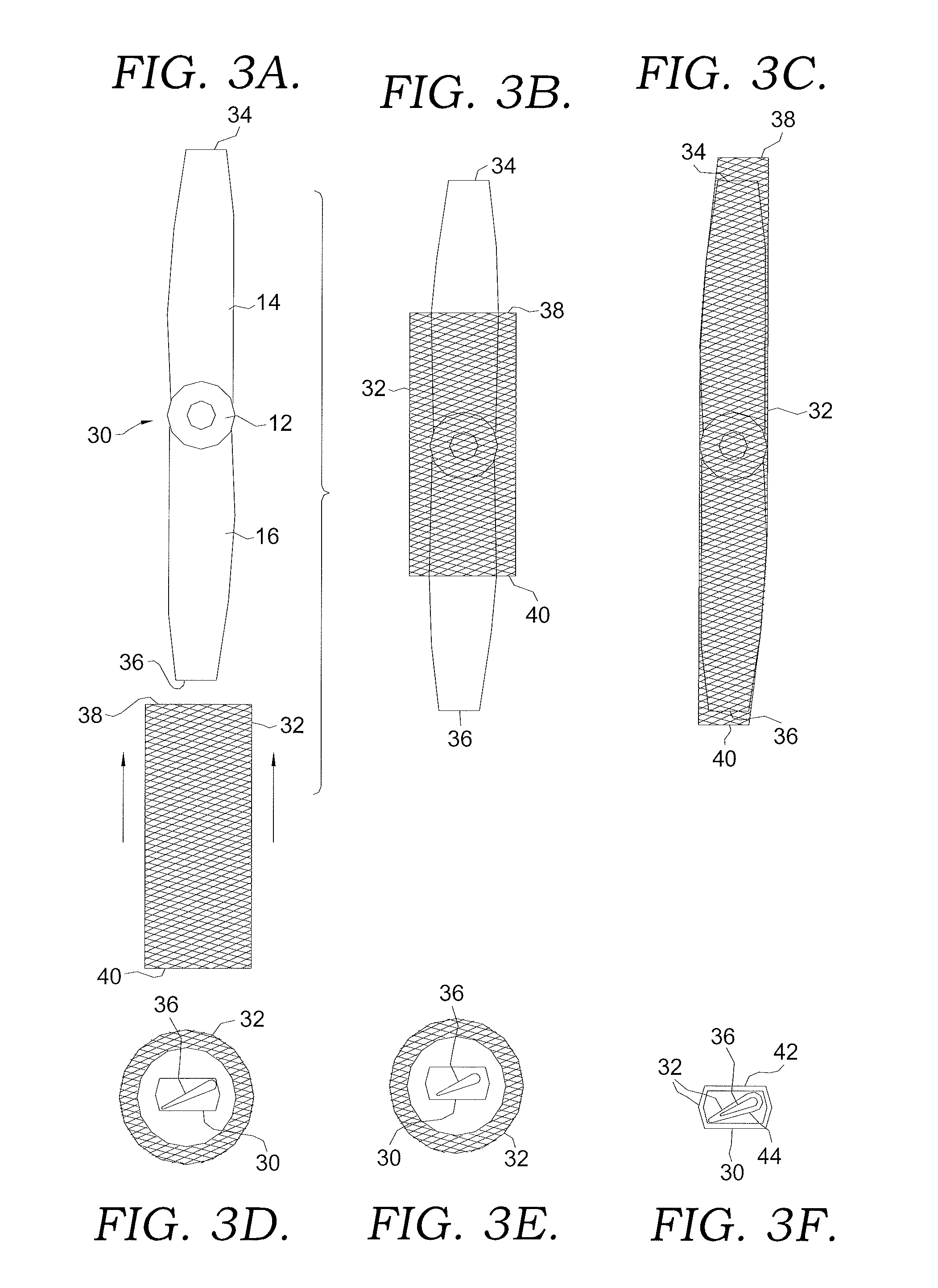

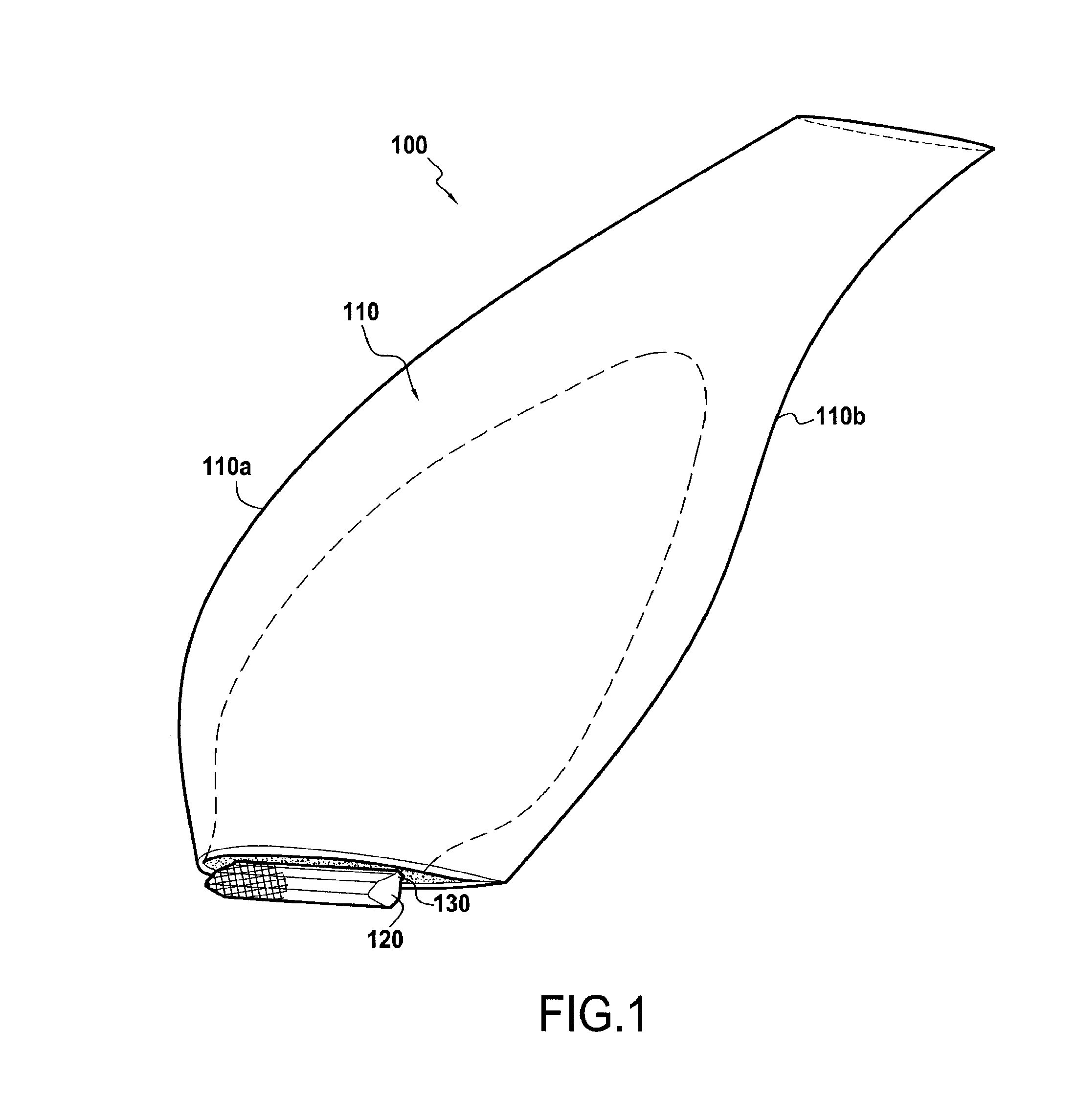

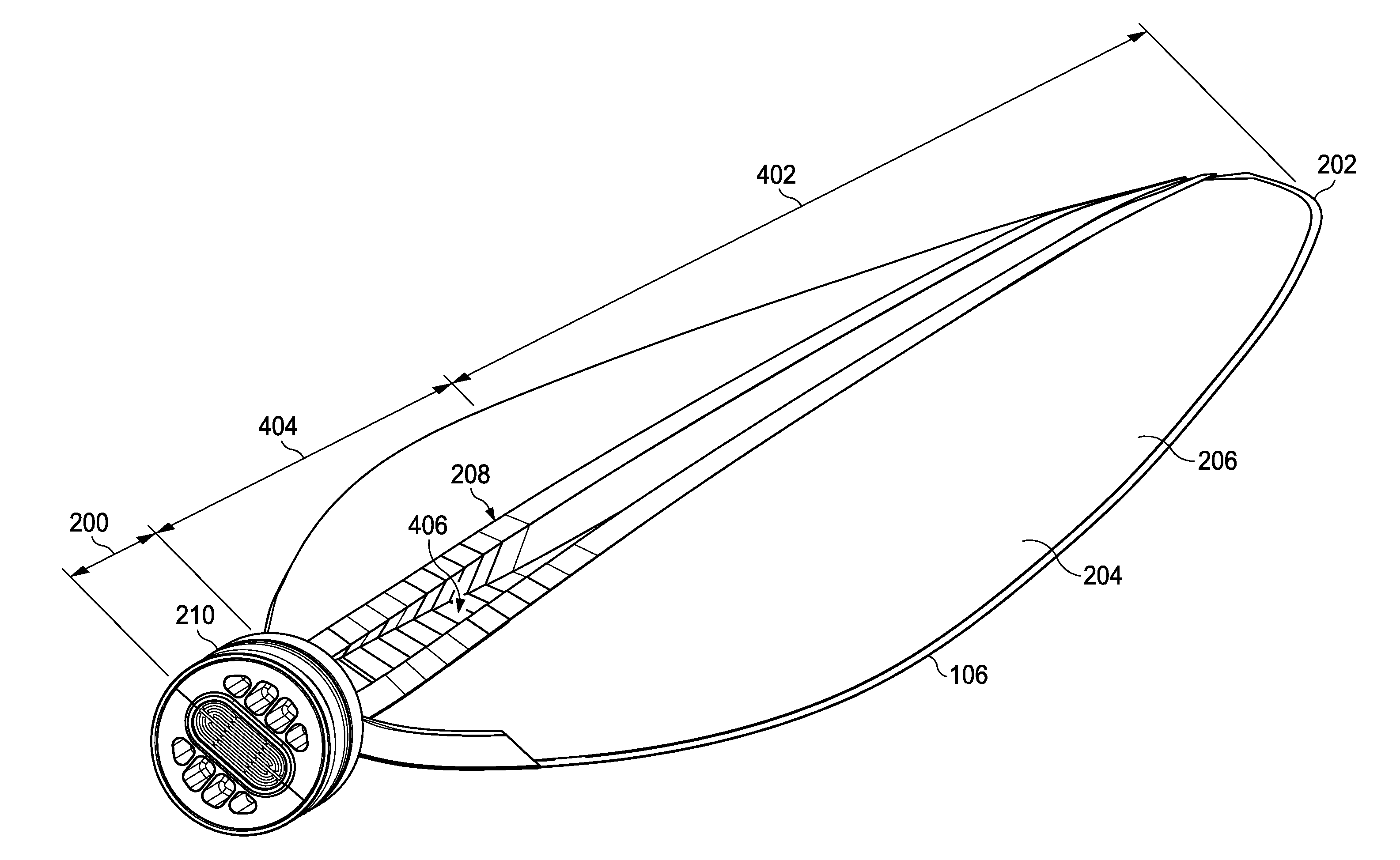

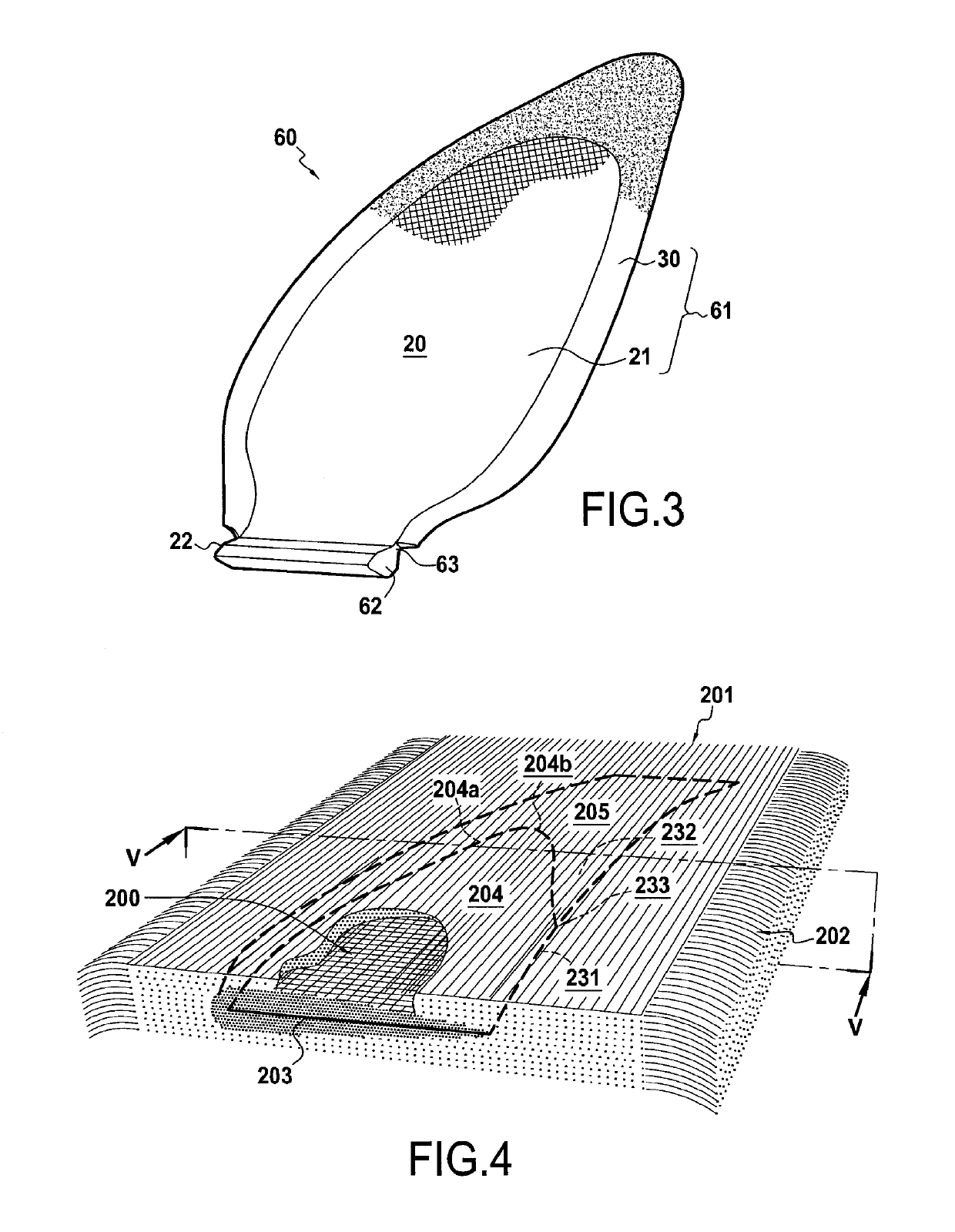

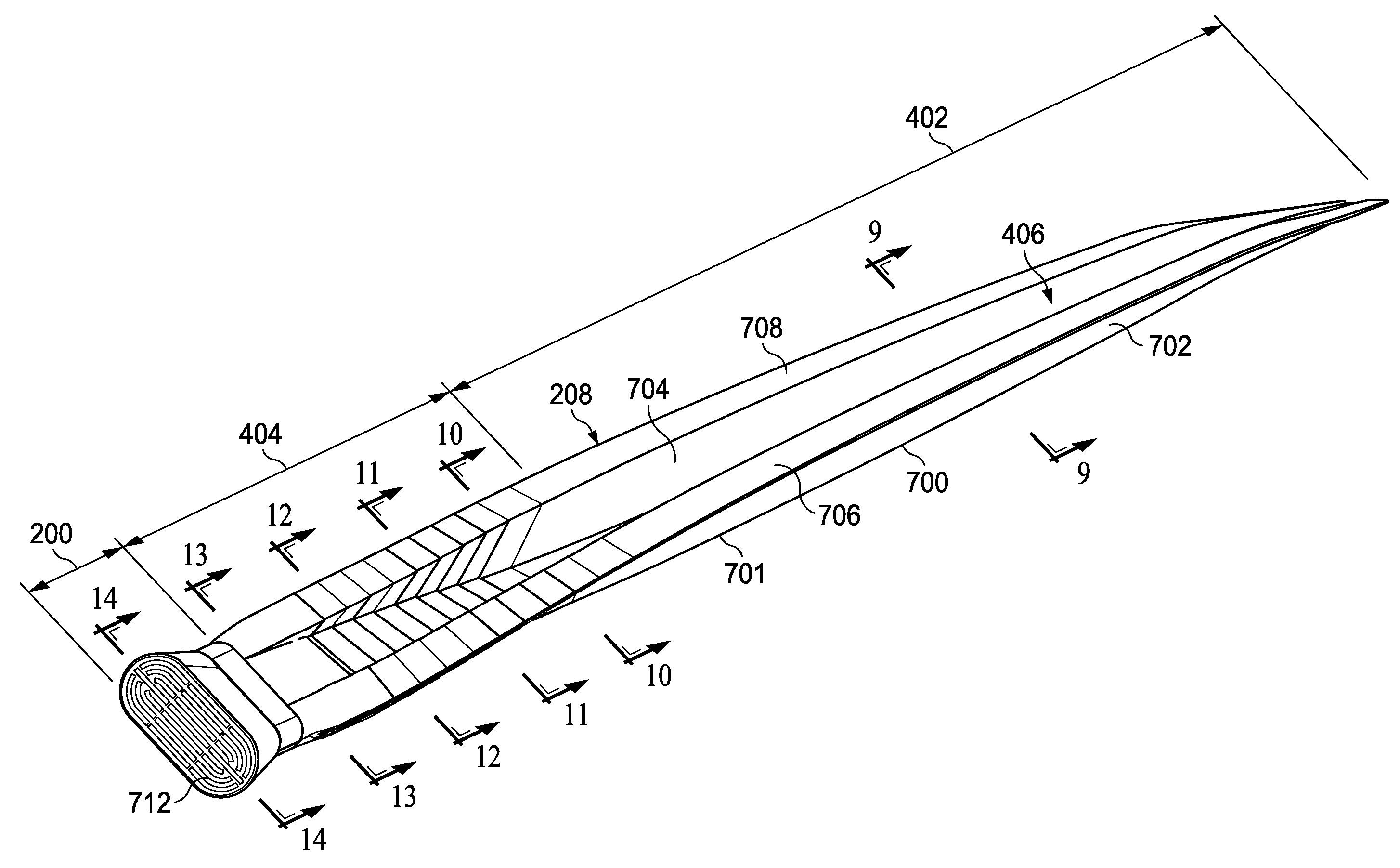

Composite Propeller Spar

A method and apparatus comprising a composite spar. The composite spar has a root section and a main section. The root section is closed and has a shape configured to be connected to a blade retention system. The main section has an open channel. The composite spar is configured for placement inside of a blade.

Owner:THE BOEING CO

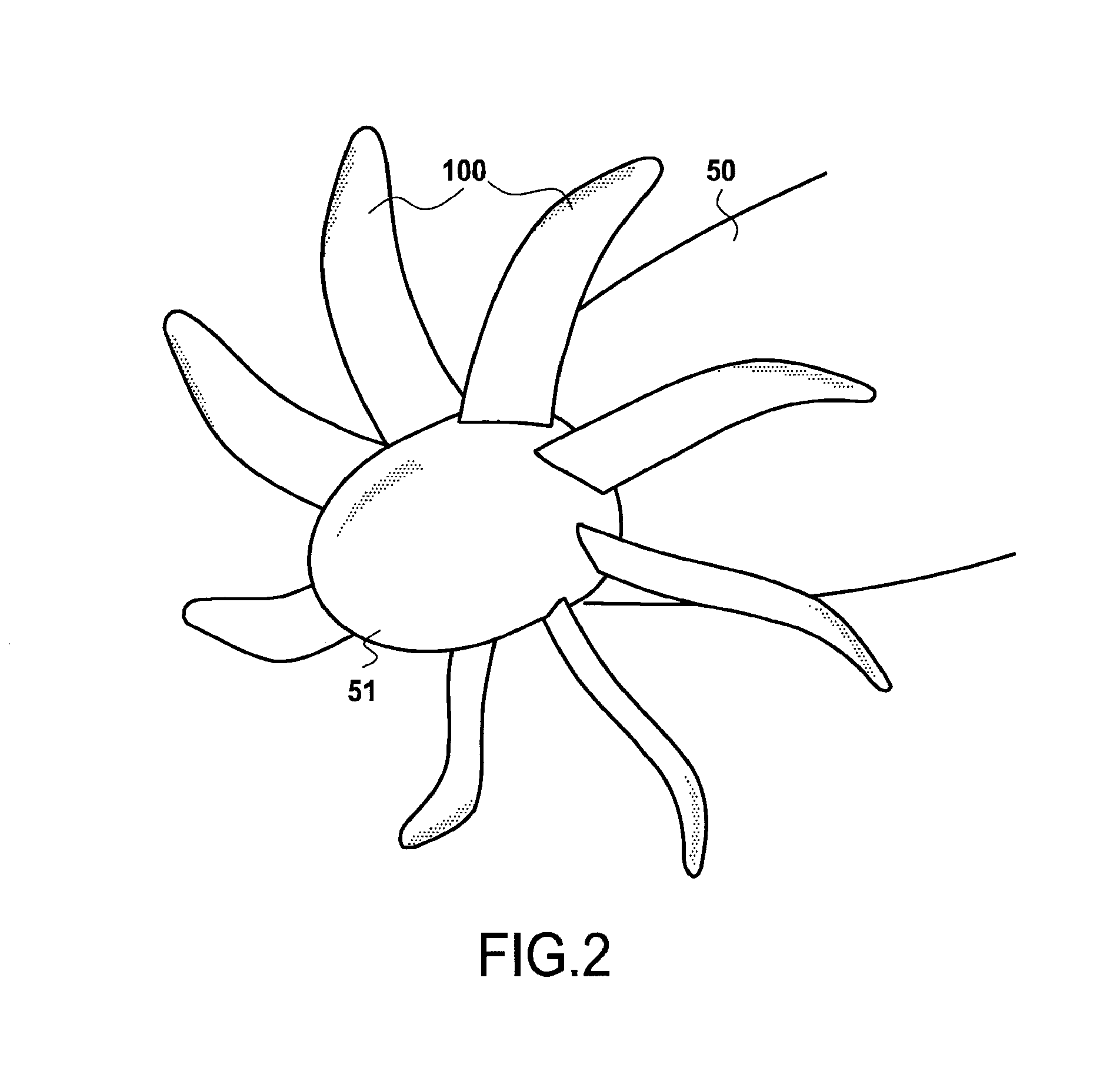

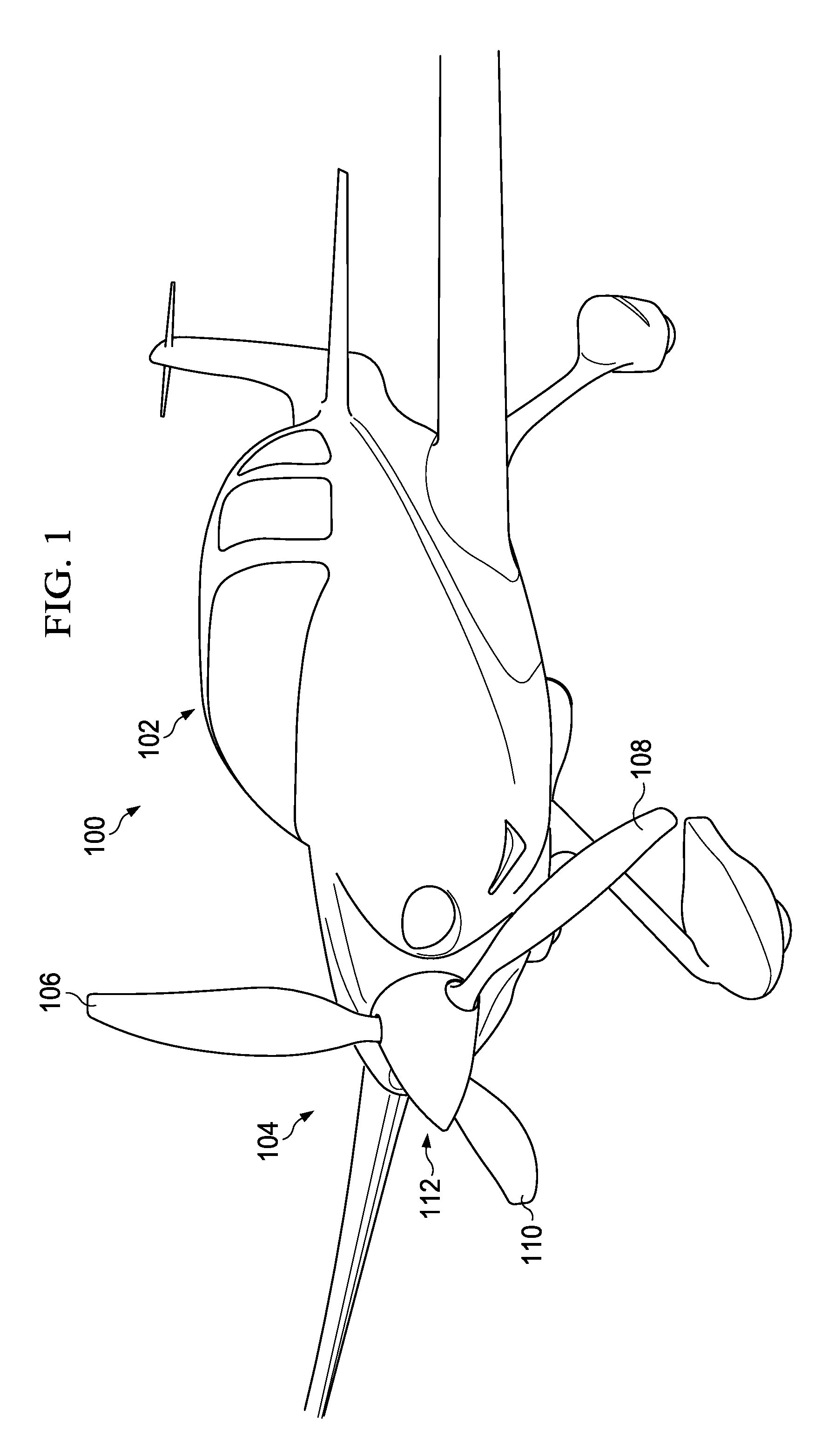

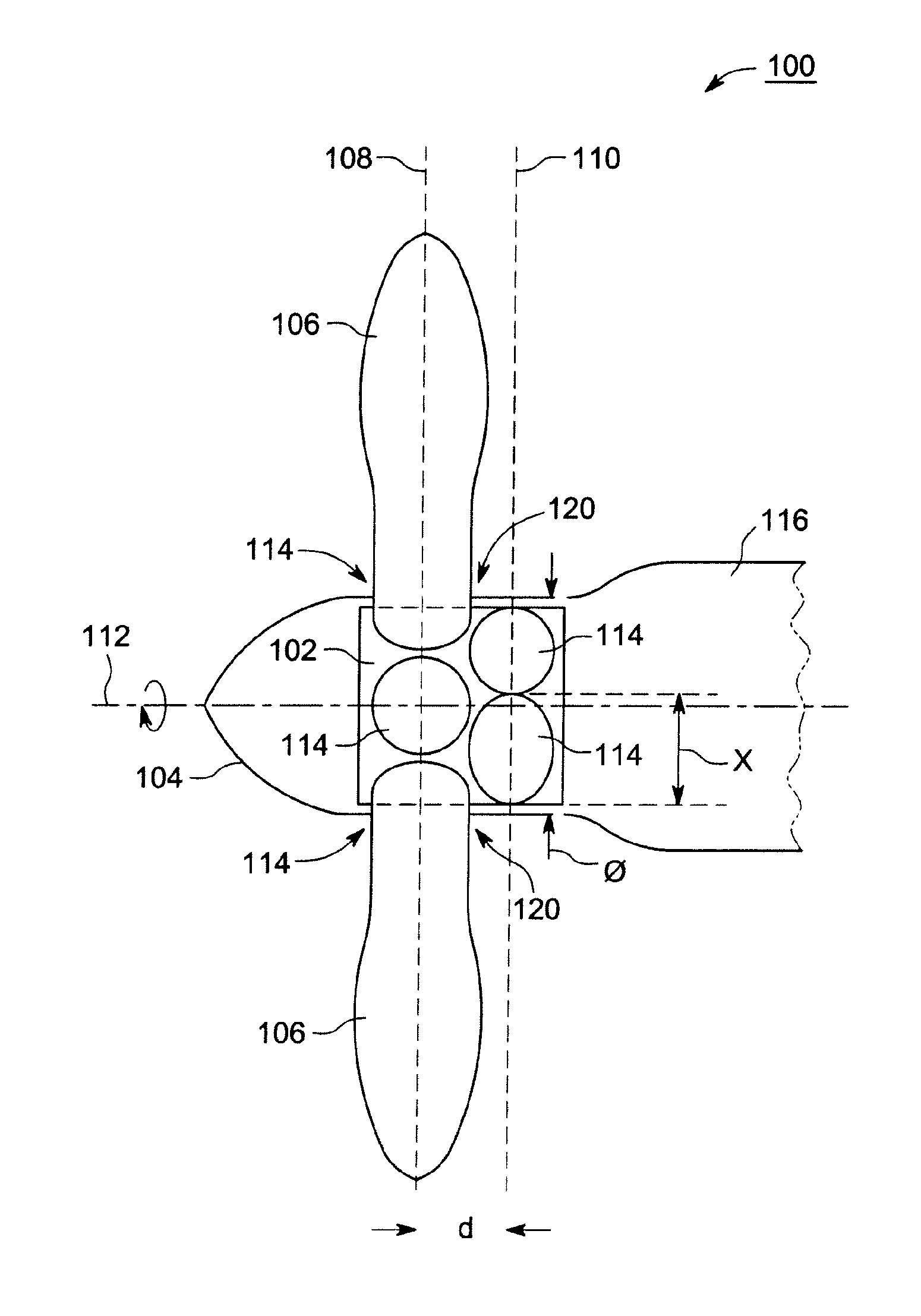

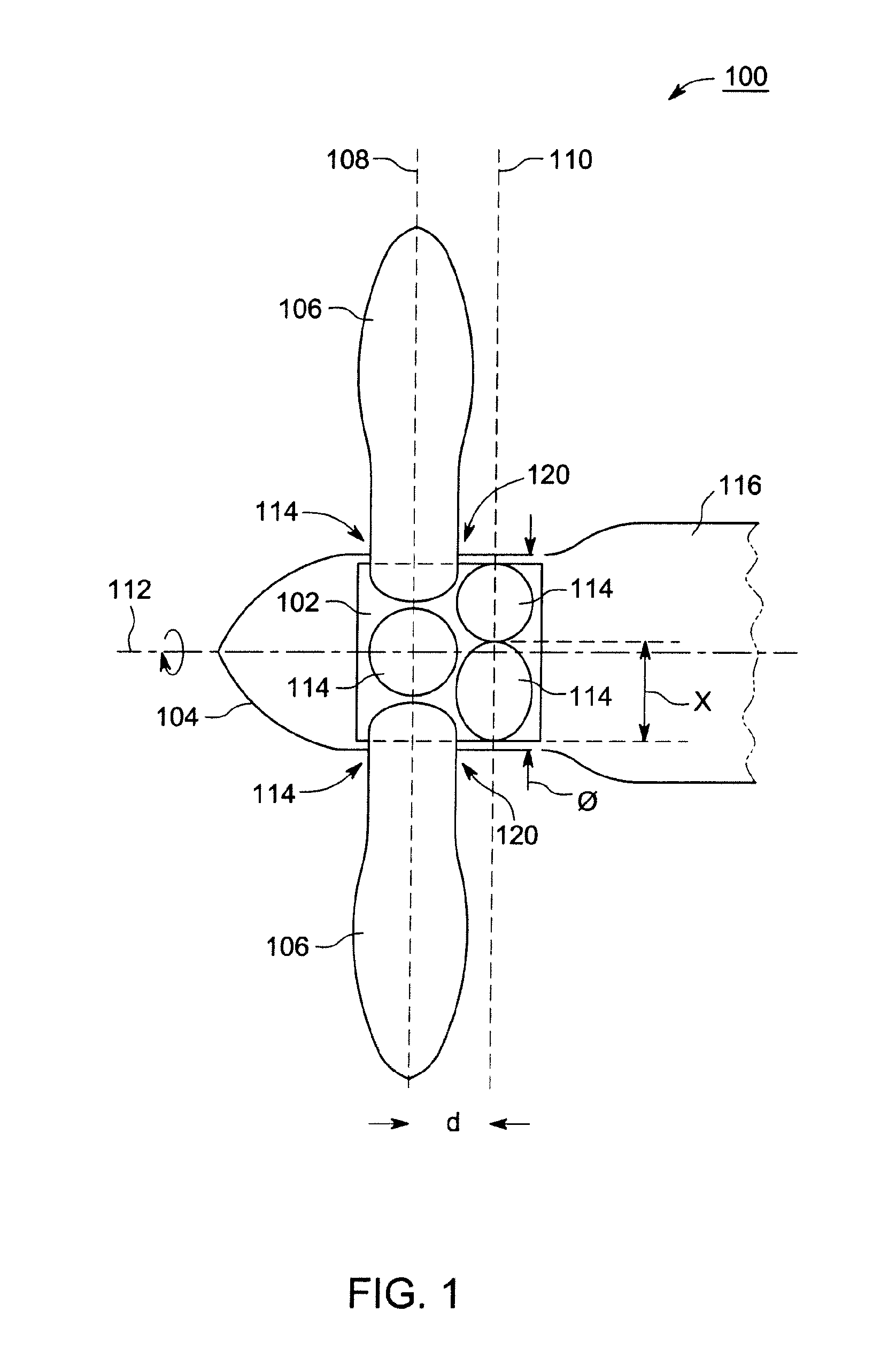

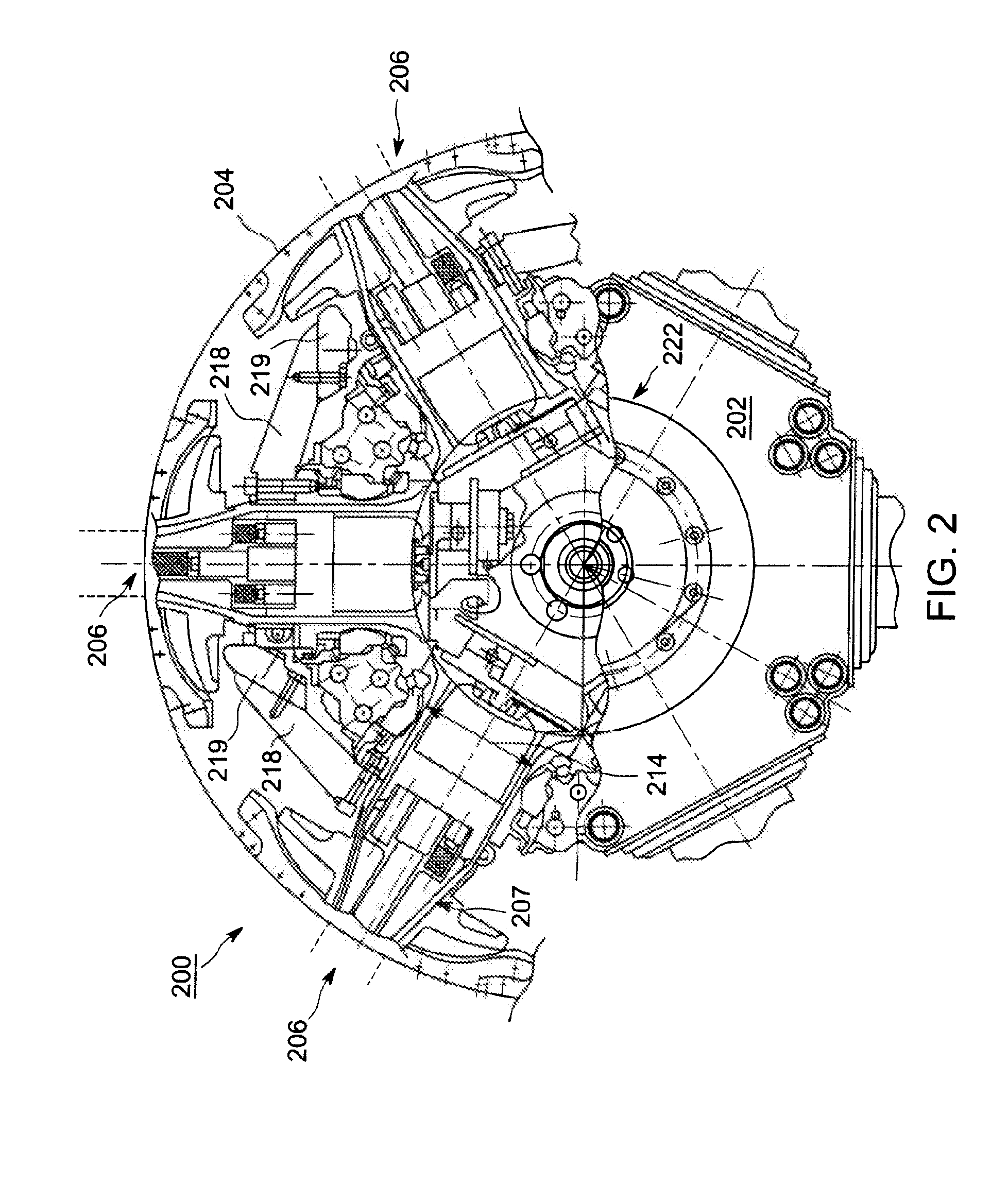

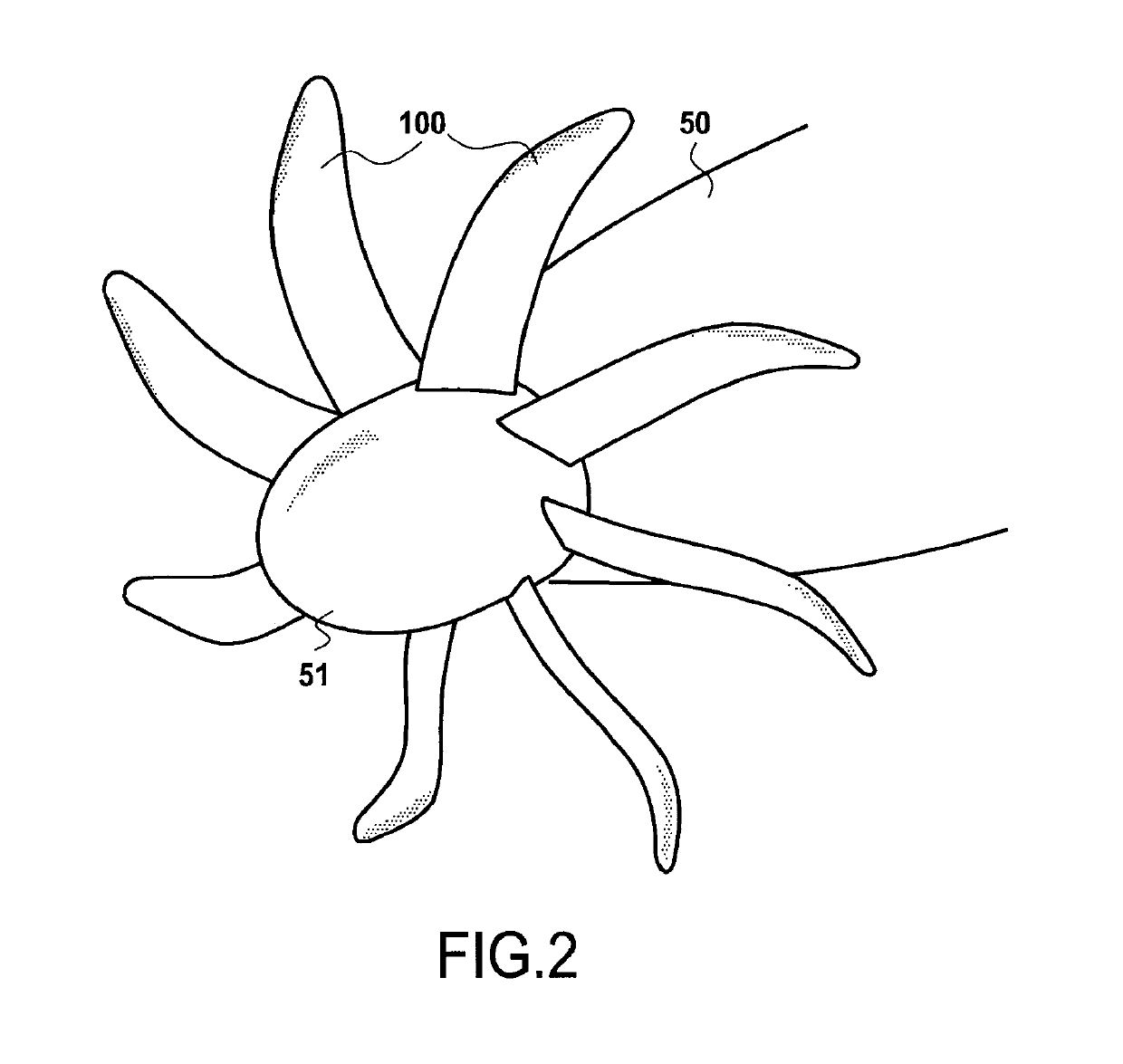

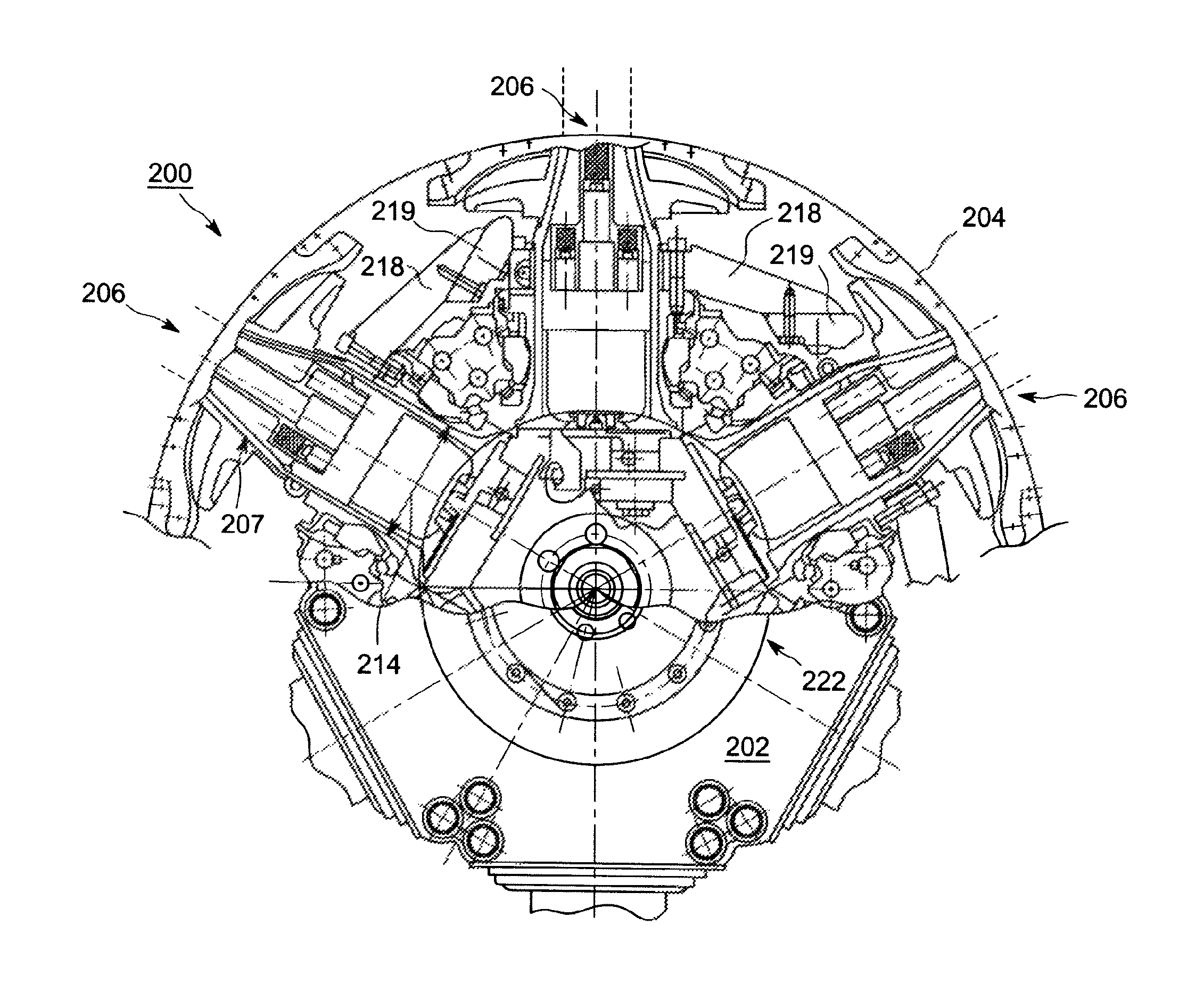

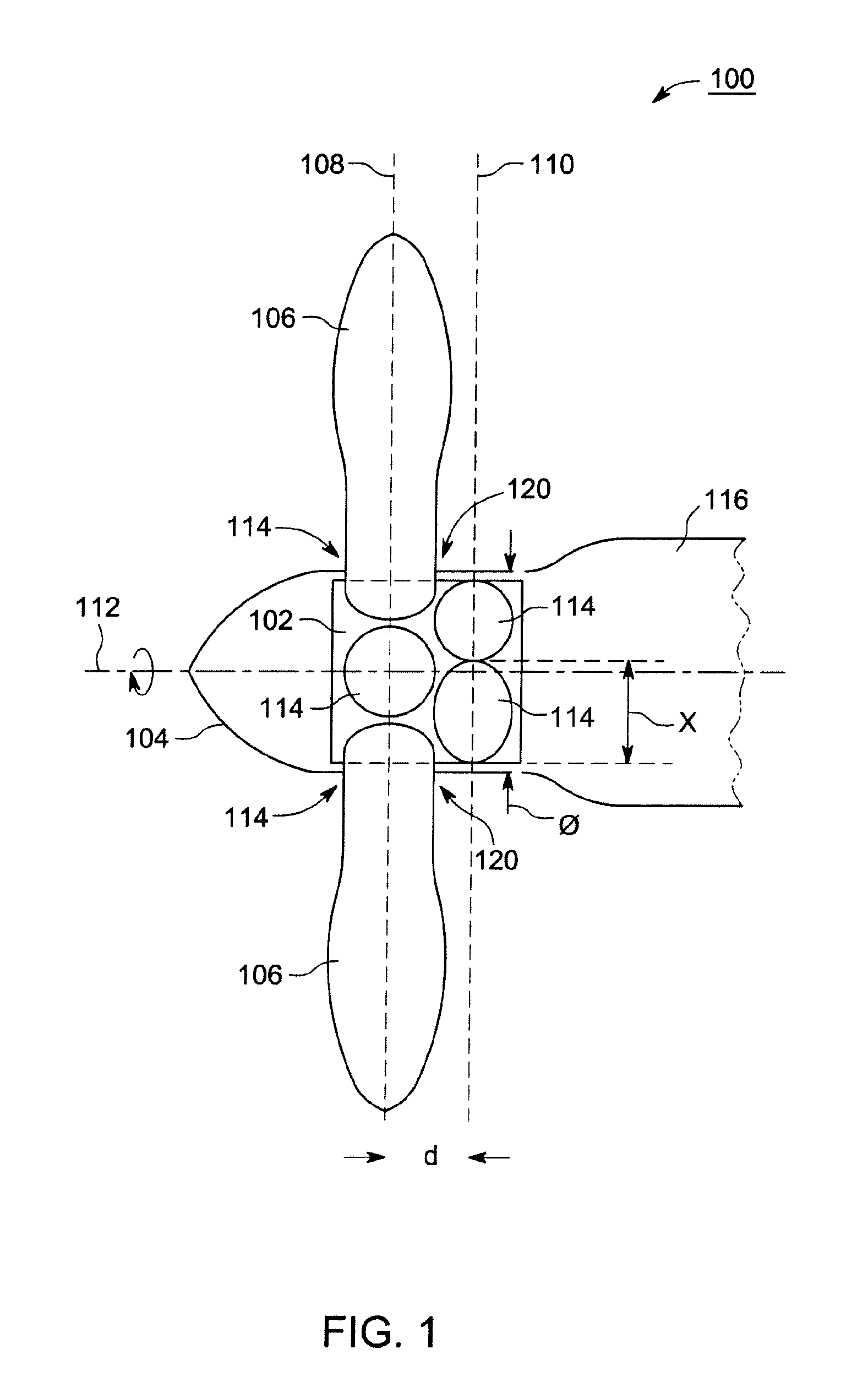

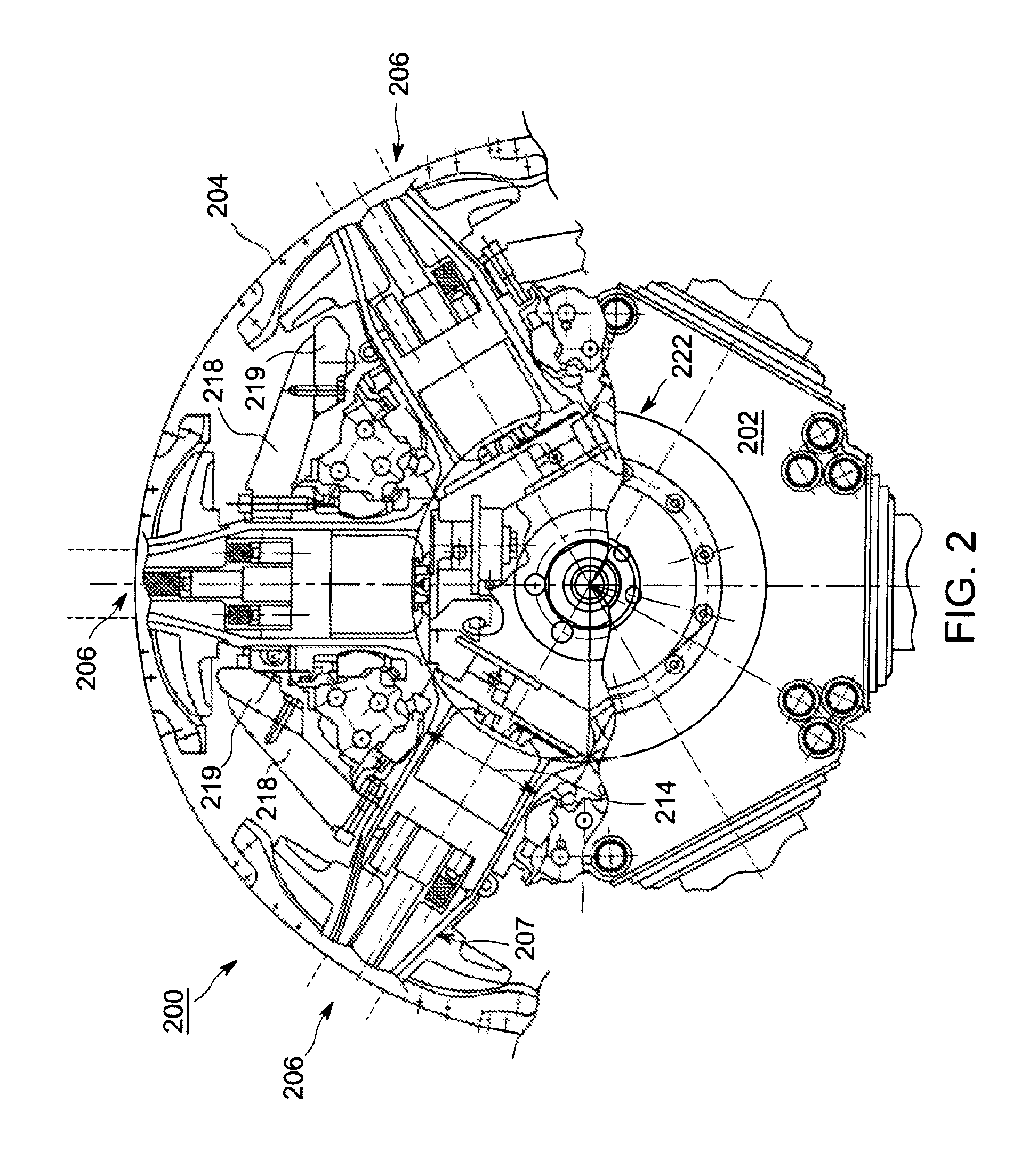

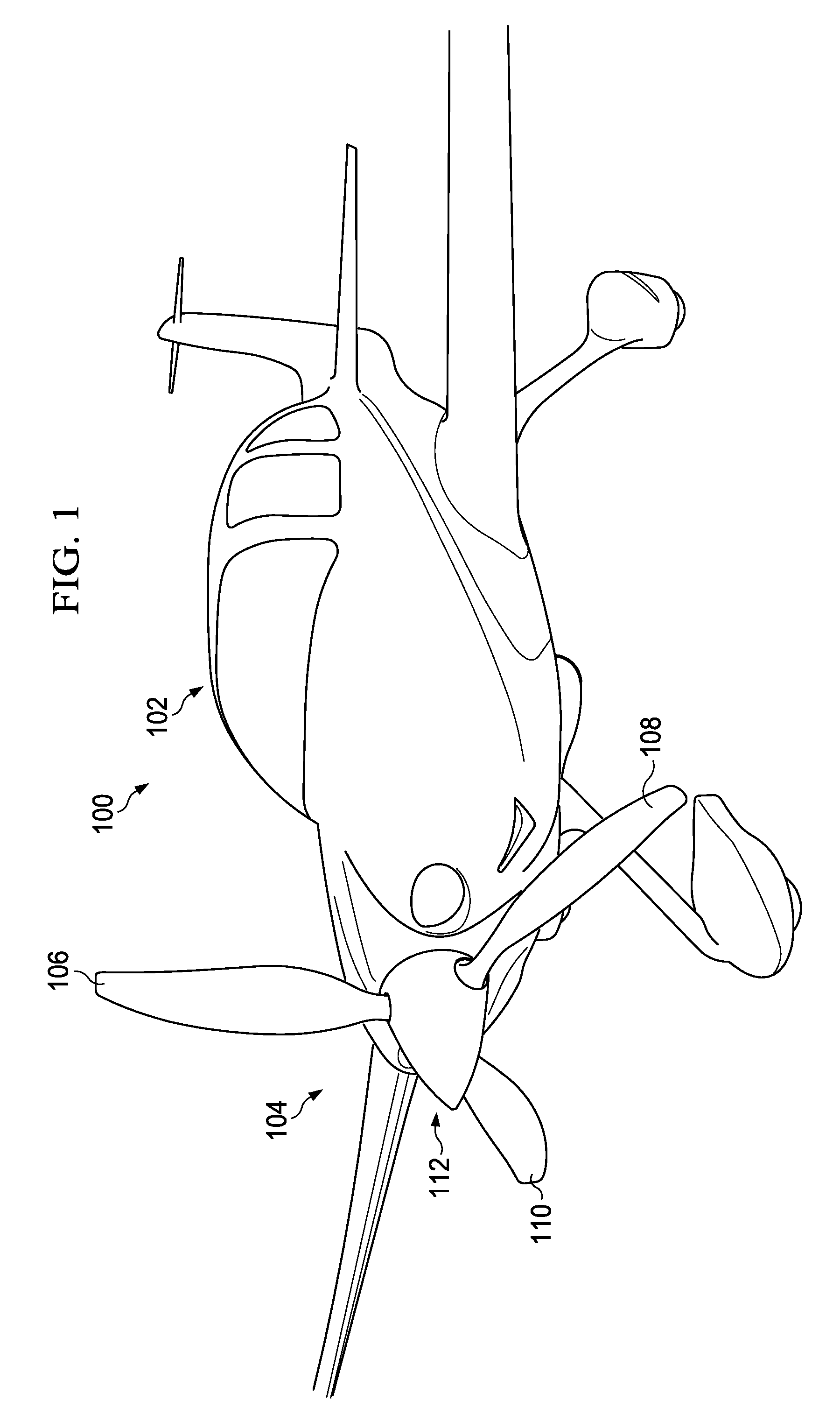

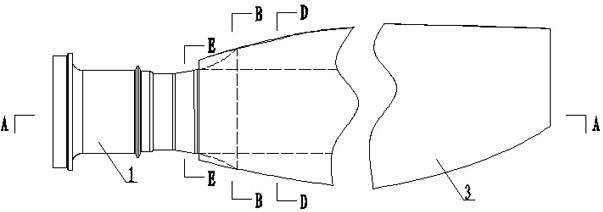

Propellers for aircraft

ActiveUS20120034095A1Improved aerodynamic profileReduce the overall diameterPropellersPump componentsNacelleComposite propeller

One aspect of the present invention provides a propeller for an aircraft. The propeller comprises a propeller hub, a spinner for streamlining the propeller and a plurality of composite propeller blades mounted to the propeller hub. The propeller blades are arranged to rotate together in the same rotational direction in at least two parallel planes substantially perpendicular to an axis of rotation of the propeller. The propeller has a reduced sized spinner with an improved aerodynamic profile that can be better matched to an engine nacelle and also has reduced drag.

Owner:GE AVIATION SYST LTD

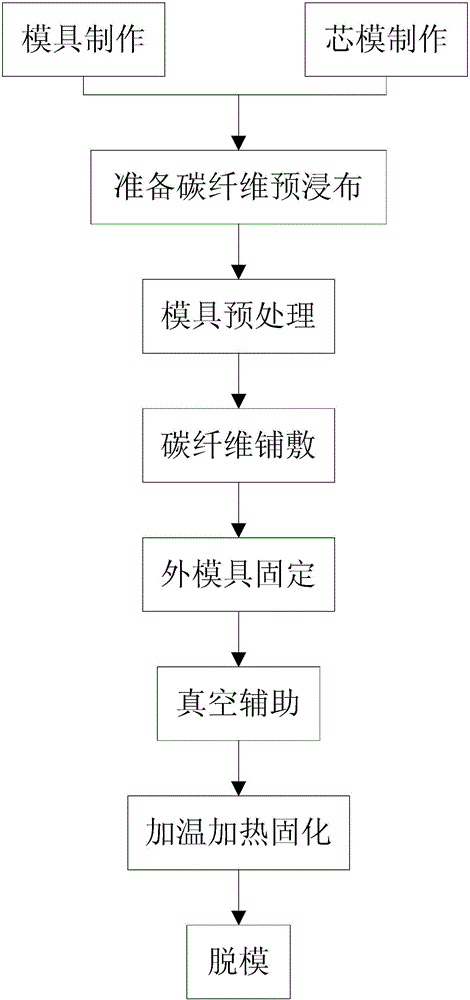

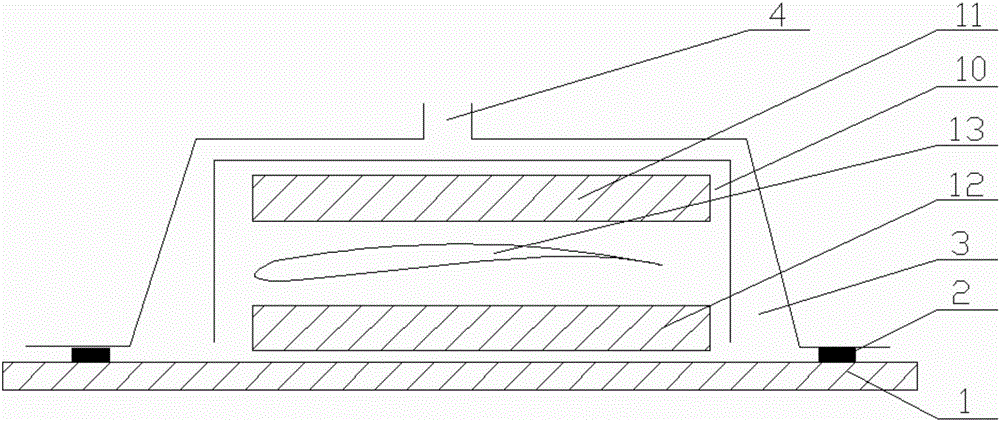

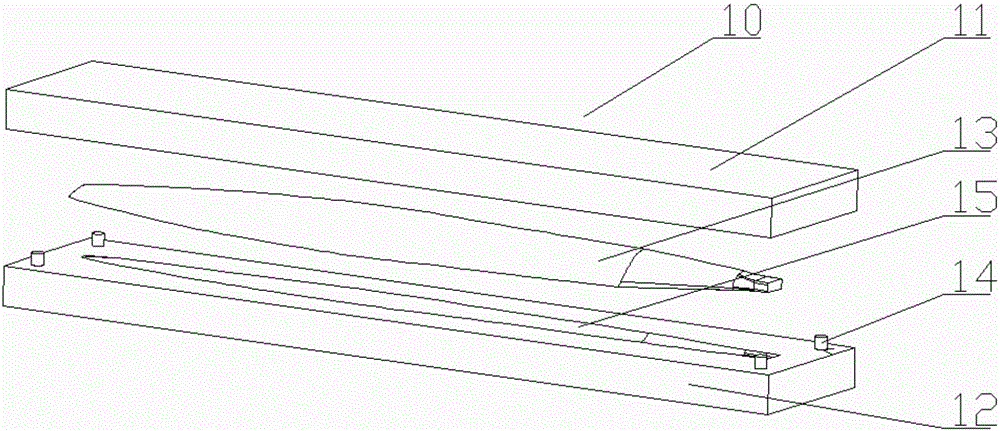

Preparation method of integrated composite propeller blade for stratospheric airship

The invention belongs to the technical field of preparation of propeller blades and relates to a preparation method of an integrated composite propeller blade for a stratospheric airship. The preparation method comprises: 1, making a mold apparatus; 2, preparing carbon fiber prepreg cloth 16; 3, preparing the mold apparatus; 4, making a preform 13; 5, assembling the mold apparatus; 6, evacuating the mold apparatus; 7, heating and pressurizing for solidifying; 8, cooling to room temperature; 9, demolding; 10, finishing preparation of the finished blade. The preparation method has the advantages that the method is simple, the blade has good quality, the blade is high in strength and light in weight, and making efficiency is high; bearing capacity of a propeller is effectively improved; overall quality of the propeller is improved; yield is effectively increased; it is ensured that the propeller bears uniform stress during solidifying such that deformation or bubbles are avoided; maneuvering property of the stratospheric airship is improved, the self-weight is reduced at the premise of ensuring overall rigidity and stability, and working efficiency of the propeller is improved.

Owner:EAGLES MEN AERONAUTIC SCI & TECH GRP

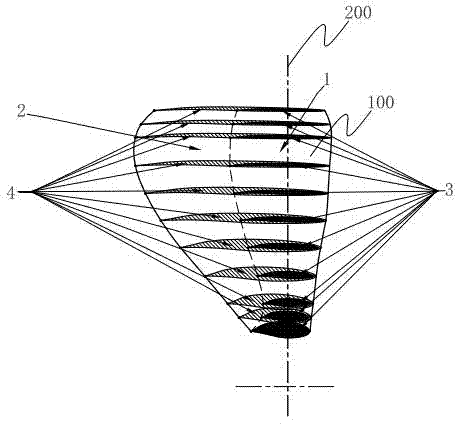

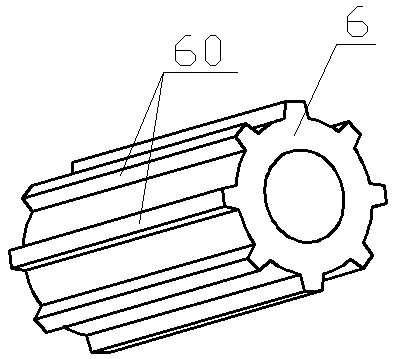

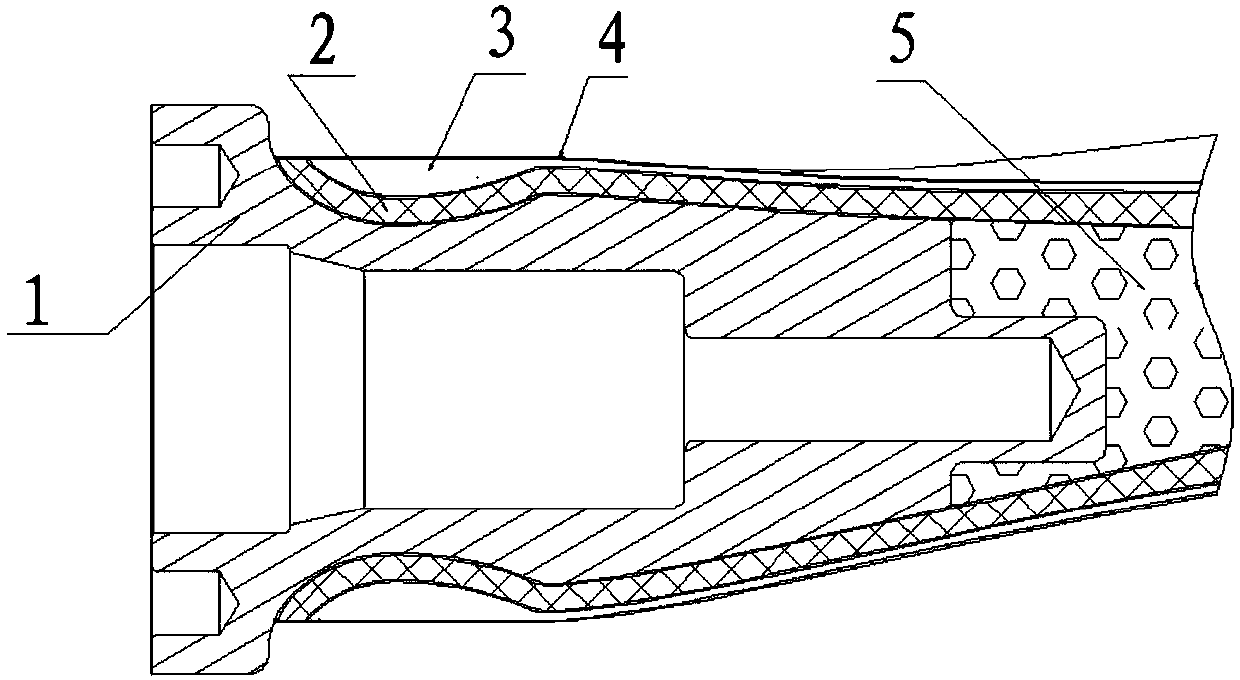

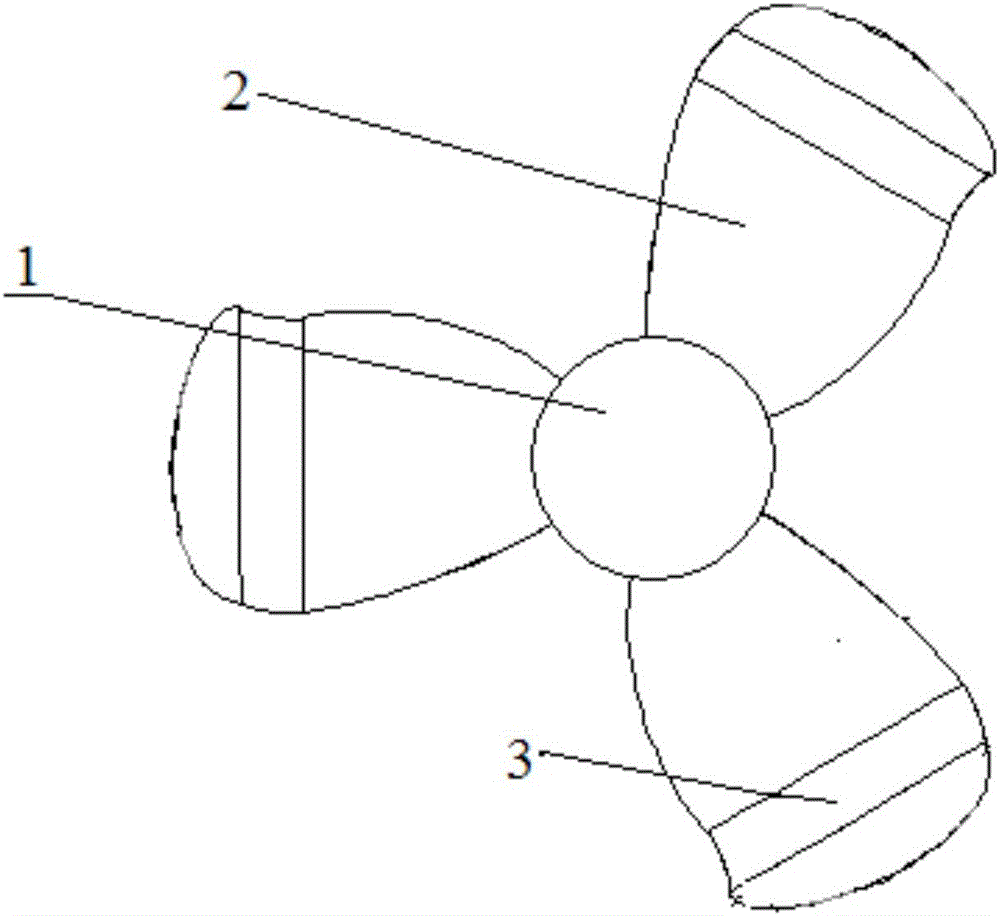

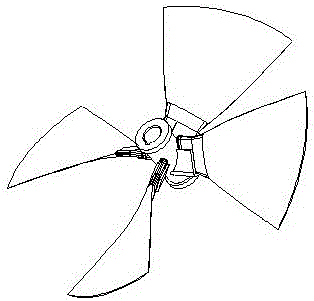

Continuous fiber reinforced composite propeller layer lay-up design and preparation method

ActiveCN107599443AShorten the manufacturing cycleReduce manufacturing costComposite propellerFiber-reinforced composite

The invention provides a continuous fiber reinforced composite propeller layer lay-up design and a preparation method. According to the method, continuous fiber prepreg sheets are adopted for coatinga metal insert; through the mold pressing process, the one-step forming of a composite propeller is achieved; a preformed mold is prepared for the preforming process of composite blades, thereby guaranteeing the continuity of the connection between the blades and a propeller hub, shortening the manufacturing cycle of the composite propeller, reducing the manufacturing cost of the composite propeller, improving the product quality, and meeting the actual usage requirements on the light weight of a propeller blade material and the noise reduction; according to the propeller prepared through themethod, the continuous fiber integral blades are adopted and integrally connected with the propeller hub part, thereby avoiding the occurrence of a secondary interface; and accordingly, the machinerystability and reliability can be effectively improved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Composite propeller blade for an aircraft

ActiveUS10414487B2High mechanical strengthEasy to holdPropellersBlade accessoriesYarnComposite propeller

An aircraft propeller blade including a streamlined structure constituted by at least one piece of fiber reinforcement obtained by three-dimensionally weaving yarns and densified by a matrix, together with a spar including an enlarged portion extending outside the fiber reinforcement and forming the root of the blade, and a shaping portion present in a housing arranged inside the fiber reinforcement. The fiber reinforcement includes a non-interlinked zone forming the housing inside the fiber reinforcement. The non-interlinked zone opens out into the bottom portion and into the rear edge of the fiber reinforcement so as to form an opening for inserting the shaping portion of the spar into the housing of the fiber reinforcement. The opening present in the rear edge of the fiber reinforcement extends over a height that is less than the height of the housing.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Composite propeller blade and blade root connecting structure

The invention belongs to mechanical structure design, and relates to a composite propeller blade and blade root connecting structure. According to the composite propeller blade and blade root connecting structure, in order to realize reliable connection between carbon girders of composite main force-bearing parts and a metal blade root, first the carbon girders are laid on the metal blade root, and the carbon girders are composed of a plurality of layers of carbon fiber one-way cloth and satin cloth; and then carbon fiber is wound around the arc-shaped surface of the metal blade root, so thatthe carbon girders and the metal blade root are fixed together. When a propeller rotates, the centrifugal load and the pneumatic load brought by rotating are transmitted to the blade root, and the radian appearance of the metal blade root and the fiber are wound so that disengaging of the carbon girders can be prevented, and then damage to the composite propeller blade is avoided. The number of parts of the blade root connecting structure is reduced from original 12 to 5, and the composite propeller blade and blade root connecting structure is simple in structure, low in weight and good in manufacturability, the manufacturing cost is further greatly reduced, and the economic benefits are obviously increased.

Owner:AVIC HUIYANG AVIATION PROPELLER

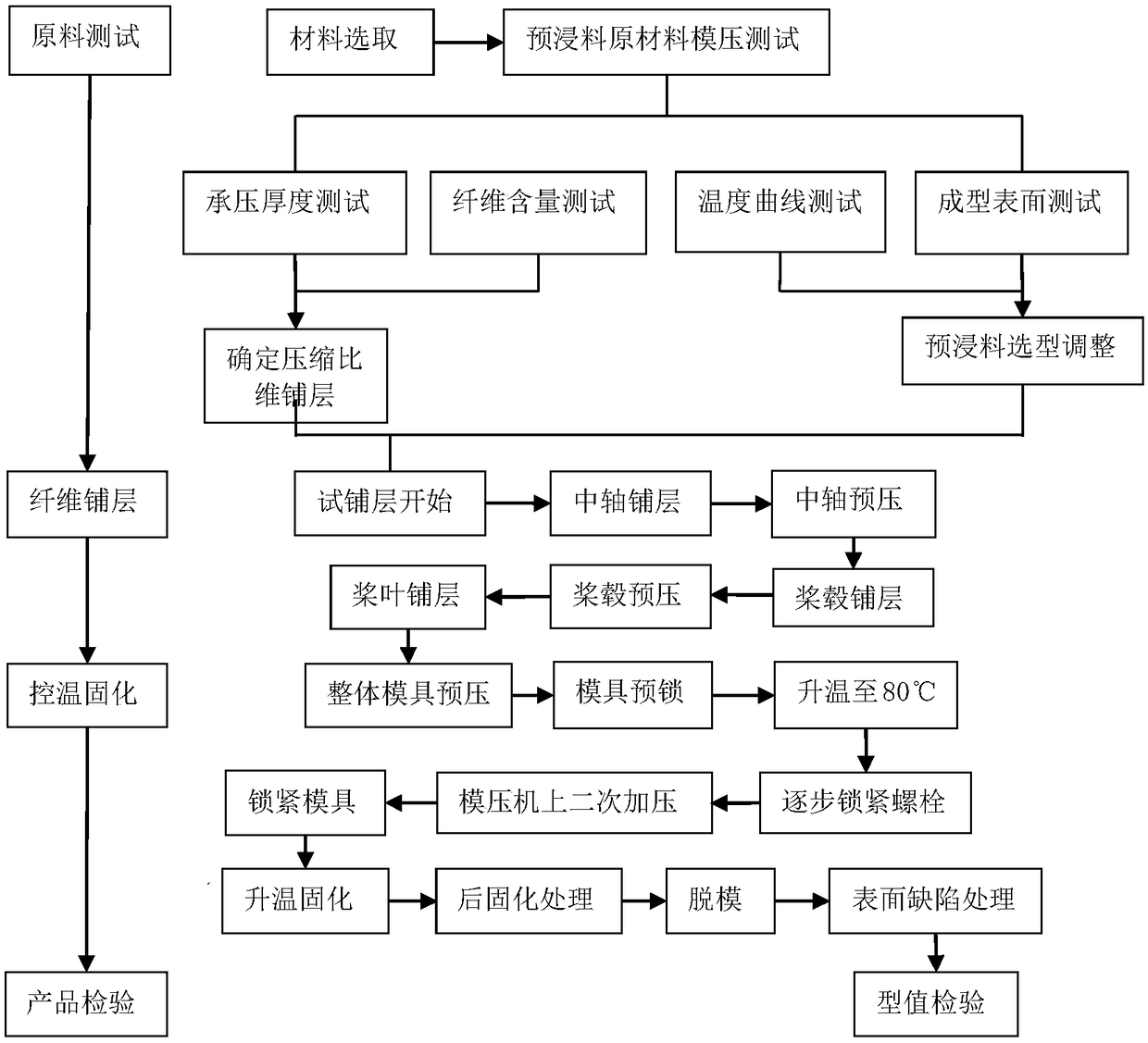

Carbon fiber composite material propeller pressing molding process

The invention discloses a carbon fiber composite material propeller pressing molding process, which comprises: S1, selecting a carbon fiber prepreg, controlling a press molding environment, and inspecting and treating a mold; S2, testing the compressive thickness, the fiber content, the temperature curve and the molding surface of the carbon fiber prepreg; S3, molding a propeller billet mold by using a prepreg pressing molding process; and S4, continuously adhering the carbon fiber prepreg on the surface of the billet mold, and carrying out pressing molding again to prepare the composite material propeller. According to the present invention, with the carbon fiber composite material propeller pressing molding process, the composite material propeller pressing molding is divided into two molding, the first molding uses the prepreg pressing molding process to mold the propeller billet mold, the prepreg is continuously adhered on the surface of the billet mold, and the pressing molding isperformed again to prepare the composite material propeller, such that the strength of the product can be ensured, the precision of the product can be ensured, and the molded product has advantages of good integrity, small molding value deviation, stable process, high strength and high propulsion efficiency.

Owner:武汉源海博创科技有限公司 +1

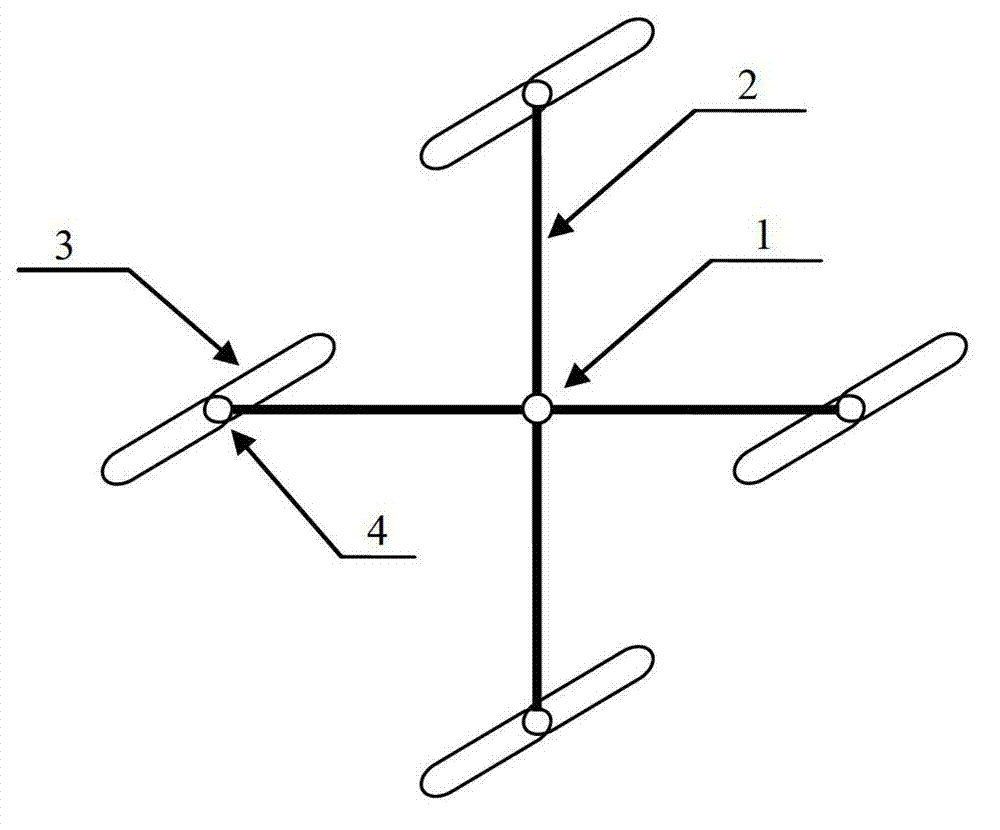

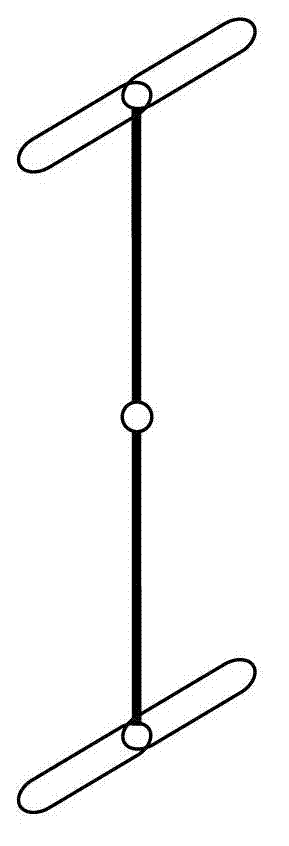

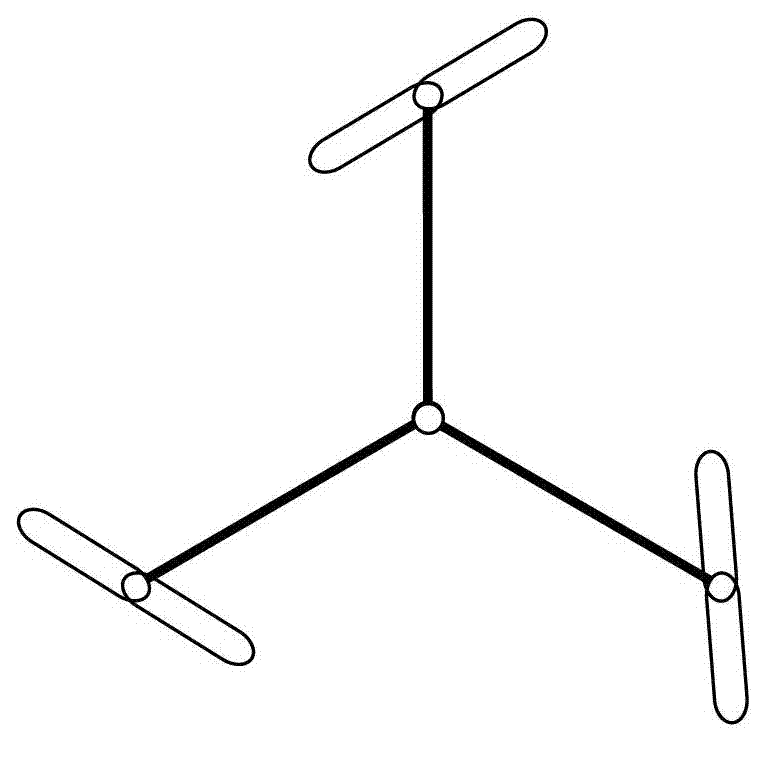

Rotor composite propeller of helicopter

The invention discloses a rotor composite propeller of a helicopter. The propeller comprises a main propeller shaft, at least two main propeller arms, rotor blades and a rotor shaft, wherein the main propeller shaft is connected with a power shaft of the helicopter and supplies power for the whole propeller; one ends of the main propeller arms are fixed on the main propeller shaft and the rotor shaft is installed at the other ends of the main propeller arms; and the rotor blades are fixed on the rotor shaft and can rotate freely. The propeller has the advantages of vertical taking off and landing, hovering, good maneuverability, and capability of gliding landing in a rotorcraft mode when the main propeller shuts down due to faults and improving flying stability and security, and the like.

Owner:SOUTH CHINA AGRI UNIV

Propellers for aircraft

ActiveUS9527578B2Reduce the overall diameterImproved profilePropellersJet aeroplaneComposite propeller

One aspect of the present invention provides a propeller for an aircraft. The propeller comprises a propeller hub, a spinner for streamlining the propeller and a plurality of composite propeller blades mounted to the propeller hub. The propeller blades are arranged to rotate together in the same rotational direction in at least two parallel planes substantially perpendicular to an axis of rotation of the propeller. The propeller has a reduced sized spinner with an improved aerodynamic profile that can be better matched to an engine nacelle and also has reduced drag.

Owner:GE AVIATION SYST LTD

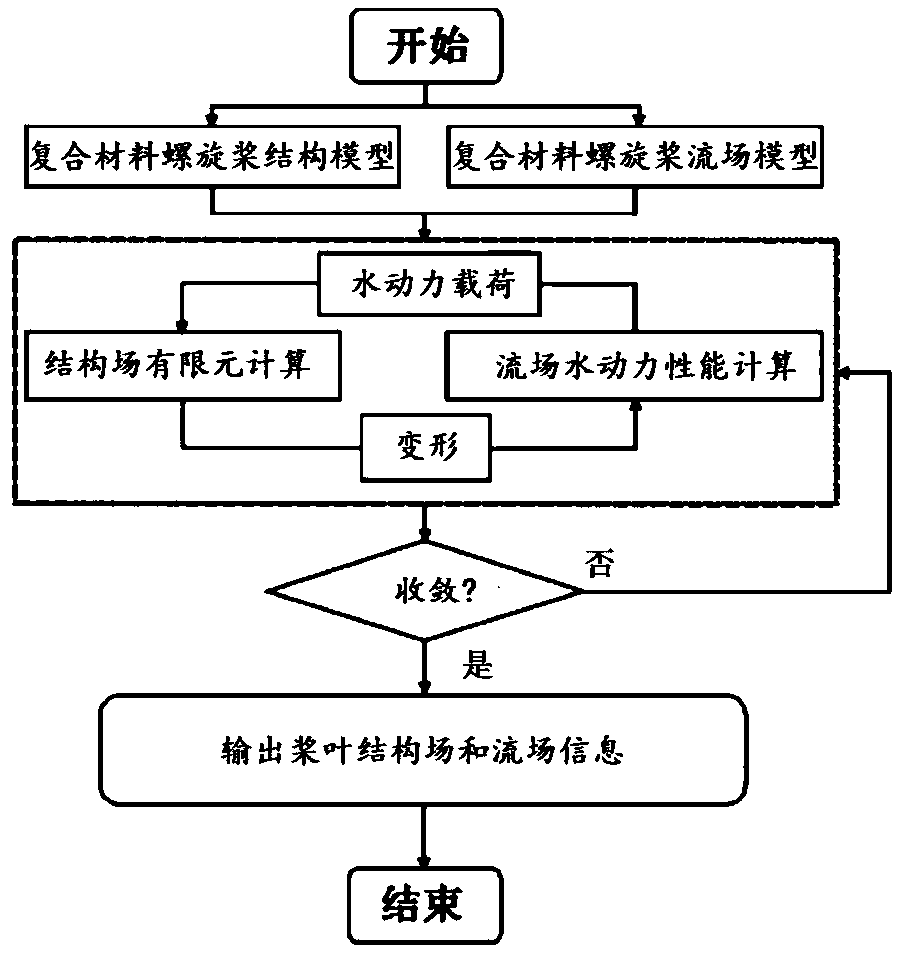

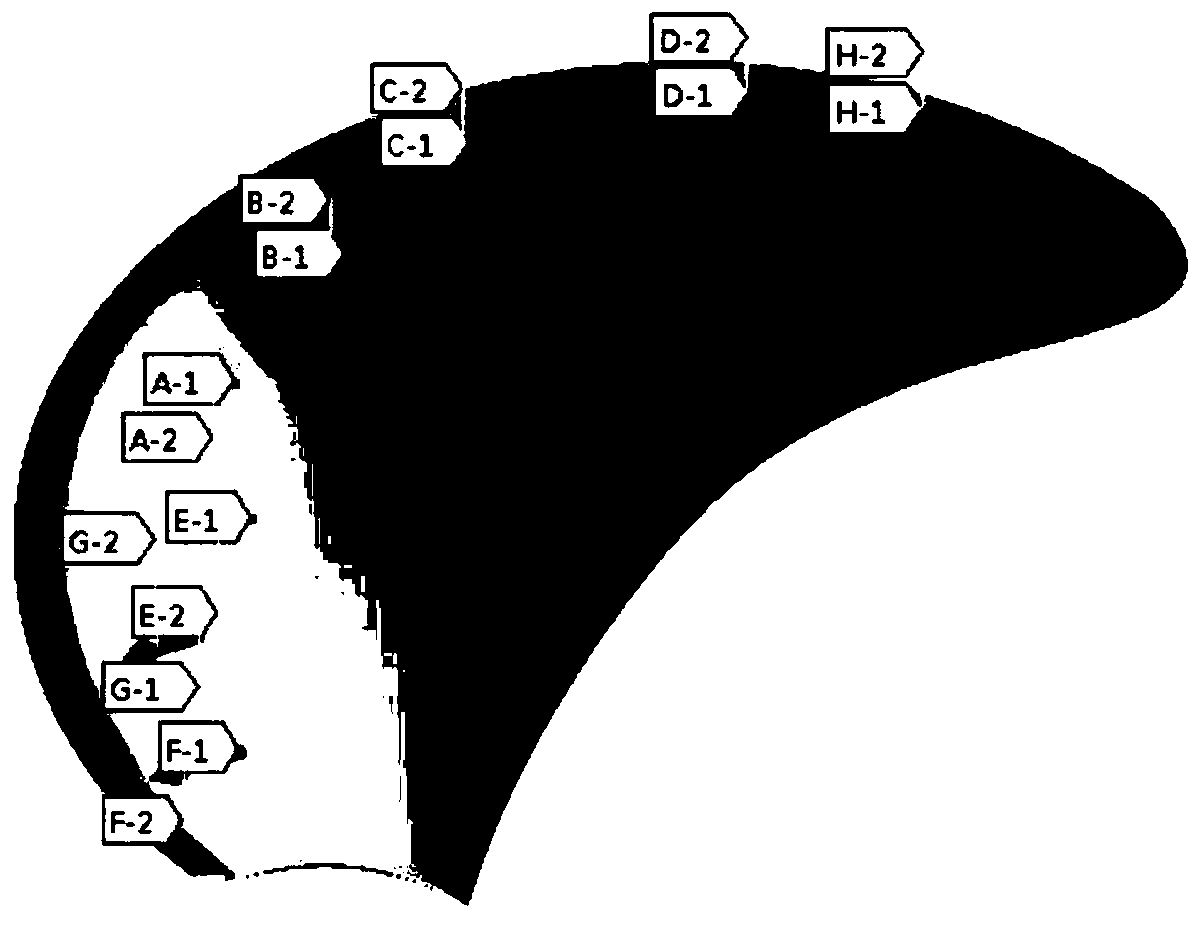

A marine composite material propeller pre-deformation optimization method

ActiveCN109711093AHigh precisionImprove general performanceRotary propellersSpecial data processing applicationsImpellerComposite propeller

The invention relates to a marine composite material propeller pre-deformation optimization method, and belongs to the technical field of impeller mechanical simulation. The method comprises the following steps: establishing a composite material propeller finite element model; and carrying out bidirectional fluid-solid coupling calculation on the deformation values and a composite material propeller calculation fluid mechanics model, extracting deformation values of the characteristic points on each blade tangent plane in the coordinate direction based on a result, and reversely superposing the deformation values into a propeller coordinate conversion formula for pre-deformation processing to finally obtain the pre-deformation composite material propeller. According to the method, changesof geometric parameters such as propeller pitch angles, lateral inclination and longitudinal inclination caused by deformation of the composite propeller blades under the fluid-solid coupling effect are comprehensively considered, and the precision of pre-deformation design is improved. In addition, the method is high in universality and universality. Compared with an existing pre-deformation design method, the method has the advantages of being small in calculation amount, easy and convenient to calculate and capable of achieving parameterized and programmed design, and a large number of calculation resources and time are saved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

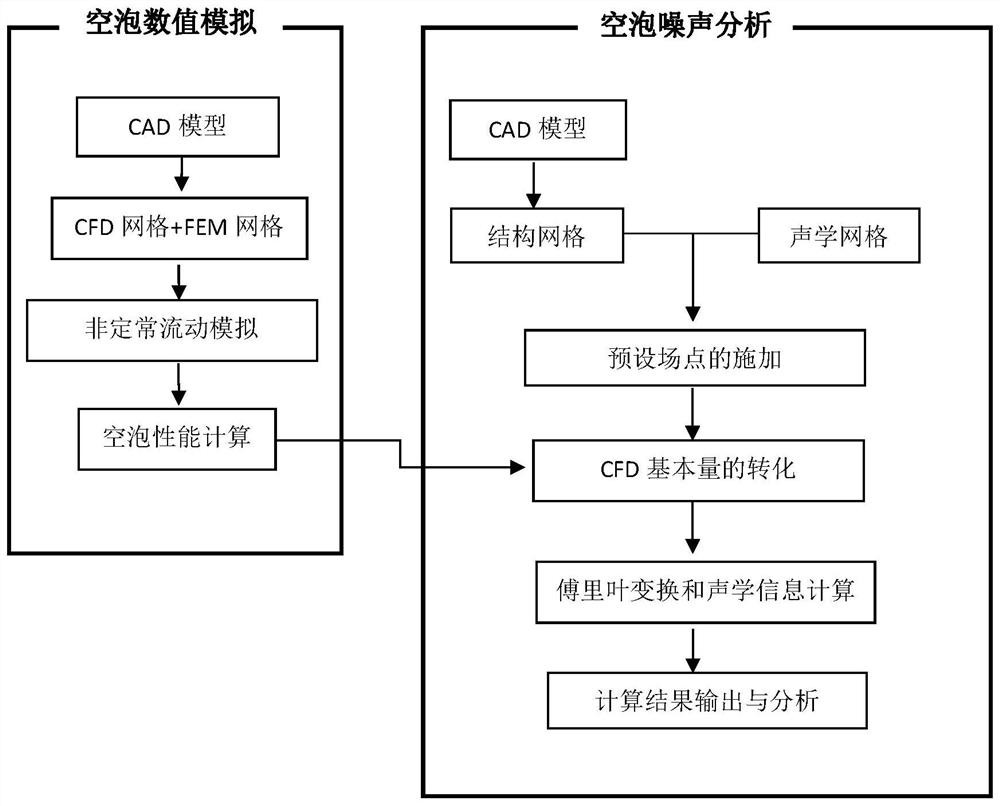

Numerical forecasting method for cavitation noise of composite propeller

PendingCN113139306AShorten the timeLow costGeometric CADSustainable transportationElement modelComposite propeller

The invention provides a numerical forecasting method for cavitation noise of a composite propeller, and the method comprises the following steps: building a geometric model of the propeller through three-dimensional configuration software according to the design size of the propeller; completing the construction of a hydrodynamic model; establishing a finite element model of the composite propeller by utilizing finite element software; carrying out cavitation performance simulation calculation on the composite material propeller to obtain a cavitation numerical simulation result, and obtaining the difference between the hydrodynamic performance and the cavitation performance of the composite material propeller and the metal material propeller; storing a cavitation numerical simulation result obtained in the fluid analysis software; constructing an acoustic calculation model of the composite propeller, and setting a plurality of monitoring points in the acoustic calculation model; and comparing and analyzing attenuation change rules of the cavitation radiation noise at different positions. According to the method, the vibration noise radiation condition of the propeller can be well predicted, and reference is provided for low-noise propeller design.

Owner:HARBIN INST OF TECH

Ship transformable propeller based on bidirectional shape memory polymer composite propeller blades

InactiveCN105966582AAchieve vibration and noise reductionRotary propellersComposite propellerEngineering

A marine deformable propeller based on a two-way shape memory polymer composite material blade relates to a marine deformable propeller. The content of the present invention is to solve the technical problem that the configuration of the current marine propeller is prepared before being installed on the ship, and the ship cannot be changed during the sailing process. A marine deformable propeller based on two-way shape memory polymer composite material blade of the present invention is composed of a hub and a plurality of blades; the plurality of blades are evenly arranged and fixedly installed on the hub along the circumferential direction; the described The blades are made from a composite of two-way shape memory polymers with fiber reinforcement. The paddle of the present invention can flexibly switch between pitching and non-pitching according to actual needs. The invention is applied to hull propellers.

Owner:HARBIN INST OF TECH

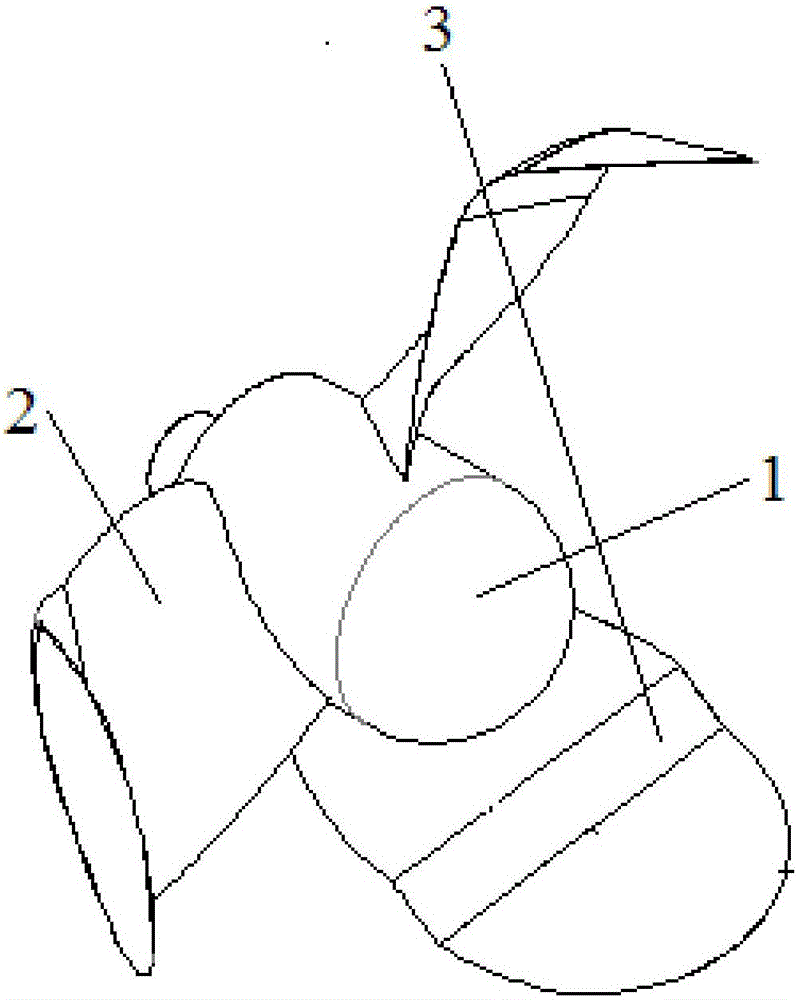

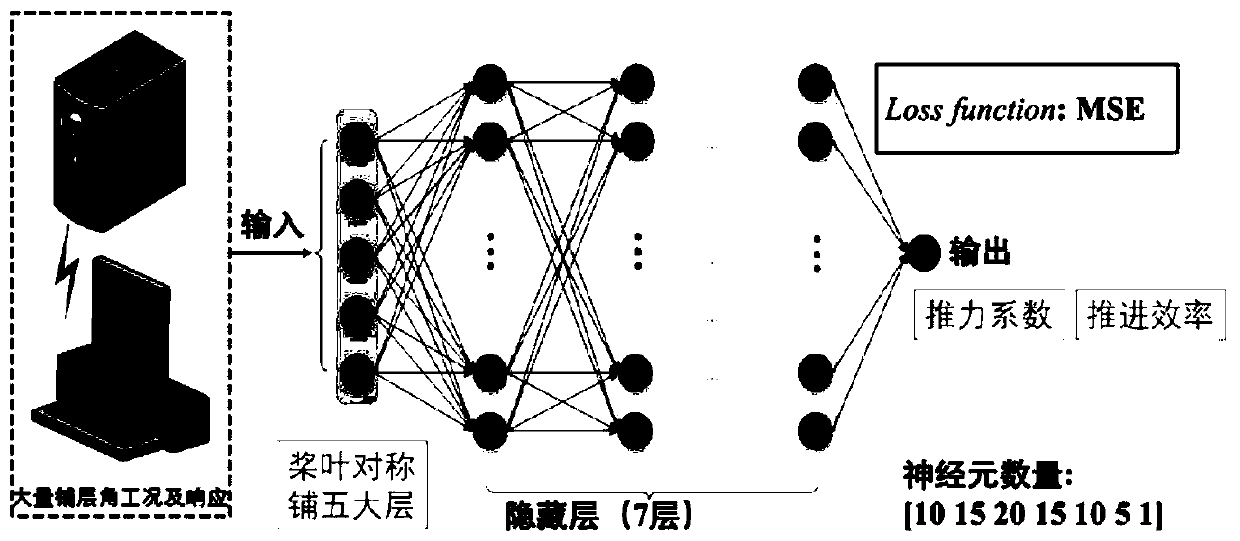

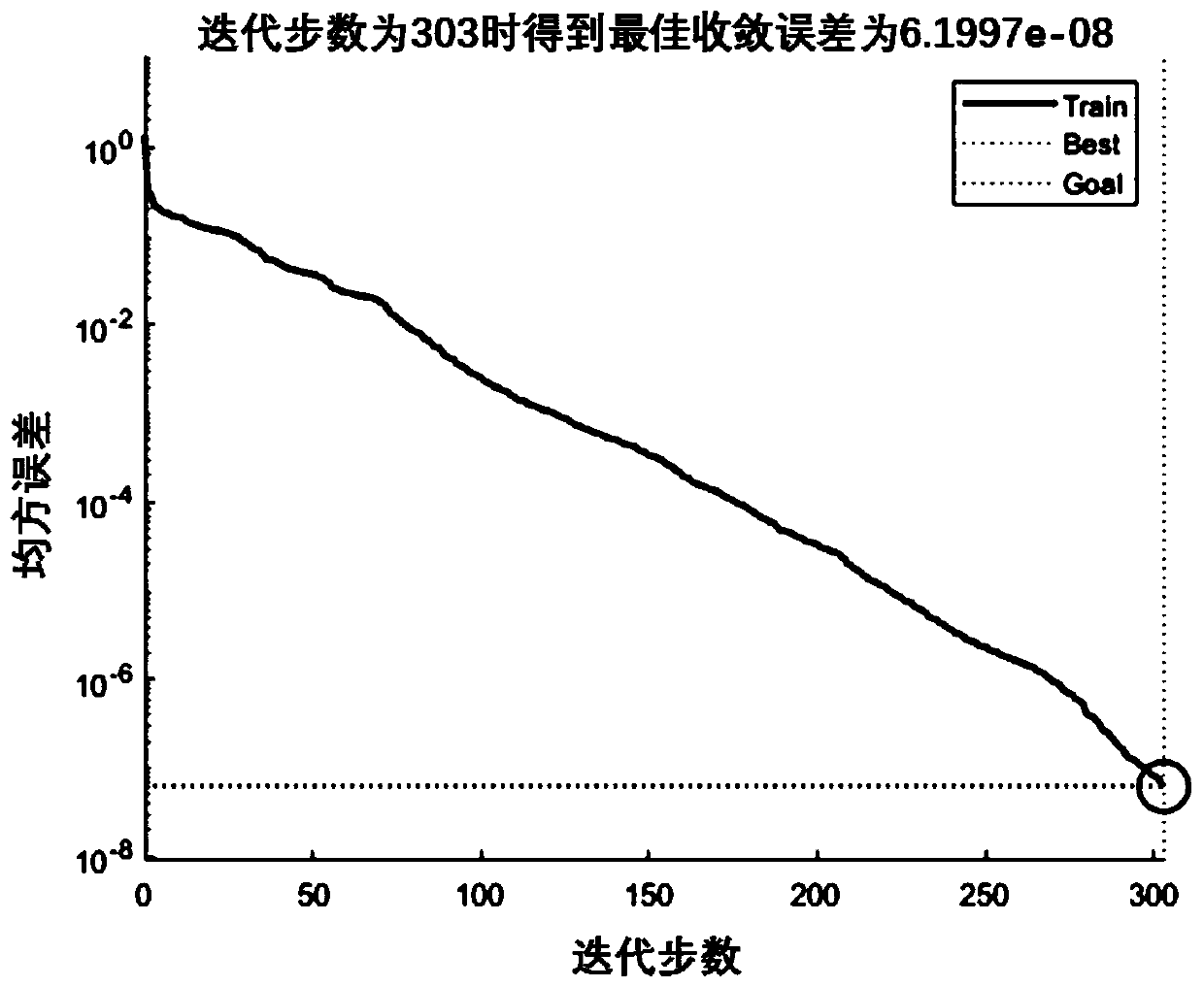

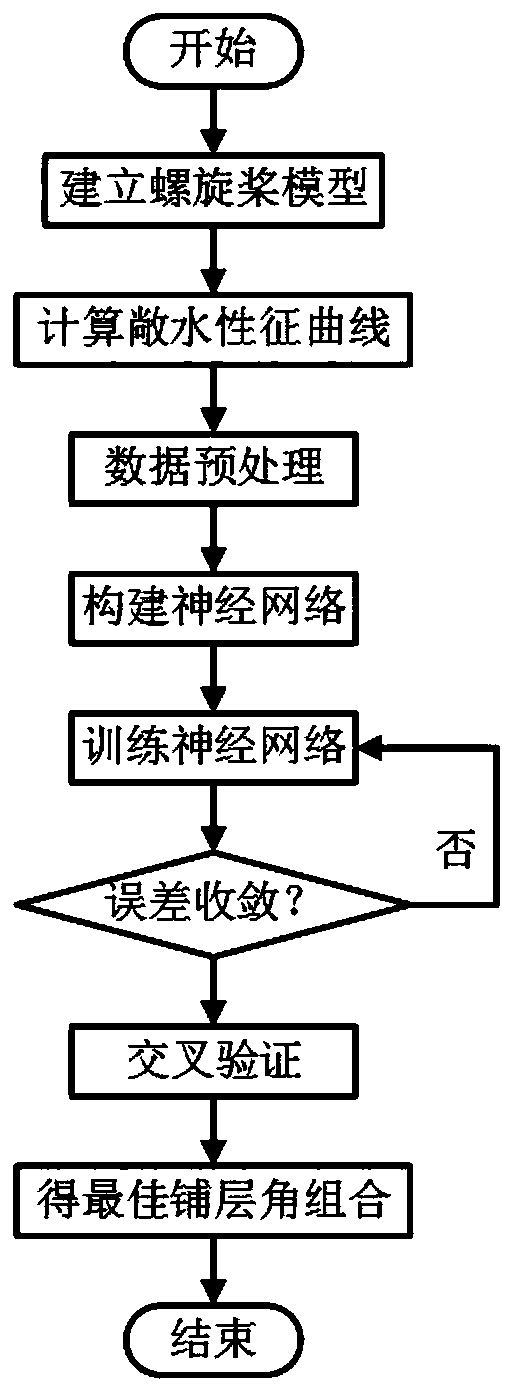

Composite material propeller layering angle optimization method based on neural network

ActiveCN111444643APly angle optimization achievedSmall amount of calculationGeometric CADGenetic modelsElement modelAlgorithm

The invention relates to a composite material propeller layering angle optimization method based on a neural network, and belongs to the technical field of turbomachinery simulation. The method comprises the following steps: establishing a composite propeller finite element model, and performing bidirectional fluid-solid coupling calculation on the composite propeller finite element model and a composite propeller computational fluid mechanics model to obtain a corresponding open-water characteristic curve; adopting an orthogonal test design method to preprocess the layering angle combinationand the corresponding hydrodynamic performance data; constructing a BP neural network with high nonlinear fitting based on numerical calculation software, training the constructed neural network by adopting a gradient descent algorithm, and finally obtaining the BP neural network with a mapping rule between the composite material propeller layering angle and the propulsion efficiency; and according to the trained BP neural network, carrying out optimization prediction on the combination situation of all the layering angles, and analyzing the obtained efficiency data to obtain the maximum network prediction value and the corresponding layering angle combination, that is, optimization of the lay-up angles of the composite propeller is realized based on the neural network.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

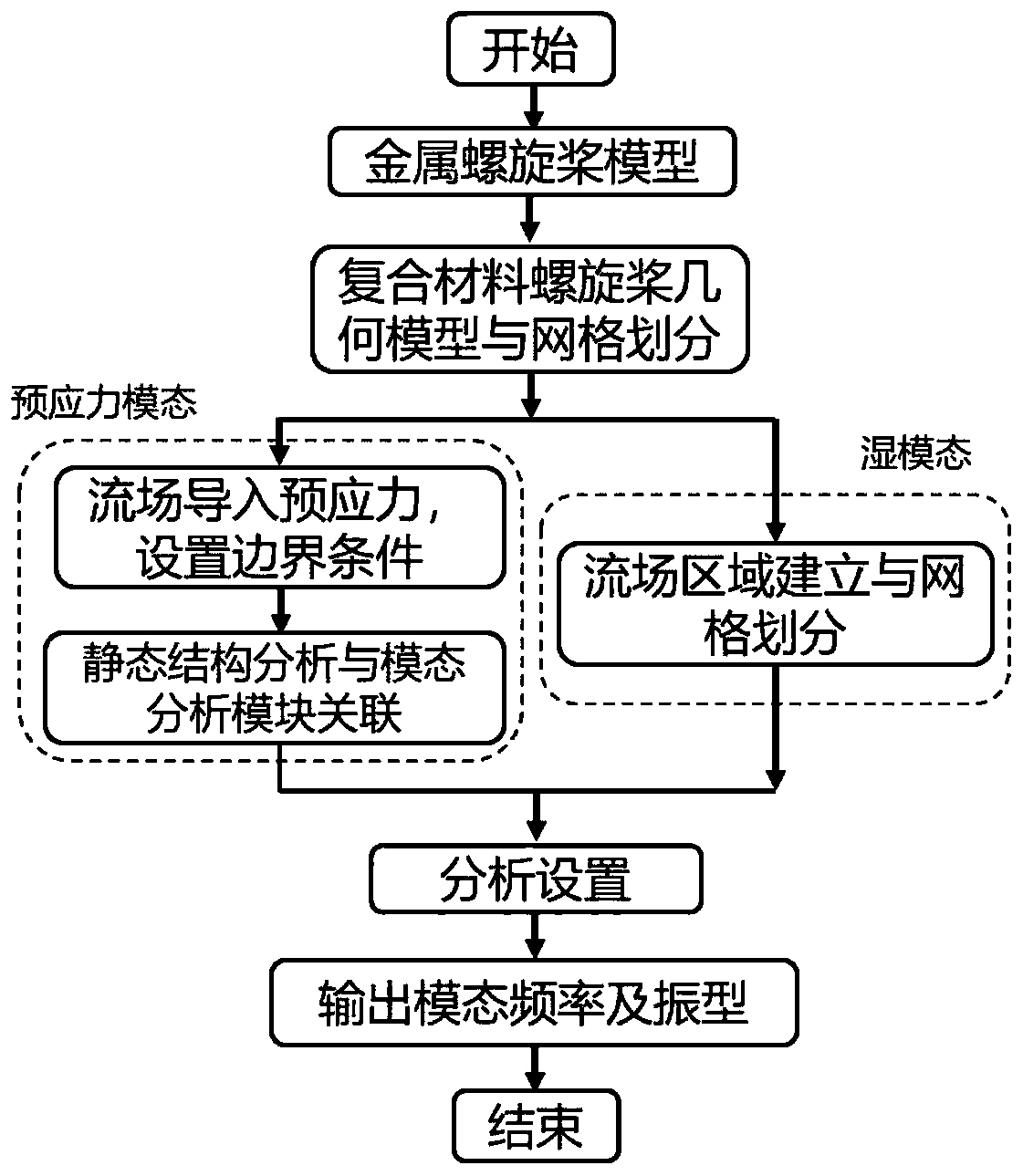

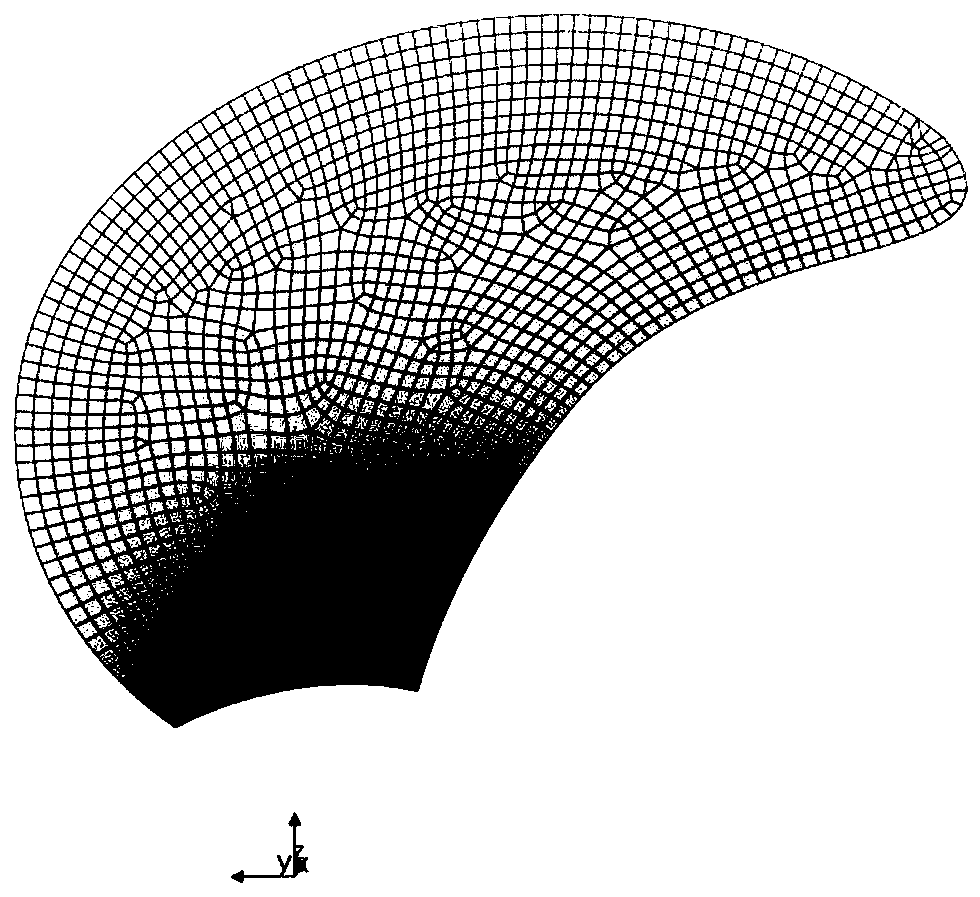

Prestress wet mode prediction method for composite propeller based on acoustic-structure coupling

ActiveCN111159950AAchieve high-precision forecastingImprove realismGeometric CADDesign optimisation/simulationImpellerComposite propeller

The invention relates to a prestress wet mode prediction method for a composite propeller based on acoustic-solid coupling, and belongs to the technical field of turbomachinery simulation. The methodcompriss the steps: based on a finite element principle, implementing fluid-solid coupling wet mode prediction of the composite propeller through an acoustic-structure coupling method; establishing acomposite material propeller model, and establishing a corresponding flow field area; carrying out mesh generation and prestress introduction on the composite material propeller model and the flow field area, and then carrying out analysis parameter setting; and finally outputting a modal analysis result to obtain a prestress wet modal frequency and a prestress vibration mode. According to the method, the actual vibration response generated by the composite propeller under the action of various vibration sources can be predicted, the influence of the additional mass of the fluid is fully considered, the high-precision prediction of the composite propeller prestress wet mode can be realized, and the prediction trueness and credibility are improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Composite propeller

InactiveCN106184672AAvoid defectsIncrease success ratePropellersRotary propellersComposite propellerSpiral blade

The invention provides a composite material propeller, comprising: a base made of metal as a whole and a plurality of slots connected together; wherein the slots are equally distributed on the circumference of the base, the opening of the slots is upward, and the spiral The root of the shaped paddle fits closely with the card slot. Based on the problems that metal material propellers are heavy and easy to corrode, and the common problem that the connection between composite materials and metal materials is easy to debond, the present invention designs the connection structure between the composite material propeller blade and the metal frame, effectively avoiding the problem caused by composite materials and metal materials Product defects occur due to poor adhesion of the frame, which improves the success rate of the product.

Owner:XIANNING HAIWEI COMPOSITE MATERIAL PROD

Composite propeller spar

A method and apparatus comprising a composite spar. The composite spar has a root section and a main section. The root section is closed and has a shape configured to be connected to a blade retention system. The main section has an open channel. The composite spar is configured for placement inside of a blade.

Owner:THE BOEING CO

Propeller blade with piezoelectric damping function for ship and preparation method thereof

ActiveCN108466686AWith piezoelectric damping functionImprove structural mechanical propertiesRotary propellersDomestic articlesComposite propellerDamping function

The invention discloses a propeller blade with a piezoelectric damping function for a ship and a preparation method thereof. The propeller blade is prepared from, by mass, 80-120 parts of piezoelectric damping composite cores and 120-200 parts of fiber-reinforced thermoplastic composite prepreg coating layers; and the piezoelectric damping composite cores are prepared from, by mass, 5-8 parts of piezoelectric ceramic powder, 0.05-0.09 part of carbon nanotube and 100 parts of thermoplastic polymers which are heated, mixed, and then demoulded at the normal temperature. Through the co-curing forming process of the piezoelectric damping composite cores and the fiber-reinforced thermoplastic composite prepreg coating layers, the composite propeller has the piezoelectric damping function and excellent overall structure mechanical performance, the vibration-reducing and noise-reducing performance of the composite propeller can be remarkably improved, and the problem that due to the underwateradded mass inertia force effect, vibration noise of a stern flow field of an existing marine composite propeller is large can be effectively solved.

Owner:HARBIN INST OF TECH AT WEIHAI

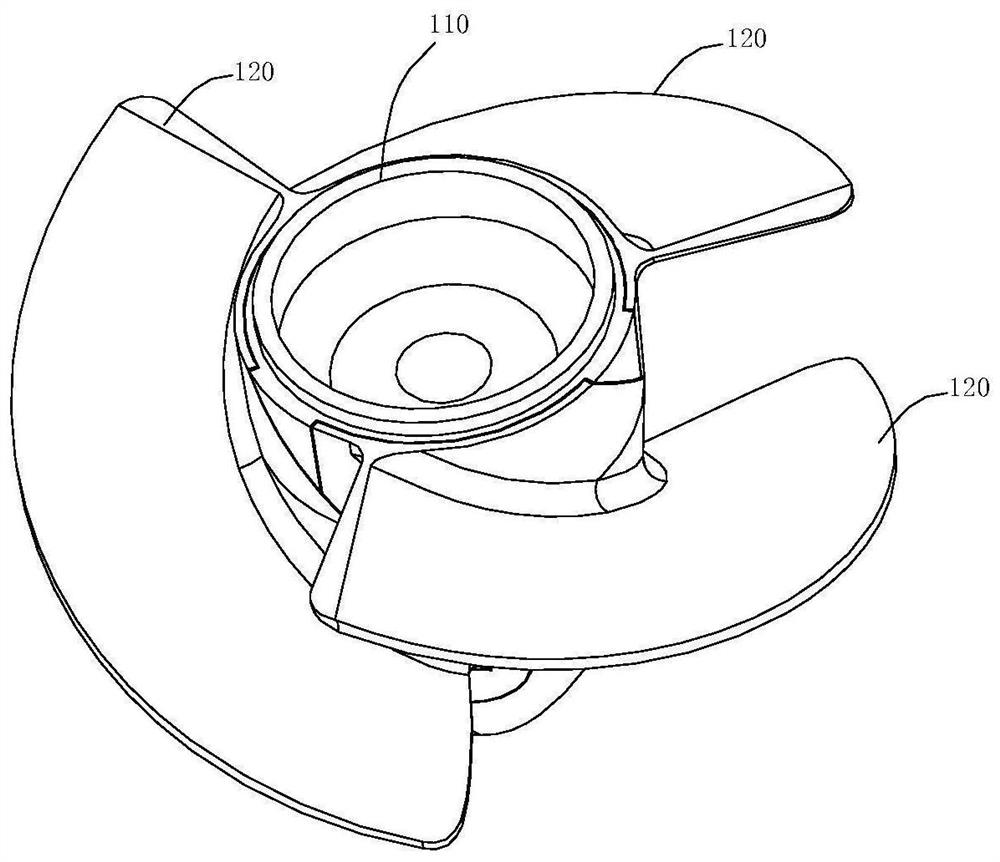

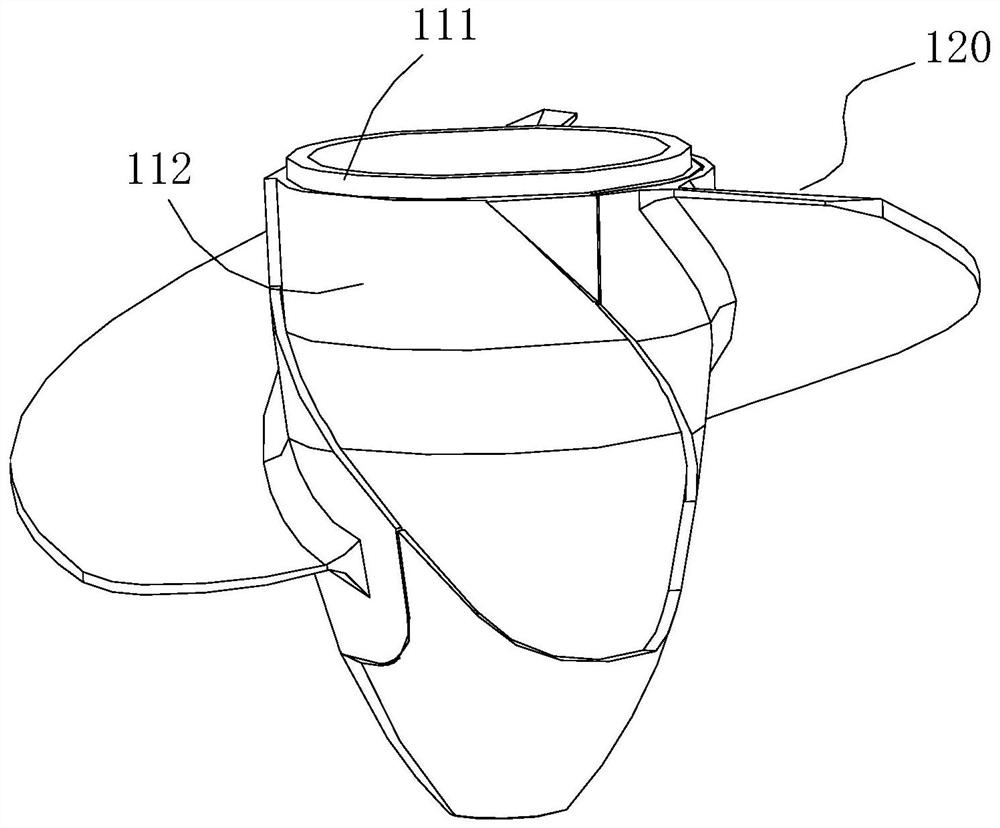

Manufacturing method of split type composite propeller and product

ActiveCN111873449AEasy to processImprove connection stabilityWeight reductionDomestic articlesComposite propellerMechanical engineering

The invention discloses a manufacturing method of a split type composite propeller and a product, and the manufacturing method comprises 1) a propeller hub manufacturing step including 1-1) a propeller hub pre-forming step: namely laying prepreg sheets according to a predetermined method to obtain a propeller hub pre-formed body; and 1-2) a propeller hub forming step: namely putting the propellerhub pre-formed body into a propeller hub forming mold, and carrying out heating and pressurizing to obtain a propeller hub; 2) a paddle manufacturing step including 2-1) a paddle pre-forming step: namely paving prepreg sheets according to a predetermined method to obtain paddle pre-formed bodies; and 2-2) a paddle forming step: namely putting the paddle pre-formed bodies into a paddle forming mold, and carrying out heating and pressurizing to obtain paddles; and 3) a bonding step: namely, respectively gluing the faying surfaces of the paddles and the first concave part of the propeller hub, then butting the faying surfaces of the more than two paddles and the first concave part of the propeller hub one by one, then performing fixing, and finally performing baking to obtain the product. Themethod has the characteristics of convenience in manufacturing, high production efficiency and good connection stability.

Owner:东莞皓宇智能复合材料有限公司

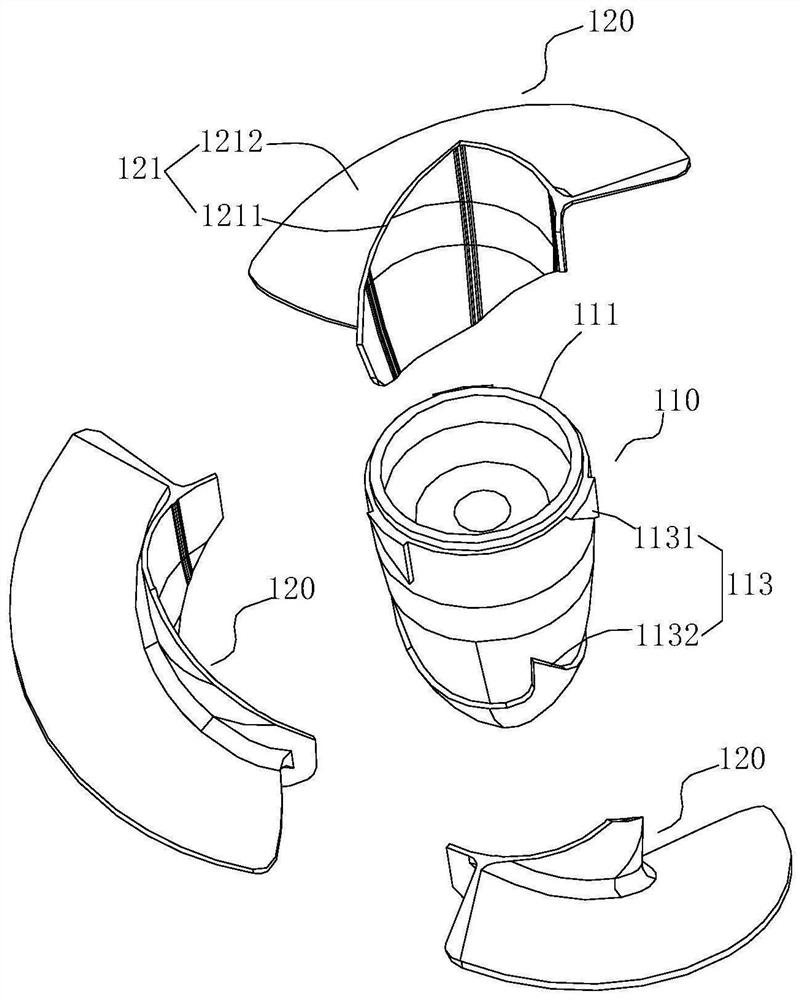

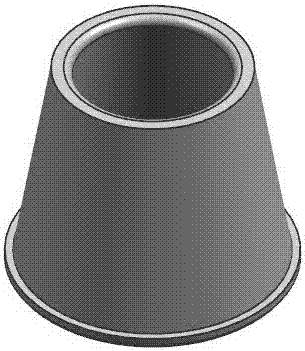

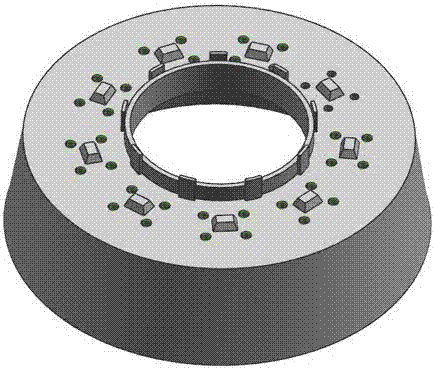

Preparation method of composite material thruster stator

InactiveCN106965455AHigh dimensional accuracyImprove yieldDomestic articlesComposite propellerEngineering

The invention discloses a preparation method of a composite material thruster stator. The thruster stator is divided into three parts including a propeller hub, paddles and a guide pipe, the roots of the paddles are connected with the propeller hub, tip parts of the paddles are connected with the guide pipe, and the overall thruster stator is made of composite materials. All paddles of the stator achieves paving in a stator paddle die in a prepreg and fiber cloth doping manner, transition fibers in certain sizes are led out at the roots and the tip parts of the paddles from the doped fiber cloth and are used for being subject to connection with the propeller hub and the guide pipe and co-curing molding subsequently, continuity of the fibers in the paddles and the guide pipes is guaranteed, and the molded stator is excellent in overall mechanical property. The composite material thruster stator prepared through the preparation method is small in weight, good in strength, high in reliability, reasonable in structure and simple and practical in molding method.

Owner:武汉海威船舶与海洋工程科技有限公司 +1

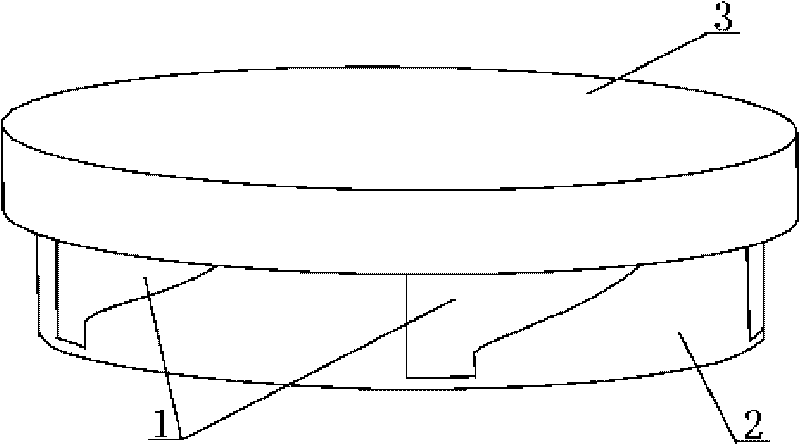

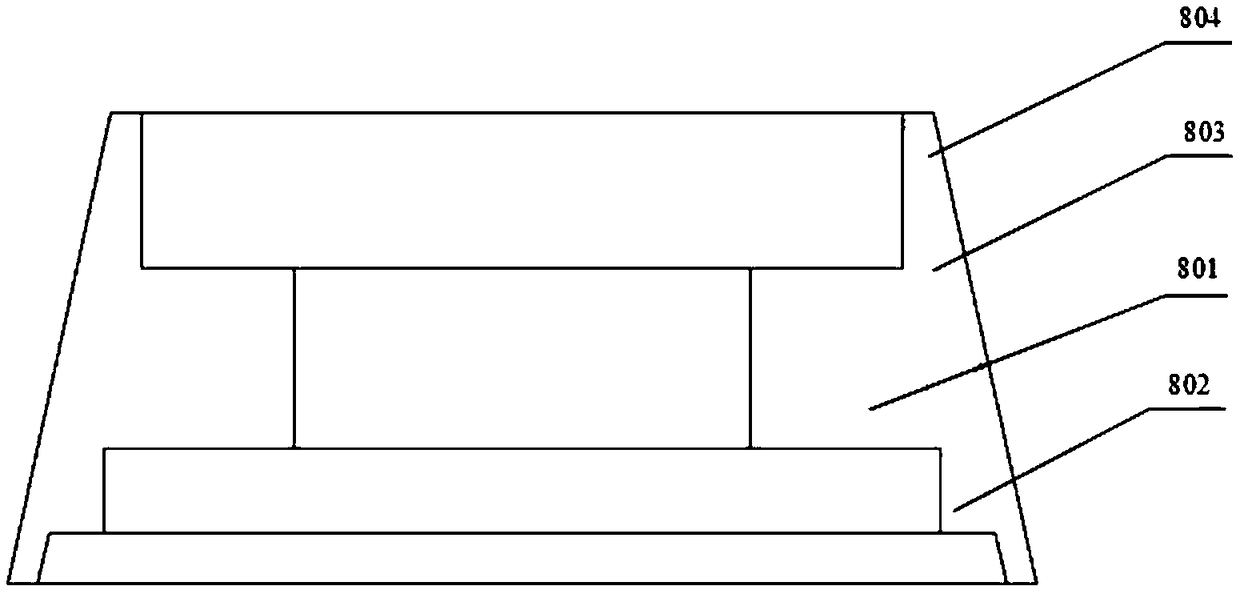

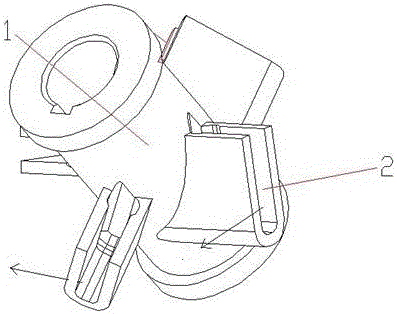

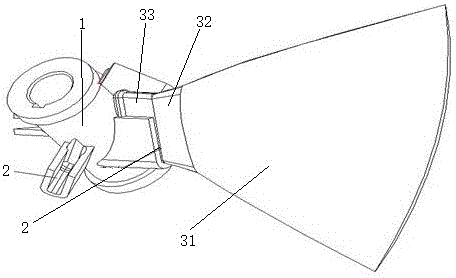

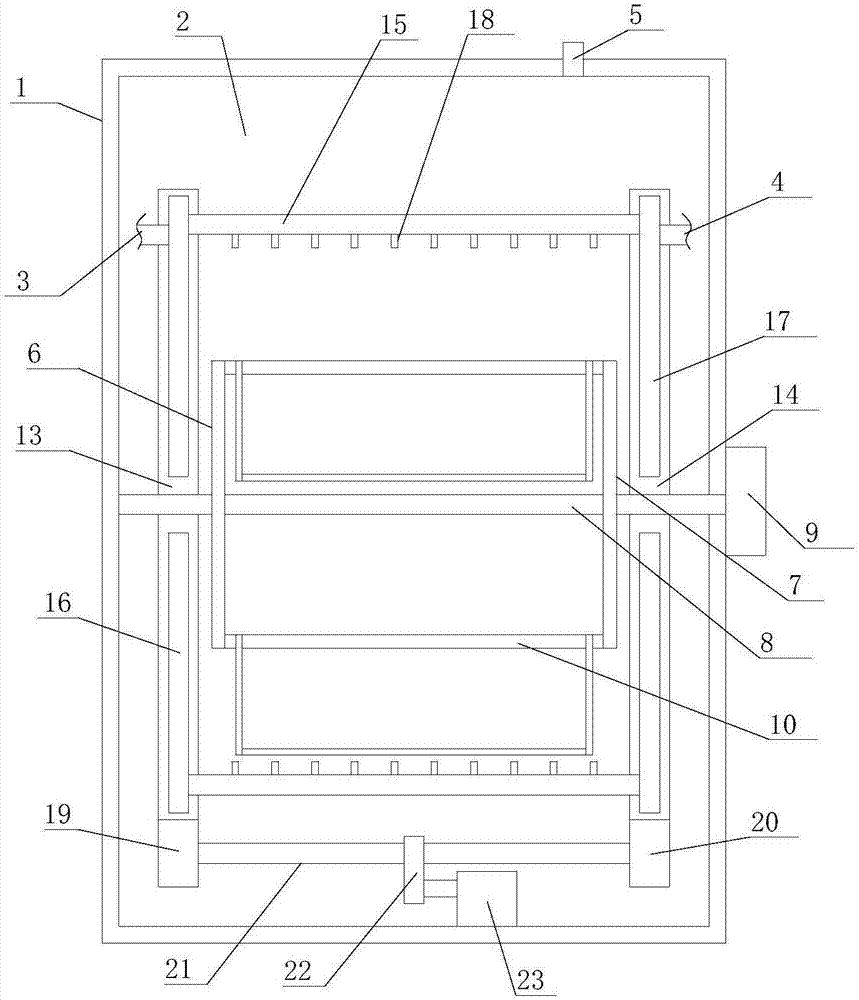

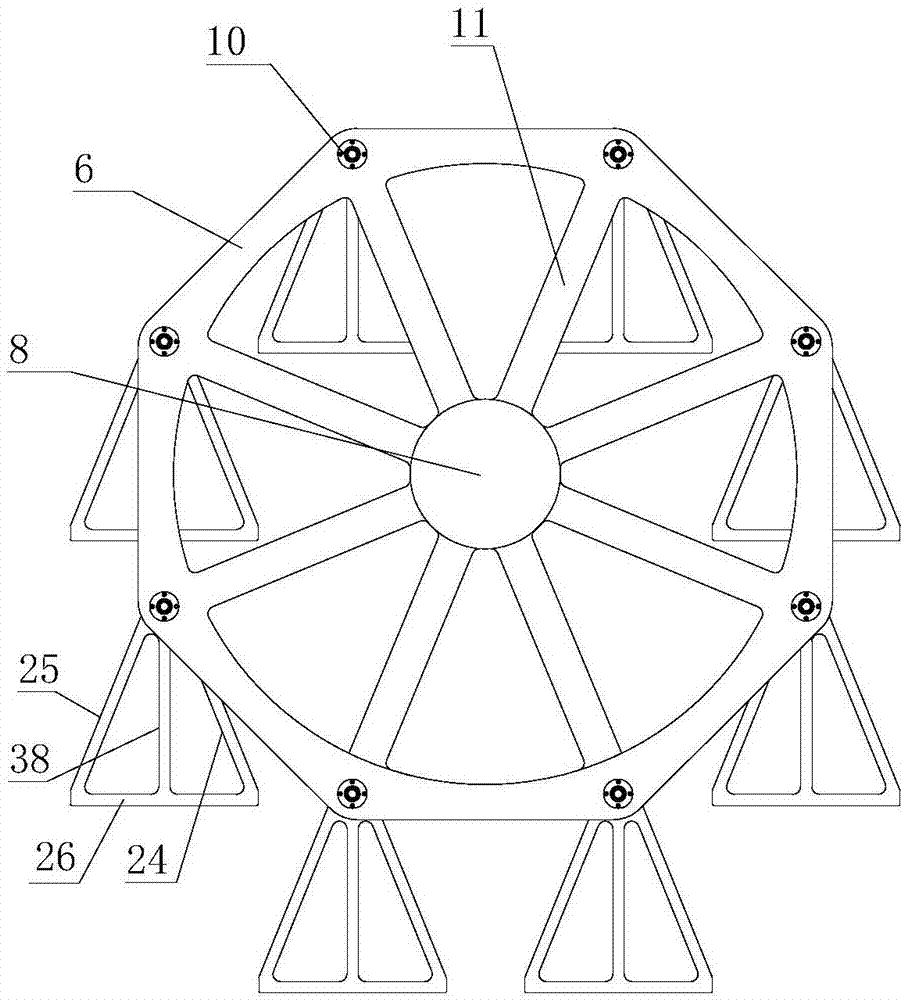

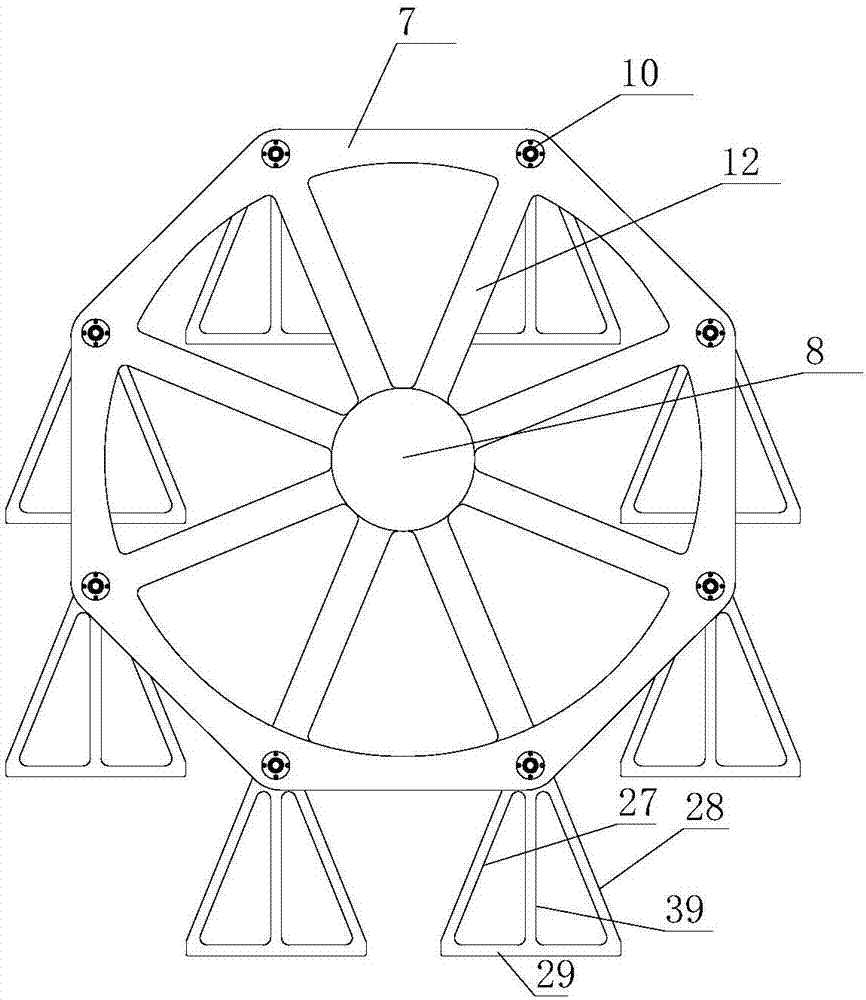

Rotary heating type composite propeller curing oven

ActiveCN107415108AUniform temperatureMeet temperature requirementsDomestic articlesComposite propellerForming processes

The invention provides a rotary heating type composite propeller curing oven comprising an oven body, a heating mechanism and a mold holding mechanism. The first end of a rotary shaft is rotationally connected with the first side wall of the oven body. The second end of the rotary shaft penetrates through the geometric centers of a first installing ring and a second installing ring sequentially to be rotationally connected with the second side wall of the oven body. The inner side of the first installing ring is fixedly connected with the rotary shaft through a plurality of first connecting rods. The inner side of the second installing ring is fixedly connected with the rotary shaft through a plurality of second connecting rods. The first ends of a plurality of support shafts are all connected with the first installing ring, and the second ends of the multiple support shafts are all connected with the second installing ring. A plurality of mold holding frames are hinged to the multiple support shafts correspondingly. A first heating disc is located on the side, away from the second installing ring, of the first installing ring and is rotationally installed on the rotary shaft. The two ends of an air conduit are connected with the first heating disc and a second heating disc correspondingly. The rotary heating type composite propeller curing oven can meet the requirement for temperature in the forming process of a composite propeller, cost is low, and in-oven temperature is uniform.

Owner:安徽劲旋风航空科技有限公司

A kind of ship composite material propeller blade preform and preparation method thereof

The invention relates to a performed composite propeller blade of a ship and a manufacturing method of the performed composite propeller blade. Compared with a metal propeller, the preformed composite propeller blade has the advantages that the weight is low, corrosion resistance is good, the hydrodynamic performance is superior, cavitation can be delayed, cavitation corrosion is reduced, the acoustic characteristic is excellent, noise of the propeller is lowered, and the stealth performance of the ship can be easily improved. Fiber covers serve as a primary bearing mechanism, and the fiber covers are designed to be of identical thickness and cover the whole blade. By means of the performed composite propeller blade of the ship and the manufacturing method of the performed composite propeller blade, quasi two-dimensionalization of complex three-dimensional weaving is effectively achieved. The problems of delamination and stripping of guide edges and following edges of an original blade are effectively solved, the weaving difficulty is reduced, and cost is reduced; and the dead load of the propeller blade can be greatly reduced, and the appearance precision of the propeller blade is improved.

Owner:中国船舶重工集团公司第七〇二研究所

Combined propeller blade structure

InactiveCN104340348AImprove performanceImprove efficiencyRotary propellersComposite propellerEngineering

A composite propeller blade structure includes at least a rotation shaft and a rotation surface on which plural blades are formed, and characterized in that: each of the blades is composed of plural blade units; and in the equivalent radius cross section of each of the blades, the installed location of a front edge of the blade unit at the downstream is defined as following: in the rotation axial direction, which is located behind a rear edge of the adjacent blade unit at the upstream, and the maximum distance thereof is not greater than 25% of the radius of the adjacent blade unit at the upstream; and in the circumferential direction, located at the pressure surface side defined on the nose-trail line of the adjacent blade unit at the upstream, and the maximum range thereof is not greater than (360° / 2N), wherein N is the quantity of the blades.

Owner:APPLIED THERMAL FLUID ANALYSIS CENT LIMITED LIABILITY

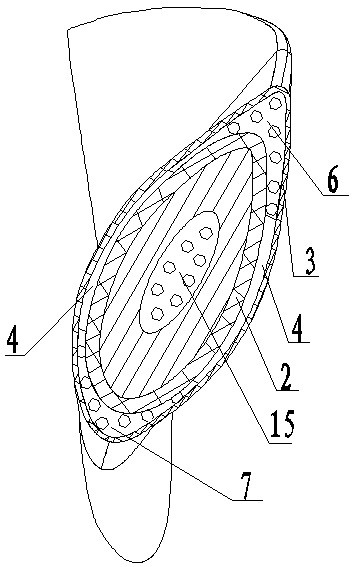

Composite propeller blade of propeller

The invention discloses a composite propeller blade of a propeller. A circular truncated cone I, a cylinder I, a circular truncated cone II, a transition cylinder II and a curved surface consistent with a propeller body molded surface in bending are sequentially arranged at the small end of a metal propeller root from the back of a tail end cylinder of a large end; an oval end protruding from thecenter of the large end of the foam core matched with the bent shape of the propeller body is inserted into an oval groove in the center of the small end of the metal propeller root; the starting endsof the carbon beams are tightly attached to and wrap the circular truncated cone I, become two parts from the curved surface and are laid along rectangular grooves in the working surface and the non-working surface of the foam core; the skin wraps the curved surface of the metal propeller root and all parts of the propeller body from the transition cylinder II; the front edge filling foam and therear edge filling foam are filled in front edge and rear edge gaps between the skin and the metal propeller root; and the carbon fiber cloth is filled in the skin, the carbon beam and the foam core and all gaps among the skin, the carbon beam and the foam core, and the carbon beam winding belt is wound on the carbon beam portion without skin wrapping. The composite propeller blade disclosed by the invention is light in weight, reliable in structure, excellent in aerodynamic performance and good in paddle root fatigue resistance.

Owner:AVIC HUIYANG AVIATION PROPELLER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com